Prosthetic foot

A prosthetic foot and heel technology, applied in prosthesis, medical science, artificial legs, etc., can solve problems that are not conducive to the accuracy of force introduction, small reset force, etc., and achieve the effect of accurate support point and long-lasting position

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

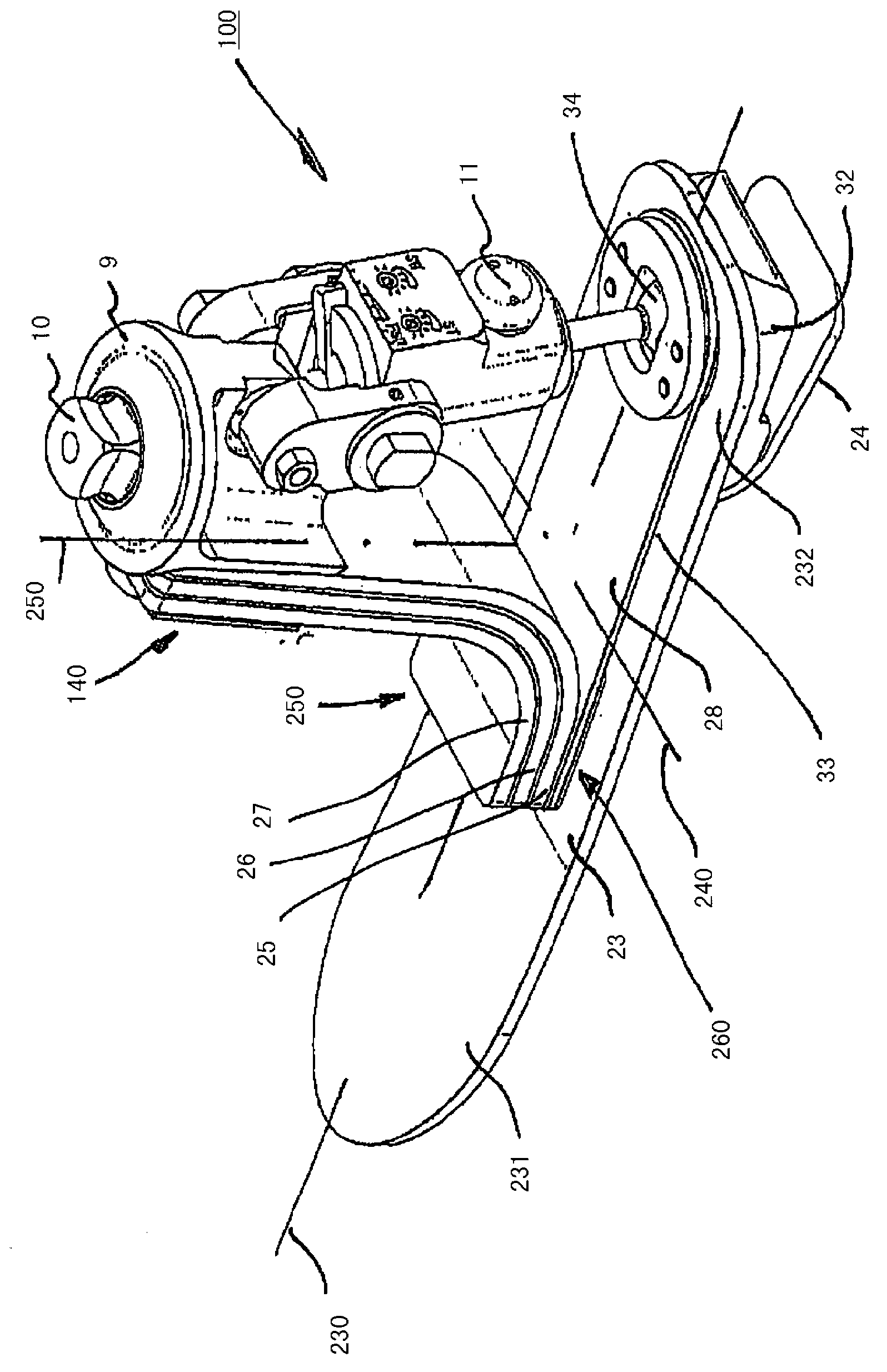

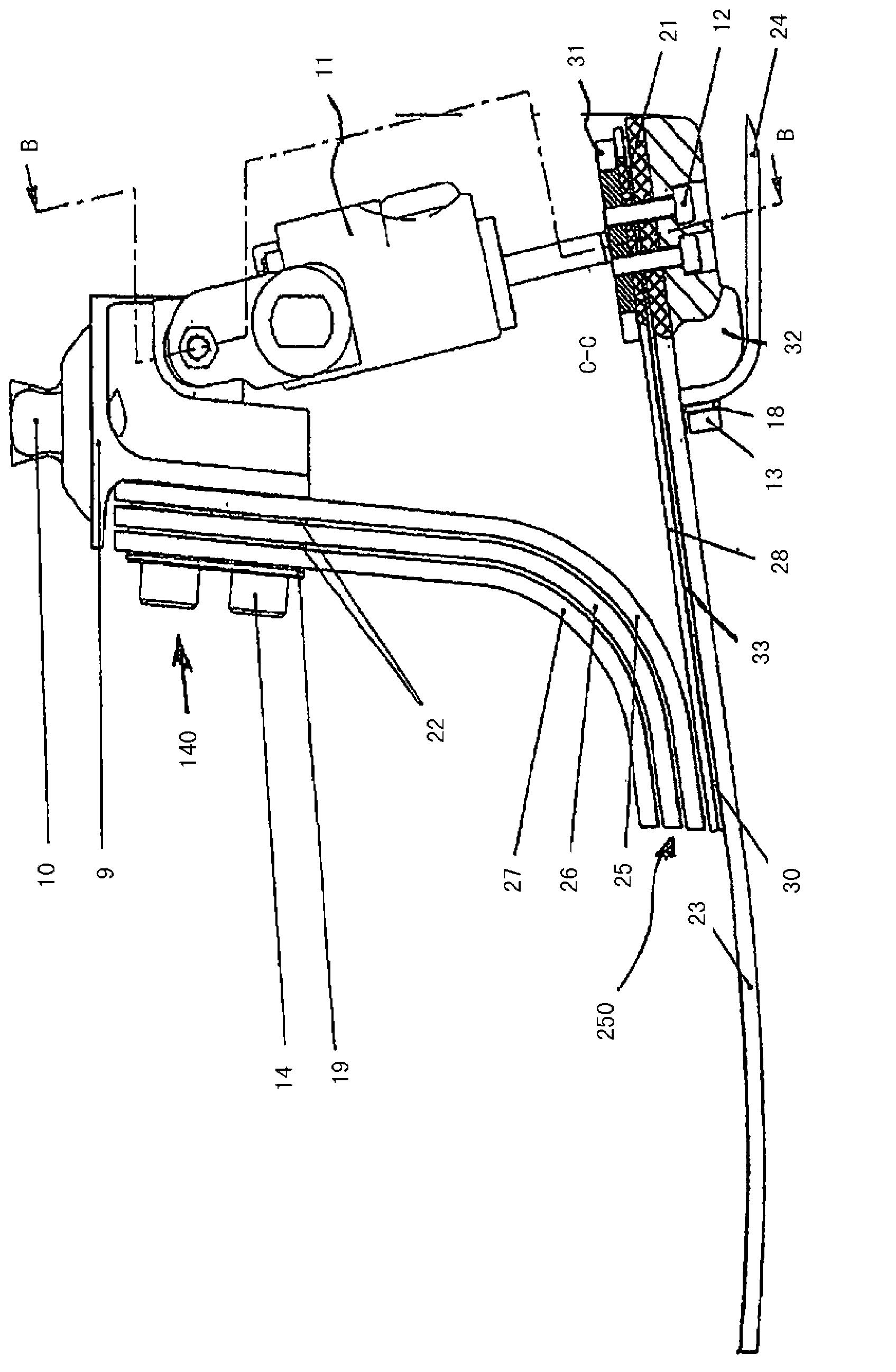

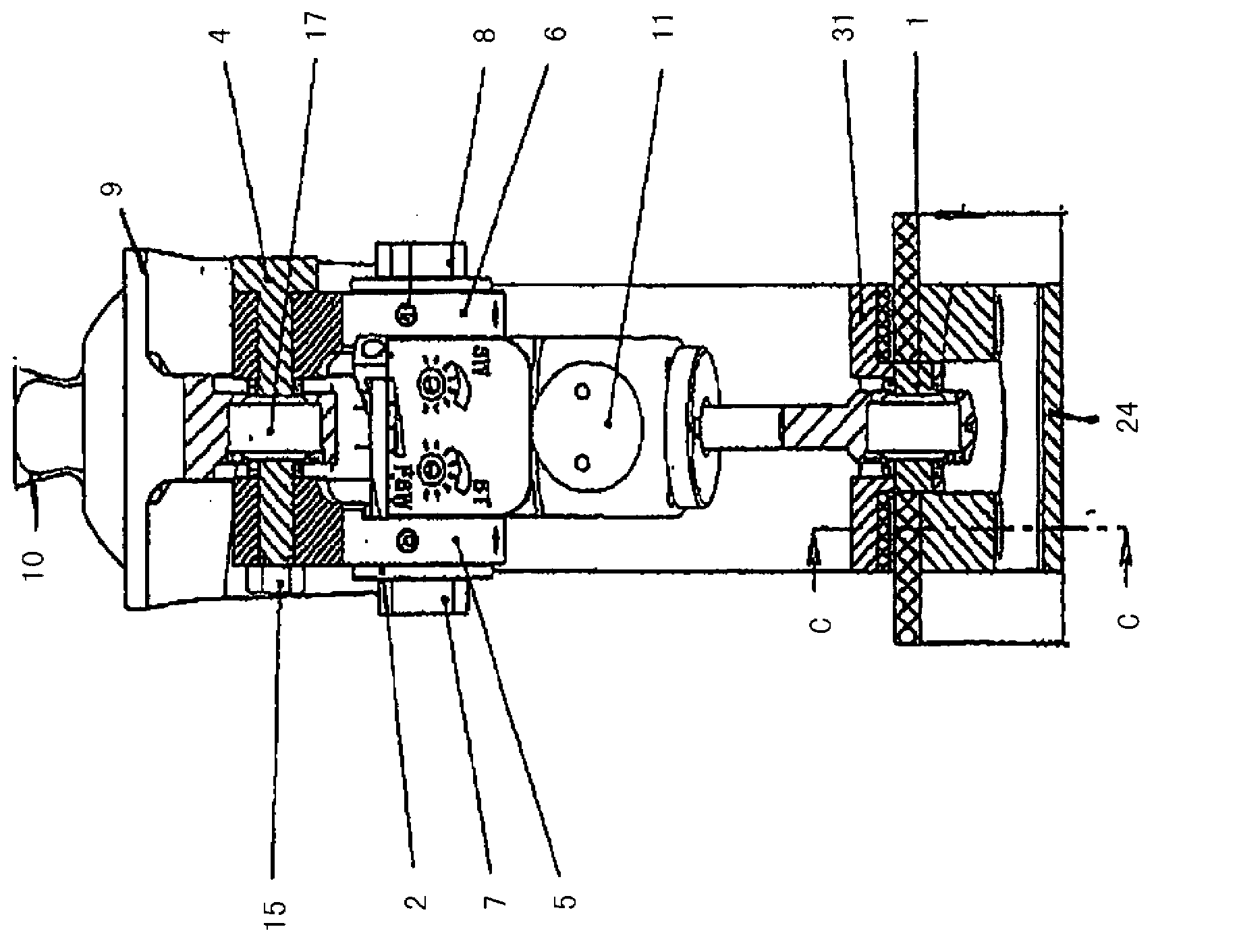

[0026] exist figure 1The prosthetic foot 100 is shown in a three-dimensional oblique top view. The prosthetic foot 100 has a base spring 23 with a forefoot region 231 and a heel region 232 . The base spring 23 is preferably produced from a fiber composite material, in particular from a carbon fiber component. The base spring 23 is elongated, wherein the prosthetic foot longitudinal axis 230 extends in the longitudinal direction. The base spring 23 is substantially straight, with a slight bend provided in the forefoot region 231 to facilitate rolling over of the prosthetic foot 100 .

[0027] A heel spring 24 is arranged on the base spring 23 in the heel region 232 . The heel spring 24 is likewise made of a fiber composite material, in particular a carbon fiber material. The heel spring 24 can be fixed exchangeably on the base spring 23 . Between the heel spring 24 and the base spring 23 there is a free space which contracts in the direction of travel, in which free space ...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com