Patents

Literature

53results about How to "Smooth linear motion" patented technology

Efficacy Topic

Property

Owner

Technical Advancement

Application Domain

Technology Topic

Technology Field Word

Patent Country/Region

Patent Type

Patent Status

Application Year

Inventor

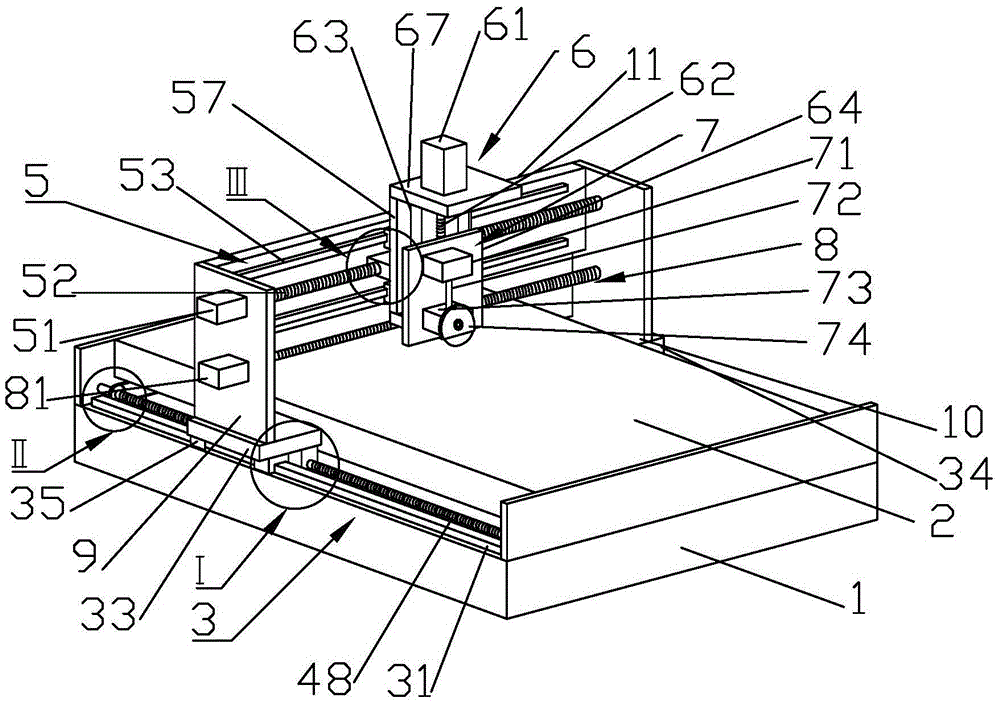

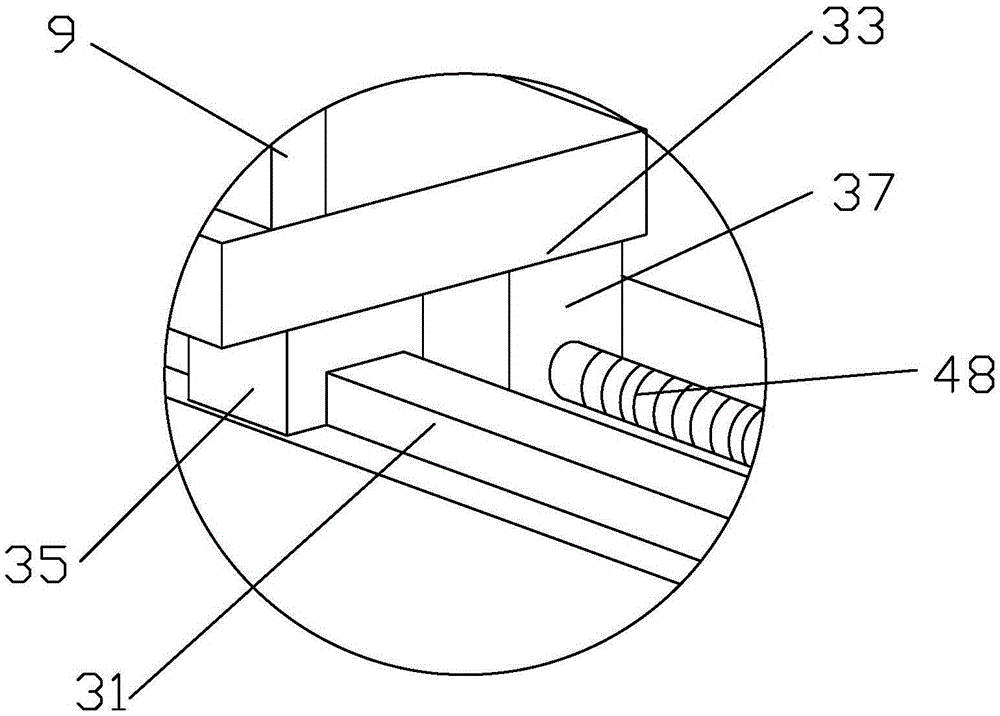

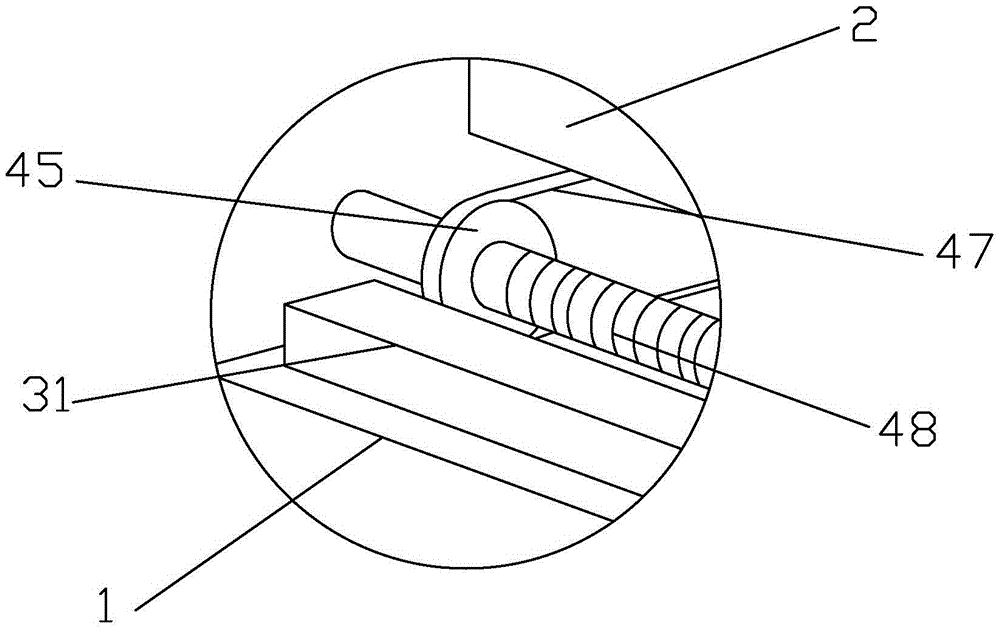

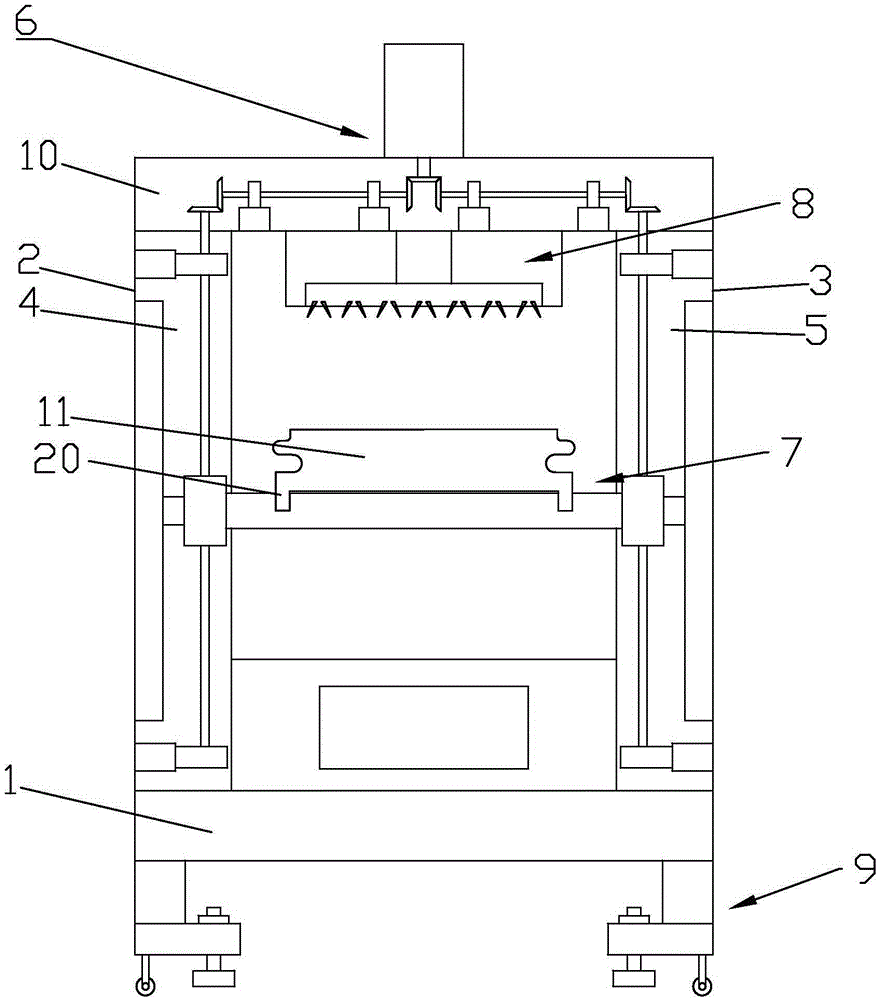

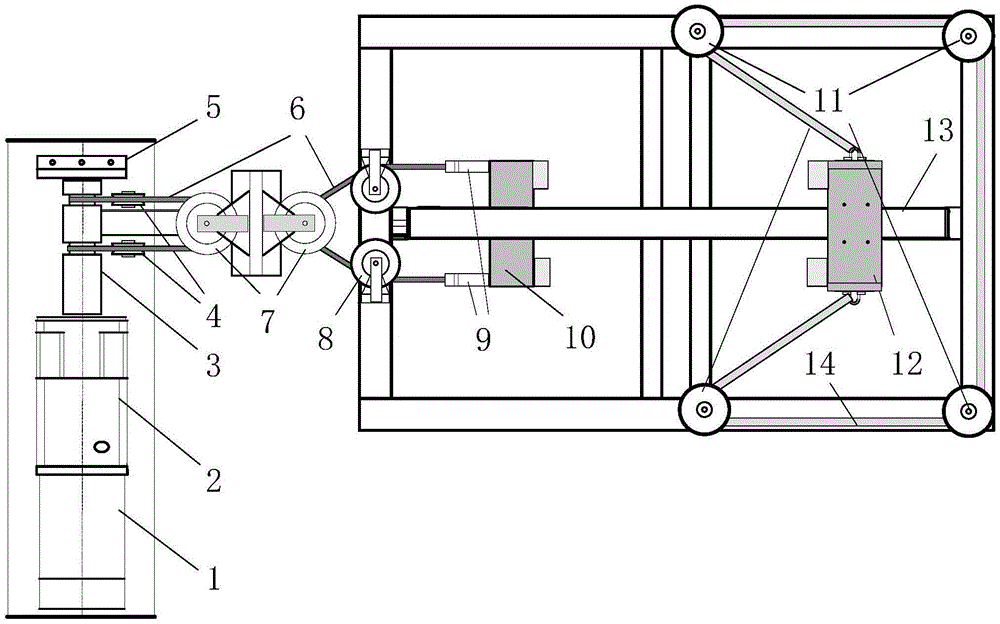

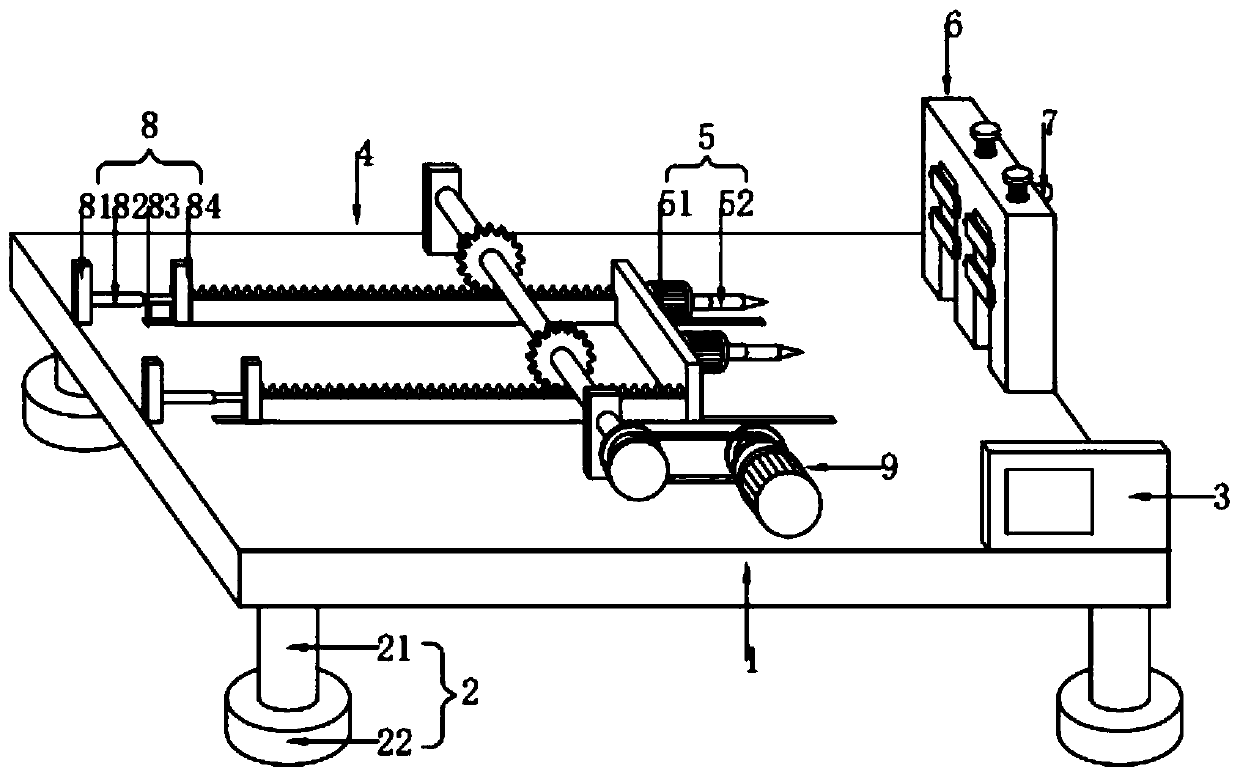

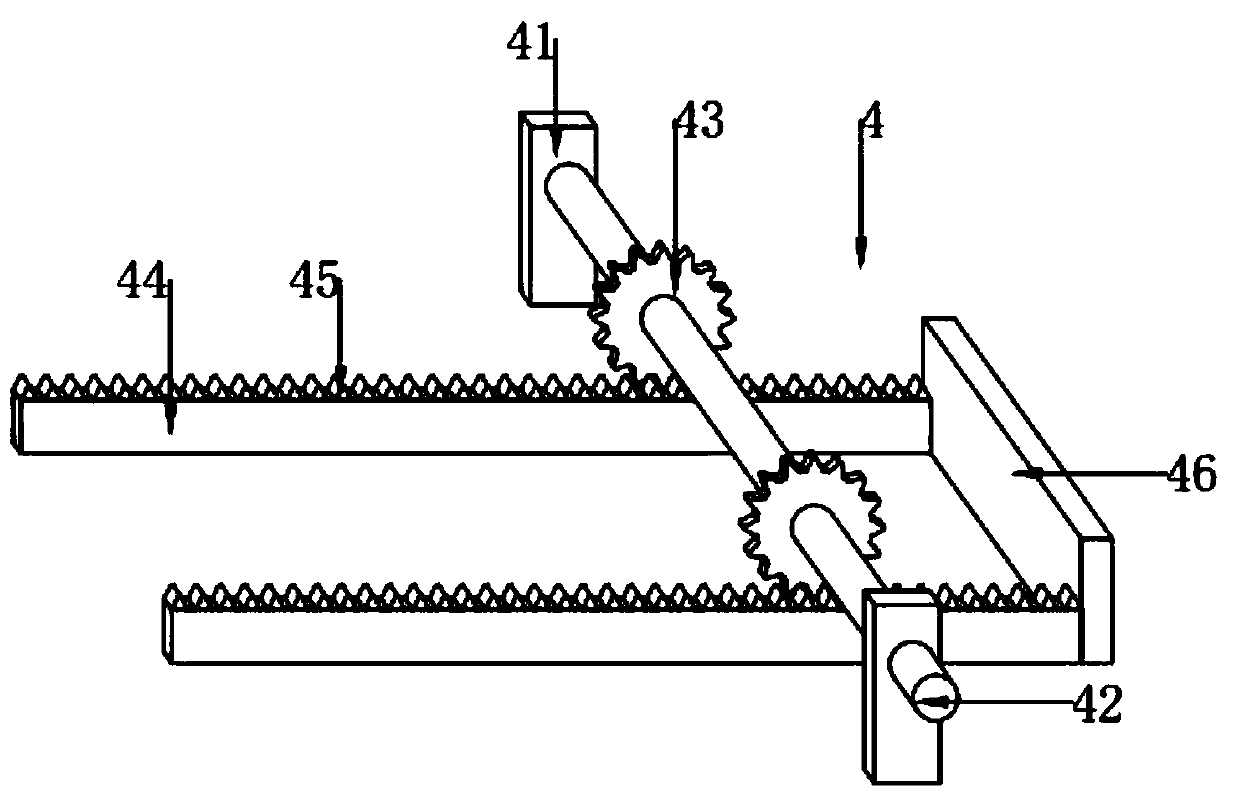

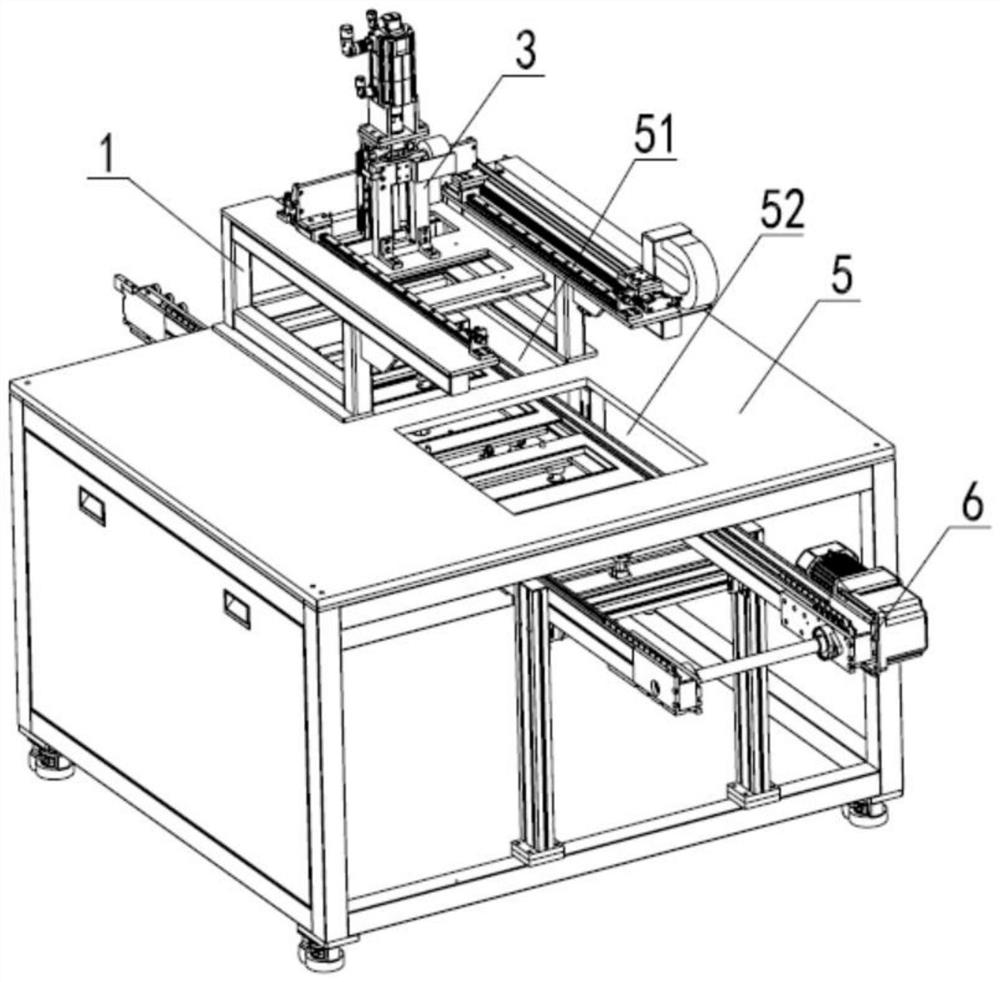

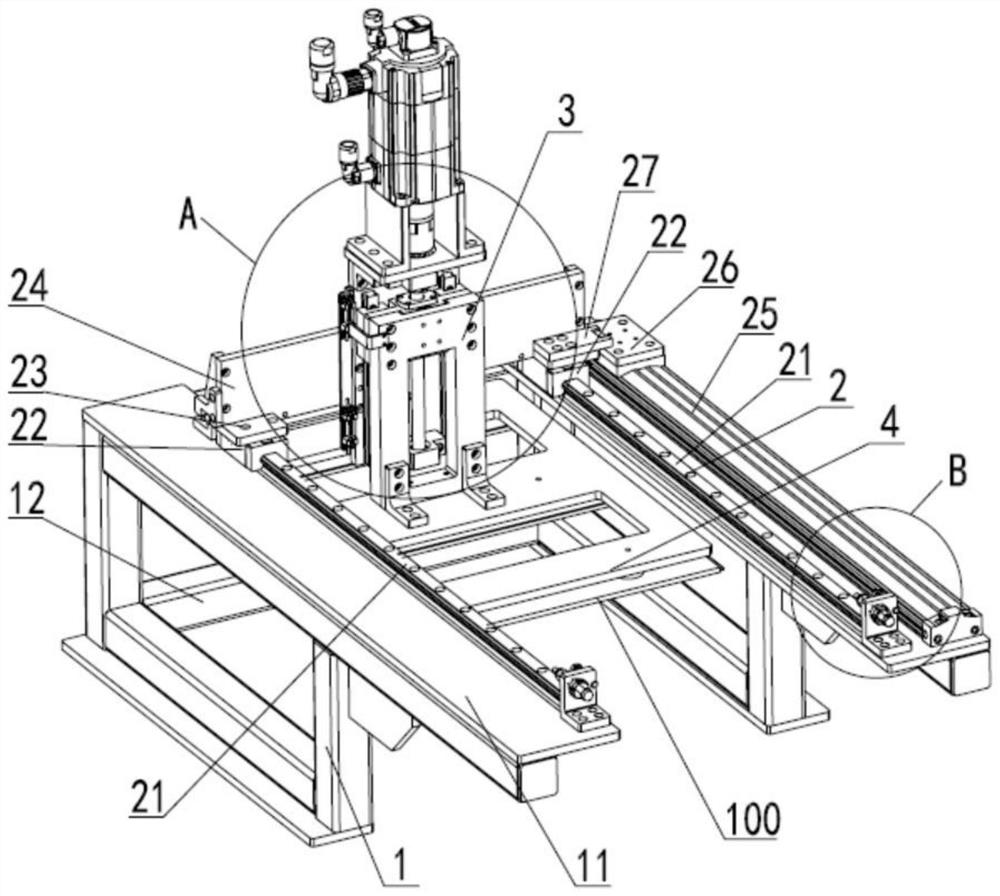

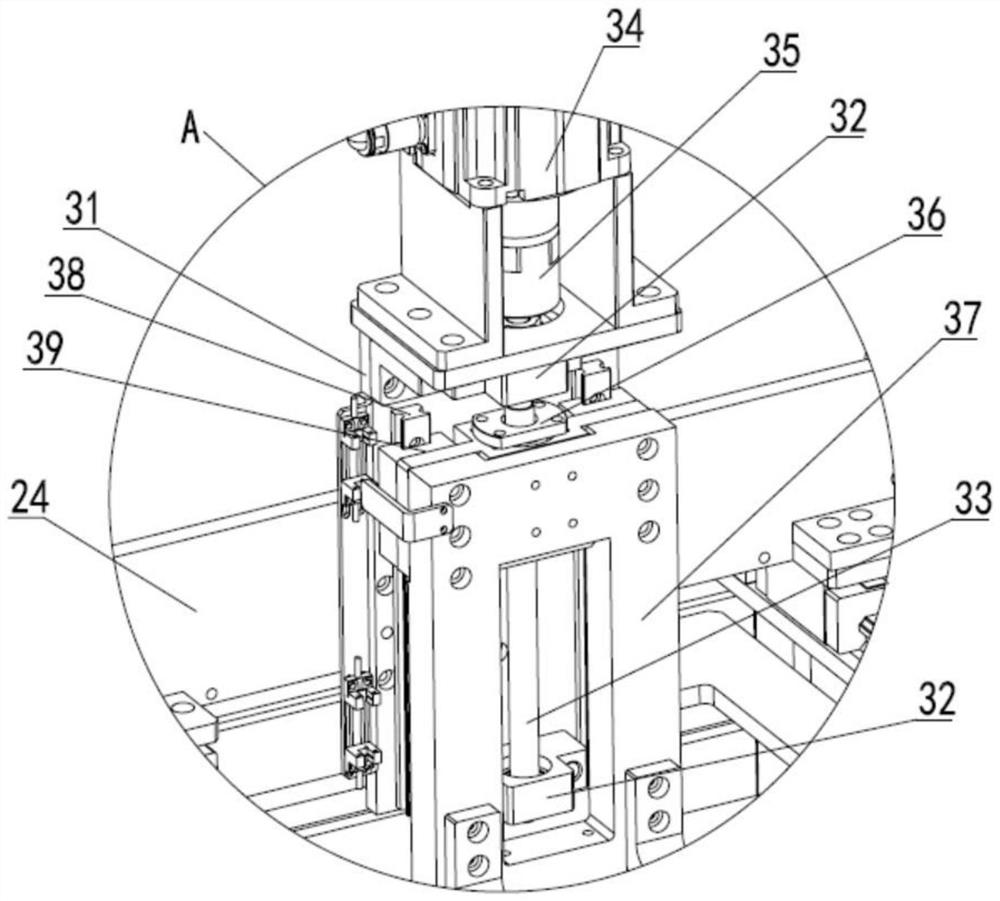

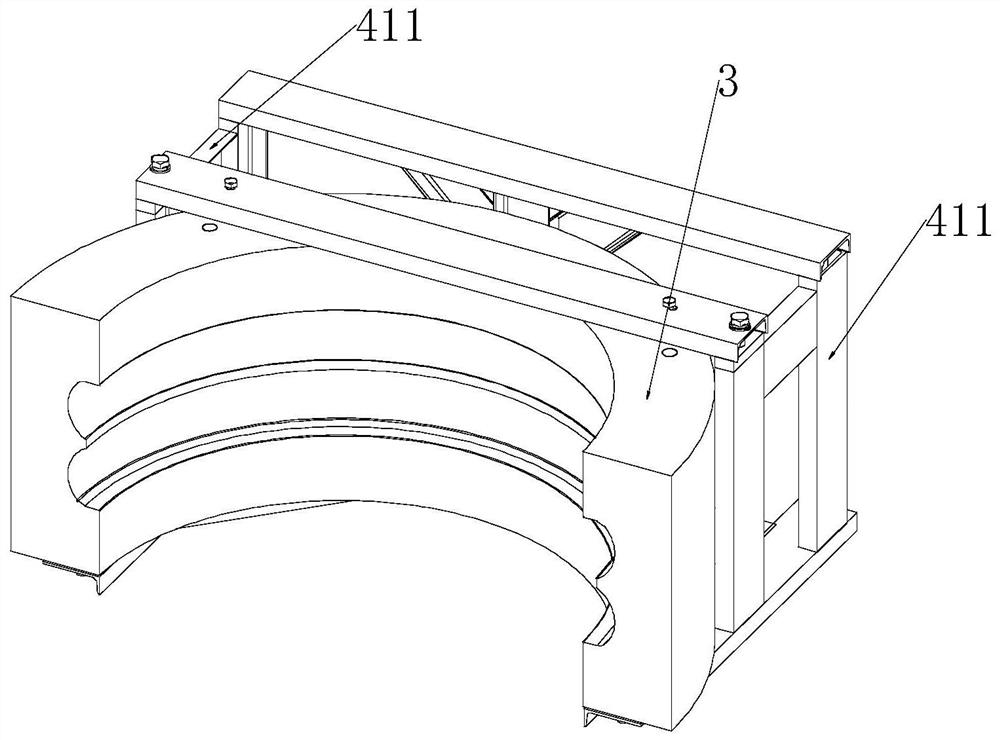

Three-shaft type board cutting machine

InactiveCN105458894ASolve cutting problemsSimple structureGrinding carriagesGrinding drivesEngineeringGrinding wheel

The invention discloses a three-shaft type board cutting machine which comprises a rack. A movable cutting platform and fixed supports are arranged on the rack. The movable cutting platform is located in the middle of the rack. The fixed supports comprise the left fixed support and the right fixed support. An X-direction moving device is arranged below the left fixed support and the right fixed support and is installed on the rack. The X-direction moving device is connected with an X-direction transmission device. A Y-direction moving device is arranged between the left fixed support and the right fixed support. The Y-direction moving device is connected with a Z-direction moving device which is provided with a cutting device. The three-shaft type board cutting machine is simple in structure, scientific, convenient to use, high in pertinence and automation degree, good in wood sawing effect and capable of well solving the cutting problem of boards. The cutting device can move freely in the work plane of the whole rack through the X-direction moving device, the Y-direction moving device and the Z-direction moving device and is matched with a grinding wheel to complete the cutting work.

Owner:嵊州市古艺木雕装饰有限公司

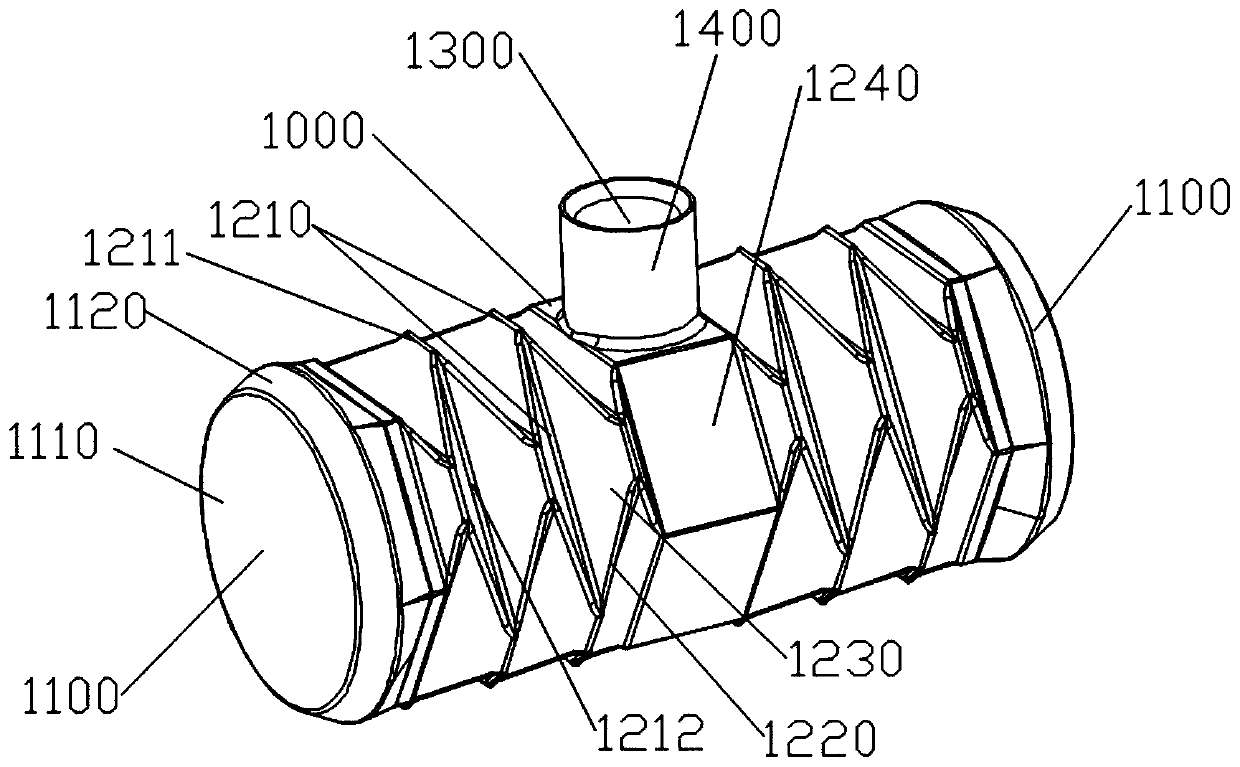

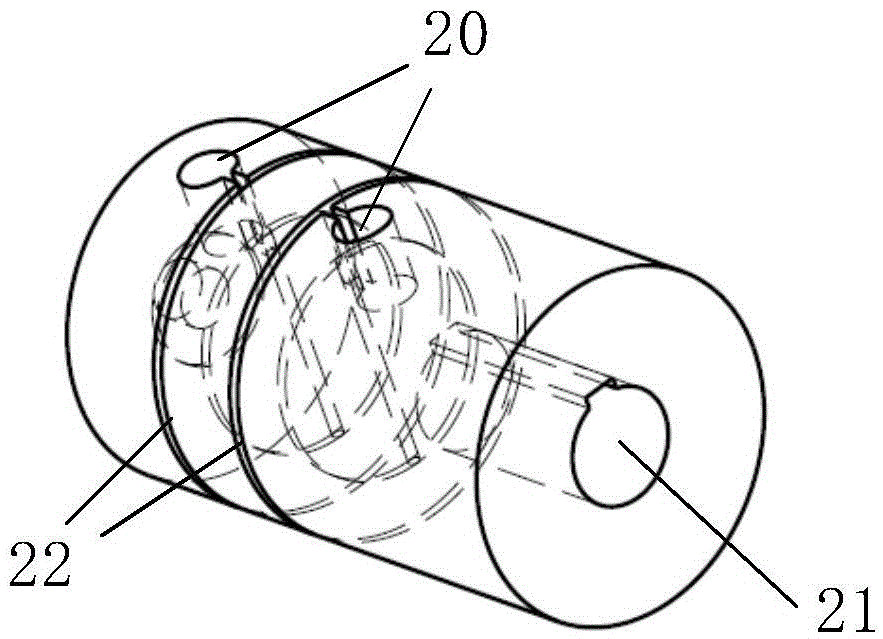

Mollusc muscle

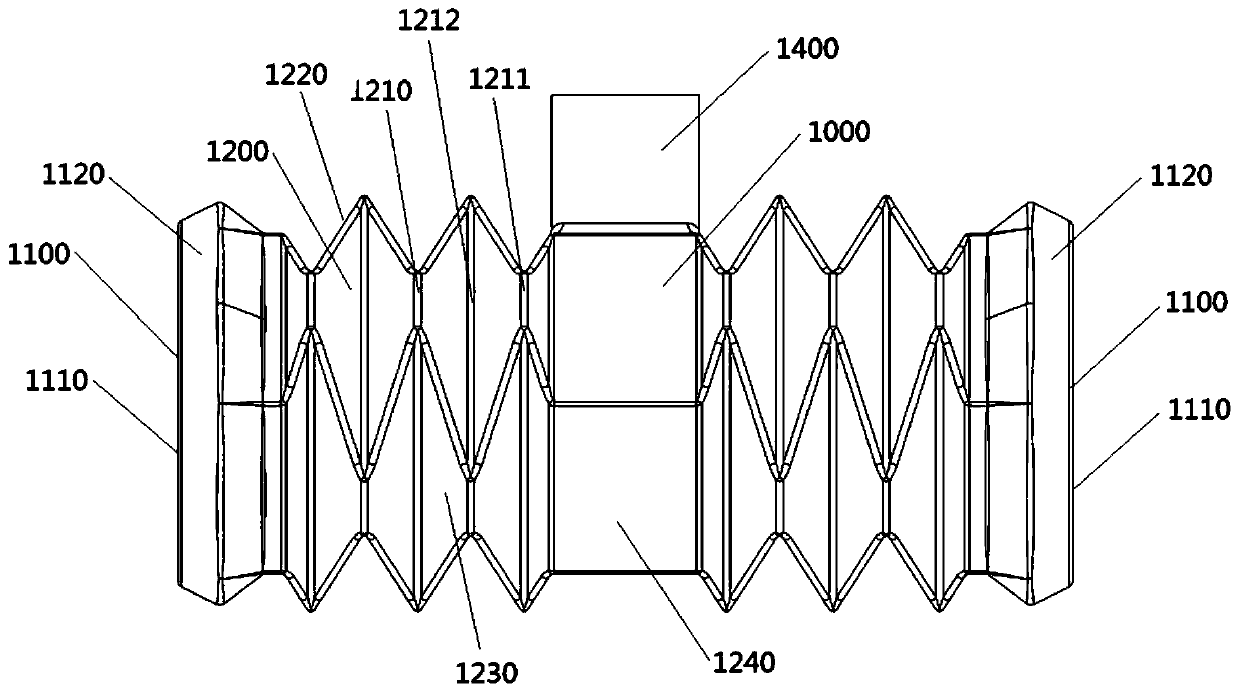

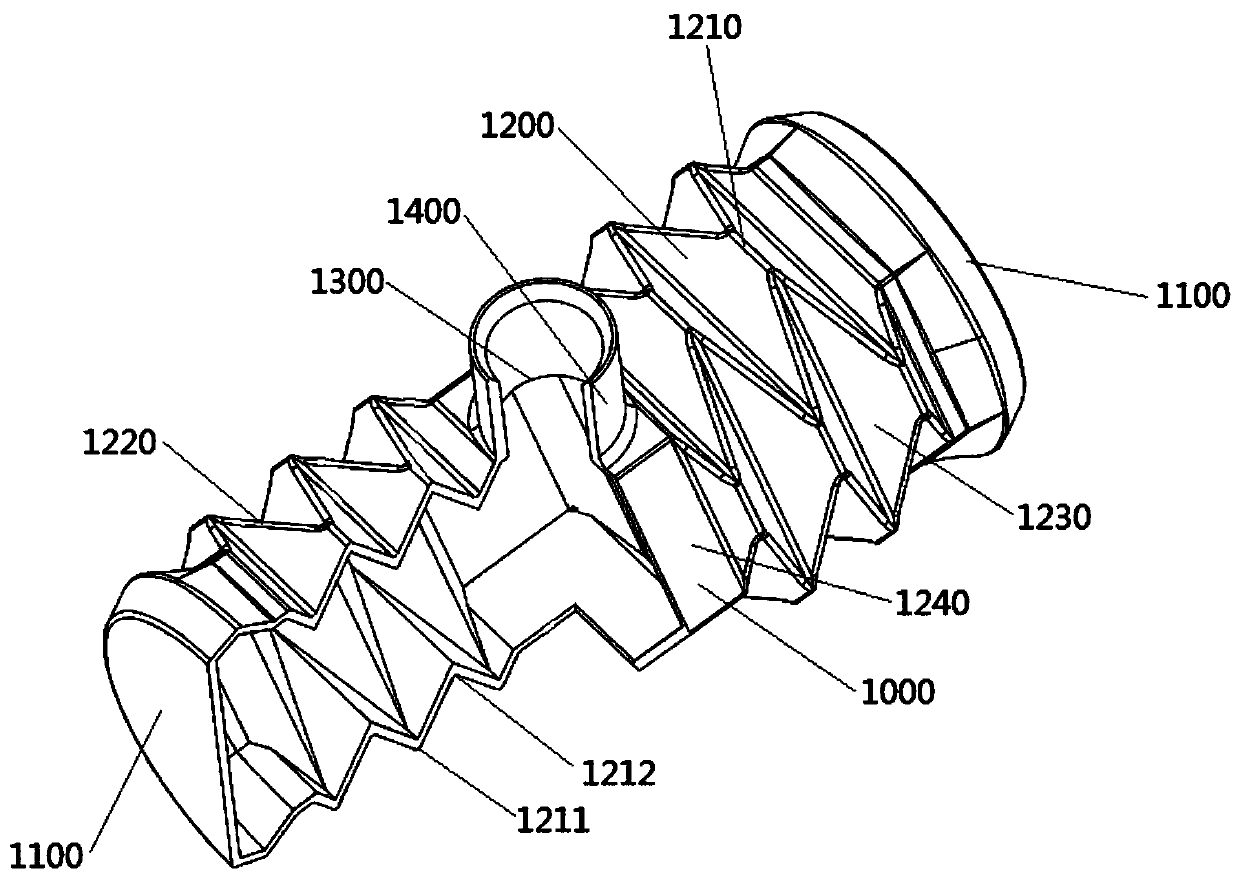

PendingCN110802574AAchieve elongationImprove structural strengthProgramme-controlled manipulatorStructural engineeringClosed cavity

The invention discloses a mollusc muscle. The mollusc muscle comprises two ends and a flexible cavity side wall. An inlet and outlet is formed in the ends or the cavity side wall, the cavity side wallis provided with a paper folding structure, the paper folding structure comprises multiple annular ridges, multiple side ridges and multiple folding surfaces, the annular ridges comprise convex ridges arranged in a protruding manner and concave ridges arranged in a recessed manner, the folding surfaces are arranged between every two adjacent side ridges and the corresponding concave ridges and convex ridges, when the pressure intensity of fluid in a closed cavity changes, the paper folding structure can deform, and therefore the paper folding structure is folded or unfolded in the axial direction of the closed cavity. When the mollusc muscle is used, the pressure fluid is input or drained through the inlet and outlet, the folding surfaces are driven to rotate around the annular ridges tobe opened and closed, the structural strength and the stability of the mollusc muscle are improved through the annular ridges, the side ridges and peaks, the mollusc muscle can stably do linear movement on the premise without an external limiting structure, and large force can be output.

Owner:深圳市韧识科技有限公司

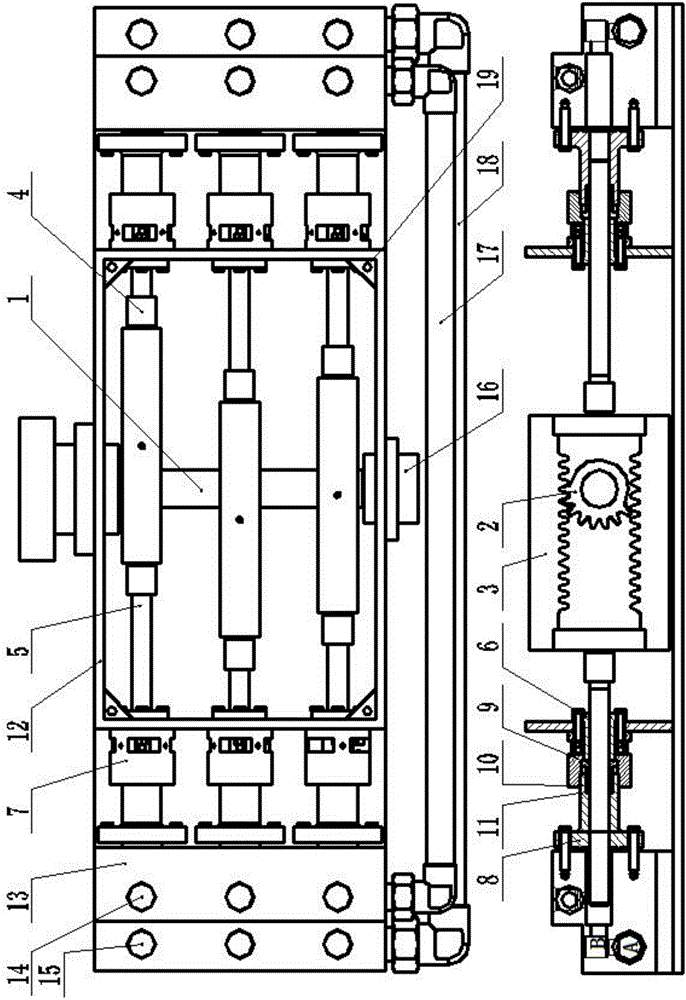

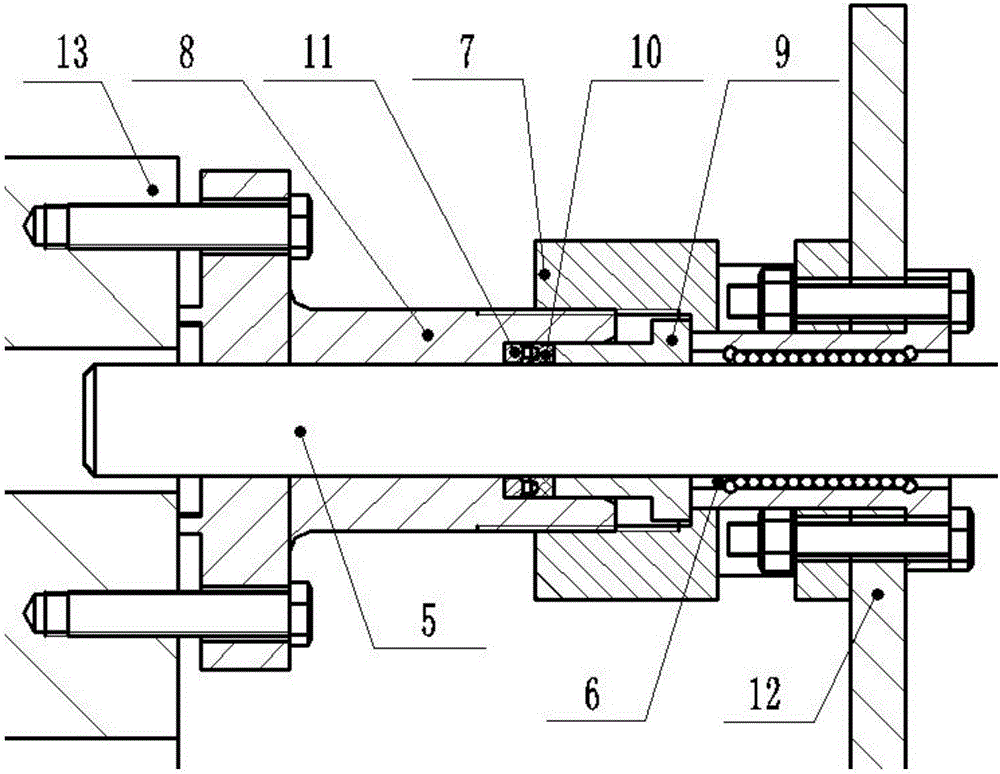

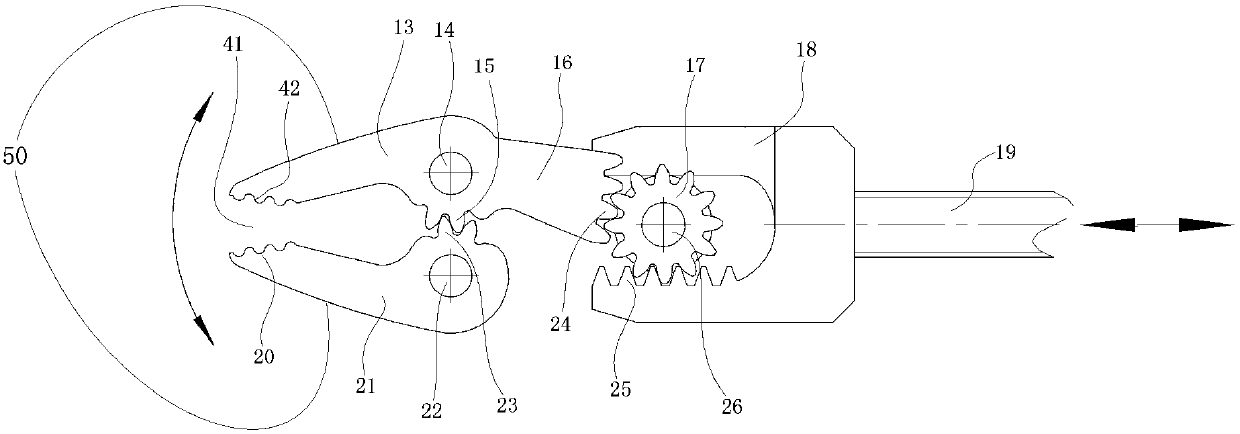

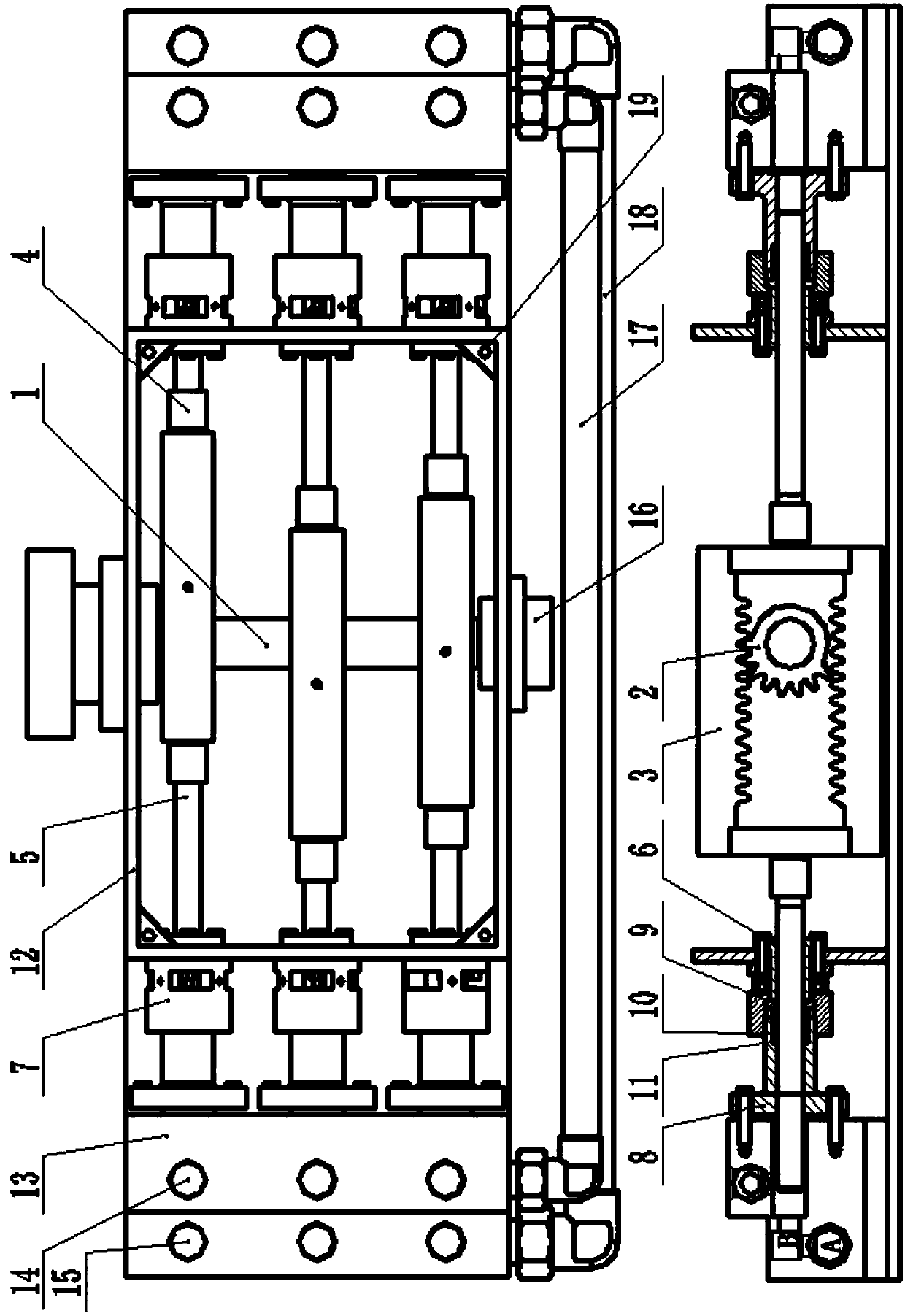

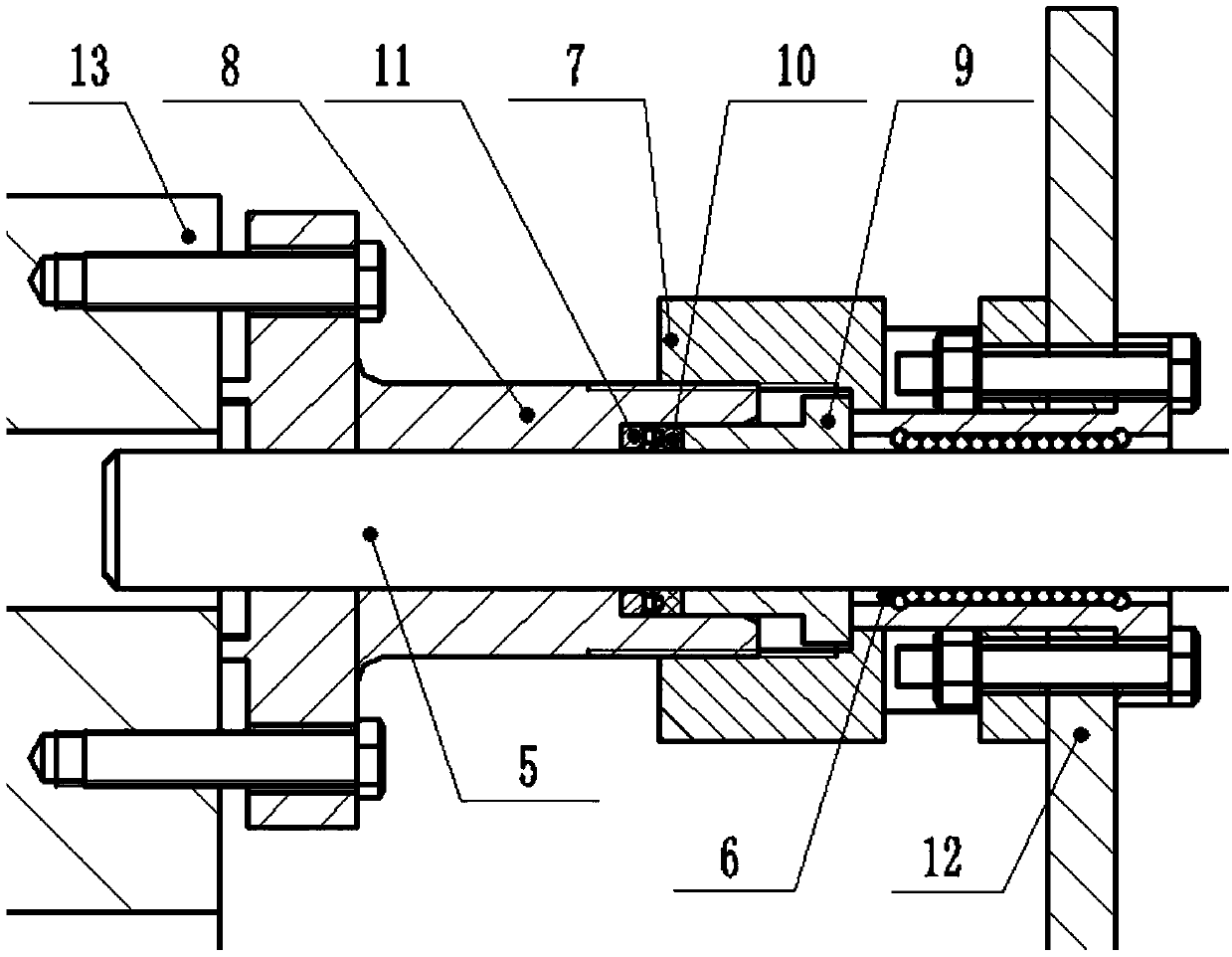

Gear-rack transmission type horizontal three-cylinder plunger reciprocating pump

InactiveCN106762500ADirect movementImprove efficiencyPositive displacement pump componentsPiston pumpsFailure ratePhase difference

The invention discloses a gear-rack transmission type horizontal three-cylinder plunger reciprocating pump. The gear-rack reciprocating pump comprises a transmission end and a hydraulic end; at the transmission end, mainly, three pairs of non-full gears with the phase difference and three pairs of racks with the phase difference are matched, and plungers and the racks are connected; at the hydraulic end, the plungers are matched with plunger cylinders, valve bodies are matched with check valves, the plunger cylinders are connected with the valve bodies, and the plunger cylinders are connected with transmission cases; and according to the connection between each plunger cylinder and the corresponding transmission case, a newly-designed gland plate component is utilized, one end of the gland plate component is used for being connected with the corresponding plunger cylinder and pressing a seal in the plunger cylinder, and the other end of the gland plate component is used for assembling a linear bearing and being connected with the corresponding transmission case. According to the gear-rack transmission type novel horizontal three-cylinder plunger reciprocating pump, the output flow and the pressure impulsiveness of the reciprocating pump are basically eliminated in theory, the interior structure of the reciprocating pump is simplified, and the mechanism failure rate is decreased; and operation is stable, reversing is quick, a precise electric control system does not need to be configured, and the development investment is greatly reduced.

Owner:BEIJING UNIV OF TECH

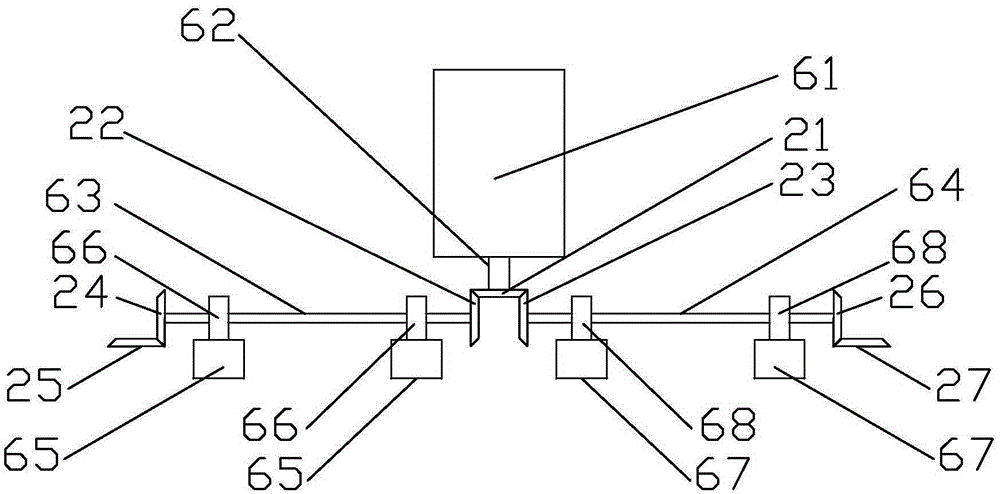

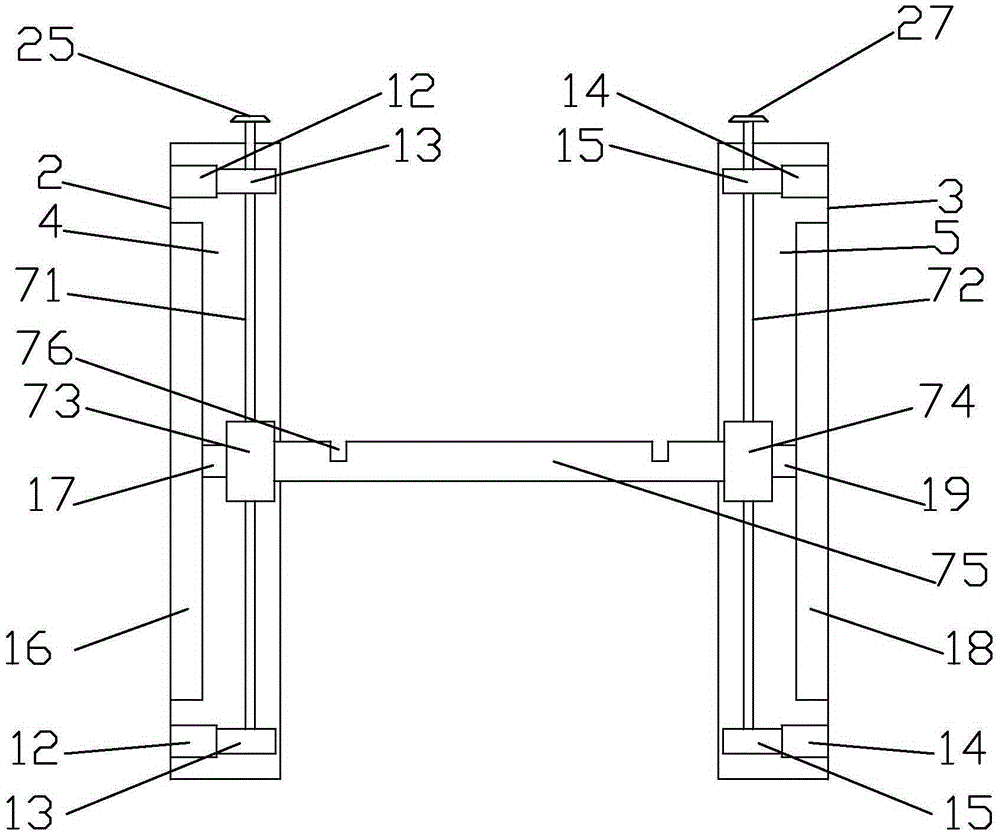

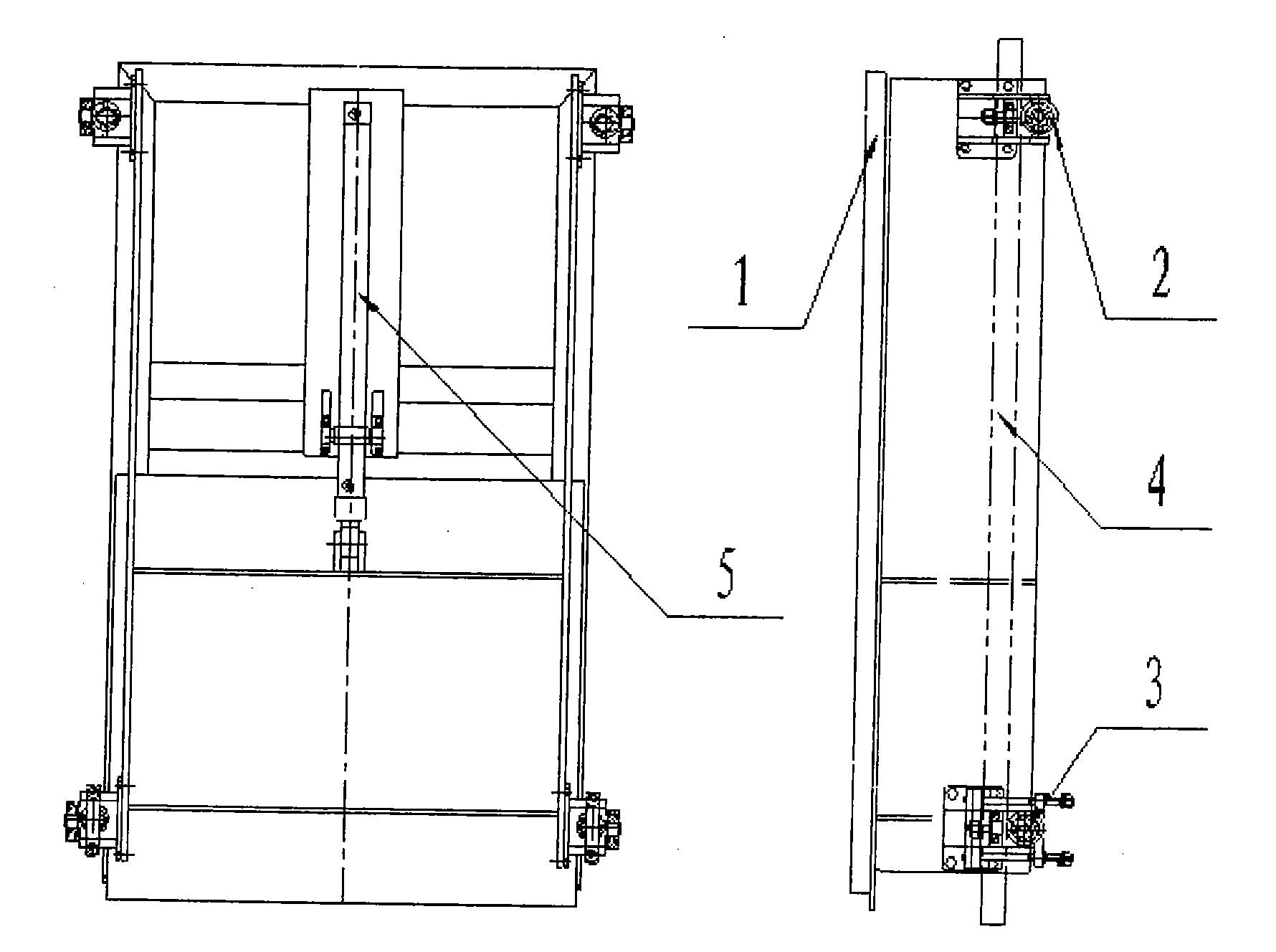

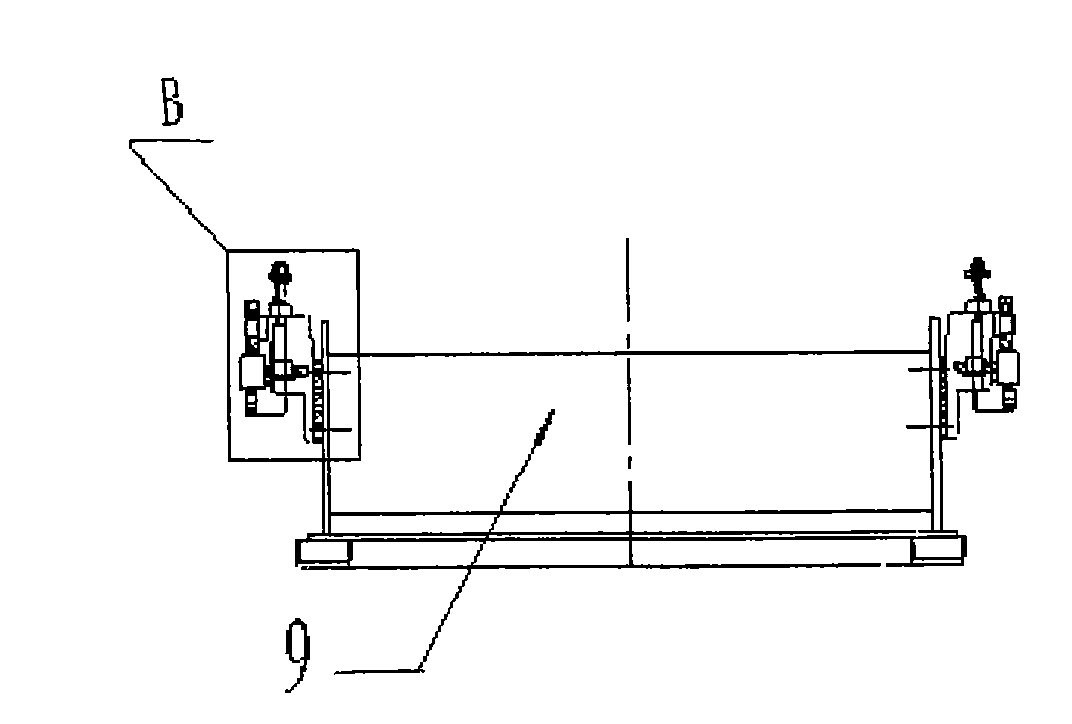

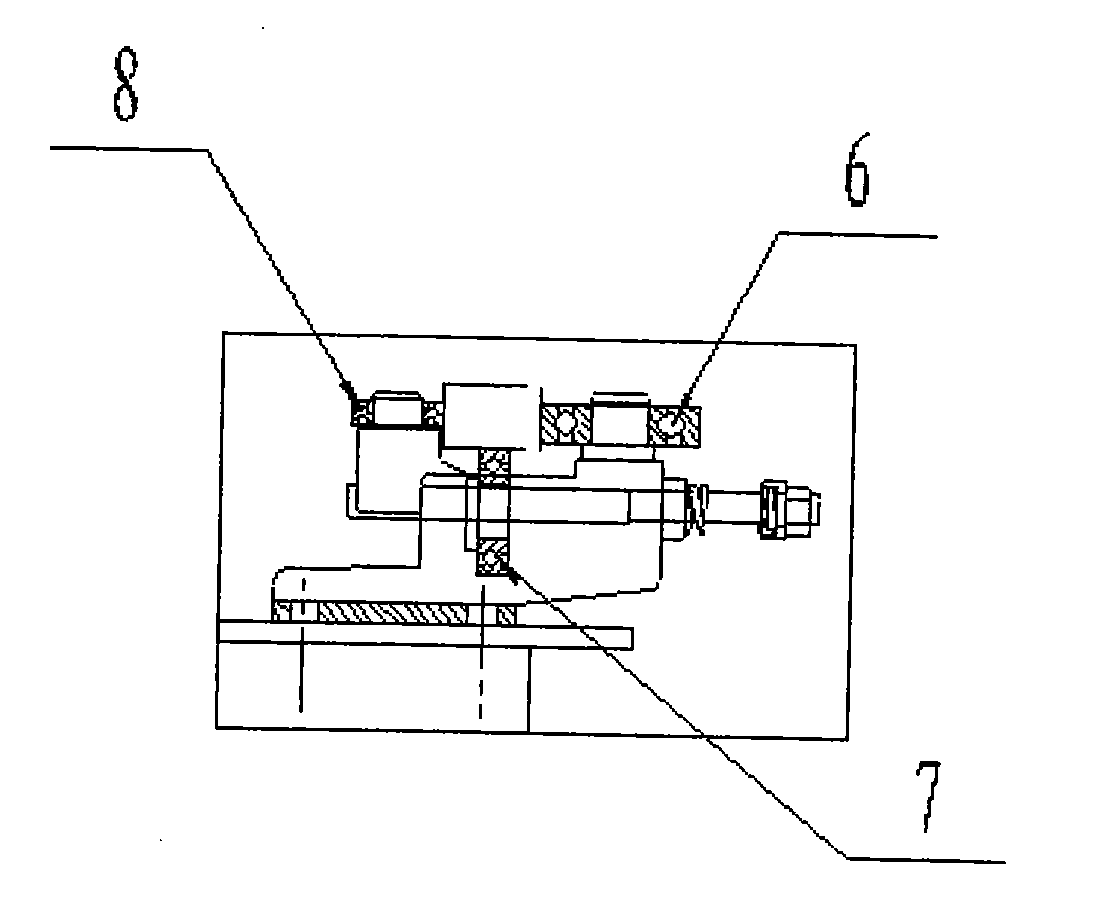

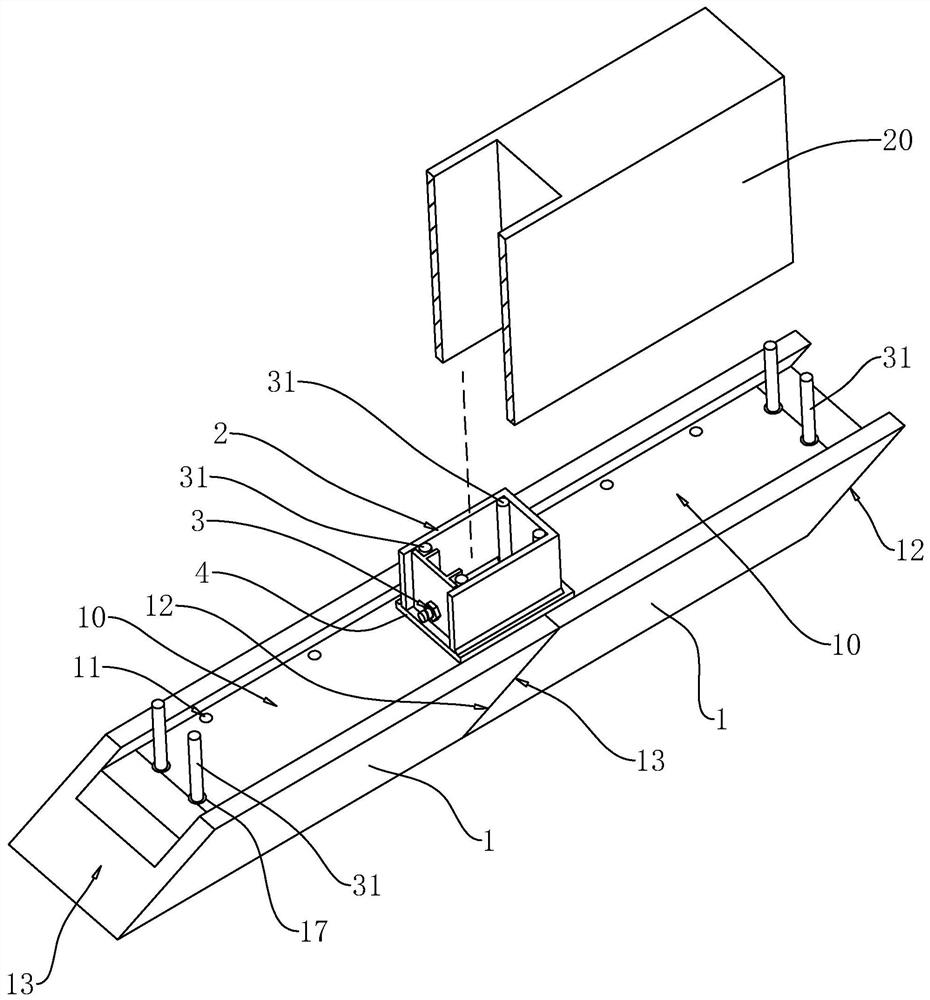

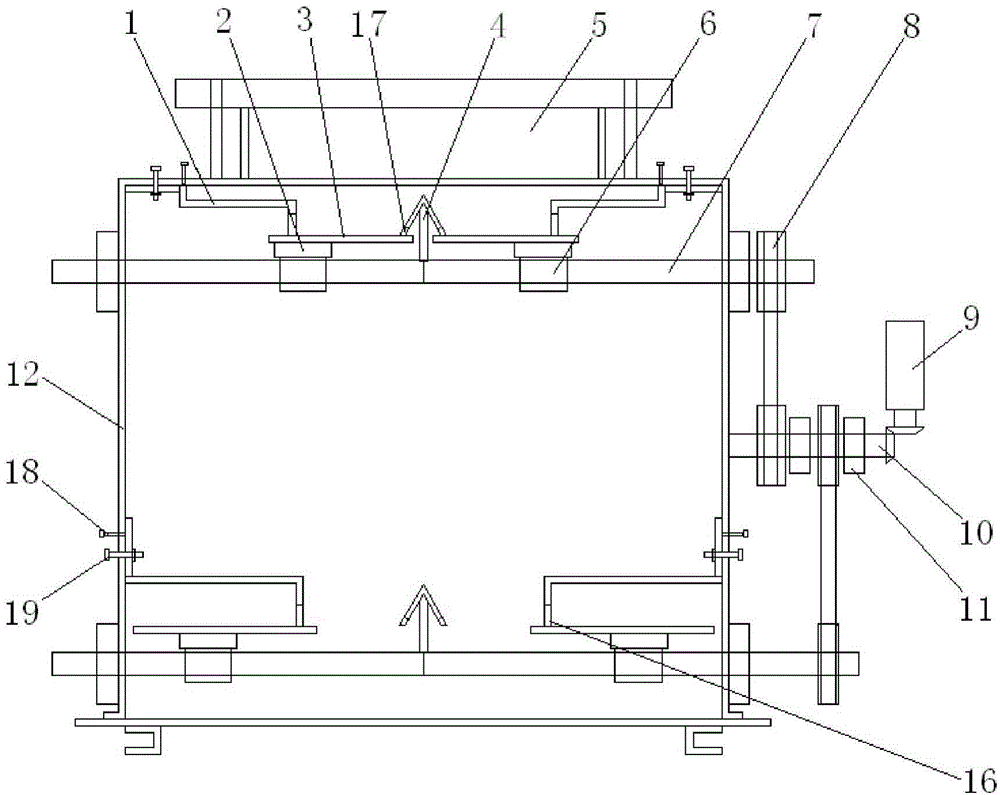

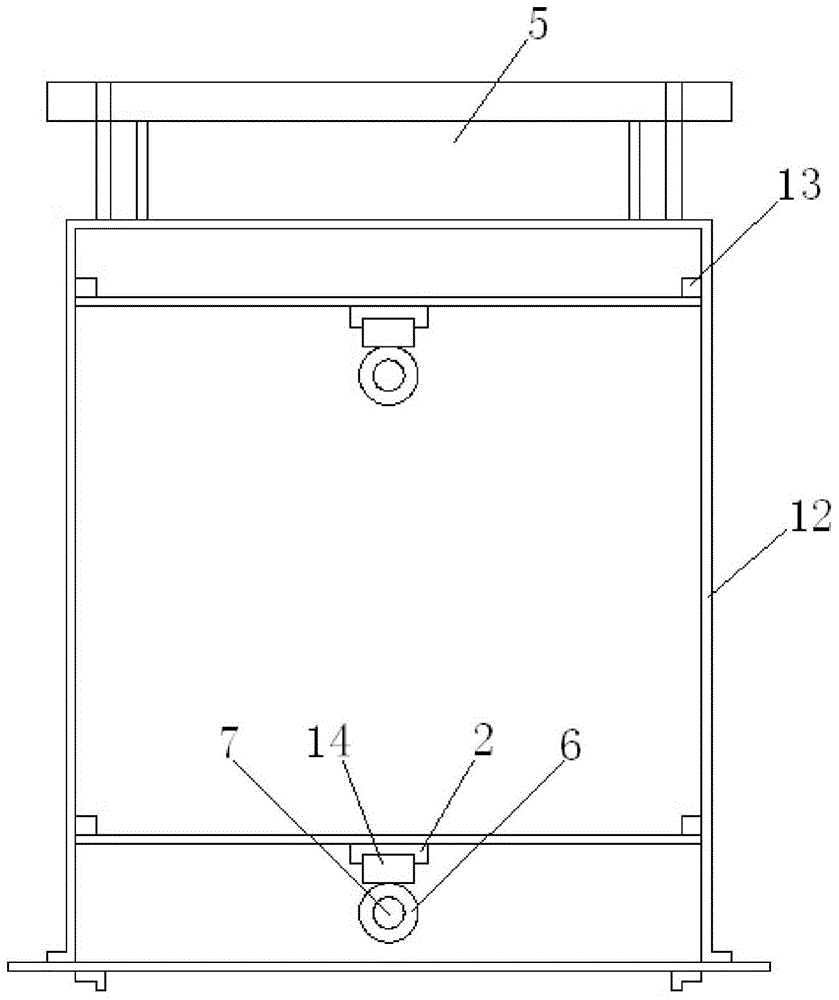

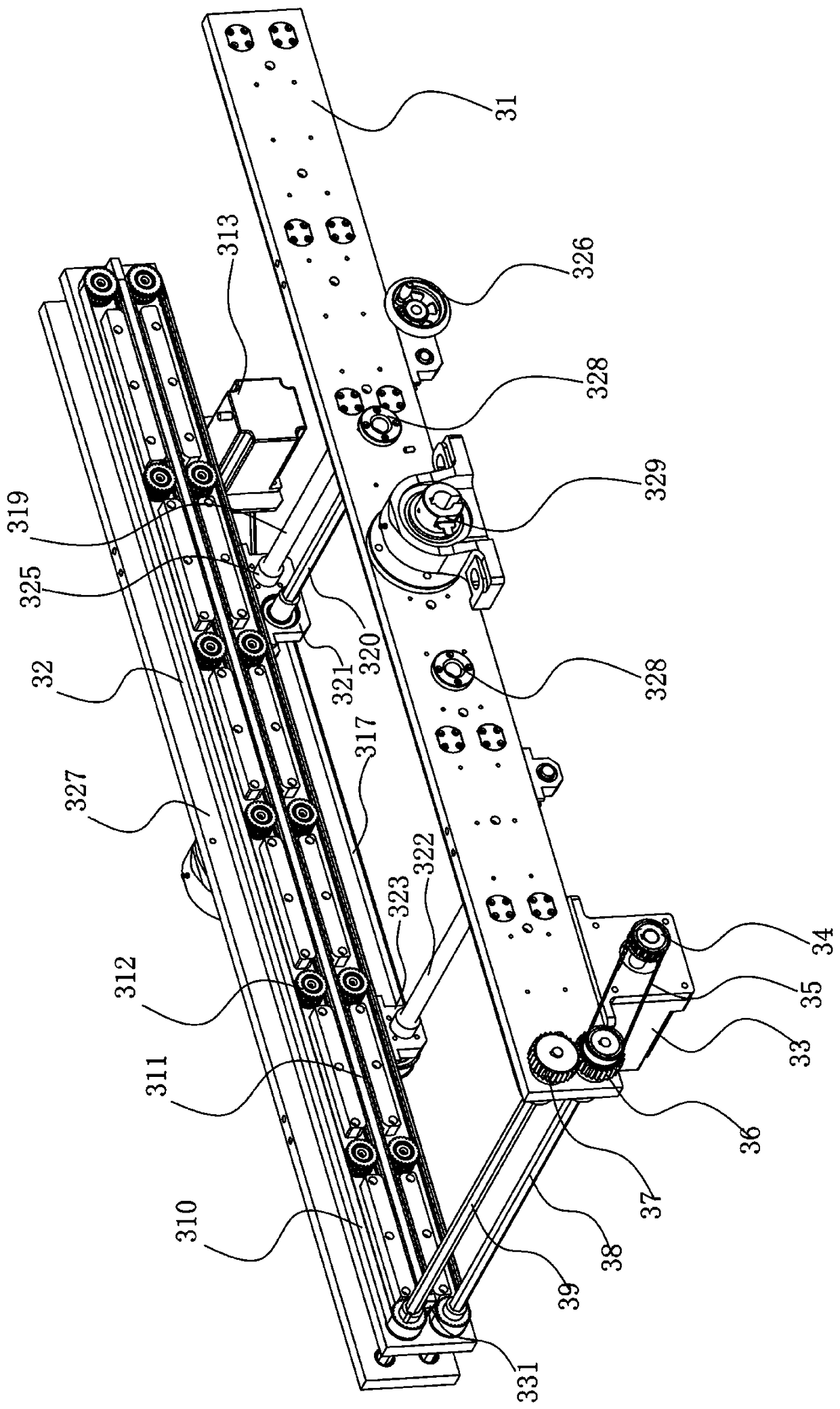

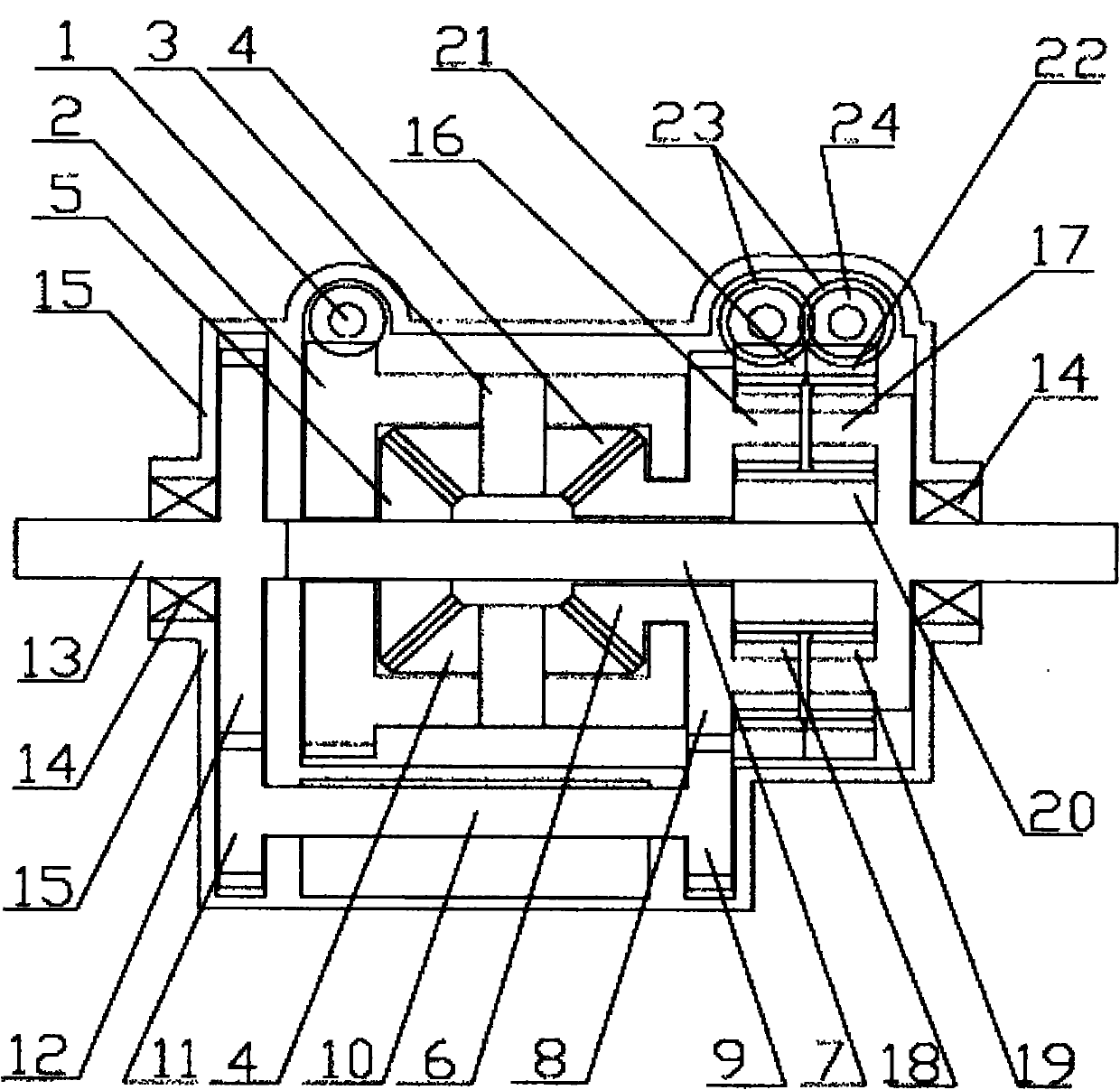

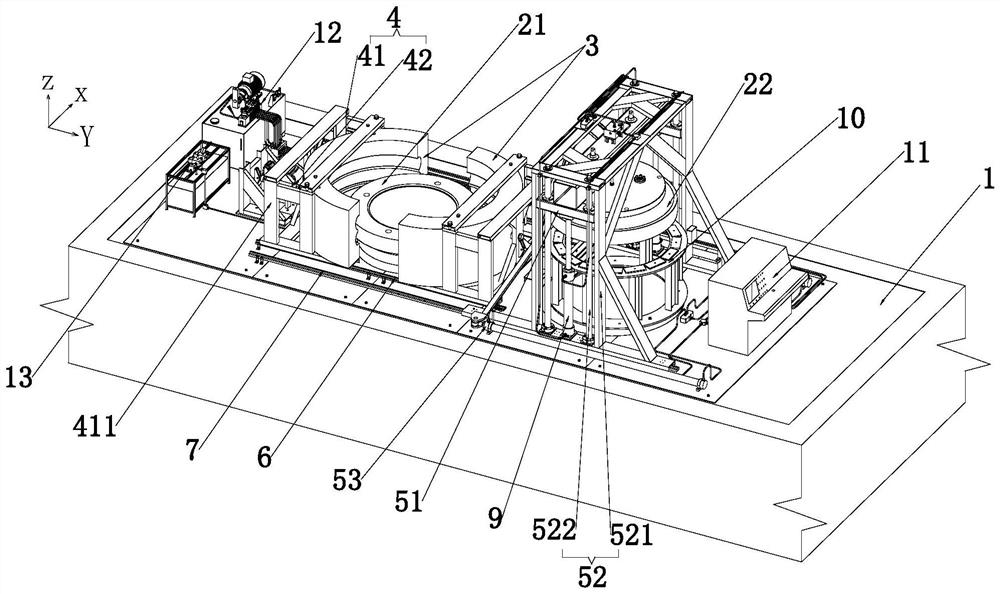

Wafer mounting and lifting conveying device of graphite boat

ActiveCN105398765ATroubleshoot loading transfer issuesSimple structureMechanical conveyorsGraphiteIndustrial engineering

The invention discloses a wafer mounting and lifting conveying device of a graphite boat. The wafer mounting and lifting conveying device comprises a rack. A lifting frame is arranged on the rack and comprises a left lifting frame body and a right lifting frame body. A lifting mechanism is arranged in the lifting frame and comprises lifting lead screws and lifting transmission seats. The lifting lead screws comprise the left lifting lead screw and the right lifting lead screw. The left lifting lead screw and the right lifting lead screw are both arranged vertically. The lifting transmission seats comprise the left lifting transmission seat and the right lifting transmission seat. The left lifting transmission seat is arranged on the left lifting lead screw, and the right lifting transmission seat is arranged on the right lifting lead screw. A lifting plate is connected between the left lifting transmission seat and the right lifting transmission seat and provided with the graphite boat. A supporting table is arranged between the left lifting frame body and the right lifting frame body and provided with a lifting transmission mechanism, and the lifting transmission mechanism is connected with the lifting mechanism. The device is simple in structure, scientific, convenient to use, high in pertinence and automation degree, good in wafer mounting effect and high in conveying efficiency, and the wafer mounting conveying problem of the graphite boat is solved well.

Owner:SHENGZHOU SIGMA TECH

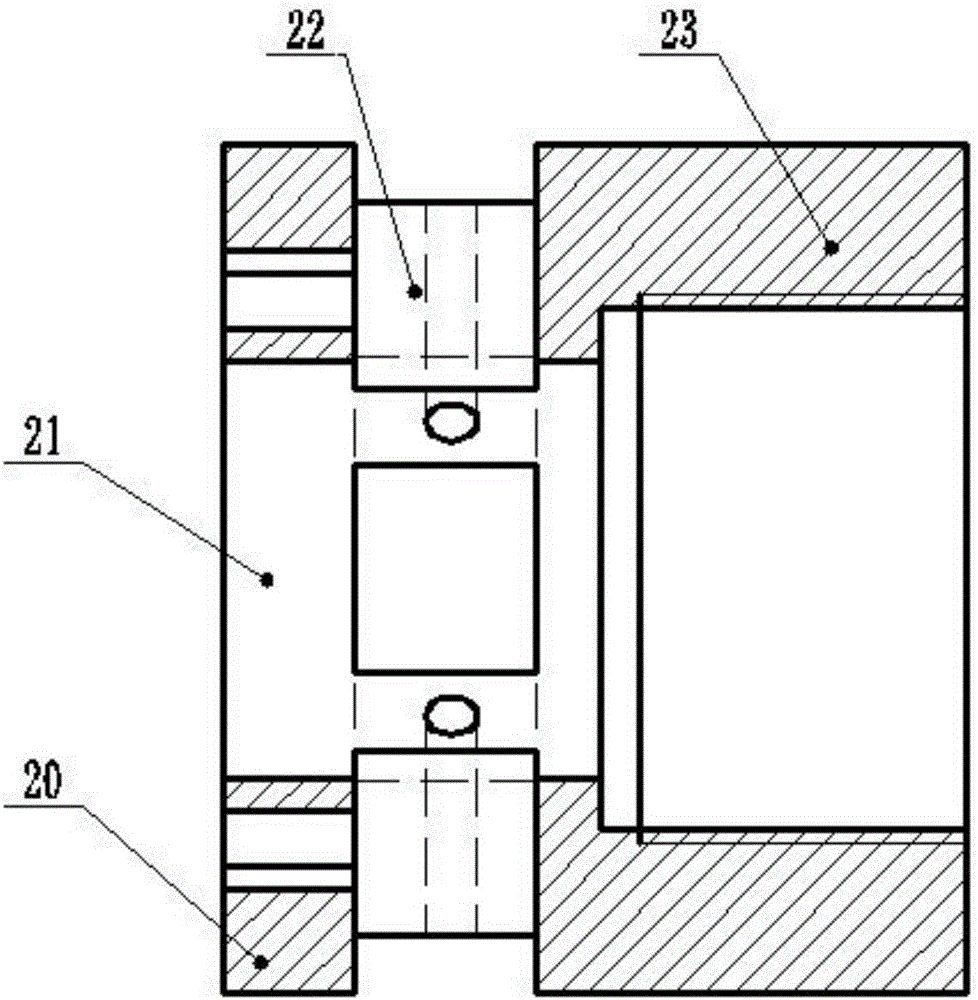

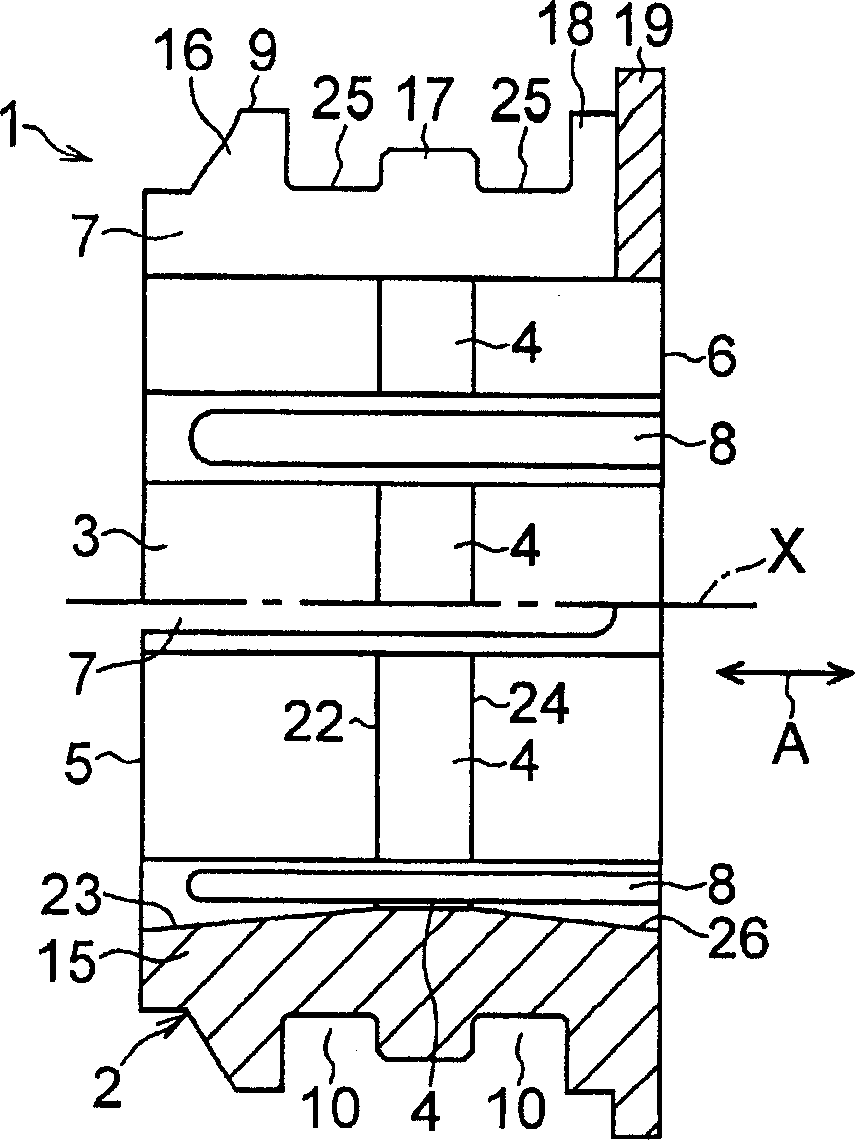

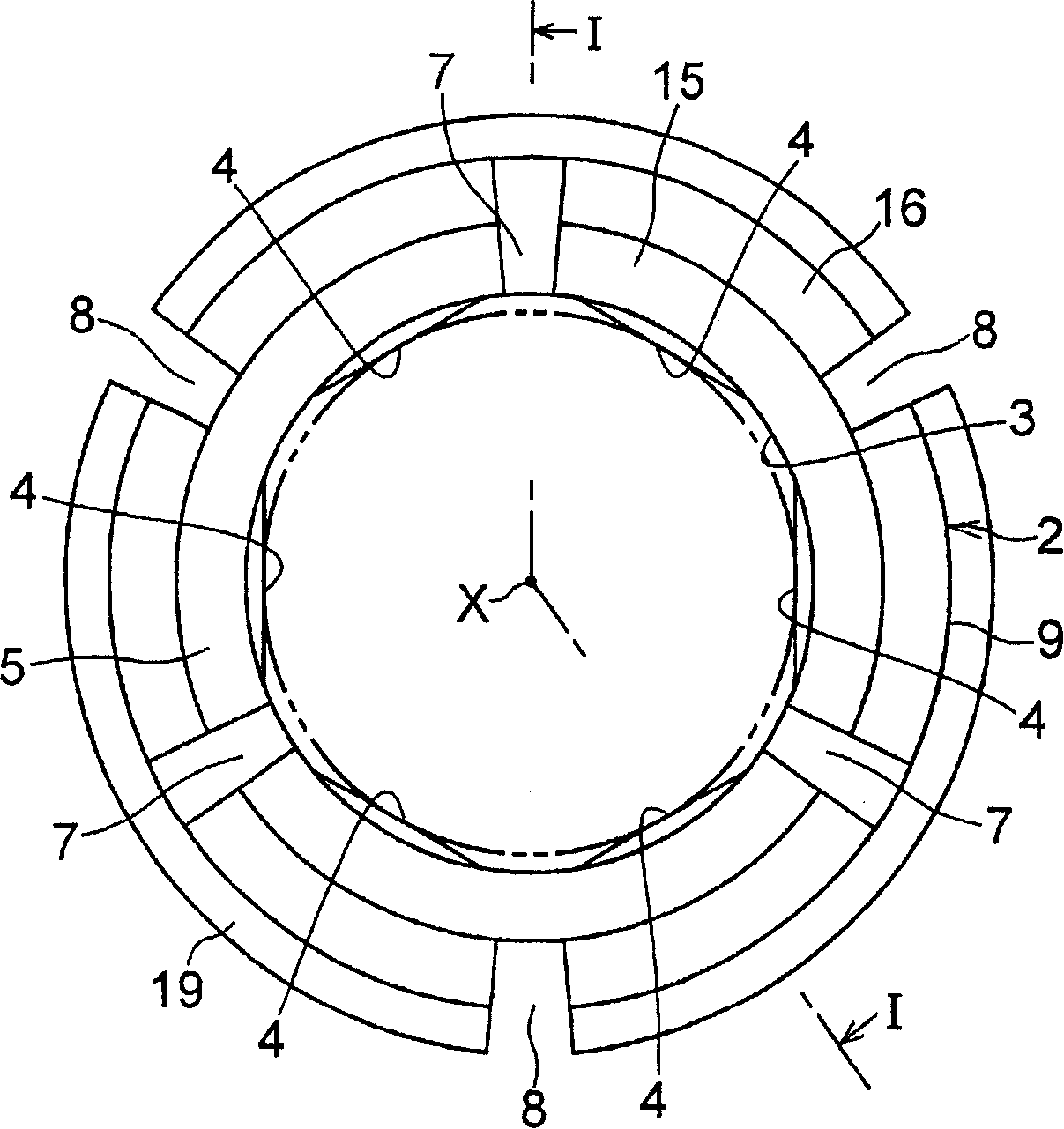

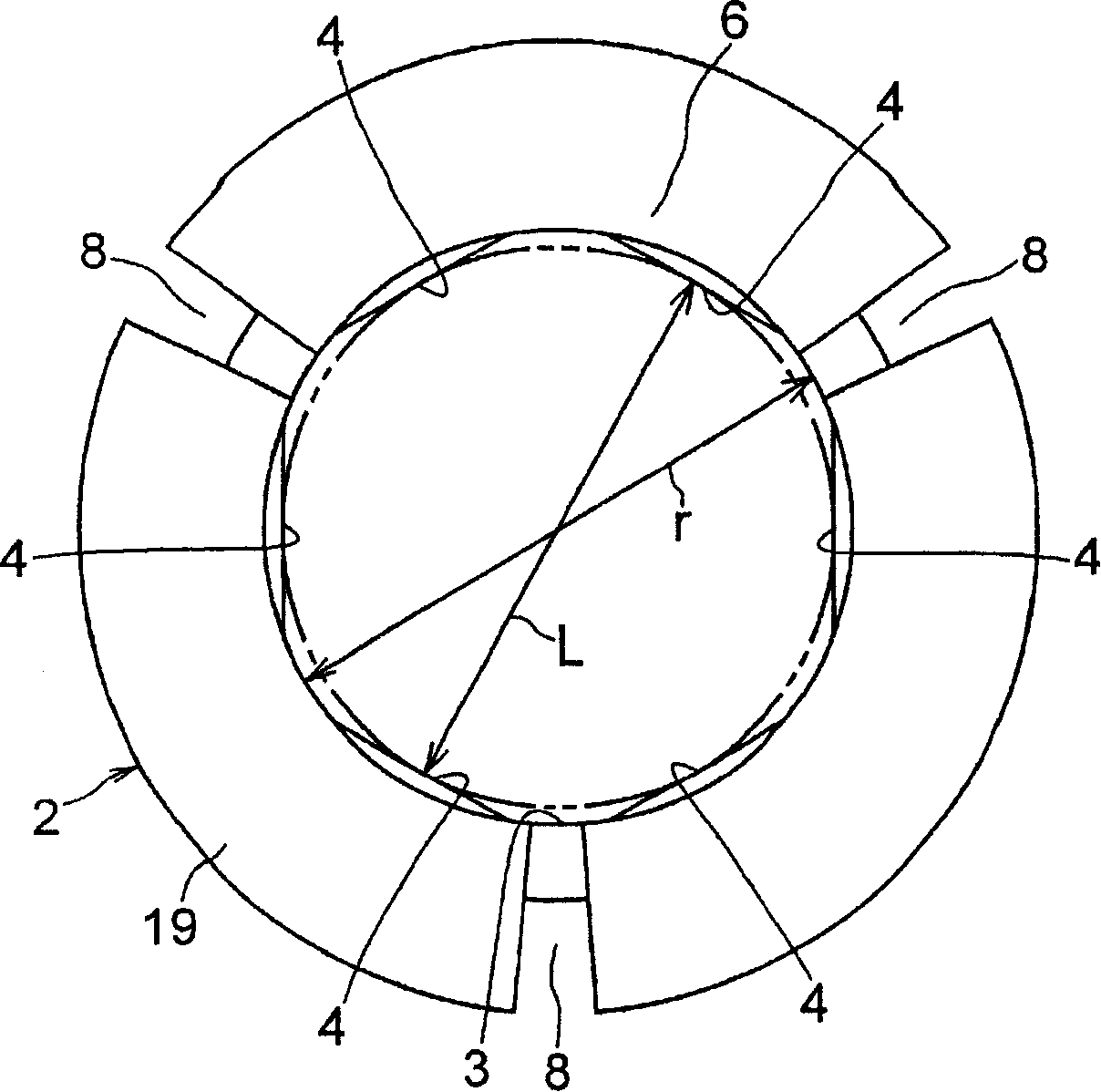

Sliding bearing and bearing mechanism having the same

A sliding bearing for a steering column includes: a cylindrical bearing body (2); flat surfaces (4) formed integrally on an inner peripheral surface of the bearing body; first slits (7) extending from one end face (5) of the bearing body to this side of the other end face (6) of the bearing body; second slits (8) extending from this side of the other end face (6) of the bearing body to the one end face (5) of the bearing body; grooves (10) formed in an outer peripheral surface of the bearing body (2); and elastic rings which are respectively fitted in the grooves in such a manner as to project from the outer peripheral surface of the bearing body (2) and to reduce the diameter of the bearing body.

Owner:OILES CORP

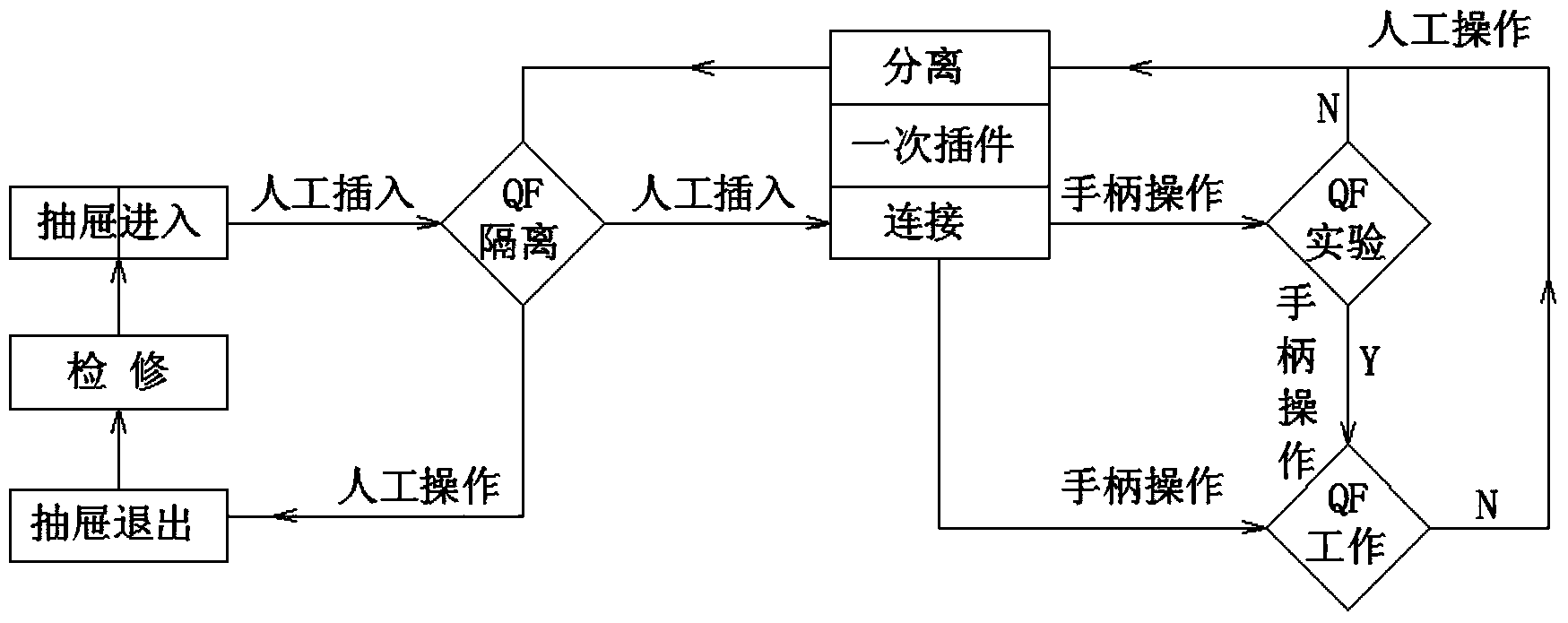

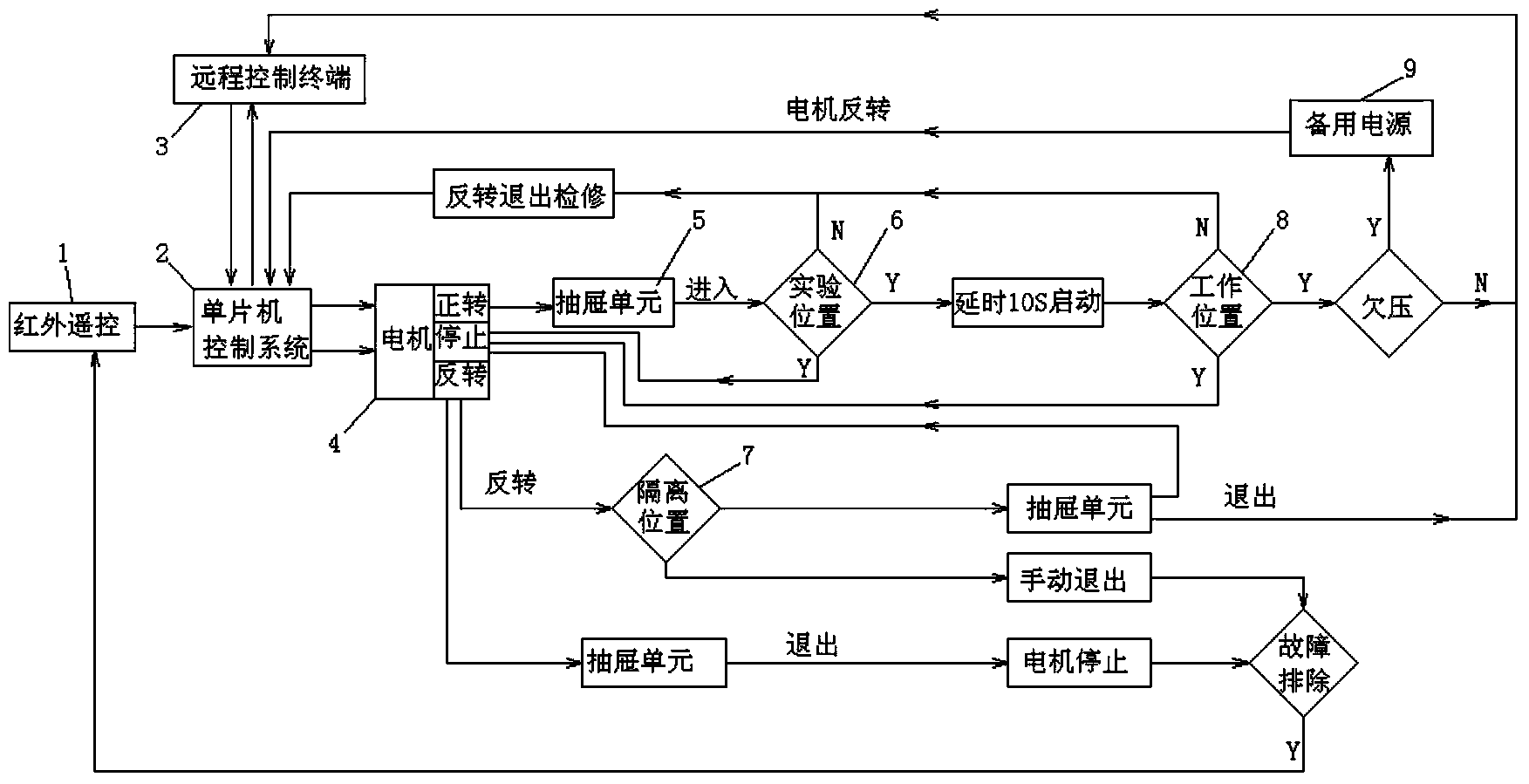

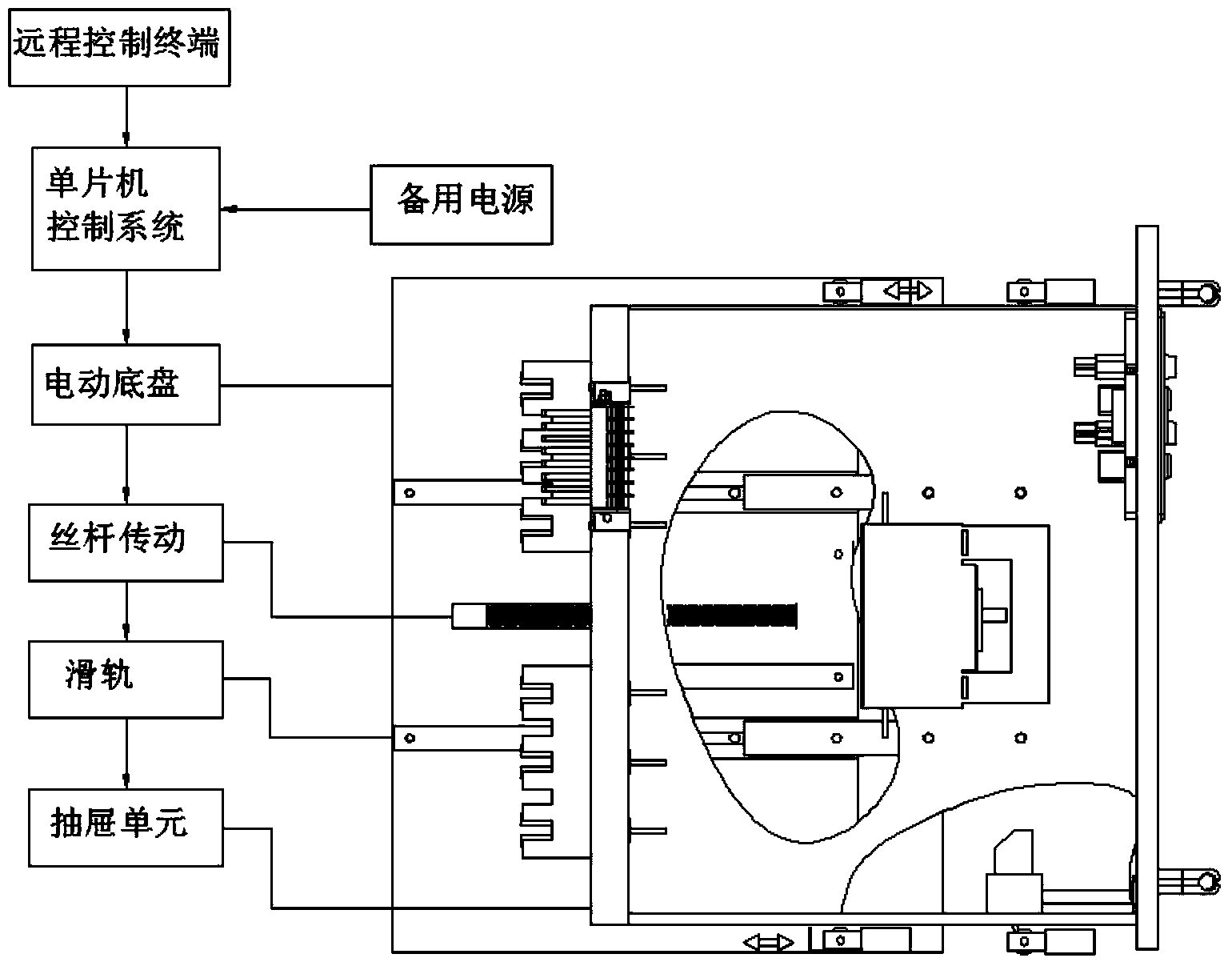

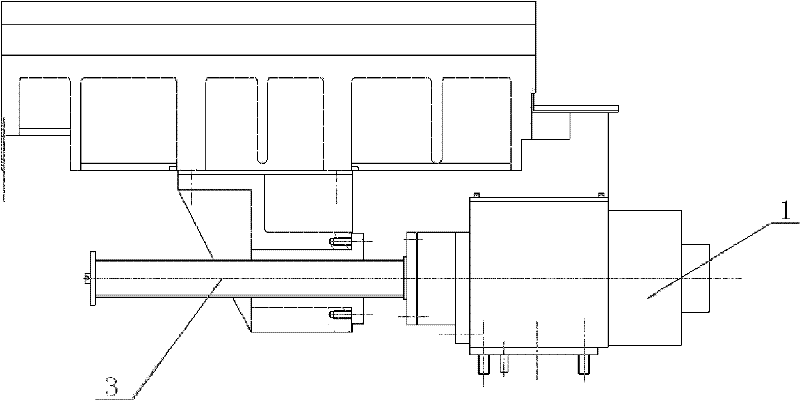

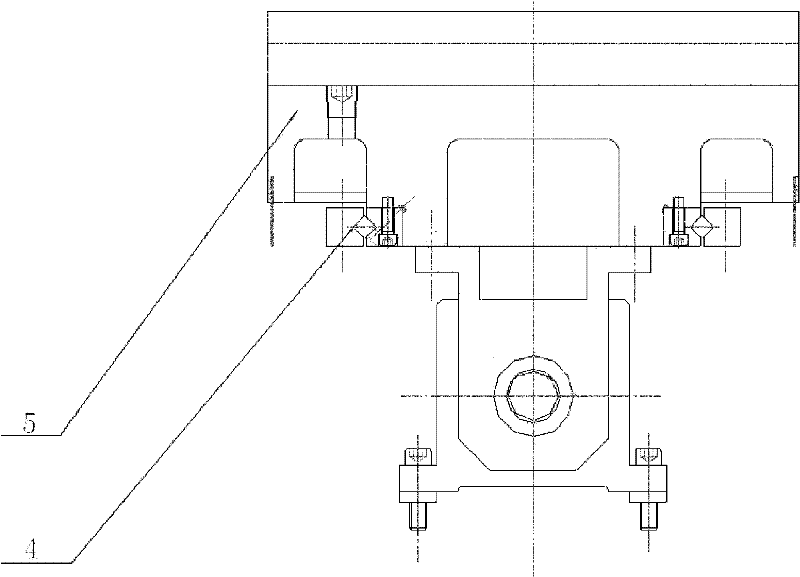

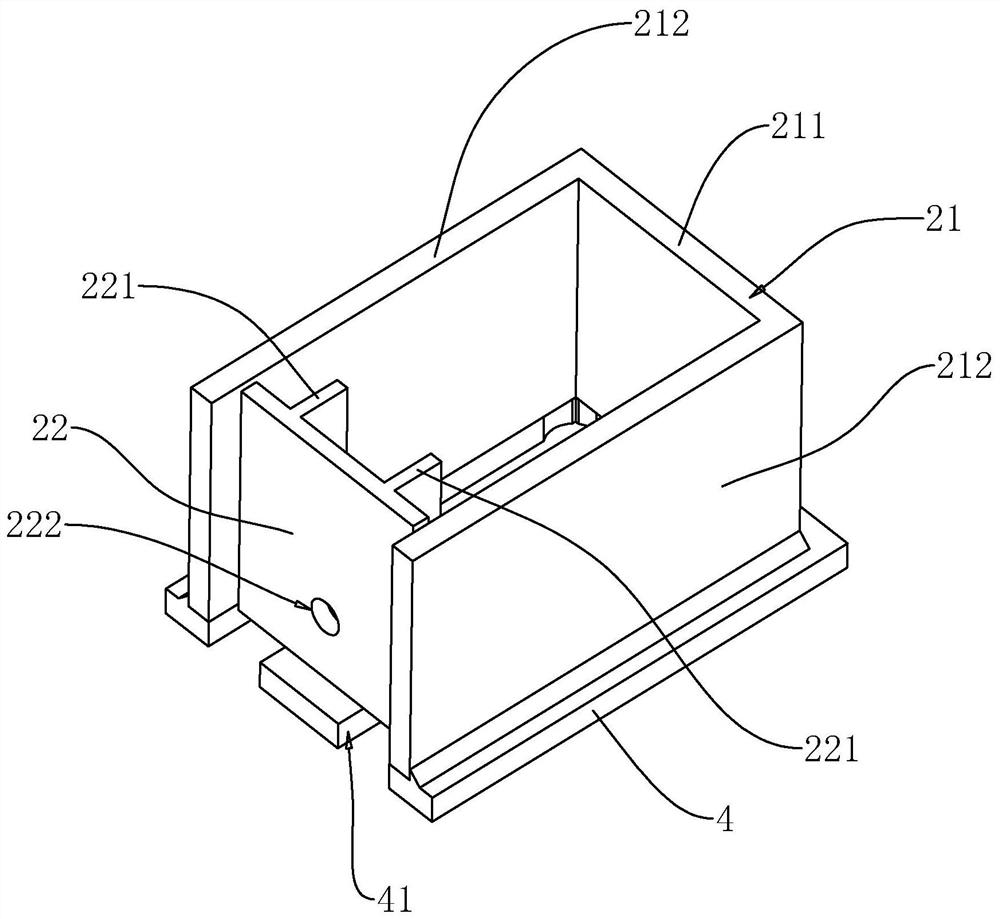

Control method of intelligent low-pressure drawer unit system

InactiveCN104037635AHigh degree of automationSmooth linear motionSwitchgear with withdrawable carriageCircuit arrangementsMicrocontrollerUnit system

The invention discloses a control method of an intelligent low-pressure drawer unit system. The control method is characterized in that a servo motor is controlled by an infrared manner to rotate clockwise and anticlockwise according to the single-chip microcomputer principle, so as to keep a drawer unit in the existing and exiting state, and the drawer running position is accurately positioned and monitored; in case of power failure or electrical accident, a backup power supply is put into use, a single-chip microcomputer controls the servo motor to rotate anticlockwise and a drawer is automatically ejected out to reach the original position, so as to realize full-automatic intelligent control; the drawer working information can also be fed back to a remote control terminal, thus the failure information can be timely found out, and the drawer can be controlled to exist and exit through a background remote terminal. With the adoption of the control method of the intelligent low-pressure drawer unit system, the drawer unit can freely exist and exit; the motor-based control mode is carried out, the motor lead-screw driving is selected as the main process, the linear motion is performed, thus the fit clearance is small, and little shaking is caused; the automatic driving avoids forced operation, and therefore, the service life of the drawer unit is also prolonged; the remote control function is realized through background remote terminal control software.

Owner:ANHUI MINGYUAN POWER EQUIP MFR

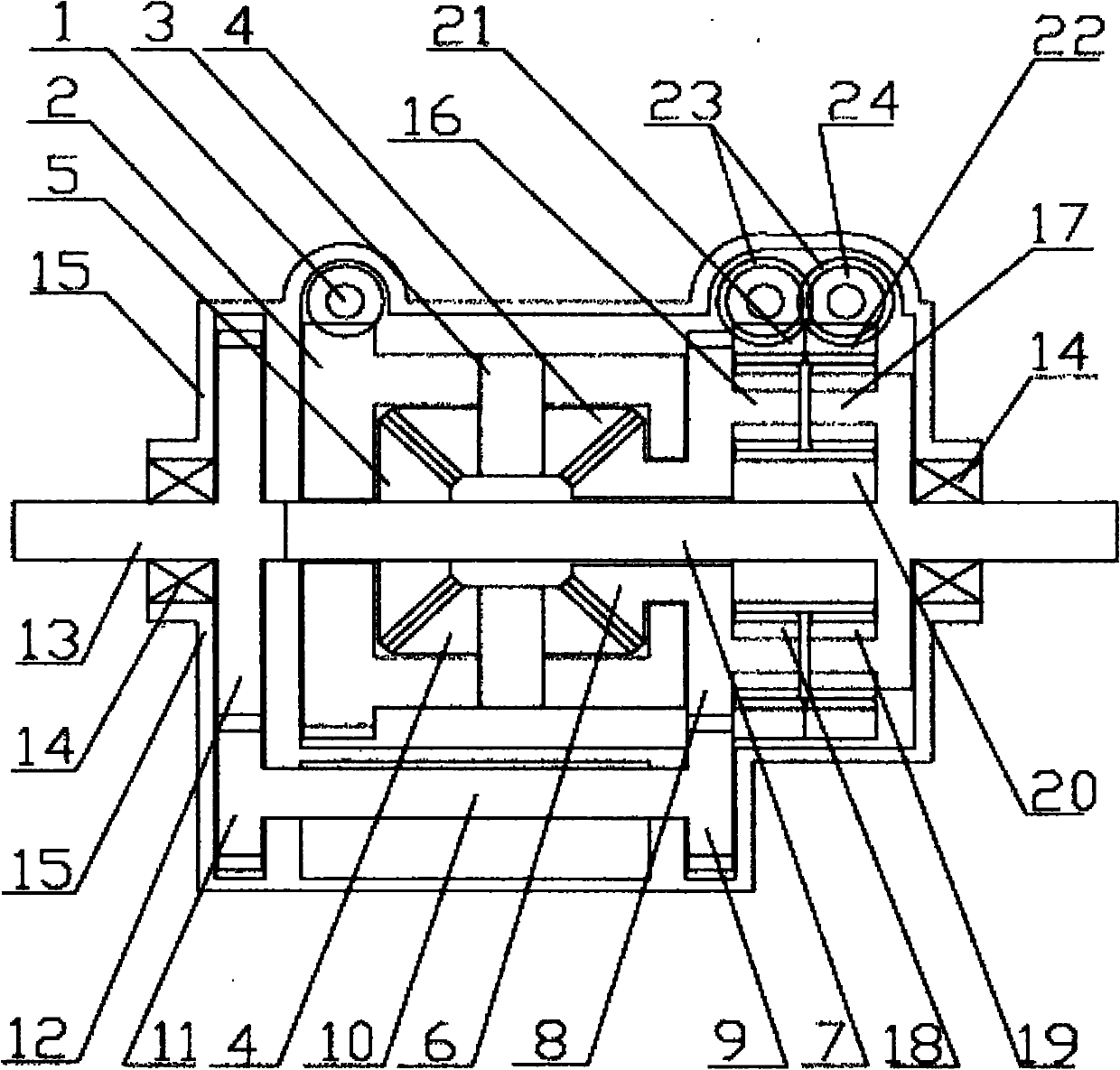

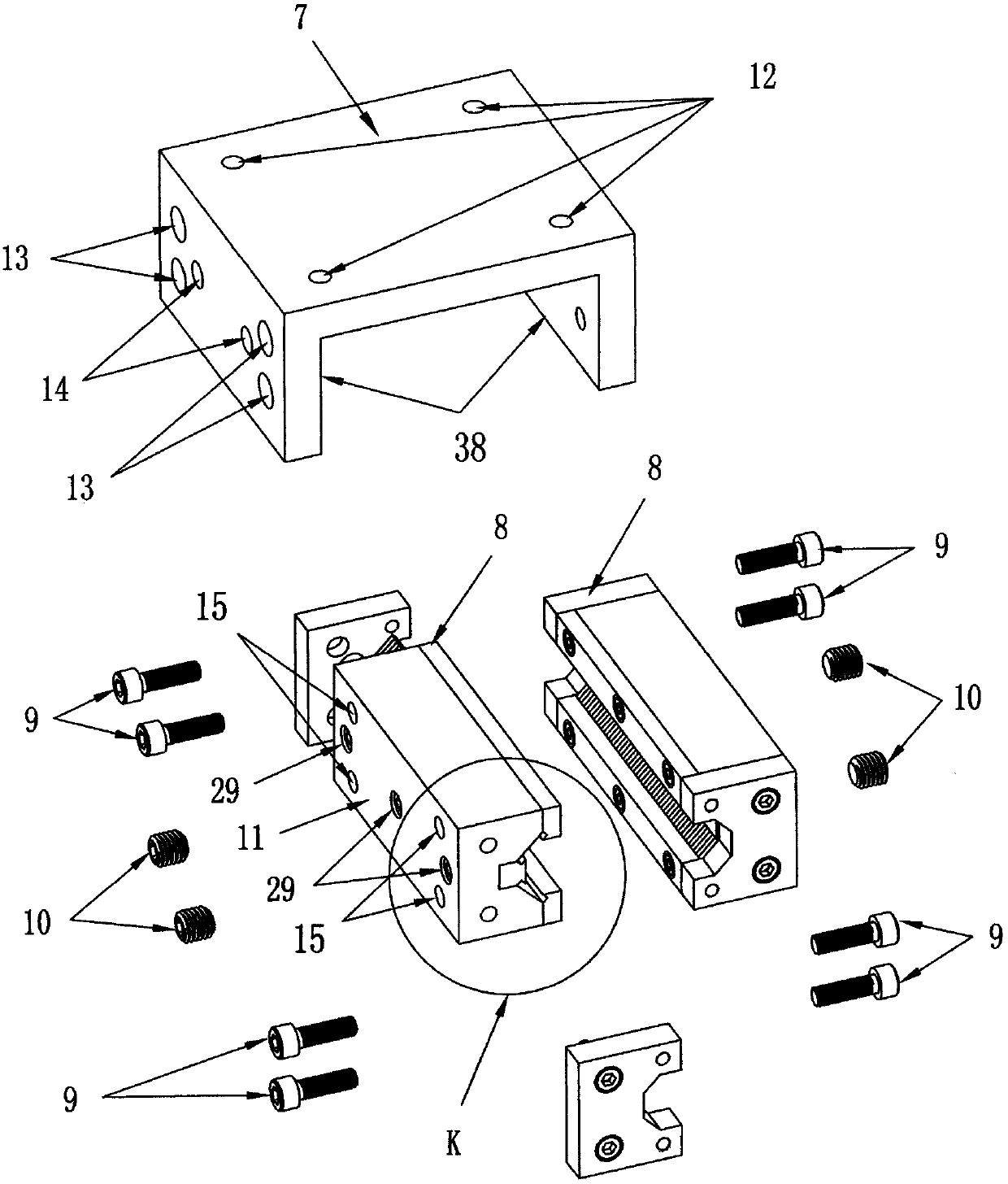

Traverse feeding device of external groove plungecut grinder

InactiveCN102172890AReduce frictional resistanceImprove stabilityGrinding drivesReduction driveReducer

The invention provides a traverse feeding device of an external groove plungecut grinder. The traverse feeding device comprises a roller cross guide rail pair, a traverse feed table and a drive unit, wherein the roller cross guide rail pair comprises guide rails, a roller retainer and a cylindrical roller, and the cylindrical roller is arranged on the guide rails through the roller retainer; the drive unit comprises a stepping motor, a harmonic speed reducer and a ballscrew, wherein the stepping motor drives the harmonic speed reducer to connect the ballscrew, an output shaft of the harmonic speed reducer is fixedly connected with a shaft end of a screw of the ballscrew, a nut of the ballscrew is connected with the transverse feed table, and the nut of the ballscrew can move forth and back on the screw of the ballscrew. By means of the transverse feeding device, the deceleration with large rotation ratio can be carried out through the harmonic speed reducer so that the transverse feeding is more stable, and the transverse feeding precision is improved by controlling the stepping motor through electric programs, thus accurate feeding and reversing are realized, and the machining precision of a bearing ring is accurate; and simultaneously, the stroke of the transverse feeding is also enlarged, the purchase cost of new equipment is reduced, and the purpose of a machine tool is widened.

Owner:HARBIN BEARING GROUP CORP

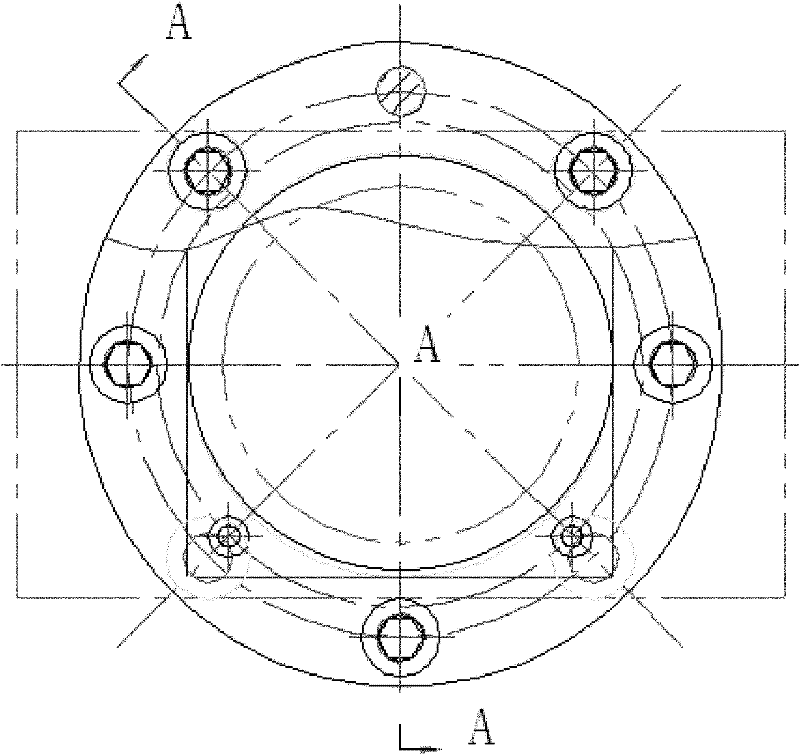

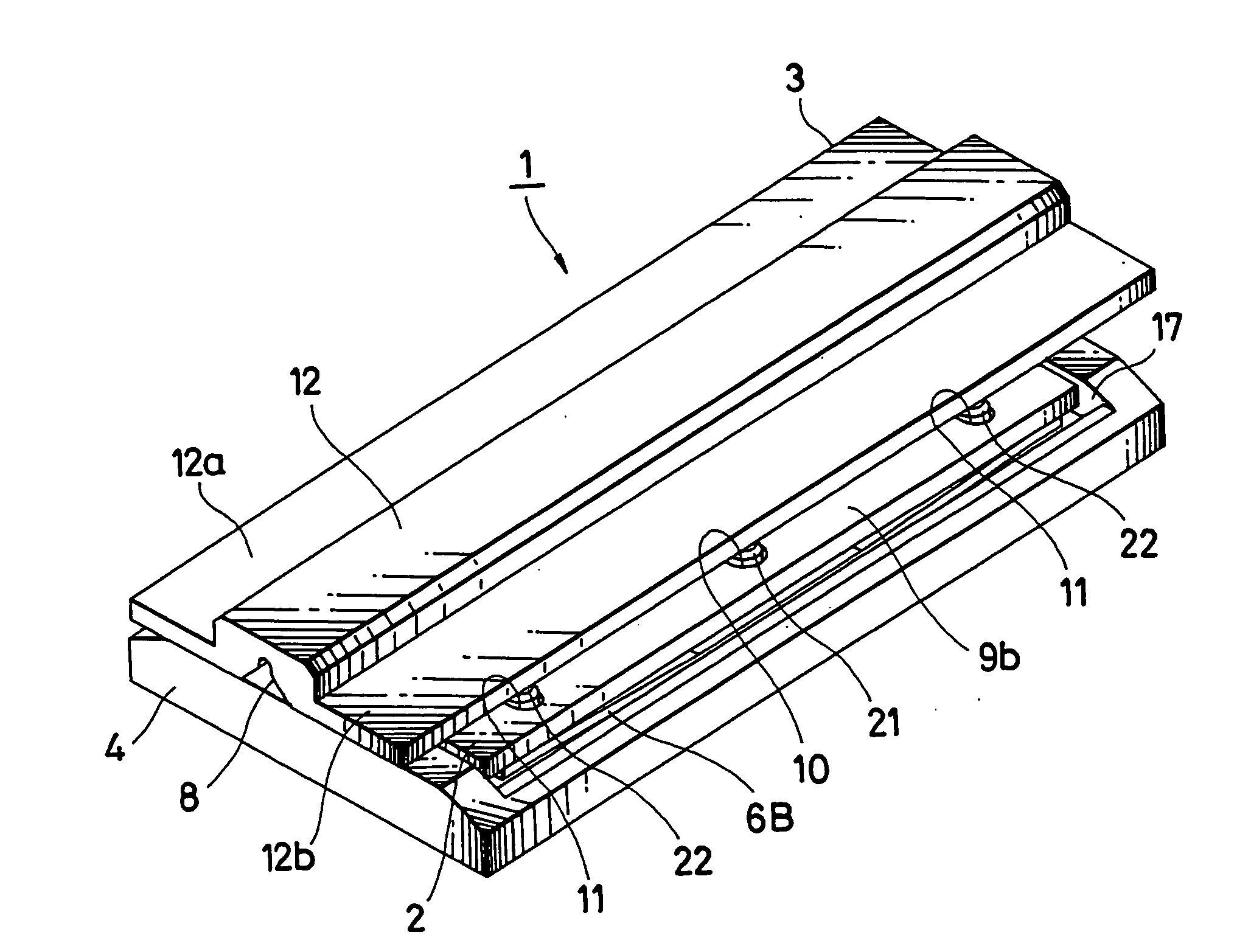

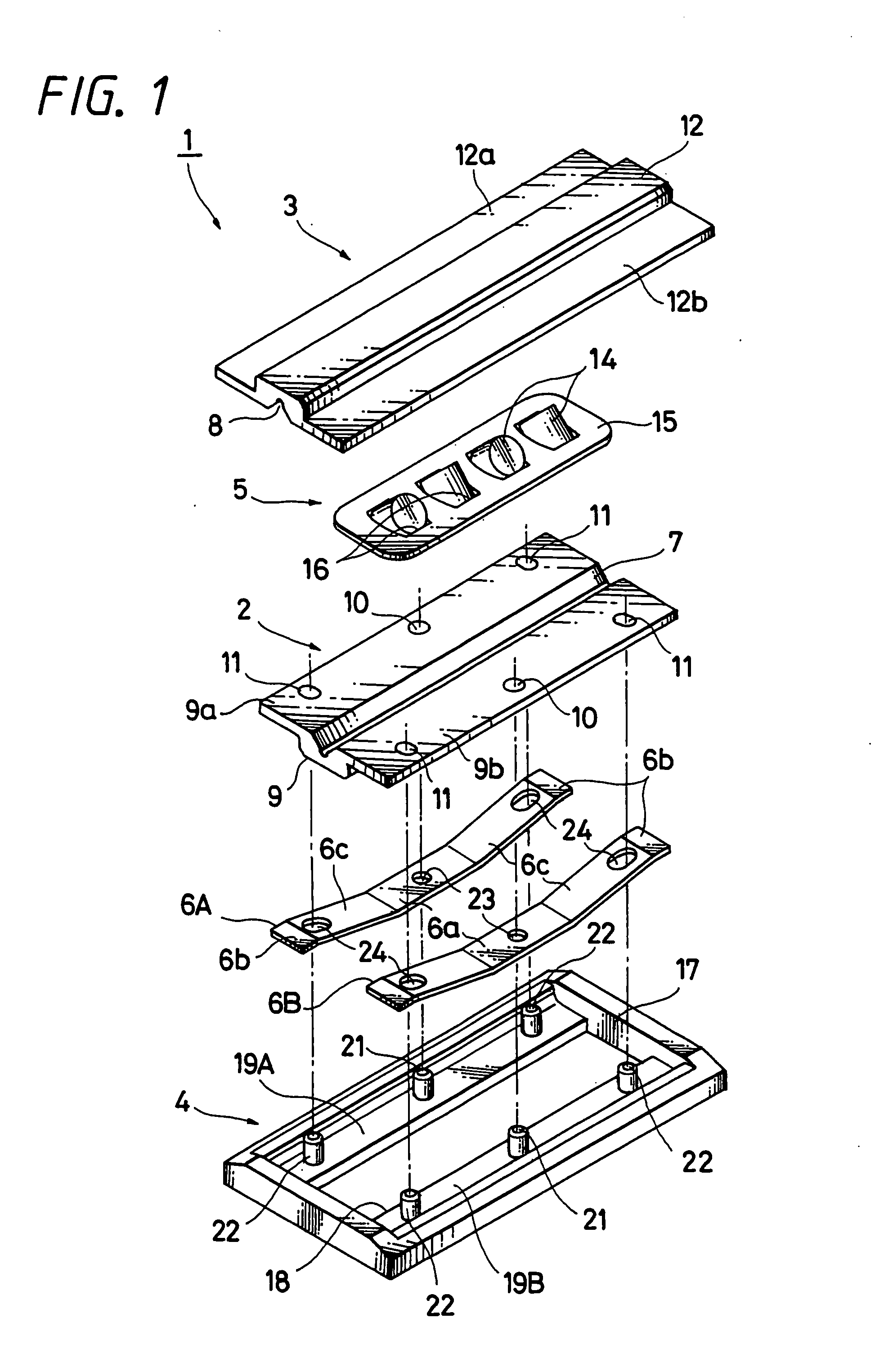

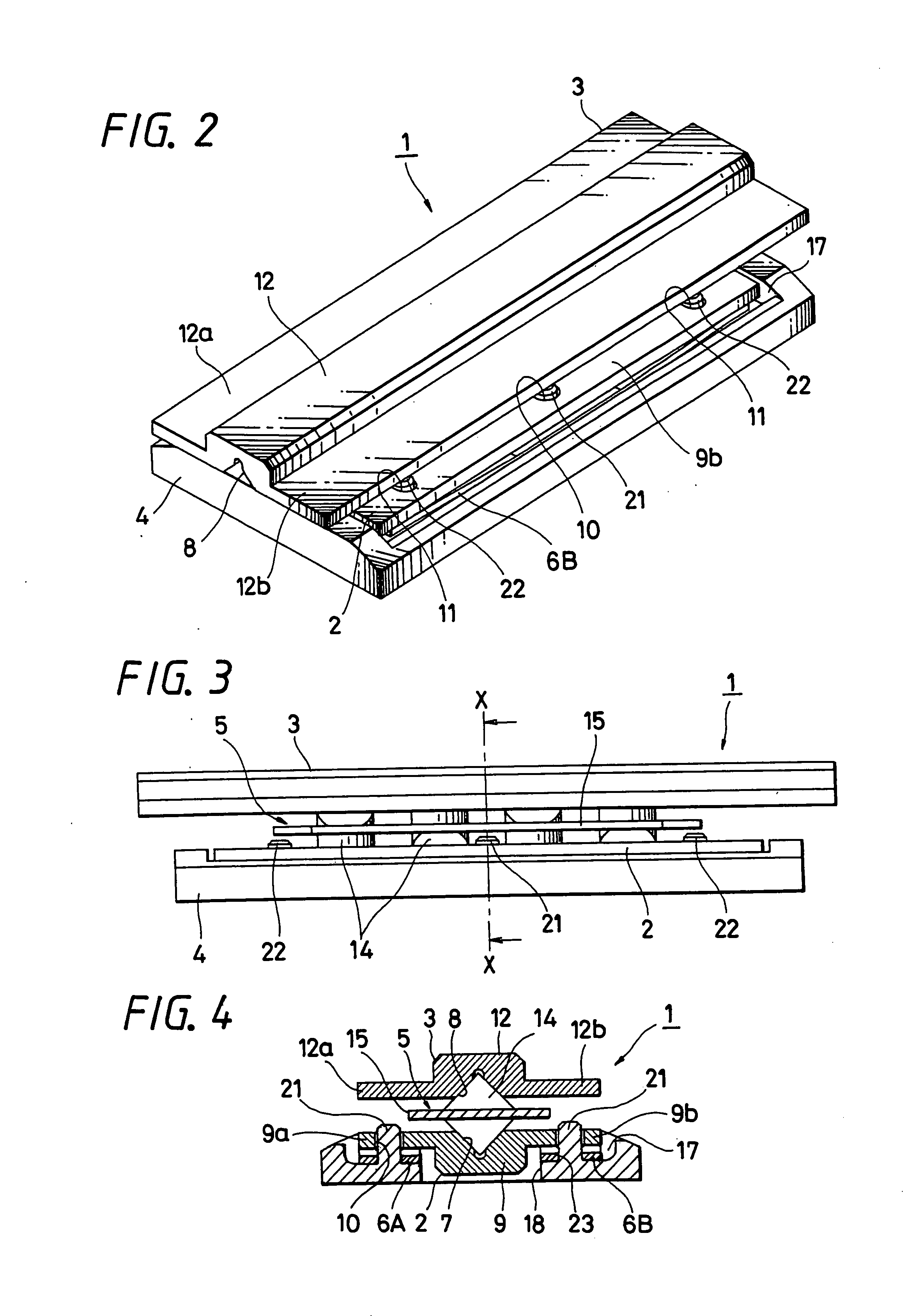

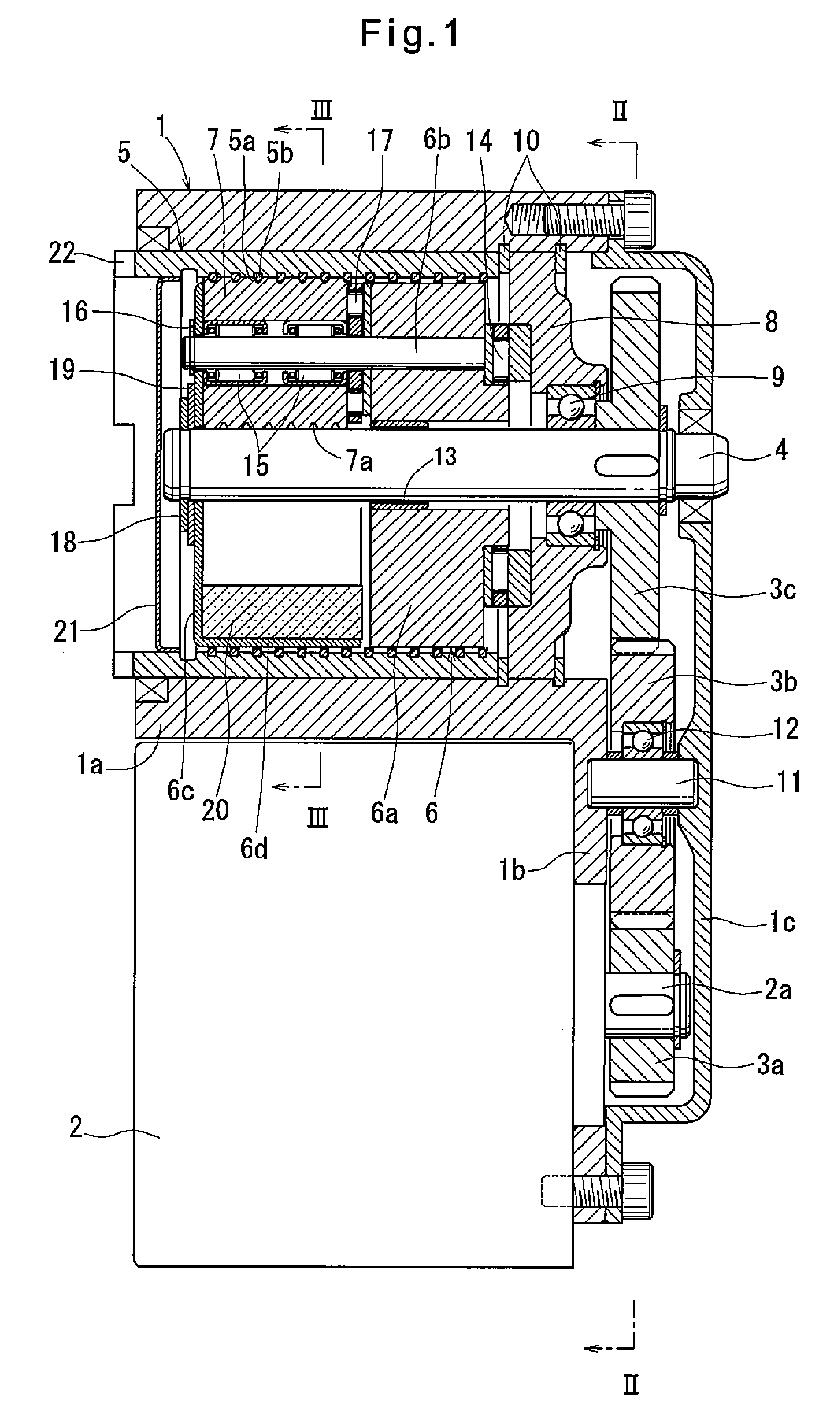

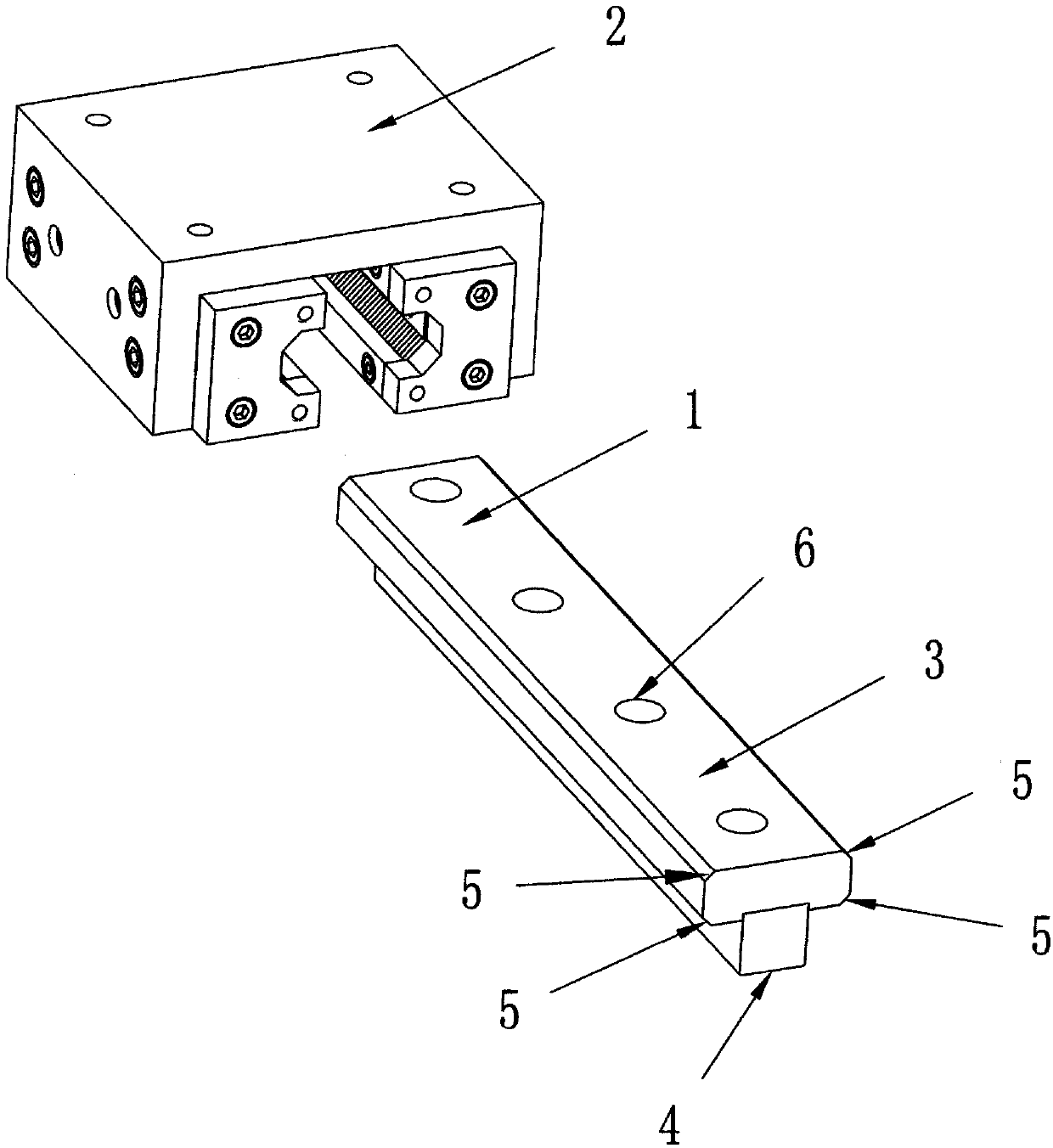

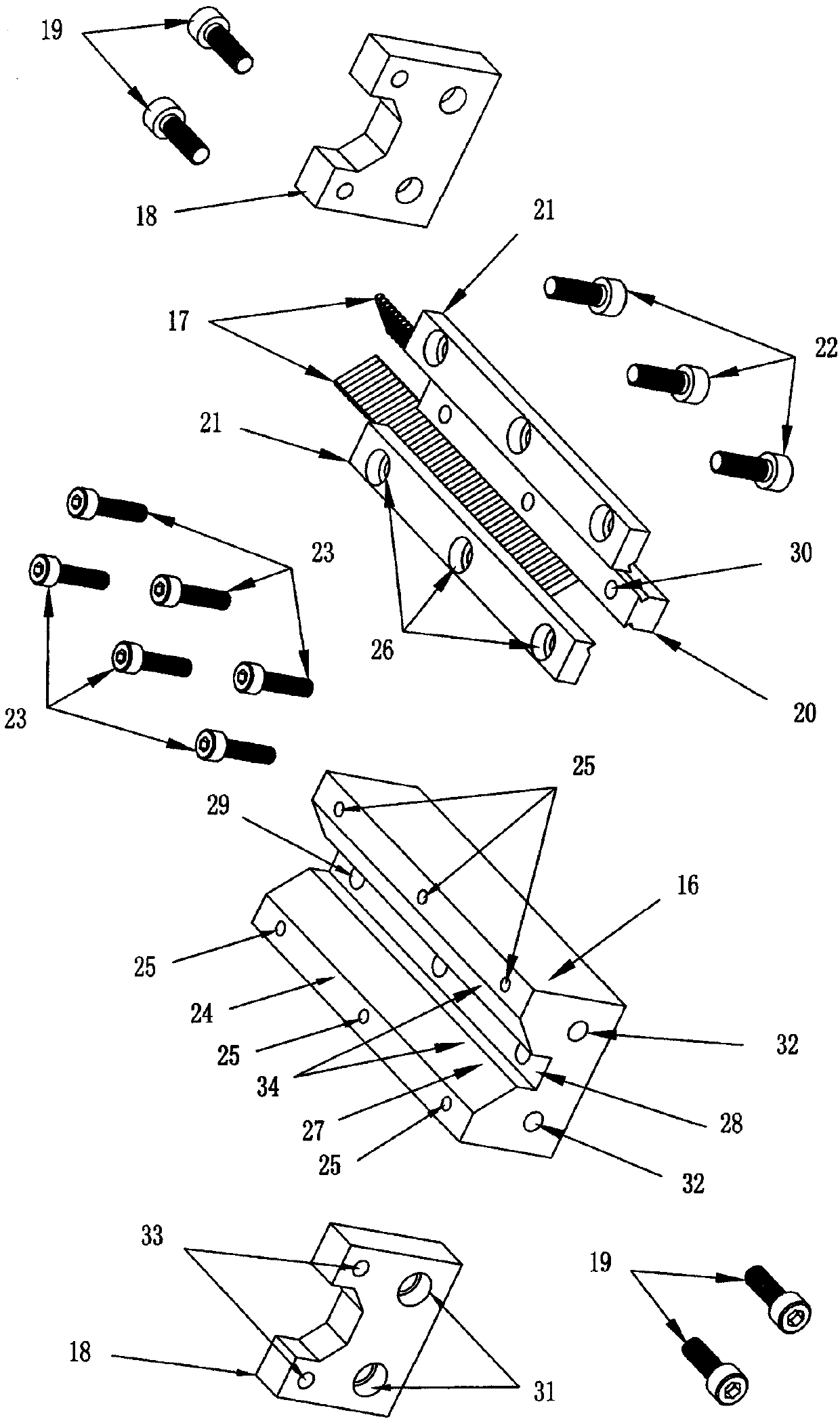

Linear Motion Rolling Guide Device and Lens Device

InactiveUS20080279491A1Smooth linear motionSmooth and stable linear movementLinear bearingsMountingsLinear motionEngineering

The present invention relates to a linear motion rolling guide device which enables a movable element to linearly move through rolling elements, and to a lens device including the linear motion rolling guide device.A linear motion rolling guide device according to the present invention includes: a guide element 2 including a first guide groove 7 extending linearly and fitting holes 11; a movable element 3 including a second guide groove 8 extending linearly and facing said first guide groove 7 with a predetermined interval; a fixed element 4 for retaining the guide element 2; a roller unit 5 including a plurality of cylindrical rollers 14, which rolls freely and is placed between the first guide groove 7 and the second guide groove 8; and a pair of spring plates 6A, 6B for giving preload to the roller unit 5 through the guide element 2 and the movable element 3. Fitting pins 22 capable of fitting into the fitting holes 11 of the guide element 2 are provided to the fixed element 4 and the fitting holes 11 are long holes extended in a direction perpendicular to a direction in which the first guide groove 7 extends.According to the present invention, a suitable preload can be given to the roller unit and a lens barrel can be moved linearly smoothly stably.

Owner:SONY CORP

Selecting method of primary positioning reference of engine connecting rod

The invention discloses a selecting method of a primary positioning reference of an engine connecting rod. The method comprises the following steps of firstly, selecting the upper end surfaces and the lower end surfaces of head holes as first positioning references, and respectively selecting a small head hole and the outer side as a second positioning reference and a third positioning reference; roughly grinding the upper end surfaces and the lower end surfaces, adopting a mutual reference method to process, and meanwhile during drilling and rough boring of the small head hole, selecting the end surfaces of the small head hole and the contour of a small head as reference surfaces; during finishing operation, adopting a uniform reference method to process, processing the small head hole by taking the end surfaces of a large head hole and the small head hole and the outer side surface of a large head as the uniform precise references, and grinding the upper end surface and the lower surface of the small head hole by taking the upper end surface and the lower surface of the small head hole as the precise references; and selecting the size, direction and action points of clamping force, wherein the direction of the clamping force faces the main positioning surface and the end surfaces of the large head and the small head. The method has the beneficial effects that the stability and easy speed adjusting in the linear movement are realized, the running precision of a machine is favorably improved, and the service life of the machine is prolonged; and meanwhile, the convenient and flexible arrangement is favorably realized according to requirements, the operation controllability is improved, and the labor strength is reduced.

Owner:WUXI WELL ELECTRO HYDRAULIC EQUIP CO LTD

Four-way positioning system of distributing vehicle

InactiveCN102464195ASolve the phenomenon of swinging left and rightSmooth linear motionMechanical conveyorsEngineeringPositioning system

The invention discloses a four-way positioning system of a distributing vehicle, comprising a chassis, a back positioning wheel of a storage bin, a front positioning wheel of the storage bin, rails and a cylinder. The rails are fixedly arranged on two sides of the chassis; the front positioning wheel and the back positioning wheel are arranged on the rails; each of the front positioning wheel and the back positioning wheel is composed of an upper bearing, a side bearing and a lower bearing; an dust bucket is arranged between the rails; and the cylinder is connected with the dust bucket. The invention can effectively solve the problem that the distributing vehicle oscillates horizontally during the distributing, and limit the distributing vehicle to jump vertically and horizontally by the rolling bearings so as to enable the distributing vehicle to move on the rails stably and linearly.

Owner:TIANJIN XINSHIFENG HYDRAULIC MACHINERY

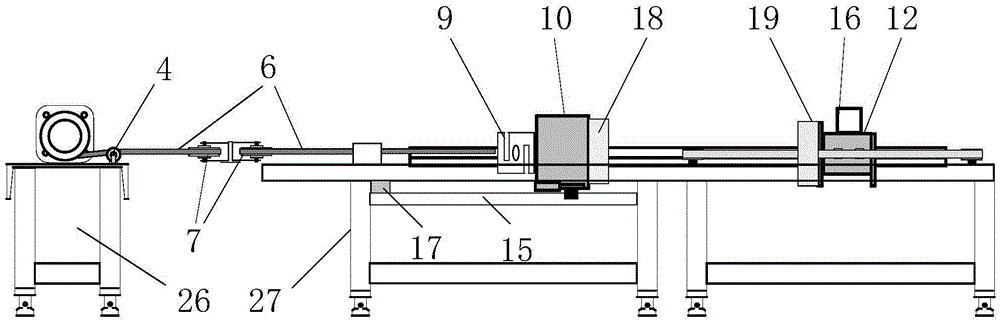

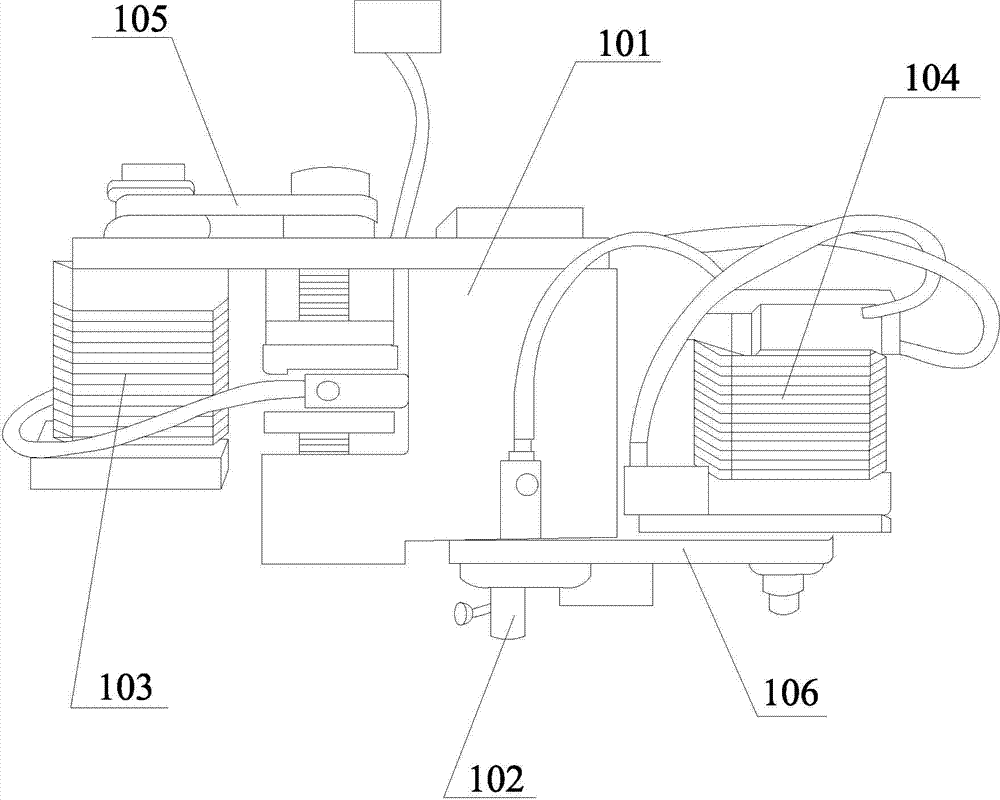

Stable dynamic linear movement generating device

InactiveCN105540507ADynamic linear motionContinuous linear motionLifting devicesHoisting equipmentsElectromagnetic lockElectric machine

The invention provides a stable dynamic linear movement generating device. The stable dynamic linear movement generating device consists of three parts including a driving module, a moving module and a supporting module; the driving module comprises a three-phase stepping motor, a motor reducer, a cable reel, a cable, a cable height guiding pulley, a cable connection pulley, a cable width guiding pulley, a tension sensor, a ball slider, a ball slider guide track, an electromagnetic lock and a photoelectrical limiting device; the moving module comprises an air floatation module, an air floatation guide track, an auxiliary equipment fixing seat, an electromagnetic lock attracting plate, an elastic rope and an elastic rope guiding pulley; and the supporting module comprises a motor platform and a guide track platform. A dynamic linear movement state generated by the device can be adjusted and set in a certain range, a movement process is stable and free of vibration, energy is recycled safely and reliably, the device is simple in structure, and can be detached, and movement and transportation are facilitated.

Owner:BEIHANG UNIV

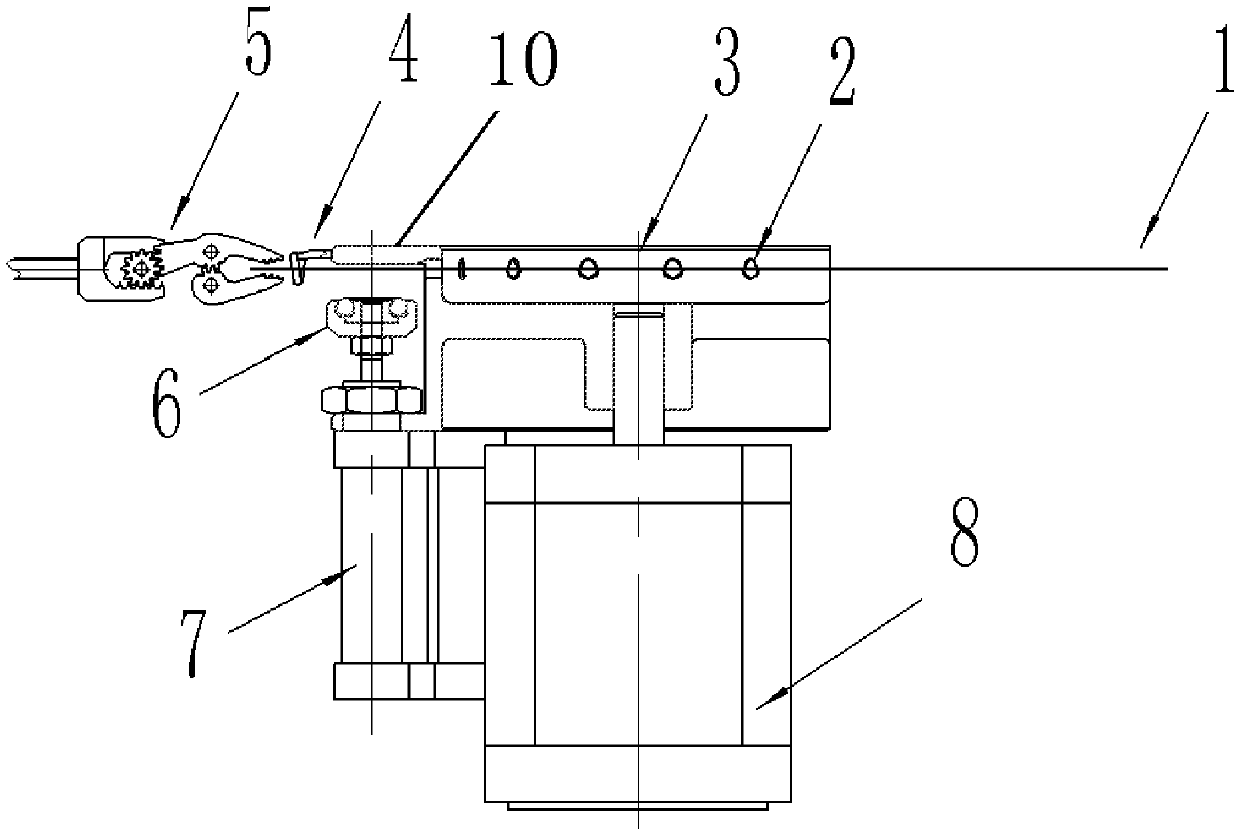

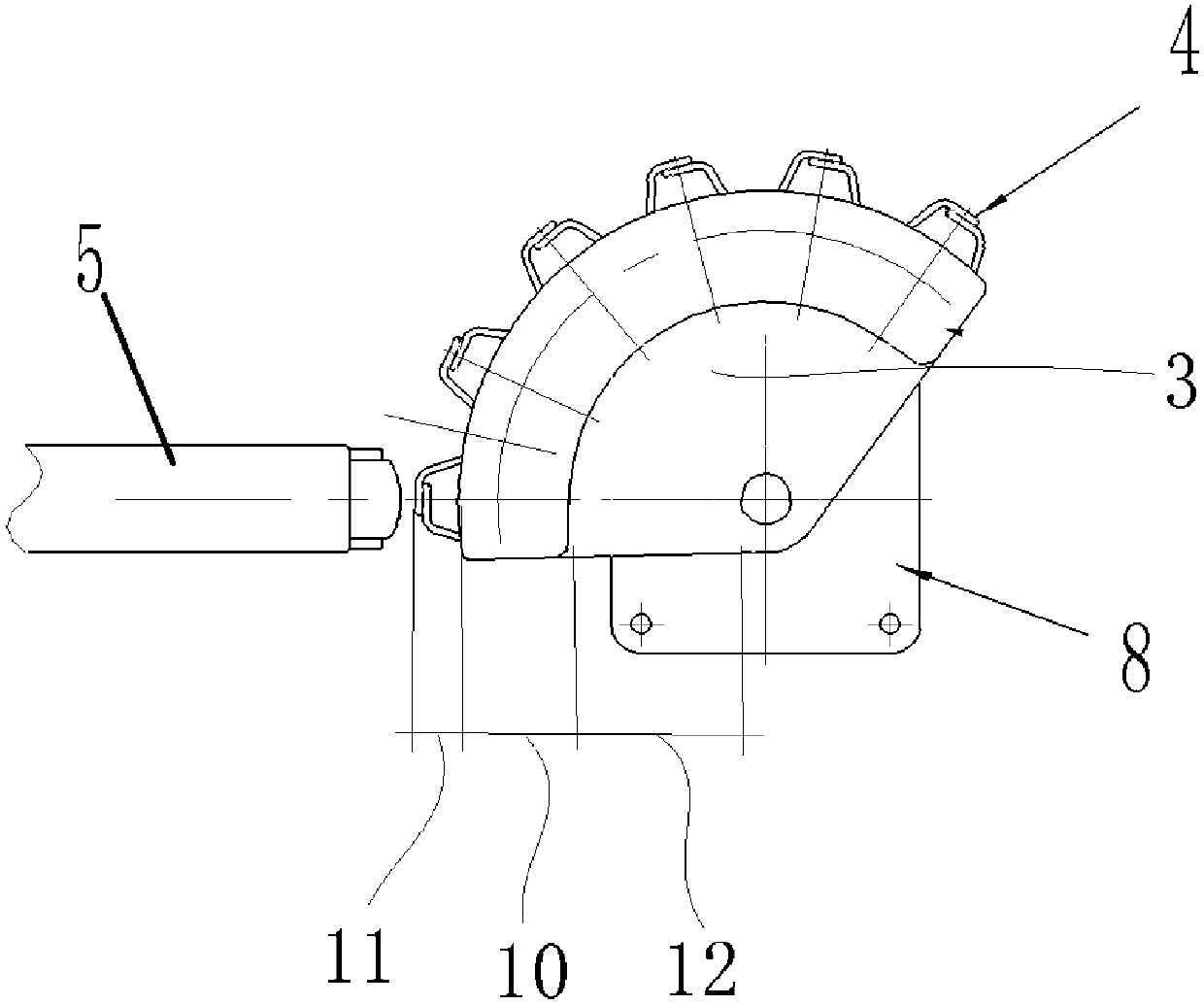

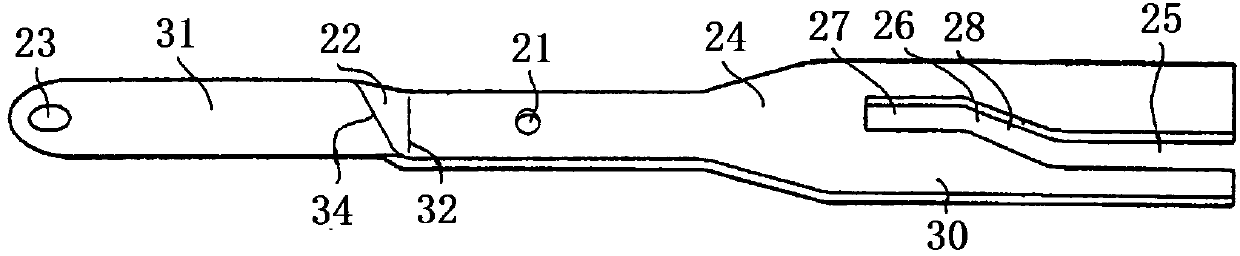

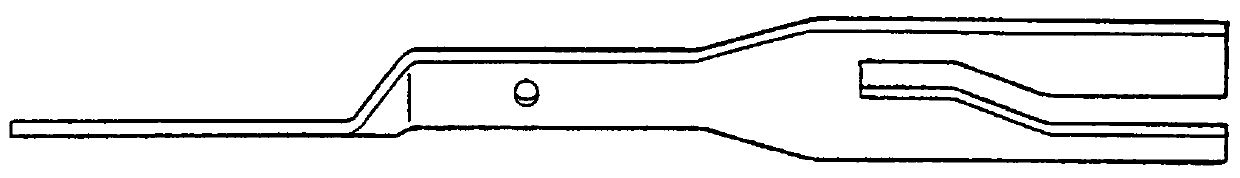

Weft selecting mechanism for big tows

The invention discloses a weft selecting mechanism for big tows. The mechanism includes a rapier clamping head and a multi-selection turntable; the multi-selection turntable is provided with multipleyarn guiding channels which can run through big tow fibers; by rotating the multi-selection turntable, the yarn discharging end of each yarn guiding channel can correspond to a clamping part of the rapier clamping head in sequence; a motor is adopted for locating, and conversion of the tows is fast and accurate.

Owner:无锡市鼎麒新材料科技有限公司

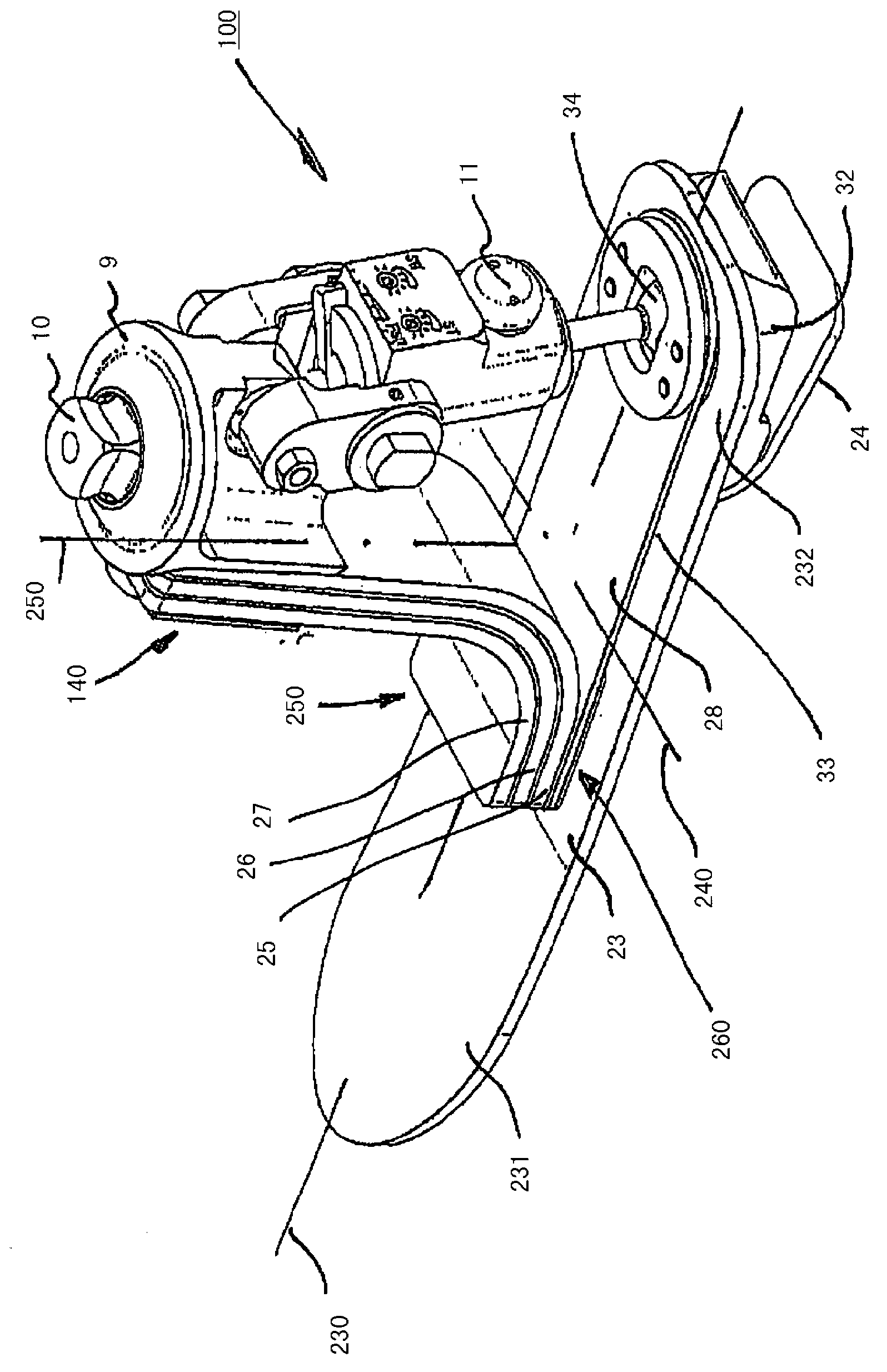

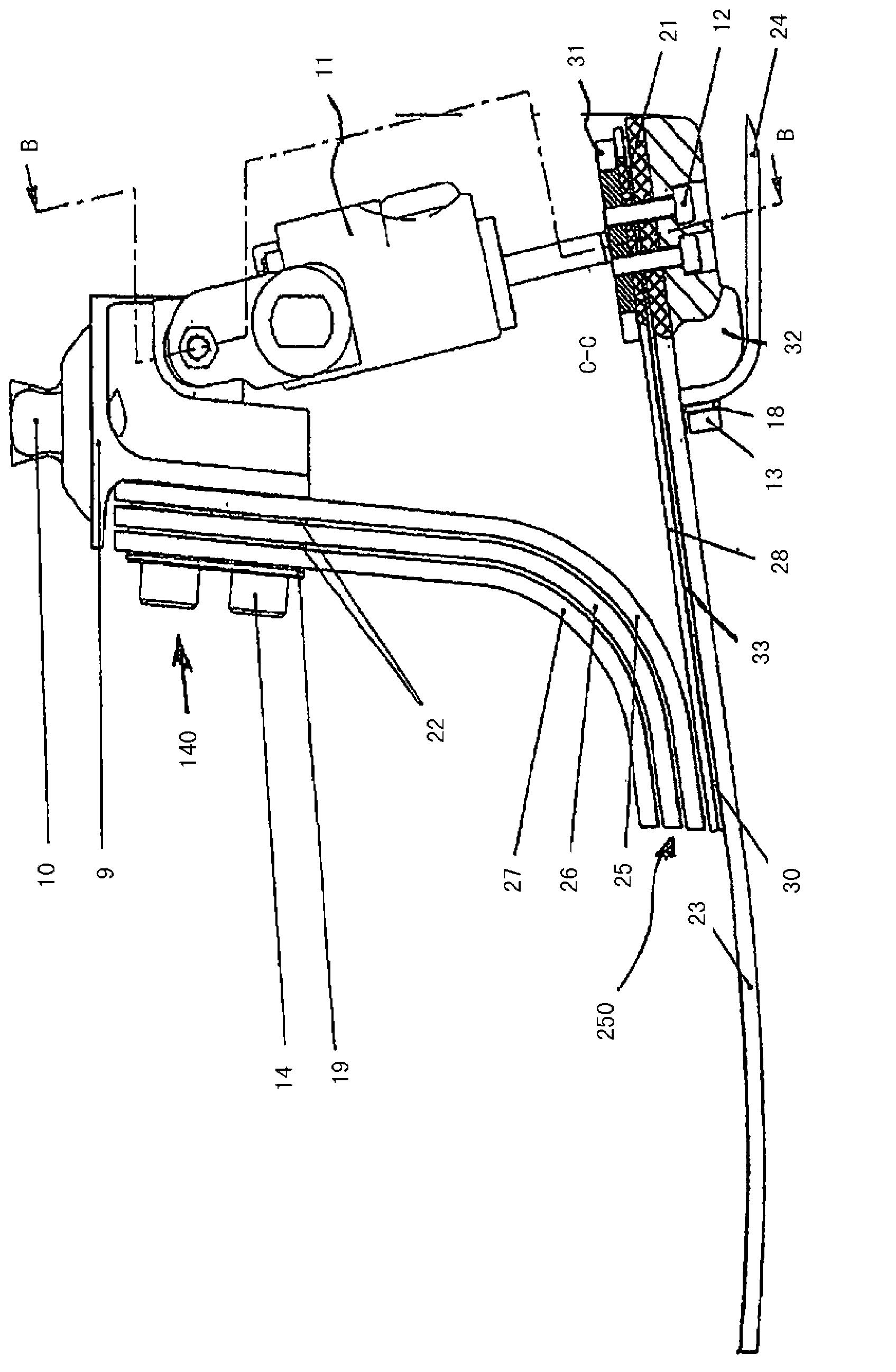

Prosthetic foot

ActiveCN103189020APrevent displaceabilityPrevent deformabilityArtificial legsEngineeringTorsion element

The invention relates to a prosthetic foot with a base spring (23) with a forefoot area (231) and a heel area (232), a connecting means (9, 10) arranged above the base spring (23) and used to fasten the prosthetic foot to a prosthesis, and a frontal support (25, 26, 27), at the upper end (140) of which the connecting means (9, 10) is arranged and which, at its lower end (250), is secured on a torsion element (28) that can twist about the longitudinal axis (230) of the prosthetic foot, wherein the torsion element (28) is designed as a leaf spring arrangement secured to the base spring (23) at one end in the heel area (232) or in the forefoot area (231).

Owner:OTTO BOCK HEALTHCARE IP GMBH & CO KG

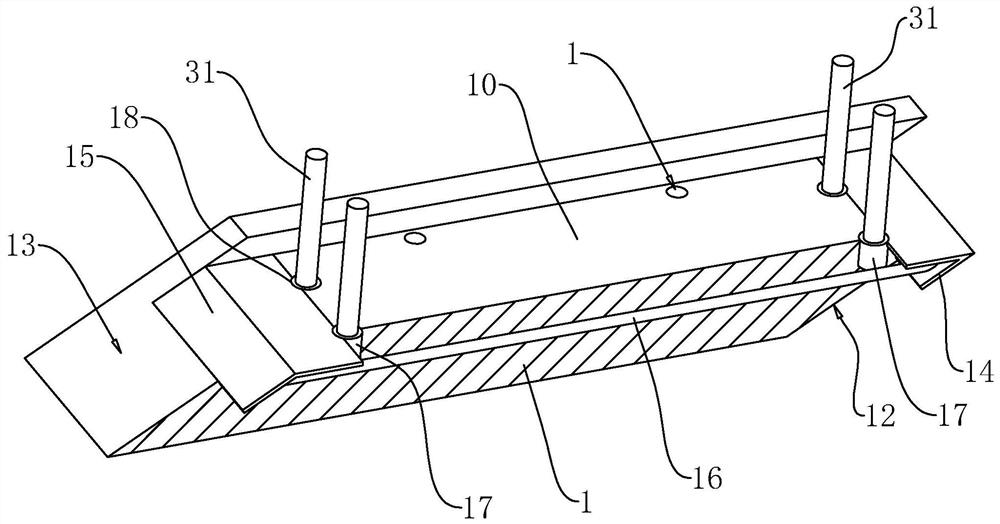

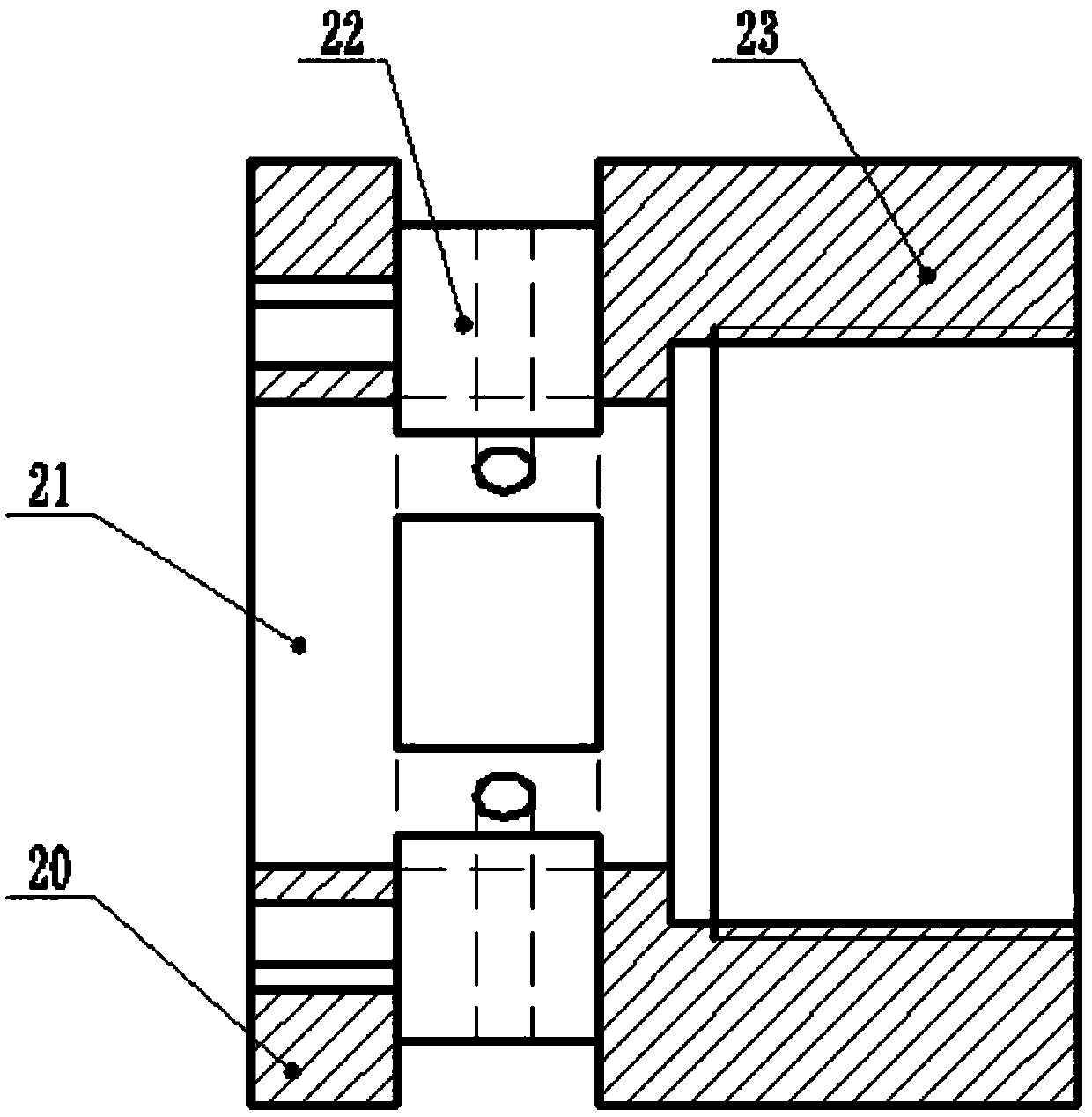

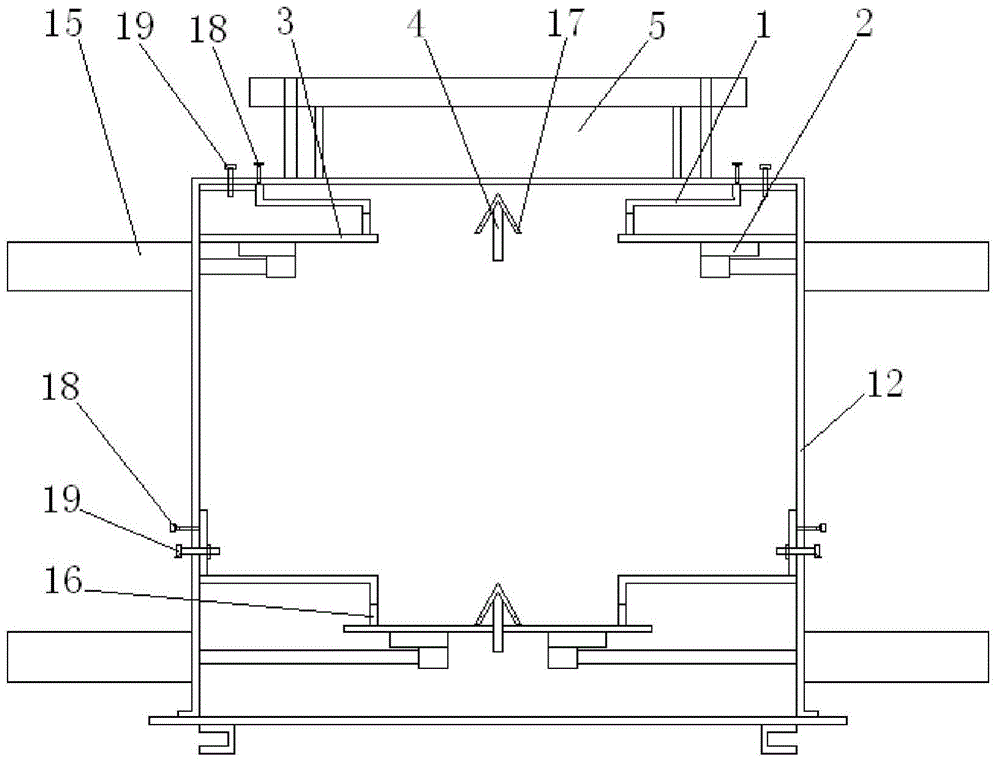

Assembled building U-shaped groove foundation and construction method thereof

ActiveCN112196091AAlleviate poor flatnessEasy to transportCellarsFoundation engineeringArchitectural engineeringStructural engineering

The invention relates to an assembled building U-shaped groove foundation and a construction method thereof. The assembled building U-shaped groove foundation comprises a U-shaped groove body with a cavity groove and a cylindrical steel component arranged in the cavity groove, wherein the U-shaped groove body comprises at least two prefabricated parts spliced in the length direction of the prefabricated parts; and the cylindrical steel component is provided with a connecting assembly used for connecting, fixing and leveling every two adjacent prefabricated parts. The assembled building U-shaped groove foundation has the effect that the U-shaped groove body is convenient to carry and transport.

Owner:福建省锦秋建筑工程有限公司

A horizontal three-cylinder plunger reciprocating pump driven by rack and pinion

InactiveCN106762500BDirect movementImprove efficiencyPositive displacement pump componentsPiston pumpsFailure ratePhase difference

Owner:BEIJING UNIV OF TECH

Oil cylinder part machining equipment

InactiveCN110961675AEfficient drillingSmooth linear motionFeeding apparatusBoring/drilling componentsElectric machineryEngineering

The invention discloses oil cylinder part machining equipment and belongs to the oil cylinder part machining technology. The equipment comprises a base and a PLC, wherein the PLC is fixed at an upperend of the base, a moving mechanism, a fixing mechanism and a driving mechanism are arranged at an upper end of the base, the driving mechanism is connected with the moving mechanism to drive the moving mechanism to slide left and right, the fixing mechanism is located on the right of the moving mechanism, the fixing mechanism is used for fixing a to-be-machined oil cylinder part, a drilling mechanism is arranged on the right side of the moving mechanism, the drilling mechanism comprises common motors and drill bits, the number of the common motors is two, the two common motors are installed on the right side of the moving mechanism, the number of the drill bits is two, the two drill bits are fixed to output ends of the two common motors respectively, the moving mechanism pushes the drilling mechanism to achieve drilling, and the driving mechanism and the drilling mechanism are both electrically connected with the PLC. The equipment is advantaged in that the equipment is high in punching efficiency, low in manual labor intensity, free of manual punching and high in automation degree.

Owner:嘉兴尚乐机电股份有限公司

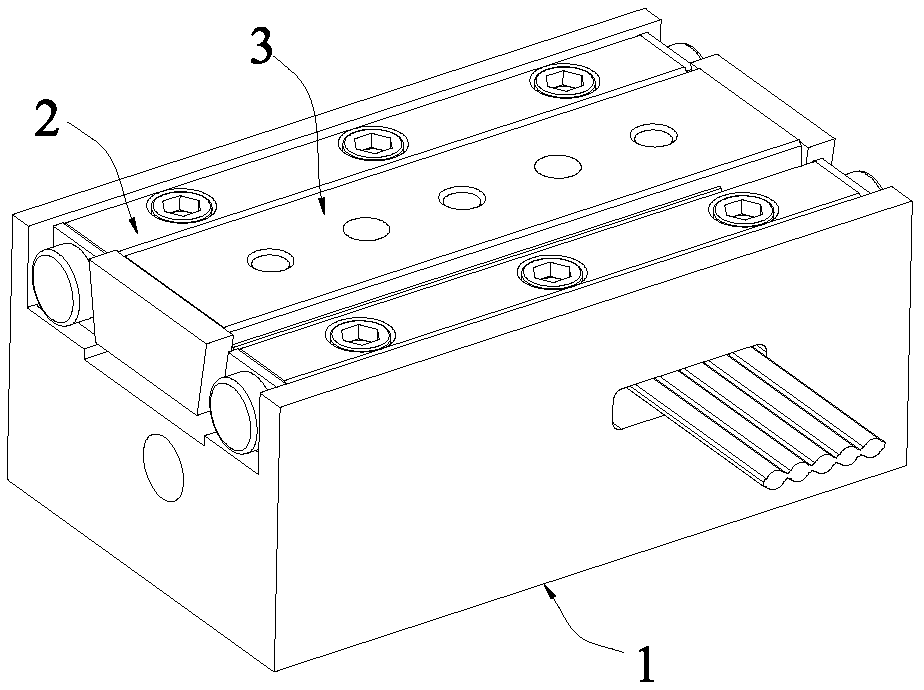

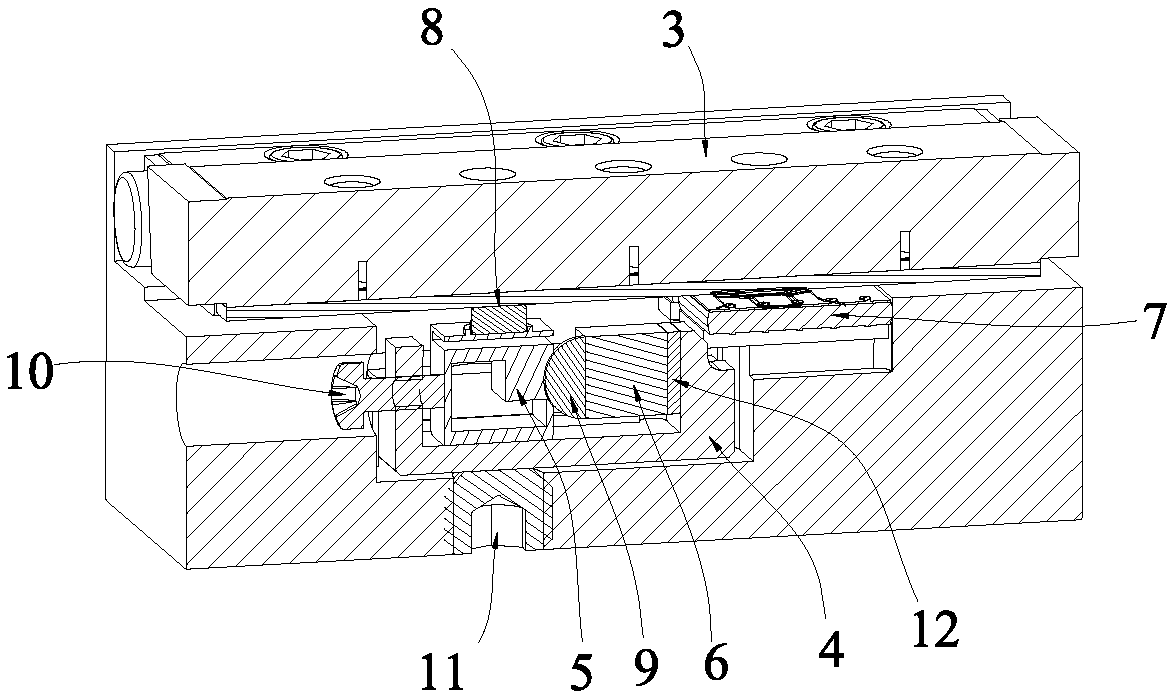

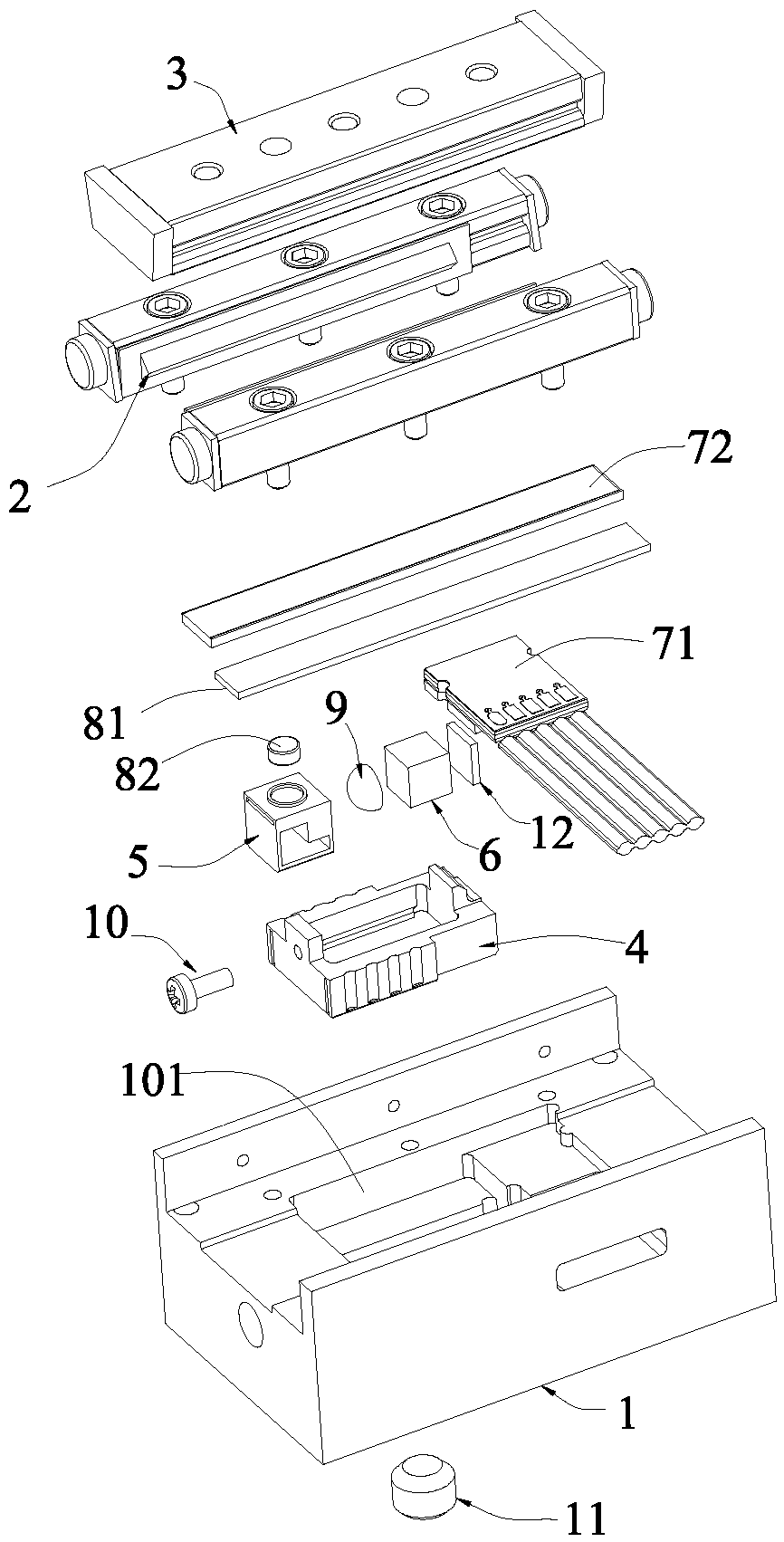

Nanoscale precision piezoelectric driving linear displacement table

PendingCN110890850AGuaranteed not to deviate fromIngenious structural designPiezoelectric/electrostriction/magnetostriction machinesEngineeringStructural engineering

The invention discloses a nanoscale precision piezoelectric driving linear displacement table which comprises a matrix, a sliding rail, a driving base, a flexible mass block, a piezoelectric driving unit, a position sensor unit and a stick-slip friction assembly. The flexible mass block and the piezoelectric driving unit are matched through a spherical contact and a spherical concave surface, a self-positioning function is realized, it can be effectively guaranteed that a stress point does not deviate, and the requirements for machining precision and assembling precision are lowered. Comparedwith a traditional point contact or plane contact mode, the contact area is increased, and the service life is prolonged. A flat bridge part on the flexible mass block has an elastic function and canaccept certain deformation, so that the influence of installation errors on plane contact is effectively eliminated. In addition, the whole structure of the nanoscale precision piezoelectric driving linear displacement table is simple and compact, the size is small, the sliding rail is driven in a stick-slip mode without up-down friction, and only single friction in the stick-slip motion exists, so that the power loss and the requirements for other parts are effectively reduced, the working stability is good, and the application range is wide.

Owner:SONGSHAN LAKE MATERIALS LAB +1

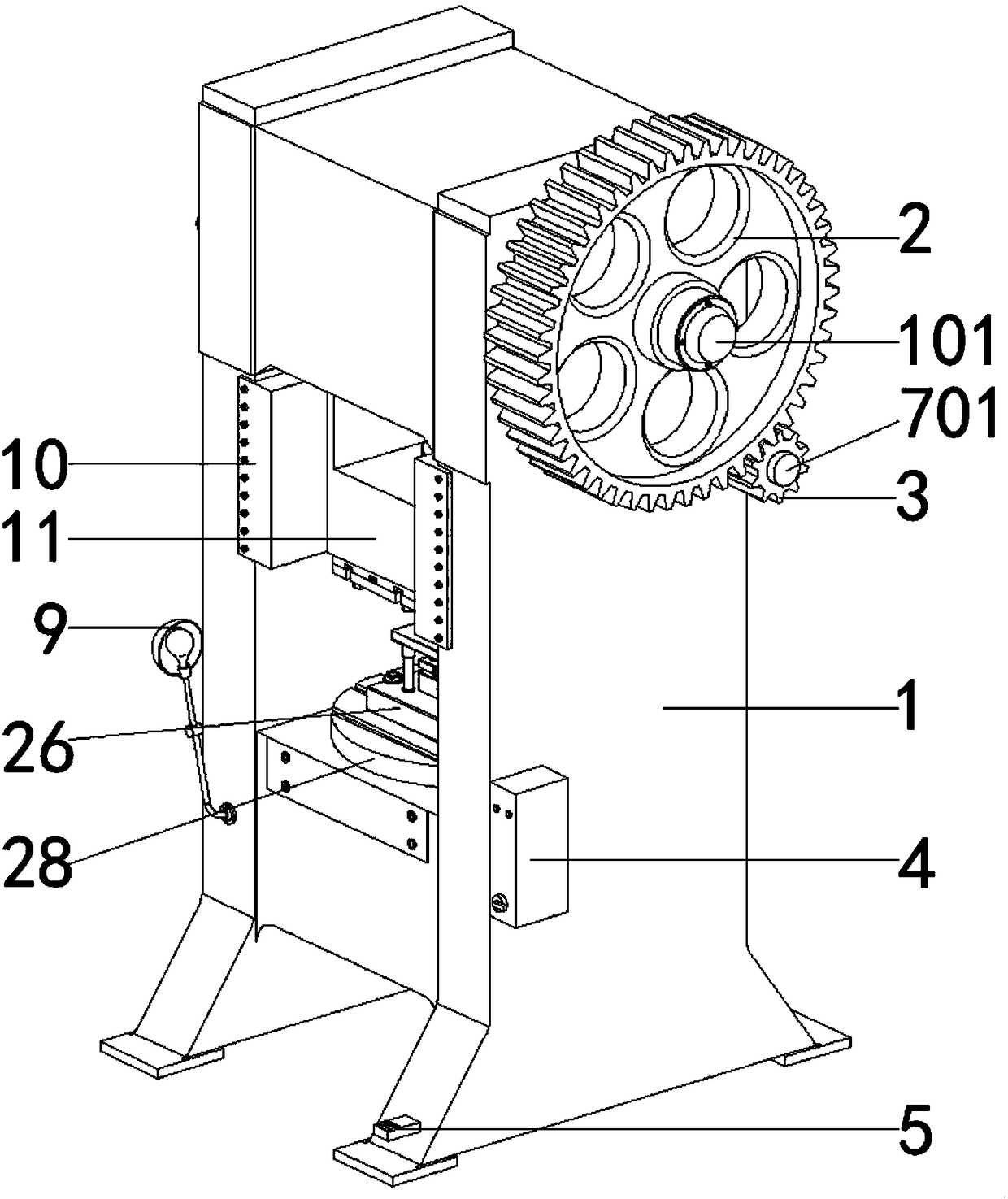

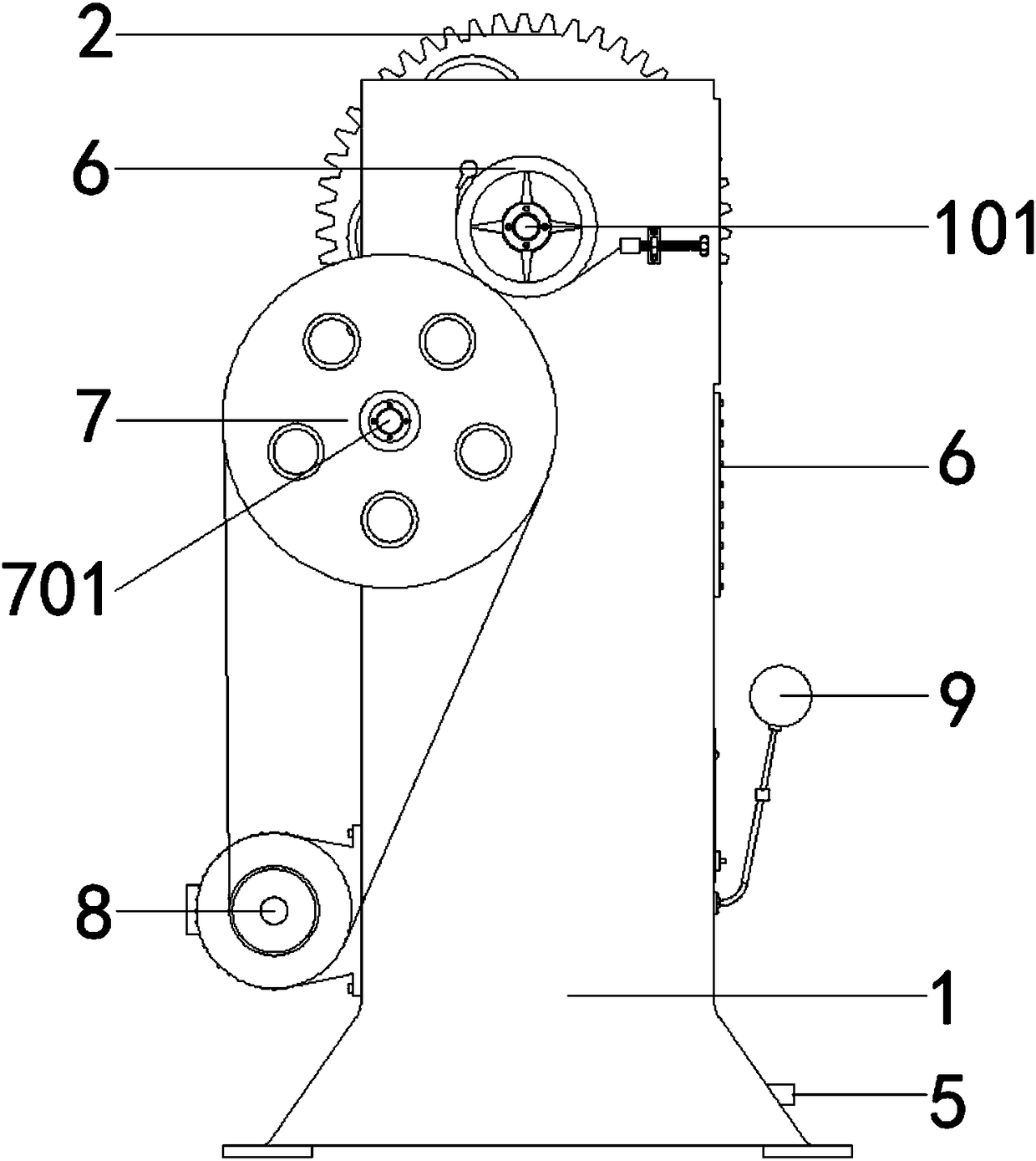

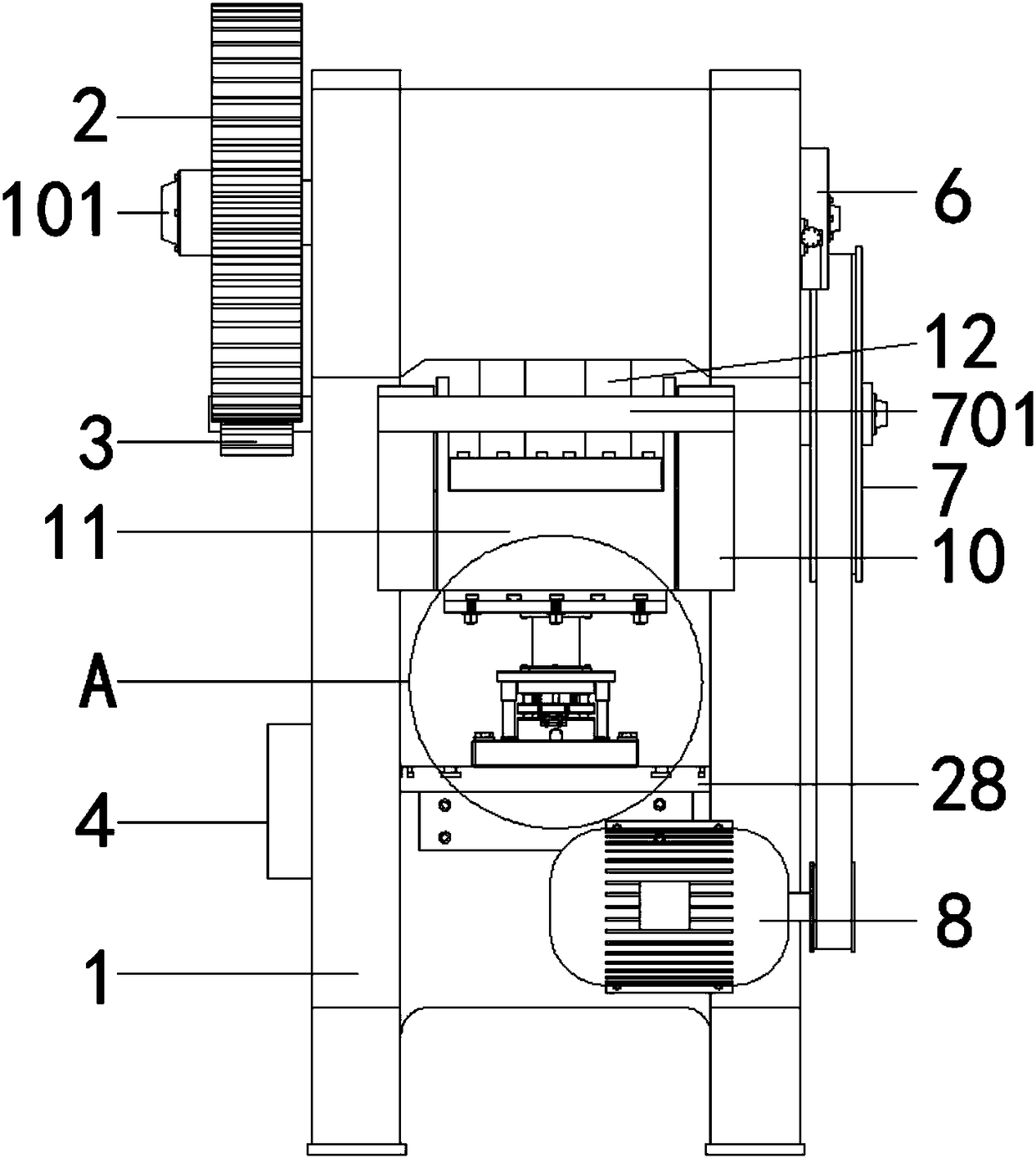

Complete punching apparatus of single-row-of-holes cylinder support

InactiveCN108555124ASmooth linear motionIncrease productivityPerforating toolsMetal-working feeding devicesPunch pressDrive shaft

The invention relates to the technical field of punching equipment, in particular to a complete punching apparatus of a single-row-of-holes cylinder support, comprising a body, a retainer carrier plate, and a retainer; the body is a pillar-type closed punch body; a crankshaft and a transmission shaft are embedded in the upper portion of the body through bearings; the left end of the crankshaft isfixedly connected with a driving gear through flat keys and keyways; the right end of the crankshaft is fixedly connected with a brake through flat keys and keyways; the rear side of a lower die plateis fixedly provided with the retainer carrier plate that is in E shape through bolts; the retainer that is in rectangular shape is arranged on the upper surface of the retainer carrier plate; the retainer is movably connected with the retainer carrier plate through bolts. The complete punching apparatus with the above structural modifications has the advantages that, for instance, the structuralstability is good, multiple holes can be punched at a time, production efficiency is high, and a cylinder support plate never moves during punching; therefore, the problems and defects of existing equipment are effectively overcome.

Owner:湖北陆驰汽车零部件科技股份有限公司

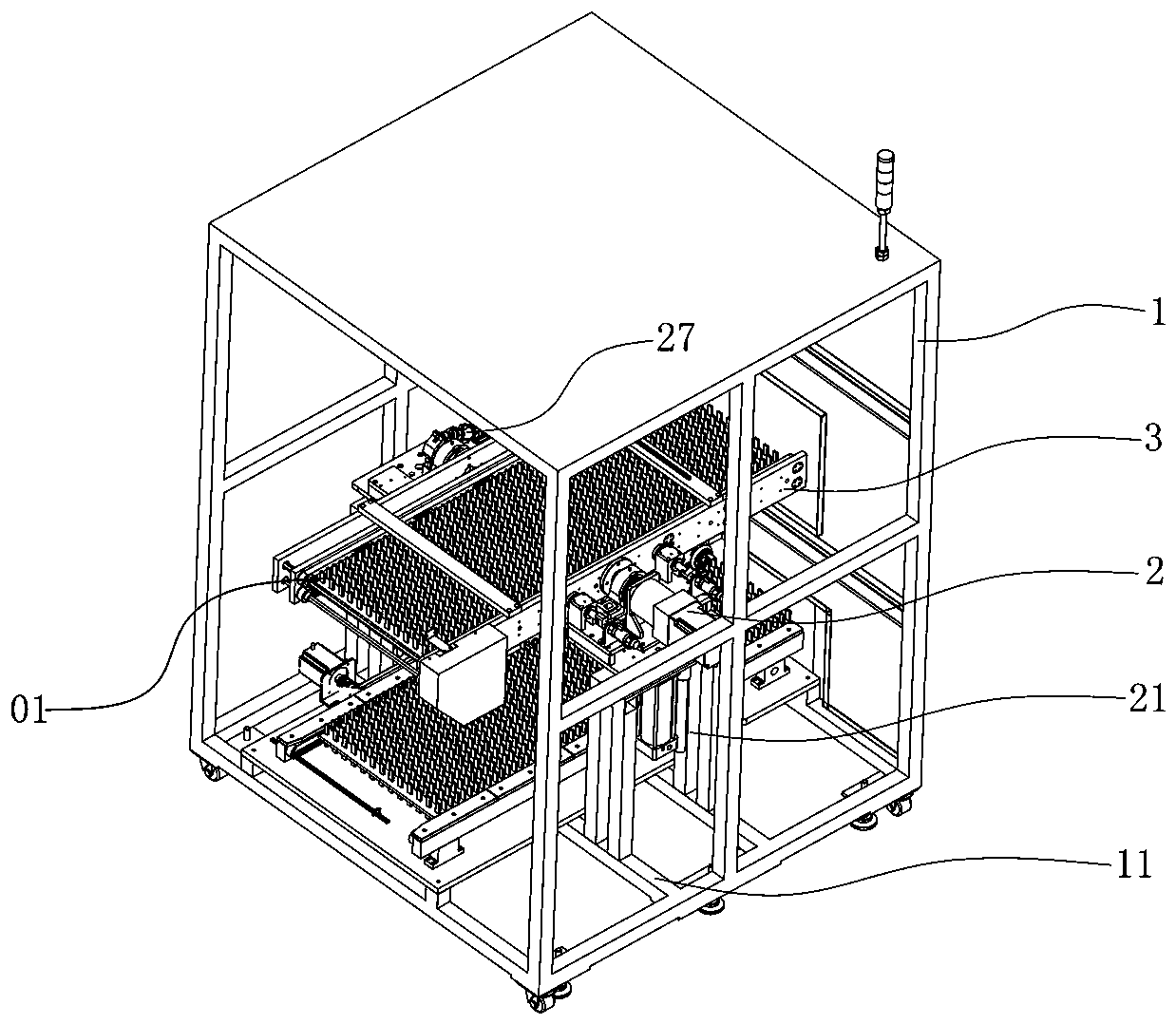

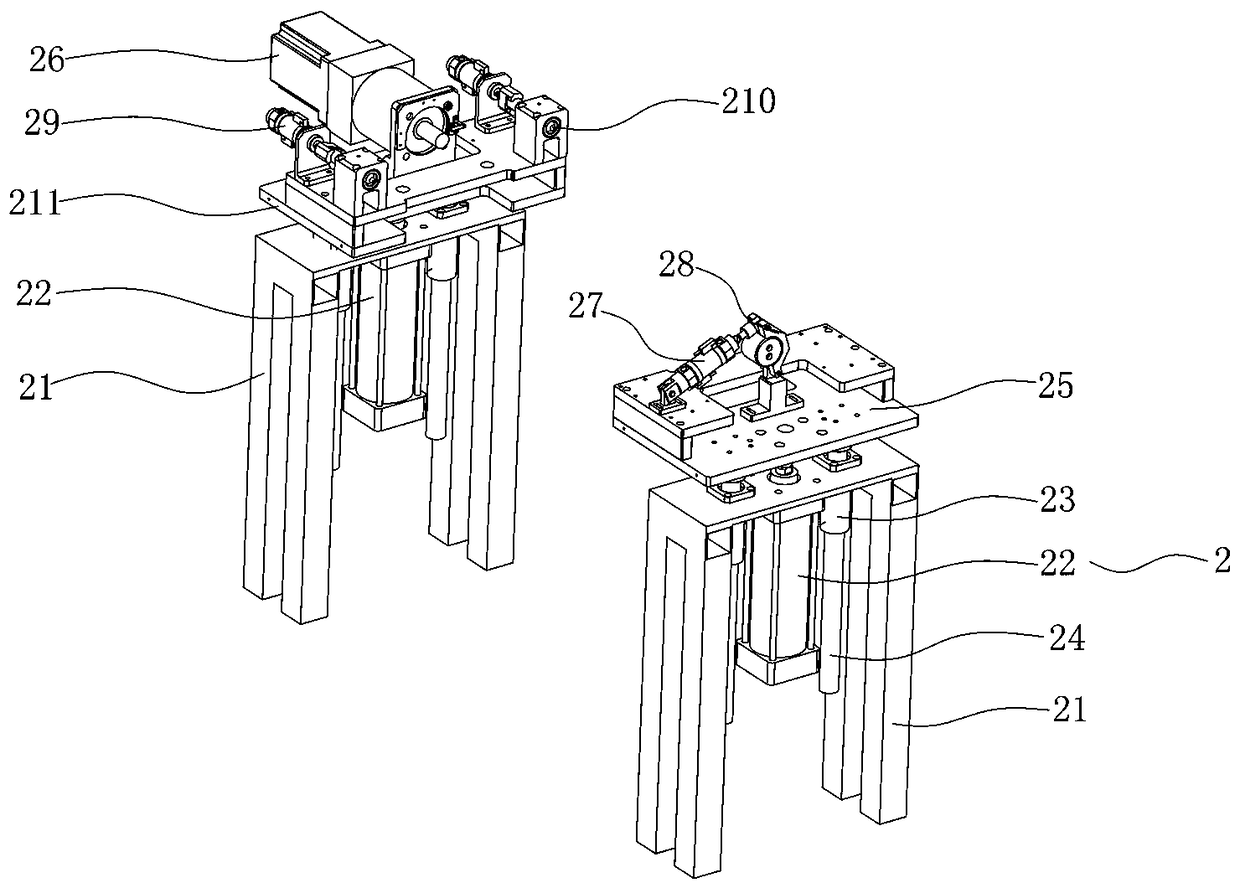

Electromagnetic transplanting mechanism, electromagnetic transplanting cover closing device and electromagnetic transplanting cover closing method

ActiveCN111942891AAvoid the phenomenon of wrinkling and deformationPrecise positioningCell component detailsFuel cell detailsStructural engineeringMachine

The invention discloses an electromagnetic transplanting mechanism, an electromagnetic transplanting cover closing device and an electromagnetic transplanting cover closing method. The electromagnetictransplanting mechanism comprises a machine table, sliding assemblies, lifting assemblies and sucking assemblies, and the machine table comprises two transverse frames arranged in parallel and longitudinal frames connected with the transverse frames and perpendicular to the transverse frames; the sliding assemblies are arranged on the transverse frames and can slide along the axes of the transverse frames; the lifting assemblies are fixedly arranged on the sliding assemblies and slide synchronously with the sliding assemblies; and the sucking assemblies are arranged on the lifting assemblies,can be driven by the lifting assemblies to relatively move up and down, and are used for accurately sucking an upper cover plate. The electromagnetic transplanting mechanism, electromagnetic transplanting cover closing device and electromagnetic transplanting cover closing method have the beneficial effects that full-automatic equipment is adopted, and the phenomenon that a dielectric film is wrinkled and deformed possibly in the manual transplanting process is avoided; and meanwhile, accurate positioning of the upper cover plate and a lower cover plate can be achieved, and the yield is greatly increased.

Owner:SUZHOU JEE INTELLIGENT EQUIP CO LTD

Energy-saving type airlock discharger

The invention discloses an energy-saving type airlock discharger, and belongs to the field of conveying machines. The energy-saving type airlock discharger comprises a discharger body and driving mechanisms. A feeding opening is formed in the upper end of the discharger body. A discharging opening is formed in the lower end of the discharger body. A feeding mechanism close to the feeding opening and a discharging mechanism close to the discharging opening are arranged inside the discharger body. The feeding mechanism and the discharging mechanism each comprise two movable plates. The two movable plates of the feeding mechanism and the two movable plates of the discharging mechanism are driven by the driving mechanisms to move towards the two sides to be separated or move towards the middle to be combined and are alternately separated and combined to convey materials. By means of the energy-saving type airlock discharger, the output power is small, the use cost can be greatly reduced, and the energy-saving type airlock discharger is economical and practical; compared with an airlock in which air locking is achieved through an impeller in the prior art, air is tightly locked, and the air locking effect is good.

Owner:付海岗

A turning machine for flipping pcb boards

The invention discloses a board turnover machine for turning over a PCB. The board turnover machine includes a frame, a turnover supporting mechanism and a turnover material guide mechanism. The frame is of a framework structure. Supporting rods are connected on the two sides of the frame. The turnover supporting mechanism is fixed to the supporting rods and extends upwardly. A turnover drive motor and a clamping cylinder are disposed on the two sides of the turnover supporting mechanism respectively. The turnover material guide mechanism is disposed between the turnover drive motor and the clamping cylinder, and is connected to the turnover drive motor and the clamping cylinder. The turnover drive motor drives the turnover material guide mechanism to rotate 180 degrees to enable the front side and the back side of a PCB on the turnover material guide mechanism to be changed in position. The clamping cylinder clamps the turnover material guide mechanism after turnover. The board turnover machine is integrated in a connector automation streamline to automatically turn over PCBs. The machine is high in automation, enables labor and time to be saved, and helps to greatly improve the production power of the streamline.

Owner:SHENZHEN XING GRAIN AUTOMATION CO LTD

Method for setting manipulator rotating mechanism of hydraulic system

InactiveCN102966621AHigh movement precisionEasy to processServomotor componentsServomotorsFuel tankHydraulic circuit

The invention discloses a method for setting a manipulator rotating mechanism of a hydraulic system. The method comprises the following steps that firstly, a section of valve control circuit is additionally arranged between a variable pump and a hydraulic cylinder, a hydraulic control reversing valve is arranged in the valve control circuit, and a swinging motor is arranged in a manipulator rotating hydraulic system; then, a one-way valve and an overflow valve are additionally arranged in a hydraulic circuit connected with the periphery of the motor, and when an electromagnetic valve returns to the middle position, because the pressures at both ends of the cycloidal motor are unbalanced, if the pressure at the left end of the cycloidal motor is larger, the hydraulic fluid flows to a hydraulic tank through the one-way valve and the overflow valve; a three-position and four-way one-way valve is adopted as the one-way valve, and the locking of the hydraulic motor and the buffering of the hydraulic fluid are realized by the additional one-way valve and the overflow valve. The method has the beneficial effects that the stability and the easy speed adjustment in the linear movement are realized, the running precision of the machine is favorably improved, and the service life of the machine is prolonged; and meanwhile, the convenient and flexible arrangement is favorably realized according to requirements, the operation controllability is improved, and the labor strength is reduced.

Owner:WUXI WELL ELECTRO HYDRAULIC EQUIP CO LTD

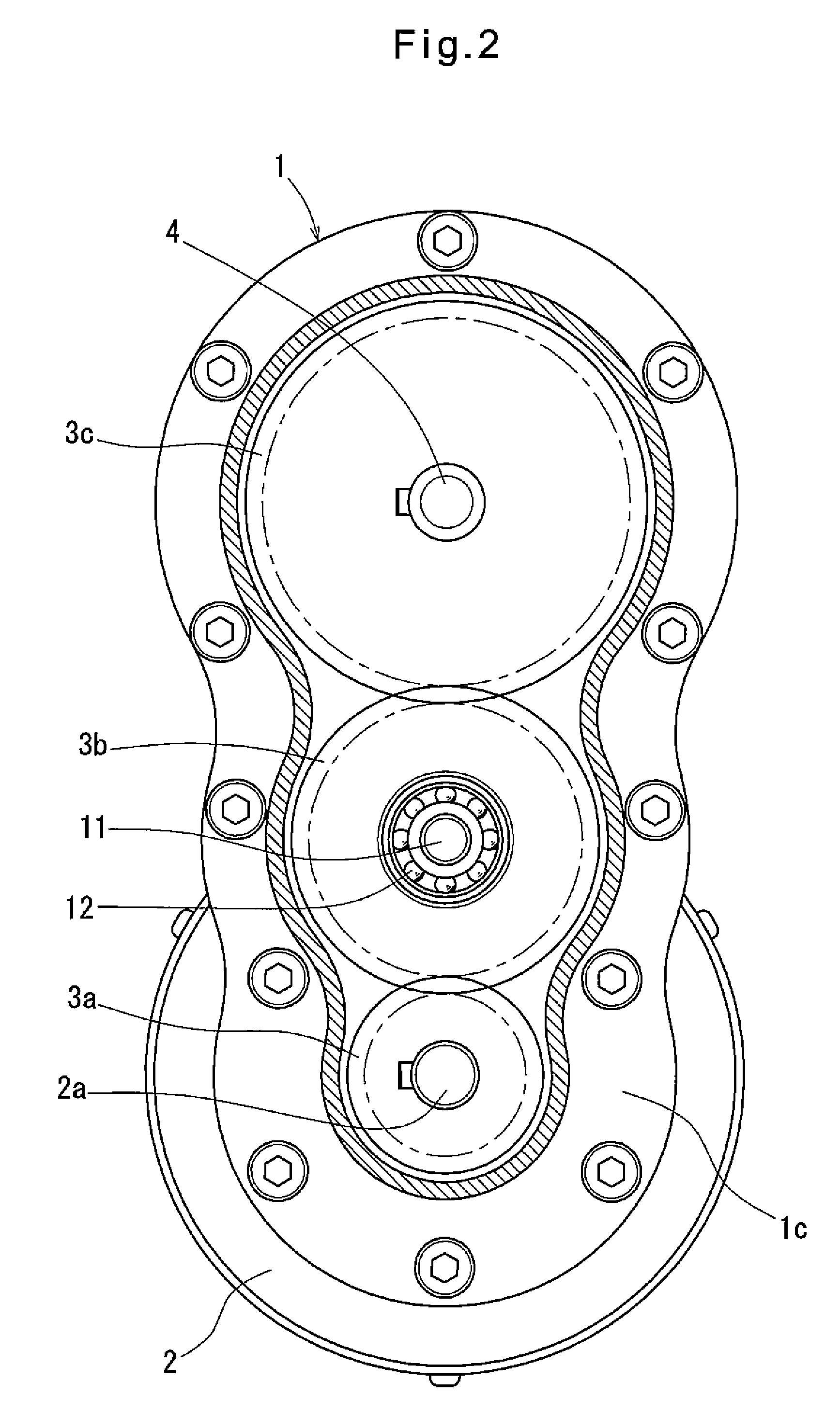

Planetary shaft difference adjusting differential mechanism

InactiveCN101949440AControl speed differenceSmooth linear motionDifferential gearingsConstant speedEpicyclic gearing

The invention relates to a planetary shaft difference adjusting differential mechanism. The differential mechanism is characterized in that: two output free degrees of the differential mechanism are input to two groups of planetary gear sets through a planetary gear frame, wherein the two groups of planetary gear sets are interlocked; the rotation speed difference between the two output free degrees is adjusted by controlling the two planetary gear sets; a constant-speed driving worm wheel (2) is directly driven by using a constant-speed driving shaft and a worm (1), wherein the constant-speed driving worm wheel (2) is integrated with a differential mechanism gear frame (3); and the differential mechanism is formed by arranging a differential mechanism planetary gear (4), a right half shaft bevel gear (5) and a left half shaft bevel gear (6) in the differential mechanism gear frame (3). Through the skillfully designed difference adjusting differential mechanism, the speed difference between two rotating wheels can be effectively controlled, complete constant-speed and precisely controllable rotation speed difference can be realized and then stable rectilinear motion and accurate steering can be realized.

Owner:张维国

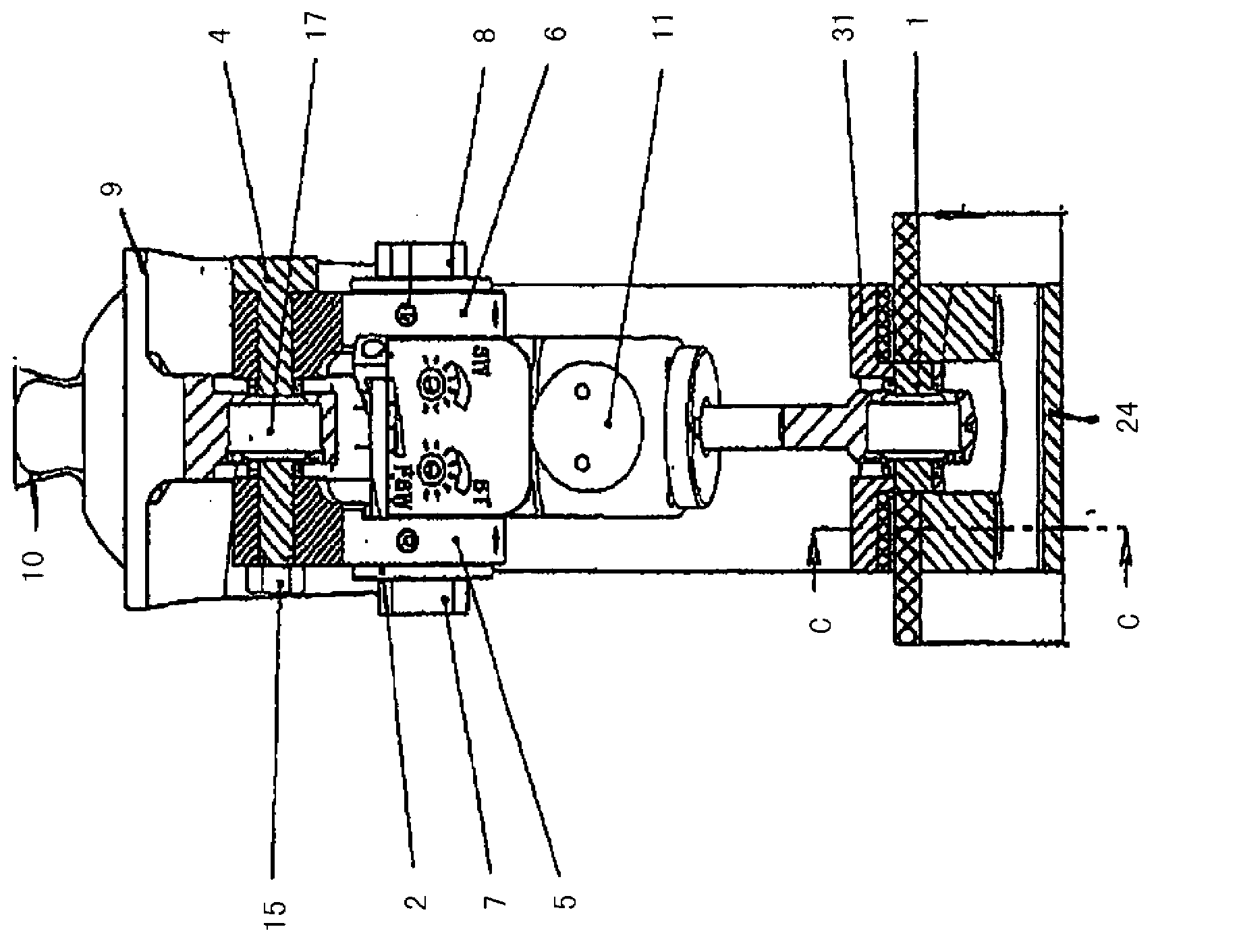

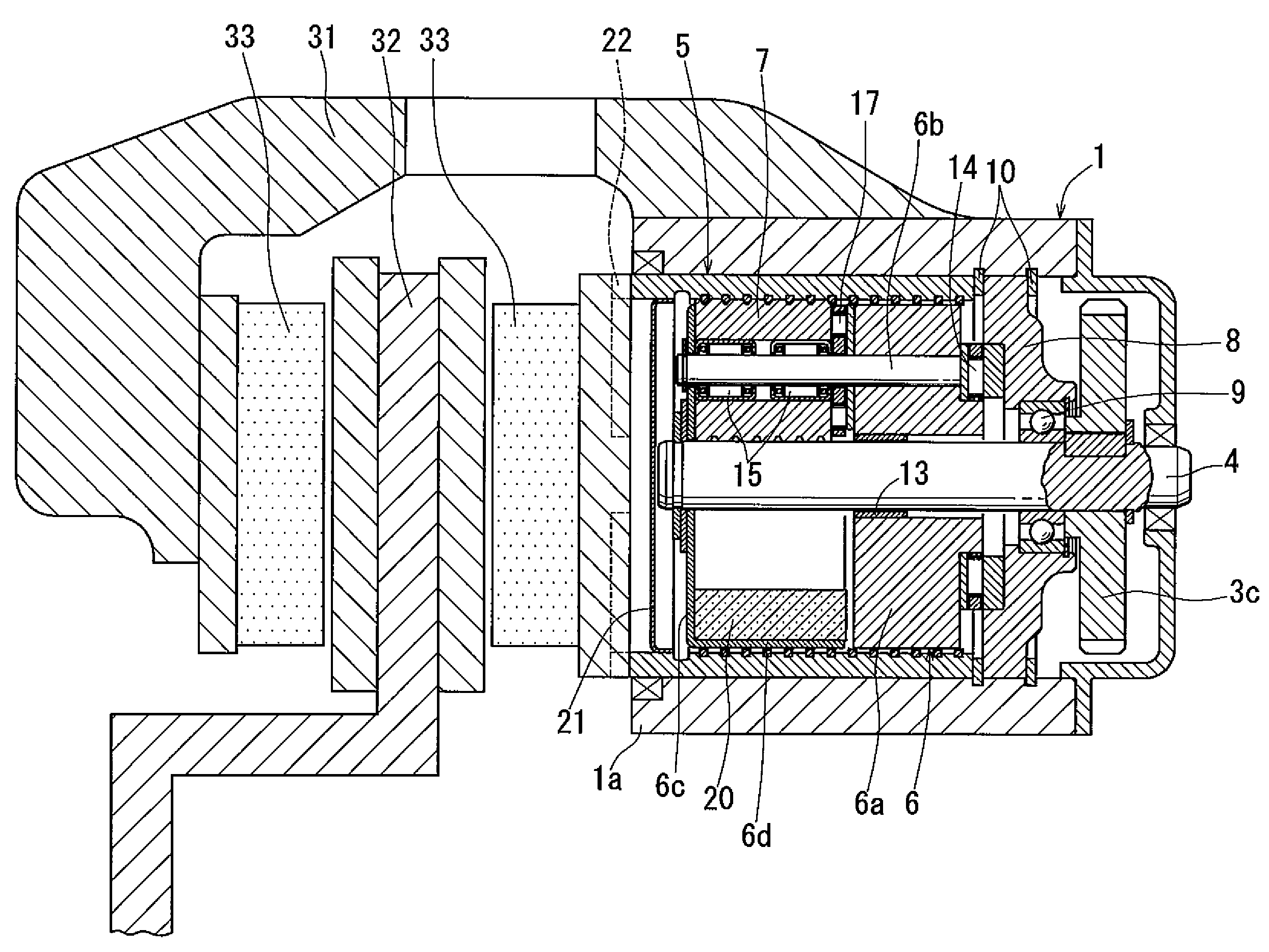

Electric linear motion actuator and electric disk brake system

ActiveUS9369024B2Smooth linear motionAvoid contactMechanically actuated brakesToothed gearingsLinear motionEngineering

A linear motion actuator has an output member that can be smoothly moved linearly even when lateral moment acts on the output member. A carrier (6) supporting planetary rollers (7) is axially immovable, while an outer ring member (5), as the output member, is axially slidably fitted in the radially inner surface of a cylindrical portion (1a) of a housing (1), and is rotationally fixed to a driven member through keys (22). Hard plating layers are formed on the radially outer surface of a rotary shaft (4), the radially outer surfaces of the planetary rollers (7), including helical grooves (7a), and the surface of a helical rib member (5b) which is fixed to the radially inner surface of the outer ring member (5) forming a helical rib.

Owner:NTN CORP

Pneumatic rotatable glass cutting machine

InactiveCN103613271ASmall knife drop pressureRaise the knife quicklyGlass severing apparatusMotor shaftWhole systems

The invention discloses a pneumatic rotatable glass cutting machine, which comprises a knife box lifting mechanism and a knife wheel rotating mechanism, wherein the knife box lifting mechanism consists of a first cylinder and a second cylinder, the first cylinder is fixedly arranged at the top of a cutting machine shell, a first cylinder check block is arranged right below the first cylinder and fixedly arranged on a mounting plate, the first cylinder check block is connected with the lower end of a lifting knife extension spring, and the upper end of the lifting knife extension spring is fixedly arranged at the top of the cutting machine shell; the second cylinder is fixedly arranged on the cutting machine shell, and a second cylinder check block is arranged right below the second cylinder and fixedly arranged on the mounting plate; and the knife wheel rotating mechanism comprises a motor, a synchronous belt driving wheel is arranged on a motor shaft and is connected with a synchronous belt driven wheel through a synchronous belt. The cutting machine adopts two-level knife falling, is accurate for a knife to fall so as not to easily crush glass, and wide in the range of application; after the cutting is completed, the knife is fast lifted by adopting the pull of the knife lifting extension spring, and the working efficiency can be improved; and the knife wheel is controlled to rotate by the motor, and the whole system is simpler.

Owner:史国罕

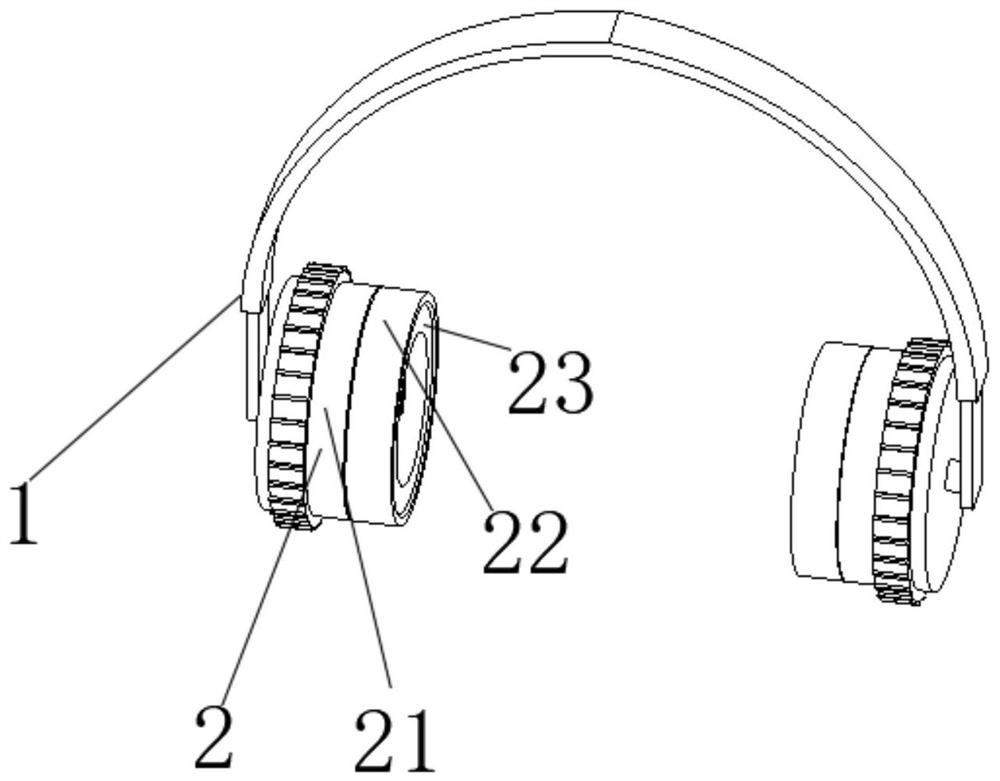

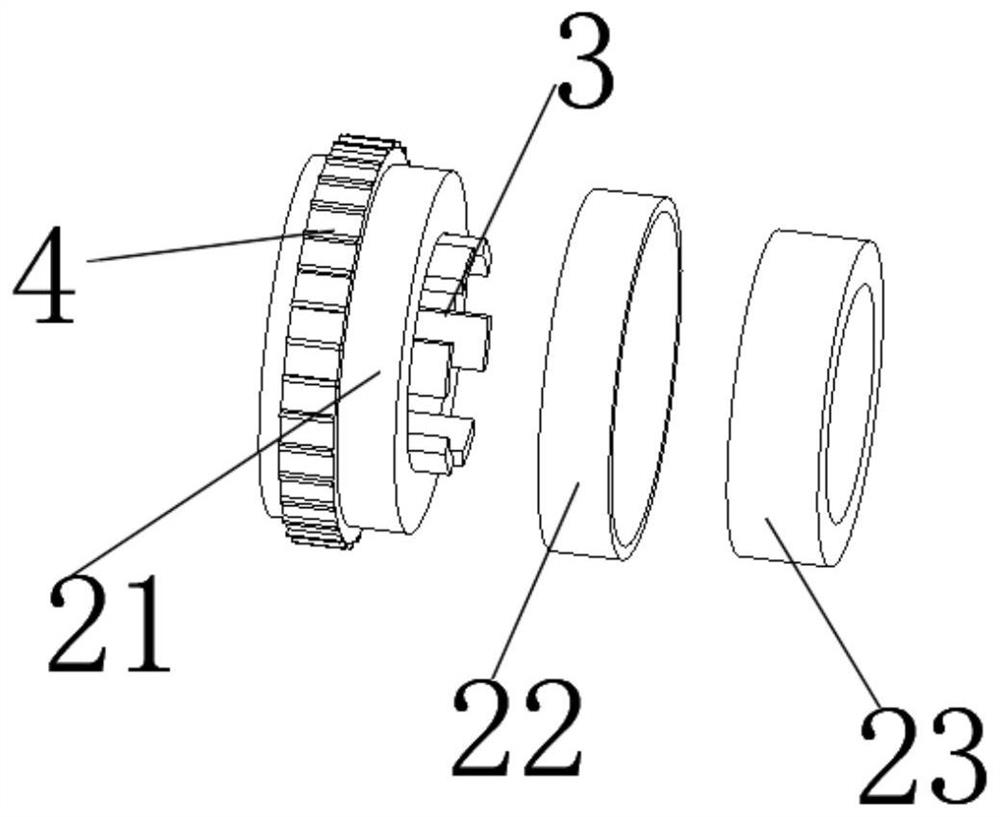

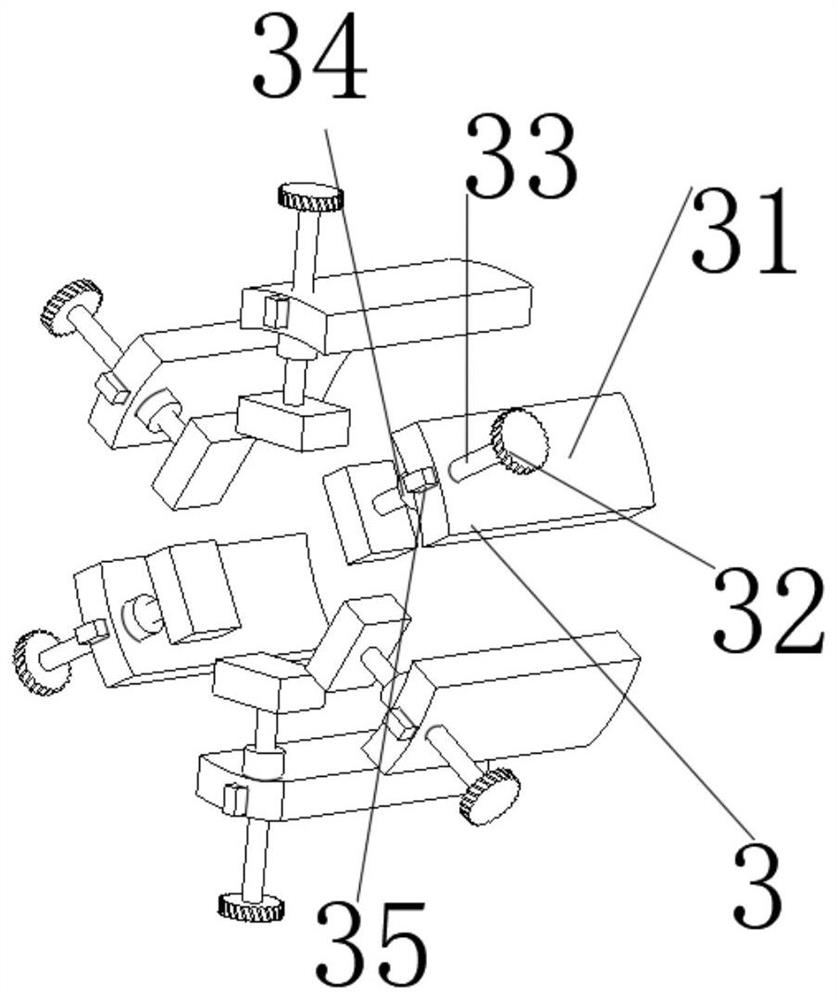

Multifunctional Bluetooth earphone with adjusting device

PendingCN113225640AChange the inner diameter of the hearing cavityPlay a limiting roleSupra/circum aural earpiecesThreaded pipeEngineering

The invention discloses a multifunctional Bluetooth earphone with an adjusting device, which comprises a Bluetooth earphone body, two groups of receivers are symmetrically arranged on the Bluetooth earphone body, and a plurality of groups of circumferentially arranged movable parts are arranged in cavities of the two groups of receivers; a driving ring is rotationally clamped on the outer wall of the receiver, and the driving ring is engaged with the input ends, located on the inner cavity wall of the receiver, of the plurality of groups of moving parts. According to the multifunctional Bluetooth earphone with the adjusting device, the driving ring and the movable part are arranged, a threaded rod can be driven to rotate through rotation, a movable plate can be driven to do linear motion through a threaded pipe, the inner diameter of a listening cavity of a receiver can be changed to adapt to the requirements of different ear sizes, a limiting sliding block is installed at the lower end of the movable plate. The movable plate can be driven by the threaded pipe to do stable linear motion, the elastic buffering cushion is fixed to the outer wall of the movable plate, the pressure between the movable plate and the ear can be buffered through the elastic buffering cushion, and the use comfort of the ear cushion is improved.

Owner:深圳市明舟精密智造有限公司

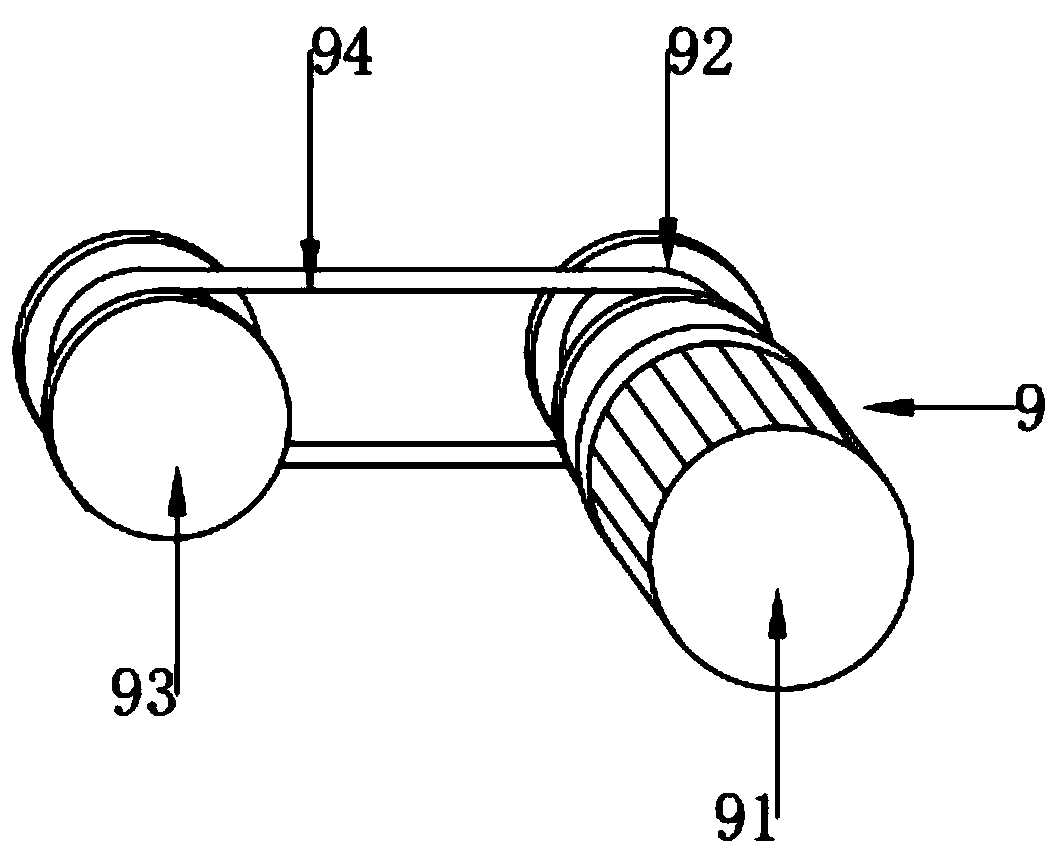

Roller guide rail pair

Owner:李子宁

Precise basis type production processing flow for engine connecting rod

The invention discloses a precise reference type production processing flow for an engine connecting rod. The production processing flow comprises the following steps of firstly, carrying out the first phase of processing before cutting of a connecting rod body and a cover, respectively carrying out blank inspection, magnetic particle inspection and rough drilling of a small-end hole, and preparing for the processing of upper and lower end surfaces, the small-end hole, two planes at bolt hole ends, an outer surface of a large-end hole, and the like in the precise basis way; then, carrying out processing after cutting of the connecting rod body and the cover, roughening the large-end hole, except for precise referencebasis, and preparing for the roughening of the bolt hole and the combining surface, and the processing of a bearing counterbored groove; and carrying out processing after cutting of the connecting rod body and the cover, and sequentially carrying out the finishing of the large-end hole after the assembly of the connecting rod, the finishing of the upper and lower end surfaces, and the finishing of the large-end hole and the small-end hole. The production processing flow has the beneficial effects that the speed of the linear movement can be smoothly adjusted, the running precision of the machine is favorably improved, the service life of the machine is prolonged, the arrangement is conveniently and flexibly realized according to requirements, the operation controllability is improved, and the labor strength is reduced.

Owner:WUXI WELL ELECTRO HYDRAULIC EQUIP CO LTD

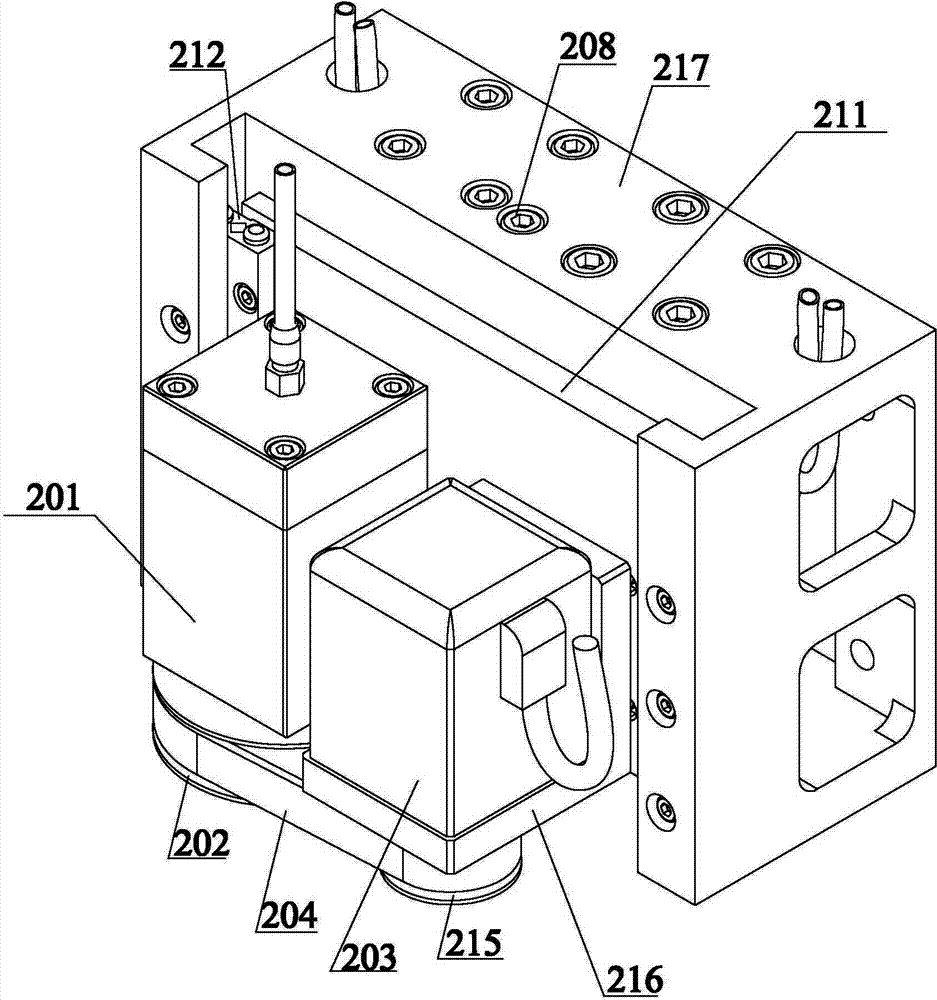

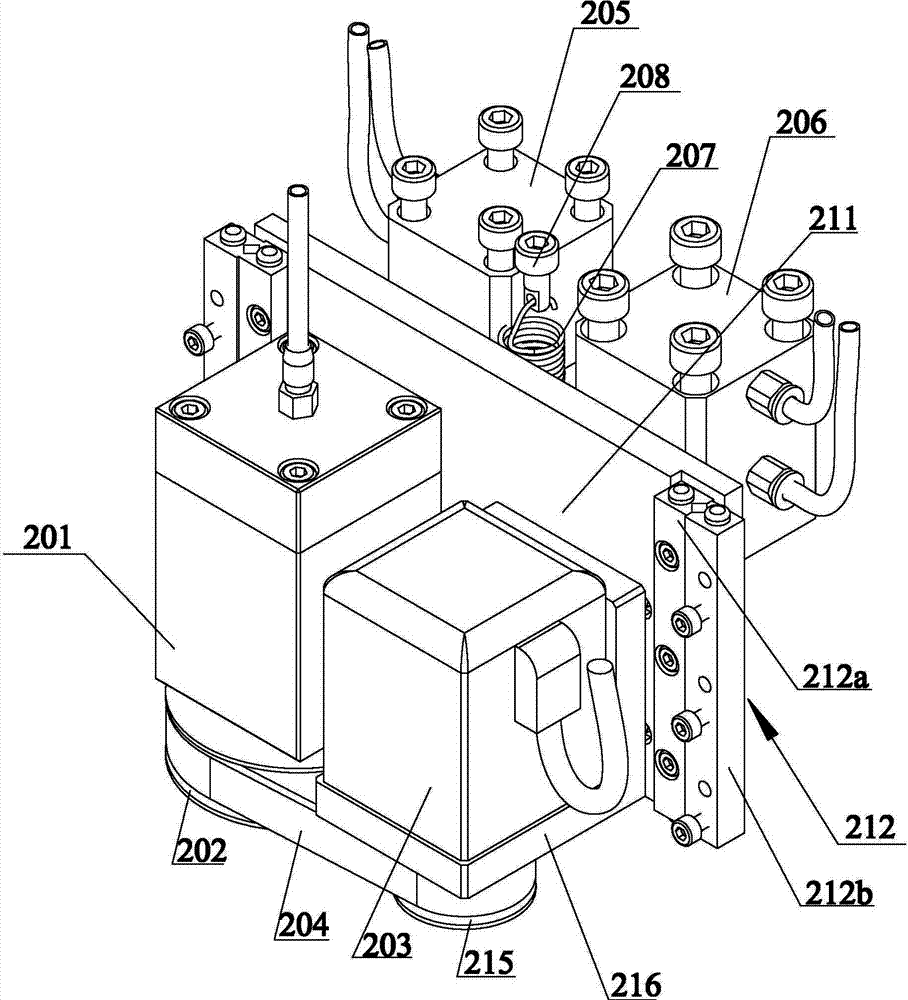

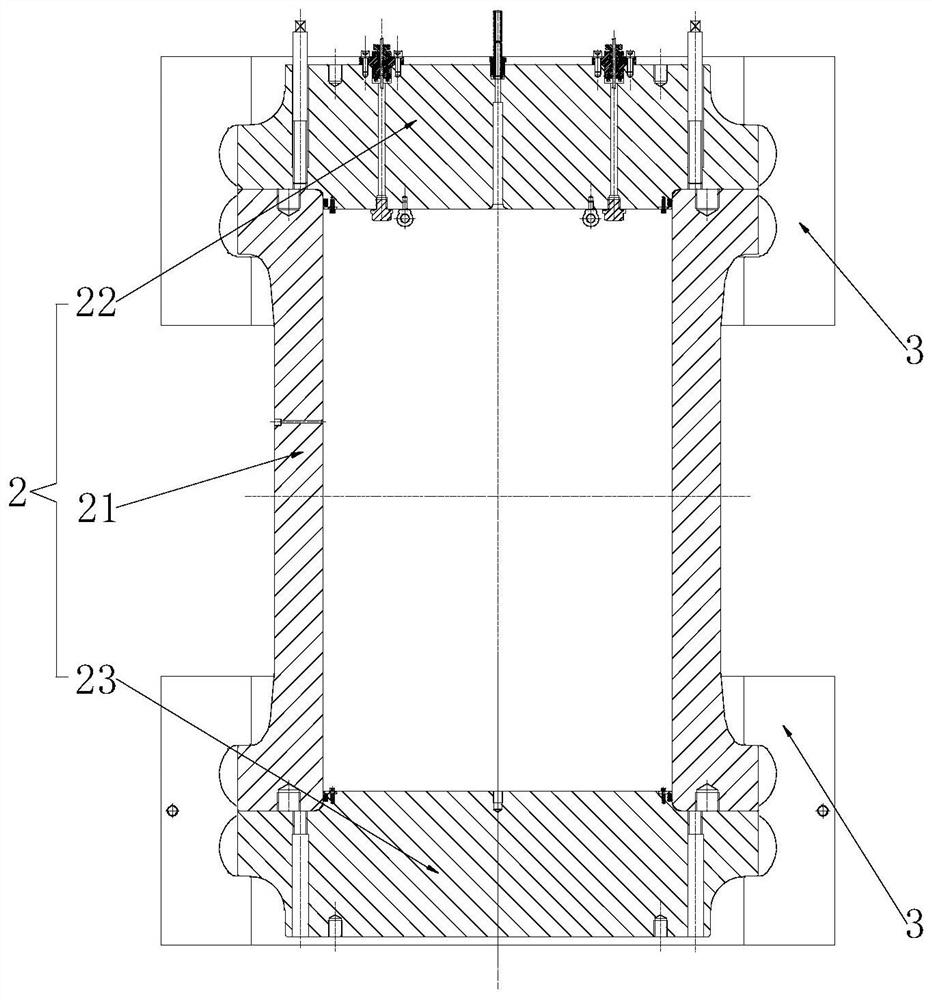

Deepwater pressure testing system

PendingCN113848125AGuaranteed accuracyAchieve shiftMaterial strength using tensile/compressive forcesStructural engineeringMechanical engineering

The invention discloses a deepwater pressure testing system, which comprises a foundation and a pressure-resistant cabin arranged on the foundation, the pressure-resistant cabin comprises a cylinder, a top cover and a bottom cover, the upper and lower ports of the cylinder are respectively buckled with the top cover and the bottom cover through hoops, and the hoops comprise two semicircular hoops; the system further comprises two connecting frames connected with the semicircular hoops respectively, and the connecting frames are movably arranged on the foundation. A top cover lifting table drives a top cover to move in the Z direction, a top cover translation frame drives the top cover to move in the Y direction, the top cover lifting table is movably connected with the top cover translation frame, and the top cover translation frame is movably arranged on the foundation. A novel pressure-resistant cabin structure, a welding-free structure and a heat sleeve body are adopted, the manufacturing cost and manufacturing difficulty of the testing system are effectively reduced, meanwhile, an original cover opening structure is changed, the cover opening mode is simplified, the automation degree of top cover opening is improved, the working efficiency of the testing system is improved, and the actual requirement for frequent use of the testing system is met.

Owner:HUNAN HANGTIAN CHENGYUAN PRECISION MACHINERY

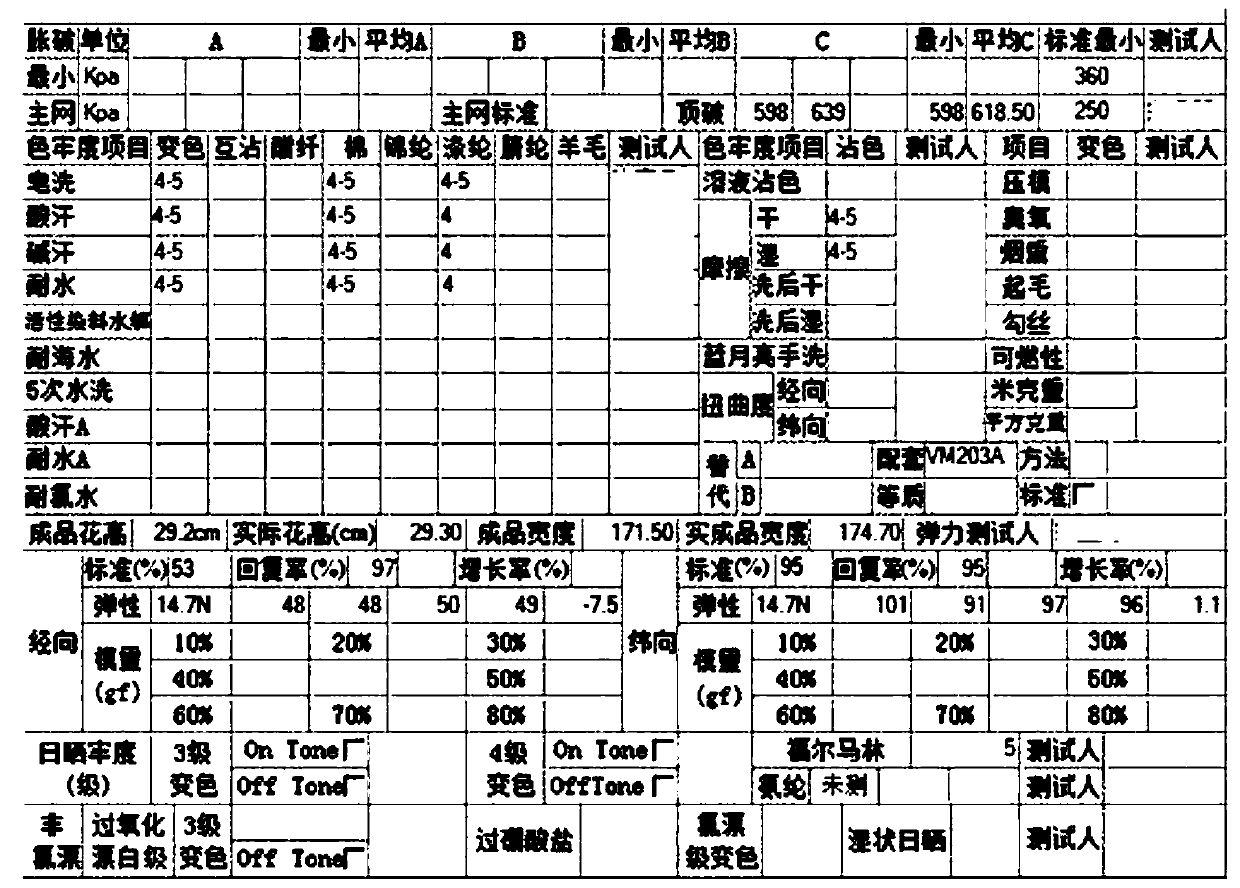

Comb tooth piece for weft-knitting computer jacquard cotton lace fabric and its production

The invention provides a fabric for a weft knitting computer jacquard cotton lace. The fabric comprises spandexes of which the total denier of the same number is 40 D, polyamide filaments of 30D and cotton yarns of 44D, and a comb tooth part for producing the fabric comprises a first plate, a middle transition plate, a deflecting triangular part and a second plate, wherein one end of the middle transition plate is connected with the first plate, and the other end of the middle transition plate is connected with the straight edge of the deflecting triangular part; the diagonal edge of the deflecting triangular part is connected with one end of the second plate; the deflecting triangular part makes the second plate deflect relative to the first plate; the first plate is provided with a guidegroove extending in the length direction, and the guide groove is matched with a guide column inserted in the guide groove; the middle transition plate is provided with an articulated hole, and the articulated hole is matched with a pivotal shaft inserted in the articulated hole; the guide groove converts the linear motion of the guide column in the length direction of the first plate into the rotary motion of the comb tooth part around the pivotal shaft.

Owner:TIANHAI LACE CO LTD

Features

- R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

Why Patsnap Eureka

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Social media

Patsnap Eureka Blog

Learn More Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com