Patents

Literature

65results about How to "Good color fastness" patented technology

Efficacy Topic

Property

Owner

Technical Advancement

Application Domain

Technology Topic

Technology Field Word

Patent Country/Region

Patent Type

Patent Status

Application Year

Inventor

Dyeing process for elastic polyester-polyurethane fabric

InactiveCN101046064AEasy to dyeNo pollution in the processFibre treatmentDyeing processColour fastnessDisperse dye

The dyeing process for elastic polyester-polyurethane fabric includes one dyeing step and one reducing and cleaning step. The dyeing step using disperse dye, ammonium acetate and dyeing assistant is performed in certain bath ratio and at certain temperature. The reducing and cleaning step using sodium hydrosulfite, sodium hydroxide and cleaning assistant is performed in certain bath ratio. The dyeing process can dye polyester component well at low temperature dyeing condition, and has well dyeing on polyurethane component and high color fastness.

Owner:毛中水

Dyeing method for multilevel-color jean yarns

The invention relates to a dyeing method for multilevel-color jean yarns. The dyeing method comprises the following steps: carrying out modification treatment on yarns by adopting a cationic modifying agent; padding 1-2 paths of pigment printing paste on the treated yarns at a room temperature and drying; then carrying out continuous rolling and dyeing by indigo blue and sulfur dyestuff or overdyeing of the indigo blue and the sulfur dyestuff. The jean yarns produced by the dyeing method are bright in color and luster, good in color fastness, pure in colored light and low in room-temperature dyeing power consumption; the quantity of indigo blue dyeing grooves is reduced by priming a high-fastness pigment; a process flow is shortened, the pollution discharge is reduced and the production cost is reduced.

Owner:SHANDONG DAIYIN TEXTILE GROUP SHARE CO LTD

Pigment printing binding agent and synthesizing method thereof

ActiveCN102182080AGood flexibilityImprove breathabilityDyeing processHazardous substanceALLYL SUCROSE

The invention provides a pigment printing binding agent and a synthesizing method thereof. The binding agent is prepared from silicone-acrylate copolymer, aqueous polyurethane, liquid rubber, an emulsifying agent and the like. By taking advantage of the high film-forming property of polyacrylic acid, the high flexibility of organic silicone, the high air permeability of polyurethane and the high elasticity of the liquid rubber, the high-fastness and super-soft pigment printing binding agent is prepared by a complex synergistic technology. The binding agent has high film-forming property, air permeability, flexibility and elasticity, good handfeel and high color fastness. After the binding agent is applied to a printing fabric, the release amount of a harmful substance, namely formaldehyde, is small.

Owner:成都德美精英化工有限公司

Method for preparing dry-type water-soluble colorful rock slices

InactiveCN101456965AIncrease elasticityGood color fastnessPolyurea/polyurethane coatingsCost savingsTin

The invention relates to a preparation method for a dry-type water colored sliver, comprising following technical steps: 1) preparation of polyurethane modification acrylic acid latex: dihydric alcohol is put into a reactor and then temperature is increased to 70 DEG C to 100 DEG C, then dihydric alcohol and organic tin dihydric alcohol is added and temperature is increased to 100 DEG C + / - 5 DEG C for 2 to 4 hour reaction, then temperature is decreased to 60 DEG C + / - 5 DEG C and methyl acrylate and dihydroxy methylpropanoic acid are added, then circumfluence temperature is controlled at 60 DEG C to 80 DEG C and reaction is carried out for 6 hours + / - 0.5 hours; when NCO value in reaction system is lower than 1, prepolymer is transferred into a dispersator and is dispersed in water dissolved in neutralizing agent of triethylamine, then water polyurethane is prepared; 50 to 100 pieces of water polyurethane are put into a reactor, temperature is increased to 70 DEG C to 90 DEG C and polyurethane modification acrylic acid co polymerization latex is obtained: step 2, the preparation of dry-type water colored sliver. The dry-type water colored sliver of the invention has the advantages of fine climate resistance performance, no conglutination on the way of transportation, fine elasticity, no discharging of organic matter with volatility and cost saving.

Owner:JIANGSU GUOLIAN TECH

Chinlon dyeing process adopting natural dye

InactiveCN104695241AReduce pollutionAvoid damageFibre typesHeating/cooling textile fabricsColour fastnessFiber

The invention provides a chinlon dyeing process adopting natural dye. The method comprises the steps of pretreatment, presetting, dyeing, soaping, fixation, softening treatment, drying, setting and rolling. The natural dye, alizarin, is adopted, rare earth chloride is adopted as dye mordant, the dyeing effect is better, the washability is greatly enhanced, and meanwhile dyed chinlon fibers have the good antibacterial property. The washing and fixation process is added, the dyeing firmness is good, environment-friendly formaldehyde-free TCD-R is adopted in the fixation process, chinlon is dried step by step after fixation, and the firmness of the chinlon is greatly improved. The softening treatment process is added, the color fastness and softness of fabric are improved, the roughness of the fabric is reduced, and the fabric is fluffy and elastic.

Owner:TAICANG TIANLONG CHEM FIBER

Dyeing process of polyester cotton fiber fabric

ActiveCN103993487AAvoid wrinklesAvoid severe shrinkageHeating/cooling textile fabricsDyeing processDisperse dyePolymer science

The invention provides a dyeing process of a polyester cotton fiber fabric. The dyeing process comprises the following steps of preforming, pretreatment, drying, dyeing, washing, soaping, color fixing, drying, forming and winding. According to the dyeing process, a high-temperature leveling agent is added during dyeing, so that the problem that level dyeing effect and penetration dyeing effect are affected and even generate color dots and color patches occur caused by gathering of dyes because the heat stability resistance of fuel is reduced due to temperature increase is avoided, and the dyeing effect is good; the temperature is increased in a stepped progressive mode in the dyeing procedure, and the temperature increase and decrease velocity and the dyeing time are strictly controlled, so that high dyeing fastness, dyeing uniformity and good dyeing stability of the polyester cotton fiber fabric are achieved; the dyes with single property are not used and dispersed dyes and neutral dyes are compounded in the dyeing procedure, and the dispersed dyes and the neutral dyes supplement each other, so that good dyeing fastness is achieved; the traditional two-bath two-step method dyeing is abandoned, and the one-bath one-step method dyeing is adopted, so that the energy is saved, and the emission amount is reduced.

Owner:广东欣薇尔服装有限公司

Production process of chemical fabric with good air permeability

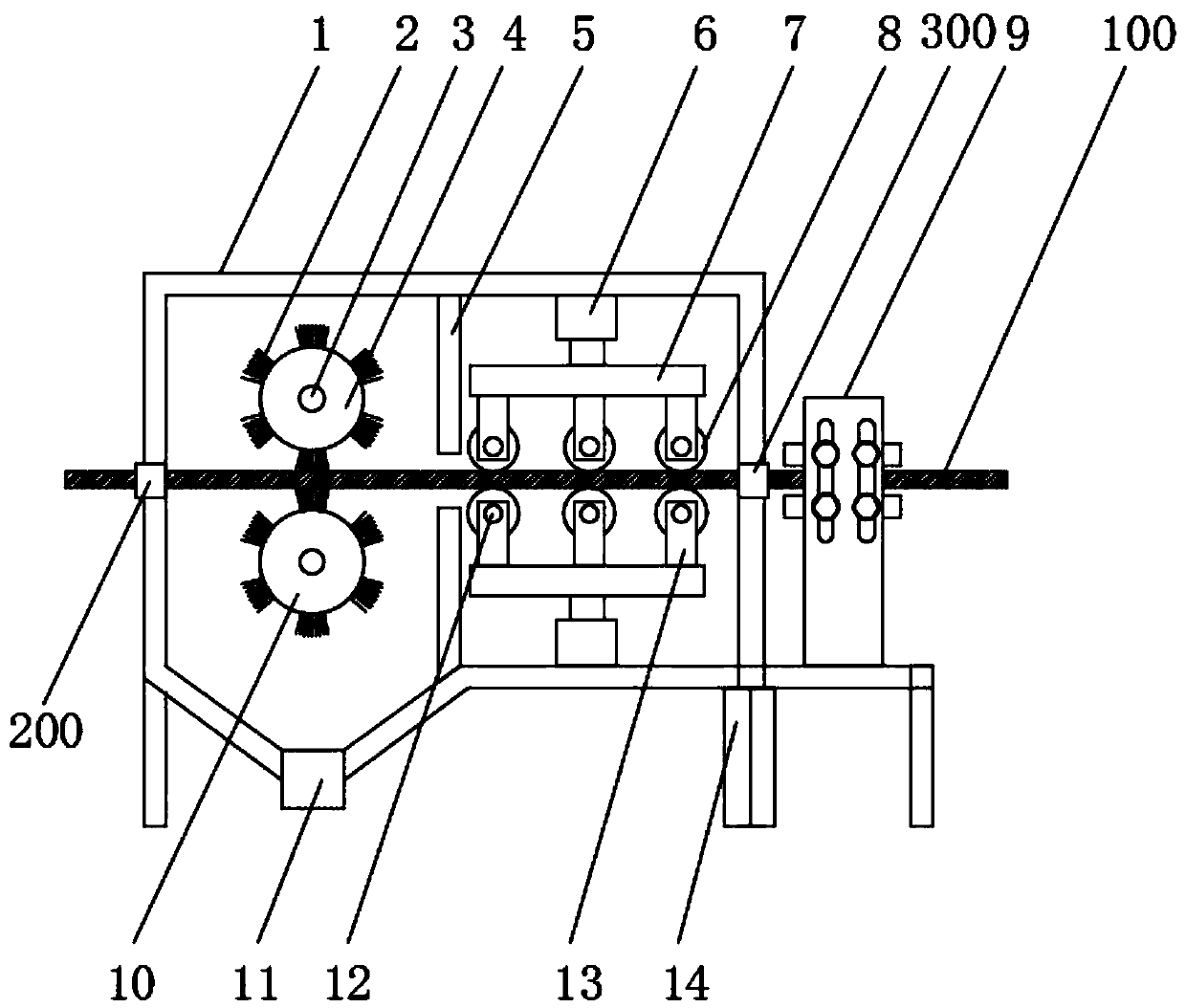

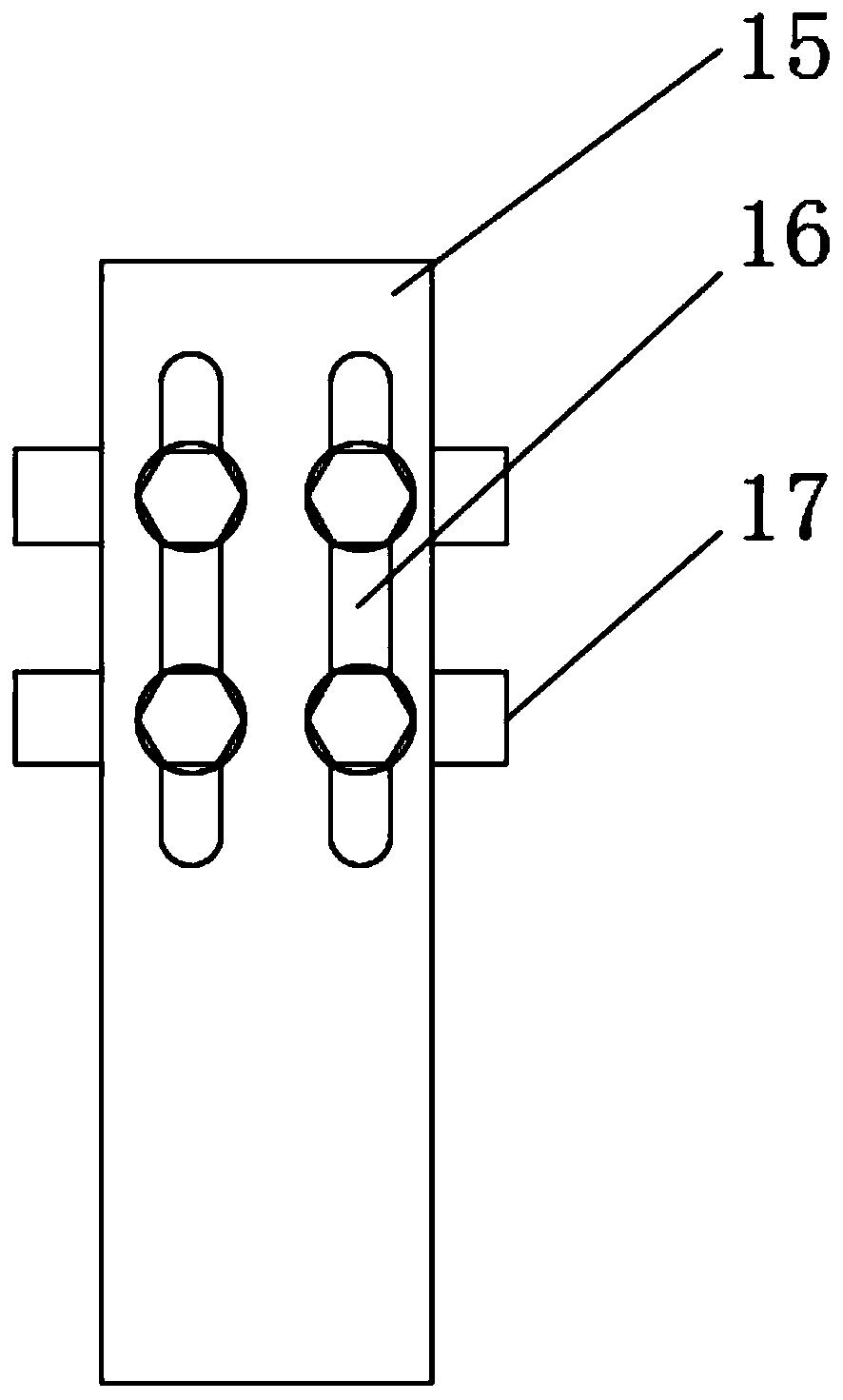

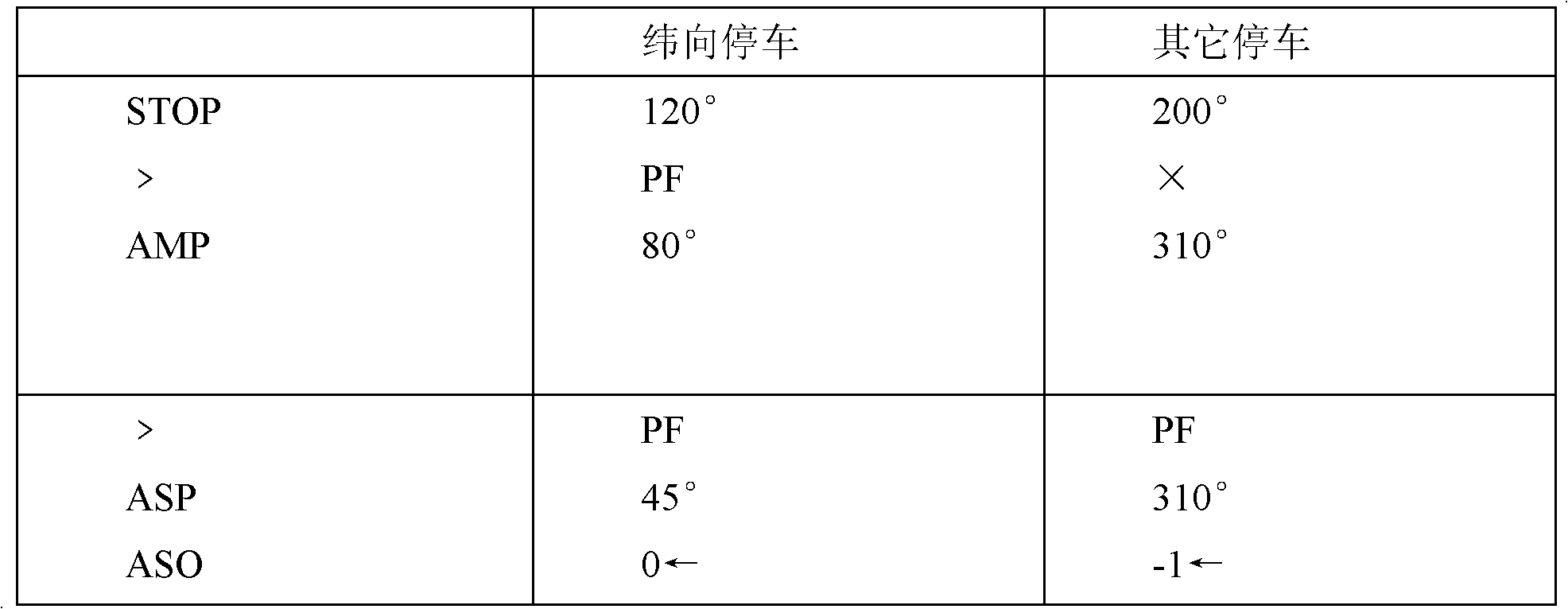

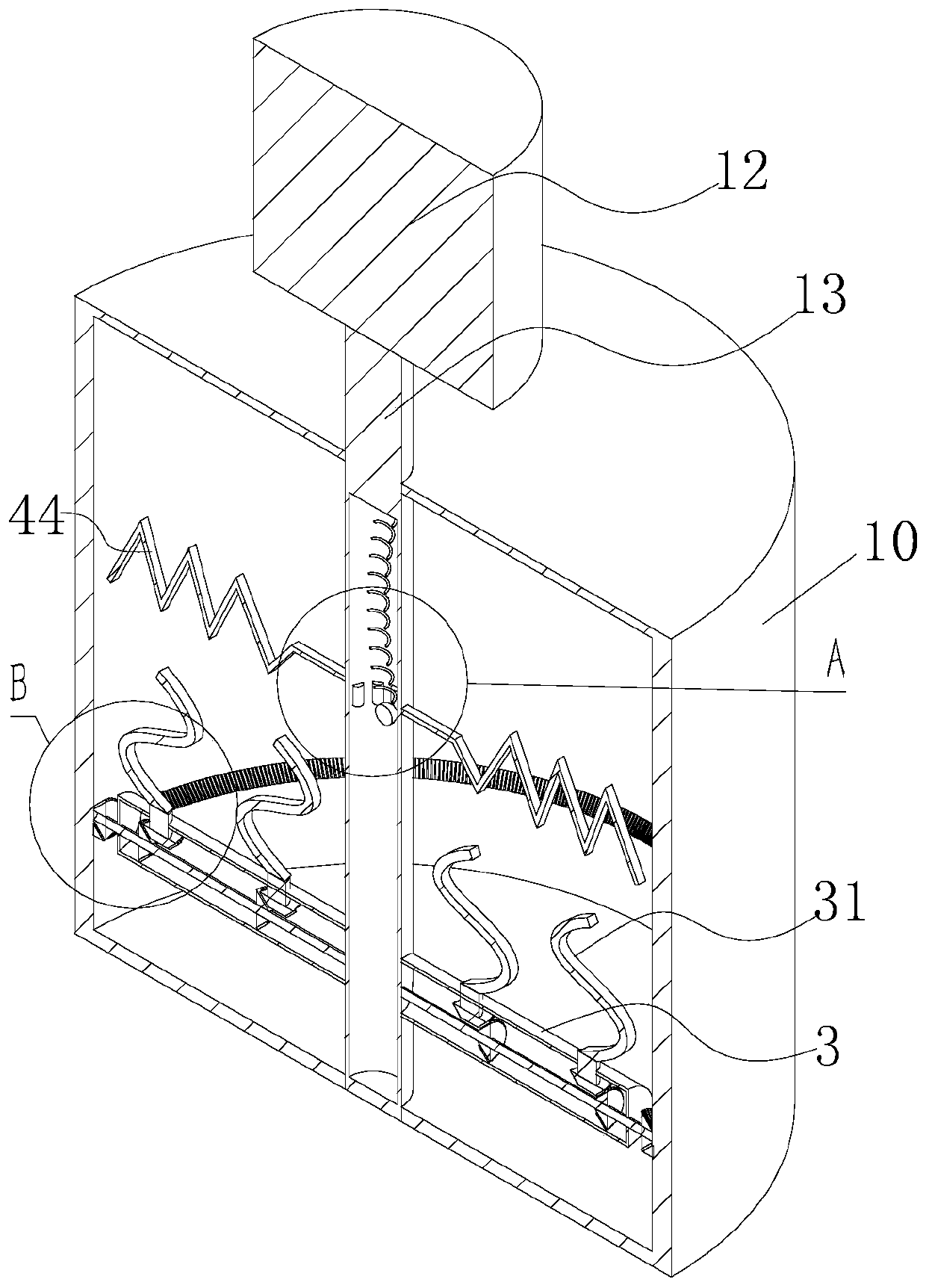

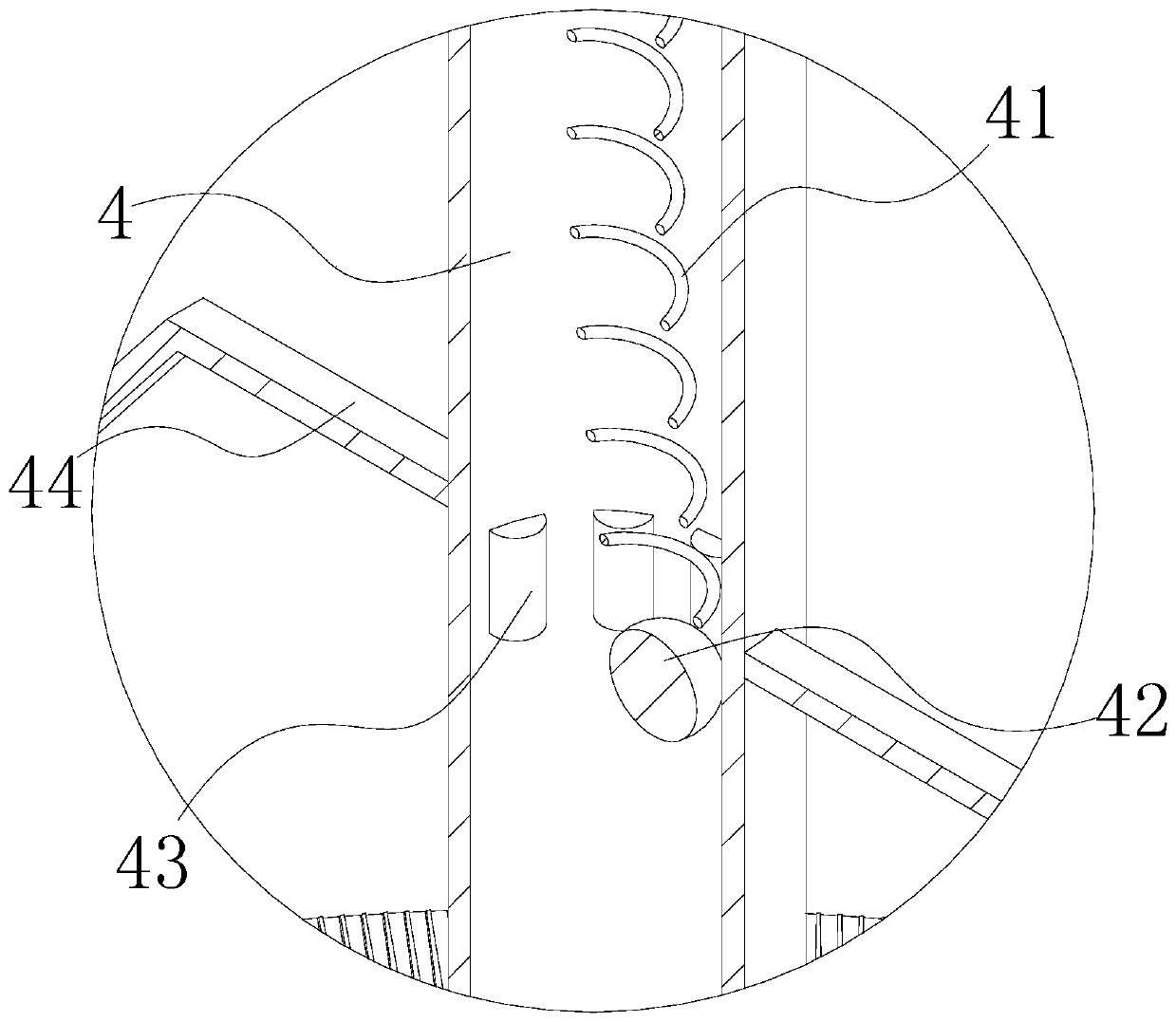

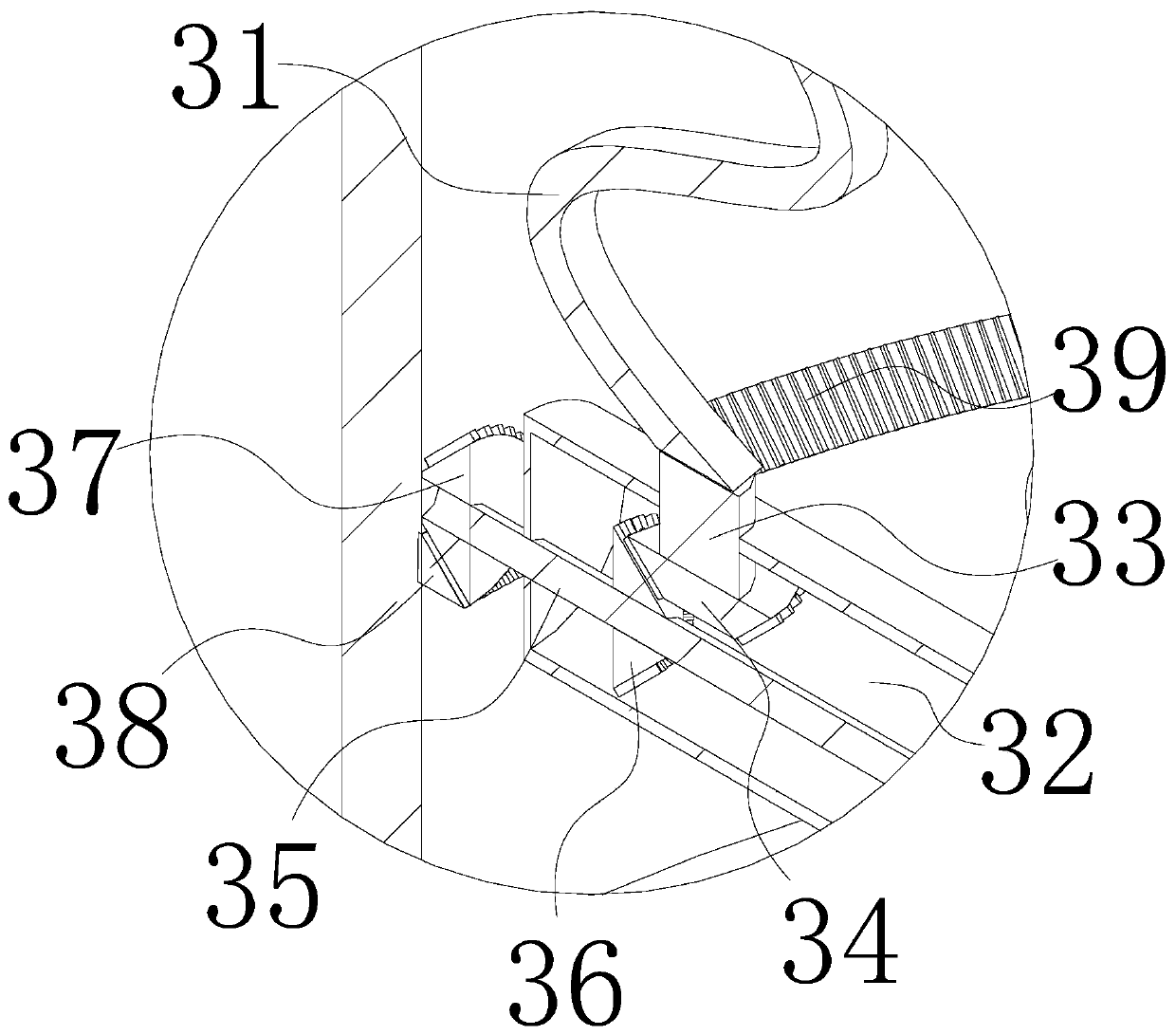

InactiveCN111041649AColorfulGood color fastnessMechanical cleaningPressure cleaningChemistryProcess engineering

The invention discloses a production process of a chemical fabric with good air permeability. The chemical fabric with good air permeability is made by mixing and weaving viscose fibers and polyesterfibers, the viscose fibers have the nature of cotton, the quality of the silk, and have the features of being smooth and cool, and air permeable, so that the air permeability of the chemical fabric isgood; a fabric cleaning device is used in the production process of the chemical fabric, when the device cleans the fabric to be cleaned, heavy sundries on the blended fabric are removed by brushes of an upper cleaning roller and a lower cleaning roller; an air blower operates to generate wind power to suck light sundries attached to the blended fabric into dust collection rollers through ventilation holes; when the blended fabric passes through a singeing mechanism, hot metal plates burn off surface lousiness of the blended fabric, and due to three times of cleaning of the device, the cleaning effect is good; the distance between upper and lower rows of the dust collection rollers of the device and the distance between two metal plates can be adjusted freely according to the thickness ofthe fabric, so that the device is applicable to a wide range.

Owner:安徽绿源高分子材料科技有限公司

High-emulation bamboo joint longitude and latitude heterochromatic textile and preparation method thereof

ActiveCN102560828AGood color fastnessGood moisture absorption and air permeabilityWoven fabricsYarnAbnormal shapedAnti wrinkle

The invention provides a high-emulation bamboo joint longitude and latitude heterochromatic textile which is woven by organzines and filling yarns, wherein the organzines comprise organzines A and organzines B, the organzines A are formed by the means that covering yarns with granularity of 32 inches are covered into spandex with 40 deniers and spun in a twisting way, the organzines B are formed by the means that covering yarns with granularity of 21 inches are covered into spandex with 40 deniers and spun in a twisting way, the covering yarns consist of cation polyster fiber with the weight percentage of 65% and viscose with the weight percentage of 35%, the filling yarns comprise filling yarns A and filling yarns B, the filling yarns A are formed by twisting the triangular abnormal-shape dacron filament which is formed by 84 single fibers and has the fineness of 150 deniers with the spandex with 40 deniers after air covering, and the filling yarns B are formed by the triangular abnormal-shape dacron filament which is formed by 84 single fibers and has the fineness of 150 deniers. The invention further discloses a preparation method of the textile. Compared with the prior art, the textile has the advantages of being abrasion-resistant, anti-wrinkle, good in size stability, good in color fastness, good in moisture absorption and air permeability, and good in elasticity.

Owner:正凯纺织有限公司

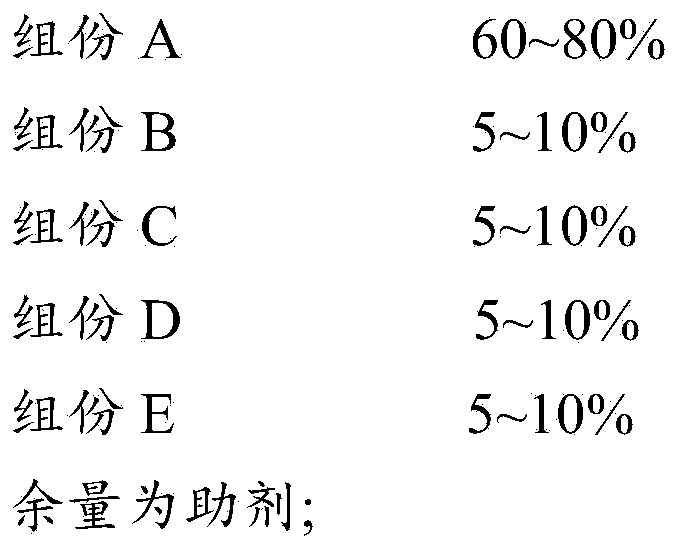

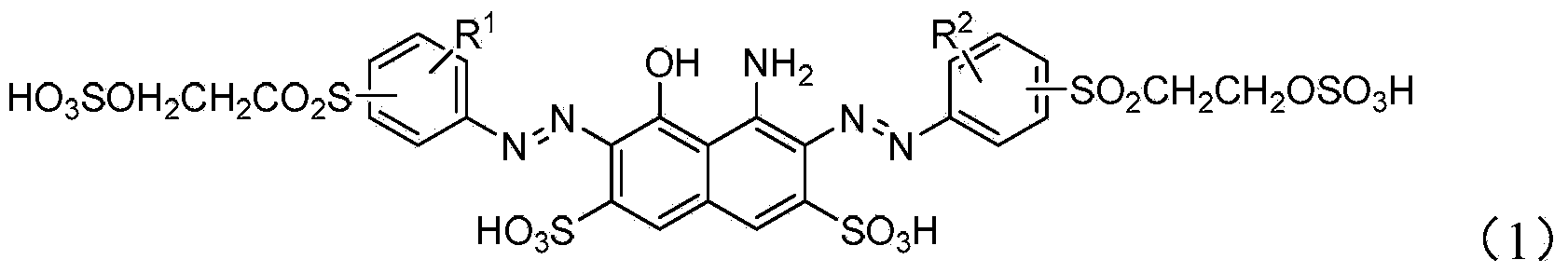

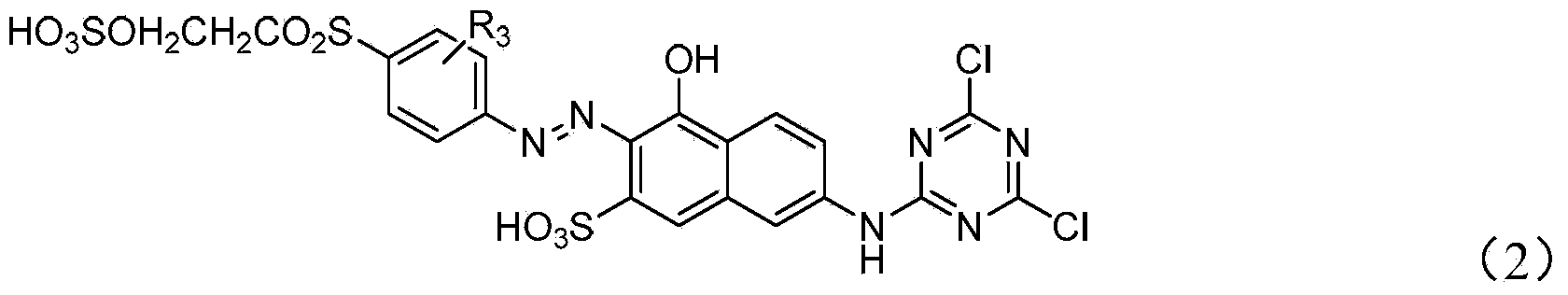

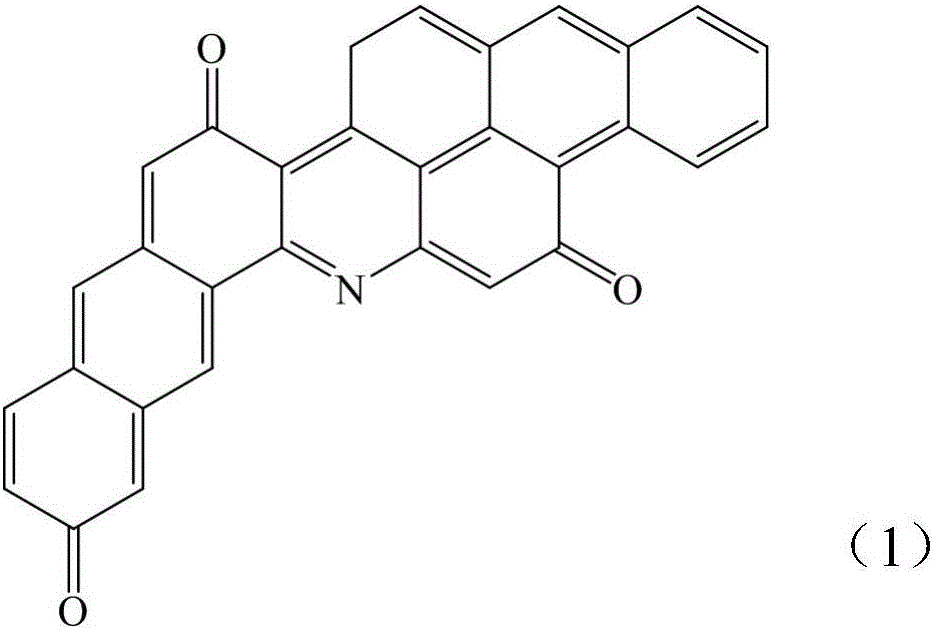

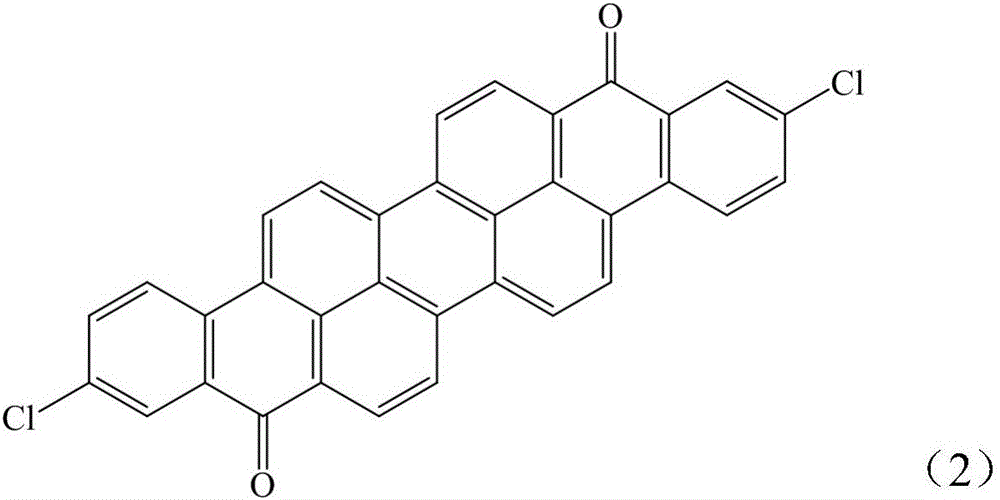

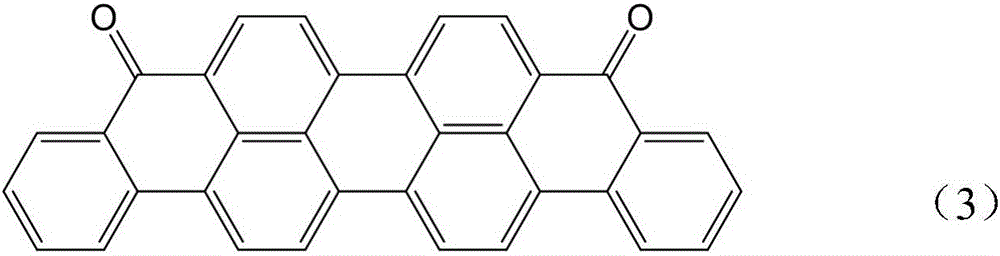

Composite activity black dye

The invention discloses composite activity black dye which comprises the following components by weight percentage: 60-80% of component A in formula (1), 5-10% of component B in formula (2), 5-10% of component C in formula (3), 5-10% of component D in formula (4), and 5-10% of component E in formula (5), wherein the component A, component B, component C, component D, component E, the formula (1), formula (2), formula (3), formula (4) and formula (5) are shown in the Specification. The composite activity black dye comprises the five components in a mixed manner, and the blackness of the dye is improved; in addition, the hydrophilia / lipophilicity and substantivity to fiber of the five components are similar, the dying and the fixation properties coordinate, the leveling property is excellent, and various fastnesses of the obtained dye are excellent.

Owner:ZHEJIANG SHUNLONG CHEM

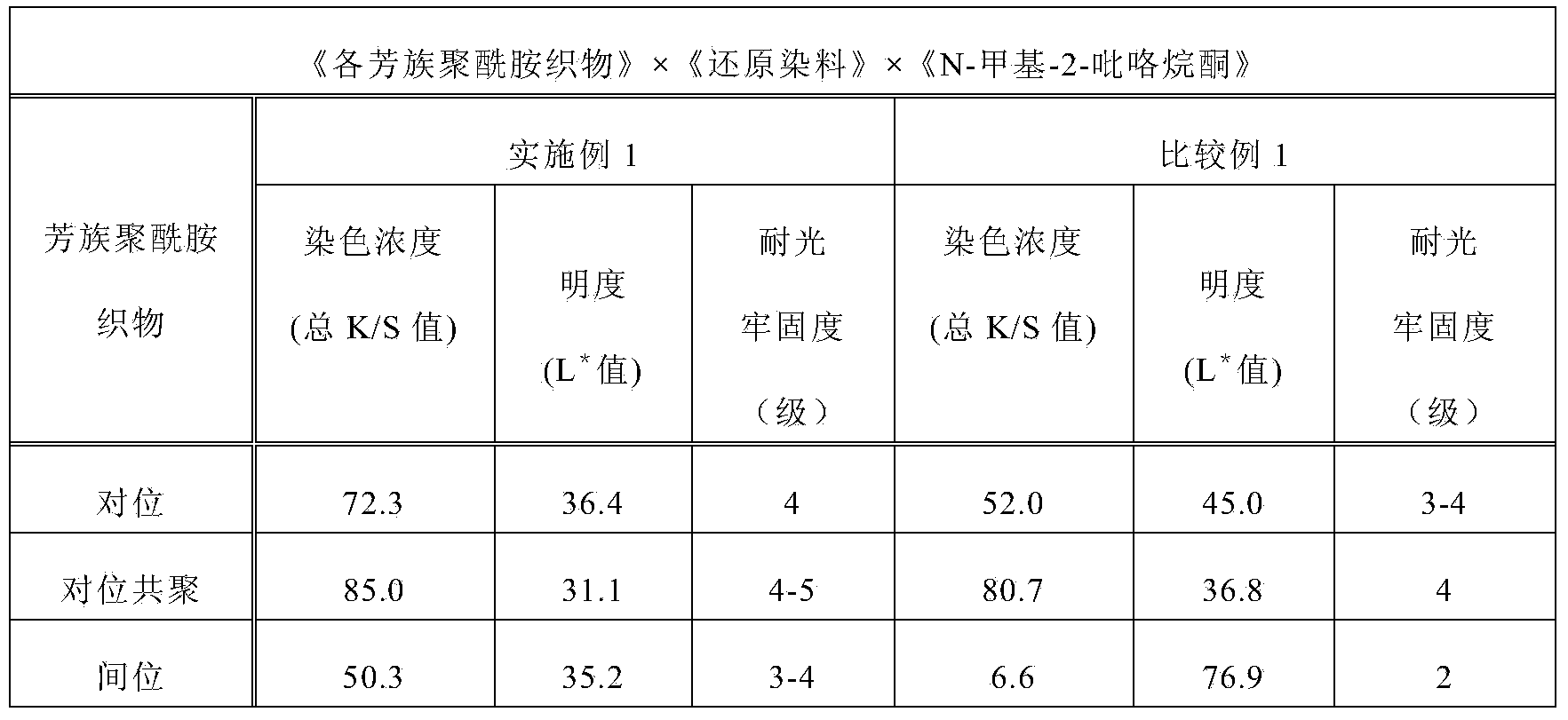

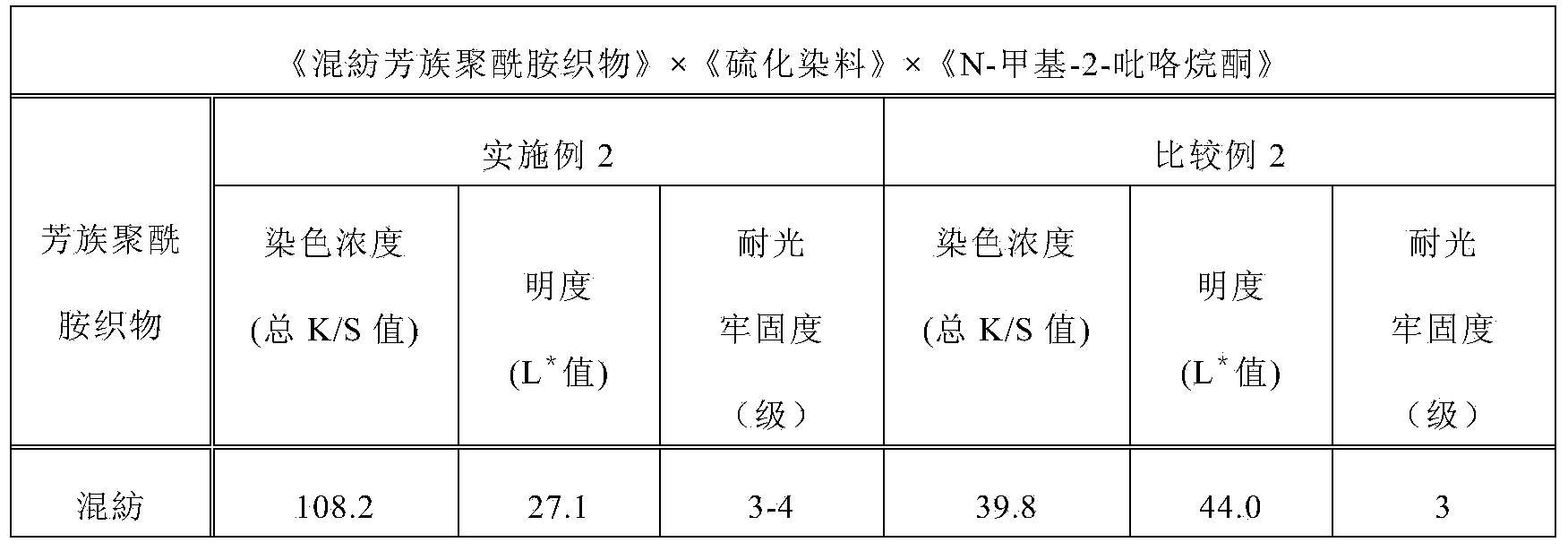

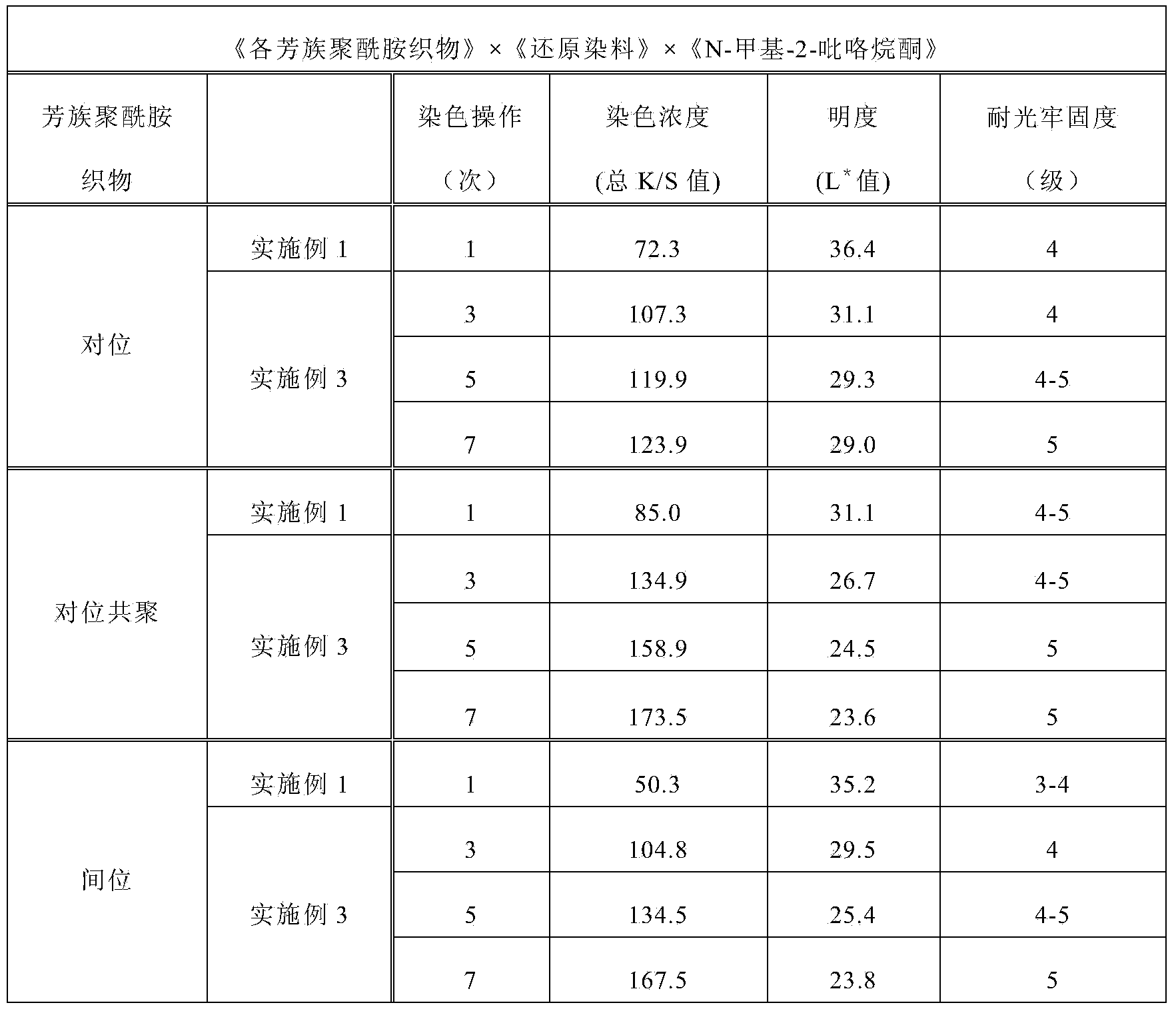

Method for dyeing aramid fibers and dyed aramid fibers

Provided are a method for dyeing aramid fibers and dyed aramid fibers. The method is applicable to any of para-aramid fibers, para-coaramid fibers, and meta-aramid fibers and by which aramid fibers are dyed in practical concentrations required for new applications of aramid fibers. The dyed aramid fibers have suffered neither considerable dyeing unevenness nor a considerable dimensional change nor a considerable decrease in material property. The dyed fibers further have satisfactory color fastness, in particular, light fastness. The dyeing method which comprises one or more dyeing operations each comprising a combination of the following steps: a dye application step in which a vat dye or a sulfur dye is applied to the aramid fibers; a solvent treatment step in which the aramid fibers are treated with a treating liquid comprising a polar solvent; and a heat treatment step in which after the solvent treatment step, the aramid fibers are heat-treated according to need.

Owner:TOKAI SENKO KK +1

Manufacturing process for indigo dye and blue-dyed printed fabric

The invention discloses a manufacturing process for an indigo dye and a blue-dyed printed fabric. The indigo dye is manufactured by the following components in percentage by weight: 20 to 25 percent of indigo, 16 to 18 percent of sodium carbonate aqueous solution, 3 to 5 percent of quick lime, 7 to 8 percent of rice wine, 5 to 6 percent of fresh pig blood, 5 to 6 percent of tea tree stem ash, and the balance of water. According to the manufacturing process, the ash which is manufactured by adopting tea tree stems which specifically exist in the Jiangnan area replaces the conventional ash manufactured by fern leaves or artemisia vulgaris, so that the colour fastness of a dyed fabric is high; the colour is bright; the process flow is short; the operation is convenient; the cost is low. The manufacturing process has the advantages that the dyed colour is bright; the colour fastness is high; the colour does not fade; the fabric can be washed together with white clothes; the process is simple; the cost is low; the operation is convenient; the dye can be reutilized; emission is avoided; the environment is not polluted. The manufacturing process has particularly outstanding effects when the manufacturing process is used in the conventional blue-dyeing technologies, such as tie-dyeing, wax-dyeing and clamp-dyeing.

Owner:杭州吴越人家工艺服饰有限公司

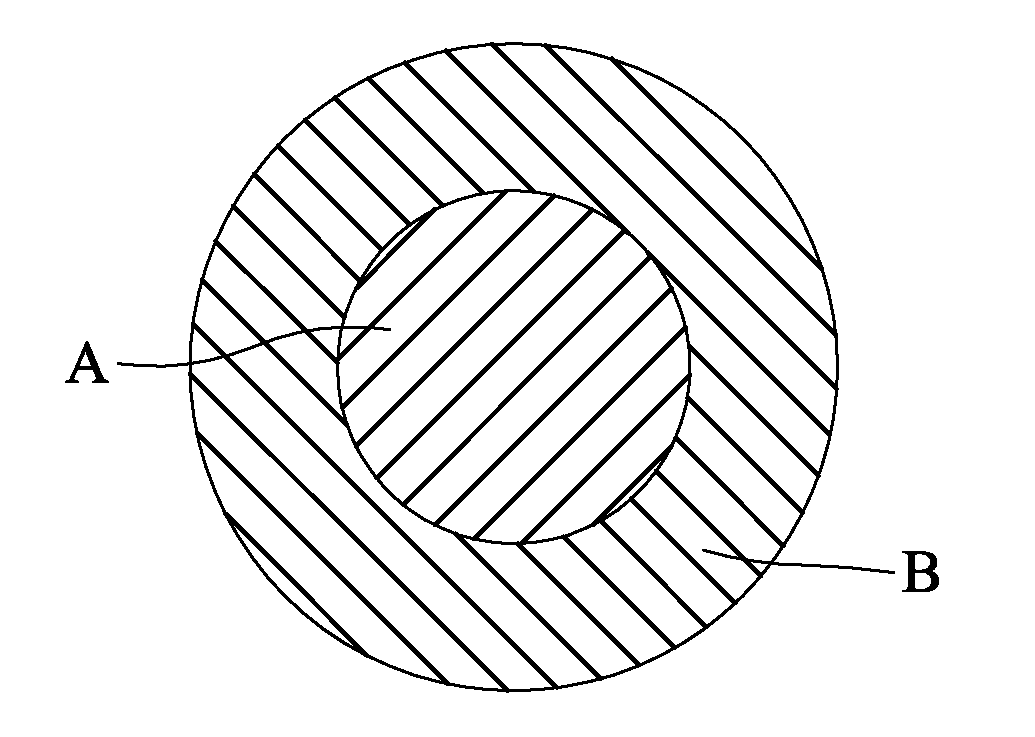

Dope-Dyed Core-Sheath Type Composite Fiber

InactiveUS20150240389A1Good color fastnessEasy to migrateFilament/thread formingConjugated synthetic polymer artificial filamentsFinenessMaterials science

A dope-dyed core-sheath type composite fiber contains a core layer (A) and a sheath layer (B) which entirely covering the core layer (A). The core layer (A) contains at least one or a plurality of dye materials with at least 0.1% wt in the core part, composites of the core layer (A) and the sheath layer (B) are both dye-soluble polymers. The fineness of the core-sheath type composite fiber is more than 0.5 Denier-per-filament, and a cross-sectional area ratio of the sheath layer X(B) and X(B) 20%.

Owner:CHEN YI YUNG

Highly functional polyethylene fiber, and dyed highly functional polyethylene fiber

ActiveCN102812170AHigh exhaustion rateLittle change in physical propertiesWeft knittingFibre typesFiberPolymer science

Provided is a highly functional polyethylene fiber which is small in changes of physical properties and has excellent dimensional stability over a wide range of product processing temperature and a wide range of product's service temperature. Also provided is a highly functional polyethylene fiber which is capable of achieving a high dye exhaustion ratio by a simple dyeing operation and has excellent color fastness. The highly functional polyethylene fibers of the present invention are characterized by having a limiting viscosity [n] of 0.8 dL / g to 4.9 dL / g (inclusive), a repeating unit that is substantially composed of ethylene, a maximum contraction stress as determined by TMA (thermomechanical analysis) of 0.4 cN / dtex or less and a thermal shrinkage at 100 DEG C of 2.5% or less.

Owner:TOYOBO MC CORP

Antibacterial printing and dyeing technology for blended fabric

InactiveCN105484019ANo pollution in the processSimple processFibre treatmentColour fastnessRoom temperature

The invention discloses an antibacterial printing and dyeing technology for a blended fabric. The antibacterial printing and dyeing technology comprises the following steps: (1) bleaching; (2) dyeing; (3) antibacterial finishing, namely dipping the dyed blended fabric into a Chinese medicinal herbal antibacterial solution at room temperature for 20-30 minutes and then dewatering, wherein the Chinese medicinal herbal antibacterial solution is prepared from the following components in percentage by mass: 20%-25% of coptis chinensis, 12%-18% of astragalus membranaceus, 4%-8% of houttuynia cordata, 15%-20% of liquorice, 6%-12% of artemisia argyi and the balance of water; and (4) drying. According to the manner, the antibacterial printing and dyeing technology is simple in process, safe and environment-friendly; and the antibacterial printed and dyed blended fabric is good in color fastness and excellent in antibacterial performance.

Owner:CHANGSHU TONGSHUN PRINTING & DYEING CO LTD

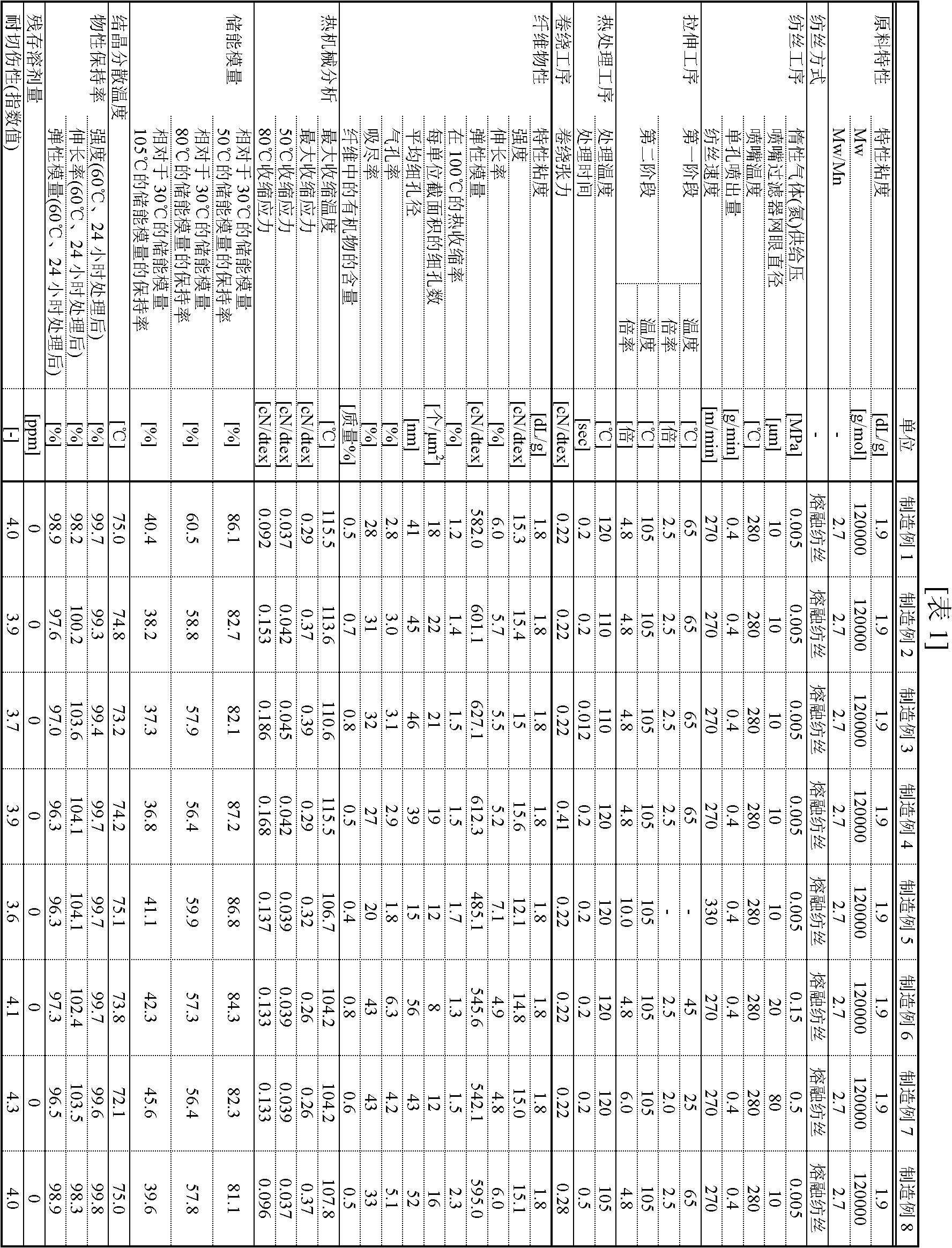

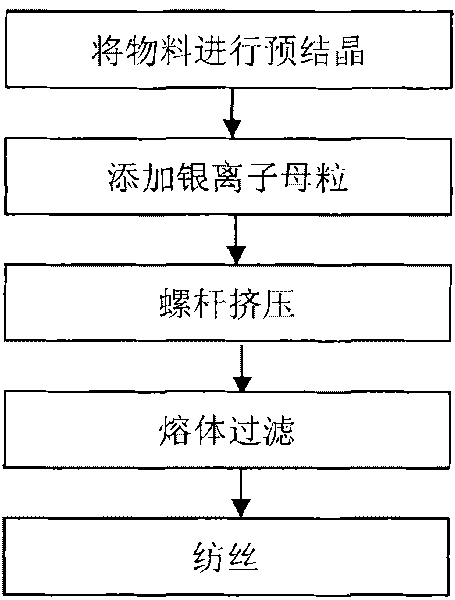

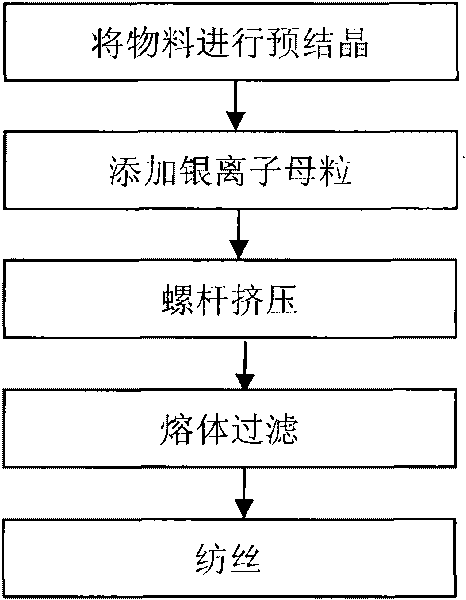

Preparation method of PBT silver-ion antibiotic moisture-absorption deodorization fibre

InactiveCN101760795AExcellent wear resistanceExcellent fiber crimpMelt spinning methodsFilament-forming treatmentFiberMoisture absorption

The invention discloses a preparation method of PBT silver-ion antibiotic moisture-absorption deodorization fibre, which comprises the following steps of: (1) crystallizing a material in advance, wherein the material is the mixture of a PBT slice and a silver-ion SHT antibiotic plastic master batch; concretely, crystallizing in advance by adopting dry hot air; (2) feeding the material in a screw type: firstly, drying the master batch by the hot air and then feeding the material obtained after mixing the master batch and the PBT slice into a screw extruder by a special master batch feeding machine which can measure the master batch; (3) filtering: filtering the mixture extruded by the extruder wherein the continuous production of spinning and the constancy of the pressure of the screw extruder are ensured during filtering; and (4) spinning: delivering the mixture from the filter to a spinning assembly, ejecting from a spinneret plate by the spinning assembly, and then coiling and forming. The fibre has favorable durability, dimensional stability and better elasticity, and the elasticity is free from the influence of the humidity.

Owner:YIZHENG XINGHAI CHEM FIBER

Chemical fiber dyeing technology with ultraviolet protection function

InactiveCN104695240AReduce pollutionAvoid damageFibre treatmentHeating/cooling textile fabricsFiberAnti bacteria

The invention provides a chemical fiber dyeing technology with the ultraviolet protection function. The chemical fiber dyeing technology comprises pretreatment, pre-shaping, dyeing, washing, soaping, color fixing, softening treatment, drying, shaping and rolling. The natural dyestuff of sophora flower bud is adopted, aluminum potassium sulfate dodecahydrate is used as a mordant, the dyeing effect is better, and the washability is greatly enhanced; meanwhile, due to the performance of the sophora flower bud, dyed chemical fiber has the good ultraviolet protection performance and the antibacterial and oxidation resistance; the washing technology and the color fixing technology are added, the dyeing firmness is good, green and environment-friendly and aldehyde-free TCD-R is adopted in the color fixing technology, and the chemical fiber obtained after color fixing is dried step by step, so that the firmness of the chemical fiber is greatly improved; the softening treatment technology is added, the fabric color firmness and flexibility are improved, the fabric roughness is lightened, and the fabric is fluffy and full of elasticity.

Owner:TAICANG TIANLONG CHEM FIBER

High-temperature environmentally-friendly chemical fiber dyeing technology

InactiveCN107164976AGuaranteed functionAvoid damageBiochemical treatment with enzymes/microorganismsDyeing processFiberCellulose

The invention relates to a high-temperature environmentally-friendly chemical dyeing technology. The technology comprises preprocessing, pre-setting, dyeing, water washing, soaping, dye fixation, softening, drying, setting and winding. A stepped heating dyeing method is adopted, and the heating and cooling rates and the dyeing time are strictly controlled, so dyeing of a fiber fabric has high fastness, the dyeing is uniform, and the dyeing has good stability; an anti-dyeing salt S is added in the dyeing process, so the destroy of potential aldehyde groups in cellulose molecules in chemical fiber filaments to a dye is greatly improved, thereby a dyed product has pure color light, the color difference of dyeing is avoided, and the reappearance and the stability of the dyeing are good. Chemical fiber filaments finally produced in the invention have the advantages of uniform dyeing, stability, strong recurrence, elasticity, softness and high dyeing fastness.

Owner:ZHANGJIAGANG JINYI CHEM FIBER

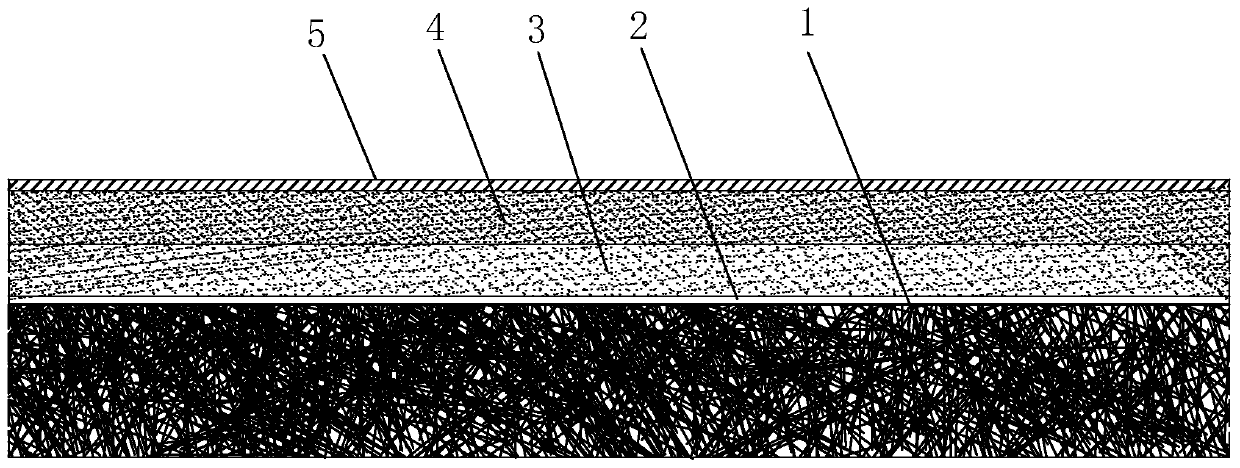

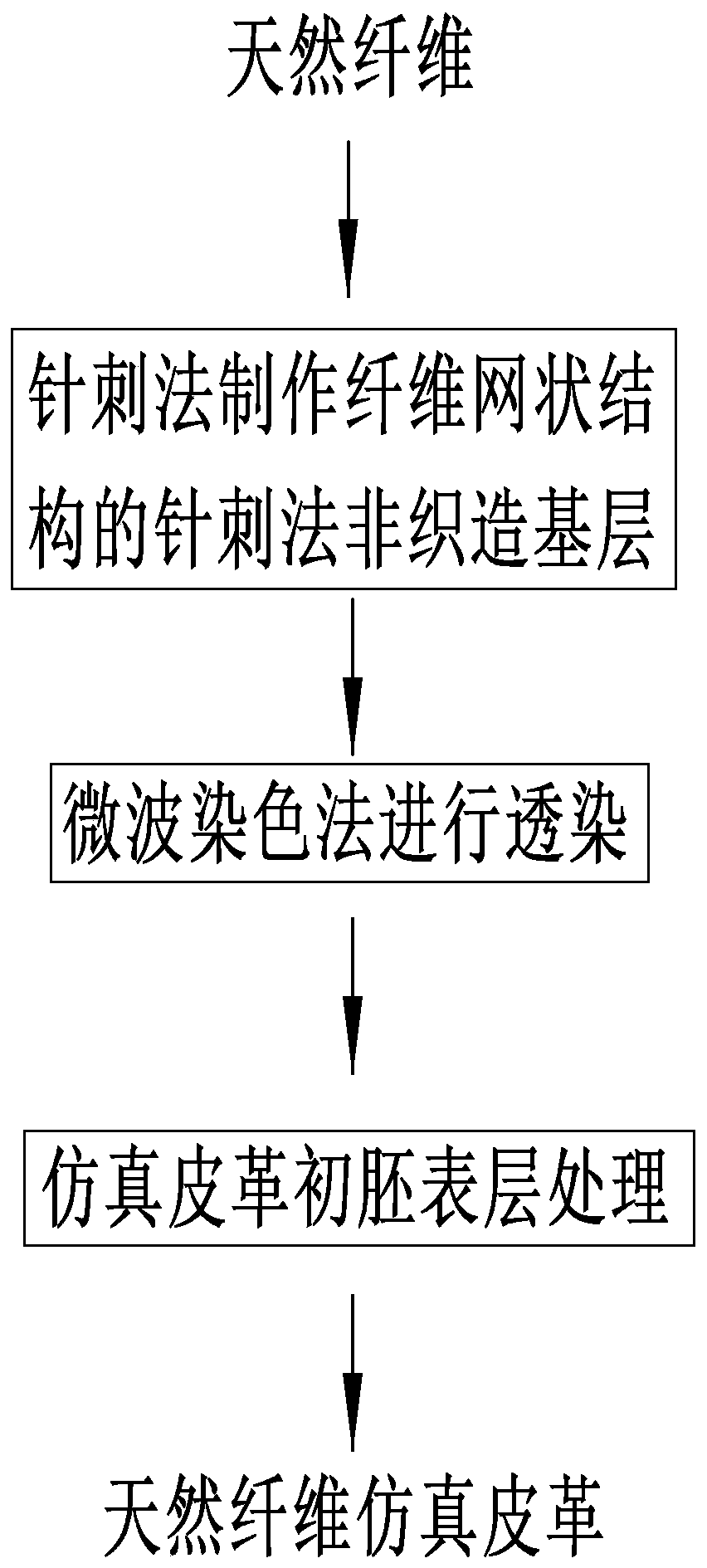

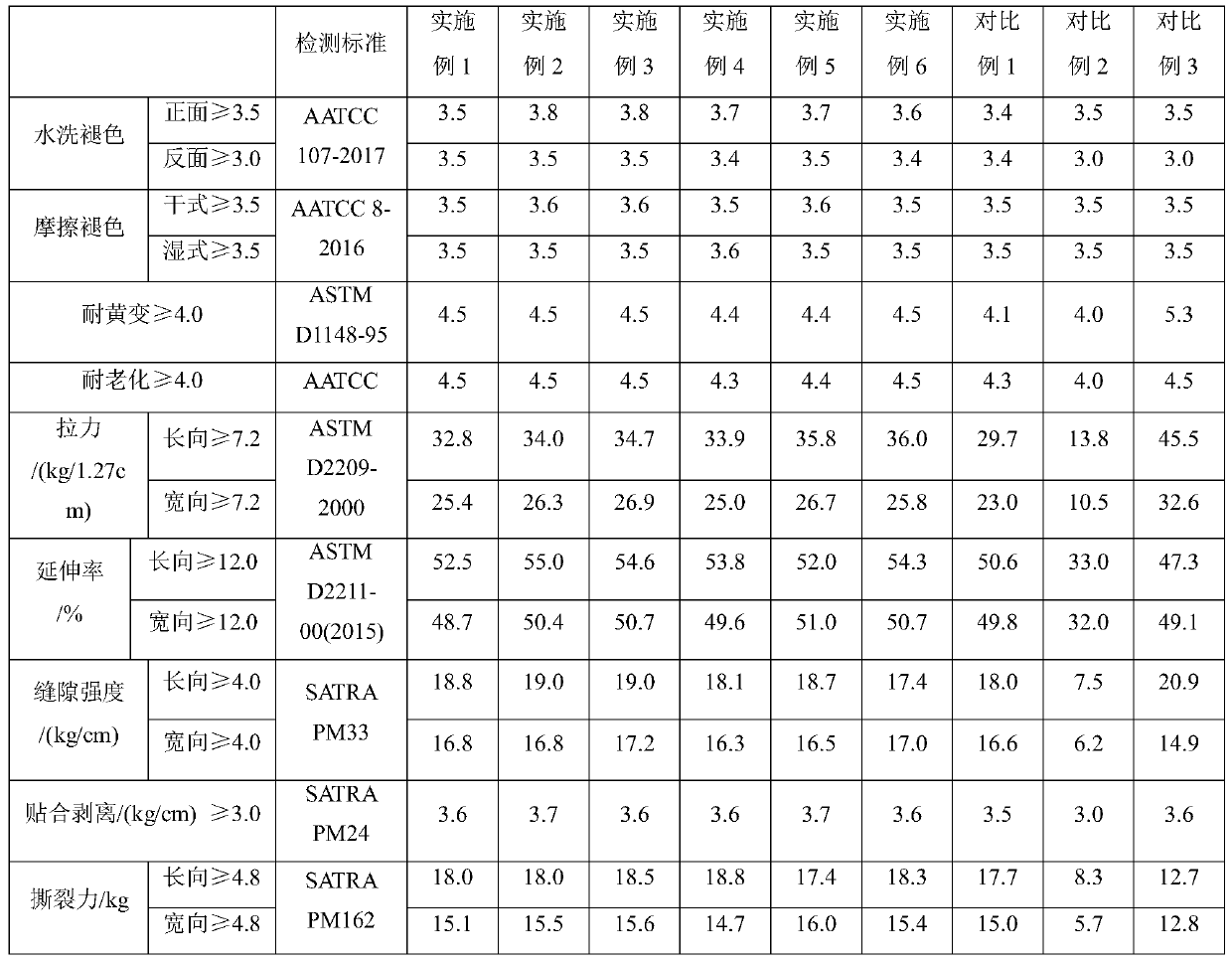

Natural-fiber artificial leather and manufacturing method thereof

ActiveCN110592968AReduce energy consumptionSolve the problem of high water consumptionTextiles and paperWaxMicrowave

The invention relates to the technical field of leather processing, in particular to natural-fiber artificial leather and a manufacturing method thereof. The natural-fiber artificial leather is obtained through the following processing steps: opening, carding and dry-process needling treatment is sequentially conducted on natural fibers to obtain a needled non-woven base layer with a fiber net structure inside; by adopting a microwave dyeing method, the needled non-woven base layer is dyed with a chemical dye in a permeating way to obtain gray artificial leather; the upper surface layer of thegray artificial leather is sequentially coated with a bottom sealing layer, a first resin layer, a second resin layer and an oil wax layer in a rolling way, and polishing is carried out to obtain thenatural fiber artificial leather. By adopting the processing technology, energy is saved, emission is reduced, the method is friendly to the environment, the processed artificial leather has excellent washing fading performance and frictional fading performance and good dyeing firmness, the yellowing resistance and aging resistance reach the standard, and various mechanical properties such as tensile strength, tearing strength and elongation are all higher than the index requirements.

Owner:辛集市宝隆科技有限公司

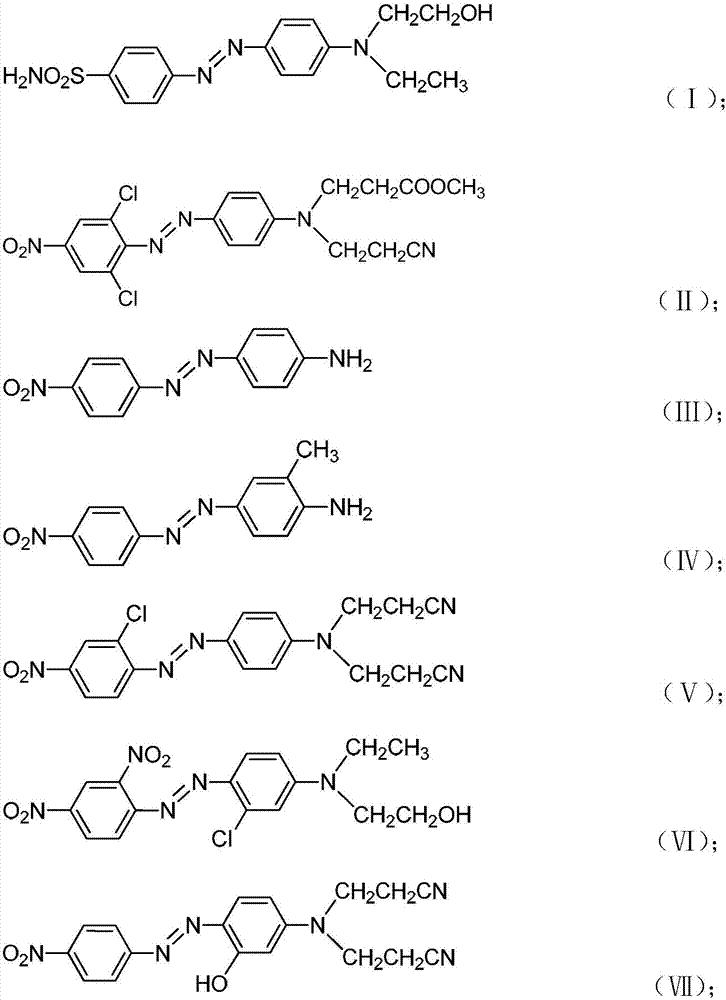

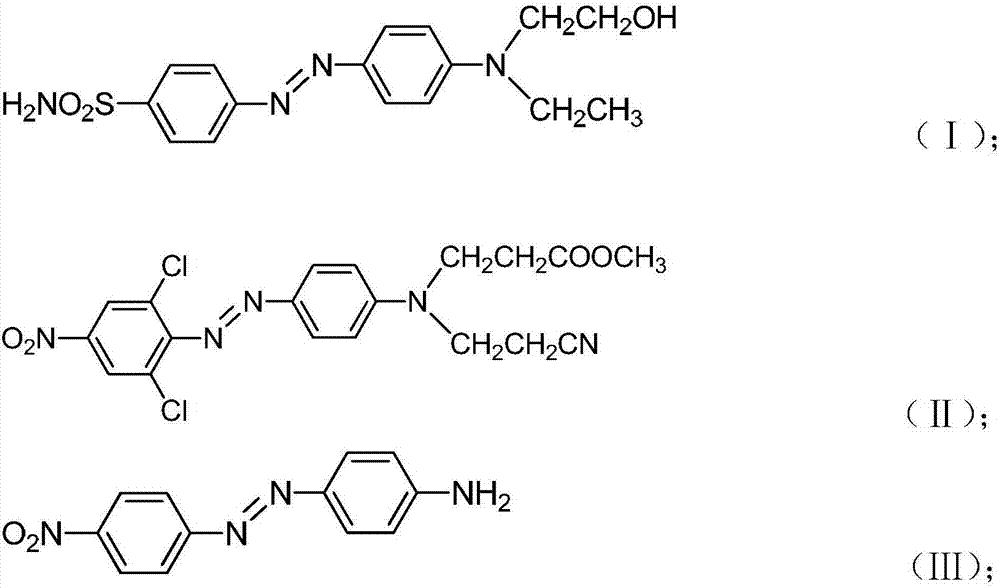

Dye composition and polyester fiber fabric alkaline dyeing method using same

InactiveCN103044964AImprove adaptabilityGood color fastnessOrganic dyesDyeing processPolyesterDyeing

The invention relates to a dye composition which is one or more than two mixtures selected from a structural general formula (I), a structural general formula (II) and a structural general formula (III), or is one or more than two mixtures selected from a structural general formula (IV) and a structural general formula (V), or is one or more than two mixtures selected from a structural general formula (VI), a structural general formula (VII), a structural general formula (VIII) and a structural general formula (IX). Taking borax as medium, the method for polyester fiber fabric alkalinity dye based on the dye composition can achieve acid dyeing effect, and the alkalinity dyeing effect is better than the acid dyeing effect. According to the method and the utilization of the dye composition, the requirement of short dyeing process is met, and the purpose of lowering the energy consumption is achieved.

Owner:SUZHOU UNIV

Dyeing and printing auxiliary agent containing sodium carboxymethyl cellulose

InactiveCN106884345AGood color fastnessHigh color fastnessDyeing processDodecylsulfonic acidGuar gum

The invention provides a dyeing and printing auxiliary agent containing sodium carboxymethyl cellulose. The dyeing and printing auxiliary agent is prepared from the following raw materials in parts by weight: 6 to 8 parts of guar gum, 13 to 15 parts of polyethylene glycol laurate, 8 to 10 parts of polyalkyl acrylate, 12 to 13 parts of the sodium carboxymethyl cellulose, 8 to 10 parts of sodium dodecyl sulfonate, 7 to 8 parts of polyalkyl acrylate, 9 to 10 parts of stearyl dimethylbenzyl ammonium chloride, 6 to 7 parts of fatty alcohol, 5 to 7 parts of ethylene oxide, 2 to 3 parts of acetic acid and 9 to 24 parts of barium chloride. Compared with the prior art, the dyeing and printing auxiliary agent has the beneficial benefits that the dyeing and printing auxiliary agent has good effects of improving the color fastness, protecting color and preventing fading; meanwhile, the utilization amount of dyestuff can be reduced; the dyeing and printing auxiliary agent is green, environment-friendly and non-toxic, and the cost is reduced, so that the dyeing and printing auxiliary agent has wide industrial prospect and wide market value.

Owner:ZHONGSHAN LVLANG ADDITIVES CO LTD

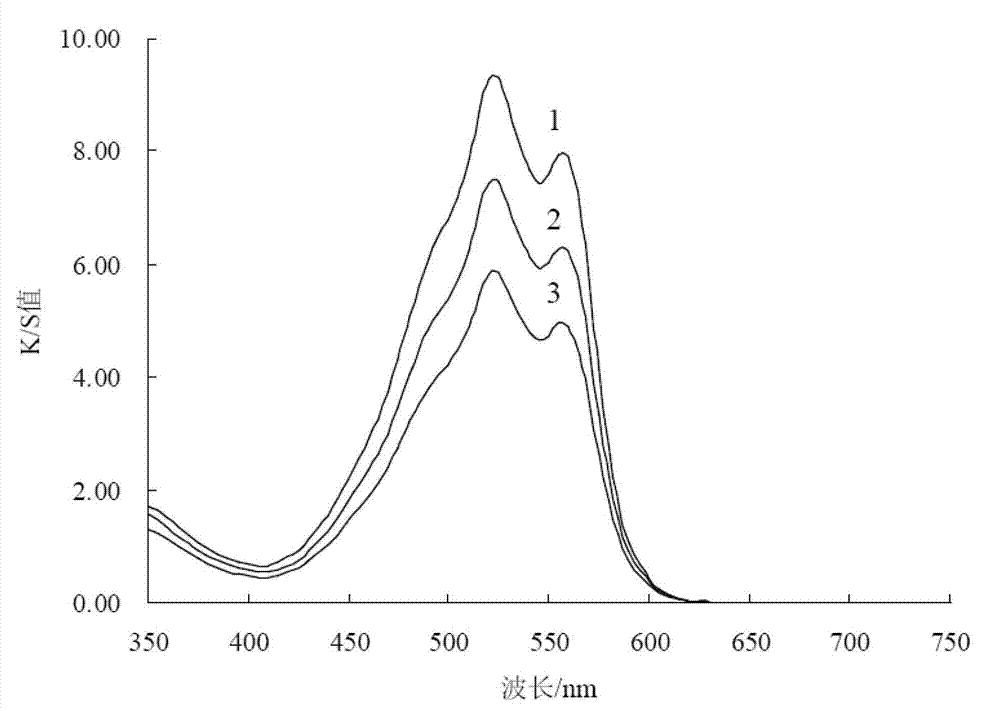

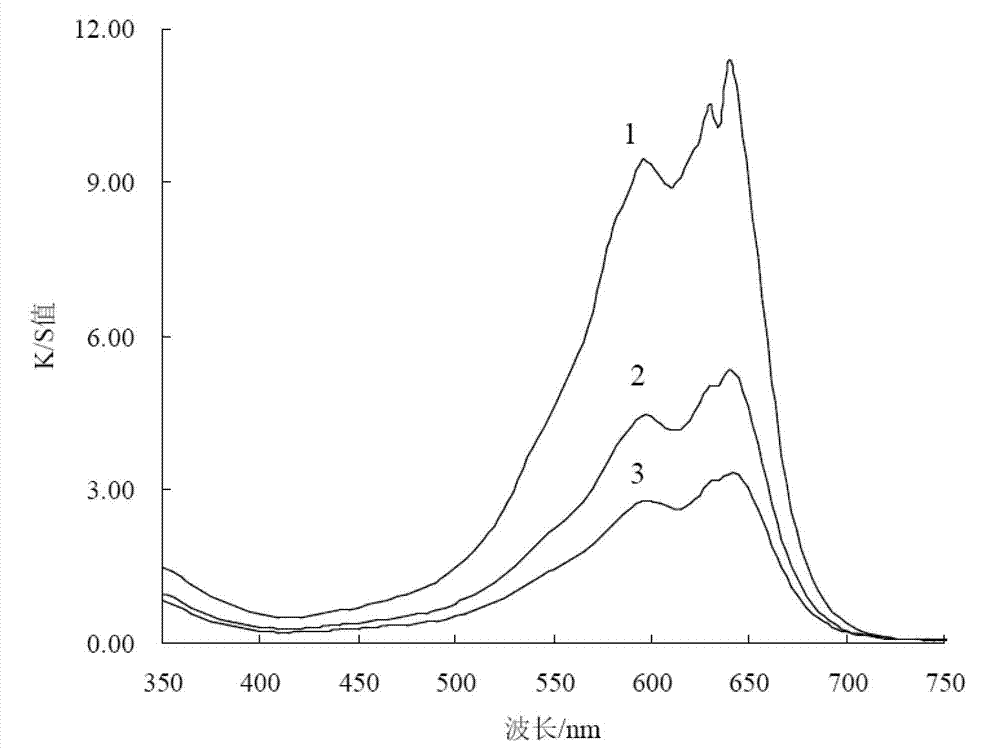

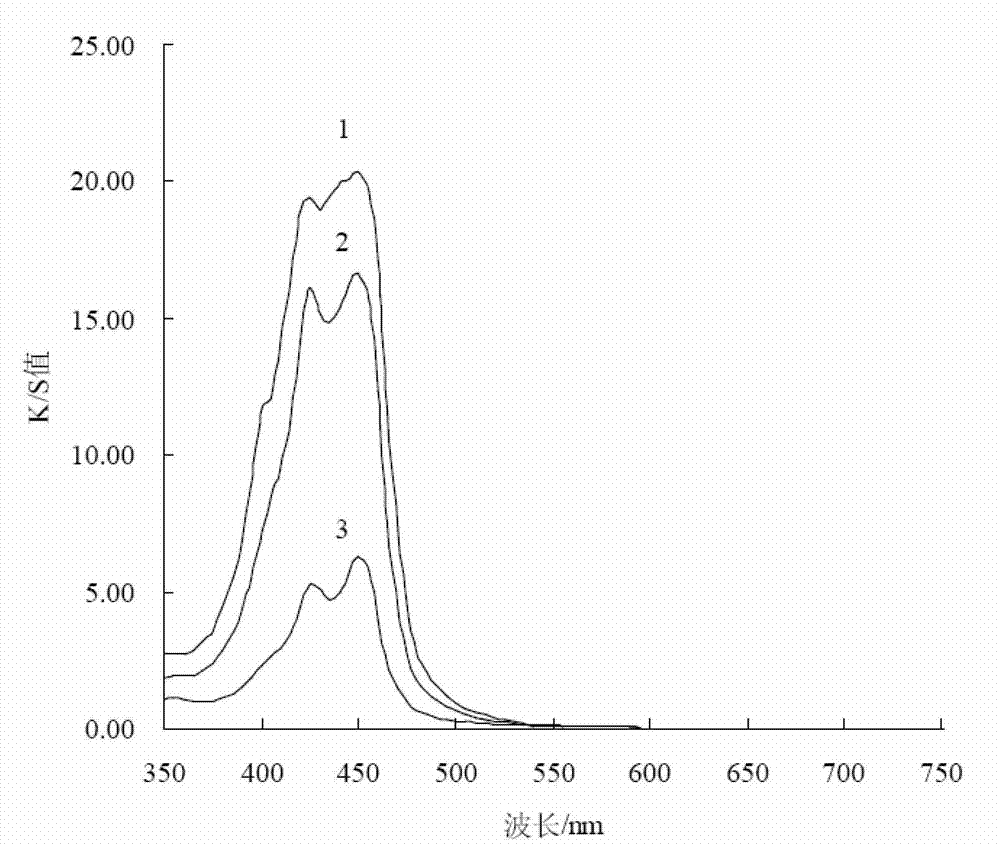

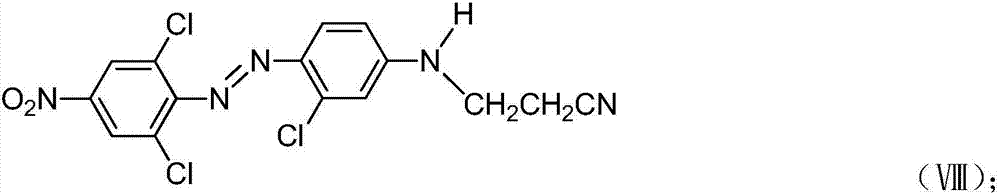

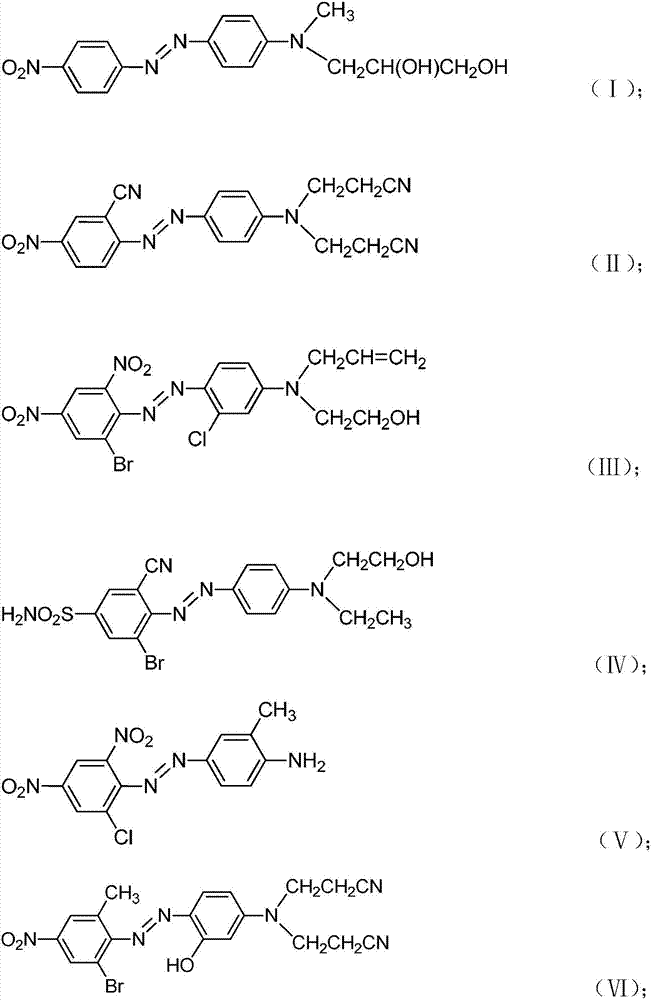

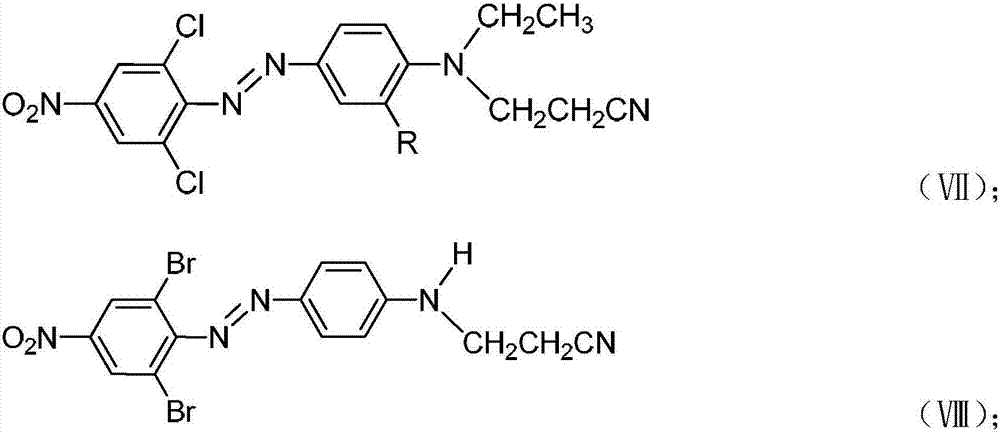

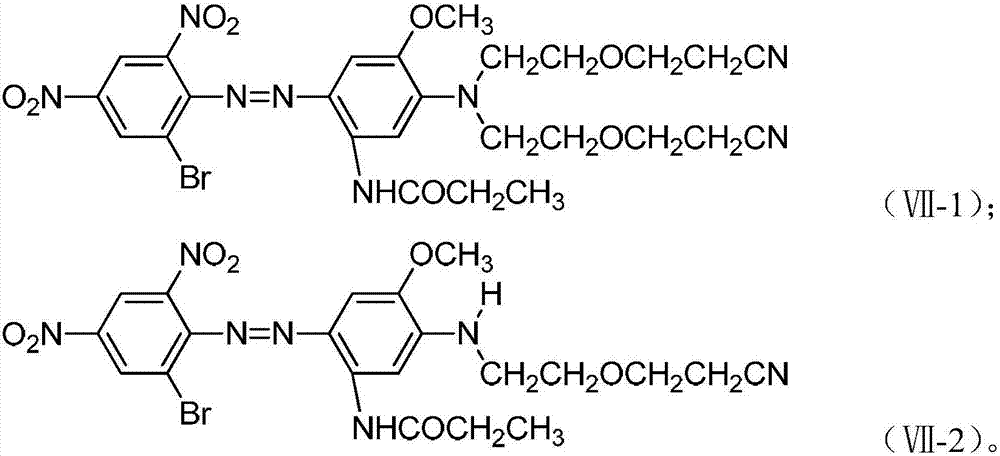

Disperse dye composition high in rubbing fastness

InactiveCN106893359AHigh rubbing fastnessGood color fastnessOrganic dyesDyeing processPerspirationRubbing

The invention discloses a disperse dye composition with high rubbing fastness. The disperse dye composition is composed of component A represented by structural formula (I), component B represented by structural formula (II), and structural formula (III). Component C shown, component D shown in structural formula (IV), component E shown in structural formula (V), component F shown in structural formula (VI), component G shown in structural formula (VII), Component H shown in the structural formula (Ⅷ) and auxiliary agents are composed; by mass fraction, the mass fraction of the component A is 2 to 10%, and the mass fraction of the component B is 3 to 10%. The mass fraction of component C is 5-10%, the mass fraction of said component D is 8-25%, the mass fraction of said component E is 4-15%, and the mass fraction of said component F is 2 ~10%, the mass fraction of the component G is 3-18%, the mass fraction of the component H is 3-9%, and the rest are auxiliary agents. The invention has excellent washing fastness, rubbing fastness, perspiration fastness, light fastness and coloring rate.

Owner:朱友富

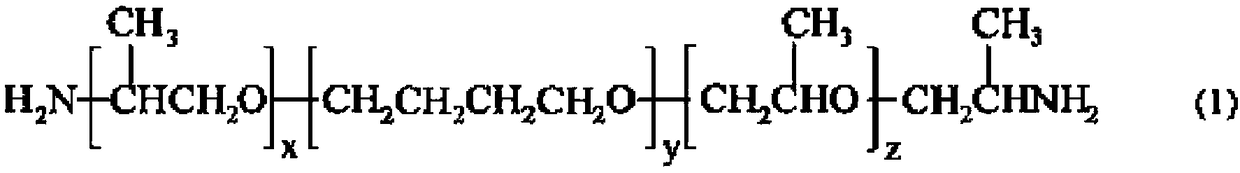

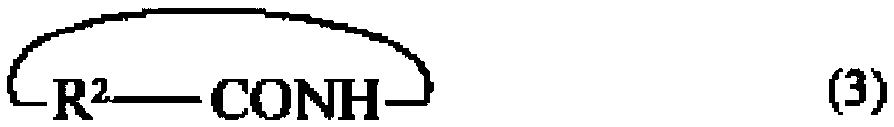

Polyamide elastomer composition, and fiber and molded article comprising same

ActiveCN108699334AImprove production stabilityImprove dyeing effectSlide fastenersClothes buttonsPhosphorous acidElastomer

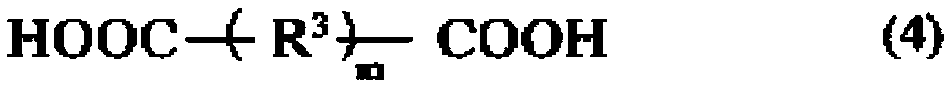

Provided is a polyamide elastomer composition capable of imparting excellent stability, dyeability, and color fastness to various molded articles. The polyamide elastomer composition contains a polyamide elastomer and a phosphorus acid compound, wherein the polyamide elastomer contains constituent unit 1 derived from a diamine compound represented by formula (1), constituent unit 2 derived from anaminocarboxylic acid compound represented by formula (2) or a lactam compound represented by formula (3), and constituent unit 3 derived from a dicarboxylic acid compound represented by formula (4),and the content rate of the phosphorus acid compound is 0.02-0.15 mass% with respect to the polyamide elastomer, and the terminal amino group concentration of the polyamide elastomer is 2.0*10-5 eq / gor more (x represents an integer of 1-20, y represents an integer of 4-50, z represents an integer of 1-20, R1 represents a linking group containing a hydrocarbon chain, R2 represents a linking groupcontaining a hydrocarbon chain, R3 represents a linking group containing a hydrocarbon chain, and m represents 0 or 1.).

Owner:UBE IND LTD

Disperse dye composition with high washing fastness

The invention discloses a disperse dye composition with high washing fastness. The disperse dye composition is composed of component A represented by structural formula (I), component B represented by structural formula (II), and structural formula (III). Component C shown, component D shown in structural formula (IV), component E shown in structural formula (V), component F shown in structural formula (VI), component G shown in structural formula (VII), Component H shown in the structural formula (Ⅷ) and auxiliary agents are composed; by mass fraction, the mass fraction of the component A is 2 to 10%, and the mass fraction of the component B is 3 to 10%. The mass fraction of component C is 5-10%, the mass fraction of said component D is 8-25%, the mass fraction of said component E is 4-15%, and the mass fraction of said component F is 2 ~10%, the mass fraction of the component G is 3-18%, the mass fraction of the component H is 3-9%, and the rest are auxiliary agents. The invention has excellent washing fastness, rubbing fastness, perspiration fastness, light fastness and coloring rate.

Owner:朱友富

Regenerative polyester fibers with color fastness

InactiveCN105442080AGood color fastnessImprove performanceMonocomponent polyesters artificial filamentArtifical filament manufacturePolyesterMasterbatch

The invention discloses regenerative polyester fibers with color fastness. The regenerative polyester fibers are prepared from the following components in parts by weight: 20-30 parts of ester, 5-10 parts of color masterbatch, 2-4 parts of a brightening agent and 60-80 parts of waste polyester materials, wherein the ester is a reactant of ethanol and carboxylic acid. According to the regenerative polyester fibers, the waste polyester product serving as a raw material is adjusted by means of a reasonable formula design and preparation process to prepare the colored polyester fibers. The regenerative polyester fibers have good color fastness performance and excellent comprehensive performance; and furthermore, the regenerative polyester fibers have the advantages of energy conservation and environmental friendliness since dyeing is not required and environmental pollutant is not generated.

Owner:CHANGSHU XIANGYING SPECIAL FIBER

Indigo cloth dyeing method

Owner:册亨县云娇布依特色染织刺绣有限公司

Fabric cleaning, printing and dyeing process

PendingCN109914129AHigh color fastnessGood dyeing stabilityDry-cleaning apparatus for textilesDyeing processFiberDecomposition

The invention discloses a fabric cleaning, printing and dyeing process. The process comprises a pre-treatment procedure, a dyeing procedure and a post-treatment procedure. According to the fabric cleaning, printing and dyeing process, the process of pre-treating fabric by a solution formed by mixing an anhydrous ethanol organic solvent and a desizing agent and a solution formed by mixing an anhydrous ethanol organic solvent and a bleaching agent is adopted, and the problems that in a traditional fabric pretreatment process, the water consumption amount is large, recycling is difficult, and pollution is serious are solved; moreover, along with the decomposition and removal of pectin substances and other substances in fibers, the interfiber space is increased, the internal passages of the fibers are opened, the fabric shows the capillary effect of fluffy and soft hand feeling and uniformity, and subsequent dyeing and finishing processing is better facilitated; by adding the anhydrous ethanol organic solvent, a sizing agent and natural impurities can be better in contact with the desizing solution and the bleaching solution to achieve the removal purpose within a short time, the waterconsumption amount in the pre-treatment process can be greatly reduced, and the energy is saved.

Owner:SHAOXING JINMU PRINTING & DYEING

Dyeing composition containing natural plant ingredients

ActiveCN105534785AGood color fastnessReduce stimulationCosmetic preparationsHair cosmeticsCentella asiatica extractSide effect

The invention relates to a dyeing composition containing natural plant ingredients. The dyeing composition is prepared from a first agent and a second agent, wherein the first agent comprises an oxidative developing alkali and a coupling agent and the second agent comprises an oxidant; the oxidative developing alkali comprises 2,5-diaminotoluene or an addition salt thereof; the coupling agent comprises ethoxyl-3,4-methylenedioxyaniline and an addition salt thereof; the first agent further comprises a tea leaf extract and an asiatic pennywort herb extract. The dyeing composition provided by the invention selects the specific oxidative developing alkali and coupling agent, and also contains the natural plant ingredients, so that the dyeing firmness of the dyeing composition is remarkably improved; the dyeing composition provided by the invention has small irritation on scalps and small side effect, and has relatively large popularization and application value.

Owner:肇庆迪彩日化科技有限公司

Reactive ink for digital printing

ActiveCN110067141AGood color fastnessGood color reproducibilityDyeing processDigital printingSolvent

The invention discloses a reactive ink for digital printing and a preparation method thereof, belongs to the field of digital printing, and solves the problems that reactive groups of reactive dyes inan existing reactive ink are easily hydrolyzed to cause the reduced color fastness of a textile and result in that a nozzle of a digital inkjet printer is clogged. The reactive ink for digital printing comprises the following components by weight percentage: 10% to 30% of a reactive dye, 10% to 30% of a viscosity modifier, 0.2% to 2% of a surface tension modifier, 0.1% to 3% of a pH value controlagent, 0.2% to 0.5% of a fungicide, 5% to 10% of a cosolvent, 0.5% to 3% of buffer salt, 0.5% to 4% of a penetrant and the balance of deionized water. The reactive ink for digital printing has the advantages of high ink stability and the like.

Owner:浙江海印数码科技有限公司

High-fastness black vat dye and preparation method thereof

The invention discloses a high-fastness black vat dye and a preparation method thereof. The dye is composed of the following components in percentage by mass: 7-10% of dye monomer A, 3-5% of dye monomer B, 7-10% of dye monomer C, 17-20% of dye monomer D, 0.5-2% of dust preventive and the balance of dispersing agent. The dye has various favorable color fastnesses, and especially has excellent fastness to chlorine bleaching, solarization and washing; the fastness to chlorine bleaching is up to Grade 4-5, and the fastness to washing is Grade 4-5; and the dye has the advantages of simple preparation method and high dye uptake, and is suitable for dye printing of textiles with high-quality requirements.

Owner:安徽融创化工科技股份有限公司

Water-based dyed mortar material and preparation method thereof

The invention discloses a water-based dyeing mortar material and a preparation method thereof in the technical field of coating preparation, the water-based dyeing mortar material comprises the following components in parts by weight: 60-80 parts of emulsion, 0.2-0.5 part of a dispersing wetting agent, 5-10 parts of a film forming auxiliary agent, 2-5 parts of other auxiliary agents, 1-1.5 parts of a pH regulator, 1-1.5 parts of toner and 10-20 parts of deionized water, has excellent color fastness, mechanical strength, water resistance, boiling water resistance, acid and alkali resistance, solvent resistance, natural aging resistance, artificial aging resistance and other outstanding performances, has environmentally-friendliness, zero VOC, no production of industrial three wastes, no color restriction, optional color mixing, convenient production, simple color mixing process, low equipment requirements, low cost, water as a solvent, low cost of raw materials, natural drying, and no energy consumption, and can be used for building interior and exterior wall paint, permeable bricks, artificial stone, integrated boards and handicrafts.

Owner:郑州科威科建筑材料有限公司

Features

- R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

Why Patsnap Eureka

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Social media

Patsnap Eureka Blog

Learn More Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com