Patents

Literature

314results about How to "Simple adaptation" patented technology

Efficacy Topic

Property

Owner

Technical Advancement

Application Domain

Technology Topic

Technology Field Word

Patent Country/Region

Patent Type

Patent Status

Application Year

Inventor

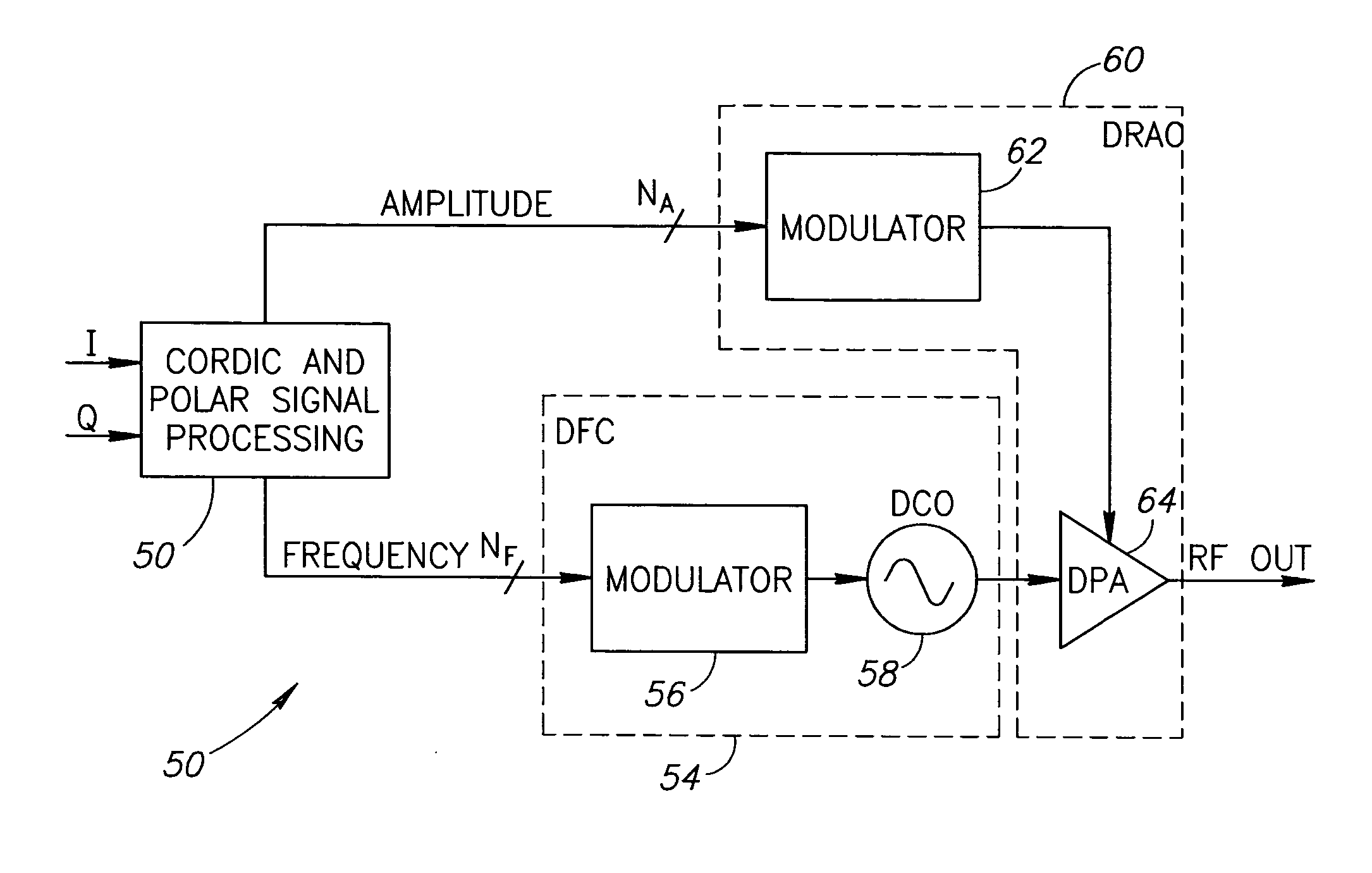

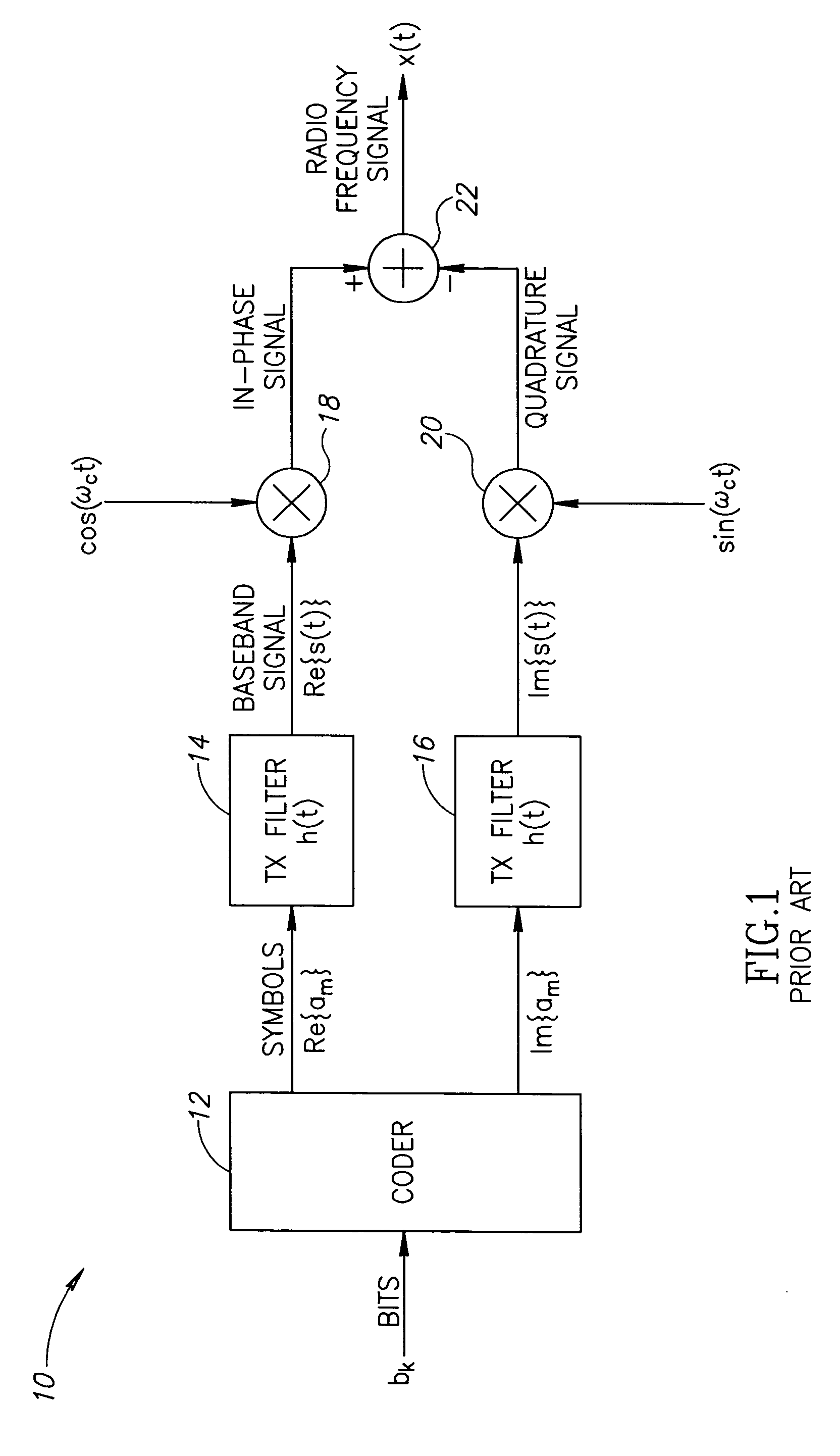

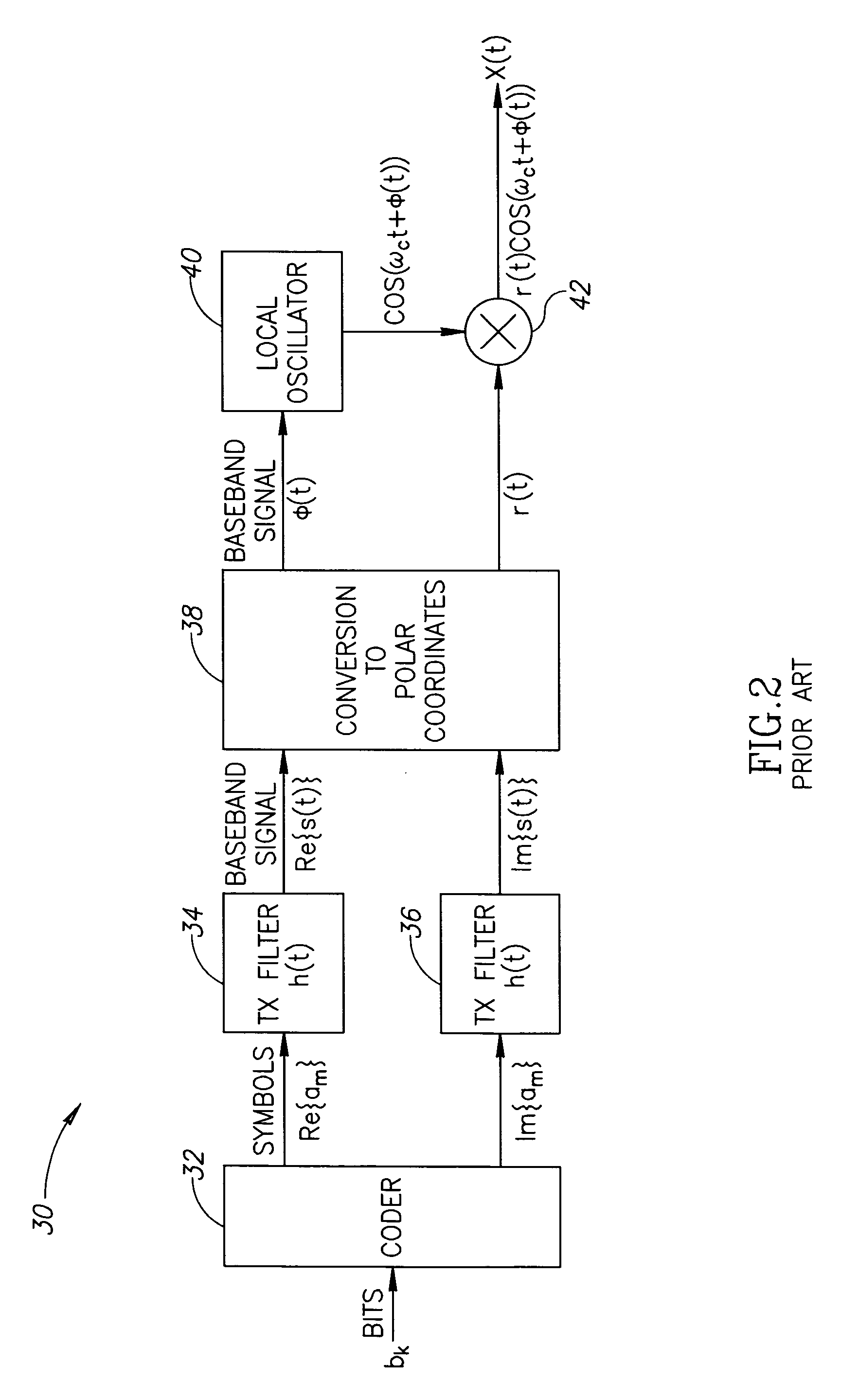

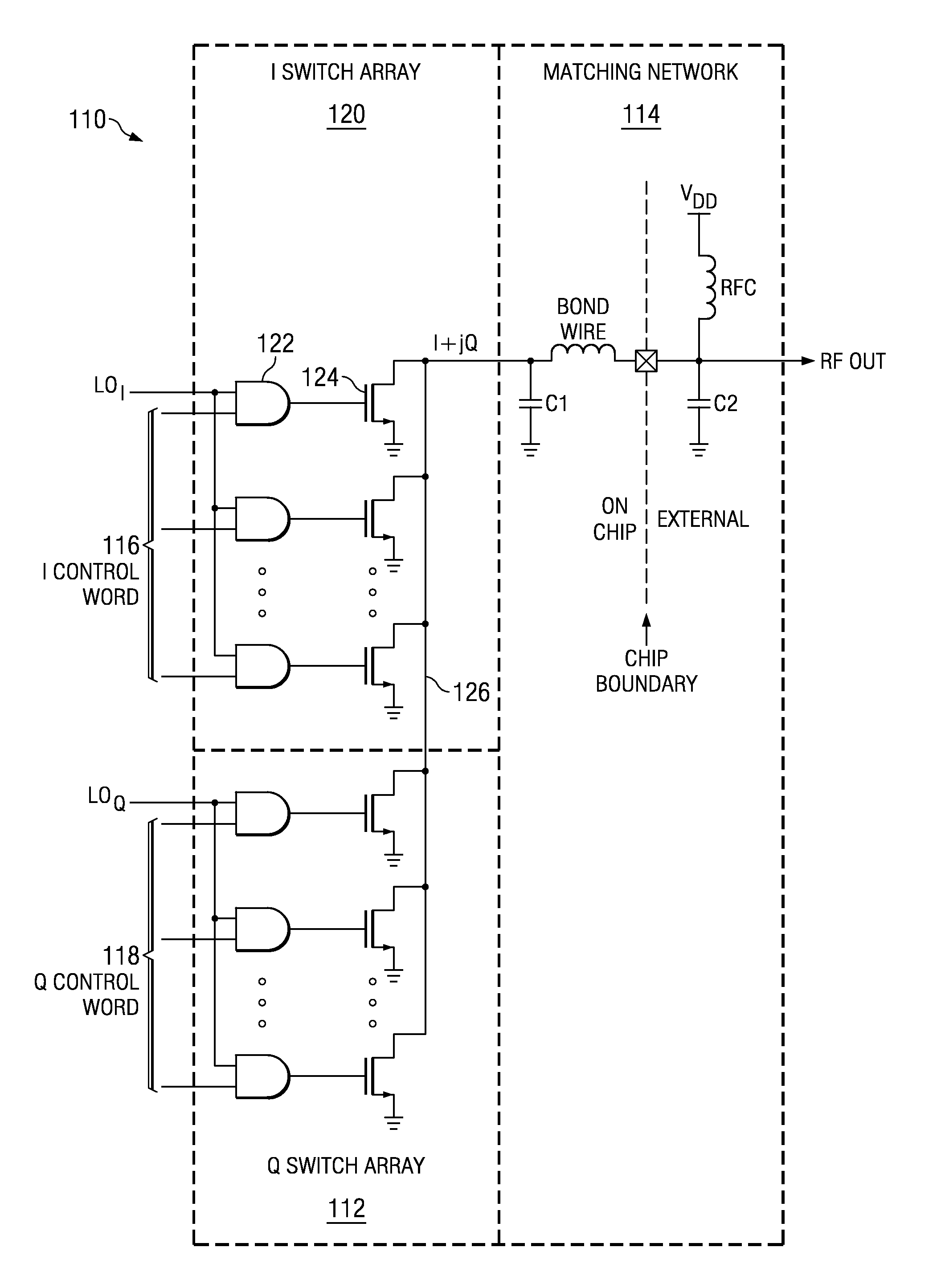

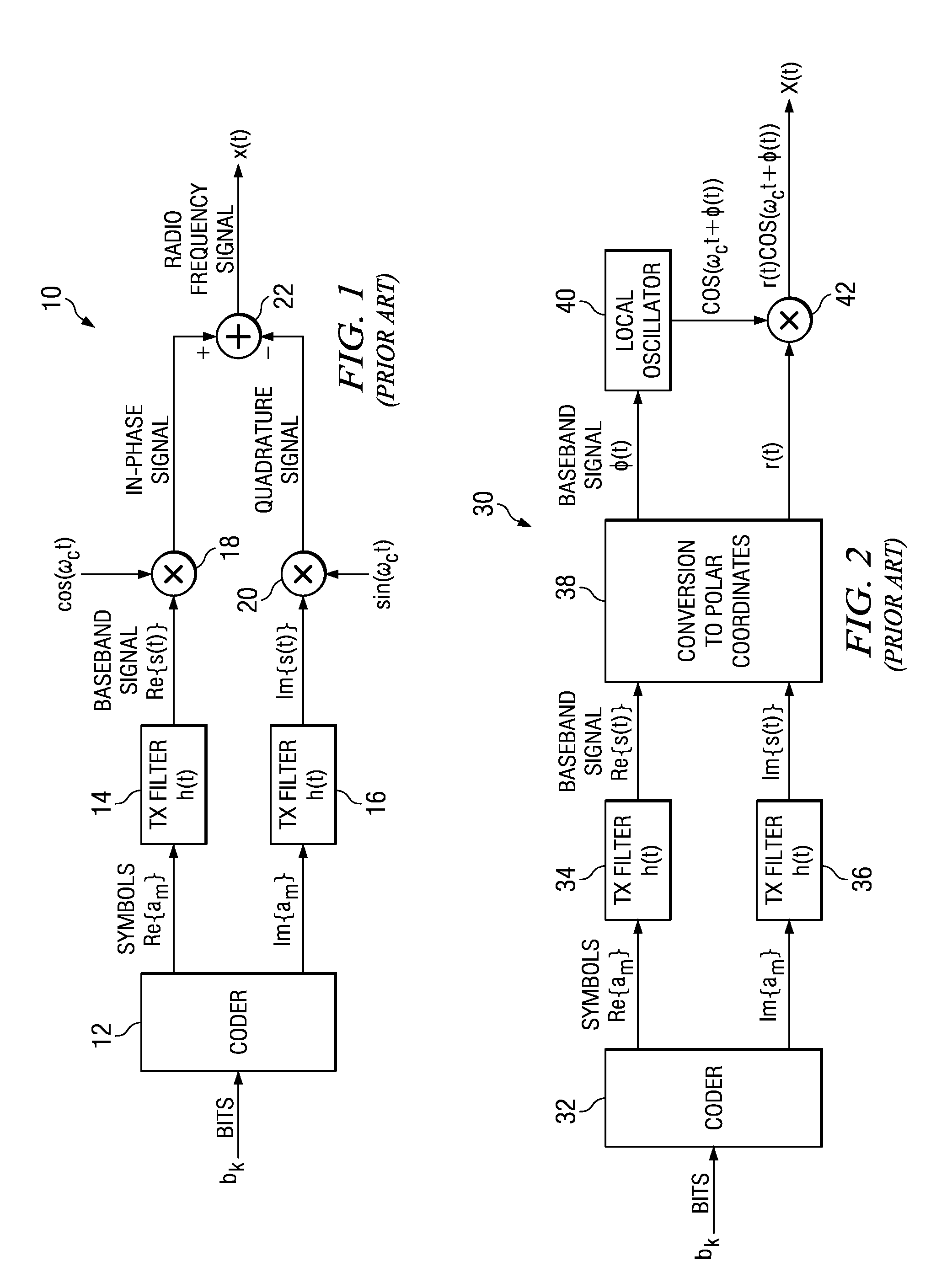

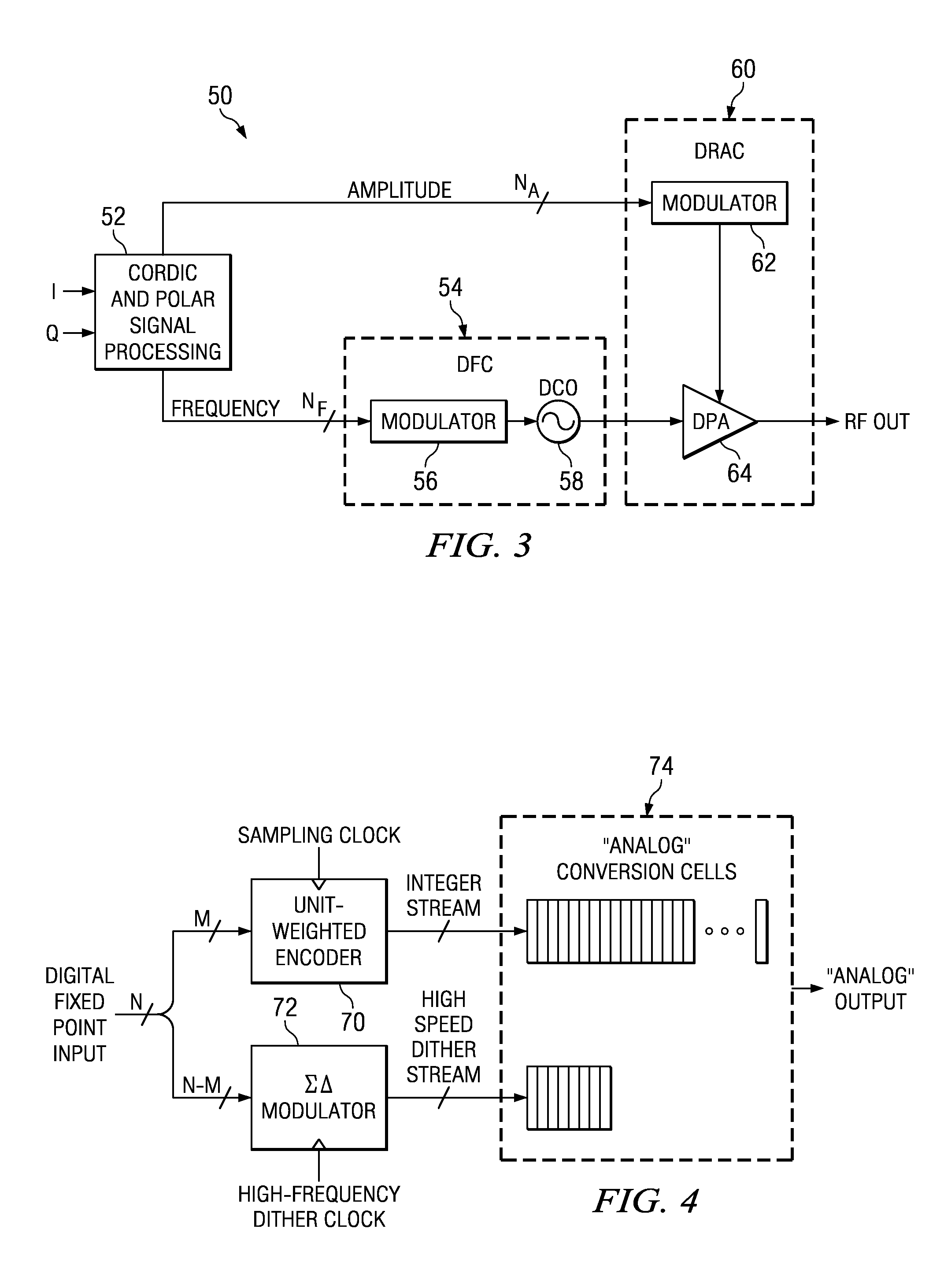

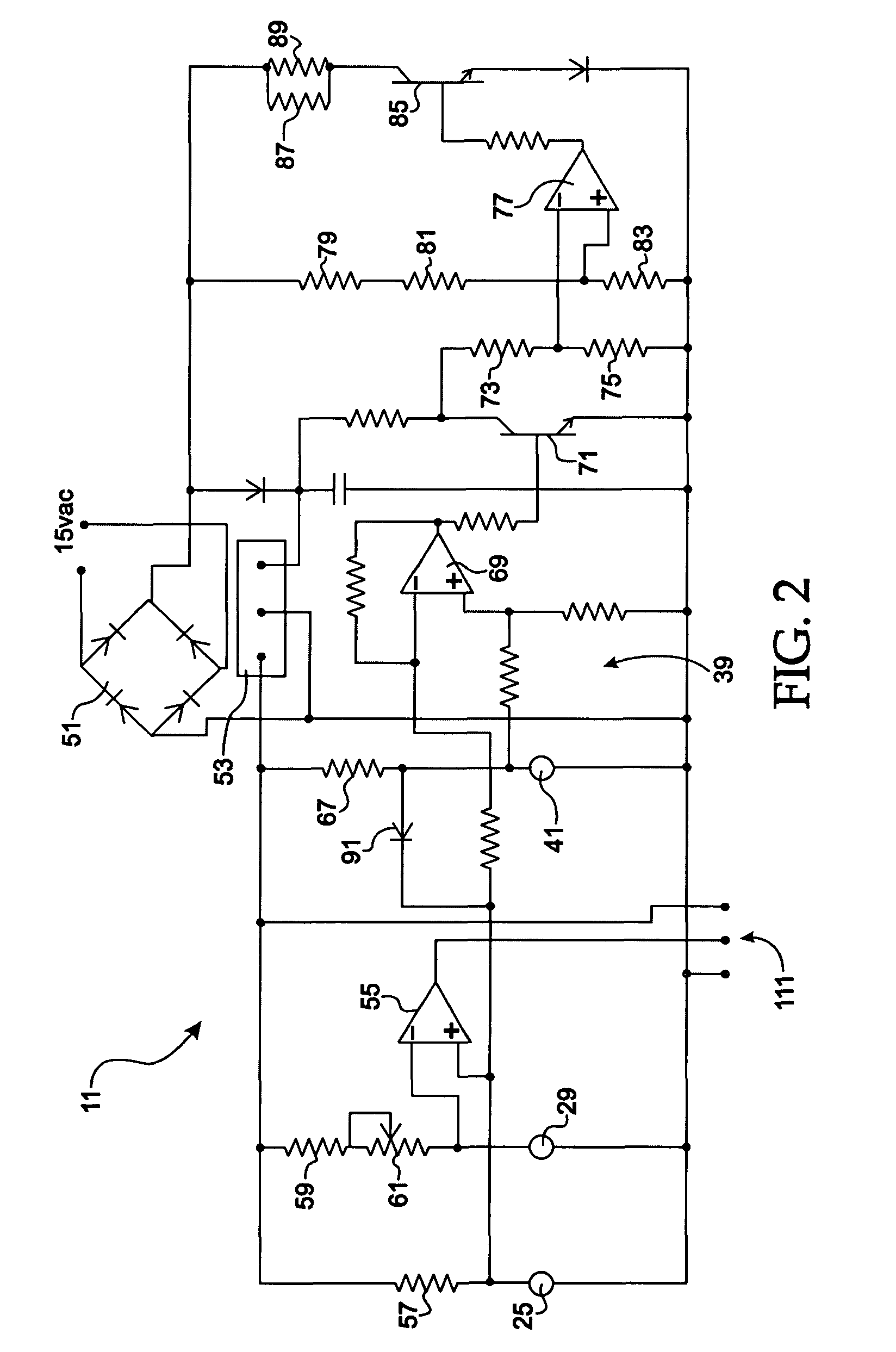

Method and apparatus for a fully digital quadrature modulator

ActiveUS20060291589A1Little or no reuseMinimize impactSimultaneous amplitude and angle modulationPower amplifiersTransistor arrayQuadrature modulator

A novel apparatus and method for a fully digital quadrature architecture for a complex modulator. The complex modulator can substitute for existing prior art analog quadrature modulator structures and those based on a digital polar architecture (r, θ). The modulator effectively operates as a complex digital-to-analog converter where the digital inputs are given in Cartesian form, namely I and Q representing the complex number I+jQ, while the output is a modulated RF signal having a corresponding amplitude and phase shift. The phase shift being with respect to a reference phase dictated by the local oscillator, which is also input to the converter / modulator. Several embodiments are provided including modulators incorporating dual I and Q transistor arrays, a single shared I / Q transistor array, modulators with single ended and differential outputs and modulators with single and dual polarity clock and I / Q data signals.

Owner:TEXAS INSTR INC

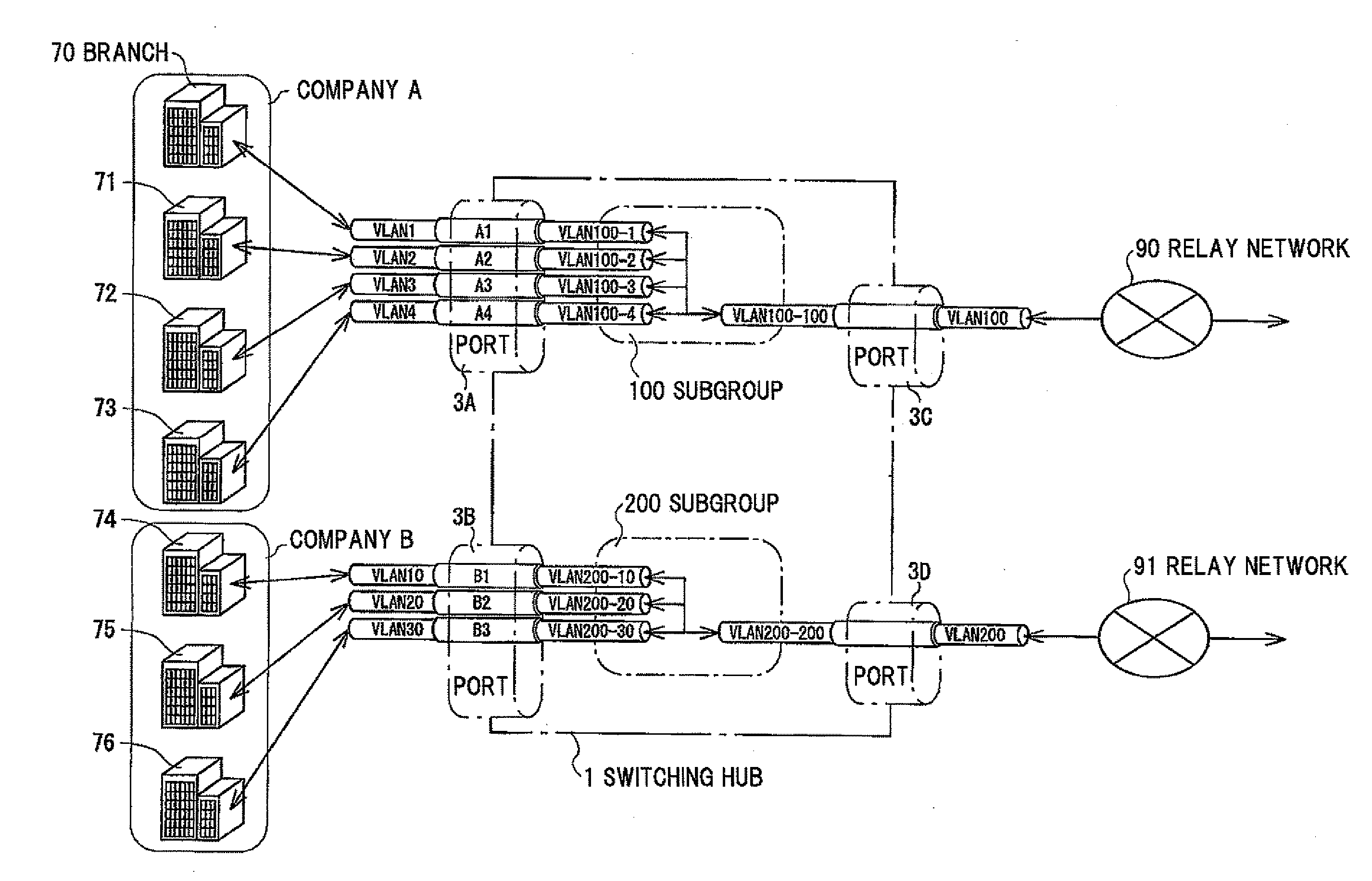

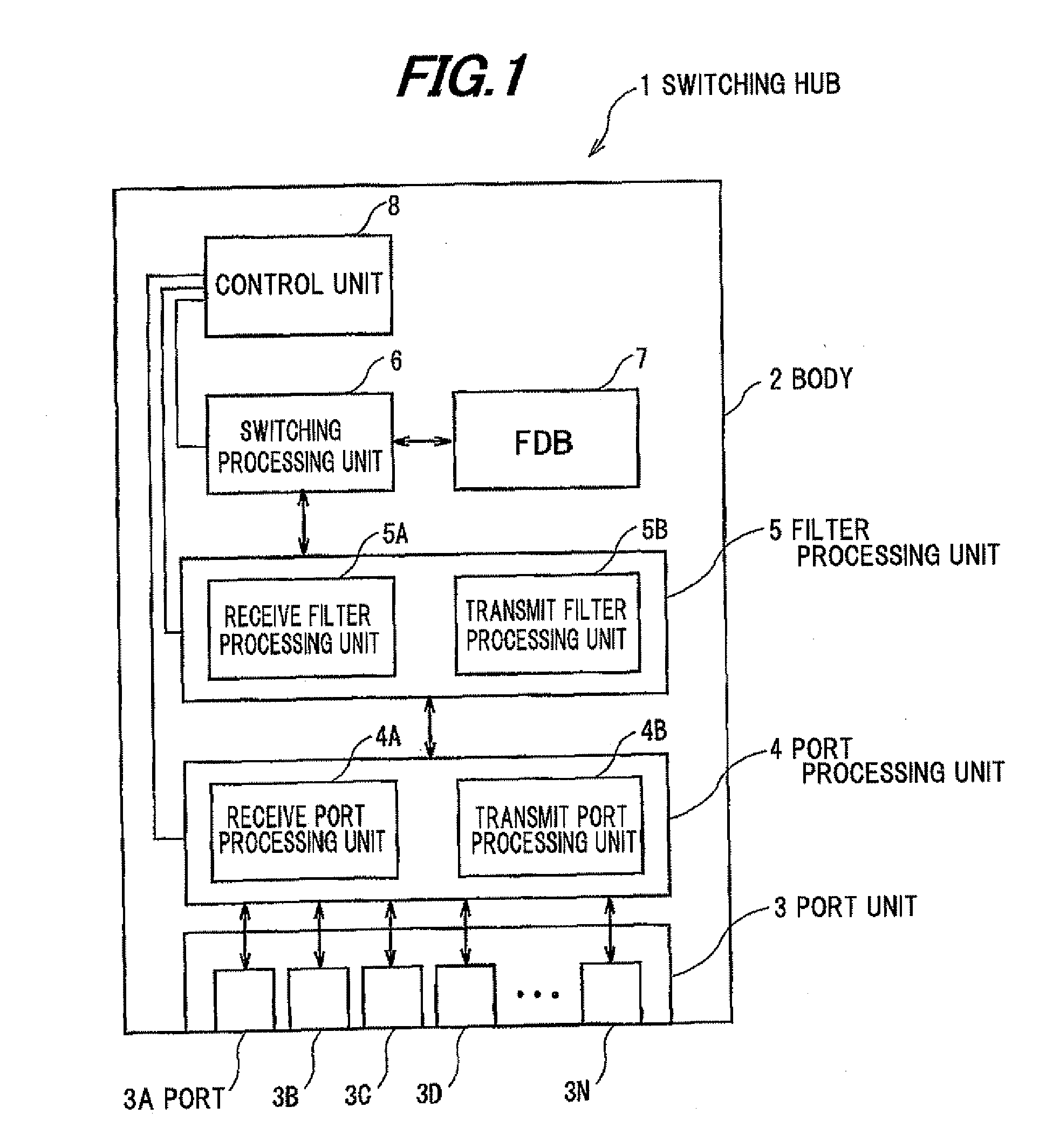

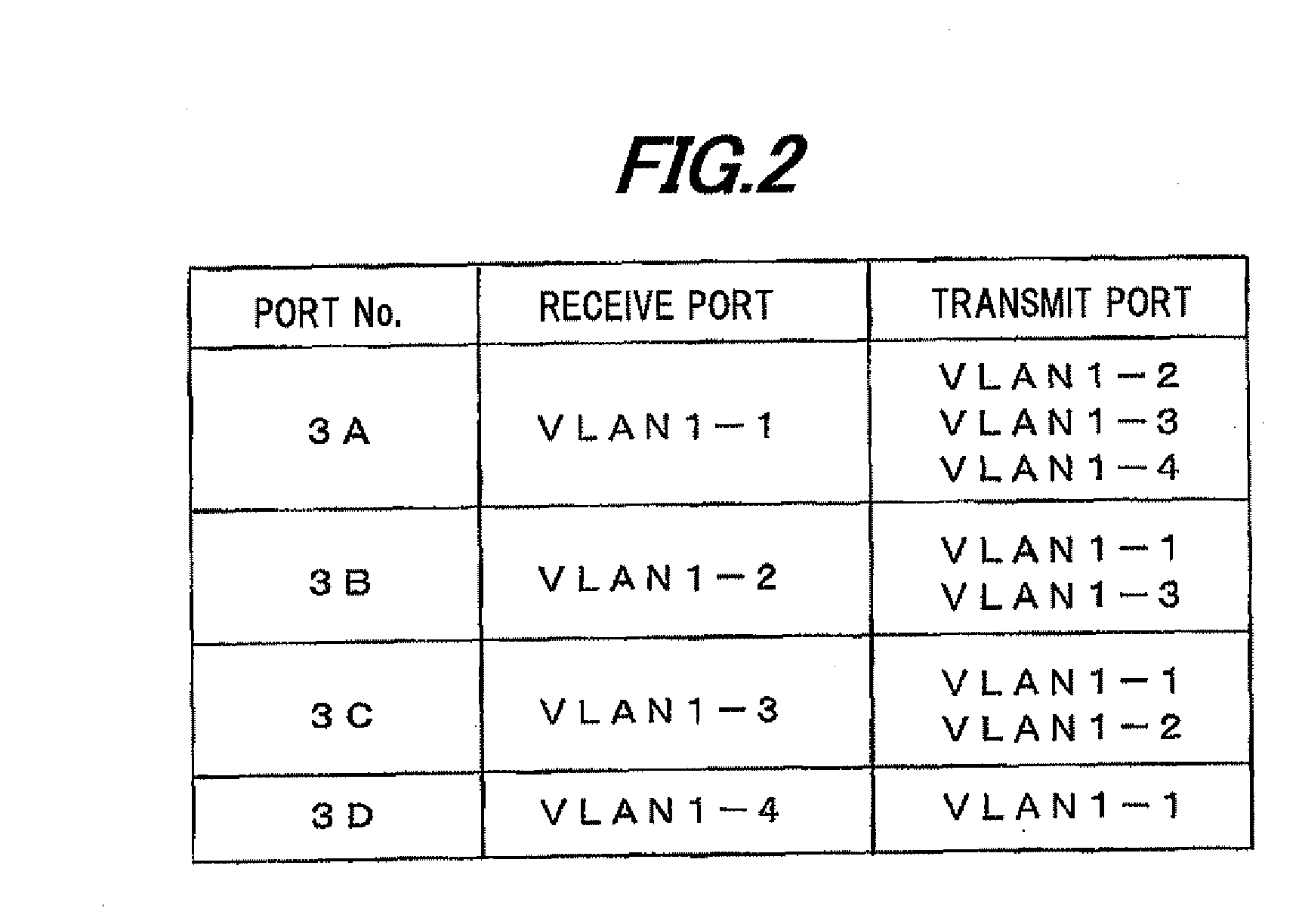

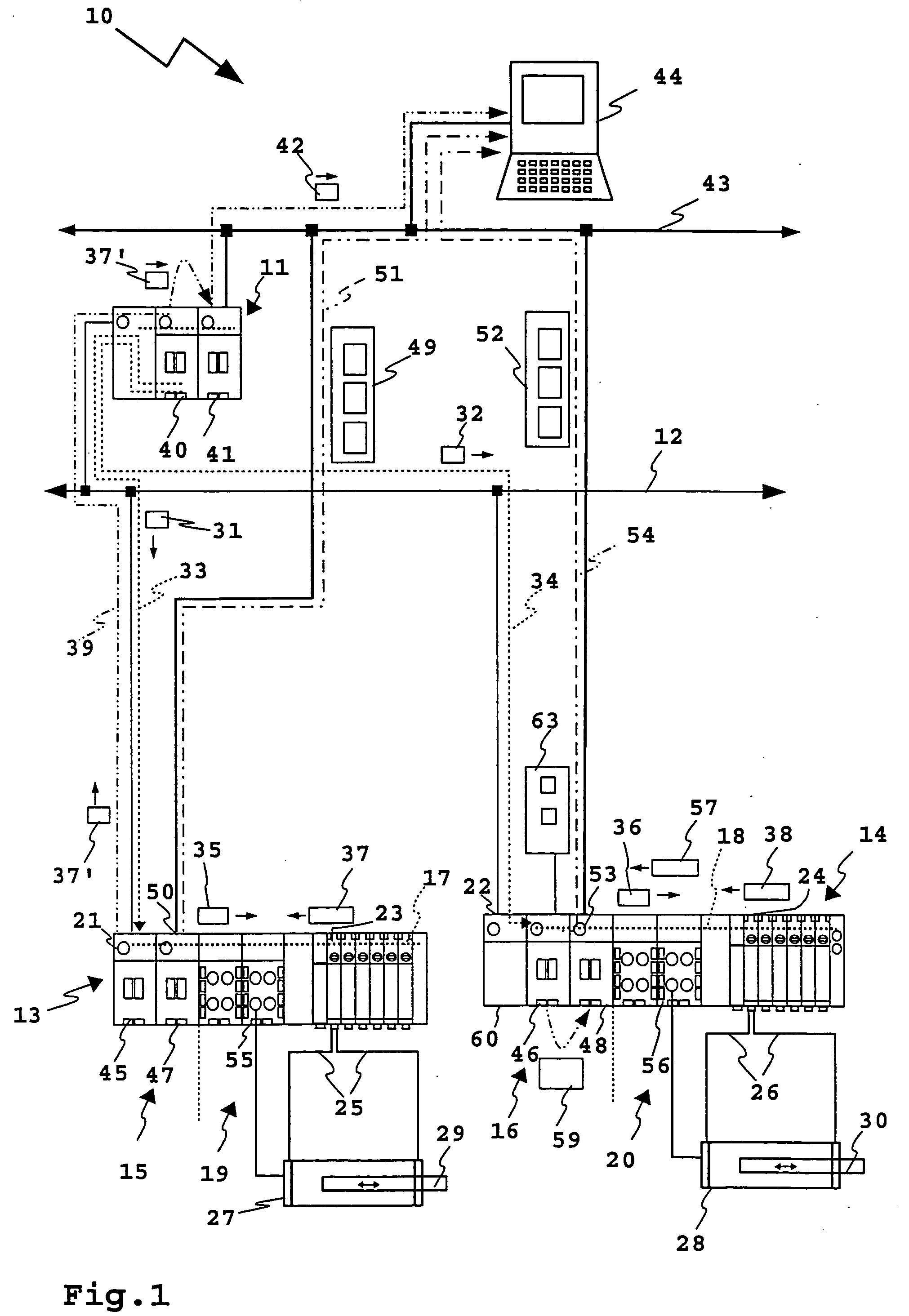

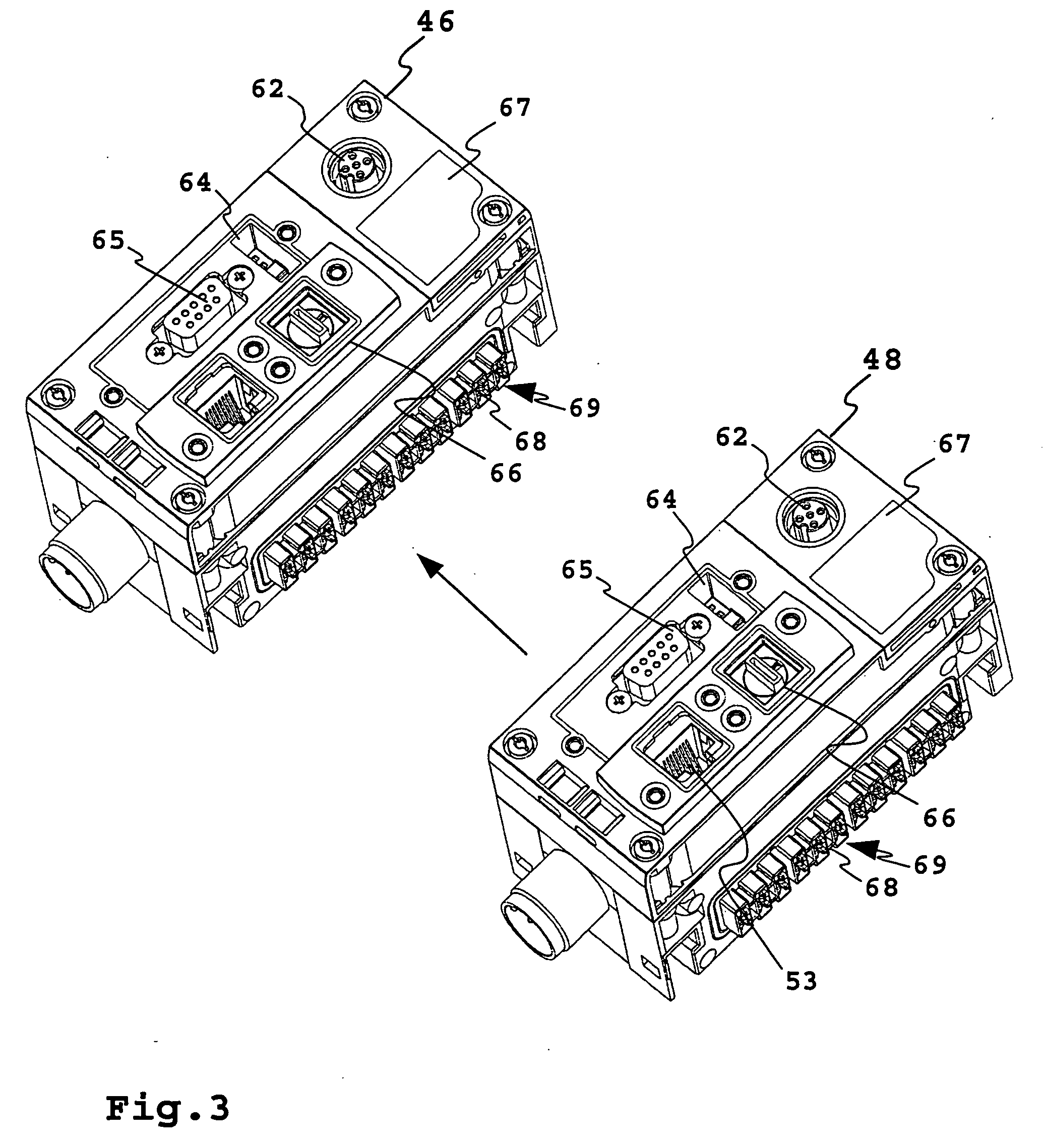

Switching hub and LAN system

InactiveUS20080186981A1Flexible adaptationSimple adaptationStar/tree networksNetworks interconnectionEngineeringMechanical engineering

A switching hub is provided with a control unit for setting, for a port, a VLAN-ID comprising a subgroup ID of a subgroup constituting a VLAN, and a sub-ID of a group contained in the subgroup ID, and a switching processing unit for relaying a frame, which contains the VLAN-ID, via the port, which matches the VLAN-ID

Owner:HITACHI METALS LTD

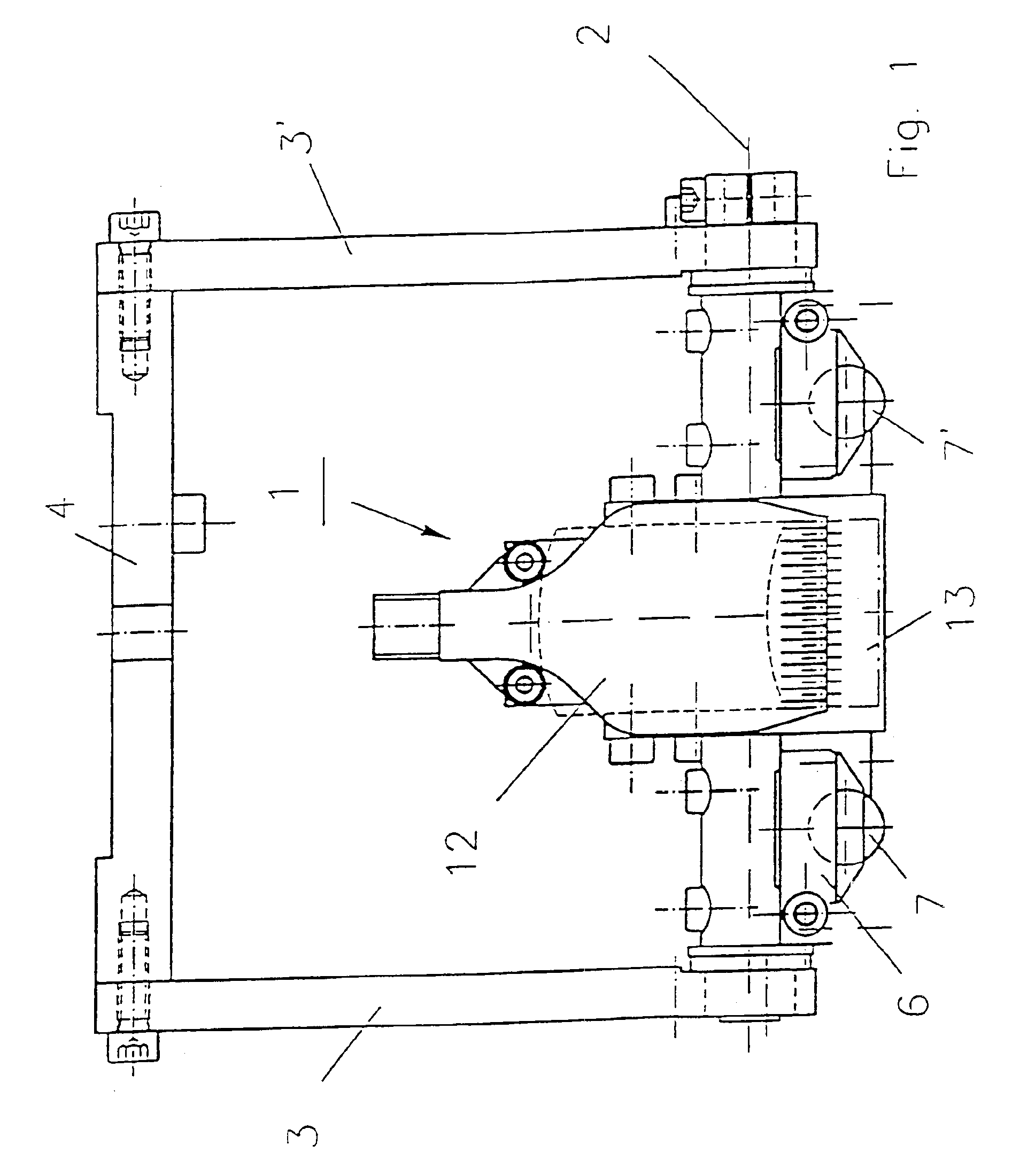

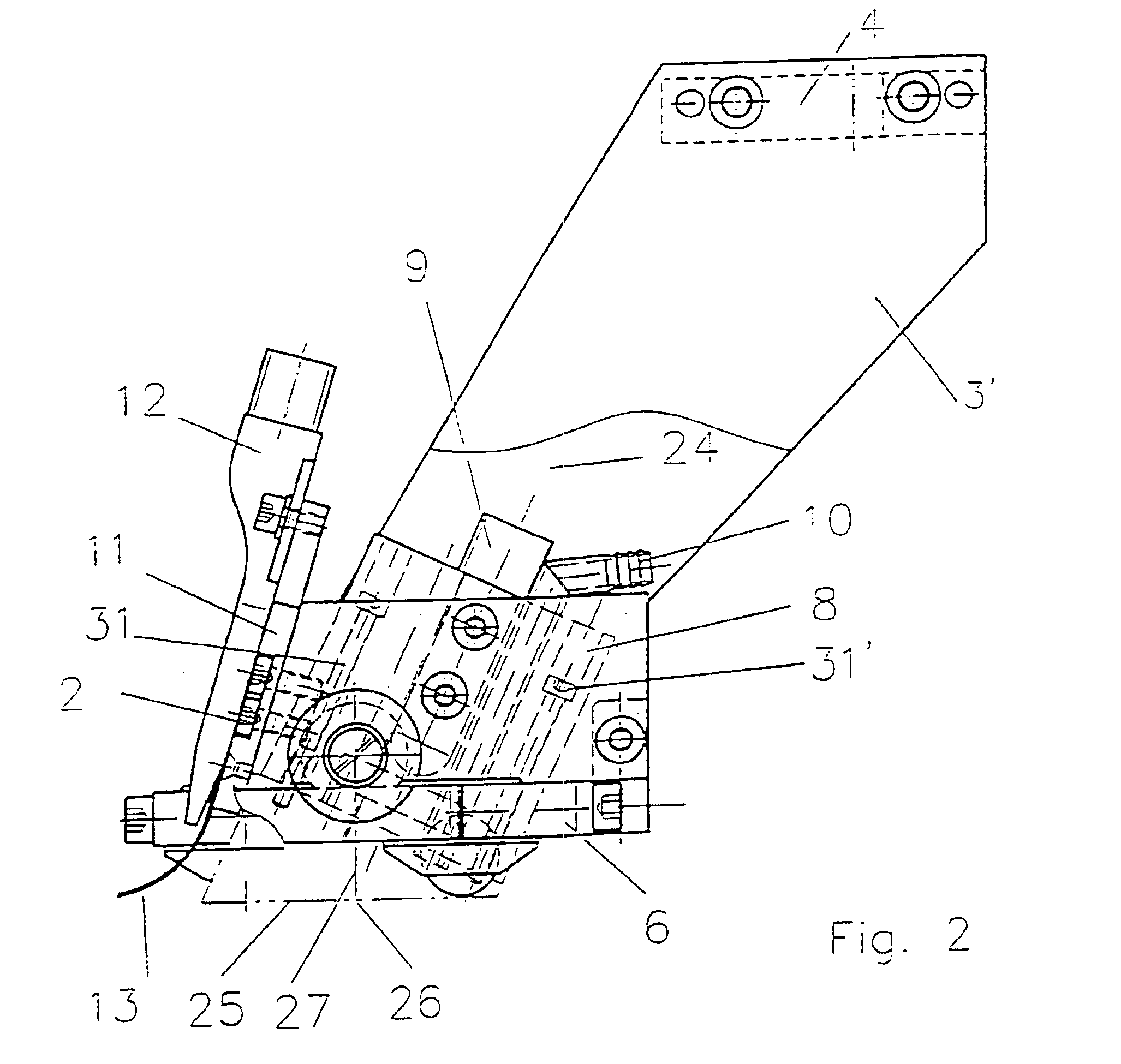

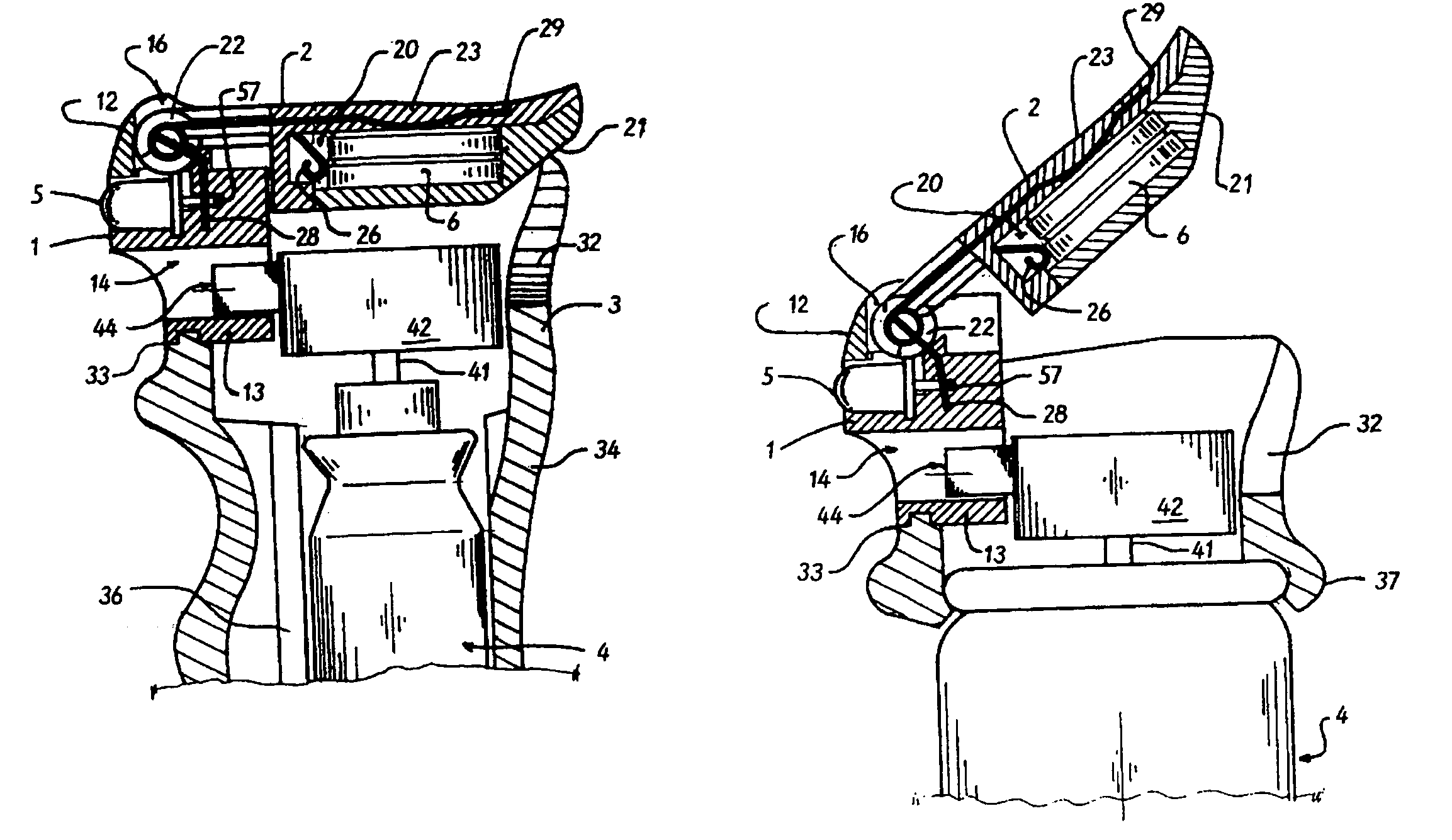

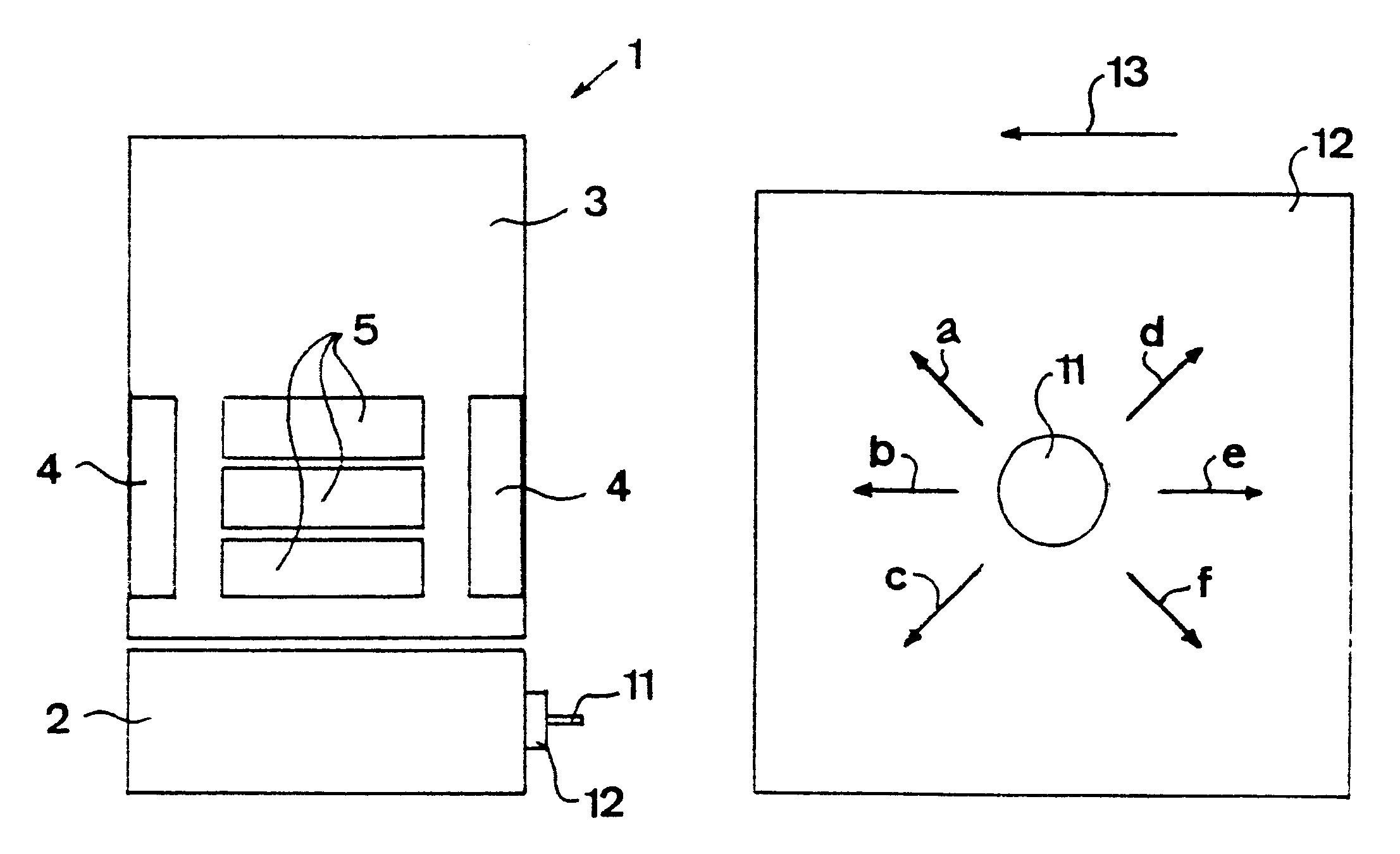

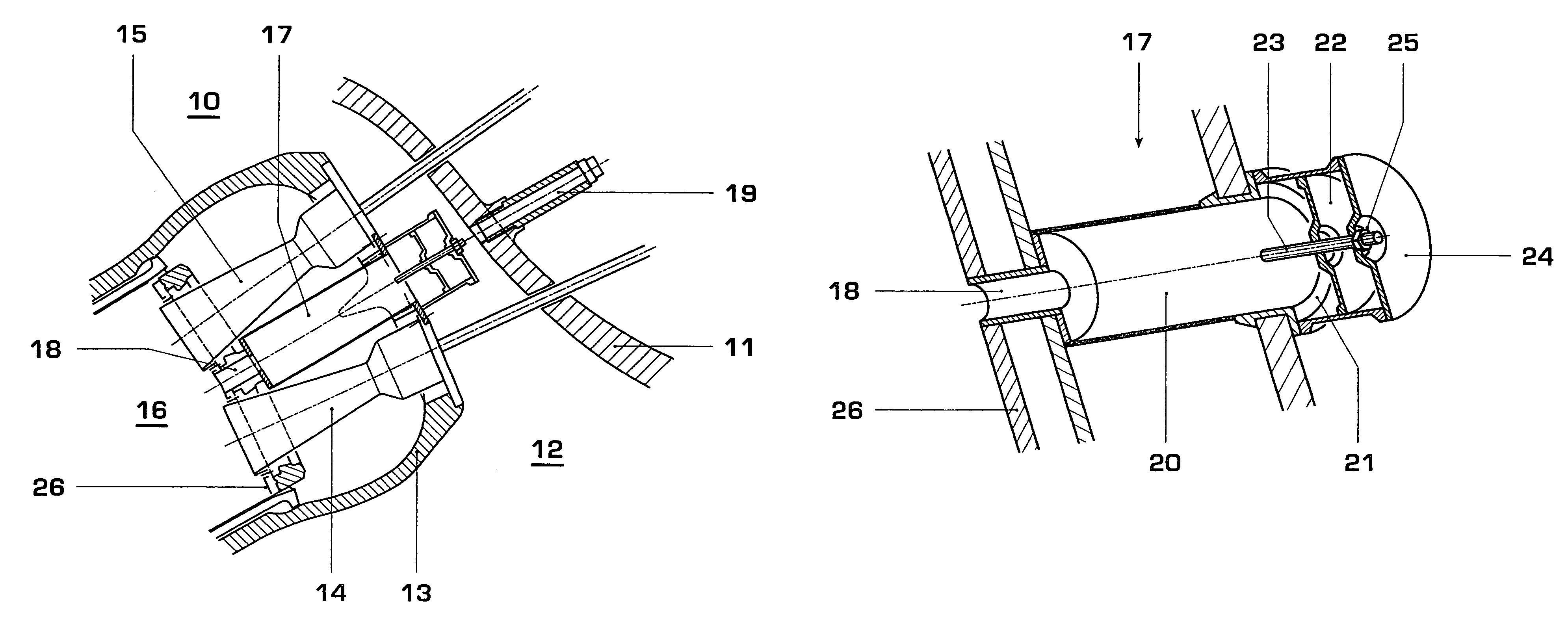

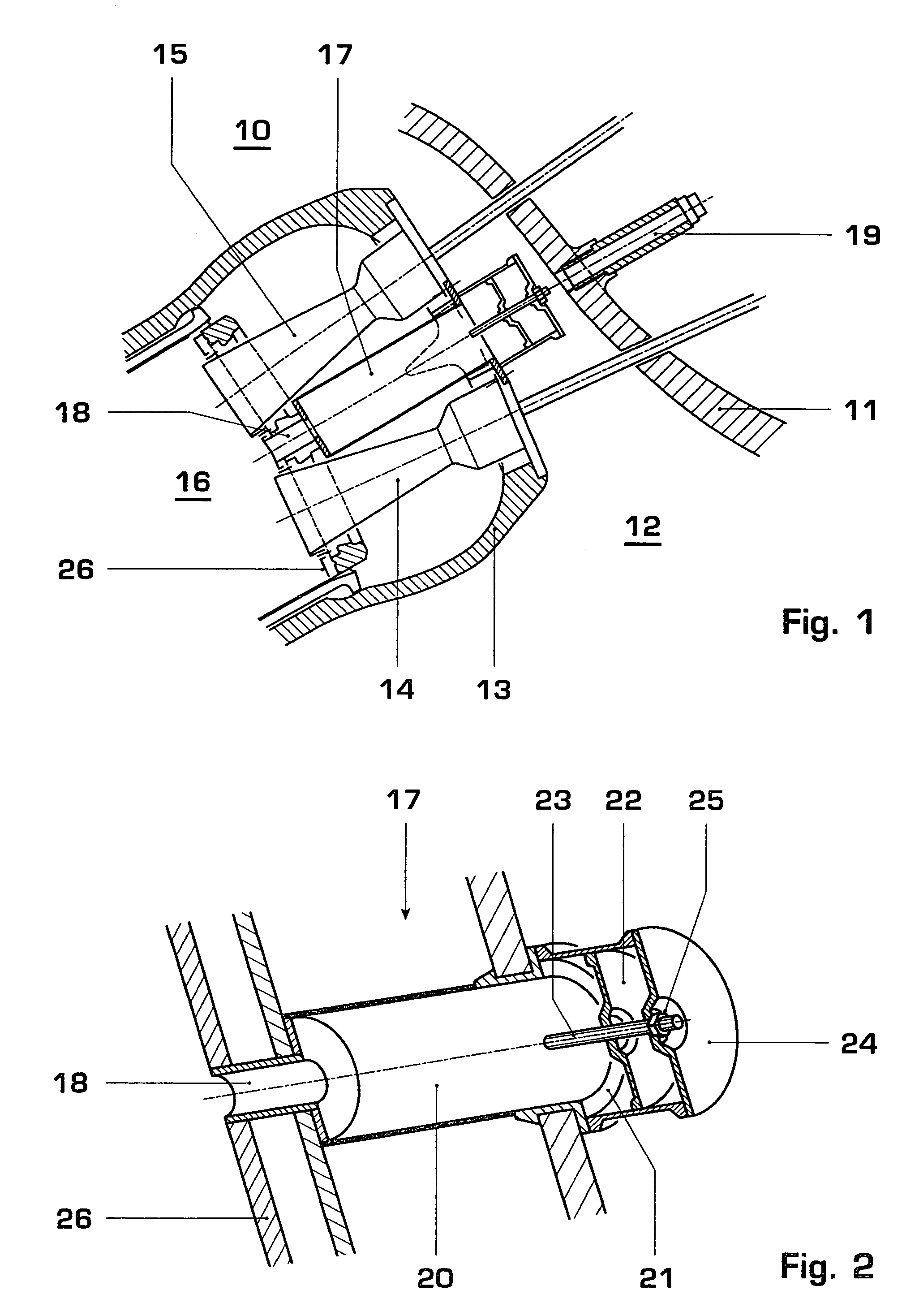

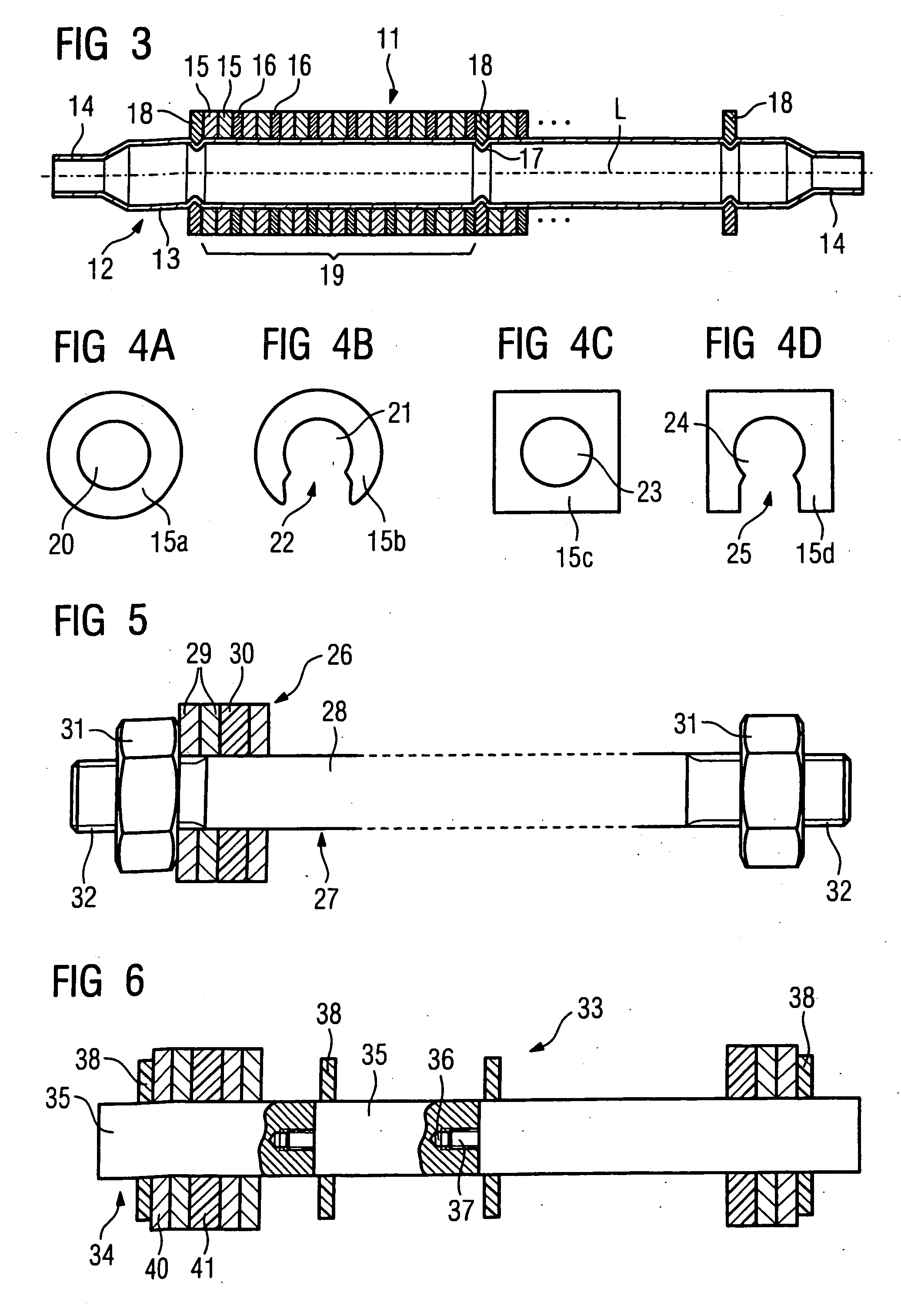

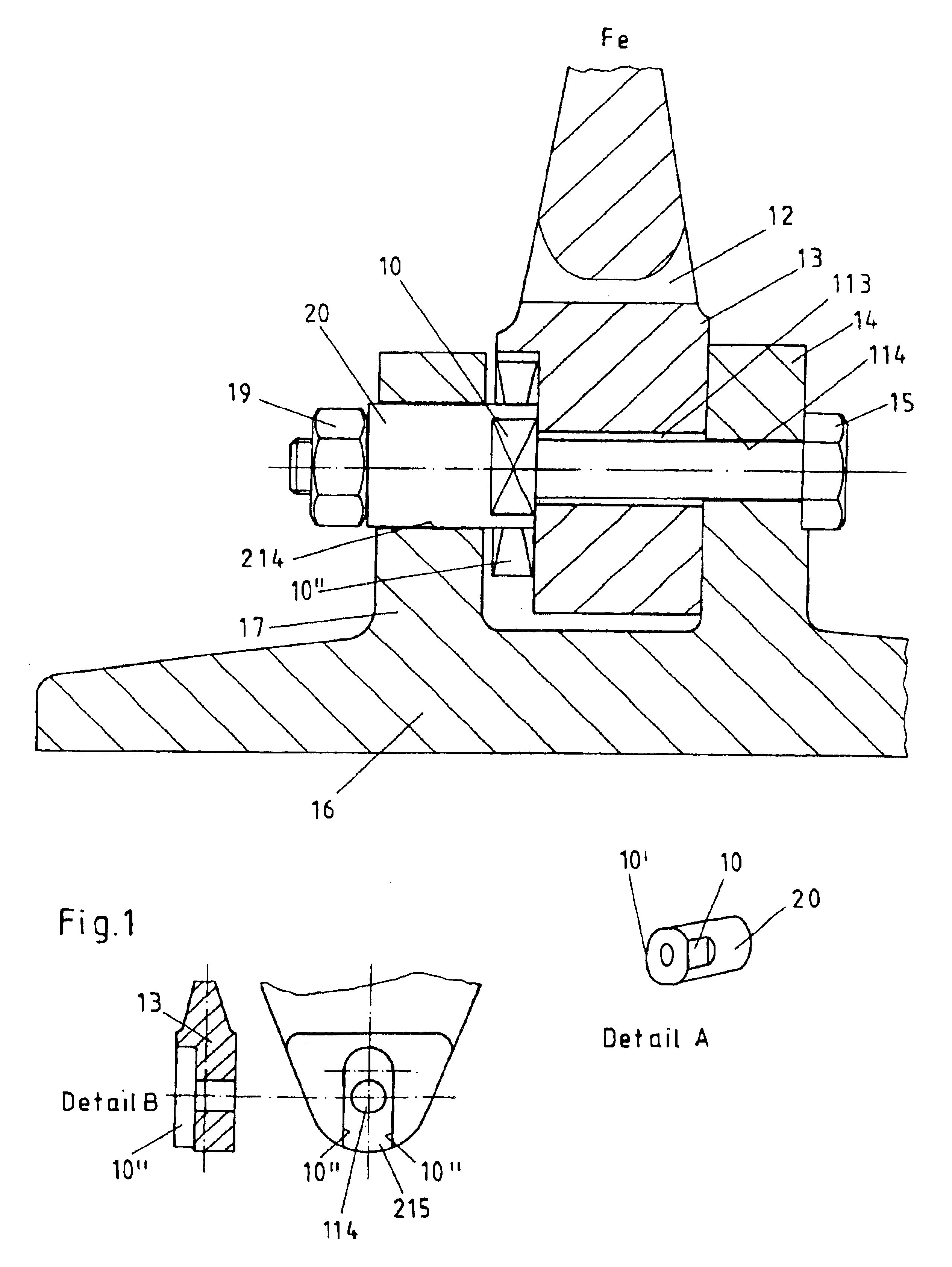

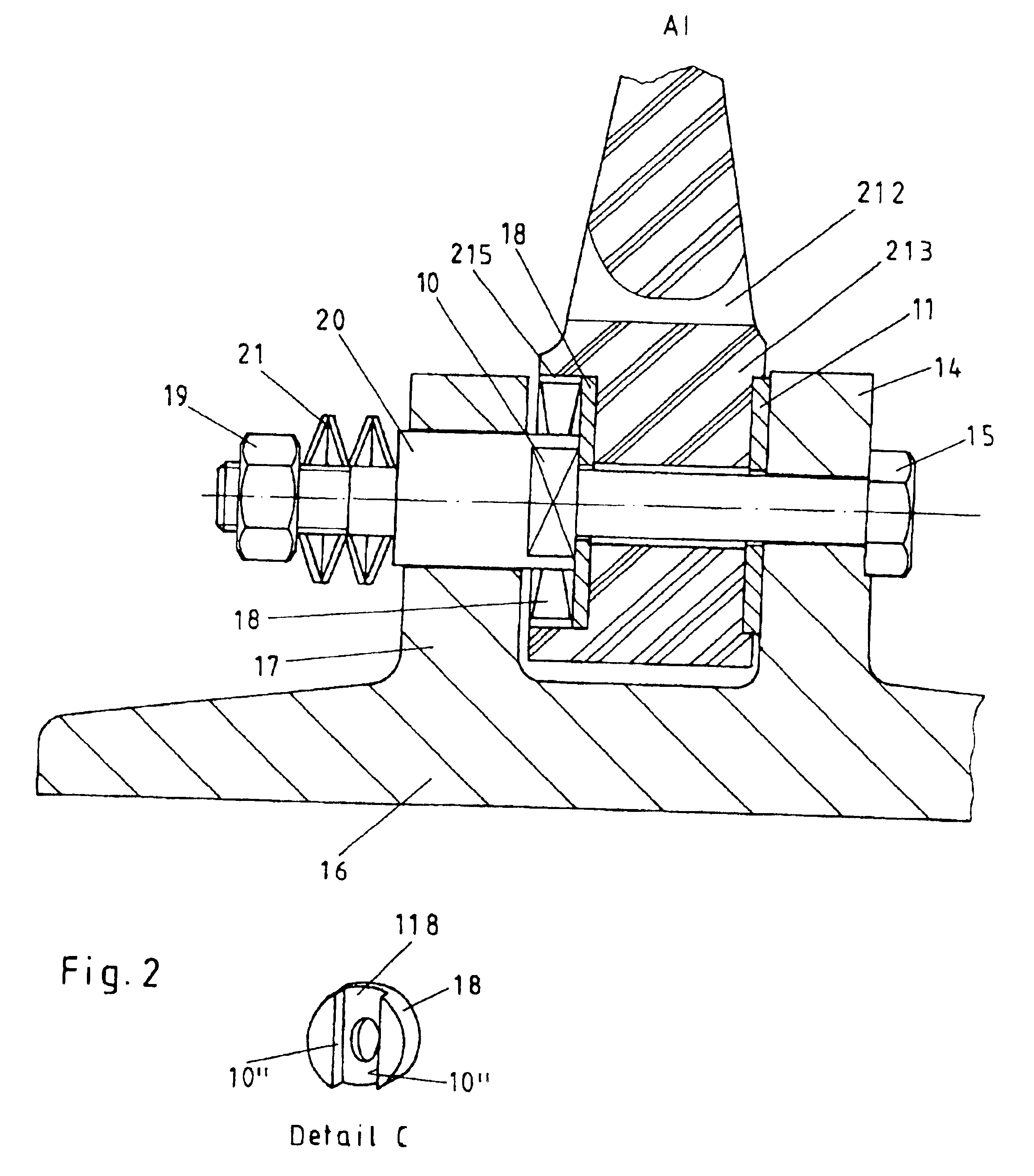

Device for ultrasonic weld seam testing of longitudinally welded pipes for longitudinal and transversal errors

InactiveUS6931931B2Simple adaptationSimplify workAnalysing solids using sonic/ultrasonic/infrasonic wavesMetal working apparatusEngineeringWeld seam

A device for ultrasonic weld seam testing of longitudinally includes two testing carriages swingably suspended and moveable on the pipe surface to the right and left of the weld seam for longitudinal flaw inspection, and one testing carriage swingably suspended in central relationship to the weld seam and moveable on the pipe surface for transverse flaw inspection. Each testing carriage has a mount for accommodating at least one testing head which includes an oscillator, and at least one coupling medium connection having a channel ending in the region of the oscillator and configured as nozzle in the outlet area. The test head for longitudinal flaw inspection can be arranged at various fixed and predefined angle positions at variable distance to the nozzle in the mount, and the test head for transverse flaw inspection can be arranged, together with the mount, at a variable distance to the pipe surface in a support element accommodating the mount.

Owner:MANNESMANN ROHRENWERKE

Method and apparatus for a fully digital quadrature modulator

ActiveUS7460612B2Little or no reuseMinimize impactSimultaneous amplitude and angle modulationPower amplifiersTransistor arrayQuadrature modulator

A novel apparatus and method for a fully digital quadrature architecture for a complex modulator. The complex modulator can substitute for existing prior art analog quadrature modulator structures and those based on a digital polar architecture (r, θ). The modulator effectively operates as a complex digital-to-analog converter where the digital inputs are given in Cartesian form, namely I and Q representing the complex number I+jQ, while the output is a modulated RF signal having a corresponding amplitude and phase shift. The phase shift being with respect to a reference phase dictated by the local oscillator, which is also input to the converter / modulator. Several embodiments are provided including modulators incorporating dual I and Q transistor arrays, a single shared I / Q transistor array, modulators with single ended and differential outputs and modulators with single and dual polarity clock and I / Q data signals.

Owner:TEXAS INSTR INC

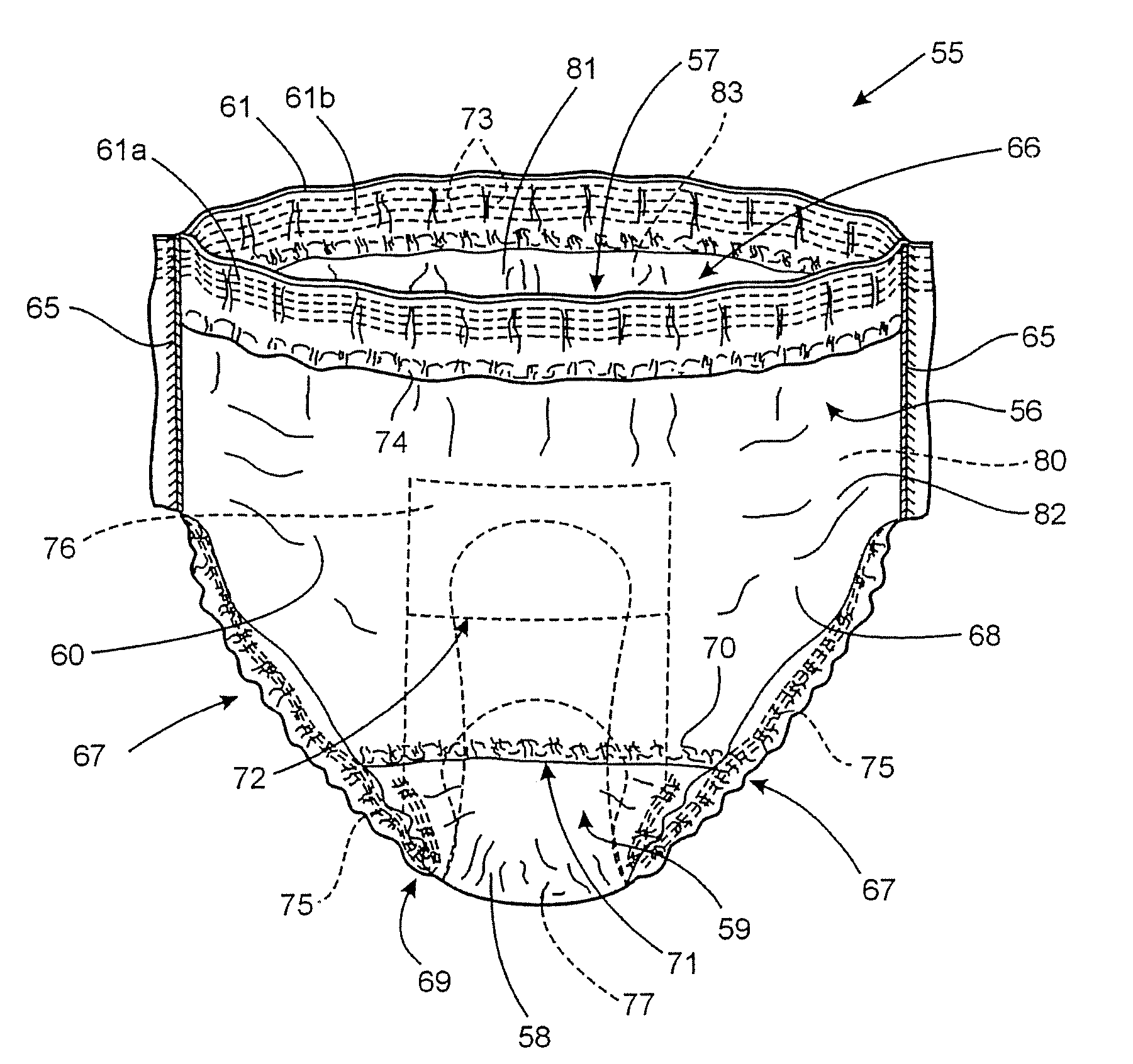

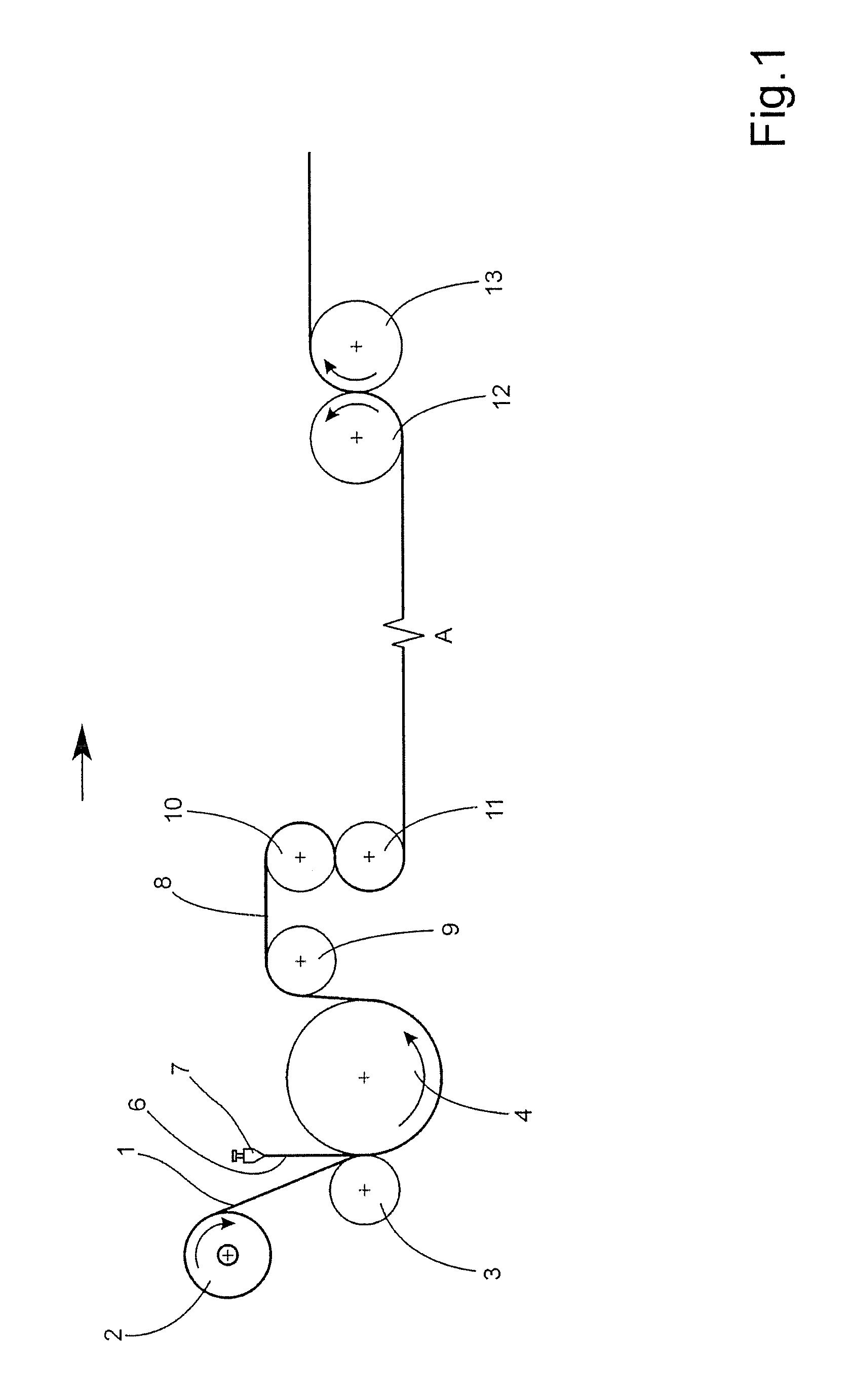

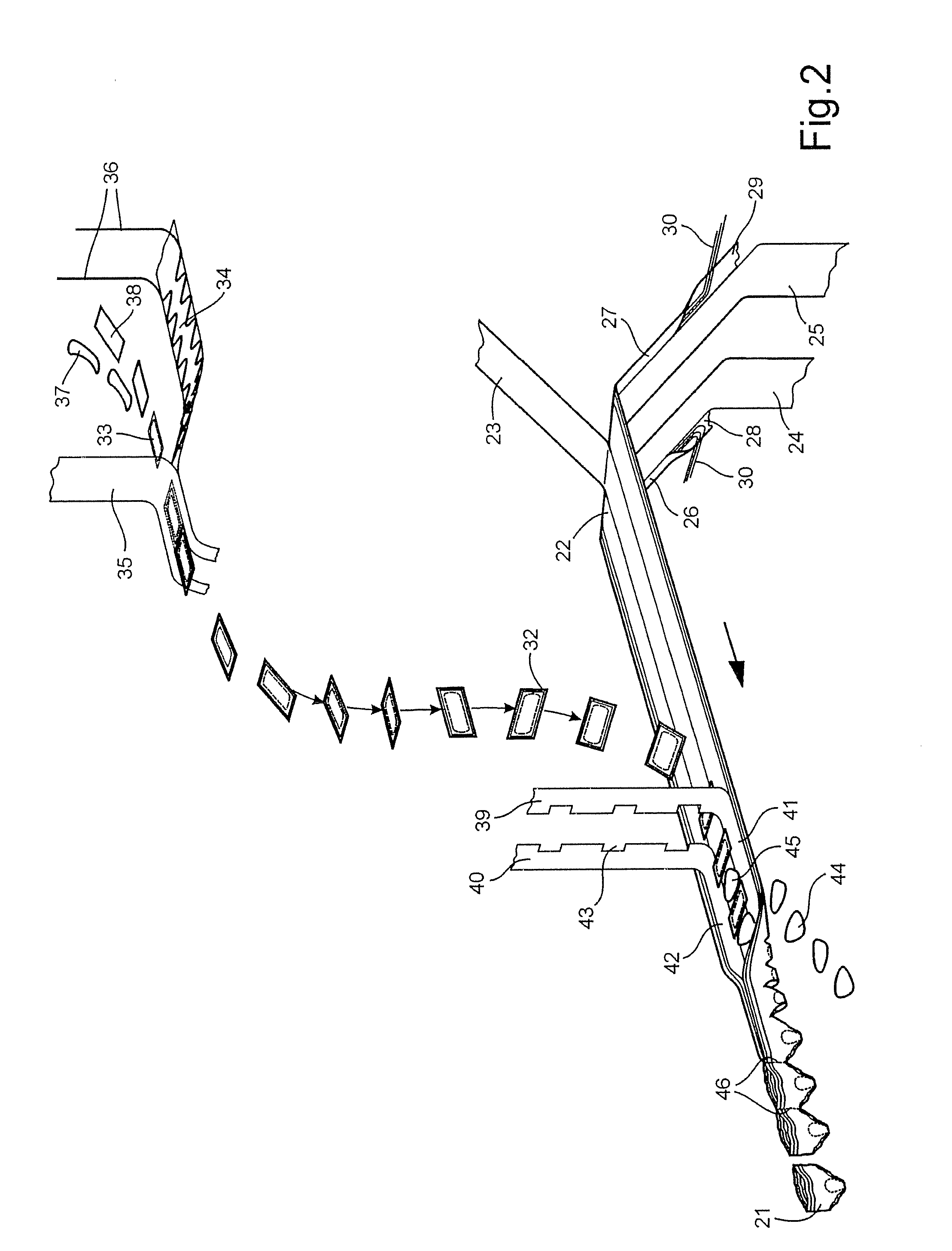

Pant-type absorbent article and a method for producing pant-type absorbent articles

InactiveUS20090326503A1Improved tensile strength in the elastic parts of the pant chassisIncrease resistanceMechanical working/deformationLamination ancillary operationsElastic fibresCore component

A method for producing pant-type absorbent articles, each article including a chassis structure having at least one elastic panel and an integrated absorbent core component, the method including a continuous pant-forming process including forming the chassis structure and incorporating the absorbent core component into the chassis structure. The at least one elastic panel is formed by a) separately producing a two-layer laminate having a first non-elastic fibrous nonwoven web and an elastic film, b) activating the two-layer laminate by incremental stretching in at least one activation direction to render the two-layer laminate (elastically stretchable, c) stretching the activated two-layer laminate by 35-200% in the activation direction, d) introducing the two-layer laminate in the pant-forming process, and e) laminating the elastic film of the stretched two-layer laminate to an elastic or nonwoven chassis component. An absorbent pant-type article produced in accordance with the method.

Owner:ESSITY HYGIENE & HEALTH AB

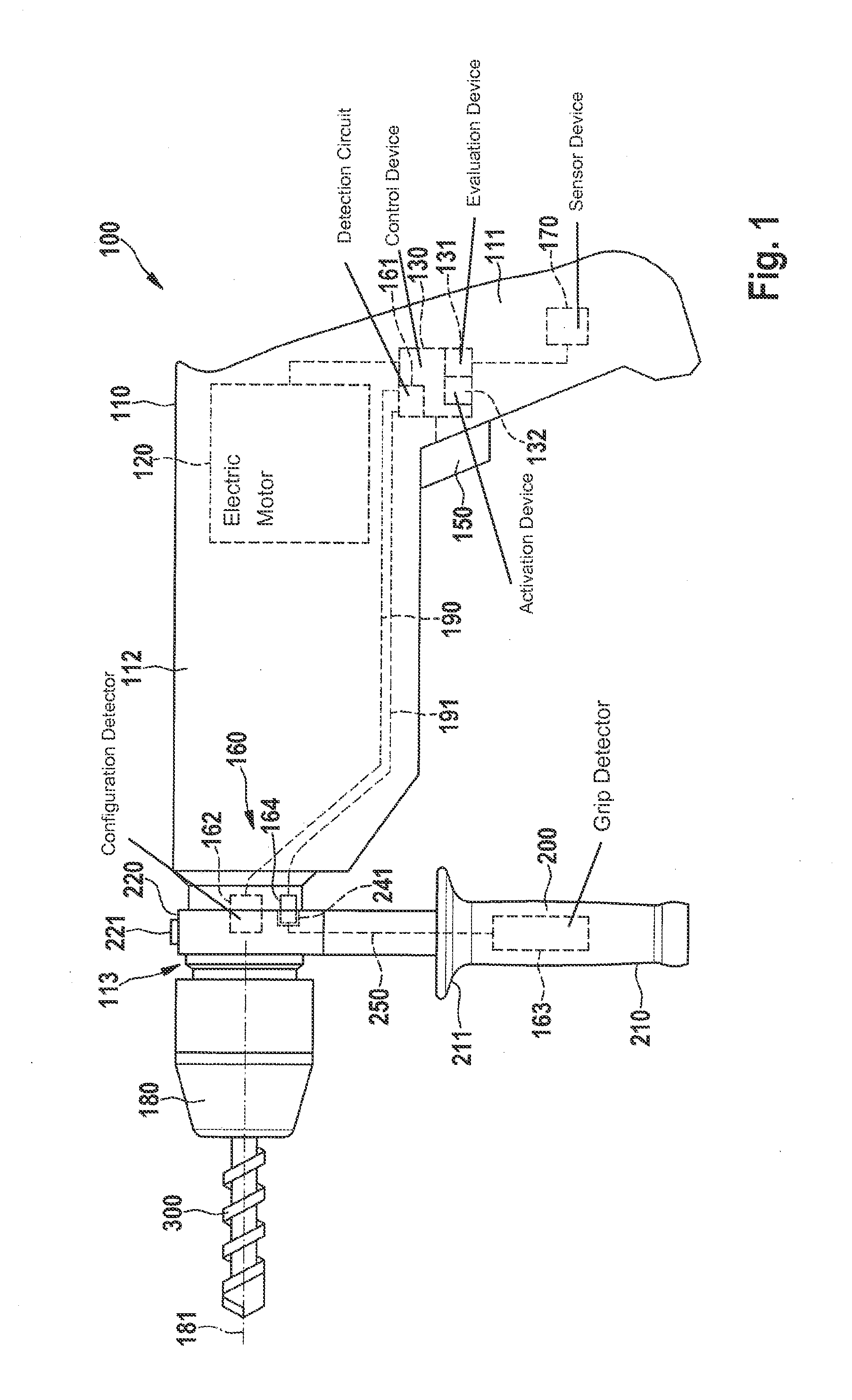

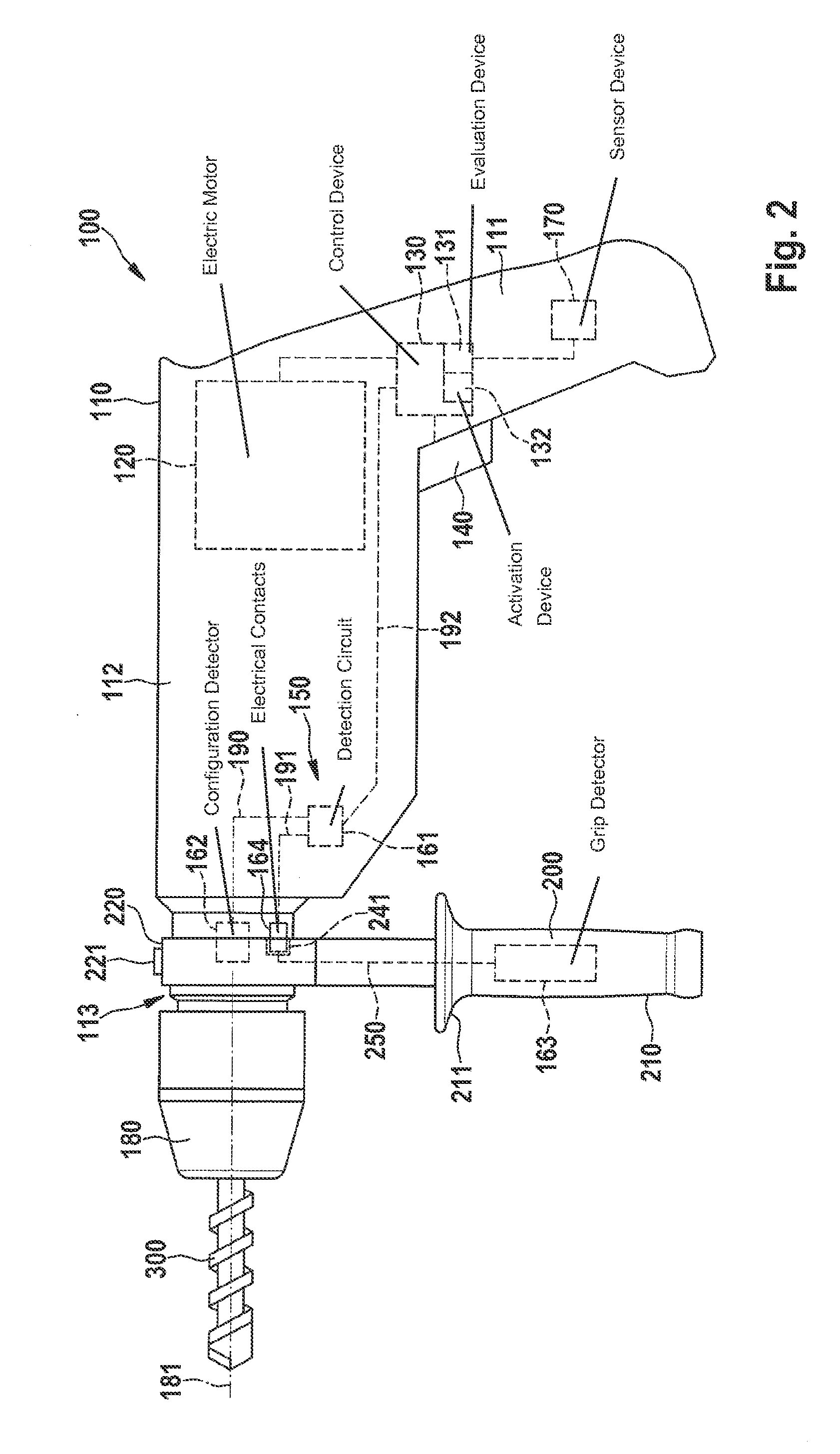

Hand-held power tool and method for operating the hand-held power tool

InactiveUS20140231113A1Operational safety is enhancedSimple adaptationDerricks/mastsPortable power-driven toolsHand heldEngineering

A method is provided for controlling an electric hand-held power tool having a device housing and a coupling device on the device housing side for securing an auxiliary handle to the device housing. It is detected whether the auxiliary handle is secured to the device housing and / or whether the auxiliary handle is gripped by a user. In addition, the instantaneous operating state is ascertained and evaluated. A protective function is activated when the occurrence of a critical operating case is recognized during the evaluation of the instantaneous operating state. It is provided that the evaluation of the instantaneous operating state and / or the activation of the protective function is / are carried out as a function of whether the auxiliary handle is secured to the device housing and / or whether the auxiliary handle is gripped by the user.

Owner:ROBERT BOSCH GMBH

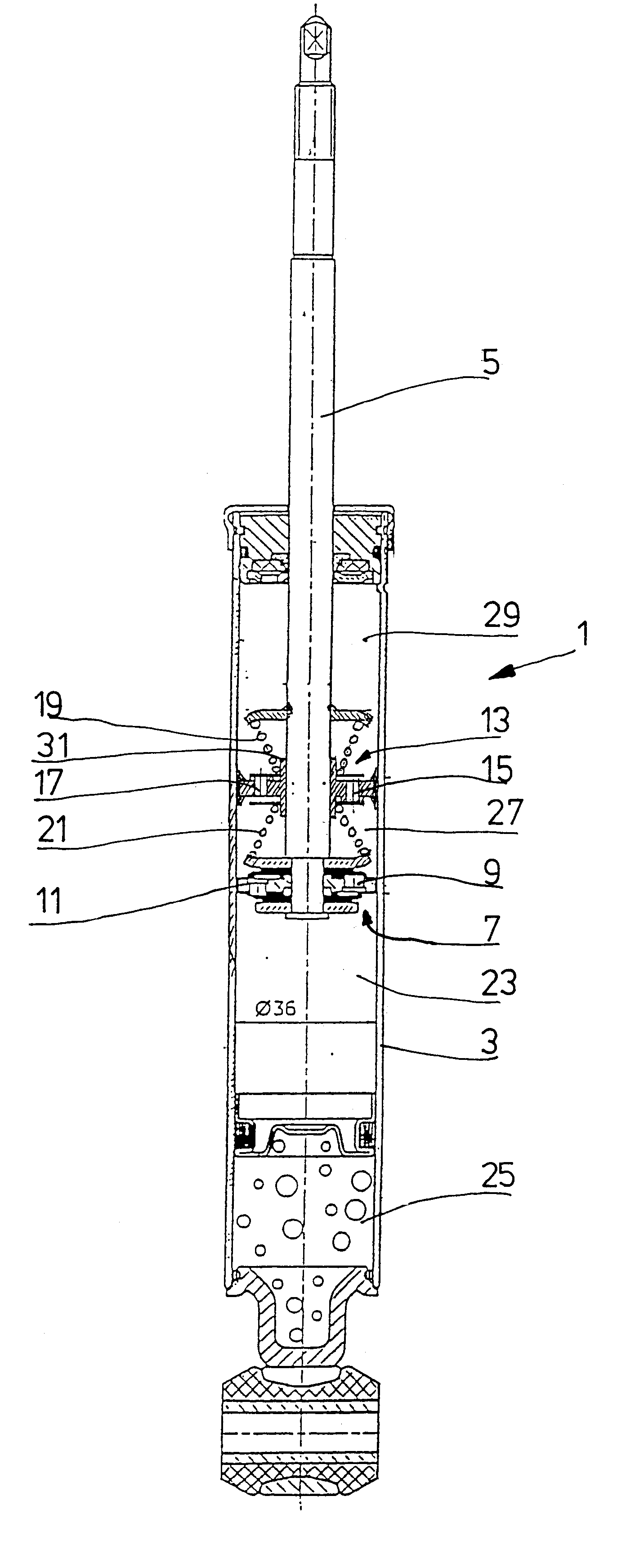

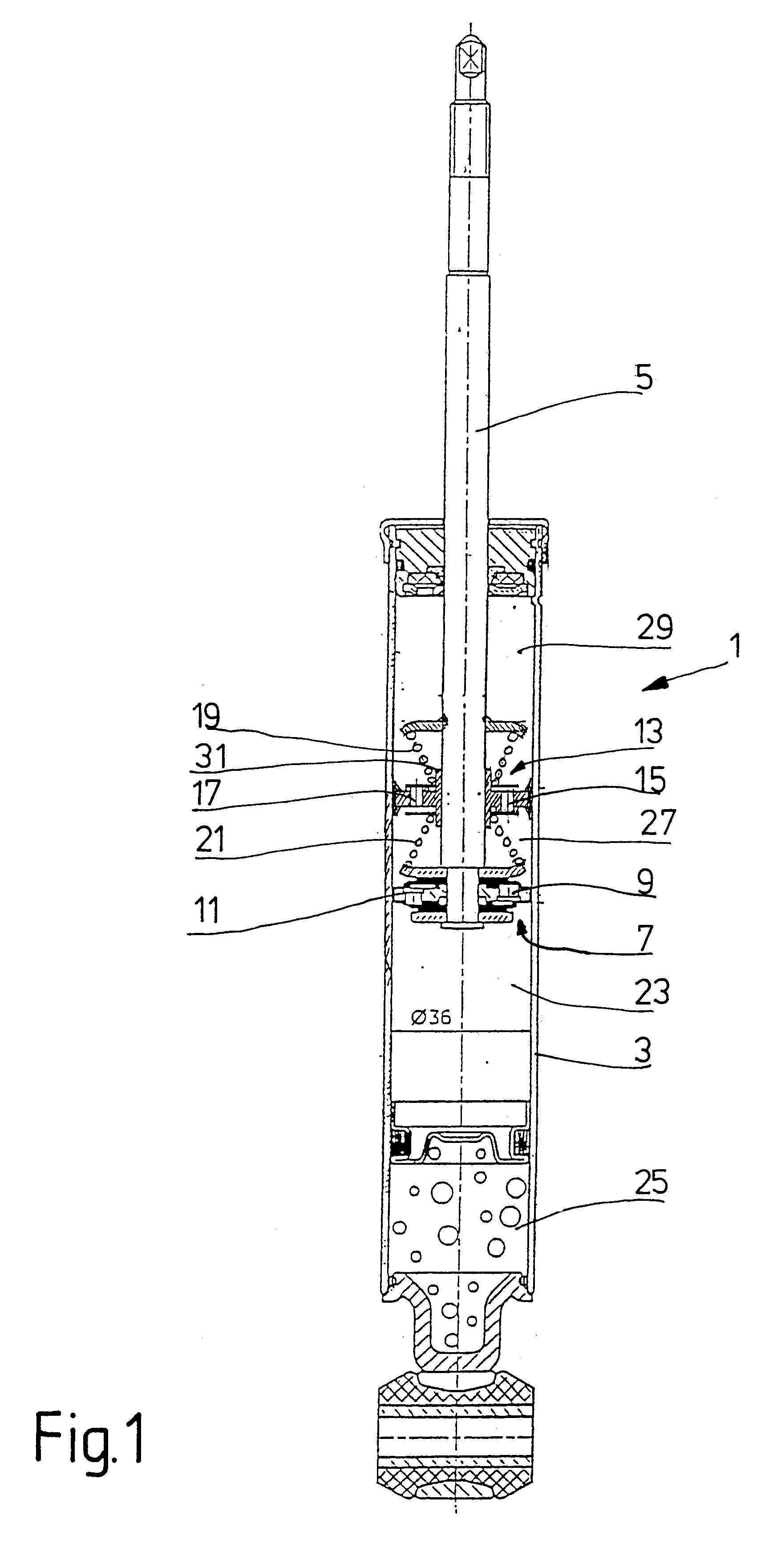

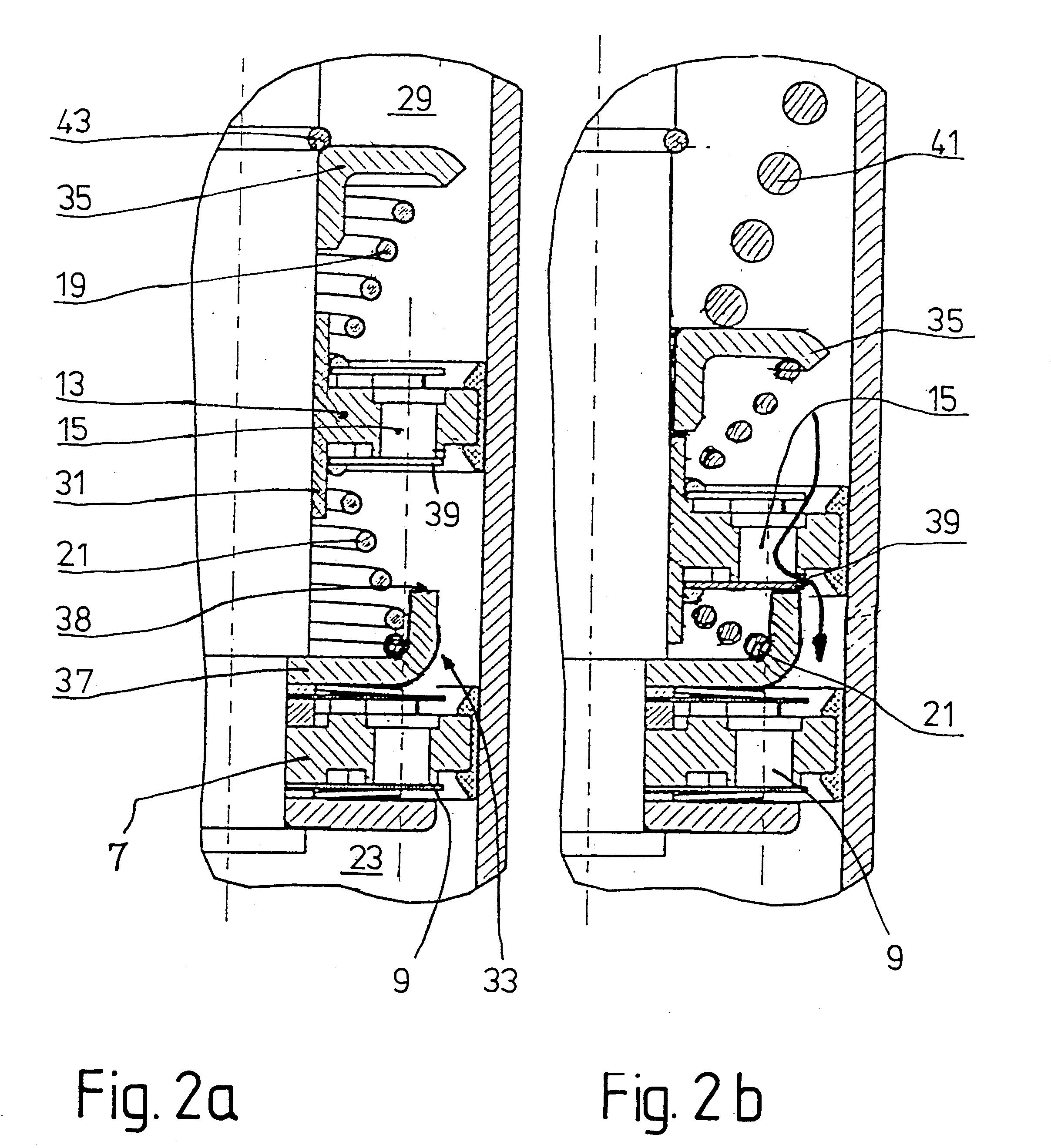

Vibration damper

InactiveUS6651787B2Reduce damping forceImprove comfortSpringsLiquid based dampersSpring forceControl theory

A vibration damper includes a cylinder in which a piston rod is guided so as to be axially movable. A first piston is mounted stationary on the piston rod and a second piston is mounted so as to be displaceable axially on the rod against a spring force. The cylinder has a work space at the piston rod side, a work space remote of the piston rod, and a work space between the two pistons. Through-openings which are outfitted with valves control a connection between the work spaces. The second piston has at least one return spring on both sides, and the piston is mounted so as to be displaceable axially in two directions against the return springs.

Owner:ZF FRIEDRICHSHAFEN AG

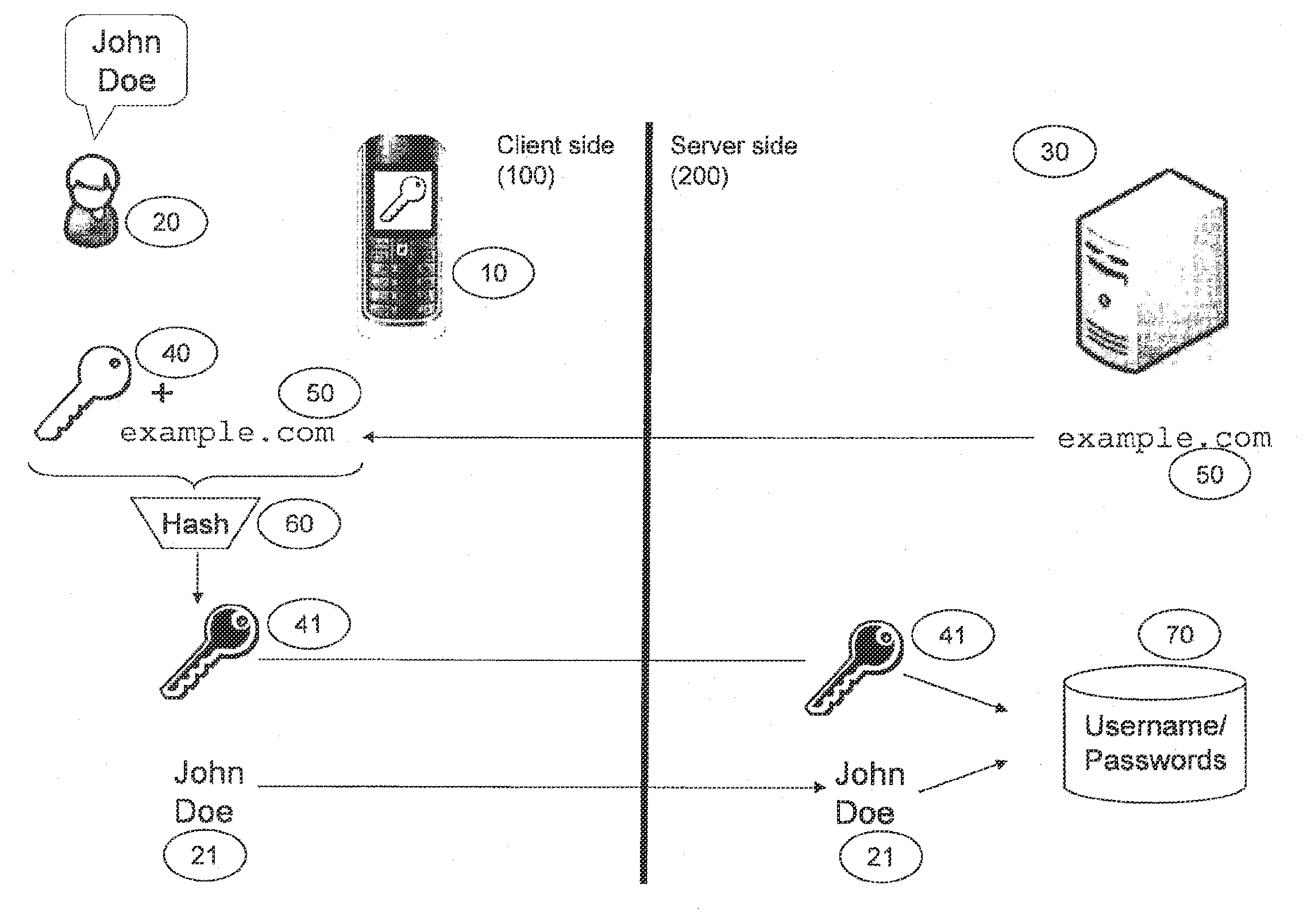

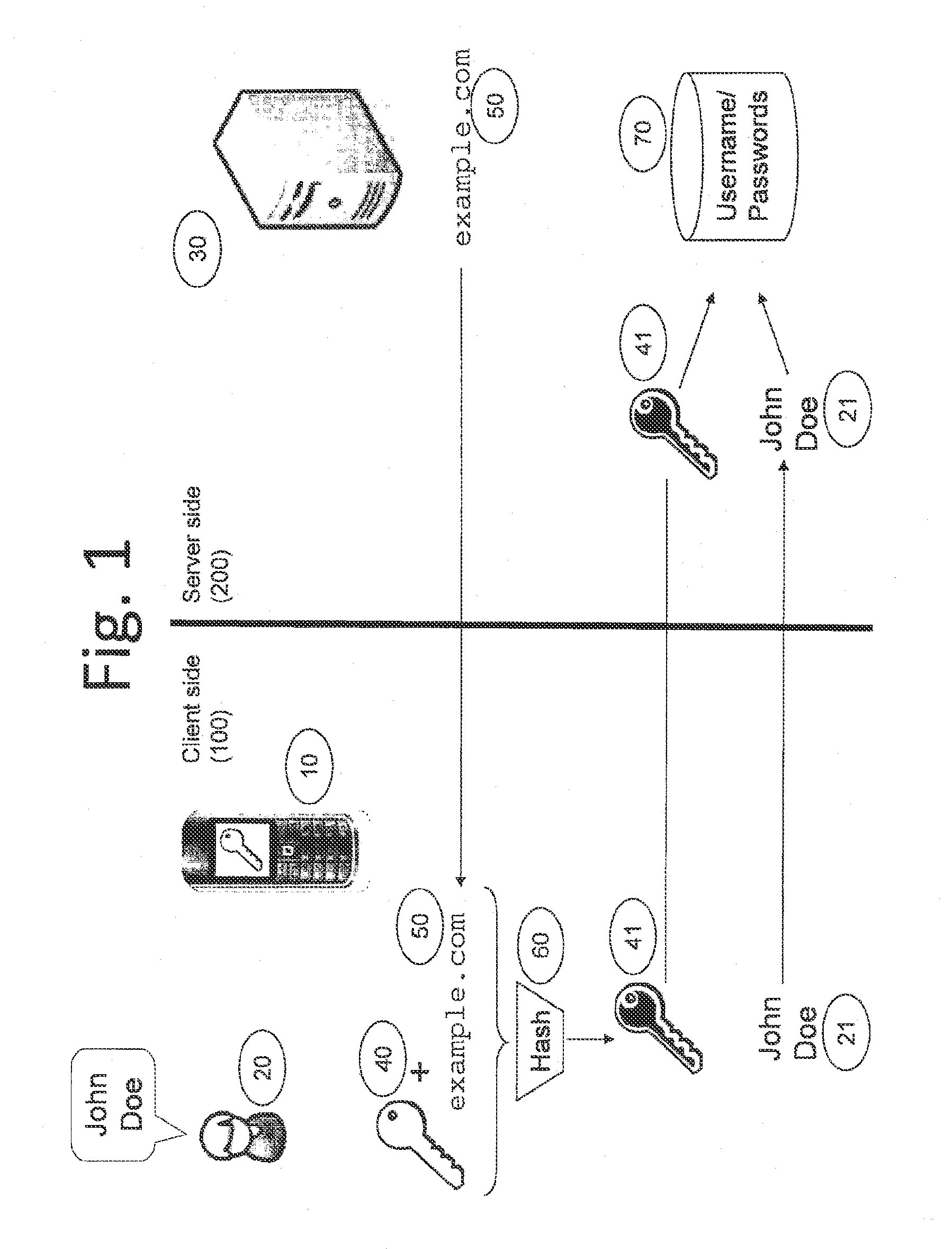

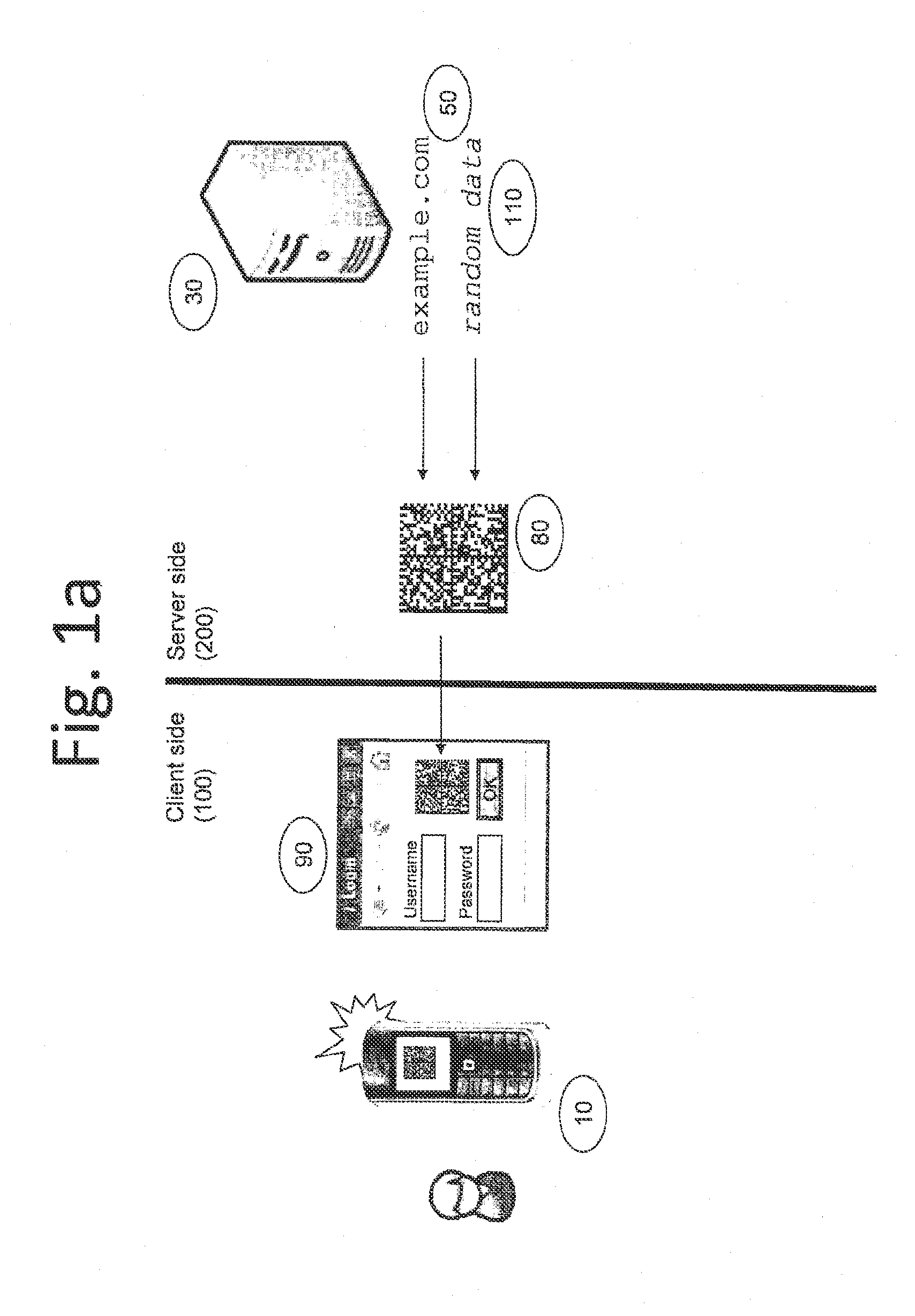

Method and system for user authentication

InactiveUS20120266224A1Simple adaptationEasier, more secure, scalable and flexibleDigital data processing detailsMultiple digital computer combinationsInternet privacySecret code

A method for user authentication for accessing from a client to a server over a packet based network using an one-time password, wherein the client includes a first secret, and the server includes a database for storing a second secret and a chosen username associated with the second secret, wherein the method includes providing the second secret associated with the first secret by the client to the server and storing the second secret and the chosen username in the database; transmitting a challenge from the server to the client; computing the one-time password by the client using the second secret and the random data decoded from the challenge; submitting the one-time password and the chosen username on the client to access the server; validating the one time password received from the client with the one-time password.

Owner:NEC EUROPE LTD

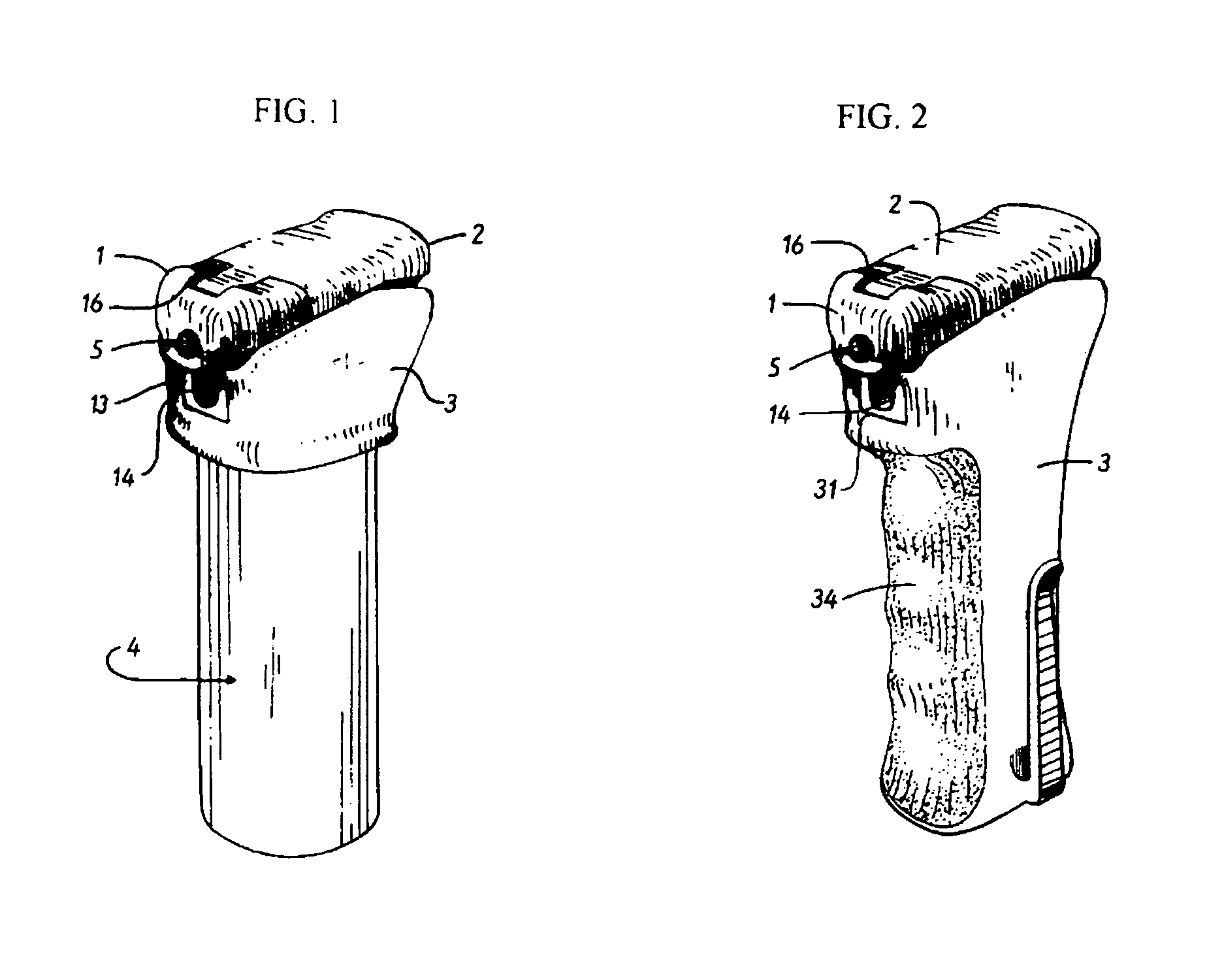

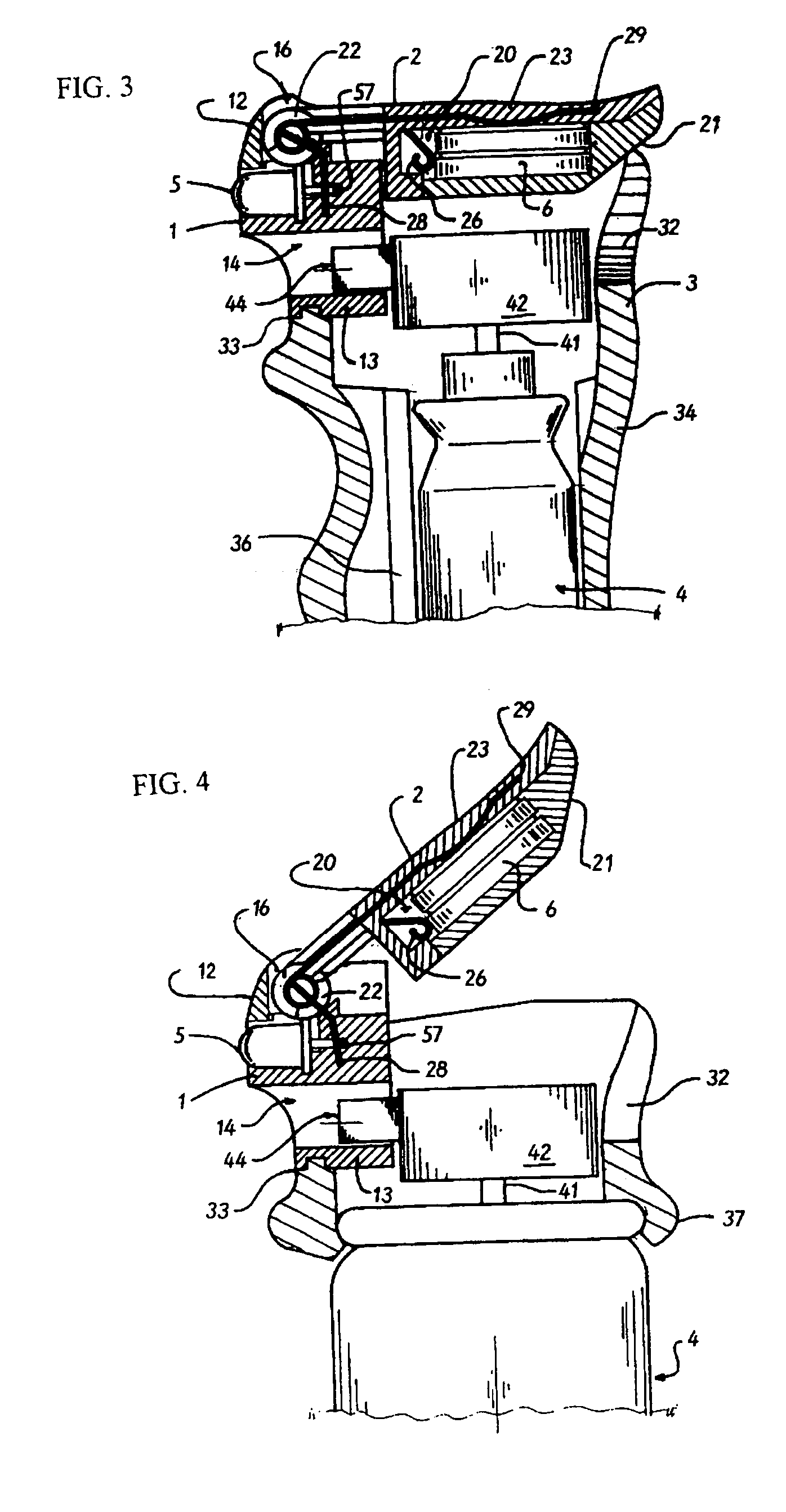

Control unit for a light source in combination with a spray defense container

ActiveUS7121432B2Minimized in sizeSimple adaptationLighting elementsSighting devicesCouplingEngineering

Owner:KOSTAL BRETISLAV +1

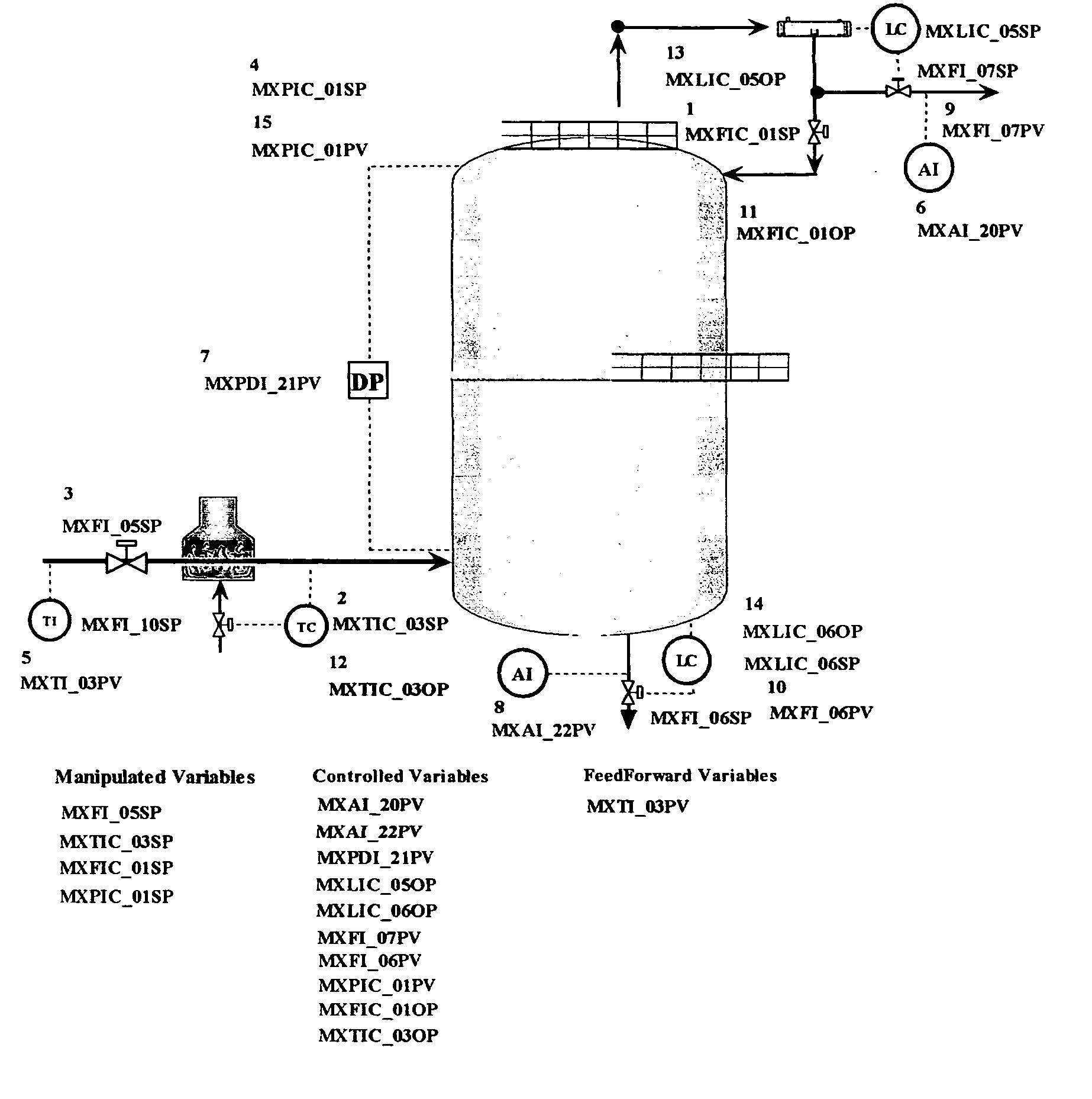

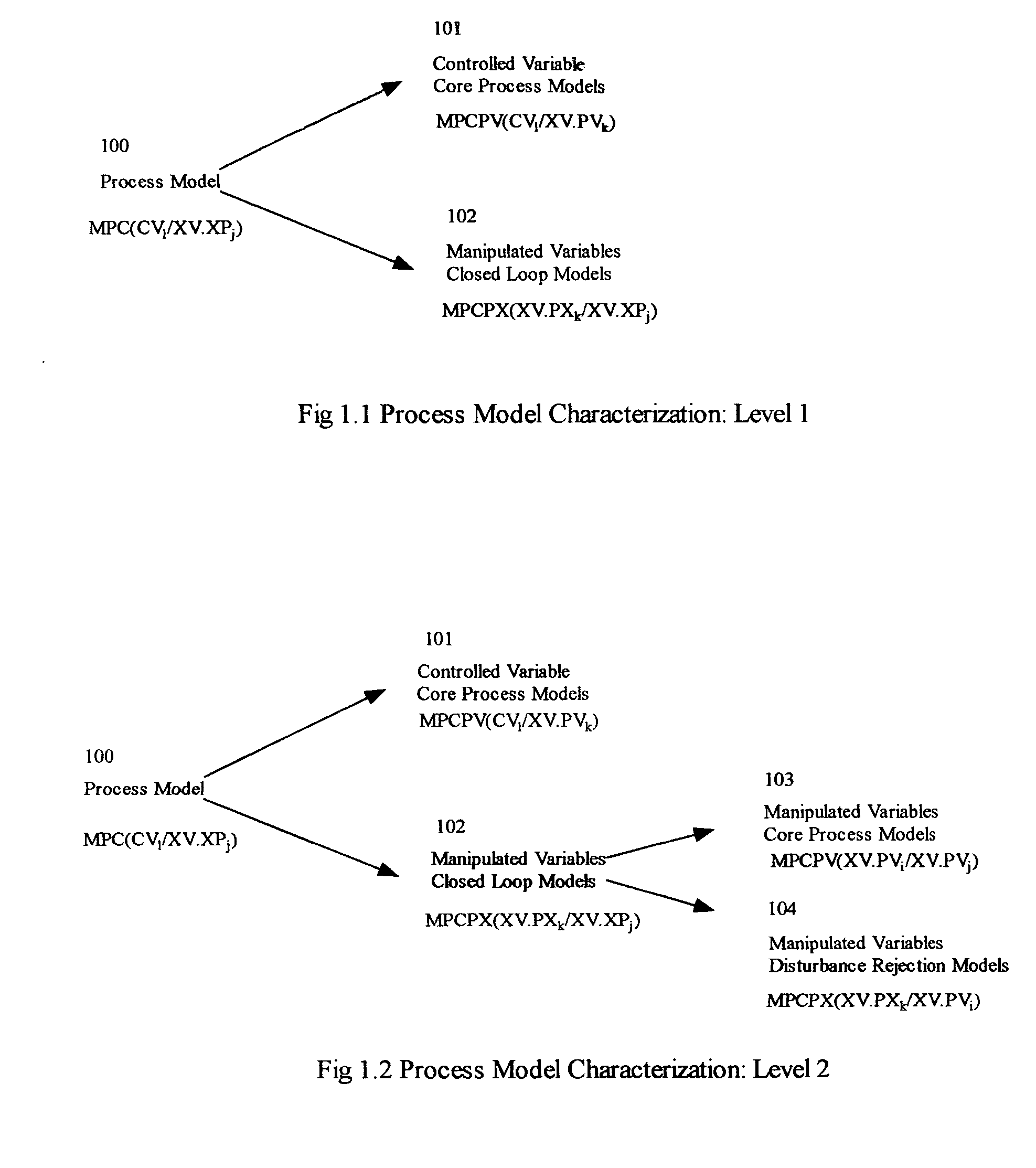

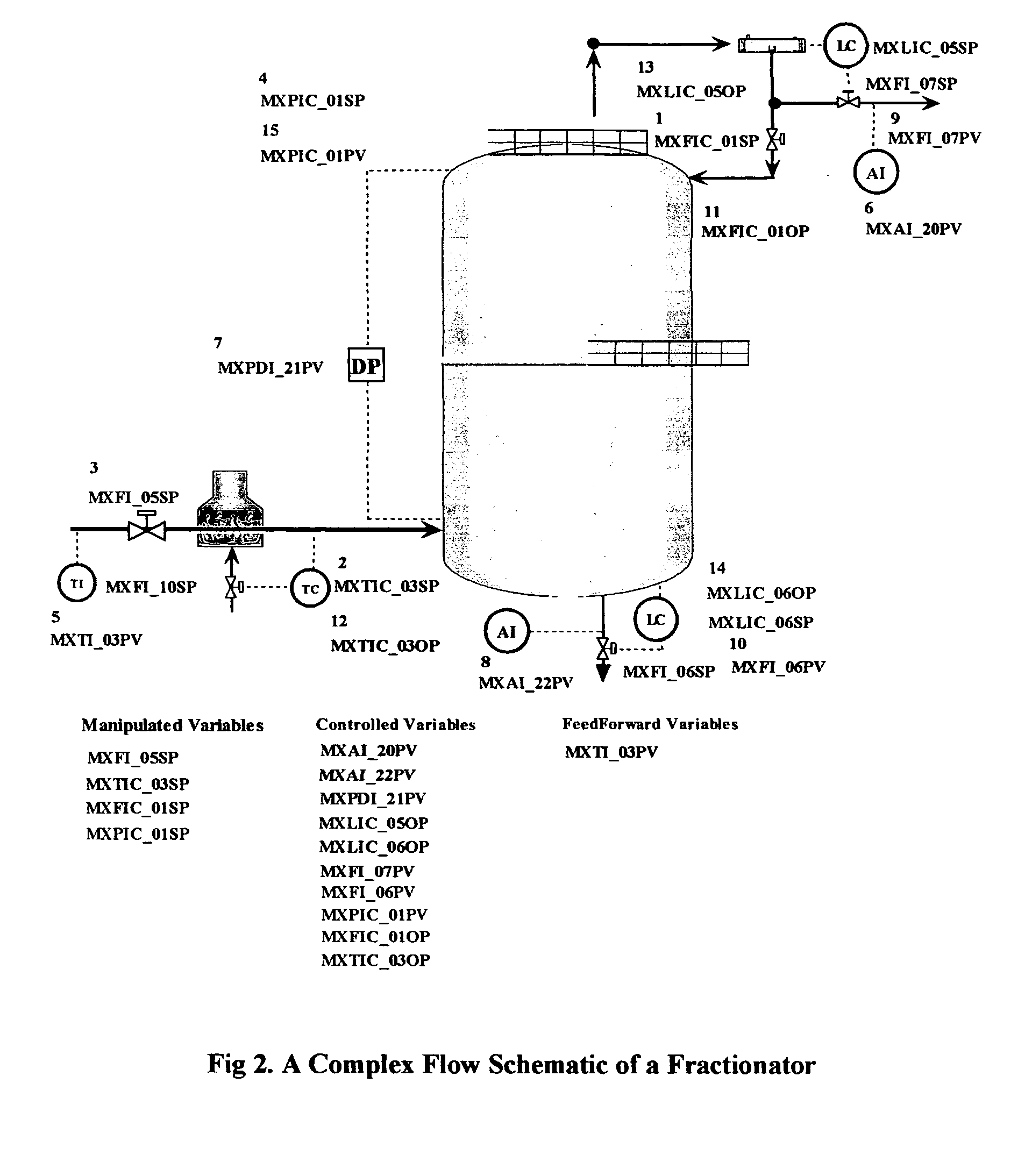

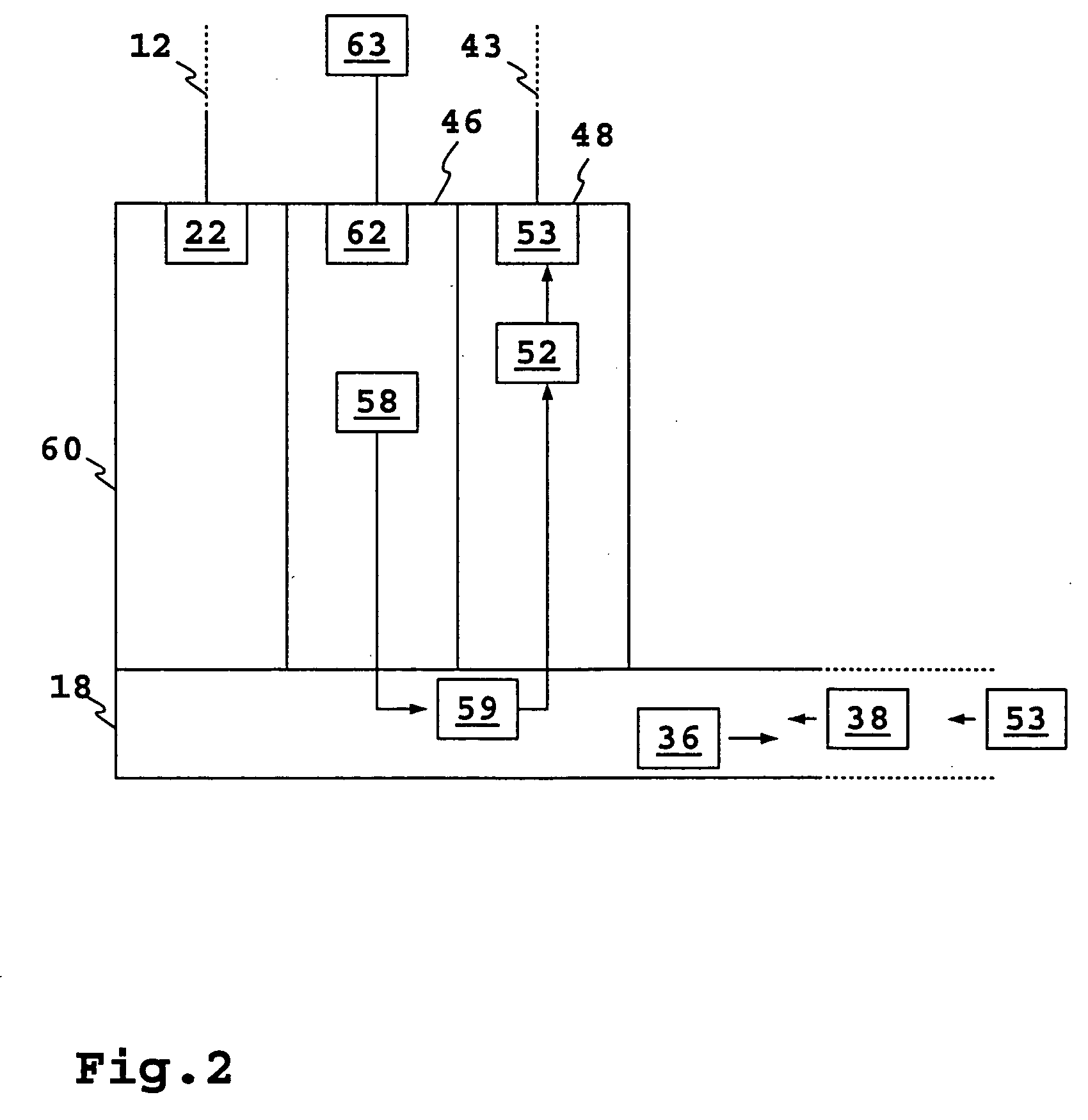

Use of core process models in model predictive controller

InactiveUS20050137721A1Simple adaptationComputer controlSimulator controlControl variableEngineering

A method is presented for updating process models (100) used in a model predictive controller when a change has been made in any regulatory controller configuration and / or it's tuning without having to conduct new full identification testing of the process. The method employs Core Process Models of Controlled Variables (101) and Manipulated Variables (103), devoid of dynamics of interacting regulatory controllers in conjunction with Manipulated Variables Disturbance Rejection Models (104). The process models (100) can be updated for use for on-line control as well as for off-line simulation studies including operator training. This allows updating of a complex multivariable process control with relatively ease with absolute minimal of additional data gathering.

Owner:ATTARWALA FAKHRUDDIN T

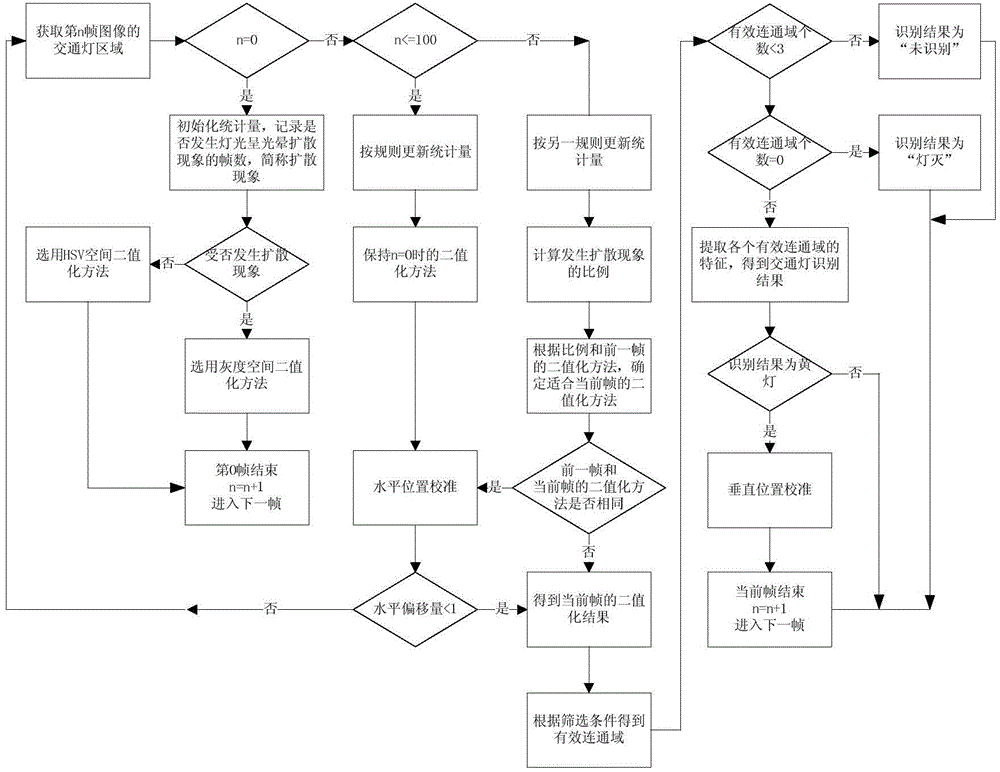

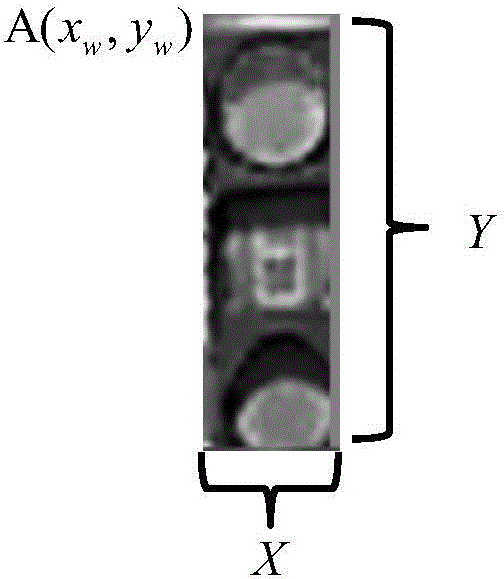

Traffic light recognition method

ActiveCN104574960ASimple adaptationAccurate identificationDetection of traffic movementCharacter and pattern recognitionColor spaceBrightness perception

The invention discloses a traffic light recognition method. The method comprises steps as follows: performing binarization on the brightness component of the HSV color space of a traffic light target area in advance, acquiring a binarization result and extracting connected domains representing a traffic light bright area from the result through switching between an RGB space gray binarization method and an HSV color space binarization method on the basis of the area characteristic of the maximum connected domain, meanwhile, calibrating horizontal coordinates of a traffic light target by using difference between bright components of traffic light images in front and back frames, then designing a classifier, acquiring a classification recognition result of the traffic light target according to the number, colors and position characteristics of the extracted connected domains, and finally, when the traffic light is a yellow light, calibrating the vertical position of the traffic light target by using the vertical coordinate of the yellow light. The method has the advantages that the method is simple to implement, high in recognition accuracy, high in adaptability to different crossroad environments and low in computational complexity, fewer resources are occupied, and positions of the traffic lights can be calibrated.

Owner:宁波中国科学院信息技术应用研究院

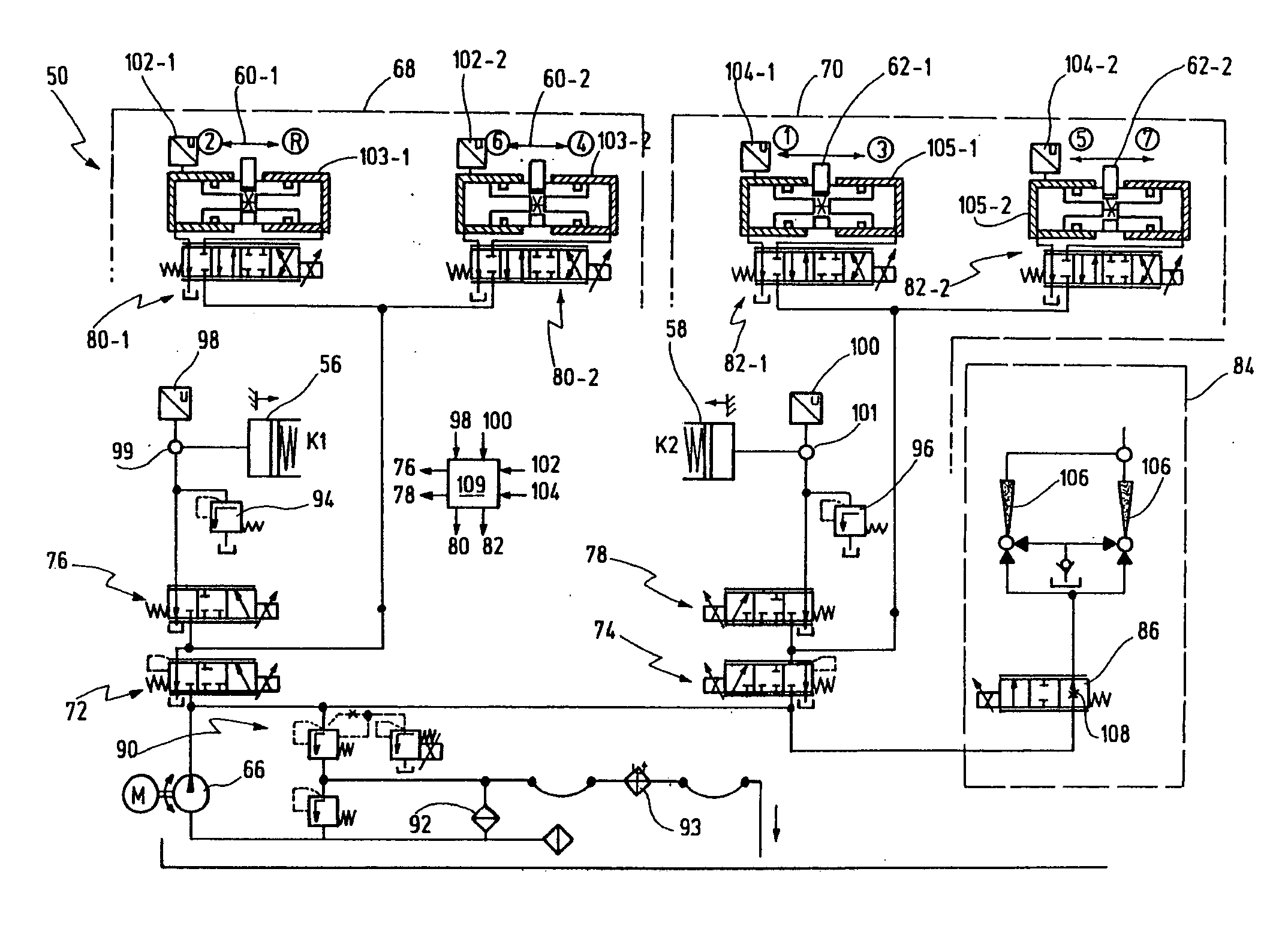

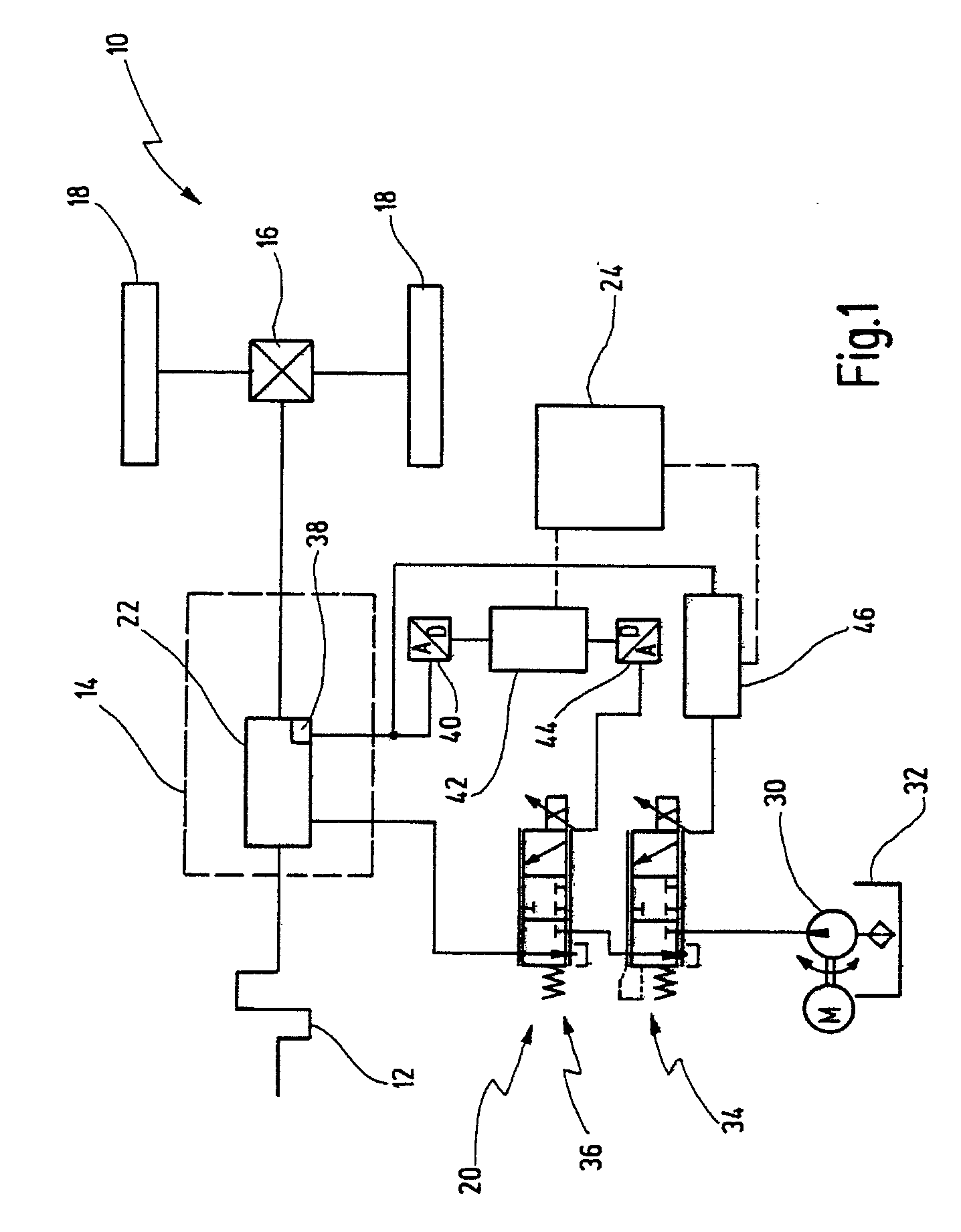

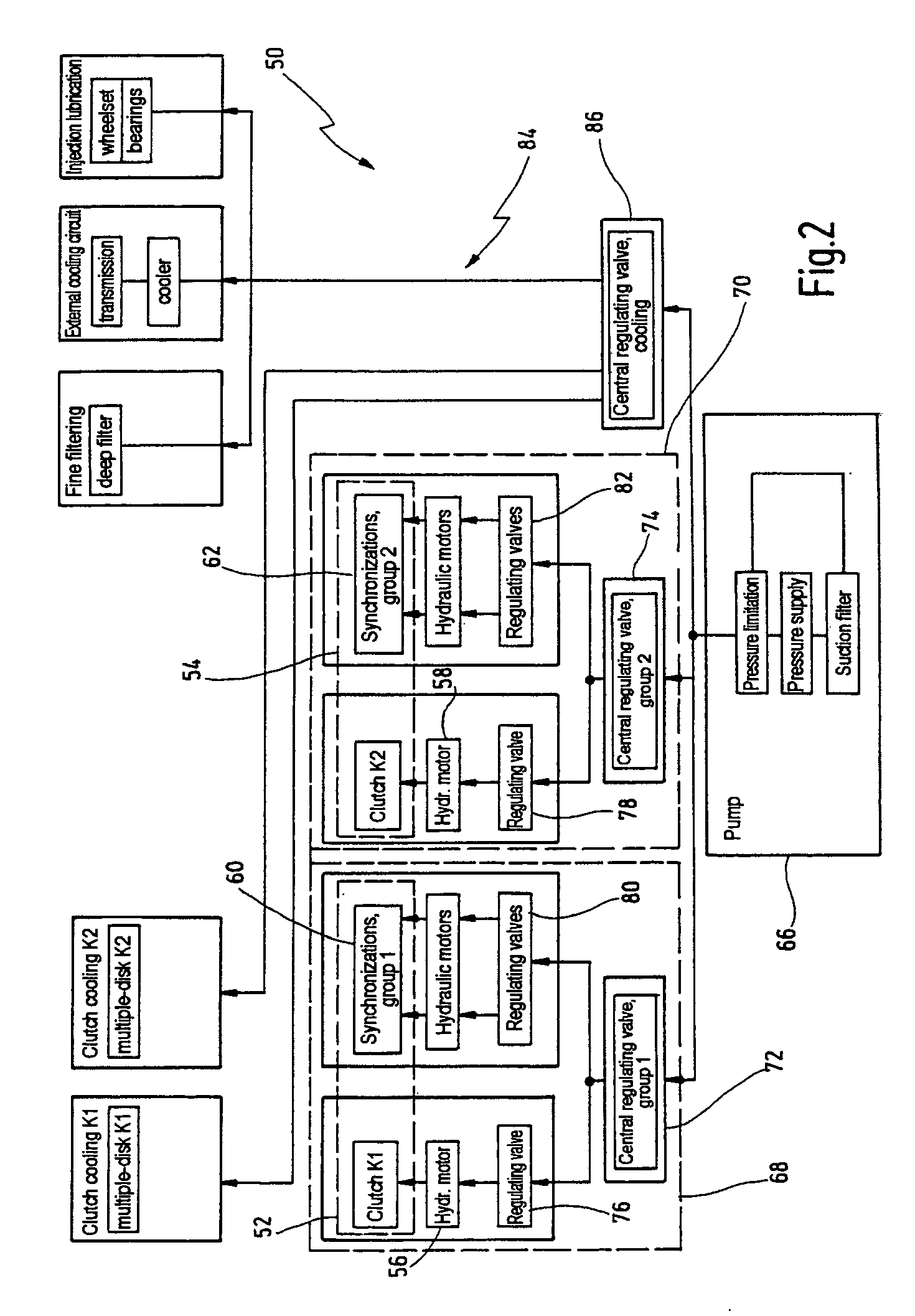

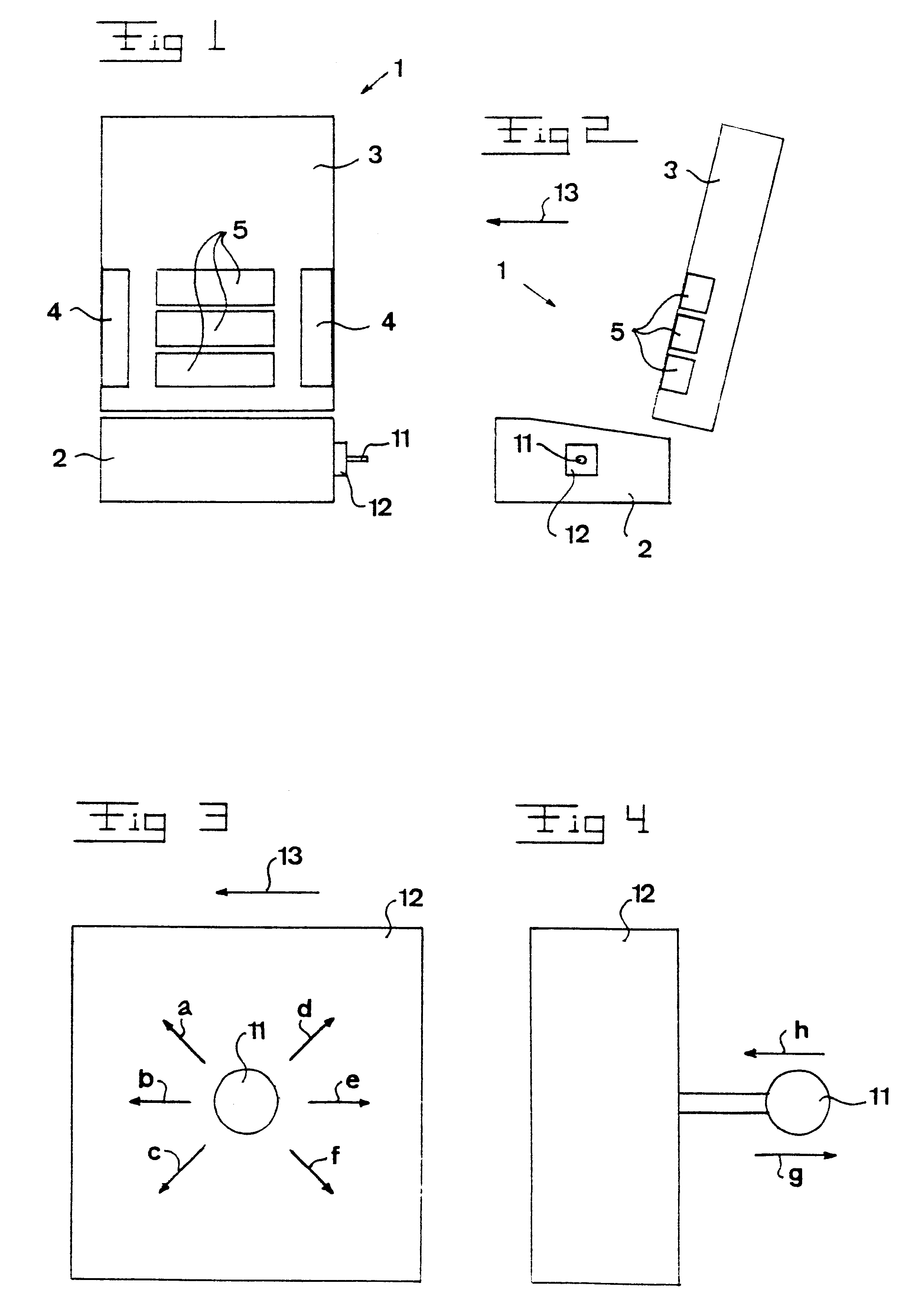

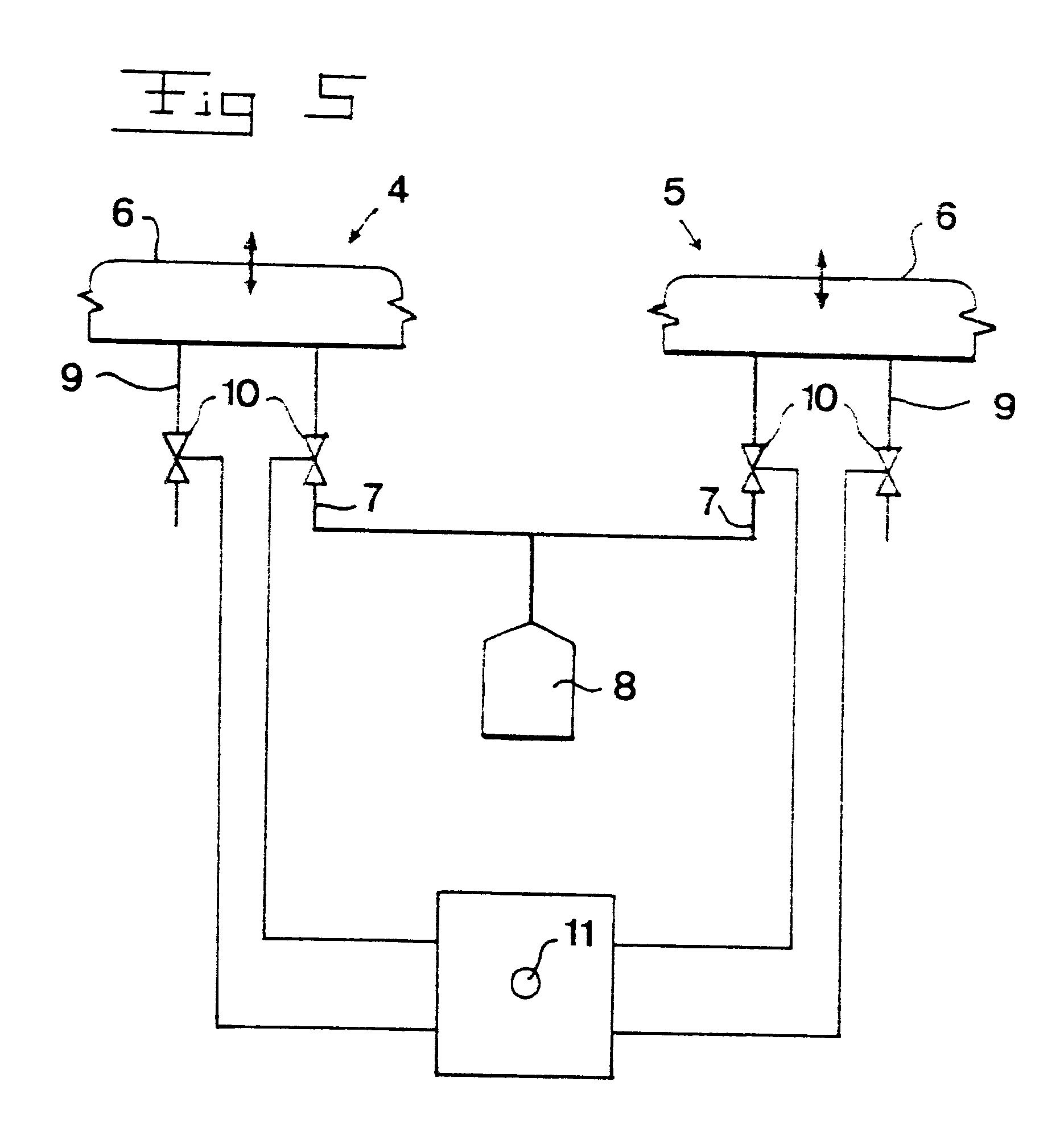

Hydraulic circuit for the control of a drive train

InactiveUS20060150762A1Possible to connectSimple adaptationToothed gearingsGearing controlVariatorEngineering

A hydraulic circuit for the control of a double clutch transmission which has two transmission groups, each with an isolating clutch and with a plurality of shift clutches for the engagement and disengagement of gear steps, the hydraulic circuit having for each transmission group a specific hydraulic branch connected to a pump in each case via a safety valve, and each hydraulic branch having in each case a clutch control valve for controlling the assigned isolating clutch and at least one shift control valve for controlling the assigned shift clutches. Here, the safety valves are designed in each case as proportional pressure regulating valves.

Owner:GETRAG GETRIEBE & ZAHNRADFABRIK HERMANN HAGENMEYER GMBH & CO KG

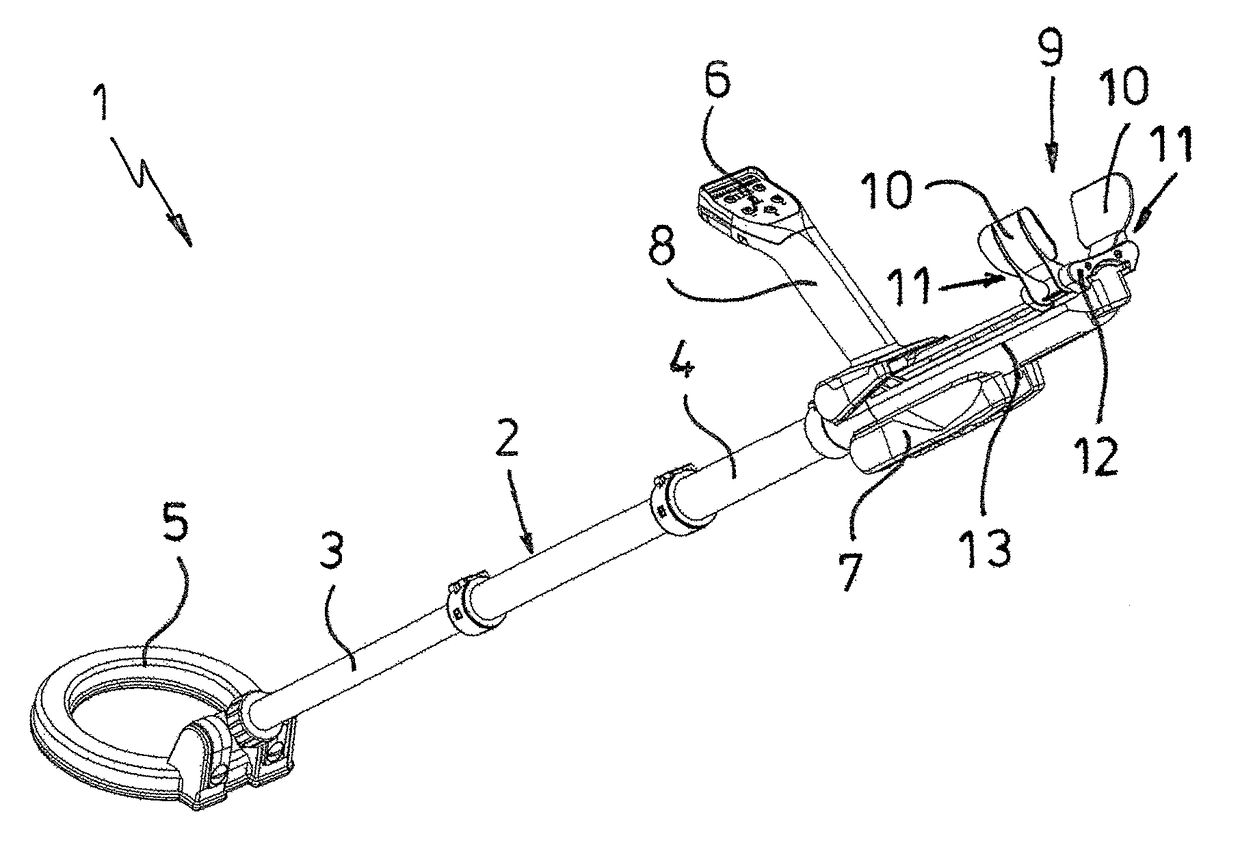

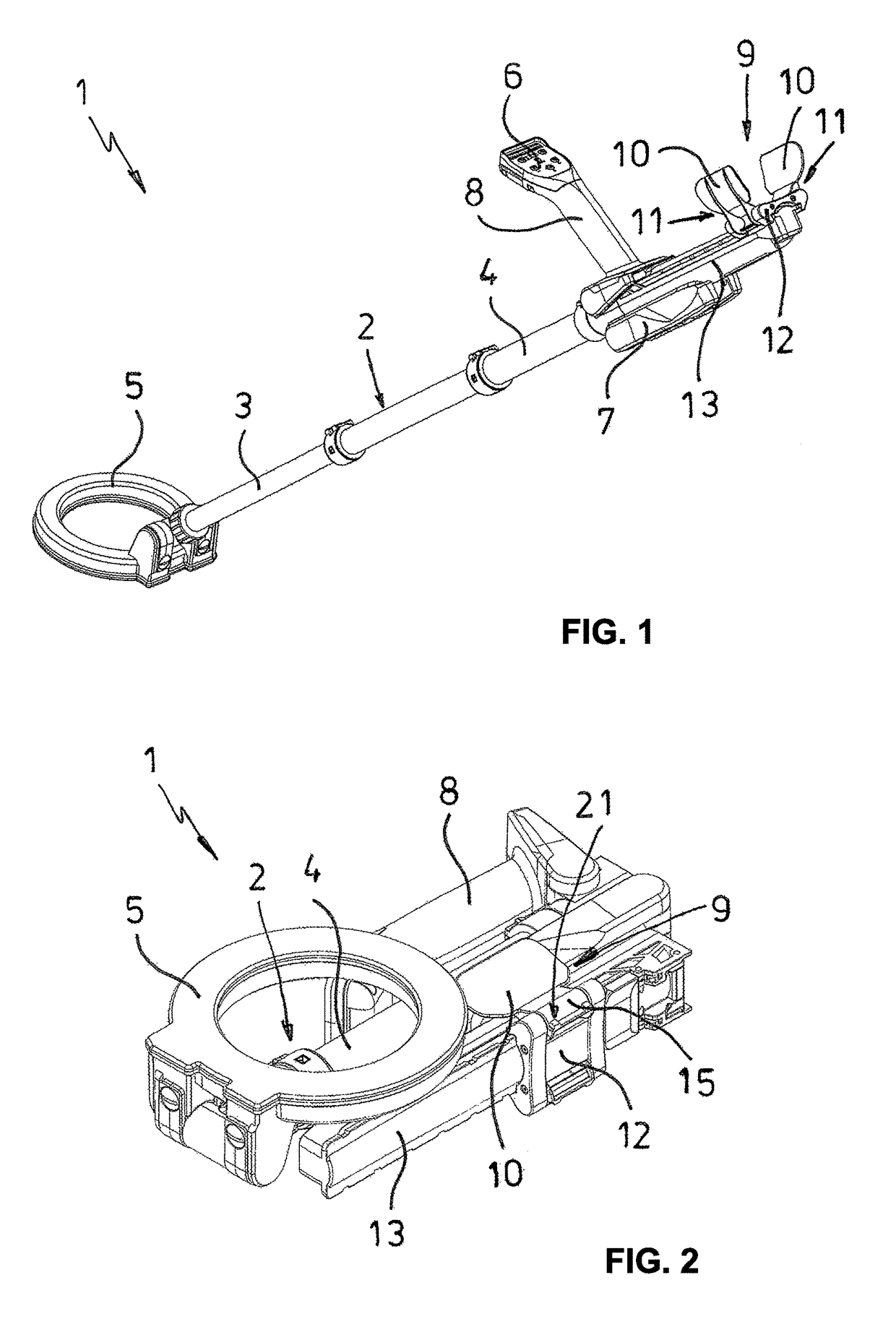

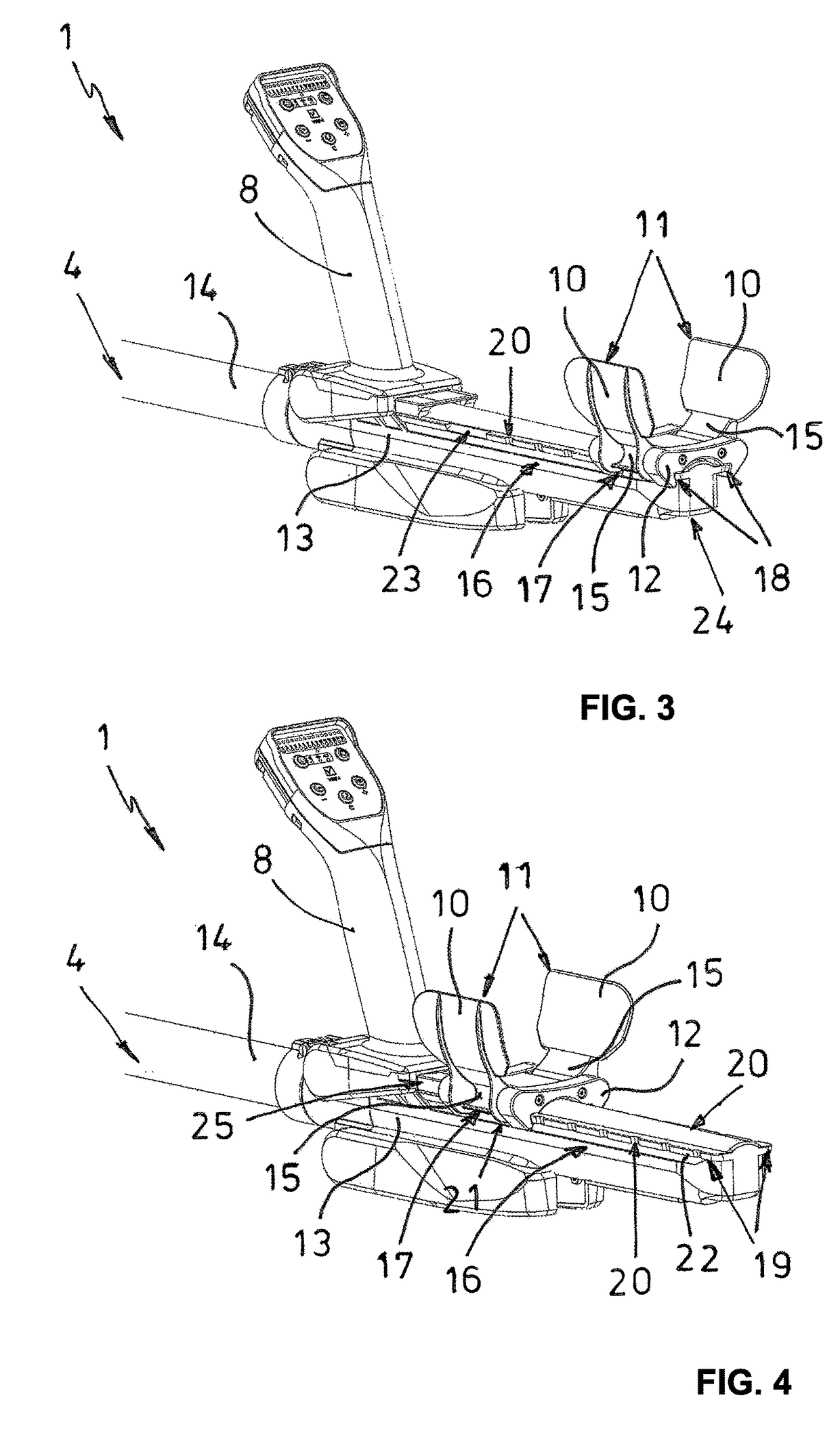

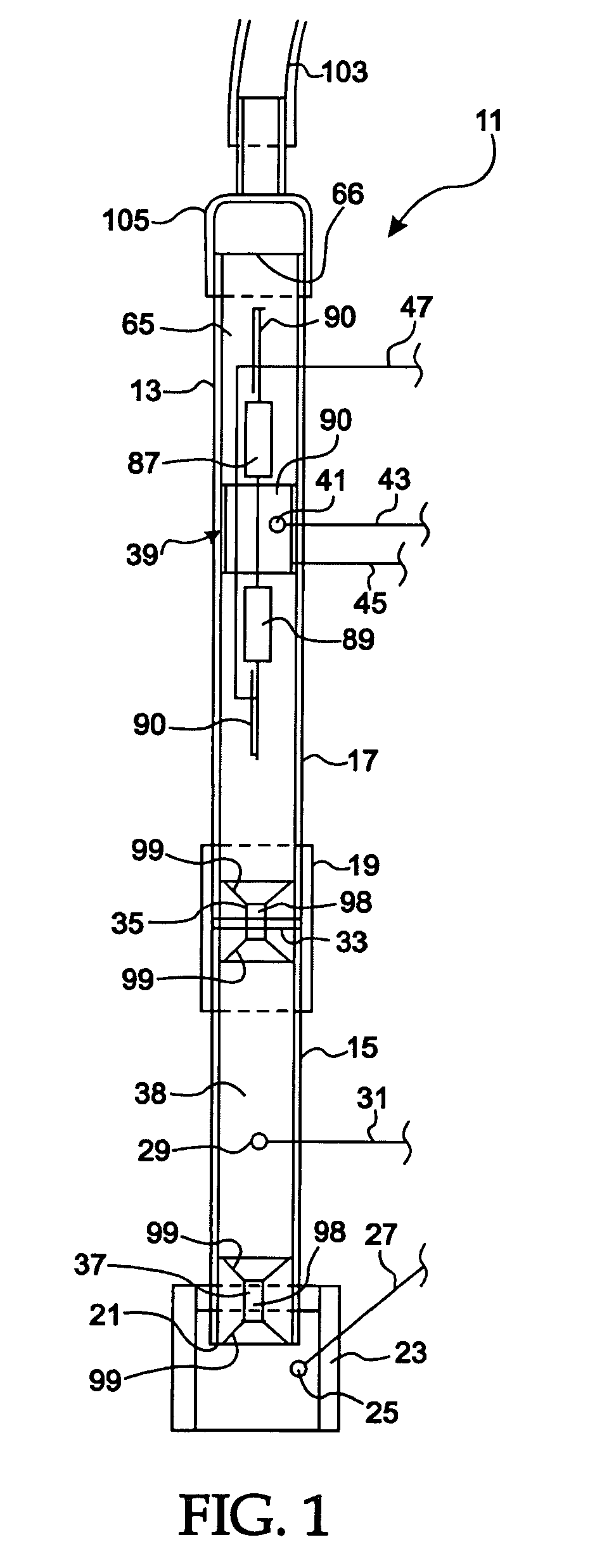

Detector with telescoping support pole and foldable arm support

ActiveUS9864089B2Simple adaptationAdjustable distanceDefence devicesElectric/magnetic detection for transportEngineeringShell element

A detector with a telescoping support tube wherein a measuring probe is arranged at a front of a forward tube element and an electronics unit with a battery compartment, a handle element and axially offset rearward therefrom a U-shaped arm shell with two arm support bars are arranged at a rear tube element, wherein the arm support bars are pivotable relative to the rear tube element. The arm shell is axially moveable relative to the handle element and includes two arm shell elements which are laterally arranged at a support slide and pivotably moveable in a transversal direction of the support tube. The support slide is supported axially moveable by a support rail. According to the invention it is provided that the support slide is fixateable in a disengageable manner at the support rail at various locations through the arm shell elements.

Owner:VALLON 72800 ENINGEN DE

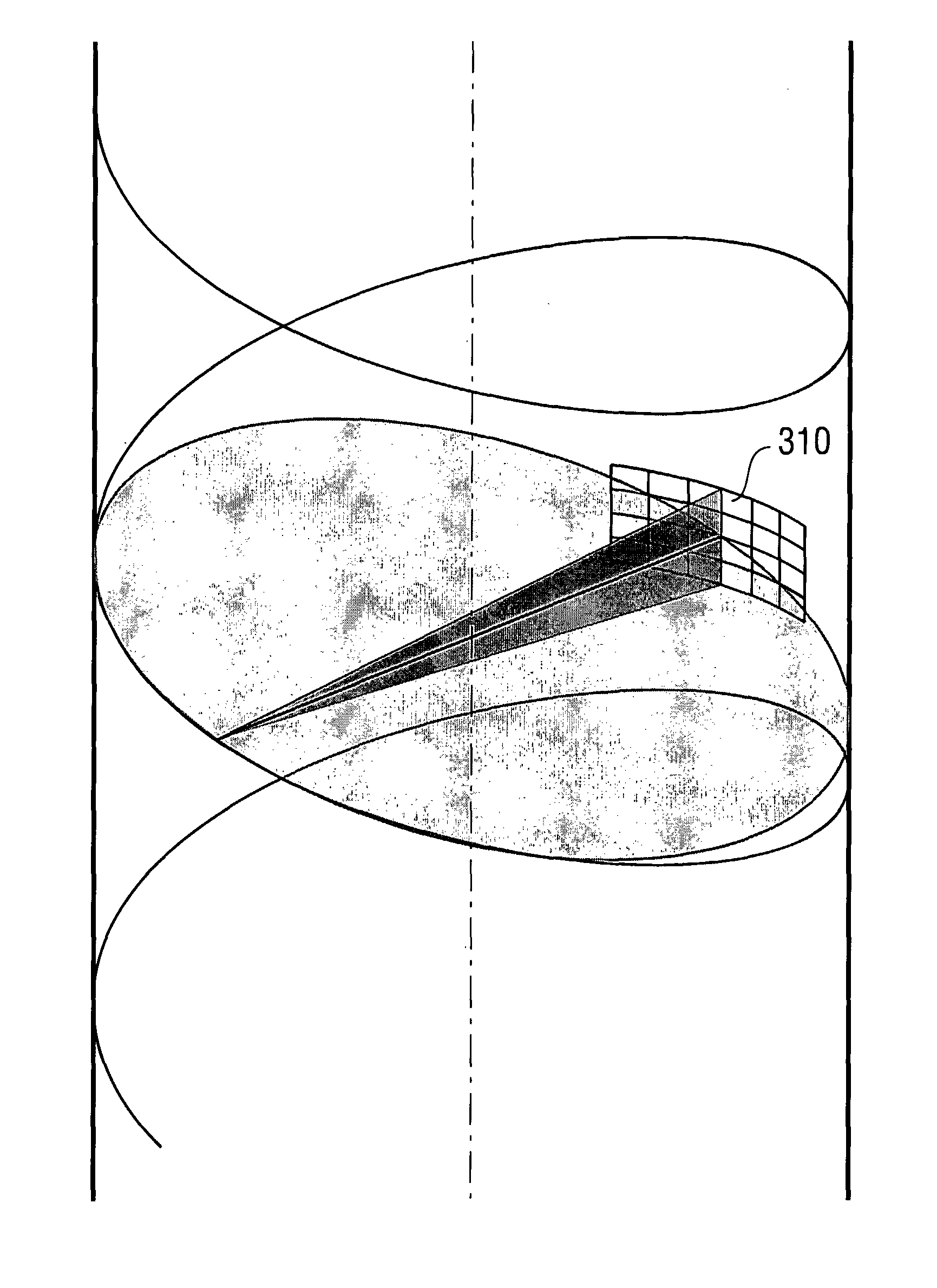

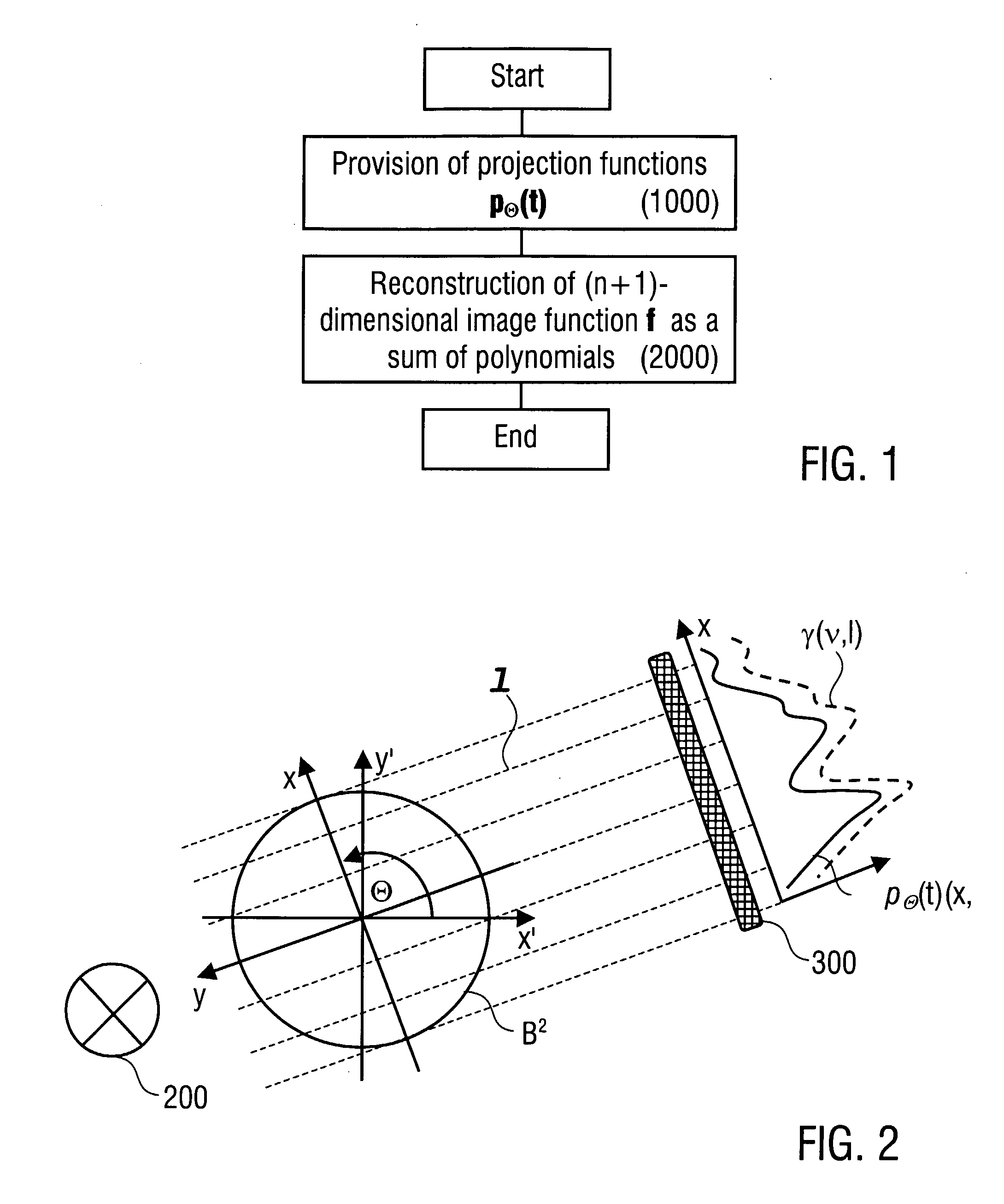

Method and Device of Reconstructing an (N+1)-Dimensional Image Function from Radon Data

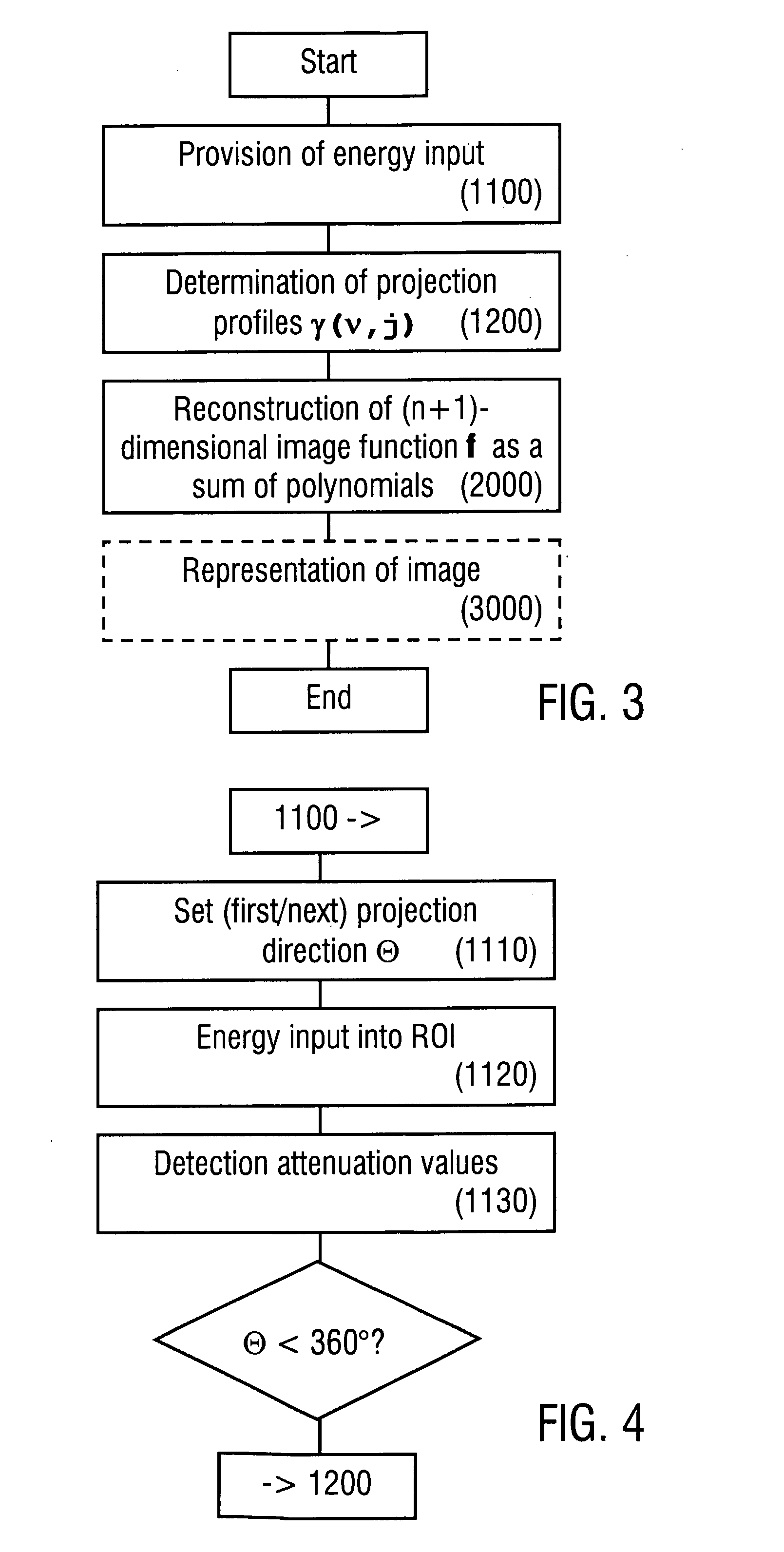

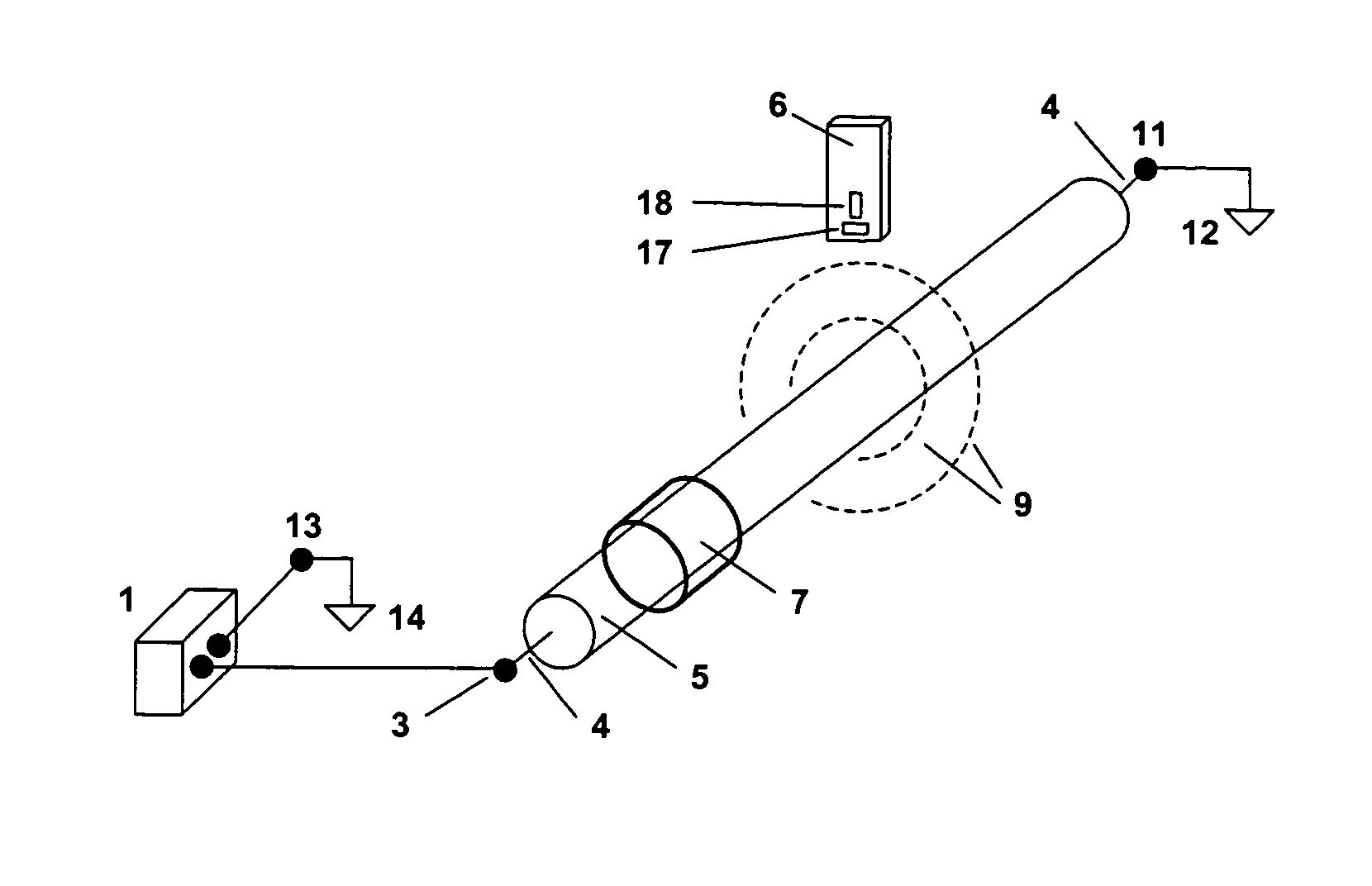

InactiveUS20080130974A1Reduce in quantityLow computing performanceReconstruction from projectionCharacter and pattern recognitionReconstruction methodTomography

A method of reconstructing an (n+1)-dimensional image function ƒ representing a region of investigation comprises determining the image function ƒ from n-dimensional or less dimensional Radon data comprising a plurality of projection functions pθ(t) measured corresponding to a plurality of predetermined projection directions (Θ), wherein the image function ƒ is determined as a sum of polynomials multiplied with values of the projection functions pθ(t). Imaging methods, imaging devices, and computer tomography devices using this reconstruction method are described.

Owner:HELMHOLTZ ZENT MUNCHEN DEUTES FORSCHUNGSZENT FUR GESUNDHEIT & UMWELT +1

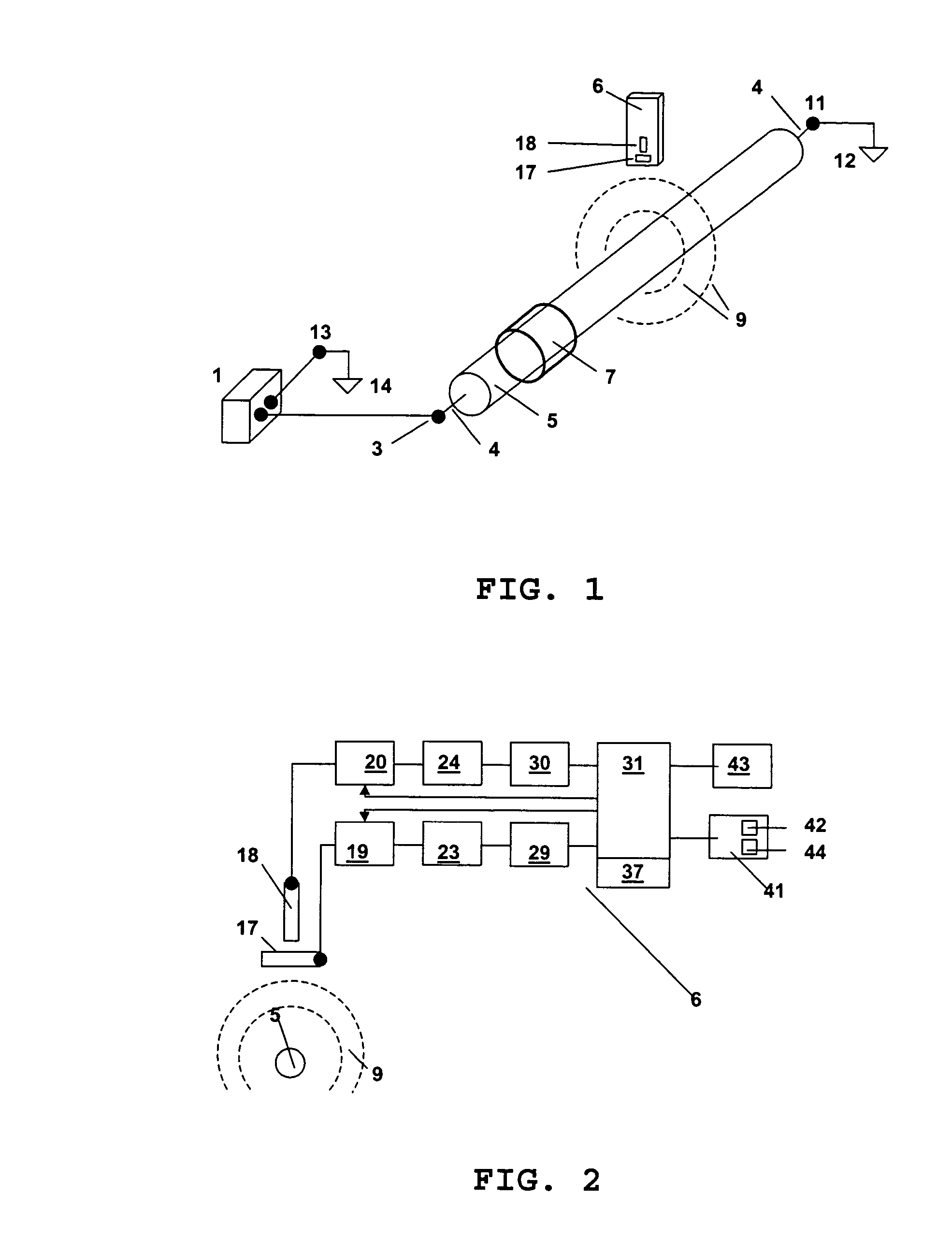

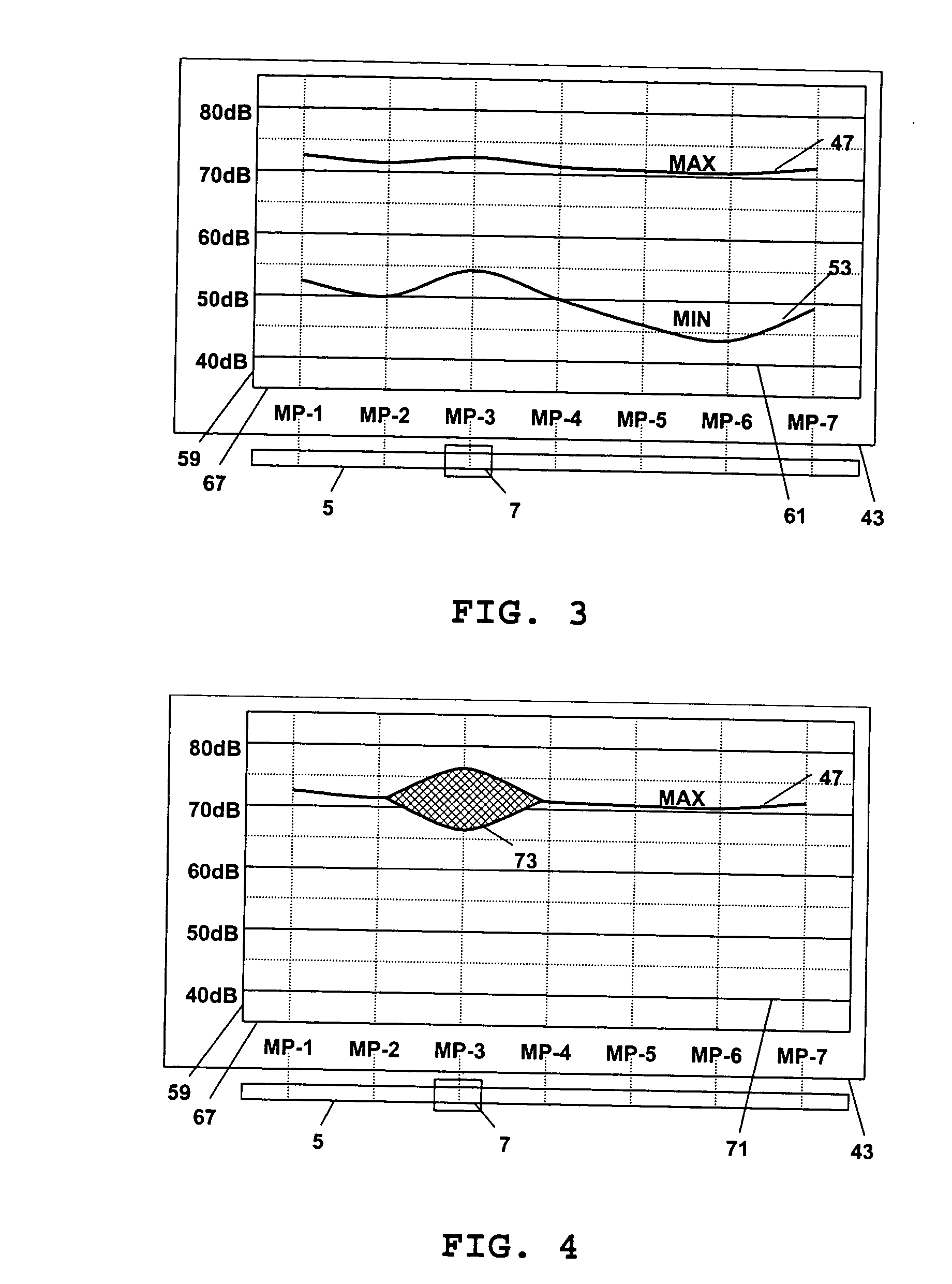

Method and apparatus for the location and indication of cable splices and cable faults

InactiveUS20060181284A1Reduce effortOptimize locationElectronic circuit testingFault location by conductor typesDisplay deviceAudio frequency

A method and apparatus for the location and indication of cable splices and cable faults is disclosed. An audio frequency generator can be coupled to a cable under test and the magnetic field generated by the cable can be monitored by a receiver. A receiver includes at least two antenna coils situated to detect orthogonal components of the magnetic field. From test values measured at various test points along the cable route, a degree of inhomogeneity of the magnetic field along the cable route can be determined and displayed. Location of a cable fault and cable splice is then apparent in the display.

Owner:HAGENUK KMT KABELMESSTECHN

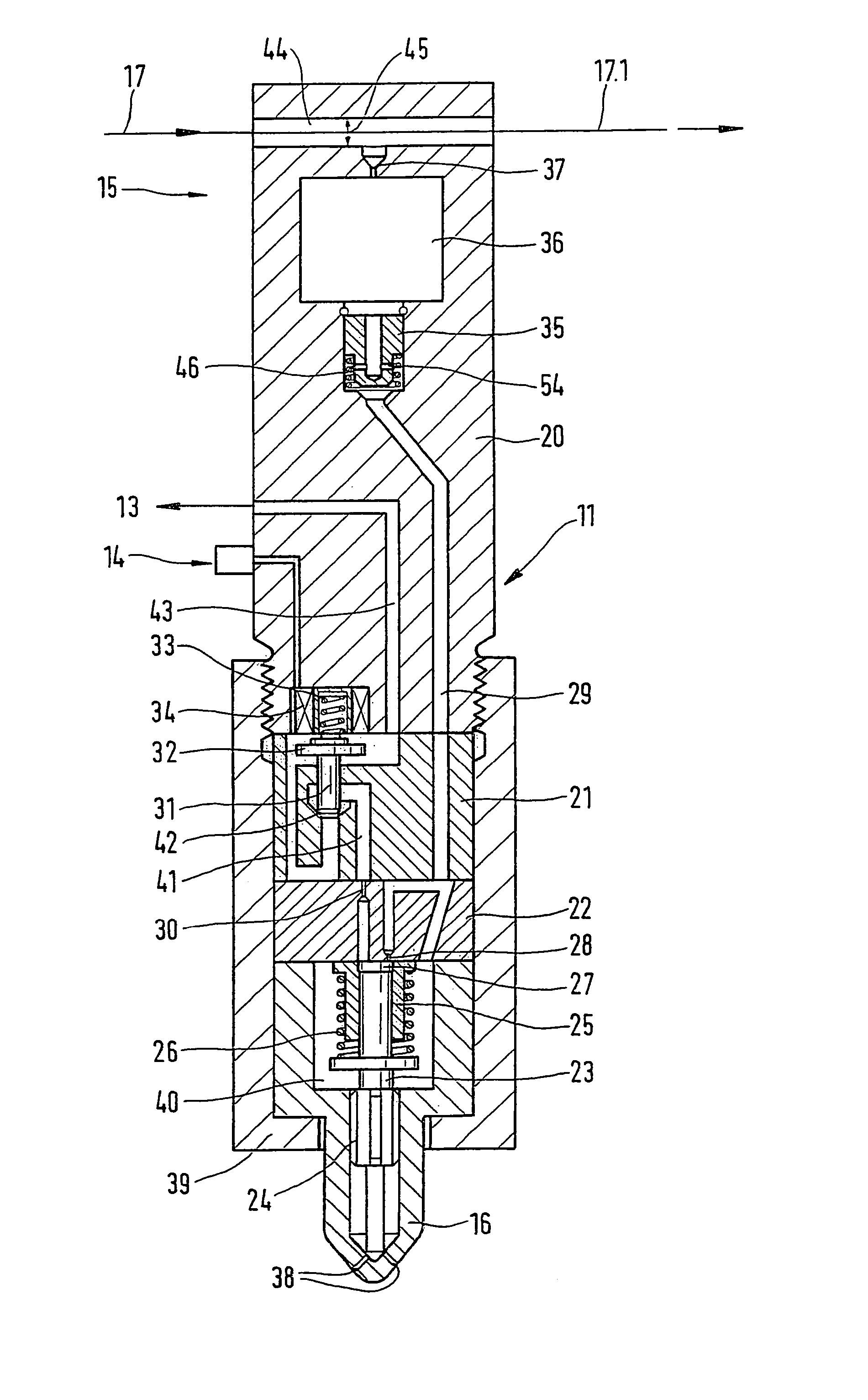

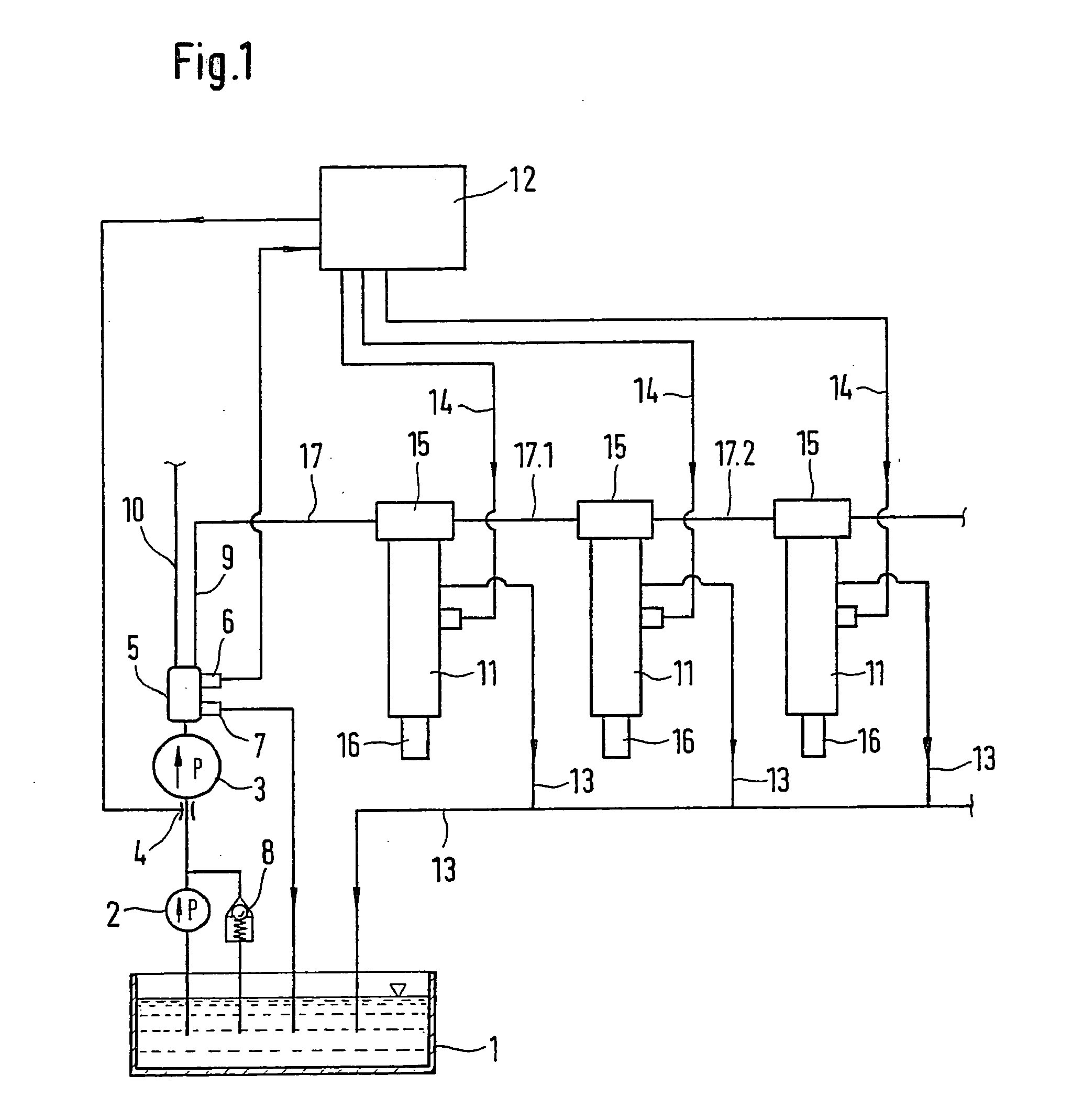

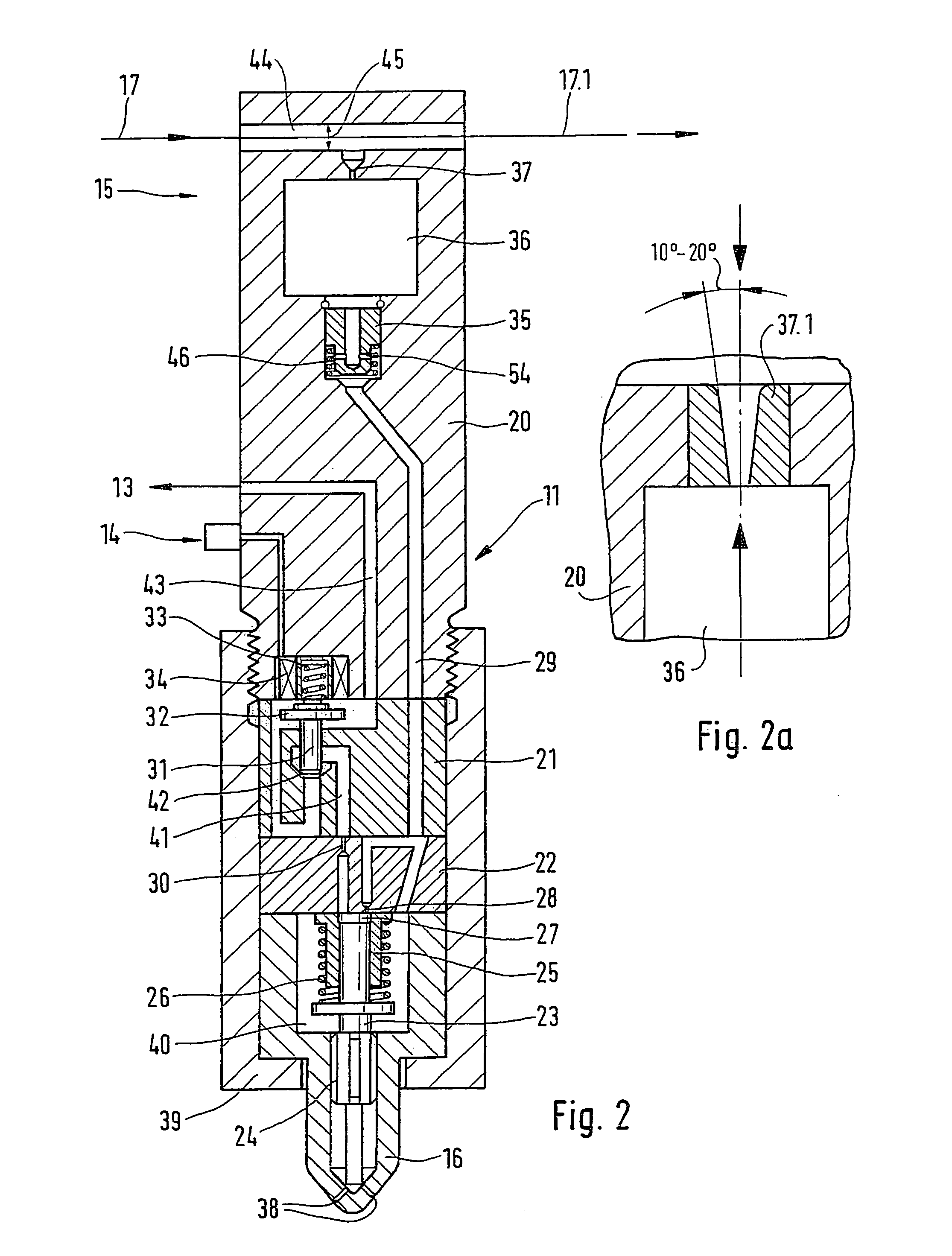

Device for injecting fuel to stationary internal combustion engines

InactiveUS20040187848A1Easy to adaptAchieve modularityCasingsCombustion enginesCombustion chamberLine tubing

The invention relates to a fuel injection system for use in internal combustion engines. The injection system has having delivery units (2, 3) for delivering fuel from a fuel reservoir (1) in order to supply at least one high-pressure line (9, 10) to the cylinders of the engine. The at least one high-pressure line (9, 10) supplies a number of fuel injectors (11), which each include an injector nozzle (16) that supplies fuel to a combustion chamber of the engine. The at least one high-pressure line (9, 10) and includes line segments (17, 17.1, 17.2) that connect the individual fuel injectors (11) to one another. The injector bodies (20) of the fuel injectors (11) each have an accumulator chamber (36, 36.1) integrated into them.

Owner:ROBERT BOSCH GMBH

Vehicle seat control lever

Owner:SCANIA CV AB

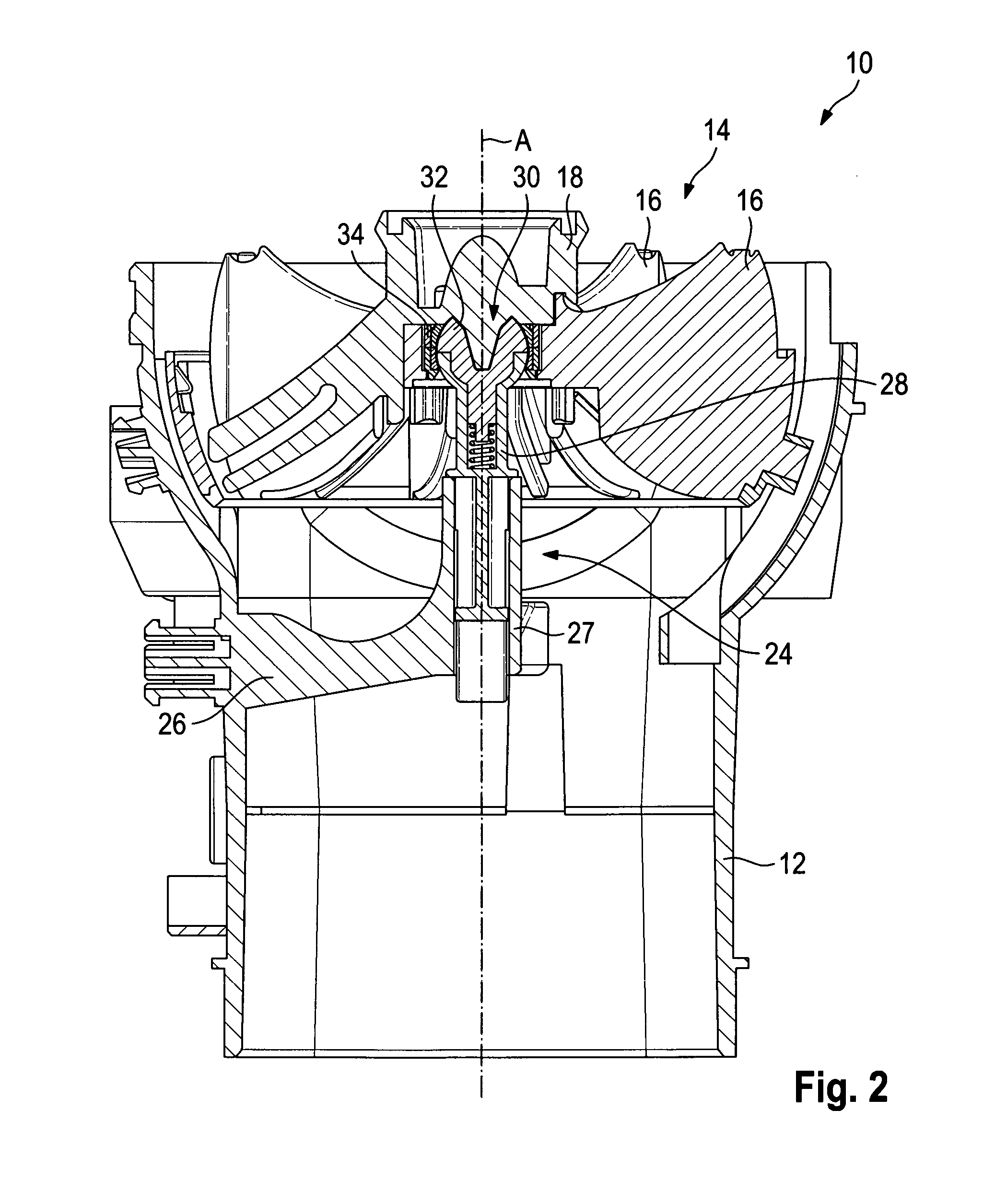

Combustion chamber for a gas turbine

InactiveUS7331182B2Simple adaptationAvoid disadvantagesBurnersContinuous combustion chamberCombustion chamberControl theory

At least one Helmholtz damper is arranged at a combustion chamber for a gas turbine in order to damp thermoacoustic oscillations; the damping volume of this Helmholtz damper is in communication with the combustion chamber via a connecting passage. Optimum damping is achieved in a simple way by virtue of the Helmholtz damper being designed in such a manner that its damping frequency is adjustable.

Owner:ANSALDO ENERGIA IP UK LTD

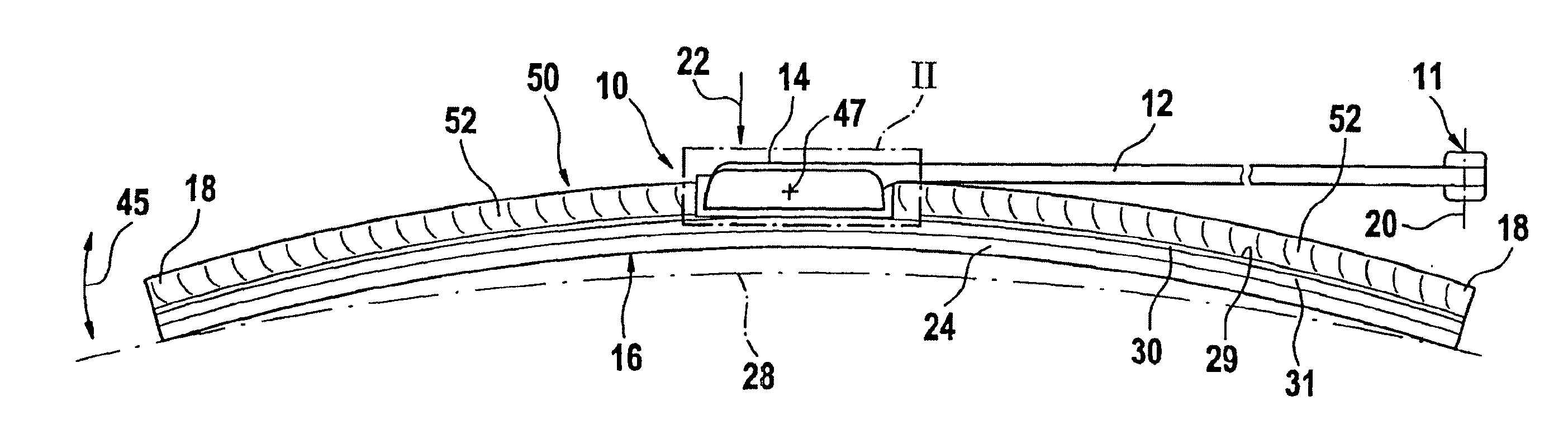

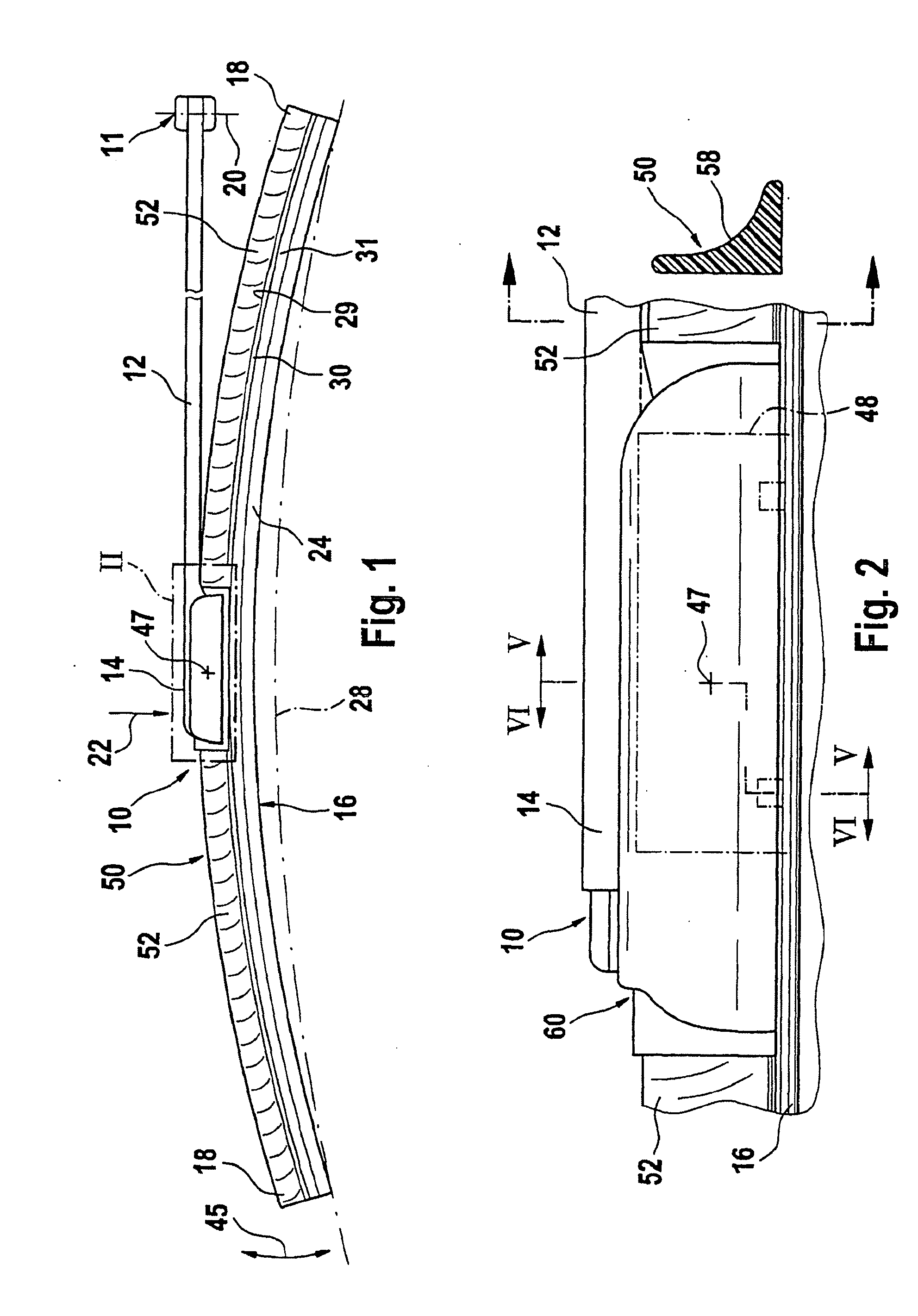

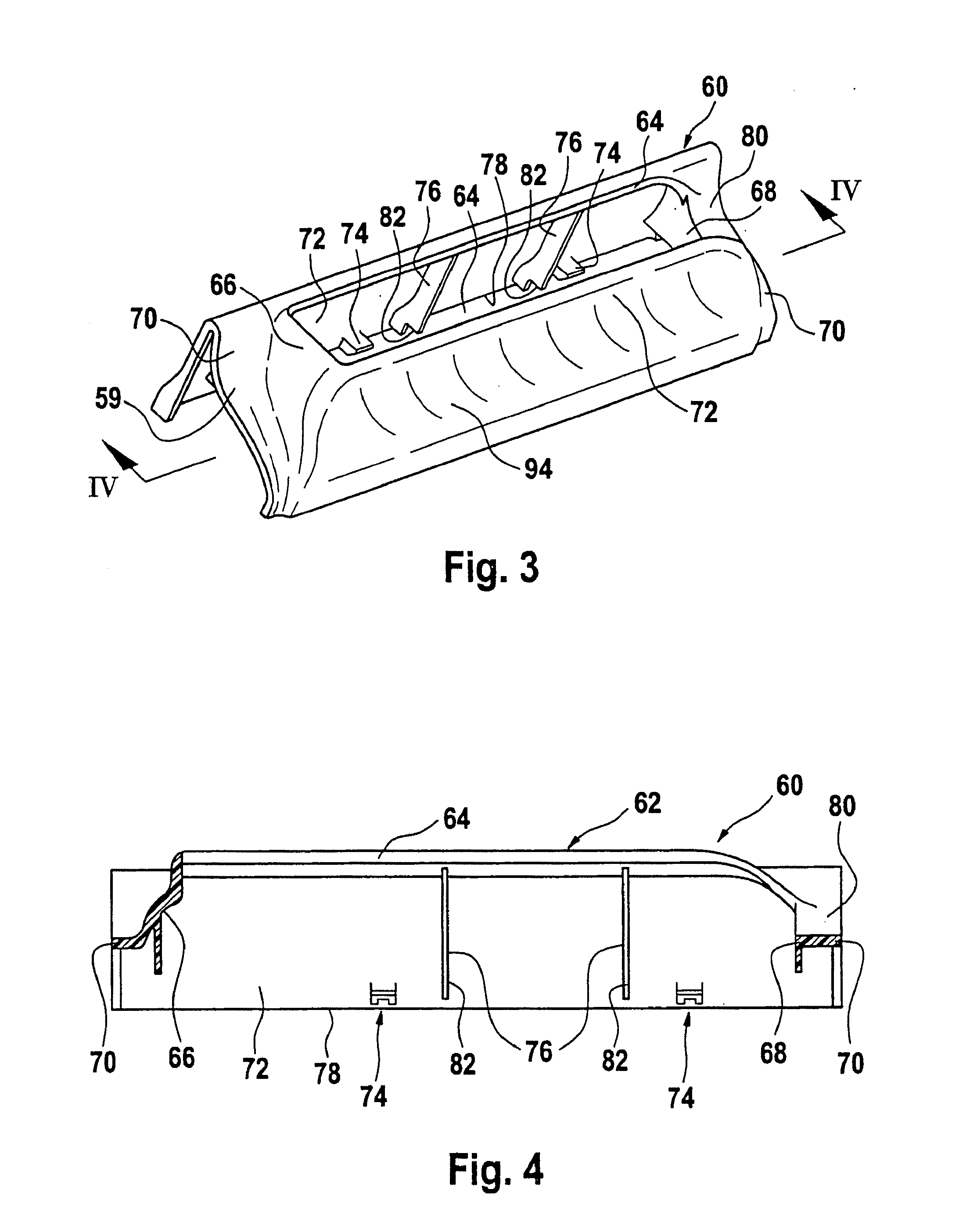

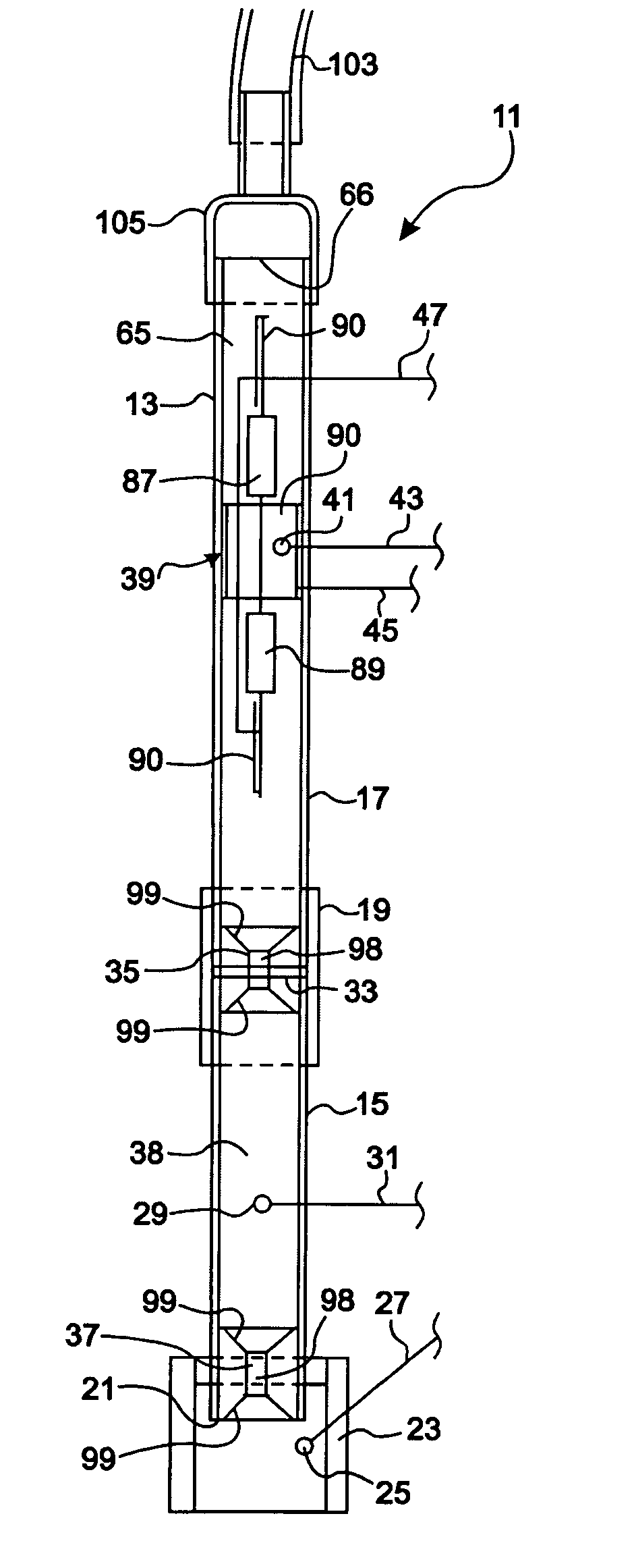

Wiper lever with a driven wiper arm and a wiper blade

InactiveUS20080034530A1Noise is generatedAvoid problemsWindow cleanersVehicle cleaningRubber elasticityControl theory

Wiper lever (10) with a driven wiper arm (12) and a wiper blade (16) linked to it for cleaning windows, particularly those of motor vehicles, which is provided with a band-like, long-stretched-out, elastic supporting element (30), which features, on its lower band surface facing the window, a long-stretched-out, rubber elastic wiper strip (24) that can be applied to it, on whose upper band surface (29), particularly in the longitudinal middle area of the supporting element (30), a coupling part (32) is situated and wind deflector strip partial sections (52) extending to the ends of the supporting element are arranged on both sides of the coupling part (32). An especially harmonic transition between the wiper blade (16) and the wiper arm (12) is achieved in the area of the joint (46, 47) connecting these two wiper lever parts if the wiper lever (10) is provided with a cap (60) to cover the connection area between the wiper blade (16) and the wiper arm (12).

Owner:ROBERT BOSCH CORP

Highly sensitive airflow direction sensing

InactiveUS8002199B2Simplicity of implementationEasy to installVolume/mass flow by thermal effectsTemperatue controlCombustionEngineering

Sensors, apparatus and methods are disclosed for detecting airflow direction between two volumes. The preferred airflow sensor includes a tube for conducting an airflow stream between the volumes, a first temperature sensor sensing ambient temperature in the first volume and a second temperature sensor sensing temperature of the airflow stream in the tube. A heat source heats air in the tube adjacent the end thereof communicating with the second volume and a comparator receives and compares output signals from the temperature sensors, providing an output indicative thereof. Various means are provided responsive to the output advancing appropriate response thereto. The disclosed sensors, apparatus and methods are particularly well adapted for indicating positive and negative pressure differentials at flues associated with combustion appliances.

Owner:HABEGGER MILLARD A

Control device, a control module, a module battery and a control system

InactiveUS20040196003A1Easy to useSimple adaptationElectric signal transmission systemsBatteries circuit arrangementsElectrical batteryBus interface

A control device for the control of a module battery, comprising a first external bus interface for the reception of external control commands from a higher level control and an internal bus interface for an internal bus, by way of which battery modules connected with the control device are able to be controlled in accordance with the external control command and by way of which the battery modules may transmit messages to the control device. The control device possesses a second external bus interface, by way of which visualizing data for visualizing at least one function of the module battery may be applied.

Owner:FESTO AG & CO KG

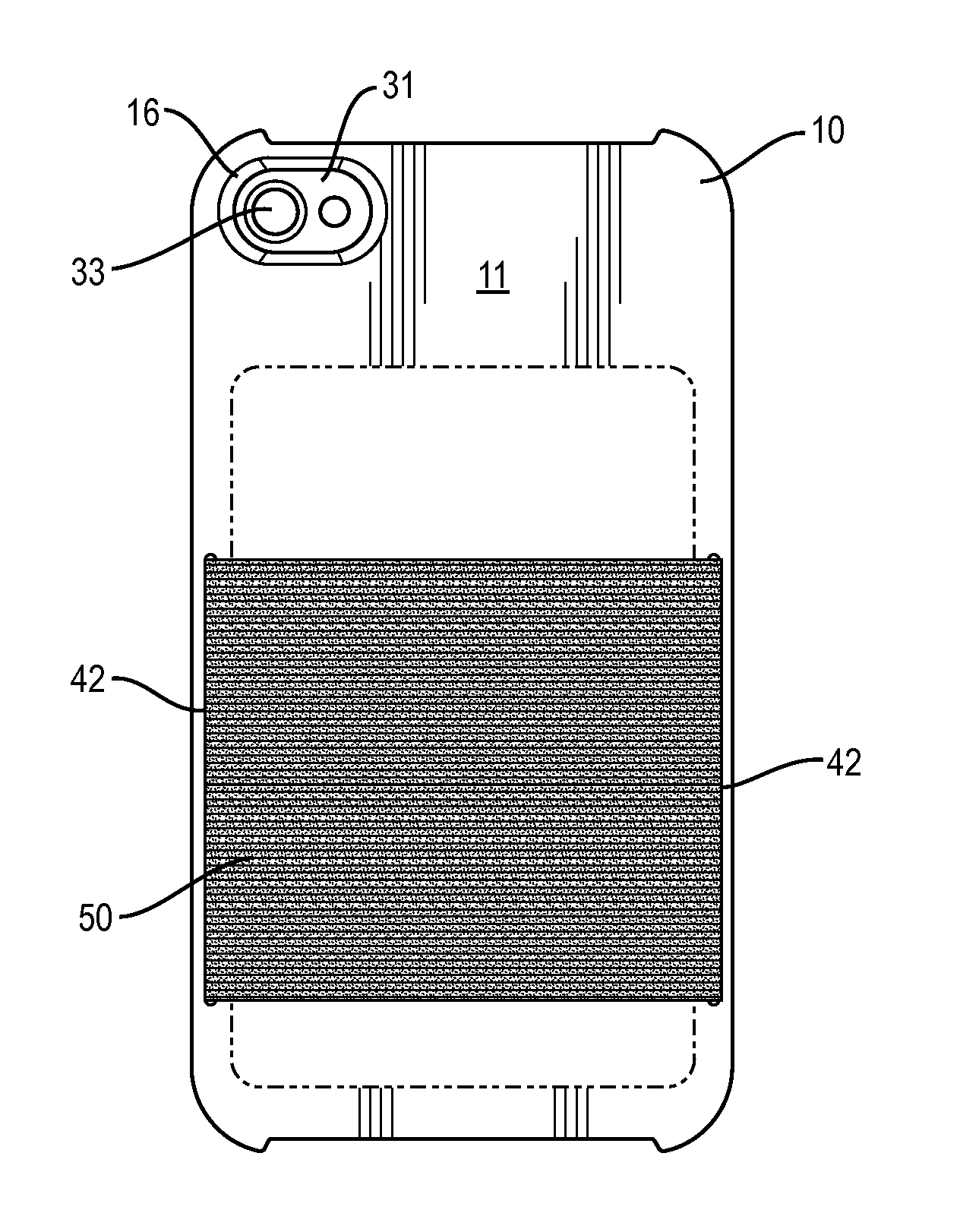

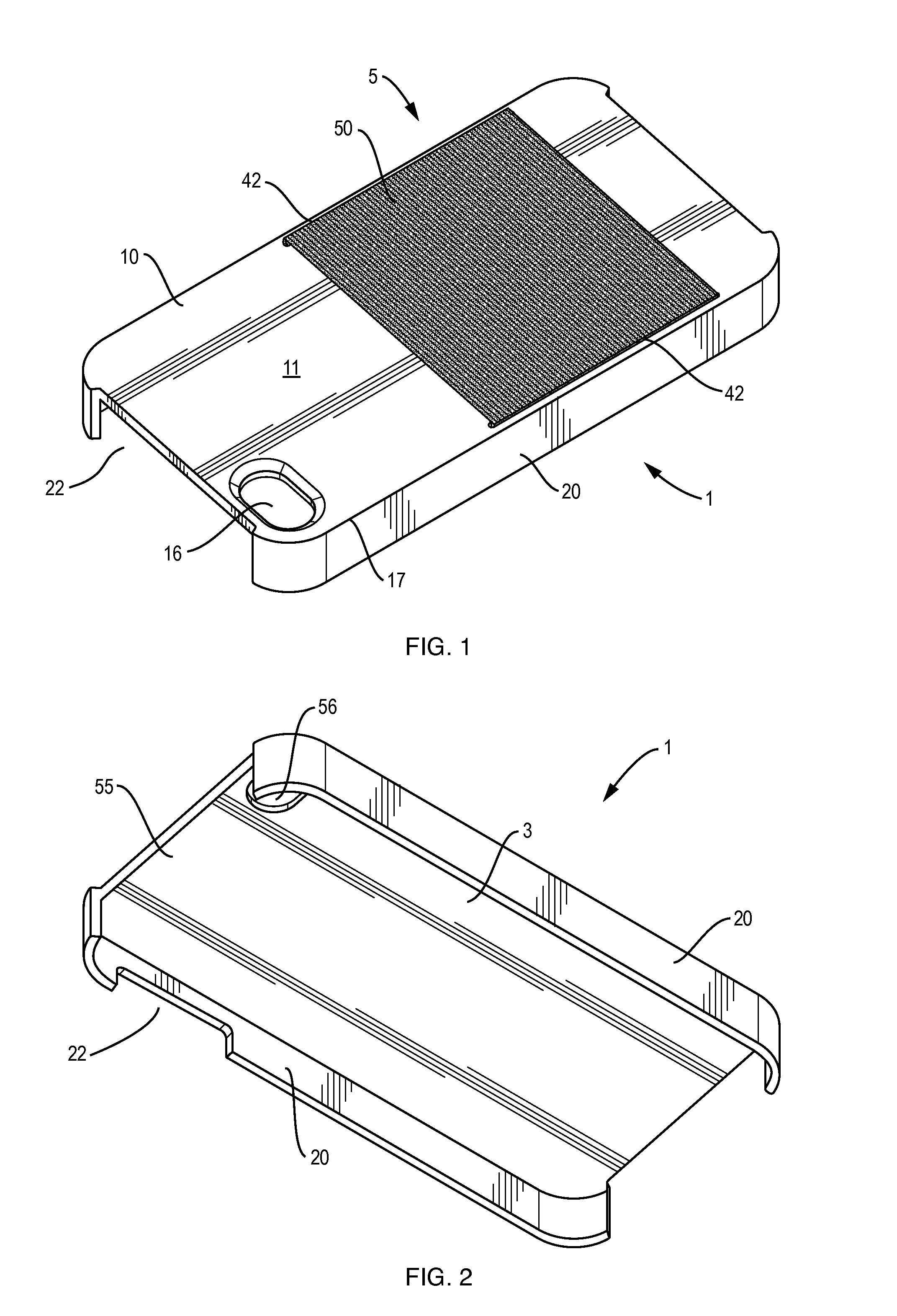

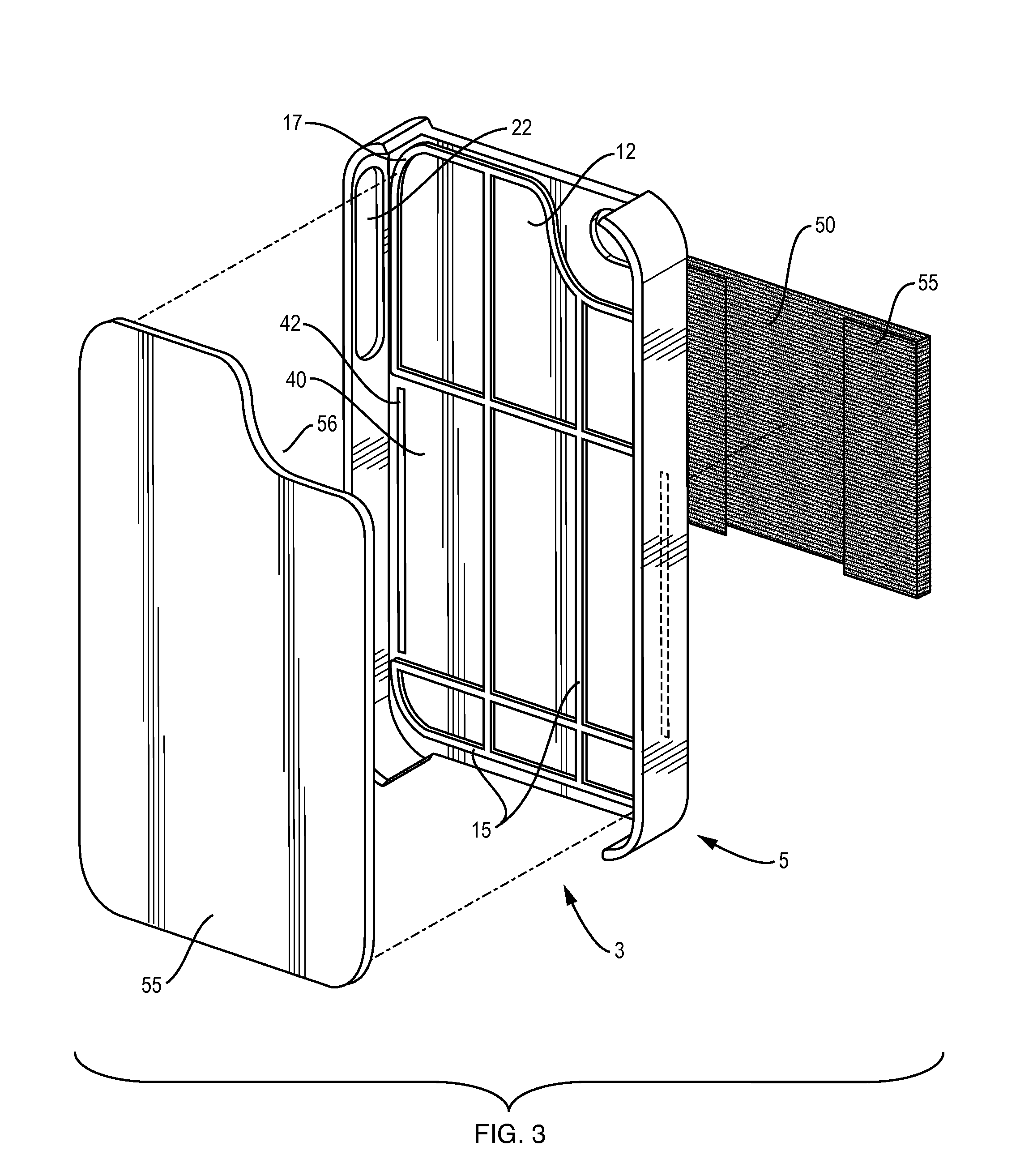

Cover Having Wallet Feature for Electronic Devices

InactiveUS20140091689A1Simple to manufactureSimple adaptationCasings/cabinets/drawers detailsFurniture partsMechanical engineering

Owner:E MISHAN & SONS

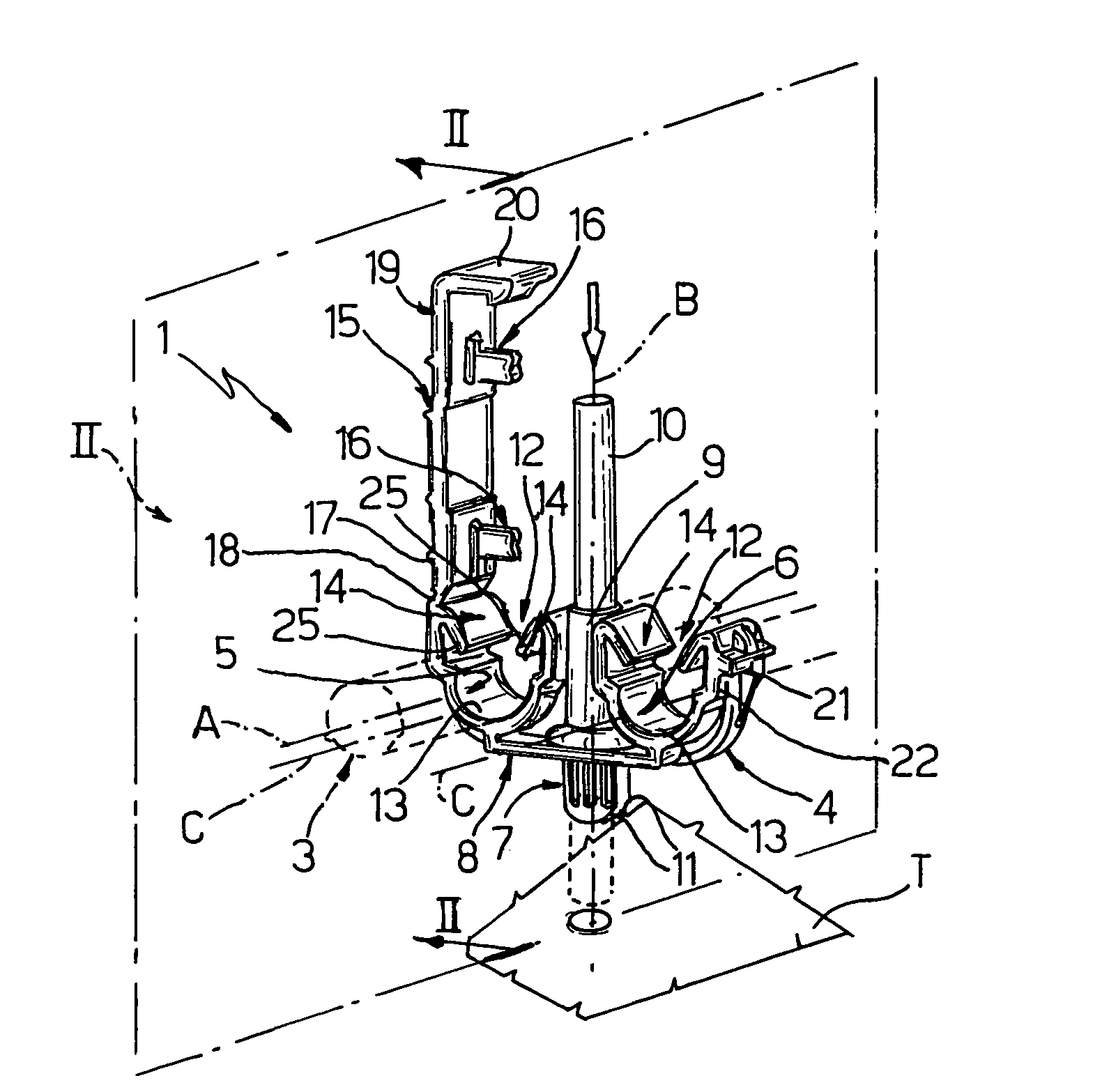

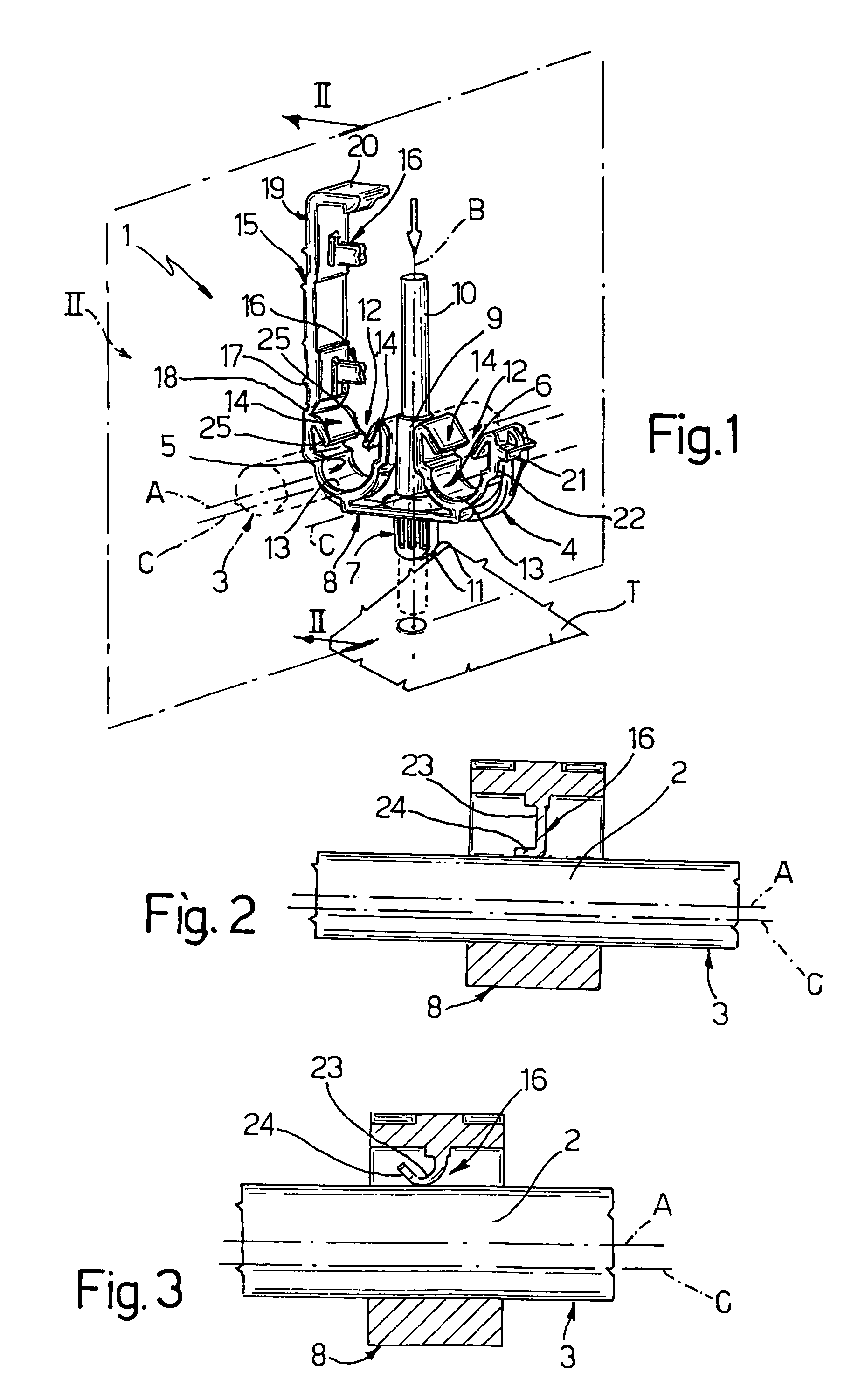

Clamp-type retention element for axisymmetrical components such as cables or tubes, in particular for application on vehicles

InactiveUS7559511B2Considerable ease of assemblyLow production costPipe supportsPipesAxis of symmetryEngineering

A clamp-type retention element for an axisymmetrical component for vehicles, such as a cable or a tube for oil or fuel, has an axis of symmetry; the retention element has at least one through seat, which has an insertion opening and is designed to house a portion of the axisymmetrical component, a snap-action closing element of the insertion opening, hooking elements designed to co-operate with a support, elastic elements designed to co-operate with the portion of the axisymmetrical component within the seat, and a guide element of the portion of the axisyrumetrical component within the seat for identifying a housing position of the portion of the axisymmetrical component under the action of the elastic elements. The elastic elements are flexible in a direction substantially parallel to the axis of symmetry when the portion of the axisymmetrical component is in the housing position.

Owner:ITW AUTOMOTIVE ITALA S R L

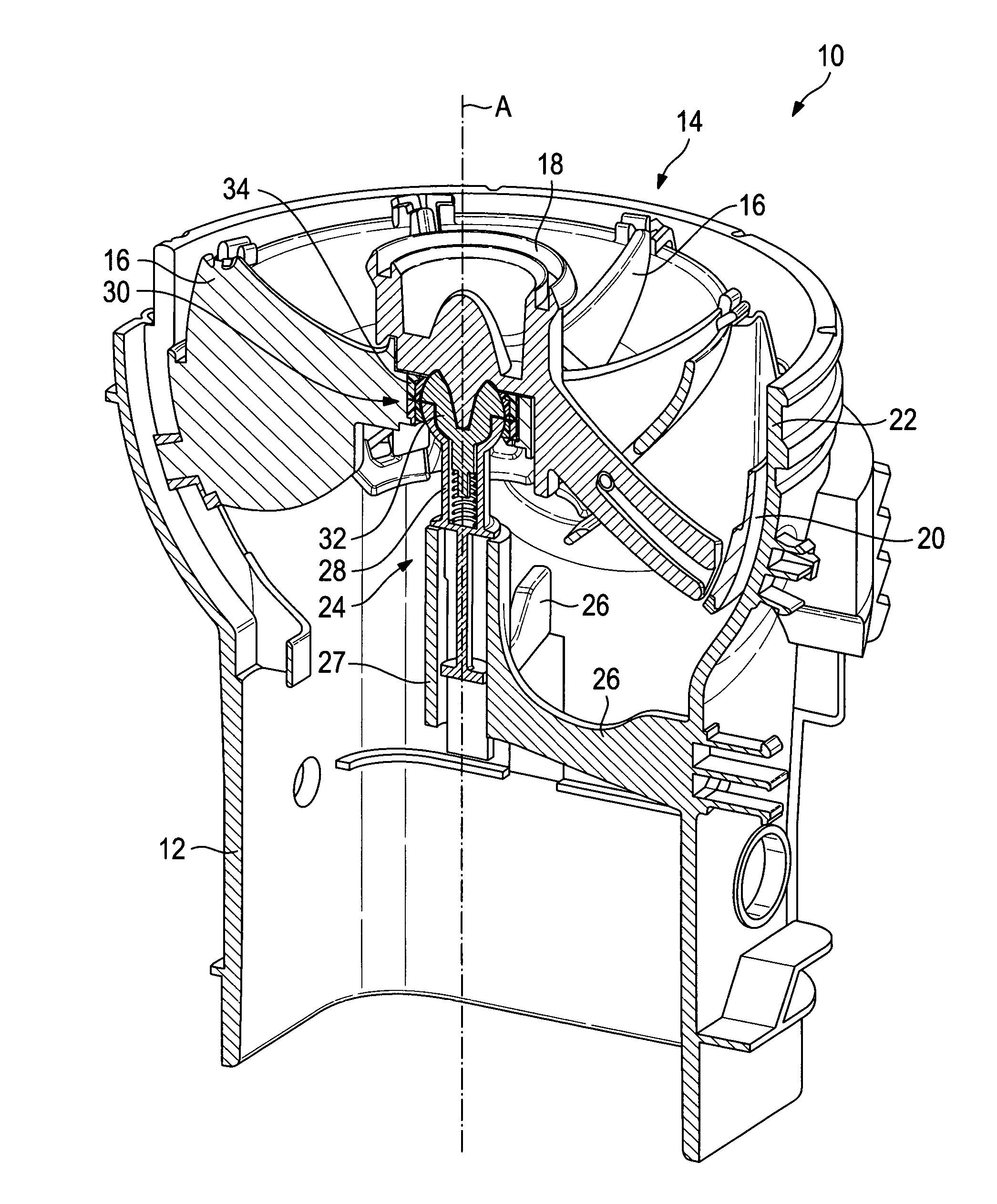

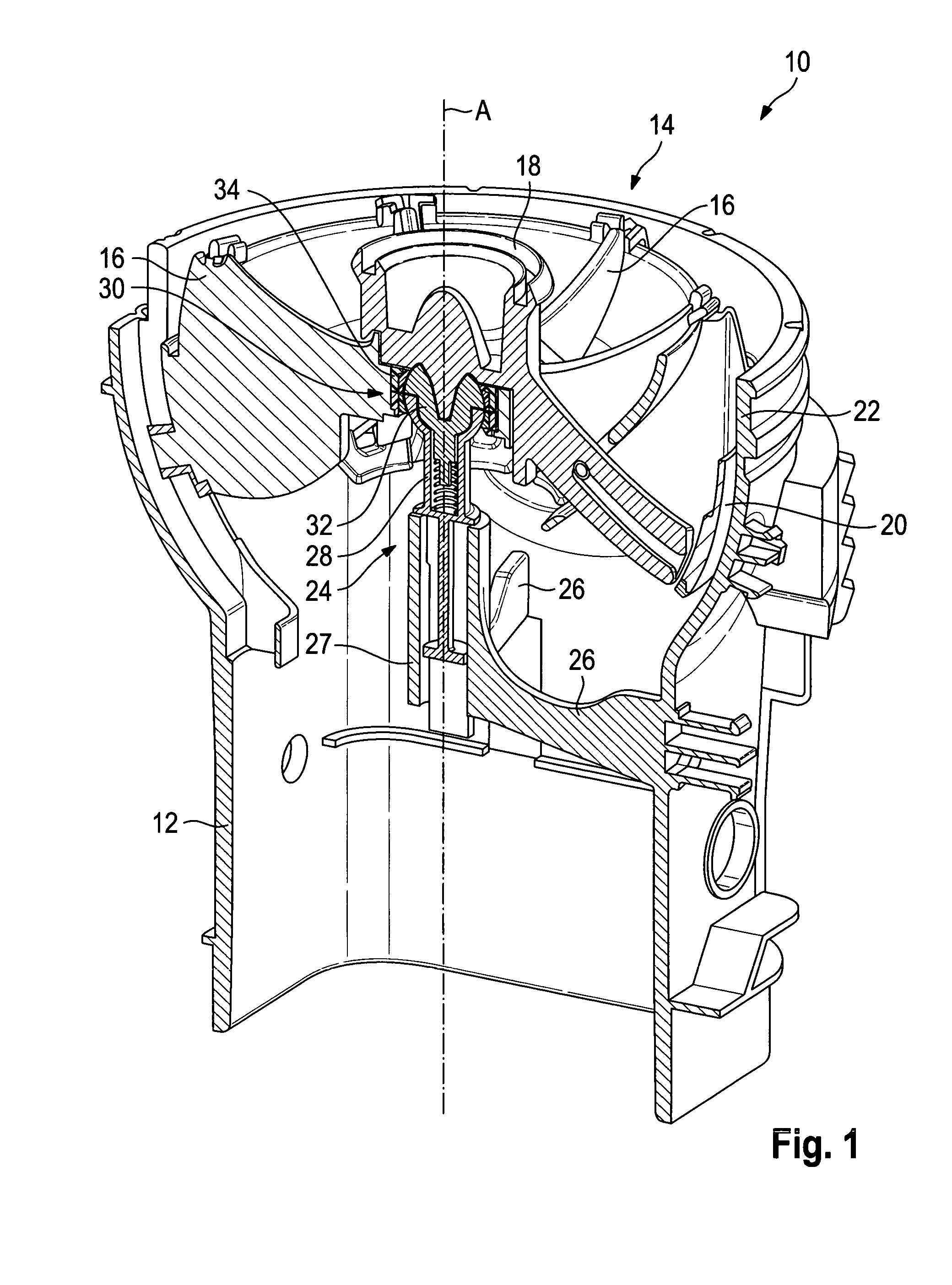

Air diffuser

ActiveUS20130210333A1Produce frictionSufficient forceAir-treating devicesVehicle heating/cooling devicesEngineeringMechanical engineering

An air vent (10) having a housing (12) and an air guiding means (14) that is swivel-mounted in the housing (12) includes a mounting (24) by means of which the air guiding means (14) is mounted on the housing (12) for swiveling about at least one swivel axis, the mounting (24) being formed by a ball joint (30) having a bearing shell (34) and a ball head (32) mounted in the bearing shell (34), and the ball head (32) being of a multipart configuration with at least two spherical segments (50, 52), and a spring member (54) being provided that acts upon the spherical segments (50, 52) of the ball head (32) with a force that seeks to push the spherical segments (50, 52) apart.

Owner:AUDI AG +1

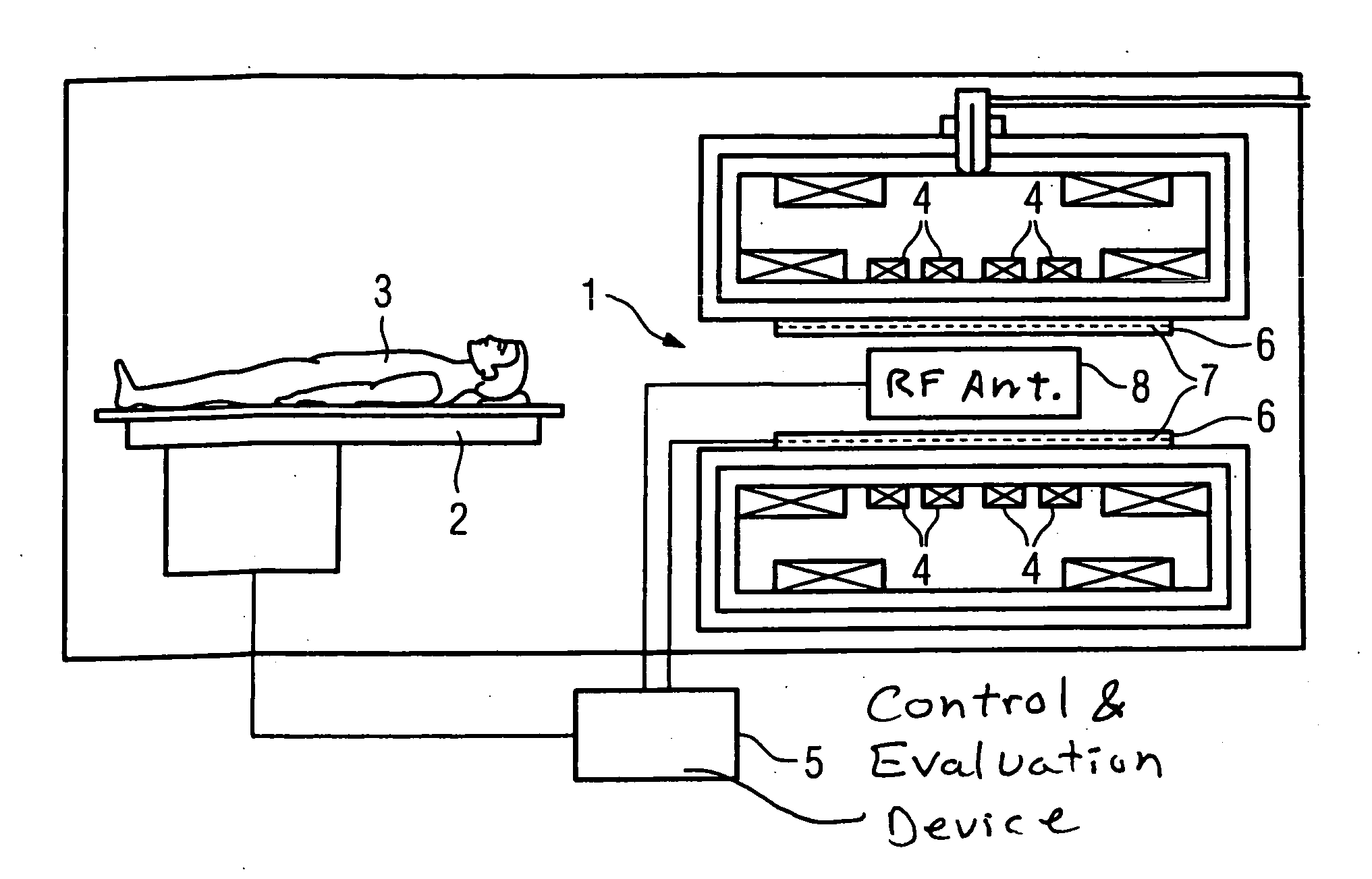

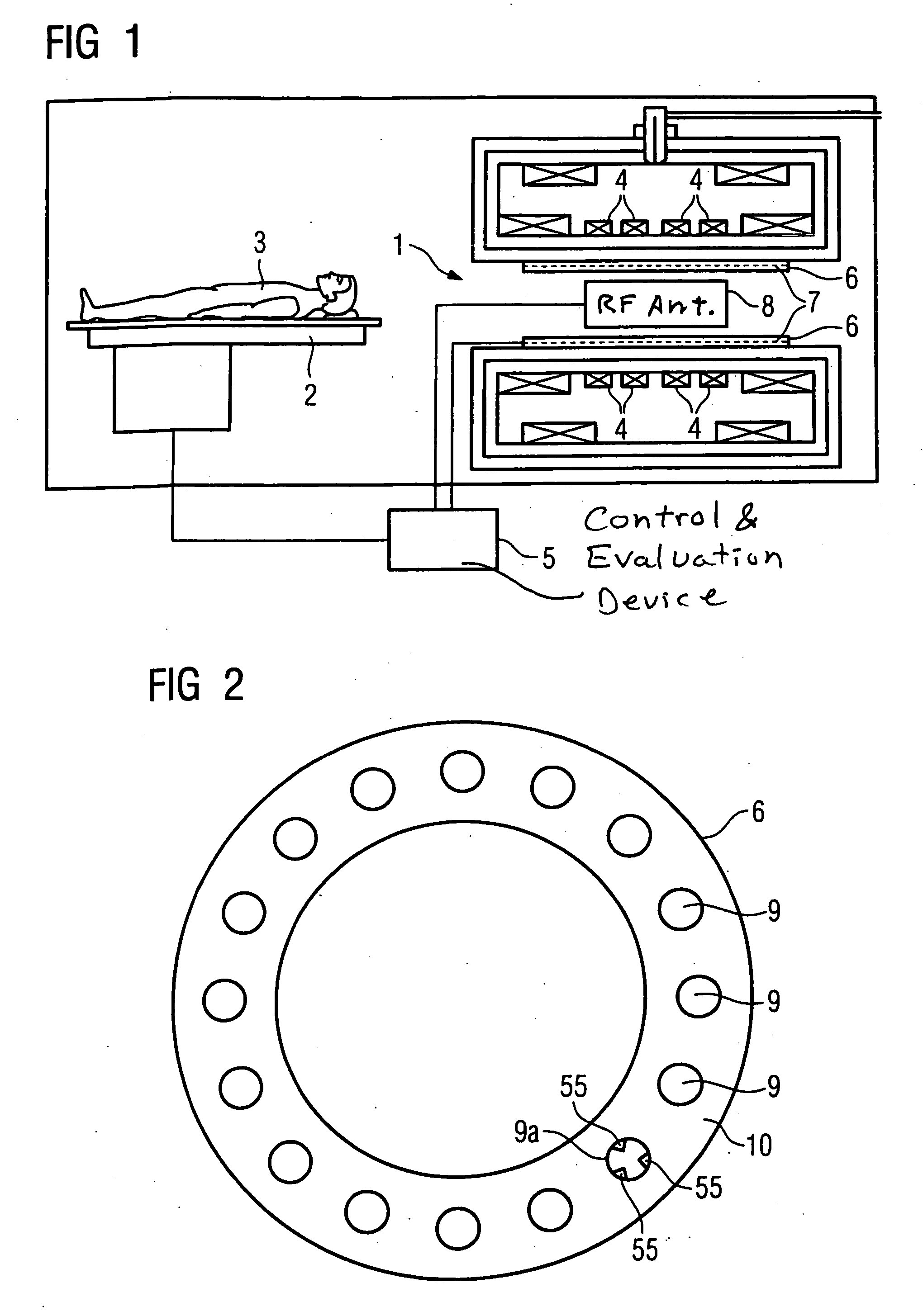

Magnetic resonance apparatus with a gradient coil unit with integrated passive shim devices

InactiveUS20060262826A1Improved and simple designSimple adaptationMagnetic measurementsOptical resonator shape and constructionResonanceMetal

A magnetic resonance apparatus has a gradient coil unit with passive shim devices inserted into side receptacles in the molded body of the gradient coil unit. Each shim device has a carrier with a number of metal elements, the metal elements being mounted on the carrier in linear succession and being situated essentially orthogonally to the longitudinal axis of the carrier.

Owner:SIEMENS HEALTHCARE GMBH

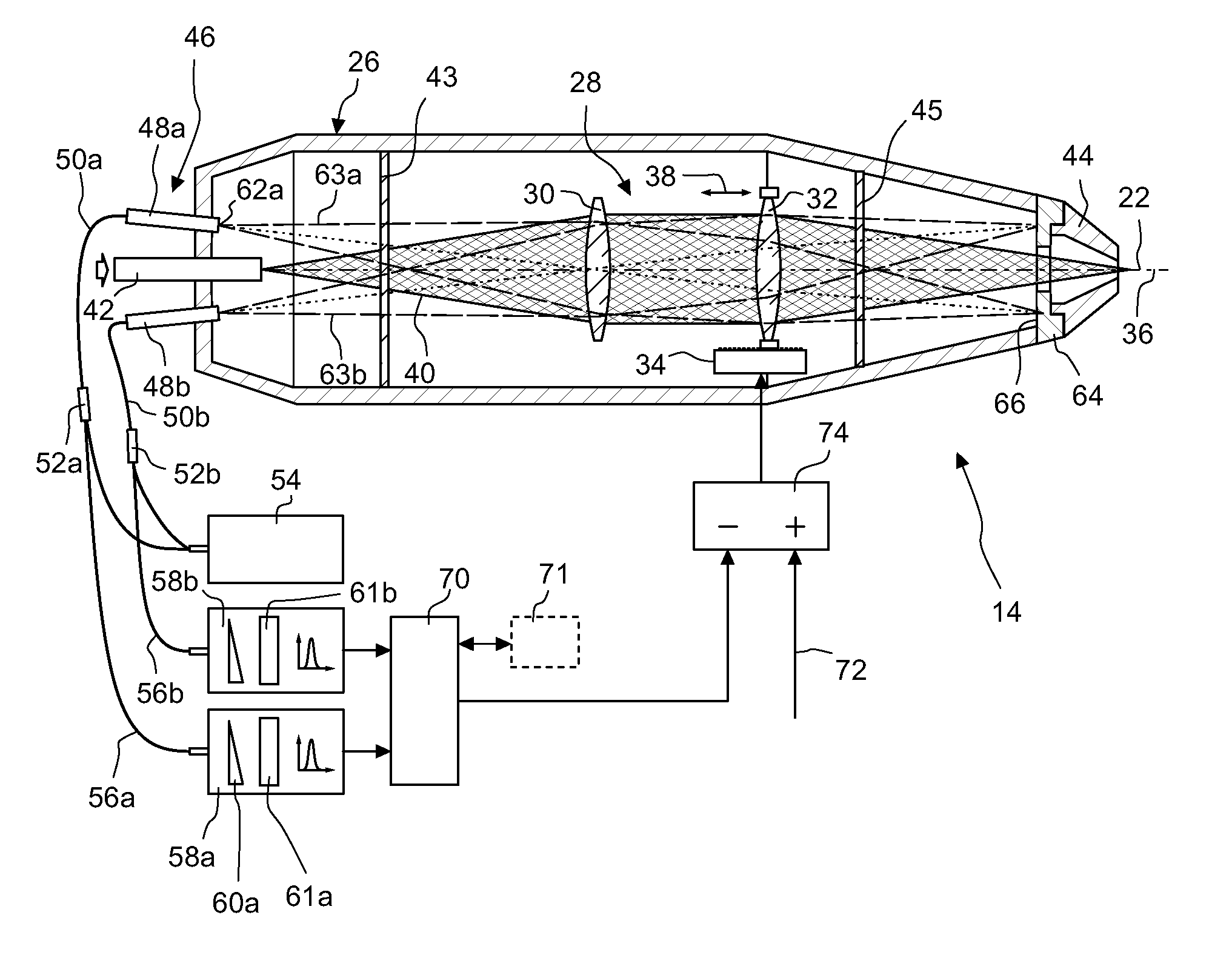

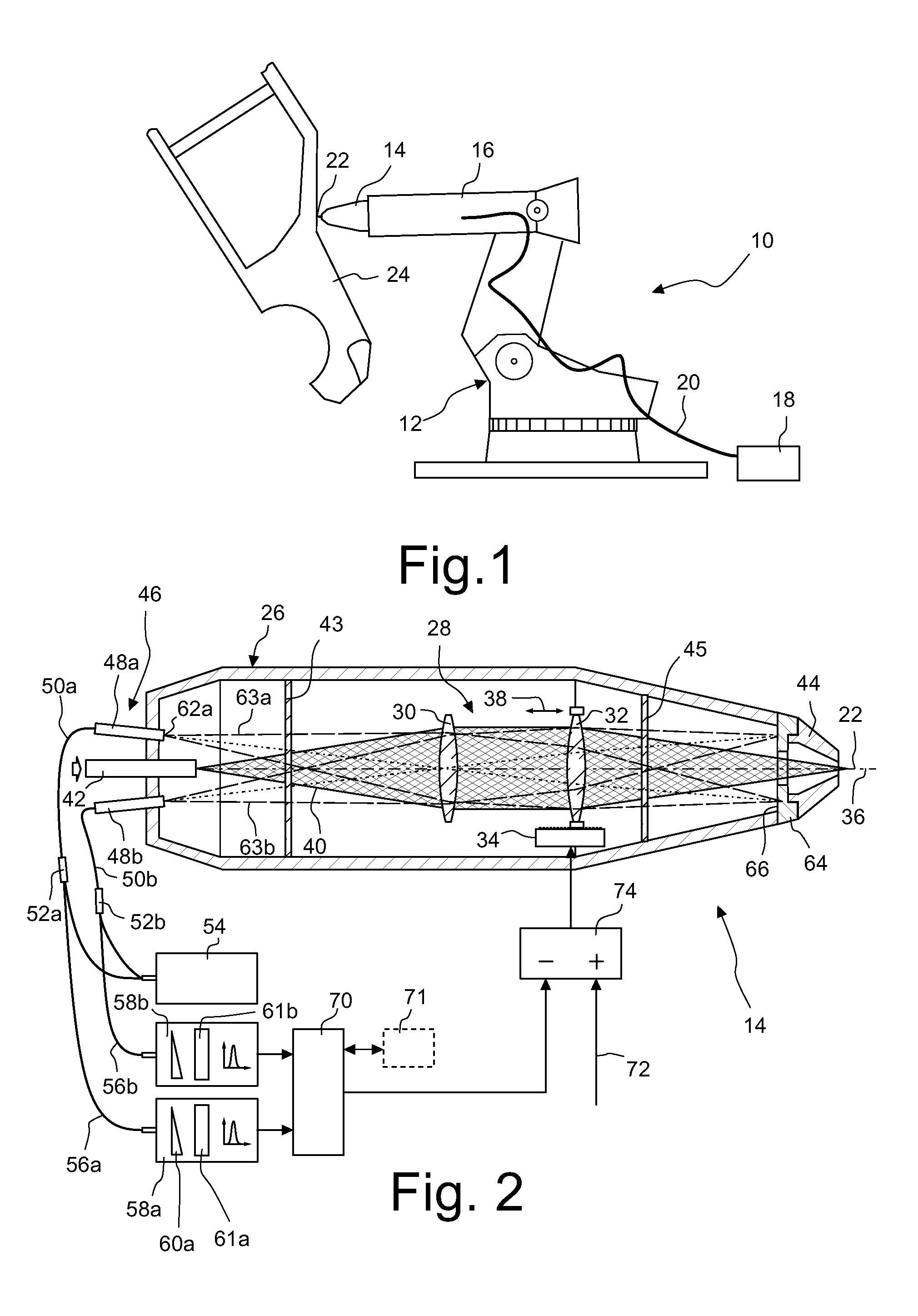

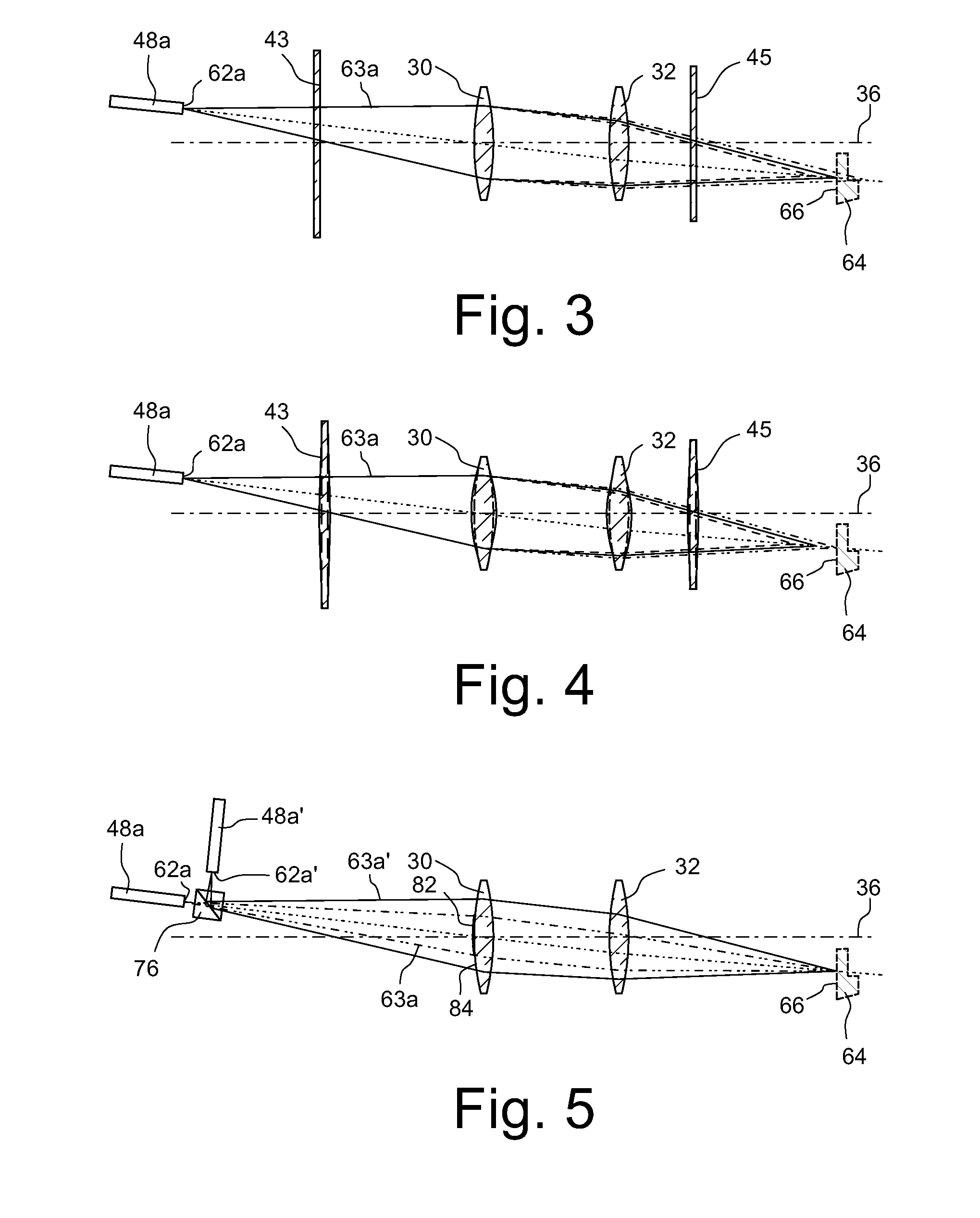

Laser Machining Apparatus with Adaptive Mirror

ActiveUS20140346155A1Position and shape of be stabilise wellStabilised betterLaser beam welding apparatusOptoelectronicsInternal pressure

A laser machining apparatus comprises a laser radiation source that generates laser radiation. A first and a second adaptive mirror are provided each having a pressure chamber connected to a pressure source and a mirror substrate that bounds the pressure chamber. An internal pressure in the pressure chamber can be changed with the aid of the pressure source in such a way that the mirror substrate deforms if the internal pressure in the pressure chamber changes. The mirror substrate of the first adaptive mirror has a thickness which varies at least within a region of the mirror substrate that bounds the pressure chamber. The mirror substrate of the second adaptive mirror has a thickness which is constant over the entire region over which the mirror substrate is deformable.

Owner:LT ULTRA PRECISION TECH

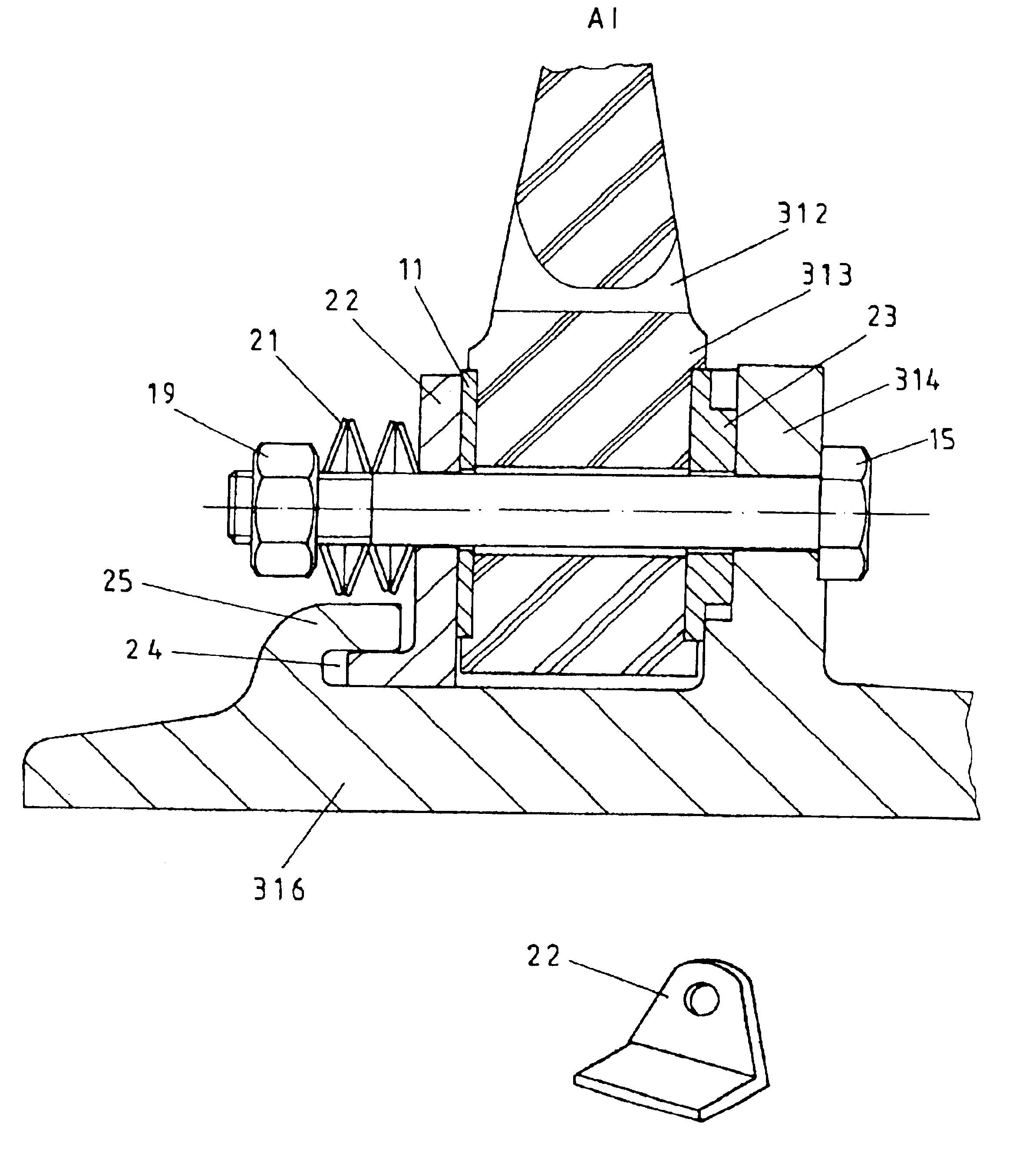

Brake disk for a disk brake

The invention relates to a brake disc for a rail vehicle, with which a hub body (16) and a brake ring (12) are connected to one another such that with braking procedures a thermal expansion of the brake ring (12) relative to the hub body (16) is possible. At the same time screws (15) pass through axially aligned openings in a hub flange (14) arranged on the hub body (16) and a brake ring flange (13) arranged on the brake ring (12). According to the invention the screws at their end exiting the brake ring flange (13), by way of a retaining element which, for example, may be a retaining lug (17) formed integrally on the hub body (16) or a retaining bracket fixed on the hub body, may be fixed relative to the hub body (16) so that an axially parallel position of the screws (15) and a centering of the brake ring (12) is ensured even with thermal expansions. The mounting of the screws (15) is effected indirectly via an axially displaceably movable sleeve (20) or by a retaining braket engaging into a groove on the hub. Furthermore there are provided radial guides for the brake ring (12) which may be realised, for example, by the guiding of the sleeve (20) in a slide block.

Owner:SAB WABCO BSI VERKEHRSTECHN PRODS

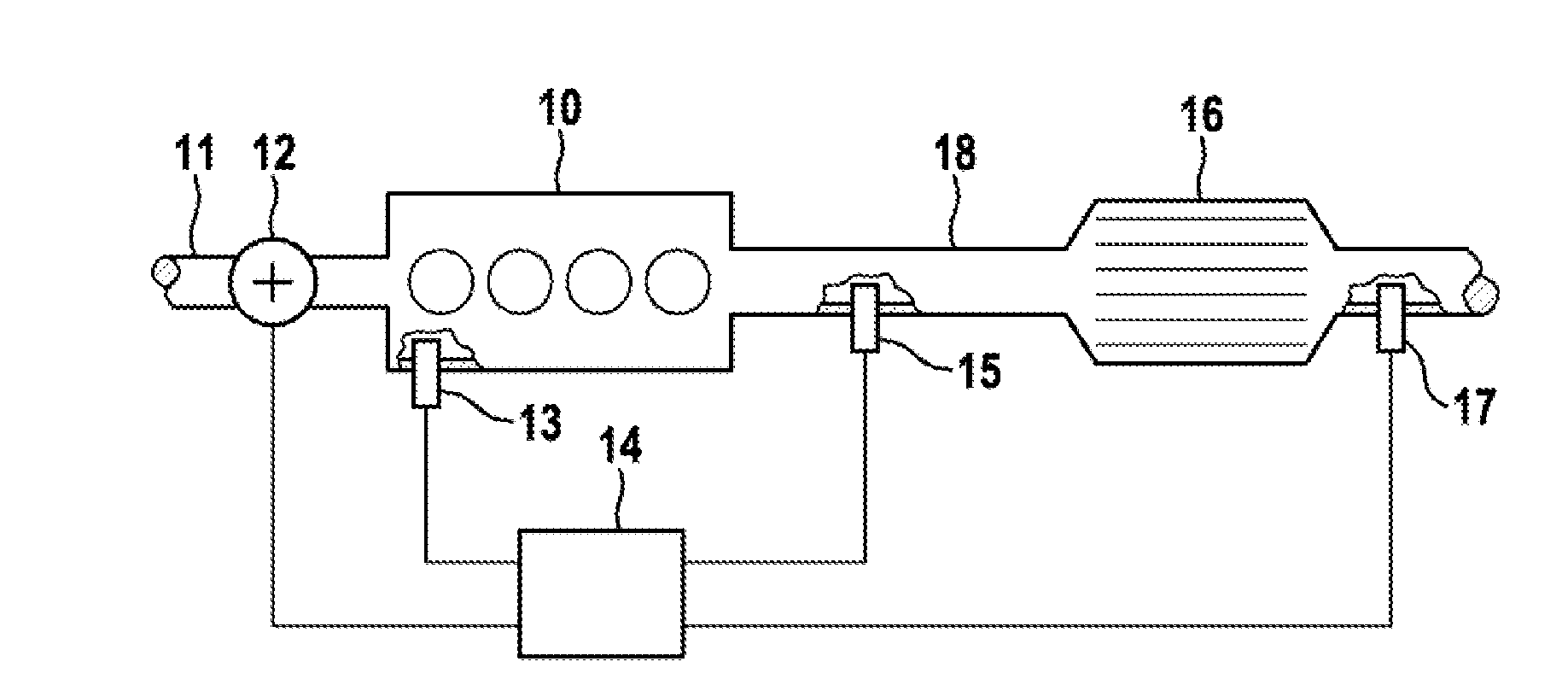

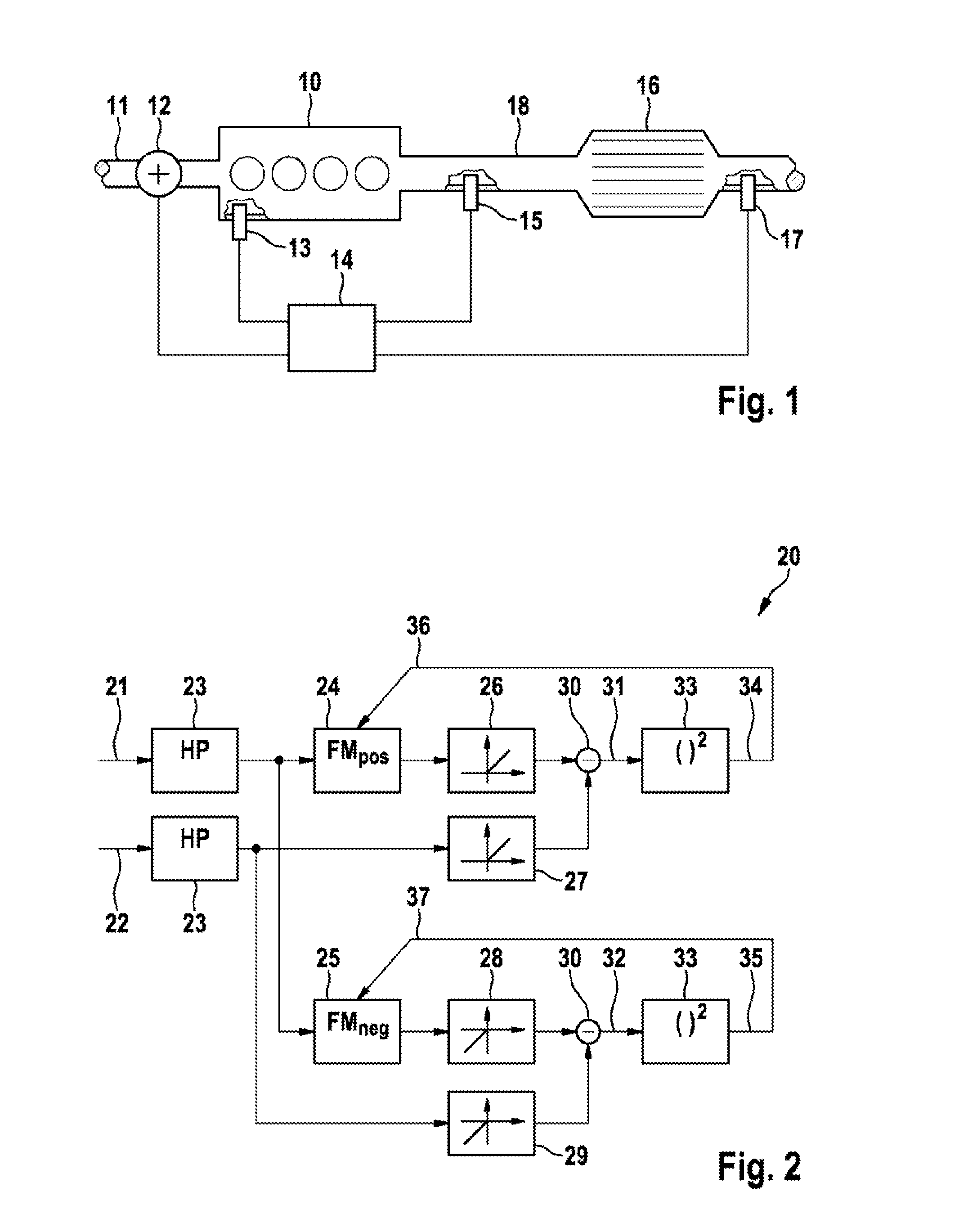

Method and device for dynamic monitoring of gas sensors

ActiveUS20140358355A1Simple adaptationVehicle testingElectrical controlState variableLogical combination

In a method for monitoring the dynamics of gas sensors of an internal combustion engine, which gas sensors exhibit a low-pass behavior as a function of geometry, measurement principle, aging, or contamination, a dynamics diagnosis is carried out, upon a change in the gas state variable to be measured, on the basis of a comparison between a modeled and a measured signal. The parameters of the low-pass behavior are determined in direction-dependent fashion by minimizing direction-dependent error signals created by high-pass filtering and logical combination with direction-dependent saturation characteristic curves, the direction-dependent error signals being calculated by comparing the modeled and the measured signal for a rising and a falling signal component.

Owner:ROBERT BOSCH GMBH

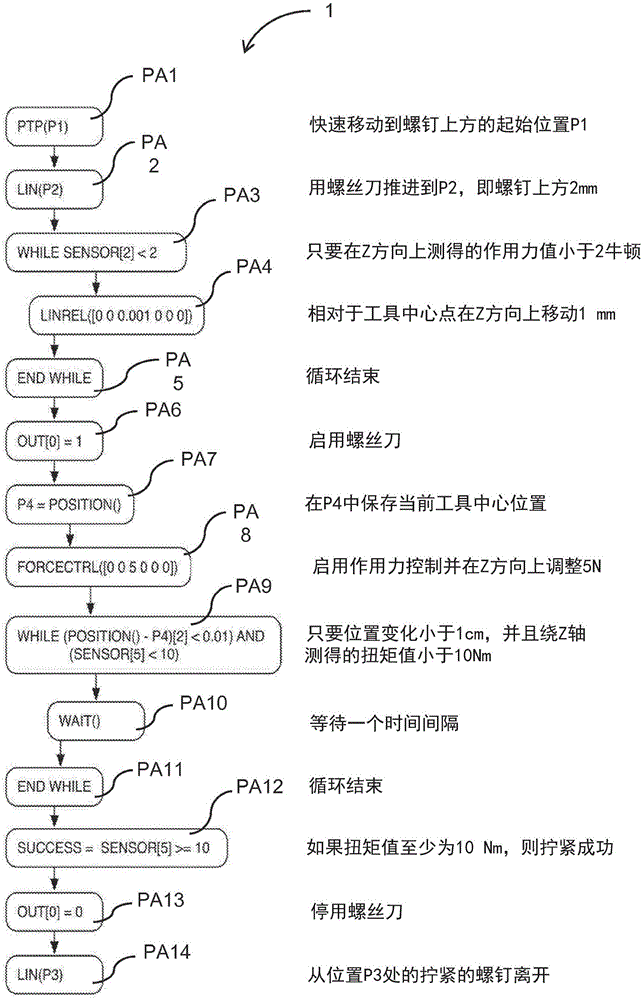

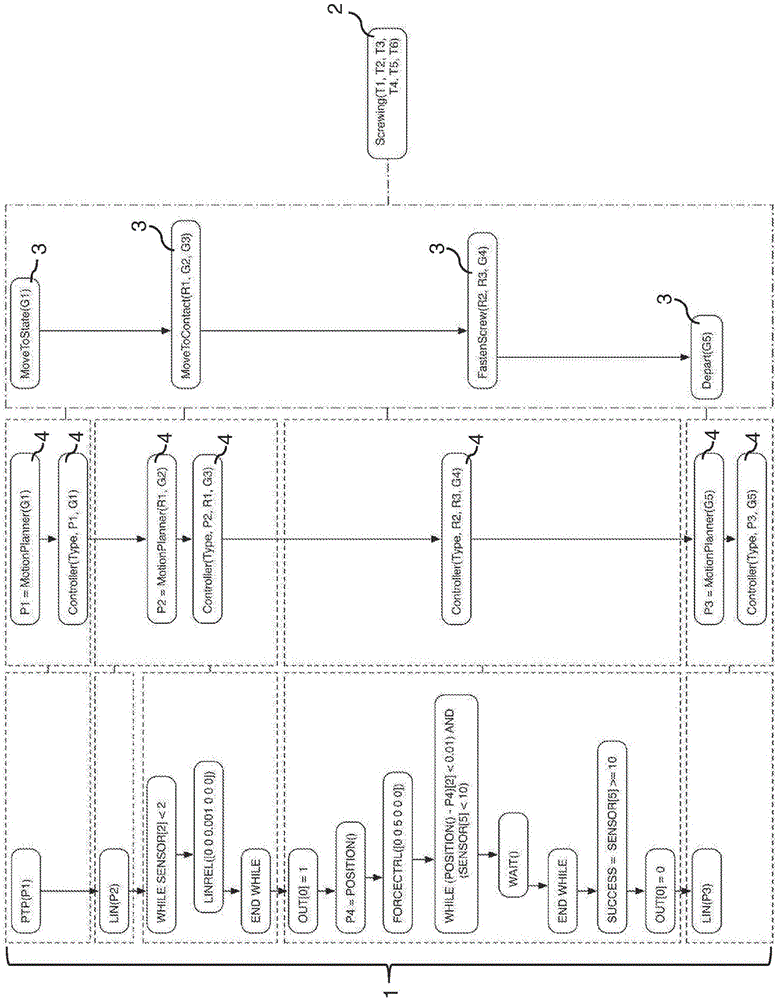

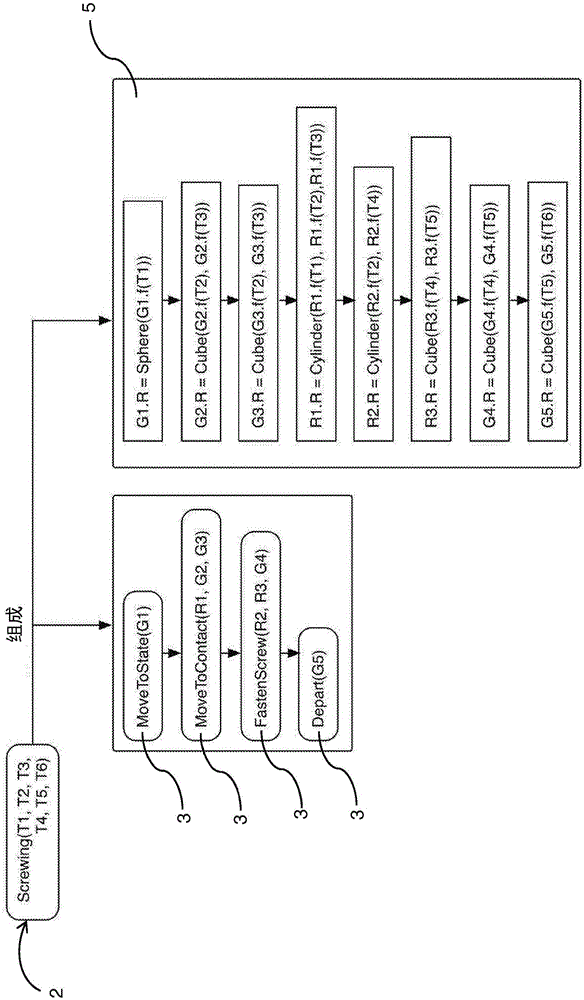

Method and system for programming a robot

ActiveCN106457565ACreate quicklyEasy to useProgramme controlProgramme-controlled manipulatorRobotic armComputer module

The invention relates to a method for programming a robot, in particular a robot comprising a robotic arm, in which method a movement to be performed by the robot is set up preferably in a robot programme by means of a predefined motion template, the motion template is selected from a database comprising a plurality of motion templates, the motion template comprises one or more execution modules that can be parameterized and at least one learning module, the one or more execution modules are used for planning and / or performing the robot movement or part of the robot movement, the leaning module records one or more configurations of the robot during an initialization process, in particular in the form of a teaching process, and the learning module calculates parameters for the one or more execution modules on the basis of the recorded configurations, preferably using an automatic learning process. Also disclosed is a corresponding system for programming a robot.

Owner:ARTIMINDS ROBOTICS

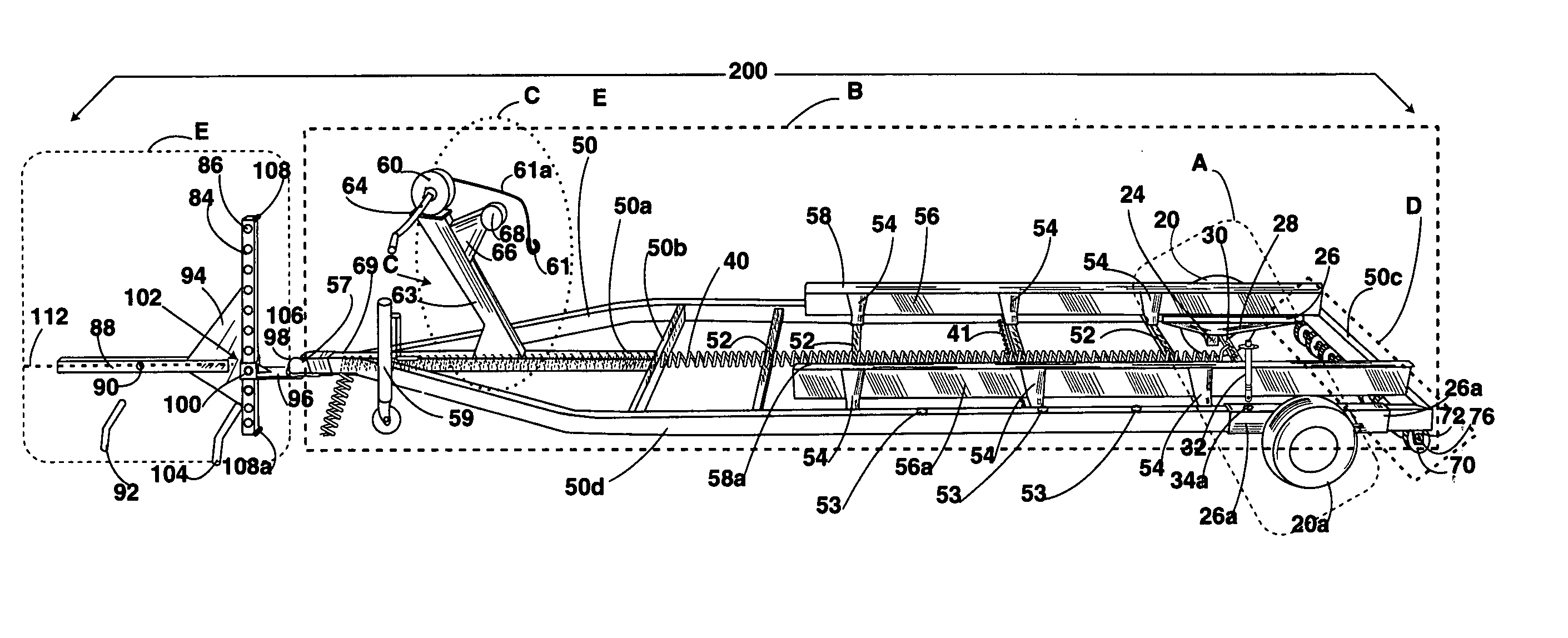

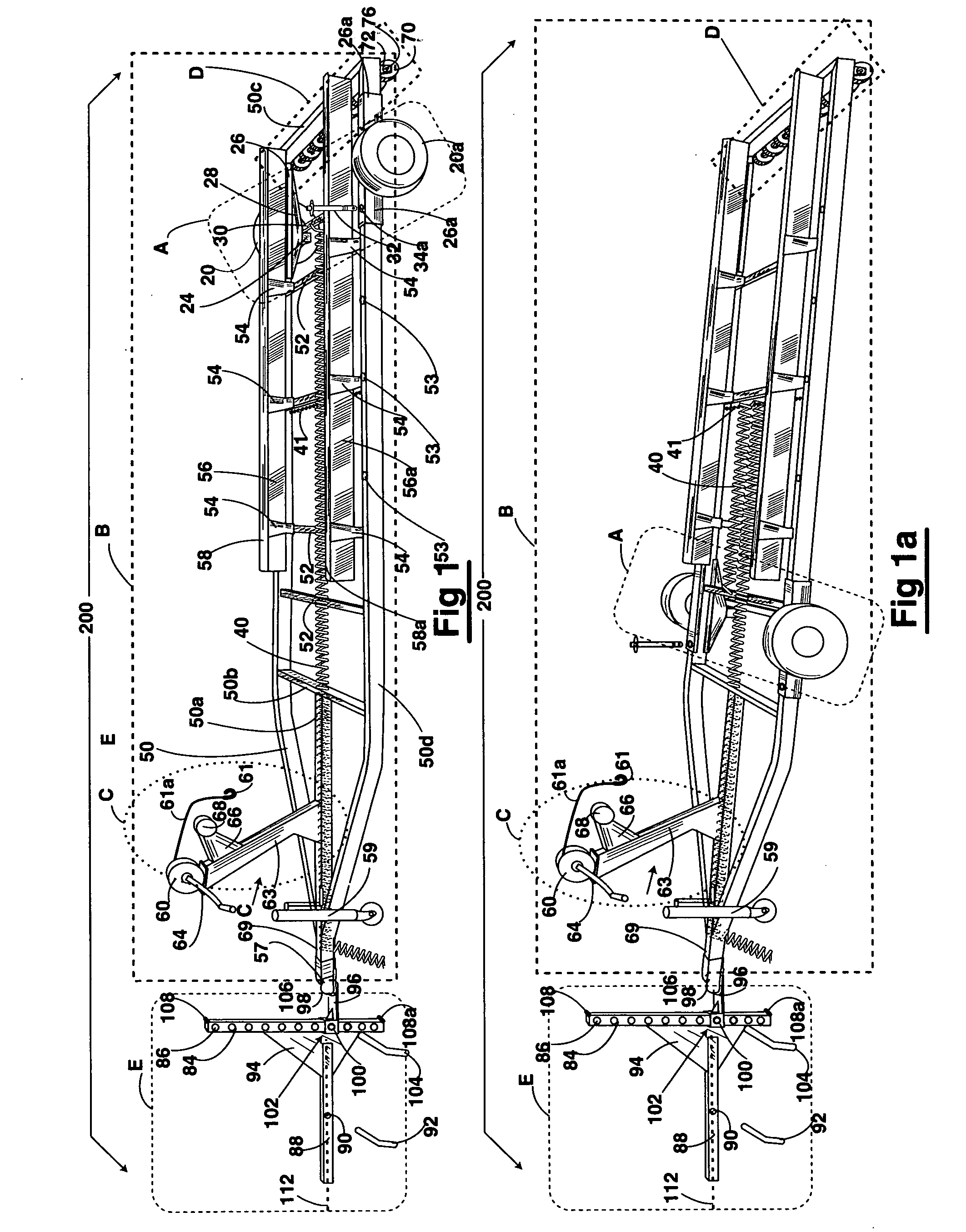

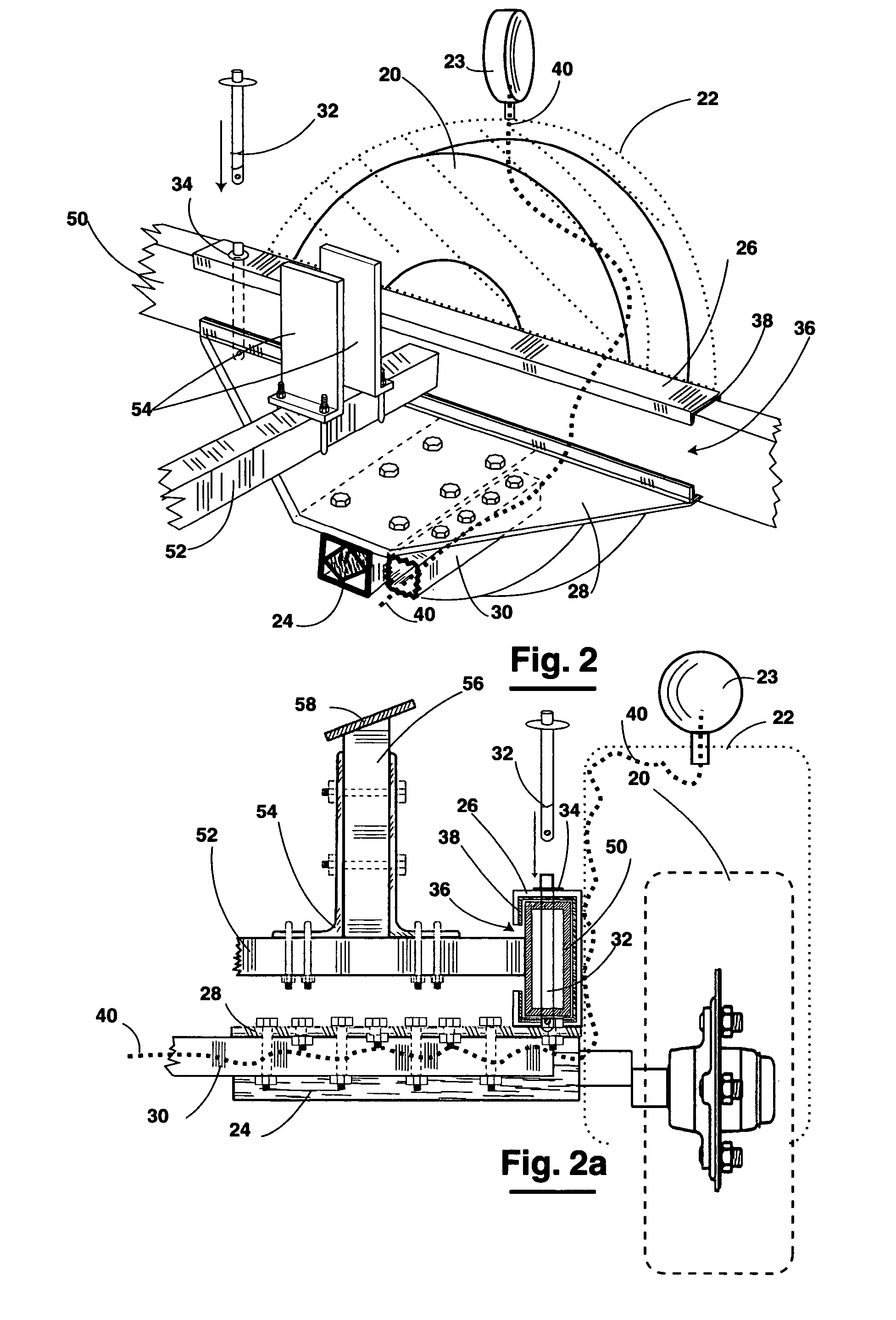

No-ramp trailer

InactiveUS20050173892A1Low maintenanceReduce accidentsSuspensionsItem transportation vehiclesHorizontal axisGround plane

A method of manufacture of vehicular trailers comprised of: a suspension system (A) slidably attached to a load bearing frame structure (B) enabling said load bearing frame structure (B) to horizontally pass over the vertical axis of said suspension system (A); a means (C) to apply force so as to cause or tend to cause motion toward the source of the force; a rotatable means (D) allowing said load bearing frame structure (B) to roll along a surface; a floating link variable height hitch assembly (E) providing a means for the tongue of the trailer to move vertically and past the horizontal axis of a generic hitch receiver (10d). The combined dynamics of (A),(B),(C), and (D) enabling said load bearing frame structure (B) to deploy or retrieve a load at or beneath a ground plane of the towing vehicle; an asymmetrical design of said floating link adjustable hitch assembly providing a means to enable adaptation to any height towing vehicle (120) by rotation in the generic hitch receiver (10d) 180°; in the case of the preferred embodiment hereof a boat trailer combination (200) providing a means to launch and retrieve a boat into or out of the water at or below the ground plane of the towing vehicle without a launching ramp or extraneous apparatus and without water contamination; in the case of an additional embodiment hereof a multiple use vehicular trailer providing a means to deploy to or retrieve to or from a ground plane equal to or beneath that of the towing vehicle.

Owner:TERMINELLO LEO FR

Features

- R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

Why Patsnap Eureka

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Social media

Patsnap Eureka Blog

Learn More Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com