Hydrostatic actuator

A hydrostatic and actuator technology, applied in the direction of non-mechanical drive clutches, fluid pressure actuators, clutches, etc., can solve the problems of large ring piston diameter, high friction torque, expensive sealing device, etc., to reduce friction , reduce the volume, reduce the effect of the cross-sectional area of the piston

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

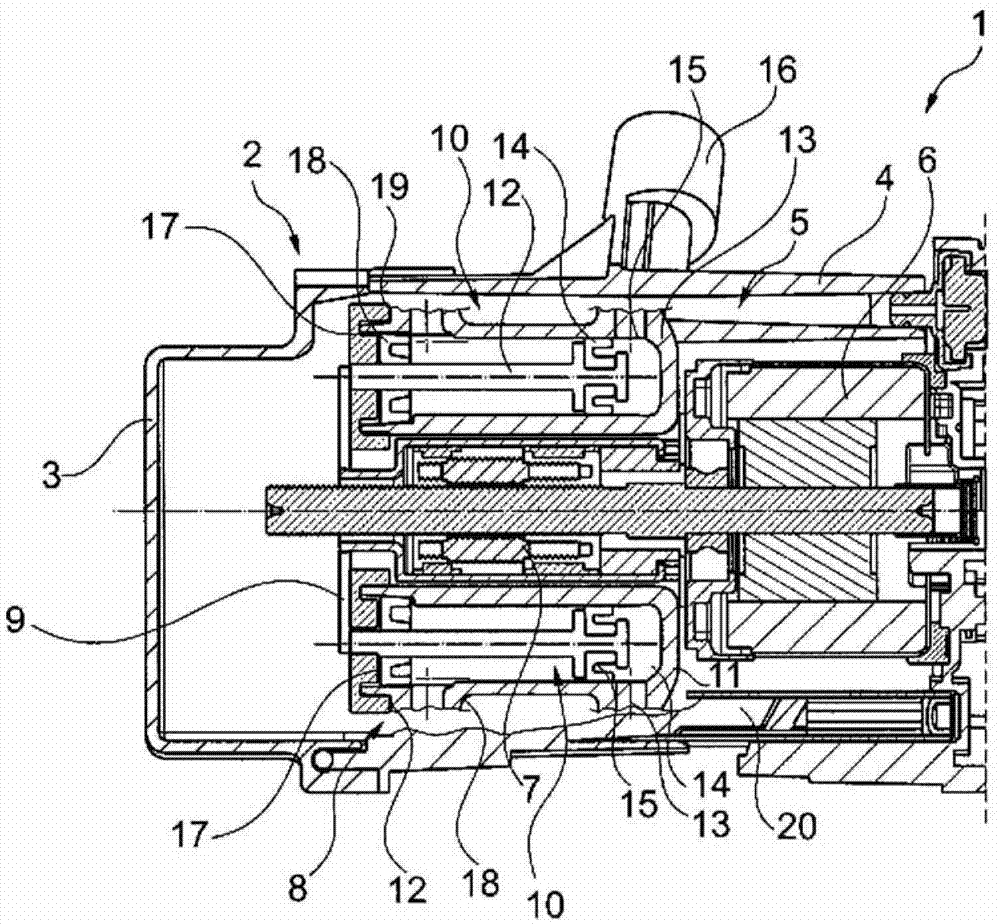

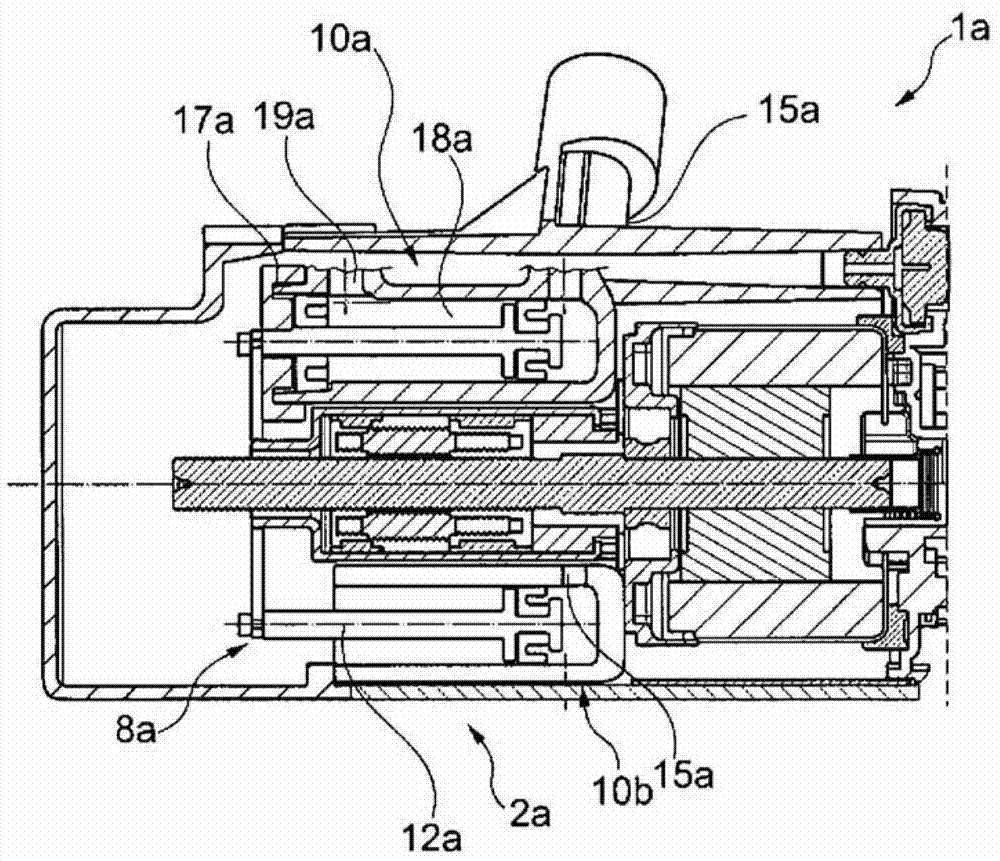

[0014] figure 1 A hydrostatic actuator 1 is shown in section, having a multi-part housing 2 with housing parts 3 , 4 . For the basic structure and function of the hydrostatic actuator 1 reference is made to the prior art mentioned above. The housing part 4 accommodates a drive unit 5 with an electric motor 6 and a planetary roller gear 7 driven by the motor rotor, as well as a master cylinder unit 8 . The housing part 3 serves as a closure cover for the housing part 4 .

[0015] The planetary roller gear 7 converts the rotational movement of the rotor into an axial movement and axially acts on the master cylinder unit 8 . For this purpose, a drive plate 9 is provided on the planetary roller gear 7 .

[0016] The master cylinder unit 8 is composed of master cylinders 10 , preferably evenly distributed over the circumference, which each have a master cylinder housing 11 and a piston 12 axially displaceable therein. The master cylinders are constructed as a separate structura...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com