Dyeing and printing technology of camouflage fabric

A processing technology and fabric technology, applied in the field of fabric processing, can solve problems such as metamerism, color difference washing, color difference, etc., and achieve the effect of improving tensile properties, satisfying finished product quality indicators, and good color fastness.

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

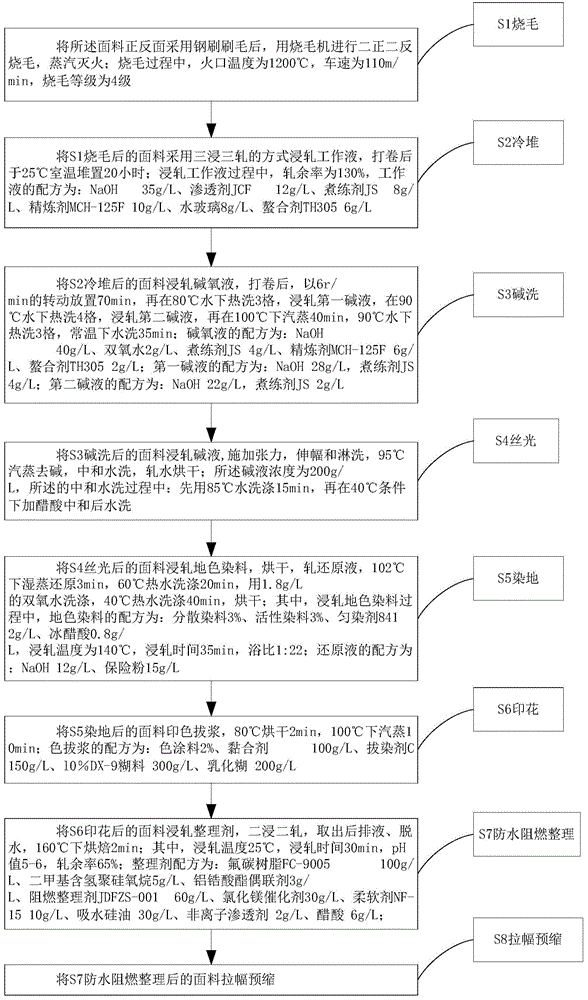

[0025] like figure 1 as shown, figure 1 It is a flow chart of the printing and dyeing process of a camouflage fabric proposed by the present invention.

[0026] refer to figure 1 , a kind of printing and dyeing process of camouflage fabric, described camouflage fabric is made of 30wt% cotton fiber, 50wt% polyester fiber, 10wt% spandex fiber, 10wt% spun silk fiber blended interweaving, comprising the following steps:

[0027] S1 singeing

[0028]After brushing the front and back of the fabric with a steel brush, use a singeing machine to singe the front and back, and put out the fire with steam; during the singeing process, the burner temperature is 1200°C, the vehicle speed is 110m / min, and the singeing grade is 4;

[0029] S2 cold stack

[0030] The fabric after S1 singeing is pad-rolled with working liquid by three-dipping and three-rolling, and stacked at room temperature of 25°C for 20 hours after coiling; during the process of pad-rolling working liquid, the excess ra...

Embodiment 2

[0044] A printing and dyeing process for a camouflage fabric, wherein the camouflage fabric is blended and interwoven with 50% cotton fiber, 30% polyester fiber, 10% spandex fiber and 10% spun silk fiber by weight percentage, comprising the following steps:

[0045] S1 singeing

[0046] After brushing the front and back of the fabric with a steel brush, use a singeing machine to singe the front and back, and put out the fire with steam; during the singeing process, the burner temperature is 1300°C, the vehicle speed is 100m / min, and the singeing grade is 5;

[0047] S2 cold stack

[0048] The fabric after S1 singeing is pad-rolled with working solution by three-dipping and three-rolling method, and stacked at room temperature of 25°C for 25 hours after coiling; during the process of pad-rolling working solution, the excess rate is 120%, and the formula of working solution is : NaOH40g / L, penetrating agent JCF10g / L, scouring agent JS10g / L, refining agent MCH-125F8g / L, water gl...

Embodiment 3

[0062] A printing and dyeing process for a camouflage fabric, the camouflage fabric is formed by blending and interweaving 30% cotton fibers, 40% polyester fibers, 10% spandex fibers, and 20% spun silk fibers by weight, comprising the following steps:

[0063] S1 singeing

[0064] After brushing the front and back of the fabric with a steel brush, use a singeing machine to singe the front and back sides, and put out the fire with steam; during the singeing process, the burner temperature is 1250°C, the vehicle speed is 105m / min, and the singeing grade is 5;

[0065] S2 cold stack

[0066] The fabric after S1 singeing is pad-rolled with working liquid by three-dipping and three-rolling, and stacked at room temperature of 25°C for 23 hours after coiling; during the process of pad-rolling working liquid, the excess rate is 125%, and the formula of working liquid is : NaOH38g / L, penetrant JCF11g / L, scouring agent JS9g / L, refining agent MCH-125F9g / L, water glass 9g / L, chelating ag...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com