Patents

Literature

53results about "Non-mechanical actuated clutches" patented technology

Efficacy Topic

Property

Owner

Technical Advancement

Application Domain

Technology Topic

Technology Field Word

Patent Country/Region

Patent Type

Patent Status

Application Year

Inventor

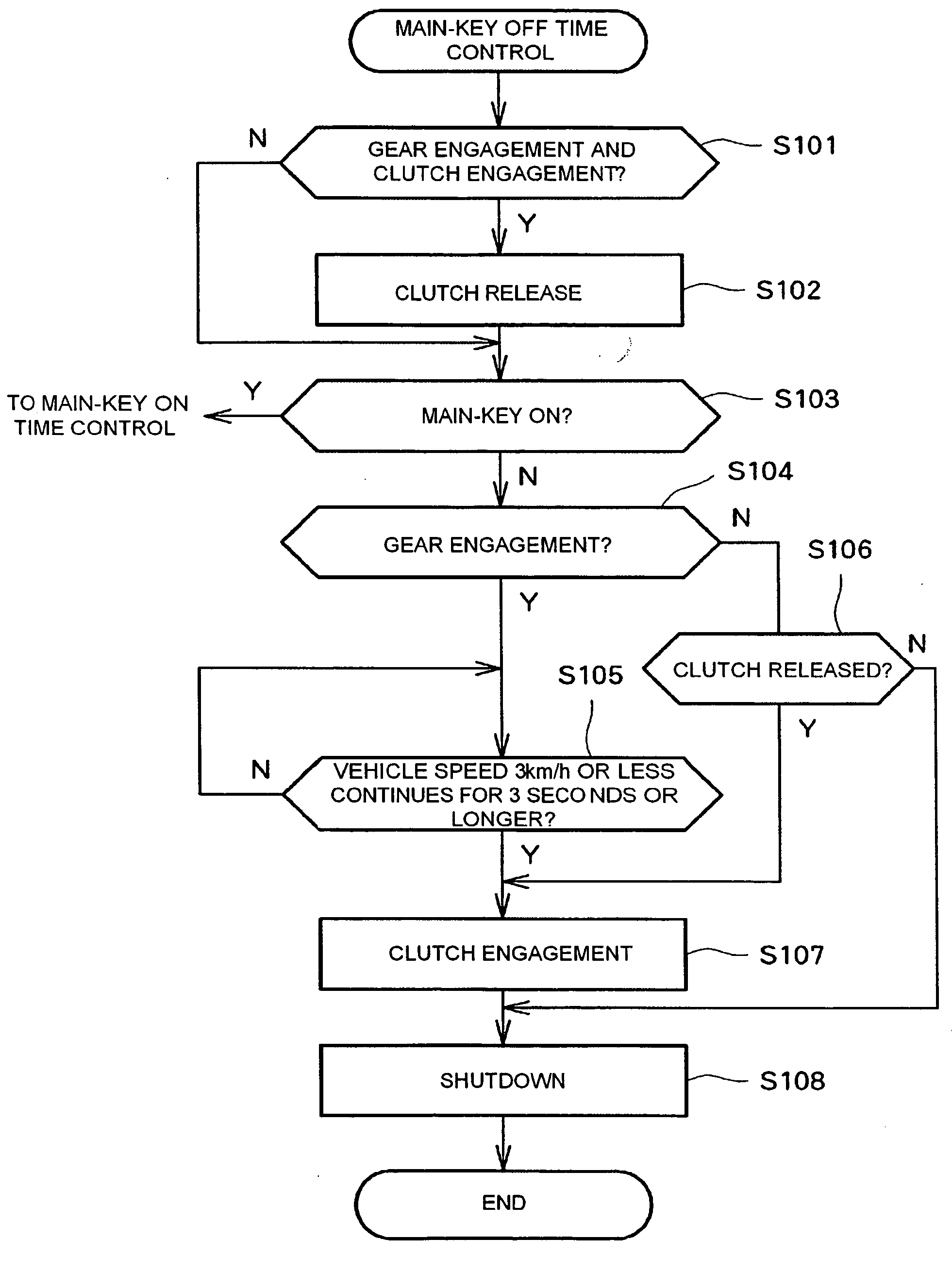

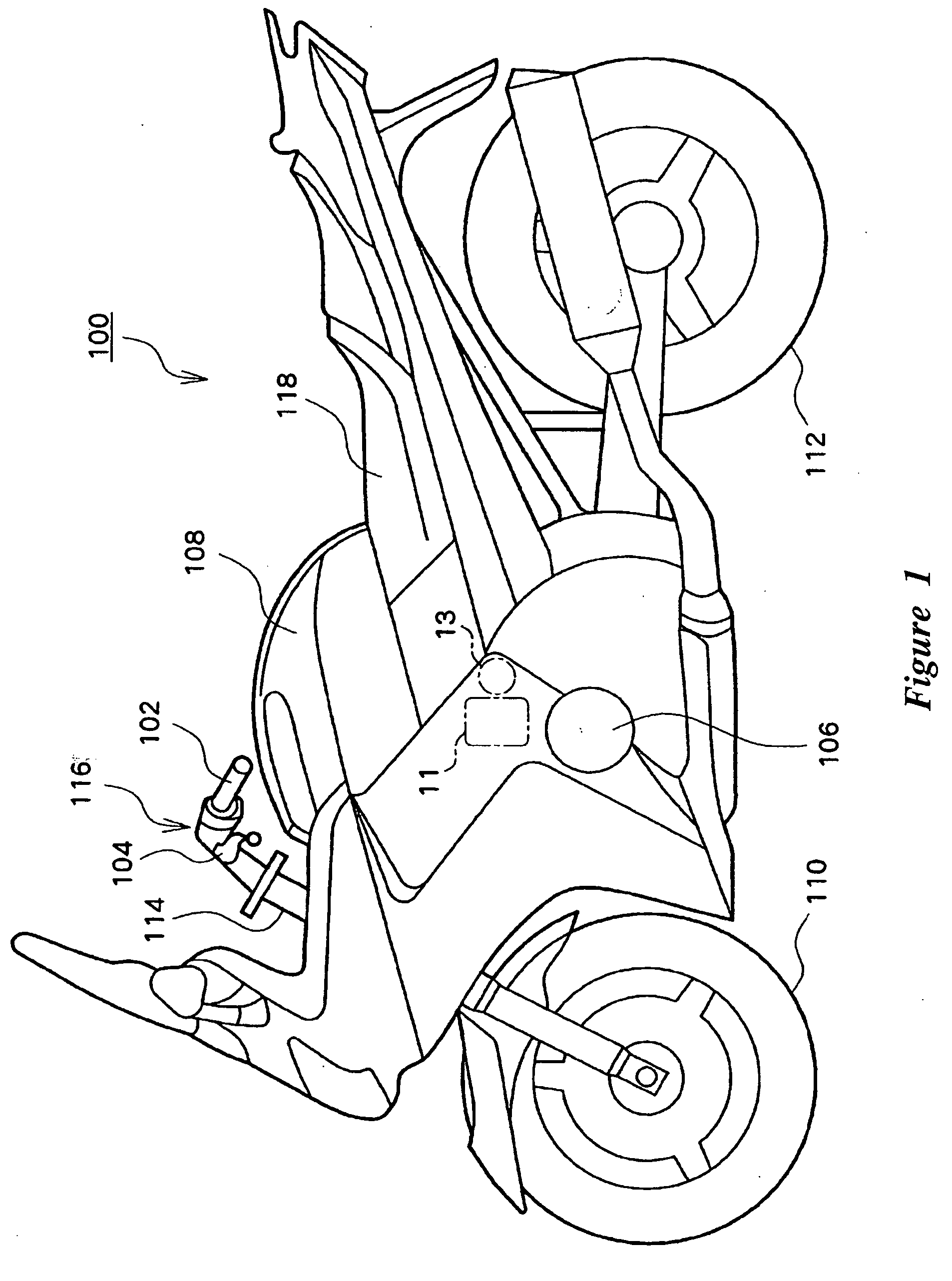

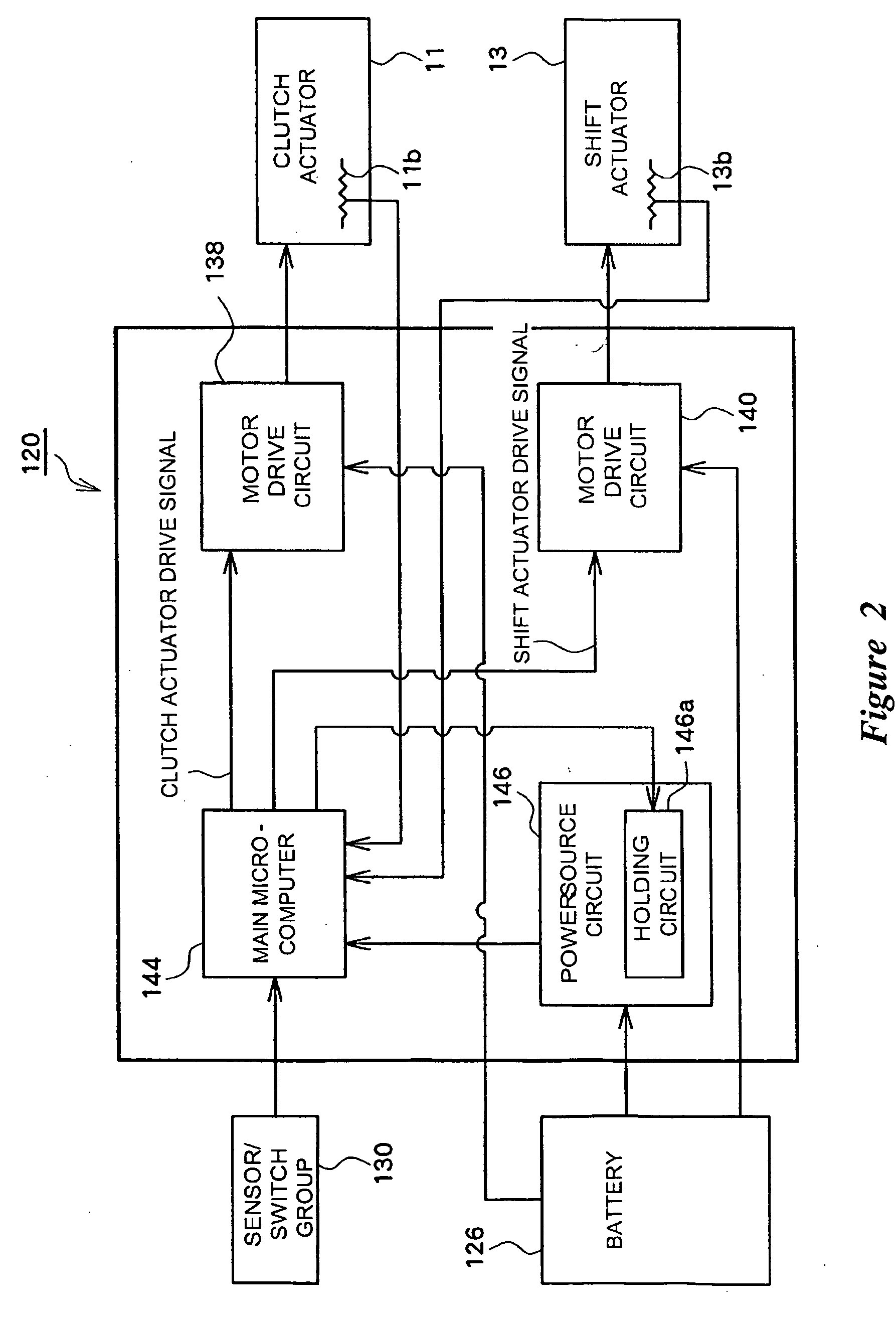

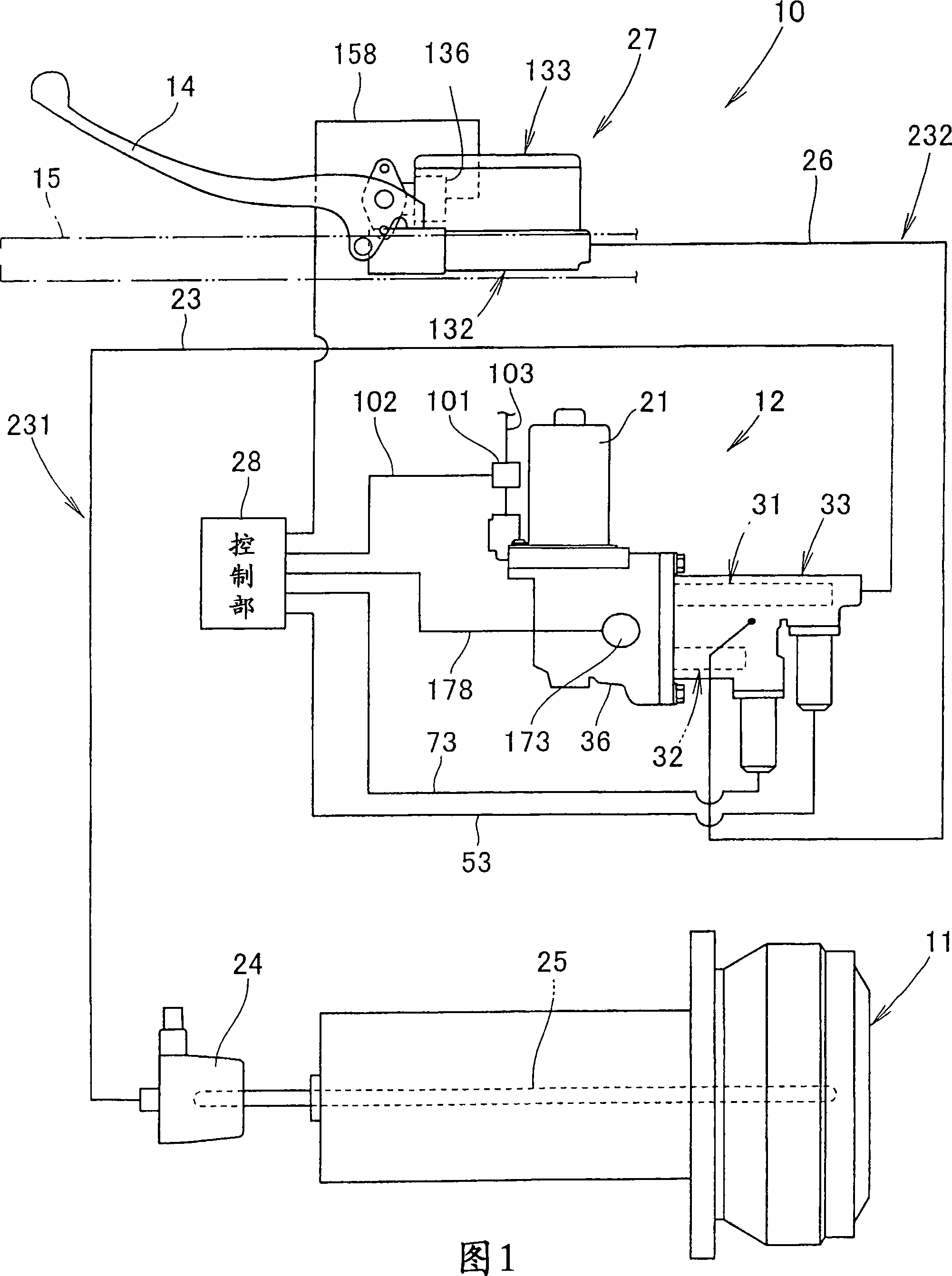

Straddle-type vehicle having clutch control device and method of using clutch control device

A clutch control device is used to engage and disengage a clutch of a straddle-type vehicle. A method of using the device comprises detecting a predetermined operation, such as positioning a key switch in an ON position, for starting use of the straddle-type vehicle, detecting application of a brake of the straddle-type vehicle, and actuating clutch control means that disconnects the clutch upon detection of application of the brake if the predetermined operation for starting use is detected.

Owner:YAMAHA MOTOR CO LTD

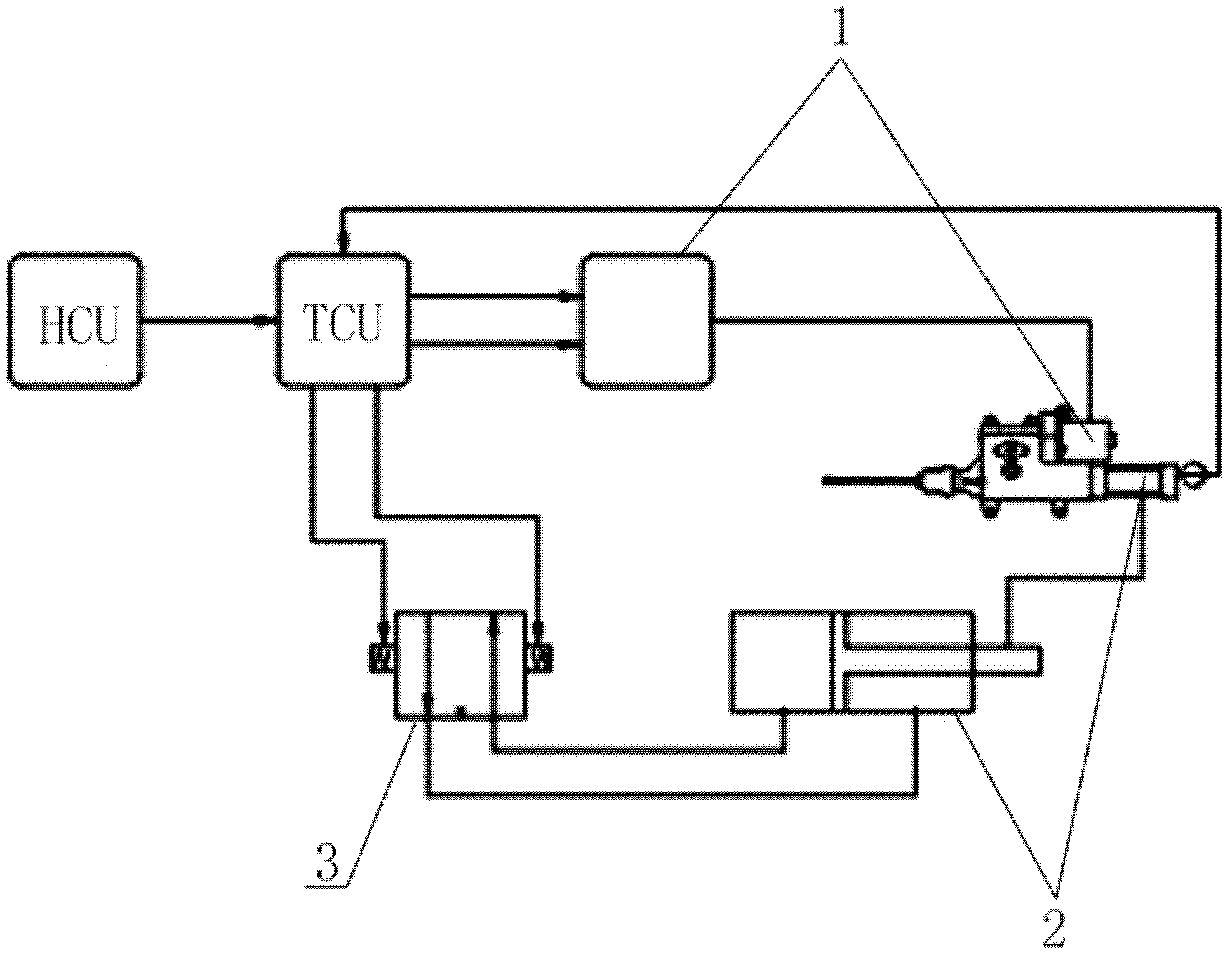

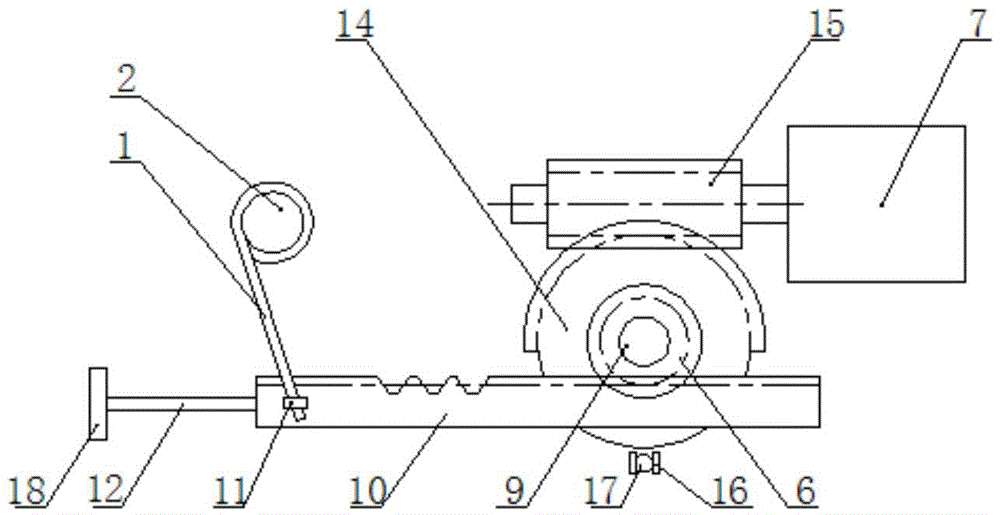

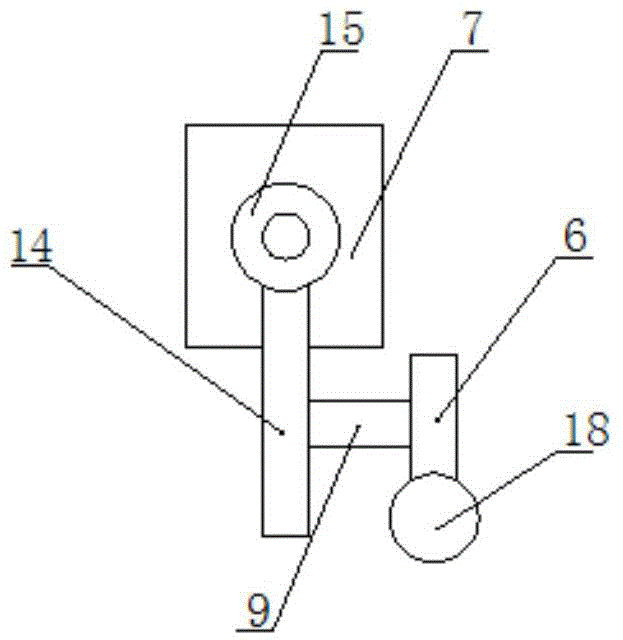

Automatic clutch actuating mechanism and control method thereof

InactiveCN102619899AStable and efficient workImprove stabilityNon-mechanical actuated clutchesSolenoid valveEngineering

The invention discloses an automatic clutch actuating mechanism. The automatic clutch actuating mechanism comprises a motor, a pulling rod and a actuating mechanism controller as well as a cylinder controlled by an electromagnetic valve, wherein the motor is connected with the pulling rod through a transmission part in a transmission way; the piston rod of the cylinder is connected with the pulling rod in a transmission way; the control ends of the motor and the electromagnetic valve are both connected to the actuating mechanism controller; and the actuating mechanism controller is used for controlling the motor and the cylinder to synchronously or independently run. According to the automatic clutch actuating mechanism, the cylinder is configured on the basis of an electric actuating mechanism to serve as an auxiliary element, so that the automatic clutch actuating mechanism can be driven by both the motor and the cylinder or also can be independently driven by the motor or the cylinder, so as to work stably and effectively for long time. The invention further discloses a control method for controlling the automatic clutch actuating mechanism.

Owner:WEICHAI POWER CO LTD

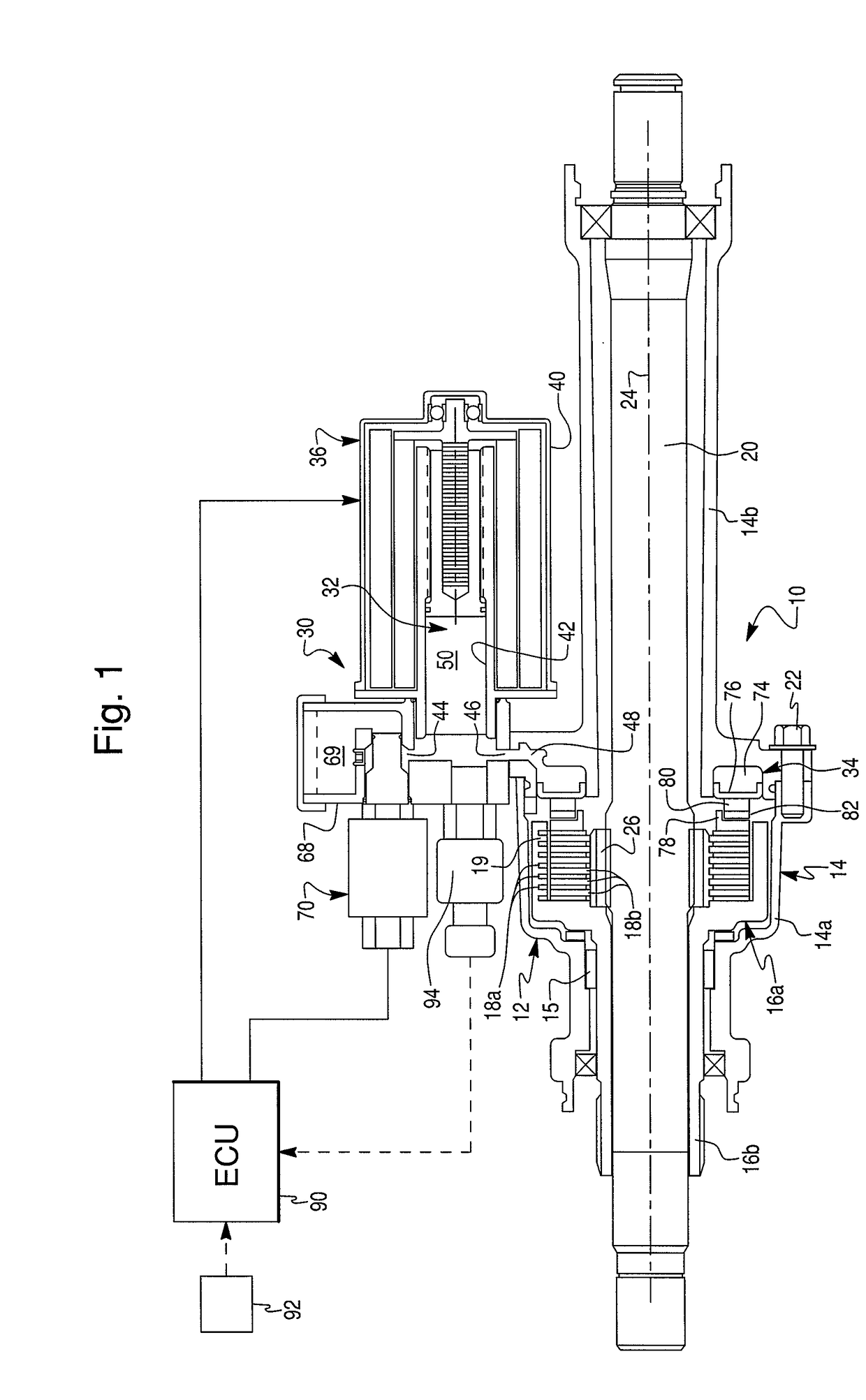

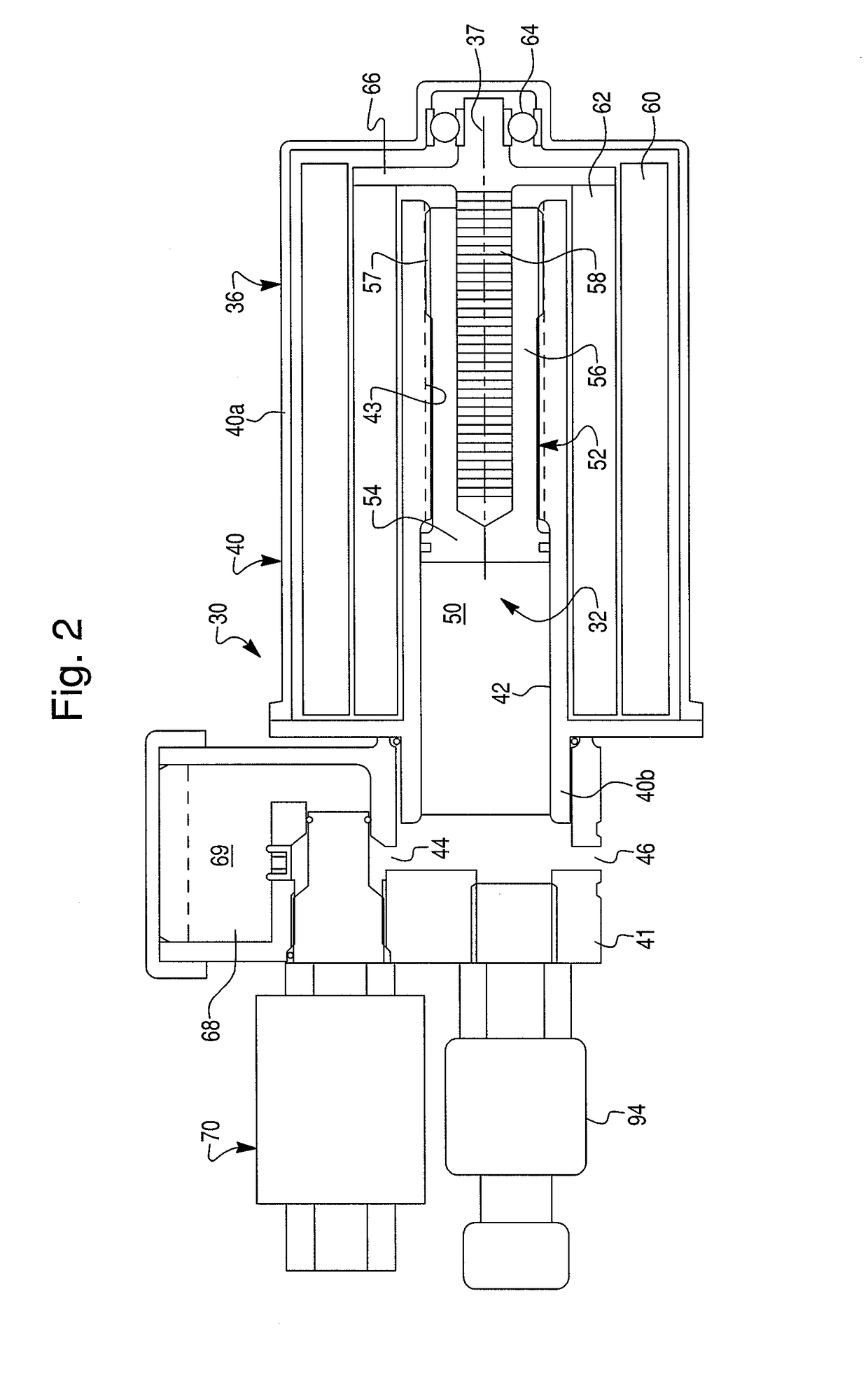

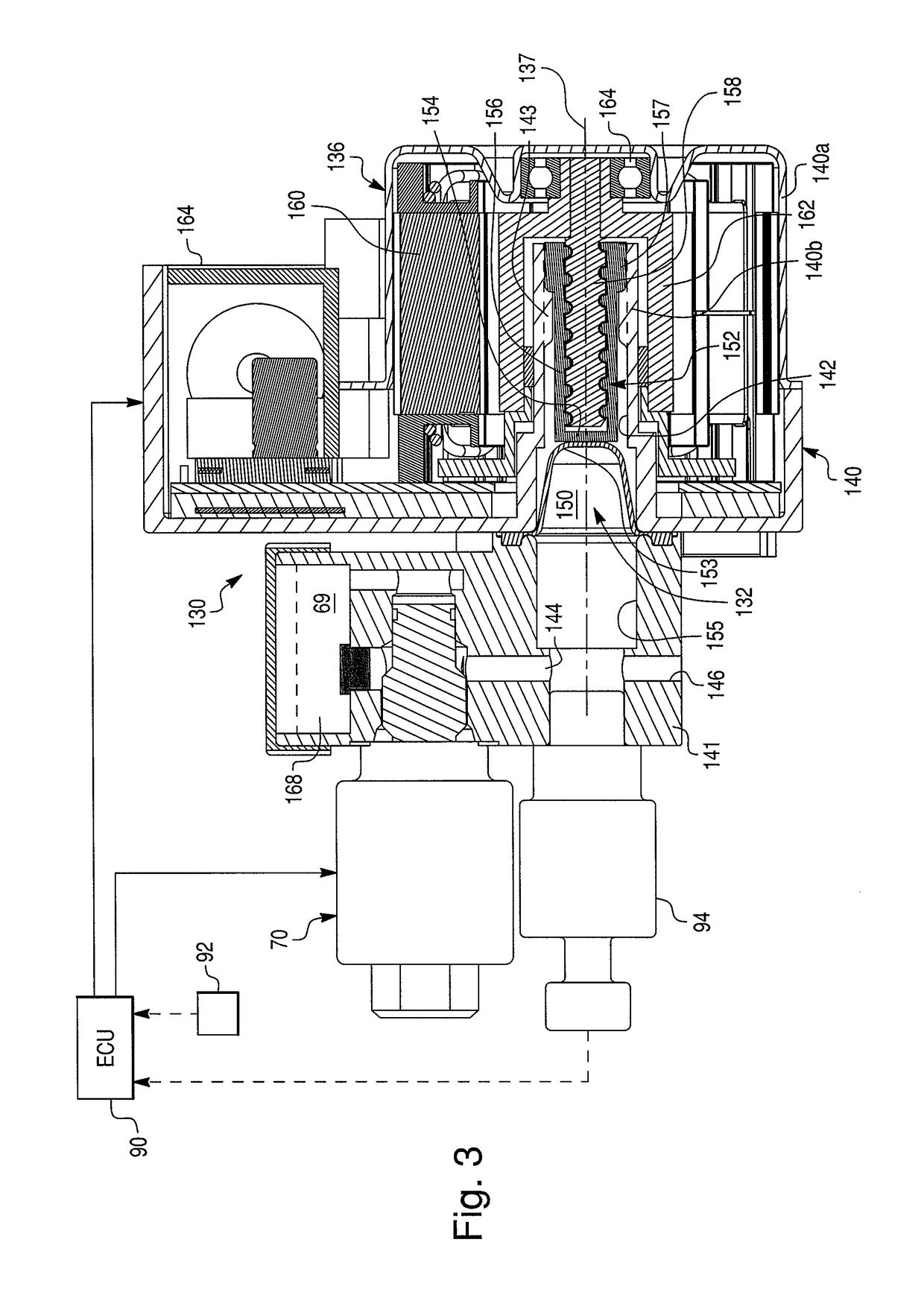

Actuator assembly

An actuator assembly for generating a fluid pressure and applying the fluid pressure to a first device. The actuator assembly comprises a first fluid chamber and a first piston disposed adjacent to the first fluid chamber, a second fluid chamber and a second piston slidably received in the second fluid chamber, a fluid passage connecting the first fluid chamber with the second fluid chamber, and an actuator motor for selectively reciprocating the first piston so that axial movement of the first piston generates a fluid pressure within the first fluid chamber. The first piston is disposed within the actuator motor. As the first chamber is fluidly communicating with the second fluid chamber, the linear motion of the first piston causes corresponding linear motion of the second piston for applying the fluid pressure to the first device.

Owner:DANA AUTOMOTIVE SYST GRP LLC

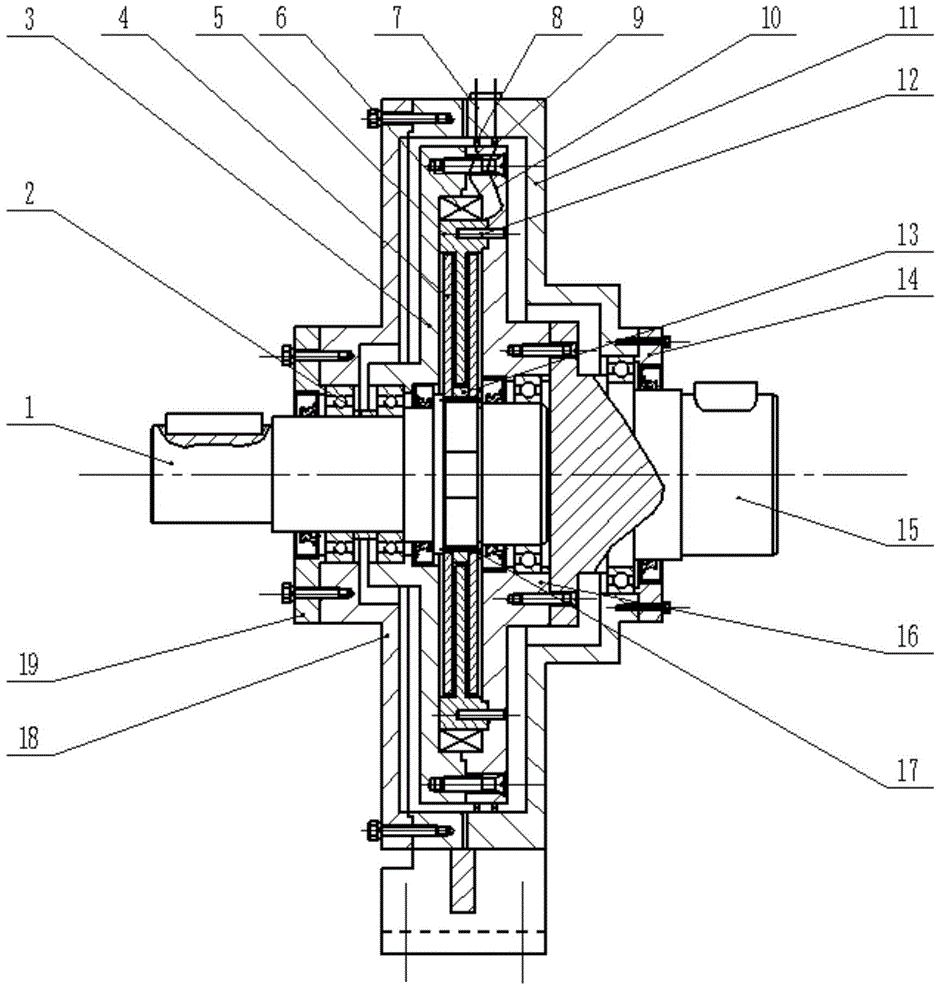

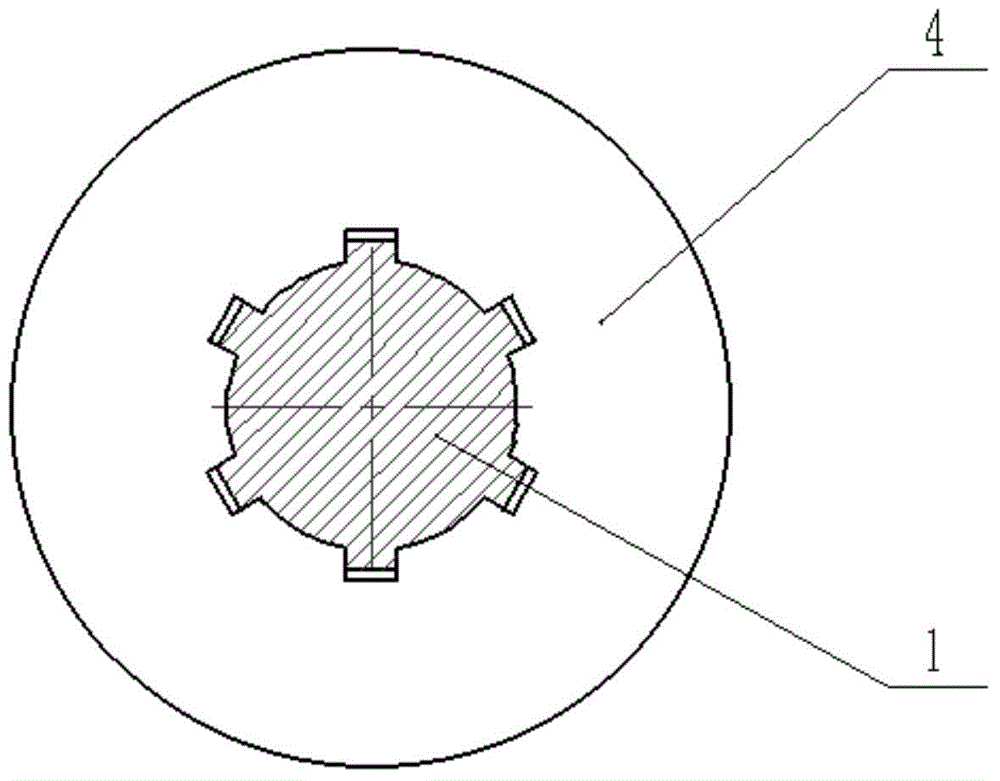

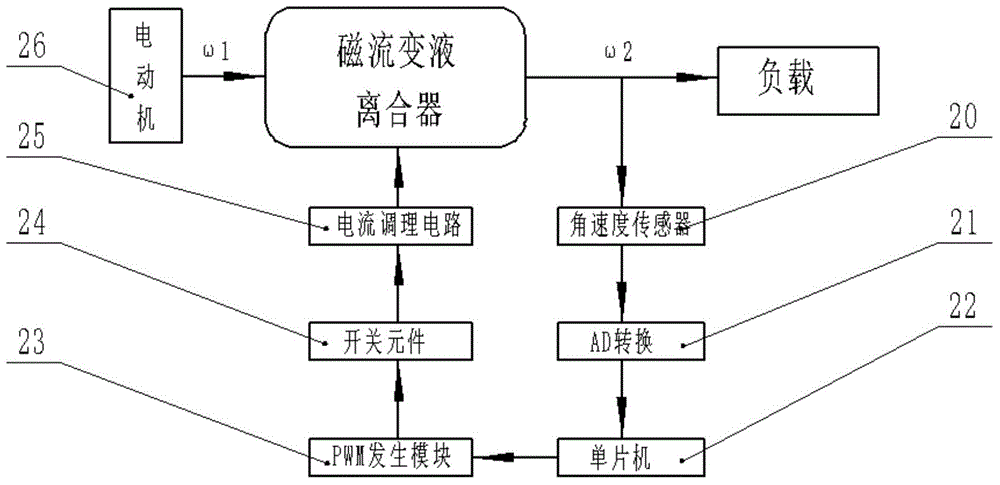

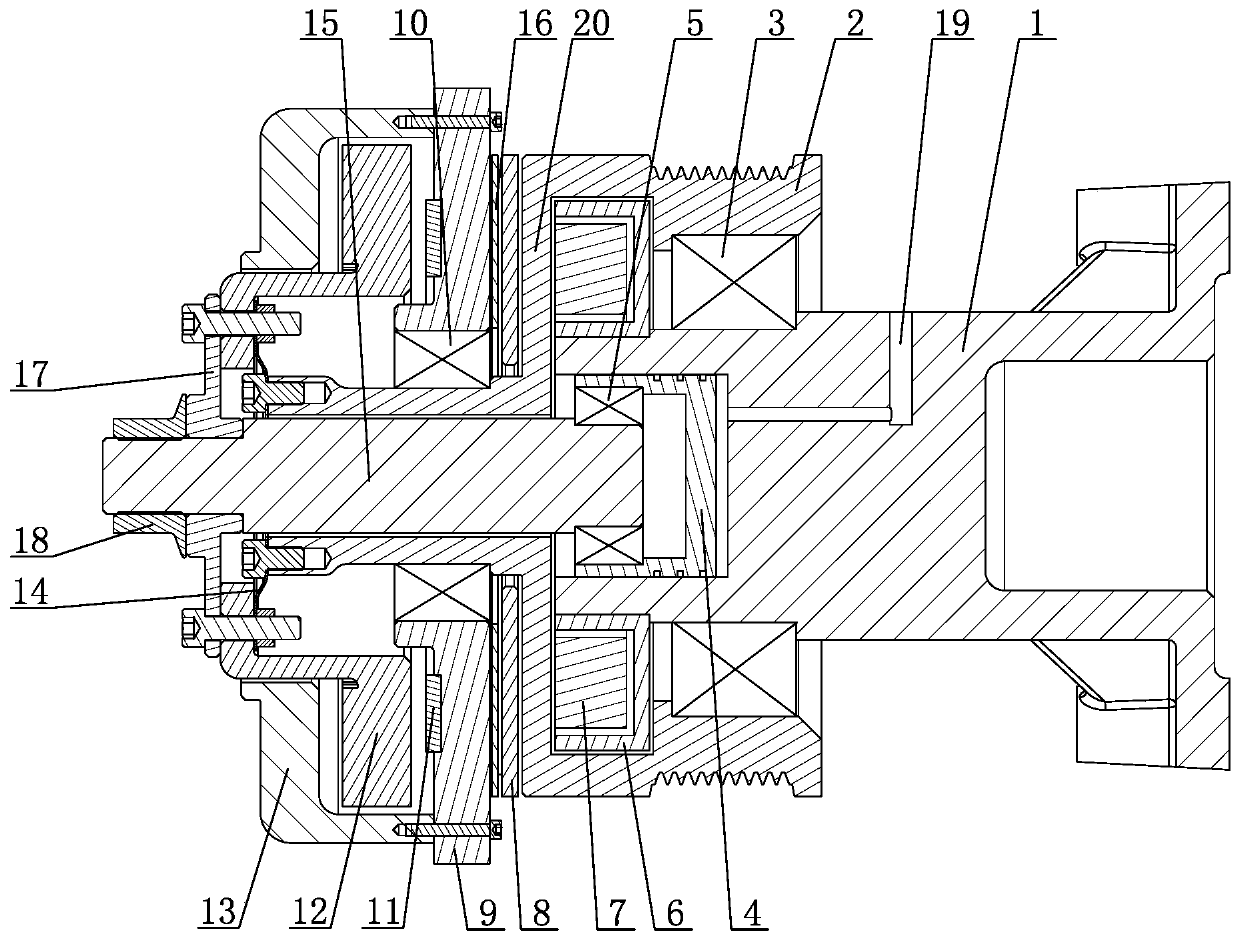

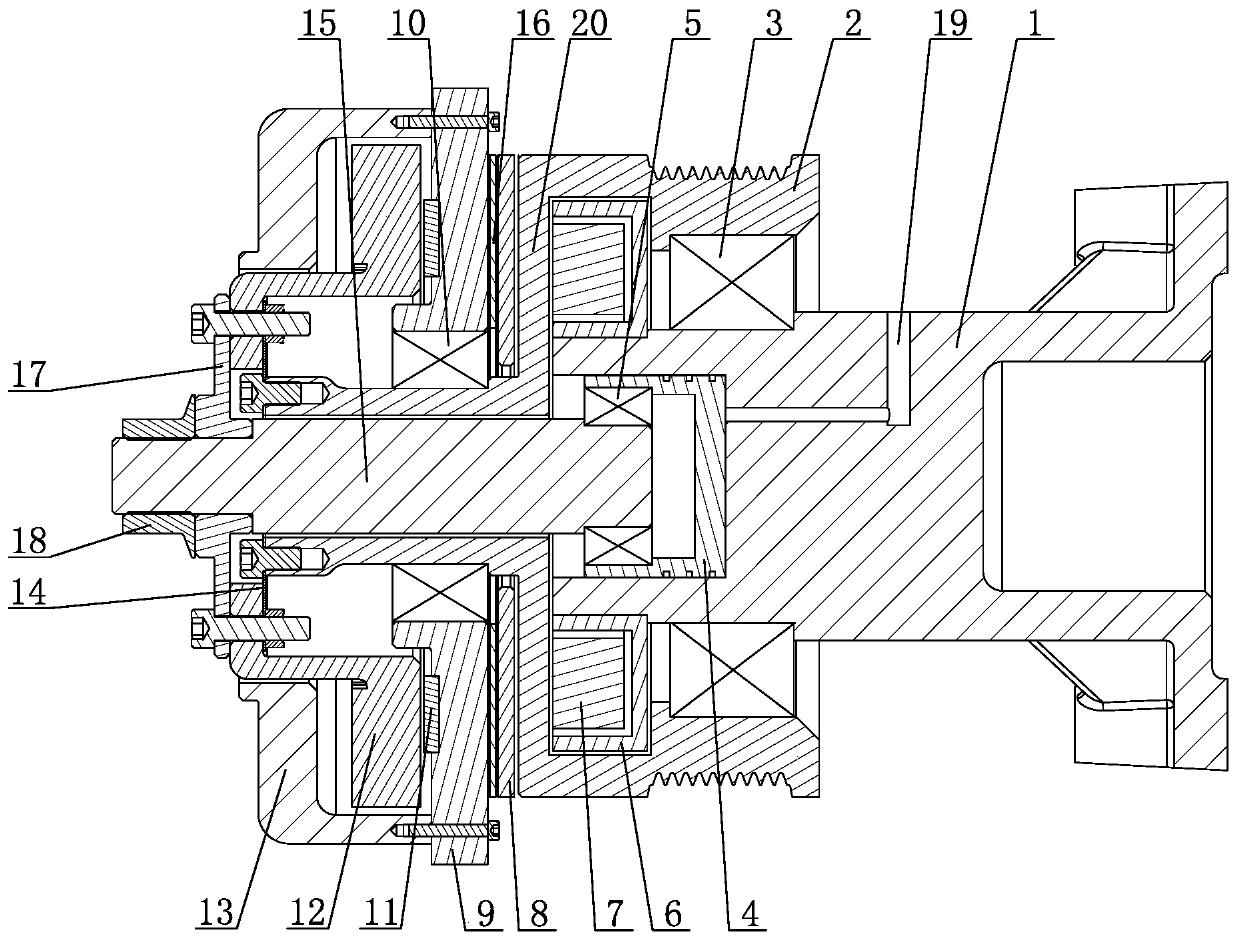

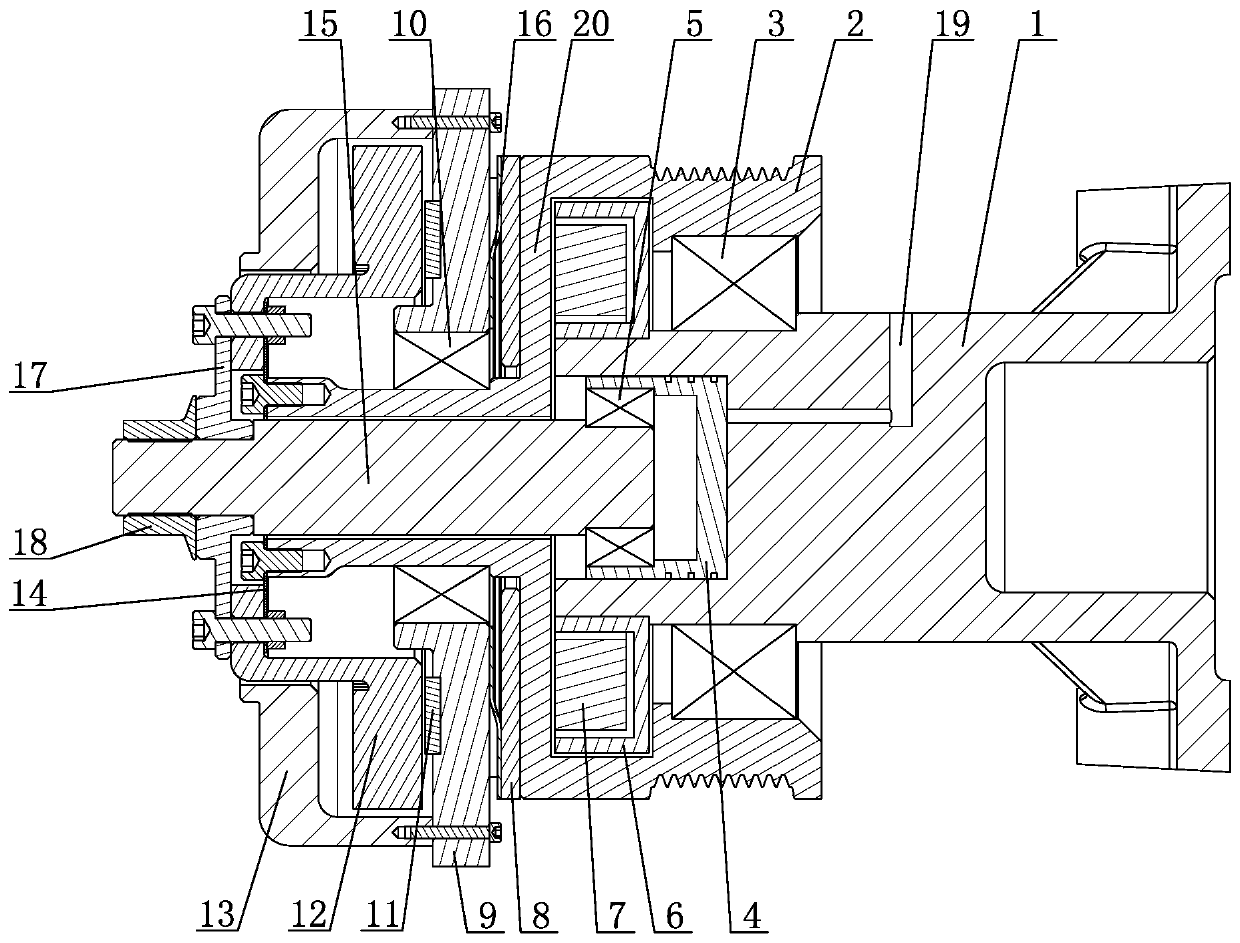

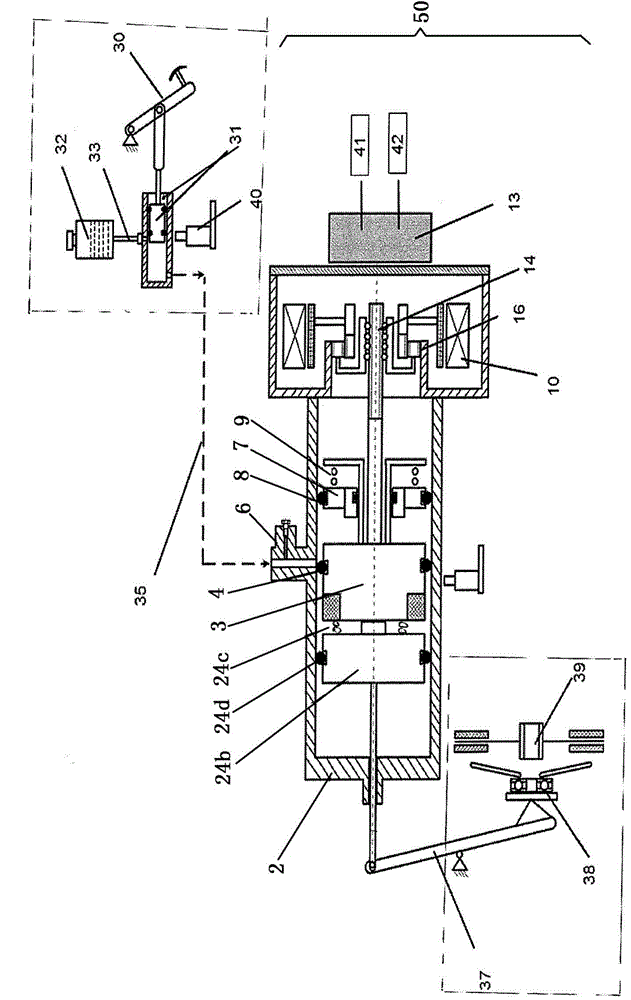

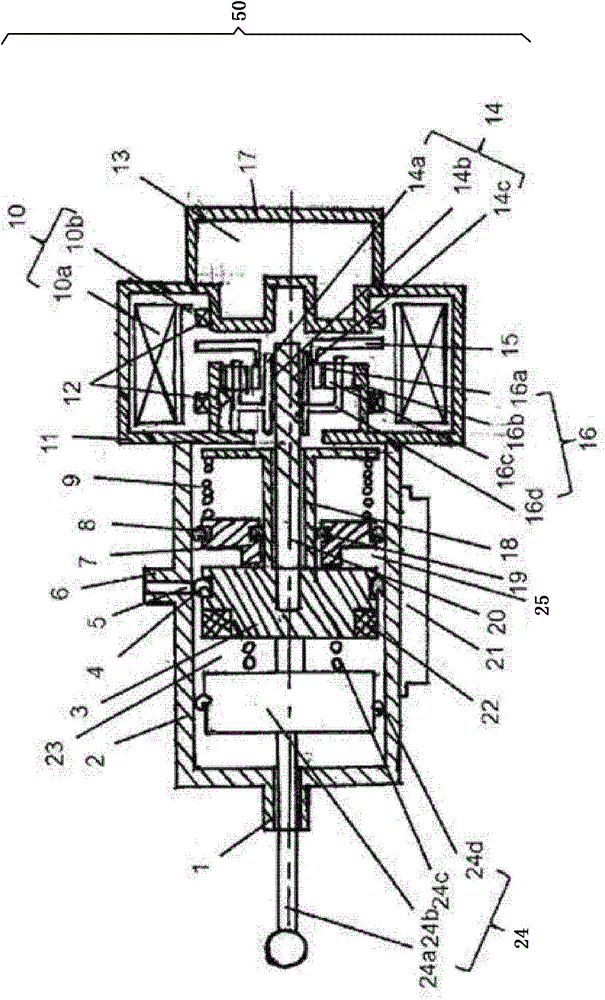

Multi-piece magnetorheological fluid electromagnetic clutch

InactiveCN103603891ACompact structureEasy to install and adjustNon-mechanical actuated clutchesPower flowAutomatic control

The invention discloses a multi-piece magnetorheological fluid electromagnetic clutch which is in a multi-piece structure. A plurality of gaps between drive and driven friction plates are filled with magnetorheological fluid serving as medium, a plurality of magnetorheological fluid operating ring surfaces are formed, magnetic field intensity of the gaps is high, distribution of the gaps is reasonable, high torque can be transmitted, high transmission power can be controlled with low excitation current, automatic control is easy to implement, and engaging and disengaging can be stabilized. Input and output shafts, both provided with end bearings, and a housing form a whole installed inside a frame. The multi-piece magnetorheological fluid electromagnetic clutch is compact in structure, high in rigidity, convenient to mount and maintain, simple in structure, high in reliability, stable in transmission, and applicable to various small- and medium-sized automatic devices and servo drivers.

Owner:NANJING UNIV OF SCI & TECH

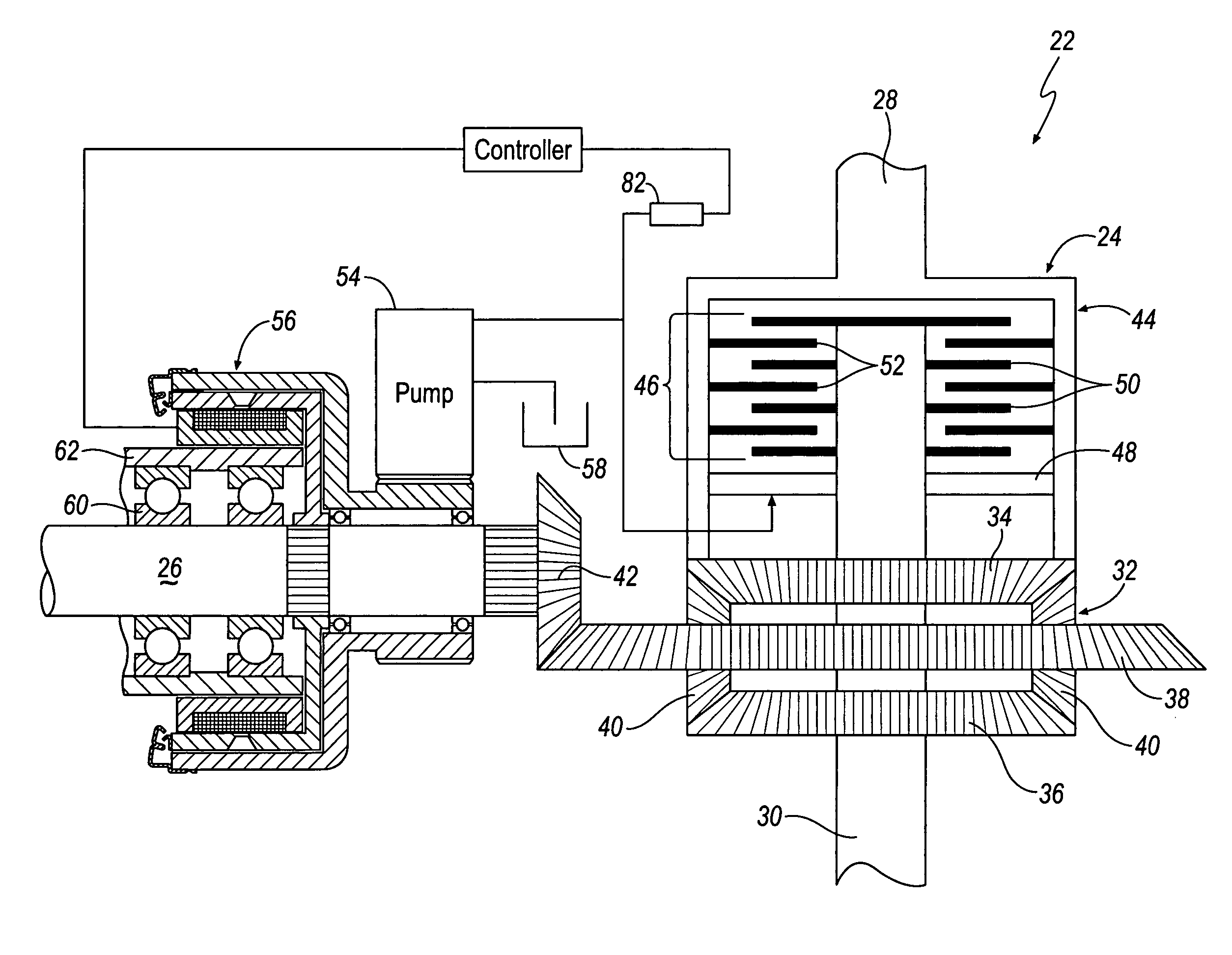

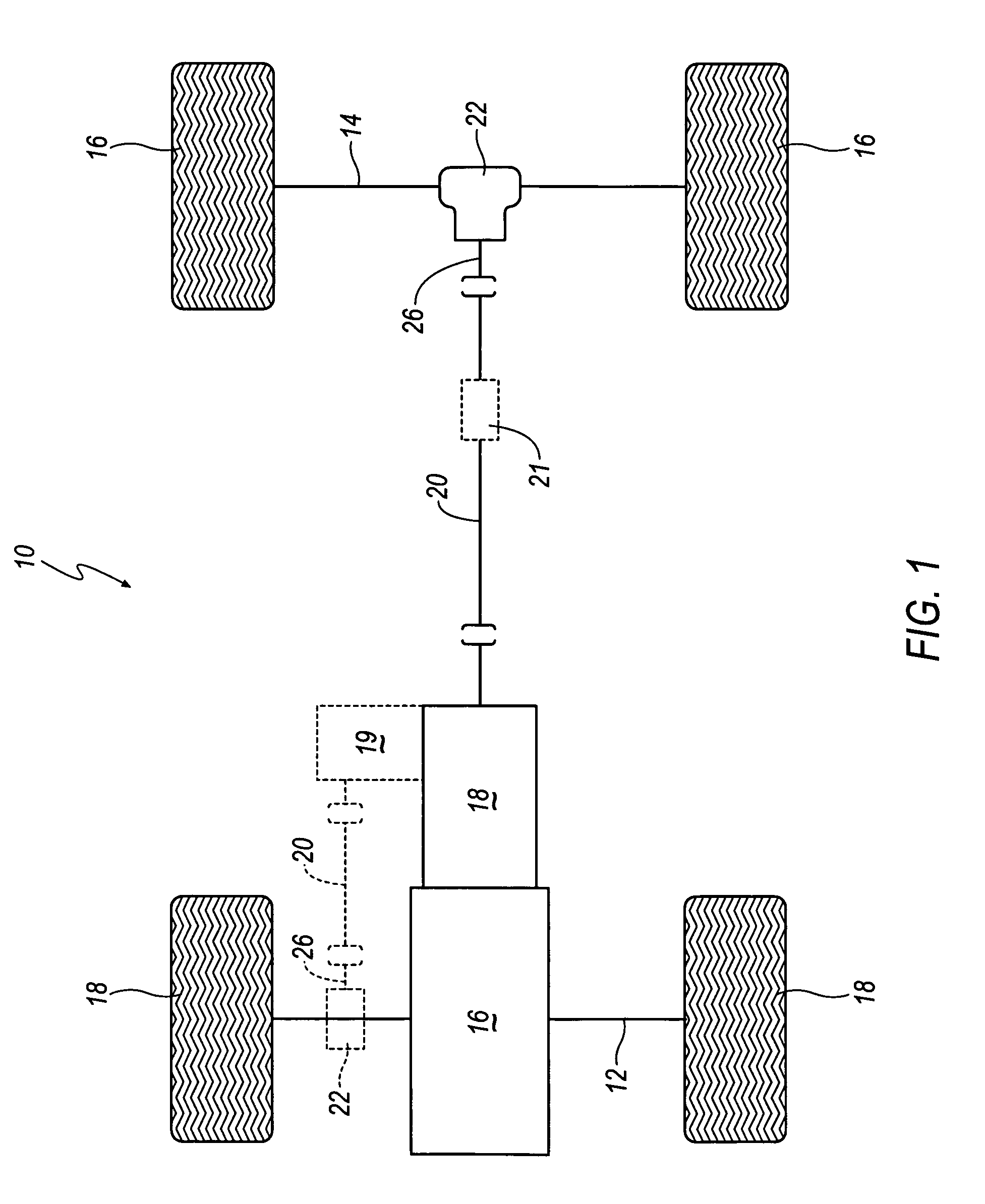

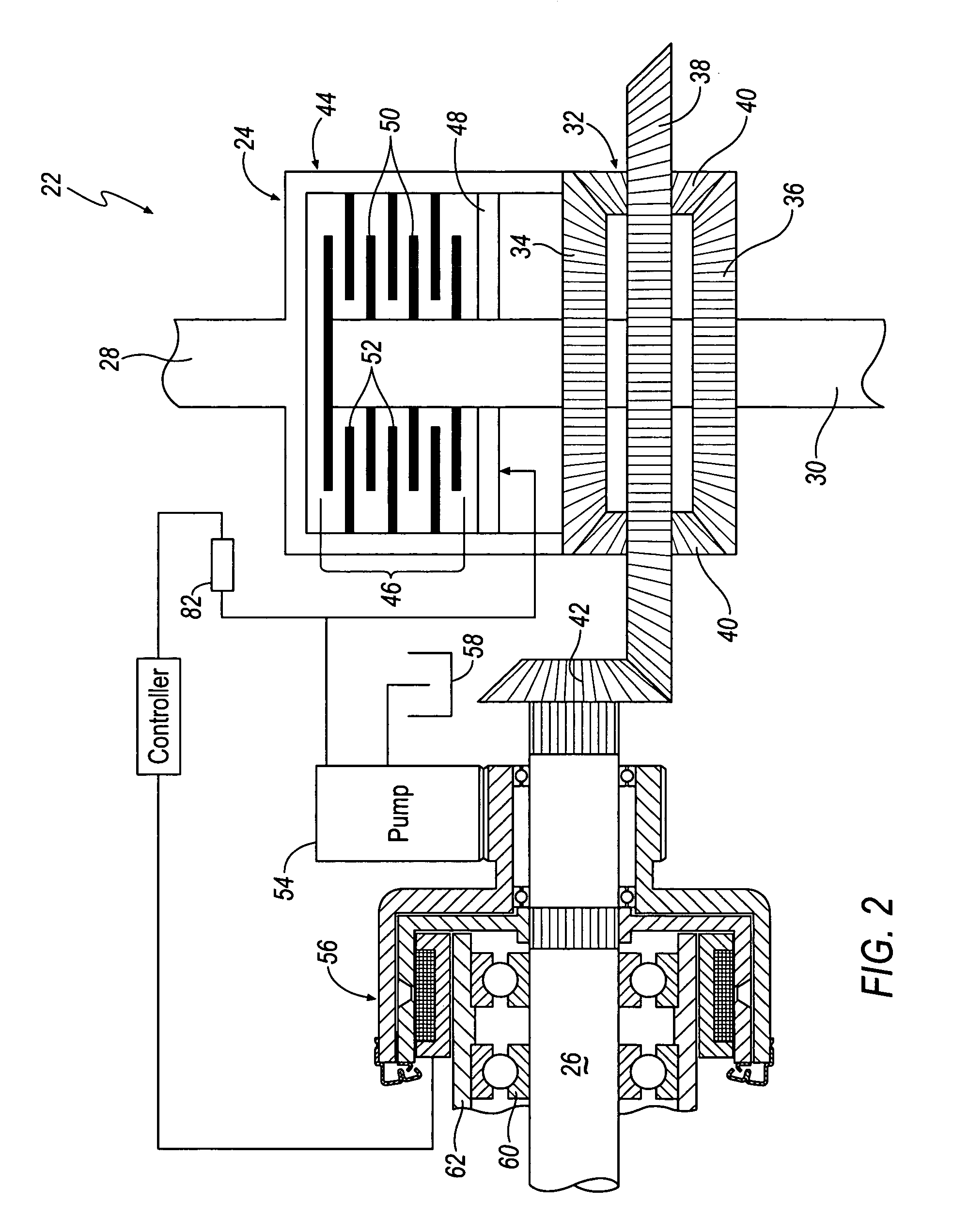

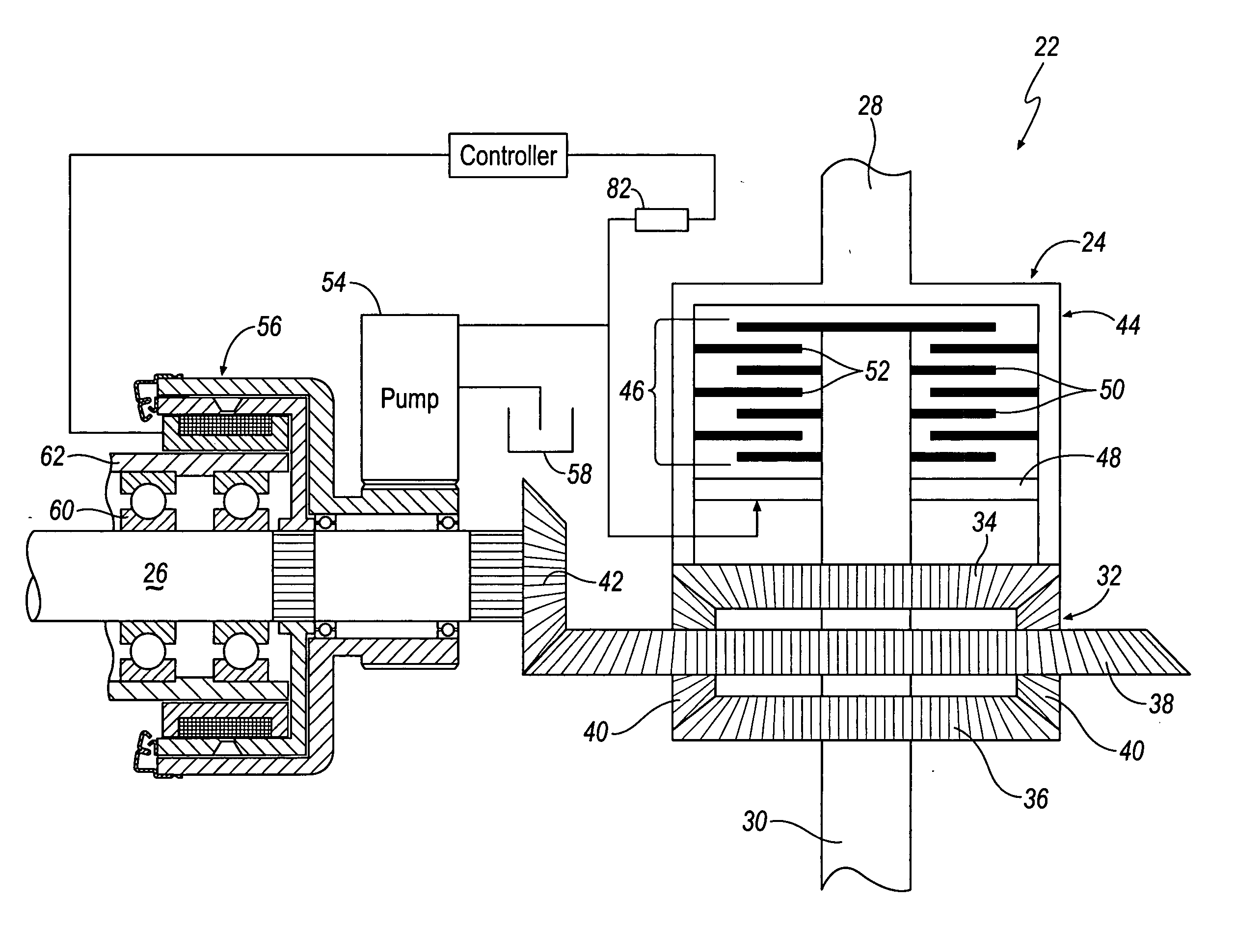

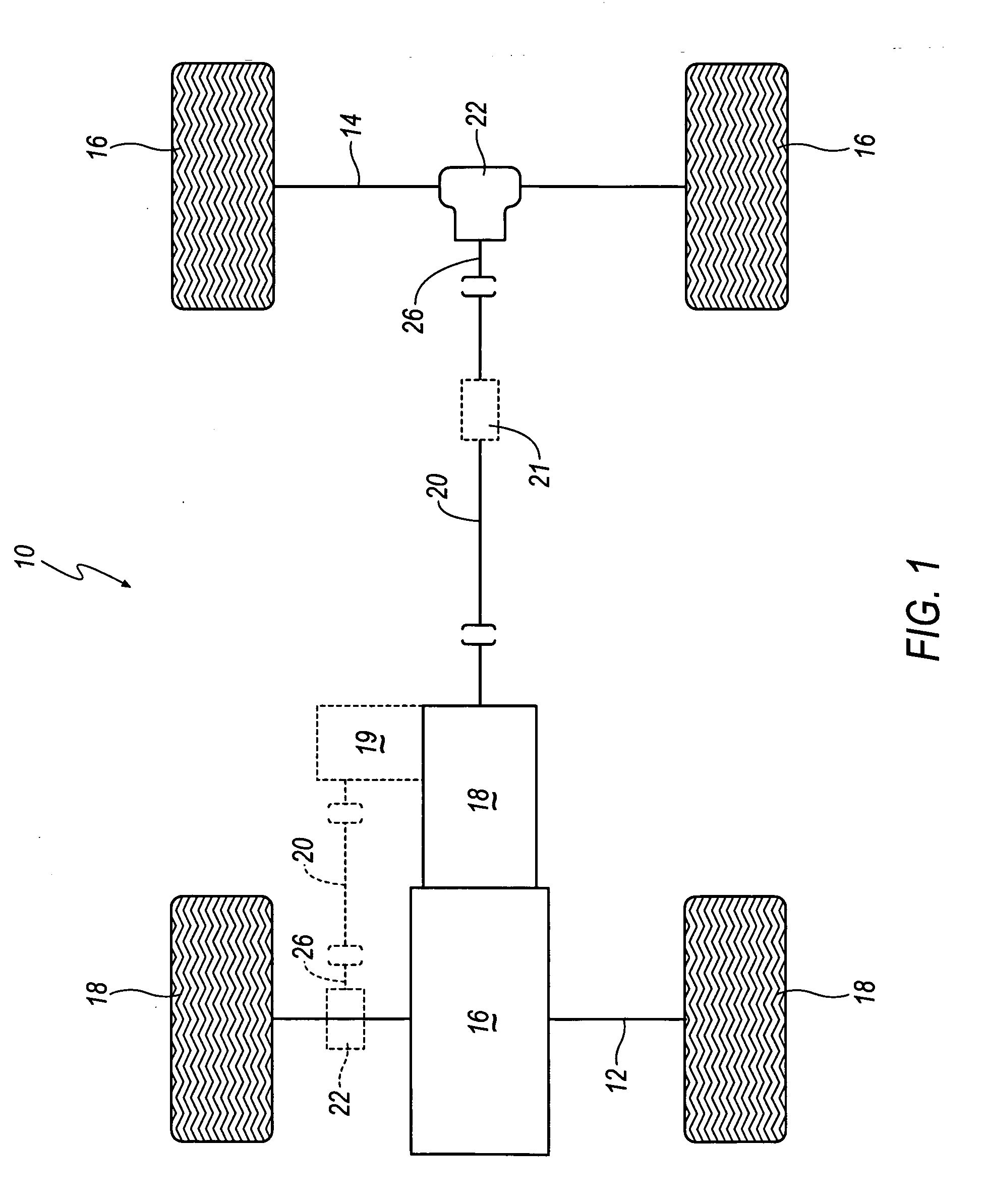

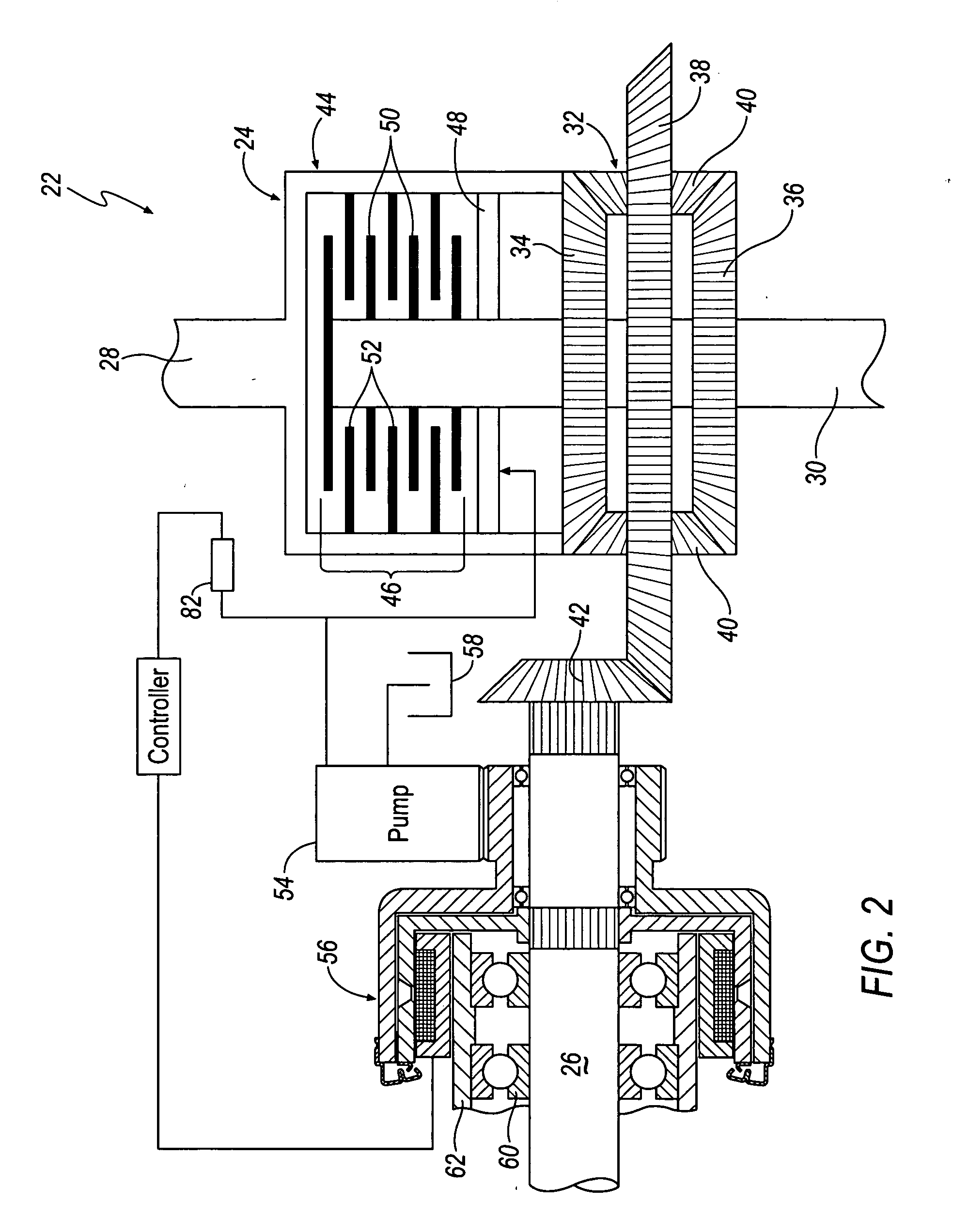

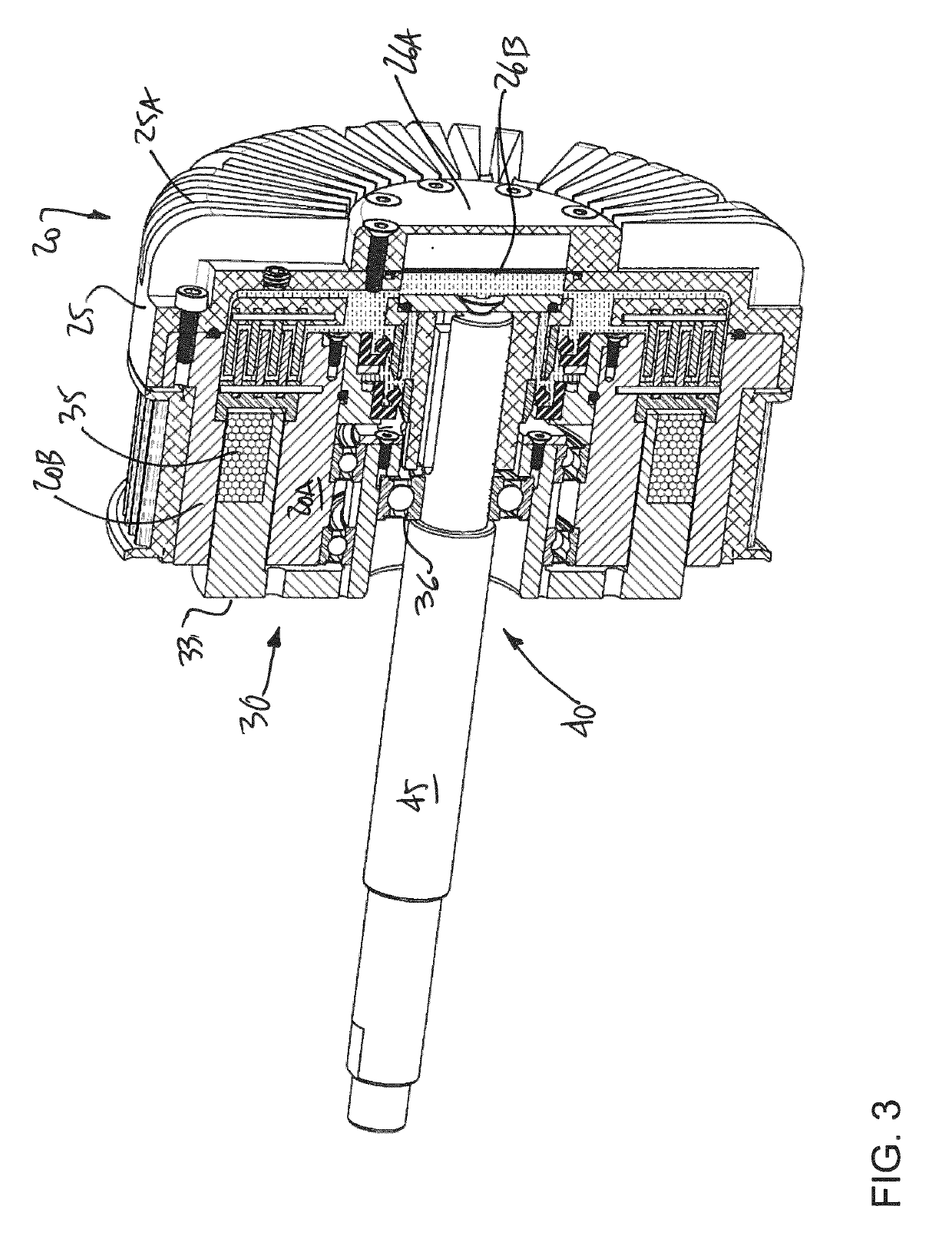

Vehicle differential including pump with variable-engagement clutch

A vehicle differential assembly is provided that includes a differential driven by an input and adapted to allow differing rotational speed between a pair of outputs. The differential includes a gear assembly connected to the outputs and a hydraulically-actuated clutch for selectively and variably coupling the outputs. A hydraulic pump is adapted to generate hydraulic fluid pressure for engagement of the hydraulically-actuated clutch. A variable-engagement clutch is operatively connected to the input and the hydraulic pump such that the input selectively drives the hydraulic pump during engagement of the clutch to provide hydraulic fluid pressure to the hydraulically-actuated clutch. A torque coupling including a variable-engagement clutch is also provided.

Owner:EATON INTELLIGENT POWER LTD

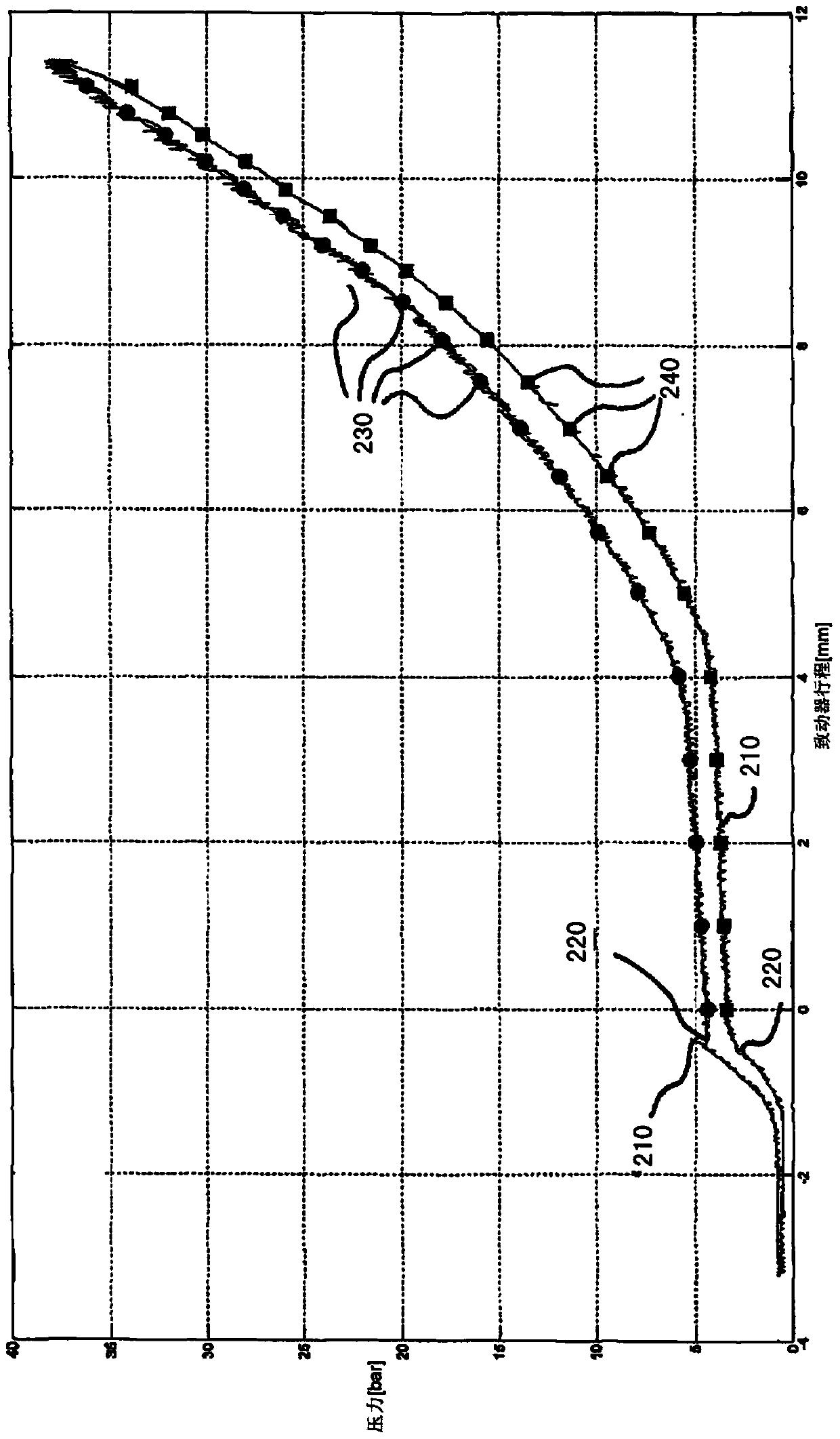

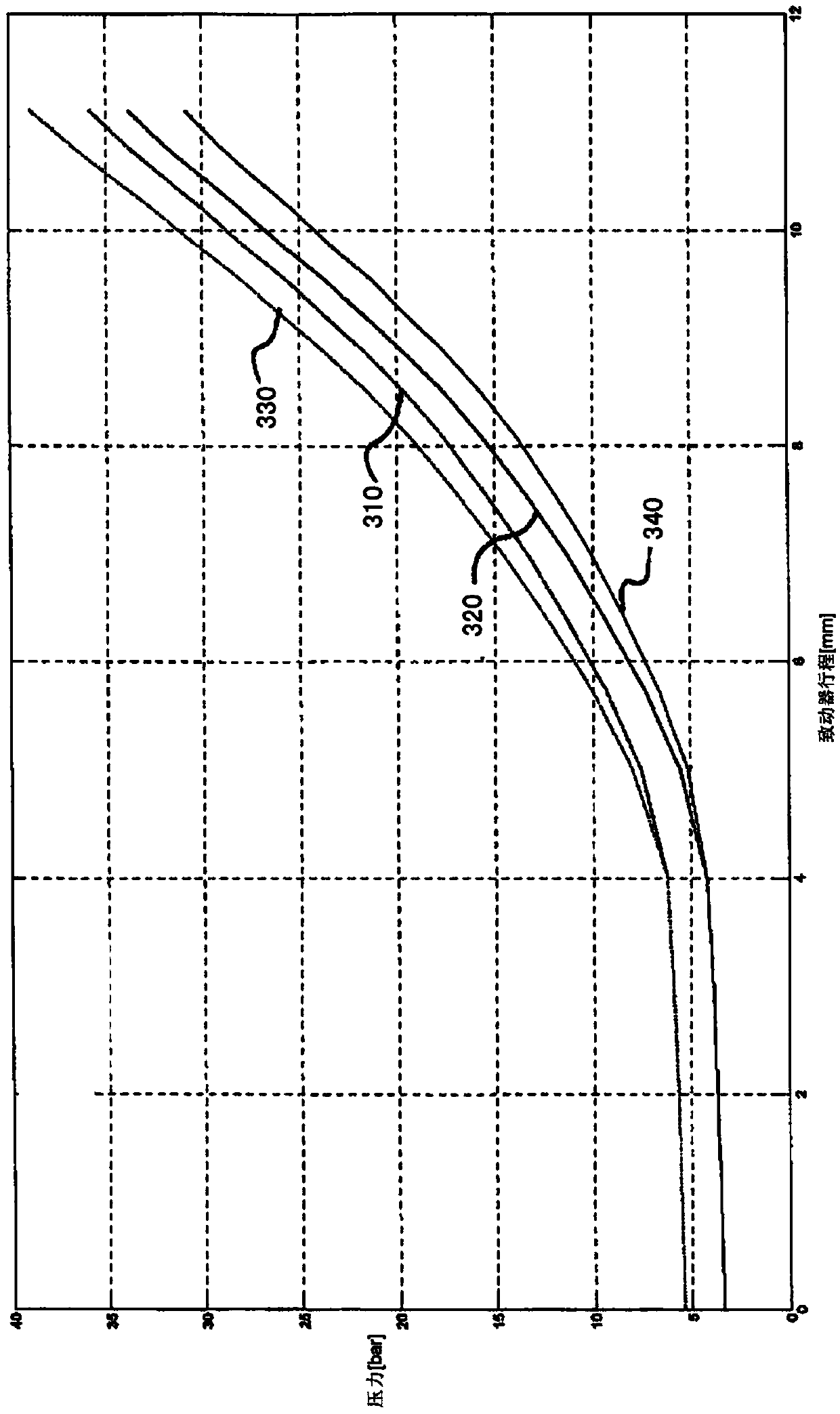

Method for adapting parameters of a clutch

The invention relates to a method for adapting parameters of a clutch of a double-clutch transmission system which has a hydrostatic clutch actuator with a pressure sensor in a motor vehicle.

Owner:SCHAEFFLER TECH AG & CO KG

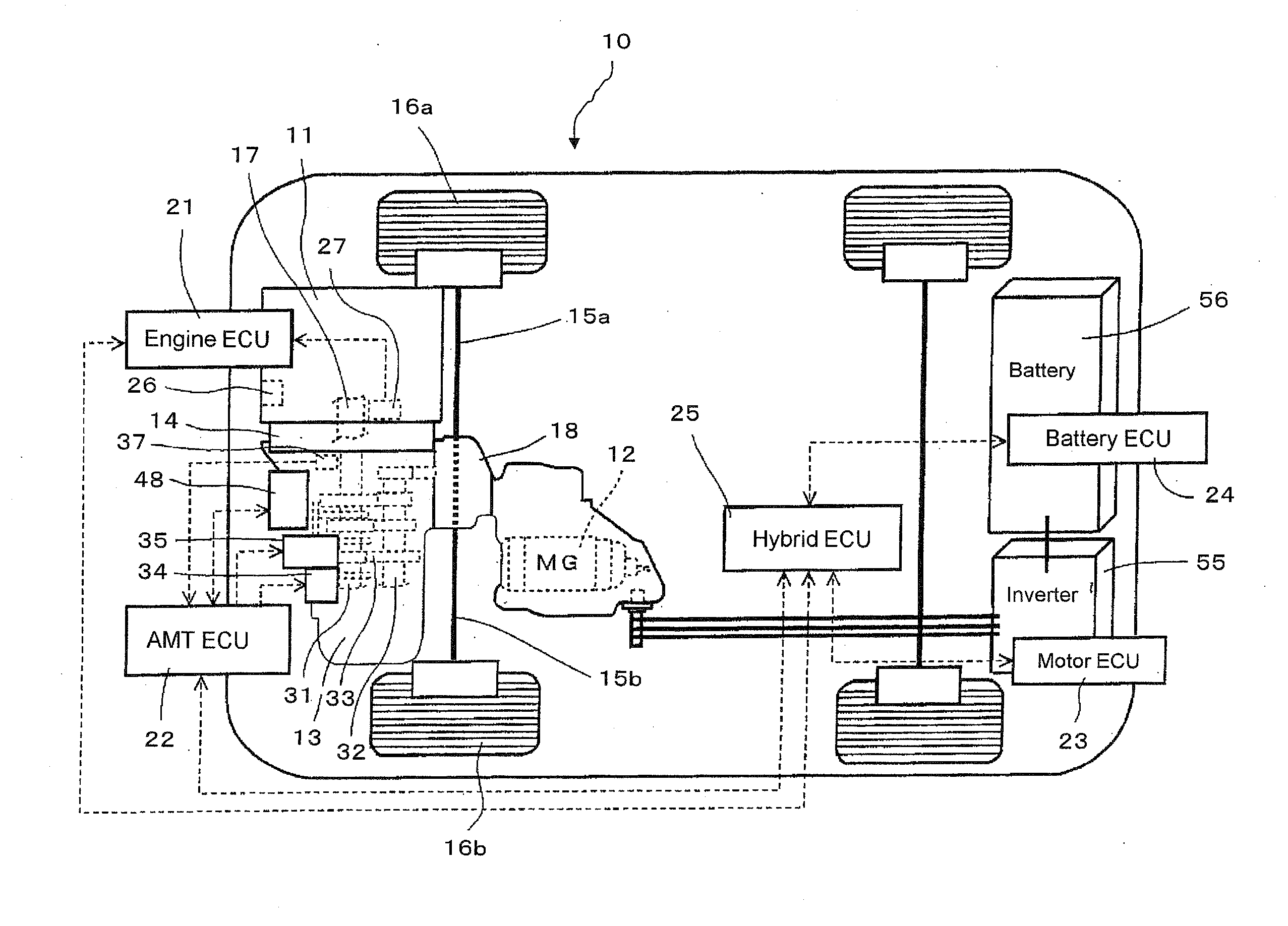

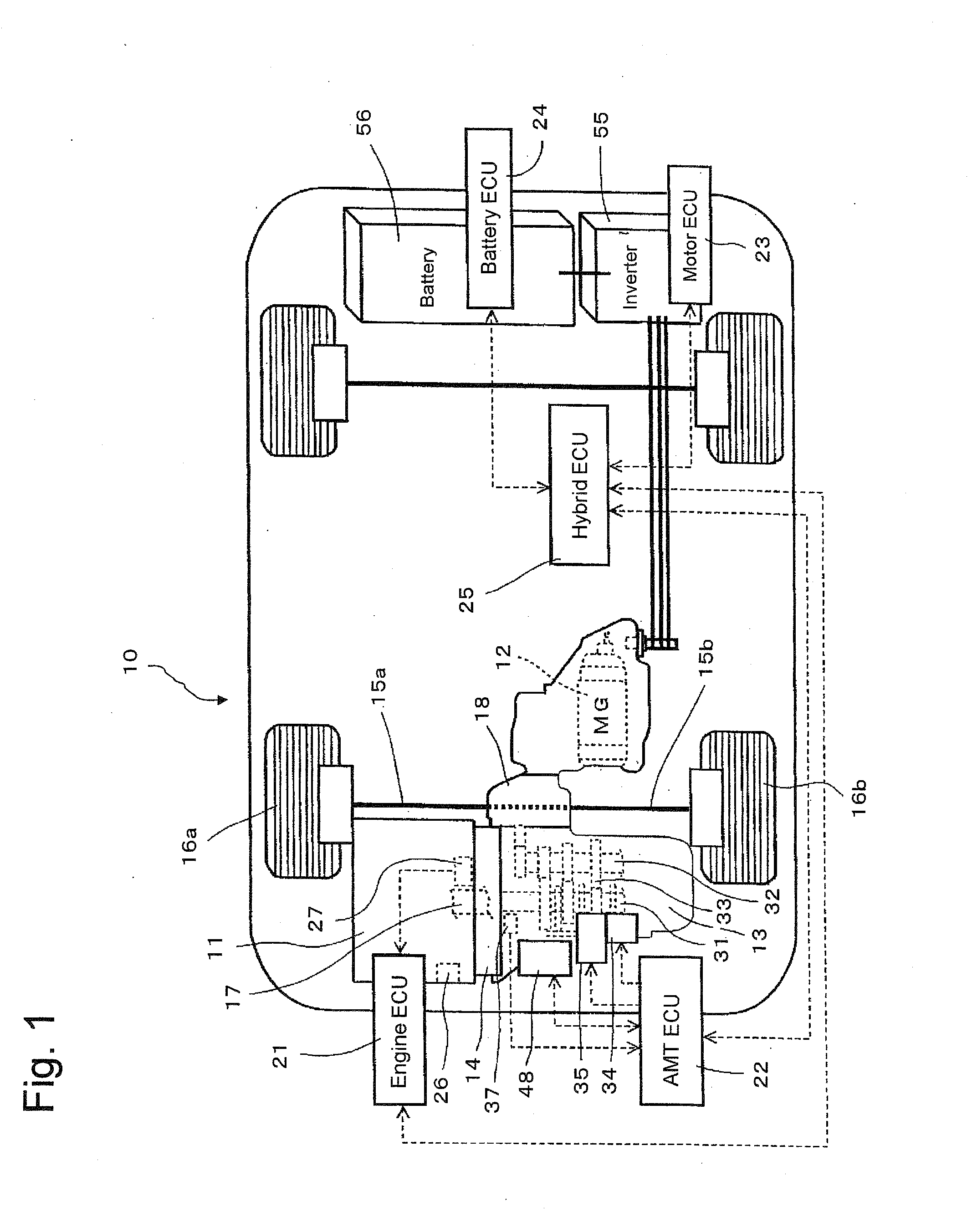

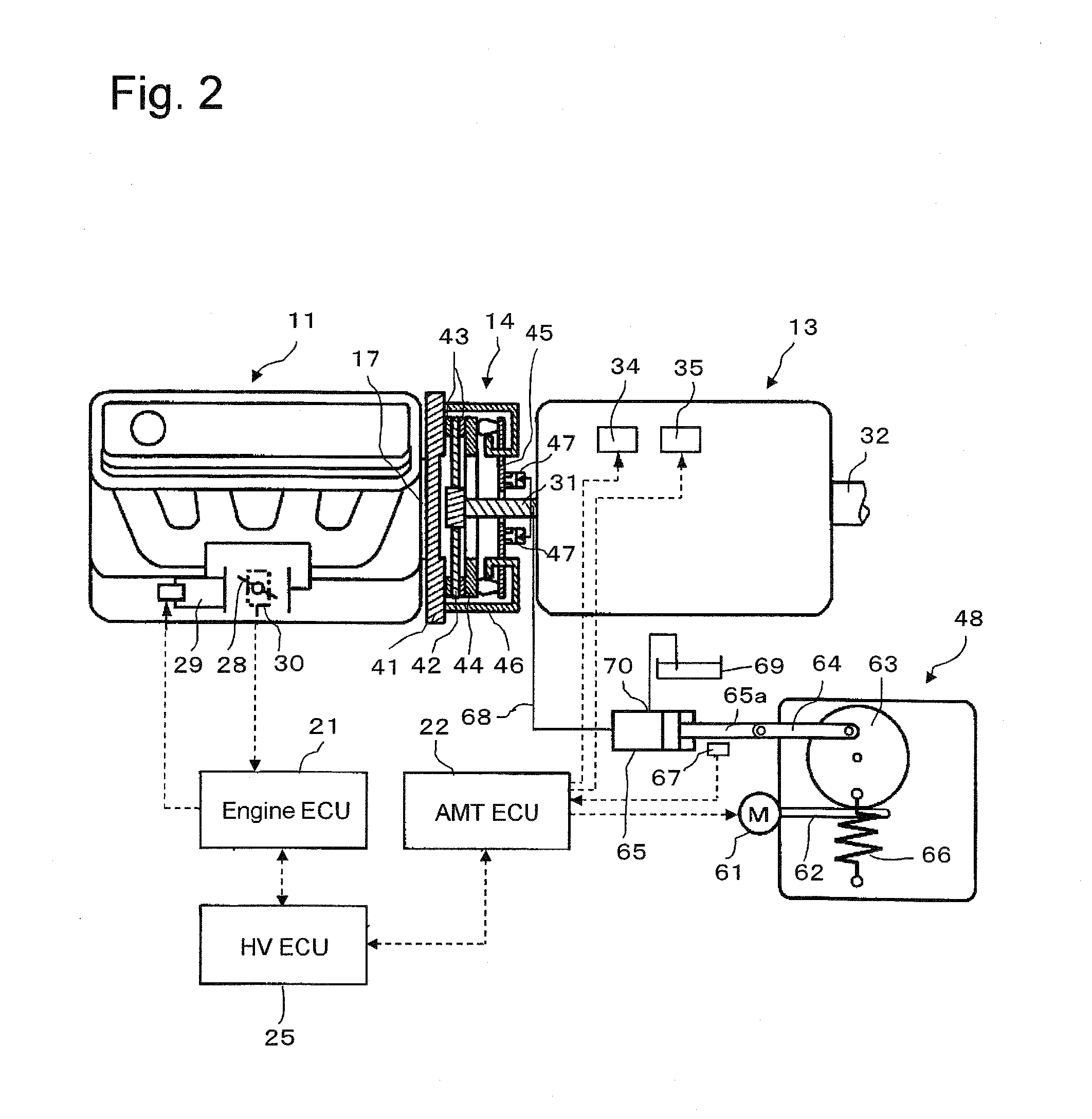

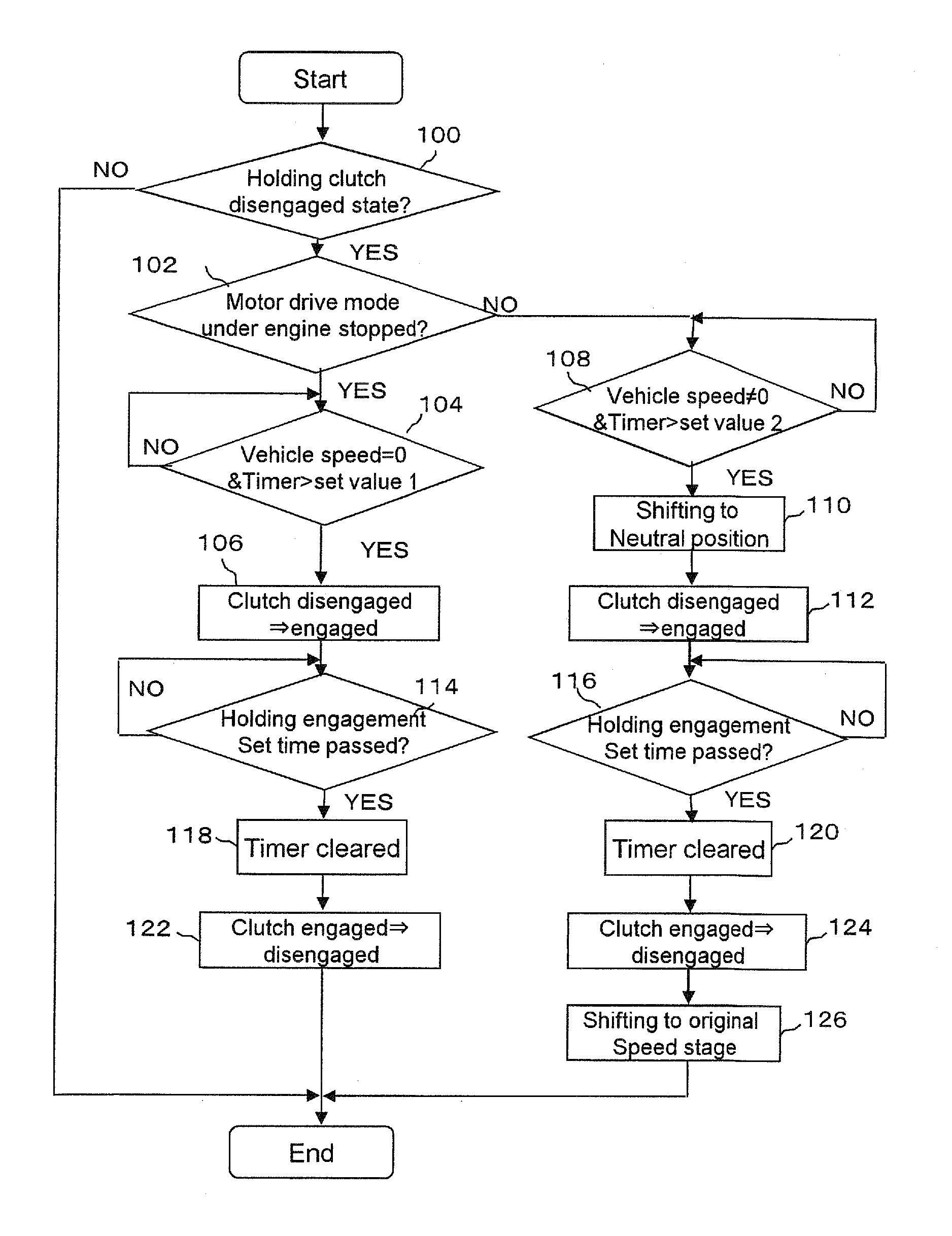

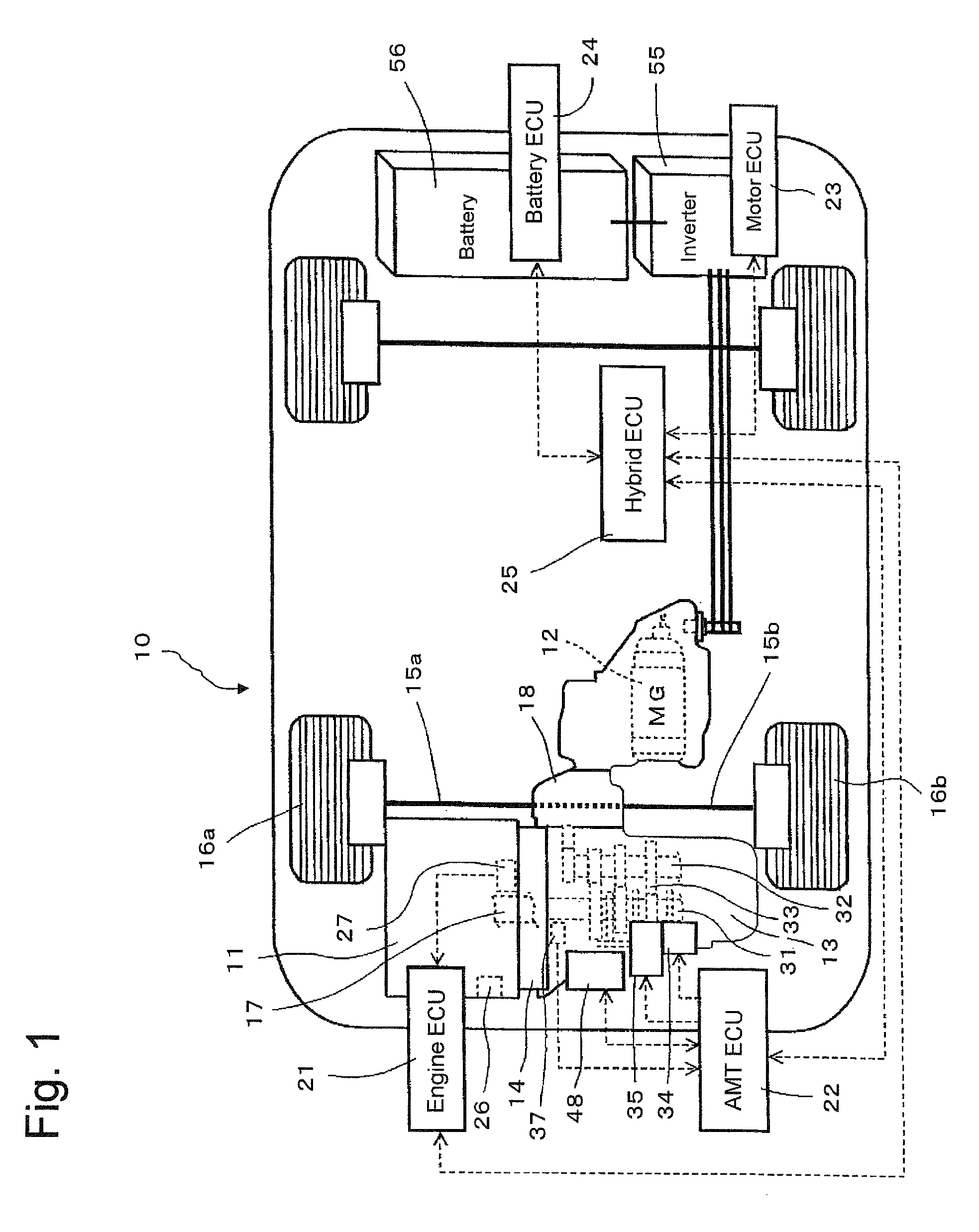

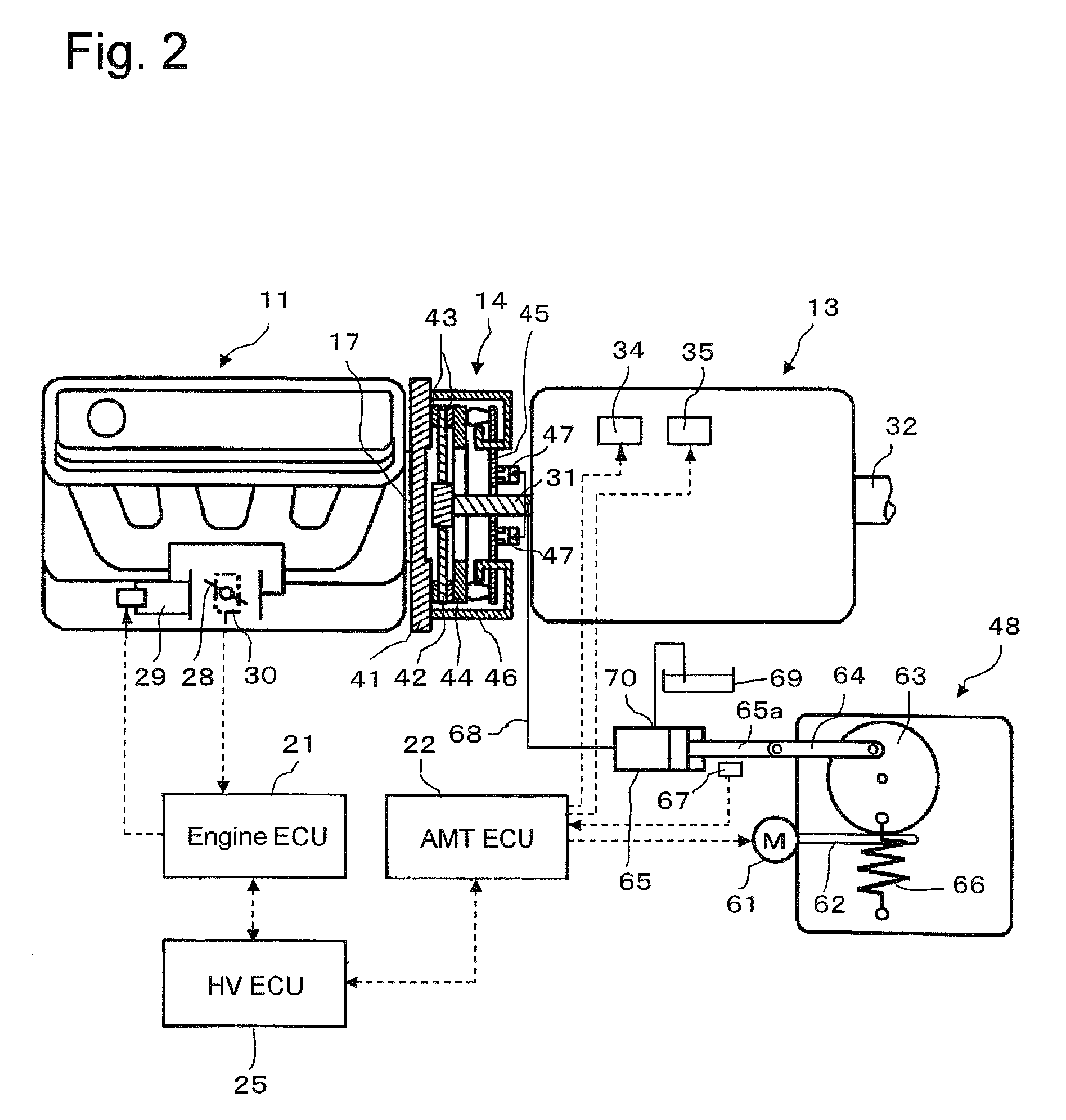

Hybrid vehicle clutch control device

InactiveUS20130310217A1Improve clutch control accuracyHigh control precisionHybrid vehiclesVehicle sub-unit featuresClutch controlMotor drive

The clutch control device for a hybrid vehicle comprises an engine, an automated manual transmission, a clutch device and a clutch actuator concluding an output rod and a master cylinder which generates a hydraulic pressure therein by closing an idle port in response to the stroke of the output rod, a slave cylinder in fluid communication with the master cylinder through a passage and controlling the clutch device to be in engagement state or disengagement state operated by the hydraulic pressure generated by the master cylinder and a clutch engagement state holding control portion for temporarily holding the clutch device to be in the engagement state by operating the master cylinder to close the idle port after the engagement state under the vehicle being running under a motor drive mode continued for a predetermined time.

Owner:AISIN SEIKI KK

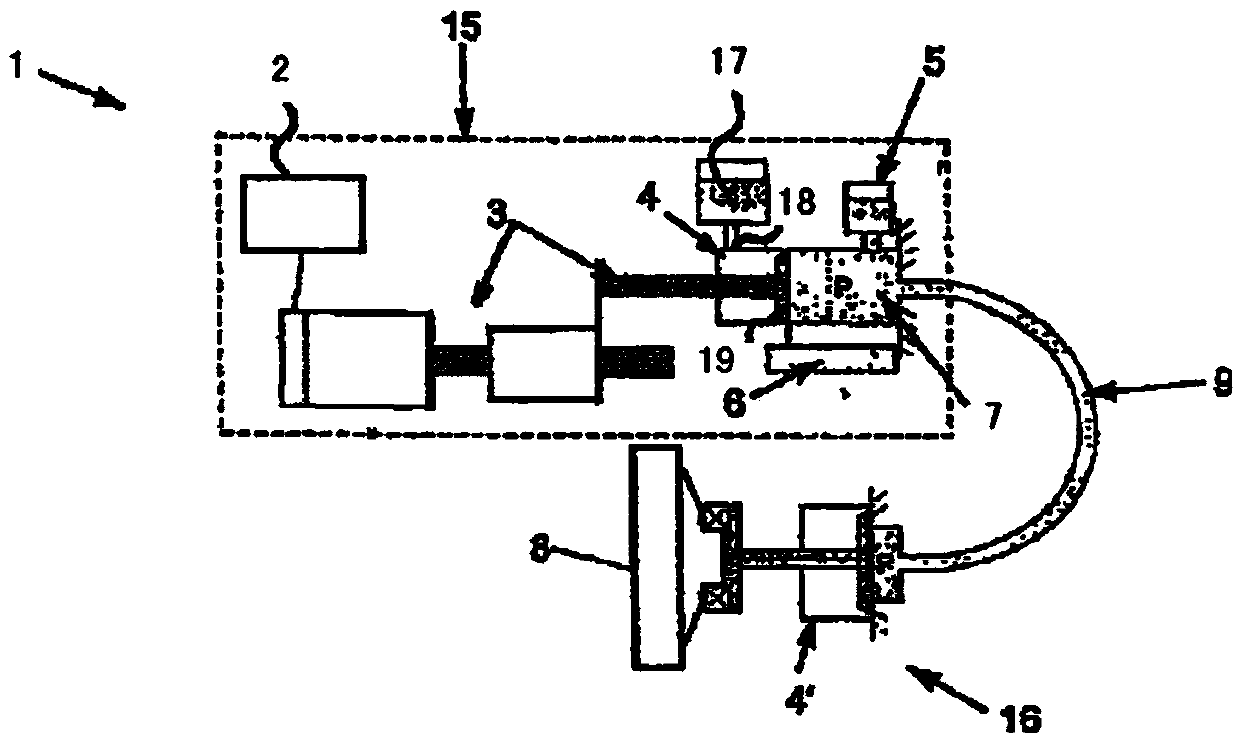

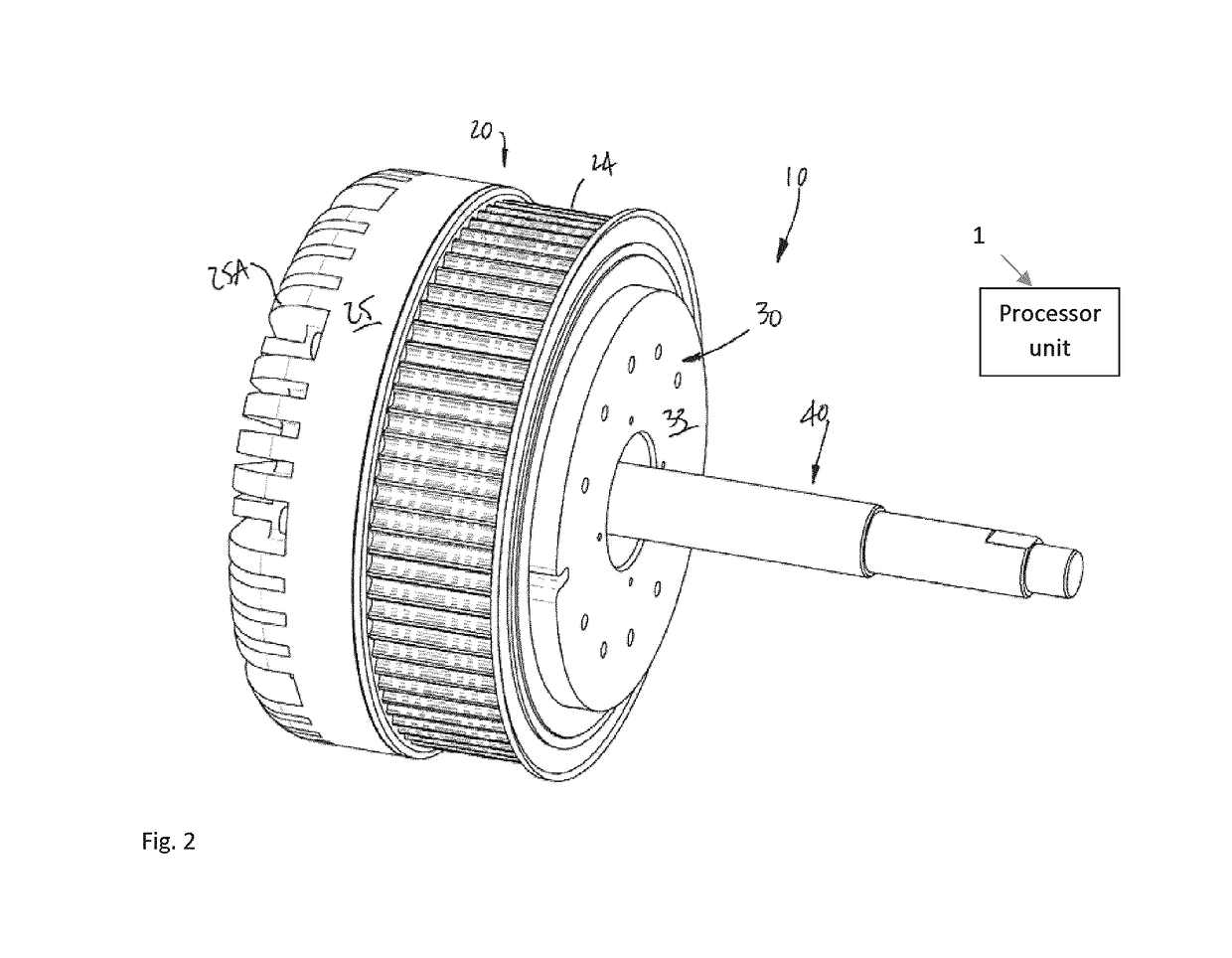

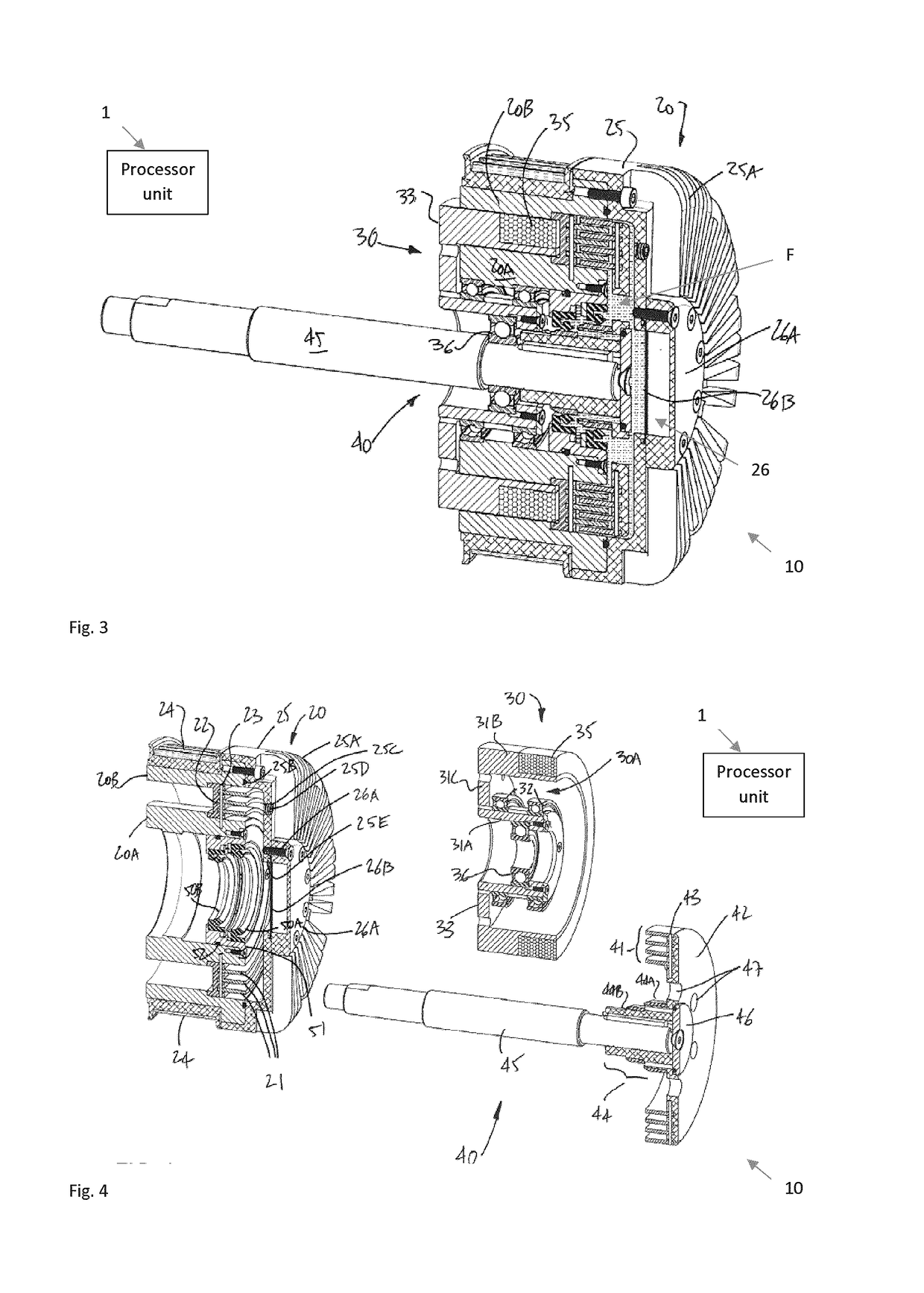

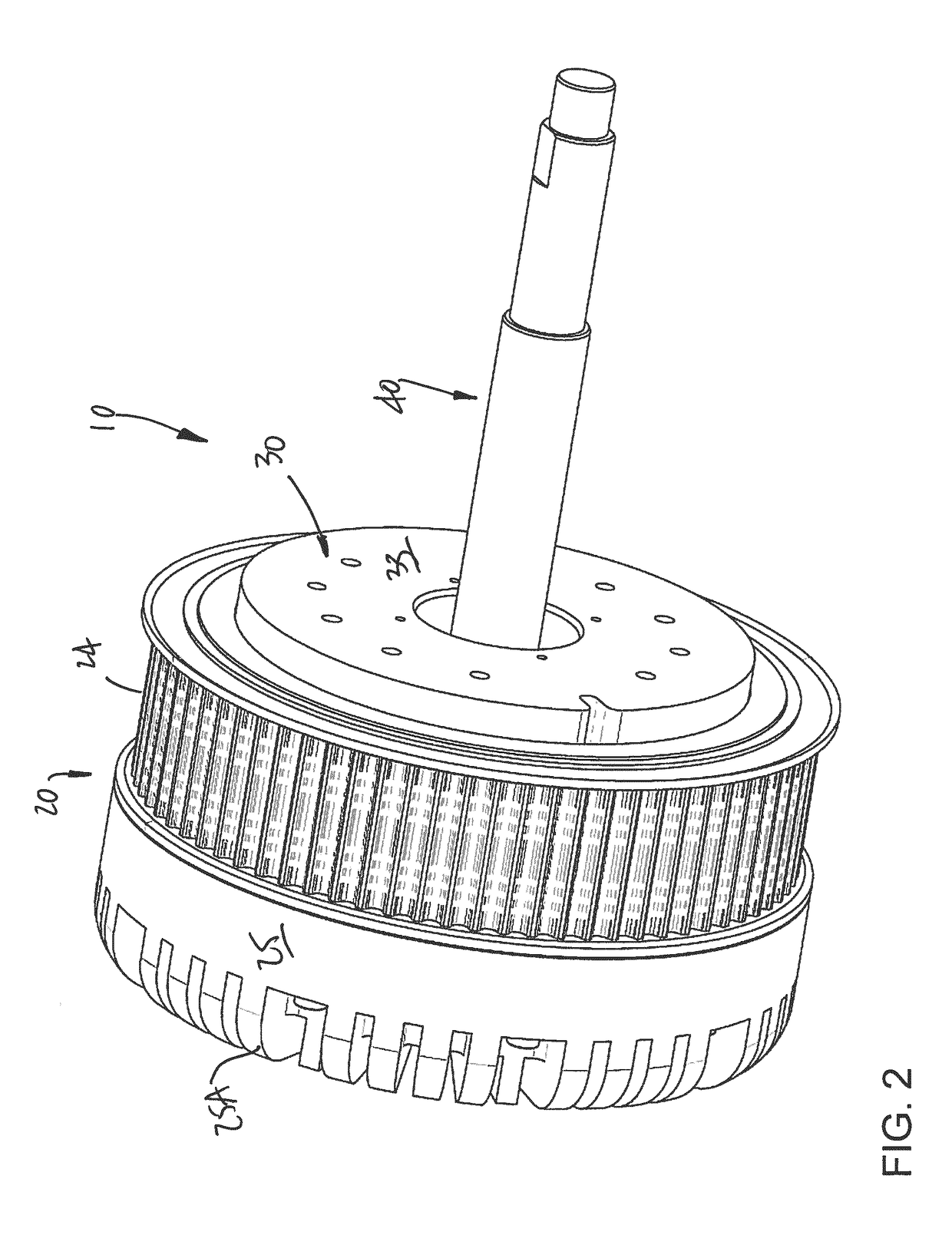

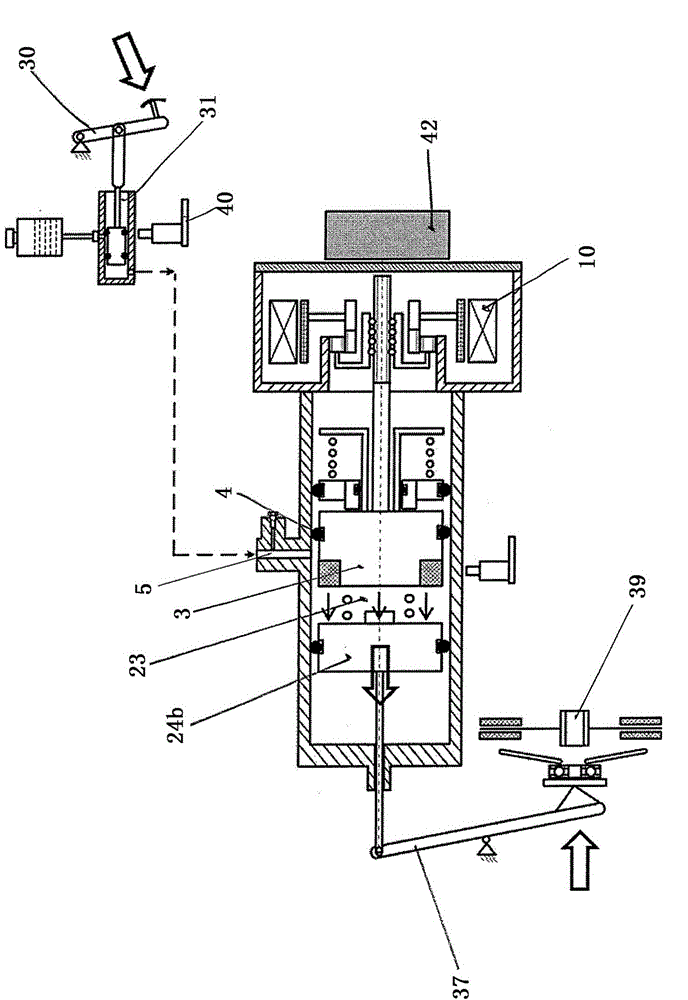

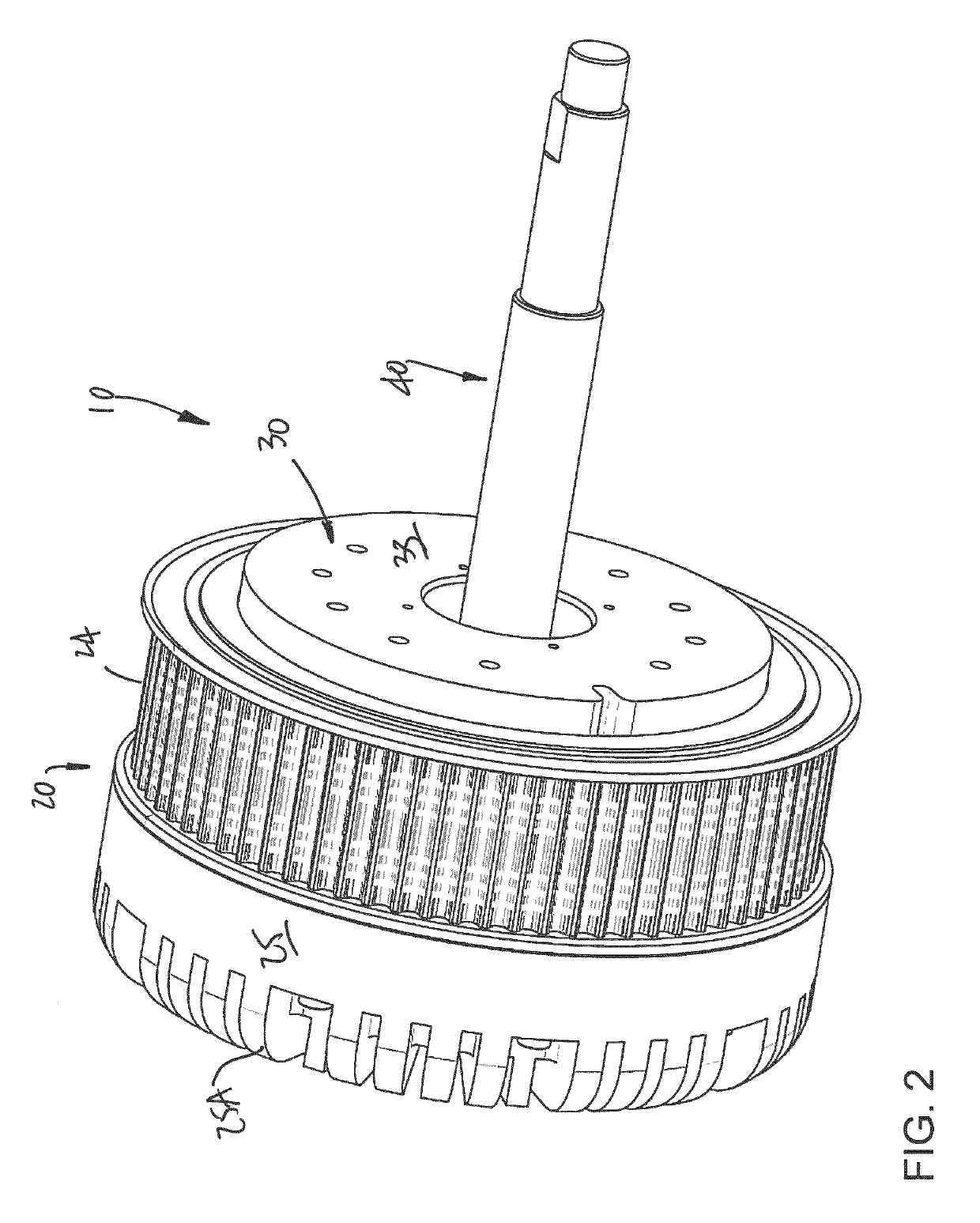

Human-hybrid powertrain for a vehicle or moving equipment using magnetorheological fluid clutch apparatus

ActiveUS20180370591A1Reduce the induced torque generated by the powertrainIncrease heightHybrid vehiclesWheel based transmissionMagnetorheological fluidActuator

A system for assisting a user in moving a device relative to a structure comprises a magnetorheological (MR) fluid actuator unit including at least one torque source and at least one MR fluid clutch apparatus having an input coupled to the at least one torque source to receive torque from the at least one torque source, the MR fluid clutch apparatus controllable to transmit a variable amount of assistance force via an output thereof. An interface is configured for coupling the output of the at least one MR fluid clutch apparatus to the device or surrounding structure. At least one sensor provides information about a movement of the device. A processor unit for controlling the at least one MR fluid clutch apparatus in exerting the variable amount of assistance force as a function of said information, wherein the system is configured for one of the MR fluid actuator unit and the interface to be coupled to the structure, and for the other of the MR fluid actuator unit and the interface to be coupled to the device for the assistance force from the MR fluid actuator unit to assist in moving the device.

Owner:EXONETIK INC

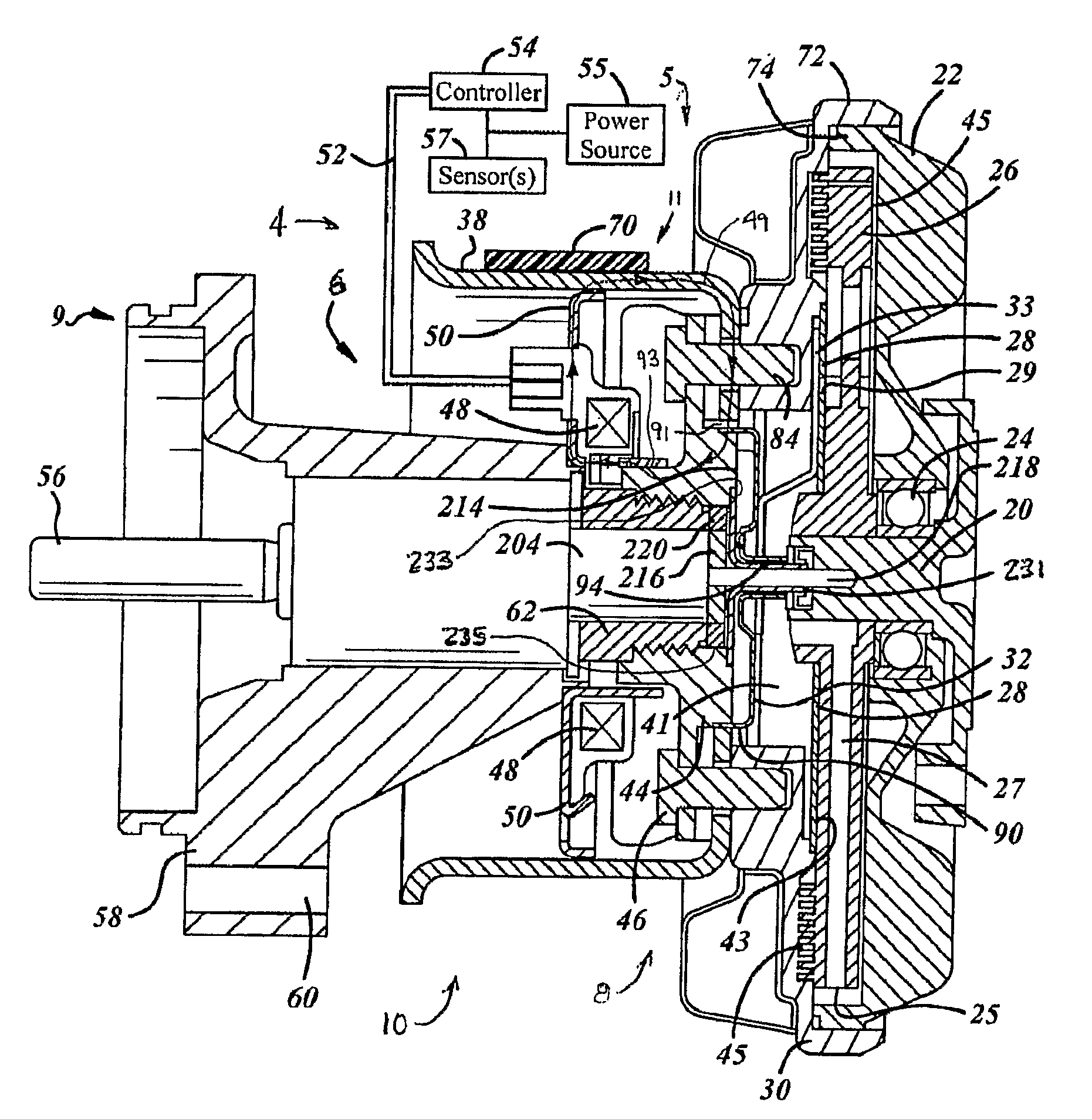

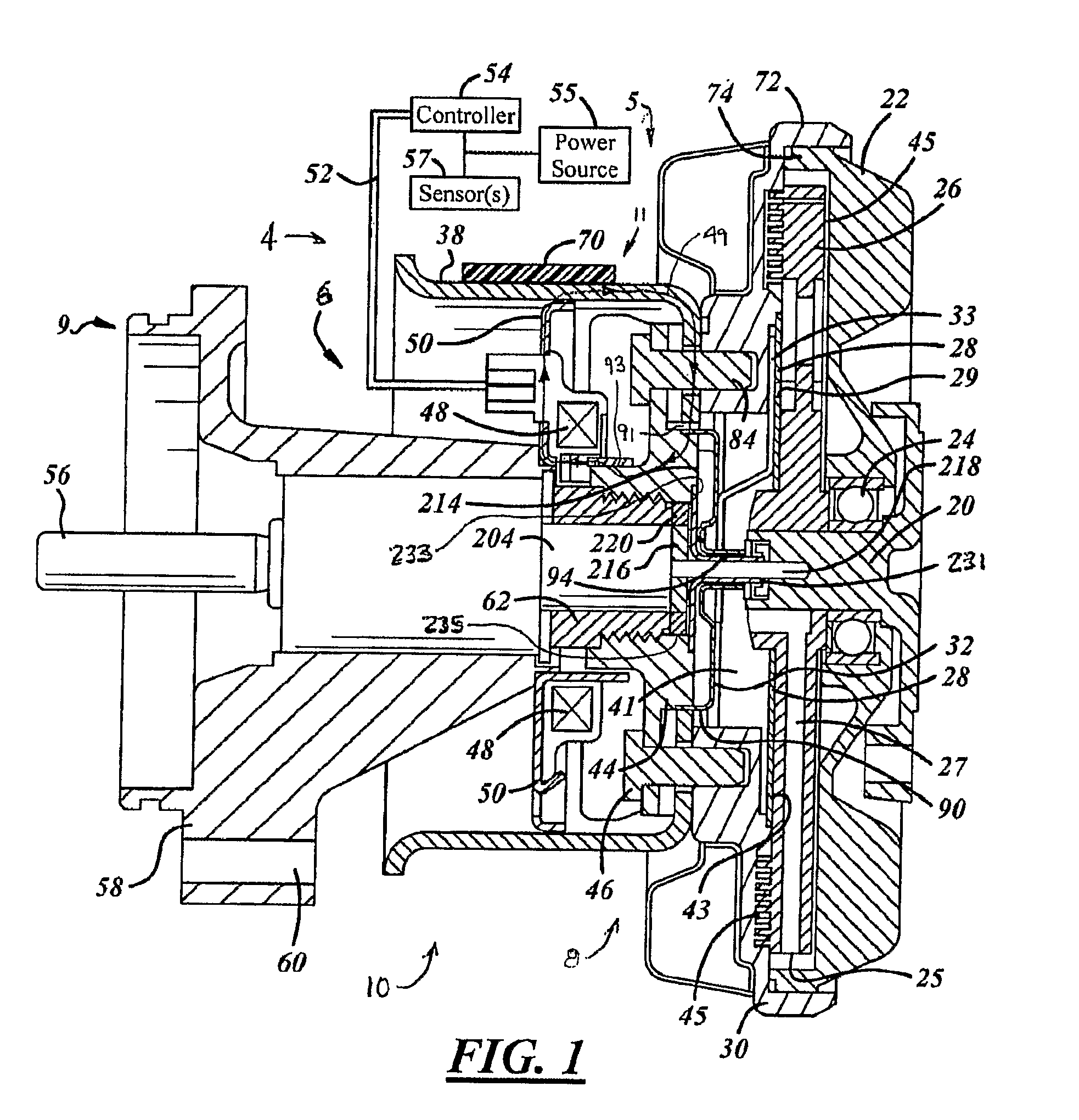

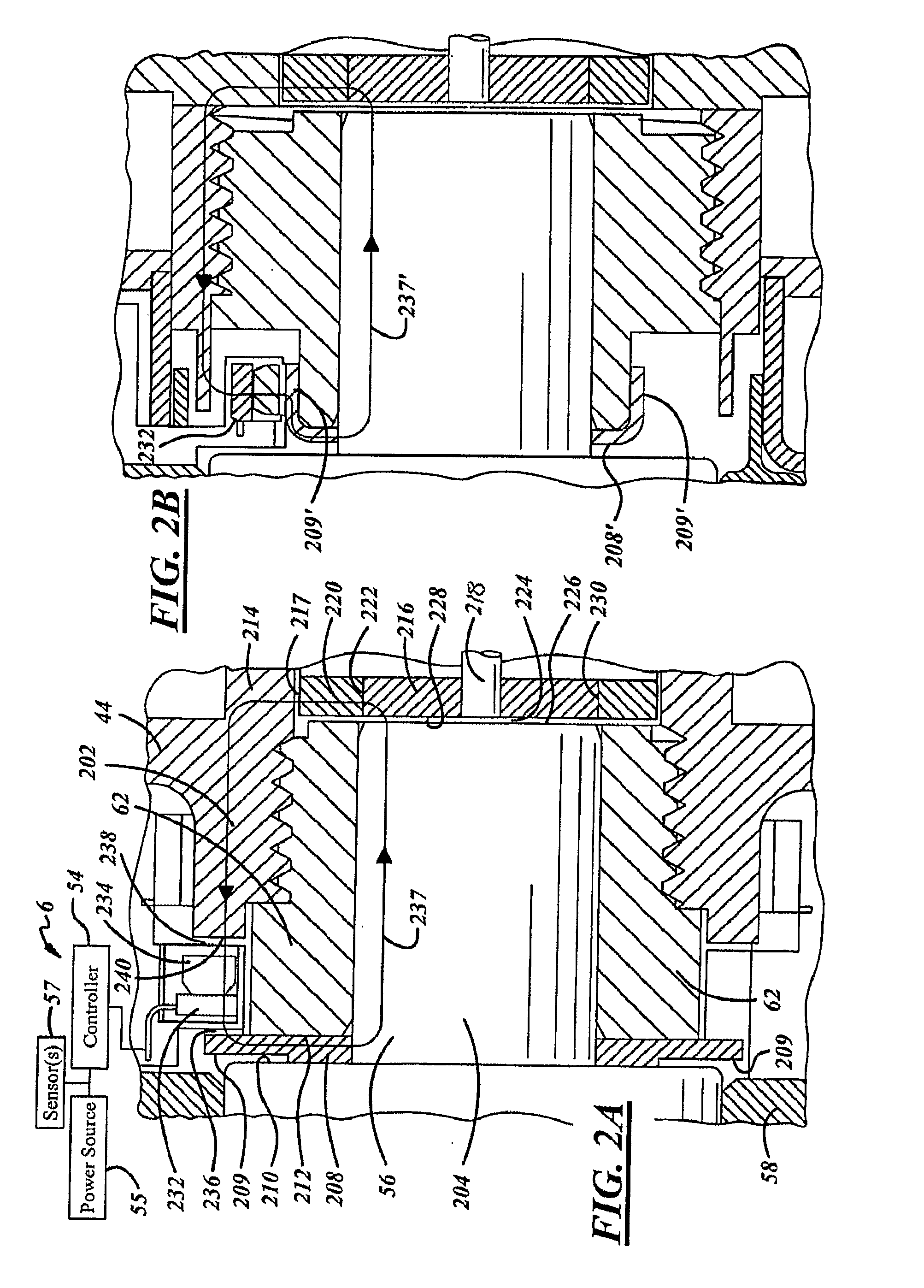

Electromagnetic differential speed control system for a fluid coupling device

ActiveUS20100059325A1Minimizes and overcomes their disadvantageEasy to controlFluid couplingsFluid clutchesFluid couplingSpeed control system

A speed monitoring system (6) for a fluid-coupling device (10) includes a hub (44) and a ring magnet (220). The hub (44) rotates at a first speed that is proportional to an input clutch speed of a fluidically engageable input member. The ring magnet (220) rotates at a second speed that is proportional to an output clutch speed of a fluidically engageable output member. A magnetic sensor (232) generates a differential speed signal of the ring magnet (220) relative to the first speed. A controller (54) generates an actual speed signal indicative of the second speed in response to said differential speed signal.

Owner:BORGWARNER INC

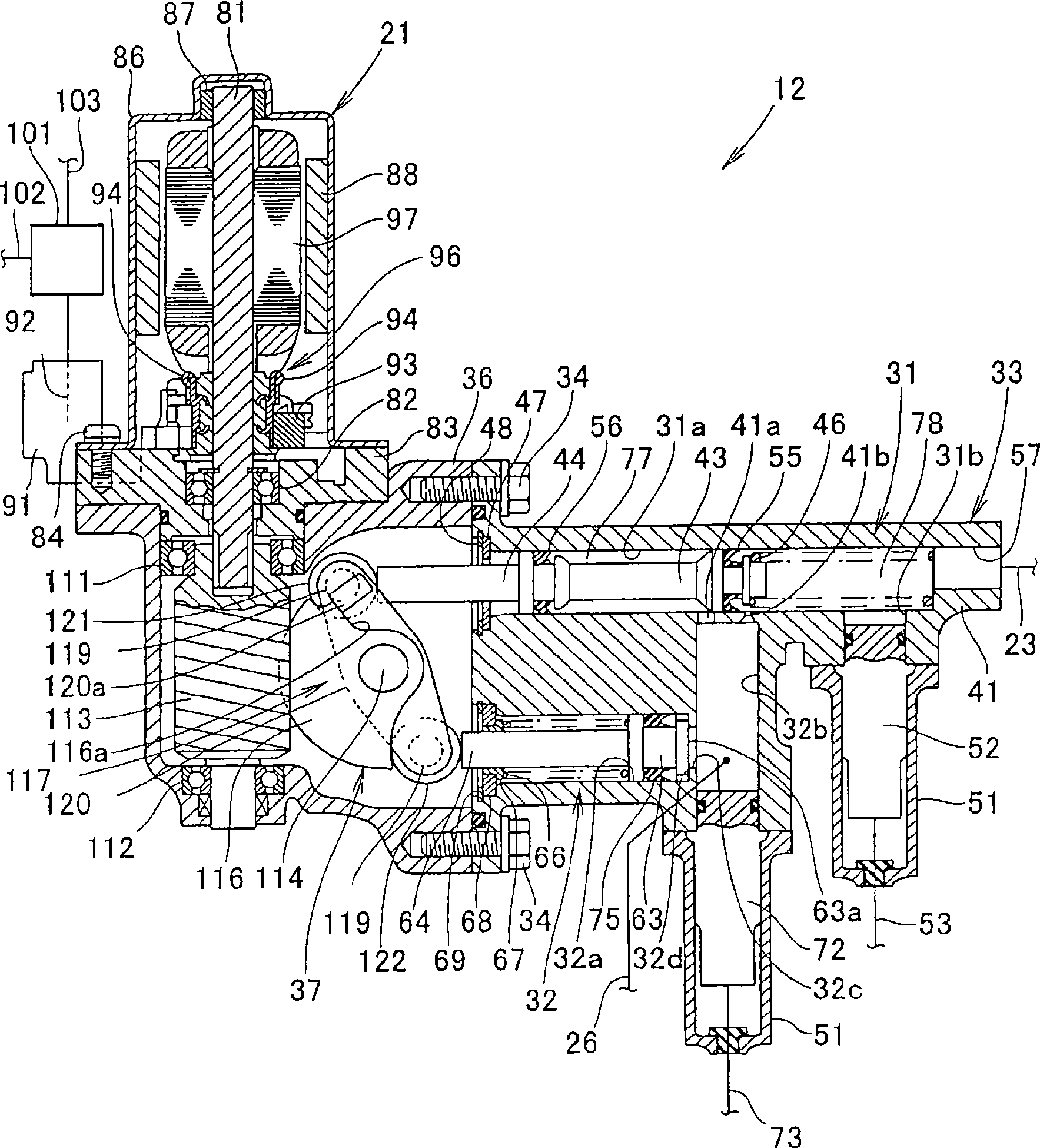

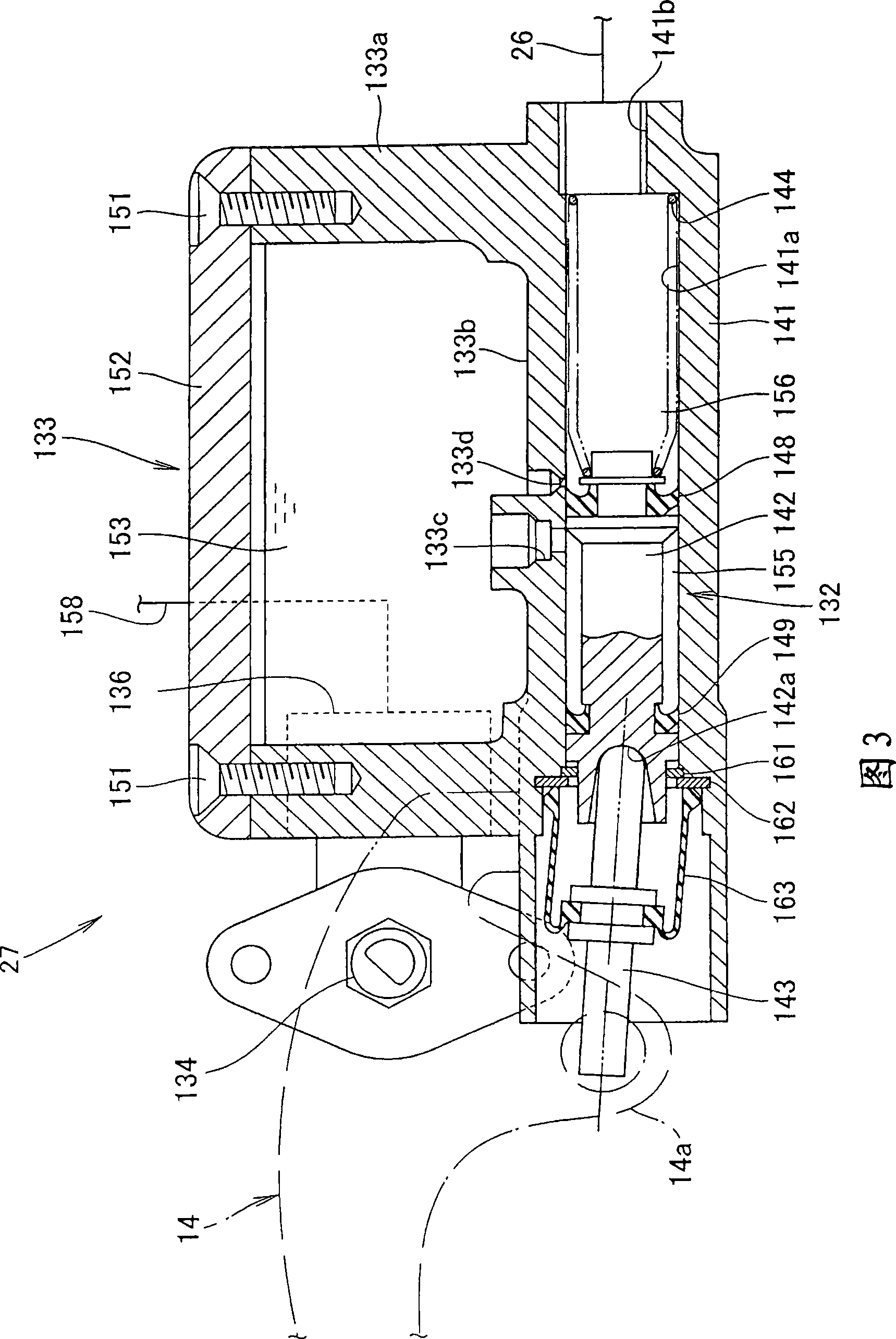

Hydraulic mechanism for vehicle

InactiveCN101376383AMiniaturizationHigh precisionFluid braking transmissionNon-mechanical actuated clutchesHydraulic cylinderMaster cylinder

The invention provides a clutch hydraulic mechanism capable of realizing miniaturization with no change in the position relationship of two hydraulic cylinders. A lever member (117) for transmitting motive power is provided between a second release cylinder (32) and a first master cylinder (31), while the first master cylinder (31) and the second release cylinder (32) are formed in the same cylinder block (41). This eliminates the need for adjusting the positions of the first master cylinder (31) and the second release cylinder (32). Besides, it is possible to dispose the first master cylinder (31) and the second release cylinder (32) close to each other.

Owner:HONDA MOTOR CO LTD

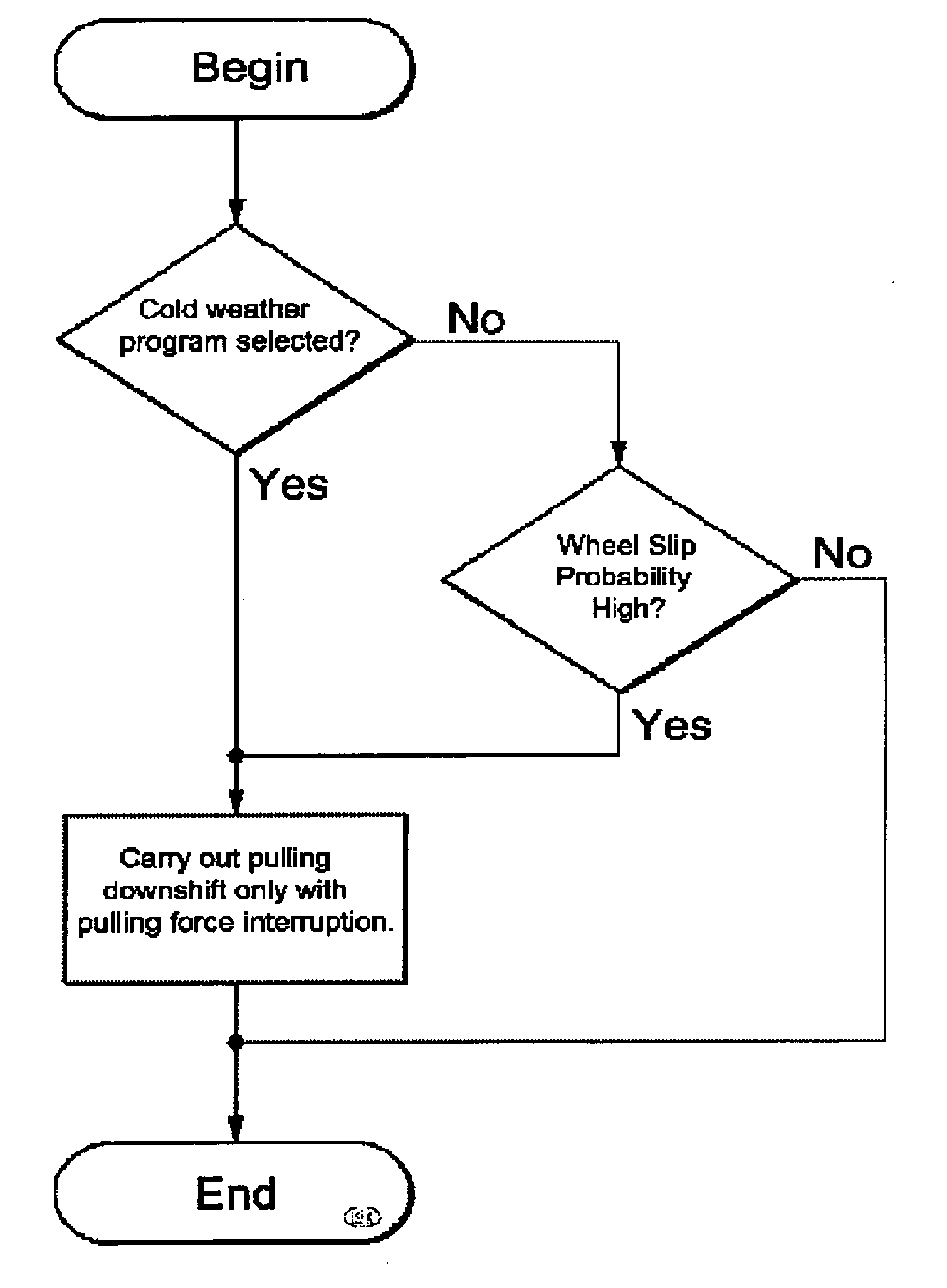

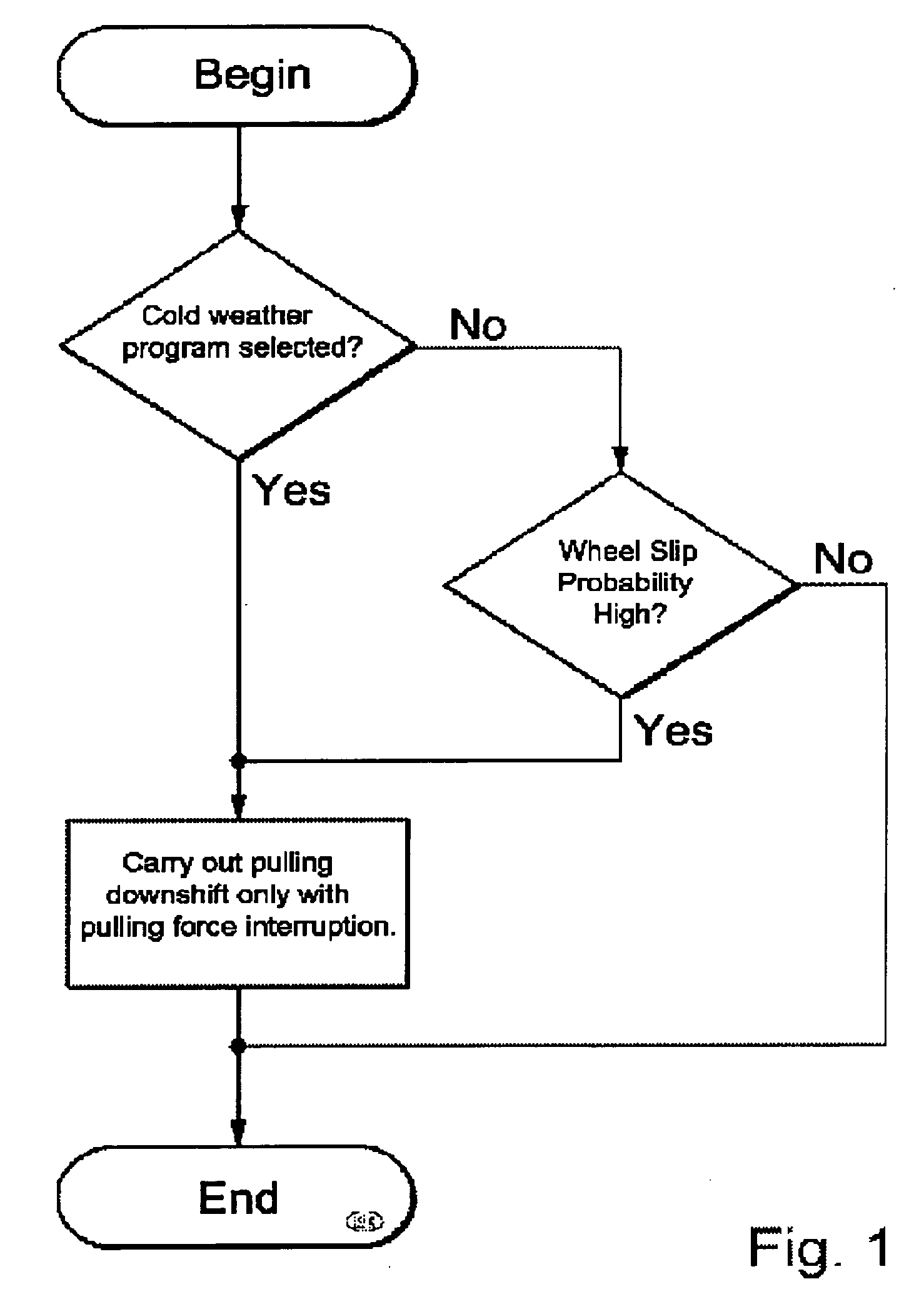

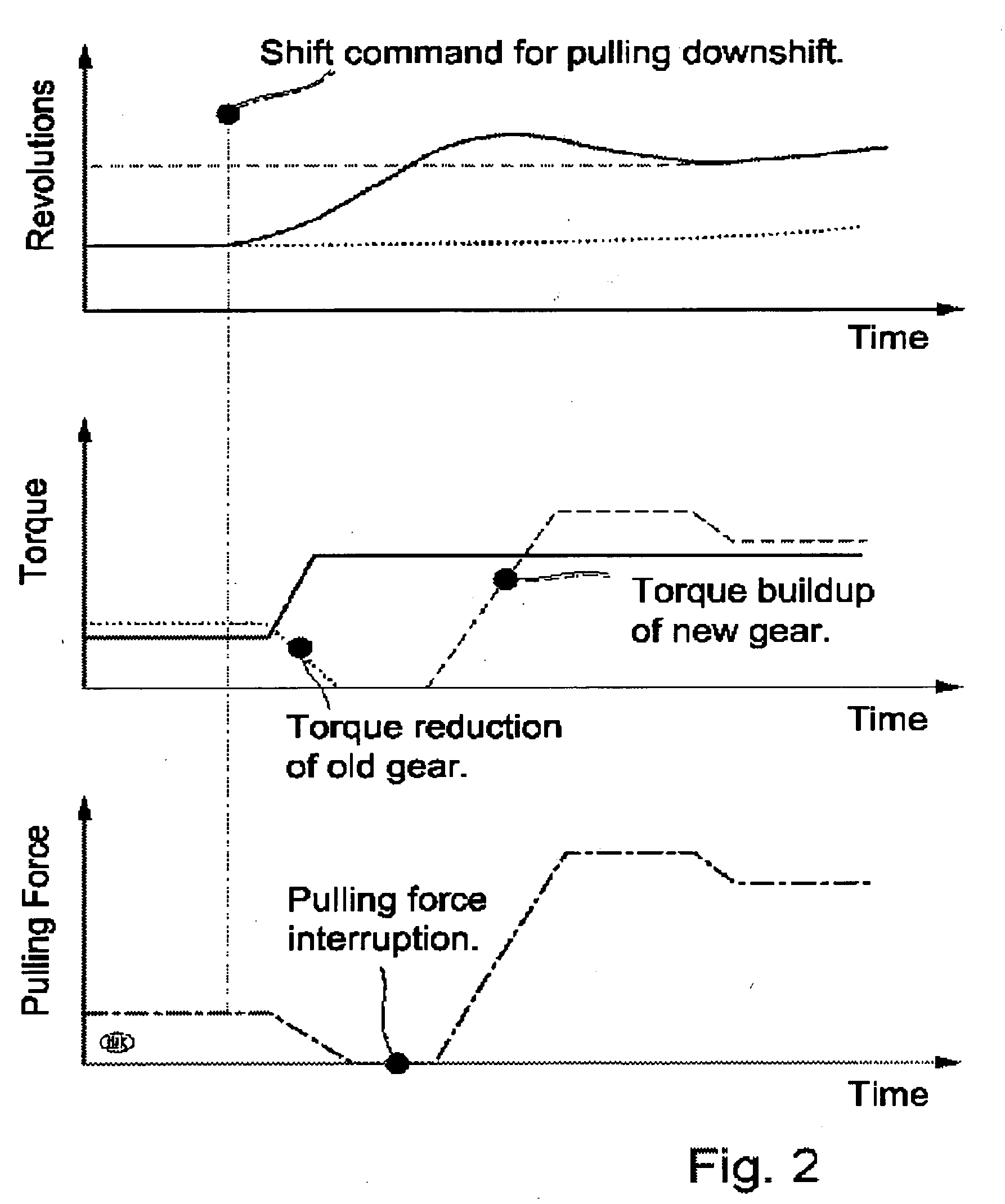

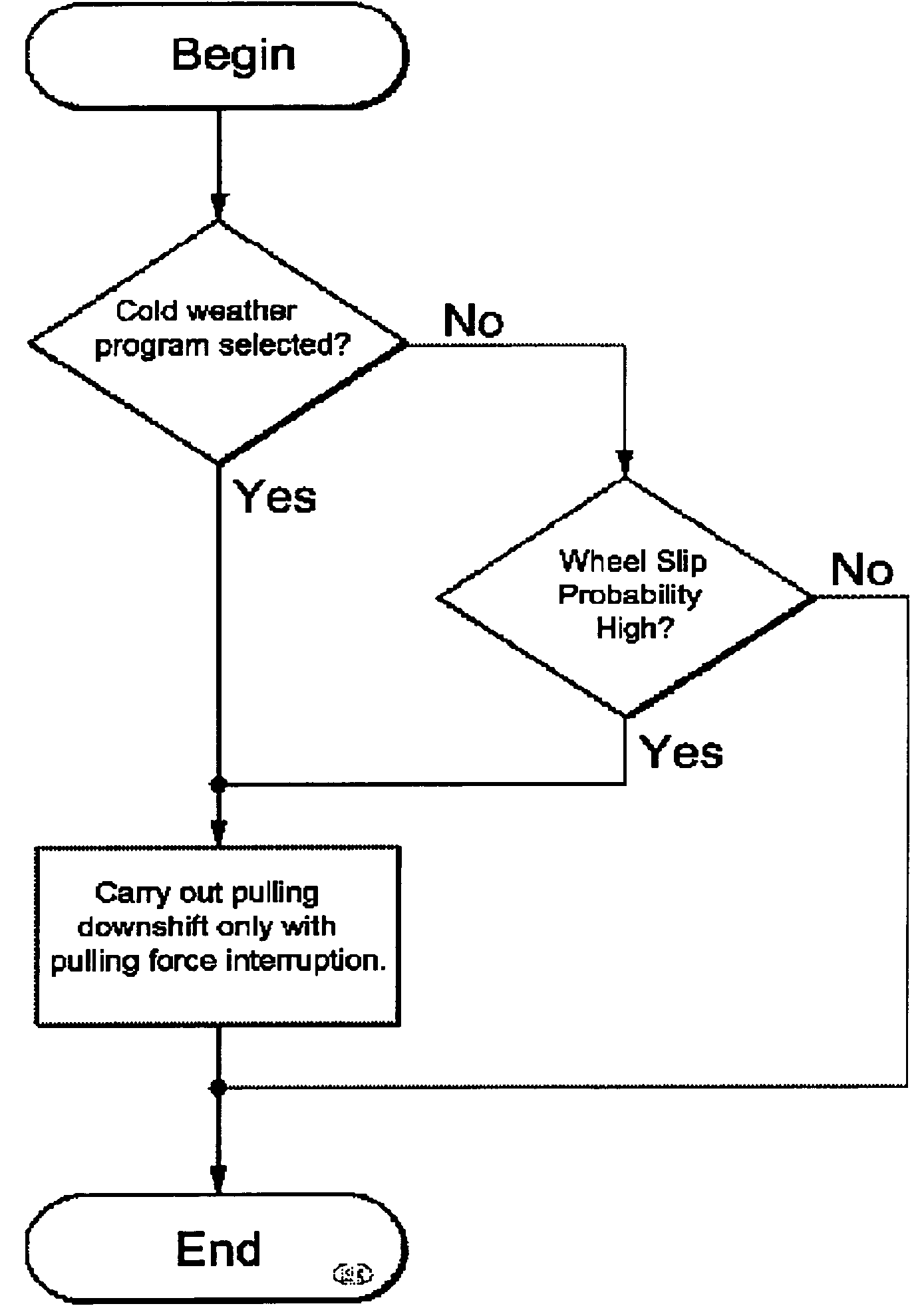

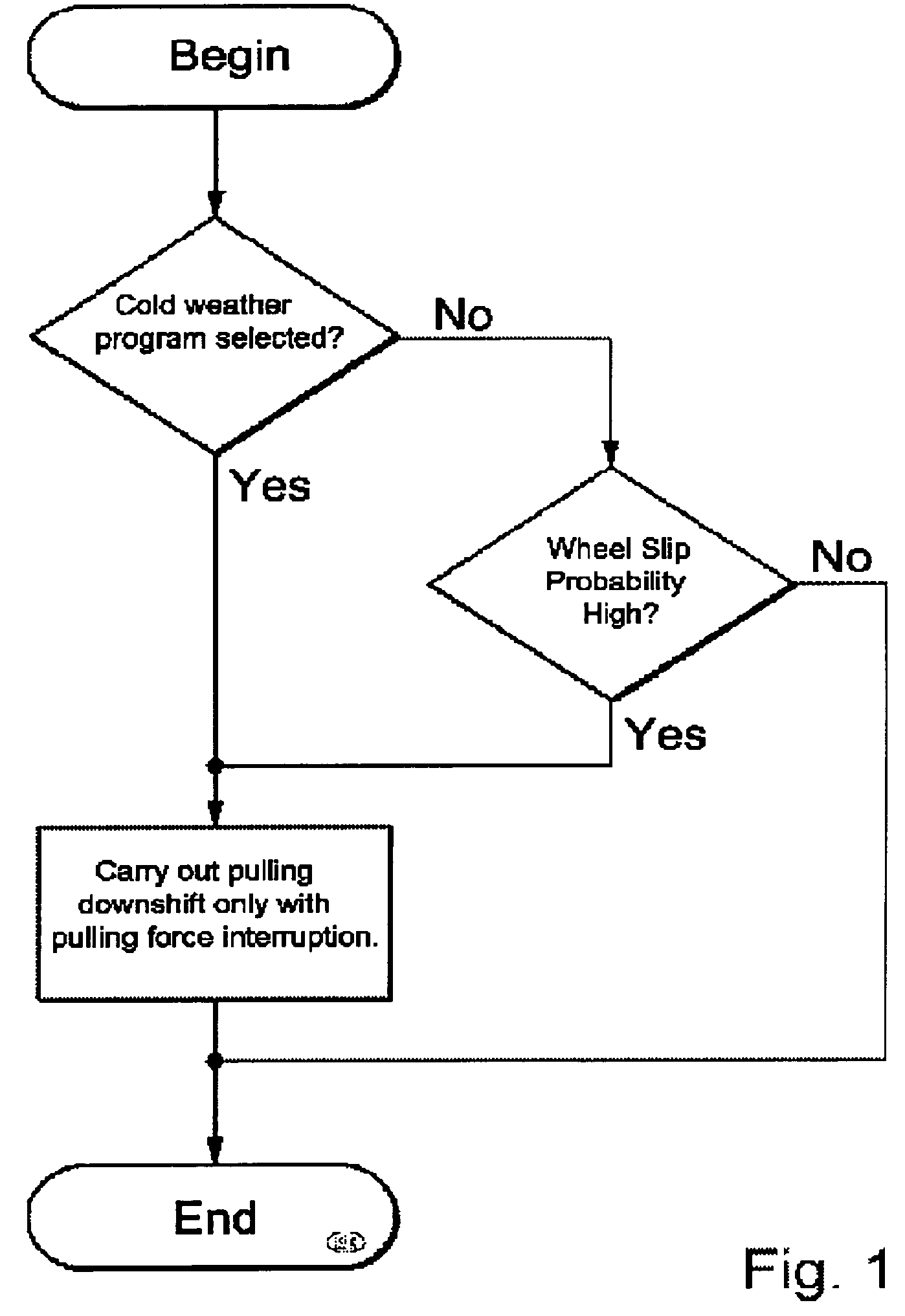

Twin-clutch transmission and method for carrying out a gearshift in a twin-clutch transmission

The invention relates to a method for carrying out a gearshift in a twin-clutch transmission, which is characterized in that a downshift is carried out subject to the kind of shift and / or of at least one predetermined vehicle parameter. The invention also relates to a twin-clutch transmission, especially for carrying out the inventive method.

Owner:LUK LAMELLEN & KUPPLUNGSBAU BETEILIGUNGS KG

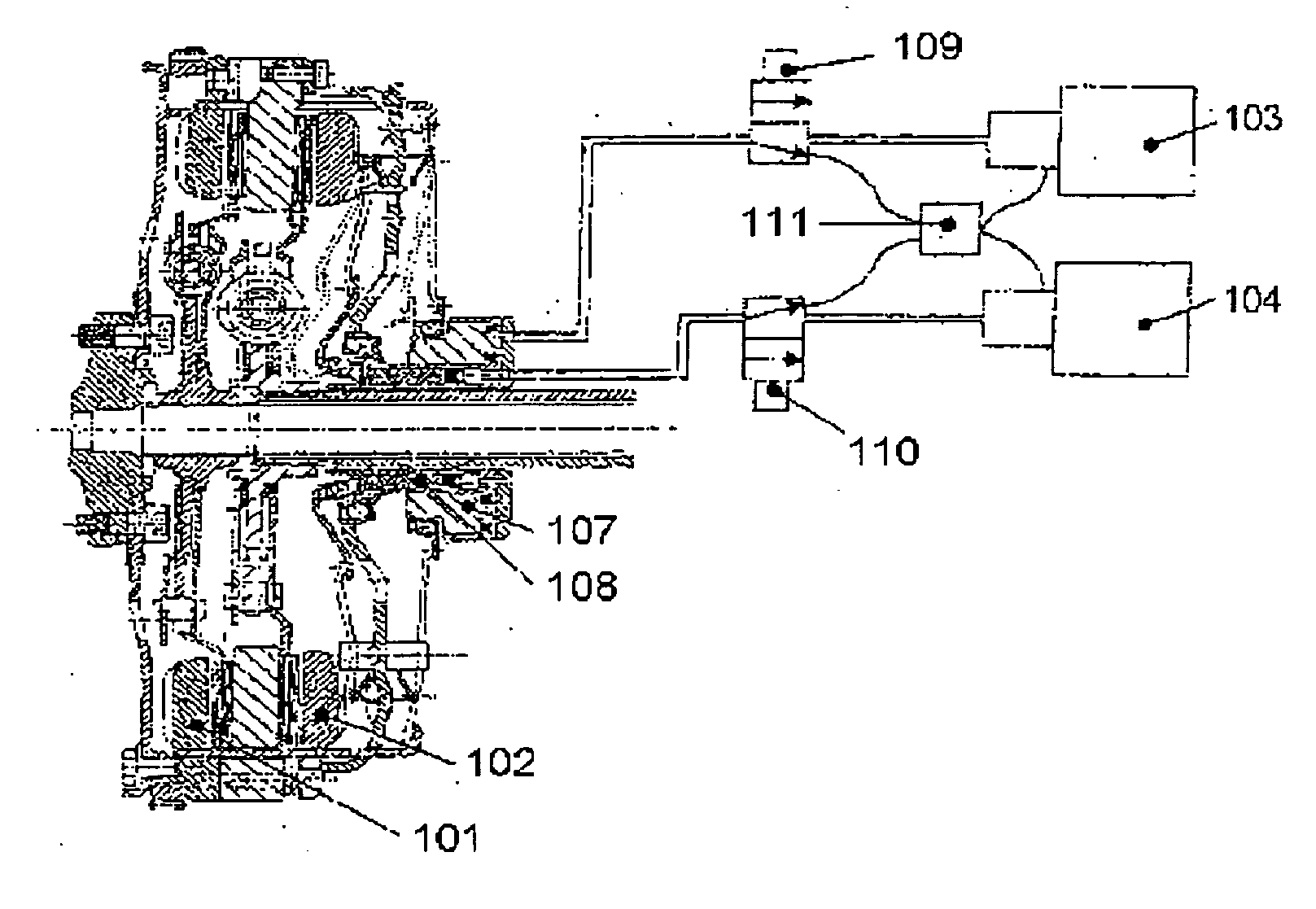

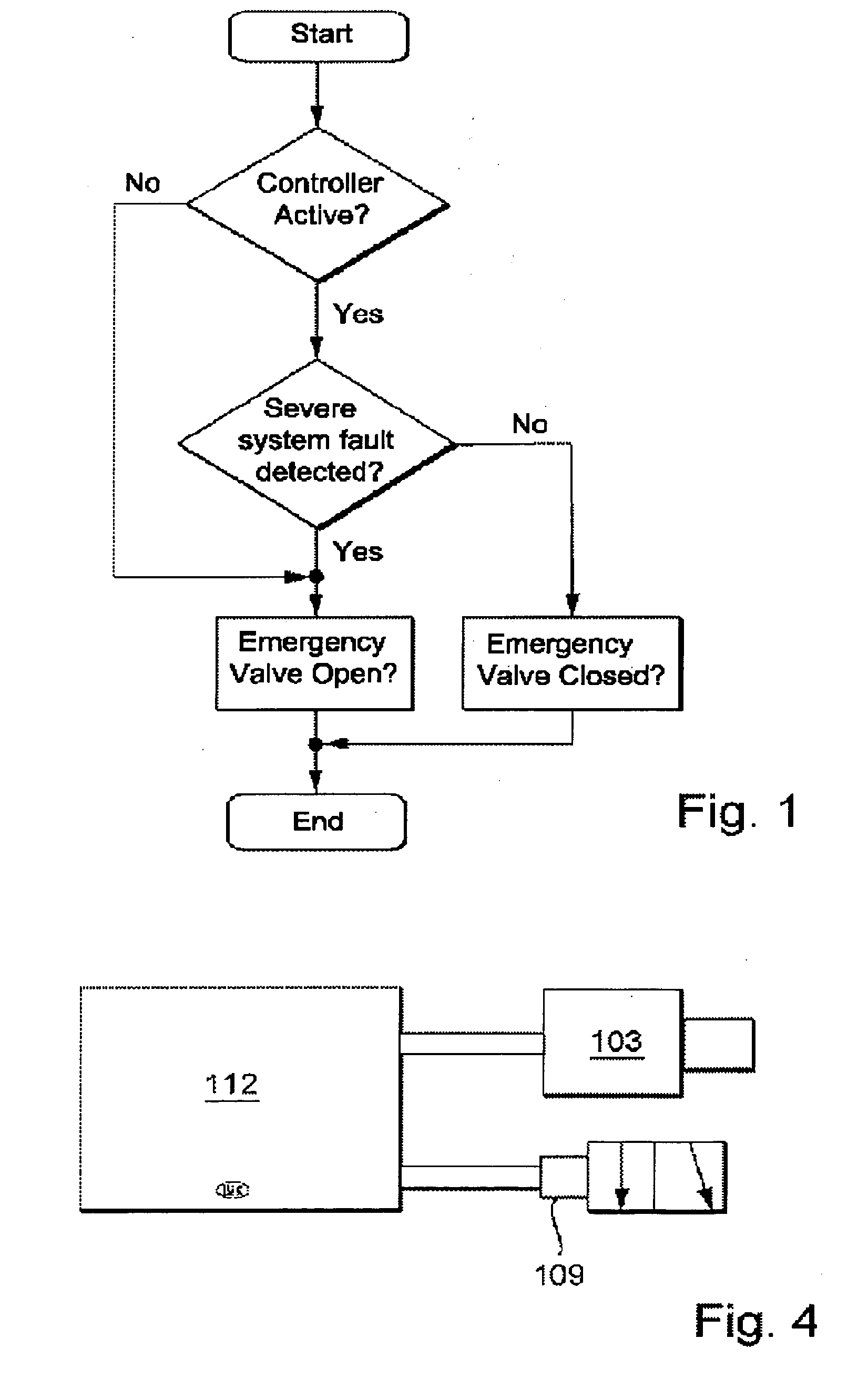

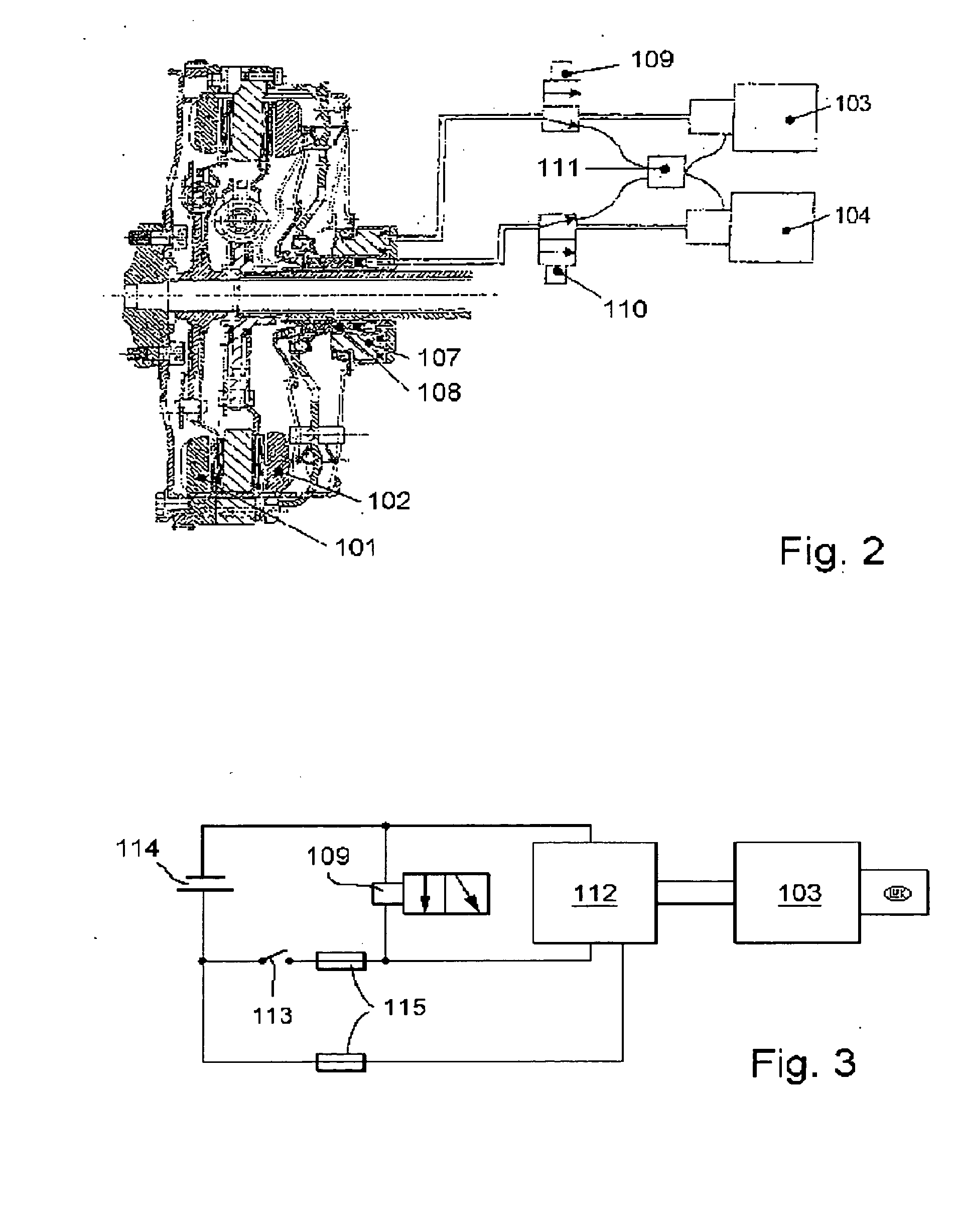

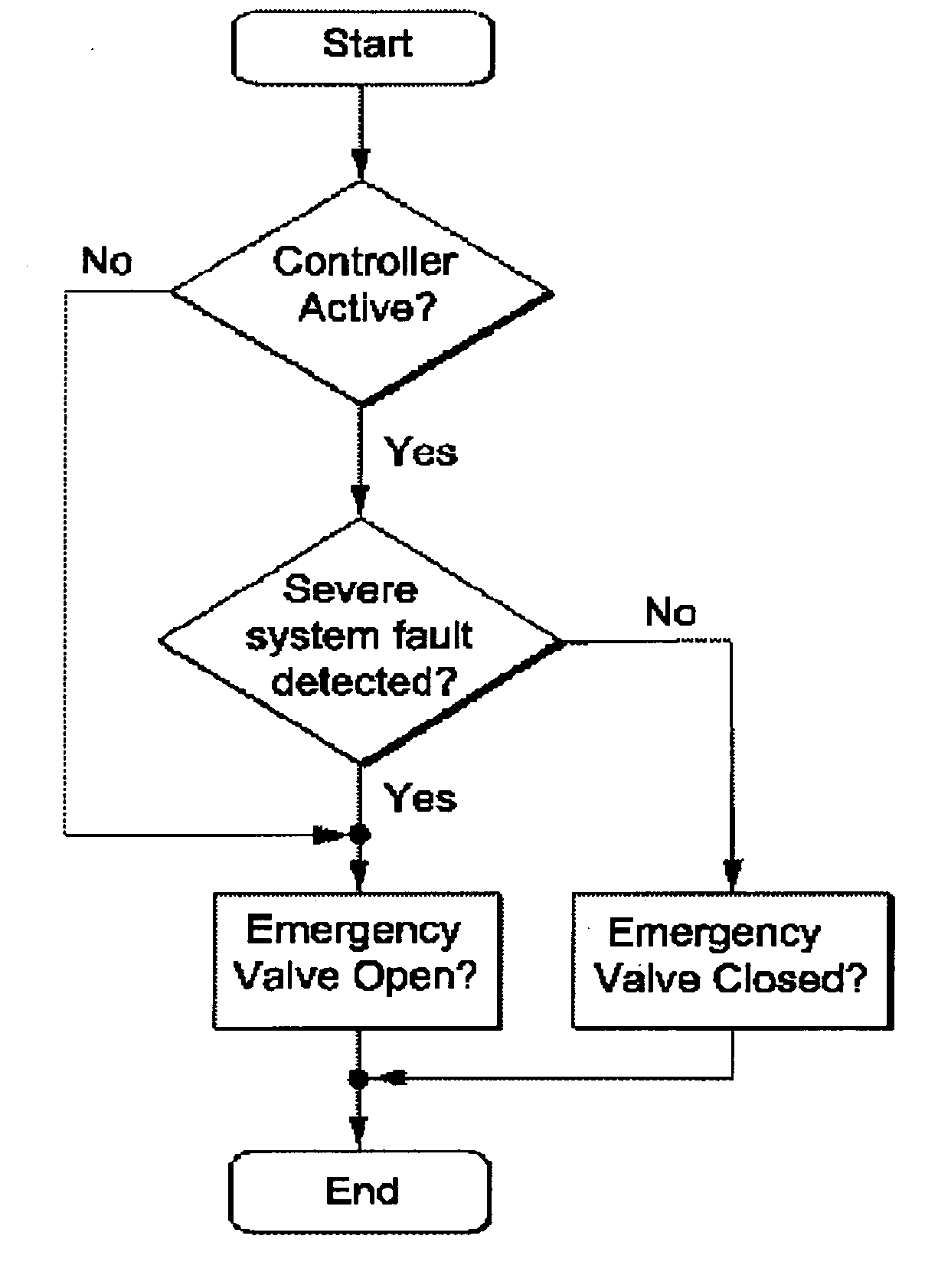

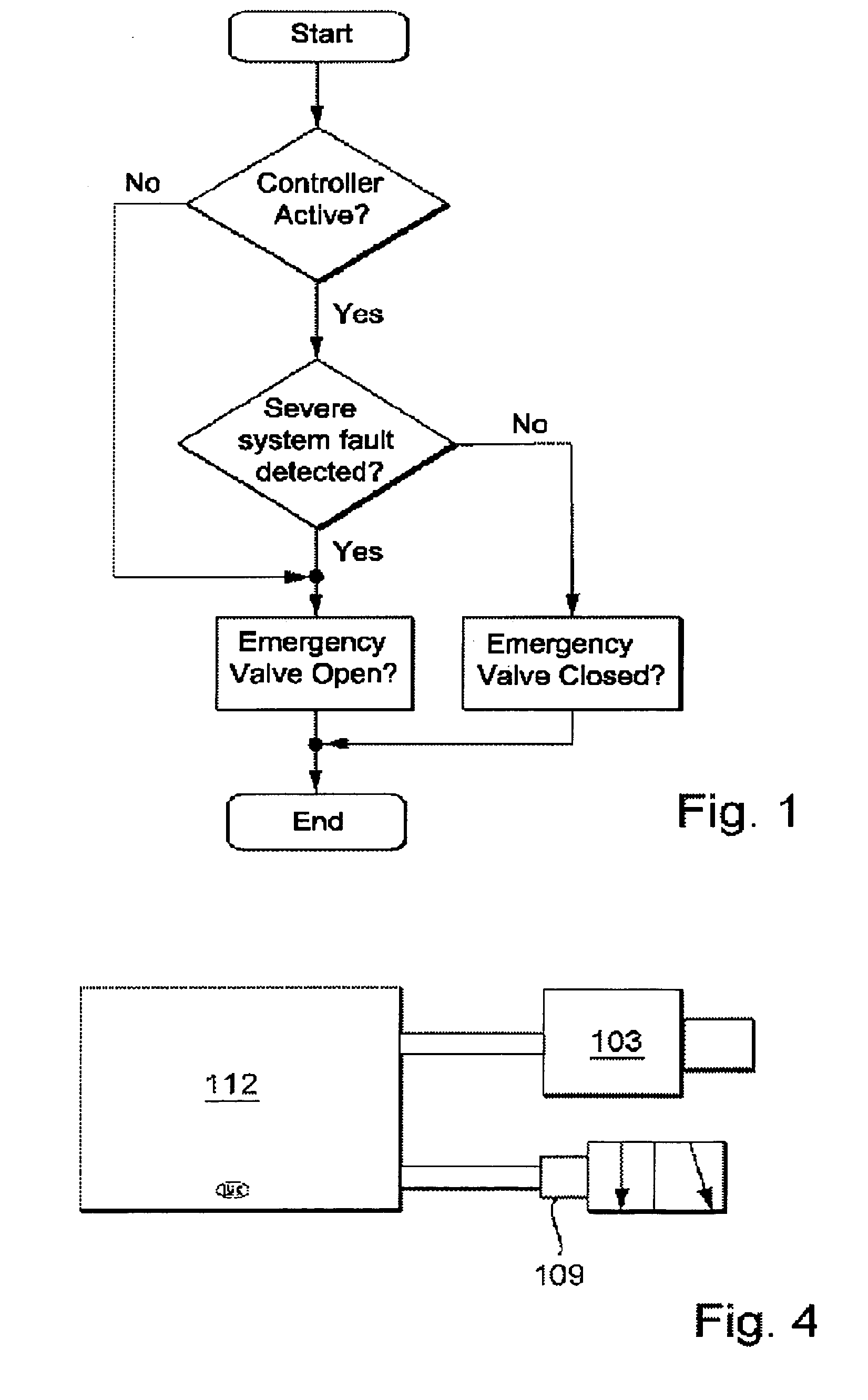

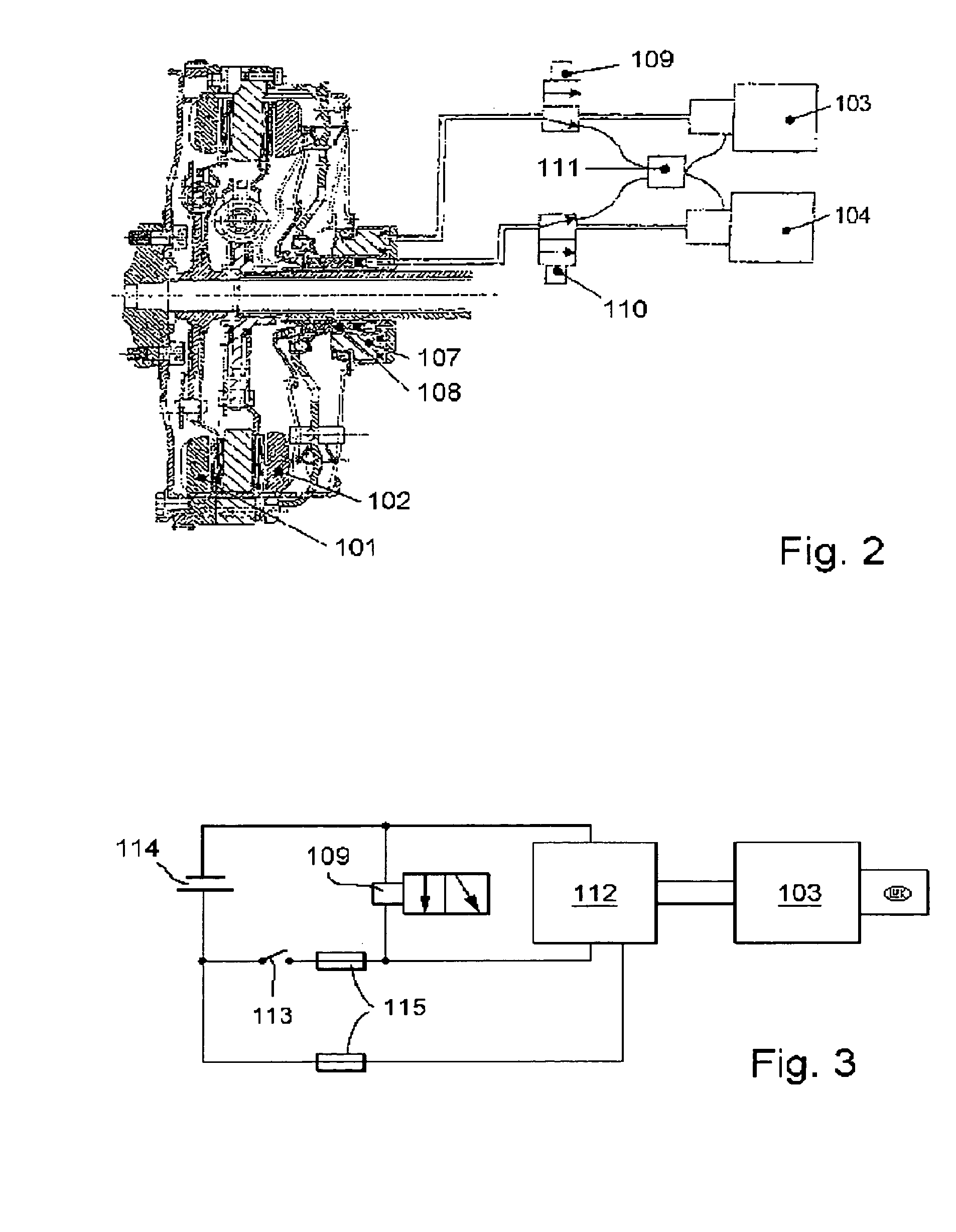

Twin-clutch gearbox and method for controlling at least two clutches in a twin-clutch gearbox of a motor vehicle

InactiveUS20050258014A1Easy to useBraking element arrangementsMechanical actuated clutchesMobile vehicleActuator

A method for controlling at least two clutches in a twin-clutch gearbox of a motor vehicle, wherein at least one clutch is opened by at least one emergency valve. A twin-clutch gearbox of a motor vehicle, consisting of at least two clutches actuated by at least one clutch actuator by means of a release system, especially for carrying out said method, whereby an emergency valve is provided in order to open at least one clutch.

Owner:LUK LAMELLEN & KUPPLUNGSBAU BETEILIGUNGS KG

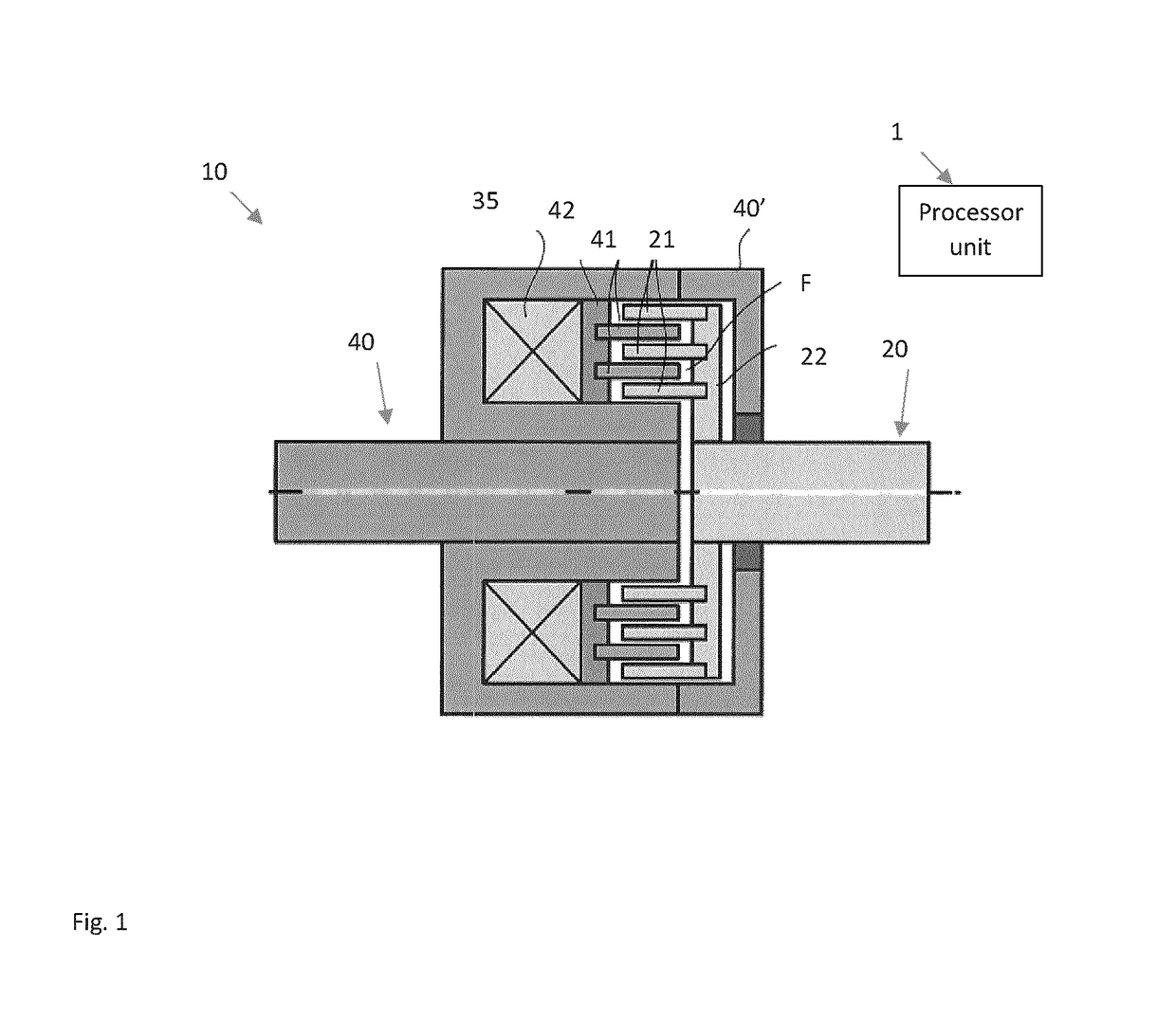

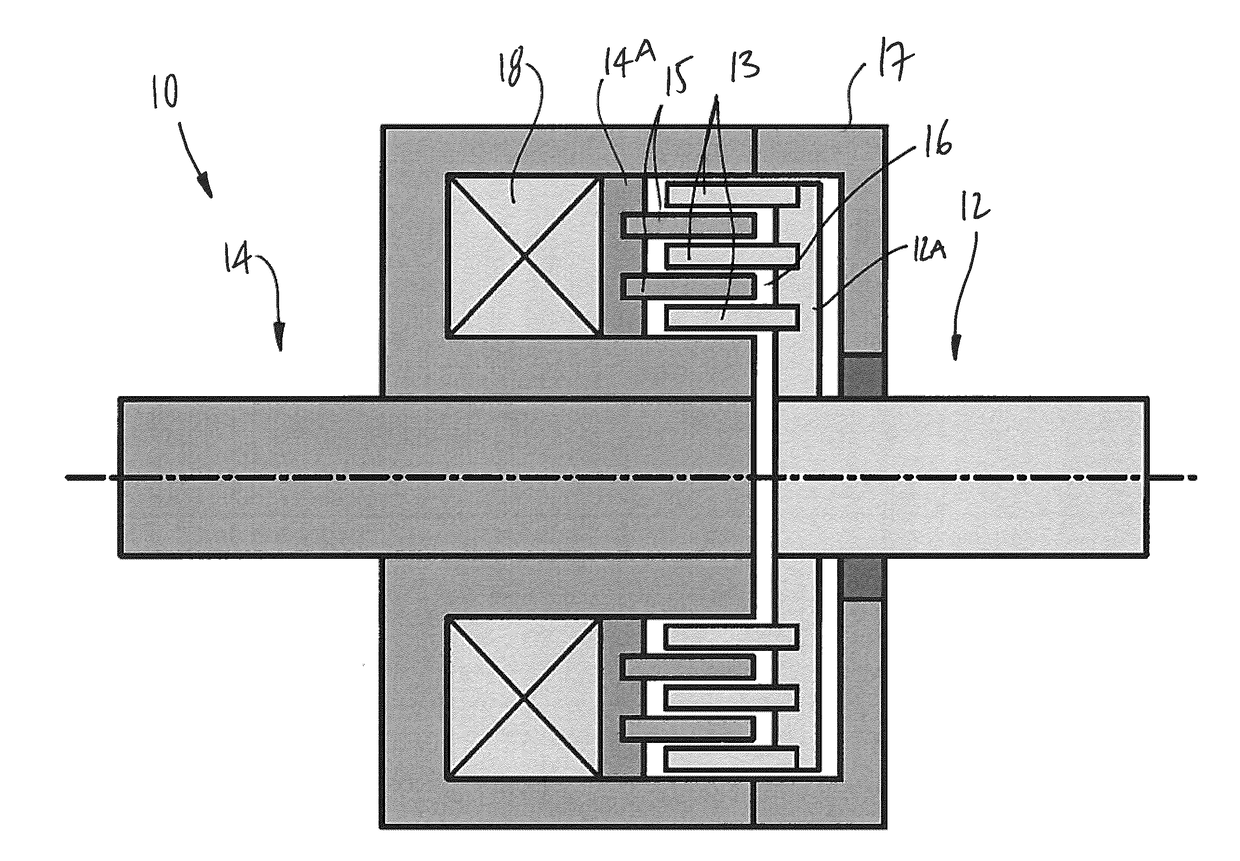

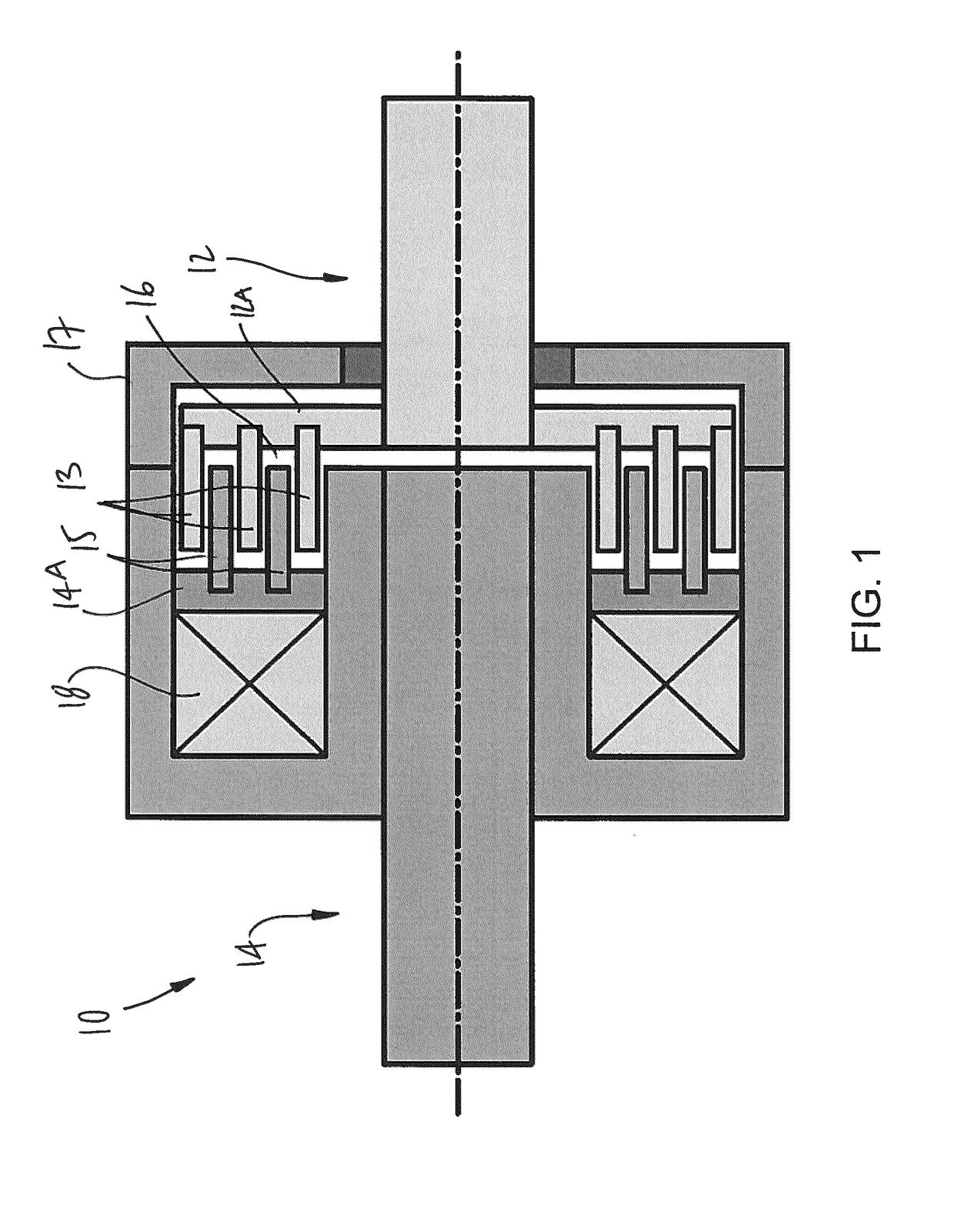

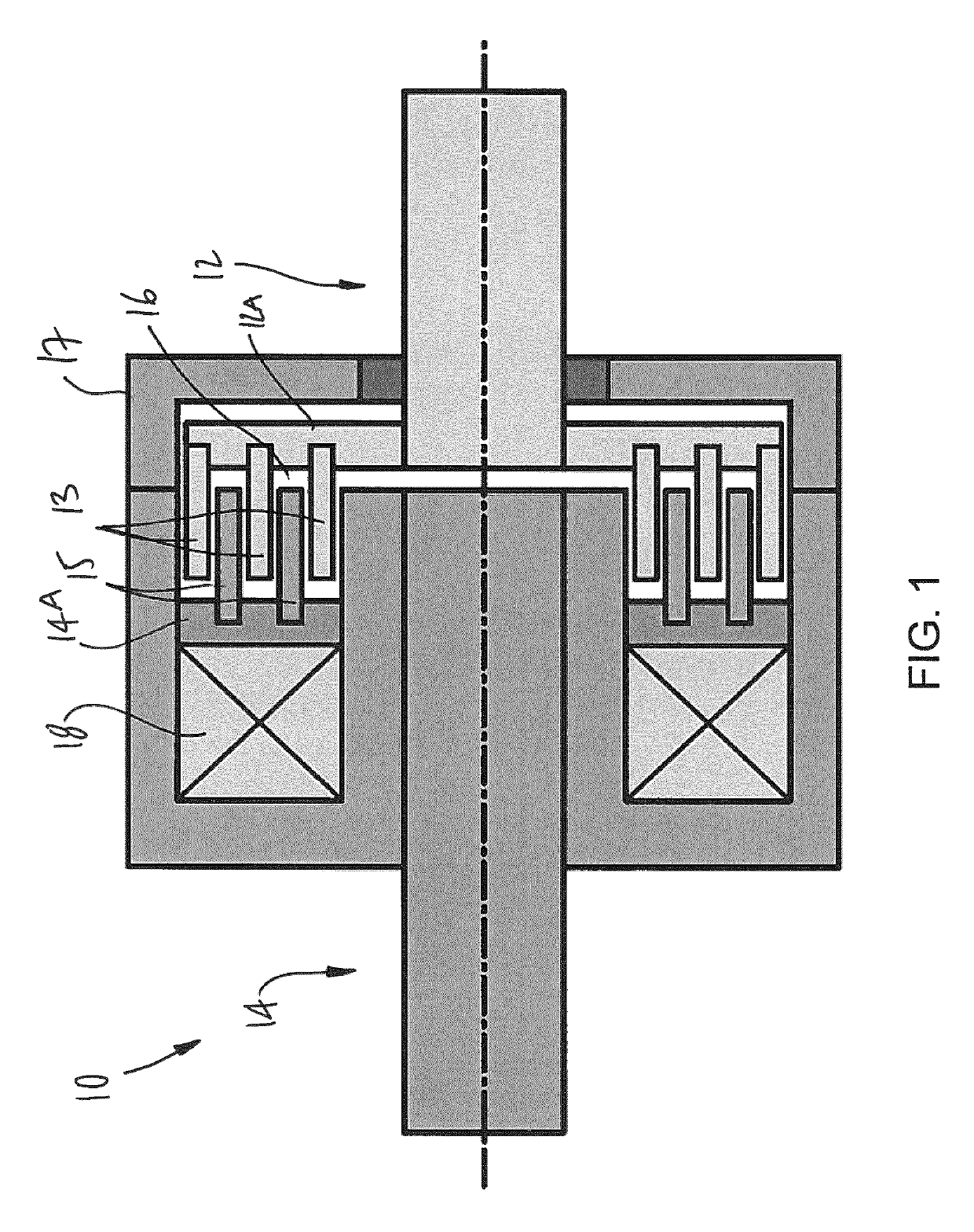

Magnetorheological fluid clutch apparatus with cylindrical fluid gap

ActiveUS20180156285A1Fluid clutchesNon-mechanical actuated clutchesMagnetorheological fluidTorque transmission

A magnetorheological fluid clutch apparatus comprises a stator having at least an annular wall; a first rotor rotatably mounted to the stator, the first rotor having at least one first shear surface; a second rotor rotatably mounted to the stator for rotating about a common axis with the first rotor, the second rotor having at least one second shear surface opposite the at least one first shear surface, the shear surfaces separated by at least one annular space. A magnetorheological (MR) fluid is in an MR fluid chamber including the at least one annular space, the MR fluid configured to generate a variable amount of torque transmission between the rotors when subjected to a magnetic field. An inner magnetic core and an outer magnetic core with an annular cavity therebetween receive the annular wall of the stator, the inner magnetic core and the outer magnetic core connected to at least one of the rotors to rotate therewith so as to be rotatably mounted to the stator. Outer and inner fluid gaps are between the inner magnetic core and the annular wall, and between the outer magnetic core and the annular wall, the outer and inner fluid gaps filled with at least one fluid. At least one coil is supported by the annular wall and actuatable to deliver a magnetic field through the MR fluid, the magnetic field following a path comprising the annular wall, the outer fluid gap, the outer magnetic core, the at least one first shear surface and the at least one second shear surface,the inner magnetic core and the inner fluid gap, wherein one of the rotors is adapted to be coupled to a power input and the other of the rotors is adapted to be connected to an output whereby actuation of the at least one coil results in a variation of torque transmission between the rotors.

Owner:EXONETIK INC

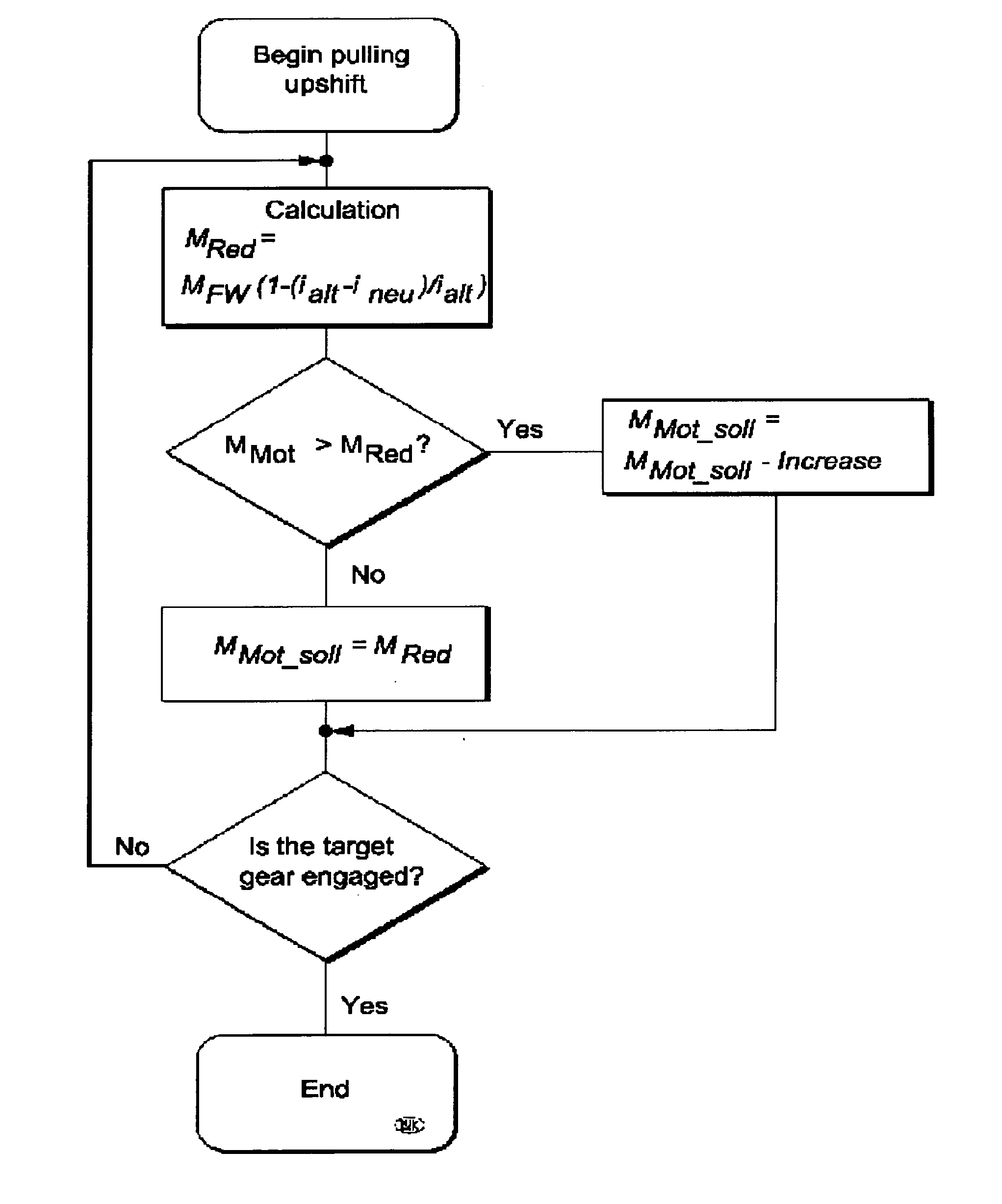

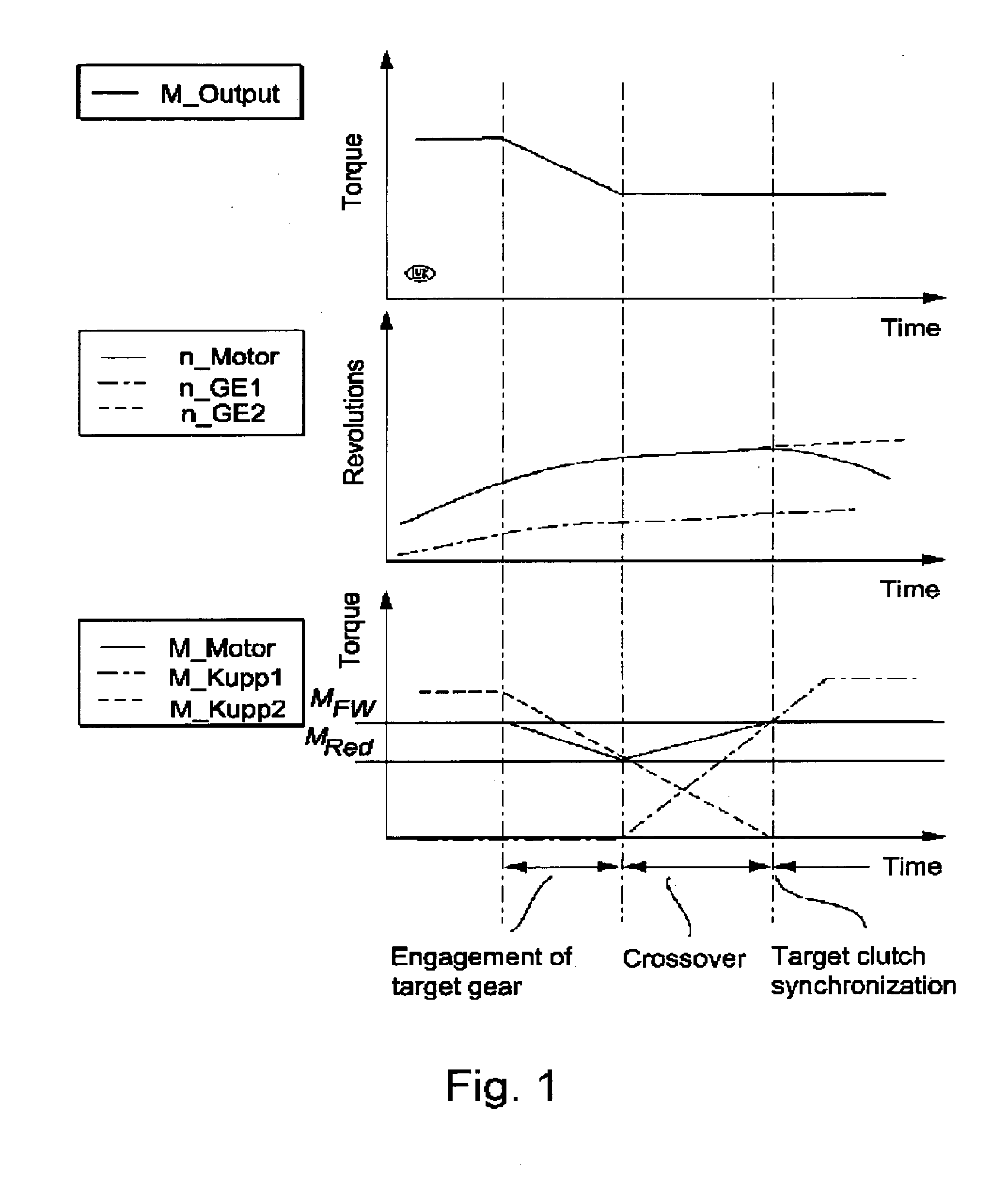

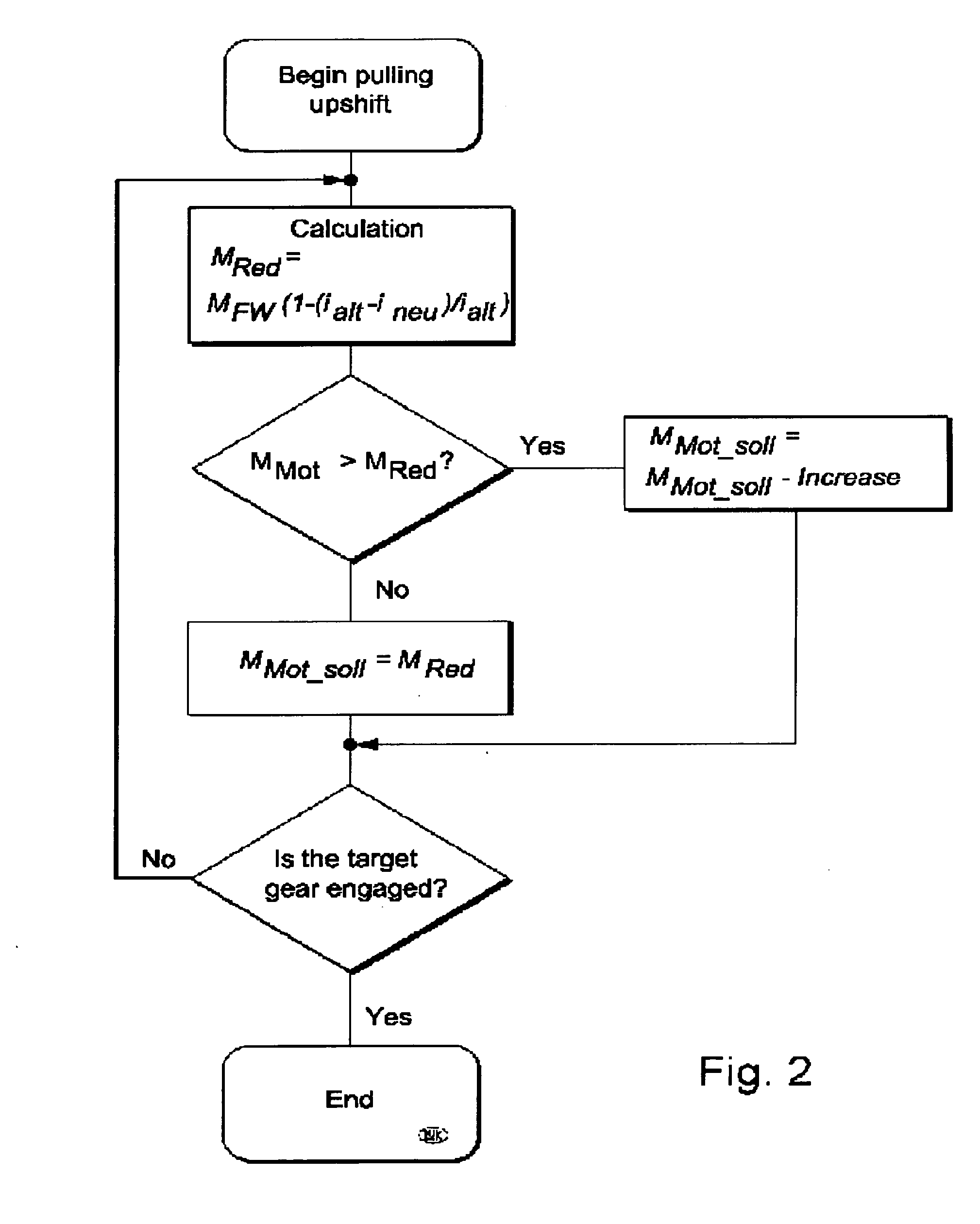

Twin-clutch gearbox and method for shifting an initial gear upwards into a target gear in the twin-clutch gearbox of a motor vehicle

The invention relates to a method for shifting an initial gear upwards into a target gear in a twin-clutch gearbox of a motor vehicle. According to the invention, the engine torque (MMotor) of the vehicle is altered when a target gear is selected incorrectly and detected thus. The output torque (MOutput) is then reduced if the correct target gear is introduced. The invention also relates to a twin-clutch gearbox, especially for carrying out said method.

Owner:SCHAEFFLER TECH AG & CO KG

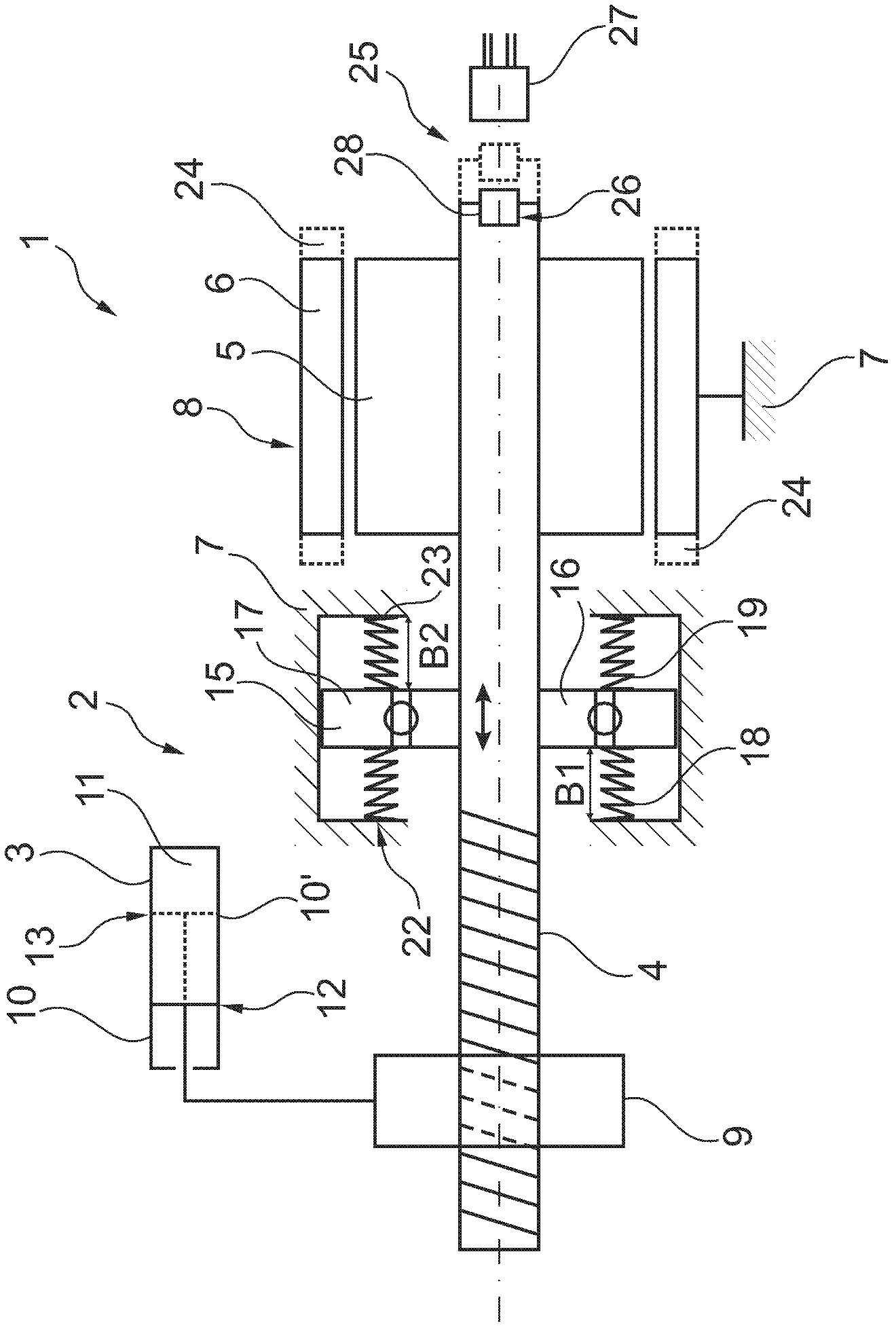

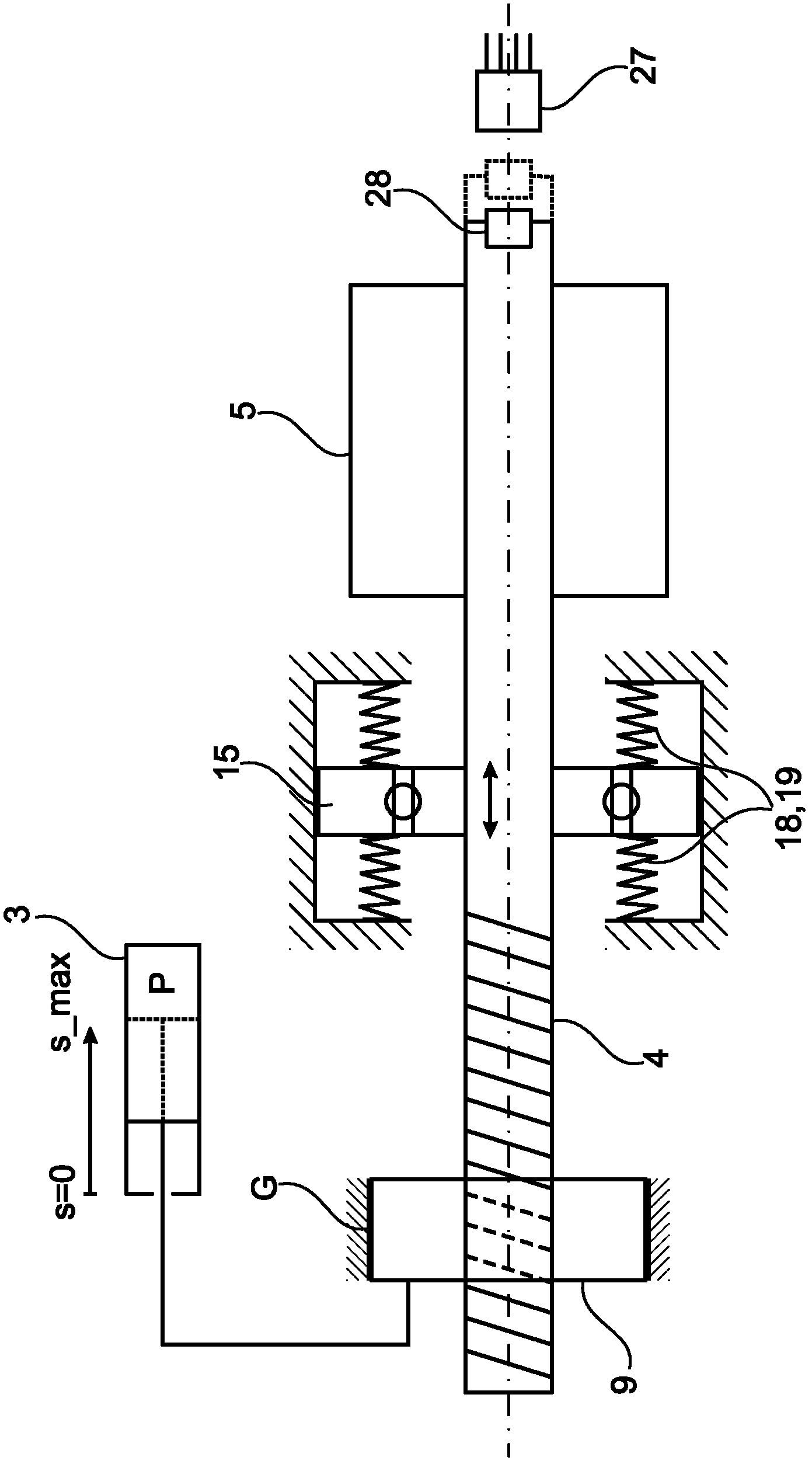

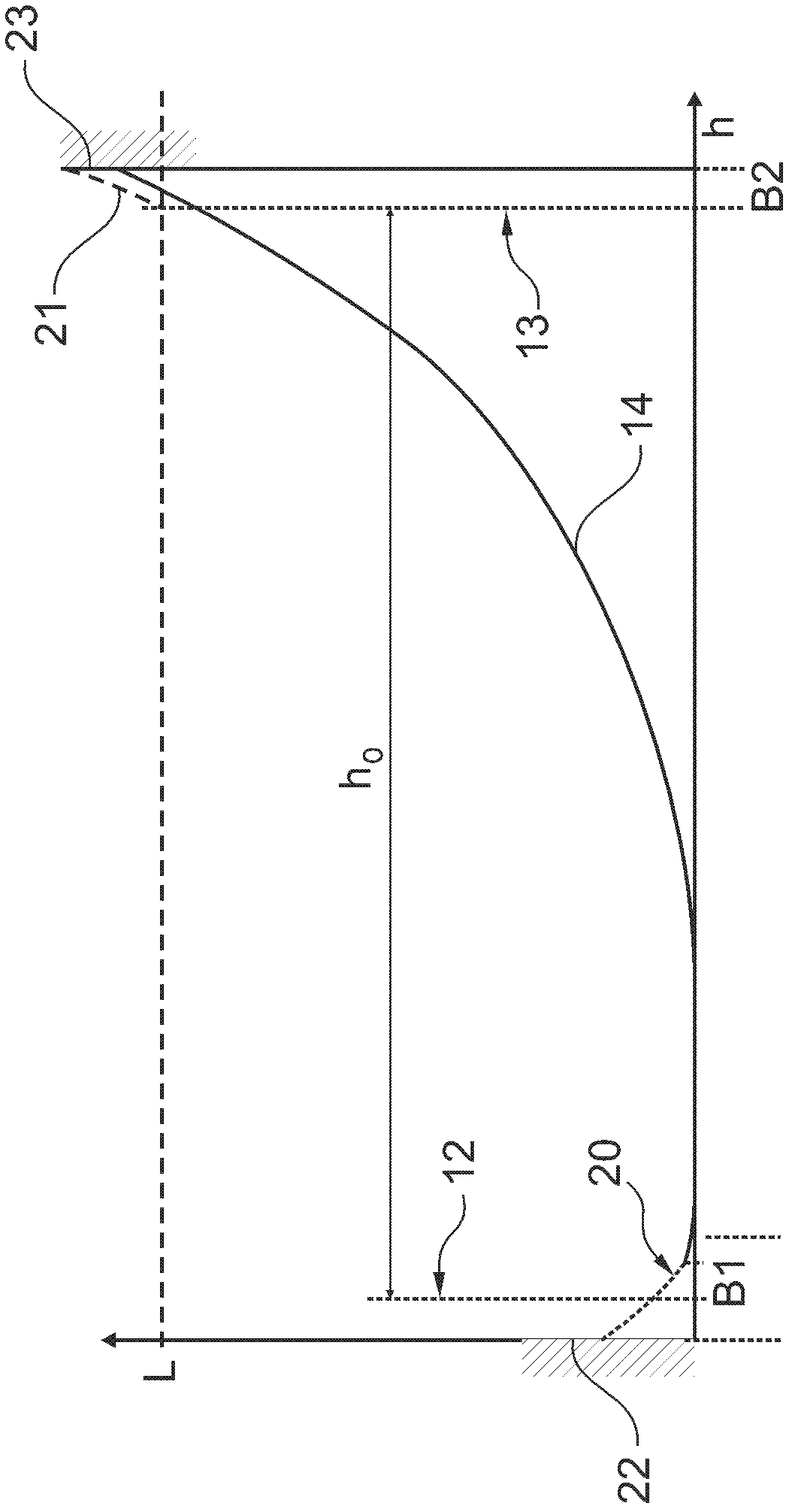

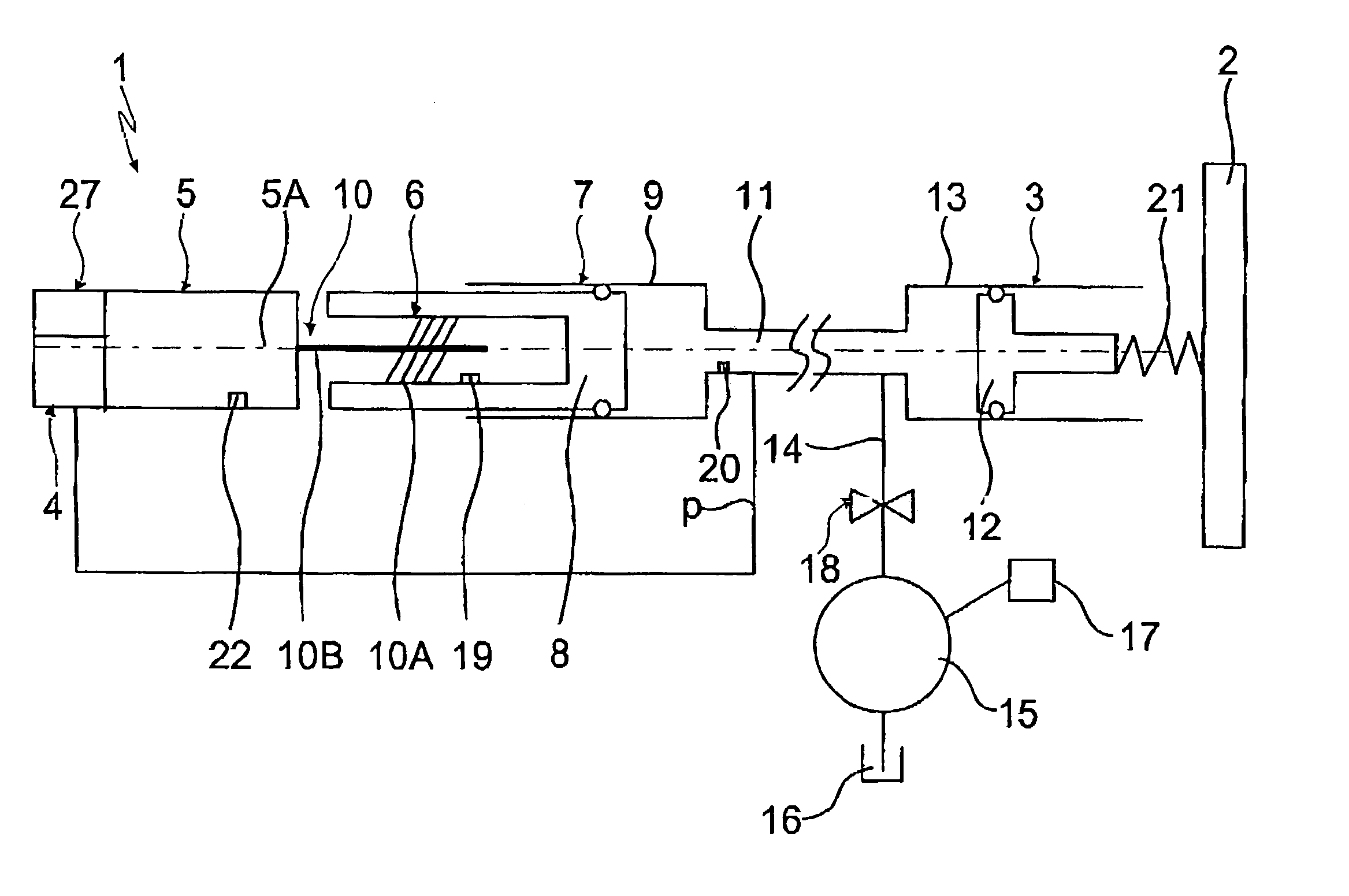

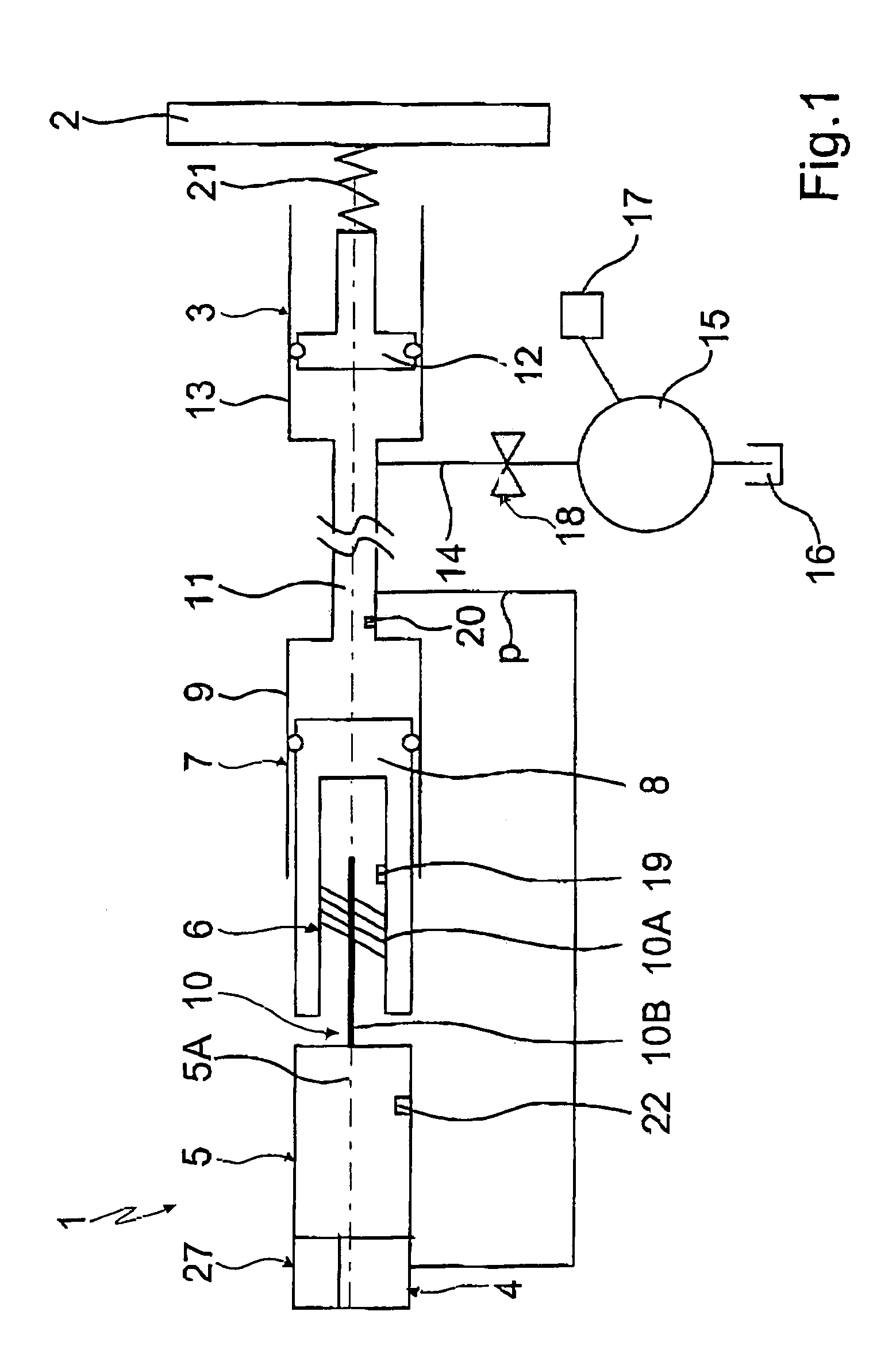

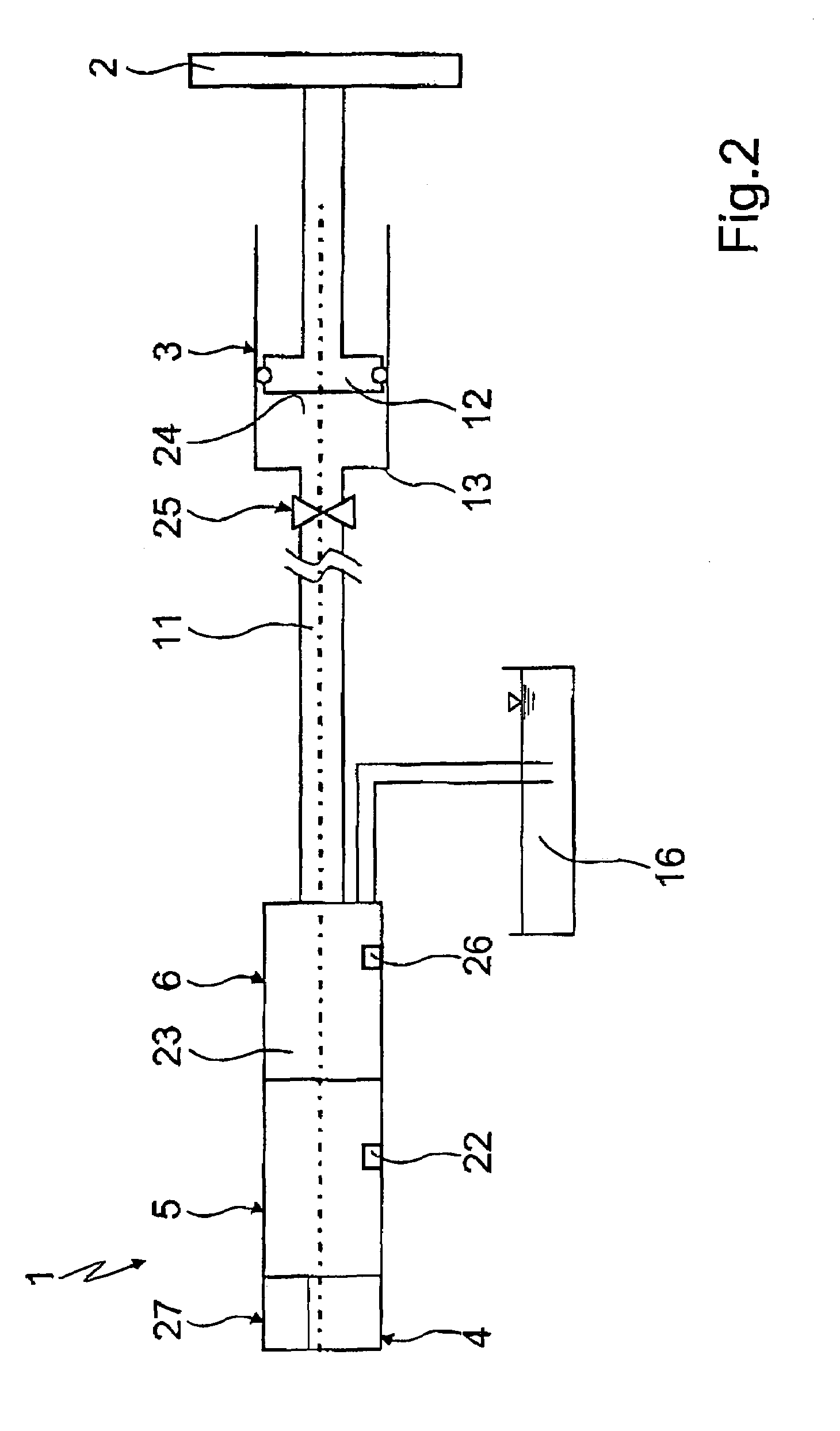

Spindle actuator

InactiveCN102549306ALimit efficiencyMobile adaptationGearingGearing controlAxial displacementLoad resistance

The invention relates to a spindle actuator (1), in particular for acting on a piston (10) of a master cylinder (3), comprising a housing (7), a threaded spindle (4) rotatably arranged on the housing, a spindle nut (9) arranged rotatably on the threaded spindle and in a rotationally-fixed manner relative to the housing, and an electric motor (8) that is accommodated in the housing and that drives the threaded spindle, the electric motor having a stator (6) and a rotor (5) rigidly connected to the threaded spindle and a sensor device (25) for detecting a load applied by the spindle nut to a component axially displaced by the spindle nut. In order to be able to determine the load applied by the threaded spindle to the axially displaced component if the load resistance is known, the threaded spindle is supported in a such a way that the threaded spindle can be axially displaced to a limited extent relative to the housing against the effect of at least one axially effective energy accumulator (18, 19), and an axial travel (B1, B2) of the threaded spindle is detected by means of the sensor device.

Owner:SCHAEFFLER TECH AG & CO KG

Twin-clutch gearbox and method for controlling at least two clutches in a twin-clutch gearbox of a motor vehicle

InactiveUS7153234B2Easy to useBraking element arrangementsMechanical actuated clutchesMobile vehicleActuator

A method for controlling at least two clutches in a twin-clutch gearbox of a motor vehicle, wherein at least one clutch is opened by at least one emergency valve. A twin-clutch gearbox of a motor vehicle, consisting of at least two clutches actuated by at least one clutch actuator by means of a release system, especially for carrying out said method, whereby an emergency valve is provided in order to open at least one clutch.

Owner:LUK LAMELLEN & KUPPLUNGSBAU BETEILIGUNGS KG

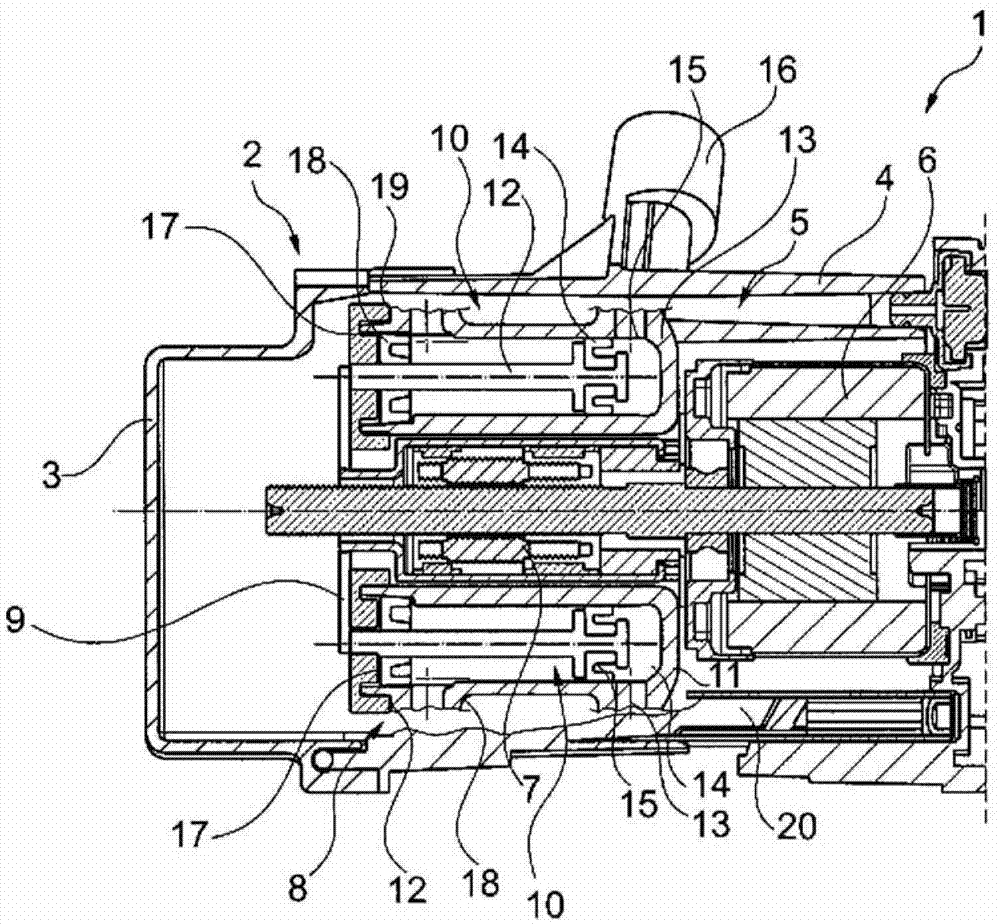

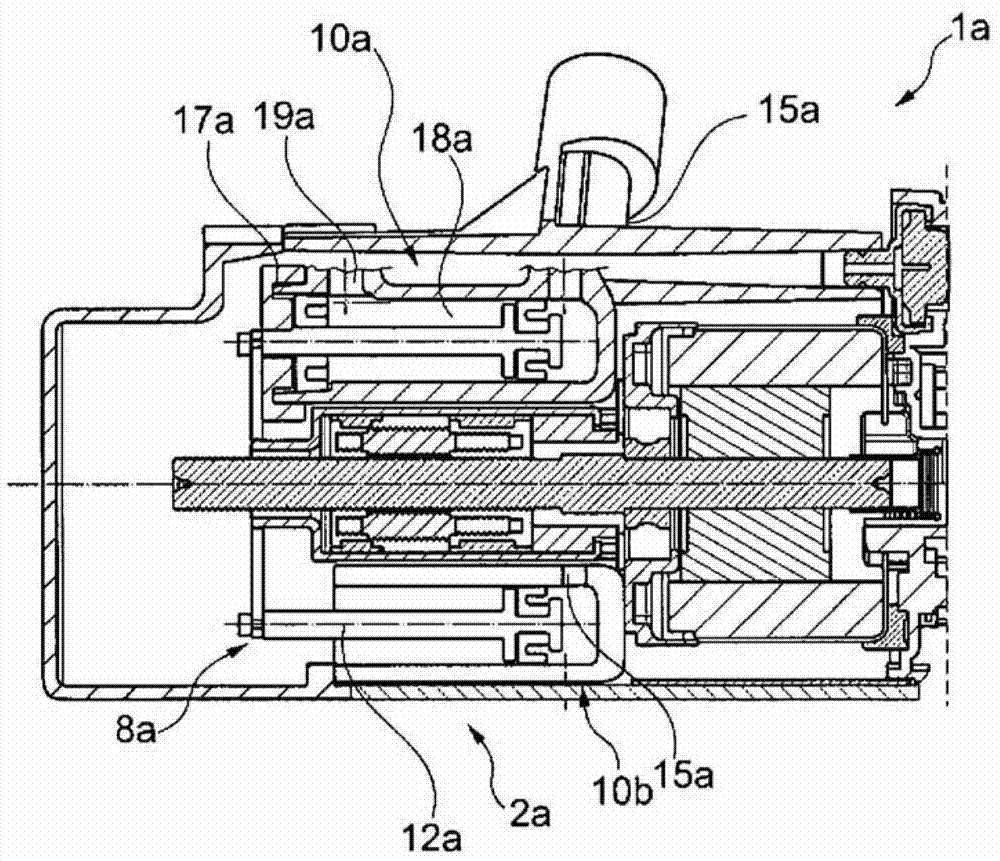

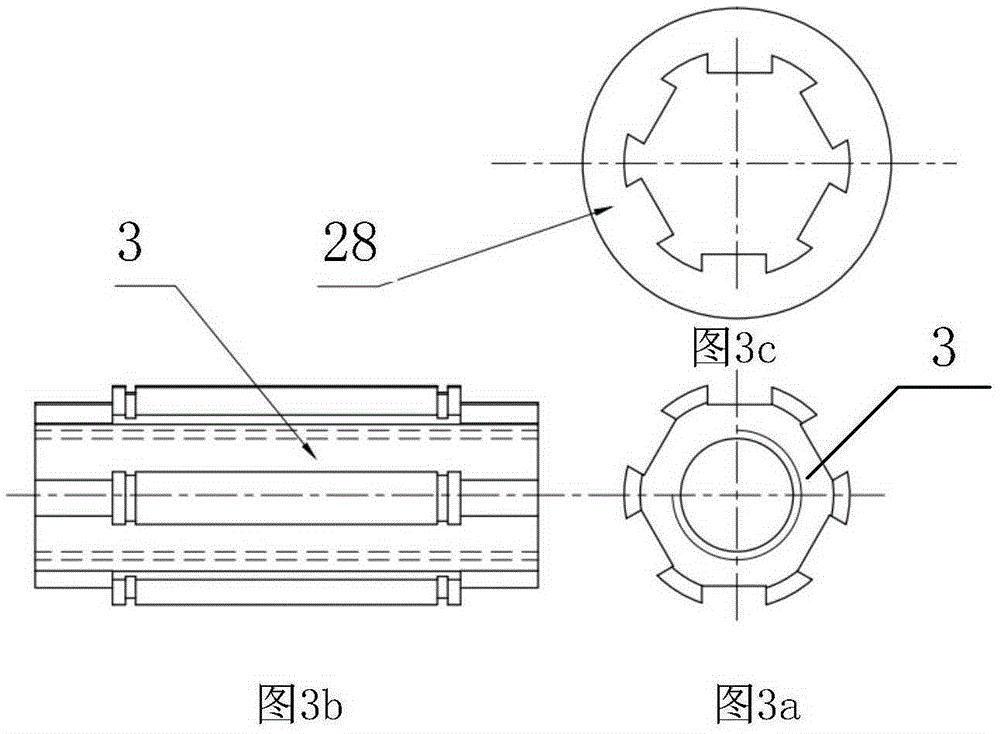

Hydrostatic actuator

InactiveCN102971547AReduce reprocessingReduce defective rateAssociation with control/drive circuitsTelemotorsRotational axisManufacturing cost reduction

The invention relates to a hydrostatic actuator (1, 1a), in particular in a motor vehicle containing a drive unit (5), comprising an electric motor (6), a planetary roller gear system (7) that is driven by a rotor of the electric motor, and a hydrostatic master cylinder unit (8, 8a) which is driven by the planetary roller gear system and which is disposed around the planetary roller gear system. The aim of the invention is to increase the efficiency and reduce the production costs. This is achieved in that the master cylinder unit is formed from multiple master cylinders (10, 10a, 10b) which are distributed over the circumference with respect to a rotational axis of the rotor and each of which is connected to the planetary roller gear system.

Owner:SCHAEFFLER TECH AG & CO KG

Device for controlling and/or regulating a hydraulically activatable shifting element of a gearing mechanism and a gearing mechanism

InactiveUS7703348B2Reduce power consumptionImprove efficiencyGas pressure propulsion mountingToothed gearingsGear wheelTransformer

A device (1) is described for controlling and / or regulating a hydraulically activatable shifting element. The shifting element (2) is configured with a piston-cylinder unit (3) that can be acted upon by a hydraulic operating pressure (p) and can be arranged in an installation space that is connected to an oil sump of the gearing mechanism device. In addition, the device (1) is provided with an electric motor (5) that can be actuated by a control and / or regulator unit (4), and which is provided with a drive-transformer device (6) that has a functional connection to the electric motor (5), by way of which the rotational drive of the electric motor (5) can be transformed into the hydraulic operating pressure (p) for the shifting element (2).

Owner:ZF FRIEDRICHSHAFEN AG

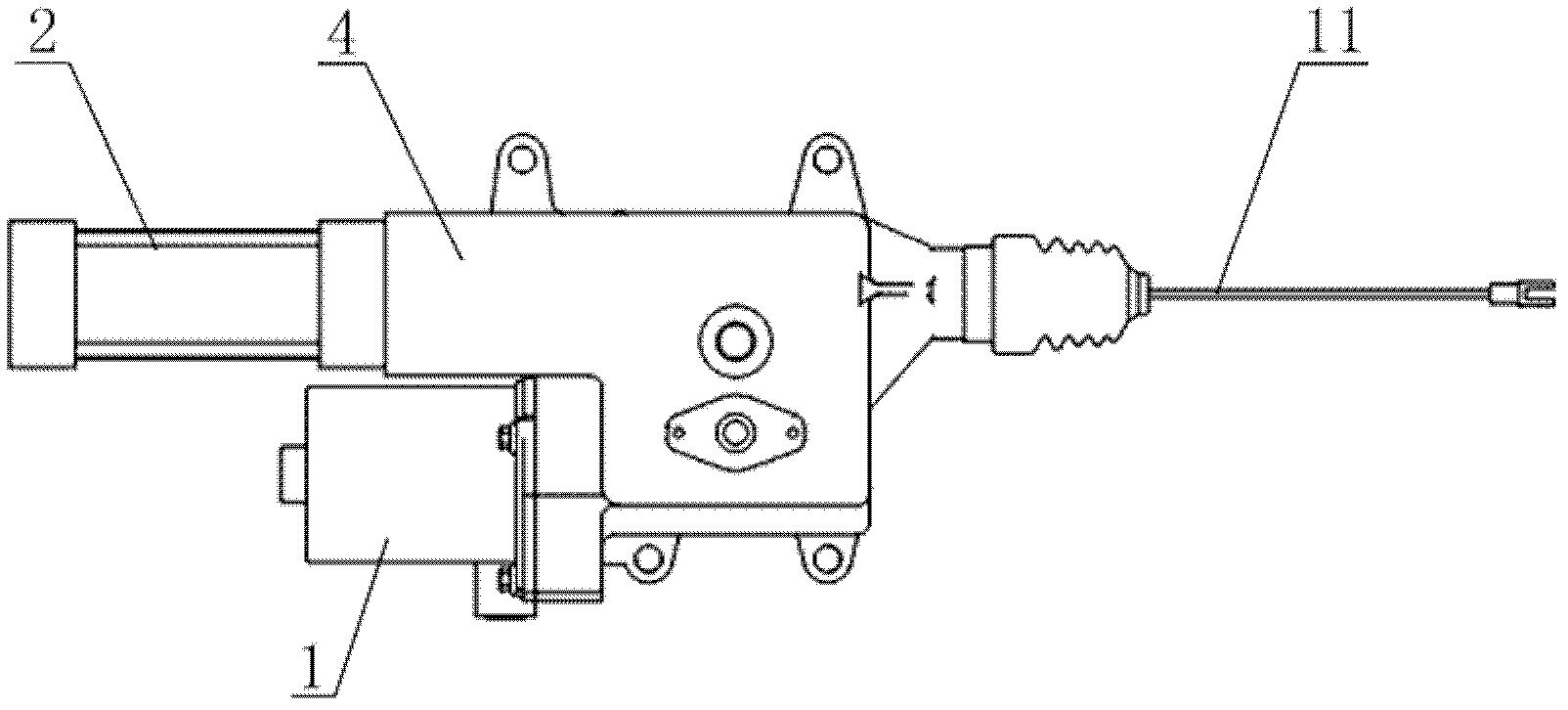

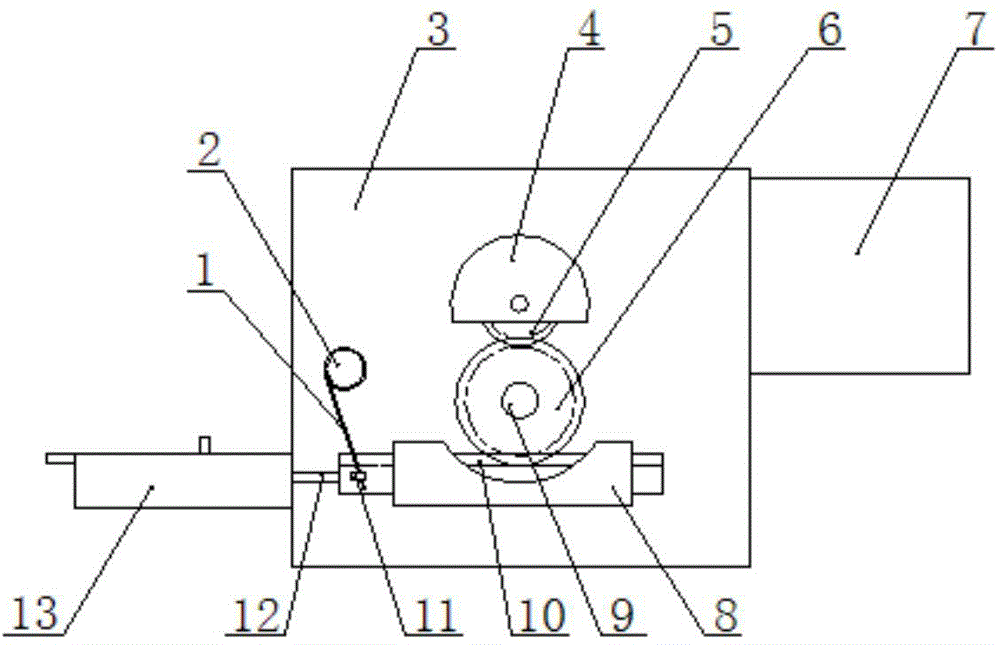

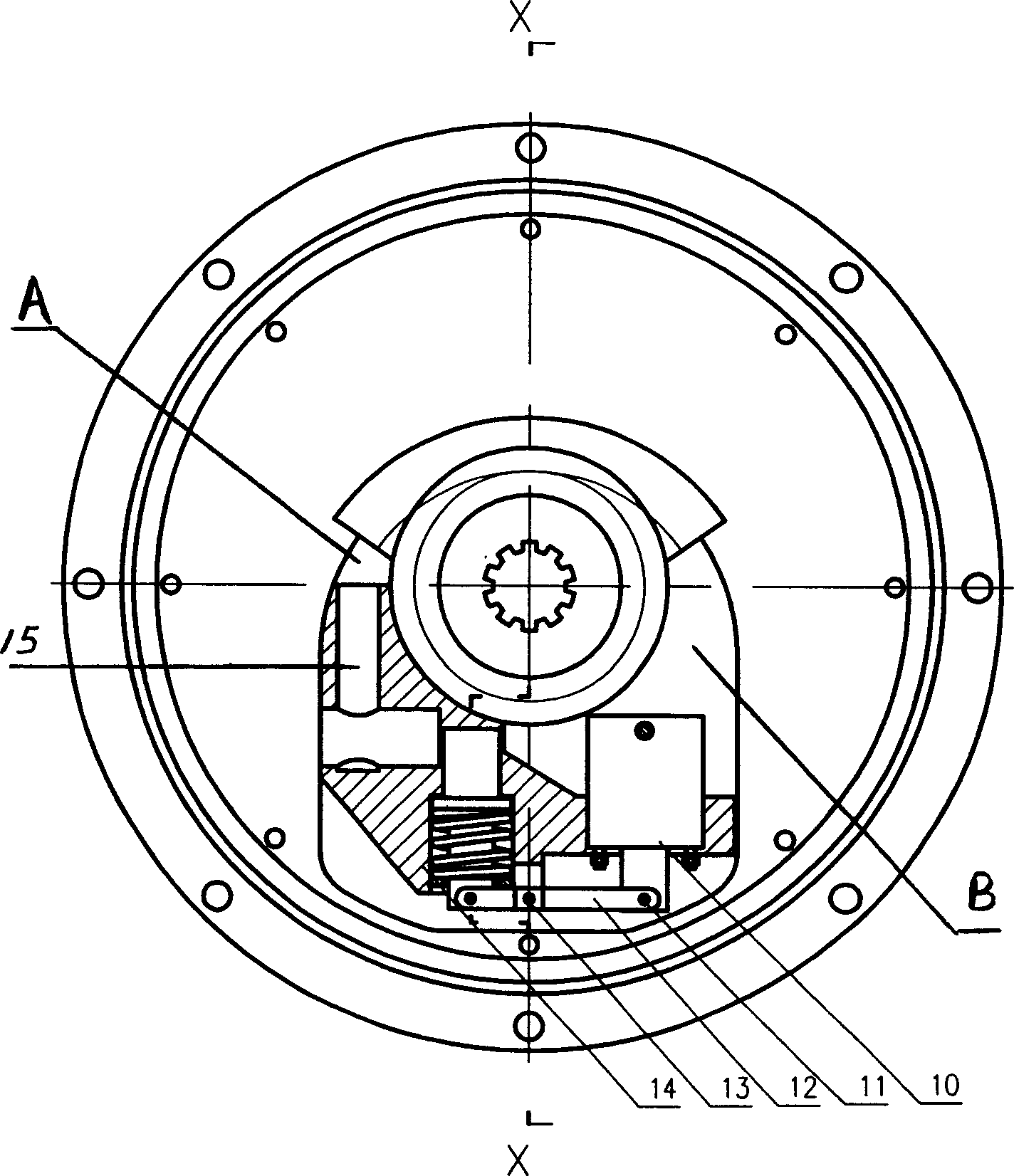

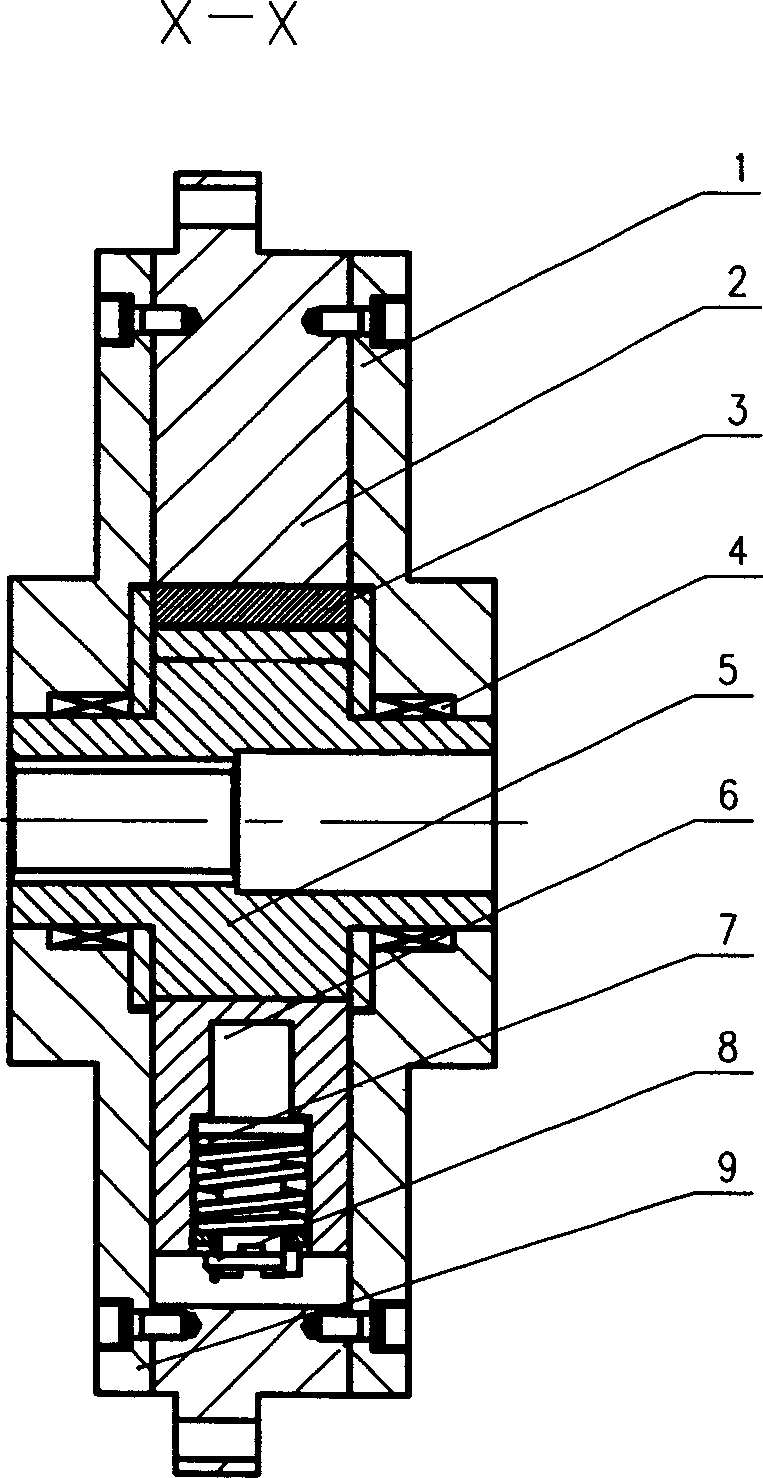

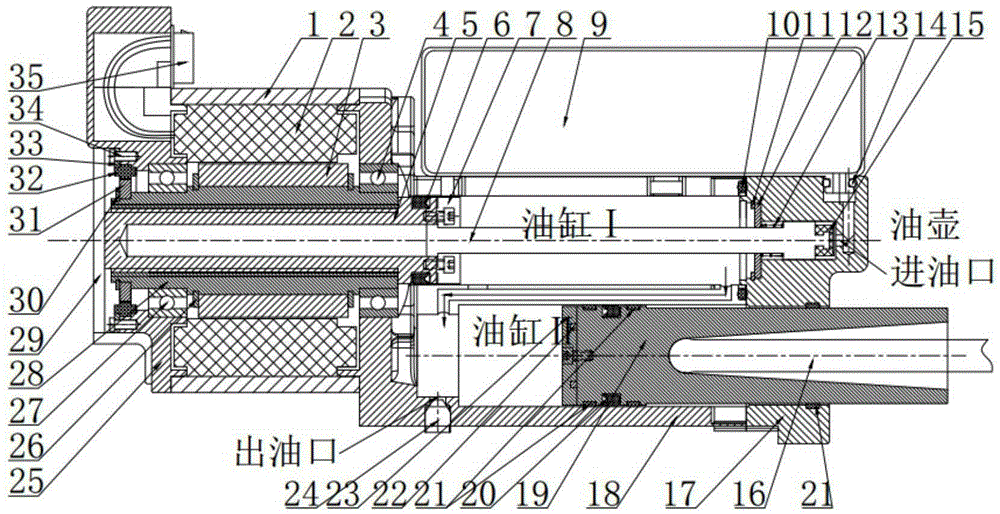

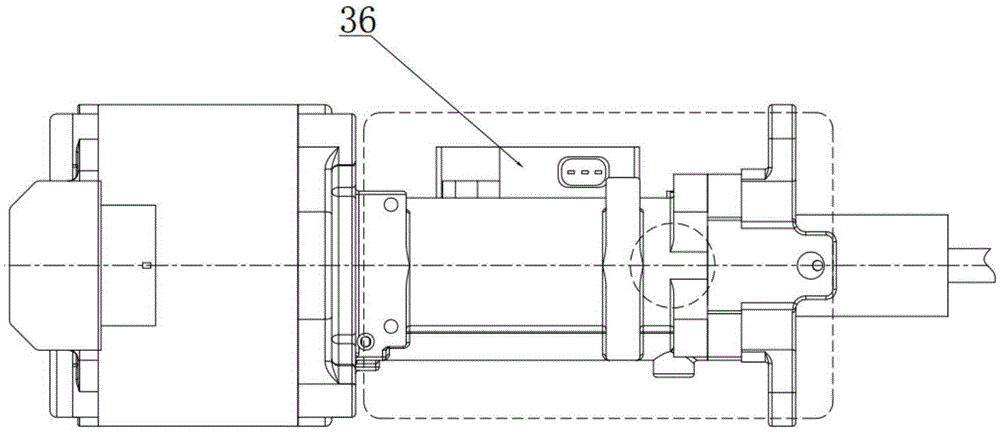

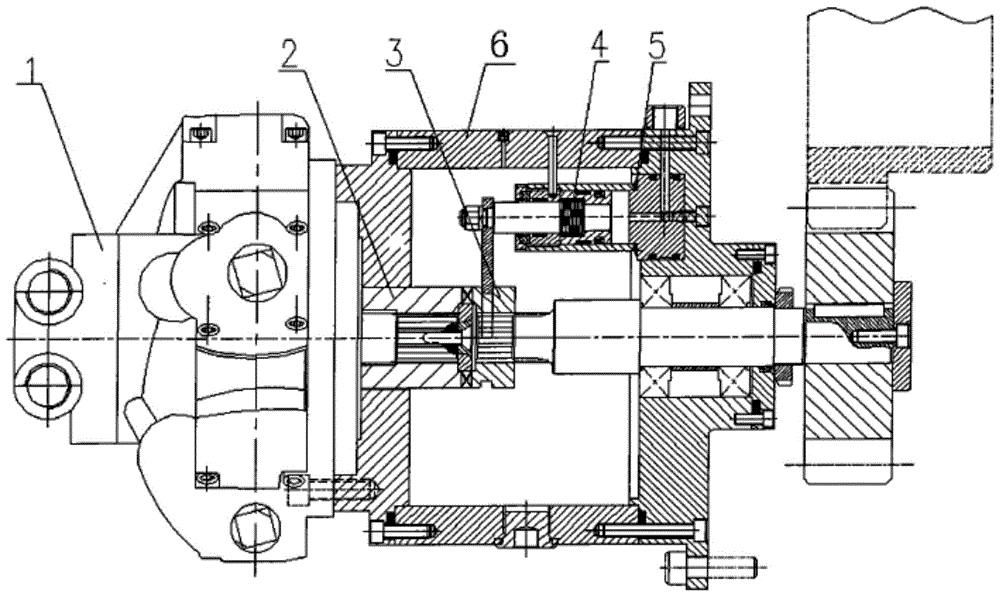

Actuating mechanism of hydraulic automatic clutch

InactiveCN103603890APrecise positioningExtended service lifeNon-mechanical actuated clutchesMaster cylinderDrive shaft

Disclosed is an actuating mechanism of a hydraulic automatic clutch. The actuating mechanism comprises a master cylinder, a driving mechanism and a position detection device, an output end of the driving mechanism is connected with a piston of the master cylinder, the position detection device is used for detecting moving information of the driving mechanism, the driving mechanism comprises a transmission box, a driving member, a pair of worm-gear mechanism, a limiting device and a pair of gear-rack mechanism, the driving member is arranged on a first outer side face of the transmission box, the worm-gear mechanism is mounted in an inner cavity of the transmission box, a worm of the worm-gear mechanism is connected with an output shaft of the driving member, a worm gear of the worm-gear mechanism is an incomplete worm gear and is fixedly arranged on a transmission shaft, one end of the transmission shaft extends out of a second outer side face of the transmission box, the limiting device is arranged in the transmission box and corresponds to one side, without gear teeth, of the worm gear, the gear-rack mechanism is arranged on the second outer side face, a gear of the gear-rack mechanism is fixedly arranged at one end, extending out of the second outer side face, of the transmission shaft, and one end of a rack is connected with the piston through a connecting rod. The actuating mechanism is accurate in clutch positioning, resistant to vibration and good in mechanical structure rigidity.

Owner:南宁市西真电子科技开发有限公司

Twin-clutch transmission and method for carrying out a gearshift in a twin-clutch transmission

The invention relates to a method for carrying out a gearshift in a twin-clutch transmission, which is characterized in that a downshift is carried out subject to the kind of shift and / or of at least one predetermined vehicle parameter. The invention also relates to a twin-clutch transmission, especially for carrying out the inventive method.

Owner:LUK LAMELLEN & KUPPLUNGSBAU BETEILIGUNGS KG

Safety Clutch

ActiveCN111140606AIncrease speedImprove cooling effectNon-mechanical actuated clutchesDrive shaftEngineering

The invention discloses a safety clutch. The safety clutch comprises a bracket, belt wheels, a transmission shaft, permanent magnets, electromagnets, iron cores, fan fixed plates, heat dissipation plates and rear covers, wherein the belt wheels are rotationally arranged to the bracket by bearings, the belt wheels sleeves the transmission shaft, and the belt wheels are provided with transmission plates; one sides of the transmission plates are provided with coils and the iron cores, and the coils and the iron cores are fixed to the bracket; the other sides of the transmission plates are provided with suction plates, first elastic pieces are fixed between the suction plates and the rear covers, the permanent magnets are fixedly arranged on the sides, far away from the suction plates, of therear covers, and the rear covers are rotationally arranged on the transmission shaft; the rear covers are fixedly connected with the fan fixing plates, the heat dissipation plates are fixedly connected with the transmission shaft, second elastic pieces are fixed between the heat dissipation plates and the belt wheels, and the heat dissipation plates and the permanent magnets are oppositely arranged; and a piston cavity is arranged in the bracket in an erected mode, a piston is arranged in the piston cavity in a sliding mode, and the transmission shaft is rotationally arranged on the piston. The safety clutch realizes flexible control by controlling gaps between the heat dissipation plates and the permanent magnets through the piston, and meanwhile has the function of failure protection.

Owner:WEICHAI POWER CO LTD

Electro-hydraulic comprehensive-control type clutch

InactiveCN1815052AExtended service lifeNo pollution in the processNon-mechanical actuated clutchesLow noiseElectro hydraulic

An electrohydraulic combination control type clutch belongs to automotive parts technology field. It features shell respectively fitting with interval of annular gear, gear and disconnecting valve, annular gear engagement transmission with gear, a crescent block fixed in shell, said crescent block having hydraulic fluid chamber having disconnecting valve to form high-pressure oil cavity A and low-pressure oil cavity B respectively on outer two ends of crescent block, disconnecting valve pivot joint with electromagnet fixed in shell. Said invention has advantages of 1, reliable product performance, long service life and low cost, 2, low noises, small impulsion, long spare service life, 3, no pollution, 4, simple installing, making and processing.

Owner:CHANGCHUN YIDONG CLUTCH

Vehicle differential including pump with variable-engagement clutch

A vehicle differential assembly is provided that includes a differential driven by an input and adapted to allow differing rotational speed between a pair of outputs. The differential includes a gear assembly connected to the outputs and a hydraulically-actuated clutch for selectively and variably coupling the outputs. A hydraulic pump is adapted to generate hydraulic fluid pressure for engagement of the hydraulically-actuated clutch. A variable-engagement clutch is operatively connected to the input and the hydraulic pump such that the input selectively drives the hydraulic pump during engagement of the clutch to provide hydraulic fluid pressure to the hydraulically-actuated clutch. A torque coupling including a variable-engagement clutch is also provided.

Owner:EATON INTELLIGENT POWER LIMITED

Motor-driven hydraulic clutch and automobile

ActiveCN105402273AClutch realizationPrecise control of rotationNon-mechanical actuated clutchesMotor driveElectric machinery

Owner:武汉理工通宇新源动力有限公司

Hybrid vehicle clutch control device

InactiveUS9096224B2High control precisionVehicle sub-unit featuresEngine controllersClutch controlMotor drive

The clutch control device for a hybrid vehicle comprises an engine, an automated manual transmission, a clutch device and a clutch actuator concluding an output rod and a master cylinder which generates a hydraulic pressure therein by closing an idle port in response to the stroke of the output rod, a slave cylinder in fluid communication with the master cylinder through a passage and controlling the clutch device to be in engagement state or disengagement state operated by the hydraulic pressure generated by the master cylinder and a clutch engagement state holding control portion for temporarily holding the clutch device to be in the engagement state by operating the master cylinder to close the idle port after the engagement state under the vehicle being running under a motor drive mode continued for a predetermined time.

Owner:AISIN SEIKI KK

Hydraulic auxiliary actuator and vehicle comprising same

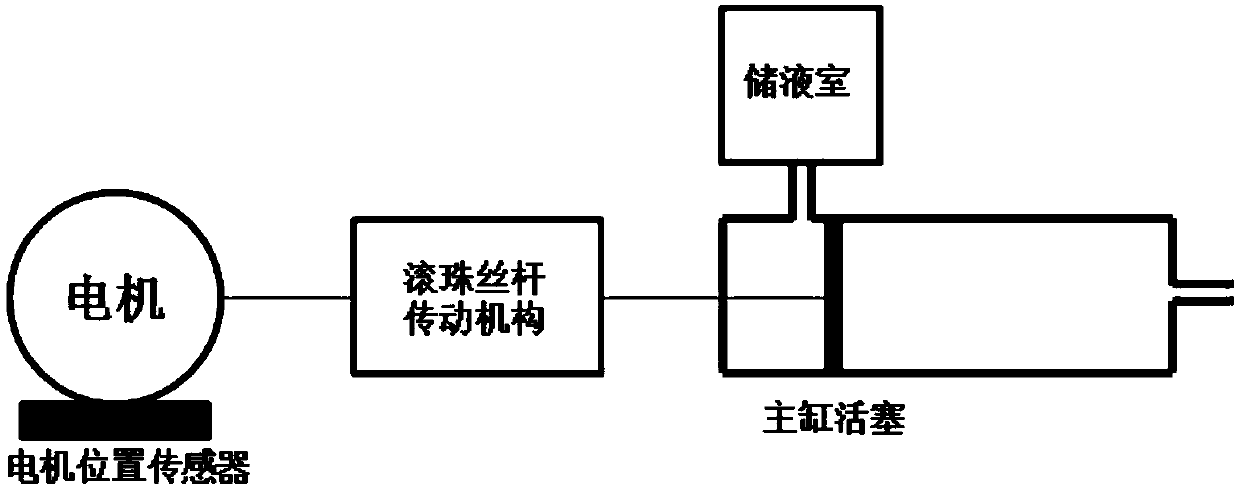

ActiveCN105570348AReduce pedal effortOptimizing Motivational BehaviorNon-mechanical actuated clutchesHydraulic cylinderBall screw drive

The invention discloses a hydraulic auxiliary actuator and a vehicle comprising the same. One side of the hydraulic auxiliary actuator is connected to a pedal assembly of the vehicle. The other side of the hydraulic auxiliary actuator is connected to a clutch assembly of the vehicle. The hydraulic auxiliary actuator comprises a motor, a ball screw and a hydraulic cylinder assembly, wherein the hydraulic cylinder assembly is connected to the ball screw so as to be driven by the ball screw. The hydraulic cylinder assembly comprises a cylinder shell, a second piston, a first piston, a third piston, a first pre-tightening spring and a second pre-tightening spring, wherein the second piston, the first piston and the third piston are sequentially arranged in the cylinder shell; the second piston is pre-tightened relative to the first piston through the first pre-tightening spring, and the third piston is pre-tightened relative to the first piston through the second pre-tightening spring. The cylinder shell is provided with a hole, so that the hydraulic cylinder assembly is in fluid communication with the pedal assembly. The hole is located between a second sealing ring of the second piston and a third sealing ring of the third piston in the axial direction of the cylinder shell, and the first piston can move to pass through the hole.

Owner:SCHAEFFLER TECH AG & CO KG

Magnetorheological fluid clutch apparatus with cylindrical fluid gap

ActiveUS10480594B2Fluid clutchesNon-mechanical actuated clutchesMagnetorheological fluidTorque transmission

A magnetorheological fluid clutch apparatus comprises a stator having at least an annular wall; a first rotor rotatably mounted to the stator, the first rotor having at least one first shear surface; a second rotor rotatably mounted to the stator for rotating about a common axis with the first rotor, the second rotor having at least one second shear surface opposite the at least one first shear surface, the shear surfaces separated by at least one annular space. A magnetorheological (MR) fluid is in an MR fluid chamber including the at least one annular space, the MR fluid configured to generate a variable amount of torque transmission between the rotors when subjected to a magnetic field. An inner magnetic core and an outer magnetic core with an annular cavity therebetween receive the annular wall of the stator, the inner magnetic core and the outer magnetic core connected to at least one of the rotors to rotate therewith so as to be rotatably mounted to the stator. Outer and inner fluid gaps are between the inner magnetic core and the annular wall, and between the outer magnetic core and the annular wall, the outer and inner fluid gaps filled with at least one fluid. At least one coil is supported by the annular wall and actuatable to deliver a magnetic field through the MR fluid, the magnetic field following a path comprising the annular wall, the outer fluid gap, the outer magnetic core, the at least one first shear surface and the at least one second shear surface,the inner magnetic core and the inner fluid gap, wherein one of the rotors is adapted to be coupled to a power input and the other of the rotors is adapted to be connected to an output whereby actuation of the at least one coil results in a variation of torque transmission between the rotors.

Owner:EXONETIK INC

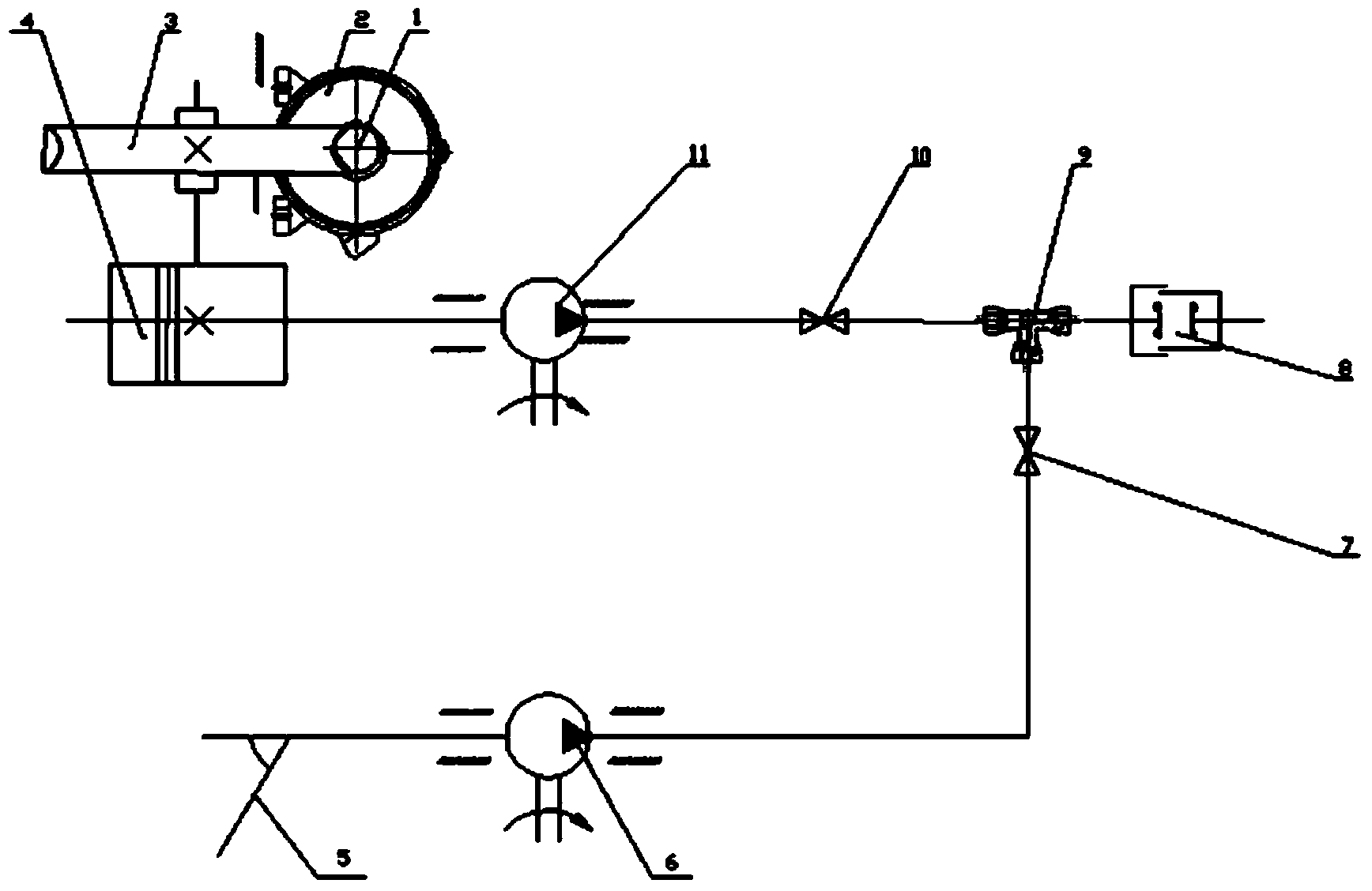

AMT clutch actuating mechanism

The invention provides an AMT clutch actuating mechanism which comprises a clutch pedal, a first clutch cylinder and a clutch. The clutch pedal controls disengaging and engaging of the clutch through the first clutch cylinder. The AMT clutch actuating mechanism further comprises a motor, a transmission mechanism, a second clutch cylinder and a three-way valve, the three-way valve is respectively connected with the clutch, a first hand control valve and a second hand control valve, the first hand control valve is connected with the first clutch cylinder, the motor acts on the second clutch cylinder through the transmission mechanism, and the second hand control valve is connected with the other end of the second clutch cylinder. The phenomenon that when the AMT clutch actuating mechanism breaks down, operators have to wait on site is avoided, the AMT clutch actuating mechanism can be used for goods vans and mining vehicles, the attendance rate is improved, and traffic accident risks caused when the vehicles are parked in the middle of a road are reduced.

Owner:SUZHOU ZIJING QINGYUAN NEW ENERGY AUTOMOBILE TECH

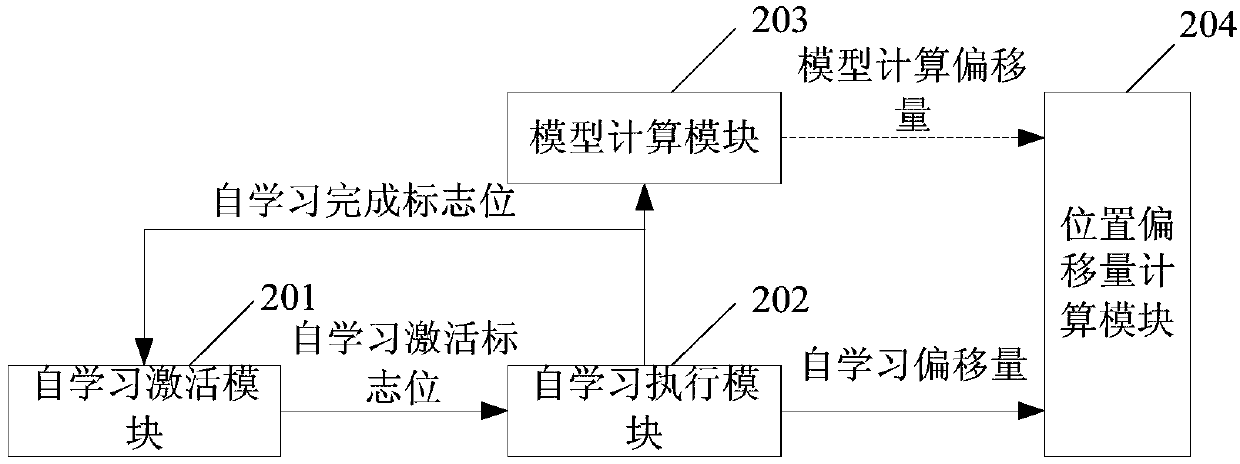

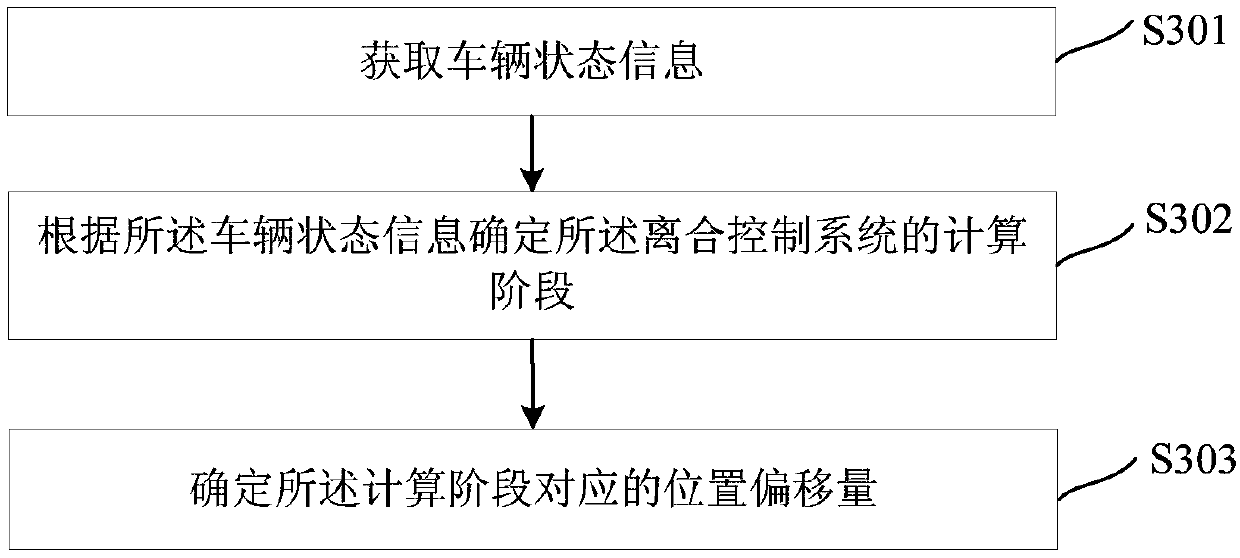

Method and device for determining position offset

ActiveCN111090914AControl displacementHigh precisionDesign optimisation/simulationNon-mechanical actuated clutchesClutch controlControl system

The invention discloses a method for determining position offset. When the position offset is required to be calculated; firstly, vehicle state information can be obtained; determining a calculation stage of the clutch control system according to the vehicle state information, the calculation stage can comprise a first stage and a second stage, the self-learning offset can be obtained when the first stage is completed, the second stage is located behind the first stage and is adjacent to the first stage, and the model calculation offset can be obtained in the process of the second stage. And then, the position offset corresponding to the calculation stage is determined, and the position offset at least comprises the self-learning offset. Therefore, when the position offset is calculated, the self-learning offset is used as much as possible to replace the model calculation offset to determine the position offset, the calculation accuracy of the position offset can be improved, and the purpose of accurately controlling the displacement of the main cylinder piston through the accumulated corner signal of the motor is further achieved. The embodiment of the invention further disclosesa device for determining the position offset.

Owner:SAIC MOTOR

Novel clutch

The invention discloses a novel clutch which comprises a motor. The novel clutch is characterized in that the novel clutch is provided with an outer wall, an output shaft of the motor extends into the outer wall, a first clutch device is sleeved outside the output shaft of the motor, a hydraulic cylinder is fixedly mounted on the inner wall of the rear end of the outer wall, a movable rod is mounted in a hydraulic cylinder, a spring is clamped between the movable rod and the hydraulic cylinder, the movable rod is connected with a second clutch device through a connecting rod, and the second clutch device is slidably sleeved on the output shaft of the motor. The novel clutch can be conveniently controlled in both a power-on state and a power-off state.

Owner:ANHUI IND & TRADE VOCATIONAL TECHN COLLEGE

Features

- R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

Why Patsnap Eureka

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Social media

Patsnap Eureka Blog

Learn More Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com