Patents

Literature

37results about How to "Solve the problem of high water consumption" patented technology

Efficacy Topic

Property

Owner

Technical Advancement

Application Domain

Technology Topic

Technology Field Word

Patent Country/Region

Patent Type

Patent Status

Application Year

Inventor

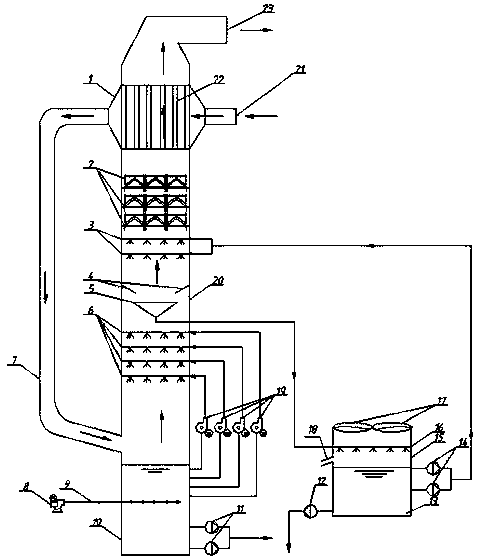

Desulfuration dust-collection white-elimination deep purification device

PendingCN108465368ASolve the problem of high water consumptionLow running costGas treatmentLighting and heating apparatusFlue gasSlurry

The invention belongs to the technical field of atmosphere pollution treatment environment protection, in particular relates to a desulfuration dust-collection white-elimination deep purification device, and aims to solve the problems that large floor spaces are required and the operation cost is high since a common process in the market is a condensation-reheating process, that is, a flue gas cooler, an air cooler and a flue gas heater are arranged outside a tower. According to the technical scheme of the invention, the device comprises an absorption tower body, wherein a flue gas inlet and aflue gas outlet are formed in the upper end of the absorption tower body; the flue gas inlet is positioned lower than the flue gas outlet; the absorption tower body is provided with a demister, a condensed water spraying layer, a liquid collection layer, a slurry spraying layer and a slurry pool from top to bottom in sequence; the liquid collection layer comprises a liquid collection plate and aliquid collection disc which is arranged below the liquid collection plate; a flue gas inlet pipeline is further arranged on one side outside the absorption tower body; one end of a flue gas inlet pipeline is parallel to the flue gas inlet; the other end of the flue gas inlet pipeline extends between the slurry spraying layer and the slurry pool; a heat exchanger is arranged at the communicating part of the flue gas inlet and the flue gas inlet pipeline.

Owner:XIAN XIKUANG ENVIRONMENTAL PROTECTION

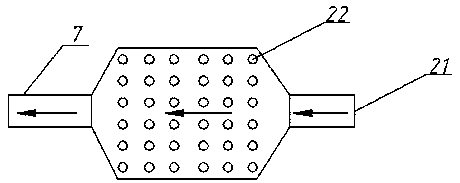

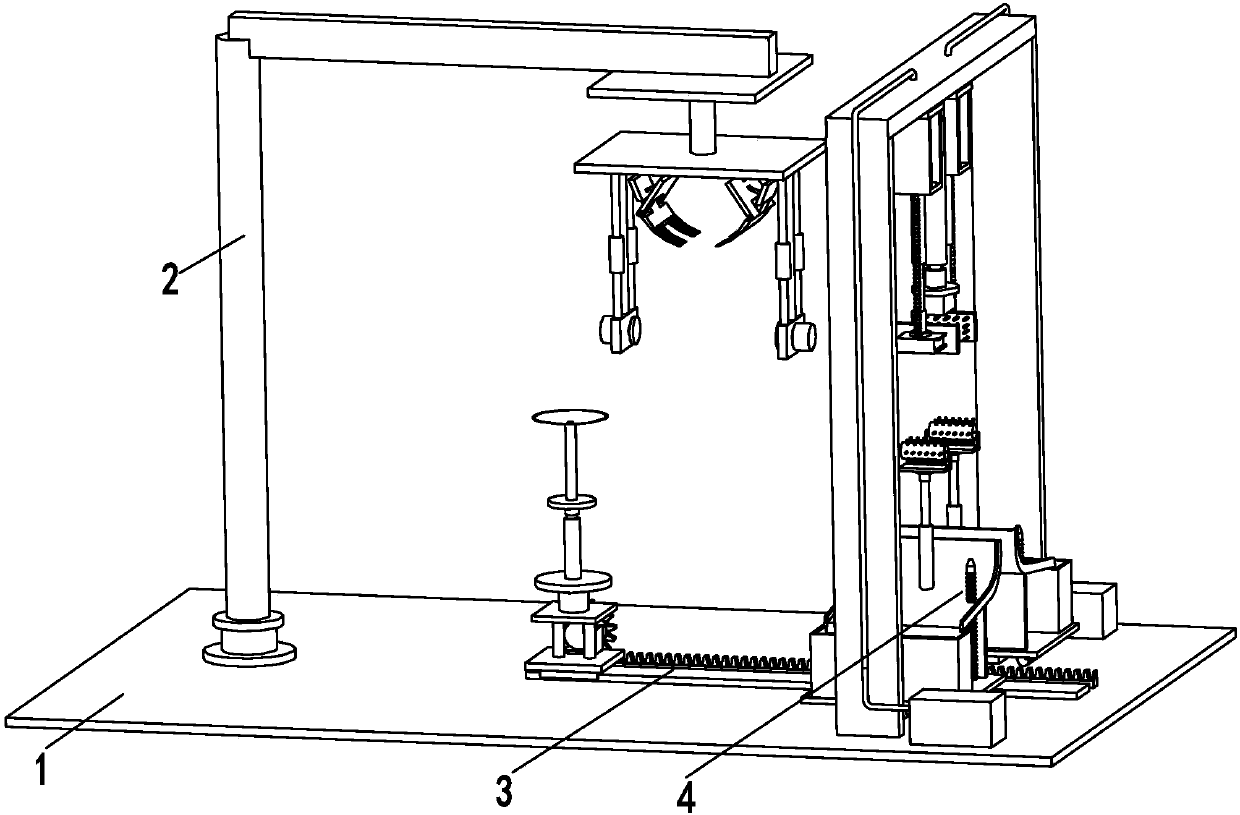

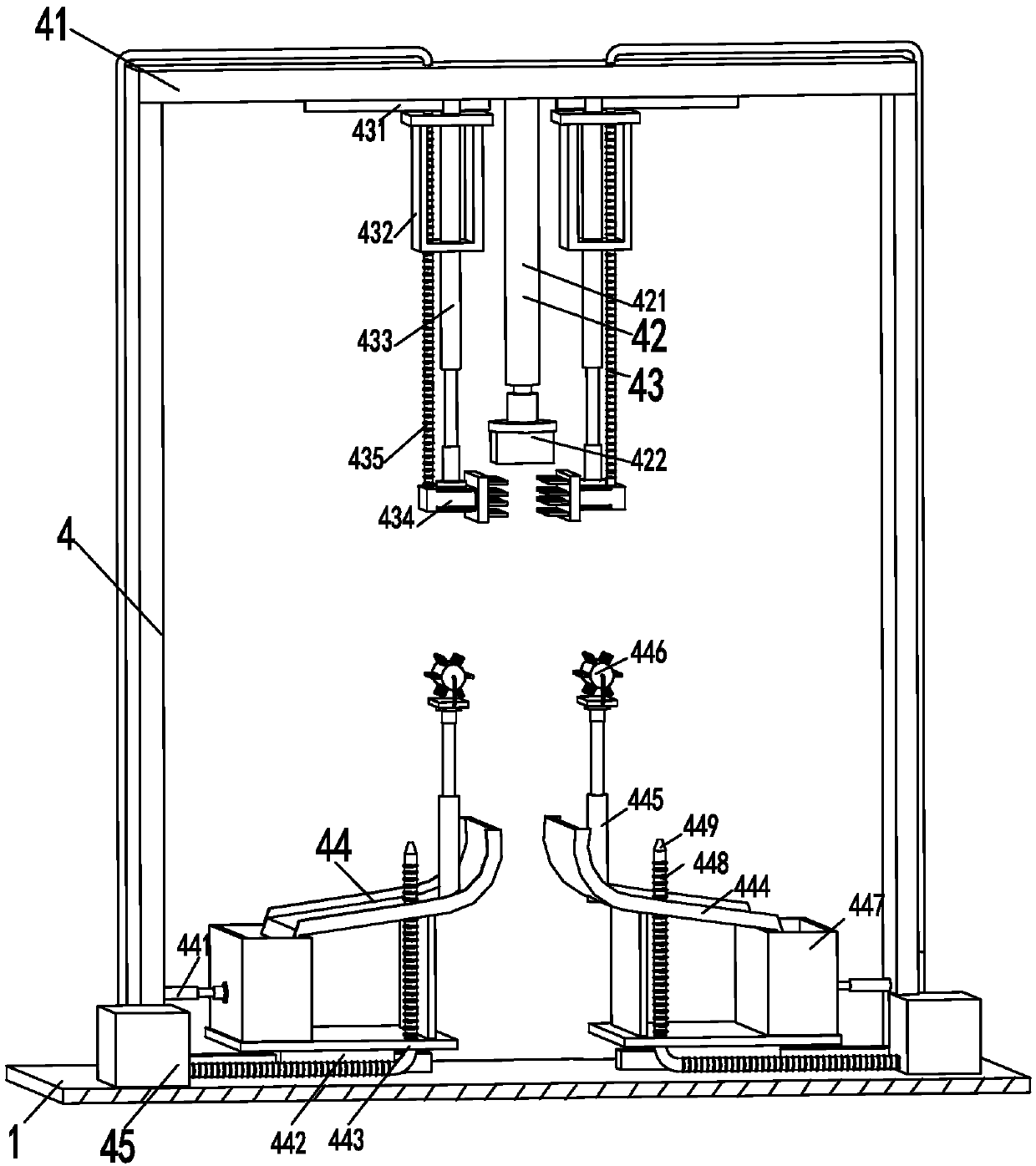

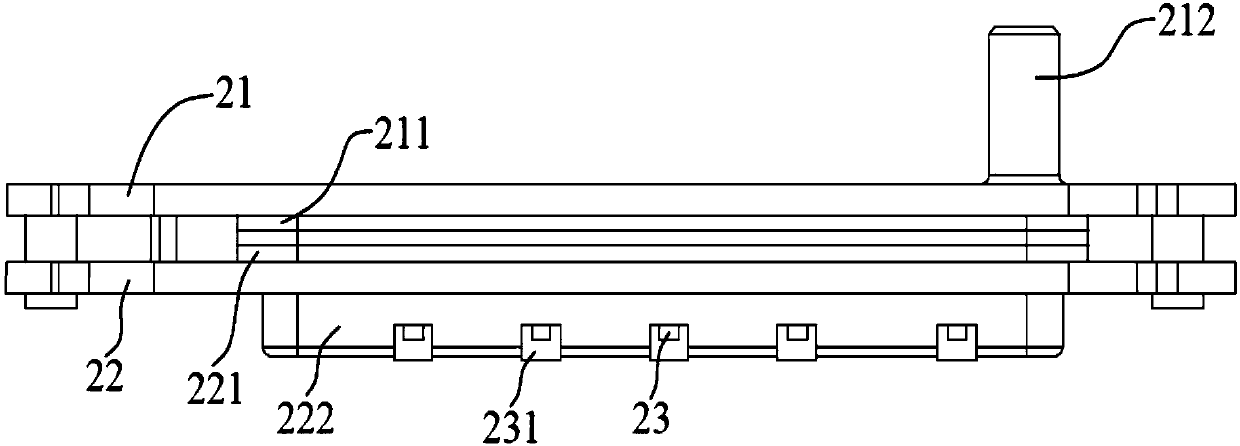

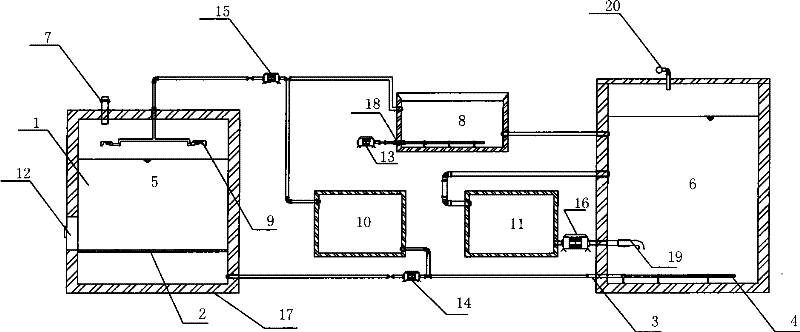

Cleaning equipment of environmental sanitation rubbish bin used for municipal bitulith road

InactiveCN107716499ARealize automatic cleaningSolve environmental problemsHollow article cleaningElectric machineWorking environment

The present invention relates to the field of environmental protection equipment for municipal asphalt concrete roads, in particular to a sanitation trash can cleaning equipment for municipal asphalt concrete roads, which includes a bottom plate, a clamping device, a moving device and a cleaning device, and the bottom plate is sequentially arranged from left to right A clamping device, a moving device and a cleaning device are installed; the moving device includes a linear guide rail, a sliding block, a mounting plate, a moving motor, a gear, a rack, a support column, an auxiliary plate, a rotating motor, a rotating panel, a rotating cylinder, a working plate with vacuum suction cups. The invention can solve the problems of unhygienic working environment, easy breeding of germs, large water consumption, inconvenient transportation, heavy labor and low work efficiency existing in the cleaning process of the existing sanitation trash can, and can realize automatic cleaning of the sanitation trash can function.

Owner:储高鹏

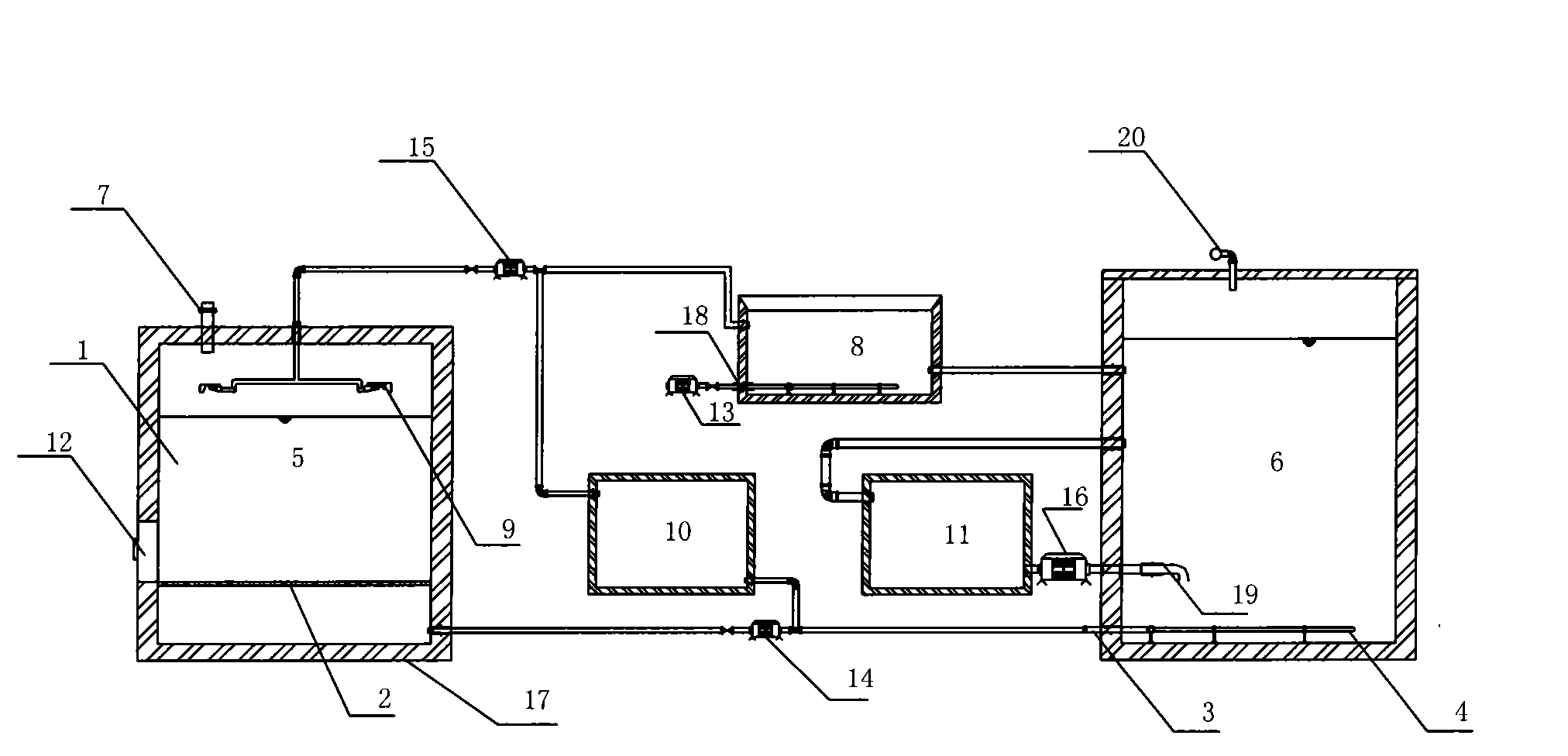

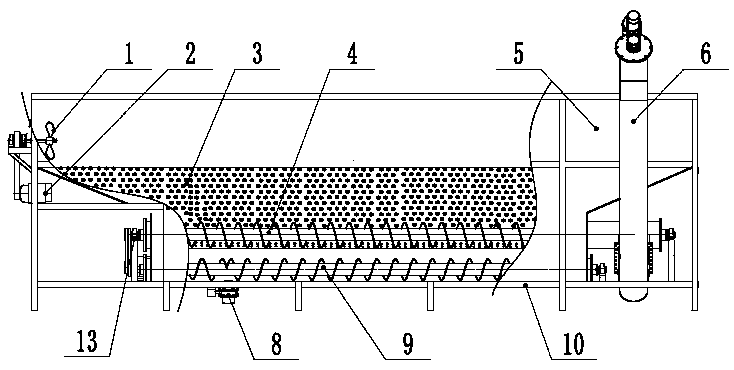

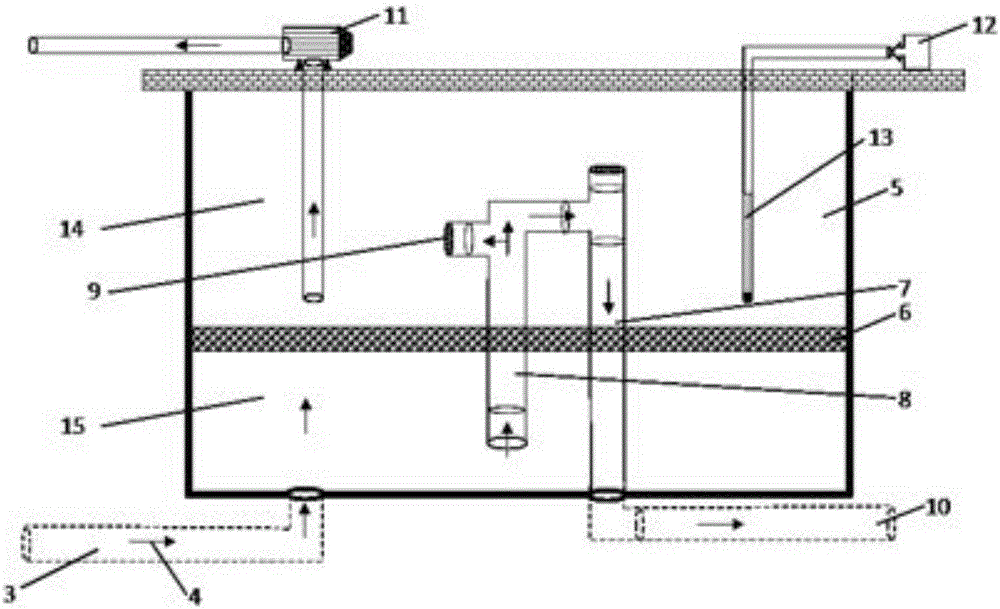

Dry manure two-phase anaerobic digestion system for pig farm

InactiveCN101654321AAchieve enrichmentEmission reductionBiological substance pretreatmentsGas production bioreactorsPig farmsSlurry

The invention discloses a dry manure two-phase anaerobic digestion system for a pig farm belonging to the technical field of environment engineering and energy, which uses a hydrolytic acidification and methane production two-phase anaerobic digestion system as a main body. The system is characterized in that the dry manure in the pig farm is treated by integrating aeration biogas slurry reflux, external culture of acid producing bacteria and methane producing bacteria, and activity maintaining device so as to solve the problem that the prior two-phase process cannot effectively treat high solid concentration pig manure and has lower efficiency, thoroughly solve the problem of large water consumption of the conventional anaerobic treatment, realize biogas slurry concentration, reduce the discharge amount of the biogas slurry, greatly reduce subsequent treatment load of biogas engineering, and realize quick degradation and efficient gas production of organic waste. After application, the system improves the comprehensive economic benefit by 20 percent compared with the prior anaerobic system; and the improvement on efficiency ensures that the biogas engineering of the dry manure pigfarm realizes self supply of energy, and maintains normal operation of the biogas engineering of the pig farm in winter, thereby achieving multiple aims of saving water, reducing discharge, protecting environment and producing energy and fertilizer.

Owner:CHINA AGRI UNIV

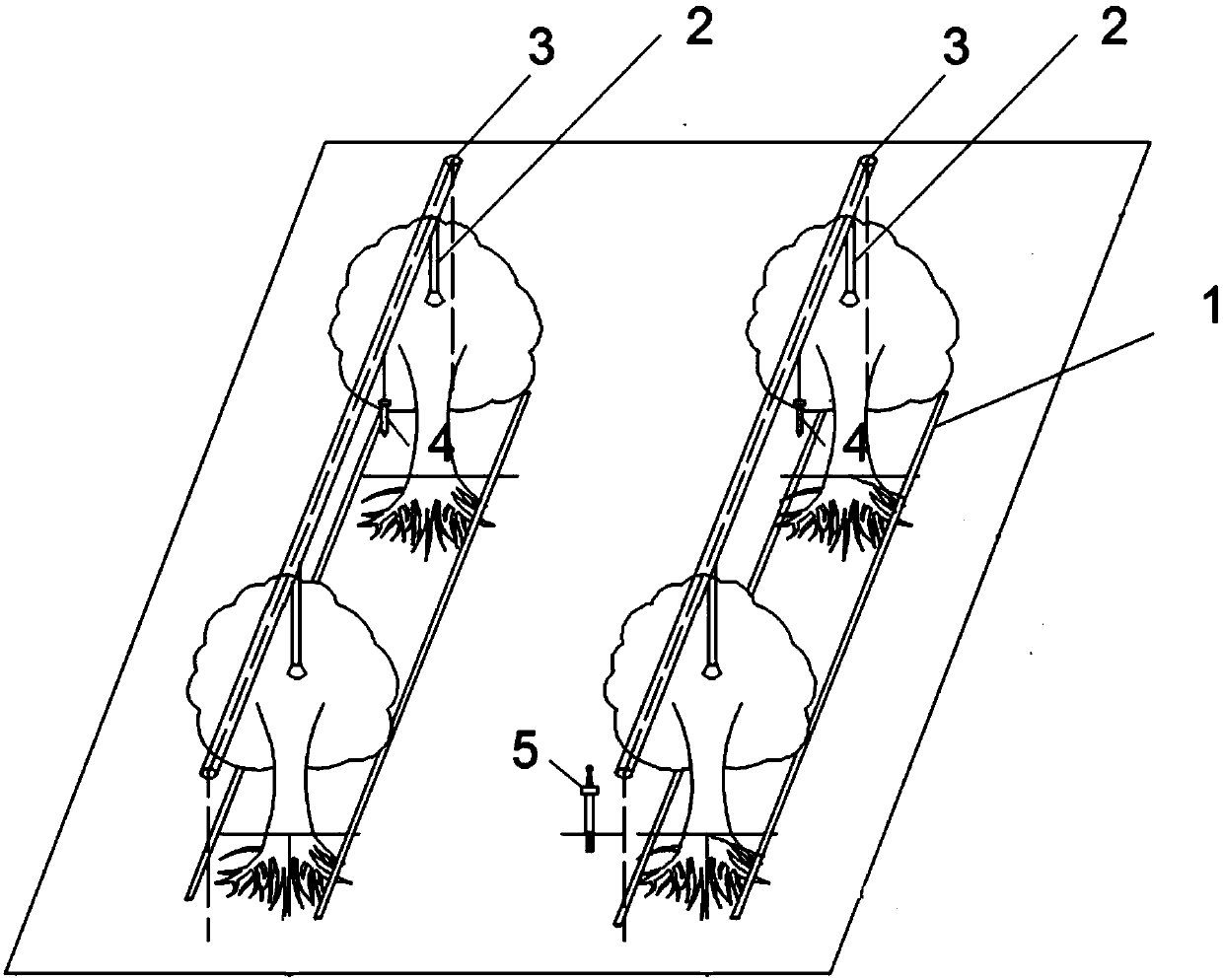

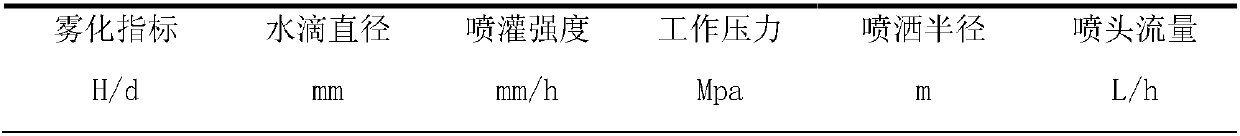

Water-saving conditioning double-source stereoscopic irrigation method for fruit trees

InactiveCN108094143ASolve choice problemsSolve the problem of high water consumptionRoot feedersClimate change adaptationAutomatic controlDrip irrigation

The invention discloses a water-saving conditioning double-source stereoscopic irrigation method for fruit trees. The water-saving conditioning double-source stereoscopic irrigation method includes establishing double-source stereoscopic automatic control fruit tree irrigation systems. Water, fertilizers, pesticides and plant growth regulators are automatically regulated and controlled in due timevia intelligent irrigation decision making systems by the aid of earth surface drip irrigation systems and aerial atomizing droplet sprinkler irrigation systems. The water-saving conditioning double-source stereoscopic irrigation method has the advantages that the yield of the fruit trees can be greatly increased by the aid of the water-saving conditioning double-source stereoscopic irrigation method, and the water use efficiency of the fruit trees can be greatly improved by the aid of the water-saving conditioning double-source stereoscopic irrigation method; the problem that requirements onexcellent growth of existing fruit trees cannot be met by independent irrigation systems in regions under extreme climatic conditions can be solved by the aid of the water-saving conditioning double-source stereoscopic irrigation method; the air humidity of fruit tree cultivation environments under extreme drought conditions can be increased, transpiration effects of leaves of the fruit trees canbe deteriorated to a great extent, accordingly, water wastage can be prevented, and fruit tree cultivation can be sustainably developed; the water-saving conditioning double-source stereoscopic irrigation method is implemented by the aid of the intelligent irrigation decision making systems, accordingly, irrigation can be automatically precisely regulated and controlled on time as needed, the labor intensity can be relieved to a great extent, and labor force can be saved.

Owner:CHINA AGRI UNIV

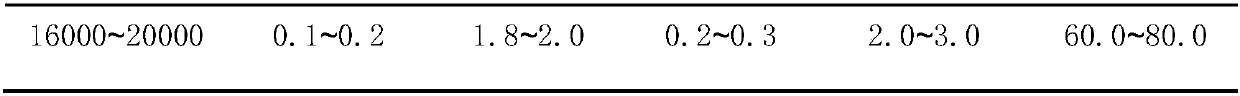

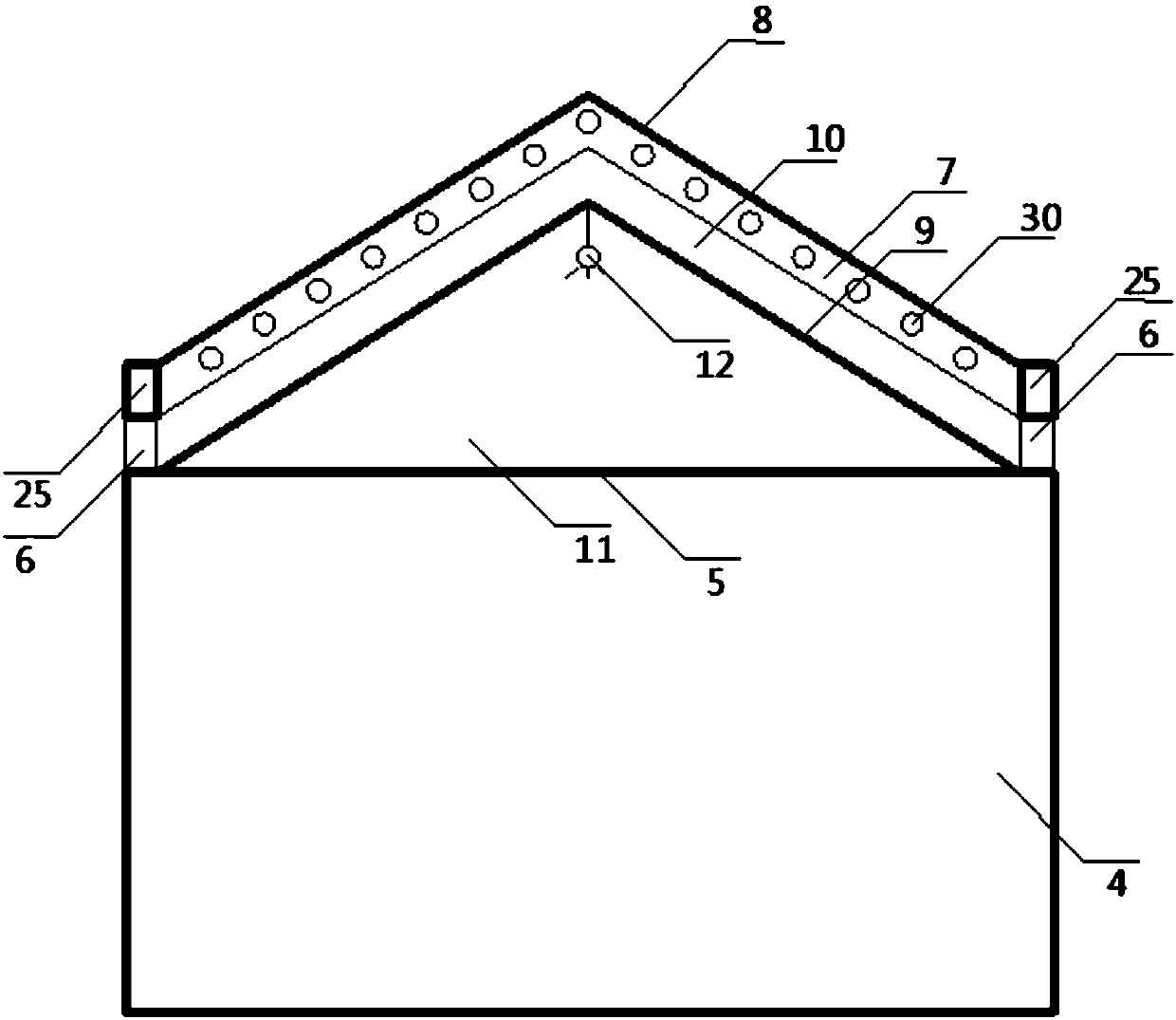

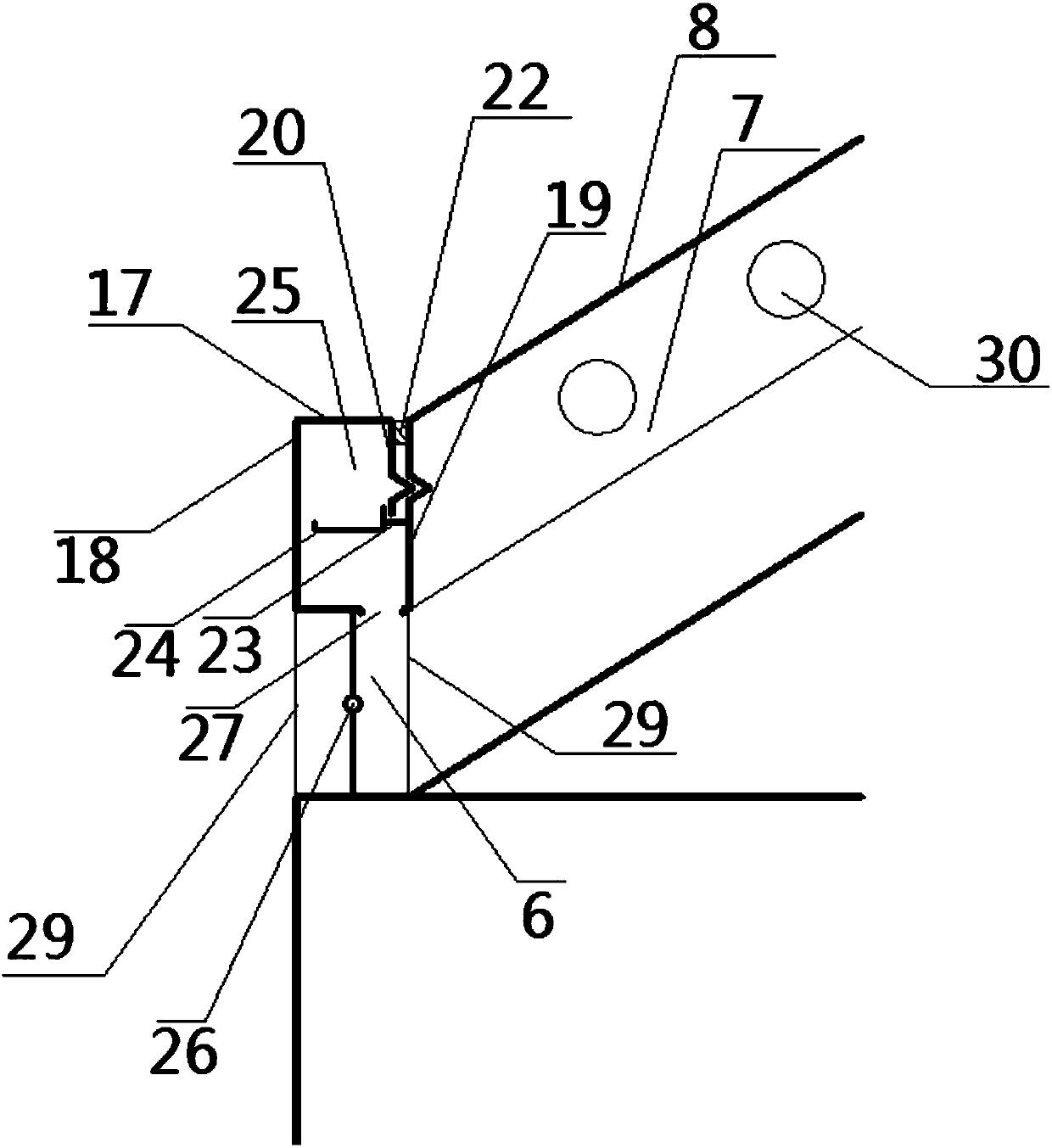

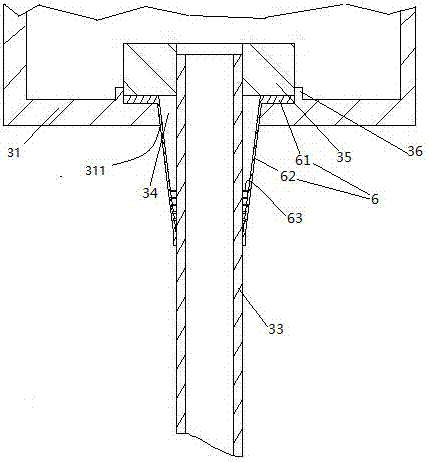

Energy-saving roof structure and use method thereof

ActiveCN107747354AStable cooling effectReduce the temperatureBuilding roofsCondensate preventionWater sourceEngineering

The invention provides a relatively-closed energy-saving roof structure utilizing condensate water of an air conditioner system and a use method of the energy-saving roof structure. The condensate water generated by an air conditioner is sprayed in a roof cavity through a spraying system, then through waste gas which is treated by a heat exchanger and then discharged from the interior of a building main body, heat in the roof cavity is brought away, and thus the effect of roof temperature decreasing is achieved. The temperature and the humidity of the waste gas which is discharged from the interior of the building main body after being treated through the air conditioner are relatively stable, and the waste gas flows through the closed roof cavity, so that the influence of the external environment on the temperature decreasing effect of the energy-saving roof structure is small, and the temperature decreasing effect is stable. The condensate water of the air conditioner is adopted as awater source of the energy-saving roof structure, and thus the problem that the water consumption is large in watering temperature decreasing is also solved.

Owner:上海市建工设计研究总院有限公司

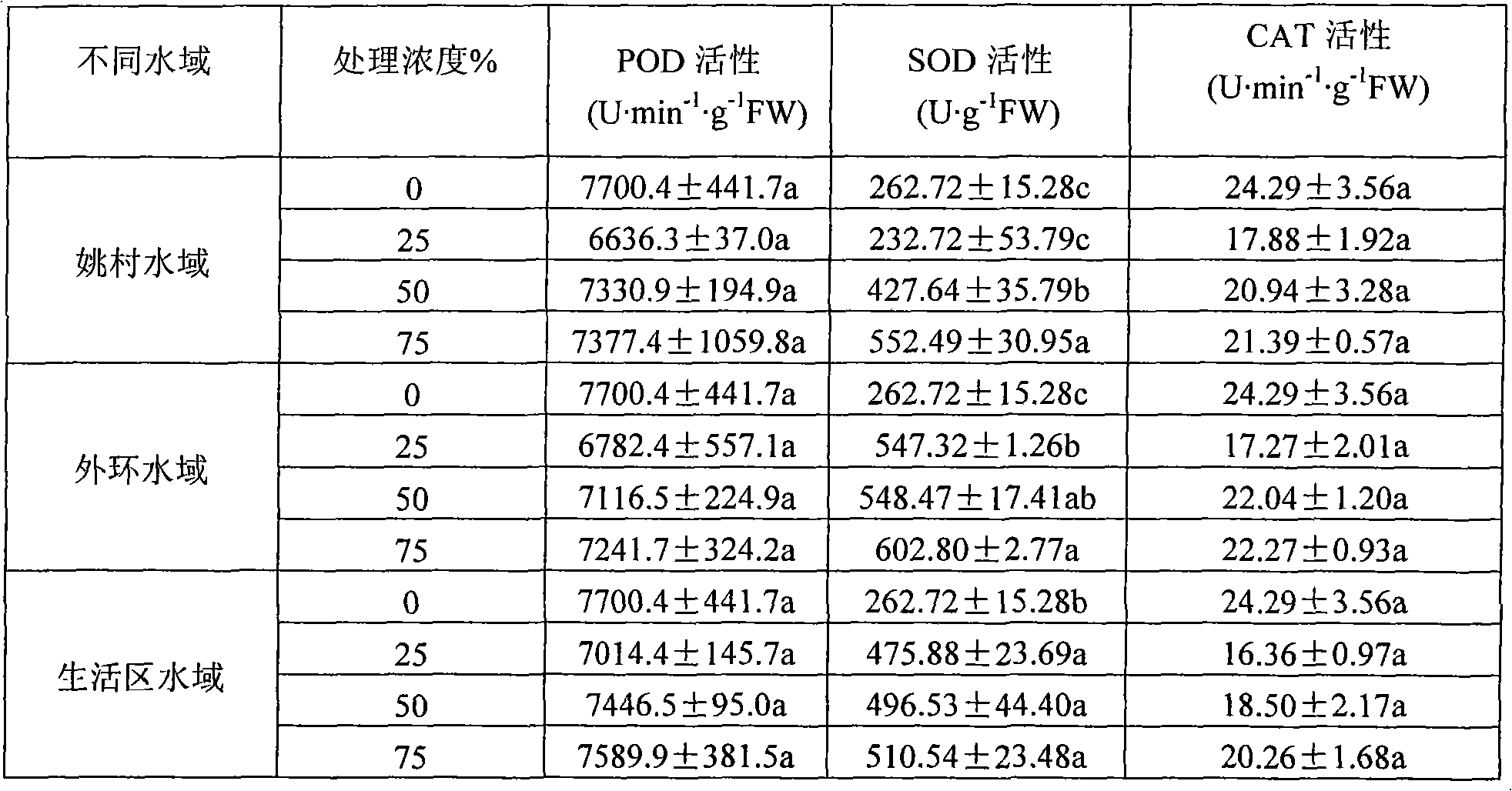

Method for regulating antioxidase of lawn plants by utilizing eutrophic water

InactiveCN101574036AReduce reprocessingLow costClimate change adaptationSewage/sludge fertilisersDismutaseOxygenase activity

The invention discloses an application of eutrophic water in the regulation of antioxidase activity of lawn plants, wherein the eutrophic water is the eutrophic water with 25 percent-75 percent of the original concentration; and the eutrophic water has TN of 9.7 mg / L-13.1mg / L, TP of 0.6mg / L -0.9mg / L and pH value of 8.12-8.99, wherein the activity of antioxidase comprises of superoxide dismutase, peroxide dismutase and catalase. Results show that the diluted eutrophic water is applied to irrigation to reinforce the activity of a protective enzyme system of lawn plants, thereby being capable of obviously improving the resistance ability of the lawn plants to adverse growing environment and providing technical support for the application of the eutrophic water in a lawn plant establishment system.

Owner:TIANJIN NORMAL UNIVERSITY

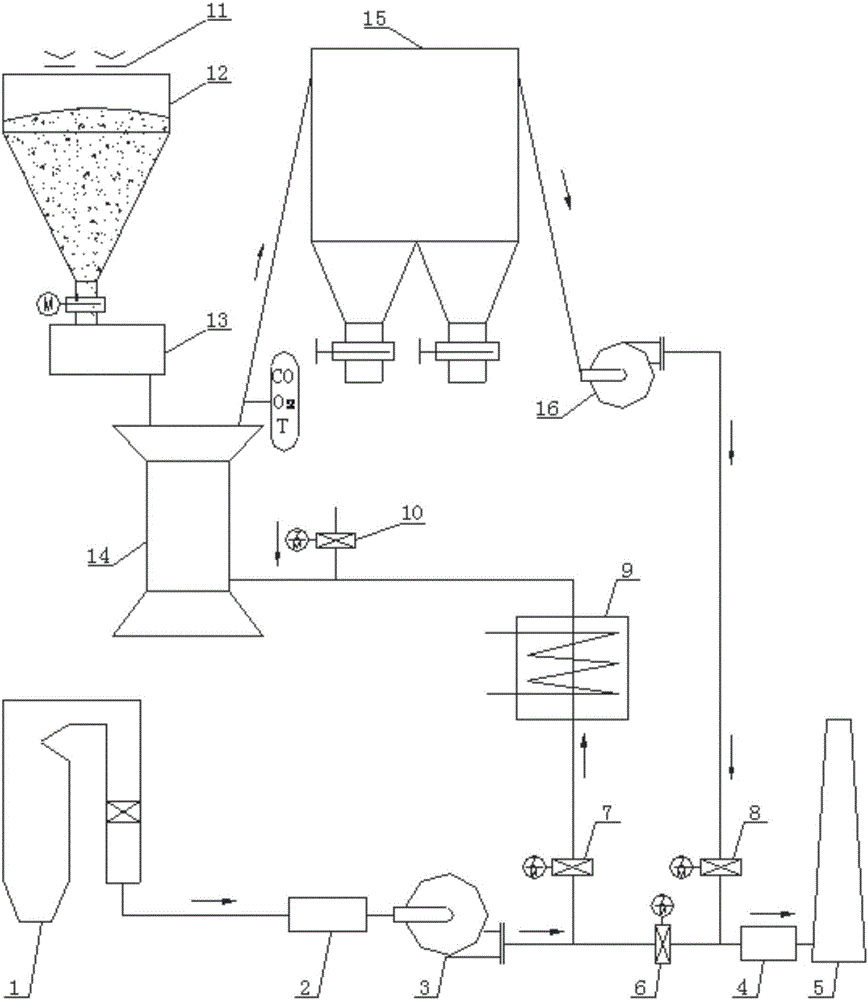

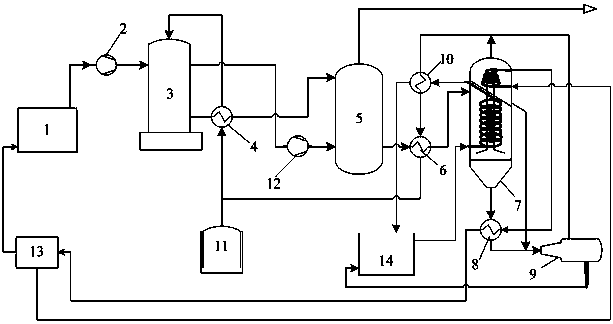

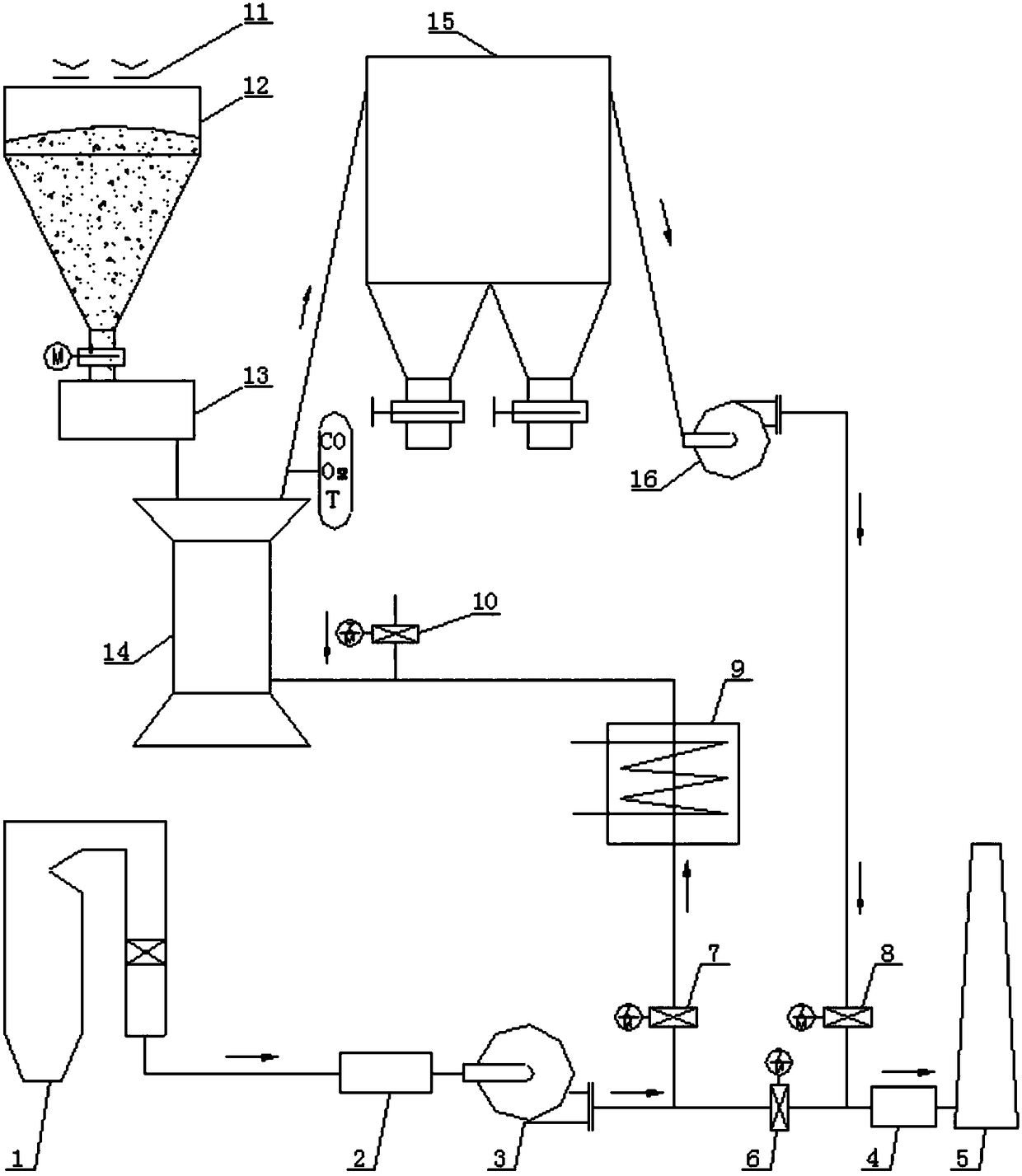

Energy-saving and environment-friendly flue gas waste heat pulverized coal preparation system

InactiveCN106196134AImprove explosion-proof performanceImprove securitySolid fuel pretreatmentDrying gas arrangementsFlue gasCoal dust

An energy-saving and environment-friendly flue gas waste heat pulverized coal preparation system comprises a belt coal feeder, a raw coal bunker, a coal feeder, a coal mill and a powder recovery bunker, wherein the dry air inlet of the coal mill communicates with the outlet of a first induced draft fan which is used for inputting high-temperature flue gas at the tail part of a boiler to the coal mill; an inert gas input passage is arranged in front of the dry air inlet of the coal mill; a first control valve is mounted on the inert gas input passage; the outlet of the coal mill communicates with the inlet of the powder recover bunker; a gas temperature detector and a gas concentration detector are mounted behind the outlet of the coal mill and connected with an alarm controller; a pulverized coal collection device is arranged in the powder recovery bunker; a second induced draft fan is mounted behind the flue gas outlet of the powder recovery bunker; and the outlet of the second induced draft fan communicates with the inlet of a flue gas desulfurization device or a chimney. The energy-saving and environment-friendly flue gas waste heat pulverized coal preparation system is a special production line for providing coal dust fuels for the pulverized coal boiler, the security of the pulverized coal preparation system can be guaranteed while the waste heat of flue gas at the tail part of the boiler is effectively utilized, energy saving and consumption reduction are realized and the environment is protected.

Owner:SHANDONG HUANNENG DESIGN INST

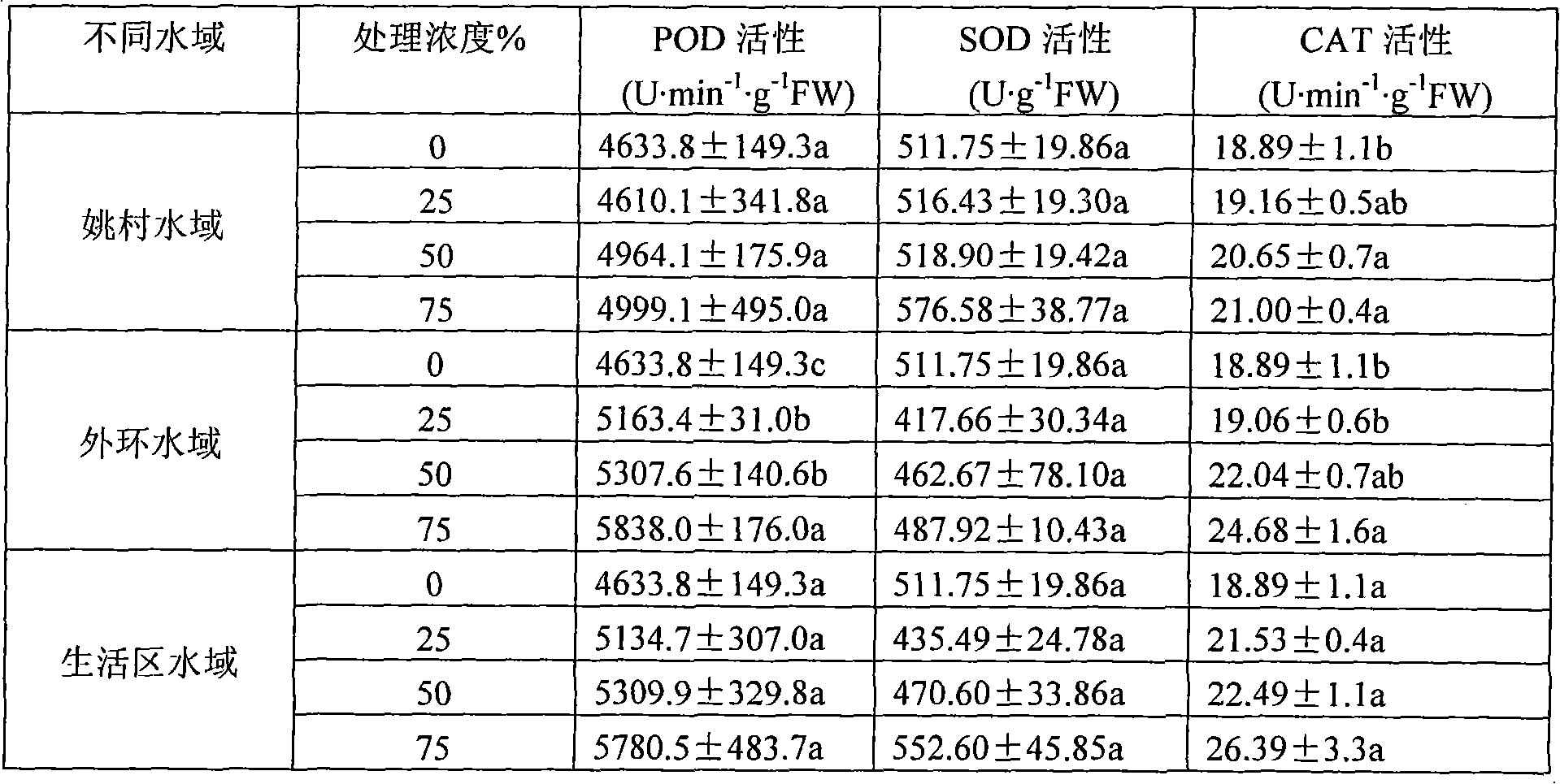

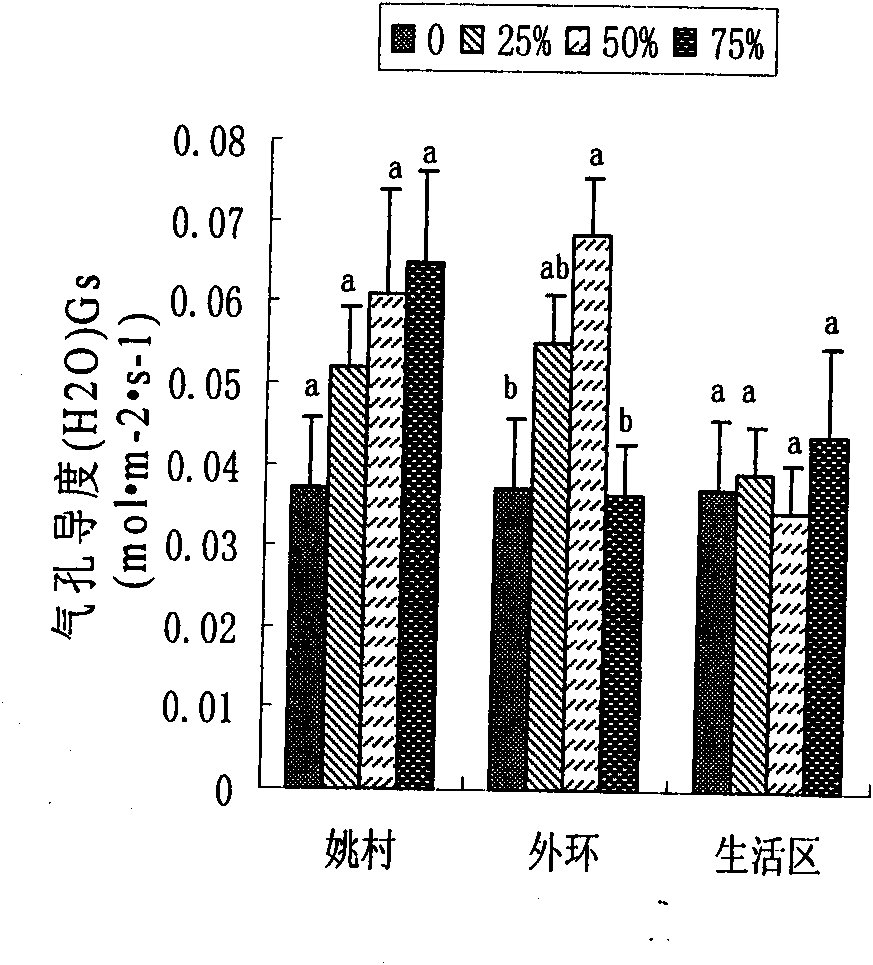

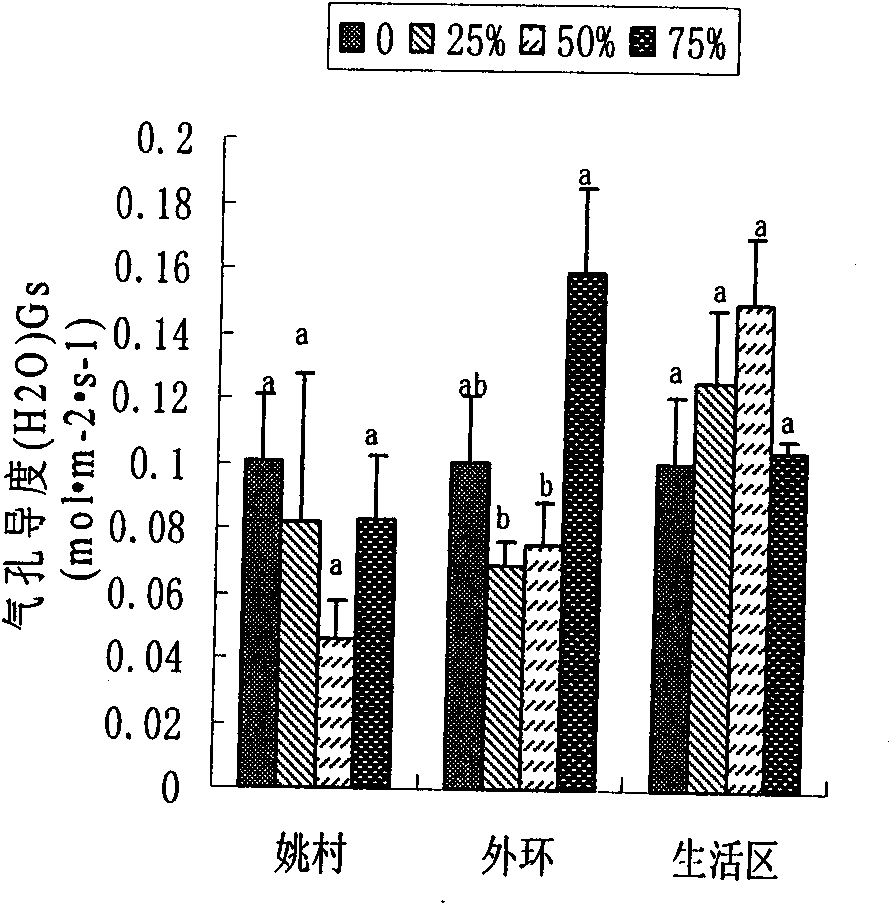

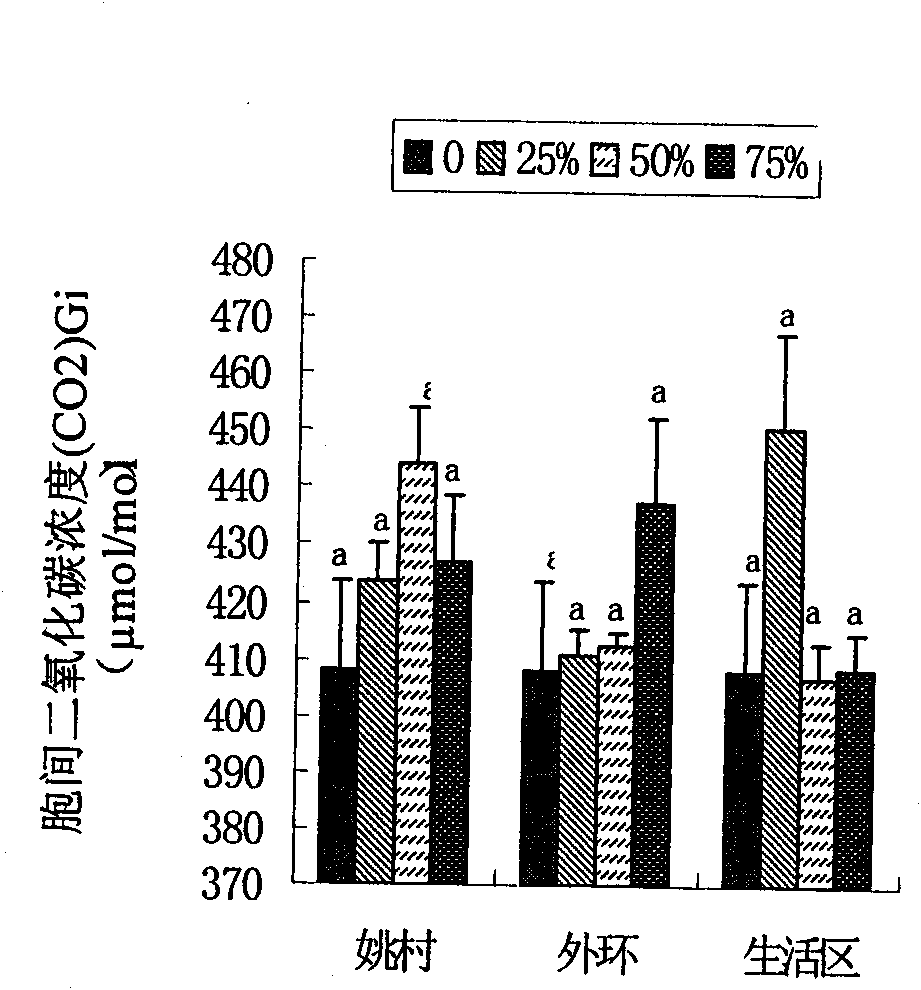

Application of eutrophic water to improvement of photosynthetic capacity of lawn plants

InactiveCN101575225APromote photosynthesisReduce reprocessingClimate change adaptationSewage/sludge fertilisersTranspirationBiology

The invention discloses an application method of eutrophic water irrigation in the improvement of photosynthetic capacity of lawn plants, wherein the eutrophic water is the eutrophic water with 25 percent-75 percent of the original concentration thereof; and the eutrophic water has TN of 9.7mg / L-13.1mg / L, TP of 0.6mg / L-0.9mg / L and pH value of 8.12-8.99. Results show that the photosynthetic performances of the stomatal conductance, the intercellular carbon dioxide concentration, the net photosynthetic rate, the transpiration rate, the water content utilization efficiency and the like are improved if the diluted 25 percent-75 percent eutrophic water is used in the irrigation, thereby achieving the purpose of improving the lawn quality characters and protecting environment.

Owner:TIANJIN NORMAL UNIVERSITY

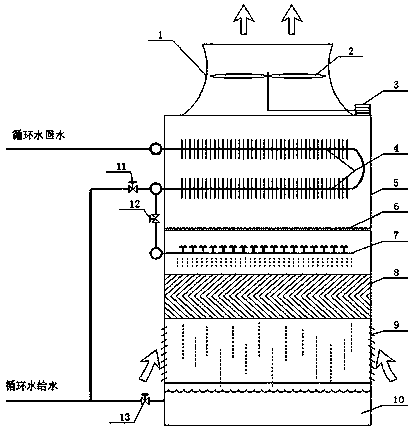

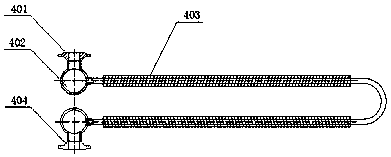

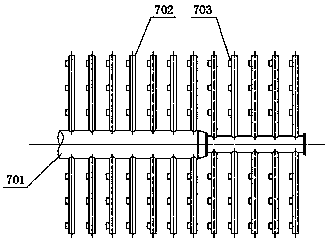

Dry and wet combined circulating water cooling tower

PendingCN107631648ALong time without waterLow equipment investment costStationary conduit assembliesStationary tubular conduit assembliesChemical industryElectricity

A dry and wet combined circulating water cooling tower comprises a tower body. The cooling tower is of an air drawing type structure. A dry cooling section and a wet cooling section are sequentially installed on the portion, below the air drawing structure, of the tower body. A dry cooling section body is a horizontally arranged dry pipe bundle. The wet cooling section sequentially comprises a dehydrator, a water distributing device, spraying filler, blinds and a water tank. The dry pipe bundle is divided into two branches at the outlet, wherein one branch is provided with a dry pipe bundle outlet valve, then communicates with a circulating water supply pipeline and leads into the water tank via a water tank outlet valve, and the other branch is provided with a water distributing header pipe valve and then communicates with a water distributing header pipe of the water distributing device. The dry and wet combined circulating water cooling tower solves the problems that an open type circulating water cooling tower is large in water consumption, and a closed type circulating water cooling device is large in investment, high in electricity consumption and difficult to popularize, andthe dry and wet combined circulating water cooling tower saves energy and water and is suitable for various circulating water cooling stations of the metallurgy industry, the electrical industry, theoil refining industry, the chemical industry and the like.

Owner:GANSU LANPEC TECH +2

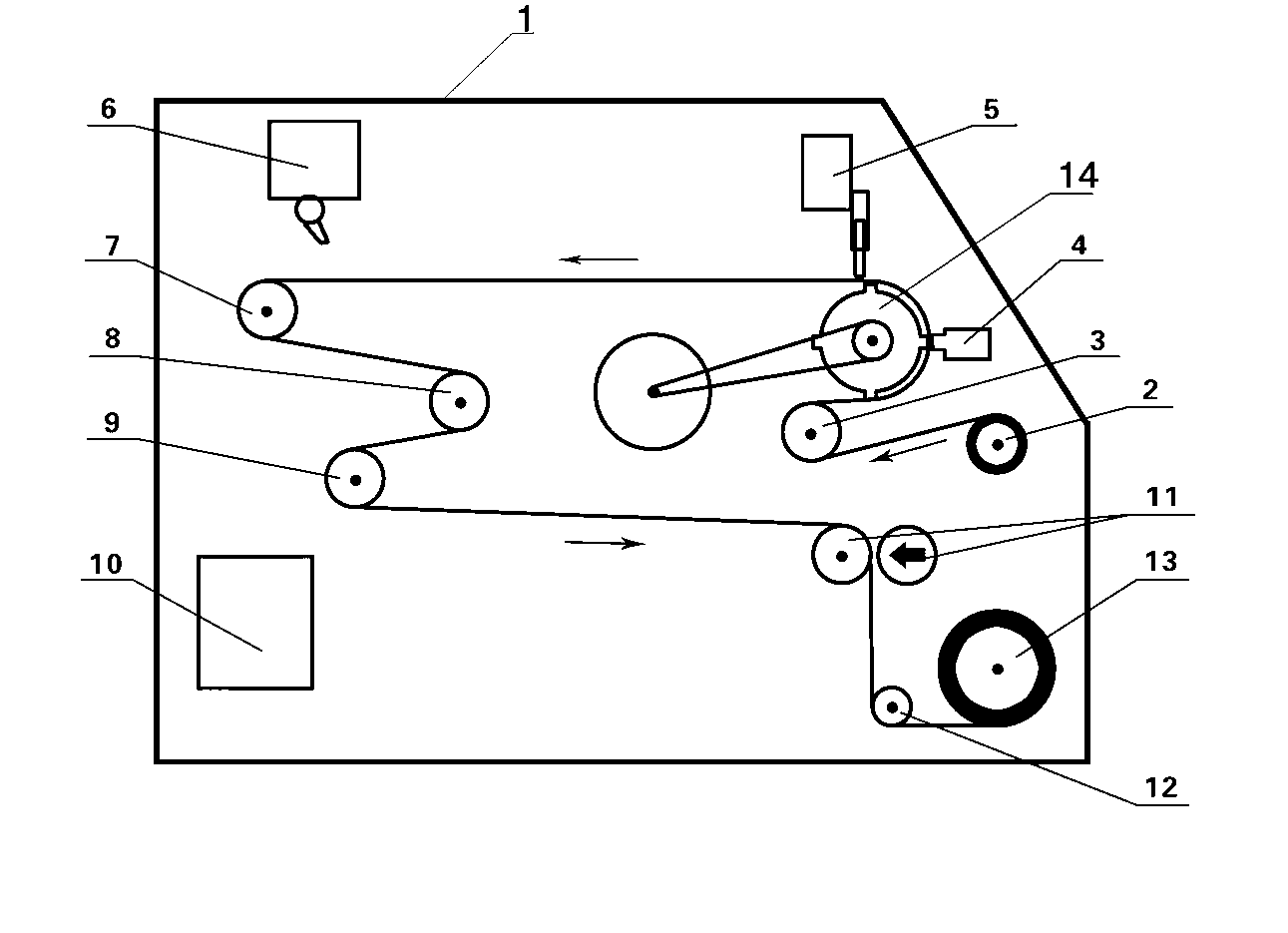

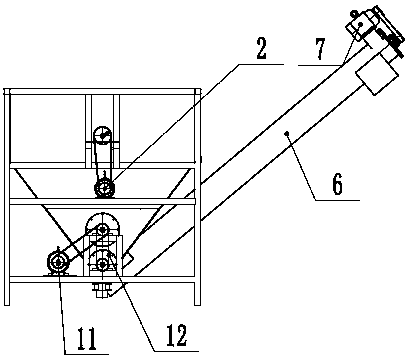

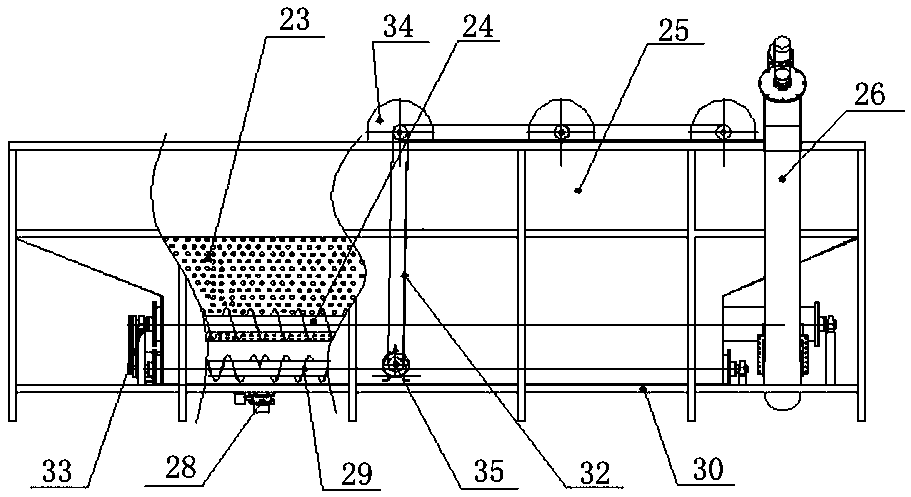

Precise seed-attaching no-tillage seeder on paddy mulching film

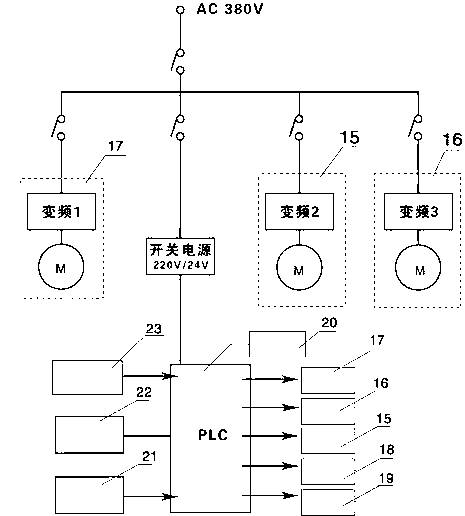

ActiveCN103238404ASolve productivitySolve the problem of high water consumptionAgriculture gas emission reductionRegular seed deposition machinesSeederProgrammable logic controller

The invention provides a precise seed-attaching no-tillage seeder on a paddy mulching film. The precise seed-attaching no-tillage seeder comprises a PLC (Programmable Logic Controller), a man-machine interaction unit, a rack, a glue spraying unit, a notch unit, a seed attaching unit, a residual seed recycling box, a cam carrier roller, a tensioning / reversing carrier roller unit, a mulching film carrier roller, a power film clamping unit, two tensioning carrier rollers, a film winding carrier roller, a displacement sensor and three frequency conversion motors, wherein the tensioning / reversing carrier roller unit, the mulching film carrier roller, the power film clamping unit, the two tensioning carrier rollers and the film winding carrier roller are respectively arranged at the two sides of the rack through bearings; power is respectively supplied to the power film clamping unit, the cam carrier roller and the film winding carrier roller by the three frequency conversion motors; the mulching film is wound on the mulching film carrier roller; and the mulching film sequentially winds around the first tensioning carrier roller, the cam carrier roller, the tensioning / reversing carrier roller unit, the power film clamping unit and the second carrier roller, and is finally wound by the film winding carrier roller. The machine disclosed by the invention is precise in positioning and accurate in sowing on the mulching film and is suitable for large-area mechanical work of direct sowing production of rice.

Owner:HEILONGJIANG JIAHE AGRI SCI & TECH DEV

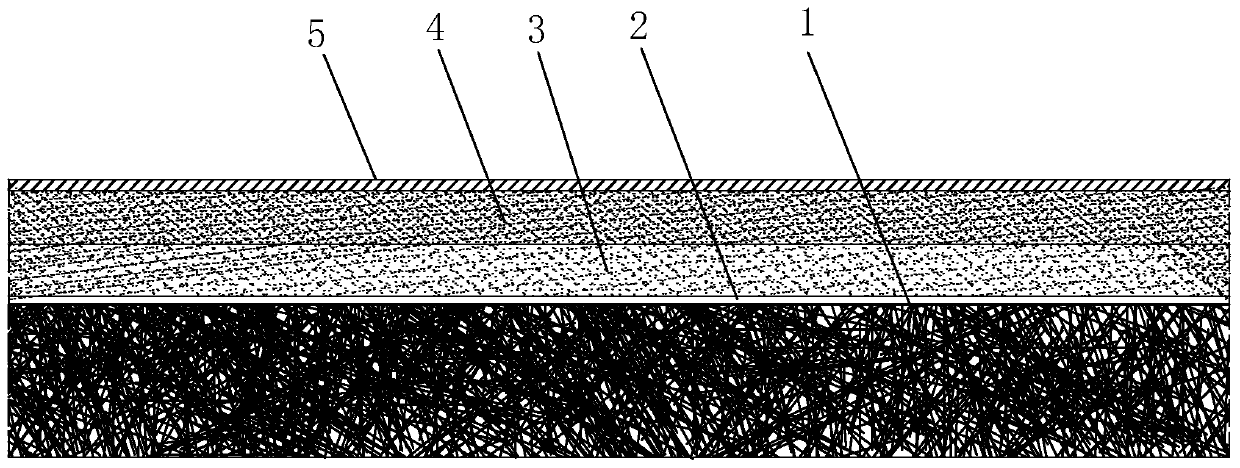

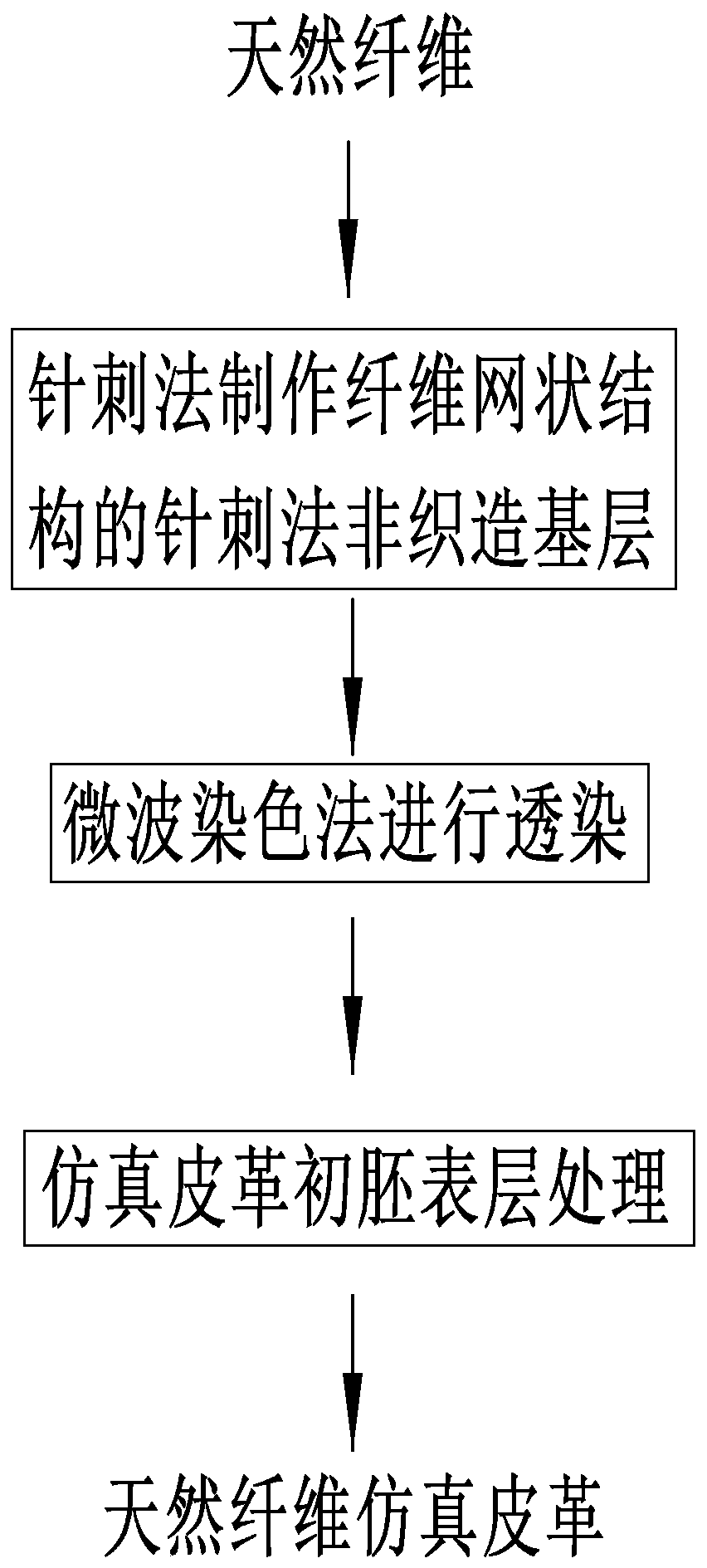

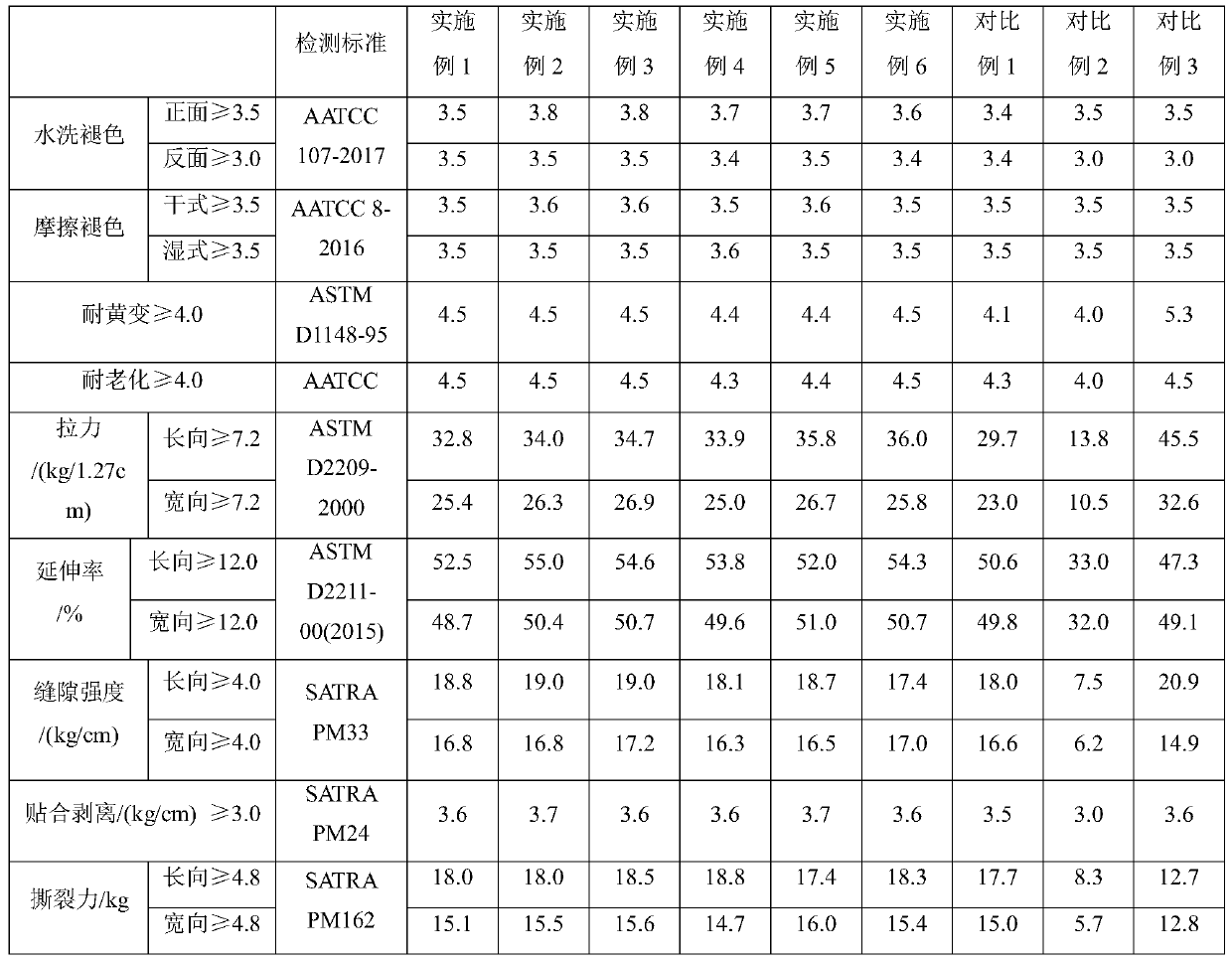

Natural-fiber artificial leather and manufacturing method thereof

ActiveCN110592968AReduce energy consumptionSolve the problem of high water consumptionTextiles and paperWaxMicrowave

The invention relates to the technical field of leather processing, in particular to natural-fiber artificial leather and a manufacturing method thereof. The natural-fiber artificial leather is obtained through the following processing steps: opening, carding and dry-process needling treatment is sequentially conducted on natural fibers to obtain a needled non-woven base layer with a fiber net structure inside; by adopting a microwave dyeing method, the needled non-woven base layer is dyed with a chemical dye in a permeating way to obtain gray artificial leather; the upper surface layer of thegray artificial leather is sequentially coated with a bottom sealing layer, a first resin layer, a second resin layer and an oil wax layer in a rolling way, and polishing is carried out to obtain thenatural fiber artificial leather. By adopting the processing technology, energy is saved, emission is reduced, the method is friendly to the environment, the processed artificial leather has excellent washing fading performance and frictional fading performance and good dyeing firmness, the yellowing resistance and aging resistance reach the standard, and various mechanical properties such as tensile strength, tearing strength and elongation are all higher than the index requirements.

Owner:辛集市宝隆科技有限公司

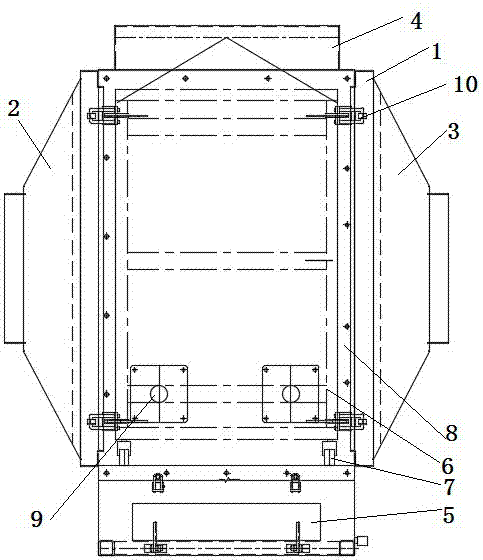

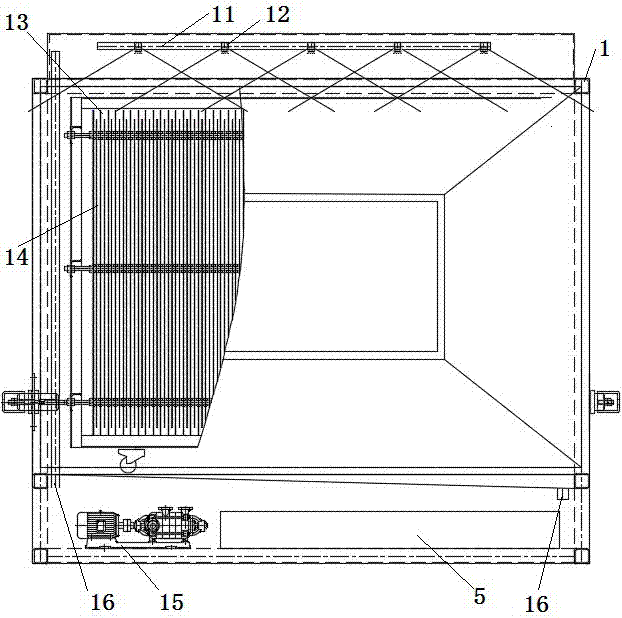

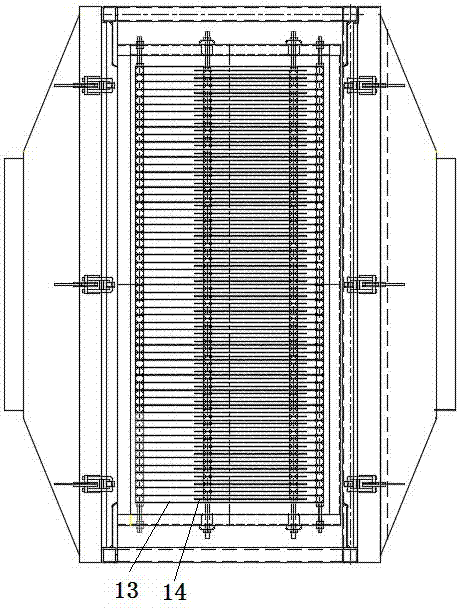

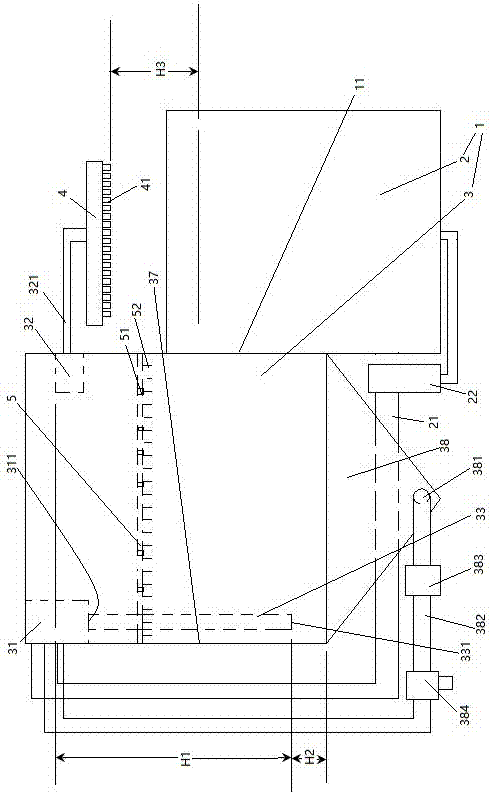

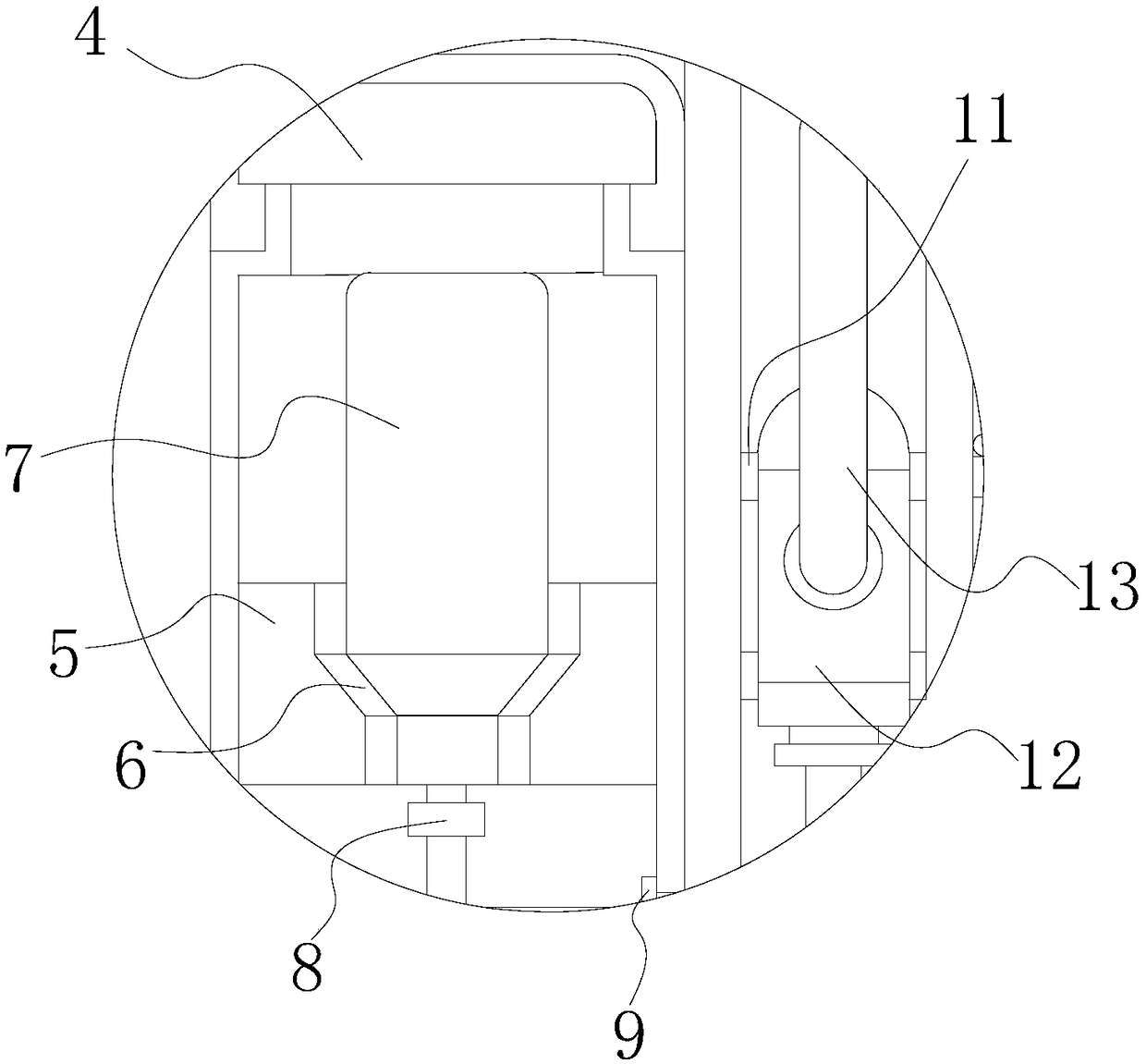

Wet electrostatic dust collector for fresh air system

PendingCN107350082ASolve maintenance difficultiesSolve the problem of high water consumptionElectrode carrying meansExternal electric electrostatic seperatorDust controlFresh air

The invention discloses a wet electrostatic dust collector for a fresh air system. An anode system and a cathode system of the wet electrostatic dust collector for the fresh air system are fixedly connected to a pole plate framework. Idler wheels are arranged at the bottom of the pole plate framework. An access door is arranged on the open side of a shell so that the anode system and the cathode system of the wet electrostatic dust collector can be replaced or maintained conveniently by directly taking the pole plate framework out, and the problem that as an existing wet electrostatic dust collector for the fresh air system is small in size, the wet electrostatic dust collector is difficult to replace and maintain is solved. Meanwhile, the wet electrostatic dust collector for the fresh air system is provided with a water collecting tank and a circulating water pump, water circulates in the water collecting tank and a spraying system by means of the circulating water pump, and the problem of high water consumption of the existing wet electrostatic dust collector for the fresh air system is solved. Meanwhile, a dual-drive electrostatic dust collection mode is adopted by the wet electrostatic dust collector for the fresh air system, so that the dust collection efficiency is high.

Owner:ZHEJIANG ZHONGTAI ENVIRONMENTAL PROTECTION EQUIP CO LTD

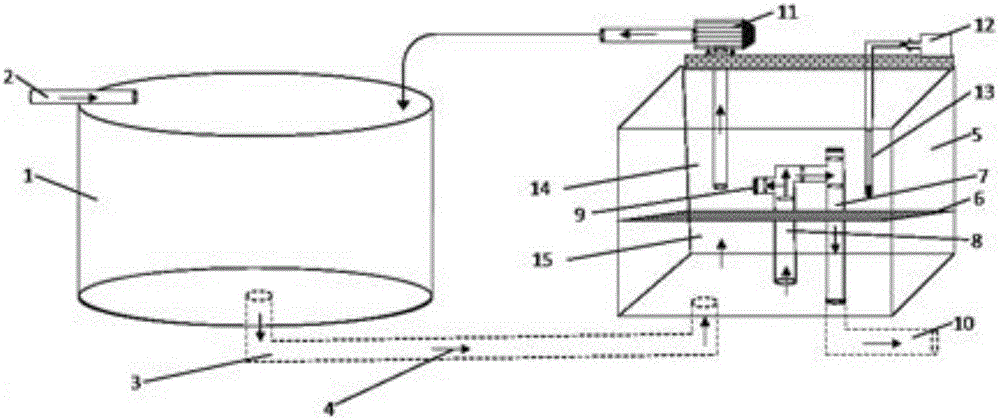

Circulating type fish tank and fish tank water purifying method

InactiveCN107018942AReduce water consumptionSolve the problem of high water consumptionPisciculture and aquariaWater storageEngineering

The invention relates to fish tanks. A circulating type fish tank comprises a fish keeping cavity and a purifying cavity, wherein a water inlet tank and an overflow tank are arranged at the upper end of the purifying cavity, a concentrated water hopper is arranged at the lower end of the purifying cavity, the water inlet tank is provided with a water inlet pipe with an outlet opens downwards, the fall between the outlet of the water inlet pipe and the upper end of the overflow tank is 1.1-1.2 m, the fall between the outlet of the water inlet pipe and the upper end of the concentrated water hopper is 0.5-0.7 m, the water inlet pipe is disconnected from the side wall of the purifying cavity, a concentrated water inlet pipe is arranged in the concentrated water hopper and communicated with the water inlet tank through a concentrated water return pipe, a concentrated water drain pump and a three-way valve are arranged on the concentrated water return pipe, water storage spaces at the same height in the fish keeping cavity are communicated horizontally, the overflow tank is higher than the fish keeping cavity and communicated with the fish keeping cavity, the fish keeping cavity is communicated with the water inlet tank through a circulating water pipe, and the circulating water pipe is provided with a circulating water pump. The fish tank has the advantage that water consumption can be reduced when the fish tank is used for keeping fish and solves the problem that existing fish tanks consume a large amount of water when used for keeping fish.

Owner:张致睿

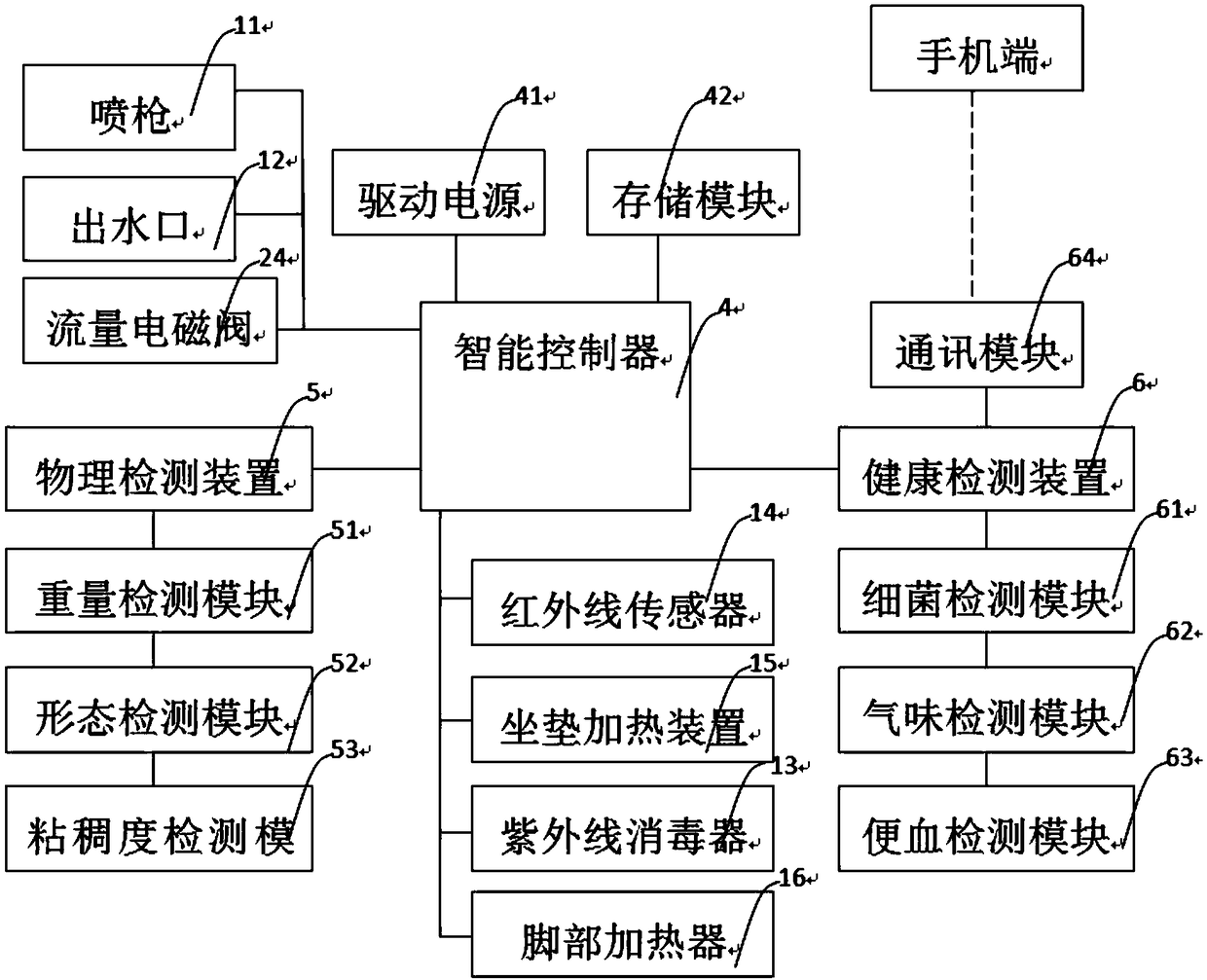

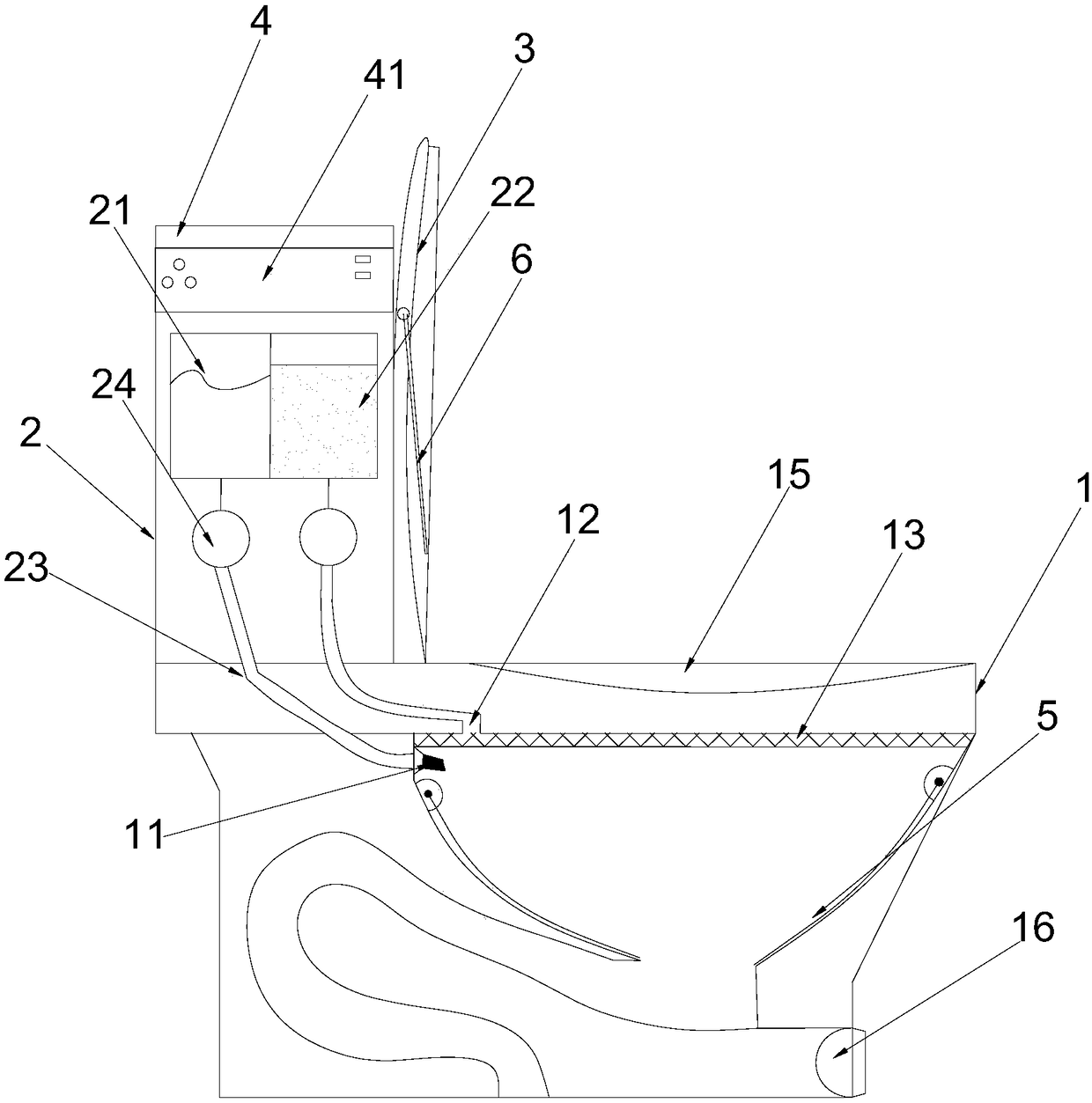

Smart household toilet

InactiveCN109024809AImprove flushing effectSolve the problem of high water consumptionFlushing devicesLavatory sanitoryLife qualitySolenoid valve

The invention belongs to the technical field of smart home equipment, in particular to a smart household toilet. The smart household toilet comprises a toilet body and a water storage tank and a toilet cover disposed on the toilet body, wherein the top of the water storage tank is provided with an intelligent controller and a driving power source. The water storage tank is provided with a detergent tank and a water tank arranged independently, and the detergent tank and the water tank are respectively connected by pipes to a spray gun and a water outlet provided on the toilet body. Flow solenoid valves are arranged on the pipes connecting the detergent tank and the water tank to the toilet. The flow solenoid valves are electrically connected to an intelligent controller. The surface of thecavity of the toilet body is provided with a physical detecting device, and the physical detecting device is electrically connected with the intelligent controller. The smart household toilet enriches the application of smart home in life, brings great convenience to people's life, improves people's quality of life, and creates a scientific and healthy living environment.

Owner:FOSHAN RISHENG ELECTRONICS

Method for improving reaction property of dissolving pulp board

ActiveCN106381742AImprove responseAvoid spendingCellulose treatment using microorganisms/enzymesWater resourcesCellulase

The invention provides a method for improving the reaction property of a dissolving pulp board. The method comprises the following steps of adopting the dissolving pulp board with the thickness being 0.05cm to 0.50cm, and controlling the moisture content of the dissolving pulp board to be 2 percent to 10 percent for standby use; adopting cellulase for preparing a cellulase solution with the mass concentration being 5 percent to 10 percent, adopting strong acidic-weak basic salt for adjusting a pH value of the cellulase solution to be 4.5 to 5.5, and obtaining a cellulase solution for standby use; sequentially and uniformly spraying the cellulase solution for standby use and water on the processed dissolving pulp board, and preparing to react; putting the dissolving pulp board into a constant temperature and humidity room for reacting, wherein the temperature of the constant temperature and humidity room ranges from 40 to 60 DEG C, and the humidity of the constant temperature and humidity room is consistent to the moisture content of the sprayed dissolving pulp board. According to the method provided by the invention, the reaction property of the dissolving pulp board is improved, meanwhile, not only is the waste of water resource avoided, but also the energy consumption is reduced, and the method is lower in cost.

Owner:FUJIAN AGRI & FORESTRY UNIV

Waste plastic cleaning and sorting device and technology

ActiveCN107139353AFull reuseReduce pollutionPlastic recyclingMechanical material recoveryWater flowPropeller

The invention relates to a waste plastic cleaning and sorting device and technology, and belongs to the technical field of waste plastic comprehensive utilization. According to the technical scheme, the device is formed by series connection of three cleaning and sorting device bodies, a high-speed-rotating propeller is used, the acute waterflow turbulence is generated, impurities bonded on the waste plastic are separated, a screening plate is used for separating heavy-impurity plastic from the impurities, the heavy-impurity plastic and the impurities are conveyed out and are subject to treatment, a dial wheel is used for cleaning and sorting the little-impurity plastic from the waste plastic and then moving the little-impurity plastic out, power consumption is reduced, the little-impurity plastic, the heavy-impurity plastic and the impurities are thoroughly separated, the waste plastic is sufficiently reutilized, the waste is turned into wealth, environment pollutions are reduced, the power consumption is low, and the device and technology are easily used and popularized. The separated-out little-impurity plastic, the heavy-impurity plastic, the impurities and the like are comprehensively used, the environment pollution is reduced, and the repeated use value of the waste plastic is improved.

Owner:唐山鼎业塑材科技有限公司

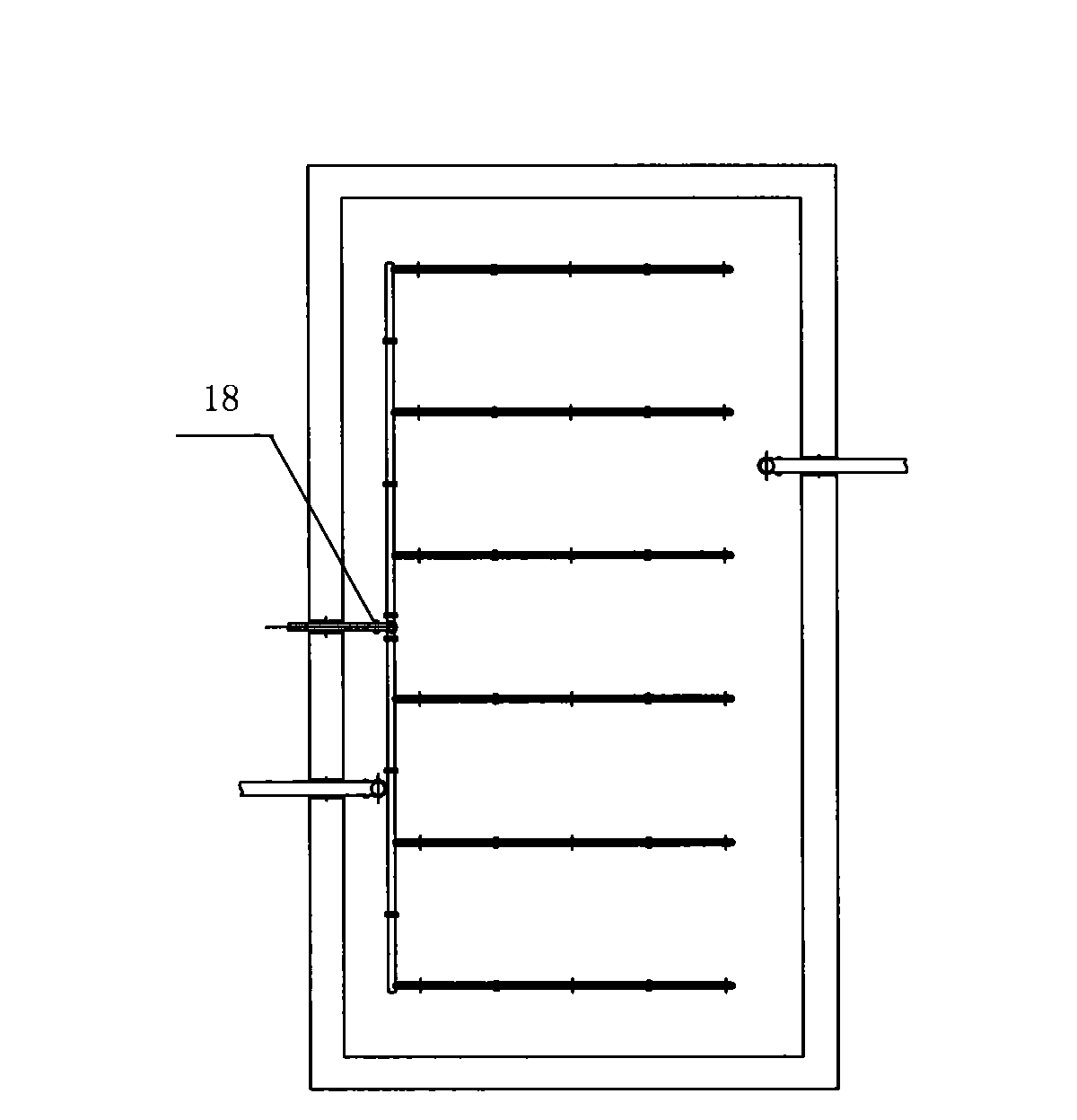

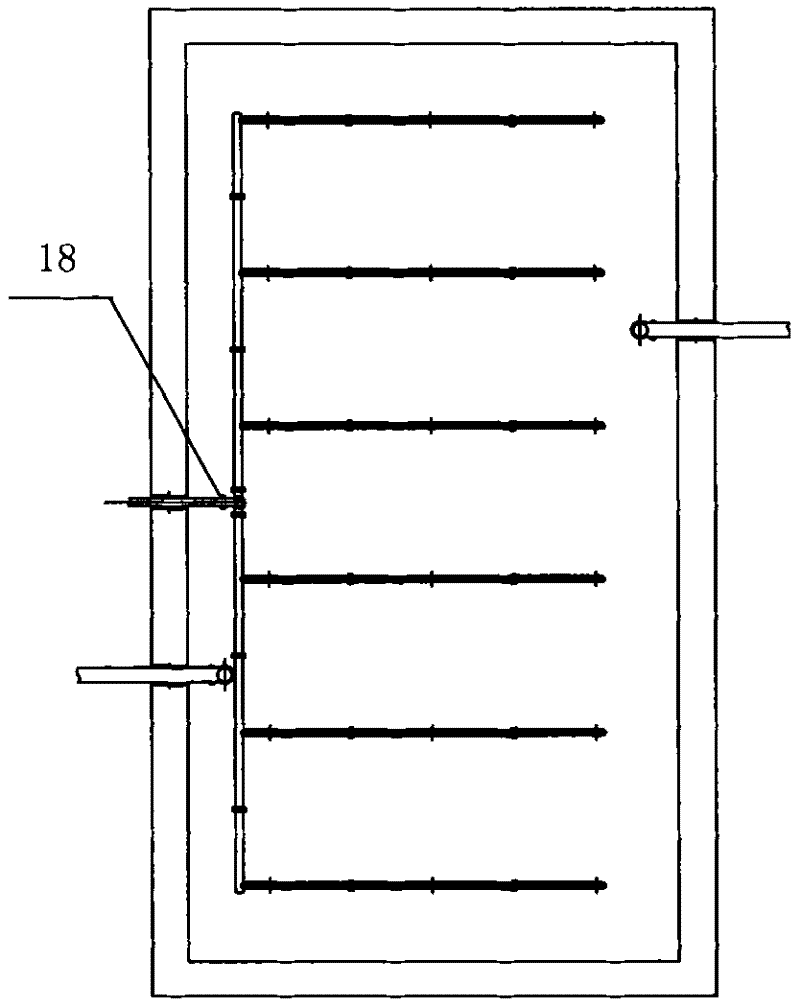

Condensing system of washing-drying integrated machine

InactiveCN107604617ASolve the problem of high water consumptionEvenly distributedTextiles and paperLaundry driersWater flowEngineering

The invention discloses a condensing system of a washing-drying integrated machine and relates to the technical field of condensers. The condensing system comprises a condenser and a sprayer arrangedat the position of a water inlet of the condenser; the sprayer is externally connected with a water pipe, a plurality of first water jets corresponding to the interior of the condenser and a pluralityof second water jets corresponding to the exterior of the condenser are arranged on the sprayer. Two different water path structures are added on the sprayer of the condenser, water streams can be evenly distributed inside and outside the condenser, orientation and heat exchange area of the water streams is increased, and the problem that the condenser is high in water consumption under the samecondensation heat exchange conditions is solved.

Owner:NANJING CHUANGWEI HOUSEHOLD ELECTRONICS APPLIANCES LTD

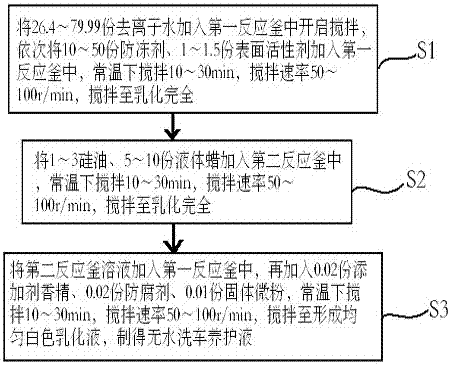

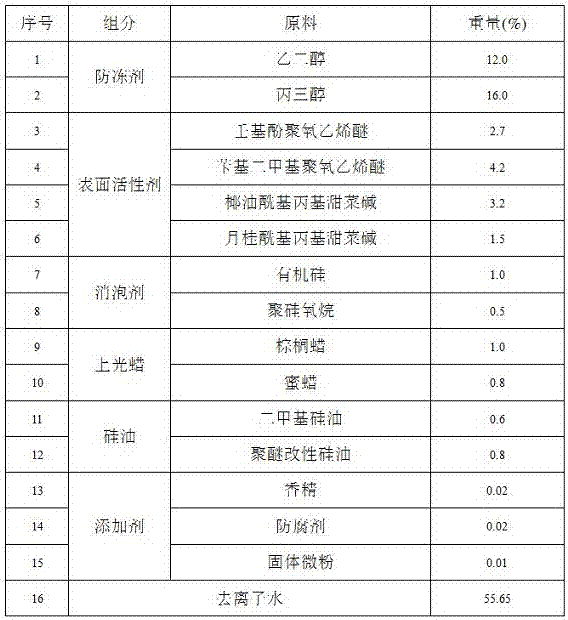

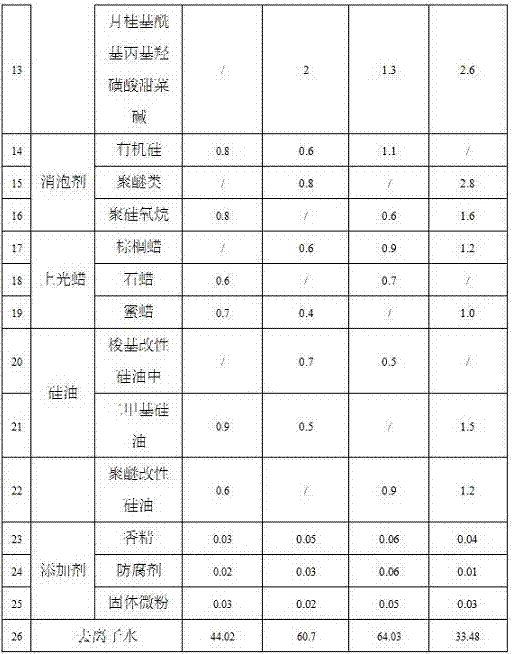

Anti-freezing anhydrous car cleaning curing liquid and preparation method thereof

InactiveCN106906070ASolve the problem of high water consumptionEasy to makeOrganic detergent compounding agentsWax coatingsWaxAnti freezing

The invention relates to anti-freezing anhydrous car cleaning curing liquid and a preparation method thereof. The curing liquid is prepared from, in weight percentage, 10-50% of anti-freezing agents, 1-1.5% of surface active agents, 2-3% of defoaming agents, 1-6% of wax polish, 1-3.5% of silicone oil, 0.01-0.2% of additive and 26.4-79.99% of deionized water. By the aid of the scheme, the anti-freezing anhydrous car cleaning curing liquid is simpler to prepare, easier to operate, simple and convenient to use and remarkable in effect, the curing liquid is directly sprayed on the surface of vehicles and cleaned by the aid of wet towel, the surfaces of the vehicles are wiped dry by the aid of a polishing towel or a towel, so that cleaning, waxing, polishing and curing are finished once, the vehicles can be cleaned in a short time and cannot be flushed by the aid of additional water, water resources can be saved, and environments cannot be polluted.

Owner:任海清

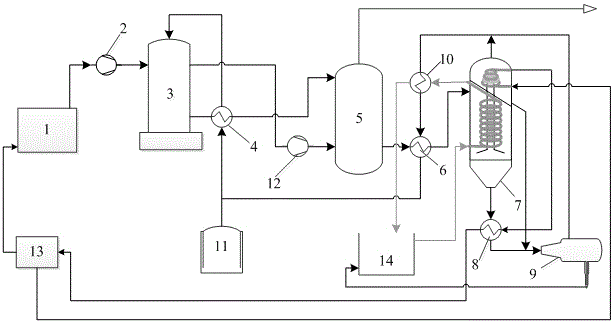

Coke oven waste gas utilization device and application method thereof

ActiveCN103808157ASolve the problem of high water consumptionNothing producedHydrogenIncreasing energy efficiencyVapor–liquid separatorProcess engineering

The invention discloses a coke oven waste gas utilization device and an application method thereof, and belongs to the technical field of coking. In the device, a coke oven is connected with a reformer through a compressor, a synthesized gas outlet at the upper end of the reformer is connected with a chemical synthesizer through a supercharger, a waste gas outlet at the lower end of the chemical synthesizer is connected with a multi-level gas liquid separator, the multi-level gas liquid separator is a cyclone spiral pipeline heat exchanger, the lower end of the multi-level gas liquid separator leads to an expansion flash vessel, a gas outlet of the expansion flash vessel is connected with the upper end of the reformer, a liquid outlet of the expansion flash vessel leads to a water reservoir, oxygen separated by an air separator leads to the coke oven along a pipeline, and liquid nitrogen separated by the air separator leads to the multi-level gas liquid separator. Firstly the heat of the waste gas and the separated CO2 and water are fully utilized, and in addition, the liquid nitrogen separated by the air separator serves as a condensing medium to cool in the multi-level gas liquid separator. The coke oven waste gas utilization device is a green and environmentally-friendly process unit. The building and construction costs of the device are low, and the device is easy to popularize and apply.

Owner:TAIYUAN UNIV OF TECH

Water-saving type running water breeding device

InactiveCN106472388ASolve the problem of high water consumptionAvoid constraintsPisciculture and aquariaWater savingWater resources

The invention provides a water-saving type running water breeding device. The water-saving type running water breeding device includes main parts, such as a breeding pool, a water collection pool, a water level control device, a breeding wastewater filtering device and a power system. The water collection pool is used for collecting breeding wastewater in the breeding pool, the filtering device is then used for filtering the breeding wastewater, clean water is obtained after separation, at the same time, oxygenation treatment is conducted on the clean water by aeration oxygenation, the treated water is pumped by the power system for use in breeding again, and a water saving purpose is achieved. Therefore, the water-saving requirement in a running water breeding mode is met, the problem that water resource consumption of a running water breeding pool is large is solved, and the restriction of water resource deficiency on the running water cultivating mode is overcome.

Owner:CHINESE STURGEON RES INST CHINA THREE GOR

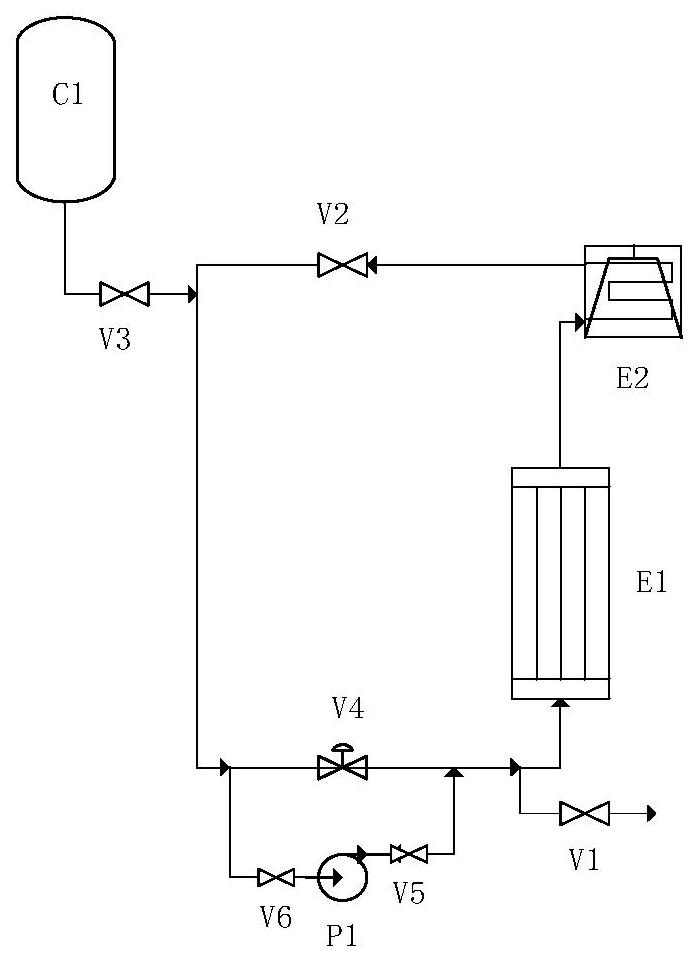

High-temperature reactor waste heat removal system

PendingCN113130103ASolve the speed problemSolve the characteristicsNuclear energy generationCooling arrangementExpansion tankCirculator pump

The invention discloses a high-temperature reactor waste heat removal system. The system comprises a water-cooled wall heat exchanger (E1) in a cabin, and an air cooler (E2) and an expansion water tank (C1) which are arranged outside the cabin, wherein an outlet of the water-cooled wall heat exchanger (E1) is connected to an inlet of the air cooler (E2), and an outlet of the air cooler (E2) and an outlet of the expansion water tank (C1) are connected to an inlet of the water-cooled wall heat exchanger (E1) through a forced circulation control valve (V4); and bypasses are arranged at the inlet end and the outlet end of the forced circulation control valve (V4), and forced circulation pumps (P1) are arranged on the bypasses. A method of combining forced circulation and natural circulation is adopted in the invention, so the defects that an existing waste heat removal system is low in cooling rate, long in consumed time, not thorough in flushing and the like are fundamentally overcome.

Owner:XIAN THERMAL POWER RES INST CO LTD

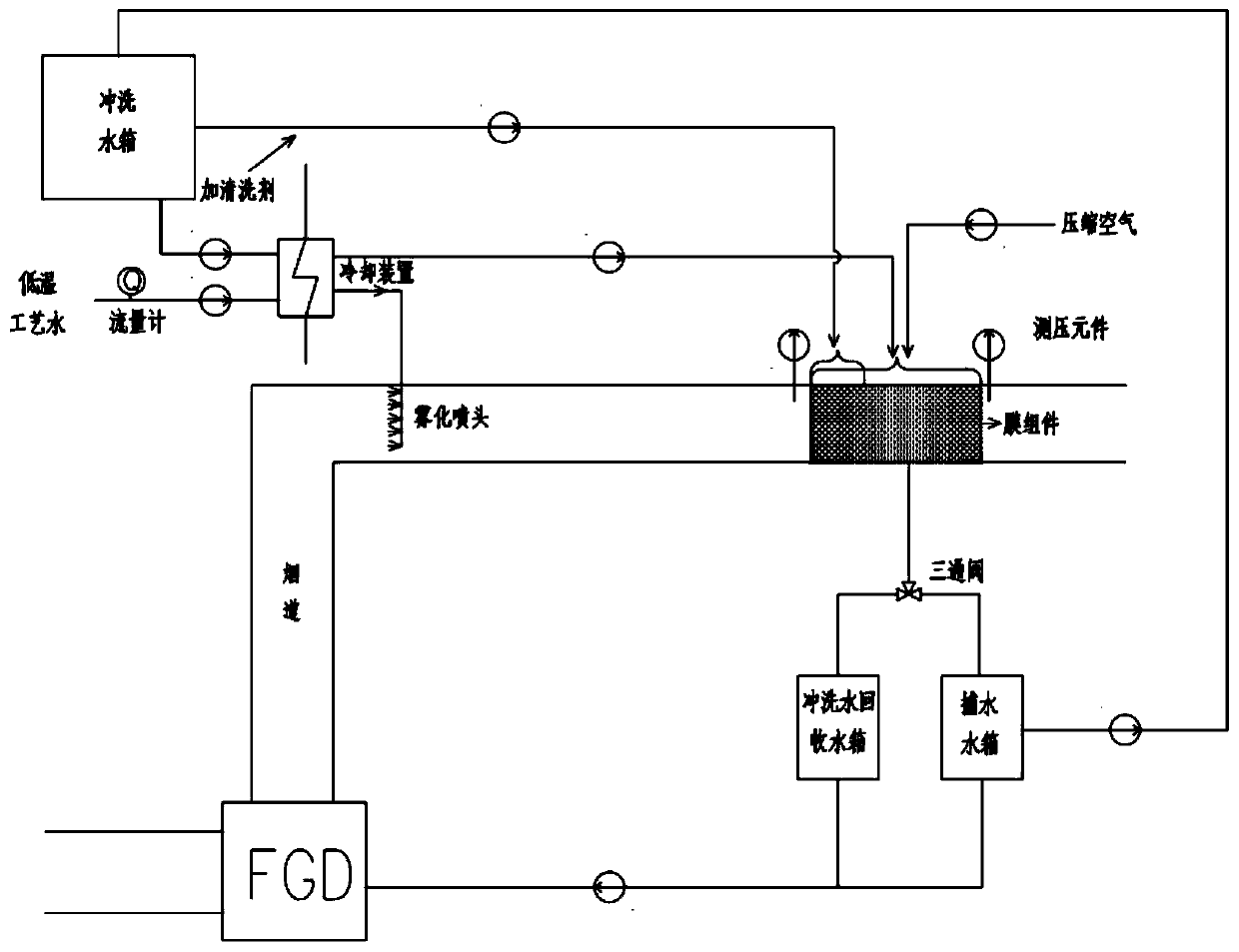

Flue gas water capture apparatus based on ceramic membrane, and ceramic membrane cleaning process

PendingCN110465163ASolve pollutionIncrease the likelihood of acid rainSemi-permeable membranesGas treatmentWater vaporFlue gas

The invention belongs to the technical field of flue gas water capture, and particularly relates to a flue gas water capture apparatus based on a ceramic membrane, and a ceramic membrane cleaning process, wherein the flue gas water capture apparatus comprises a ceramic membrane unit, a chemical cleaning unit, a gas-liquid alternating backwashing unit and a low-temperature process spraying unit. According to the present invention, with the apparatus, the problems of large water consumption, incomplete cleaning and chemical cleaning agent consumption of the mechanical cleaning are solved, the problem of environmental pollution caused by tiny fine particles in flue gas and acid gas is further solved, and the capturing efficiency of the water vapor by the ceramic membrane assembly is further improved.

Owner:NORTH CHINA ELECTRIC POWER UNIV (BAODING)

Coke oven waste gas utilization device and application method thereof

ActiveCN103808157BSolve the problem of high water consumptionEasy to separateHydrogenIncreasing energy efficiencyVapor–liquid separatorProcess engineering

The invention discloses a coke oven waste gas utilization device and an application method thereof, and belongs to the technical field of coking. In the device, a coke oven is connected with a reformer through a compressor, a synthesized gas outlet at the upper end of the reformer is connected with a chemical synthesizer through a supercharger, a waste gas outlet at the lower end of the chemical synthesizer is connected with a multi-level gas liquid separator, the multi-level gas liquid separator is a cyclone spiral pipeline heat exchanger, the lower end of the multi-level gas liquid separator leads to an expansion flash vessel, a gas outlet of the expansion flash vessel is connected with the upper end of the reformer, a liquid outlet of the expansion flash vessel leads to a water reservoir, oxygen separated by an air separator leads to the coke oven along a pipeline, and liquid nitrogen separated by the air separator leads to the multi-level gas liquid separator. Firstly the heat of the waste gas and the separated CO2 and water are fully utilized, and in addition, the liquid nitrogen separated by the air separator serves as a condensing medium to cool in the multi-level gas liquid separator. The coke oven waste gas utilization device is a green and environmentally-friendly process unit. The building and construction costs of the device are low, and the device is easy to popularize and apply.

Owner:TAIYUAN UNIV OF TECH

Dry manure two-phase anaerobic digestion system for pig farm

InactiveCN101654321BAchieve enrichmentEmission reductionBiological substance pretreatmentsGas production bioreactorsPig farmsSlurry

The invention discloses a dry manure two-phase anaerobic digestion system for a pig farm belonging to the technical field of environment engineering and energy, which uses a hydrolytic acidification and methane production two-phase anaerobic digestion system as a main body. The system is characterized in that the dry manure in the pig farm is treated by integrating aeration biogas slurry reflux, external culture of acid producing bacteria and methane producing bacteria, and activity maintaining device so as to solve the problem that the prior two-phase process cannot effectively treat high solid concentration pig manure and has lower efficiency, thoroughly solve the problem of large water consumption of the conventional anaerobic treatment, realize biogas slurry concentration, reduce the discharge amount of the biogas slurry, greatly reduce subsequent treatment load of biogas engineering, and realize quick degradation and efficient gas production of organic waste. After application, the system improves the comprehensive economic benefit by 20 percent compared with the prior anaerobic system; and the improvement on efficiency ensures that the biogas engineering of the dry manure pig farm realizes self supply of energy, and maintains normal operation of the biogas engineering of the pig farm in winter, thereby achieving multiple aims of saving water, reducing discharge, protecting environment and producing energy and fertilizer.

Owner:CHINA AGRI UNIV

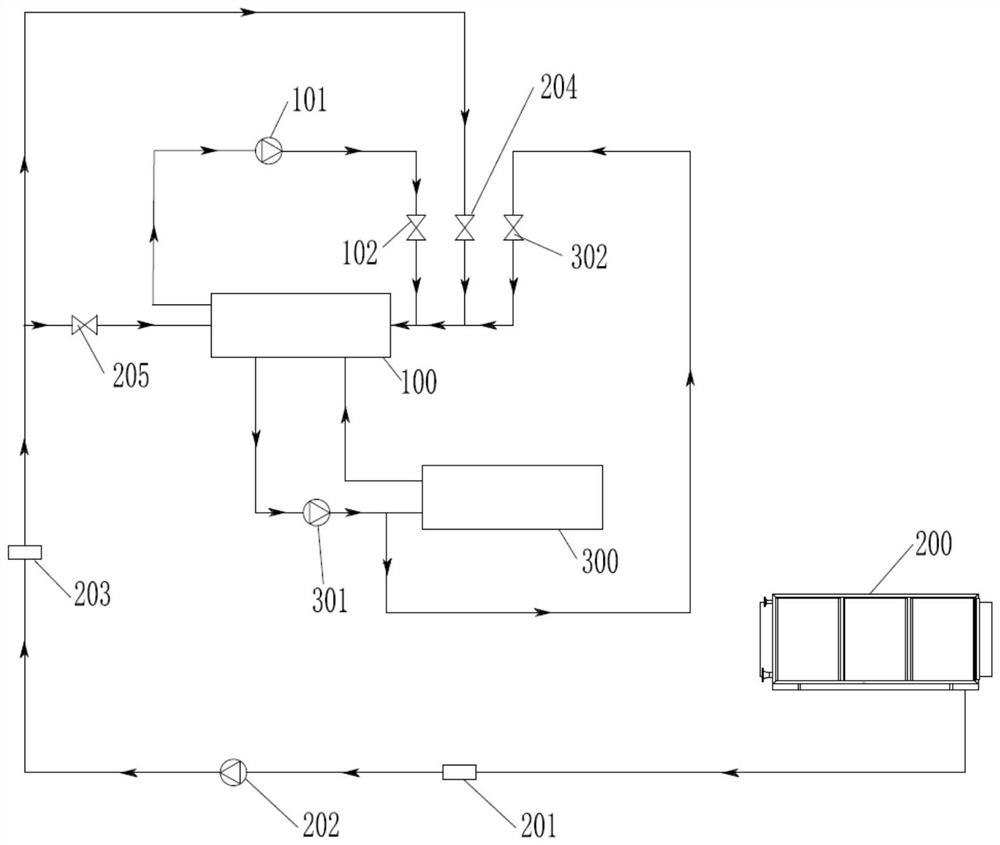

Water supply mechanism for cooling tower, cooling tower, air conditioning system and control method

PendingCN114413361ANormal coolingGuaranteed uptimeSpace heating and ventilation safety systemsSpace heating and ventilation control systemsWater supplyChilled water

The invention discloses a water supply mechanism for a cooling tower, the cooling tower, an air conditioning system and a control method, relates to the technical field of air conditioners, and solves the problem of single driving water source of a hydraulic fan of the cooling tower in the prior art. The water supply mechanism comprises a spray water supply assembly, a condensate water supply assembly and a chilled water supply assembly, and the water outlet ends of the spray water supply assembly, the condensate water supply assembly and the chilled water supply assembly are connected with a water inlet of a hydraulic fan of the cooling tower. And water is supplied to a hydraulic fan of the cooling tower through at least one of the spray water supply assembly, the condensate water supply assembly and the chilled water supply assembly. The water supply mechanism comprises three sets of hydraulic fan driving water sources, when the spray water supply assembly breaks down, water can be supplied to a hydraulic fan of the cooling tower through the condensate water supply assembly and / or the chilled water supply assembly, the hydraulic fan is driven to rotate, it is guaranteed that the cooling tower can dissipate heat normally, and therefore long-term stable operation of the cooling tower is guaranteed.

Owner:PINGDINGSHAN TIANAN COAL MINING +2

A flue gas waste heat energy-saving and environmentally friendly pulverized coal preparation system

InactiveCN106196134BImprove explosion-proof performanceImprove securitySolid fuel pretreatmentDrying gas arrangementsProduction lineFlue gas

An energy-saving and environment-friendly flue gas waste heat pulverized coal preparation system comprises a belt coal feeder, a raw coal bunker, a coal feeder, a coal mill and a powder recovery bunker, wherein the dry air inlet of the coal mill communicates with the outlet of a first induced draft fan which is used for inputting high-temperature flue gas at the tail part of a boiler to the coal mill; an inert gas input passage is arranged in front of the dry air inlet of the coal mill; a first control valve is mounted on the inert gas input passage; the outlet of the coal mill communicates with the inlet of the powder recover bunker; a gas temperature detector and a gas concentration detector are mounted behind the outlet of the coal mill and connected with an alarm controller; a pulverized coal collection device is arranged in the powder recovery bunker; a second induced draft fan is mounted behind the flue gas outlet of the powder recovery bunker; and the outlet of the second induced draft fan communicates with the inlet of a flue gas desulfurization device or a chimney. The energy-saving and environment-friendly flue gas waste heat pulverized coal preparation system is a special production line for providing coal dust fuels for the pulverized coal boiler, the security of the pulverized coal preparation system can be guaranteed while the waste heat of flue gas at the tail part of the boiler is effectively utilized, energy saving and consumption reduction are realized and the environment is protected.

Owner:SHANDONG HUANNENG DESIGN INST

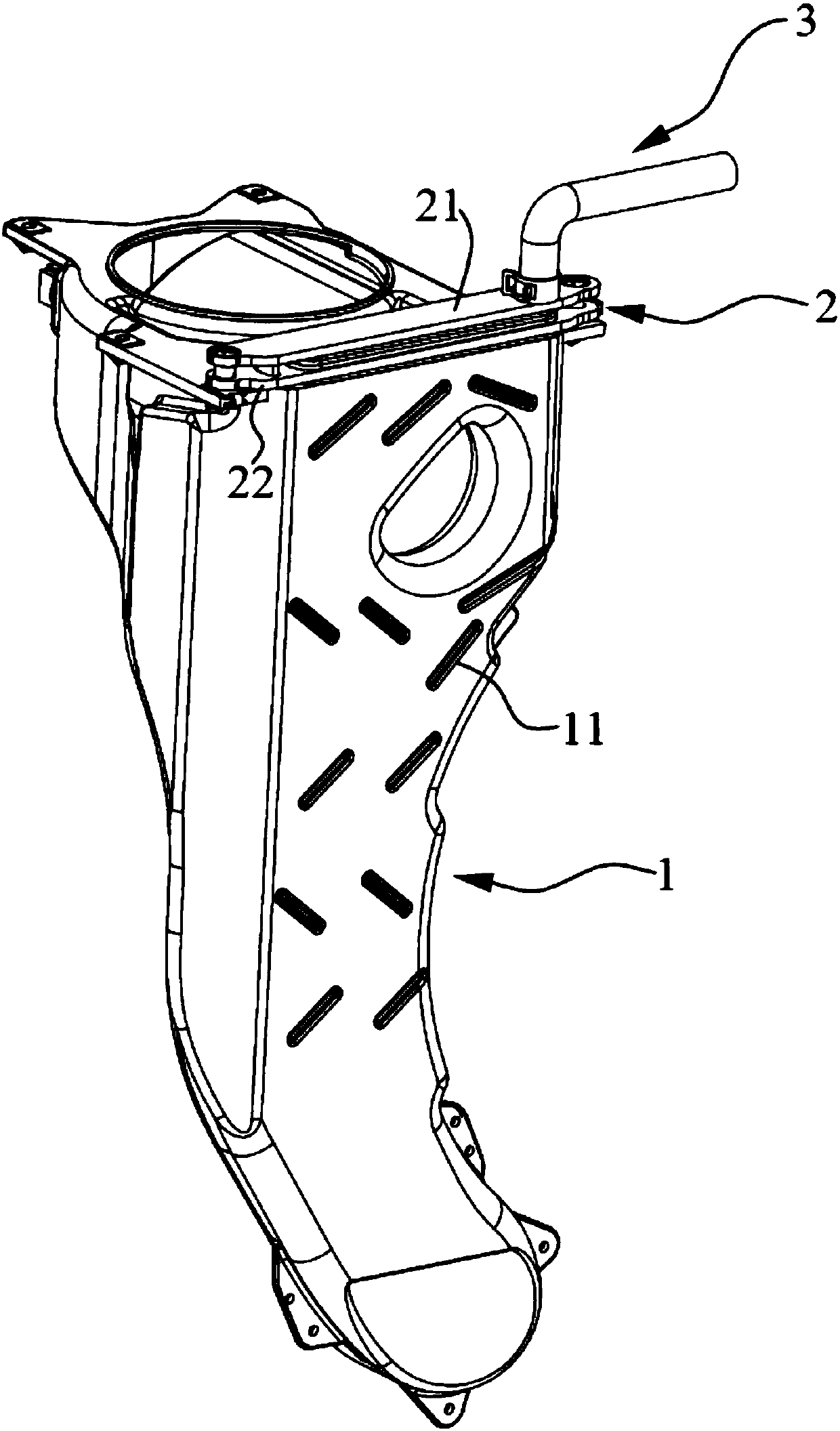

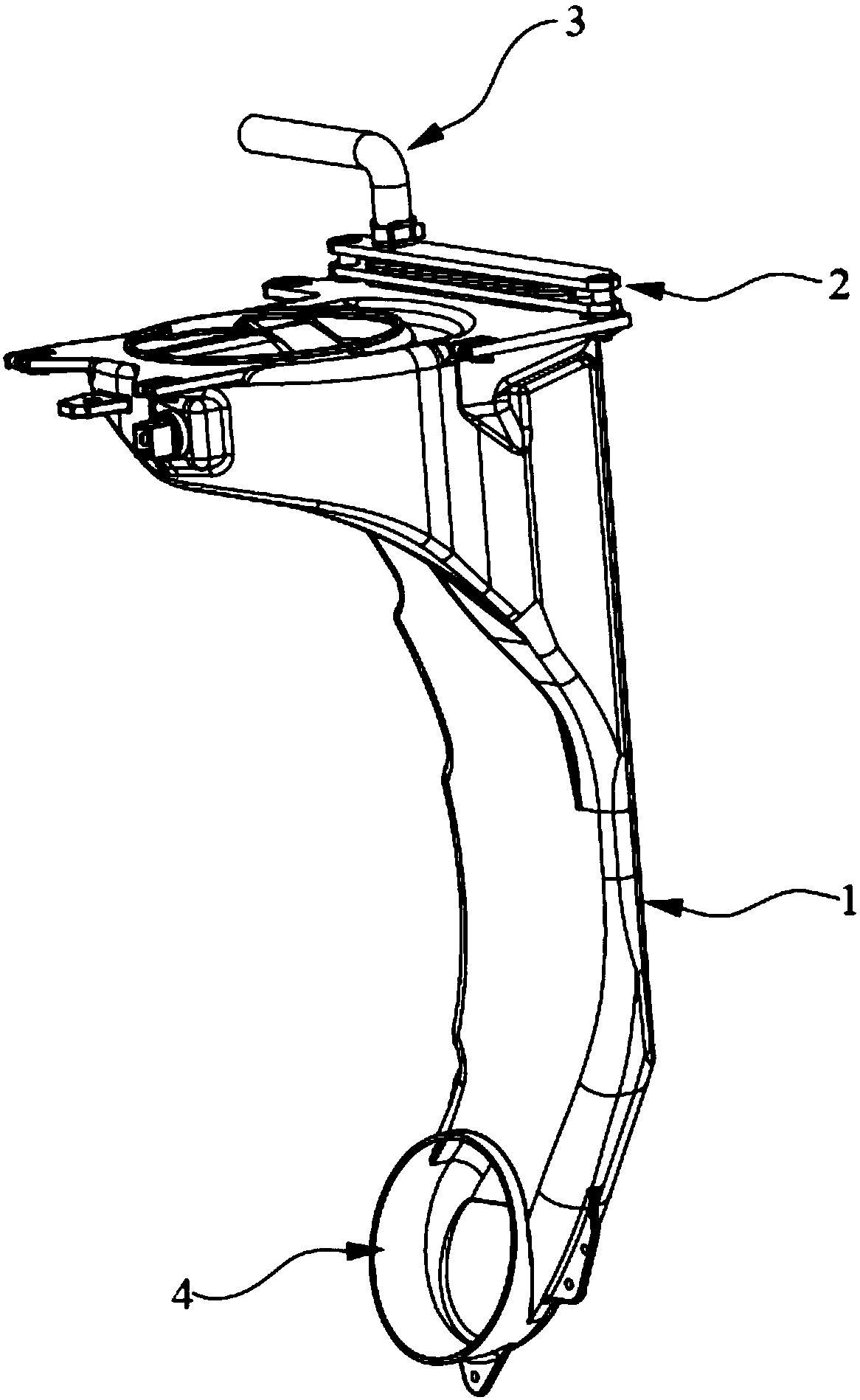

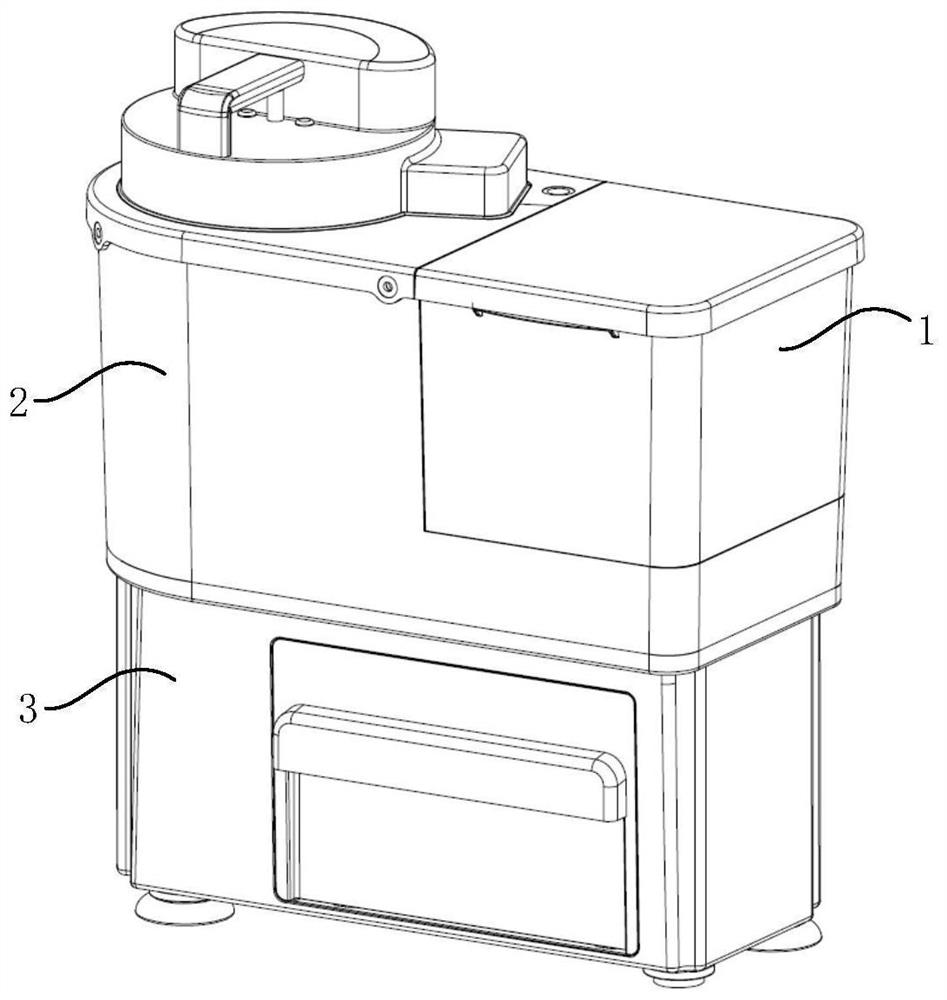

Washing equipment

PendingCN113969480AAchieve beat washingSolve the problem of high water consumptionOther washing machinesTextiles and paperPower unitIndustrial engineering

The invention belongs to the field of clothes treatment equipment, and particularly provides washing equipment. The washing equipment aims to solve the problems that existing washing equipment is high in water consumption and not portable when being used for washing small clothes. The washing equipment comprises a washing module, the washing module comprises a top cover, a first power unit, a hammering assembly and a washing barrel, the first power unit is arranged in the top cover, the output end of the first power unit extends out of the top cover and then is connected with the hammering assembly, the top cover covers the top of the washing barrel, the hammering assembly is located on the inner side of the washing barrel, the first power unit is used for driving the hammering assembly to do linear motion so as to achieve hammering washing of the small clothes. According to the washing equipment, the small clothes can be independently washed, the first power unit is arranged in the top cover, the top cover is arranged on the top of the washing barrel in a covering mode, through hammering from top to bottom, the trouble that sealing is difficult due to telescopic movement does not need to be worried about.

Owner:QINGDAO HAIER WASHING MASCH CO LTD +1

A method for improving the reaction performance of dissolving pulp plates

ActiveCN106381742BImprove responseAvoid spendingCellulose treatment using microorganisms/enzymesWater resourcesCellulase

The invention provides a method for improving the reaction property of a dissolving pulp board. The method comprises the following steps of adopting the dissolving pulp board with the thickness being 0.05cm to 0.50cm, and controlling the moisture content of the dissolving pulp board to be 2 percent to 10 percent for standby use; adopting cellulase for preparing a cellulase solution with the mass concentration being 5 percent to 10 percent, adopting strong acidic-weak basic salt for adjusting a pH value of the cellulase solution to be 4.5 to 5.5, and obtaining a cellulase solution for standby use; sequentially and uniformly spraying the cellulase solution for standby use and water on the processed dissolving pulp board, and preparing to react; putting the dissolving pulp board into a constant temperature and humidity room for reacting, wherein the temperature of the constant temperature and humidity room ranges from 40 to 60 DEG C, and the humidity of the constant temperature and humidity room is consistent to the moisture content of the sprayed dissolving pulp board. According to the method provided by the invention, the reaction property of the dissolving pulp board is improved, meanwhile, not only is the waste of water resource avoided, but also the energy consumption is reduced, and the method is lower in cost.

Owner:FUJIAN AGRI & FORESTRY UNIV

Biological medical sterilizing disinfecting box

InactiveCN109350756ASolve the problem of high water consumptionGuaranteed temperatureLavatory sanitoryHeatWater leakageDisinfectant

The invention provides a biological medical sterilizing disinfecting box, and relates to the field of biological medicines. The sterilizing disinfecting box comprises a disinfecting carrier, one sideof the disinfecting carrier is provided with a liquid mixing box, and the right side of the liquid mixing box is fixedly connected with the left side of the disinfecting carrier. According to the sterilizing disinfecting box, by arranging a water leakage pipe and through the cooperative arrangement of a filtering tank, a heating pipe, a heating ring, a protecting housing and a flow guiding pipe, accumulated disinfectant in a lining flows into the filtering tank through the water leakage pipe, so that the filtered disinfectant flows into the heating pipe, the disinfectant in the heating pipe starts boiling to evaporate steam through the heating of the heating ring in the protecting housing, so that the steam flows into the lining and an interlayer of the disinfecting carrier through the flow guiding pipe, the steams in the interlayer can increase the temperature of the lining, excess steam is discharged through a steam discharging head, the temperature of the inner wall of the disinfecting carrier is ensured, and the breeding of bacteria in the sterilizing carrier can be prevented by higher internal temperature of the disinfecting carrier.

Owner:张梅

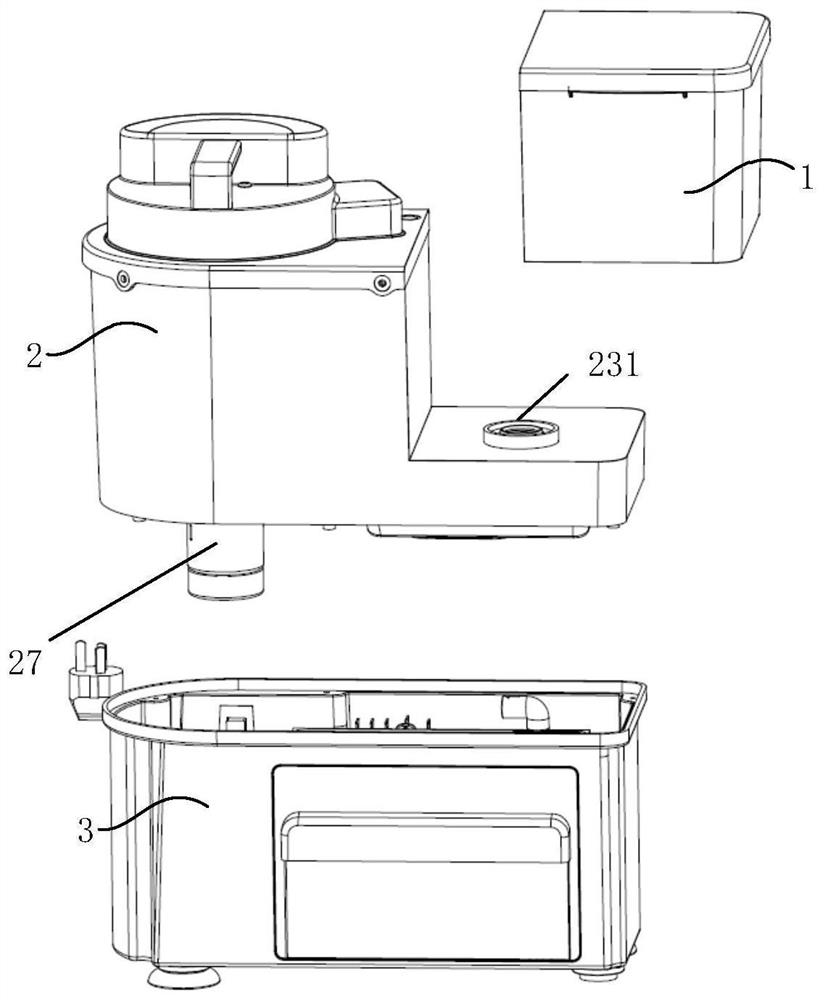

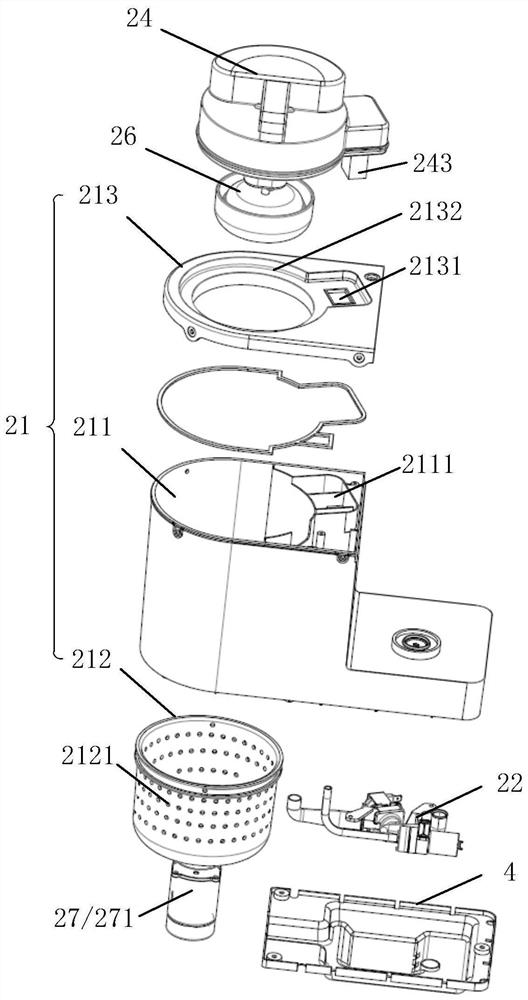

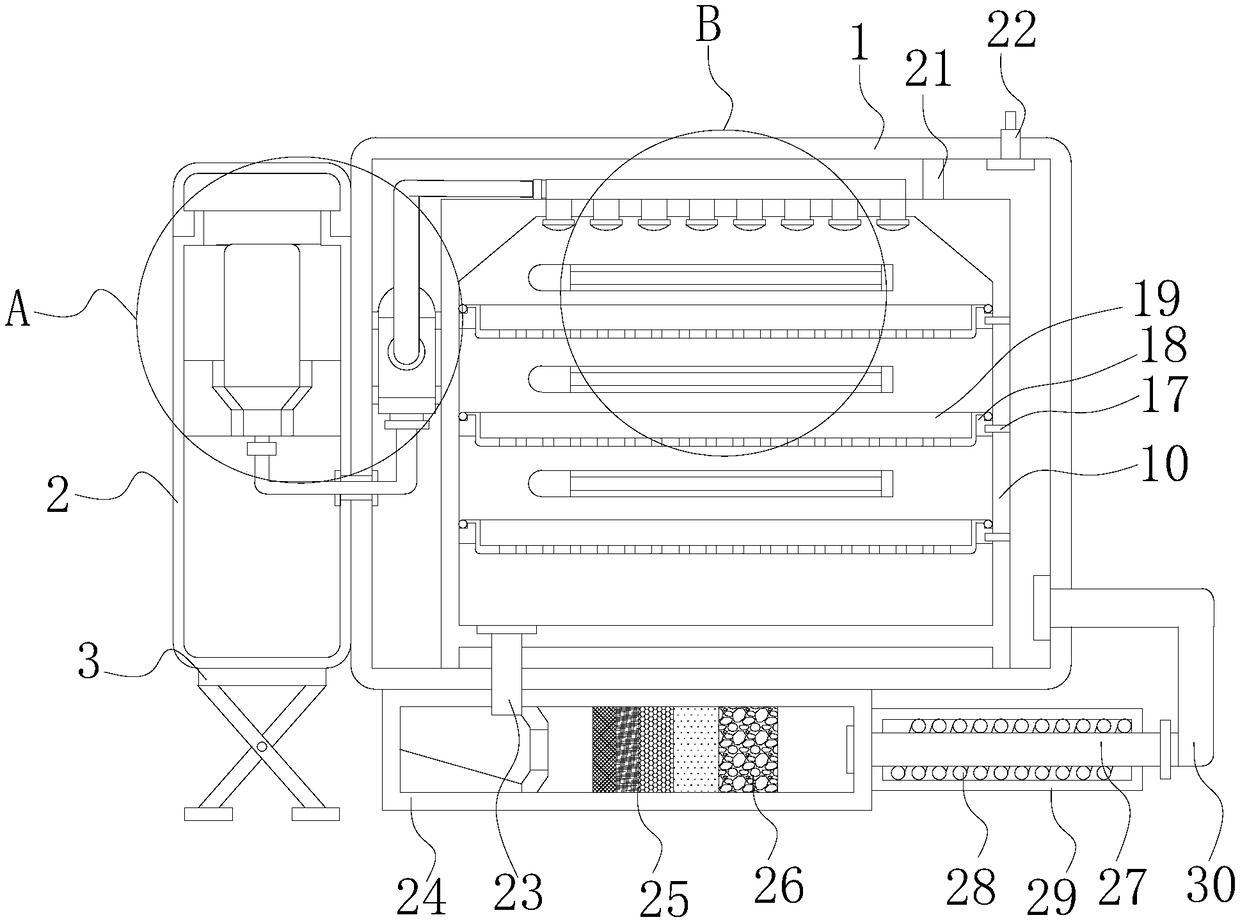

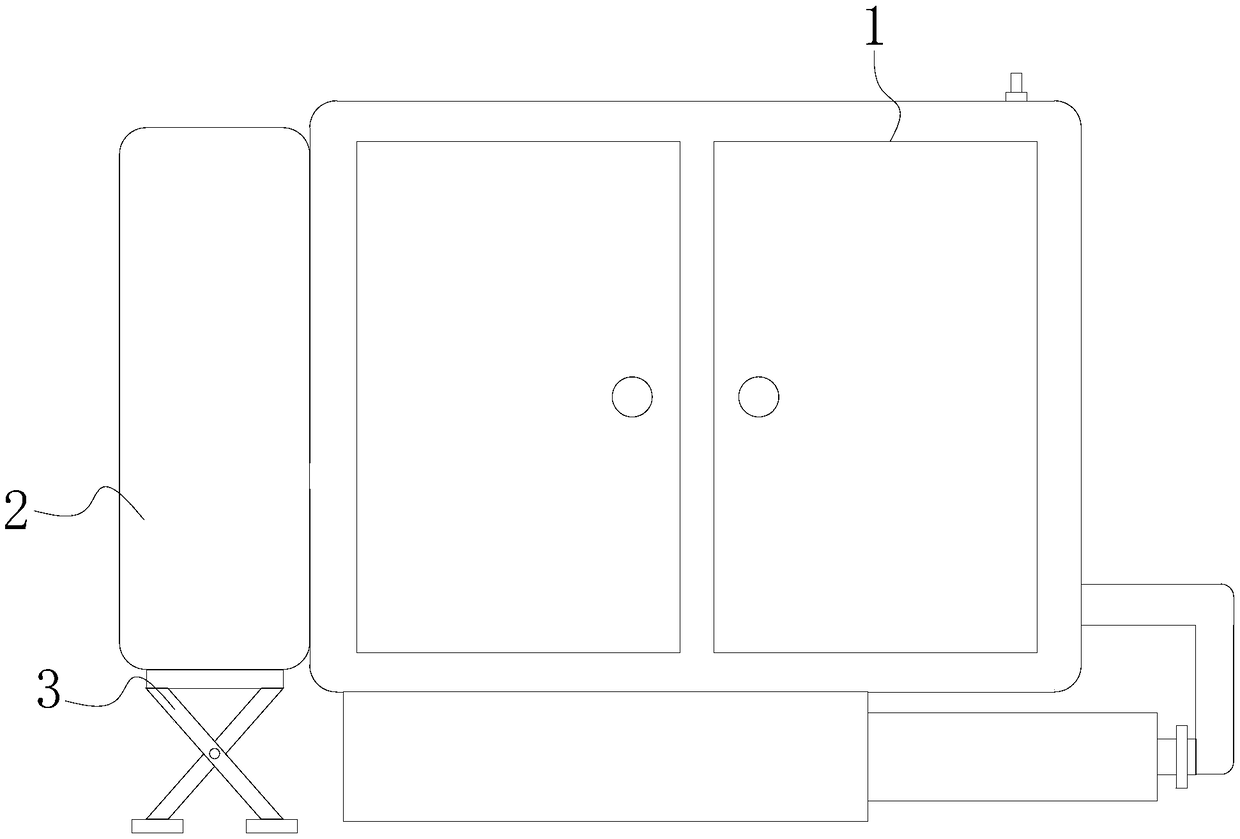

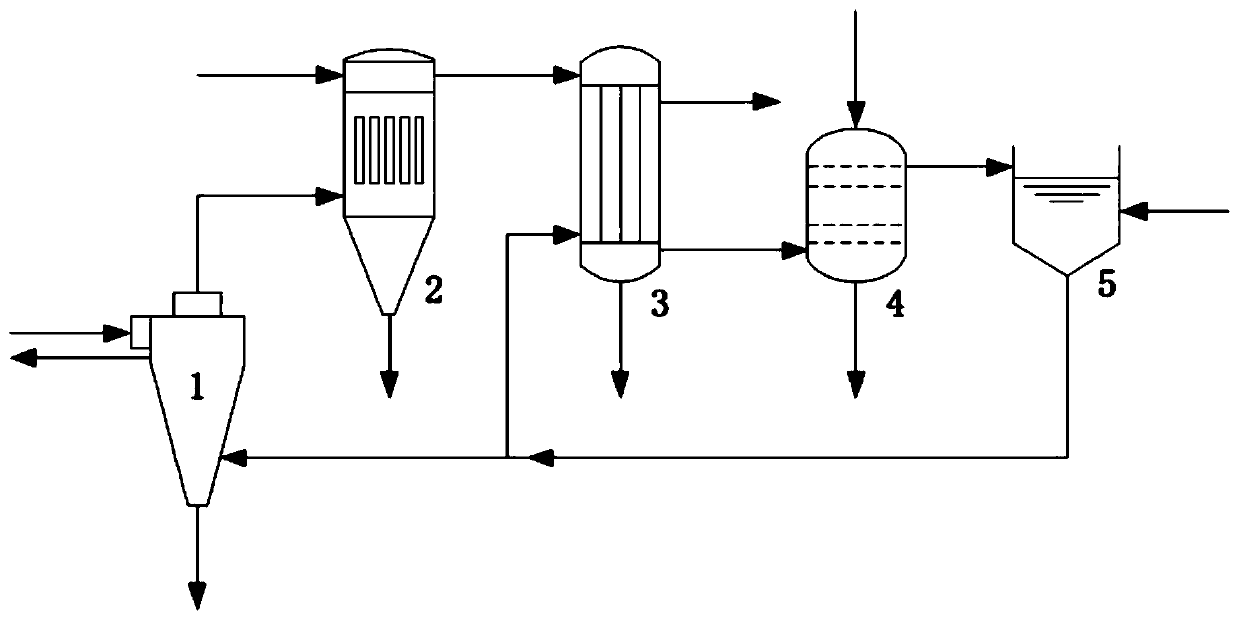

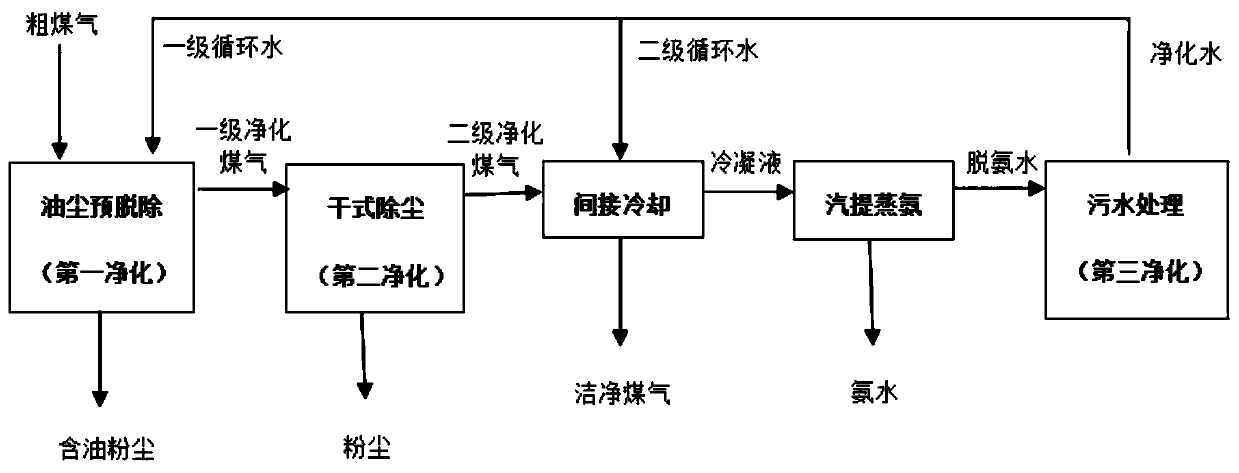

Device and method for dry-type collaborative purification and indirect cooling of fixed bed gas oily dust

PendingCN111534334AImprove purification effectSolve the problem of sticking and cloggingCombination devicesGas purification by non-gaseous materials condensationFixed bedPhenol

The invention provides a device and a method for dry-type collaborative purification and indirect cooling of fixed bed gas oily dust, and belongs to the technical field of gas treatment. The device provided by the invention is reasonable in overall structure arrangement, good in coal gas purification effect, energy-saving and environment-friendly. Specifically, an oily dust pre-removal device 1, adry dust collector 2 and an indirect cooler 3 are adopted, dust and tar in coal gas can be efficiently and synergistically purified and separated, and the content of impurities in coal gas condensateis low, so that the problems of oil-containing, phenol-containing and dust-containing wastewater pollution and difficulty in treatment in the traditional coal gasification direct cooling process canbe solved. The oily dust pre-removal device 1 and the dry dust collector 2 are adopted, so that the dust and tar separation efficiency is high, and the problem that tar contained in the coal gas adheres to and blocks a dust removal system can be solved; the indirect cooler 3 and a steam stripping ammonia distillation system 4 are adopted, condensate water with ammonia nitrogen removed can be usedas circulating water replenishing water, and water consumption is low, and therefore, the problem that ammonia nitrogen in coal gas condensate water is difficult to treat and a water balance problem can be solved.

Owner:中科合肥煤气化技术有限公司

Features

- R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

Why Patsnap Eureka

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Social media

Patsnap Eureka Blog

Learn More Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com