Method and system for programming a robot

A technology of robots and programs, applied in the field of robotics, can solve problems such as uneconomical engineering work, reprogramming of short production runs, etc., to achieve the effect of tolerance of geometric shape deviation, simple programming, and robust setting

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

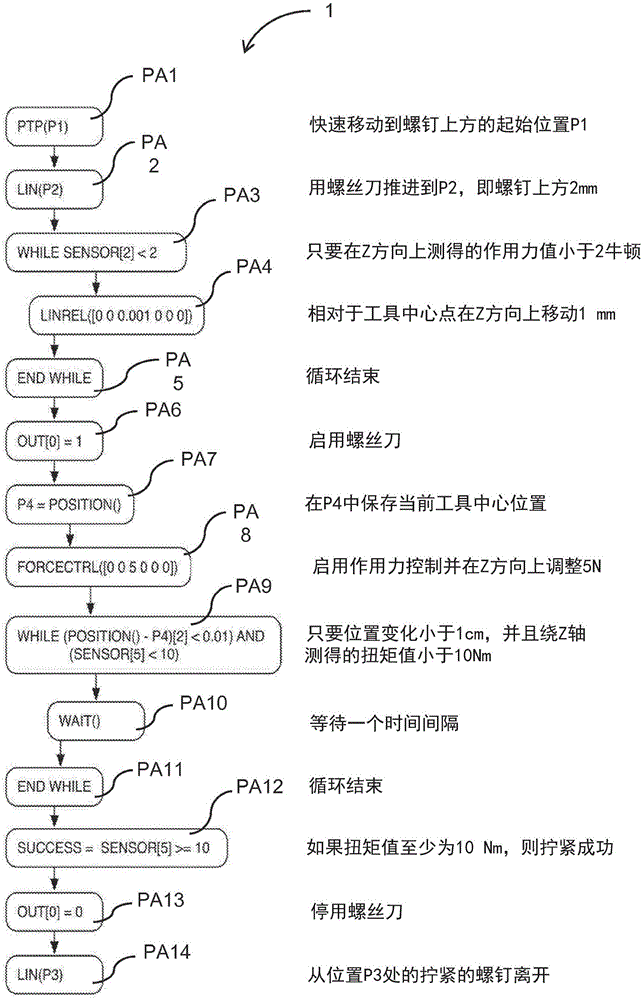

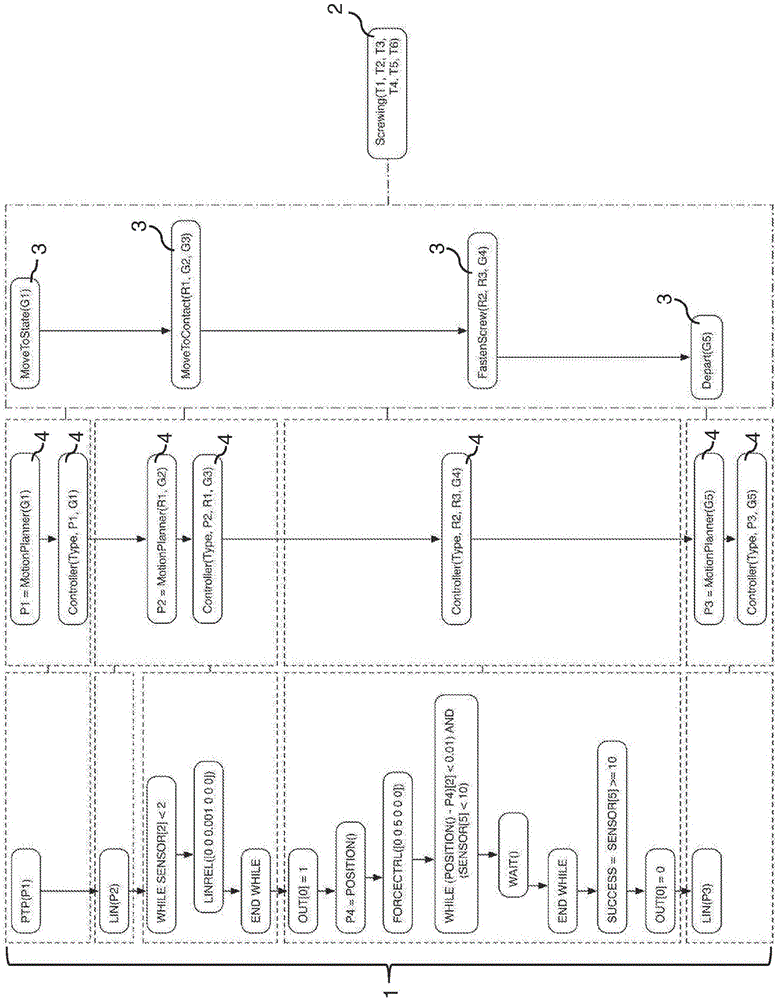

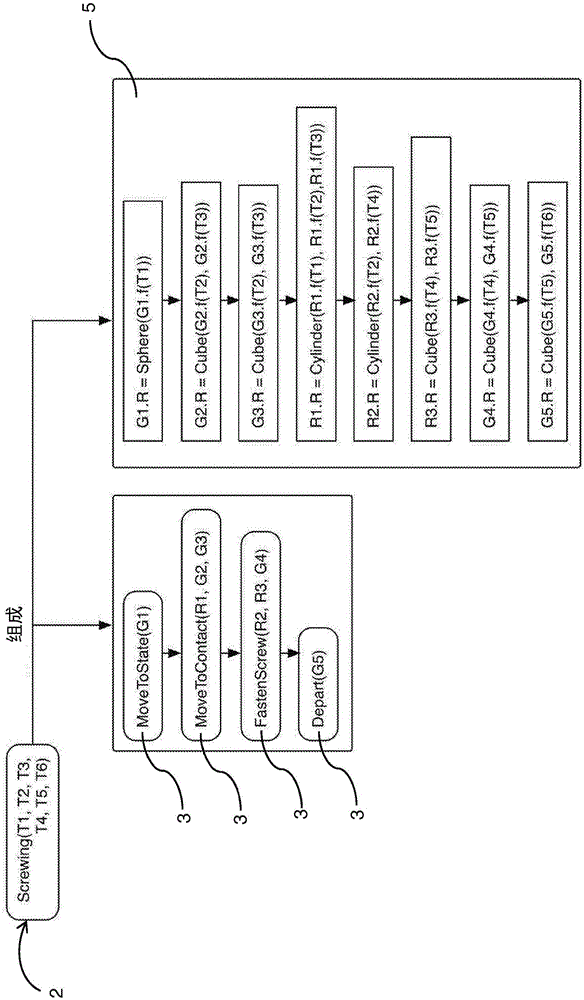

[0188] Figure 1 to Figure 12 An example of a common application is included, namely the programming of a robot that tightens a screw into a workpiece to a specific torque.

[0189] figure 1 A schematic diagram of an exemplary robot program 1 is shown, wherein a human will manually create a robot program 1 according to the prior art to tighten a screw to a predeterminable torque with a robot. In this specific example, according to figure 1 , the robot program 1 comprises instructions or robot commands intended to perform / do said tasks (in particular, in such a way that a human would currently have to program or create them manually). These boxes are individual robot commands with parameters. P1 , P2, P3 and P4 are teach points, preferably manually integrated by the programmer into the program as parameters. SENSOR[2] reads the Z value of the force / torque sensor on the robot; SENSOR[5] reads the torque around Z. OUT[0] = 1 or 0 enables or disables the screwdriver on the ro...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com