Actuating mechanism of hydraulic automatic clutch

An automatic clutch and actuator technology, applied in non-mechanical drive clutches, clutches, mechanical equipment, etc., can solve the problems of high vibration intensity, short life, inaccurate positioning, etc., to increase the service life of the mechanism, good mechanical rigidity, and positioning precise effect

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment

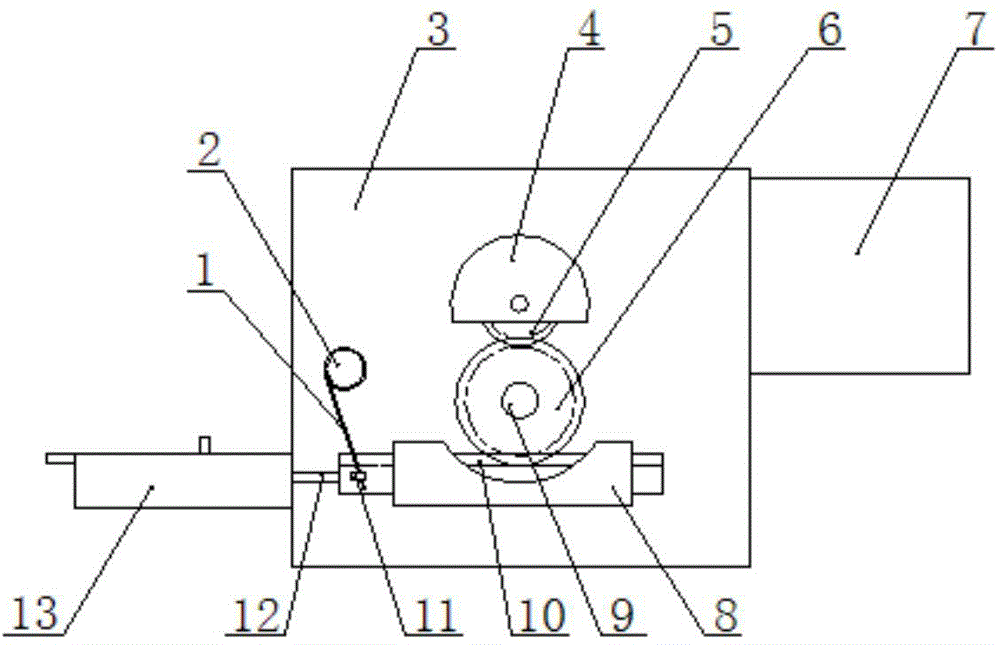

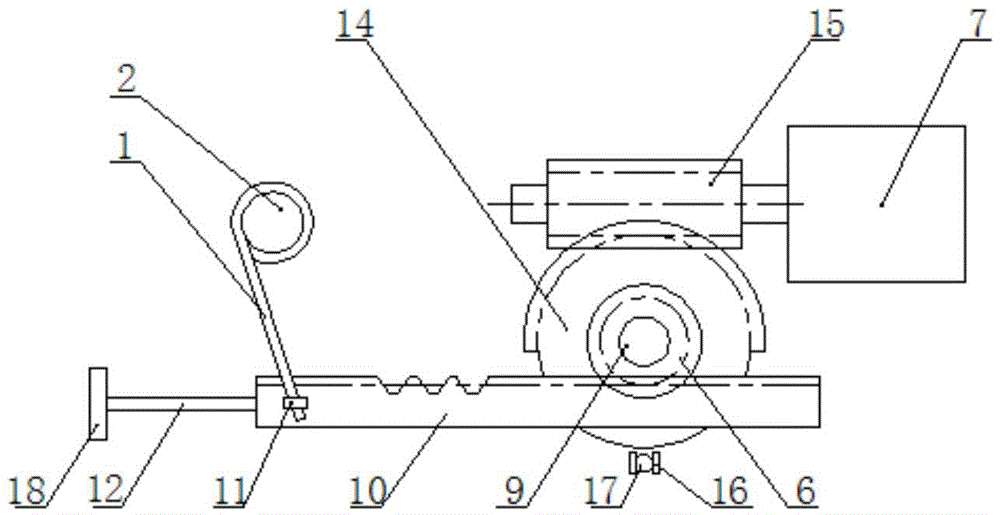

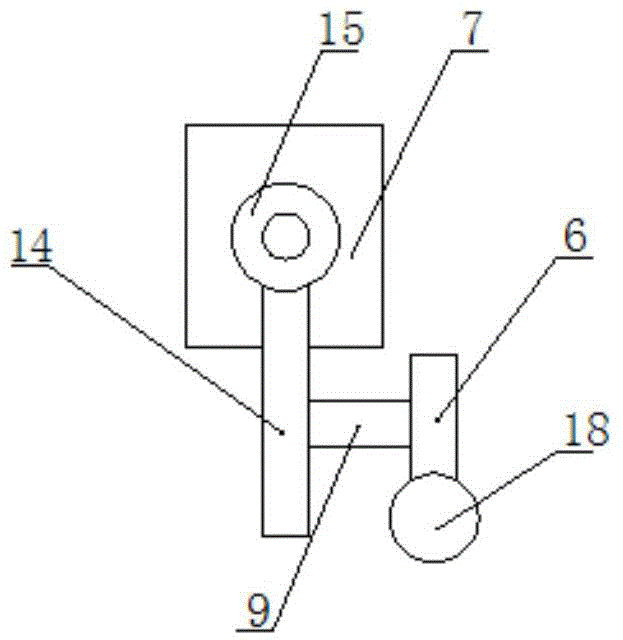

[0041] Such as Figure 1 to Figure 3 As shown, an actuator of a hydraulic automatic clutch includes: a transmission box 3, a pair of worm and gear mechanisms are arranged in the transmission box 3, and its worm 15 is driven by a motor 7, and the motor 7 is a 12V brushed DC motor, so it can Power is directly supplied by the car battery, and the motor 7 is fixedly arranged on the right side outer wall of the transmission box 3, and its output shaft extends into the transmission box 3 and is connected with the worm 15 to drive the worm 15 to rotate, and the worm gear meshed with the worm 15 for transmission 14 is an incomplete worm gear, which is fixed on the transmission shaft 9, the transmission shaft 9 is perpendicular to the worm screw 15, the transmission shaft 9 is installed in the transmission case 3 in a rotatable manner through the bearing, and one end of it stretches out from the transmission case 3 The upper wall surface, and this end is fixedly connected with the tran...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com