Static-eliminating cleaning agent for textile materials and preparation method thereof

A technology for textile materials and static electricity removal, applied in detergent compositions, detergent compounding agents, textiles and papermaking, etc., can solve problems such as poor biodegradability and environmental impact, and achieve good biodegradability, strong detergency, The effect of good antistatic properties

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

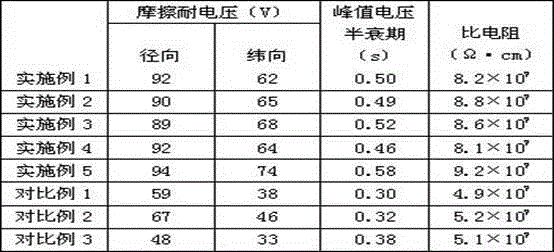

Examples

Embodiment 1

[0030] An antistatic cleaning agent for textile materials, which consists of the following components in weight percentage: 10 parts of sodium alginate, 6 parts of titanate, 5 parts of polydimethylsiloxane diquaternary ammonium salt, polyethylene Alcohol is 3 parts, ethoxylated alkyl ammonium sulfate is 1.5 parts, polymethylcyclotetrasiloxane is 0.8 parts, acetic acid aqueous solution is 0.5 parts, solvent is 3 parts, deionized water is 60 parts, lauroyl creatine 3 parts of sodium phosphate, 2 parts of polymethyl methacrylate, 7 parts of fatty alcohol polyoxyethylene ether, 80 parts of sodium α-alkenyl sulfonate solution; the titanate is composed of ethyl titanate and tetra-normal titanate The composition of propyl ester is 1:1; the relative molecular weight of the polyvinyl alcohol is 1500; the content of acetic acid in the acetic acid aqueous solution is 56wt%; the solvent is composed of ethanol and propanol in a ratio of 1:1.

[0031] The preparation method of described ant...

Embodiment 2

[0035] An antistatic cleaning agent for textile materials, which consists of the following components in weight percentage: 20 parts of sodium alginate, 10 parts of titanate, 10 parts of polydimethylsiloxane diquaternary ammonium salt, polyethylene Alcohol is 7 parts, ethoxylated alkyl ammonium sulfate is 3 parts, polymethylcyclotetrasiloxane is 1.4 parts, acetic acid aqueous solution is 2 parts, solvent is 7 parts, deionized water is 100 parts, lauroyl creatine 7 parts of sodium phosphate, 6 parts of polymethyl methacrylate, 12 parts of fatty alcohol polyoxyethylene ether, 120 parts of sodium α-alkenyl sulfonate solution; the titanate is composed of n-butyl titanate and tetra-titanate The composition of butyl ester is 1:1; the relative molecular weight of the polyvinyl alcohol is 2500; the content of acetic acid in the acetic acid aqueous solution is 68wt%; the solvent is composed of methanol and butanol at a ratio of 1:1.

[0036] The preparation method of described antistatic...

Embodiment 3

[0040] An antistatic cleaning agent for textile materials, which consists of the following components in weight percentage: 12 parts of sodium alginate, 7 parts of titanate, 6 parts of polydimethylsiloxane diquaternary ammonium salt, polyethylene Alcohol is 4 parts, ethoxylated alkyl ammonium sulfate is 2 parts, polymethylcyclotetrasiloxane is 1 part, acetic acid aqueous solution is 1 part, solvent is 4 parts, deionized water is 80 parts, lauroyl creatine 4 parts of sodium phosphate, 3 parts of polymethyl methacrylate, 8 parts of fatty alcohol polyoxyethylene ether, 100 parts of sodium α-alkenyl sulfonate solution; the titanate is composed of n-butyl titanate and tetra-titanate The composition of butyl ester is 1:1; the relative molecular weight of the polyvinyl alcohol is 1800; the content of acetic acid in the acetic acid aqueous solution is 60wt%; the solvent is composed of butanol and ethylene glycol at a ratio of 1:1.

[0041] The preparation method of described antistati...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com