Patents

Literature

64results about How to "Reduce reprocessing" patented technology

Efficacy Topic

Property

Owner

Technical Advancement

Application Domain

Technology Topic

Technology Field Word

Patent Country/Region

Patent Type

Patent Status

Application Year

Inventor

Preparation method for poly(p-phenylene terephthamide) membrane

The invention relates to a preparation method for a poly(p-phenylene terephthamide) (PPTA) membrane, and belongs to the technical field of membrane materials and polymer polymerication. The preparation method comprises: adding a certain amount of a surfactant in a PPTA low-temperature solution polymerization process, adding a large amount of a solvent N-methylpyrolidone (NMP) into the polymerization system after polymerization is performed to a certain degree, so as to disperse the polymerization system, then adding a large amount of a dispersing agent to washing out the surfactant, and then performing reduced-pressure filtering on the PPTA dispersion solution, so as to obtain the membrane. The preparation method starts from a PPTA monomer, and the high-performance PPTA membrane with small shrinkage, high strength and isotropy is prepared through steps of polymerization, swelling, dispersing, filtering and drying. The employed surfactant is soluble polyoxyethylene ether high molecules with different molecular weight and different end groups, and the dispersing agent employs water, alcohols and other polar solvents. The preparation method has the characteristics of being simple and practicable in membrane preparation technology, safe in process, efficient, controllable and the like, and has good industrial application prospect.

Owner:TSINGHUA UNIV +1

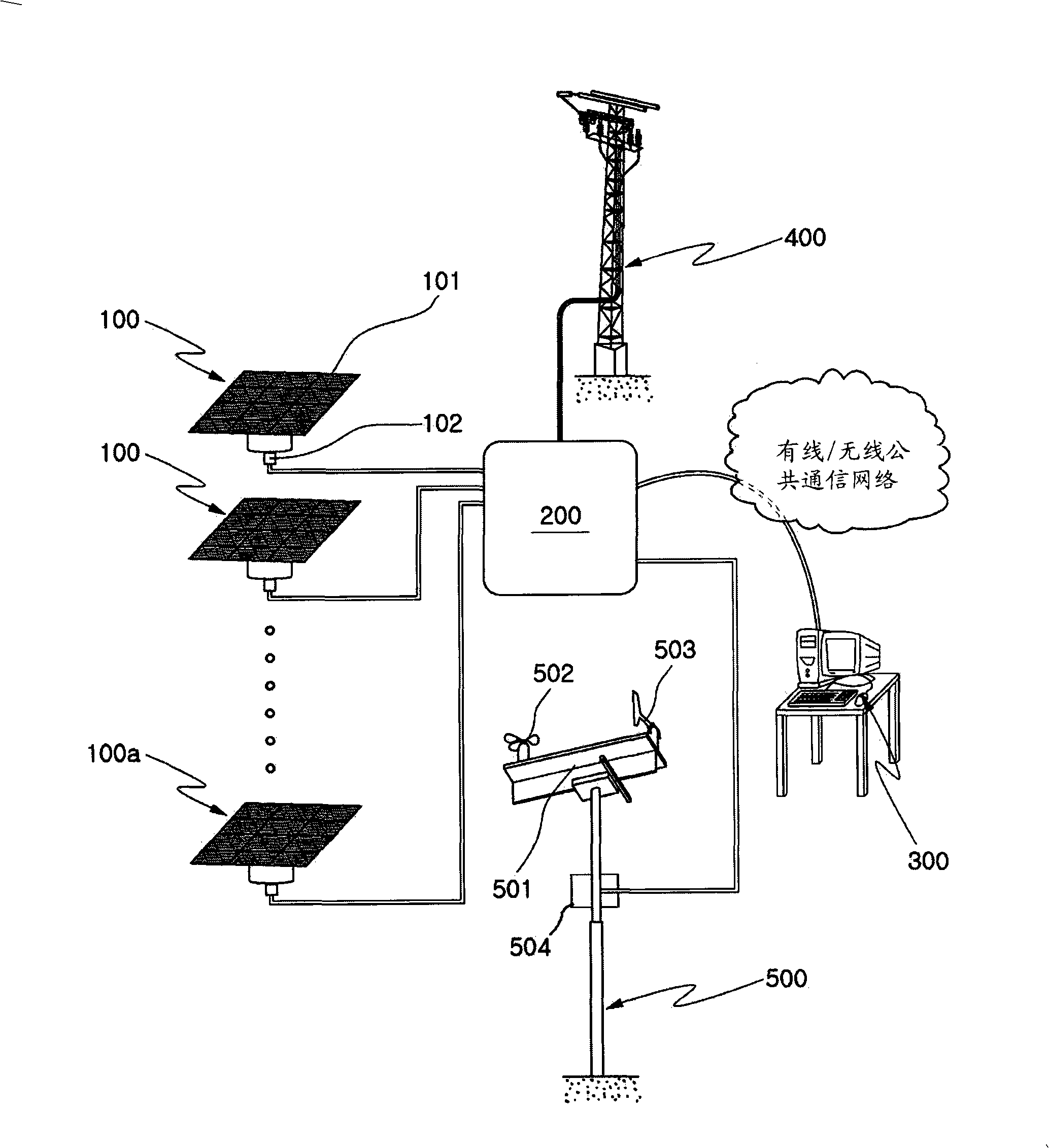

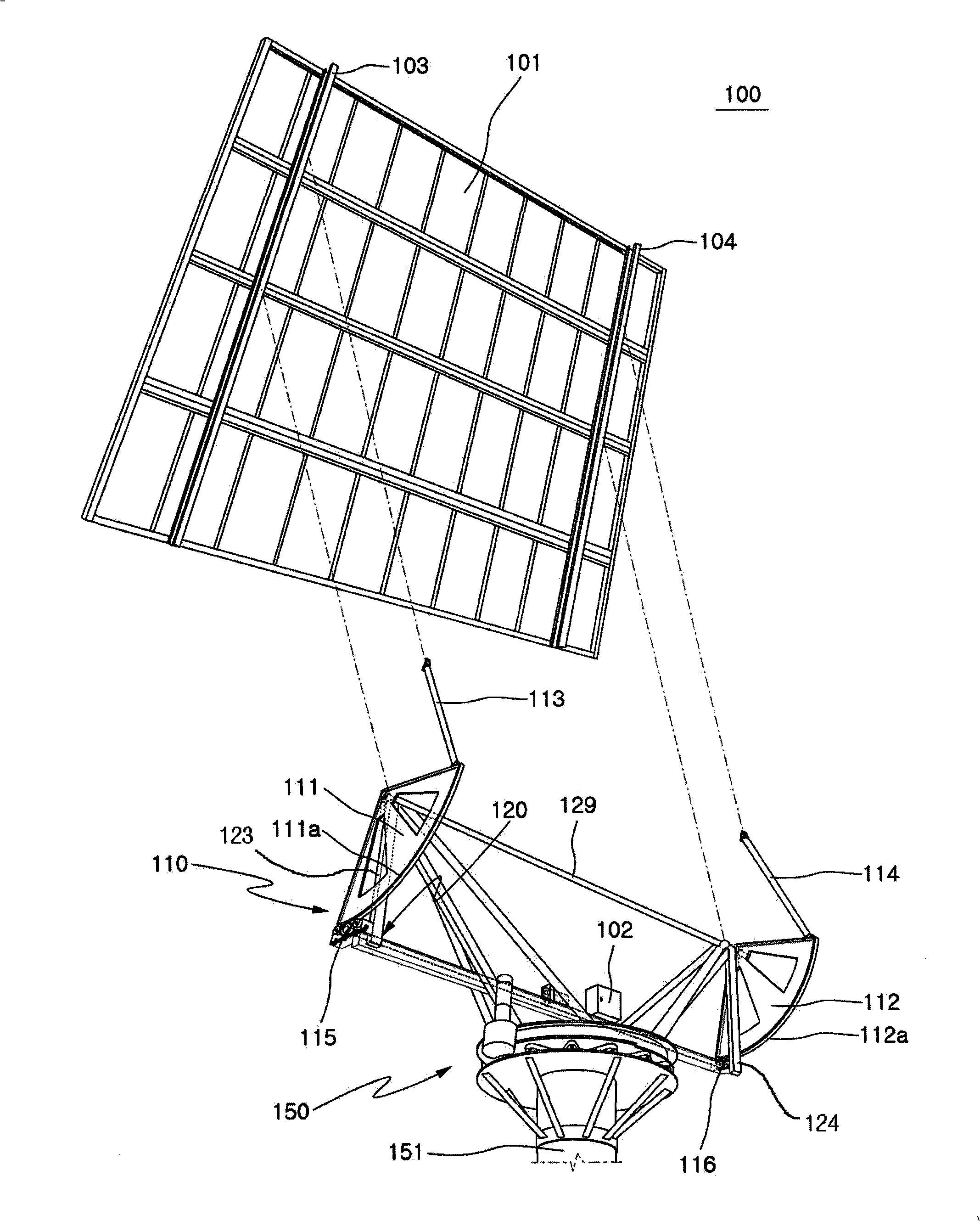

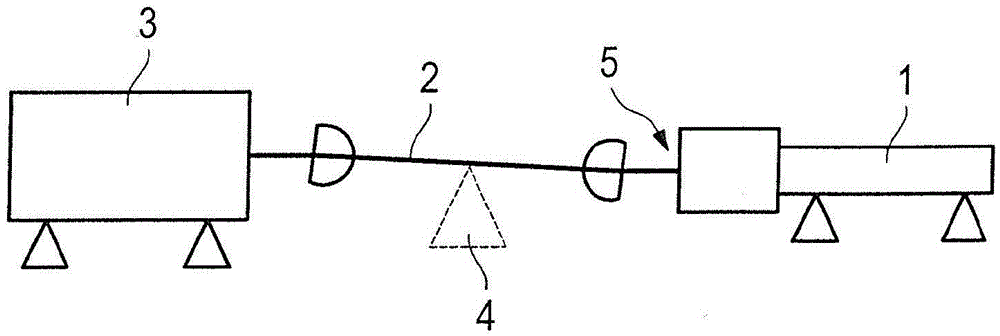

Photovoltaic system

InactiveCN101291123AEasy to operateReduce reprocessingPhotovoltaic supportsSolar heating energyElectricityExternal energy

A photovoltaic system is configured as minimizing the possibility of collapse relying on the self durability under any weathers or the other terrible conditions. The photovoltaic system comprises a plurality of solar tracking mechanisms arranged with a large solar energy panel enabling the solar energy panel incline and / or rotate along the solar track; a plurality of part control units for controlling one of the battery recharging, the external system communication and the electric motor driving, operation of the heater and the energy generating by the management; a central control unit connecting to a plurality of part control units at the same time to manage the collection of the photovoltaic energy; a measuring unit comprising the communication module arranged on the upper part of the supporting piece, a pyranometer, an anemoscope and a weathercock. The components are electrically-connected to the central control unit; a power delivery tower for delivering the energy collected by the central control unit to the external energy managing system; a monitoring unit connected to th e central control unit for monitoring all the units of the system.

Owner:DAULENC CO LTD +2

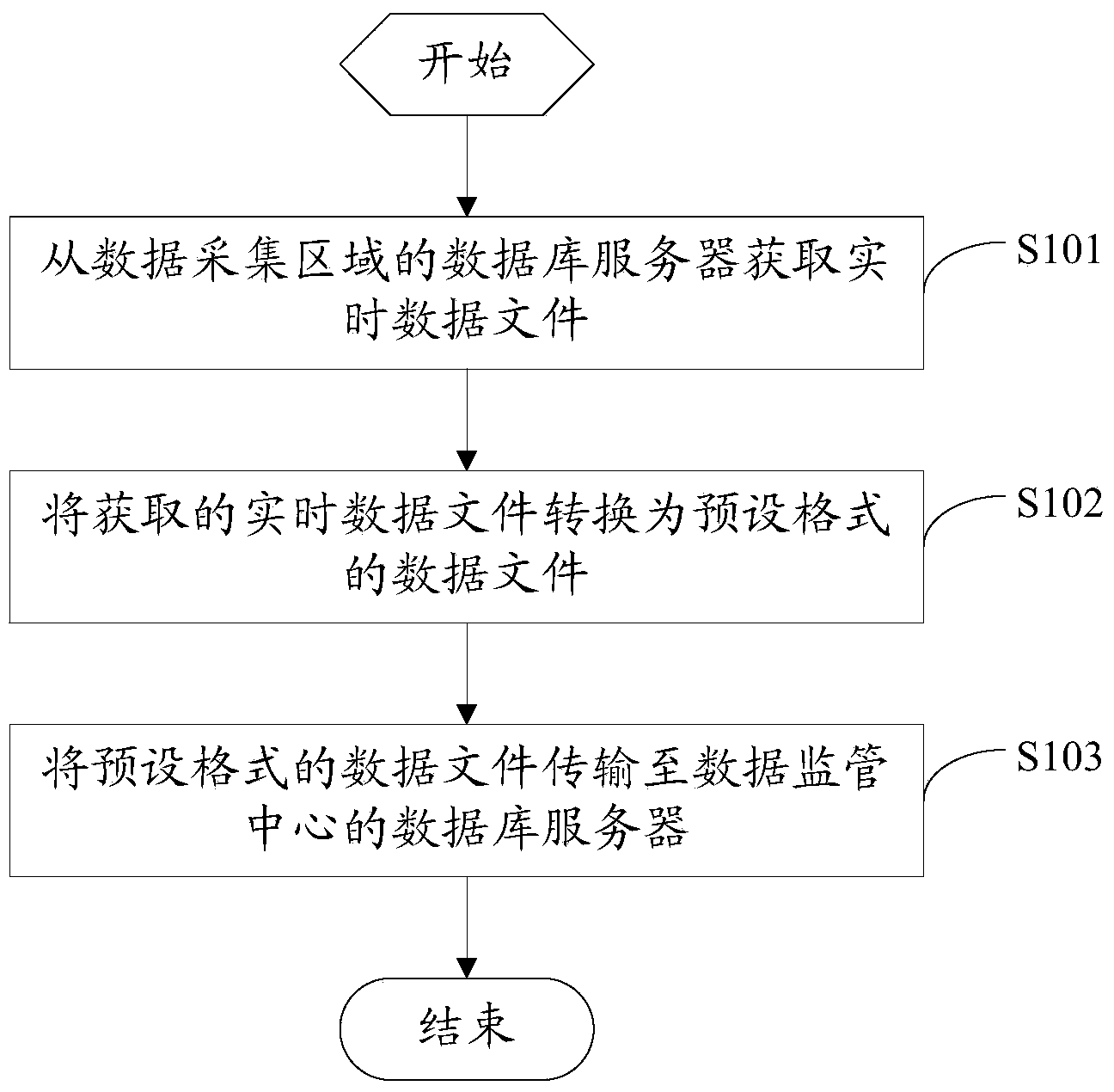

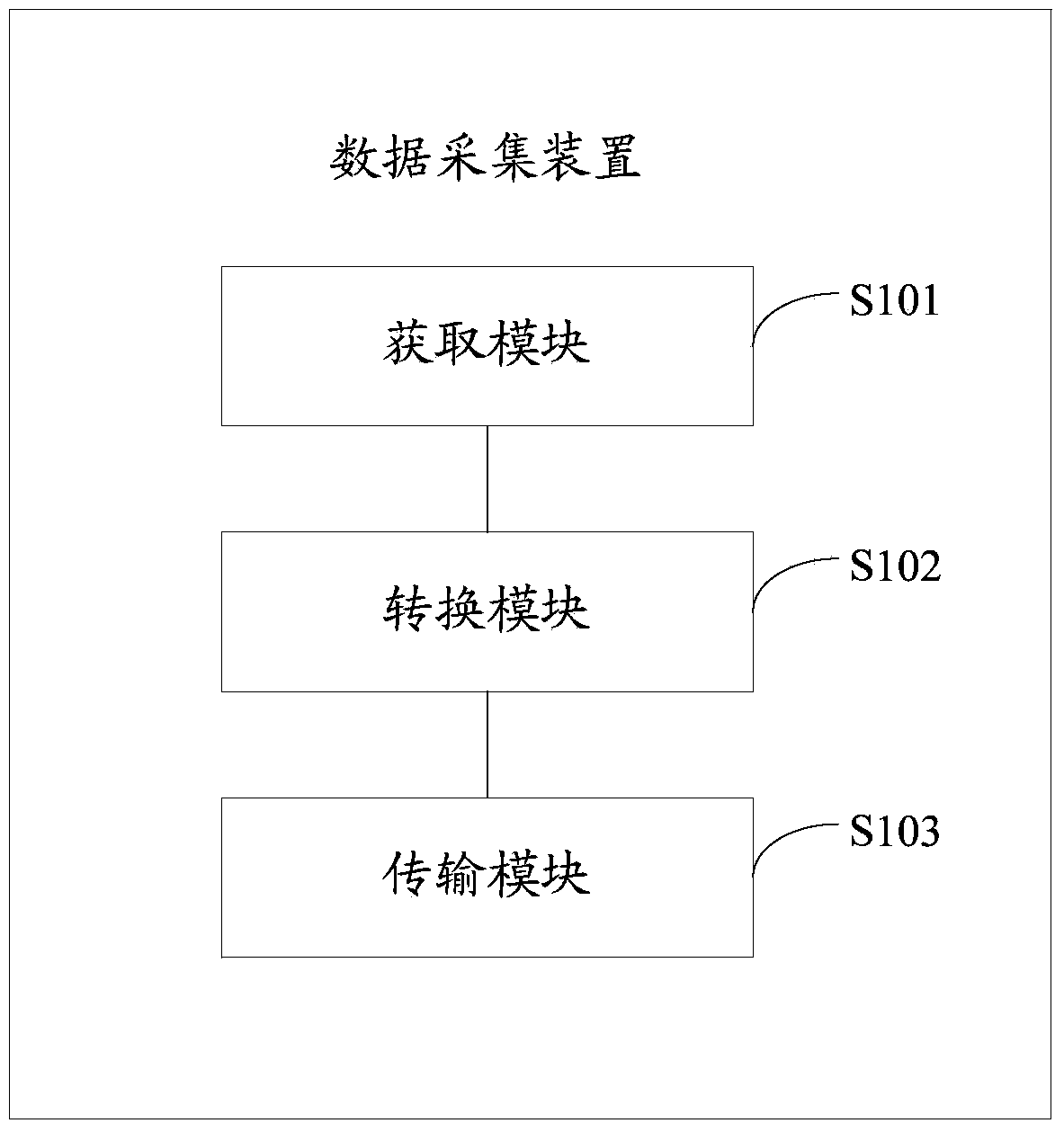

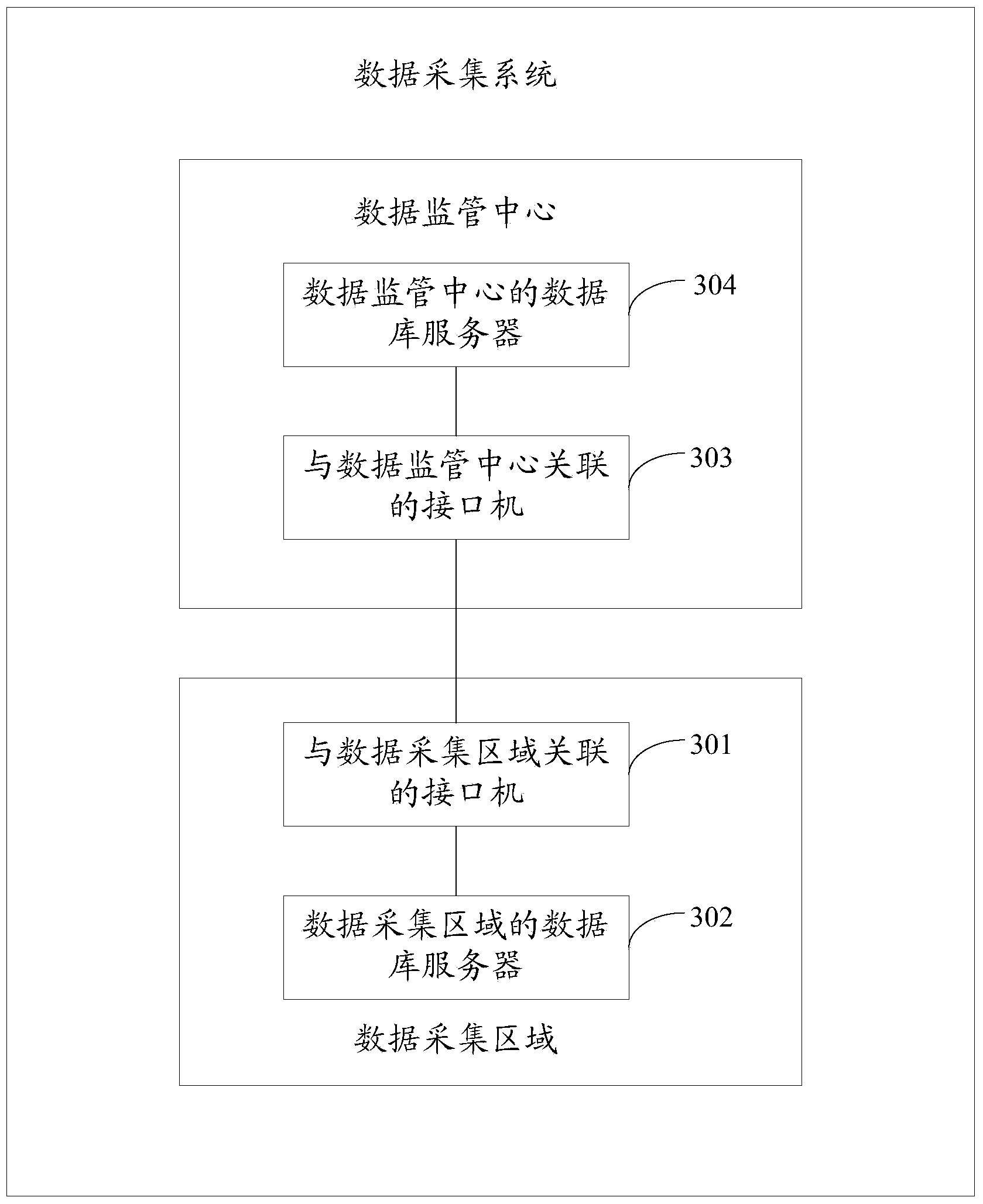

Data acquisition method, device and system

InactiveCN103473719AGuaranteed accuracyGuaranteed real-timeData processing applicationsSpecial data processing applicationsReal-time dataDatabase server

The invention provides a data acquisition method, device and system. The data acquisition method is applied to an interface machine which is connected with a data acquisition area. The data acquisition method comprises the steps that real-time data files are obtained from a database server of the data acquisition area, the obtained real-time data files are converted into data files of a preset format, and the data files of the preset format are transmitted to a database server of a data supervision center. According to the data acquisition method, device and system, the real-time data files are directly obtained from the database server of the data acquisition area, the accuracy and real-time performance of data are ensured, the obtained real-time data files are converted into the data files of the preset format, then the data files of the preset format are transmitted to the database server of the data supervision center, and due to the fact that the data of the data acquisition area are all converted into the data files of the standard format, reprocessing process of the data is reduced.

Owner:杭州意能软件有限公司 +2

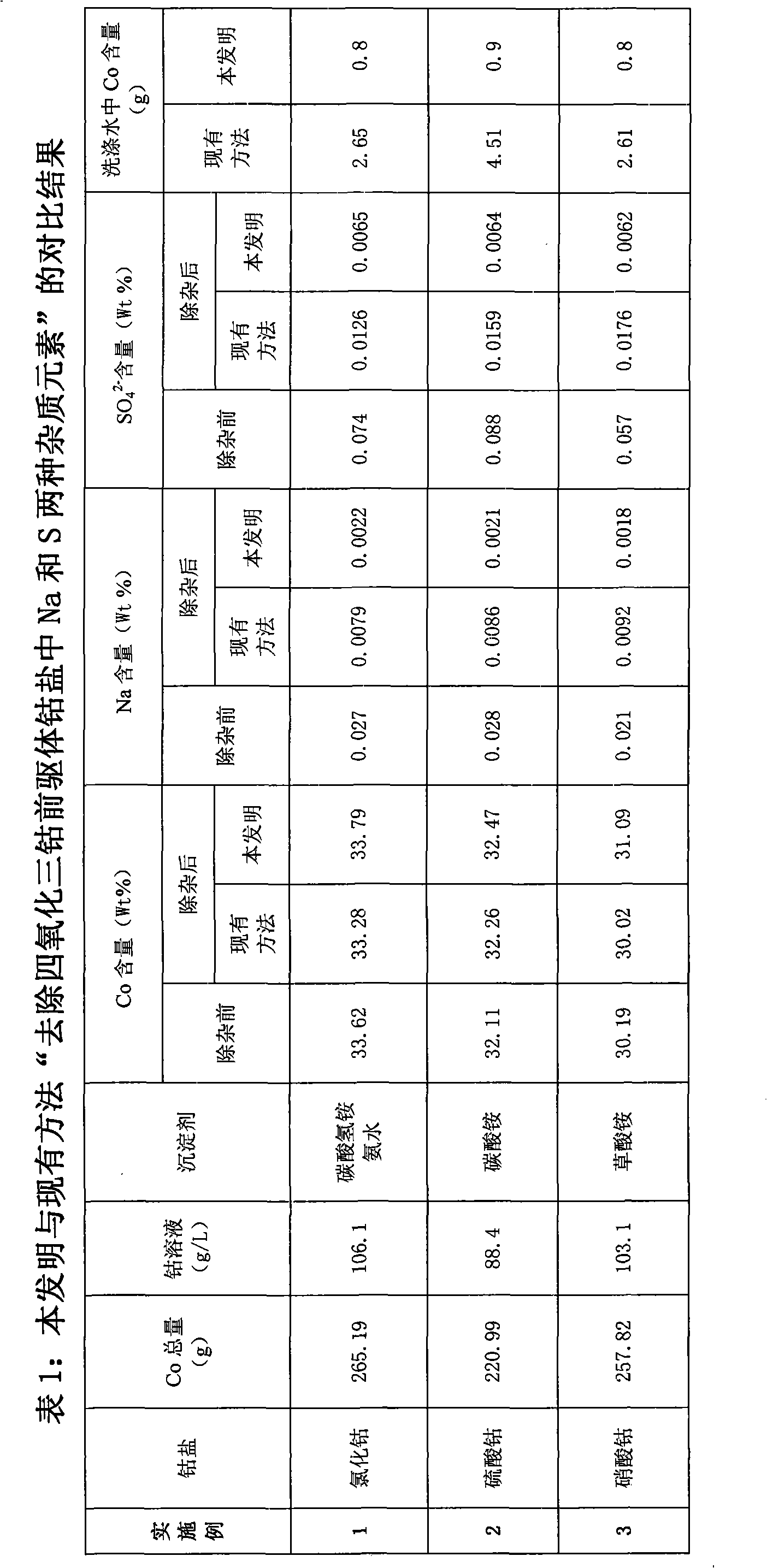

Method for removing impurity element Na and S in precursor cobalt salts of cobaltosic oxide

InactiveCN101337696AAvoid hydrolysisInhibition of dissolutionCobalt oxides/hydroxidesCobalt(II,III) oxidePhysical chemistry

The invention relates to a method for removing impurity elements Na and S from the precursor cobalt salt of cobaltosic oxide. The method comprises the steps of adding proper a washing assistant in the process of washing cobalt salt with pure water so as to wash impurity ions Na, SO4<2 minus> contained in the cobalt salt and enable the impurity ions to enter waste washing water, thereby obtaining high purity precursor cobalt salt; calcinating to obtain the high purity cobaltosic oxide. The method has the advantages of simple operation, good impurity removing effect, and less cobalt loss. Both the weight ratio and the content ratio of Na and S to Co in the processed cobalt salt are lower than 1:15000, thereby ensuring the electrochemical activity and building a foundation for promoting the electrochemical properties of lithium cobalt oxide in lithium ion battery anode.

Owner:JIANGSU DONGXIN ENERGY TECH

Bast fiber plate waste recycling-based short fiber-reinforced composite material for automotive interiors and preparation method of bast fiber plate waste recycling-based short fiber-reinforced composite material

InactiveCN105504504ASolve the difficulty of blankingReduce reprocessingAntioxidantFiber-reinforced composite

The invention discloses a bast fiber plate waste recycling-based short fiber-reinforced composite material for automotive interiors. The bast fiber plate waste recycling-based short fiber-reinforced composite material is prepared from the following raw materials in parts by weight: 20-60 parts of crushed bast fiber plate materials, 100 parts of thermoplastic resin, 2-5 parts of an antioxidant, 1-3 parts of a light stabilizer, 2-5 parts of a lubricant and 0-10 parts of a flexibilizer. The bast fiber plate waste recycling-based short fiber-reinforced composite material has the beneficial effects that compared with the prior art, the bast fiber plate waste is recycled and changed into treasures; and the cost is reduced. The bast fiber plate is crushed and pelletized as a processing raw material for the short fiber-reinforced composite material, so that the problem that a bast fiber is difficult to feed is solved; the reprocessing technology of the bast fiber is reduced; the short fiber-reinforced composite material can be applied to the automotive interiors through an injection molding process; relatively complicated part injection molding manufacturing in the automobile industry can be further achieved; and the application situation that only the bast fiber plate is marketized in the field of the automotive interiors is also changed.

Owner:SHANGHAI PRET COMPOSITES

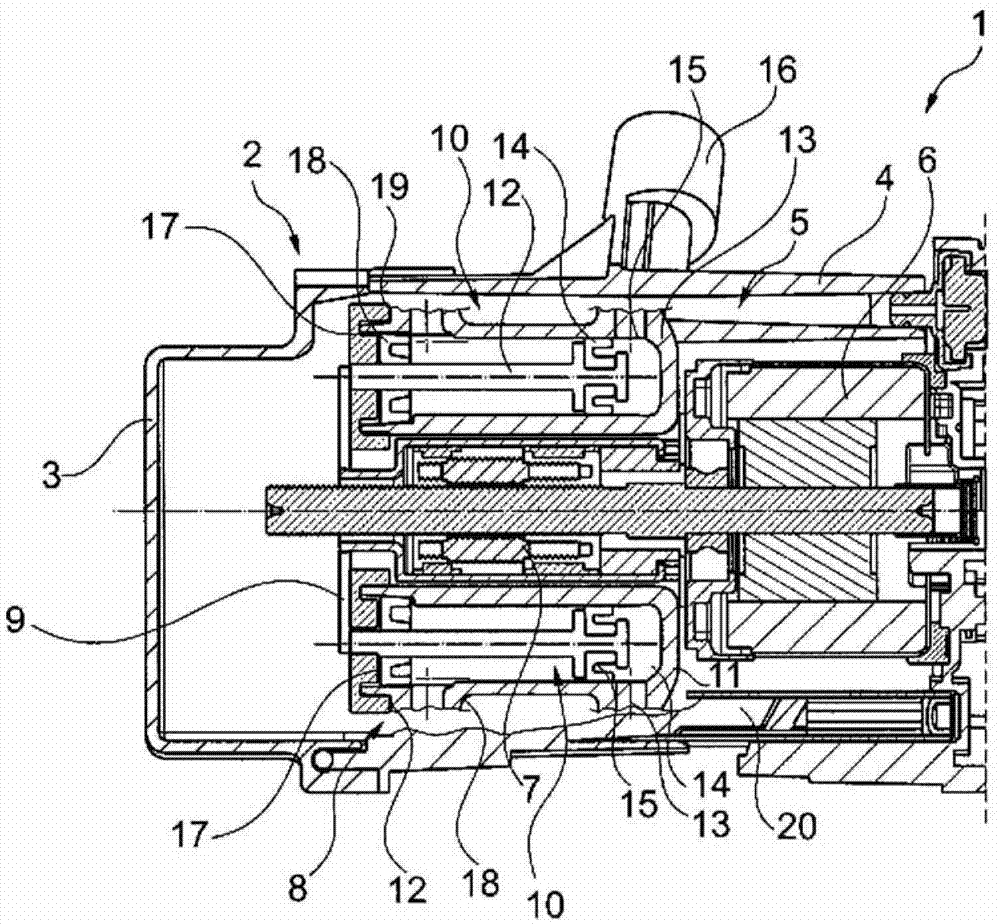

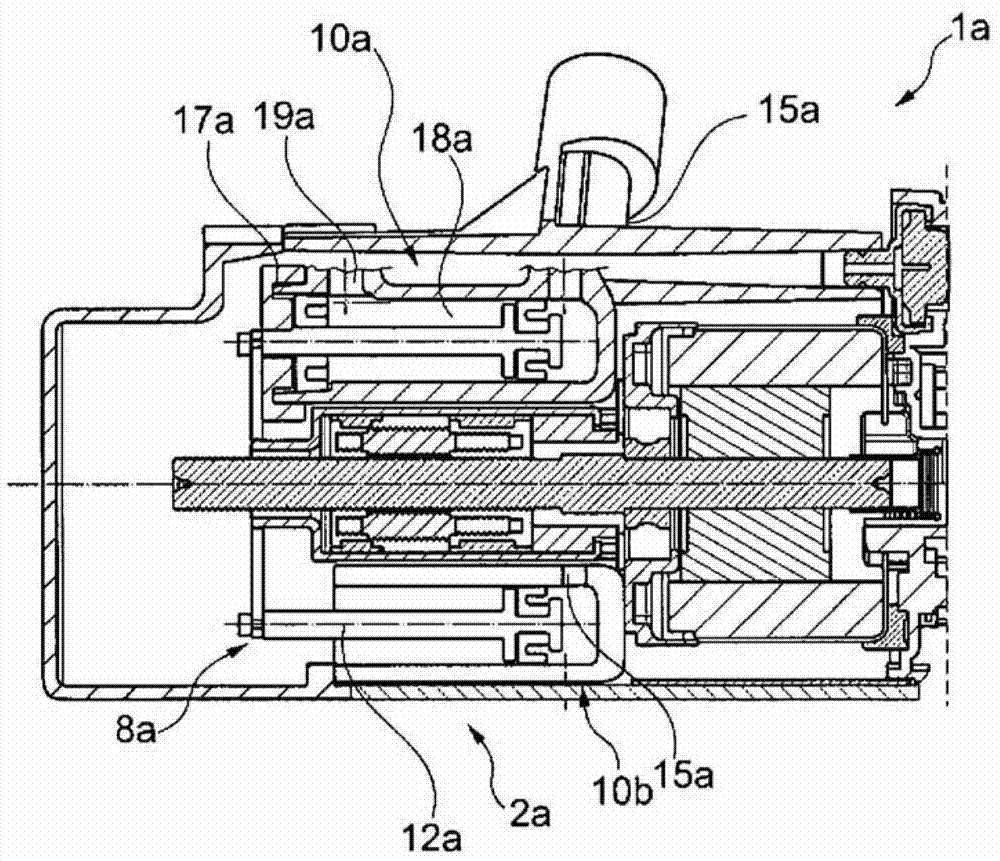

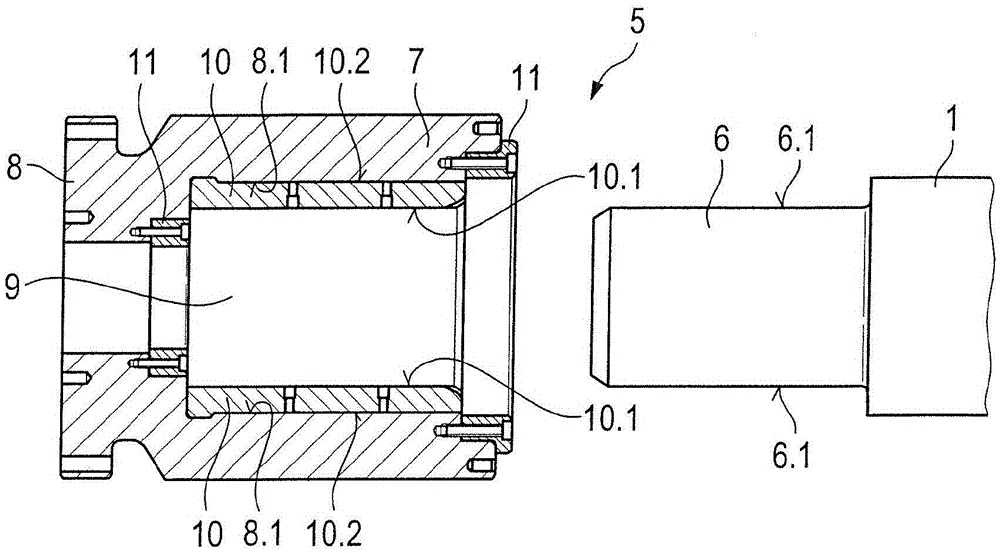

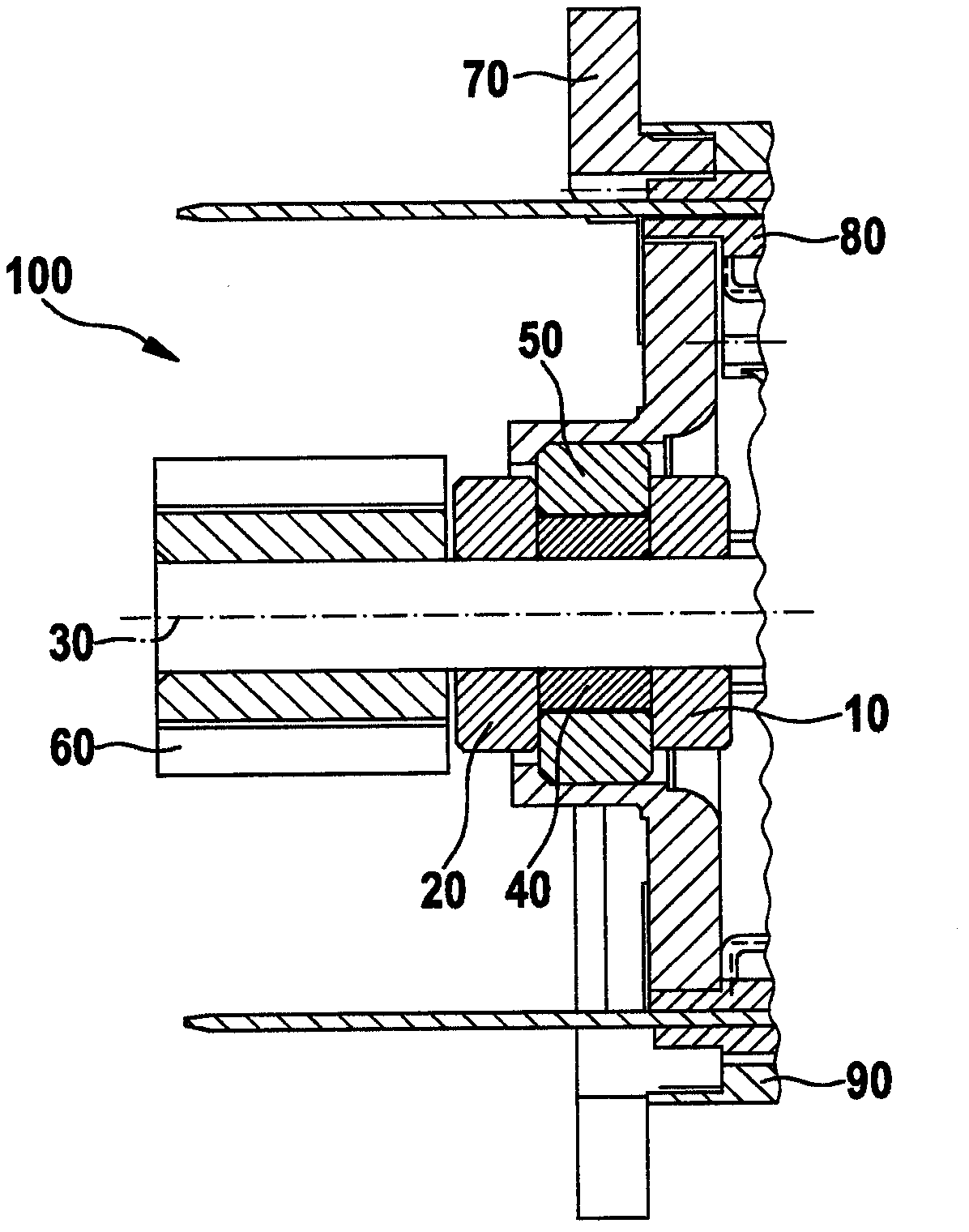

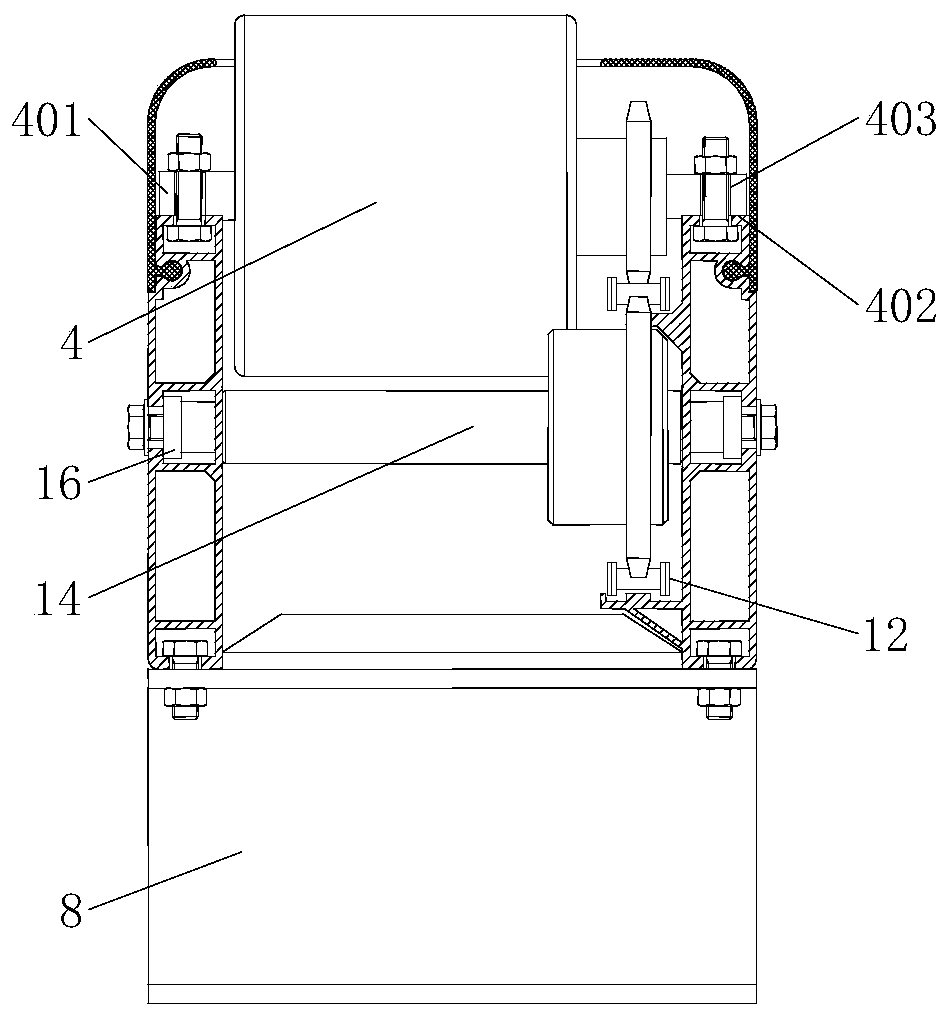

Hydrostatic actuator

InactiveCN102971547AReduce reprocessingReduce defective rateAssociation with control/drive circuitsTelemotorsRotational axisManufacturing cost reduction

The invention relates to a hydrostatic actuator (1, 1a), in particular in a motor vehicle containing a drive unit (5), comprising an electric motor (6), a planetary roller gear system (7) that is driven by a rotor of the electric motor, and a hydrostatic master cylinder unit (8, 8a) which is driven by the planetary roller gear system and which is disposed around the planetary roller gear system. The aim of the invention is to increase the efficiency and reduce the production costs. This is achieved in that the master cylinder unit is formed from multiple master cylinders (10, 10a, 10b) which are distributed over the circumference with respect to a rotational axis of the rotor and each of which is connected to the planetary roller gear system.

Owner:SCHAEFFLER TECH AG & CO KG

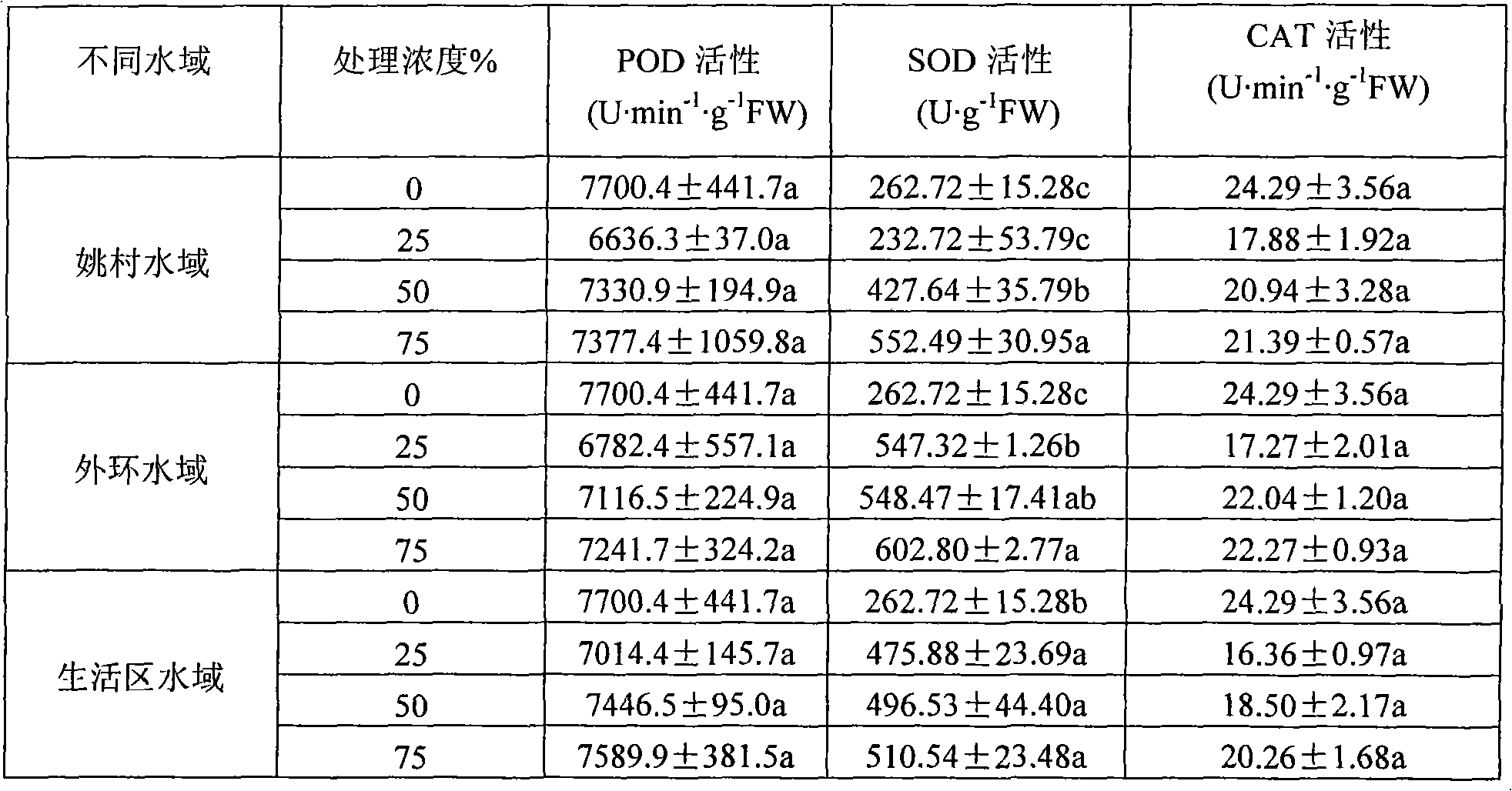

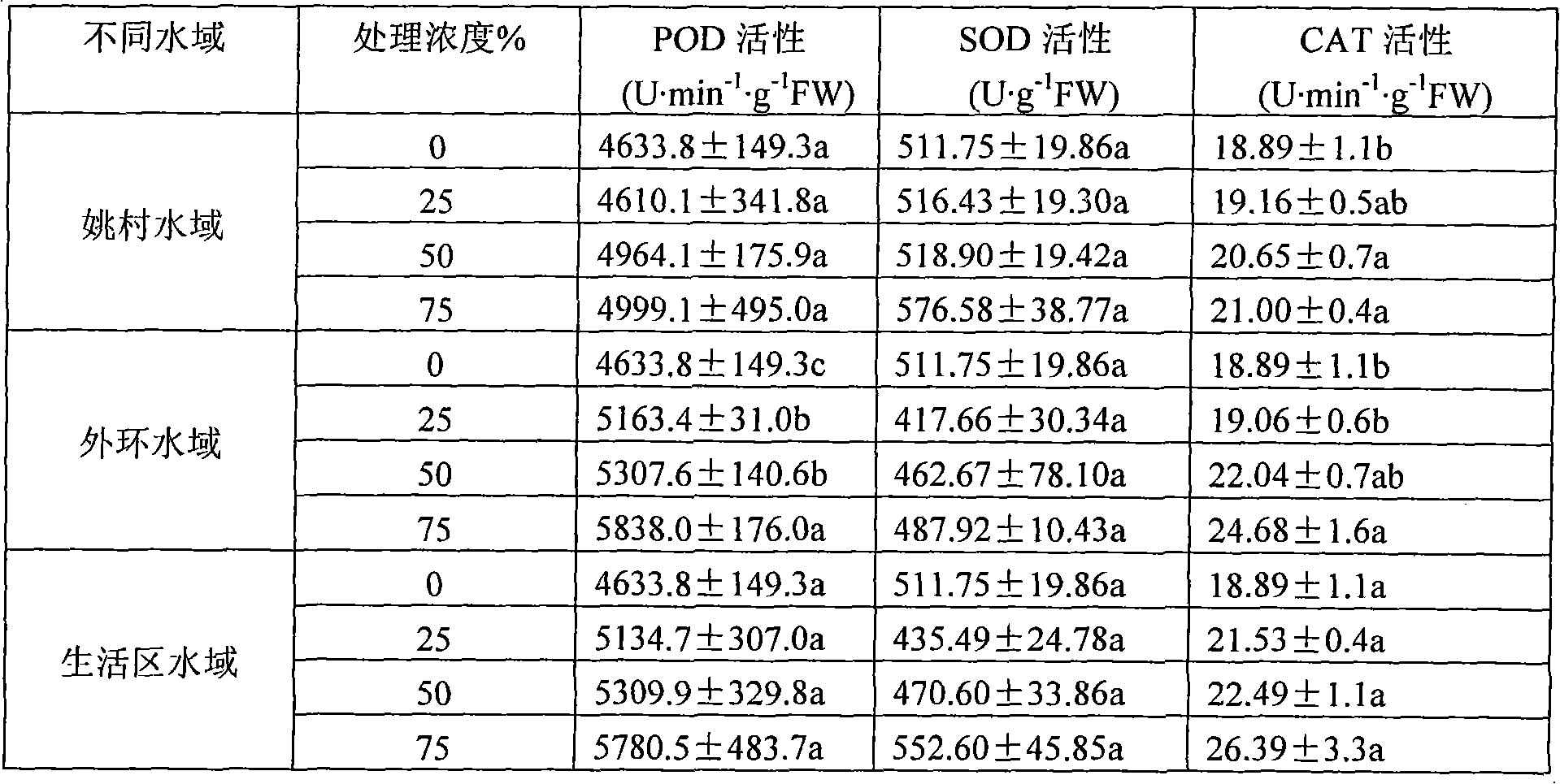

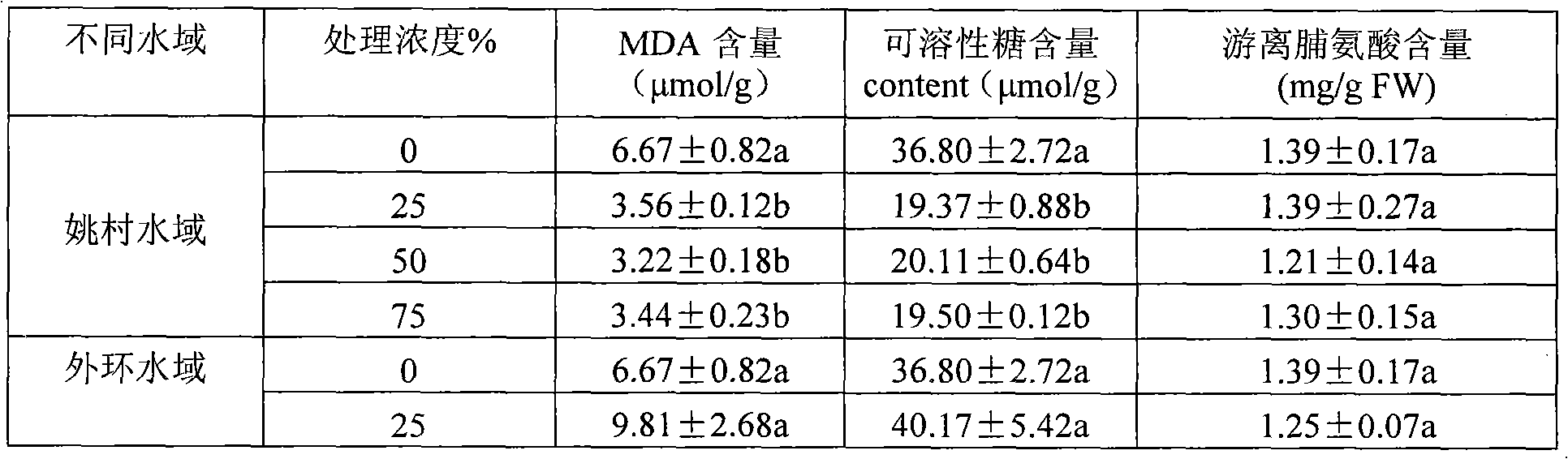

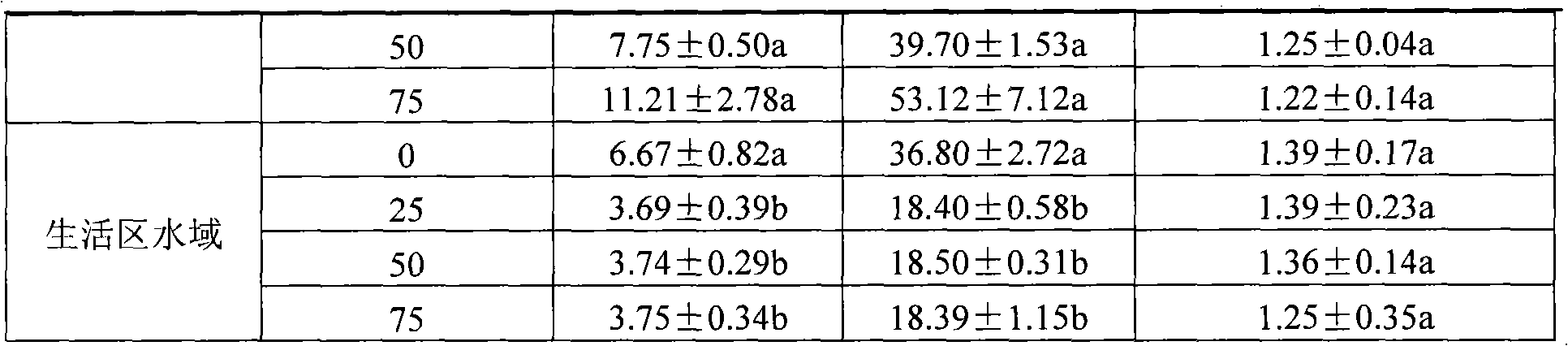

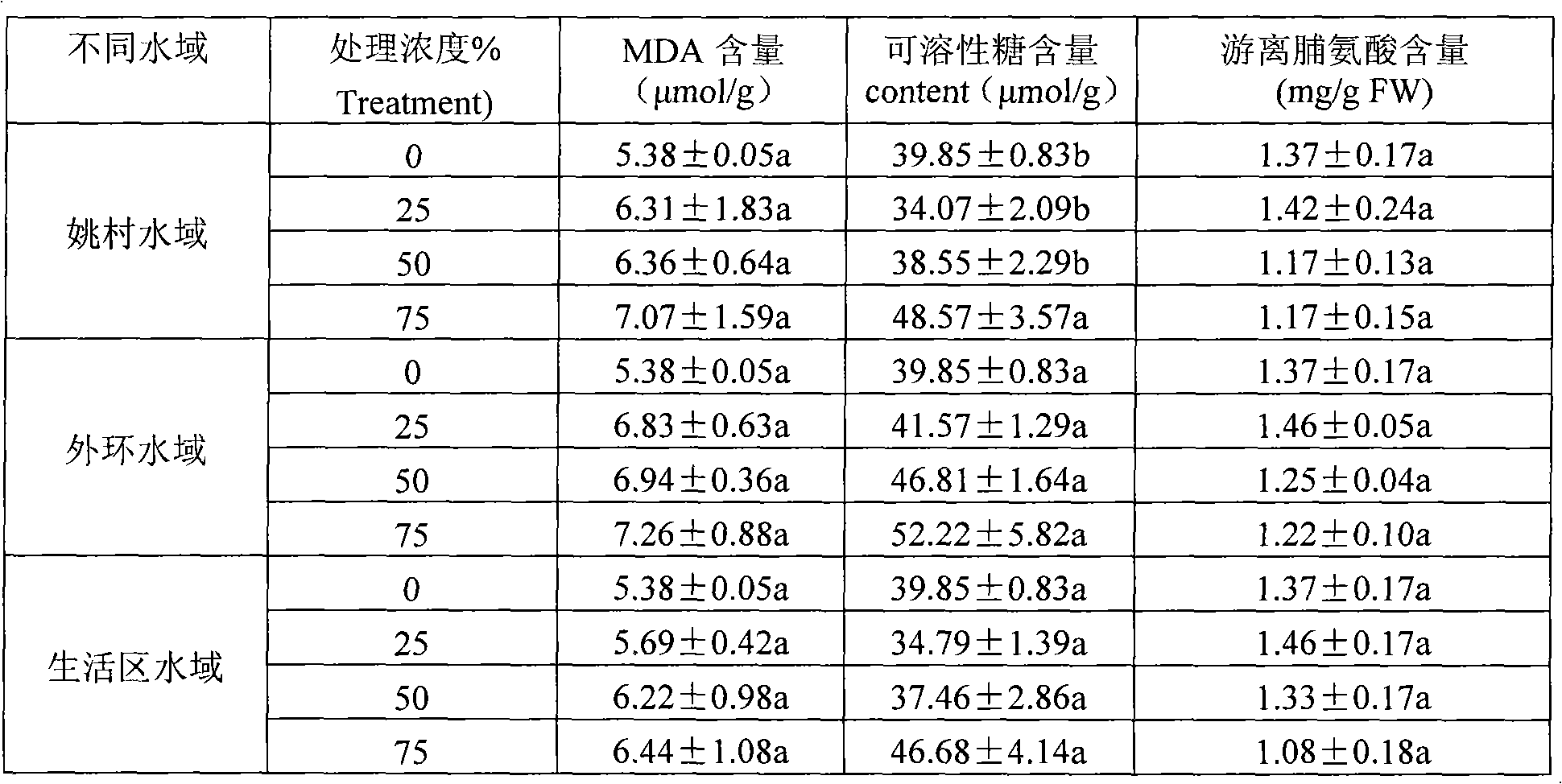

Method for regulating antioxidase of lawn plants by utilizing eutrophic water

InactiveCN101574036AReduce reprocessingLow costClimate change adaptationSewage/sludge fertilisersDismutaseOxygenase activity

The invention discloses an application of eutrophic water in the regulation of antioxidase activity of lawn plants, wherein the eutrophic water is the eutrophic water with 25 percent-75 percent of the original concentration; and the eutrophic water has TN of 9.7 mg / L-13.1mg / L, TP of 0.6mg / L -0.9mg / L and pH value of 8.12-8.99, wherein the activity of antioxidase comprises of superoxide dismutase, peroxide dismutase and catalase. Results show that the diluted eutrophic water is applied to irrigation to reinforce the activity of a protective enzyme system of lawn plants, thereby being capable of obviously improving the resistance ability of the lawn plants to adverse growing environment and providing technical support for the application of the eutrophic water in a lawn plant establishment system.

Owner:TIANJIN NORMAL UNIVERSITY

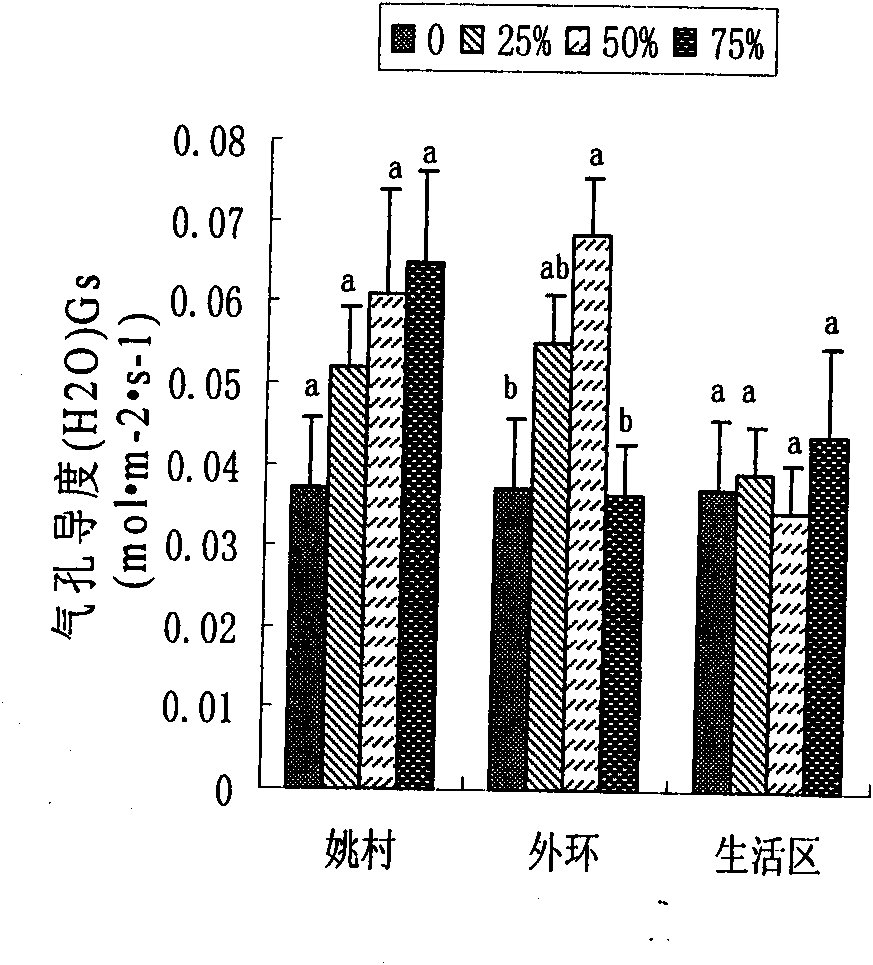

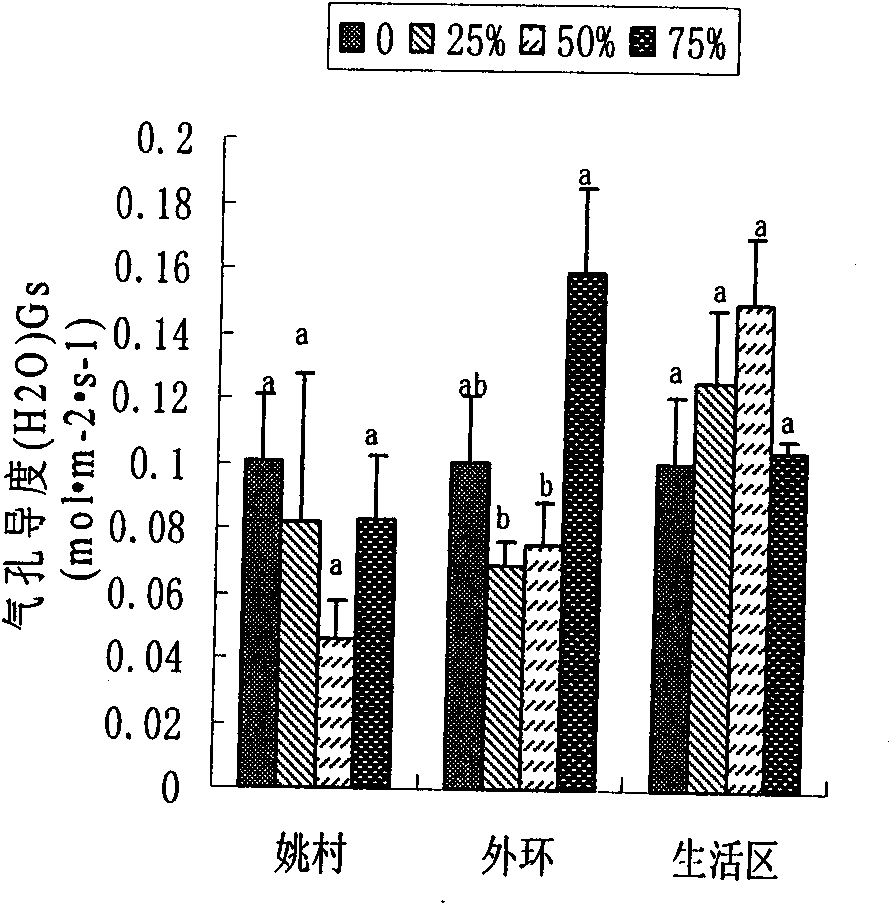

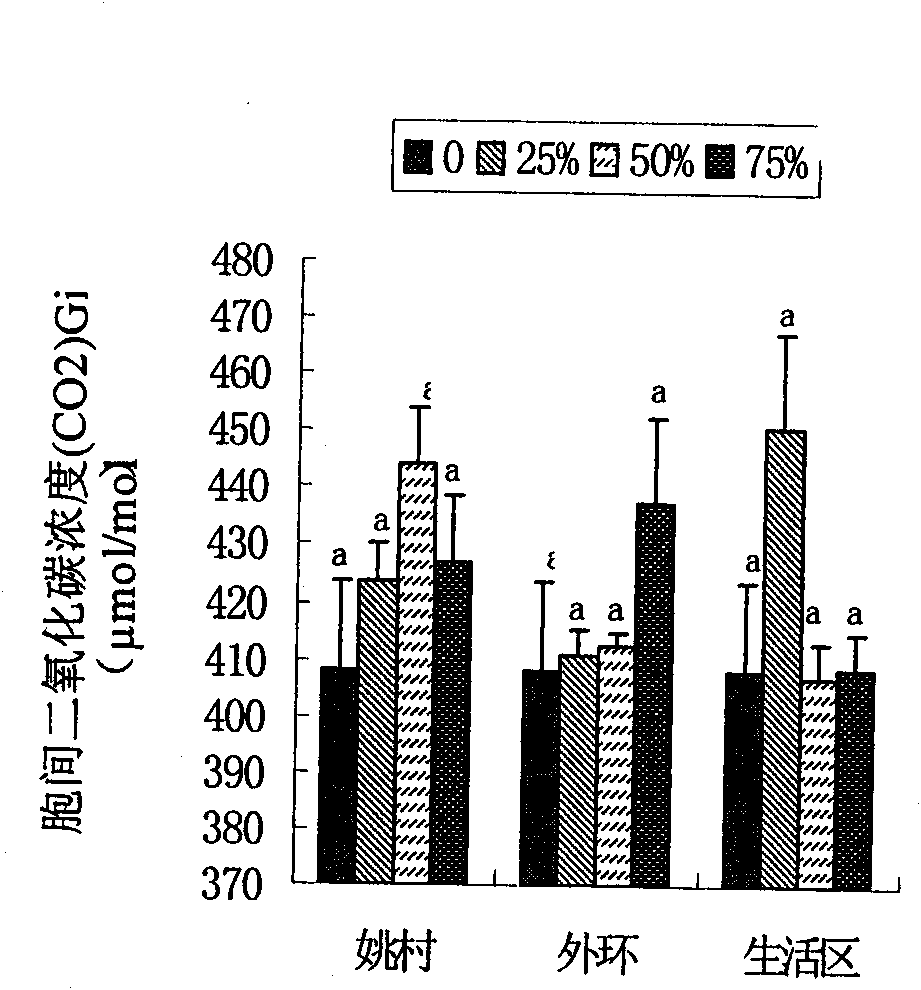

Application of eutrophic water to improvement of photosynthetic capacity of lawn plants

InactiveCN101575225APromote photosynthesisReduce reprocessingClimate change adaptationSewage/sludge fertilisersTranspirationBiology

The invention discloses an application method of eutrophic water irrigation in the improvement of photosynthetic capacity of lawn plants, wherein the eutrophic water is the eutrophic water with 25 percent-75 percent of the original concentration thereof; and the eutrophic water has TN of 9.7mg / L-13.1mg / L, TP of 0.6mg / L-0.9mg / L and pH value of 8.12-8.99. Results show that the photosynthetic performances of the stomatal conductance, the intercellular carbon dioxide concentration, the net photosynthetic rate, the transpiration rate, the water content utilization efficiency and the like are improved if the diluted 25 percent-75 percent eutrophic water is used in the irrigation, thereby achieving the purpose of improving the lawn quality characters and protecting environment.

Owner:TIANJIN NORMAL UNIVERSITY

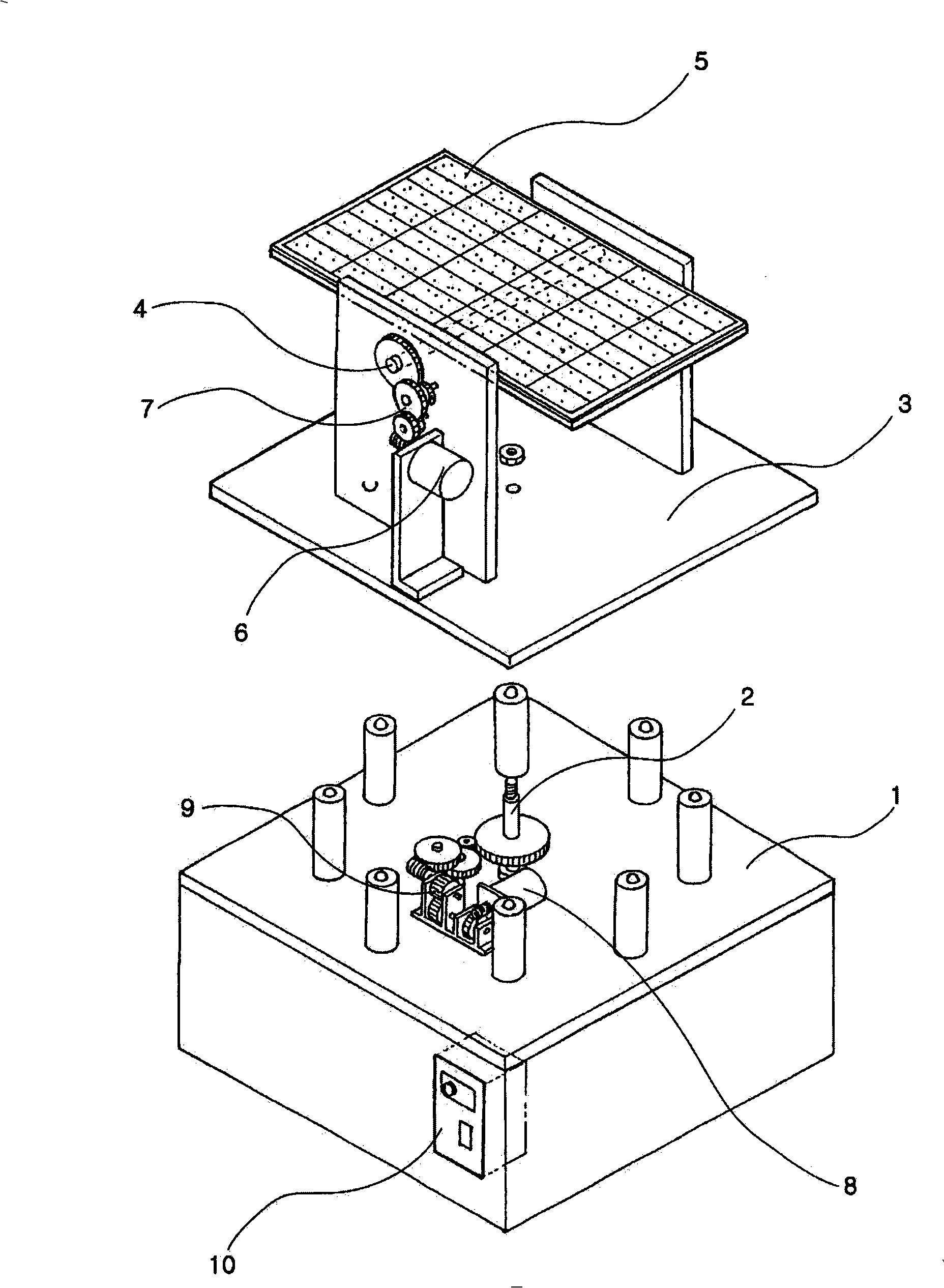

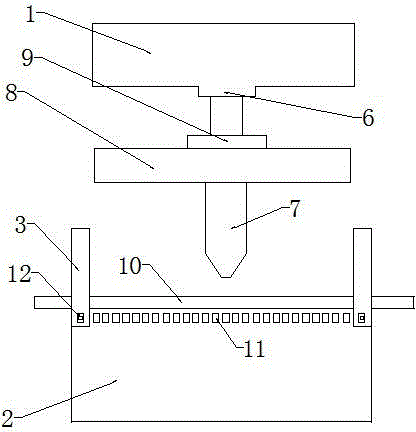

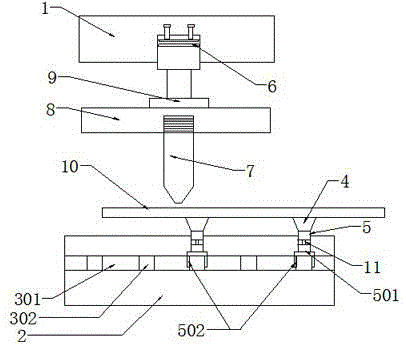

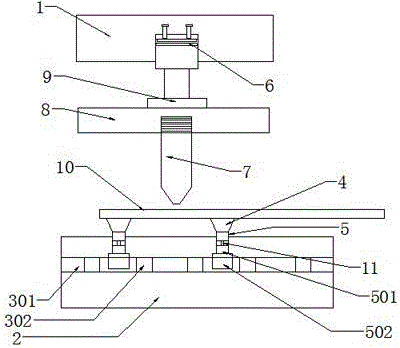

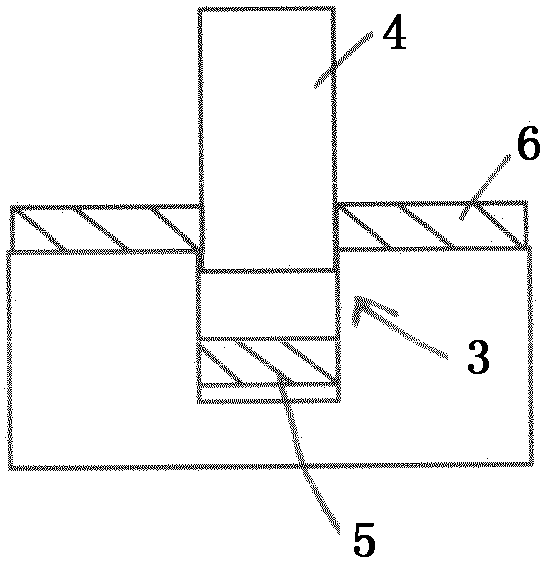

Multidirectional positioning and stamping die

ActiveCN104942174AImprove product qualityReduce reprocessingShaping toolsMetal-working feeding devicesGear wheelStamping process

The invention discloses a multidirectional positioning and stamping die. The multidirectional positioning and stamping die comprises an upper die holder, a lower die holder for containing products, a stamping assembly arranged on the upper die holder, a positioning assembly arranged on the lower die holder, and a movable assembly for driving the positioning assembly to move. The positioning assembly comprises a positioning rod moving on the lateral side of the lower die holder, a telescopic part fixed to the positioning rod and perpendicular to the products, and a pressure plate arranged below the telescopic part and pressing the products; the movable assembly comprises a clamping groove arranged in the lower die holder, a gear rolling on the clamping groove and arranged on the positioning rod, and a driving part for driving the gear to move. The positioning assembly can automatically move on the edge of the lower die holder, the positioning position is selected according to the shapes or the stamping positions of the products, the positioning assembly with the position selected presses the products on the lower die holder stably, the products are prevented from shifting in the stamping process, the product quality is ensured, reprocessing is reduced, and accordingly the cost is reduced.

Owner:襄阳市旭豪鸿泰机械制造有限公司

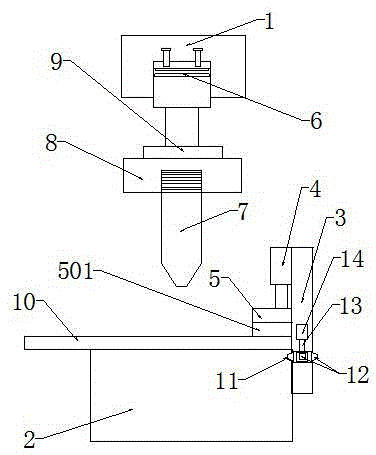

Boiler waste gas treatment device

The invention discloses a boiler waste gas treatment device, which comprises a boiler exhaust port. The boiler exhaust port is connected to a No. 1 induced draft fan through an exhaust pipe. The pipe is connected to the heat exchanger, the heat exchanger is connected to the cooling tower through the exhaust pipe, the cooling tower is connected to the desulfurization tower through the exhaust pipe, the desulfurization tower is connected to the demister through the exhaust pipe, and the desulfurization tower is connected to the water tank through the water pipe Connect the slurry pump through the slag discharge pipeline, the slurry pump is connected to the belt filter through the slag discharge pipeline, the belt filter is connected to the waste residue collection box through the slag discharge pipeline, the demister is connected to the No. 2 induced draft fan through the exhaust duct, and the No. 2 induced draft fan The activated carbon filter box is connected through the exhaust pipe, and the activated carbon filter box is connected to the chimney through the exhaust pipe. The boiler exhaust gas treatment device can effectively treat the atmosphere, have sustainable circular reaction, low reaction cost, and effectively protect the environment.

Owner:赵魁

HRB400E twisted steel bar added with high-nitrogen reinforced alloy and production process thereof

PendingCN112575250AHigh strengthImprove toughnessPackagingProcess efficiency improvementFerrovanadium alloyRebar

The invention relates to the field of steel bar processing technologies, in particular to an HRB400E twisted steel bar added with a high-nitrogen reinforced alloy and a production process thereof. Thetwisted steel bar comprises, by mass: 0.22-0.25% of C, 0.45-0.55% of Si, 1.40-1.50% of Mn, 0.010-0.020% of Ti, less than or equal to 0.040% of P, less than or equal to 0.040% of S, 0.009-0.012% of N,and the balance Fe and inevitable impurities. In the production process, the high-nitrogen reinforced alloy is added during smelting to replace a ferrovanadium alloy, a vanadium-nitrogen alloy and the like to be used for producing hot-rolled ribbed steel bars, and precipitation strengthening of N compounds is promoted through controlled rolling. Through a composite strengthening process, the strength, toughness and ductility of steel are improved, the steel has good welding performance and fatigue performance, and the cost per ton of steel is reduced. The problems that the production cost ofthe hot-rolled ribbed steel bars is high and vanadium resources are in shortage are solved, and the requirements of market development are met.

Owner:ANYANG YONGXING IRON & STEEL CO LTD OF JIANGSUSHAGANG GRP

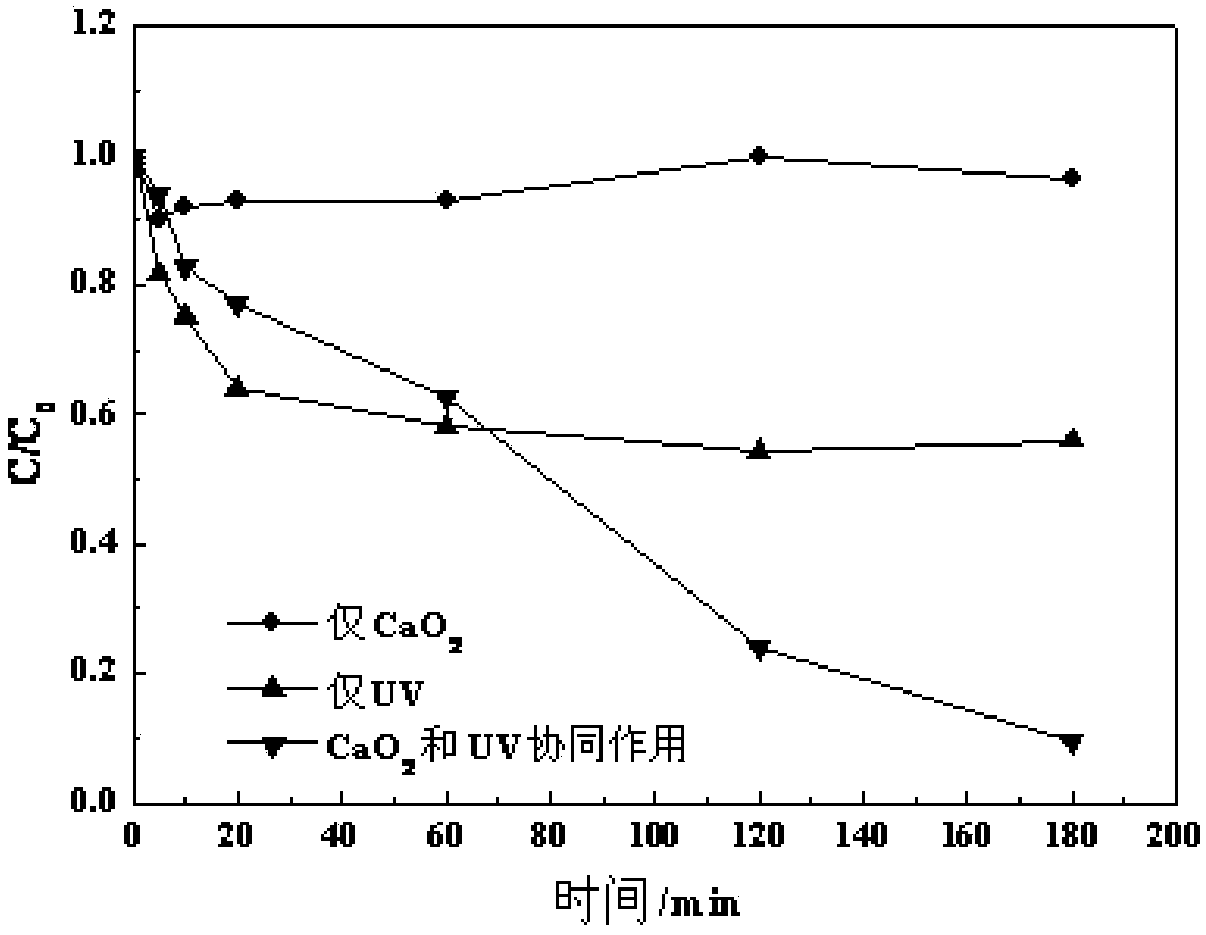

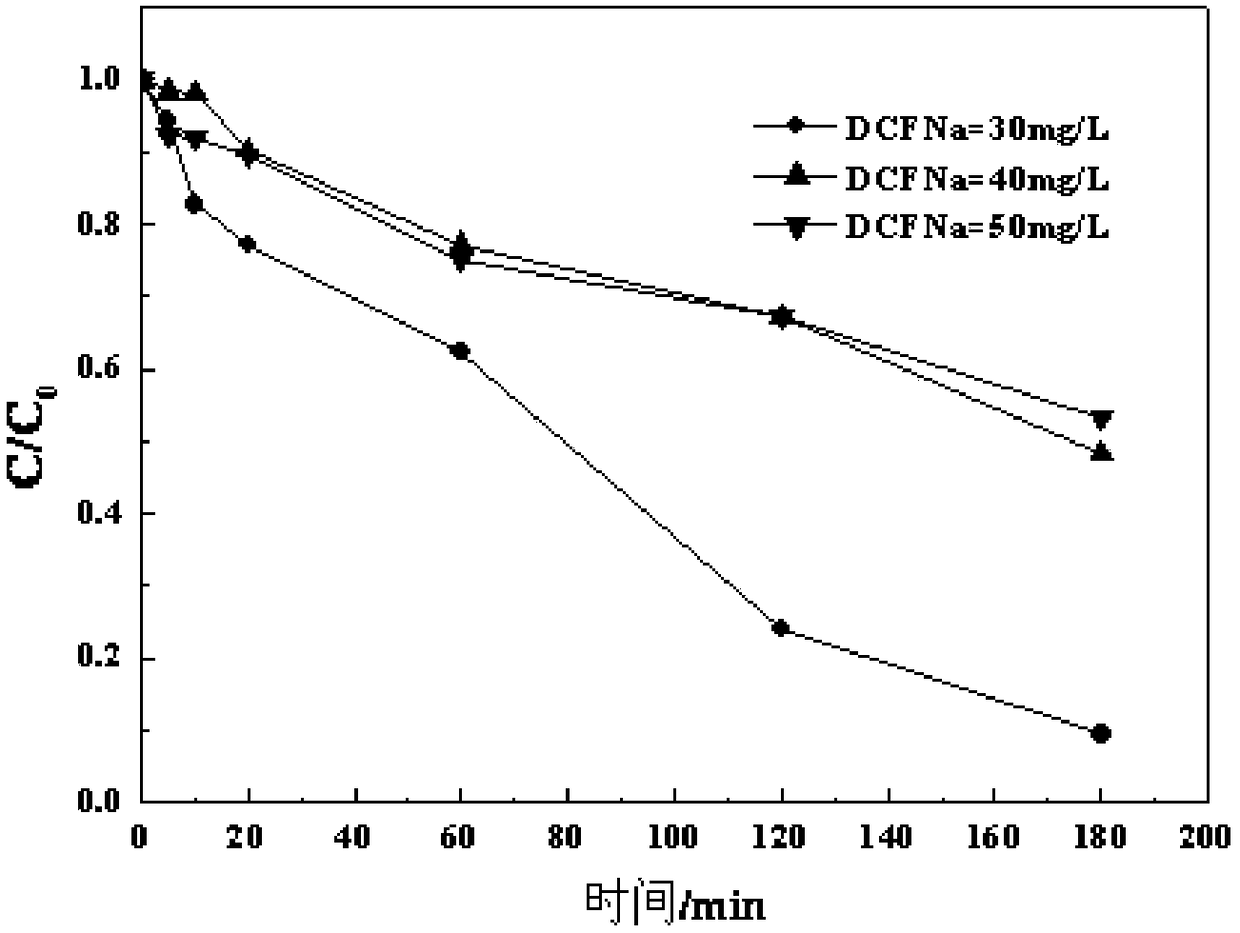

Method for removing organic pollutants in water through photocatalytically activating calcium peroxide

ActiveCN109231414AAction and effect fastAvoid Reprocessing QuestionsWater/sewage treatment by irradiationWater treatment compoundsPollutantEnvironmental chemistry

The invention discloses a method for removing organic pollutants in water through photocatalytically activating calcium peroxide. The method is characterized by comprising the following steps: addingwater into the calcium peroxide to prepare suspension liquid; meanwhile, regulating the pH (Potential of Hydrogen) value of the suspension liquid by utilizing a pH regulator according to different oxygen release and oxidization requirements; putting wastewater to be treated into a photocatalytic reactor; starting the reactor; after pre-heating a lamp tube and stably outputting a light source, adding the calcium peroxide suspension liquid into the wastewater; activating the calcium peroxide under the illumination of the light source to generate an active substance, so that degradation of the organic pollutants in the wastewater is realized. According to the method, the organic pollutants in the water are removed by photocatalytically activating CaO2; compared with a single oxidization repairing technology or a photocatalytic technology, the acting effect is more rapid, and the applicable range on the pollutants is wider.

Owner:DONGHUA UNIV

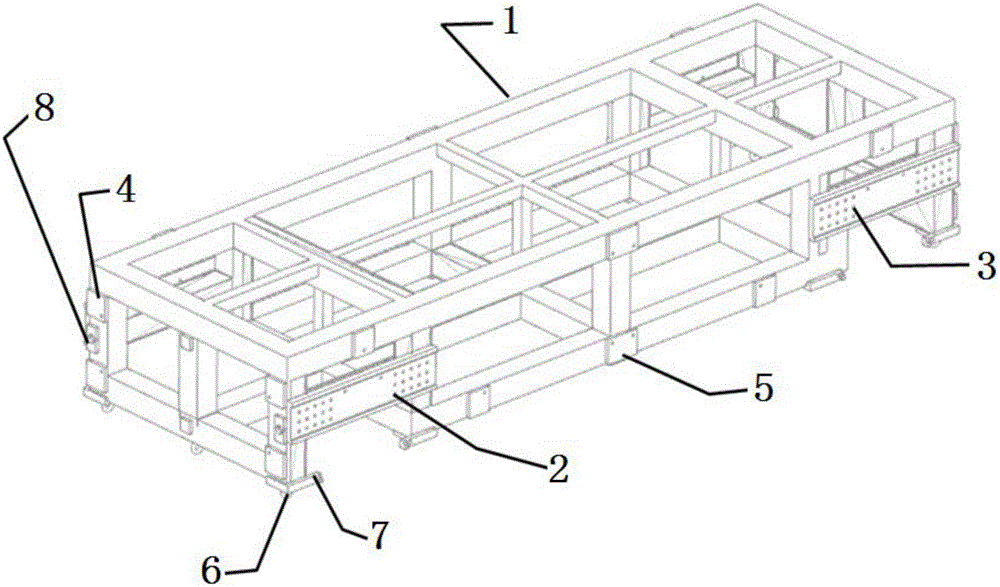

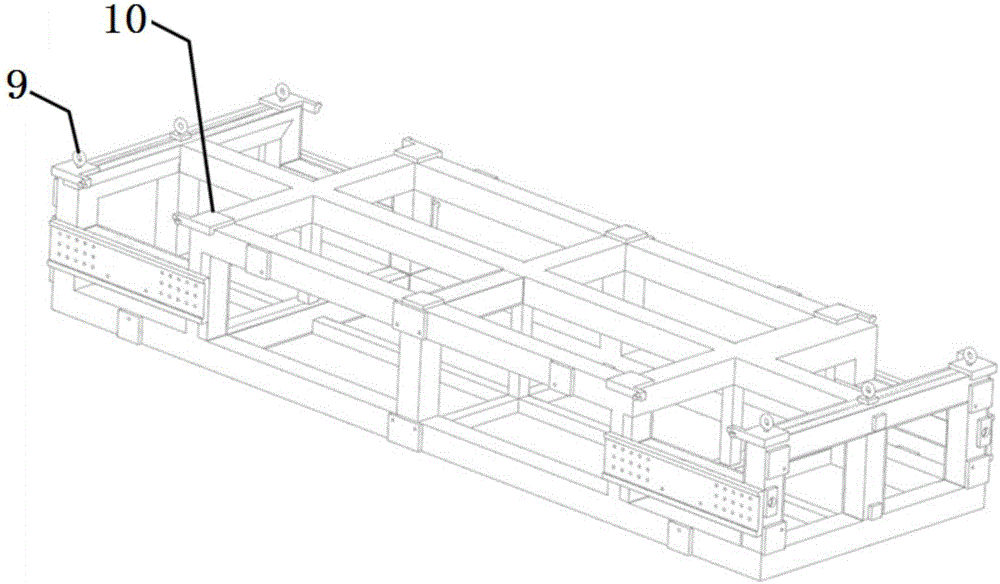

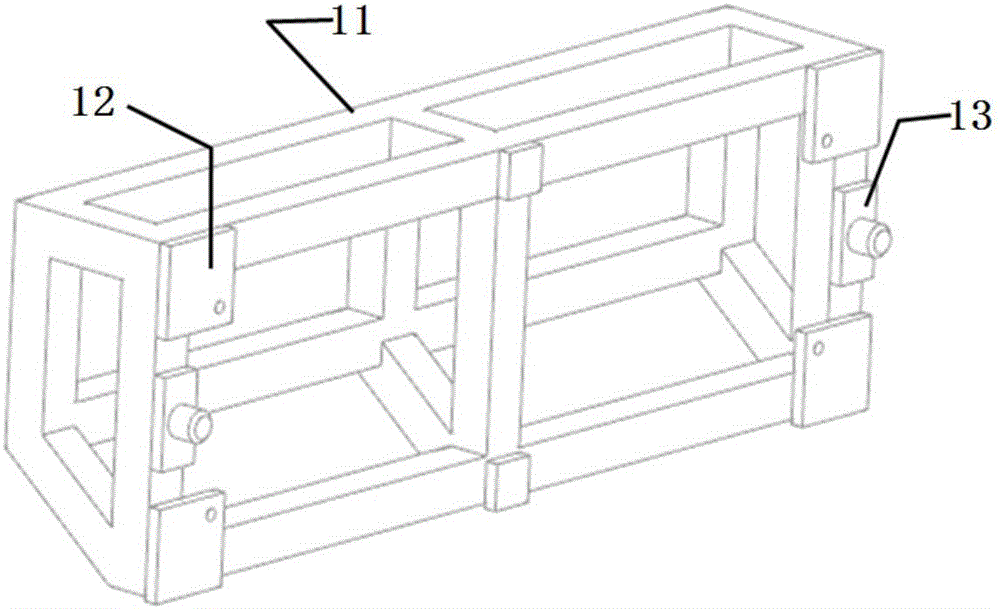

General frame system for automobile exterior verification model

The invention relates to a general frame system for an automobile exterior verification model. The frame system includes a main frame, a front tyre support and a front protective frame arranged at the front end of the main frame, and a rear tyre support and a rear protective frame arranged at the rear end of the main frame, the left and right sides of the main frame are respectively provided with a front-wheel support lock adjusting panel and a rear-wheel support lock adjusting panel, the front tyre support and the rear tyre support perform transverse adjustment along the length direction of the main frame by means of the front-wheel support lock adjusting panel and the rear-wheel support lock adjusting panel, and the frame system further includes a pair of side wall frames symmetrically arranged at the left and right sides of the main frame. Compared with the prior art, the general frame system is simple and compact in integral structure, and is economical and practical in use, and after the frames are modularized, the frames are relatively small and can be conveniently manufactured, the tyre supports can adjust the vehicle posture and axle distance, and when the automobile model is verified, an appropriate effect can be obtained.

Owner:SHANGHAI HAOYI AUTOMOBILE DESIGN CO LTD

Positioning and stamping die

InactiveCN104942150AAvoid displacementQuality assuranceShaping toolsMetal-working feeding devicesEngineeringMechanical engineering

The invention discloses a positioning and stamping die. The positioning and stamping die comprises an upper die holder, a lower die holder, a stamping assembly arranged on the upper die holder, a clamping rail arranged inside the lower die holder, and a positioning assembly clamped on the clamping rail and bearing products. The positioning assembly comprises a clamping block clamped on the clamping rail and a sucker arranged on the clamping block. Products are sucked on the sucker, the positioning and stamping die adapts to the product shape or stamping position by clamping the sucker on the clamping rail, products are prevented from shifting when impacted, the product stamping quality is ensured, reprocessing is reduced, and accordingly the cost is reduced.

Owner:昆山—邦泰汽车零部件制造有限公司

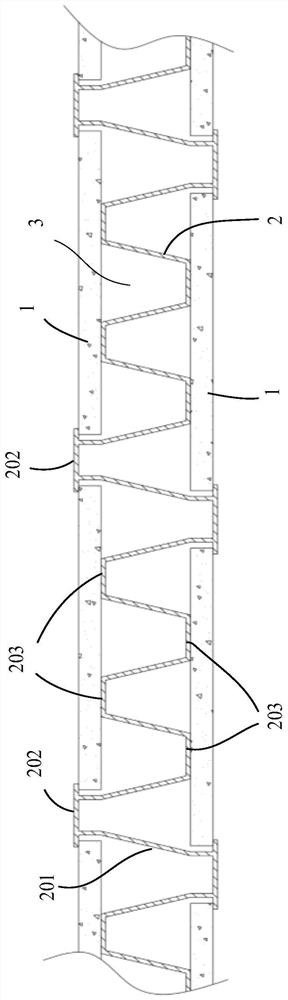

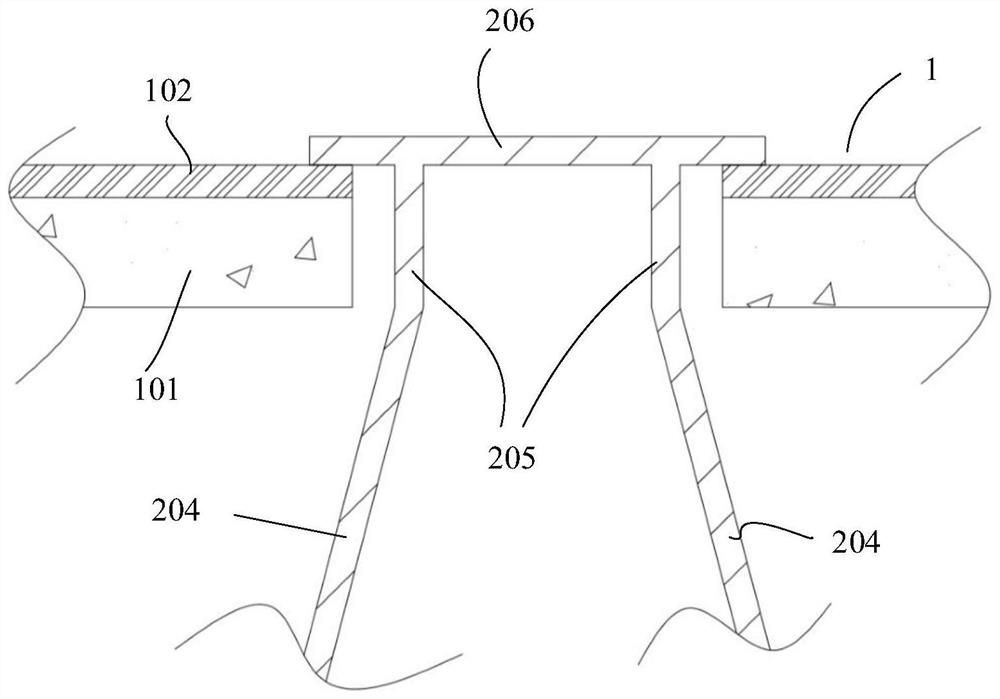

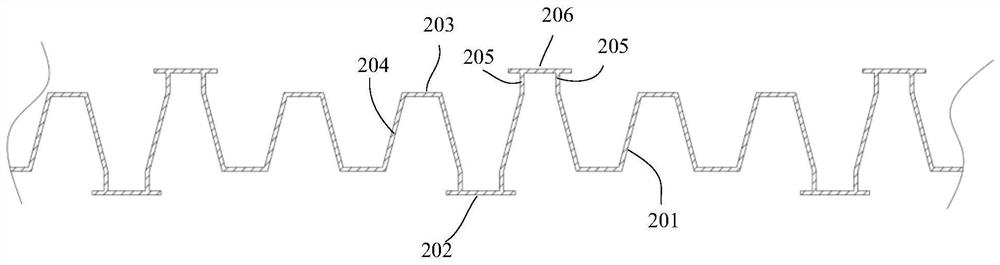

Wall convenient to install

The invention discloses a wall convenient to install. The wall comprises a plurality of wall plates and a steel plate keel, wherein the steel plate keel is vertically arranged and extends in the length direction of the wall; the wall plates are arranged on the two sides of the steel plate keel; a plurality of protruding connecting parts are arranged on the two sides of the steel plate keel and arranged in the length direction of the wall; any wall plate is arranged between every two adjacent connecting parts in the length direction of the wall; the connecting parts protrude out of the wall plates; and the two ends of each wall plate are buckled with the connecting parts correspondingly. The invention relates to the field of buildings and provides the wall convenient to install. The wall iscomposed of the steel plate keel and the wall plates buckled on the steel plate keel. The steel plate keel replaces a keel framework, so that the keels do not need to be spliced in the machining process, the wall is faster to manufacture, time and labor are saved, and the strength is guaranteed.

Owner:CHINA NAT BUILDING MATERIALS TECHCAL INNOVATION & RES INST LIMITED

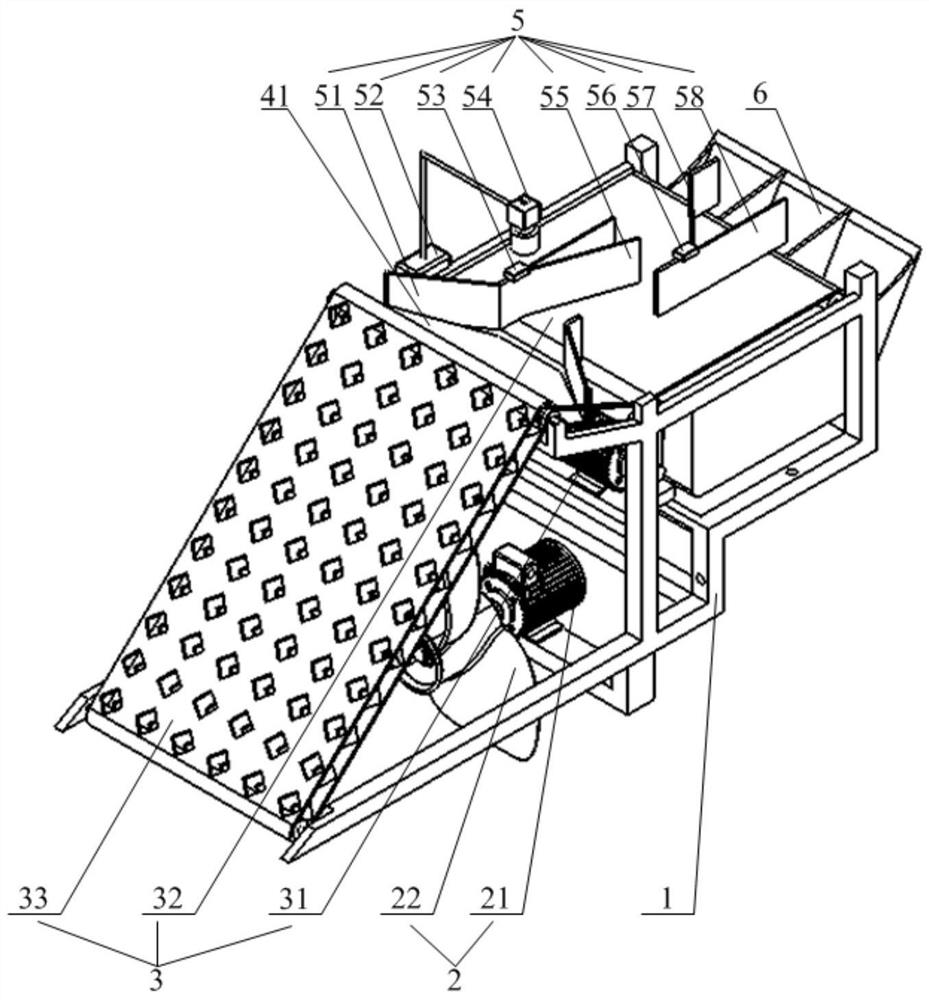

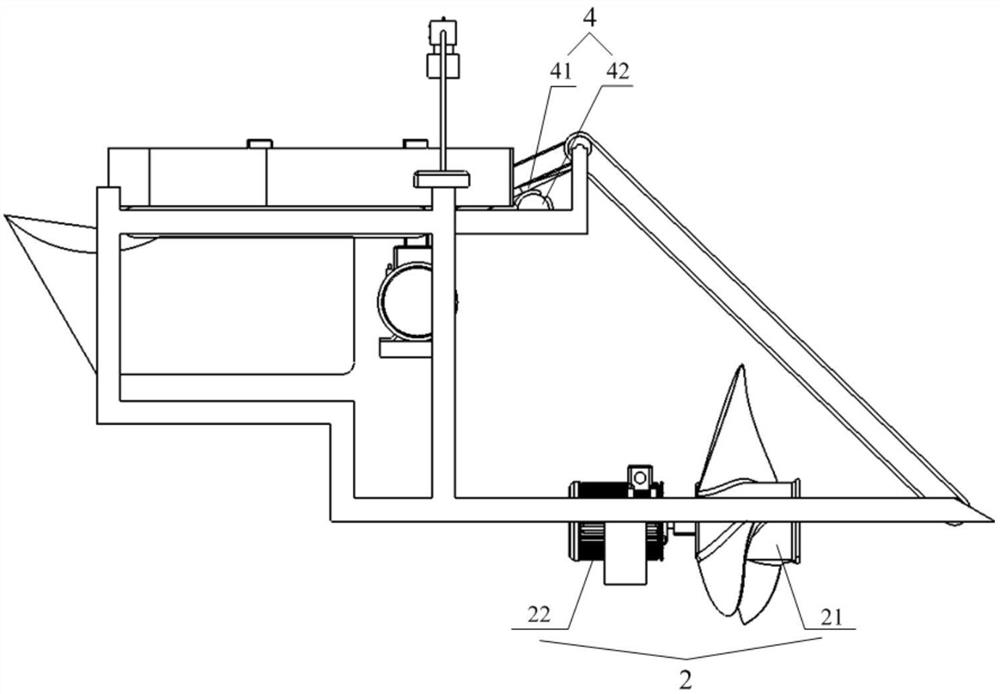

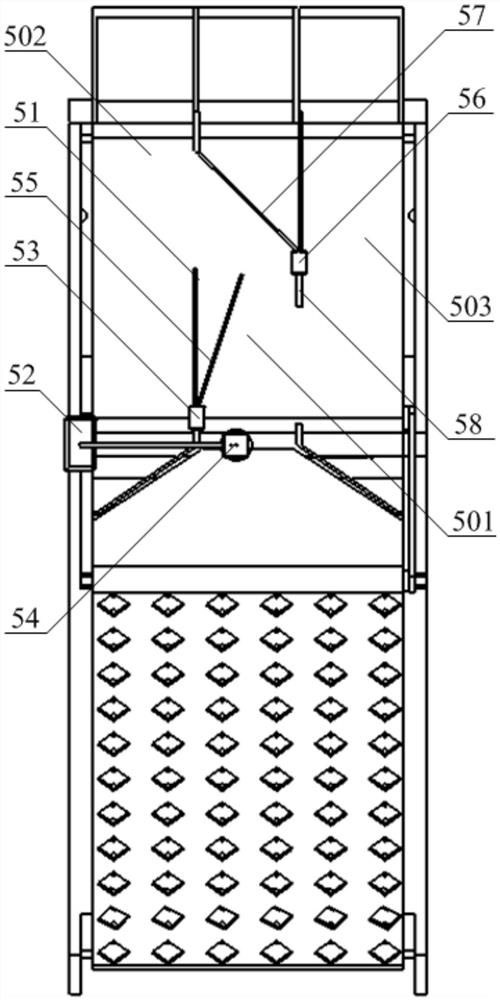

Water surface garbage collecting and classifying device and method based on machine vision

PendingCN113086110ASave on inconvenience and energy wastageChange collection directionWater cleaningWaterborne vesselsGarbage collectionElectric machinery

The invention discloses a water surface garbage collecting and classifying device and method based on machine vision. The device comprises a support, a drainage device, a conveying belt set, a garbage classifying device, a vibration device and classified garbage cans. The support is installed on a ship and used for supporting the whole collecting and classifying device. The drainage device is arranged on the support and used for guiding garbage on a water surface to flow to the conveying belt set. The conveying belt set comprises a final conveying belt, a near-water conveying belt and a conveying belt motor, and the garbage on the water surface is conveyed to the vibration device through the near-water conveying belt. The vibration device vibrates and disperses the received garbage through rapid vibration and conveys the garbage to the garbage classifying device; and the garbage classifying device classifies garbage through image processing and carries out classifying operation on the garbage after planning the path of the garbage on the final conveying belt, and the final conveying belt conveys the classified garbage into the classified garbage cans. The garbage collecting and classifying method is used for collecting and classifying garbage on a normal water surface and aims at reducing environmental pollution and improving the garbage recycling rate.

Owner:GUILIN UNIV OF ELECTRONIC TECH

Method for producing a bearing ring, in particular for a tapered roller bearing

InactiveCN103415361AGood dimensional stabilityImprove surface qualityRoller bearingsShaftsEngineeringMechanical engineering

The invention relates to a method for producing a bearing ring (20, 29), in particular a tapered roller bearing ring, comprising the following steps: making available an annular disc (8; 9), and forming the disc (8; 9) to give a substantially cylindrical bearing ring and producing a raceway (19; 28) of the bearing ring in a single operation by extrusion. According to the invention, the method achieves the object of providing a simple method for producing bearing rings, in particular for tapered roller bearings, which delivers high unit numbers and in which it is possible to dispense with a finishing operation.

Owner:SCHAEFFLER TECH AG & CO KG

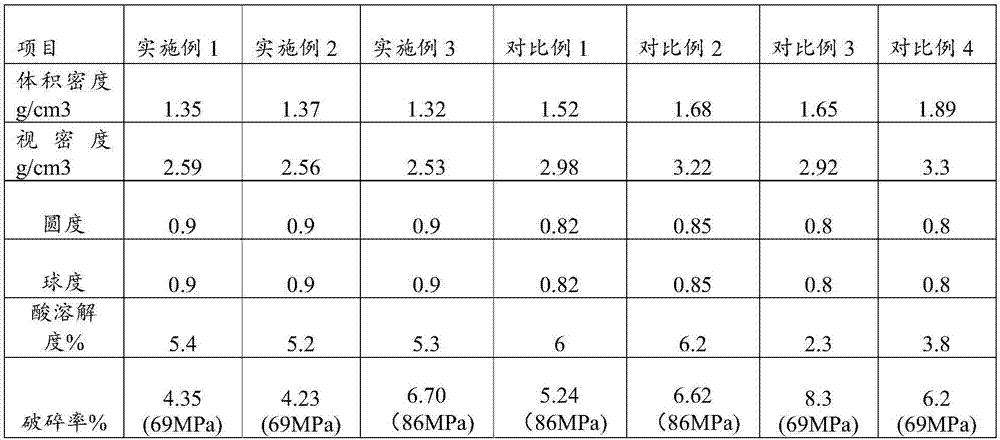

Fracturing propping agent and preparation method thereof

InactiveCN106967409AReduce procurement costsAct as a skeleton supportFluid removalDrilling compositionPotassiumPotassium feldspar

The invention provides a fracturing propping agent and a preparation method thereof, and relates to the field of petroleum and gas exploration materials. The fracturing propping agent is mainly prepared from the following raw materials in percentage by mass: 60-75% of shale, 10-25% of bauxite propping agent wastes and 5-15% of potassium feldspar. By adopting the fracturing propping agent, the technical problems that in the prior art a fracturing propping agent is high in price of raw materials, high in production cost and low in cost performance are solved, and technical effects that the raw material cost is lowered, the production cost is lowered and the cost performance is improved are achieved.

Owner:ZHENGZHOU RUNBAO REFRACTORY MATERIAL CO LTD

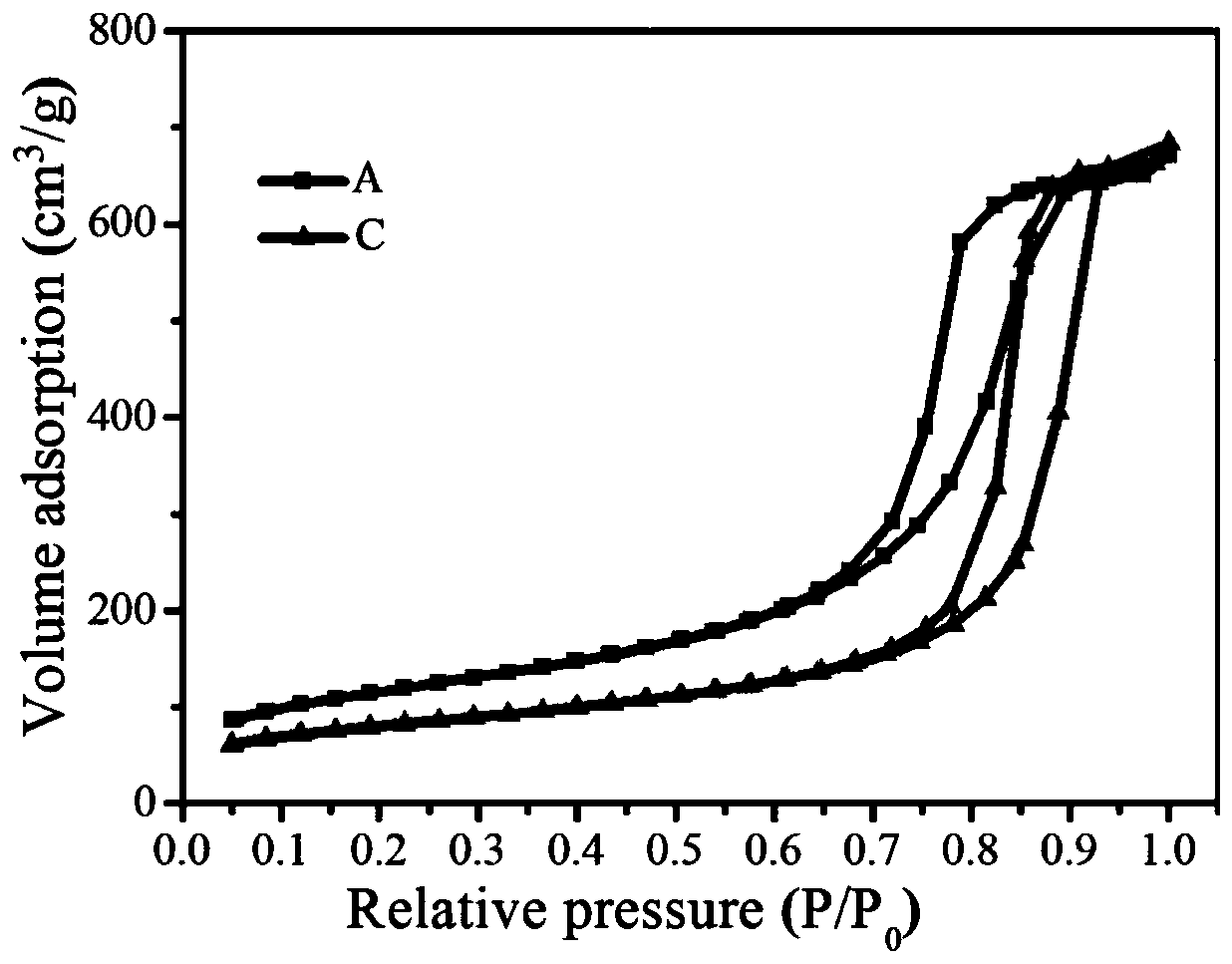

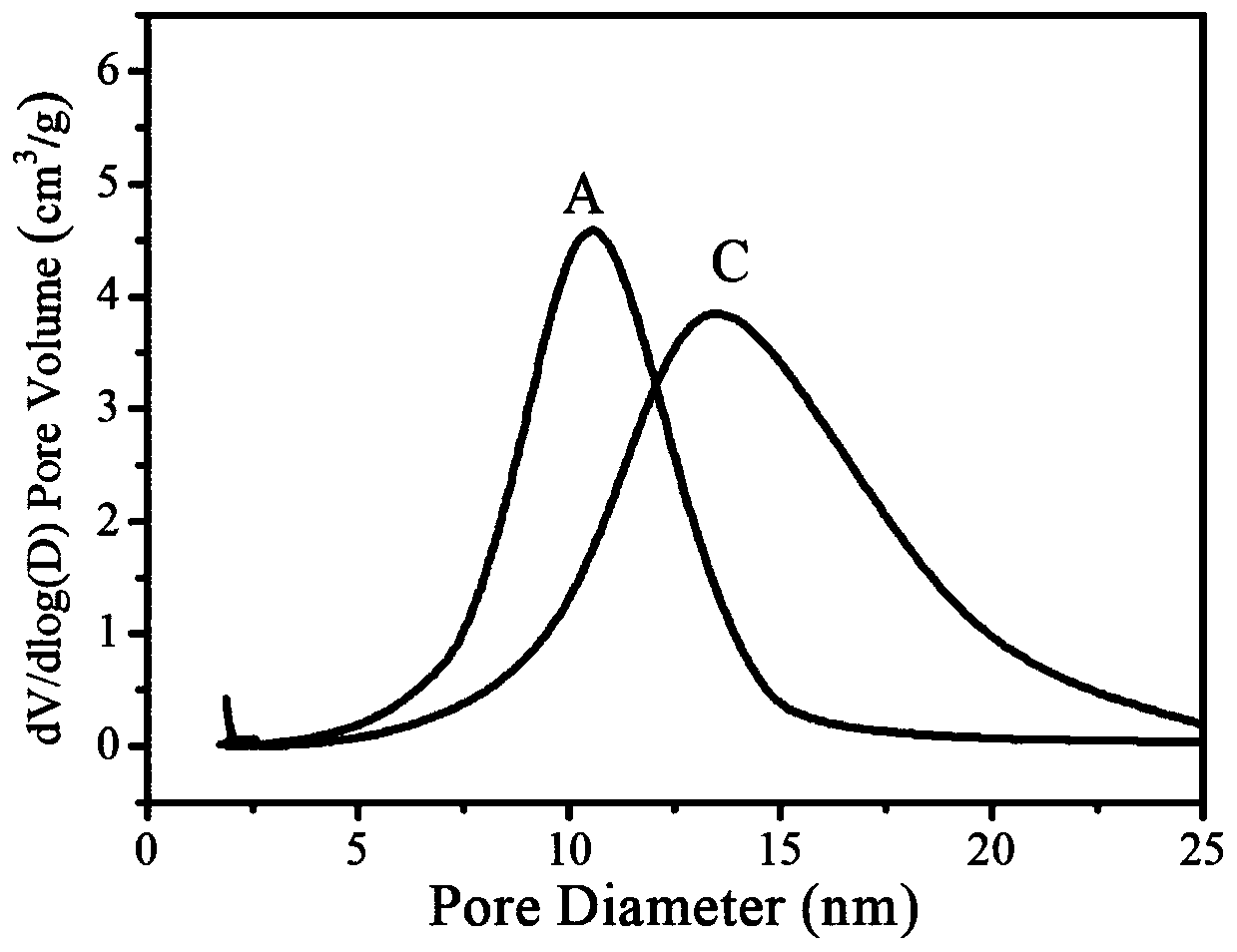

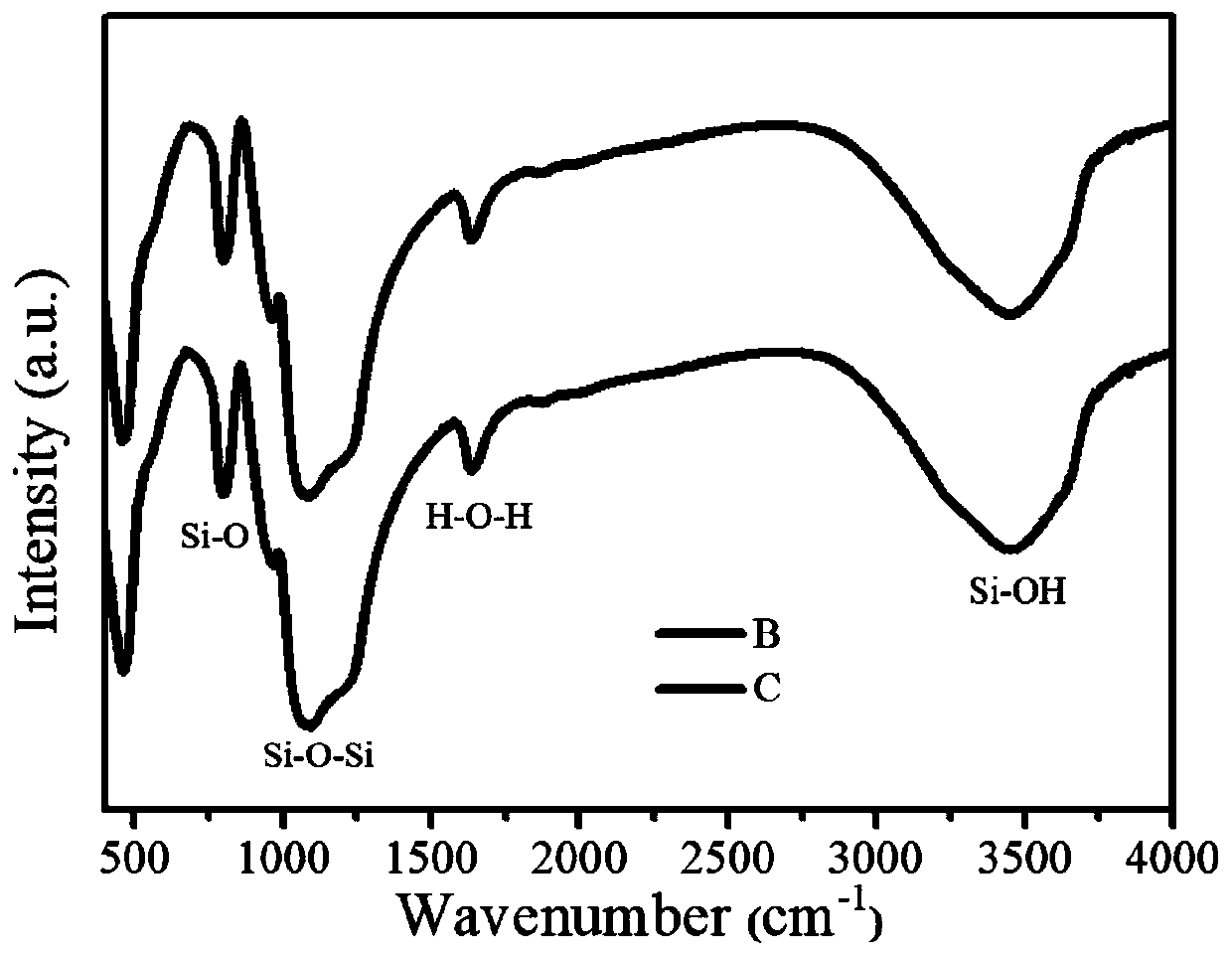

Mesoporous silica (SiO2) and preparation method thereof

ActiveCN110342530ASimplify the original processHigh bonding capacitySilicaSolid sorbent liquid separationMesoporous silicaInorganic chemistry

The invention provides mesoporous silica (SiO2) and a preparation method and application thereof, and belongs to the field of silicone fillers. The specific surface area of the mesoporous SiO2 is 367-407 m2 / g, and the average pore diameter is 11.26-13.65 nm; and the content of surface hydroxyl is 0.498-0.541 mmol / g. The method for preparing the mesoporous SiO2 comprises the steps: a natural mineral (olivine or serpentine) is adopted as a silicon source, the mesoporous SiO2 is prepared through a one-step method, firstly the natural mineral silicon source is added into an acid, surfactant and porogenic agent mixed solution, the mixture is stirred for a period of time at the specific temperature to sufficiently react, after reacting is completed, centrifugal separation is conducted, a silicon-containing precursor is obtained, the silicon-containing precursor is subjected to still standing, filtered, washed and dried and then calcined at the high temperature, then the mesoporous SiO2 is obtained, and then the obtained mesoporous SiO2 is bonded to C18 and then used for high performance liquid chromatography fillers.

Owner:中谱科技(福州)有限公司

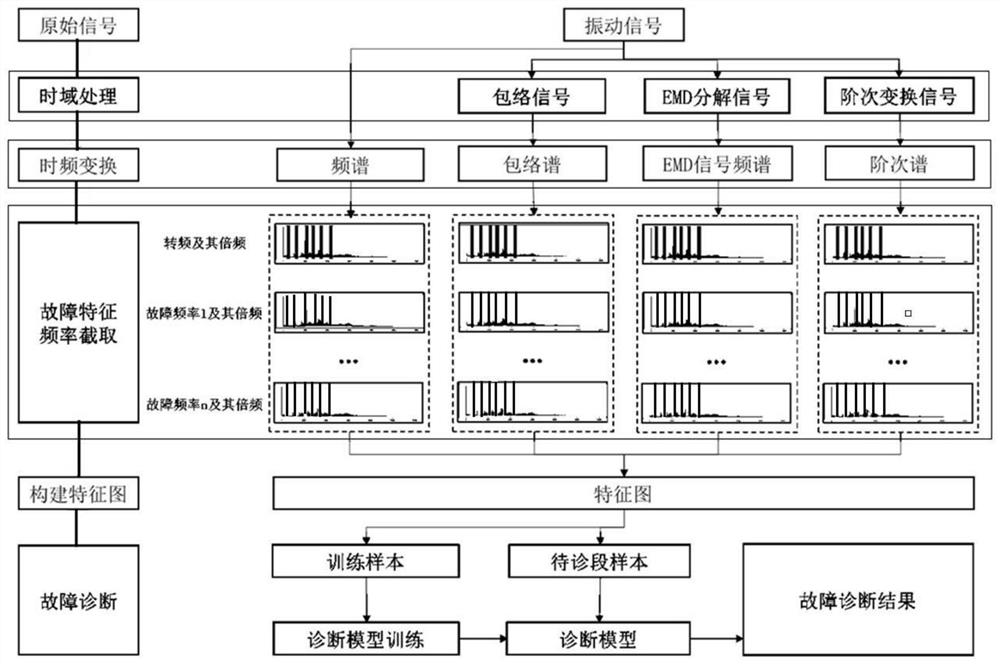

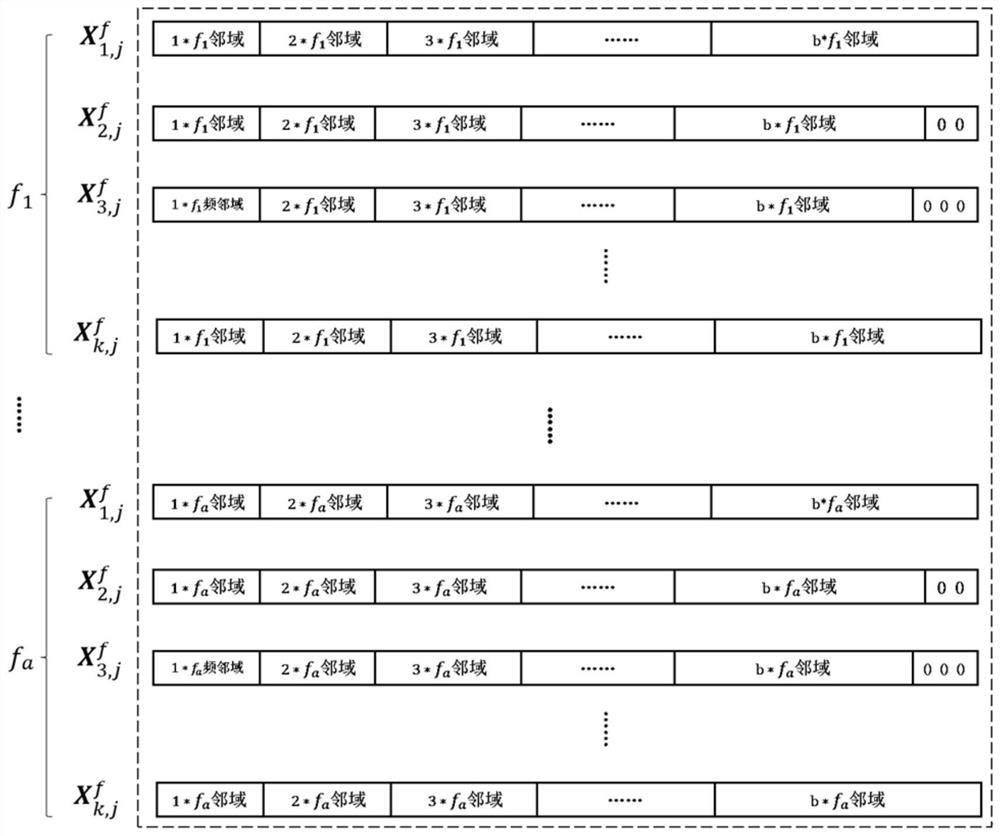

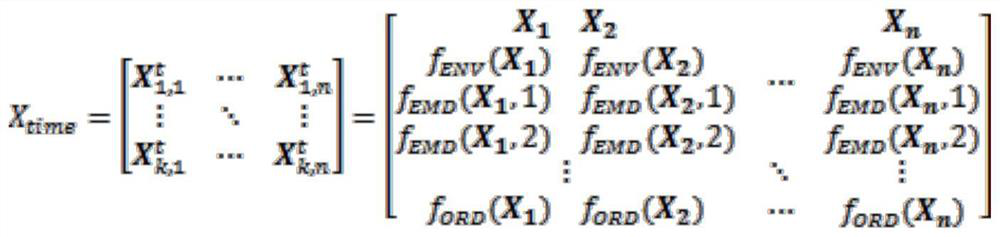

Bearing fault diagnosis method based on multi-channel vibration characteristics

PendingCN114593916AReduce reprocessingSmall amount of calculationMachine part testingSustainable transportationTime domainDiagnostic data

The invention provides a multi-channel vibration characteristic-based bearing fault diagnosis method, which comprises the following steps of: acquiring an original signal to obtain an original vibration signal sample set; performing time domain processing on the original vibration signal sample set to obtain a time domain signal sample set; performing time-frequency transformation on the time-domain signal sample set to obtain a multi-channel frequency spectrum signal; intercepting a fault characteristic frequency by using the multi-channel frequency spectrum signal and constructing sample characteristic graphs, wherein the sample characteristic graphs form a fault diagnosis sample set; and constructing a fault diagnosis model by using the fault diagnosis sample set, inputting the feature graph of the to-be-diagnosed data into the fault diagnosis model, and outputting a diagnosis result by the fault diagnosis model. According to the method, the complexity of time-frequency analysis can be reduced, the influence of subjective factors of personnel on a diagnosis result is reduced, the specific fault frequency information of the bearing and machine learning are fused, the calculation amount and the over-fitting risk are reduced, and the diagnosis accuracy is improved.

Owner:HANGZHOU ANMAISHENG INTELLIGENT TECH CO LTD

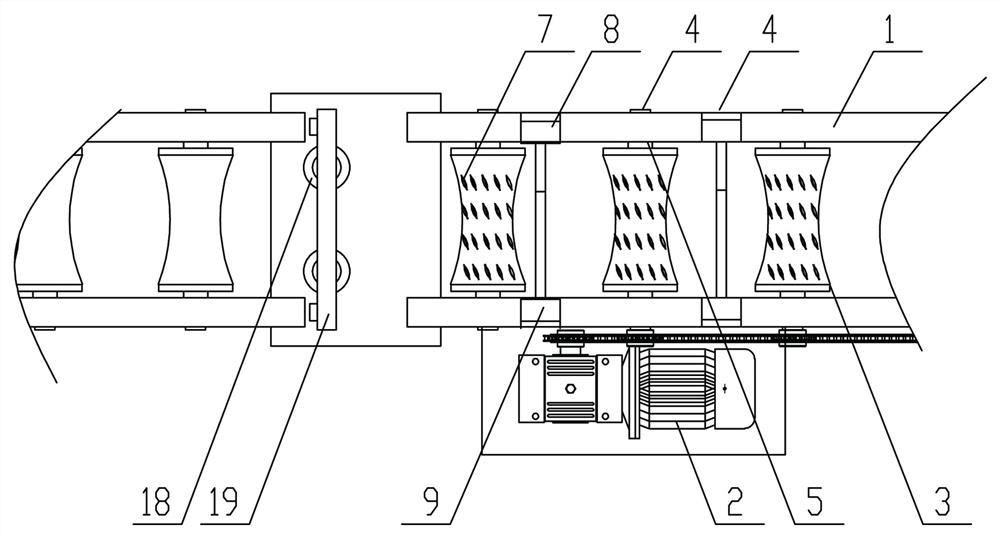

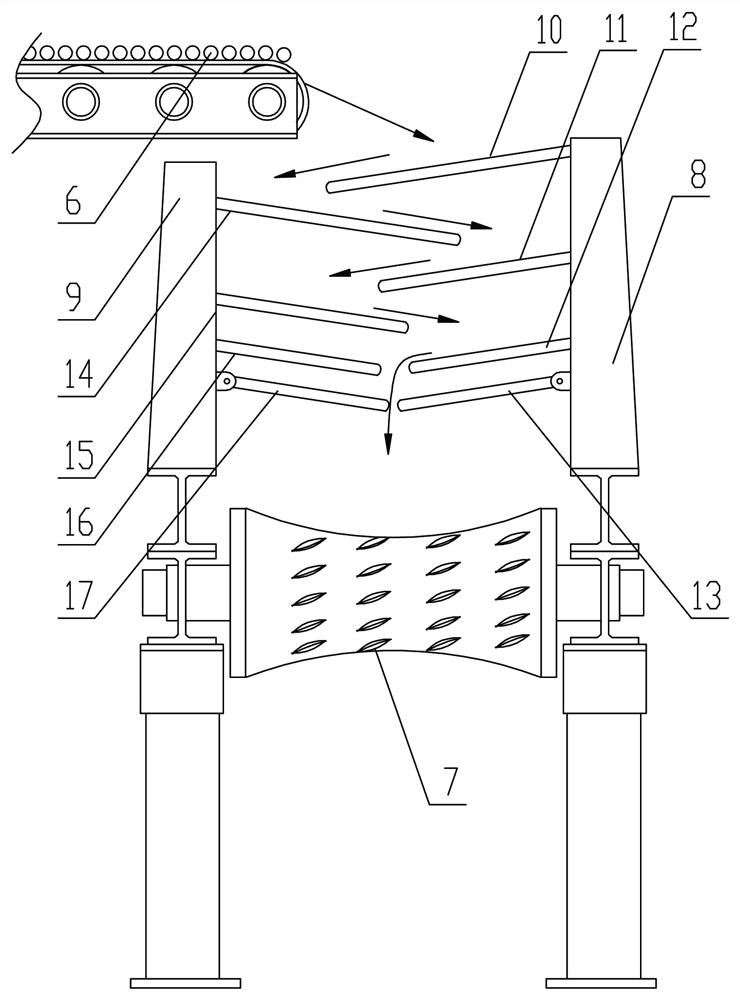

Shot peening machine

ActiveCN111203809AImprove practicalityIncrease the number of shotsAbrasive machine appurtenancesAbrasive blasting machinesClassical mechanicsElectric machinery

The invention belongs to the technical field of shot peening equipment, in particular to a shot peening machine. The shot peening machine comprises a shot peening box, an operation unit, a working unit and a controller, wherein the controller is used for controlling the shot peening machine to work; the operation unit comprises a groove-shaped upper supporting plate, a groove-shaped lower supporting plate, a sliding block, an installation block, a connecting shaft, a forward and reverse rotation motor, an elastic first lead screw and a fixing block; and the working unit comprises a first motor, a first shaft and a first rod. Under the action of the forward and reverse rotation motor, the fixing block passes through the shot peening box twice, so that the shot peening times of the shot peening box on a tubular object are increased, and the shot peening effect of the tubular object is improved; and meanwhile, when the working unit penetrates through the shot peening box, the first motoris used for driving the first shaft to rotate, so that the tubular object is subjected to shot peening treatment without dead corners, the dead corners, which are not subjected to shot peening treatment and need to be treated again in the later period, of the tubular object are reduced, the shot peening cost is reduced, and the practicability of the shot peening machine is improved.

Owner:山东吉华重工机械有限公司

Application of eutrophic water to resistance regulation of lawn plants

InactiveCN101574035AStrong stress resistanceSerious pollutionClimate change adaptationSewage/sludge fertilisersEutrophic waterLawn

The invention discloses an application of eutrophic water to resistance regulation of lawn plants, wherein the eutrophic water is the eutrophic water with 25 percent-75 percent of the original concentration; the eutrophic water has TN of 9.7mg / L-13.1mg / L, TP of 0.6mg / L-0.9mg / L and pH value of 8.12-8.99; and the evaluation indicator of the resistance refers to the change in contents of proline, soluble sugar and malonaldehyde. Results show that the diluted eutrophic water is applied to irrigation to improve the resistance of the lawn plants to adverse growing environment and achieve the purpose of resource conservation and environmental protection.

Owner:TIANJIN NORMAL UNIVERSITY

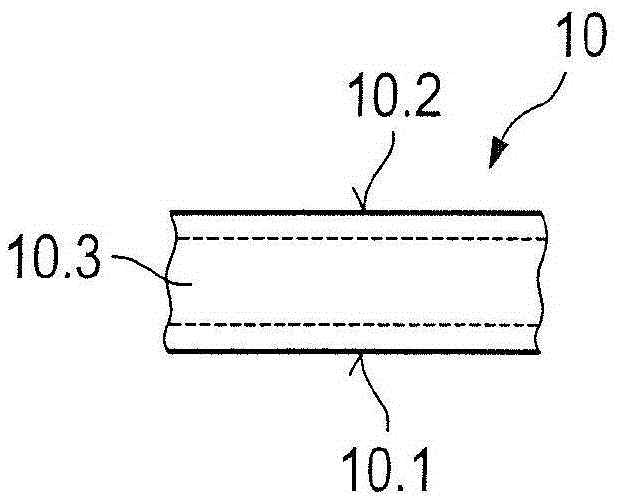

Pin receiving portion for a hub, in particular in a rolling mill

ActiveCN105636714AReduce hardnessExtended service lifeCouplings for rigid shaftsRolling mill drivesHardnessRolling mill

The invention relates to a pin receiving portion (7) for a hub for receiving the pin (6) of a connection unit, in particular of a roller (1), said pin receiving portion (7) having a main part (8) with an opening (9), which is at least partly lined with at least one wear plate (10), for inserting the pin (6). The wear plate (10) has a front surface (10.1) for bearing on the pin (6), said front surface delimiting the opening for the pin (6), and the wear plate (10) has a rear surface (10.2) which faces away from the front surface (10.1) and which rests against a receiving surface (8.1) of the main part (8) at least temporarily. The wear plate (10) has a lower hardness on the wear plate rear surface (10.2) than the receiving surface (8.1) of the main part (8).

Owner:VOITH PATENT GMBH

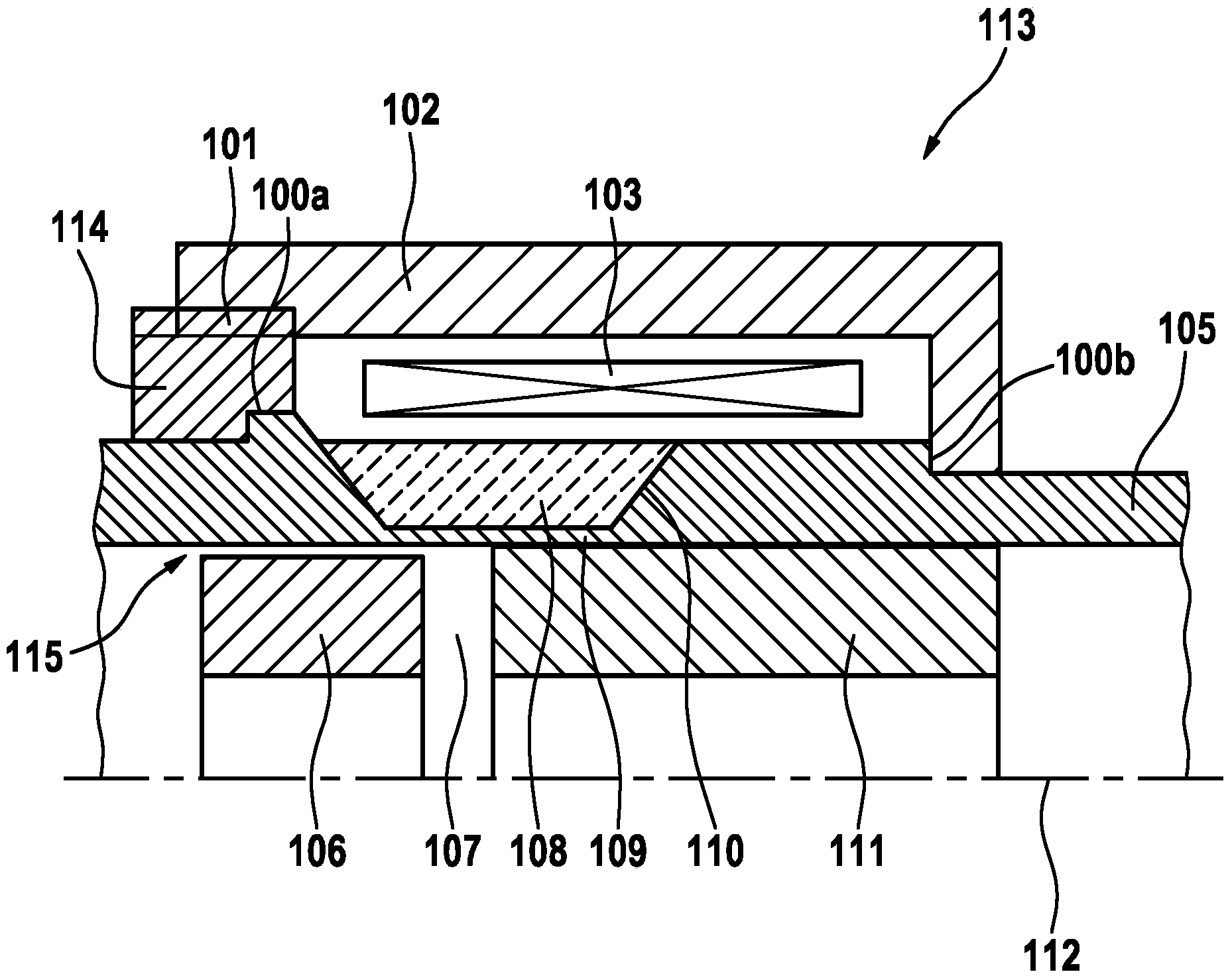

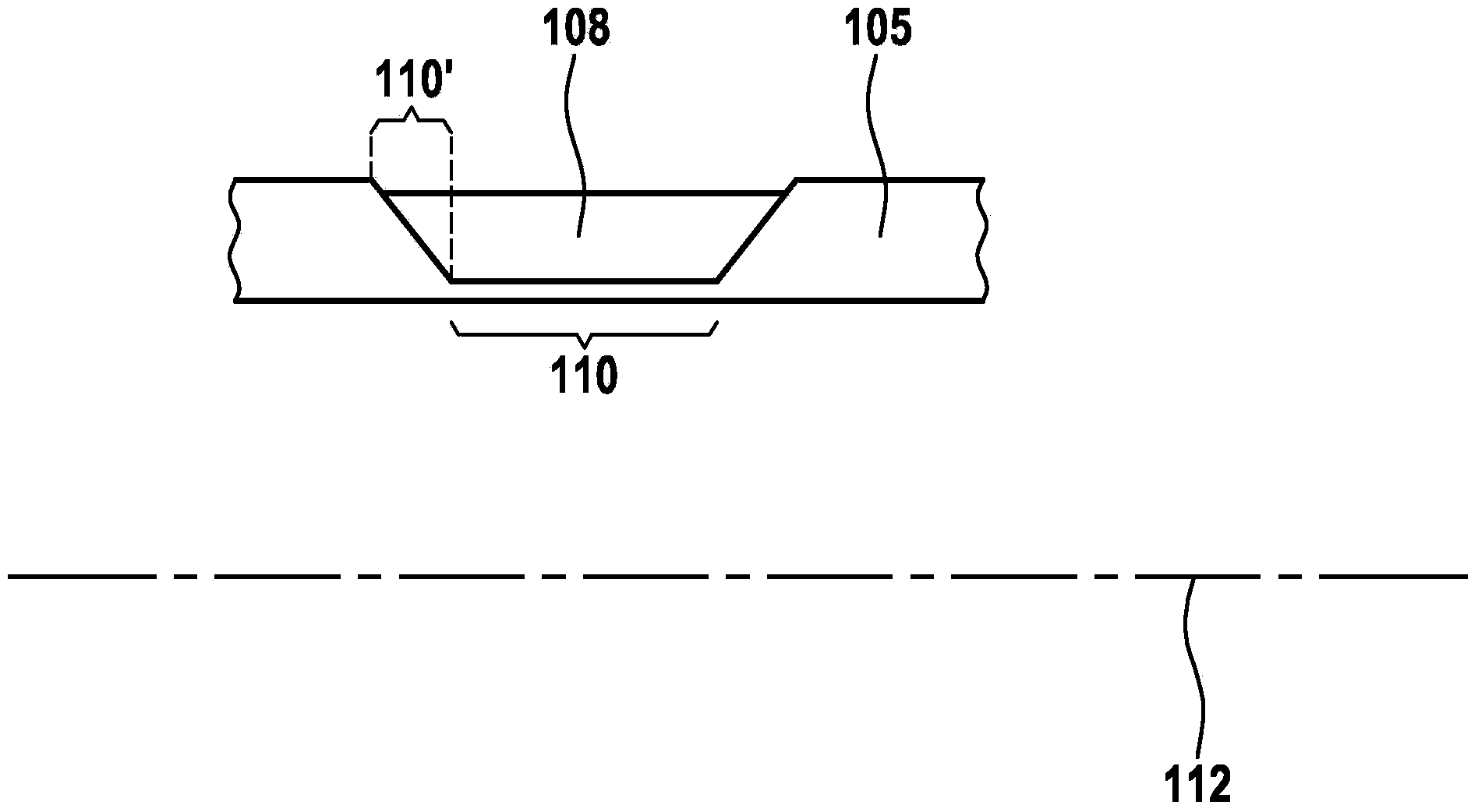

Method for producing a magnetic separation for a solenoid valve

InactiveCN103890871AHigh tensile strengthImprove rigidityOperating means/releasing devices for valvesMagnetic flux influencing fuel injectionSolenoid valveMagnet coil

The invention relates to a method for producing a solenoid valve, in particular a fuel injection valve, wherein the solenoid valve has a sleeve, a valve needle, which is arranged inside the sleeve in a radial direction and guided in a displaceable manner, a magnetic coil, which is arranged outside the sleeve in a radial direction, a magnetic core, which is arranged inside the sleeve in a radial direction, and a magnetic armature, which is arranged inside the sleeve in a radial direction, axially opposite the magnetic core, wherein the magnetic armature is arranged on the valve needle, wherein the sleeve has a smaller wall thickness in a thin-walled region arranged between the magnetic armature and the magnetic coil, wherein the thin-walled region is reinforced by means of a reinforcement element to absorb radial forces, wherein the method has a method step in which the reinforcement element is applied to the sleeve in the radial direction outside the sleeve in the thin-walled region by means of a melt bath spraying method or by means of a cold gas spraying method during the method step.

Owner:ROBERT BOSCH GMBH

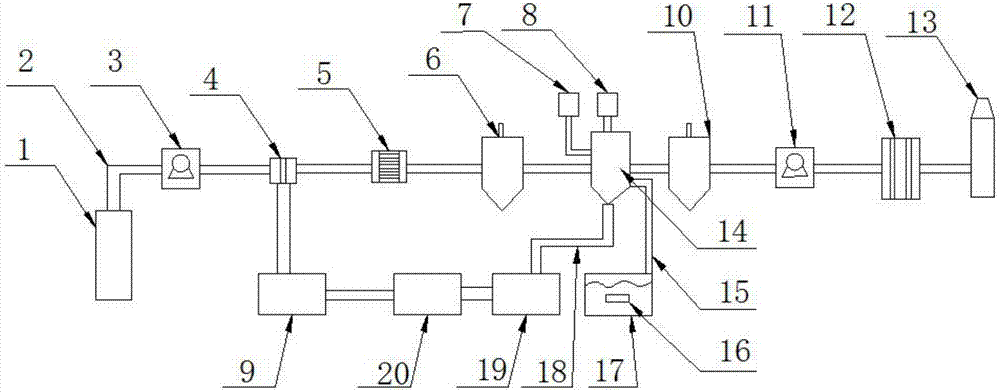

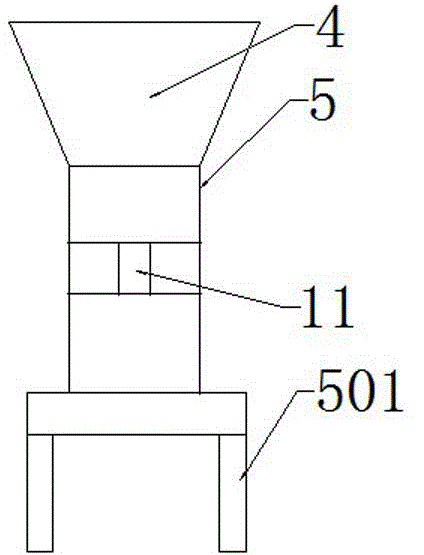

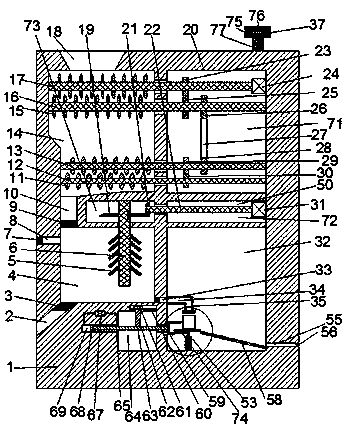

Environment-friendly fertilizer device based on databases

InactiveCN108585969AFully fermentedSimple structureClimate change adaptationOrganic fertilisersEngineeringMechanical transmission

The invention discloses an environment-friendly fertilizer device based on databases. The environment-friendly fertilizer device comprises a working box, a smashing space is arranged in the working box, a smashing and driving space is arranged in the right end wall of the smashing space, a smashing mechanism is arranged in the smashing and driving space, a transmission space is arranged in the lower end wall of the smashing space, a driving space is arranged in the lower end wall of the smashing and driving space, a stirring space is arranged in the lower end wall of the transmission space, aquantifying space is arranged in the lower end wall of the driving space, a hydraulic space is arranged in the lower end wall of the stirring space, and a stirring mechanism is arranged in the drivingspace. The environment-friendly fertilizer device is simple in structure and convenient to operate. Energy-saving transmission of the device is achieved under mechanical transmission when the deviceworks, operation of the device is achieved under the situation that the power source is less, meanwhile, the device can sufficiently ferment kitchen waste, and thus the re-treatment process in the follow-up steps is reduced.

Owner:PINGHU QIANYE IMPORT & EXPORT CO LTD

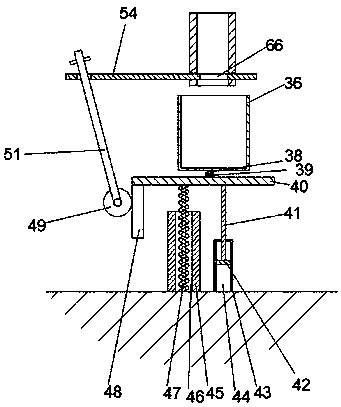

Method for adjusting the axial play between a motor armature and a bearing, and seat for an armature shaft

InactiveCN103404006ASave high testing costsQuality improvementSliding contact bearingsMechanical energy handlingEngineeringElectric motor

The invention relates to a method for adjusting the axial play between a motor armature and a bearing (50) that is secured to an armature shaft (30) and for axially securing the motor armature, comprising the following steps : - pressing a first washer (10) onto the armature shaft (30) in the predetermined mounting position of said washer on the armature shaft (30), to form a press-fit, - pressing a spacer sleeve (40) onto the armature shaft (30) to form a press-fit and to bring the spacer sleeve (40) into contact with the first washer (10), - mounting the armature shaft (30) in a second bearing of a motor housing (90), - positioning a motor cover (70), which is provided with the bearing (50), on the armature shaft (30) and securing the motor cover (70) on the motor housing (90), - pressing a second washer (20) onto the armature shaft (30) to form a press-fit and to bring the second washer (30) into contact with the spacer sleeve (40).

Owner:ROBERT BOSCH GMBH

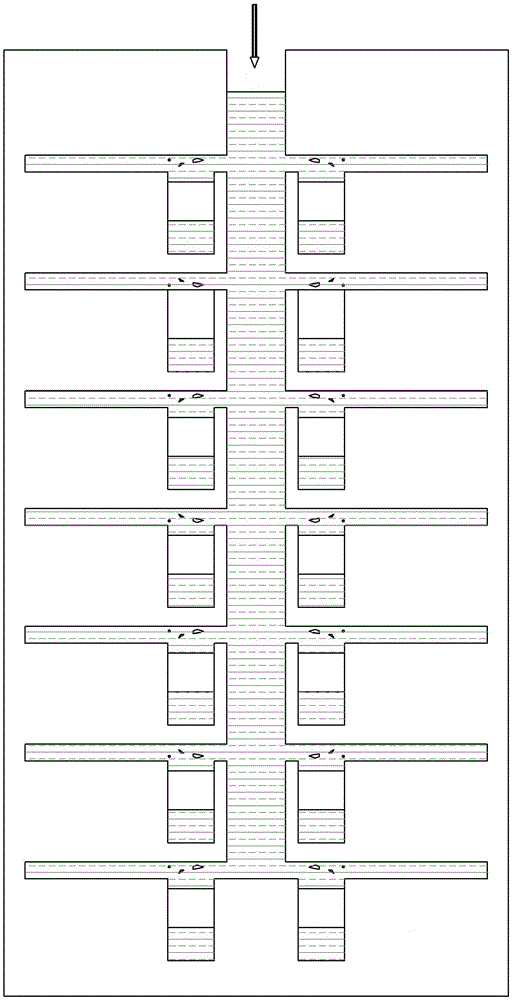

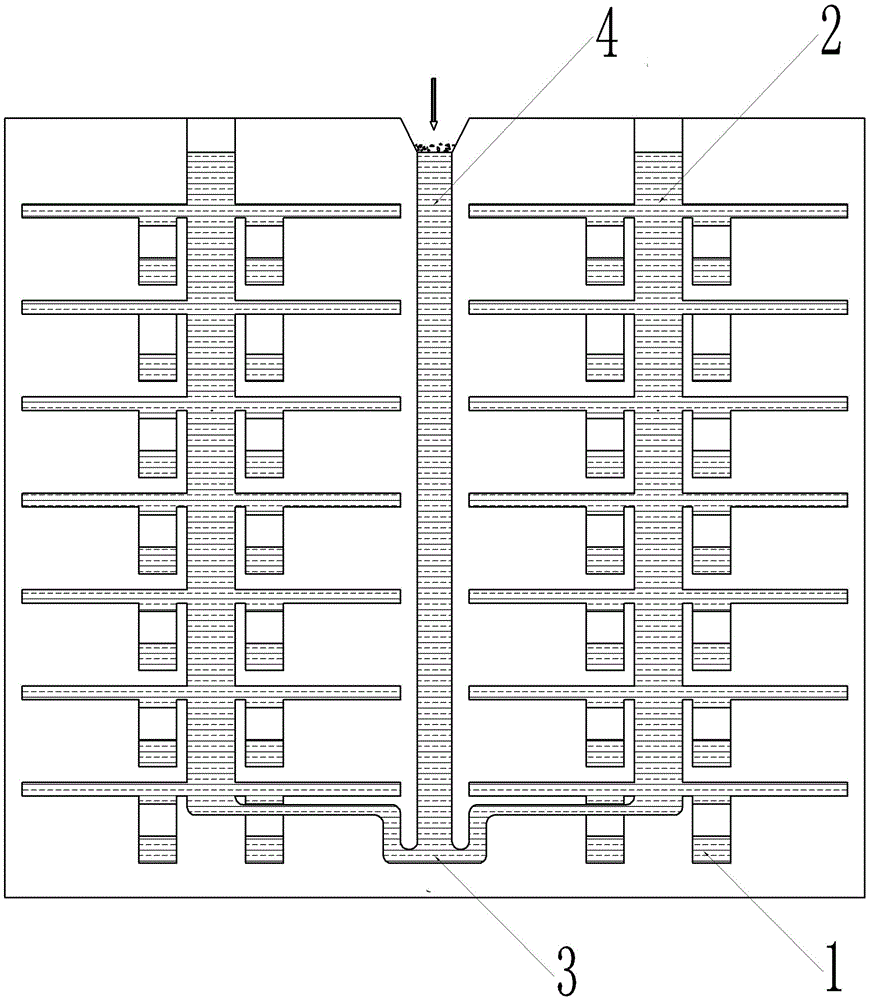

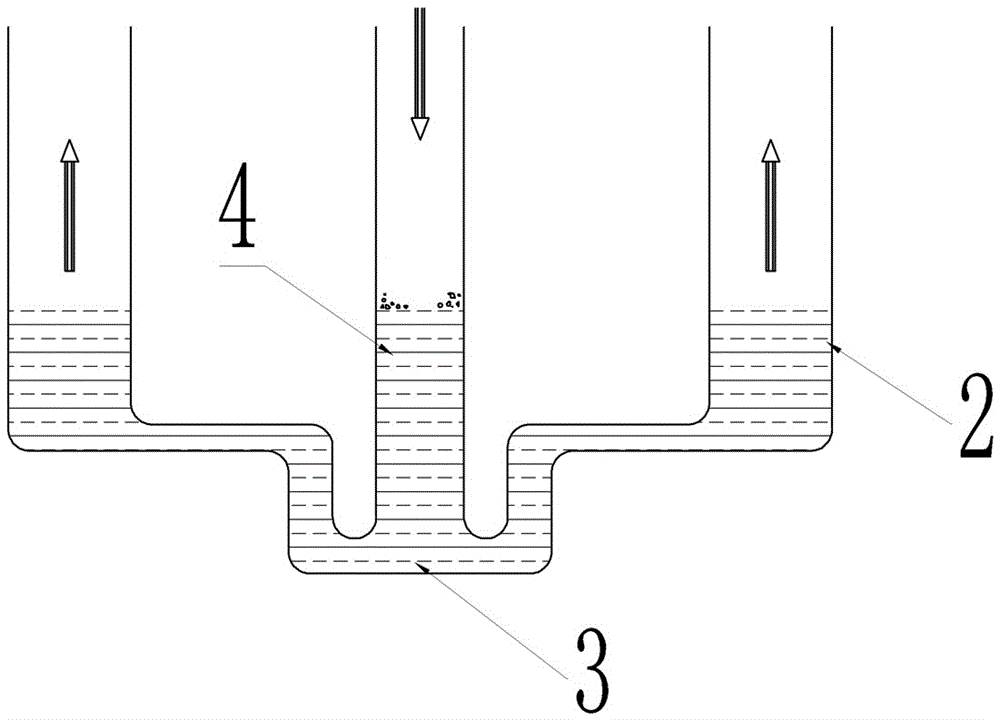

Precoated sand mold for copper piece casting and copper piece casting method

The invention discloses a precoated sand mold for copper piece casting. The precoated sand mold comprises casting cavities, a casting liquid channel, a slag avoiding inner core and a casting nozzle channel. The casting cavities are distributed around the casting liquid channel and communicated with the casting liquid channel. The slag avoiding inner core is communicated with the bottom of the casting liquid channel and the bottom of the casting nozzle channel, and the position of the slag avoiding inner core is lower than that of the casting liquid channel. The invention further provides a copper piece casting method. The copper piece casting method comprises the steps that the precoated sand mold is manufactured; then casting is carried out; the casting temperature of pure copper is controlled to range from 1,150 DEG C to 1,200 DEG C, and the casting temperature of copper alloy is controlled to range from 950 DEG C to 1,050 DEG C; casting is carried out based on the flow control principle of carrying out casting slowly and then carrying out casting fast; and after casting is finished, cooling molding is carried out, and the sand mold is removed. The precoated sand mold is high in production efficiency, a produced copper casting material is high in material utilization rate and rate of finished products, the defect of slag inclusion in the casting can be effectively overcome, and a good foundation is laid for next finish machining.

Owner:赵景涛

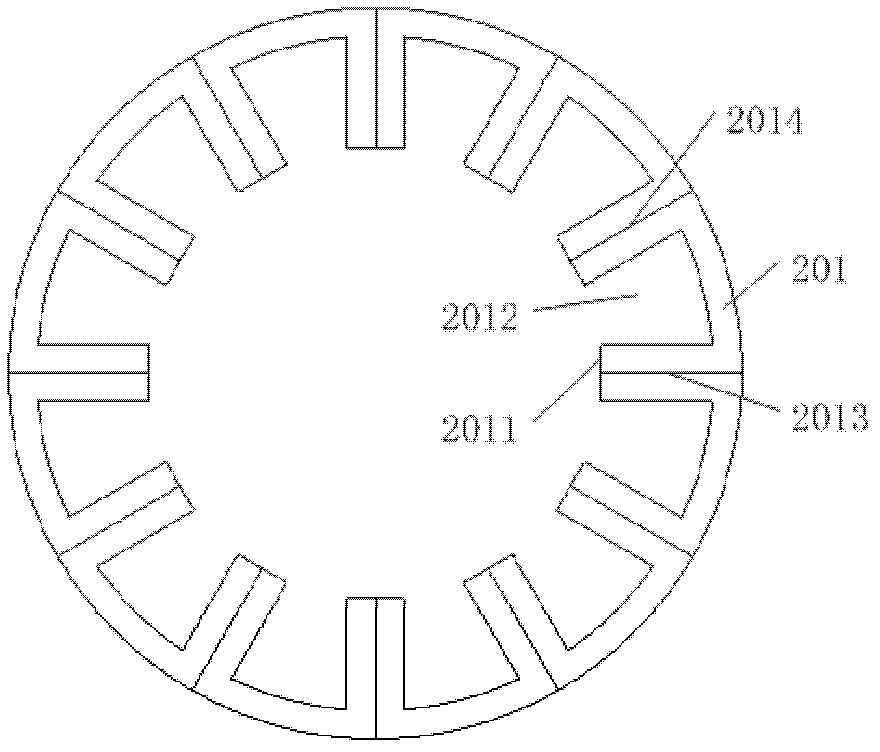

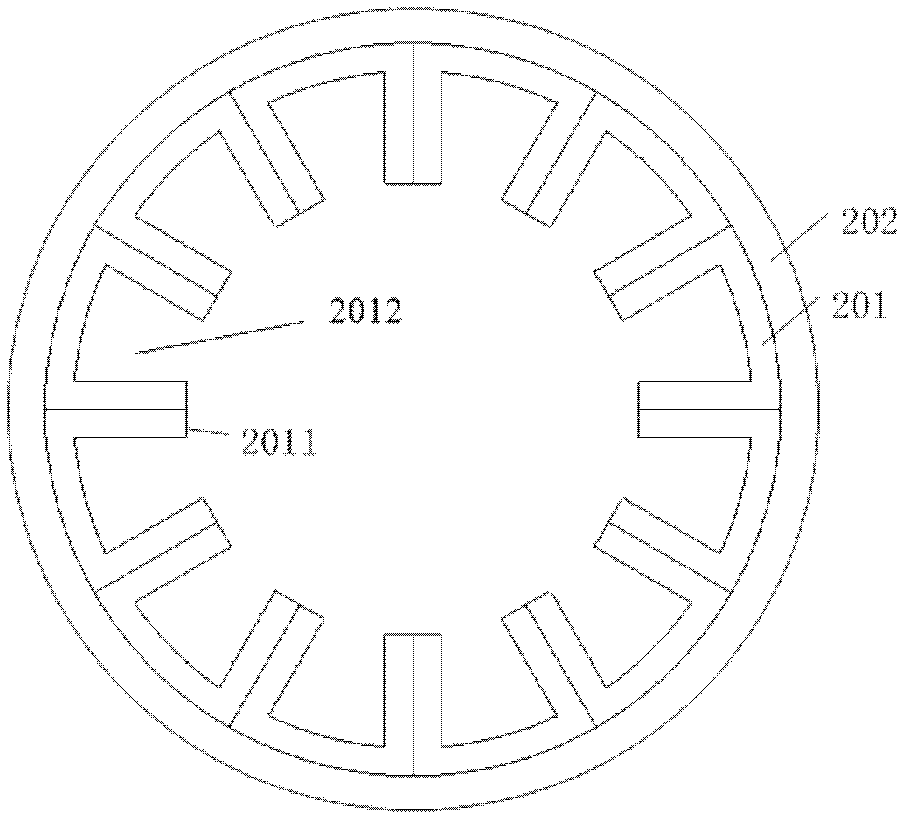

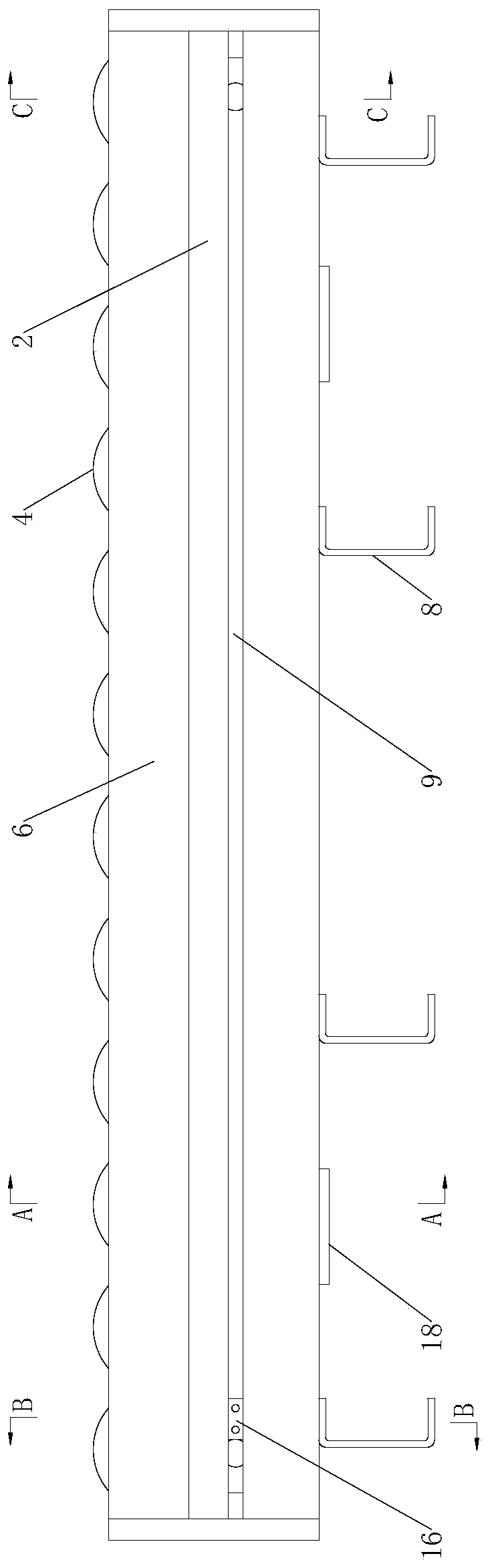

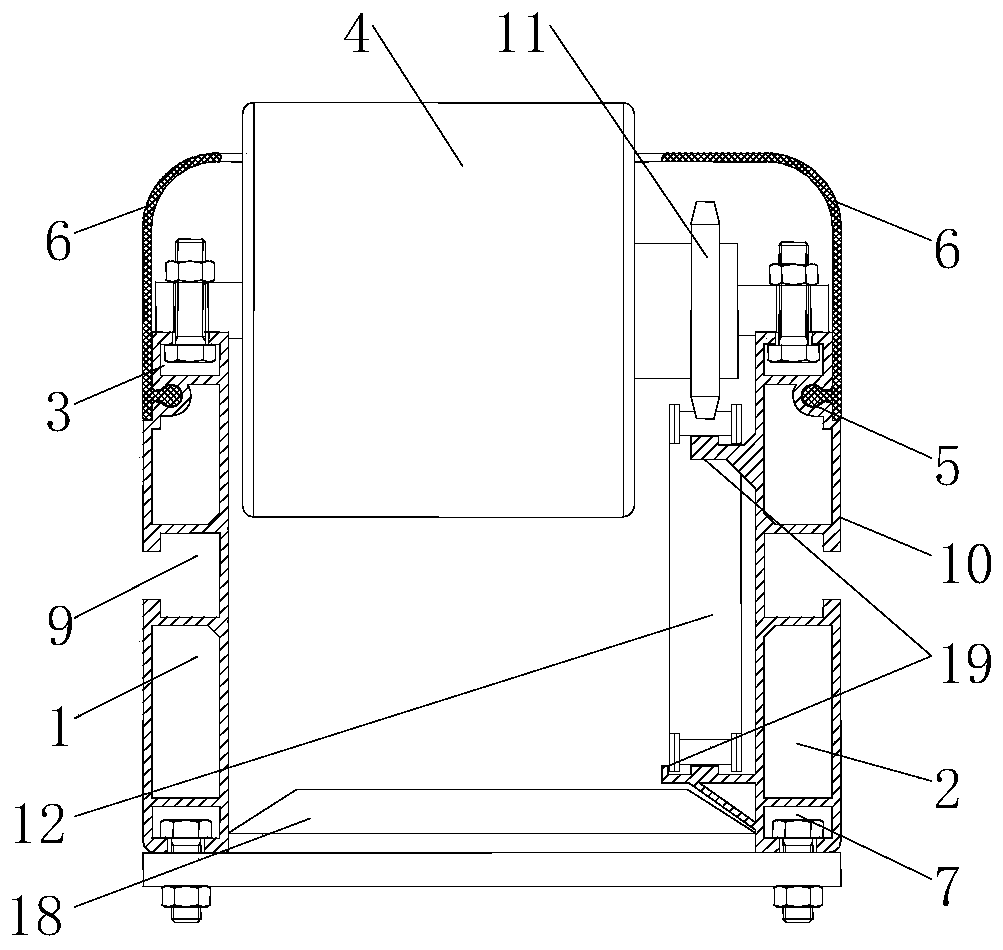

Radial magnetic field motor with amorphous alloy

ActiveCN102545415BInhibition of recrystallizationAvoid stressMagnetic circuit stationary partsMagnetic circuit characterised by magnetic materialsConductor CoilAmorphous metal

The invention discloses a radial magnetic field motor with an amorphous alloy. A stator iron core (2) of the radial magnetic field motor comprises n*Q U-shaped amorphous alloy iron cores (201) which are classified into n groups and stacked with one another axially; Q annularly arranged U-shaped amorphous alloy iron cores (201) are involved in each group; n is more than or equal to 1, and Q is the number of motor slots; each group of Q U-shaped amorphous alloy iron cores (201) are compactly attached in a transverse direction to form an annular stator iron core with a tooth slots; a motor stator slot consists of half-encircled regions (2012) of the U-shaped amorphous iron cores; an armature winding (3) passes through the stator slot; amorphous alloy thin strips are stacked to form an amorphous stacked block (211); and the amorphous stacked block (211) is bent to form each U-shaped amorphous alloy iron core (201). Stator tooth slots are not required to be cut in the motor stator iron core (2), so that the processing difficulty of the amorphous stator iron core is reduced, and a phenomenon that the magnetic performance of an amorphous alloy material is attenuated caused by processing is avoided. Furthermore, the size of the motor stator iron core is not limited by the width of an amorphous alloy strip material, so that a motor is easily enlarged.

Owner:INST OF ELECTRICAL ENG CHINESE ACAD OF SCI

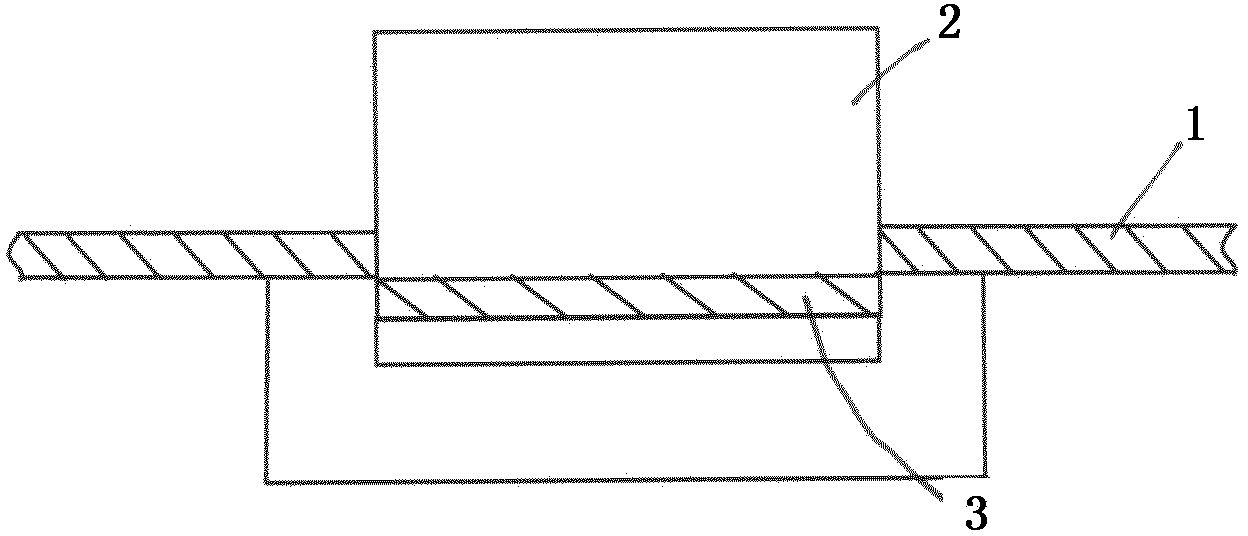

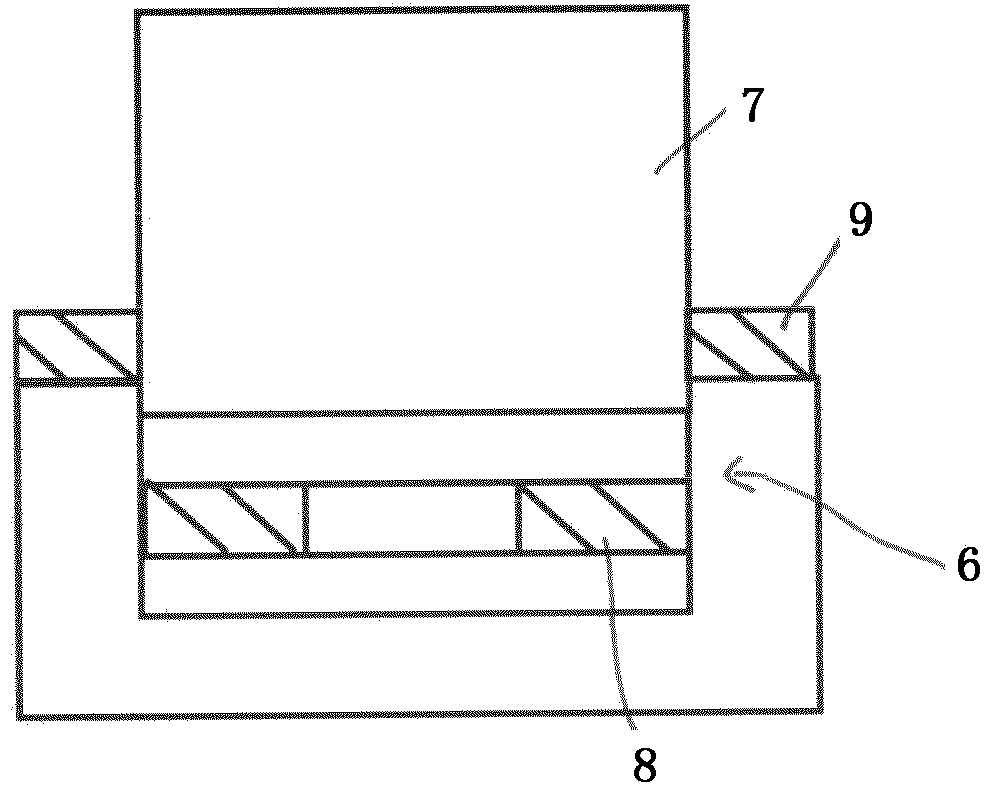

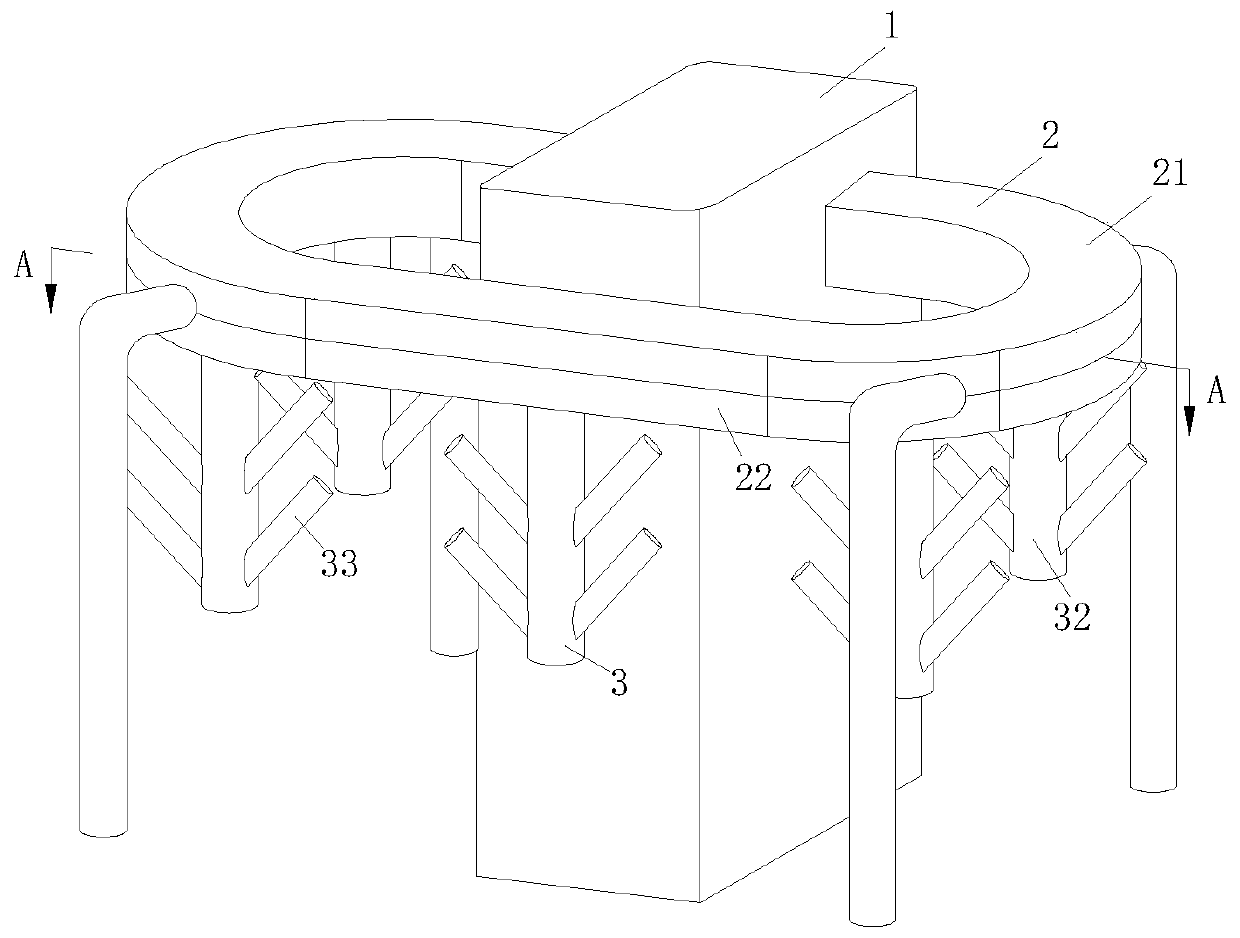

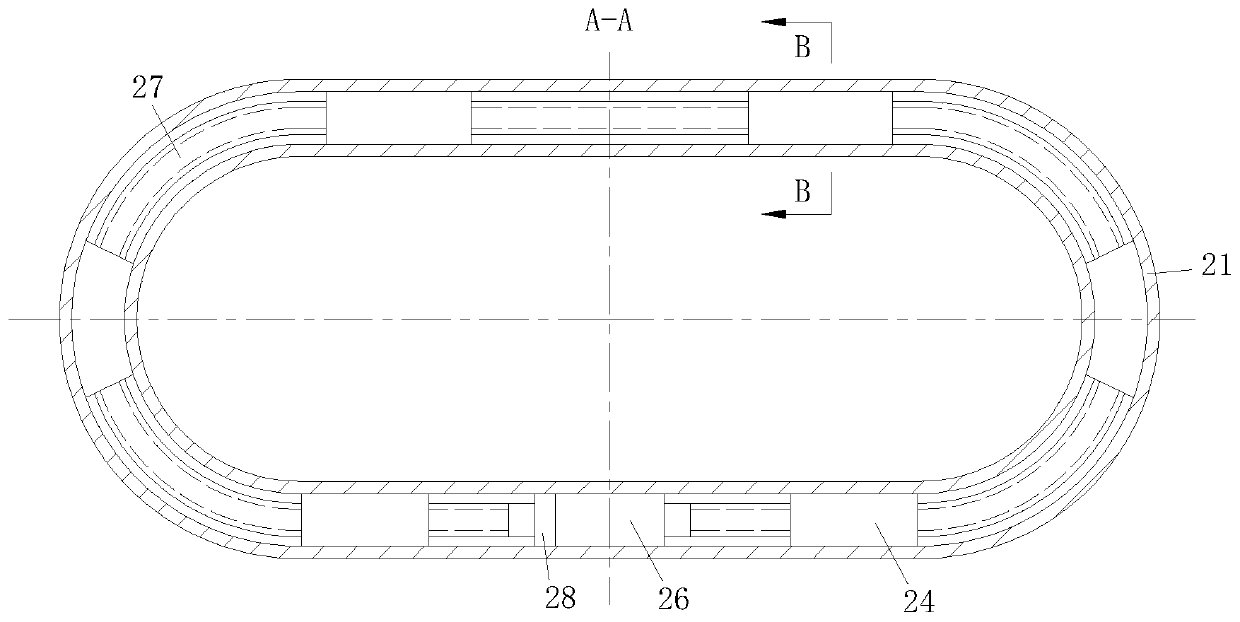

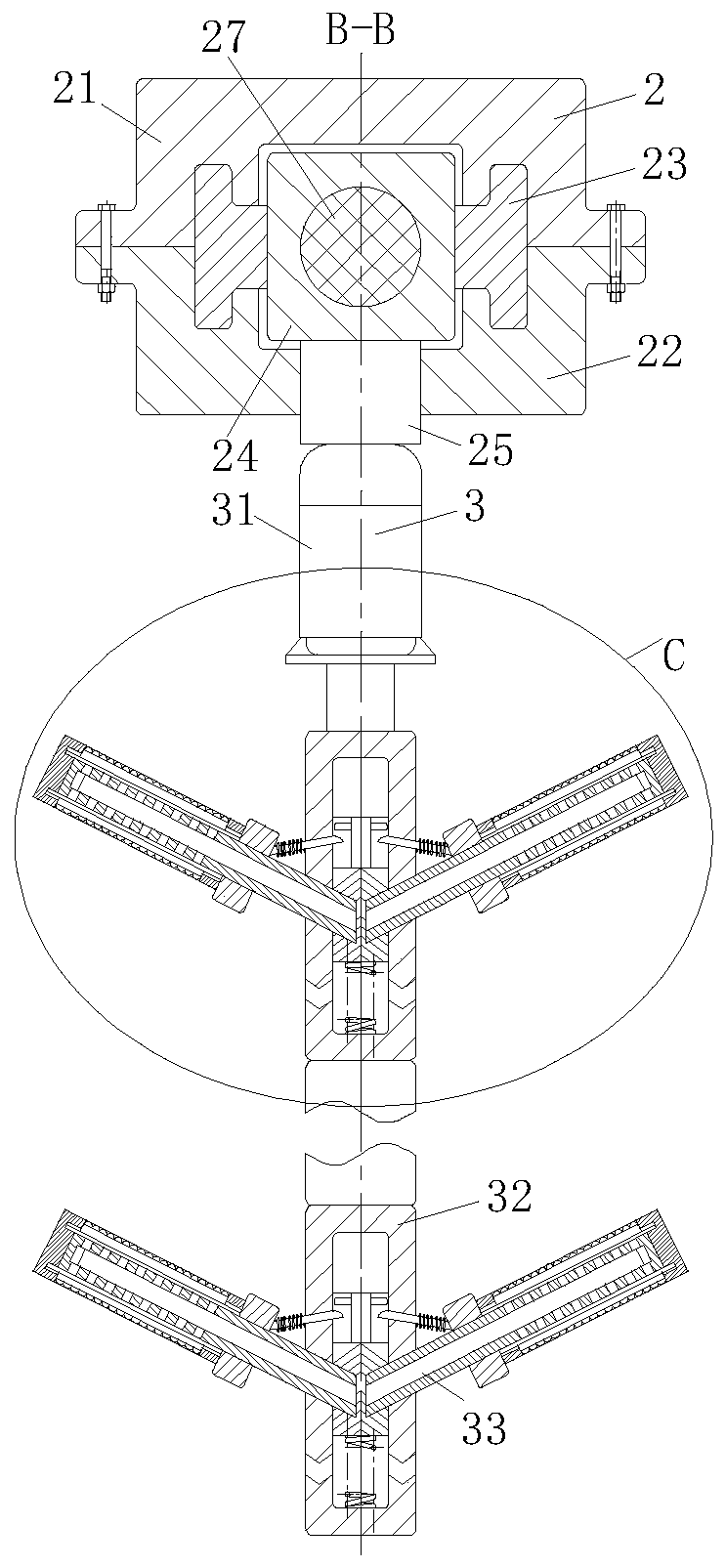

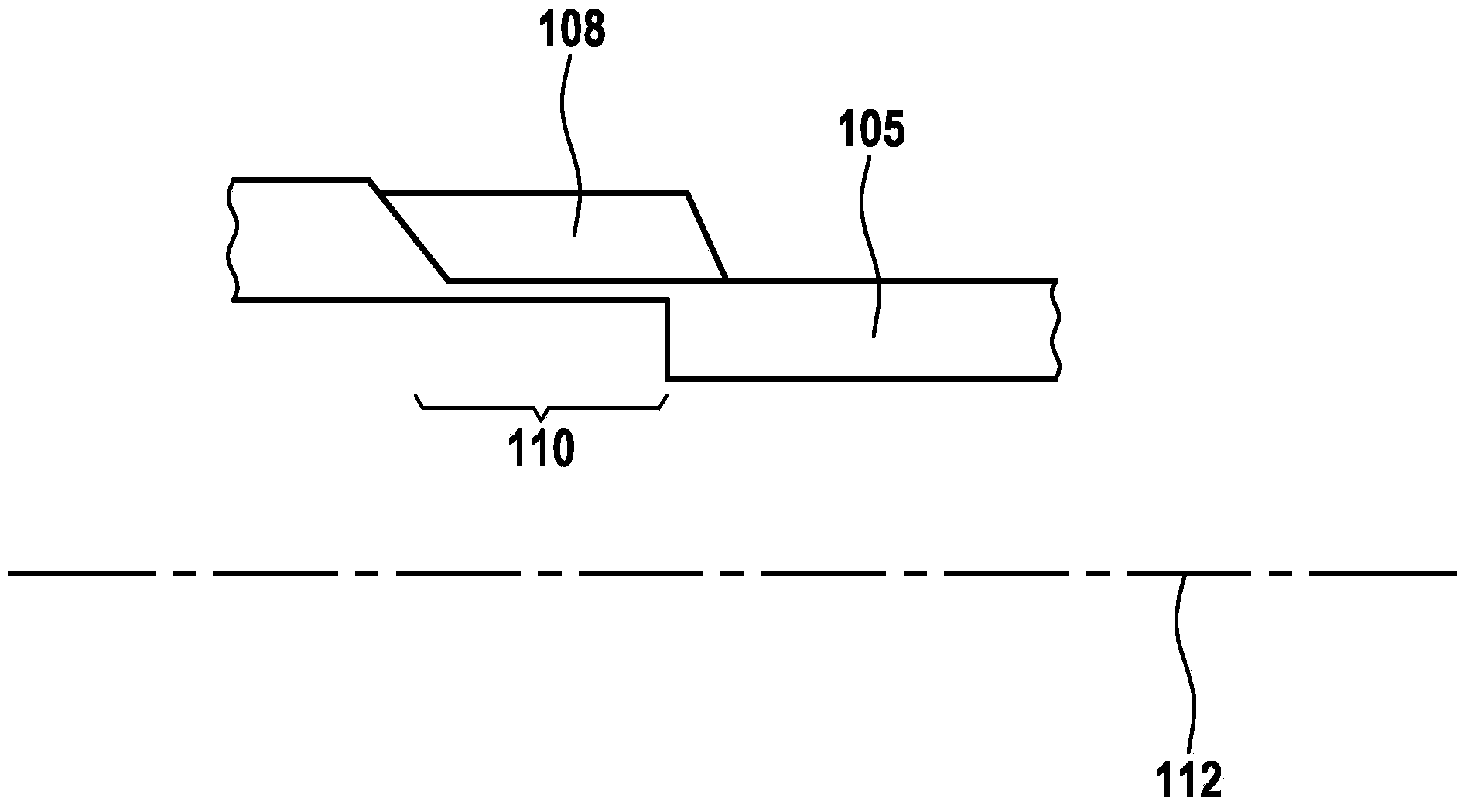

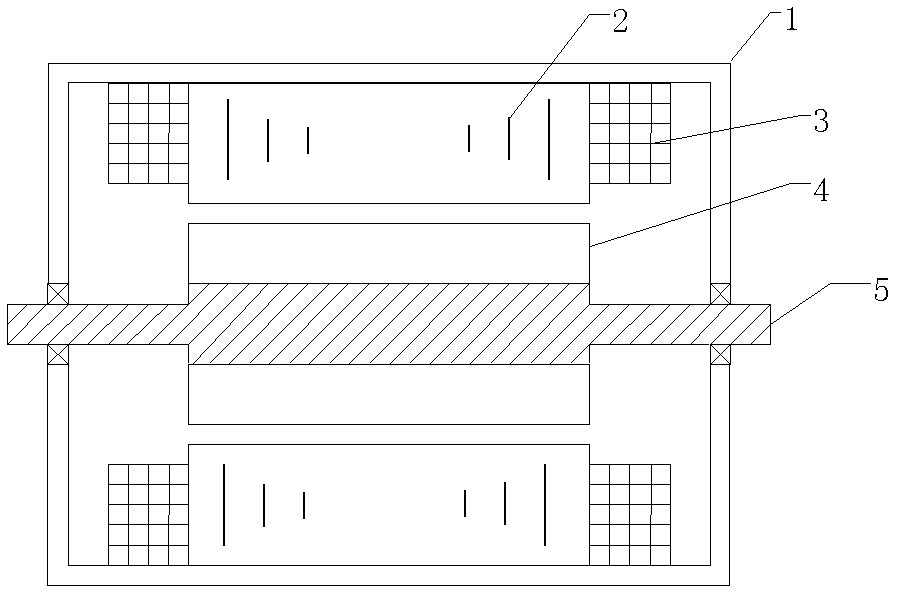

Mattress conveying mechanism easy to disassemble and assemble

ActiveCN111439526AReduce in quantityReduce reprocessingRoller-waysStructural engineeringMechanical engineering

The invention discloses a mattress conveying mechanism easy to disassemble and assemble. The mattress conveying mechanism comprises a mounting assembly which is formed by a left mounting rack (1) anda right mounting rack (2) through mutual connection, wherein multiple rollers (4) are connected to the mounting assembly through first mounting grooves (3), sealing plates (6) are in buckled connection with tops of two sides of the mounting assembly through second mounting grooves (5), a supporting seat (8) is connected to the bottom of the mounting assembly through third mounting grooves (7), andfourth mounting grooves (9) are formed in the middles of the two sides of the mounting assembly; and the left mounting rack (1), the right mounting rack (2) and the sealing plates (6) on the two sides are all aluminum alloy parts which are integrally formed by casting. The mattress conveying mechanism has the characteristics of small equipment weight, low production cost and convenience in assembly.

Owner:浙江宇诗科技有限公司

Features

- R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

Why Patsnap Eureka

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Social media

Patsnap Eureka Blog

Learn More Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com