Patents

Literature

171results about How to "Noise is generated" patented technology

Efficacy Topic

Property

Owner

Technical Advancement

Application Domain

Technology Topic

Technology Field Word

Patent Country/Region

Patent Type

Patent Status

Application Year

Inventor

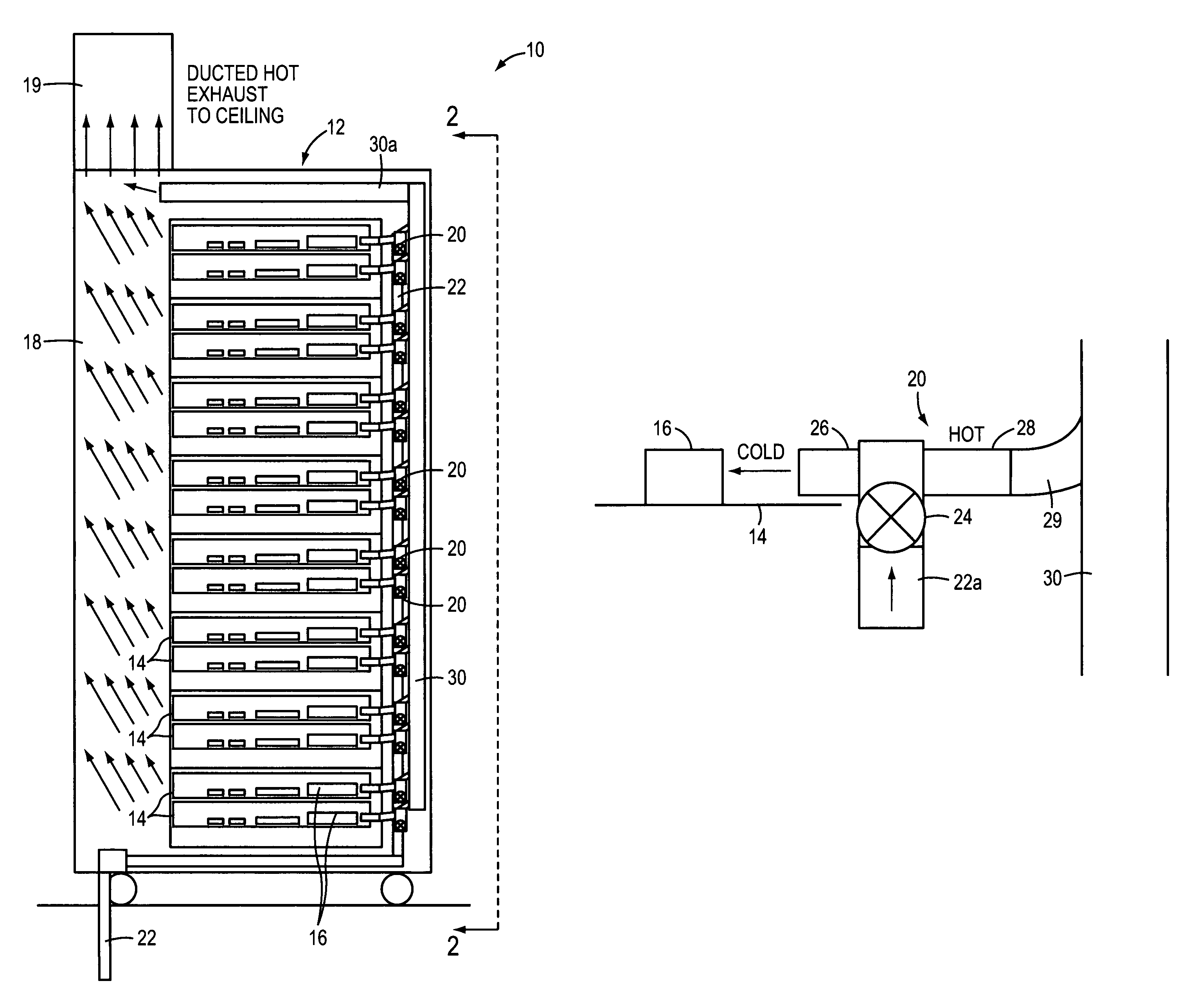

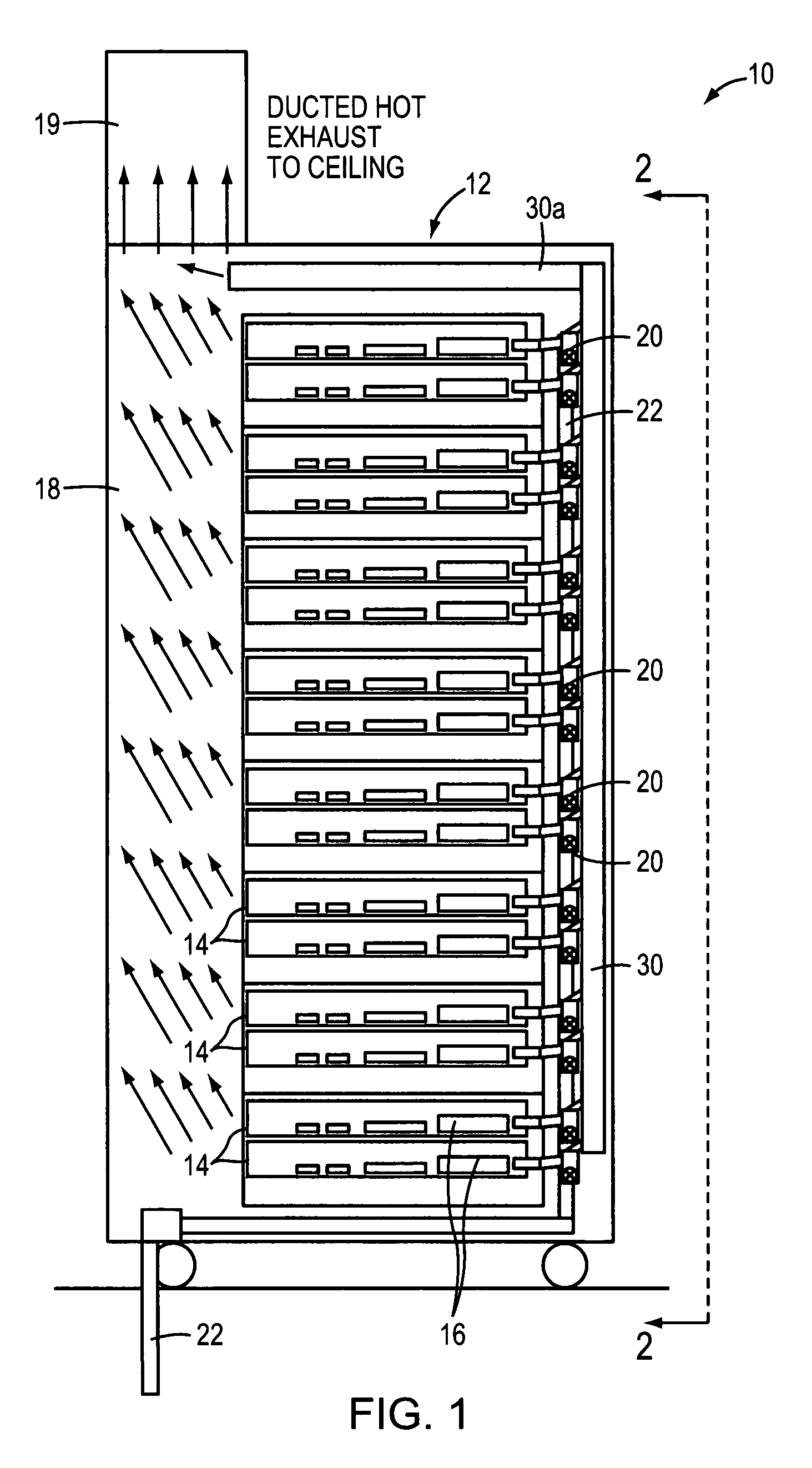

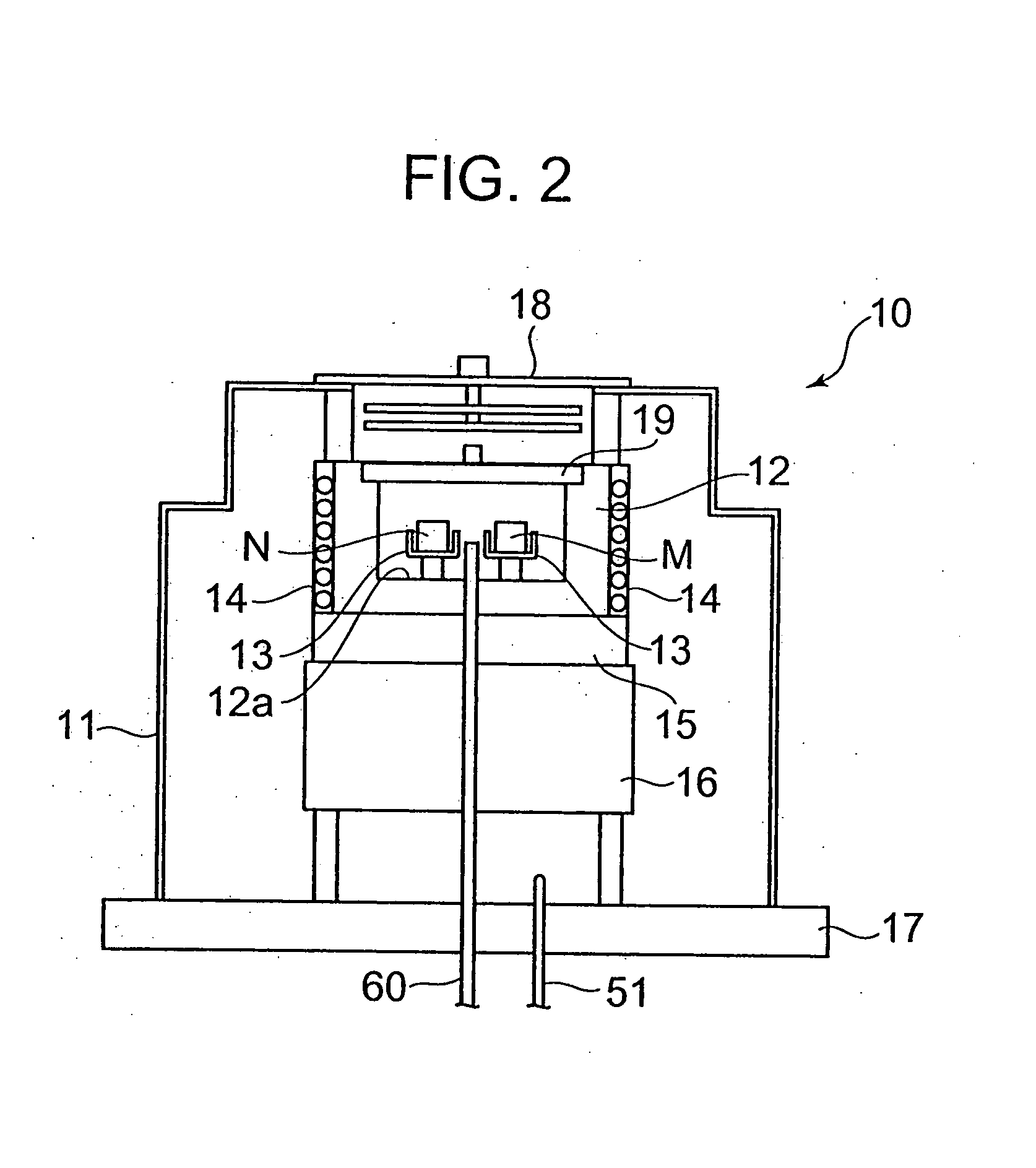

Method and system for providing cooling of components in a data storage system

ActiveUS7751188B1Improve cooling effectConsume high powerDomestic cooling apparatusCompression machinesCold airElectronic systems

Owner:EMC CORP

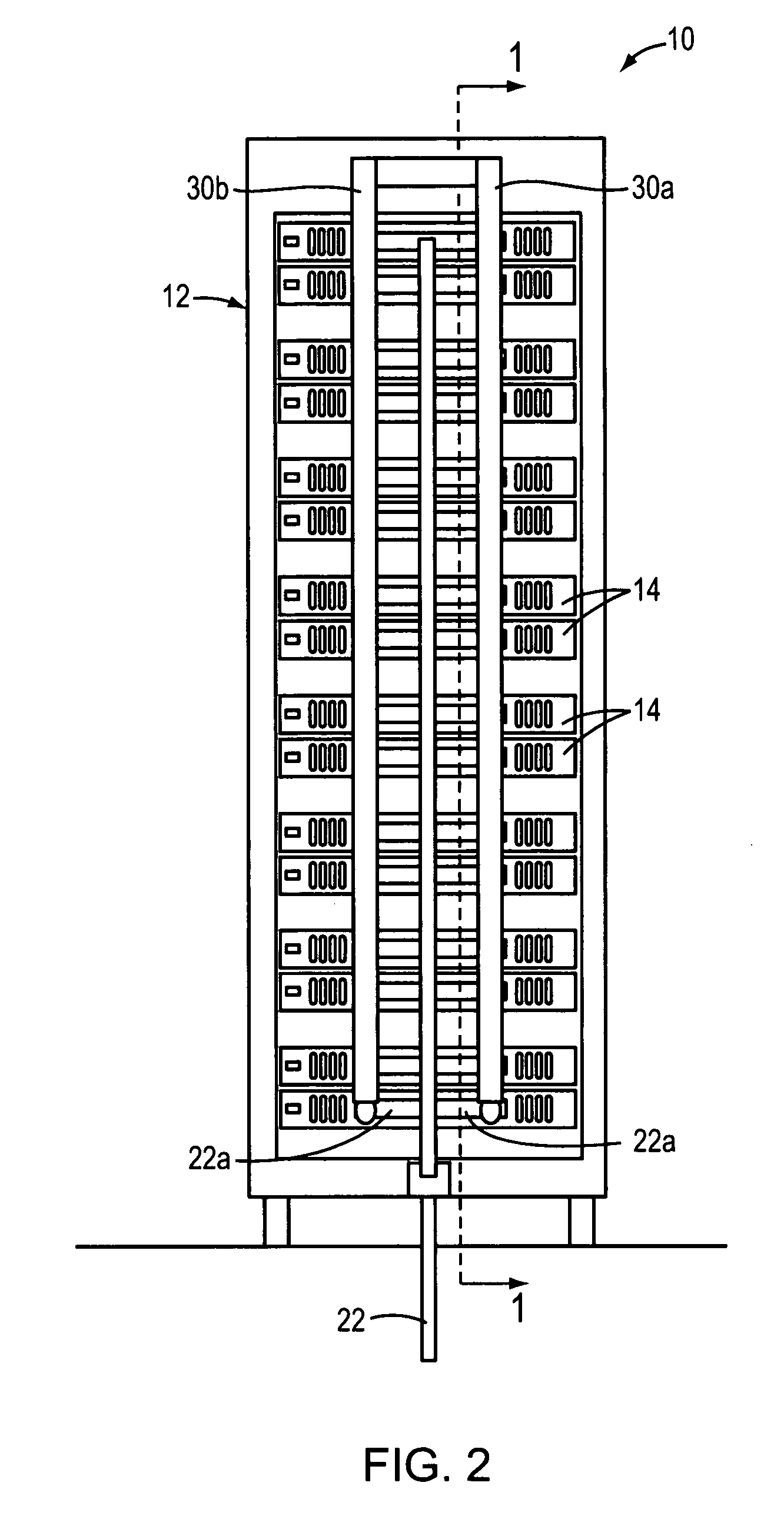

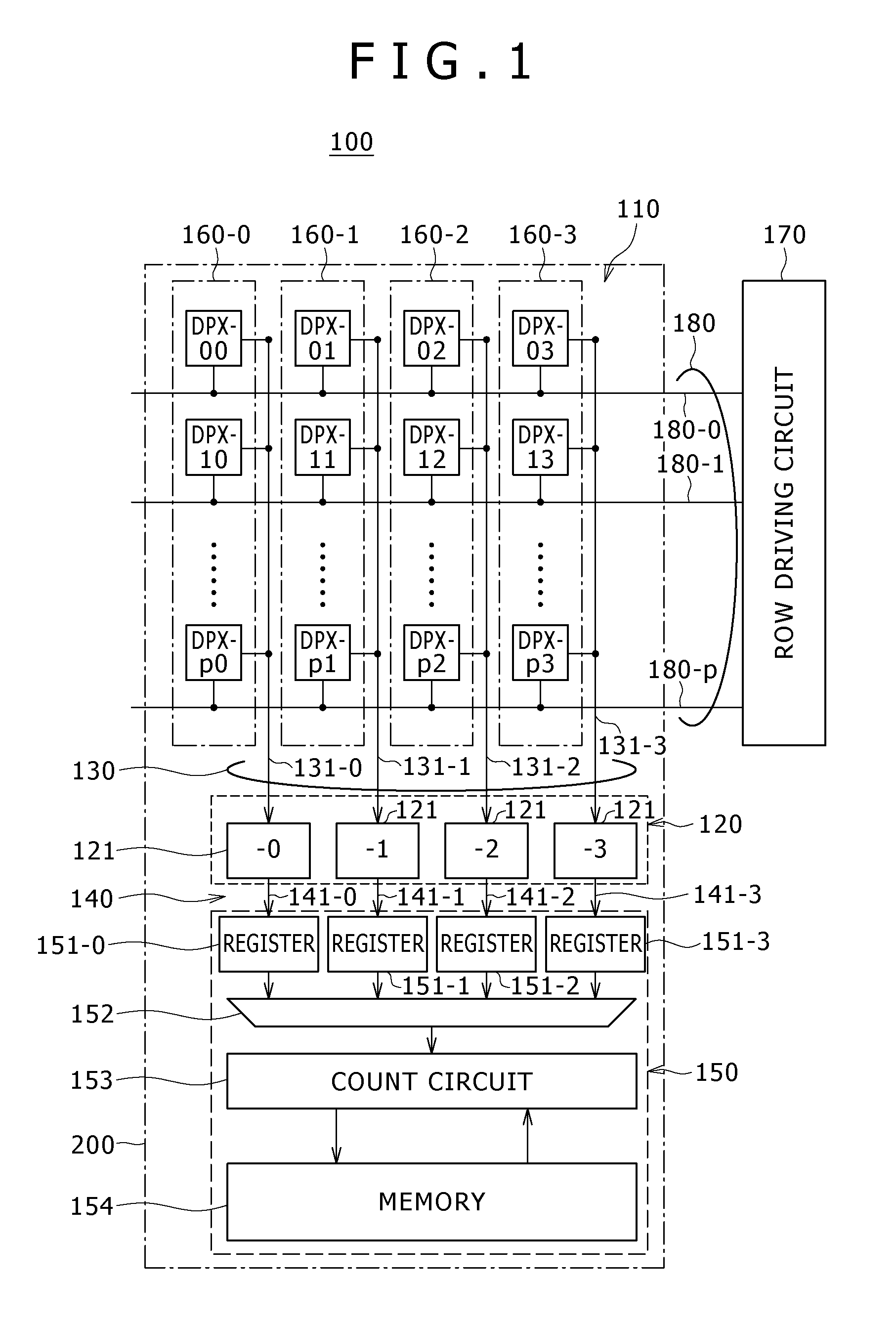

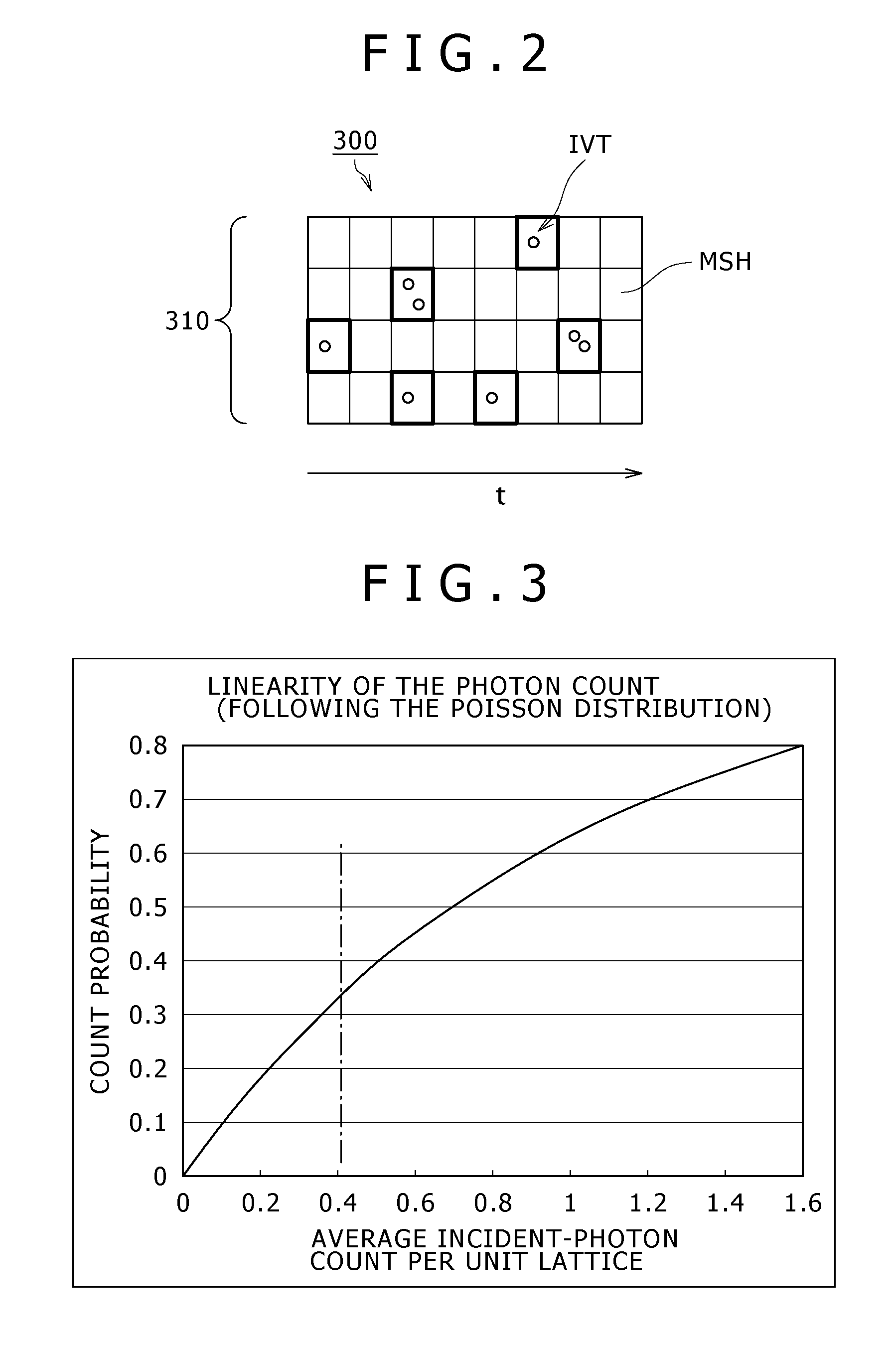

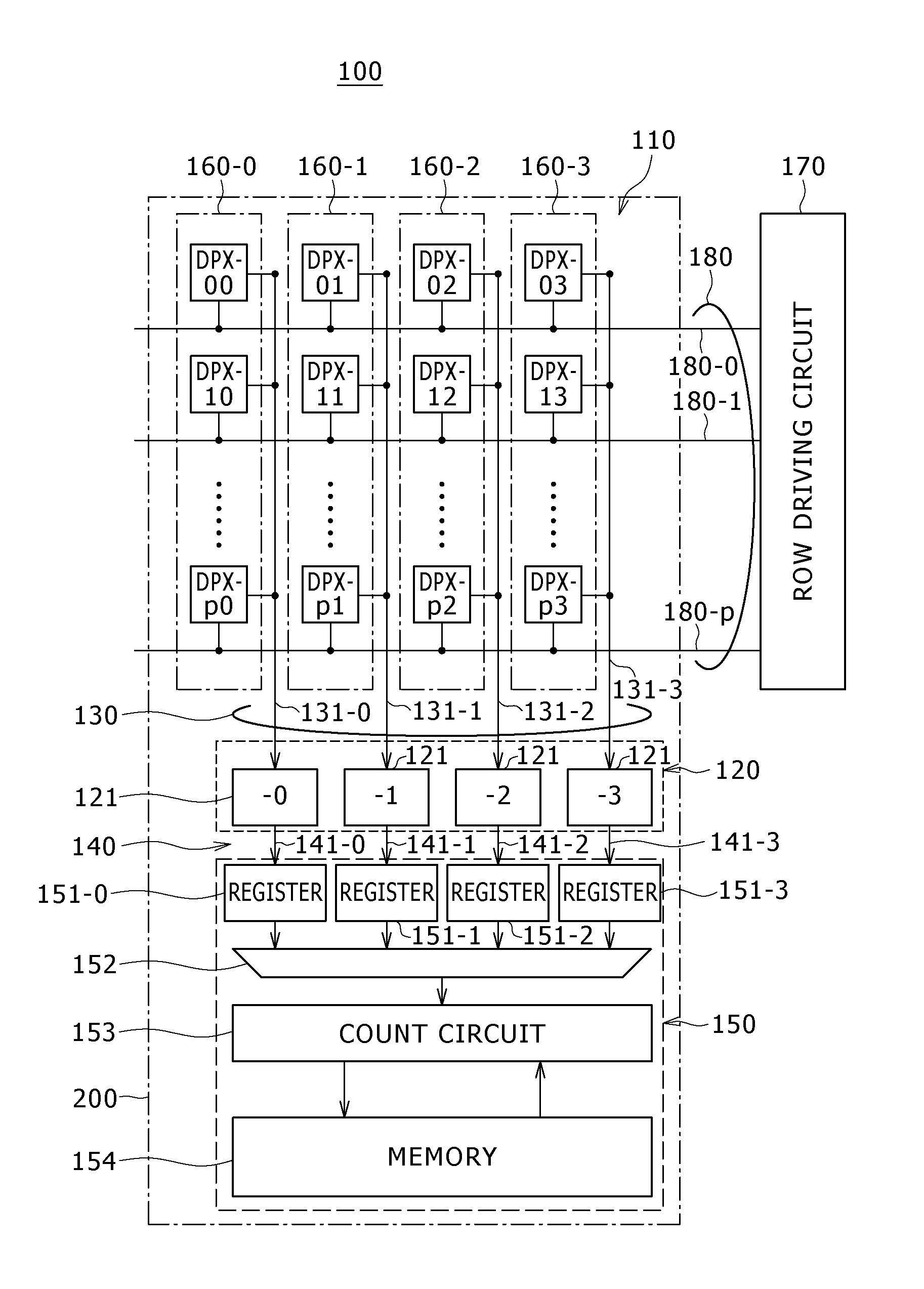

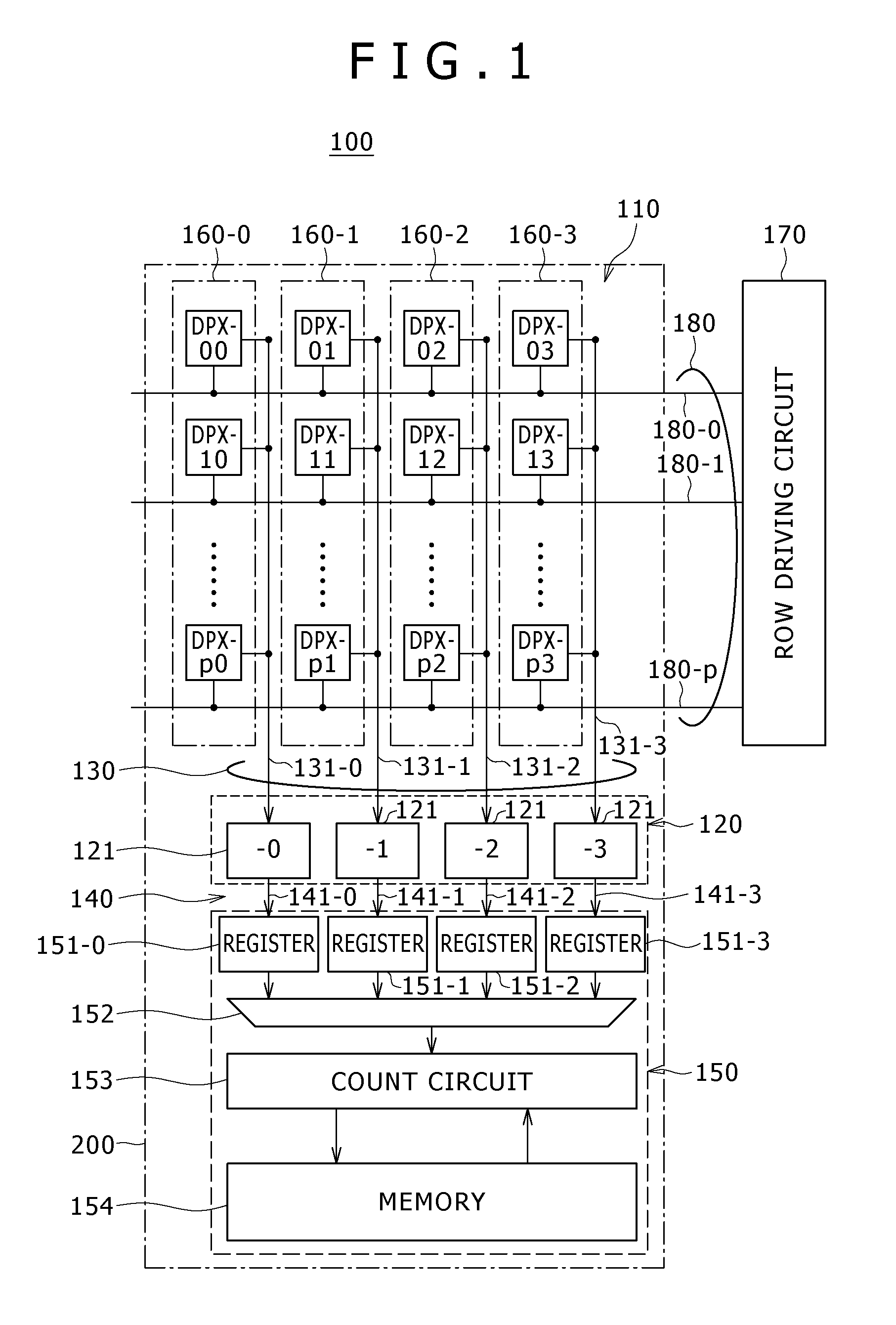

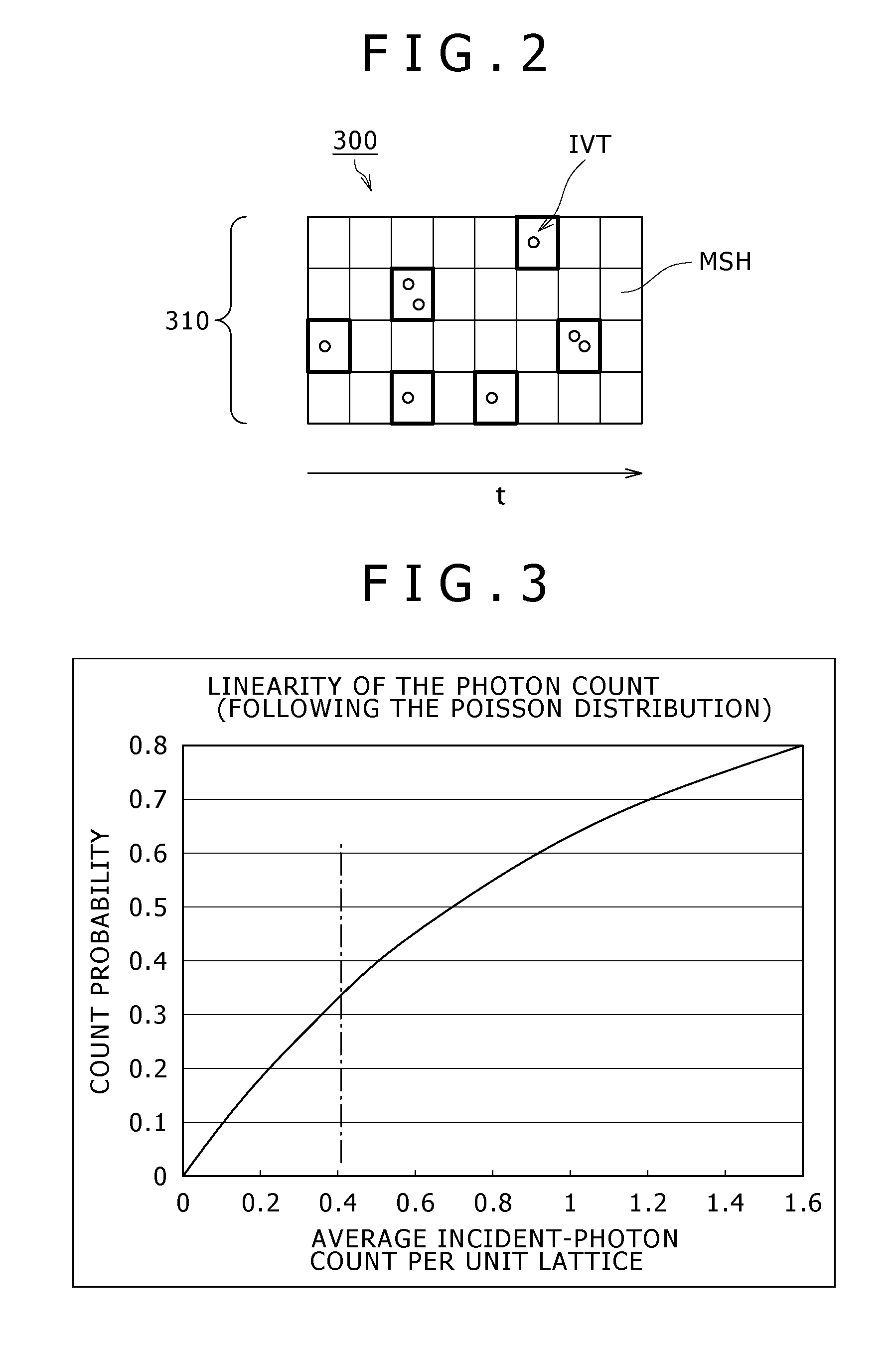

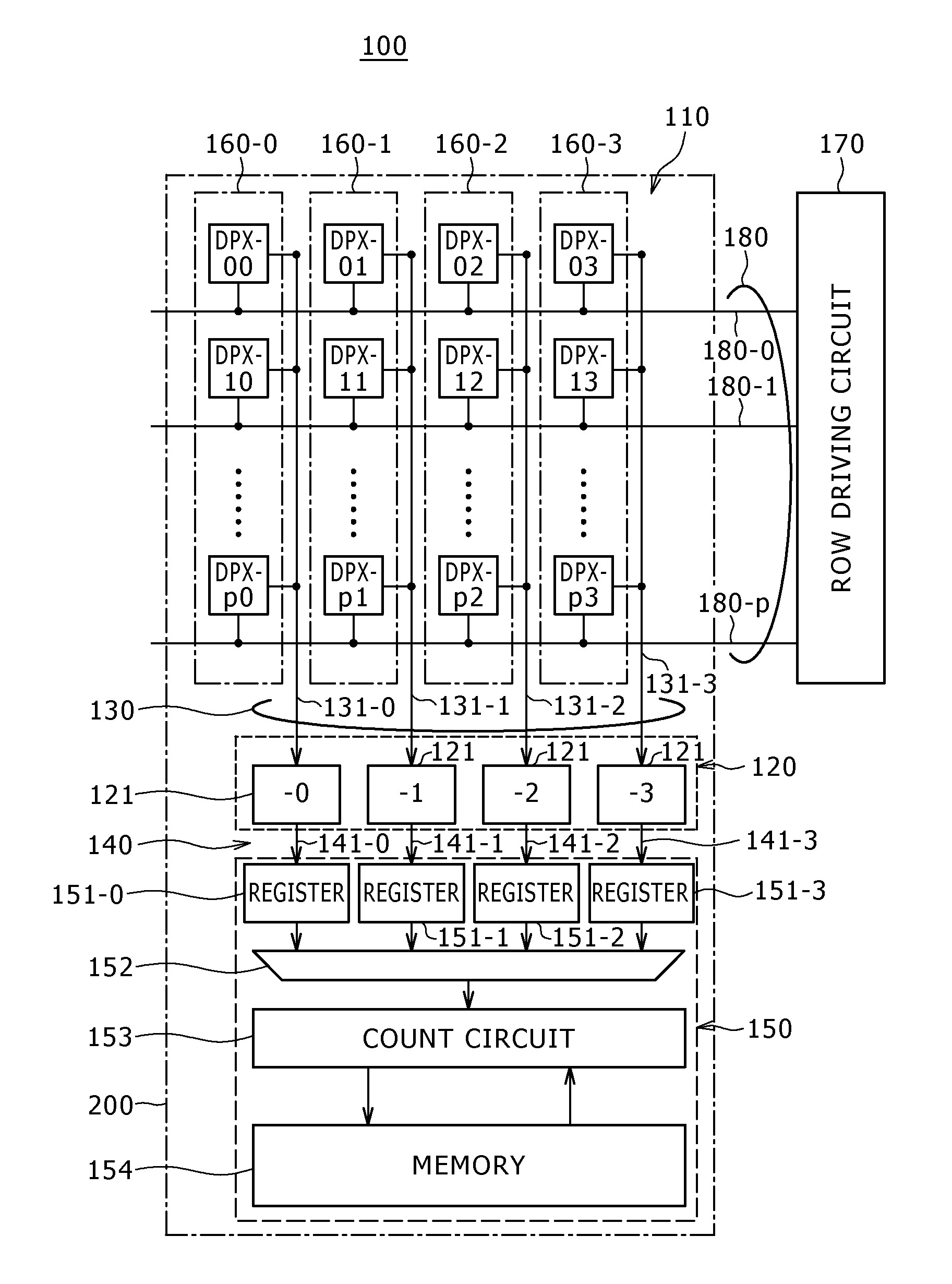

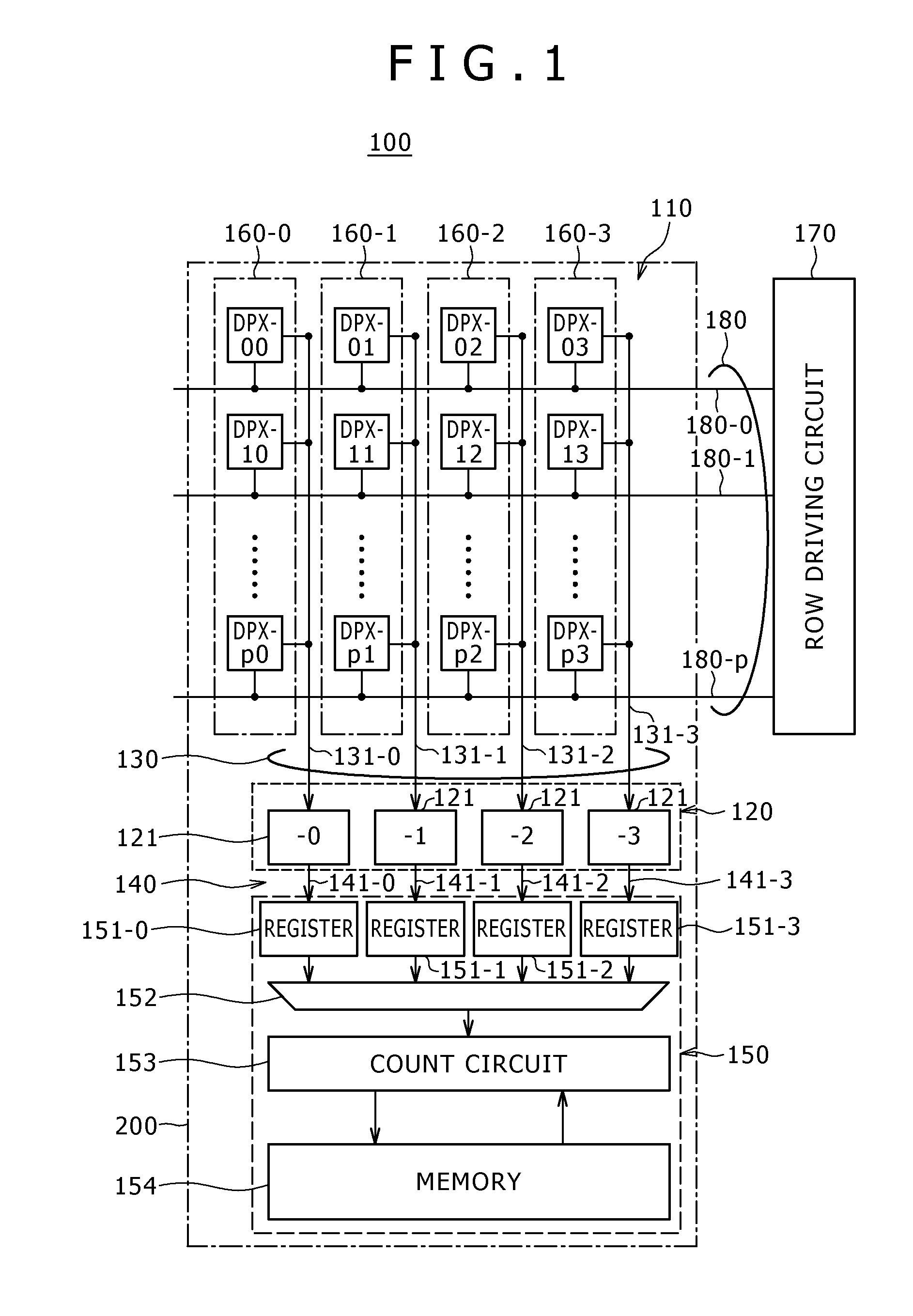

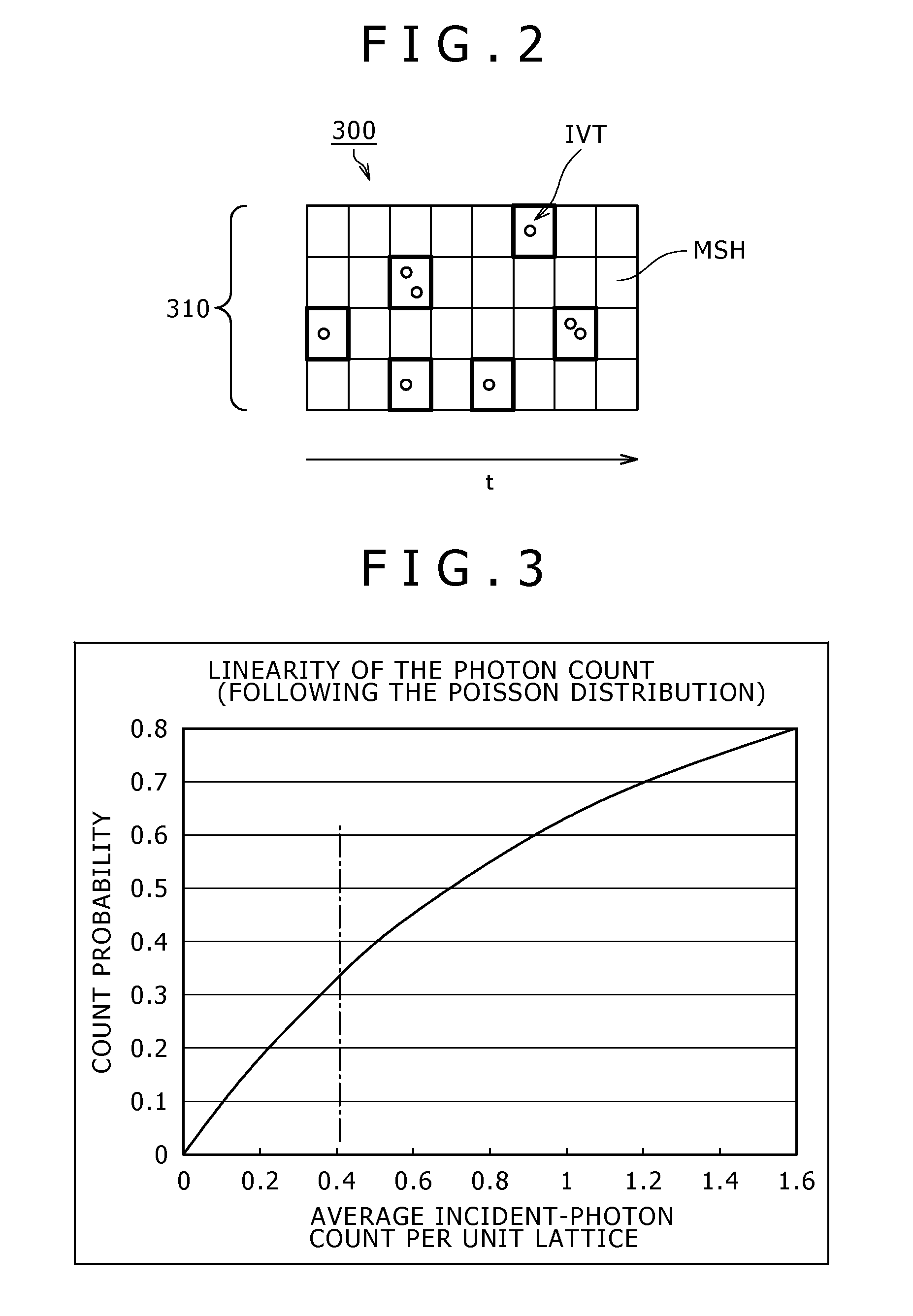

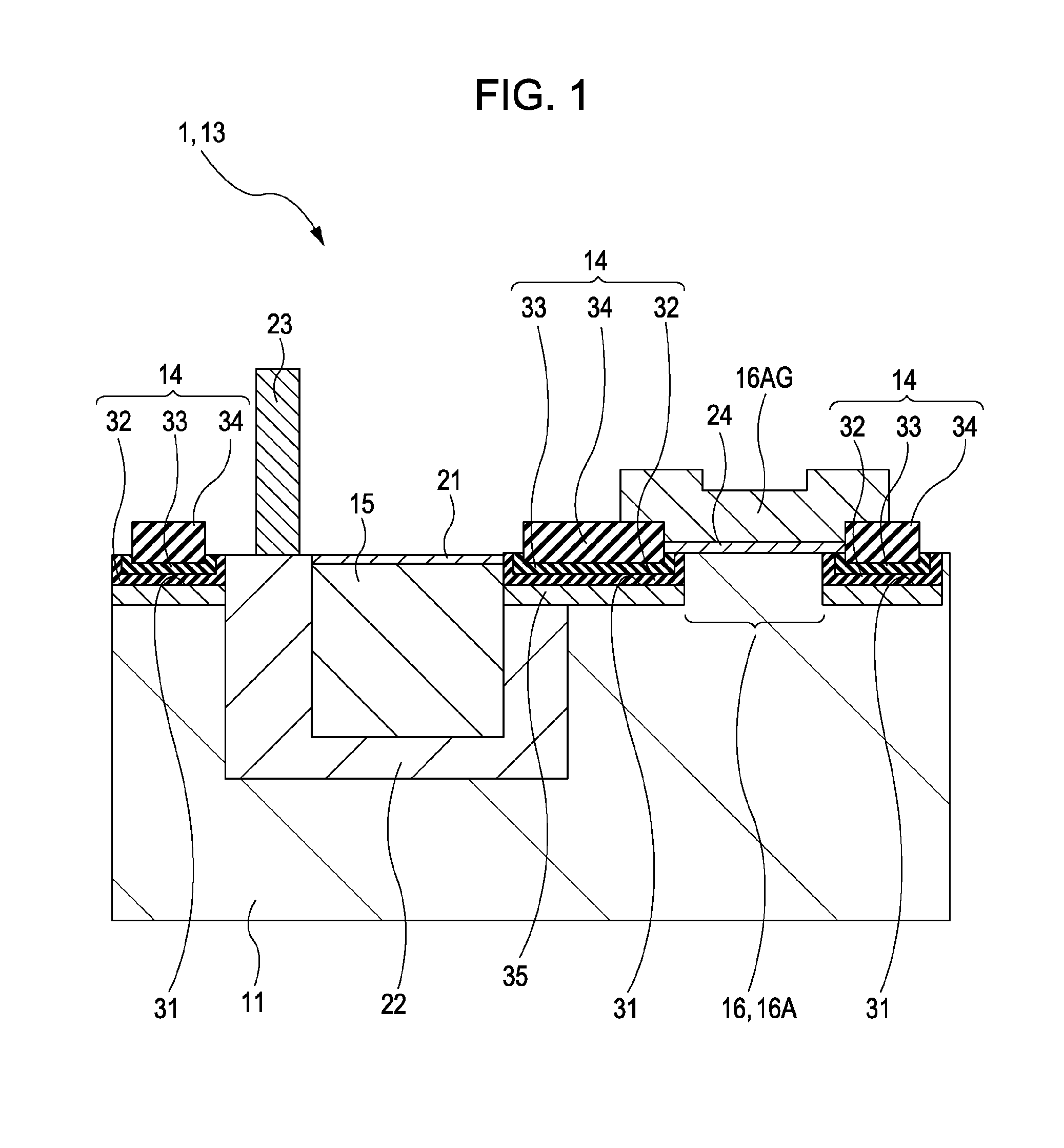

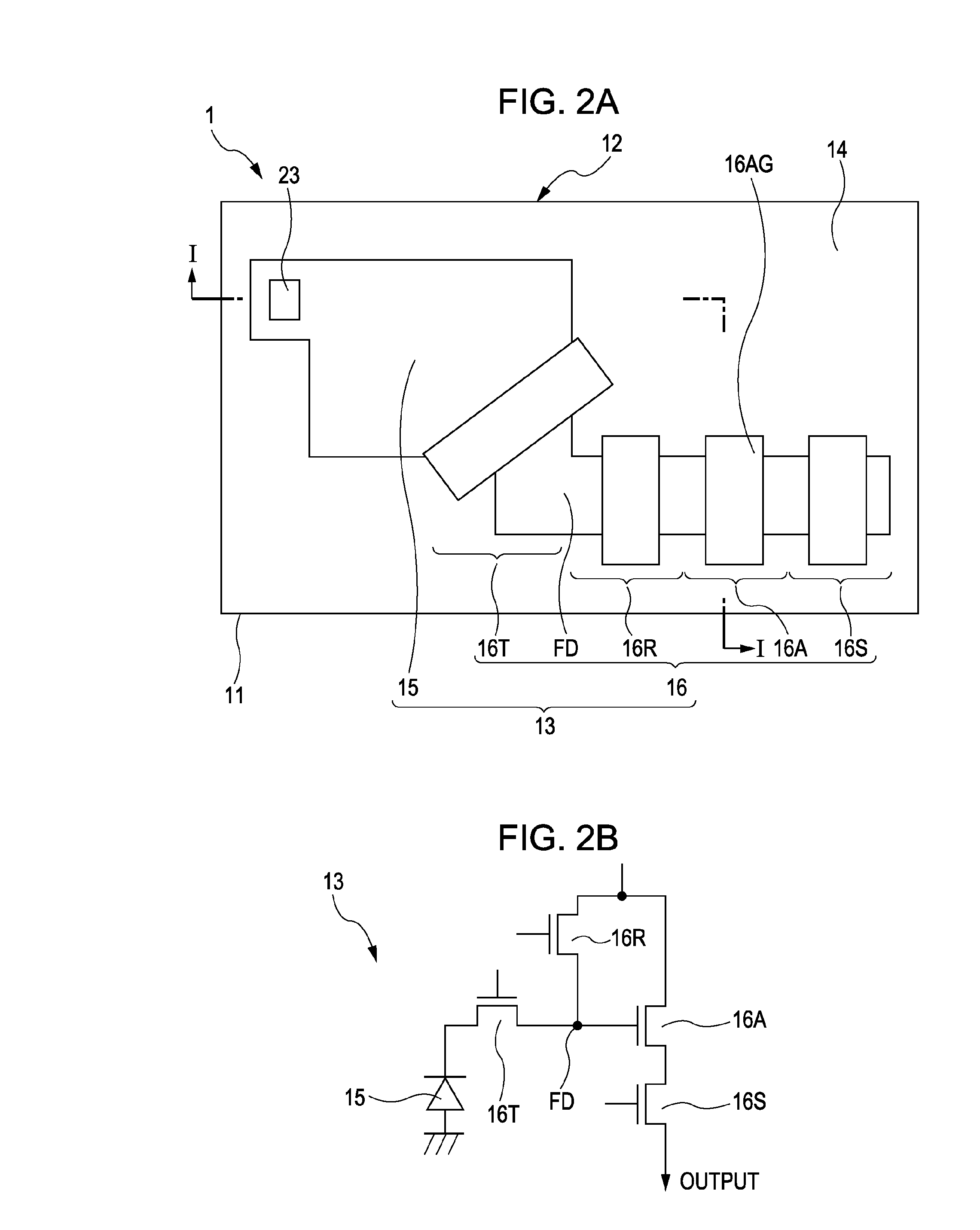

Image taking device and camera system

ActiveUS20110080510A1Reduce noiseLarge dynamic range without reducing the pixel aperture ratioTelevision system detailsTelevision system scanning detailsImage sensorBand counts

An image sensor includes a plurality of pixels, a plurality of sense circuits, and a count circuit. Each sense circuit is configured to read out electrical signals from at least one pixel associated with the sense circuit in order to generate data representing whether or not photons have been received by the sense circuit. The count circuit is in communication with a sense circuit selected from the plurality of sense circuits. The count circuit is configured to provide integration results for the pixels associated with the sense circuits based on the data received from the sense circuits.

Owner:SONY SEMICON SOLUTIONS CORP

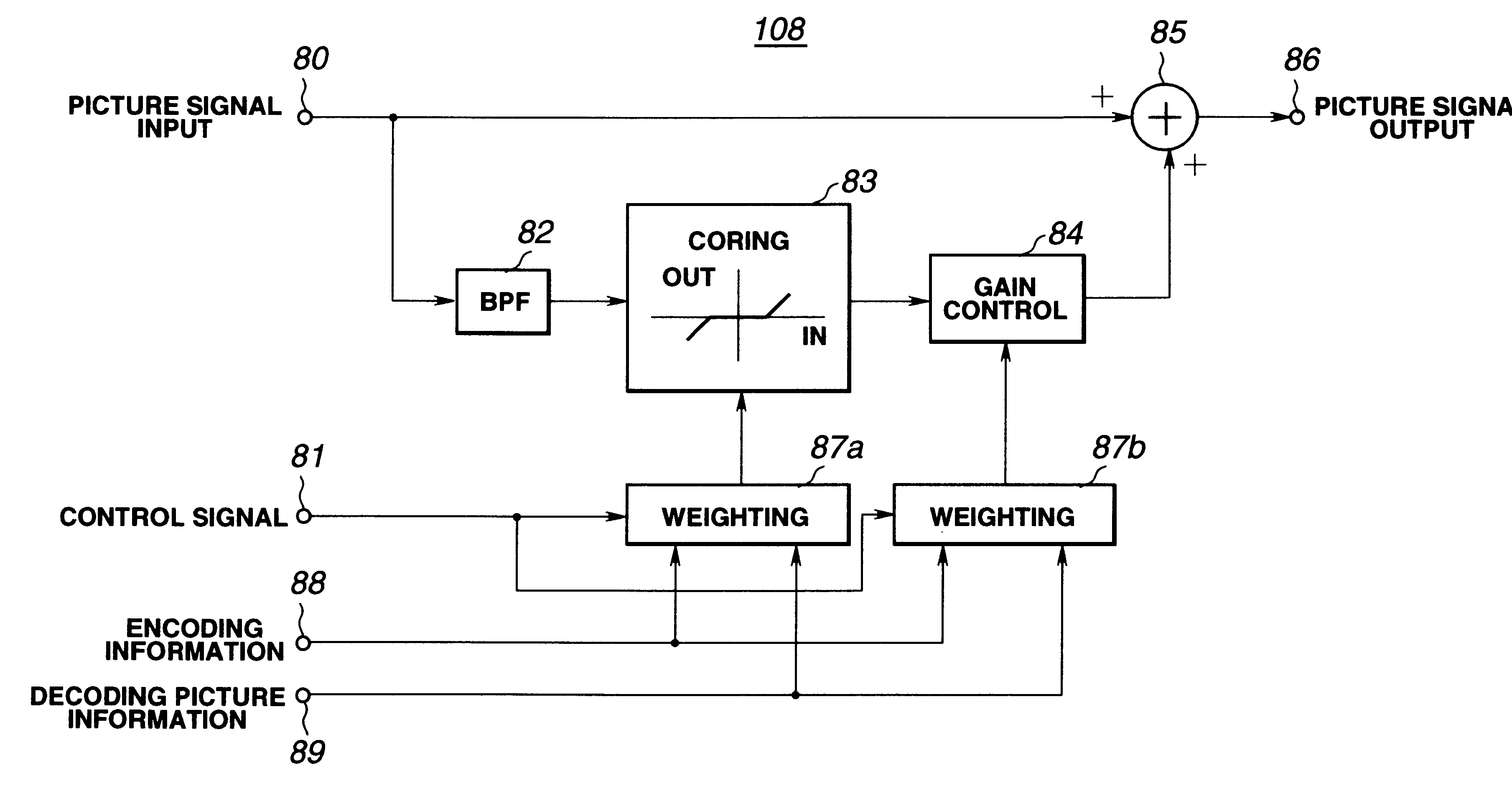

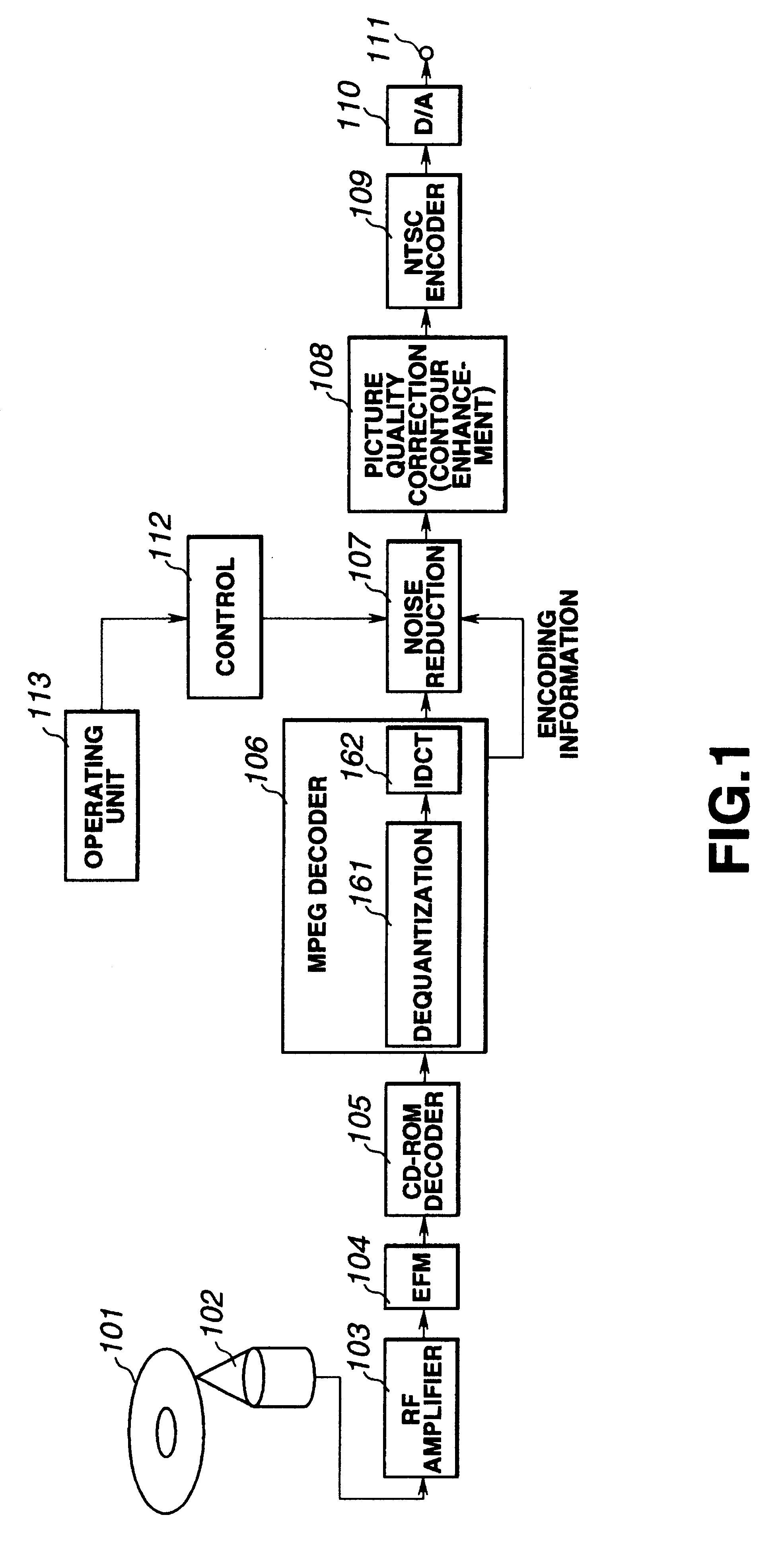

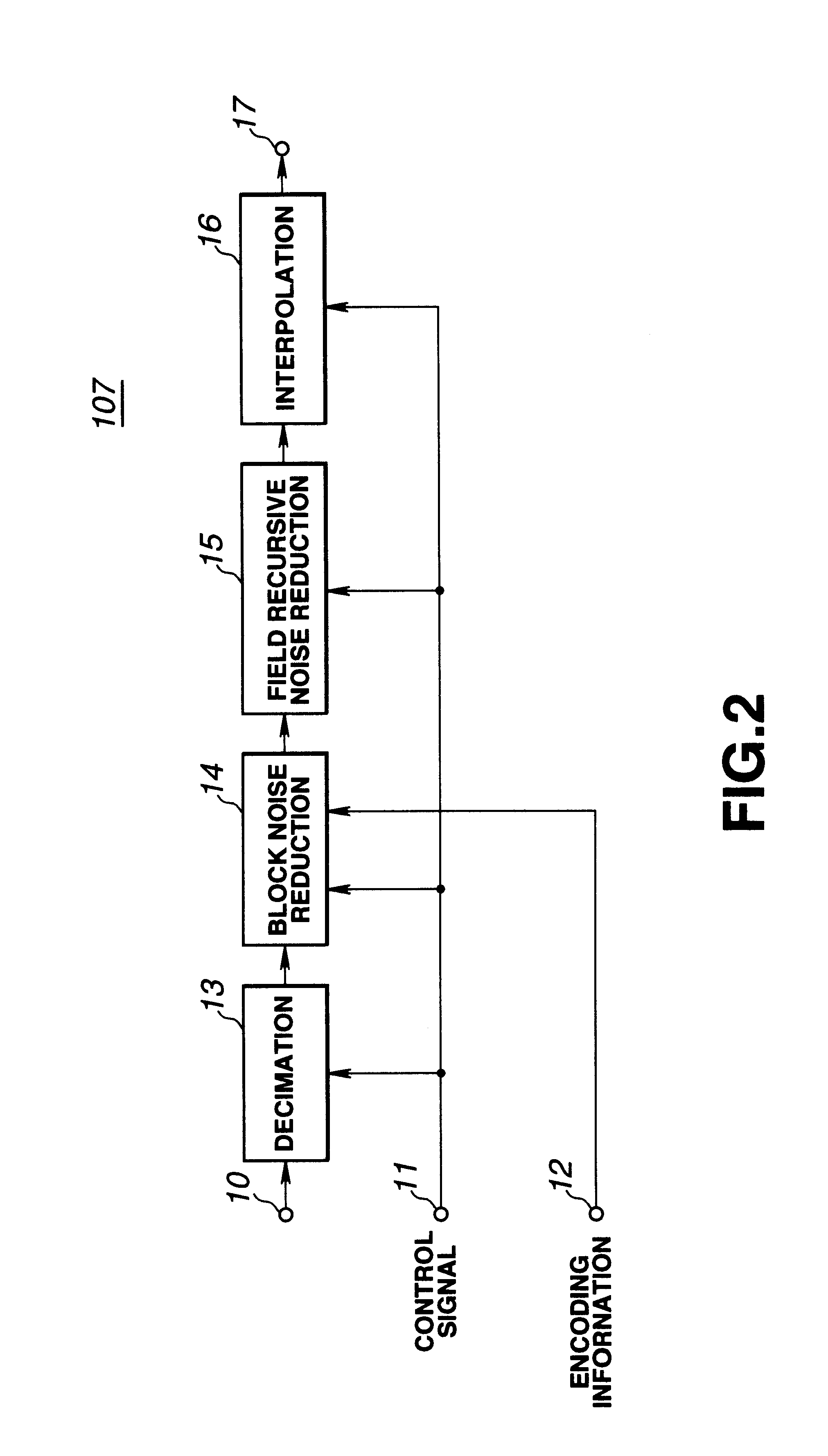

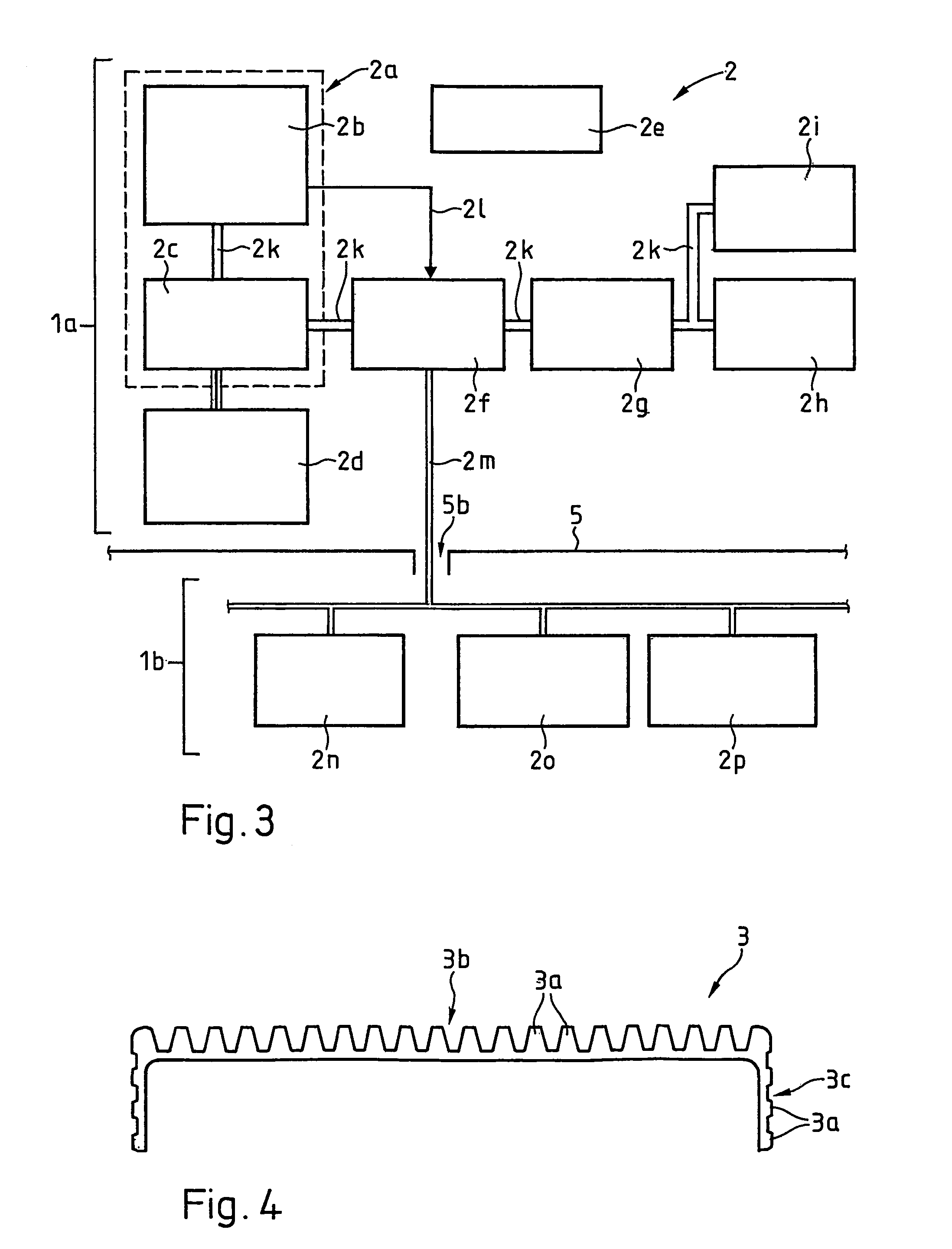

Picture signal encoding method and apparatus

InactiveUS6175596B1Reduce noiseNoise is generatedTelevision system detailsImage enhancementAlgorithmDistortion reduction

A picture signal processing method and apparatus in which the block distortion or the mosquito noise generated on picture compression / expansion using block encoding or the like is removed and picture quality correction such as contour enhancement is carried out effectively. Compression-encoded picture signals are expanded and decoded by a MPEG decoder 106 and the decoded picture signals are sent to a noise reducing circuit 107. The noise reducing circuit 107 reduces the noise by block distortion reduction or by field recursive type noise reduction. The resulting noise-reduced or noise-freed picture signals are sent to a picture quality correction circuit 108, which then performs picture quality correction, such as contour enhancement.

Owner:SONY CORP

Image taking device and camera system

ActiveUS8493483B2Large dynamic range without reducing the pixel aperture ratioNoise is generatedTelevision system detailsTelevision system scanning detailsComputer hardwareEngineering

An image sensor includes a plurality of pixels, a plurality of sense circuits, and a count circuit. Each sense circuit is configured to read out electrical signals from at least one pixel associated with the sense circuit in order to generate data representing whether or not photons have been received by the sense circuit. The count circuit is in communication with a sense circuit selected from the plurality of sense circuits. The count circuit is configured to provide integration results for the pixels associated with the sense circuits based on the data received from the sense circuits.

Owner:SONY SEMICON SOLUTIONS CORP

Image taking device and camera system

ActiveUS20130299677A1Large dynamic range without reducing the pixel aperture ratioNoise is generatedTelevision system detailsSolid-state devicesComputer sciencePhoton

Owner:SONY SEMICON SOLUTIONS CORP

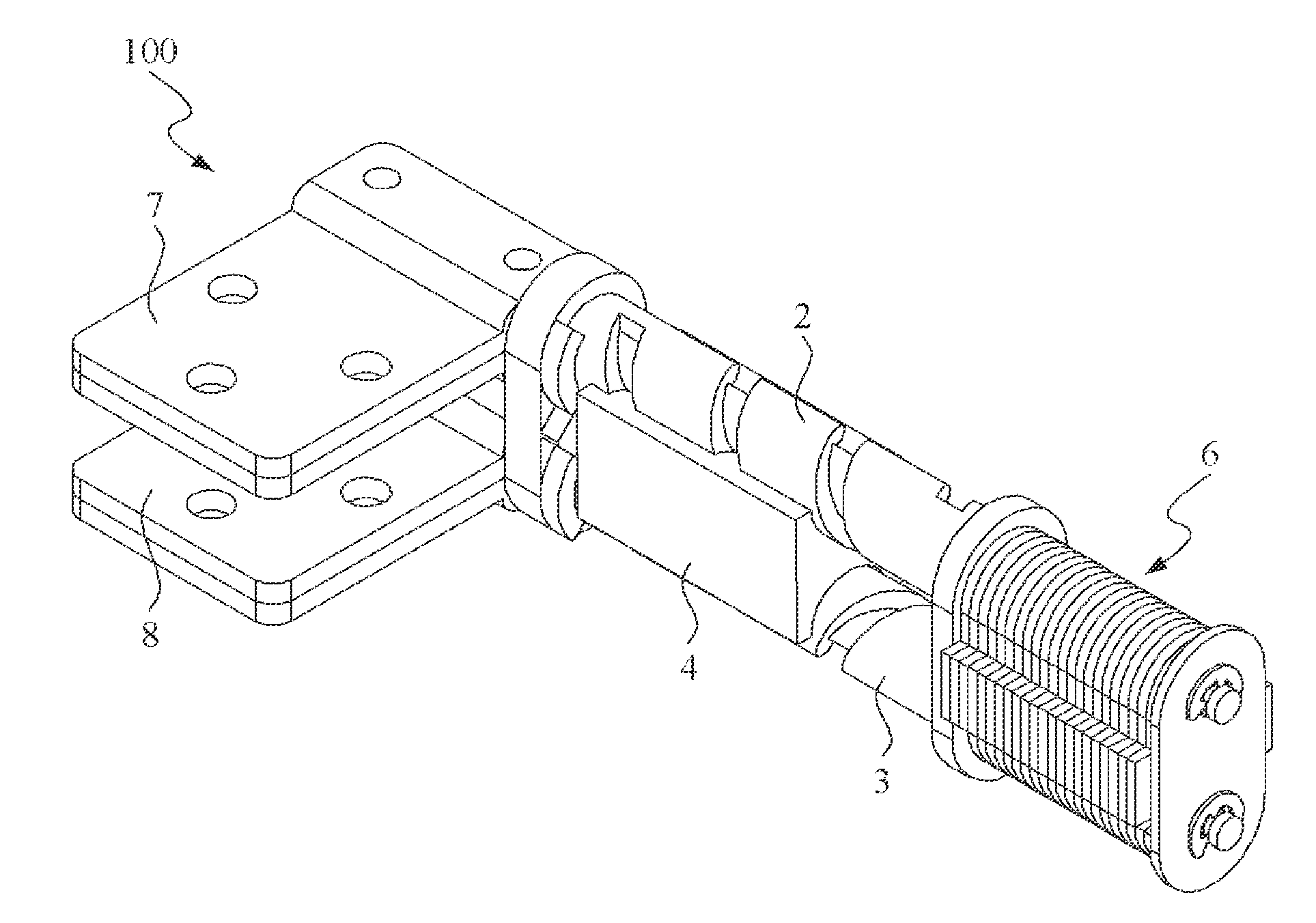

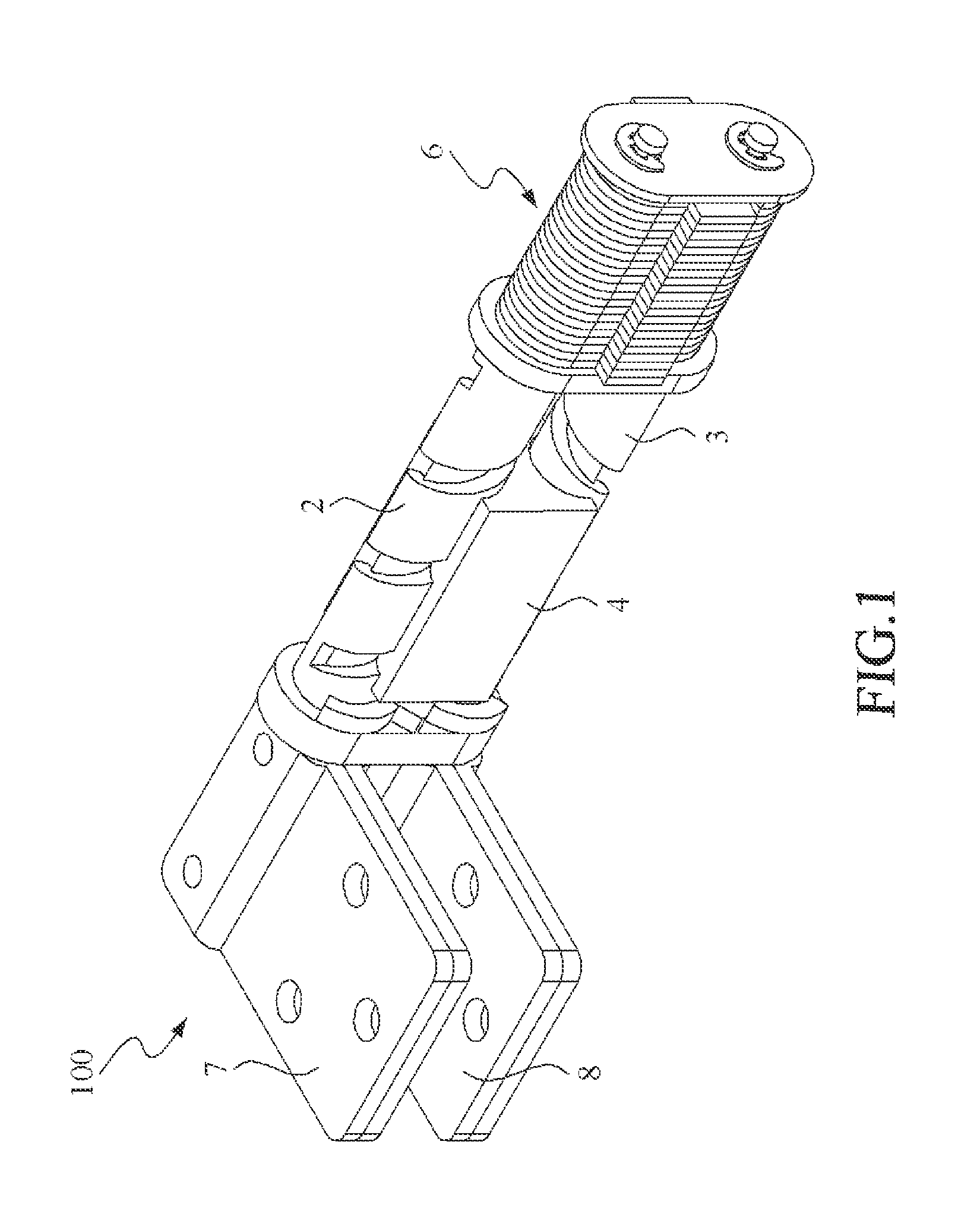

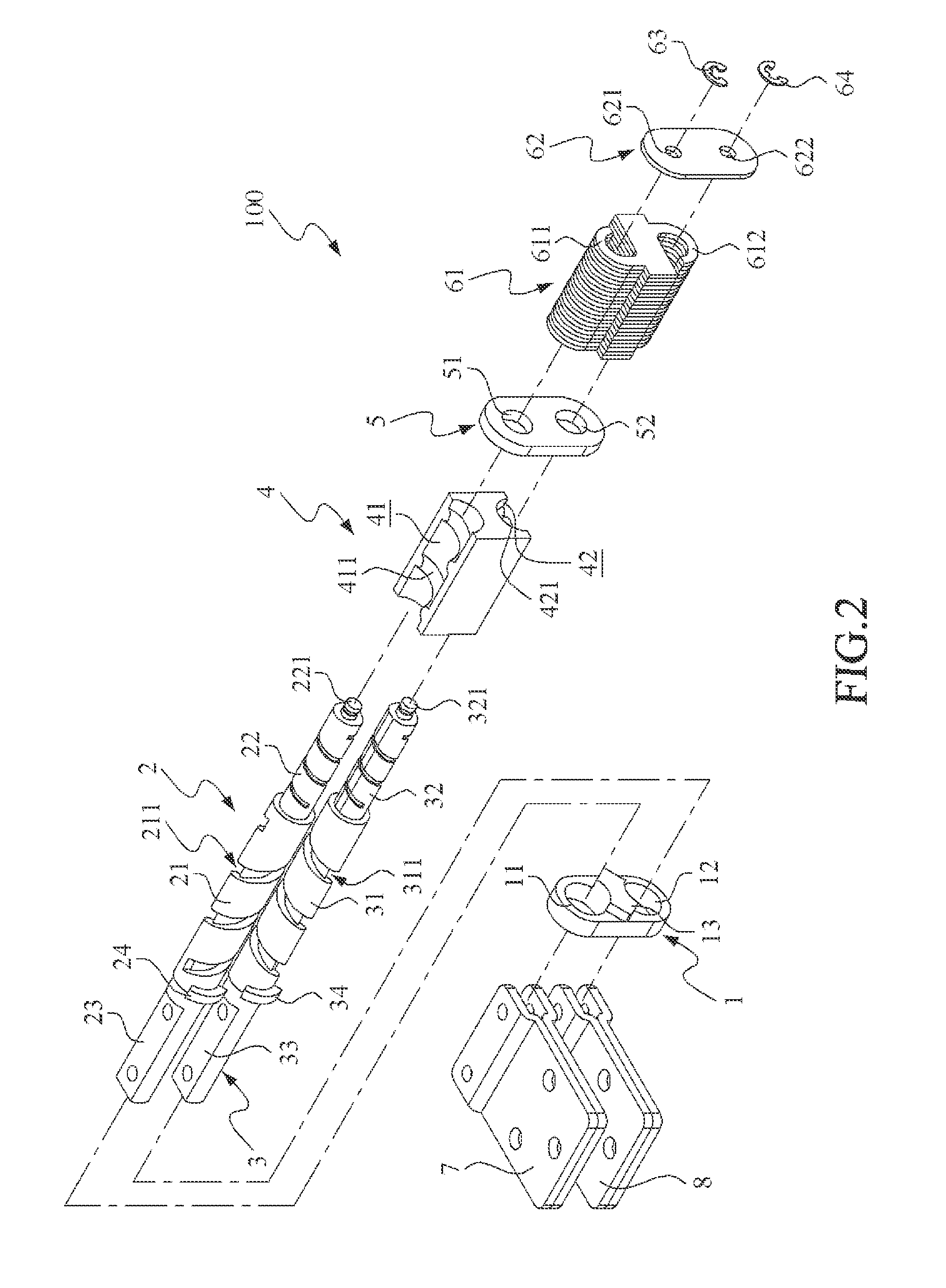

Hinge unit with simultaneous rotatable axles

InactiveUS20150160695A1Little noiseNoise is generatedWing accessoriesPin hingesEngineeringMechanical engineering

Owner:YUAN DENG METALS IND

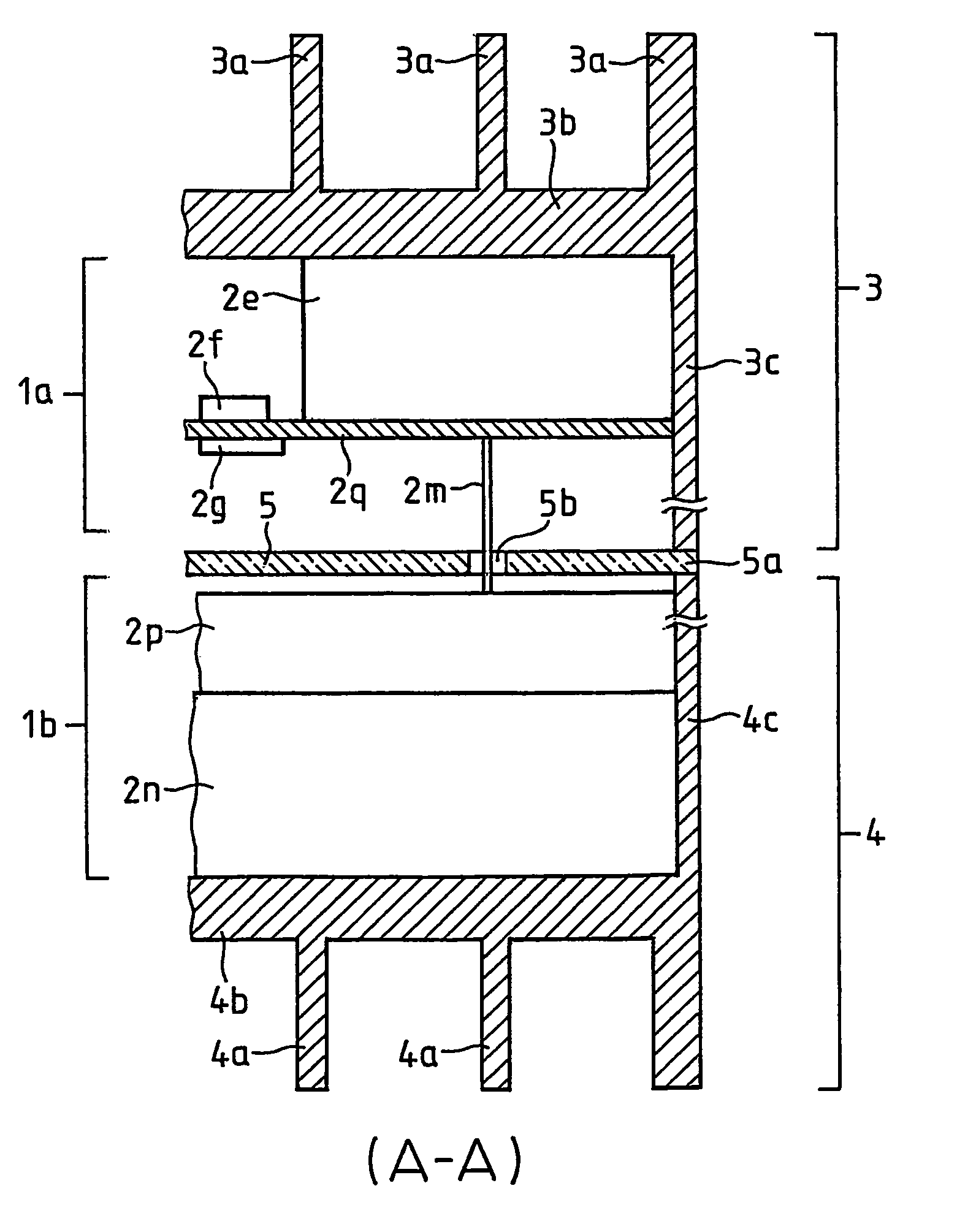

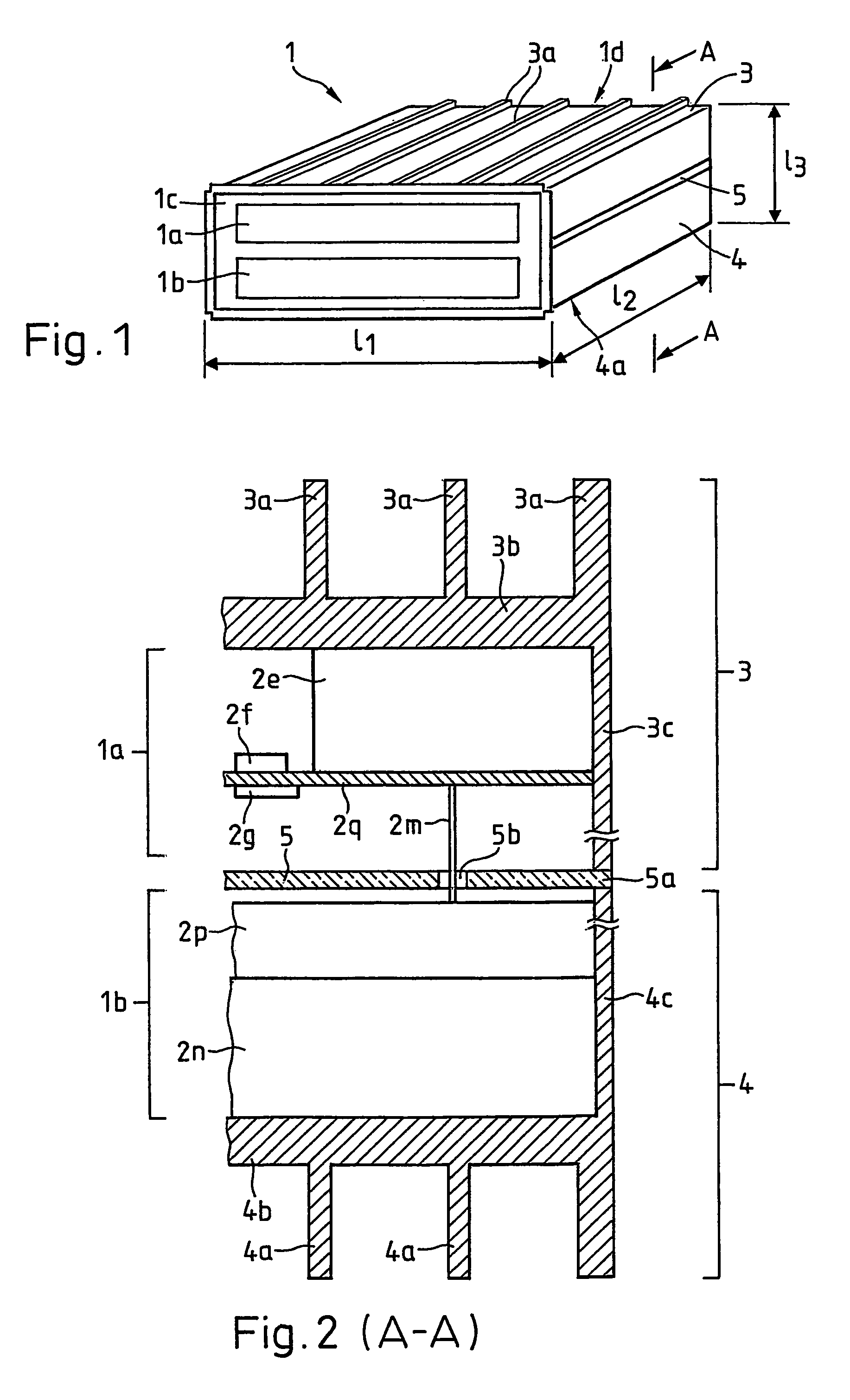

Housing for a passively cooled computer

InactiveUS7095611B2Avoid large buildupNoise is generatedSemiconductor/solid-state device detailsSolid-state devicesPassive coolingPetroleum engineering

Owner:KONTRON

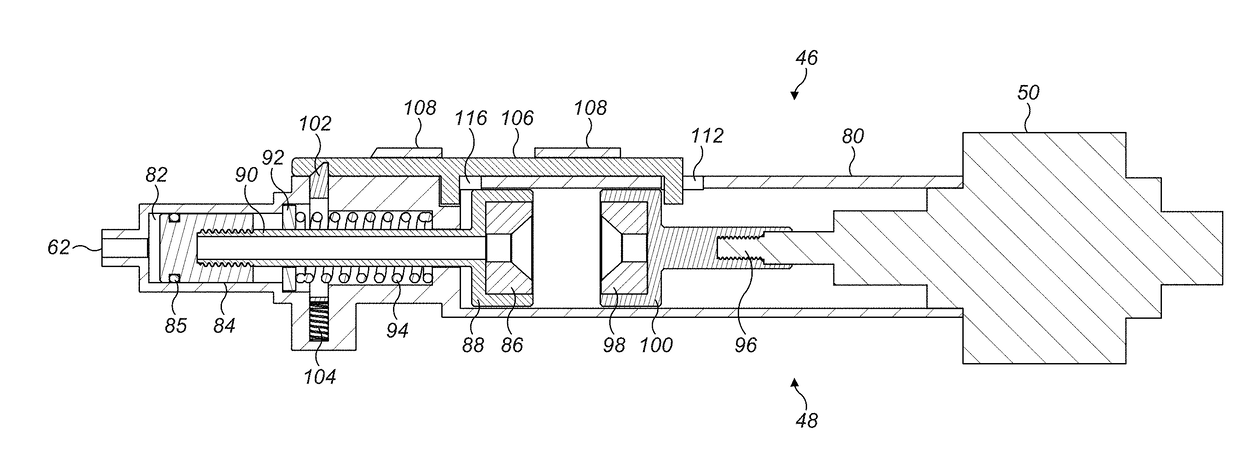

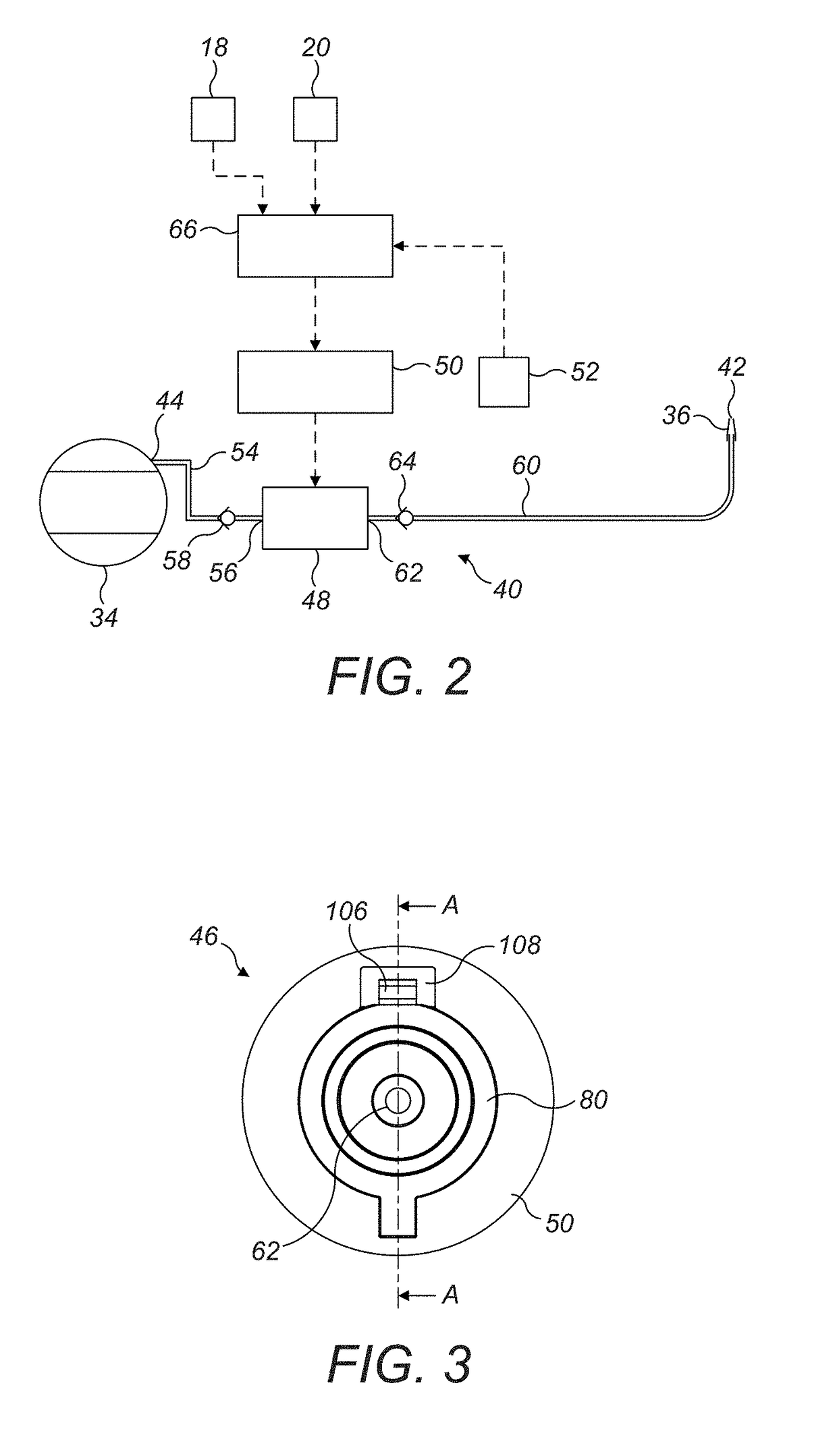

Cleaning appliance

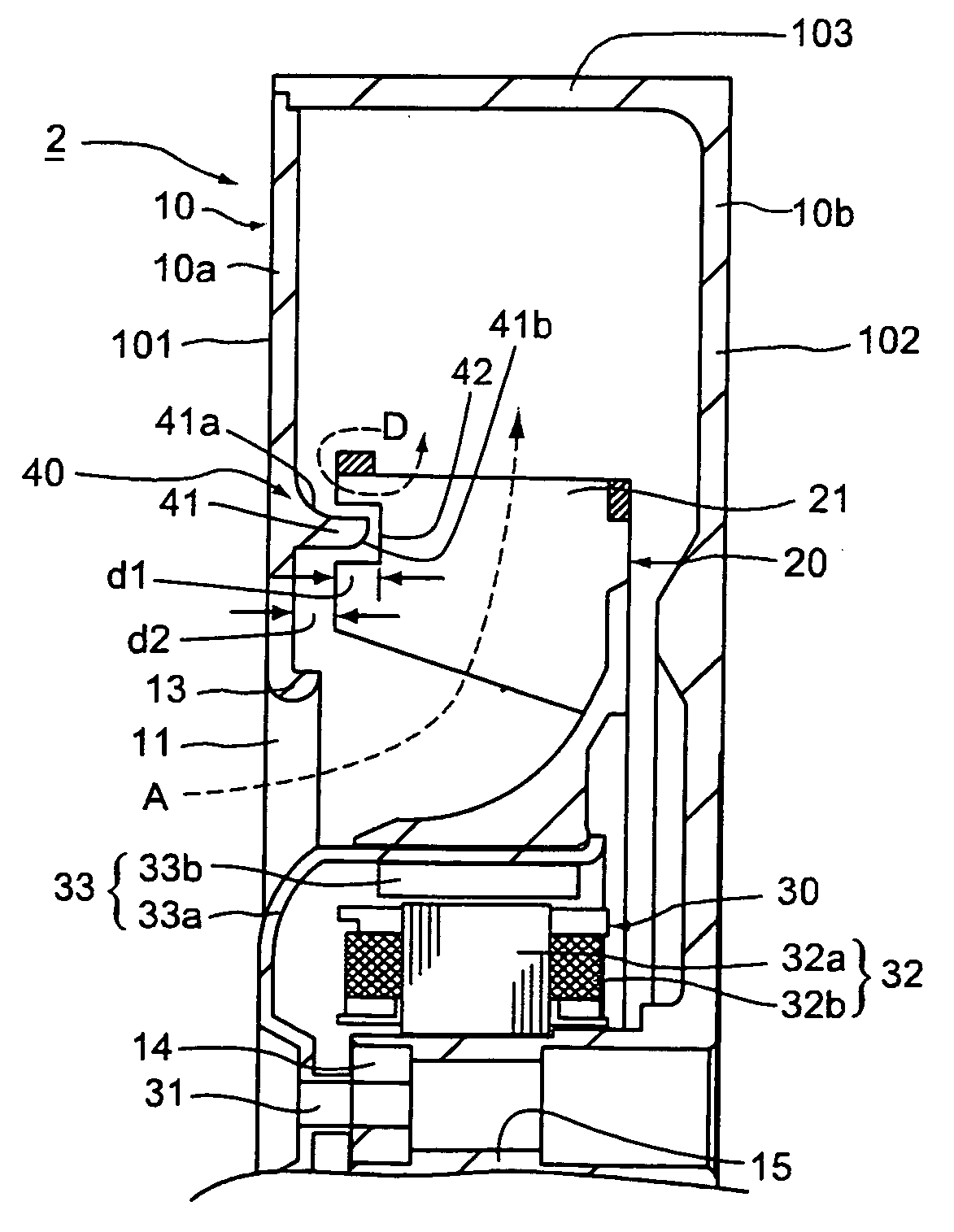

ActiveUS20180084898A1Narrow profileEasy to holdPositive displacement pump componentsBrush bodiesDental cleaningPiston

A pump assembly for a dental cleaning appliance includes a fluid chamber, a piston, and a drive. Magnets, connected respectively to the piston and the drive, enable the drive to couple to the piston and move it within the fluid chamber to draw fluid into the fluid chamber. A stop prevents the piston from being pulled beyond a stop position so that through continued actuation of the drive the magnets separate to allow a spring to push the piston away from the stop position to urge a burst of fluid from the fluid chamber.

Owner:DYSON TECH LTD

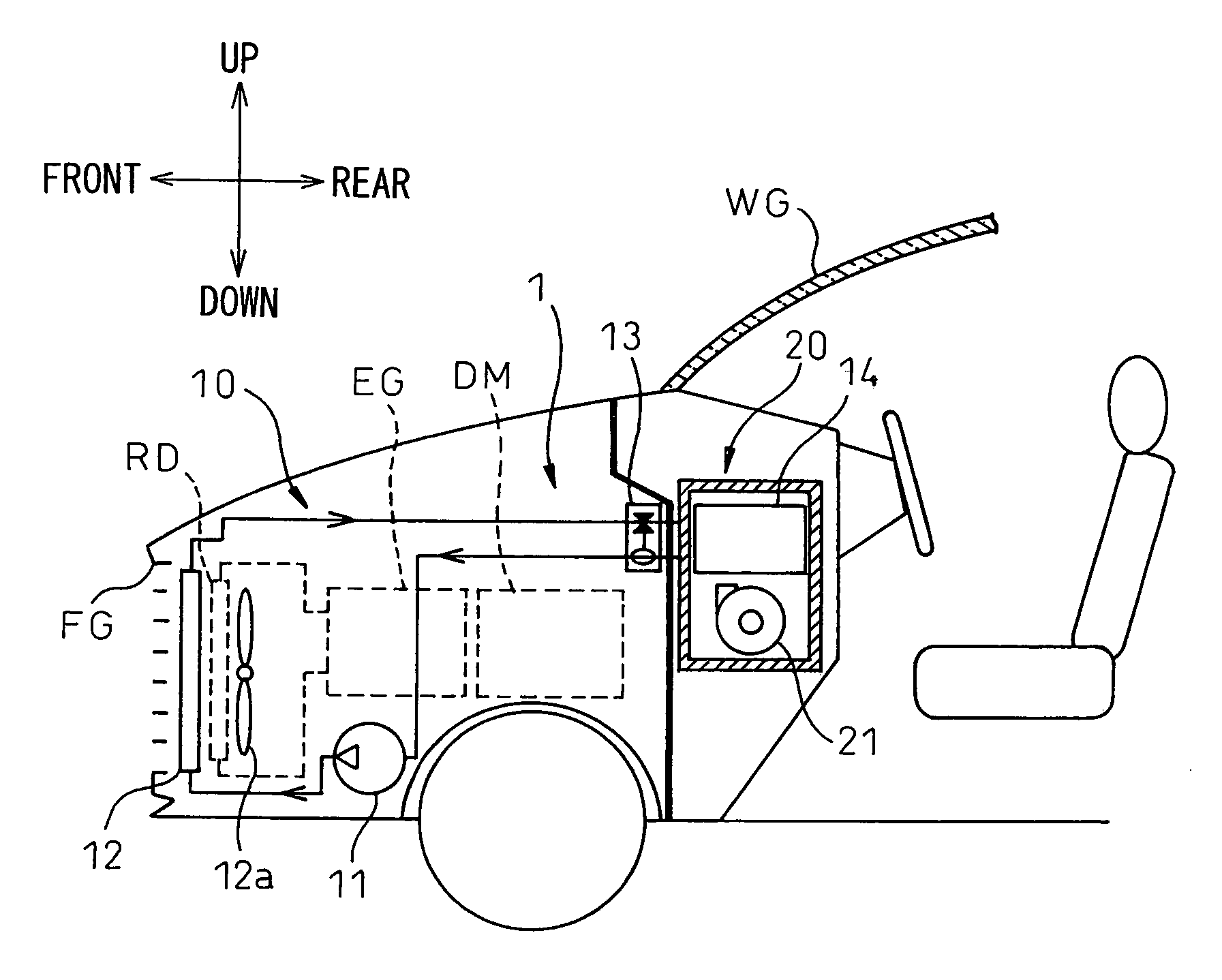

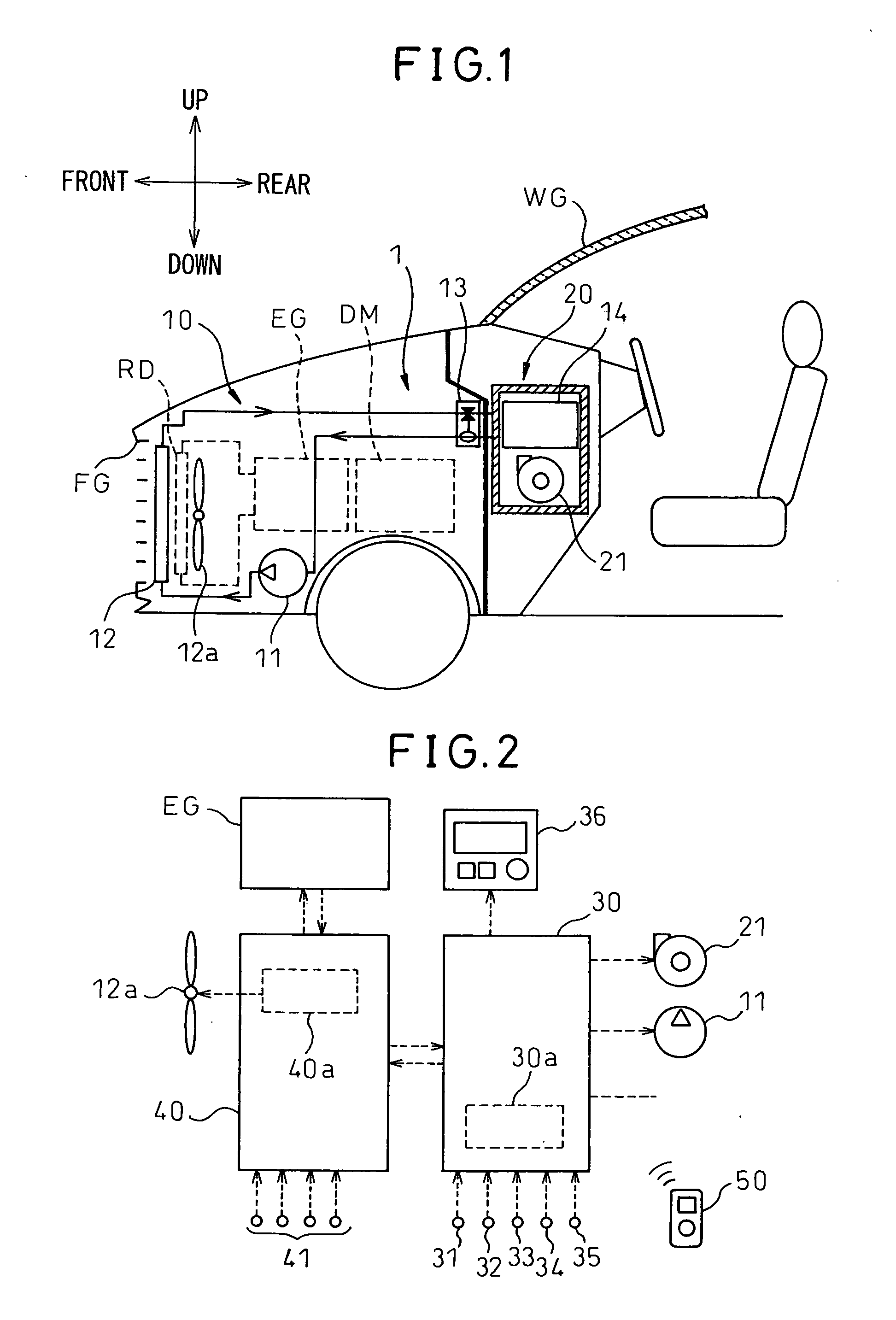

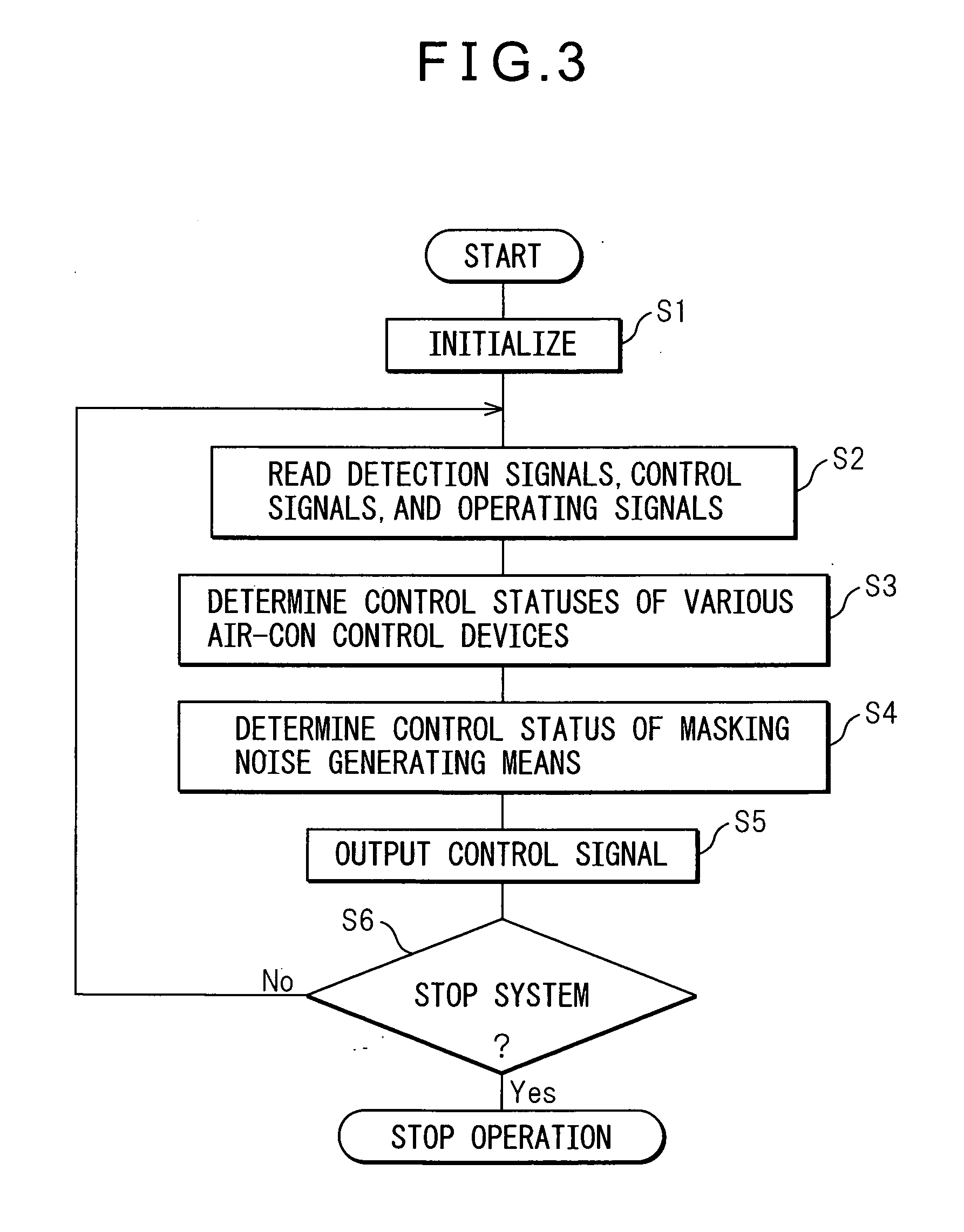

Vehicular refrigeration cycle apparatus

InactiveUS20110146320A1Stay efficientNoise is generatedVehicle heating/cooling devicesRefrigeration devicesAir conditioning loadAir blower

A vehicular refrigeration cycle apparatus where, at the time of startup before starting the operation of a compressor, the speed of a condenser-use blower which blows outside air toward the condenser is increased in accordance with the air-conditioning load. Due to this, the operating noise of the condenser-use blower familiar to the users becomes masking noise helping to prevent the operating noise of the compressor from being heard by the user and the unfamiliar operating noise of the compressor can be kept from being heard by the user.

Owner:DENSO CORP

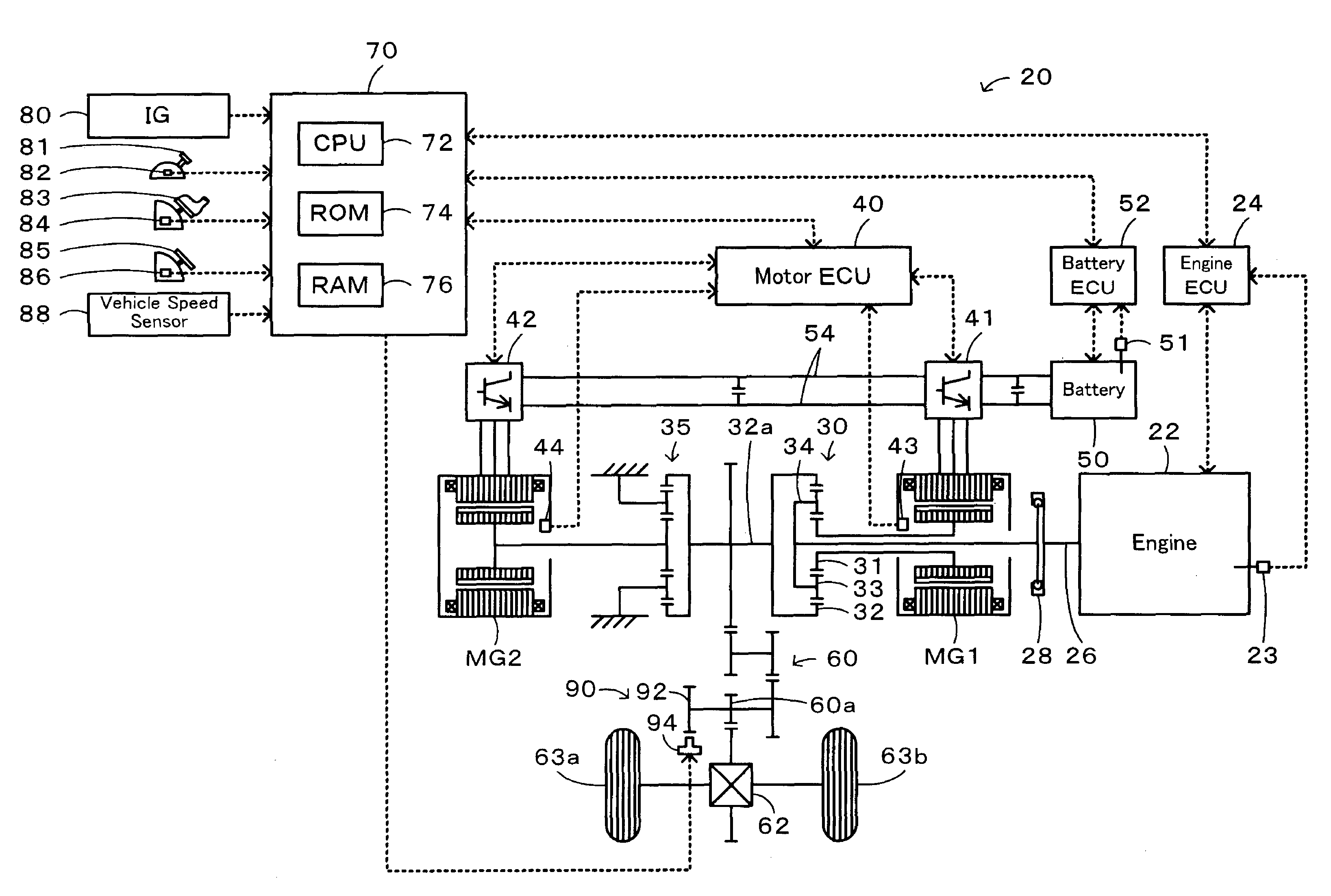

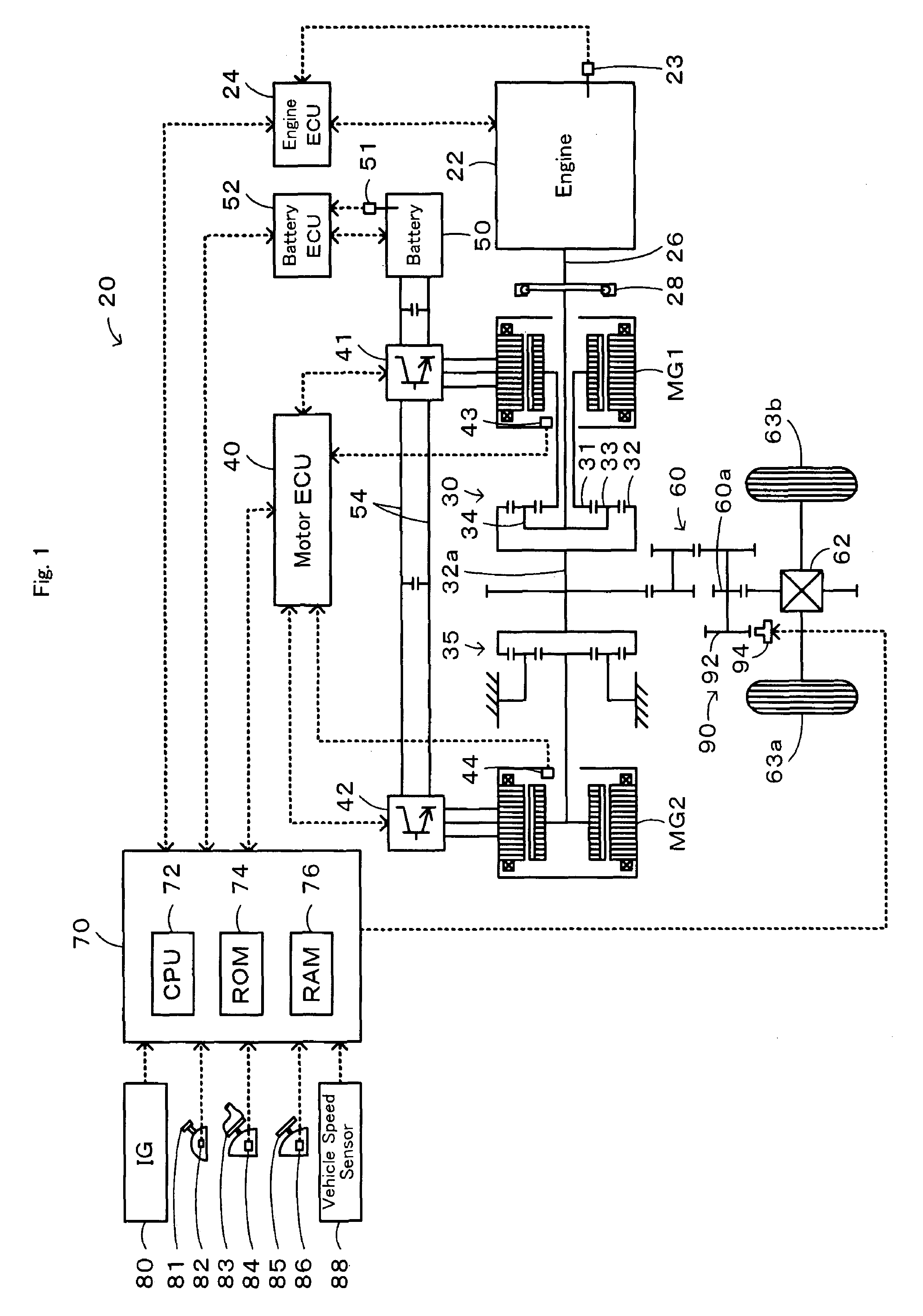

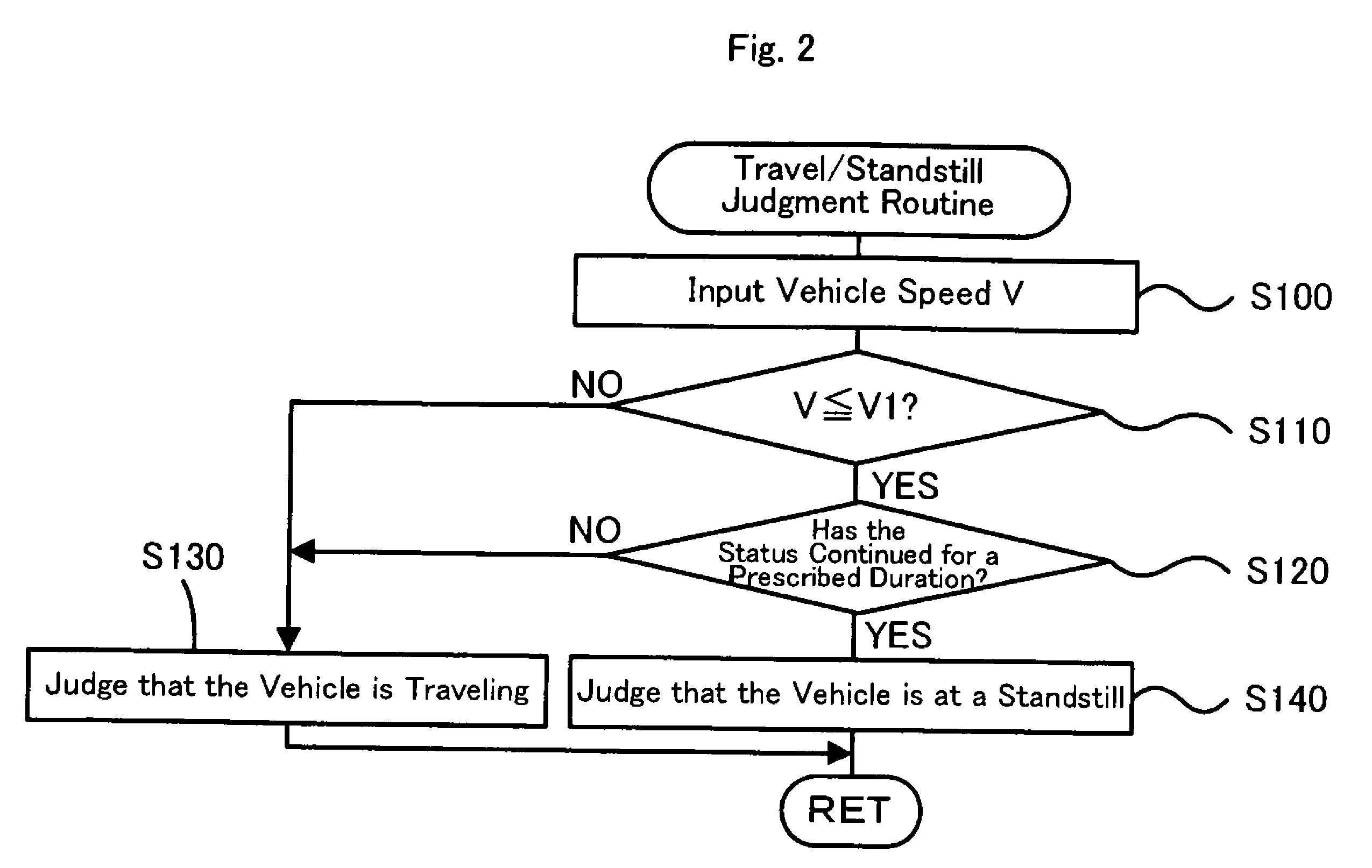

Vehicle, driving apparatus and control method of both

ActiveUS7946951B2Increase fuel consumptionNoise is generatedHybrid vehiclesMotor/generator/converter stoppersIdle speedControl theory

Owner:TOYOTA JIDOSHA KK +2

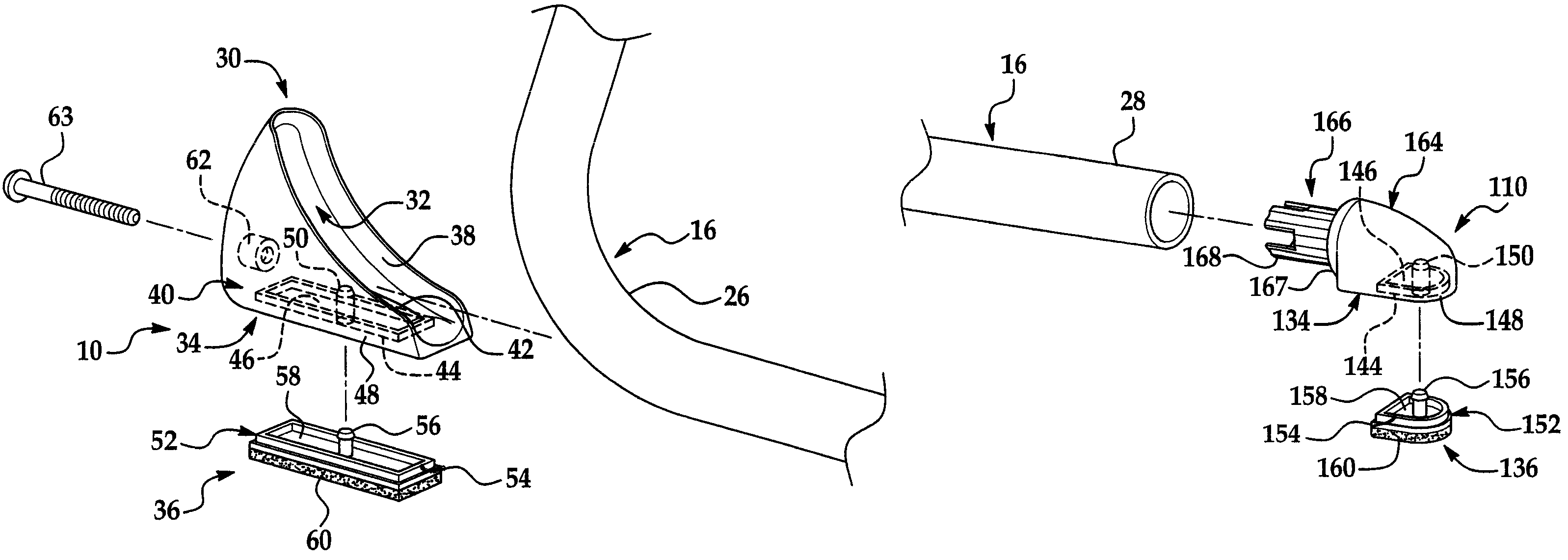

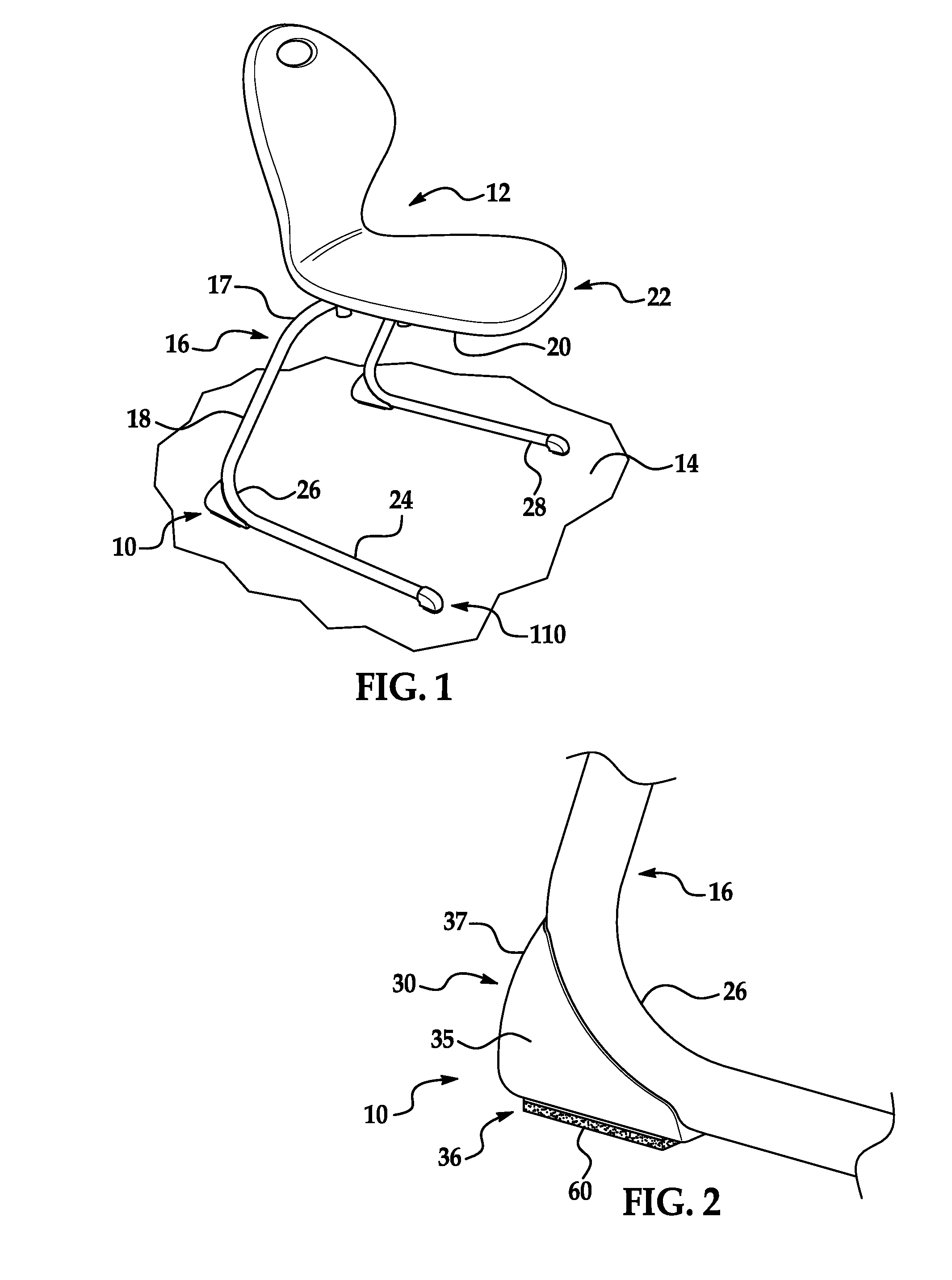

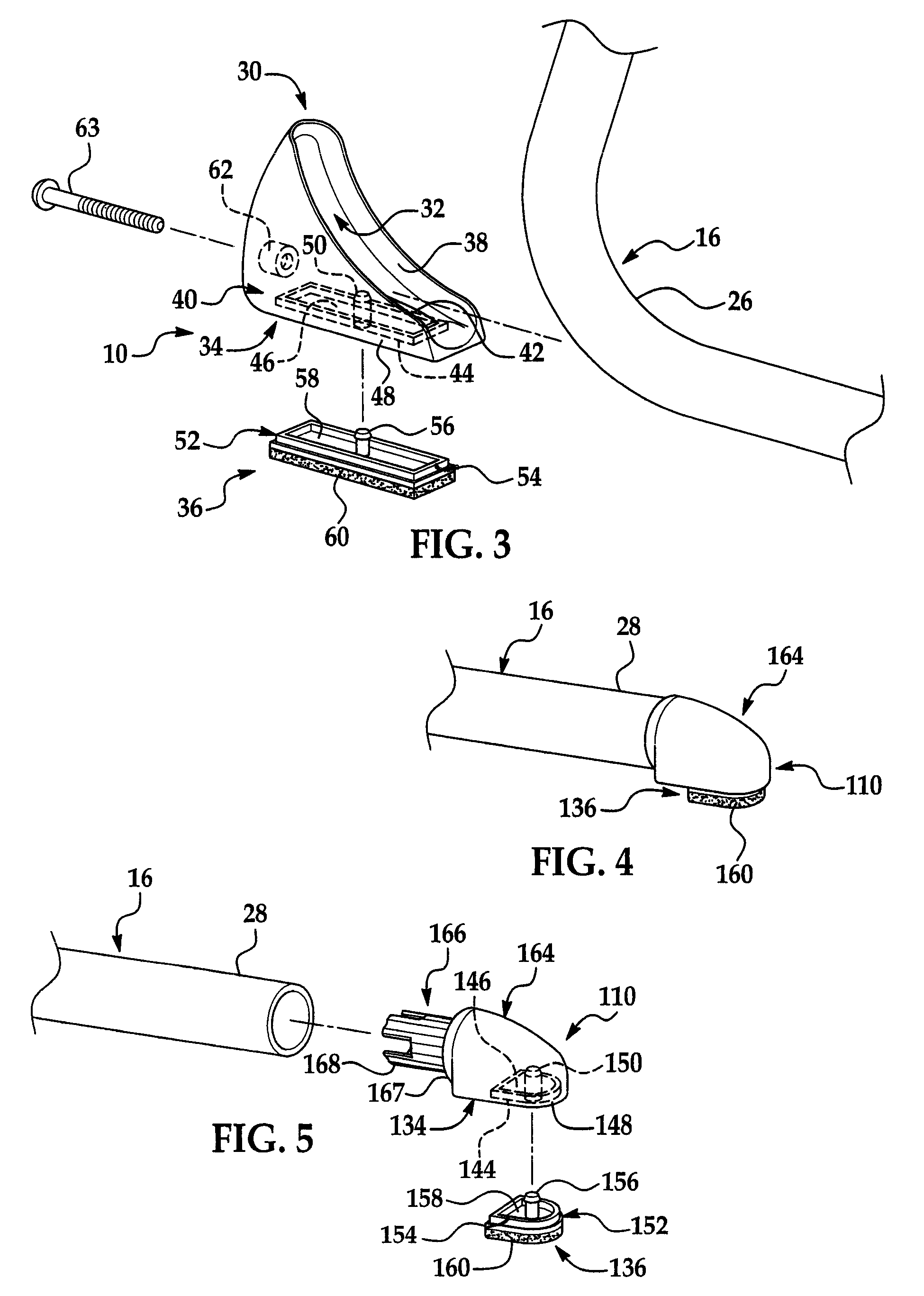

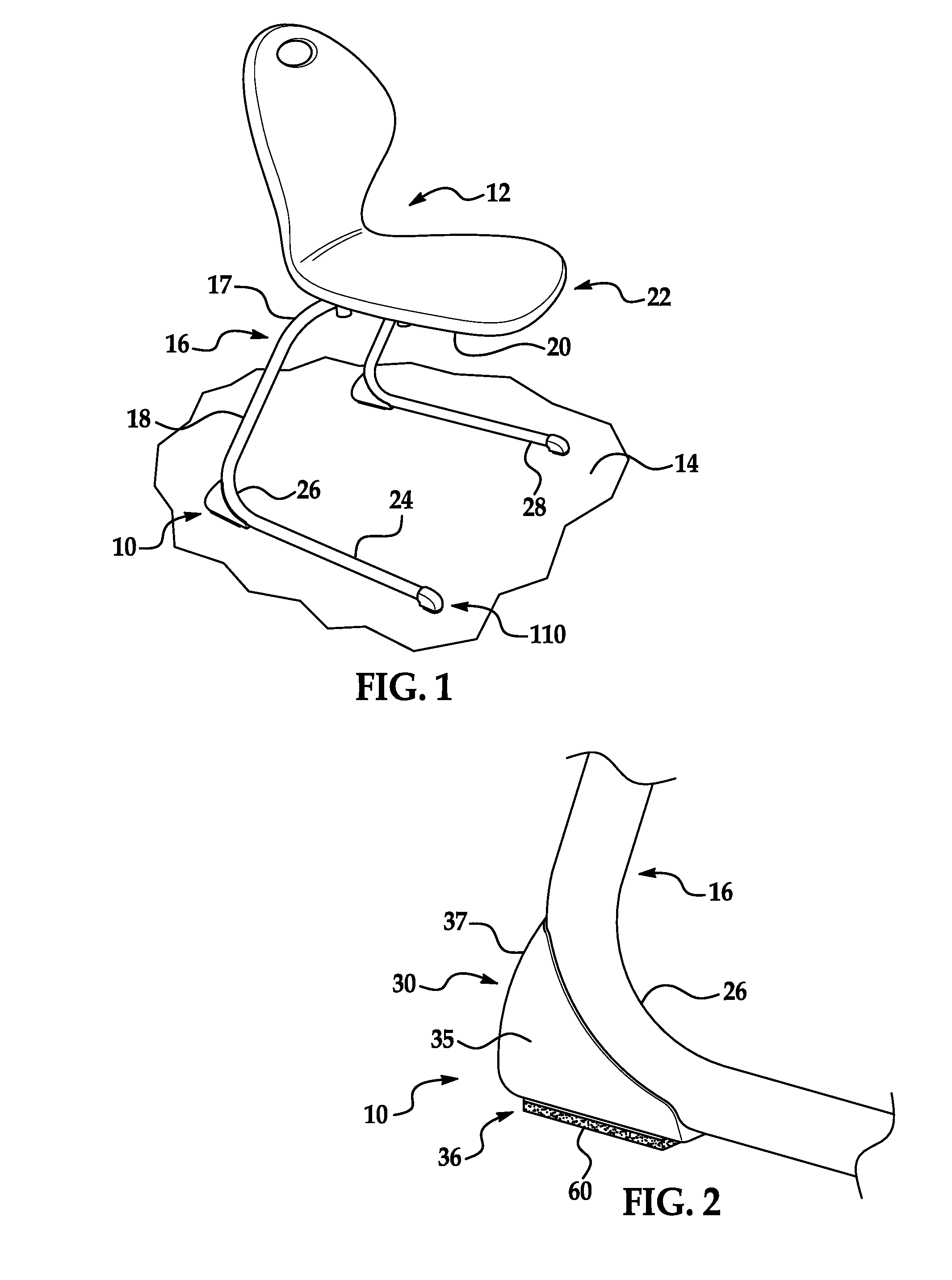

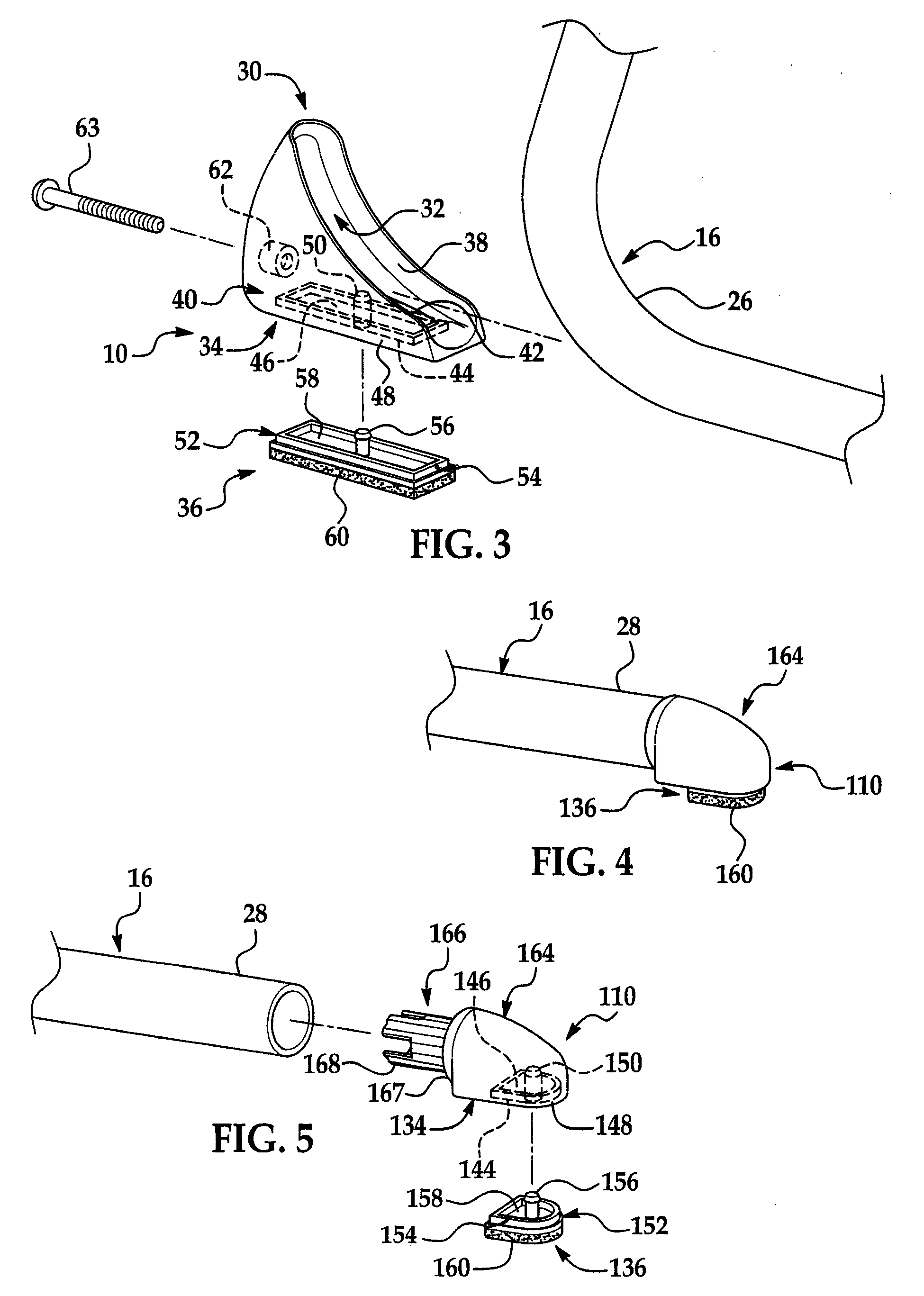

Furniture-foot assemblies

ActiveUS7837161B2Easy and efficient and inexpensiveReduce morbidityStoolsStands/trestlesEngineeringMechanical engineering

A foot assembly is adapted to be removably attached to the elbow of a sled-type leg of a piece of furniture that is adapted to be supported upon a surface. The furniture-foot assembly includes a body defining a hollow interior adapted to removably receive the elbow of the leg and a bottom exterior portion. A glide is adapted to be removably mounted to the bottom exterior portion of the body and supported upon the surface for gliding movement of the furniture-foot assembly relative to the surface.

Owner:HIWATT PROD

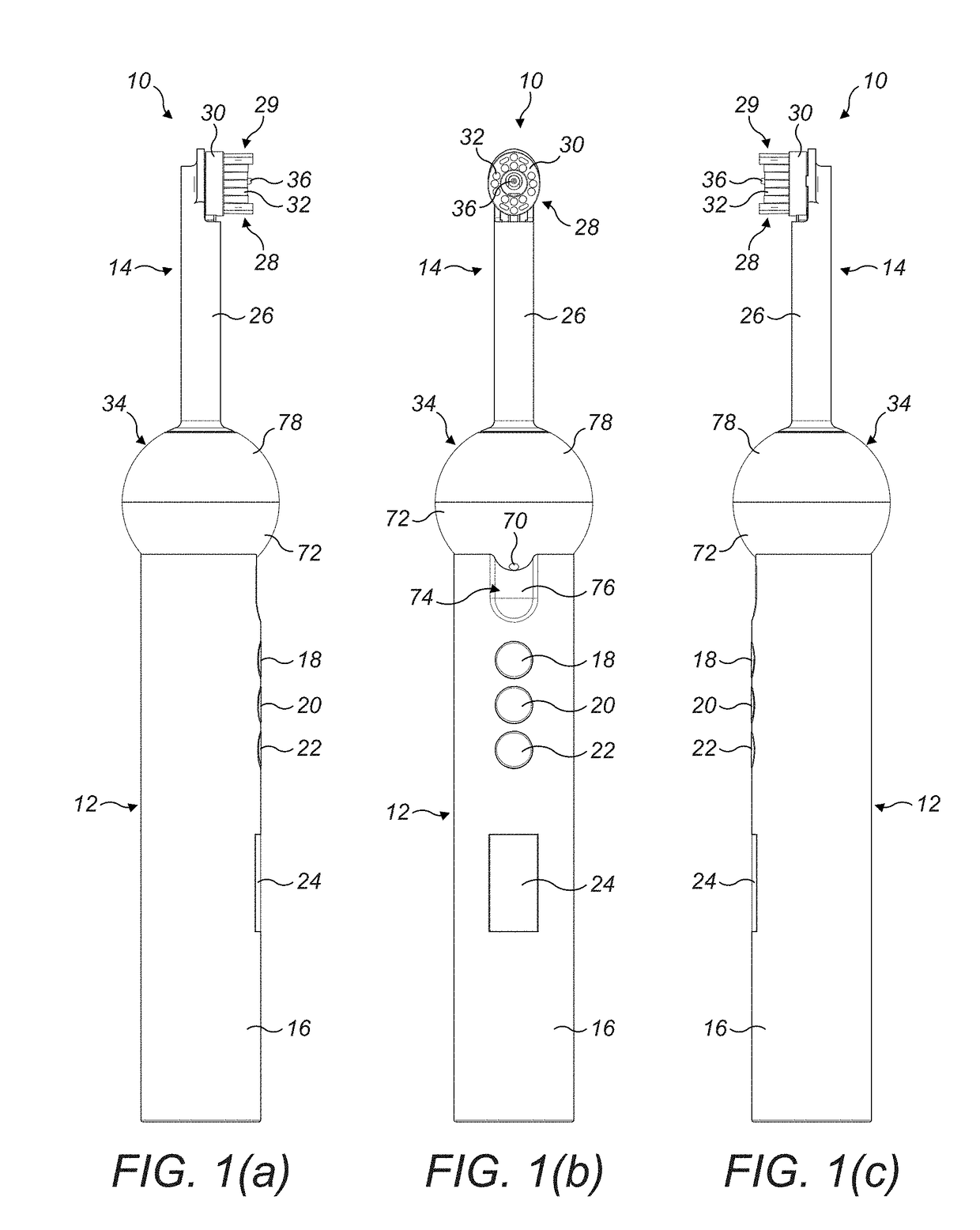

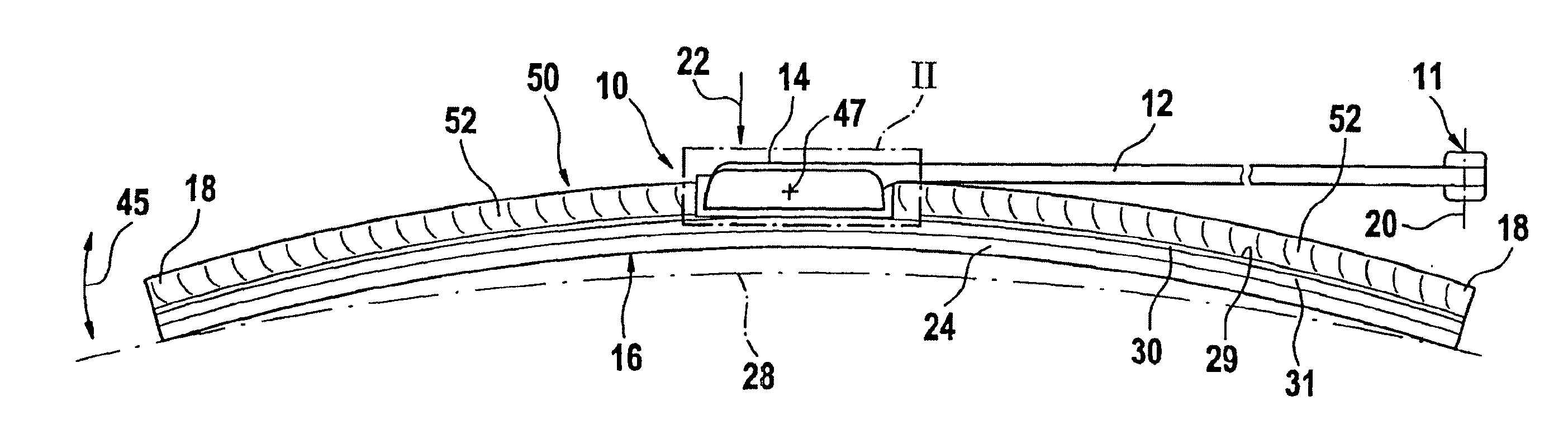

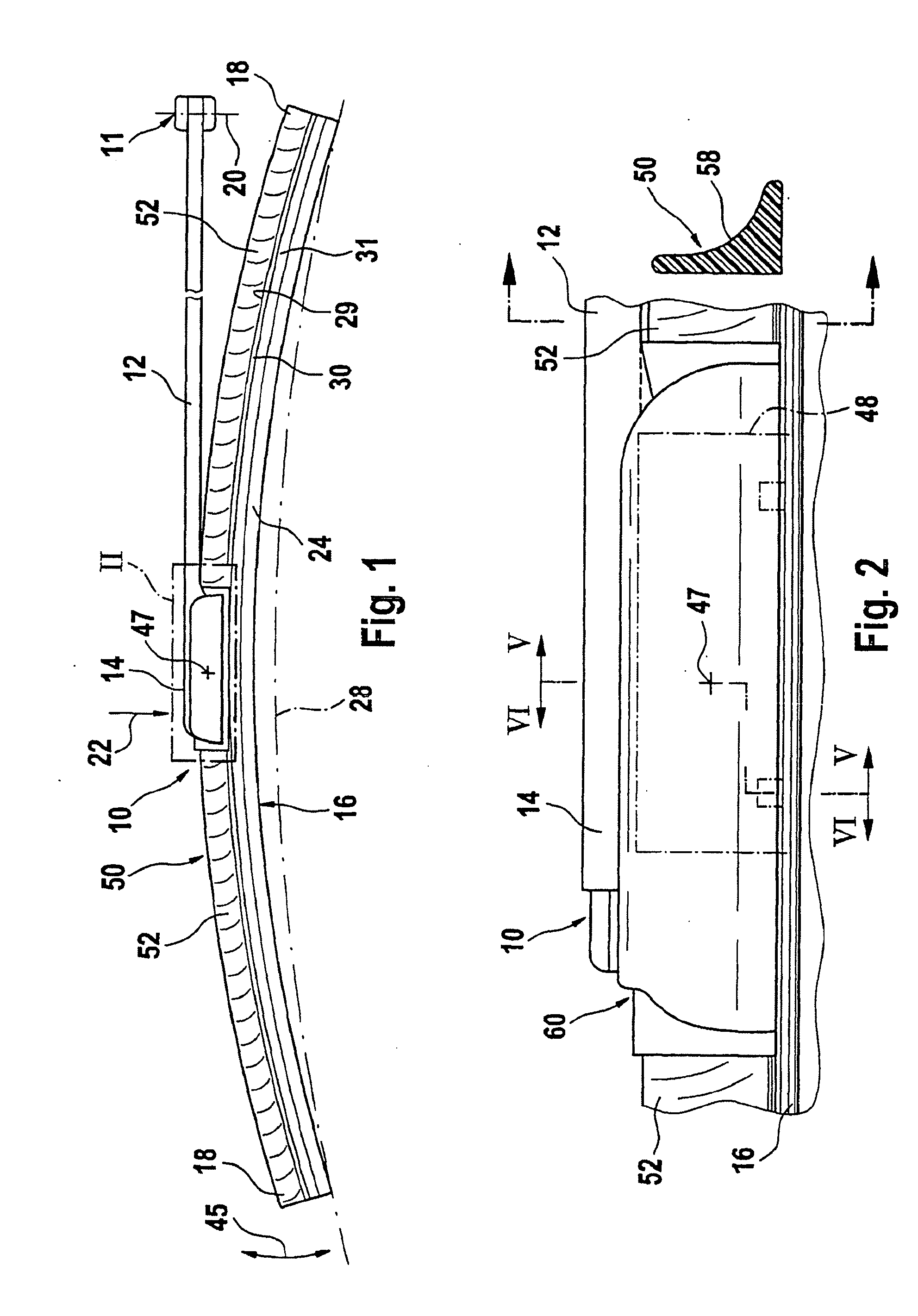

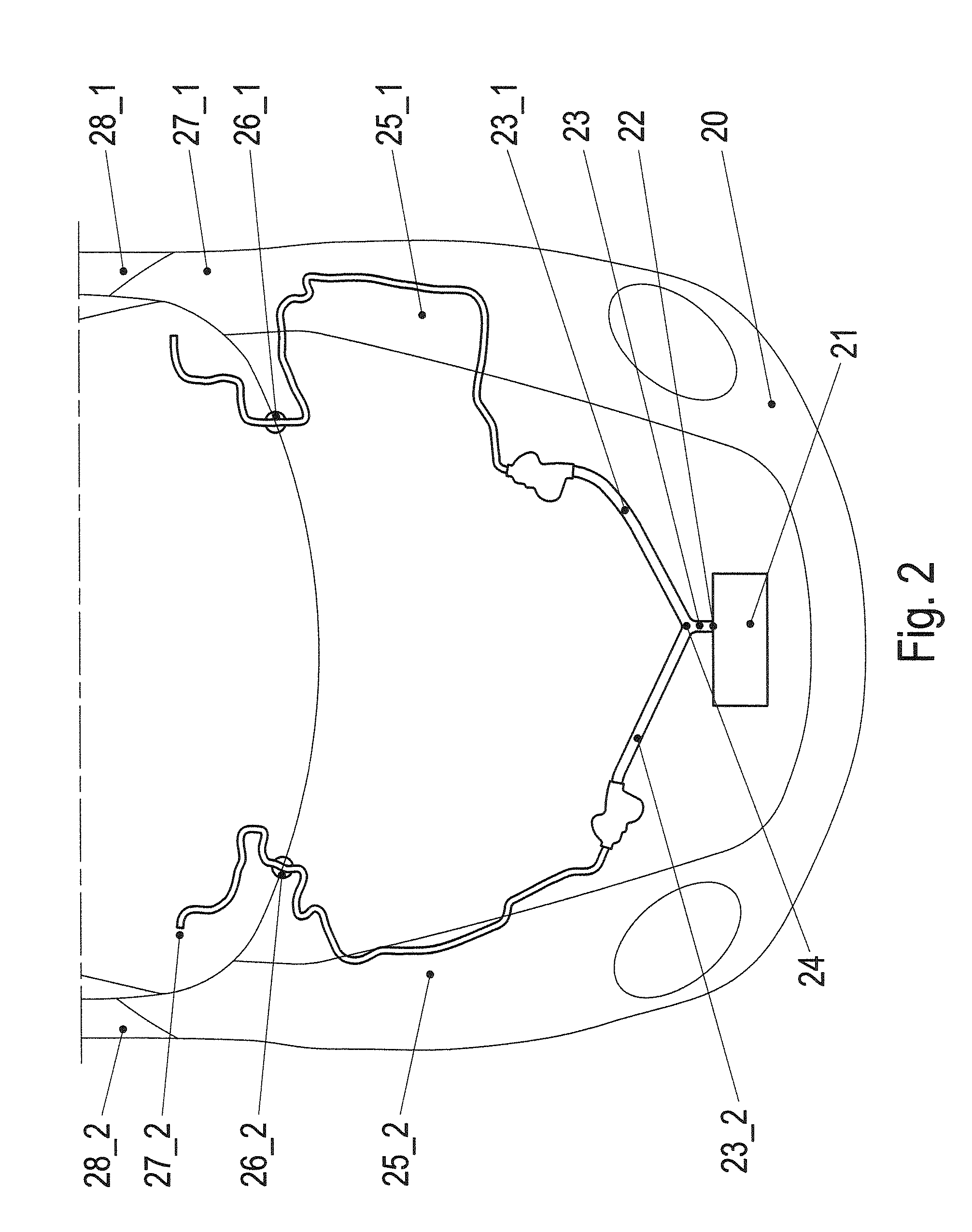

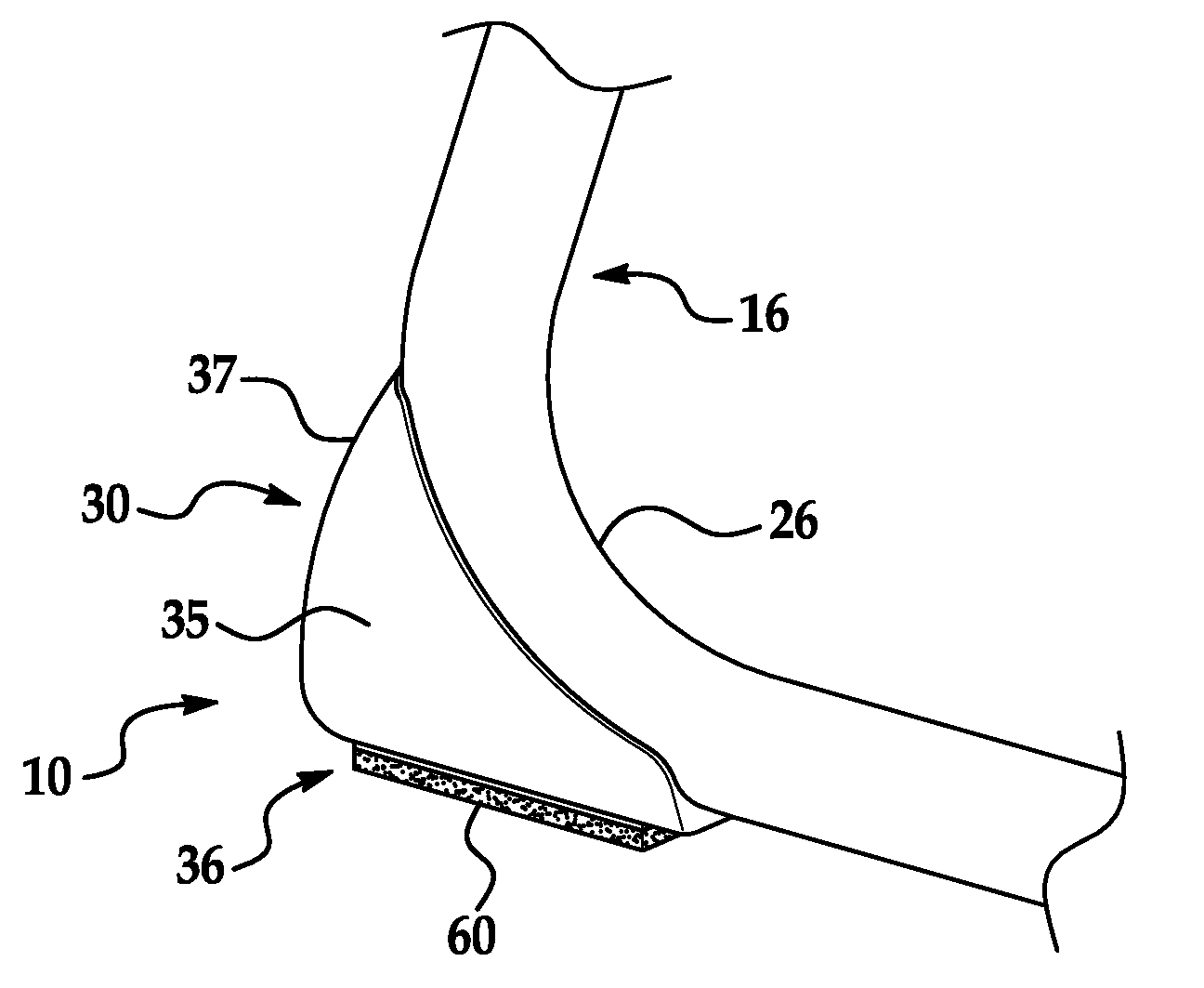

Wiper lever with a driven wiper arm and a wiper blade

InactiveUS20080034530A1Noise is generatedAvoid problemsWindow cleanersVehicle cleaningRubber elasticityControl theory

Wiper lever (10) with a driven wiper arm (12) and a wiper blade (16) linked to it for cleaning windows, particularly those of motor vehicles, which is provided with a band-like, long-stretched-out, elastic supporting element (30), which features, on its lower band surface facing the window, a long-stretched-out, rubber elastic wiper strip (24) that can be applied to it, on whose upper band surface (29), particularly in the longitudinal middle area of the supporting element (30), a coupling part (32) is situated and wind deflector strip partial sections (52) extending to the ends of the supporting element are arranged on both sides of the coupling part (32). An especially harmonic transition between the wiper blade (16) and the wiper arm (12) is achieved in the area of the joint (46, 47) connecting these two wiper lever parts if the wiper lever (10) is provided with a cap (60) to cover the connection area between the wiper blade (16) and the wiper arm (12).

Owner:ROBERT BOSCH CORP

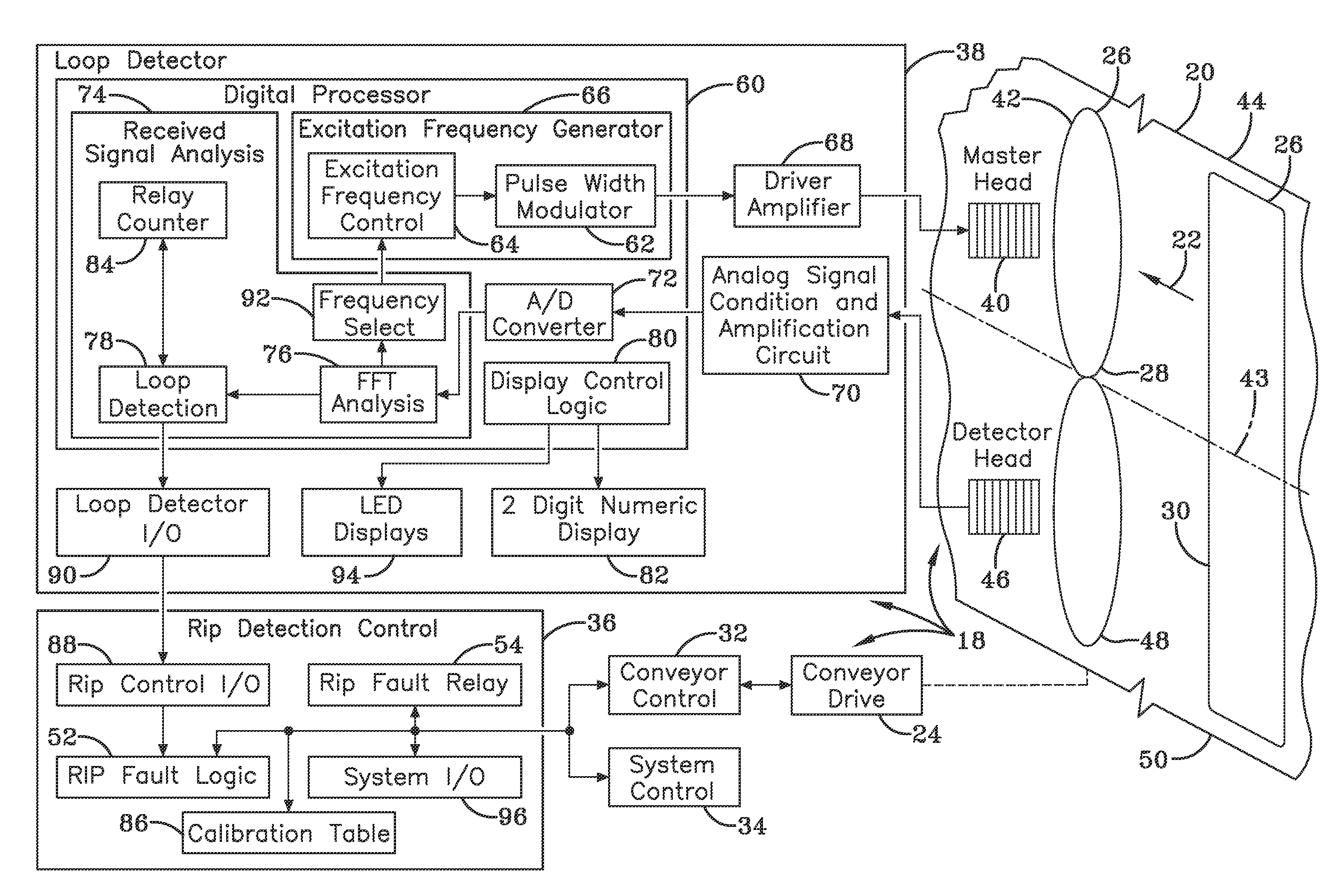

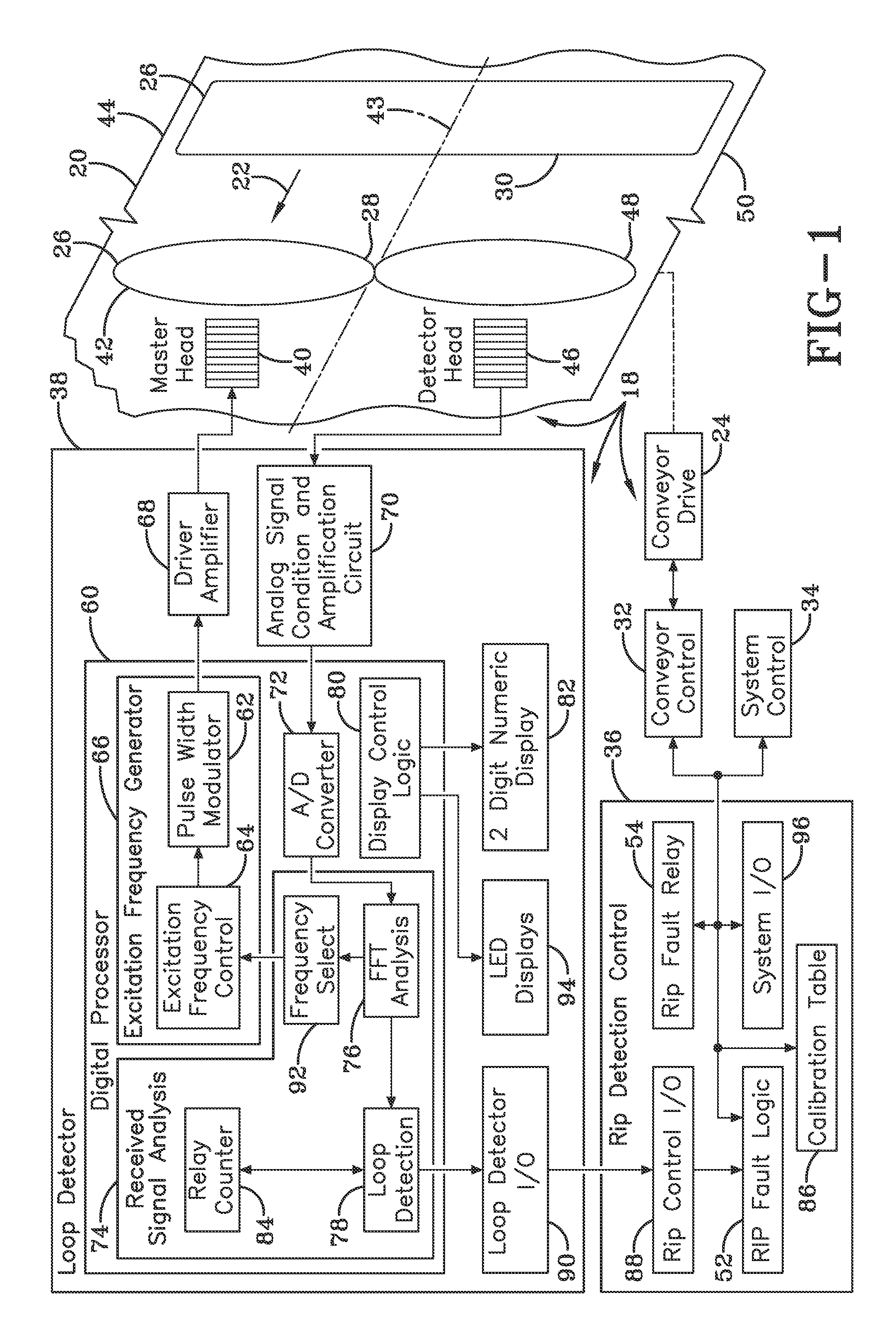

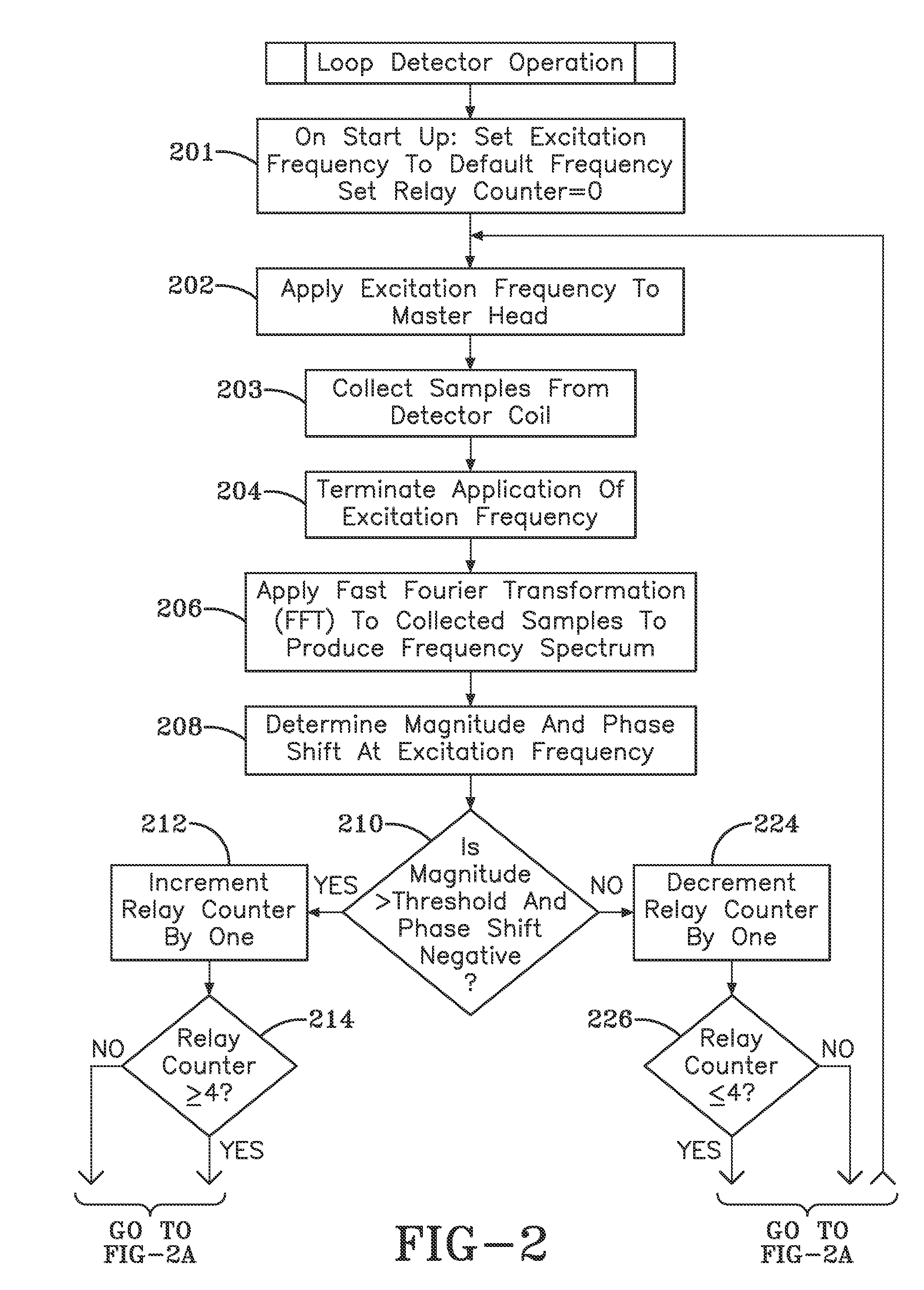

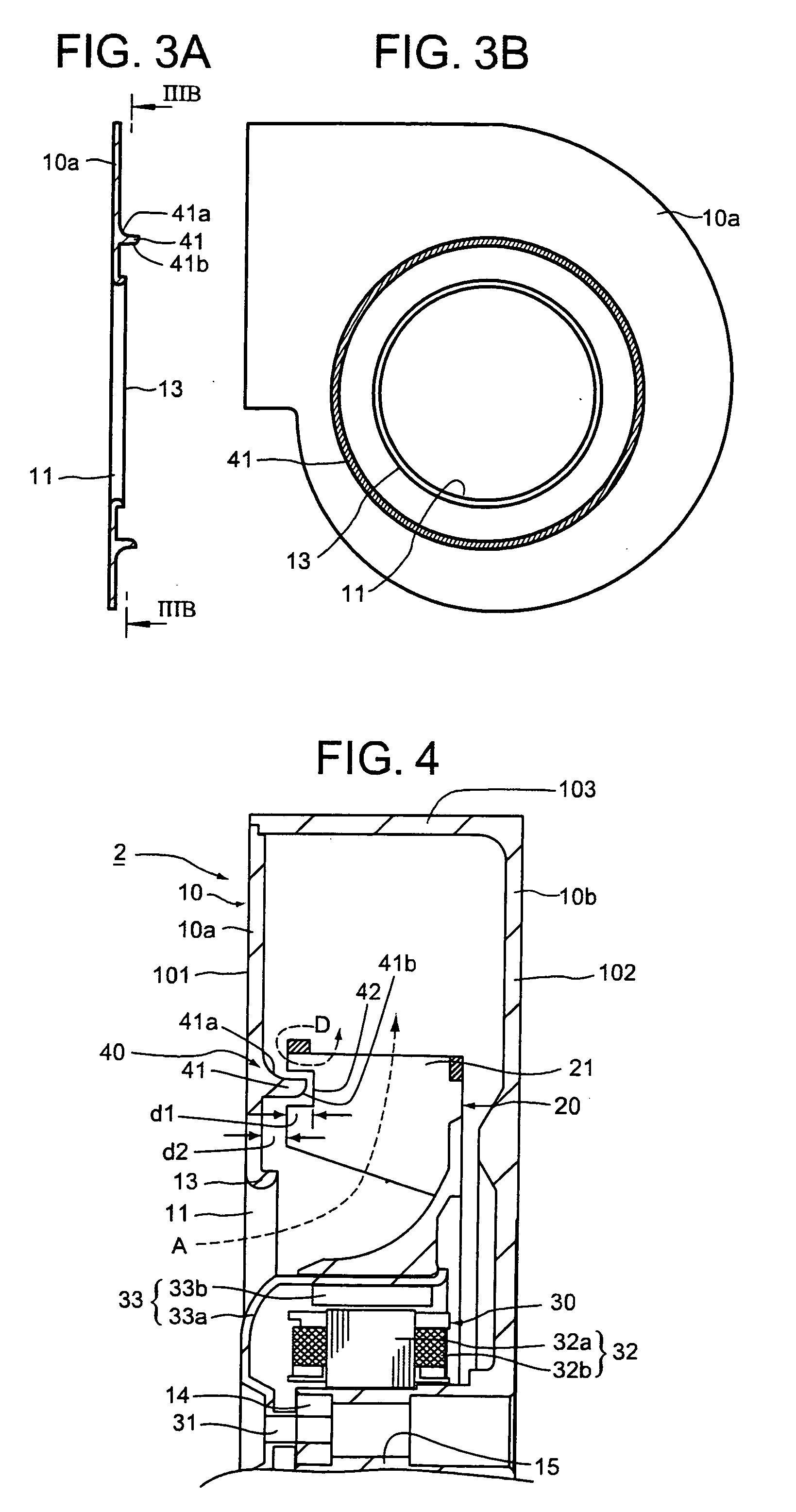

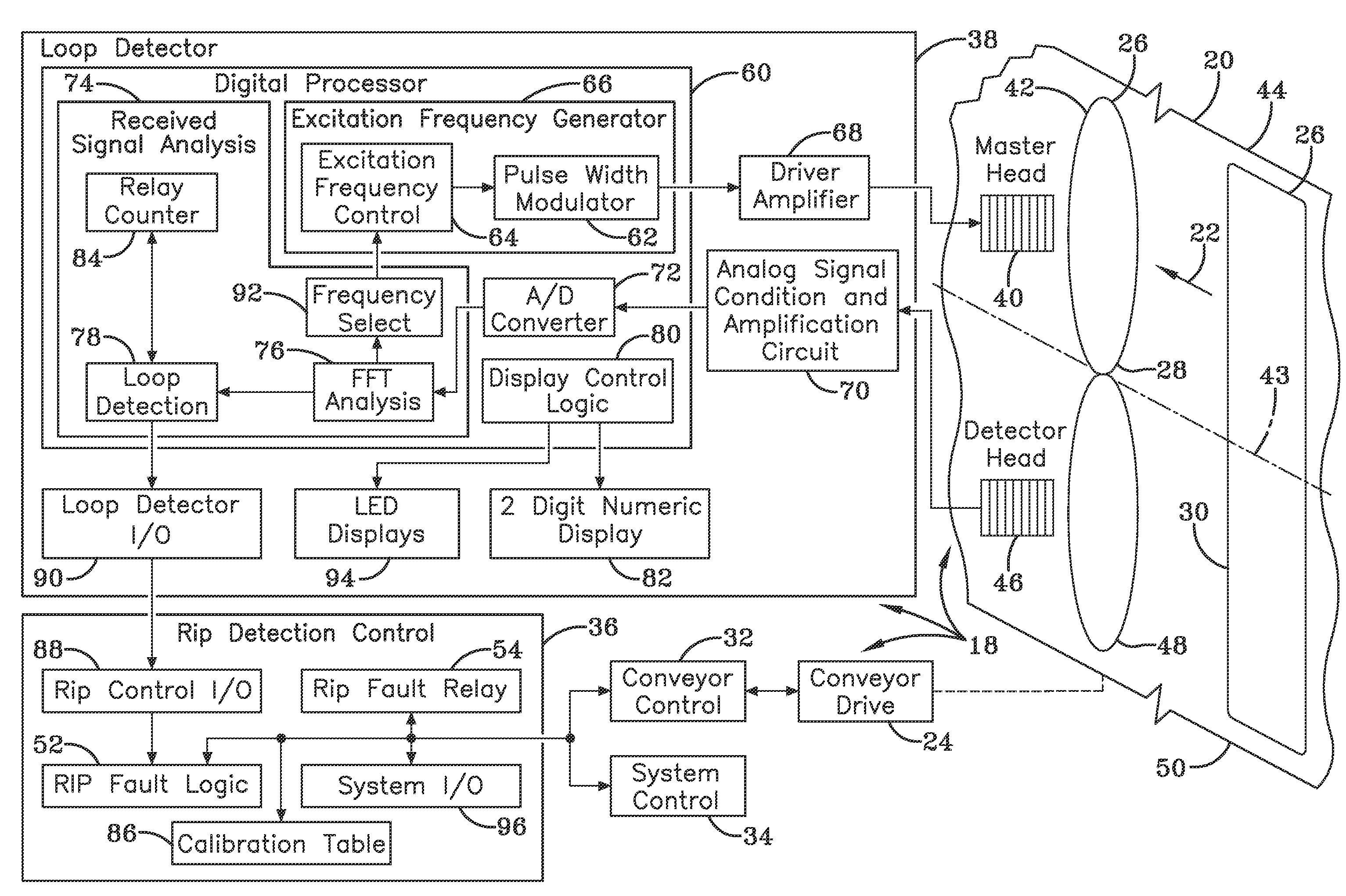

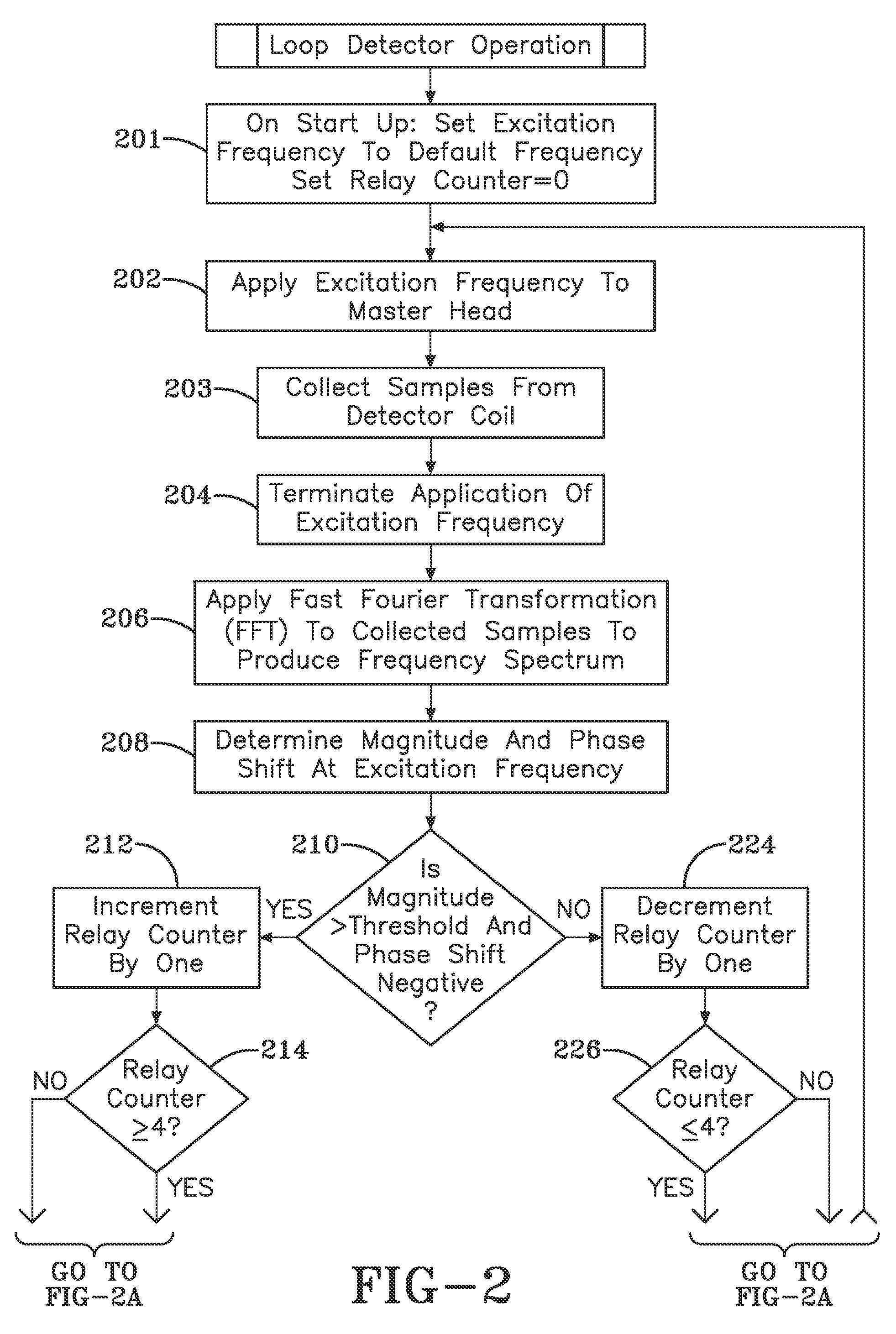

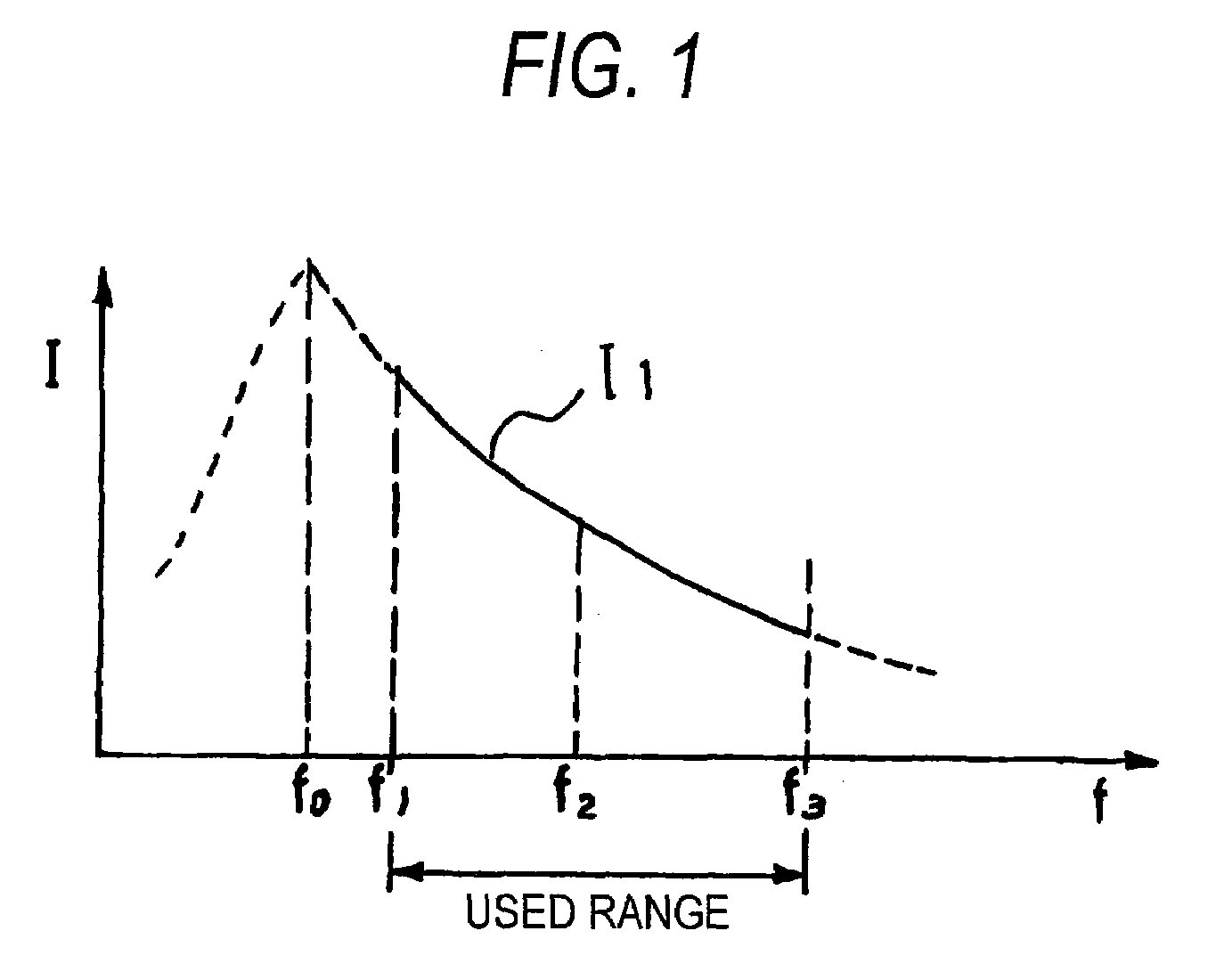

Digital Processor Sensor Loop Detector and Method

ActiveUS20070278068A1Reduce environmental noiseGreat read rangeMachine part testingMaterial analysis by electric/magnetic meansFrequency spectrumEngineering

A digital processor for use in a conveyor belt rip detector, which provides excitation signals at a selected frequency to inverted and noninverted sensor loops on a conveyor belt and then, detects corresponding received signals from the sensor loops. The digital processor then performs FFTs on the corresponding received signals to provide respective received signal frequency spectrums. Next magnitude and phase values of the selected frequency in the respective received signal frequency spectrums are used to determine a qualitative state of the sensor loops. The selected frequency has a lowest detected ambient noise level, and the magnitude value is a normalized magnitude value.

Owner:CONTITECH USA INC

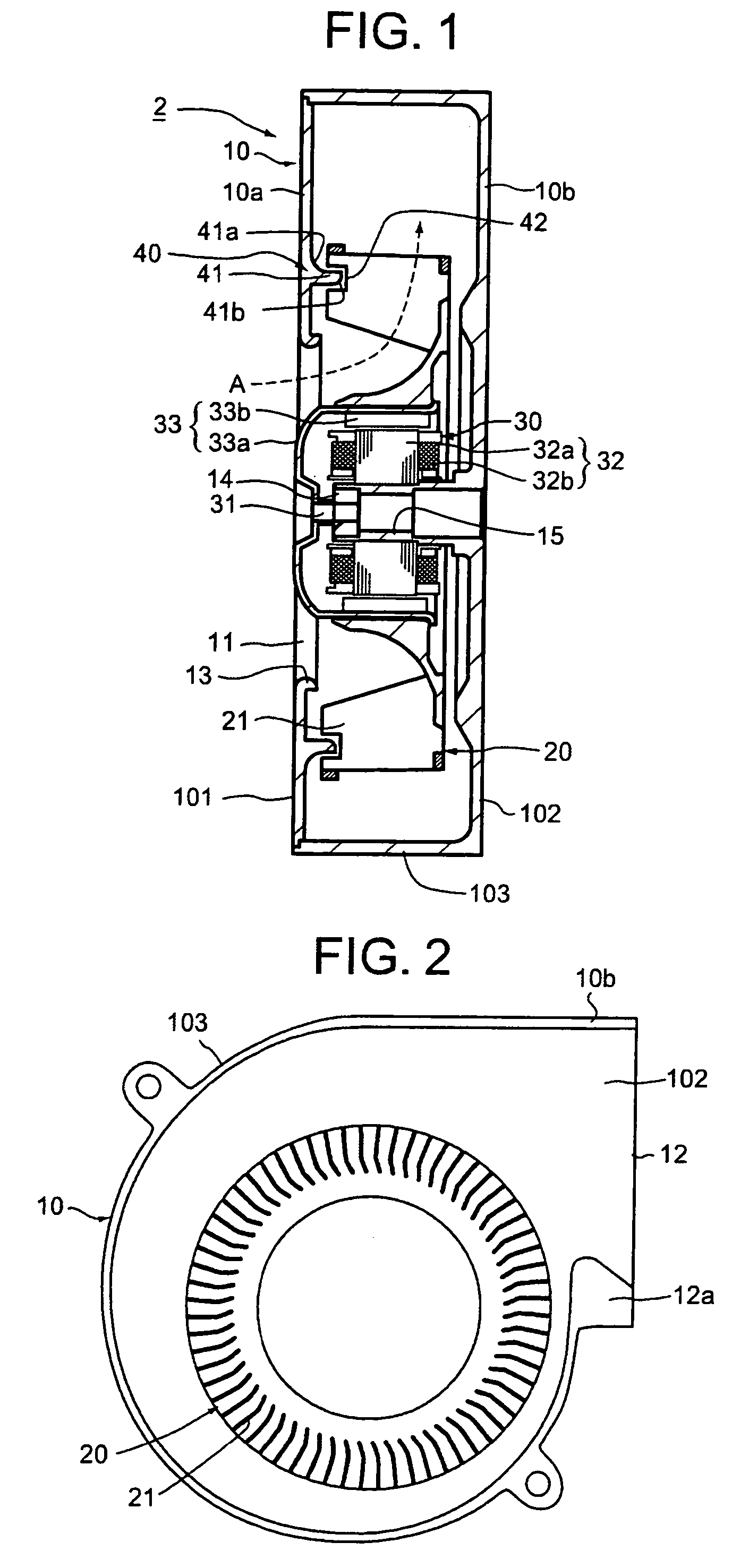

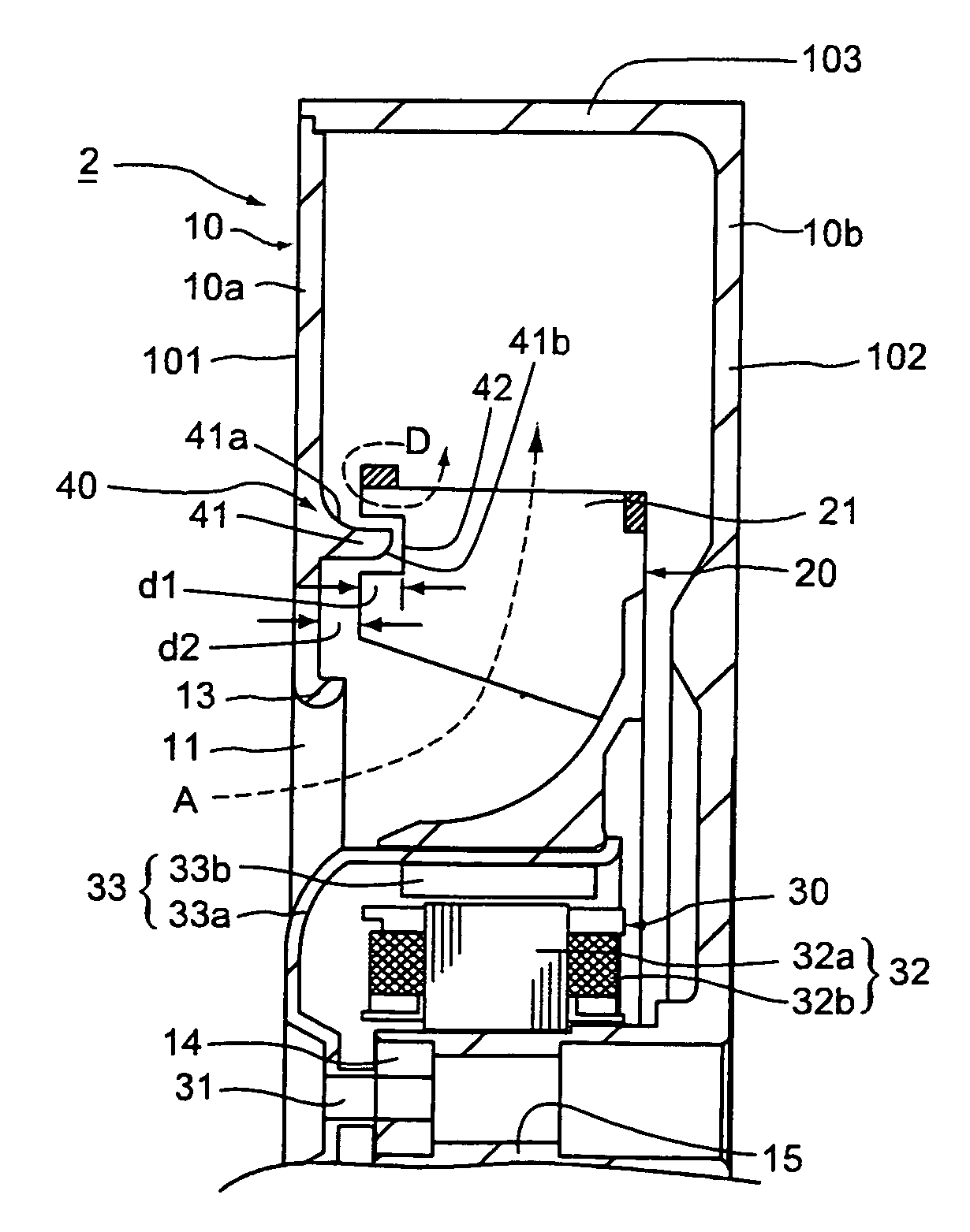

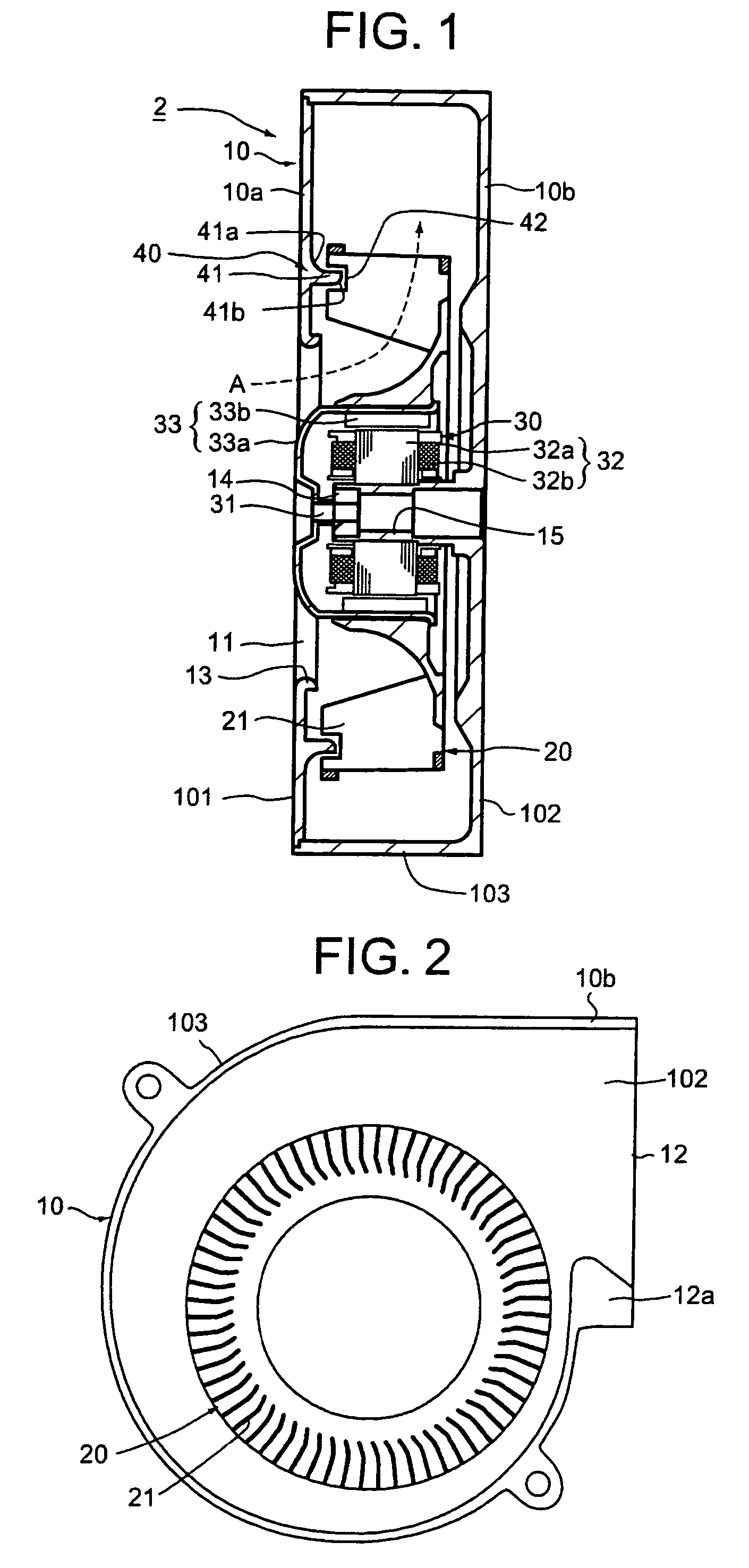

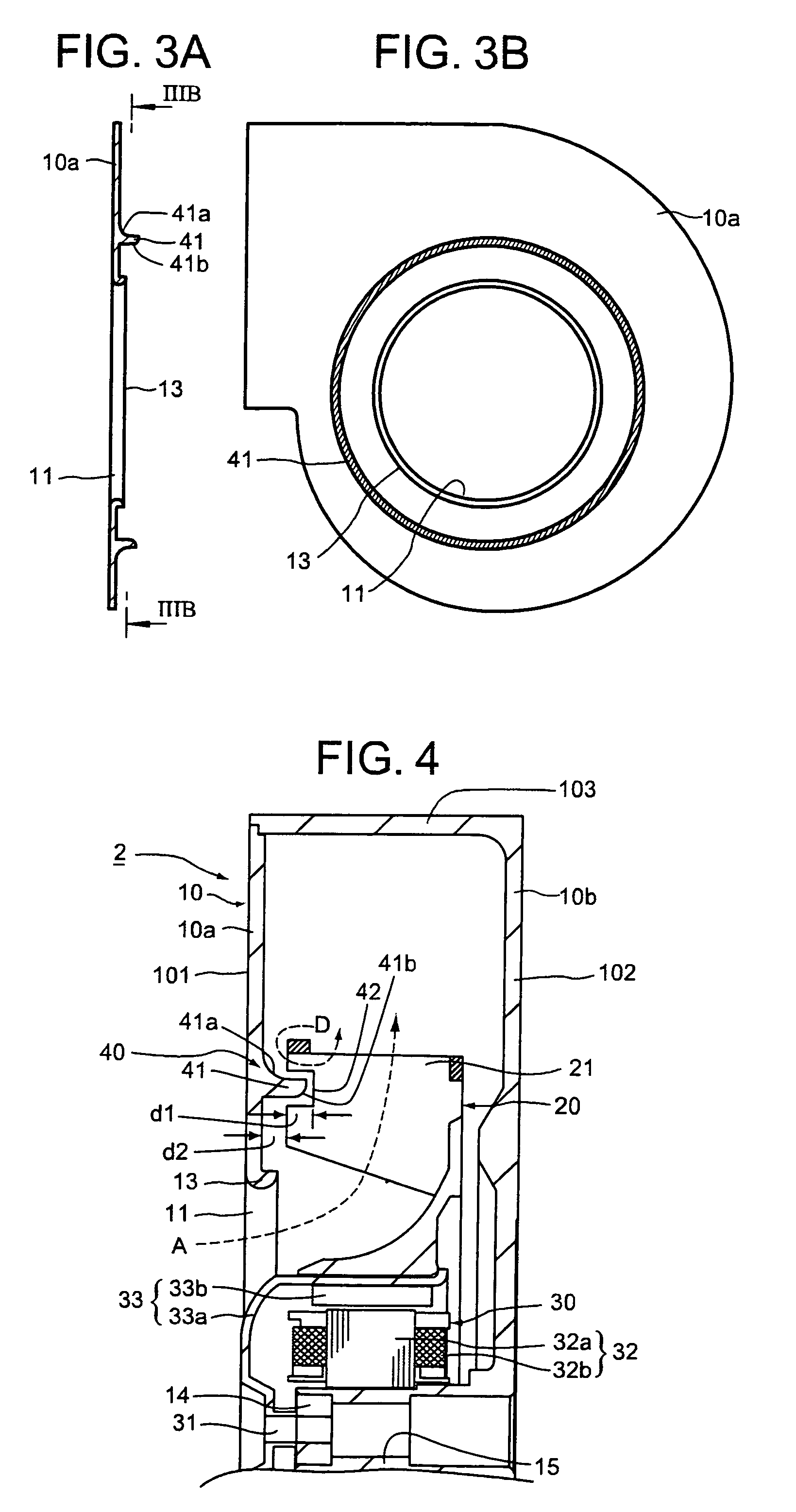

Centrifugal fan

ActiveUS20060222491A1Inhibit deteriorationAvoid it happening againPump componentsReaction enginesImpellerEngineering

A centrifugal fan includes a scroll casing having first and second flat base walls, and a circumferential side wall. An air inlet is formed on a center portion of the first base wall and an exhaust port is formed on the circumferential side wall. An airflow correction mechanism that forms smooth airflow when an impeller rotates is provided. The mechanism has an annular rib that is formed on the inside surface of the first base wall so as to be jutted to the side of the second base wall and to be concentric with the rotating shaft, and a recess portion that is formed on every blade of the impeller so that the annular rib is inserted therein with a predetermined gap. The annular rib and the recess portion are configured to change the direction of airflow directed to the air inlet back to a space between the blades.

Owner:NIDEC SERVO CORP

Digital processor sensor loop detector and method

ActiveUS7740130B2Optimization rangeReduce sensitivityMachine part testingMaterial analysis by electric/magnetic meansFrequency spectrumExcitation signal

A digital processor for use in a conveyor belt rip detector, which provides excitation signals at a selected frequency to inverted and noninverted sensor loops on a conveyor belt and then, detects corresponding received signals from the sensor loops. The digital processor then performs FFTs on the corresponding received signals to provide respective received signal frequency spectrums. Next magnitude and phase values of the selected frequency in the respective received signal frequency spectrums are used to determine a qualitative state of the sensor loops. The selected frequency has a lowest detected ambient noise level, and the magnitude value is a normalized magnitude value.

Owner:CONTITECH USA INC

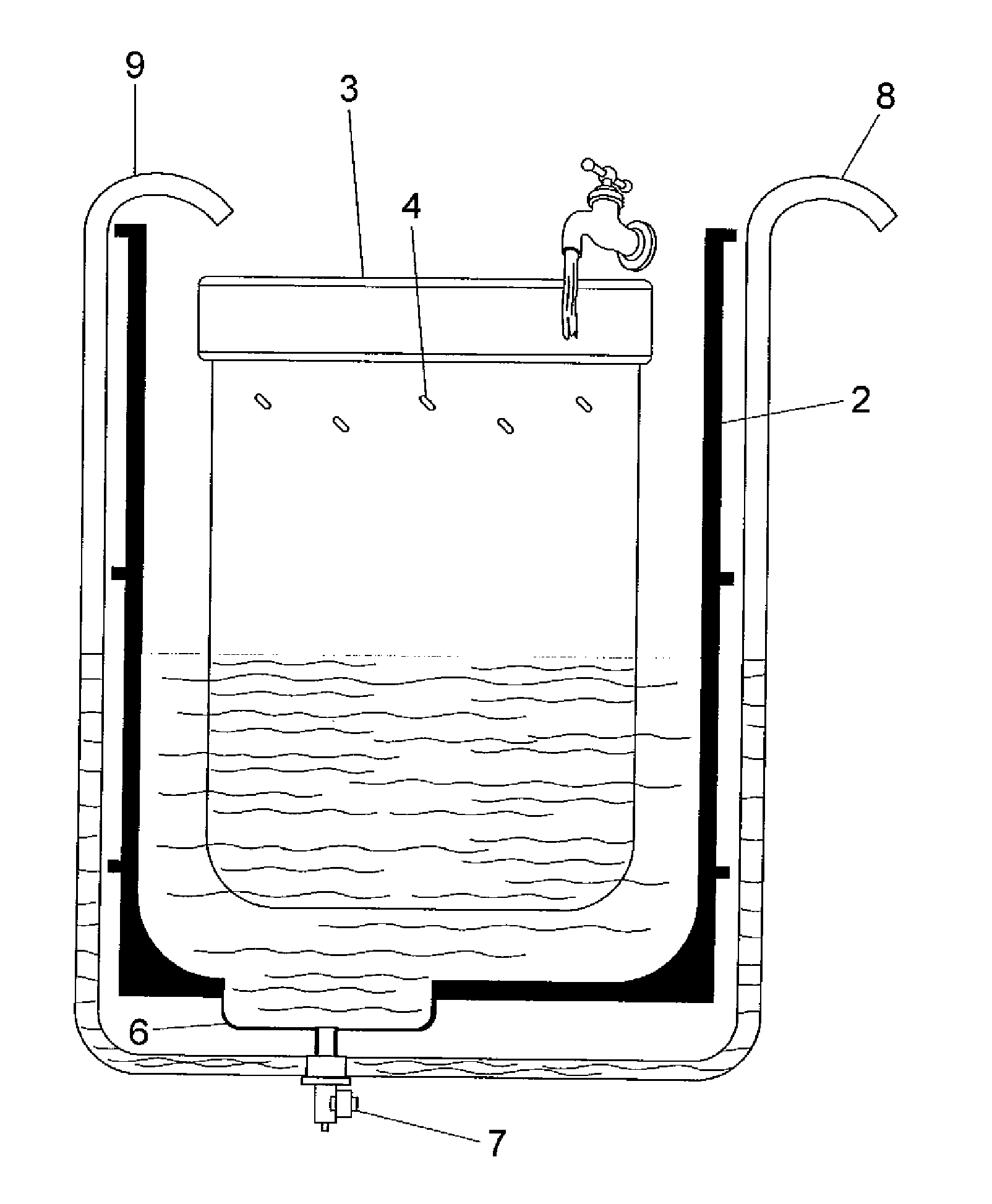

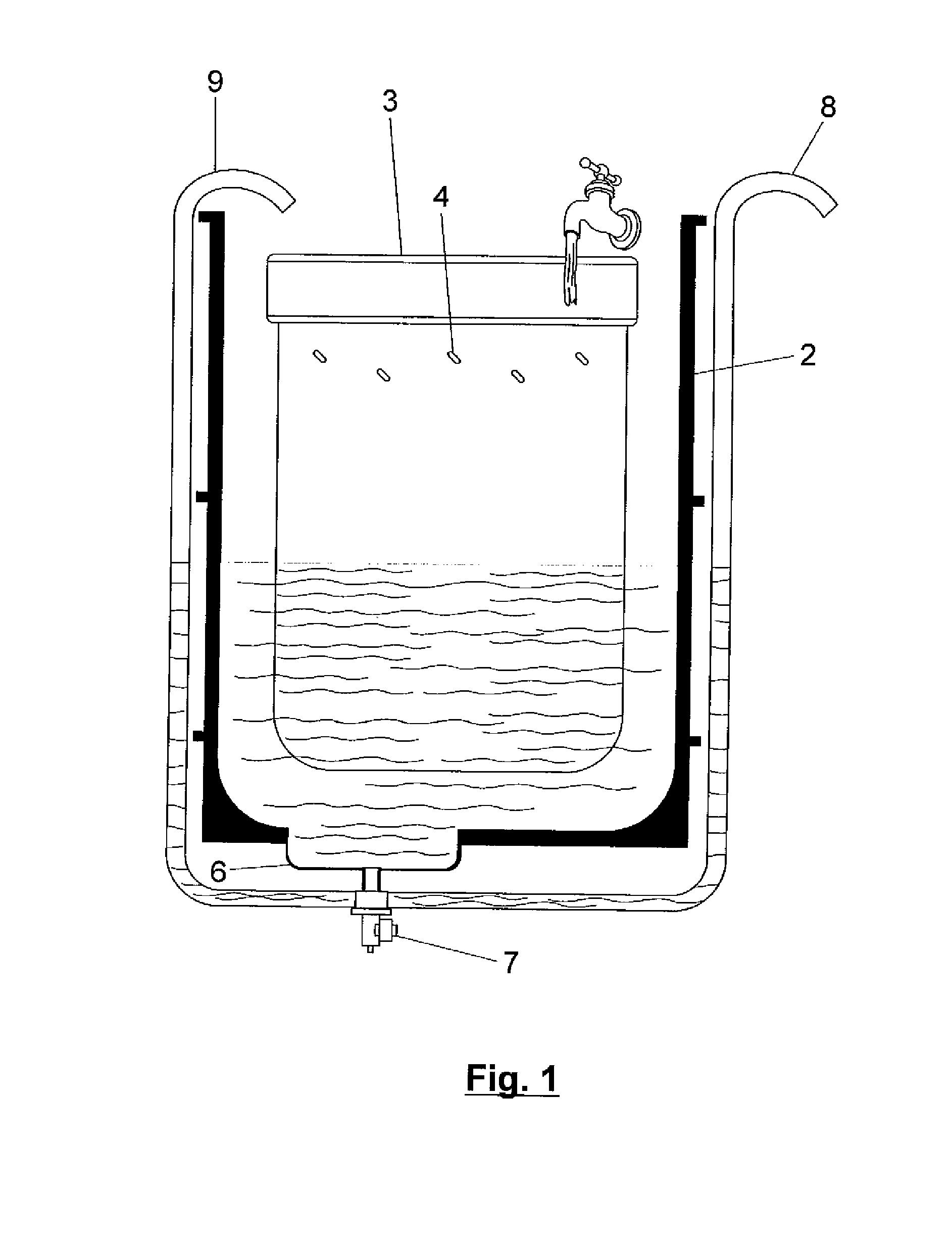

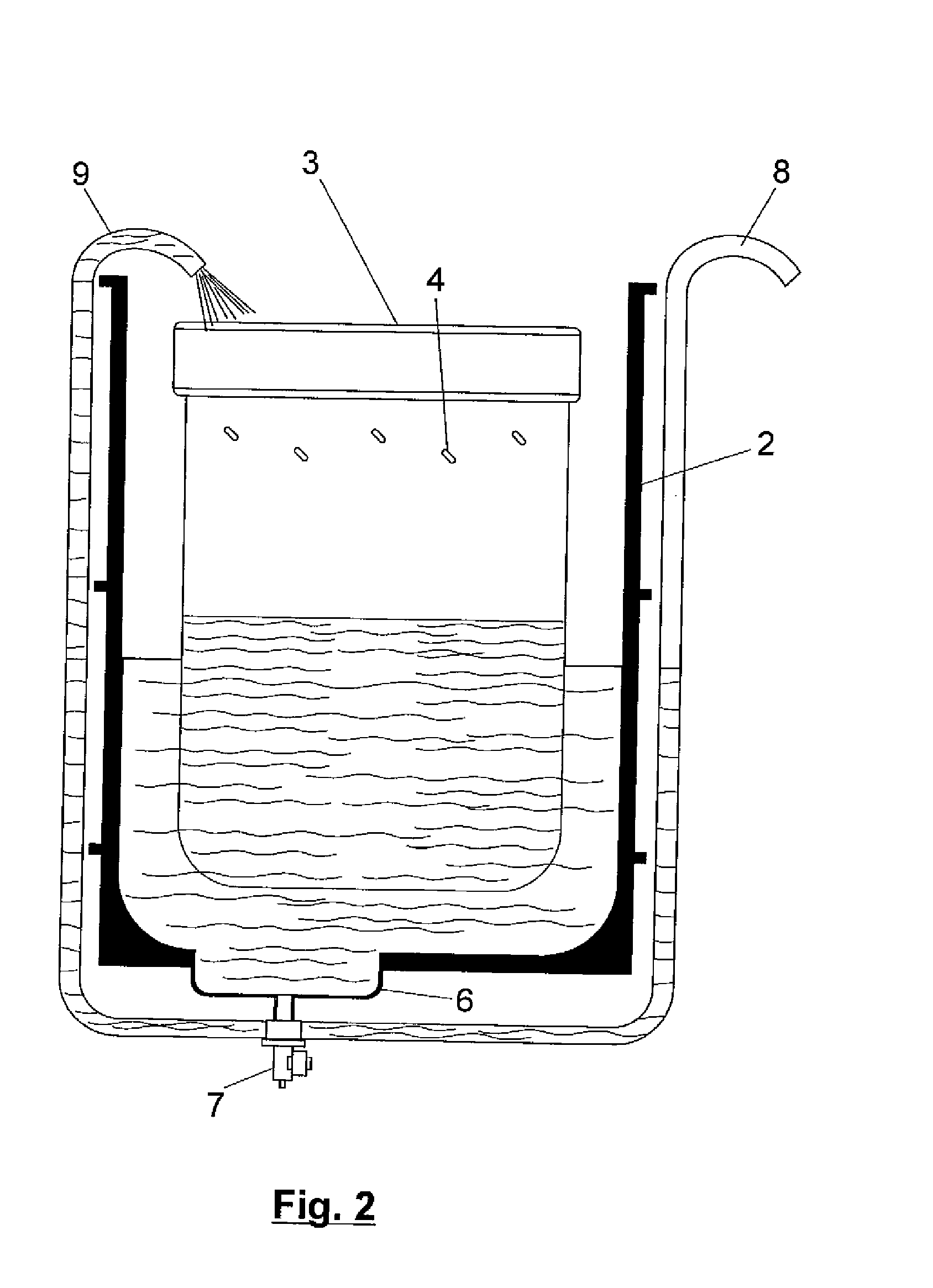

Method and washing machine provided with recirculation with controlled flow

ActiveUS20110138543A1Easy to operateEffective washing of clothingOther washing machinesControl devices for washing apparatusControl flowLevel sensor

A washing machine provided with recirculation with controlled flow. It further presents a method to control the level of the washing liquid, associated to the said machine, providing economy of resources such as water and cleaning products, guaranteeing an effective washing of clothes and similar articles, still associated with a decreases foam formation and lower nose emissions during the process, thus improving the operation of the equipment. The washing machine is provided with a washing tub (2), a basket (3), a two-way pump (7), level sensor (5), pool (6), recirculation hose (9), drainage hose (8) and control circuit.

Owner:ELECTROLUX DO BRASIL

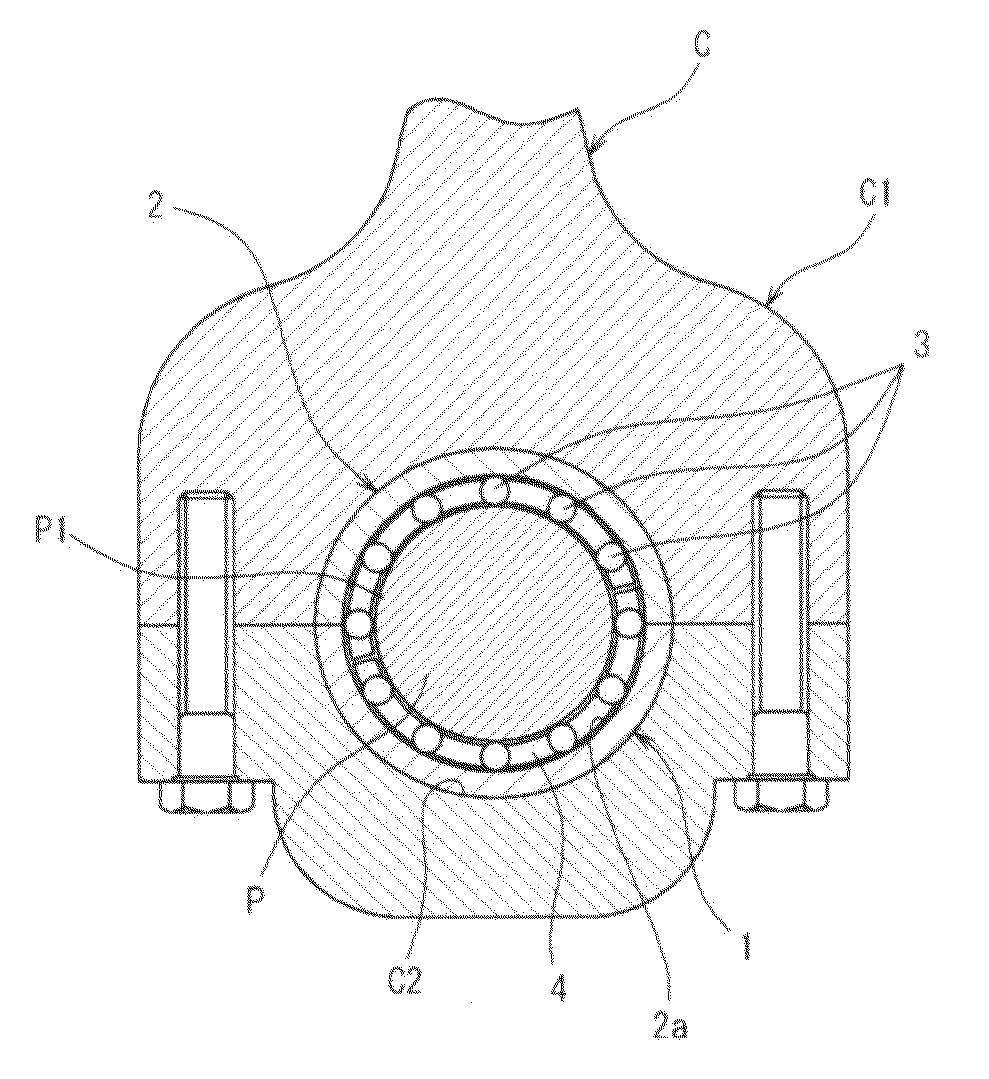

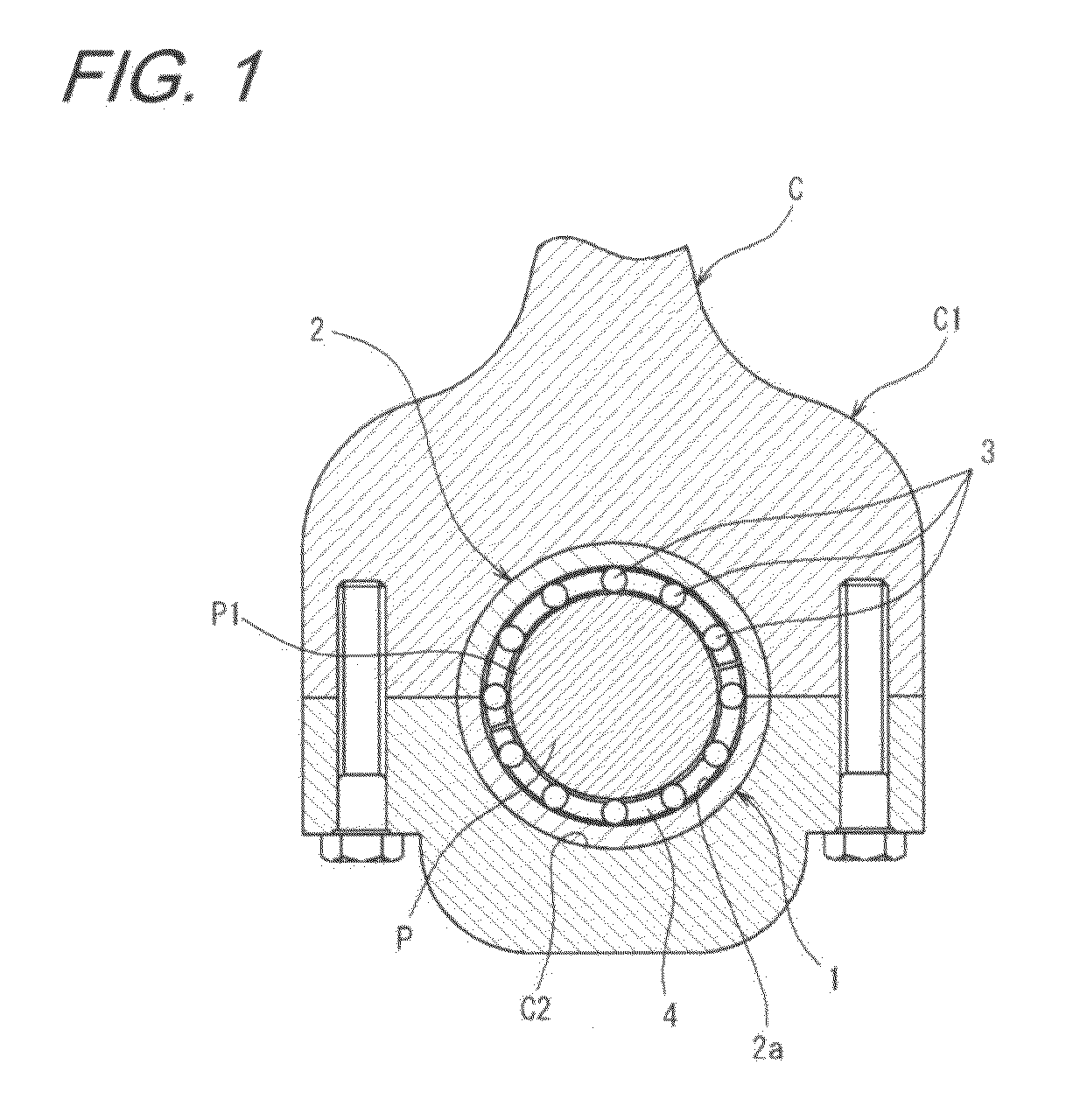

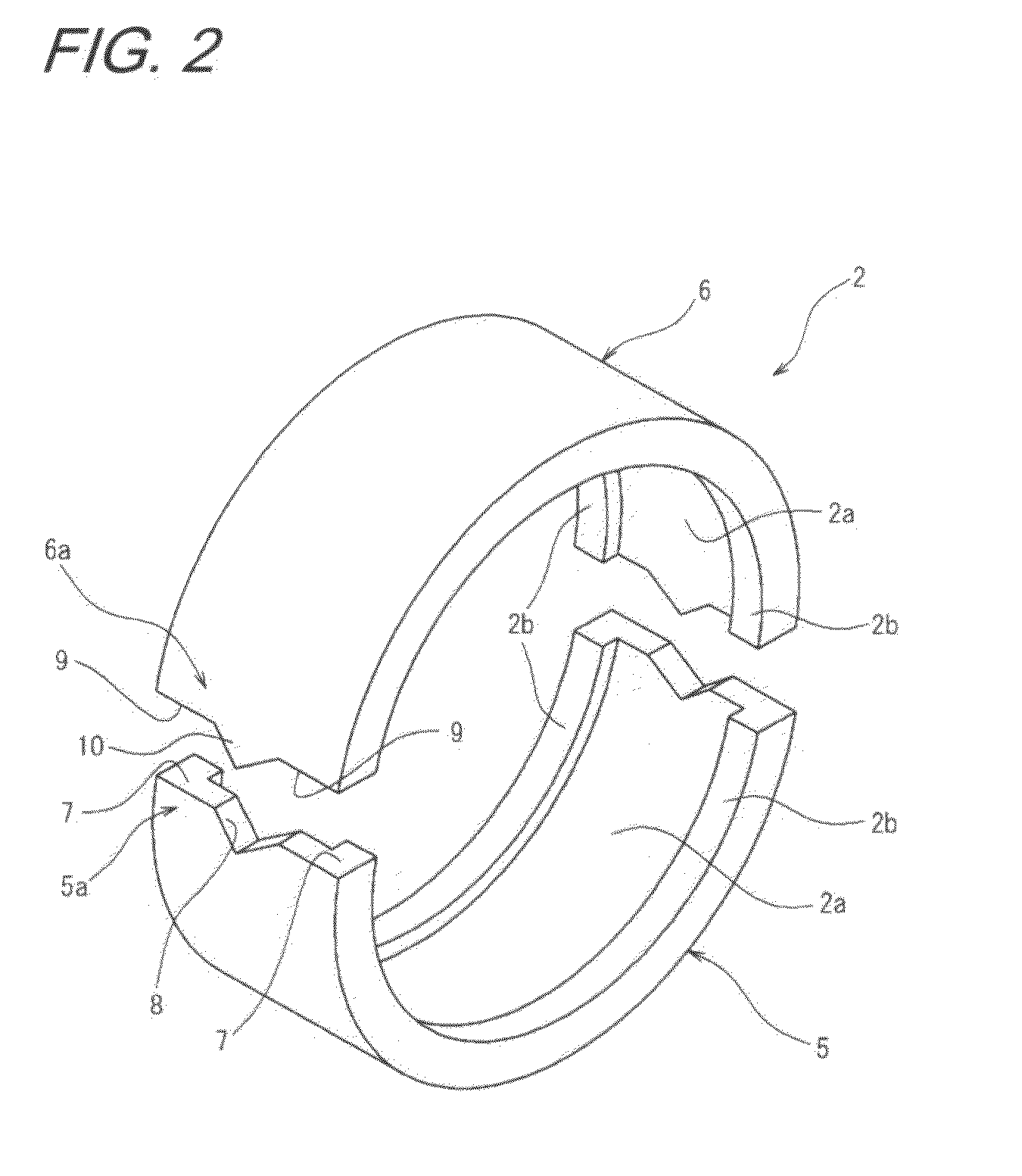

Split outer ring, split rolling bearing using the same ring and construction and method of mounting the same rolling bearing

InactiveUS20110064350A1Increased durabilitySuppress noiseConnecting rod bearingsRolling contact bearingsEngineeringAbutment

There are provided a split outer ring which can suppress the reduction in durability and which can suppress largely the generation of noise or vibration which is caused in association with the passage of rolling elements over a mating surface and a split rolling bearing which employs the same outer ring.A split outer ring 2 according to the invention has first and second split outer ring members 5, 6 which are formed into a cylindrical shape by being butted against each other at circumferential end portions. First flat plane portions 7 and a V-shaped recess portion 8 which is recessed in a circumferential direction are formed at one end portion 5a of the circumferential end portions which are butted against each other. Secondary flat plane portions 9 which are to be brought into abutment with the first flat plane portions 7 and a projecting portion 10 which projects in the circumferential direction from the second flat plane portion 9 so as to be introduced into the recess portion 8 are formed at an end portion 6a which is to be butted against the end portion 5a. A space S is formed between the recess portion 8 and the projecting portion 10 so as to avoid a contact between a bottom portion 8b of the recess portion 8 and a vertex portion 10b of the projecting portion 10.

Owner:JTEKT CORP

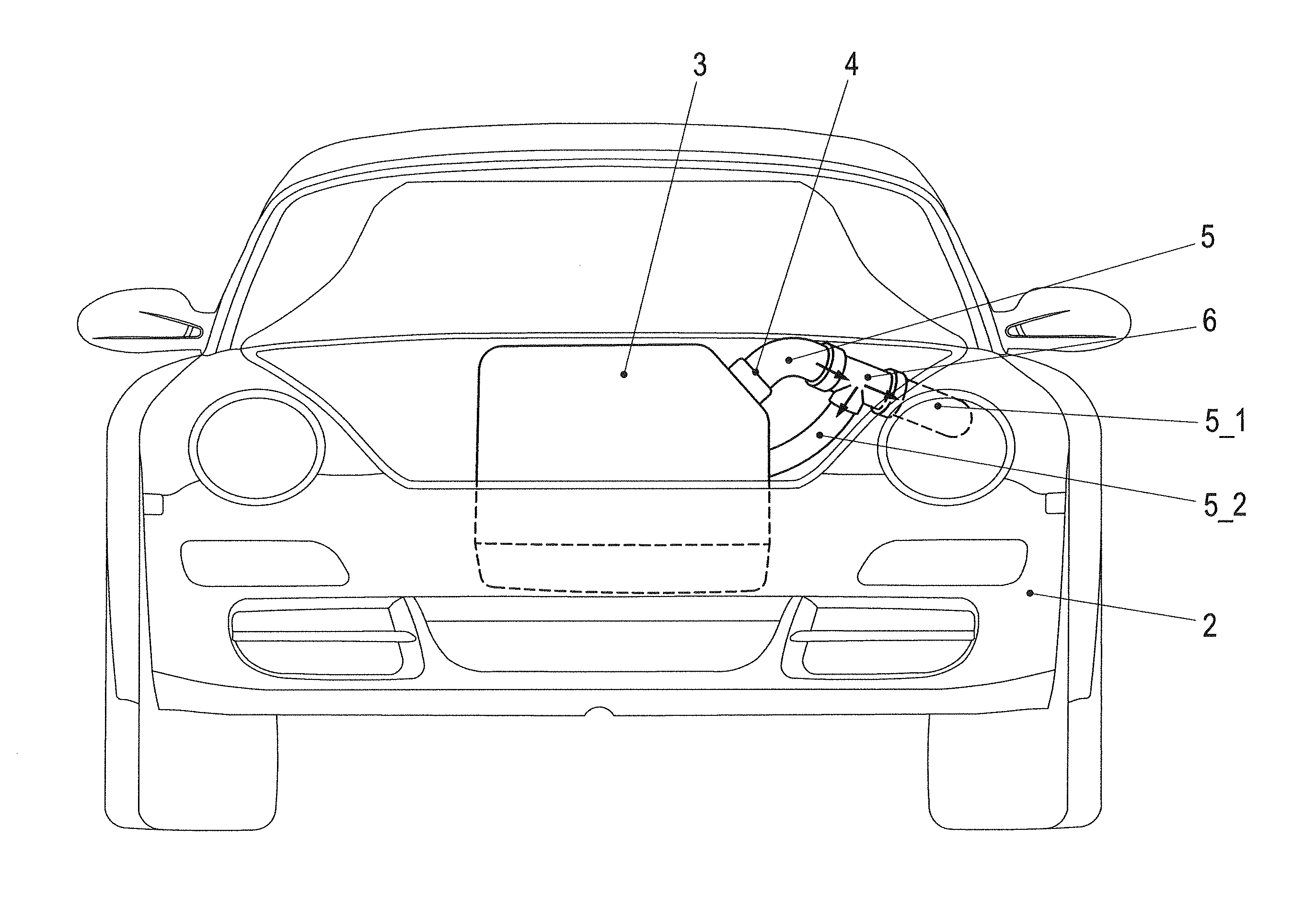

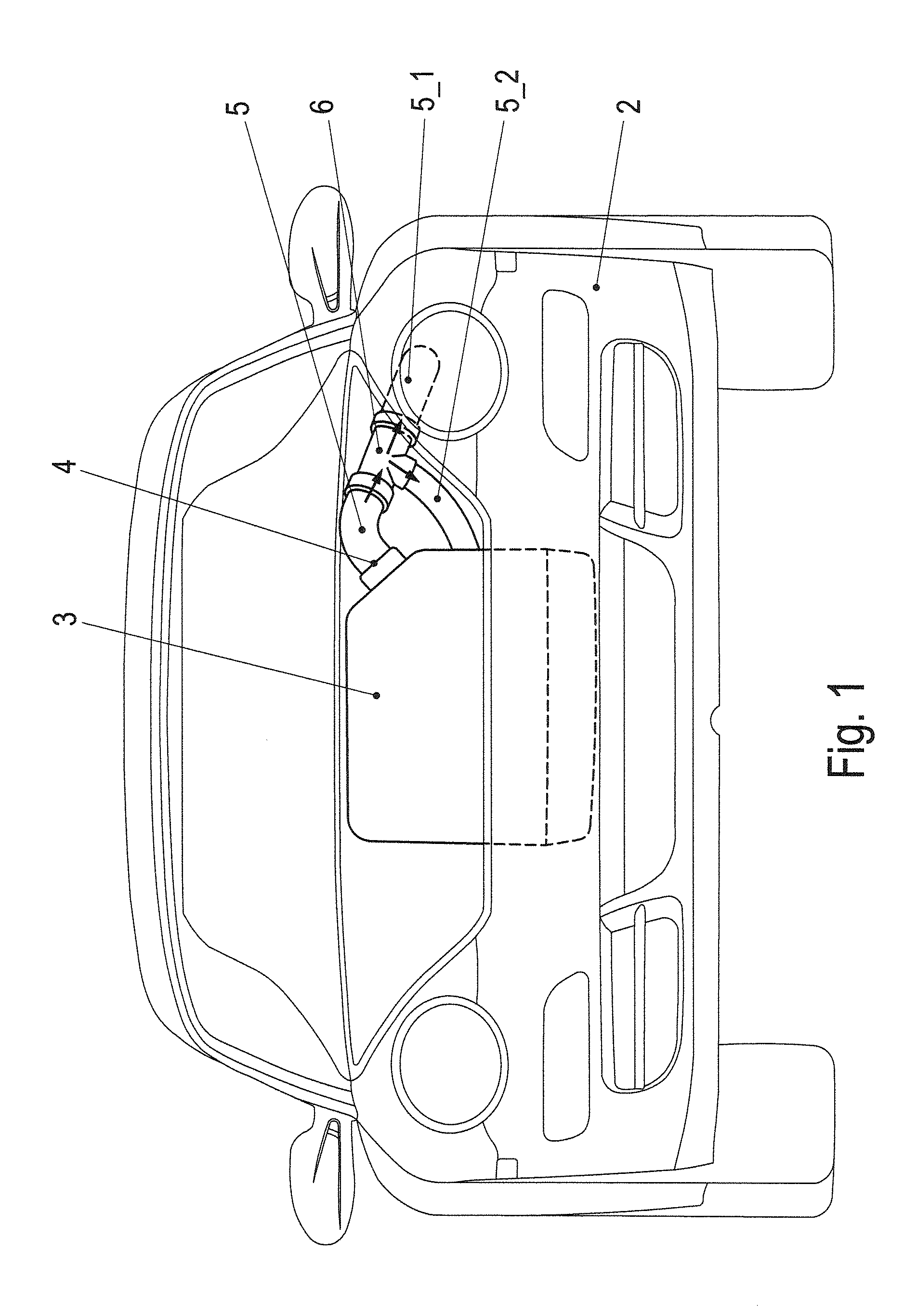

Method and device for generating noise in the vehicle interior and vehicle exterior of a motor vehicle

ActiveUS20140055258A1AmplifyPowerful and authentic soundAcoustic signal devicesOptical signallingAcoustic transmissionMotor vehicle part

A method is provided for generating noise in an interior and exterior of a motor vehicle in which a control unit is provided which can be activated and which is operatively connected to a noise generator. The noise generator is connected to at least one noise emitting device (3). The noise emitting device (3) is mounted underneath a hood of the motor vehicle, and is connected to the vehicle interior via at least one hose with at least one sound transmitting element. Sound waves are extracted from the noise emitting device (3) and are transmitted into the vehicle interior.

Owner:DR ING H C F PORSCHE AG

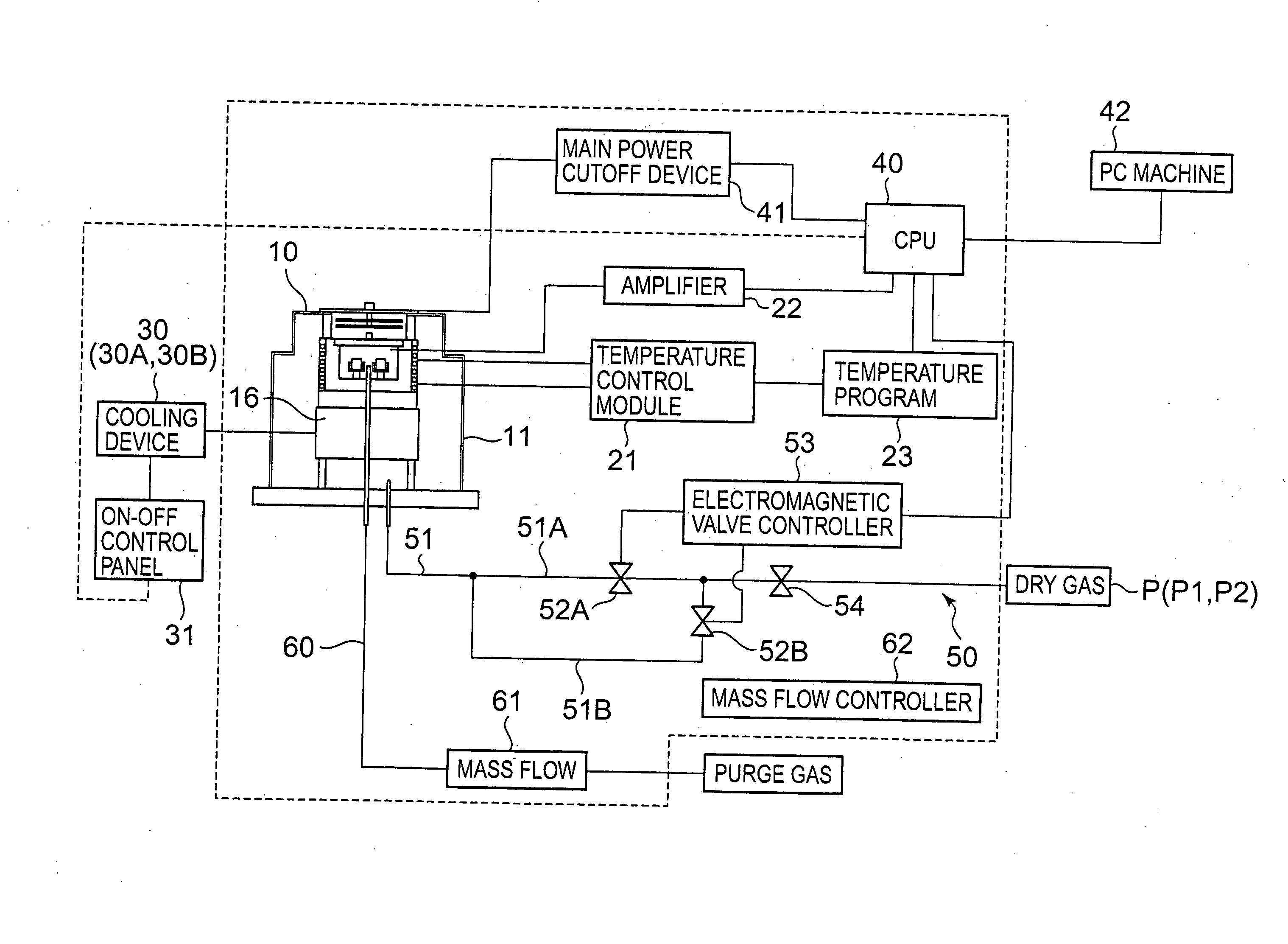

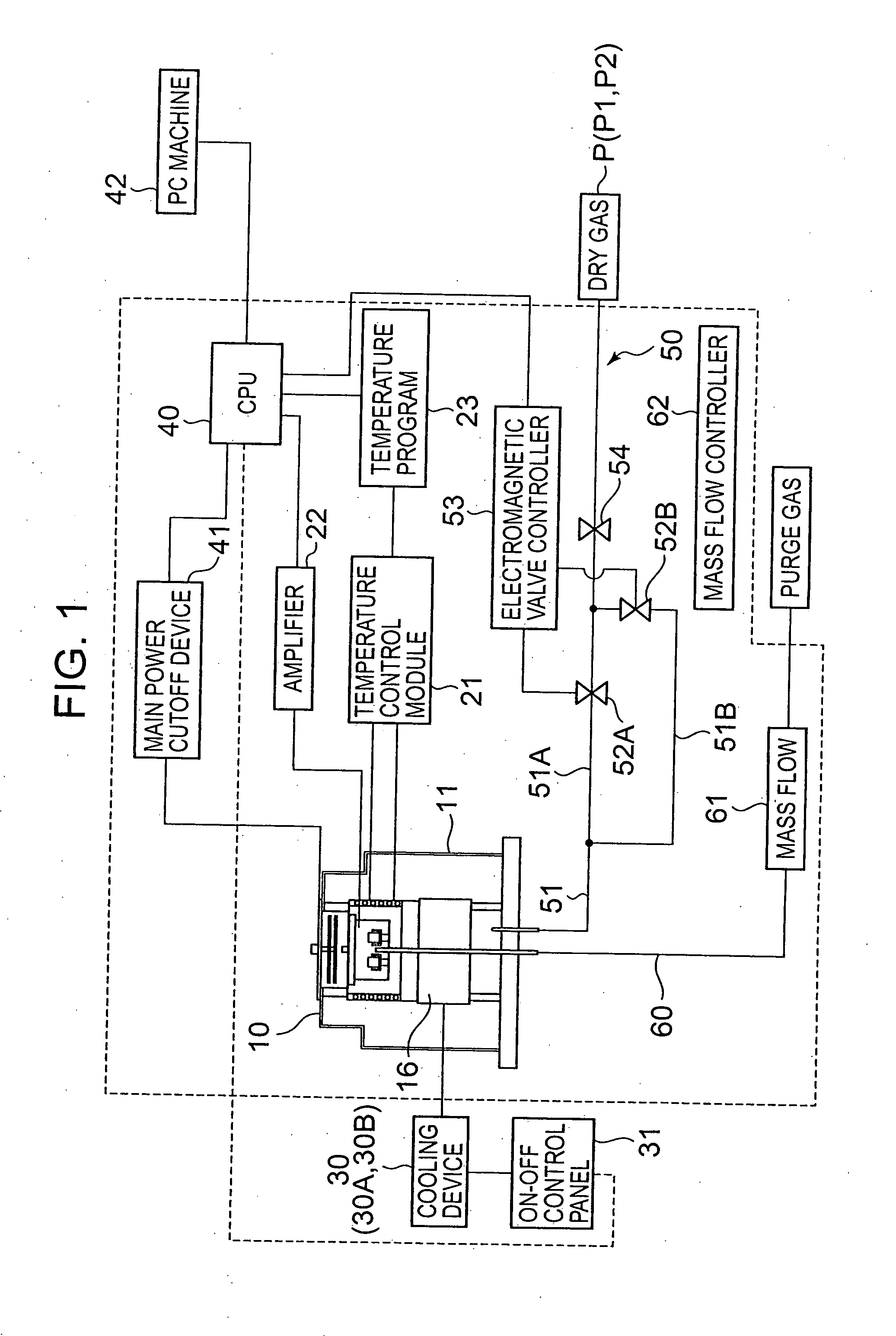

Thermal analysis system and method of drying the same

InactiveUS20080025364A1Accurate measurementFree laborDrying solid materials with heatMaterial heat developmentTemperature controlEngineering

To enable the reduction in working efforts by hand by performing control a drying operation by appropriately selecting dry conditions depending on the connection mode of the cooling device, and removal of moisture and the like without fail. The thermal analysis system uses a heater and a cooling device to raise and decrease the temperature inside the purge box. In the drying method for the thermal analysis system, the drying operation is performed by: previously setting dry conditions depending on the connection mode of the cooling device; starting control of an opening time dry process upon activation of the thermal analysis system; supplying a predetermined amount of dry gas into the purge box in accordance with the dry conditions corresponding to the selected connection mode of the cooling device with the cooling device kept off; and making the temperature control module control the temperature of the dry gas.

Owner:HITACHI HIGH TECH SCI CORP

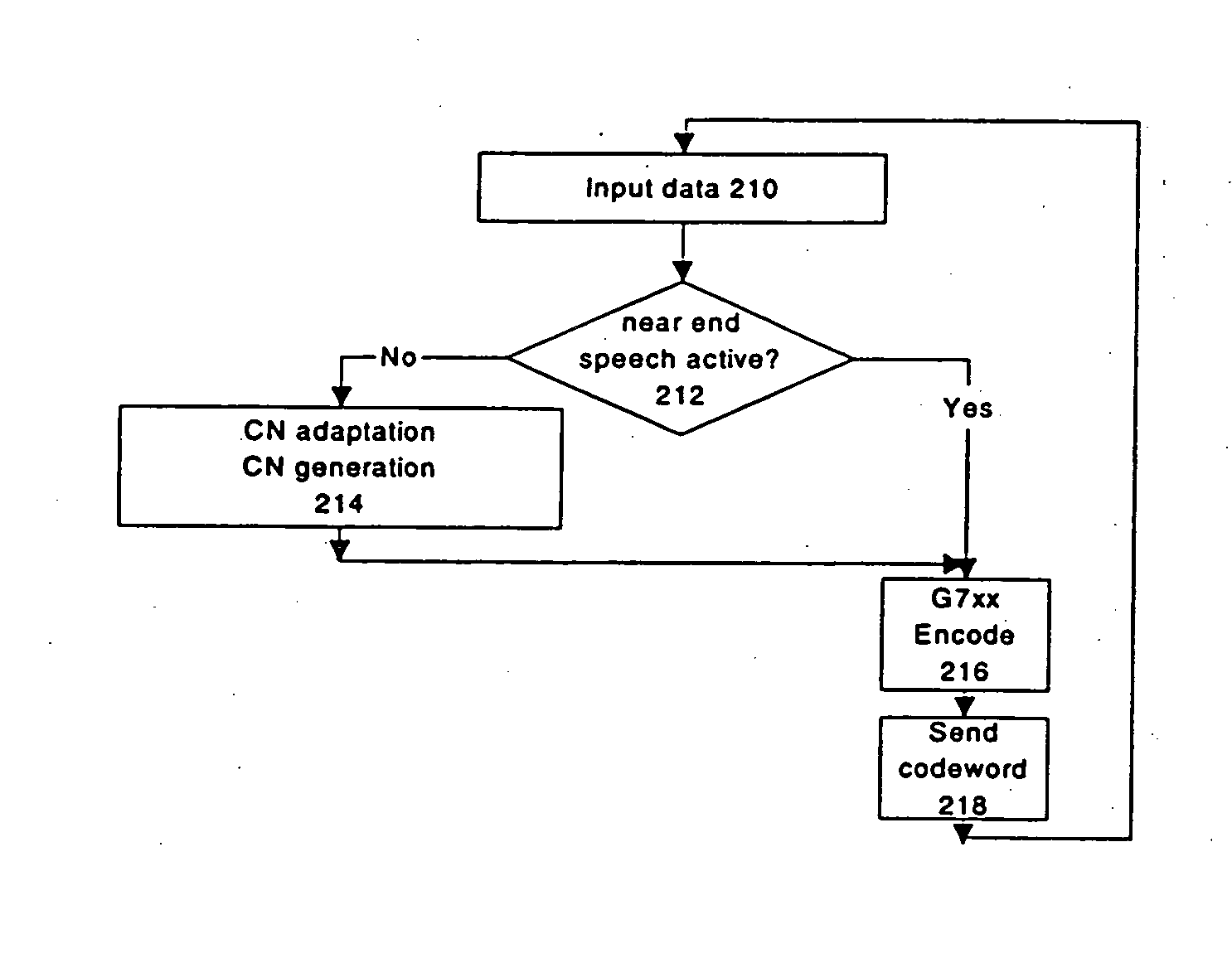

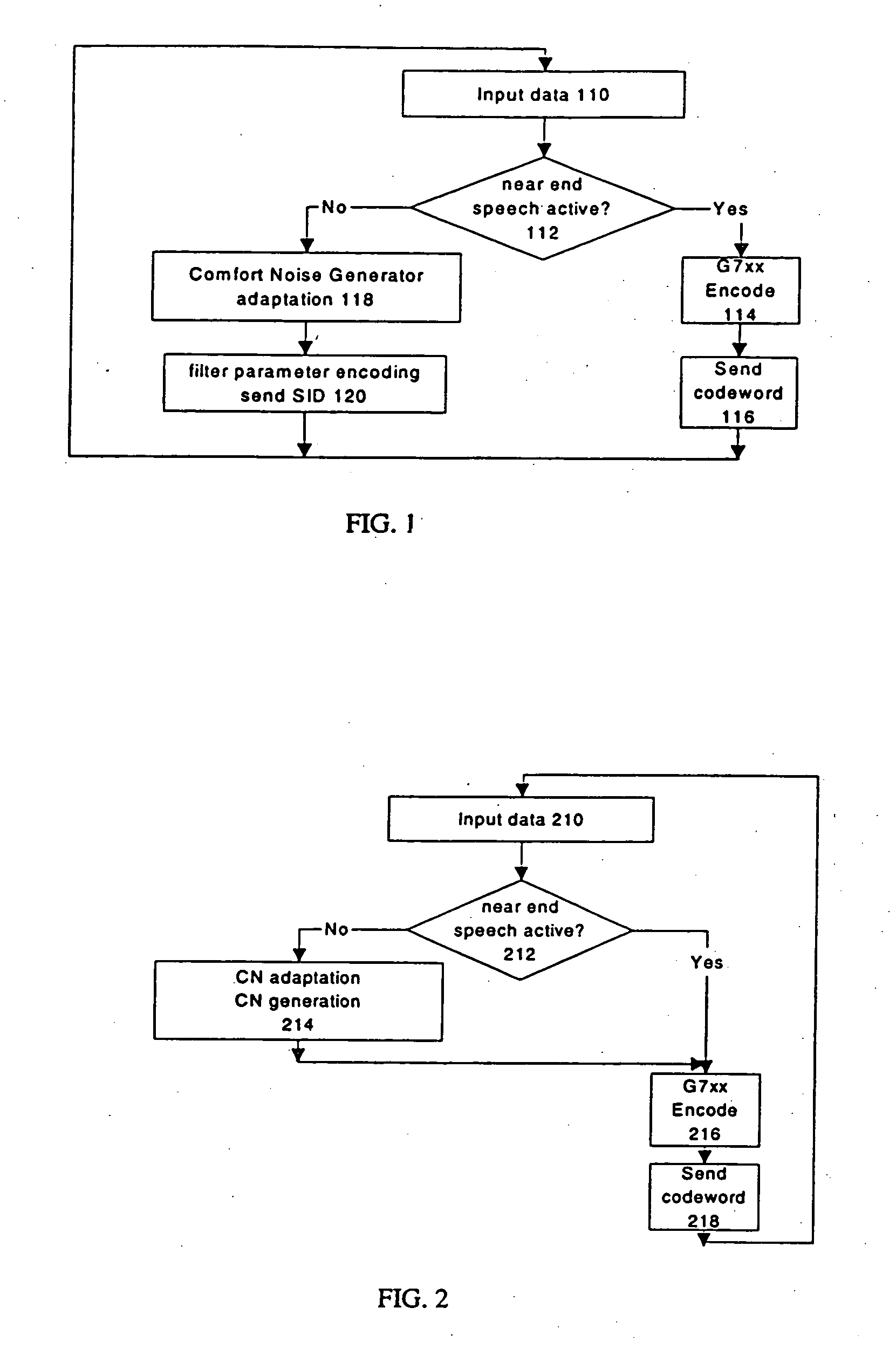

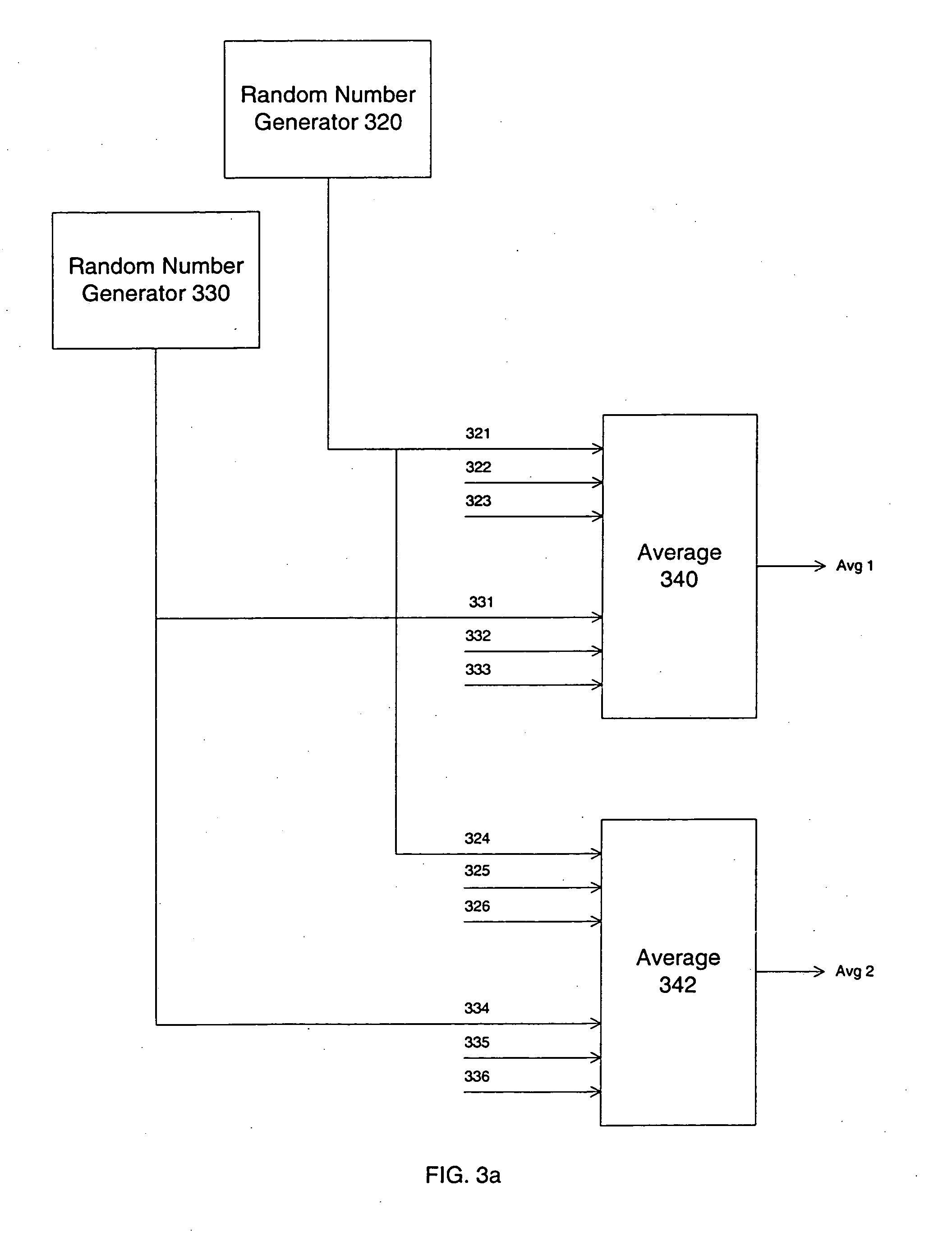

Method and system for generating colored comfort noise in the absence of silence insertion description packets

InactiveUS20060020449A1Reduce complexityEnhance flexibilityMultiple-port networksDelay line applicationsComfort noiseSpeech sound

A method and system for utilizing information content in speech and a transition hangover between speech and noise to generate comfort noise on the decoder side. This adaptation to noise may be accomplished using various algorithms of estimating the spectrum of color noise. According to an embodiment of the present invention, an adaptation algorithm may be implemented that adapts, with time, rather than a block based algorithm to prevent the repeated generation of artifacts present in the block that are being adapting to. The method and system of the present invention generates comfort noise in the absence of silent insertion descriptions containing spectrum information thereby saving bandwidth and generating colored comfort noise that reflects the spectrum of the actual noise.

Owner:IKANOS COMMUNICATIONS

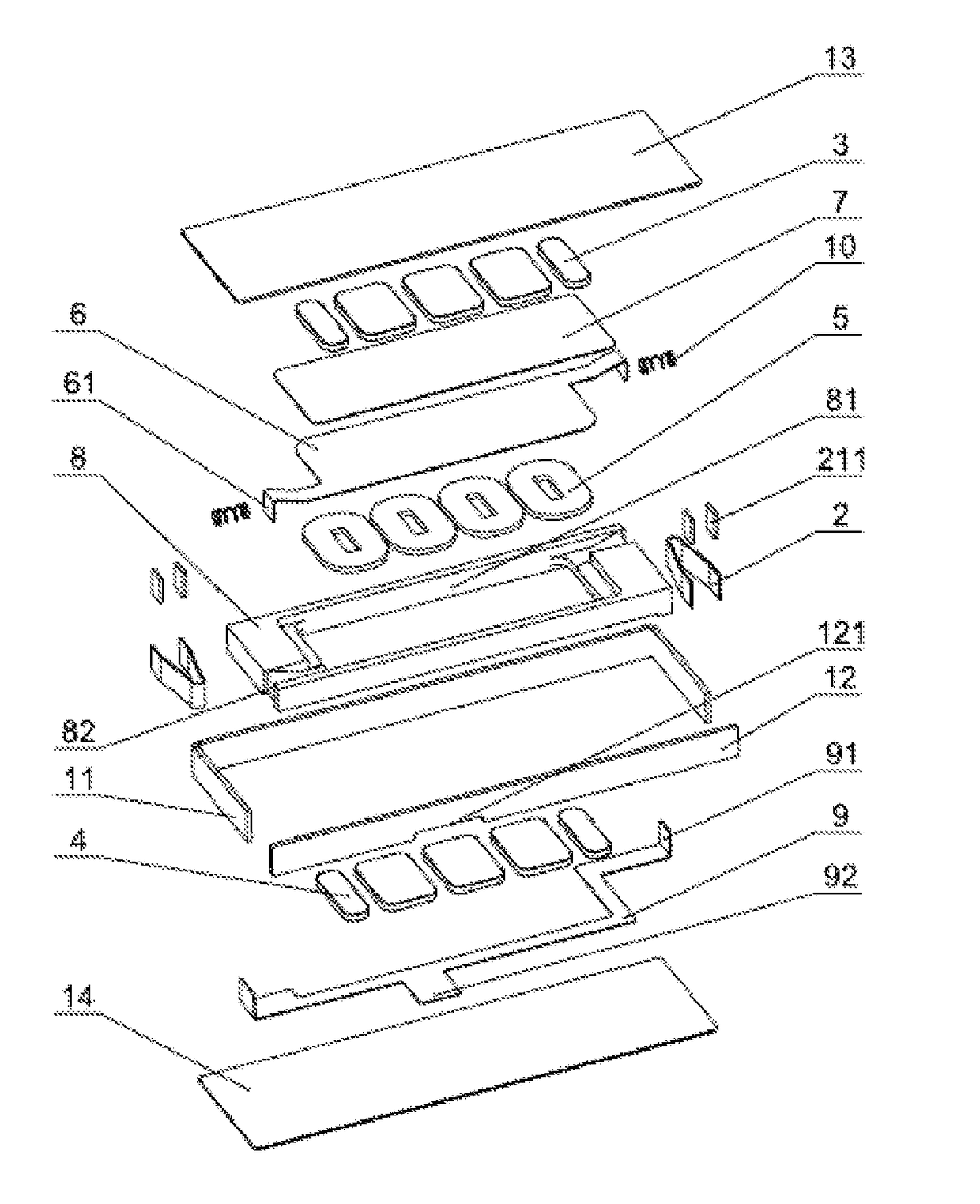

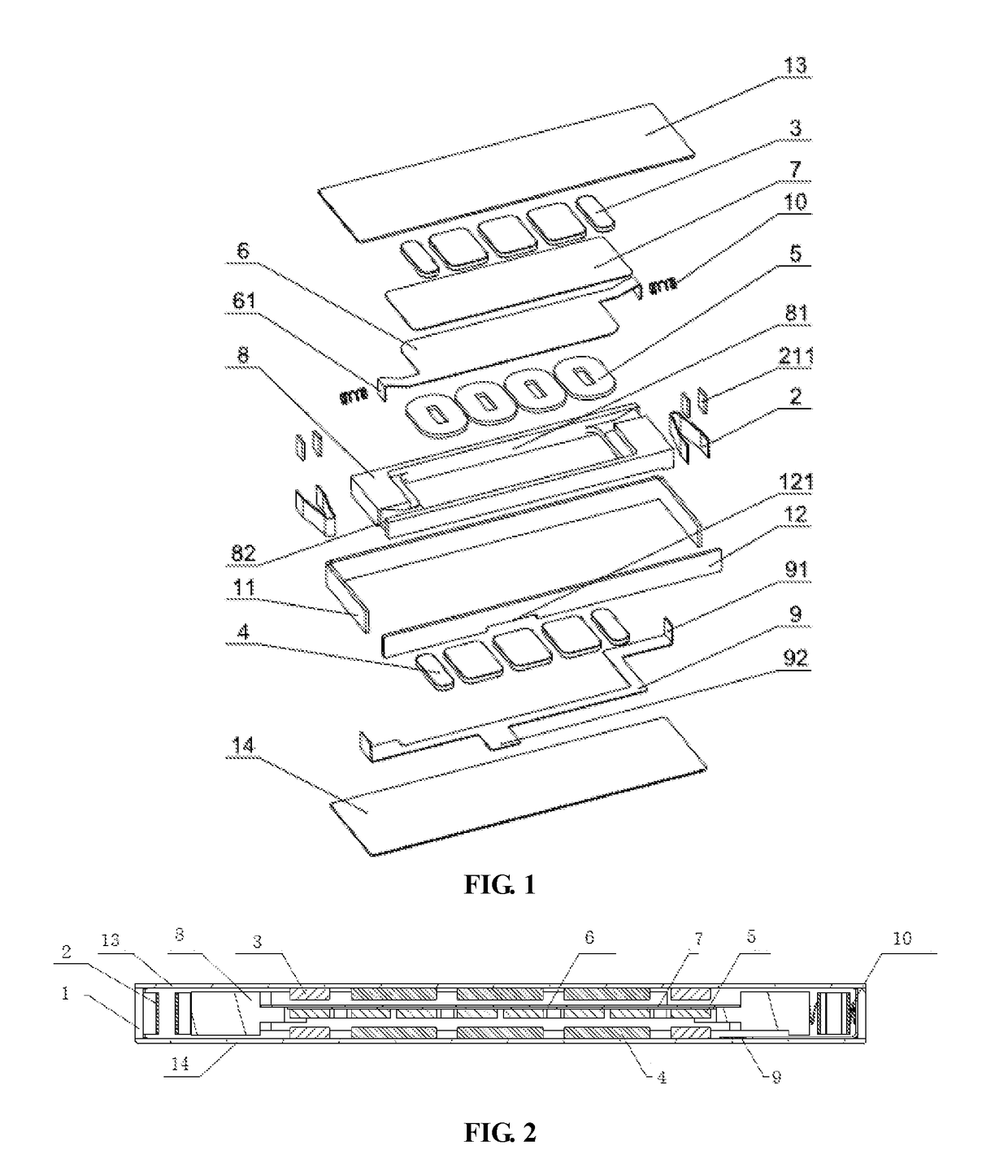

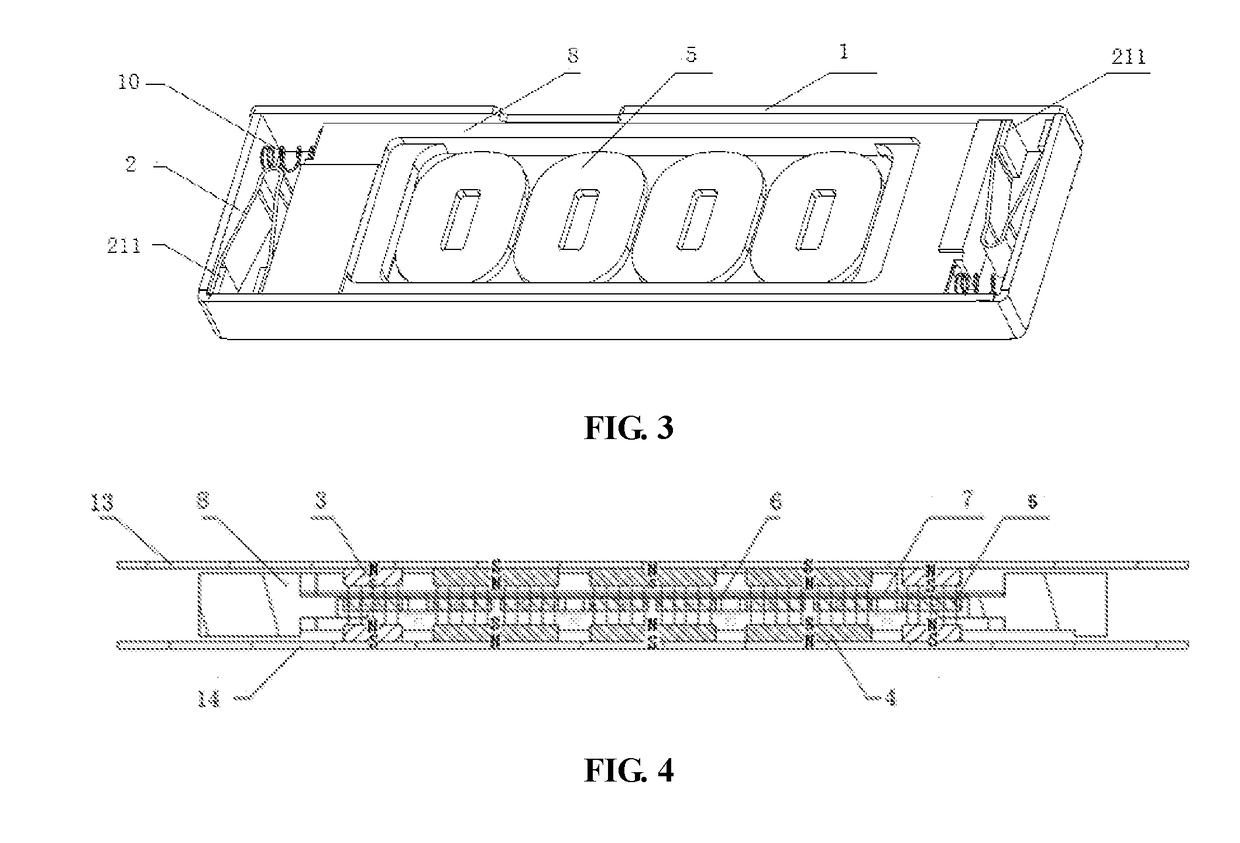

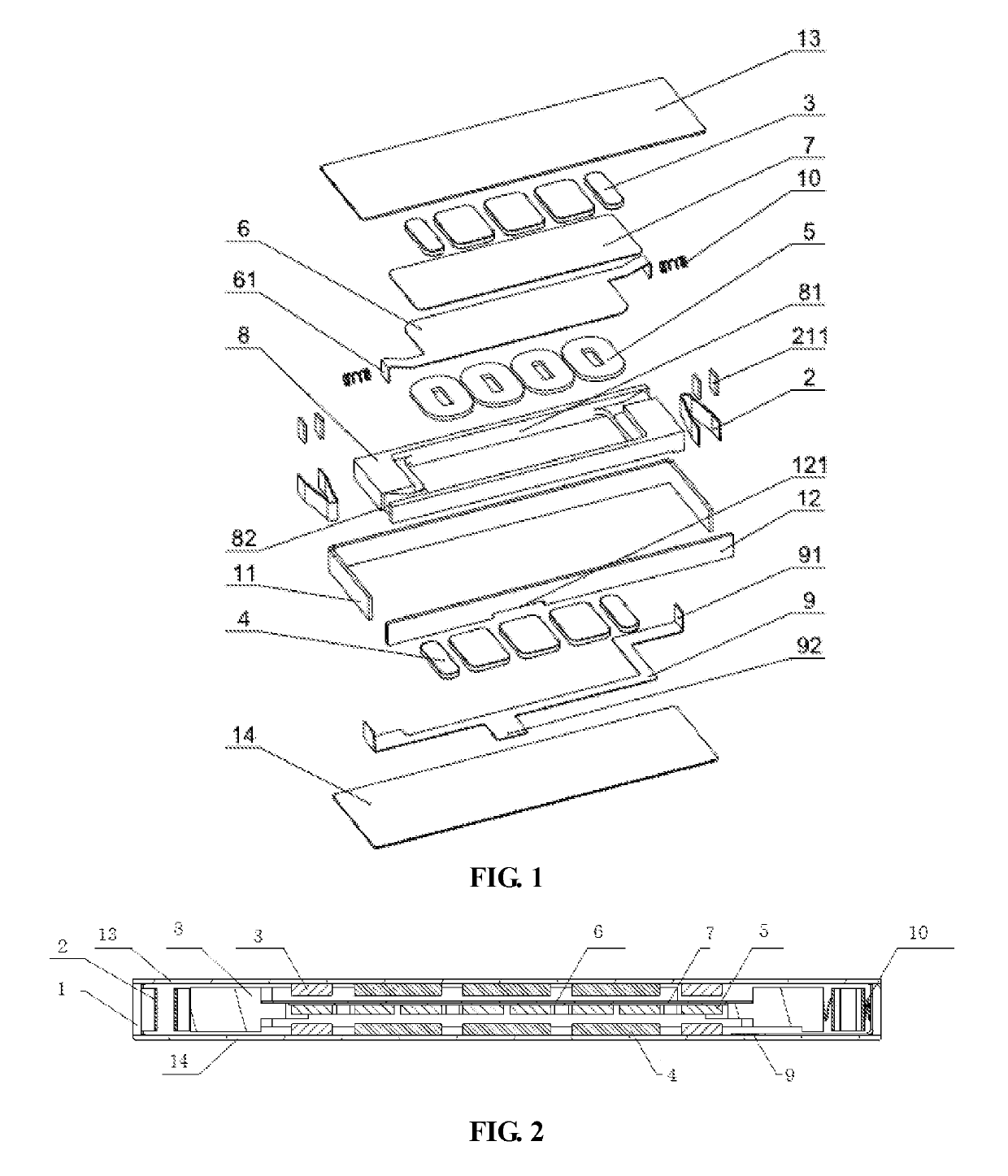

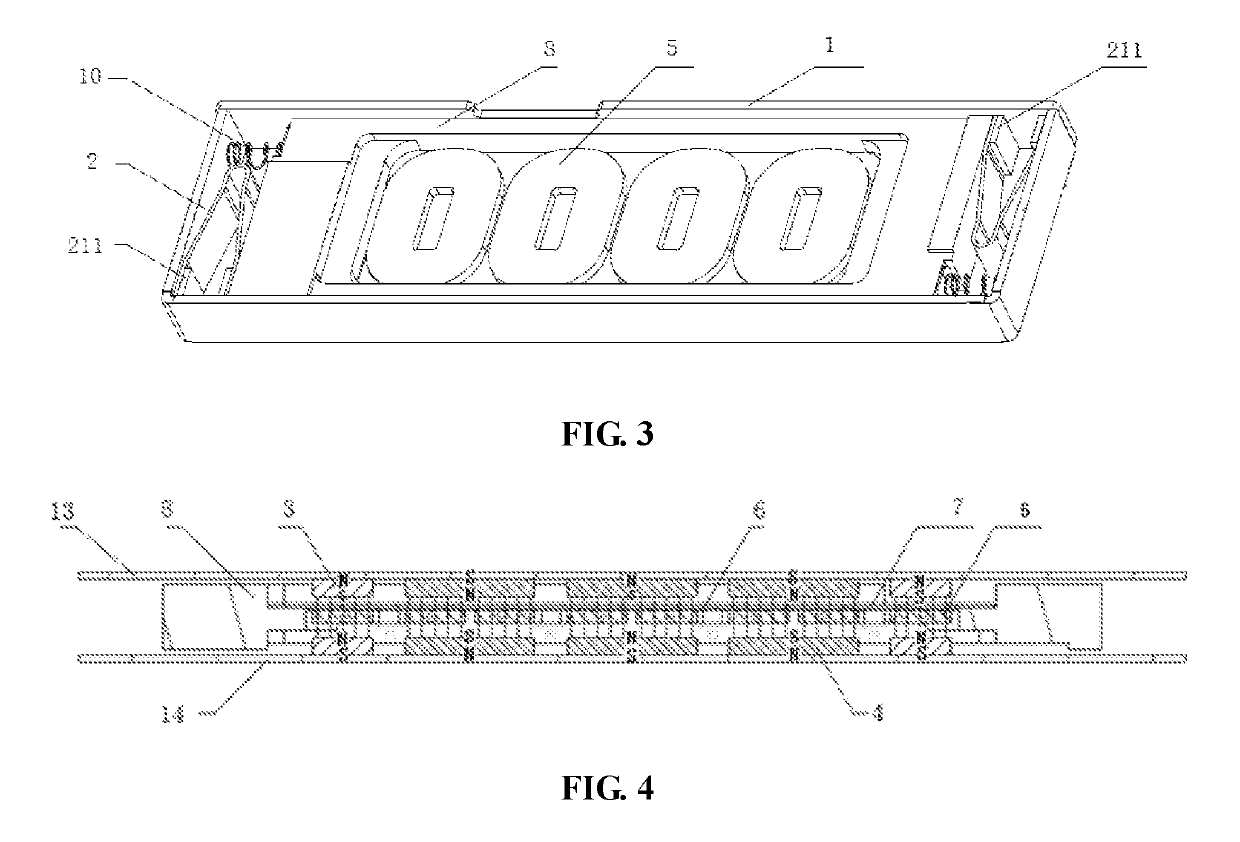

Linear motor

ActiveUS20170288521A1Improve stabilityFavorable for miniaturizationWindingsSupports/enclosures/casingsClassical mechanicsLinear motor

The present invention provides a linear motor, wherein, a coil is fastened on a mass block that is suspended inside a housing, a first magnet and a second magnet that have opposite magnetic poles are symmetrically disposed at an upper side and at a lower side relative to the coil in the middle and positioned parallel to the centric plane of the coil, by arranging an upper magnetic steel and a lower magnetic steel at an upper side and at a lower side relative to the mass block in the middle and parallel to the mass block. In the linear motor of the present invention, the design route that utilizes coil motion to drive mass block motion is different from the traditional route that utilizes magnet motion to drive mass block motion. When the coil moves to either of the two lateral sides of the housing, both the first magnet and the second magnet simultaneously generate forces along a vertical direction of the housing, and as the first magnet and the second magnet having opposite magnetic poles are symmetrically disposed on both sides of the coil, the electromagnetic forces generated by the two magnets are equal in magnitude and opposite in direction, thus being counterbalanced with each other in the vertical direction, so as to ensure that the coil only moves back and forth in a horizontal direction, without generating vibration in a vertical direction, therefore, no noise related to vertical vibration is caused.

Owner:JINLONG MACHINERY & ELECTRONICS CO LTD

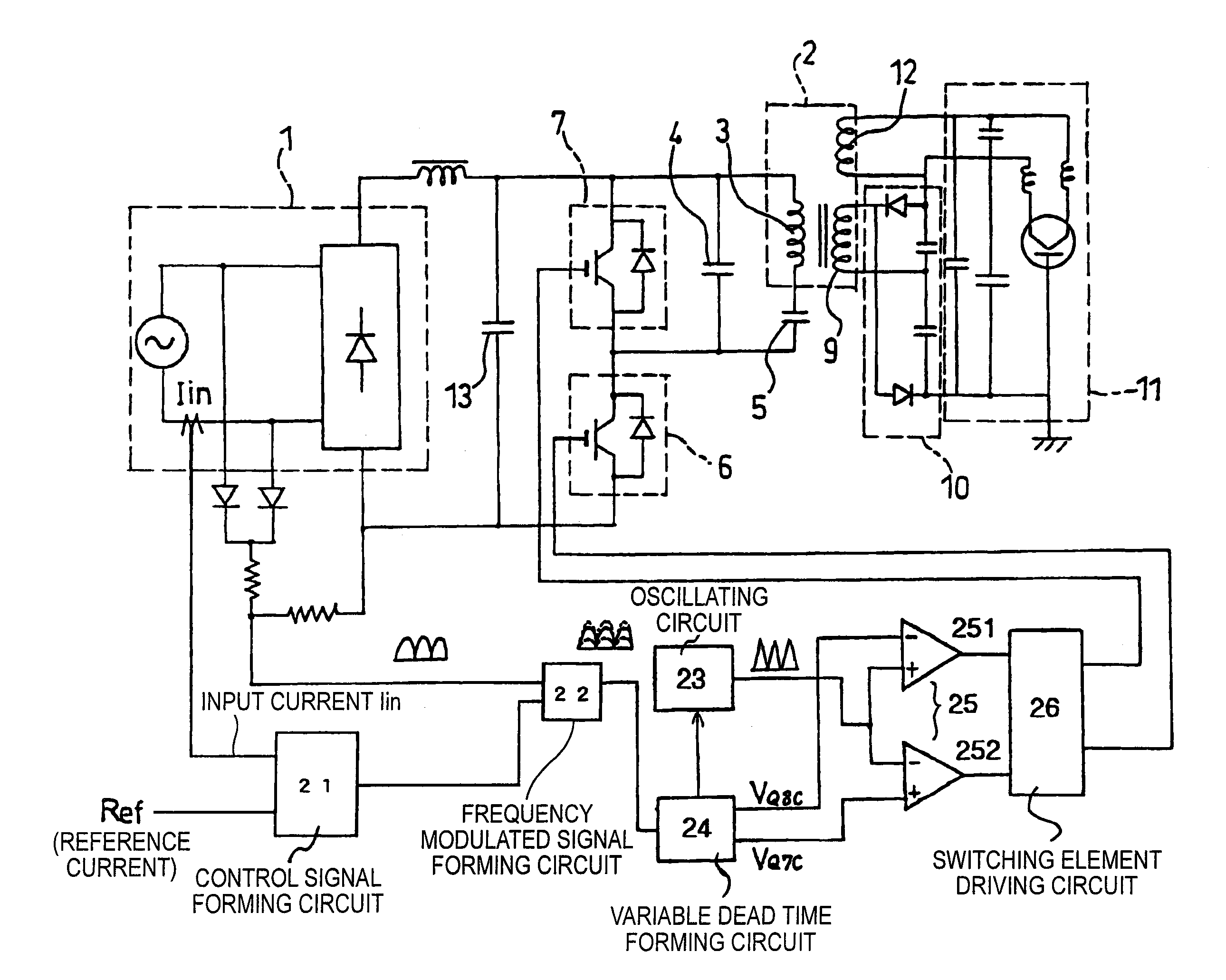

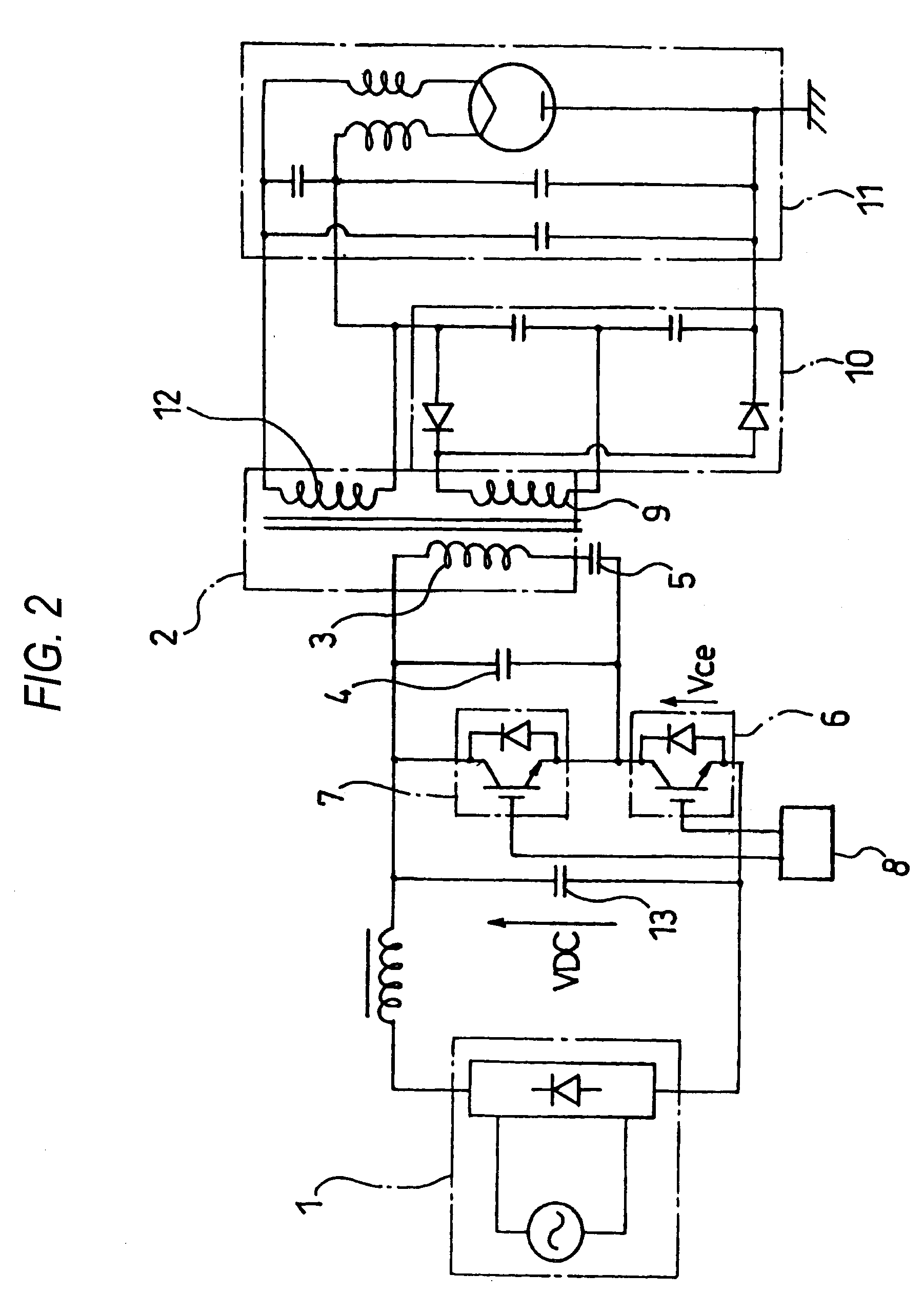

High-frequency heating apparatus

ActiveUS7282682B2Does not consume energyNoise is generatedConversion with intermediate conversion to dcDc-dc conversionTransformerHeat losses

A purpose of the present invention is to provide an inverter circuit capable of firmly turning ON IGBTs under limited condition, while a heat loss and noise can be hardly produced in semiconductor switching elements.In a resonant type high frequency heating apparatus which is arranged by employing a DC power supply; a series connection circuit constructed of two semiconductor switching elements which are connected to the DC power supply; another series connection circuit constituted by a capacitor and a primary winding of a leakage transformer connected to both the terminals of one of the two semiconductor switching elements; and a driving means for driving the respective semiconductor switching elements respectively, a variable dead time forming circuit is provided in the driving means, while the variable dead time forming circuit makes a dead time constant at a switching frequency lower than, or equal to a predetermined switching frequency, and also, rapidly increases a dead time at a switching frequency higher than, or equal to the predetermined switching frequency. Furthermore, when the switching frequency becomes high, a limitation is provided by which the dead time is not further widened.

Owner:PANASONIC CORP

Linear motor with electric current injection assembly with springs connected to movable coil inside a mass block and upper and lower stationary magnets

ActiveUS10447133B2Buffer slight vibrationNoise is generatedWindingsSupports/enclosures/casingsVertical vibrationMagnetic poles

The present invention provides a linear motor, wherein, a coil is fastened on a mass block that is suspended inside a housing, a first magnet and a second magnet that have opposite magnetic poles are symmetrically disposed at an upper side and at a lower side relative to the coil in the middle and positioned parallel to the centric plane of the coil, by arranging an upper magnetic steel and a lower magnetic steel at an upper side and at a lower side relative to the mass block in the middle and parallel to the mass block. In the linear motor of the present invention, the design route that utilizes coil motion to drive mass block motion is different from the traditional route that utilizes magnet motion to drive mass block motion. When the coil moves to either of the two lateral sides of the housing, both the first magnet and the second magnet simultaneously generate forces along a vertical direction of the housing, and as the first magnet and the second magnet having opposite magnetic poles are symmetrically disposed on both sides of the coil, the electromagnetic forces generated by the two magnets are equal in magnitude and opposite in direction, thus being counterbalanced with each other in the vertical direction, so as to ensure that the coil only moves back and forth in a horizontal direction, without generating vibration in a vertical direction, therefore, no noise related to vertical vibration is caused.

Owner:JINLONG MACHINERY & ELECTRONICS CO LTD

Centrifugal fan

ActiveUS7476076B2Inhibit deteriorationAvoid it happening againPump componentsReaction enginesImpellerEngineering

A centrifugal fan includes a scroll casing having first and second flat base walls, and a circumferential side wall. An air inlet is formed on a center portion of the first base wall and an exhaust port is formed on the circumferential side wall. An airflow correction mechanism that forms smooth airflow when an impeller rotates is provided. The mechanism has an annular rib that is formed on the inside surface of the first base wall so as to be jutted to the side of the second base wall and to be concentric with the rotating shaft, and a recess portion that is formed on every blade of the impeller so that the annular rib is inserted therein with a predetermined gap. The annular rib and the recess portion are configured to change the direction of airflow directed to the air inlet back to a space between the blades.

Owner:NIDEC SERVO CORP

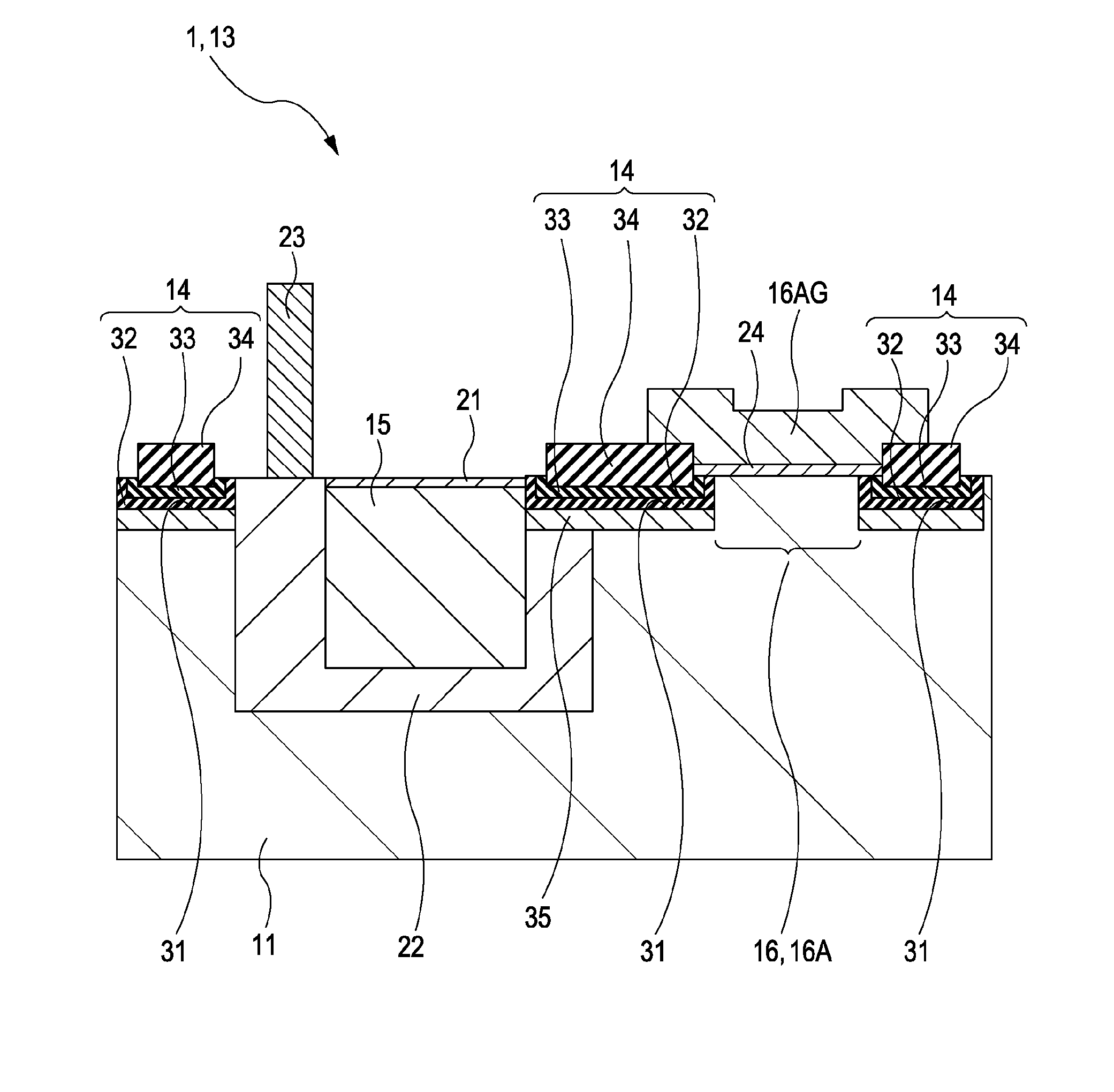

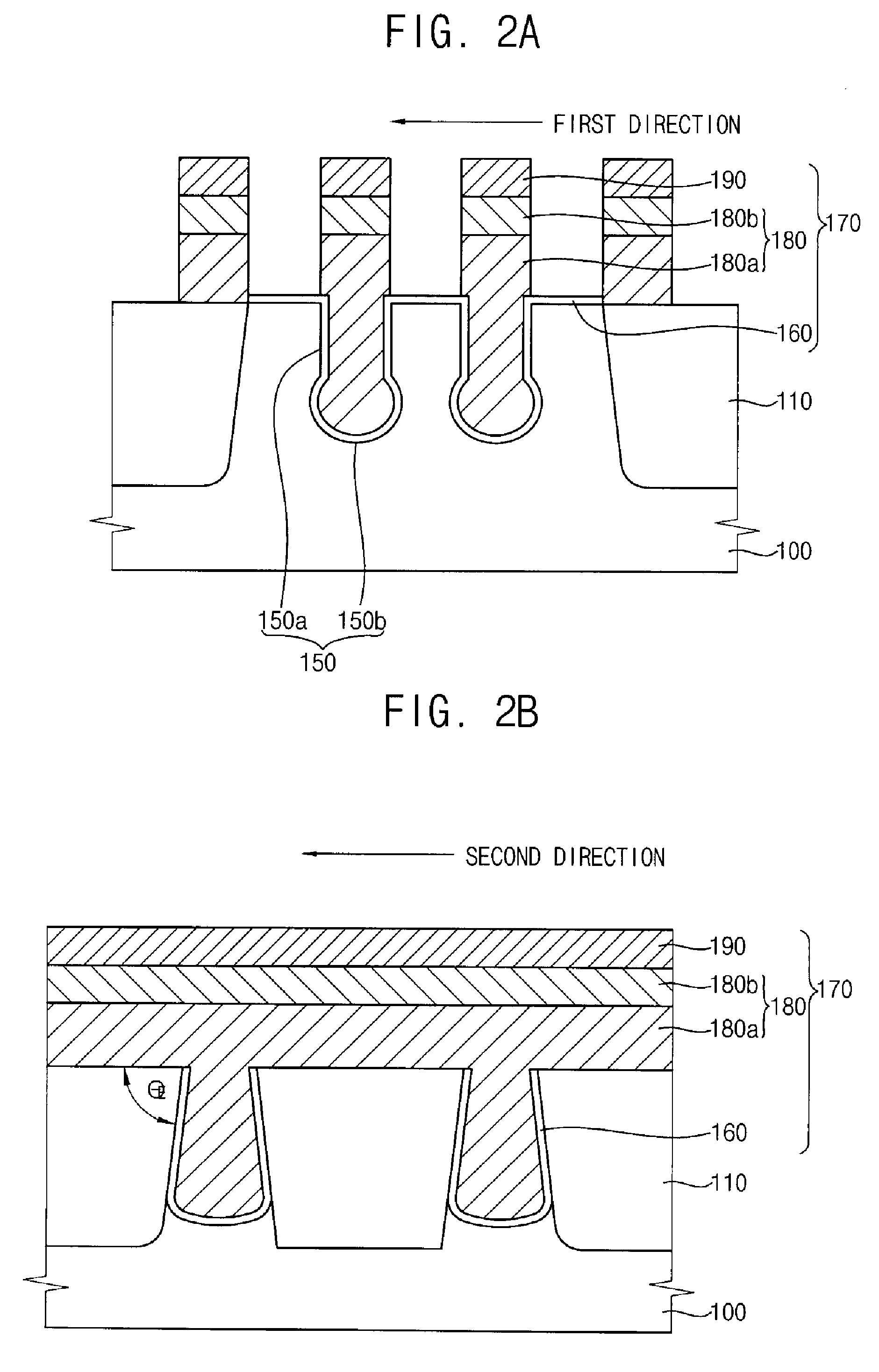

Solid-state imaging device, method for manufacturing solid-state imaging device, and imaging apparatus

ActiveUS20100128161A1Reduce widthNoise is generatedTelevision system detailsSolid-state devicesEngineeringPhotoelectric conversion

A solid-state imaging device includes, on a semiconductor substrate, a pixel portion having a plurality of pixels provided with a photoelectric conversion portion, which photoelectrically converts incident light to obtain a signal charge and a pixel transistor portion, which converts the signal charge read from the photoelectric conversion portion to a voltage, wherein an element isolation region disposed in the pixel portion includes an insulating film buried in a trench disposed in the semiconductor substrate, and the insulating film includes an insulating film having a negative charge.

Owner:SONY CORP

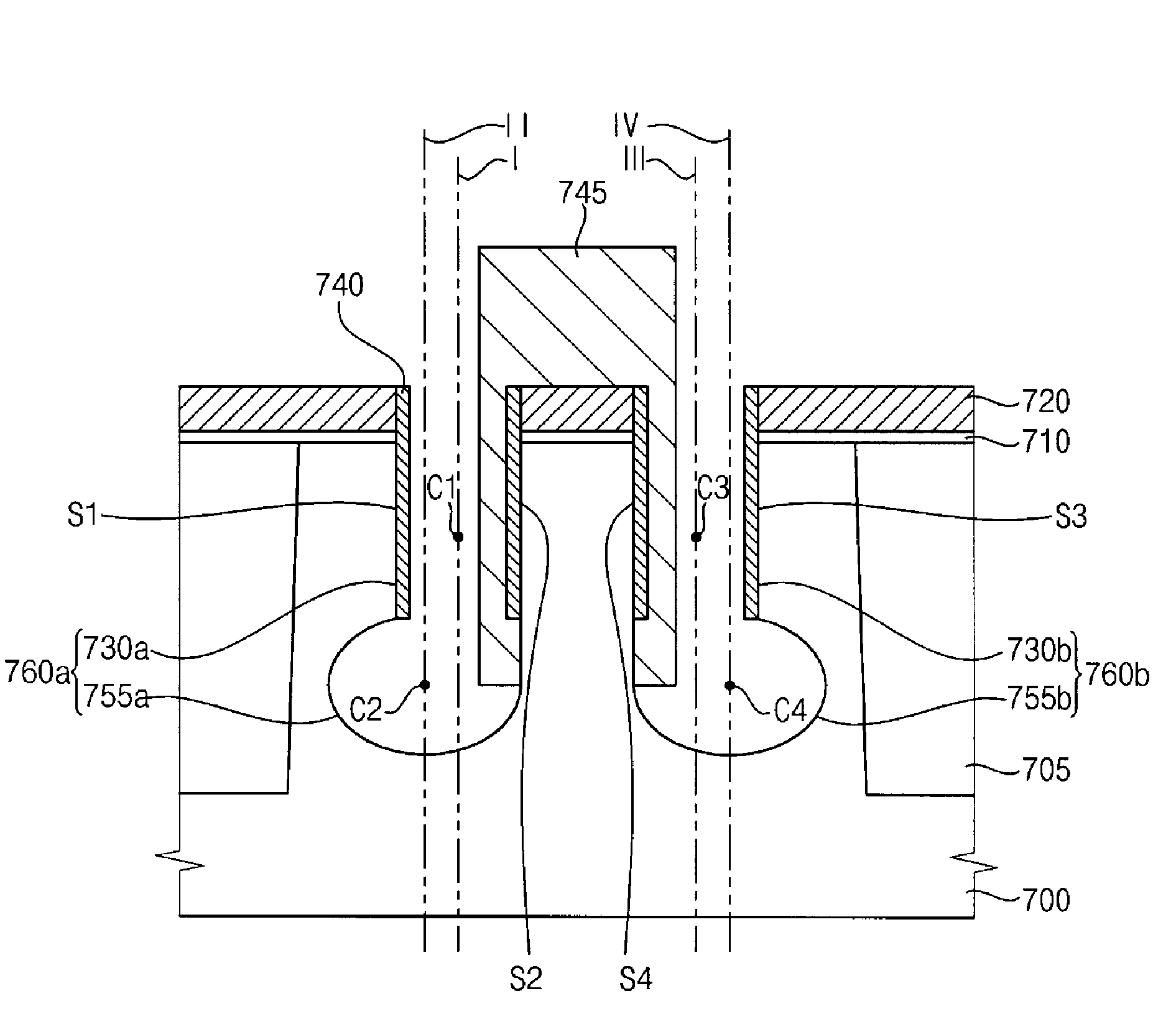

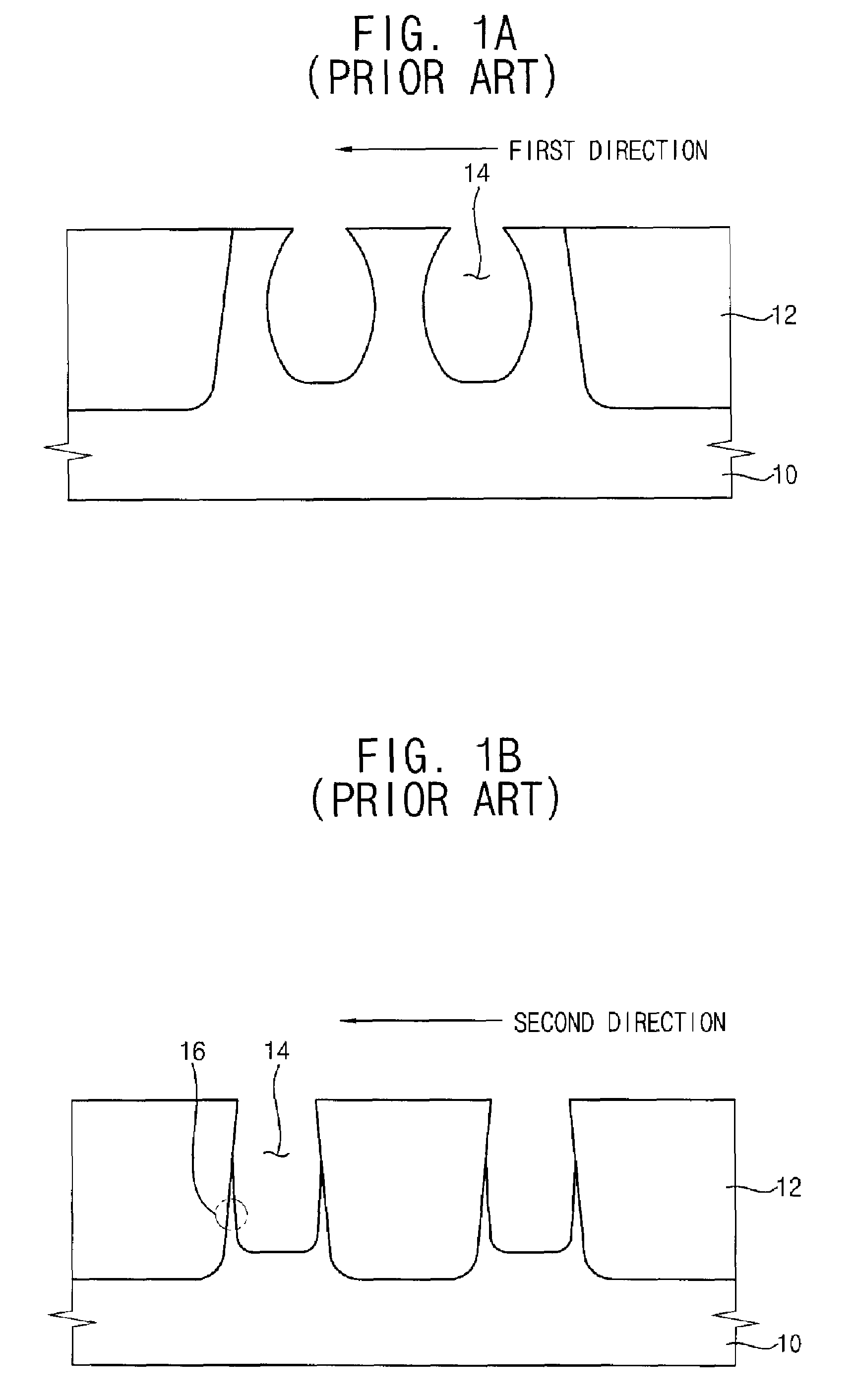

Methods of forming asymmetric recesses and gate structures that fill such recesses and related methods of forming semiconductor devices that include such recesses and gate structures

InactiveUS7560359B2Improve featuresReduce leakage currentTransistorSolid-state devicesEngineeringSemiconductor

Owner:SAMSUNG ELECTRONICS CO LTD

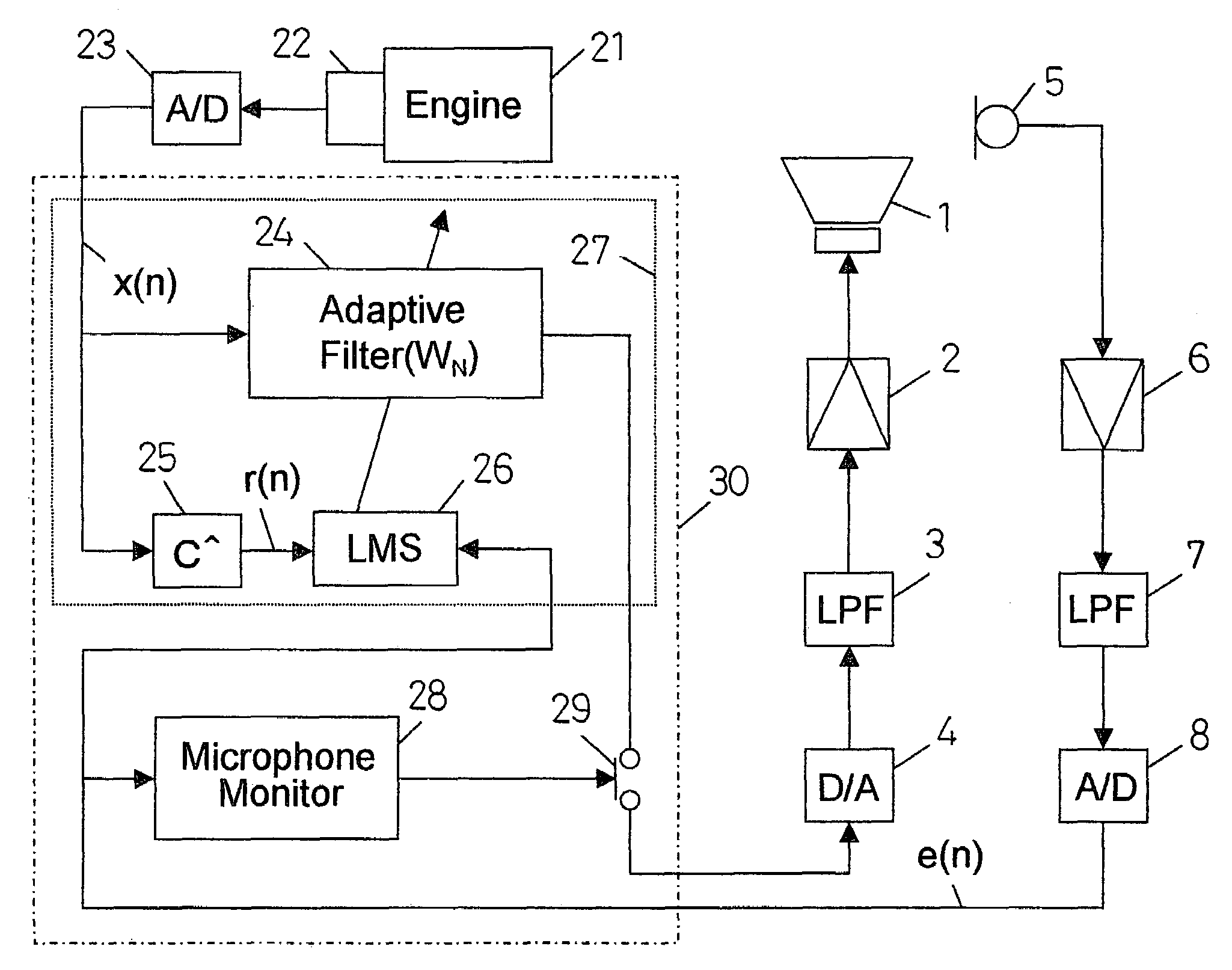

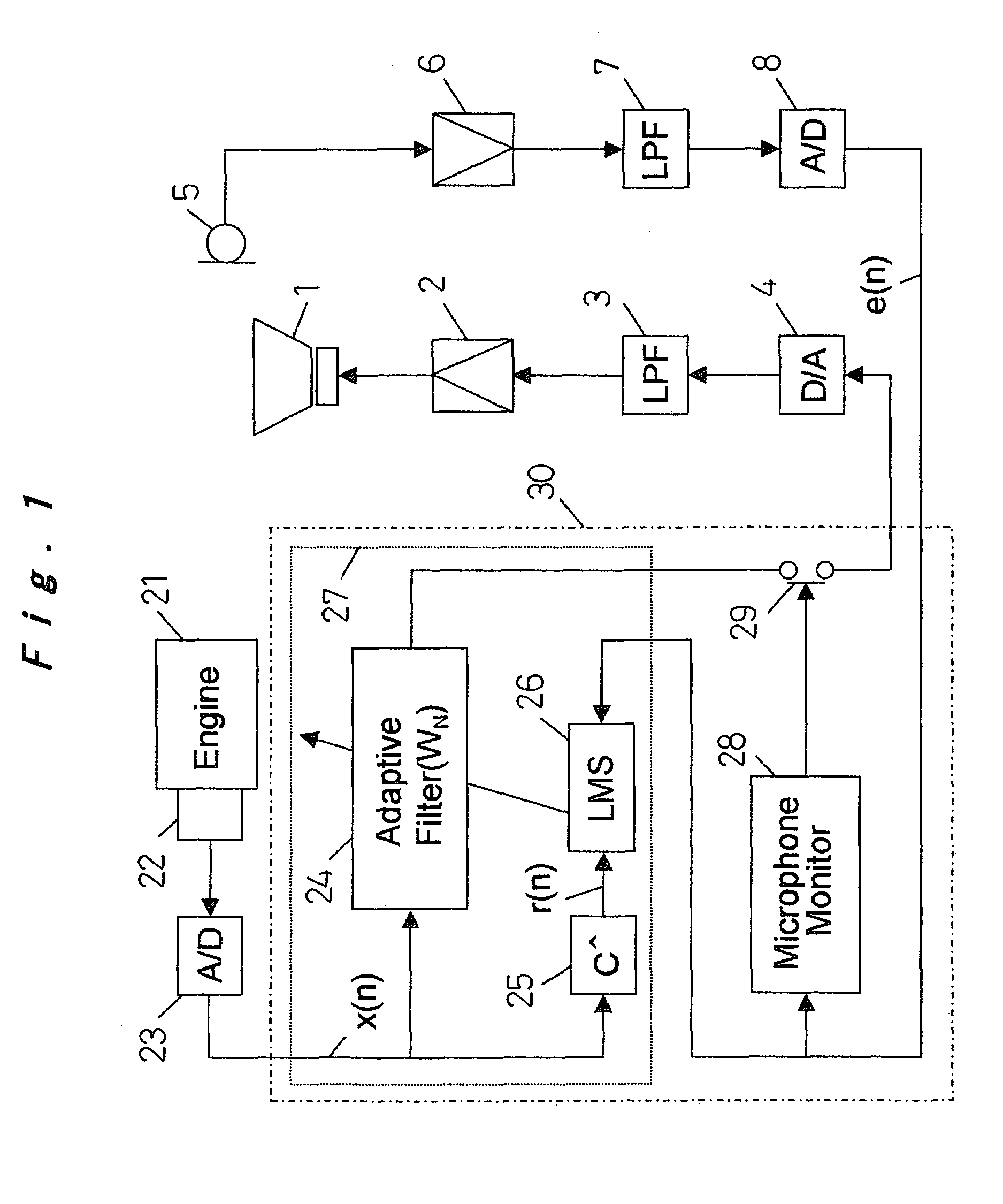

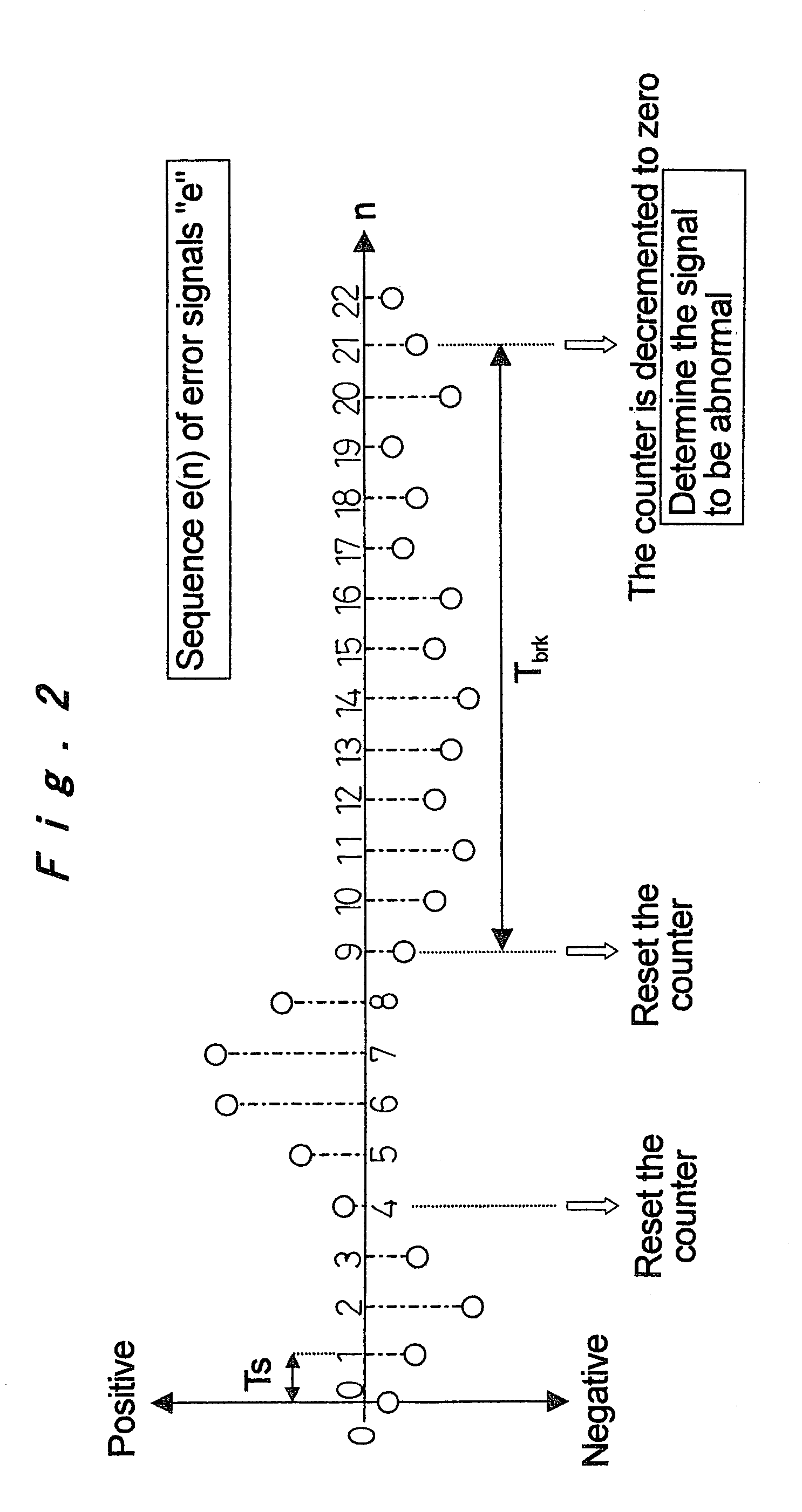

Active noise control system

An active noise control system is provided which cancels a noise using a secondary noise from a speaker that is operated in accordance with an output from an adaptive controller. The system is configured such that microphone monitor interrupts a switch to thereby stop the secondary noise from being produced, when an error signal delivered by a microphone used for an adaptive computation in an LMS processing portion has the same sign for a predetermined duration. This allows the system to prevent the user from hearing an abnormal acoustic noise resulting from an abnormal operation or divergence of an adaptive filter even when the output signal from the microphone used for the adaptive computation is indicative of an abnormal level.

Owner:PANASONIC CORP

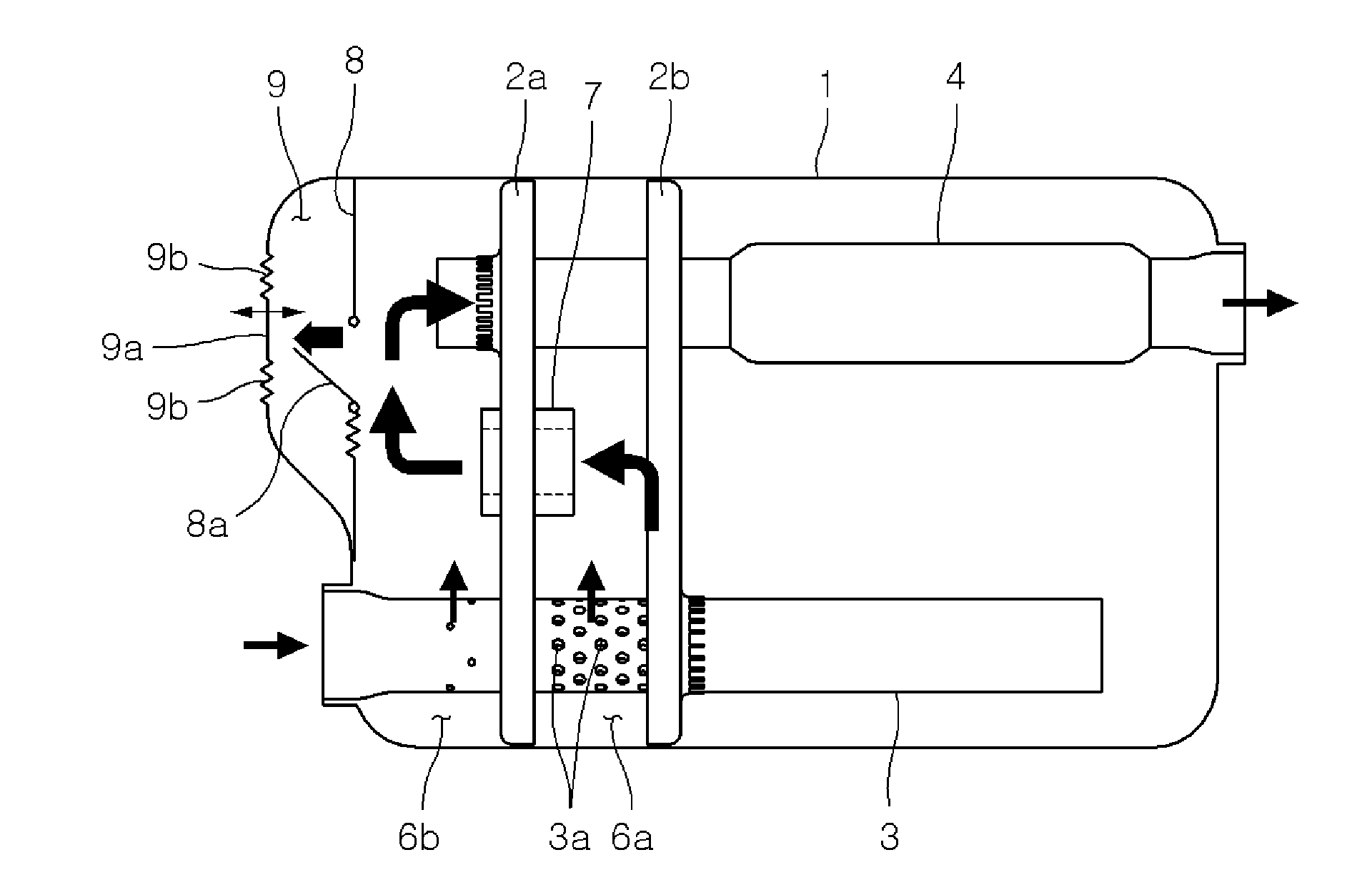

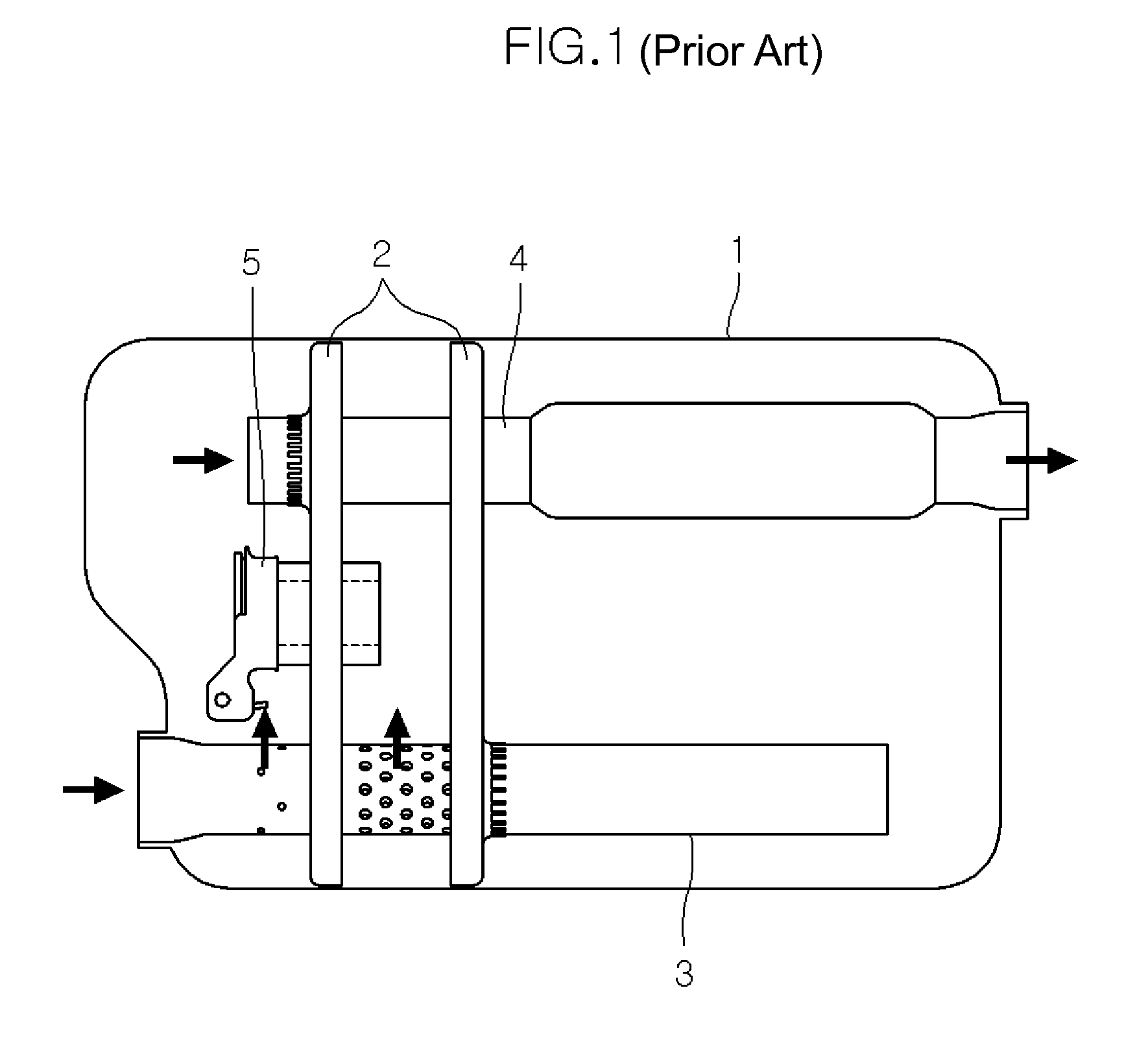

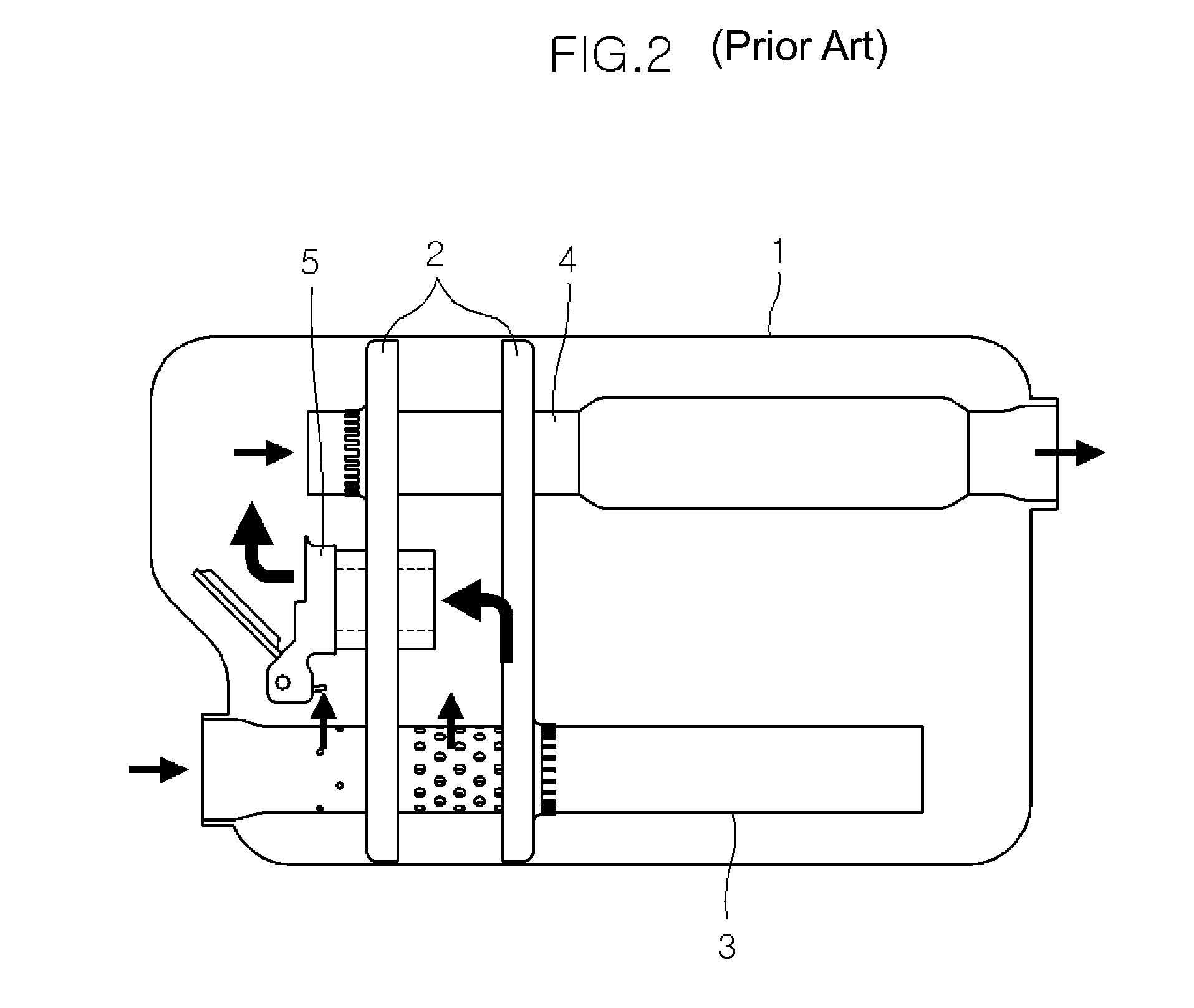

Muffler for vehicle

InactiveUS20110127105A1Effective in acceleration sound tuning of the vehicleIncrease impressionExhaust apparatusSilencing apparatusLoudspeakerMuffler

A muffler apparatus for a vehicle may include a speaker chamber that produces sound while vibrating by pressure of an exhaust gas flowing into a muffler housing, wherein the speaker chamber is formed in the muffler housing, the pressure of the exhaust gas being greater than a predetermined value.

Owner:HYUNDAI MOTOR CO LTD

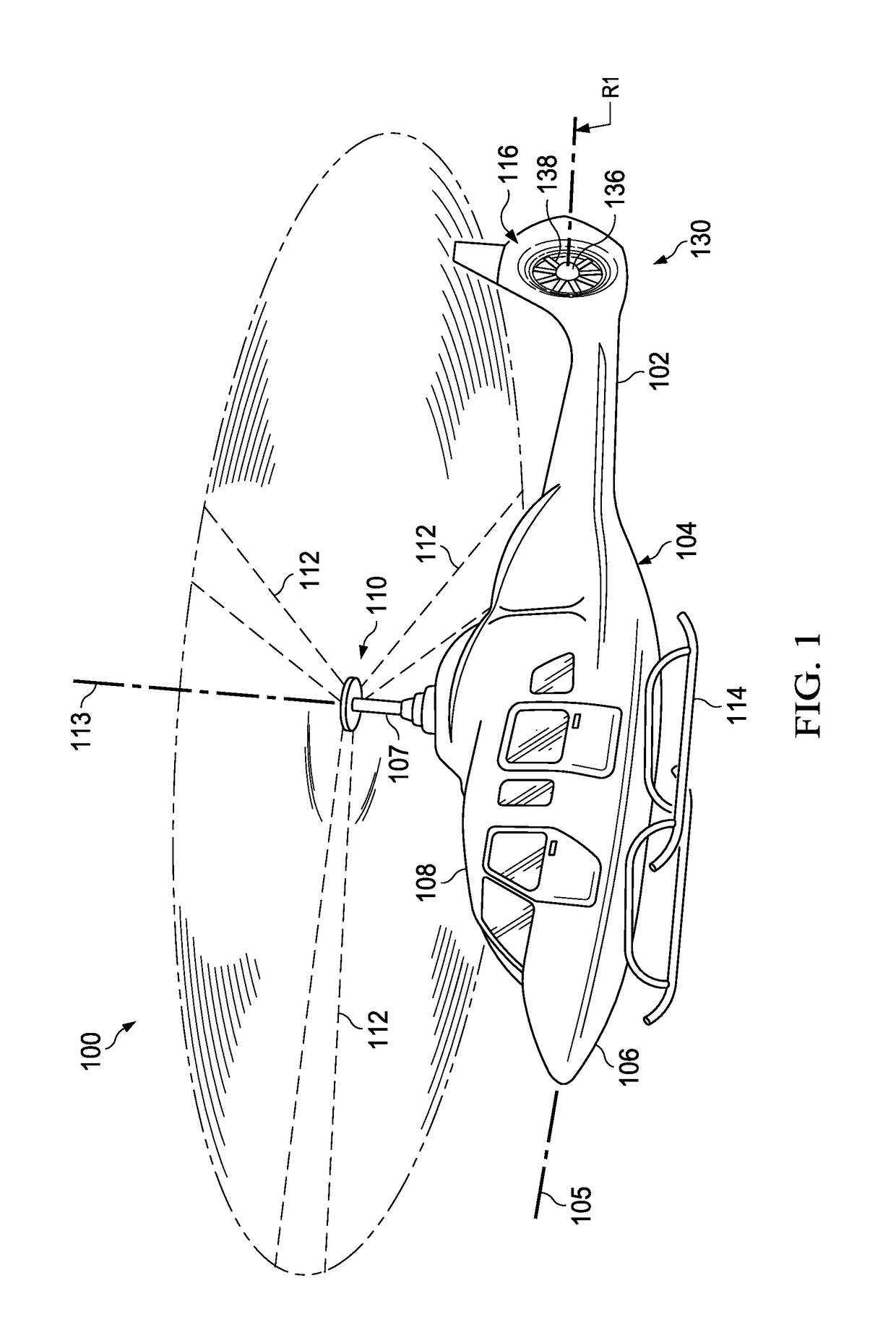

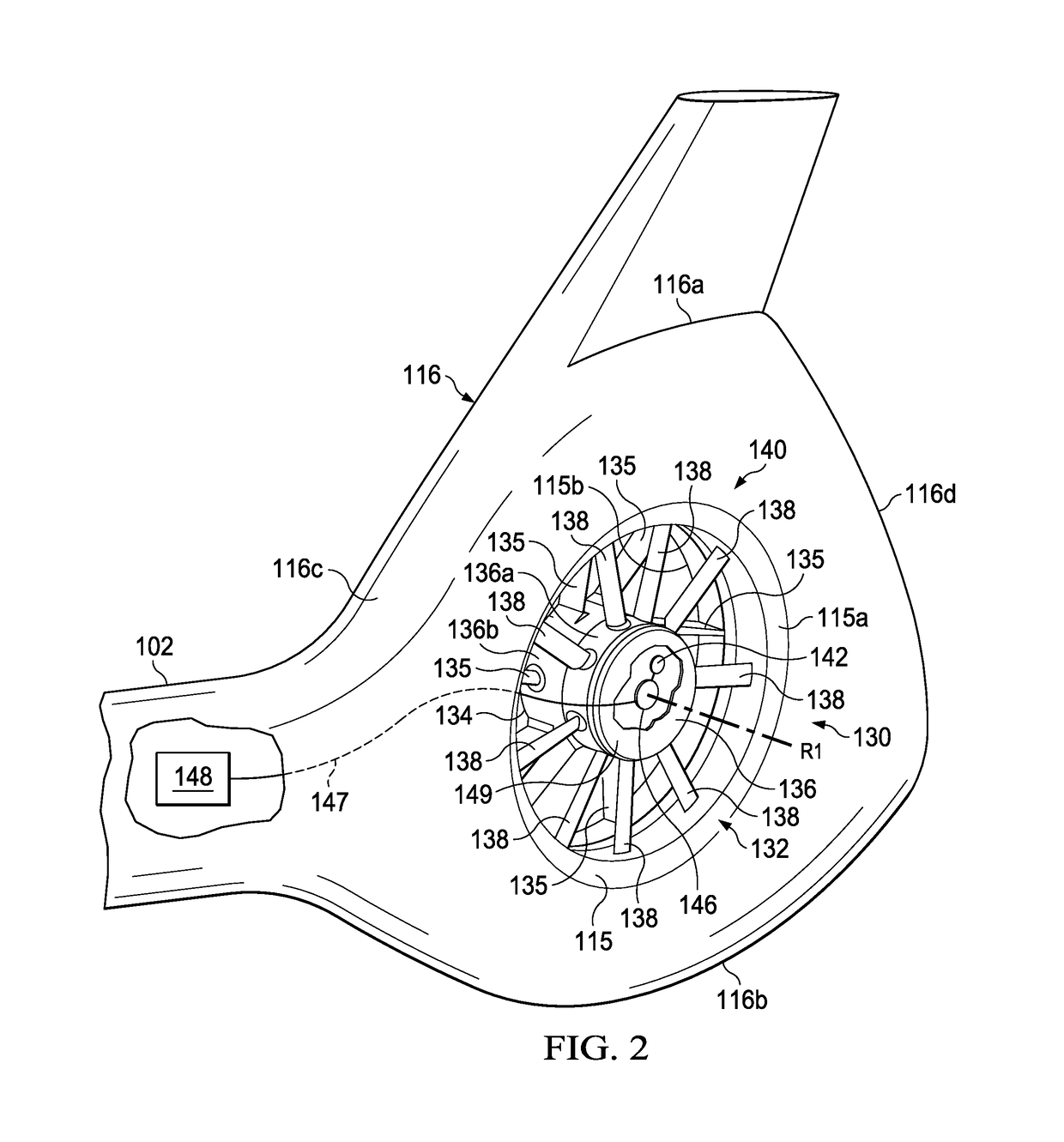

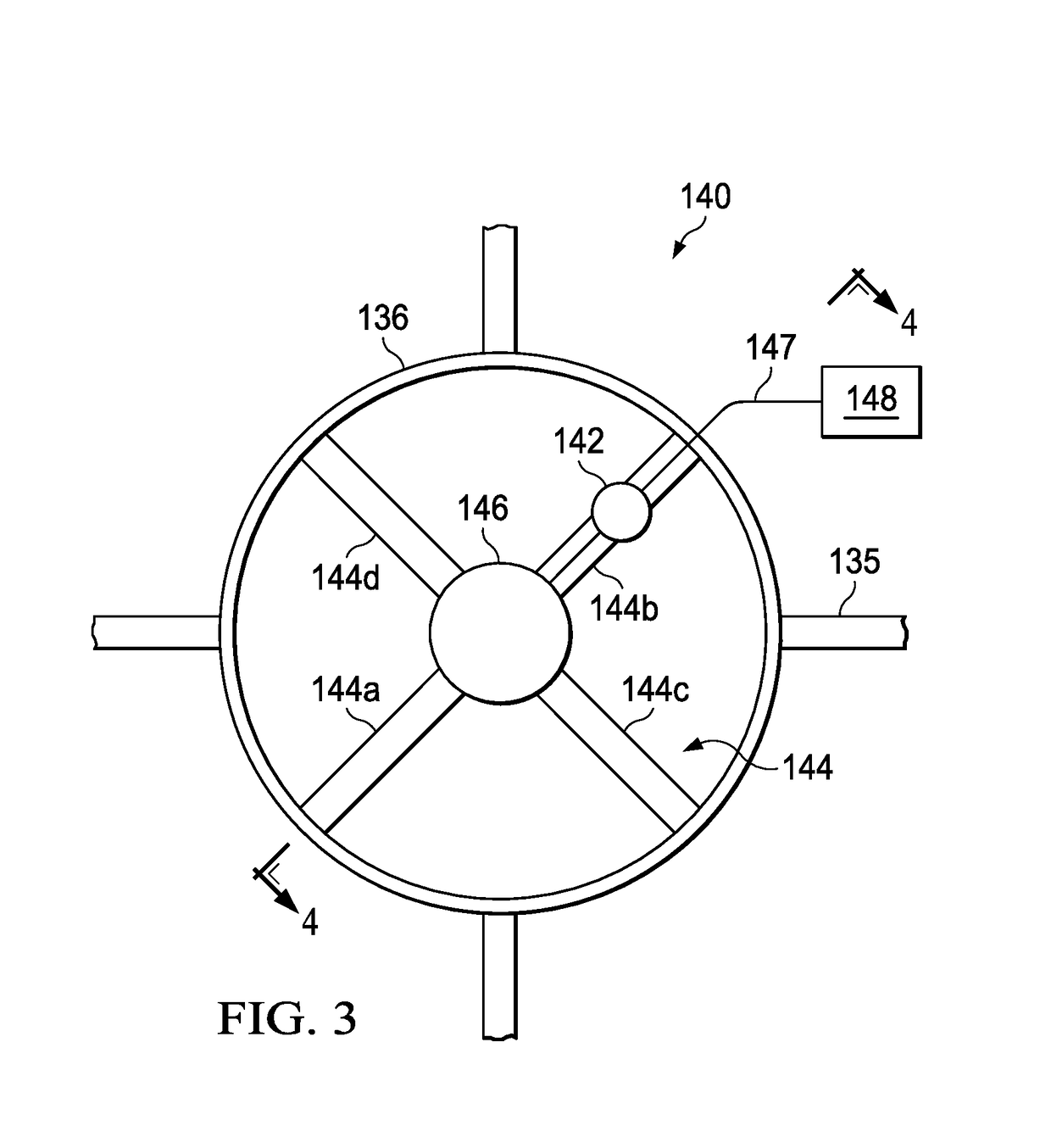

Noise control system for a ducted rotor assembly

ActiveUS10210856B1Reduce acoustic signatureReducing an acoustic signatureMicrophonesLoudspeakersNoise controlControl system

A noise control system for a ducted rotor assembly, the ducted rotor assembly including a hub, a duct, and two or more blades coupled to the hub and supported by the duct. The noise control system including a microphone configured to receive a sound input generated by the ducted rotor assembly, the microphone configured for association with the hub; a speaker unit configured to generate a cancellation noise, the speaker configured for association with the hub; and a controller operably connected to the microphone and the speaker unit, the controller configured to selectively adjust harmonics of the cancellation noise to reduce an acoustic signature of the ducted rotor assembly. In another aspect, there is provided a rotorcraft with a ducted rotor assembly in a tail portion including a noise control system. In a third aspect, there is a method of reducing an acoustic signature of a ducted rotor assembly.

Owner:BELL HELICOPTER TEXTRON INC

Furniture-foot assemblies

ActiveUS20100187399A1Easy and efficient and inexpensiveReduce morbidityStoolsStands/trestlesEngineeringMechanical engineering

A foot assembly is adapted to be removably attached to the elbow of a sled-type leg of a piece of furniture that is adapted to be supported upon a surface. The furniture-foot assembly includes a body defining a hollow interior adapted to removably receive the elbow of the leg and a bottom exterior portion. A glide is adapted to be removably mounted to the bottom exterior portion of the body and supported upon the surface for gliding movement of the furniture-foot assembly relative to the surface.

Owner:HIWATT PROD

Features

- R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

Why Patsnap Eureka

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Social media

Patsnap Eureka Blog

Learn More Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com