Mattress conveying mechanism easy to disassemble and assemble

A conveying mechanism, easy disassembly technology, applied in the directions of transportation, packaging, roller table, etc., can solve the increase of the overall weight and production cost of the roller conveyor, reduce the processing difficulty and assembly efficiency of the conveyor roller table, and reduce the processing efficiency of the roller conveyor. and other problems, to achieve the effect of reducing the cost and weight of raw materials, reducing the overall weight of the mechanism, and reducing the number of assemblies

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

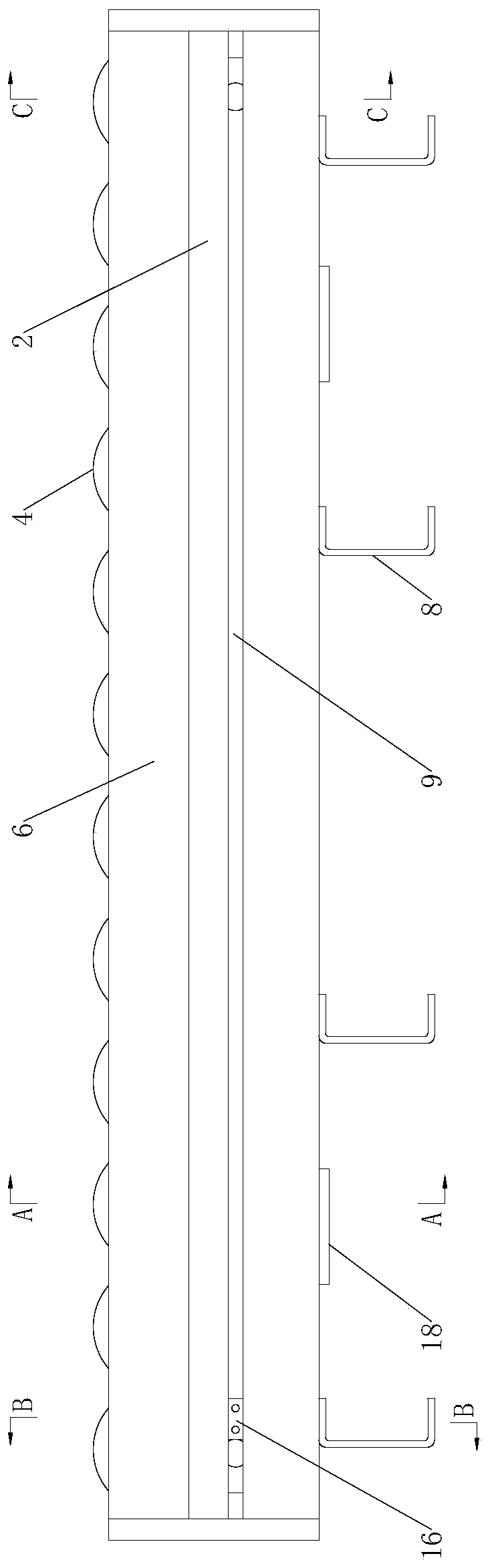

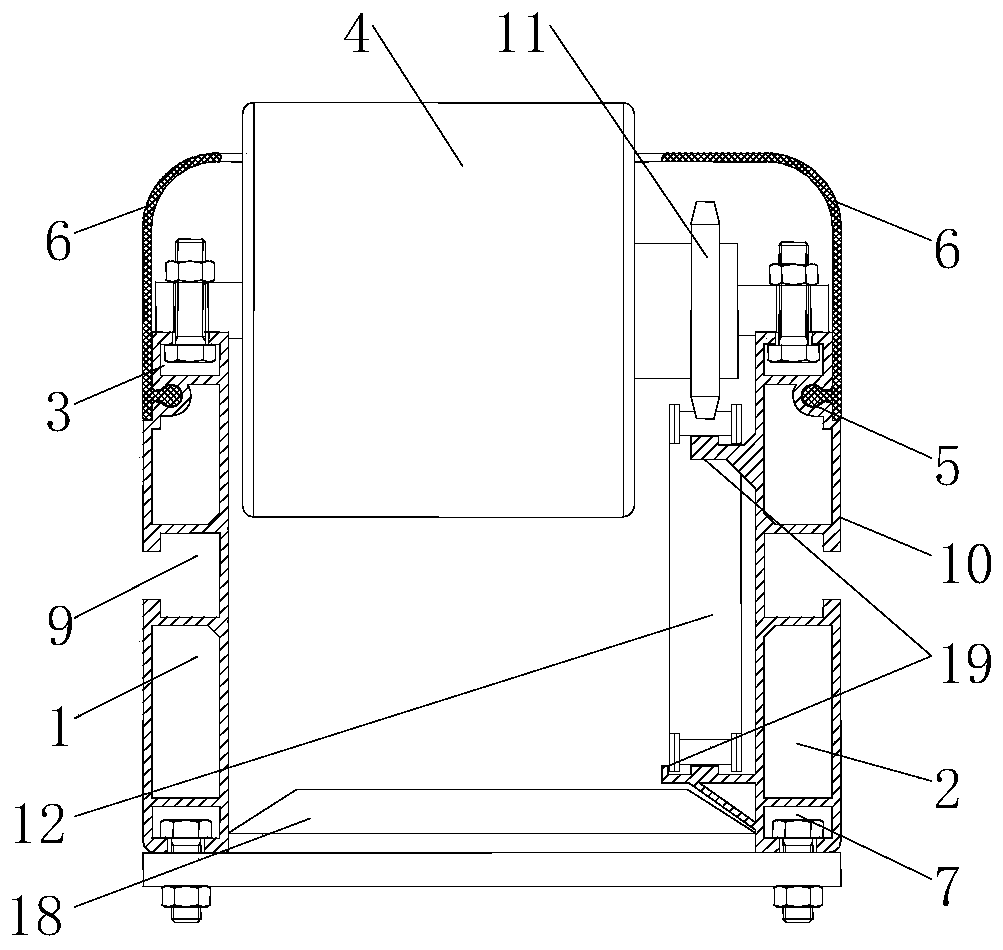

[0032] Example 1. A driving type easy-to-detachable mattress conveying mechanism, which is composed of Figure 1-4 As shown, it includes a mounting assembly formed by connecting the left mounting frame 1 and the right mounting frame 2. The mounting assembly is connected with a plurality of rollers 4 through the first mounting groove 3, and the plurality of rollers 4 are arranged at intervals along the length direction. On the installation assembly, the top of both sides of the installation assembly is fastened with the sealing plate 6 through the second installation groove 5, the bottom of the installation assembly is connected with the support seat 8 through the third installation groove 7, and the middle part of the two sides of the installation assembly is provided with a fourth installation Groove 9, the first installation groove 3, the second installation groove 5, the third installation groove 7 and the fourth installation groove 9 are all symmetrically arranged on the l...

Embodiment 2

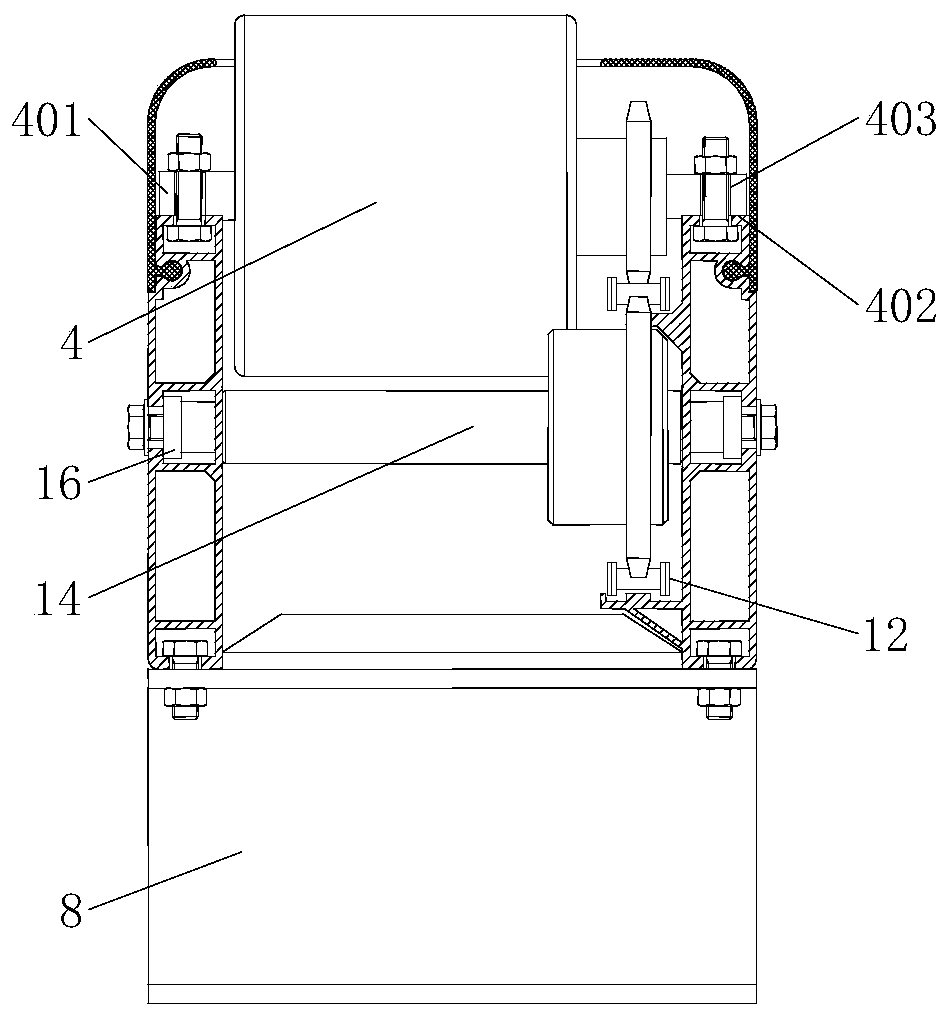

[0046] Example 2. A driven and easily disassembled mattress conveying mechanism, which is composed of Figure 5 As shown, it includes a mounting assembly formed by connecting the left mounting frame 1 and the right mounting frame 2. The mounting assembly is connected with a plurality of rollers 4 through the first mounting groove 3, and the plurality of rollers 4 are arranged at intervals along the length direction. On the installation assembly, the top of both sides of the installation assembly is fastened with the sealing plate 6 through the second installation groove 5, the bottom of the installation assembly is connected with the support seat 8 through the third installation groove 7, and the middle part of the two sides of the installation assembly is provided with a fourth installation Groove 9, the first installation groove 3, the second installation groove 5, the third installation groove 7 and the fourth installation groove 9 are all symmetrically arranged on the left...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com