Sliding bearing and bearing mechanism having the same

A technology of sliding bearings and bearing bodies, applied in the field of bearing mechanisms, to achieve the effects of reducing linear motion friction force or friction torque, reducing the difference of linear motion friction resistance or friction torque, and preventing collision noise

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

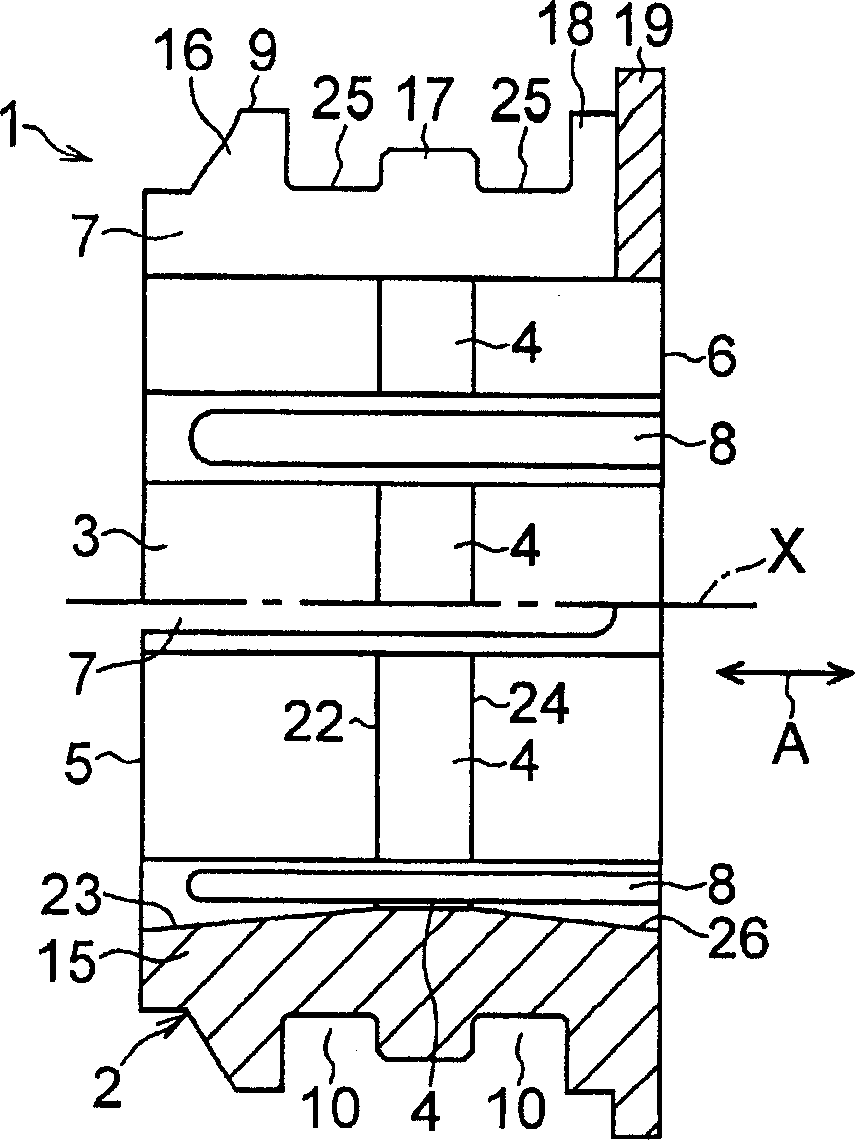

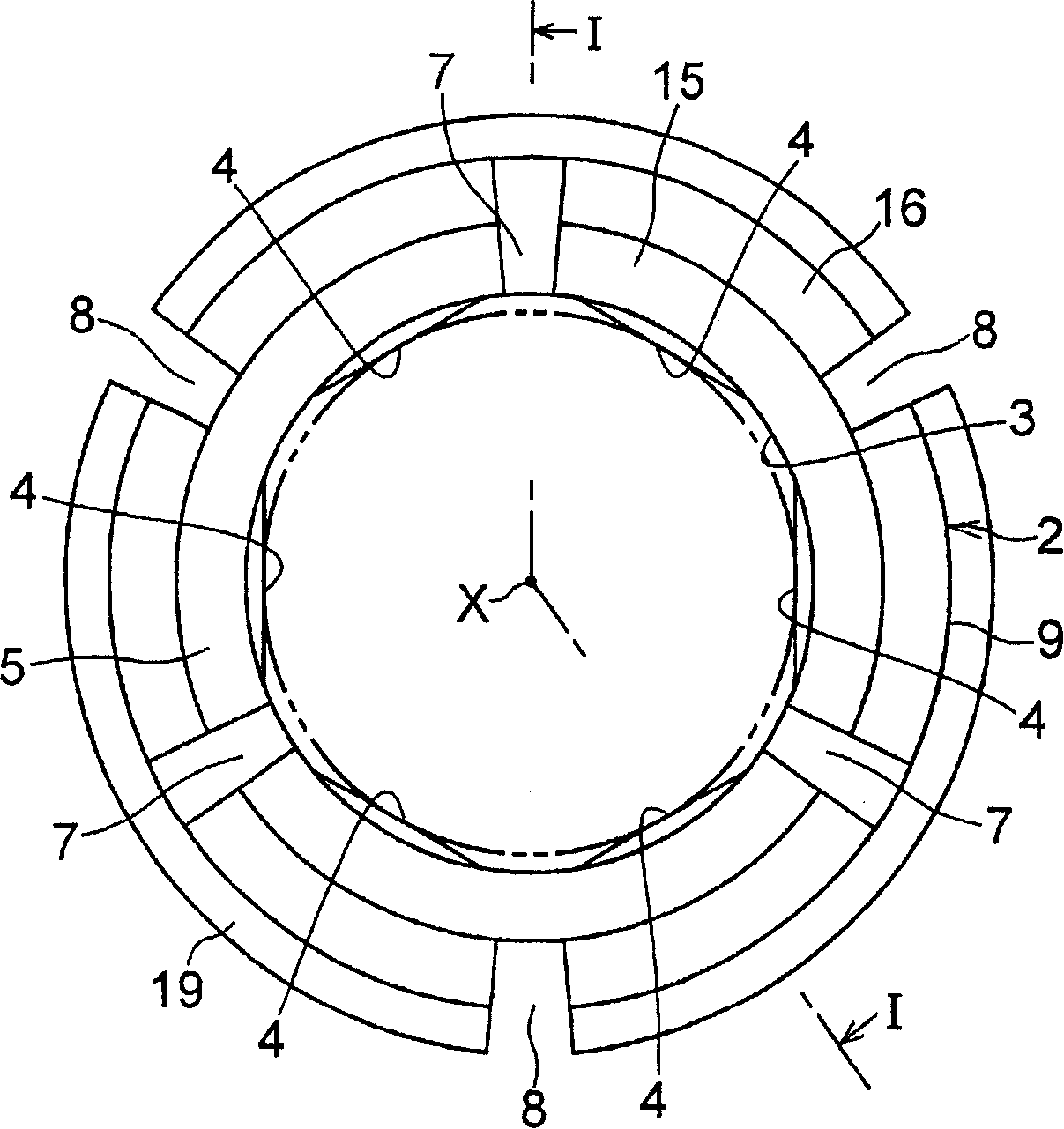

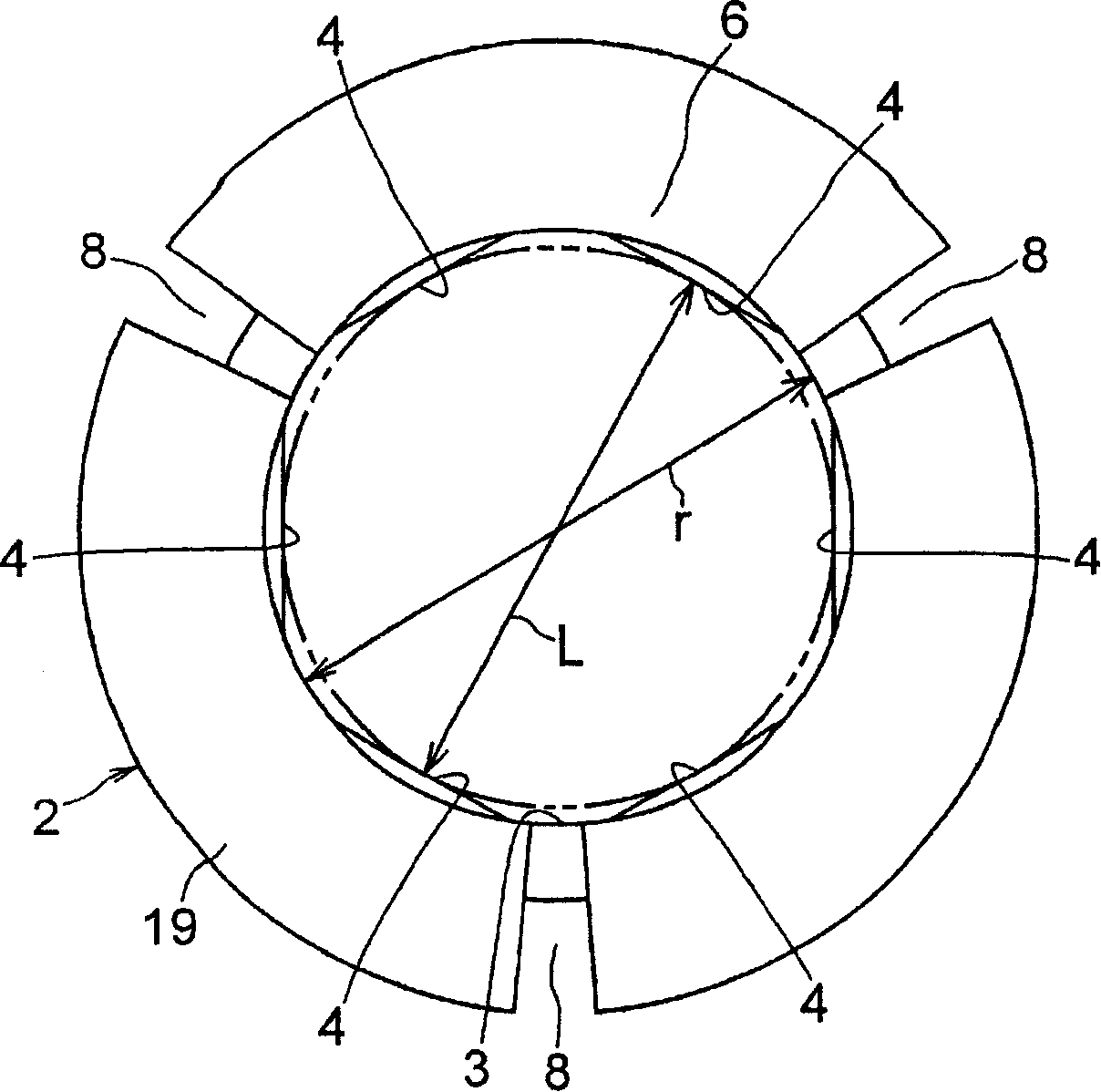

[0051] exist Figures 1 to 4 Among them, the sliding bearing for the steering column of this embodiment as a sliding bearing includes: a cylindrical bearing body 2; surface 3 and used as a sliding surface; three slots 7, which are arranged on the bearing body 2 and are adjacent to this side along the axial direction A from one end surface 5 of the bearing body 2 to the other end surface 6 of the bearing body 2 Extend between the planes 4; three slots 8, which are arranged on the bearing body 2 and along the axial direction A from the other end face 6 of the bearing body 2 to this side of the end face 5 of the bearing body 2 in the adjacent plane 4; at least one (two in this embodiment) groove 10 provided on the outer peripheral surface 9 of the bearing body 2; and at least one (two in this embodiment) elastic ring 11, they are arranged respectively in the grooves 10 to protrude from the outer peripheral surface 9 of the bearing body 2 and reduce the diameter of the bearing bo...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com