Vehicular refrigeration cycle apparatus

a technology of refrigeration cycle and electric compressor, which is applied in the direction of domestic cooling apparatus, lighting and heating apparatus, refrigeration components, etc., can solve the problems of sometimes being heard by users, operating noise of electric compressor, and sometimes bothering users, so as to effectively keep the unfamiliar operating nois

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Benefits of technology

Problems solved by technology

Method used

Image

Examples

first embodiment

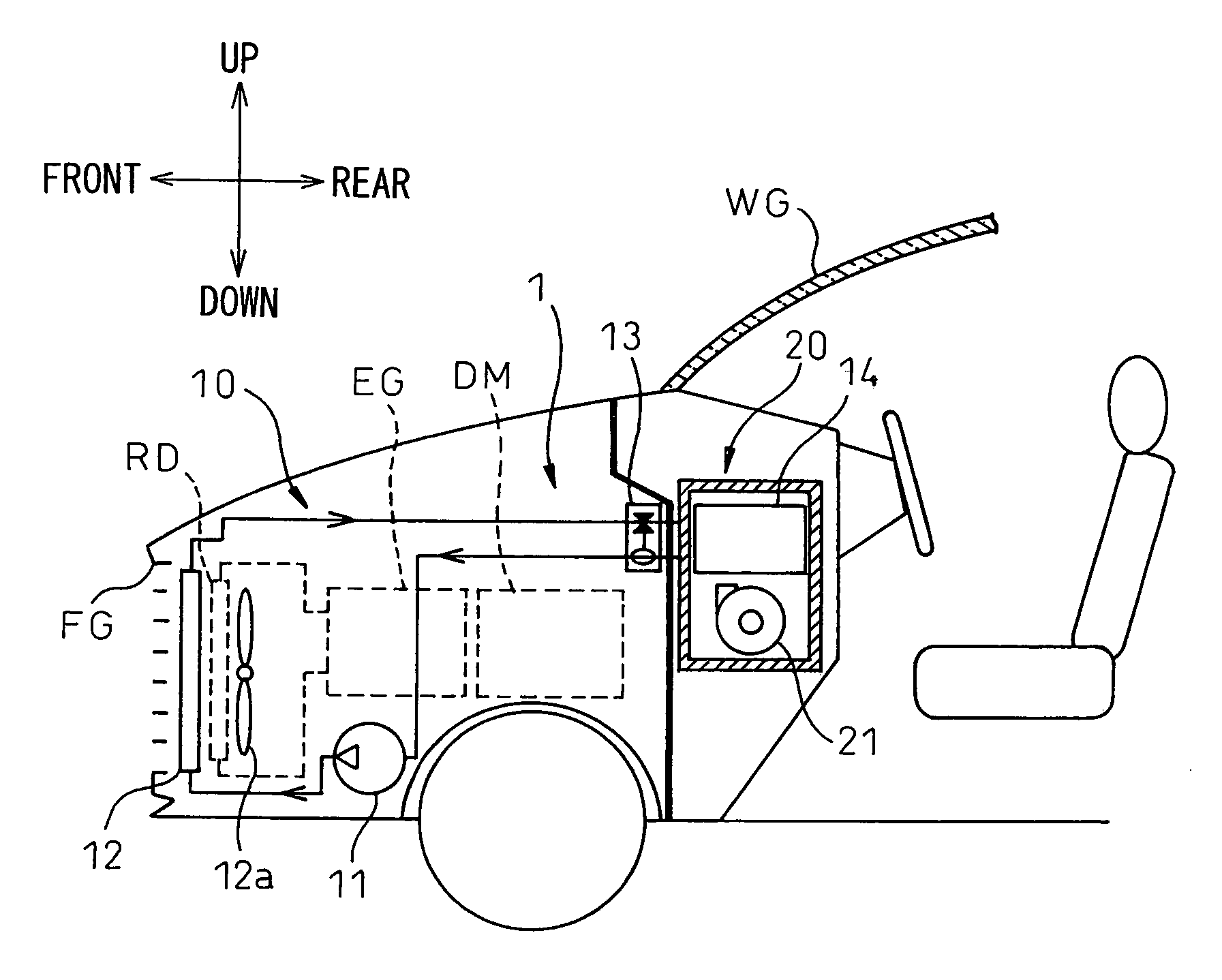

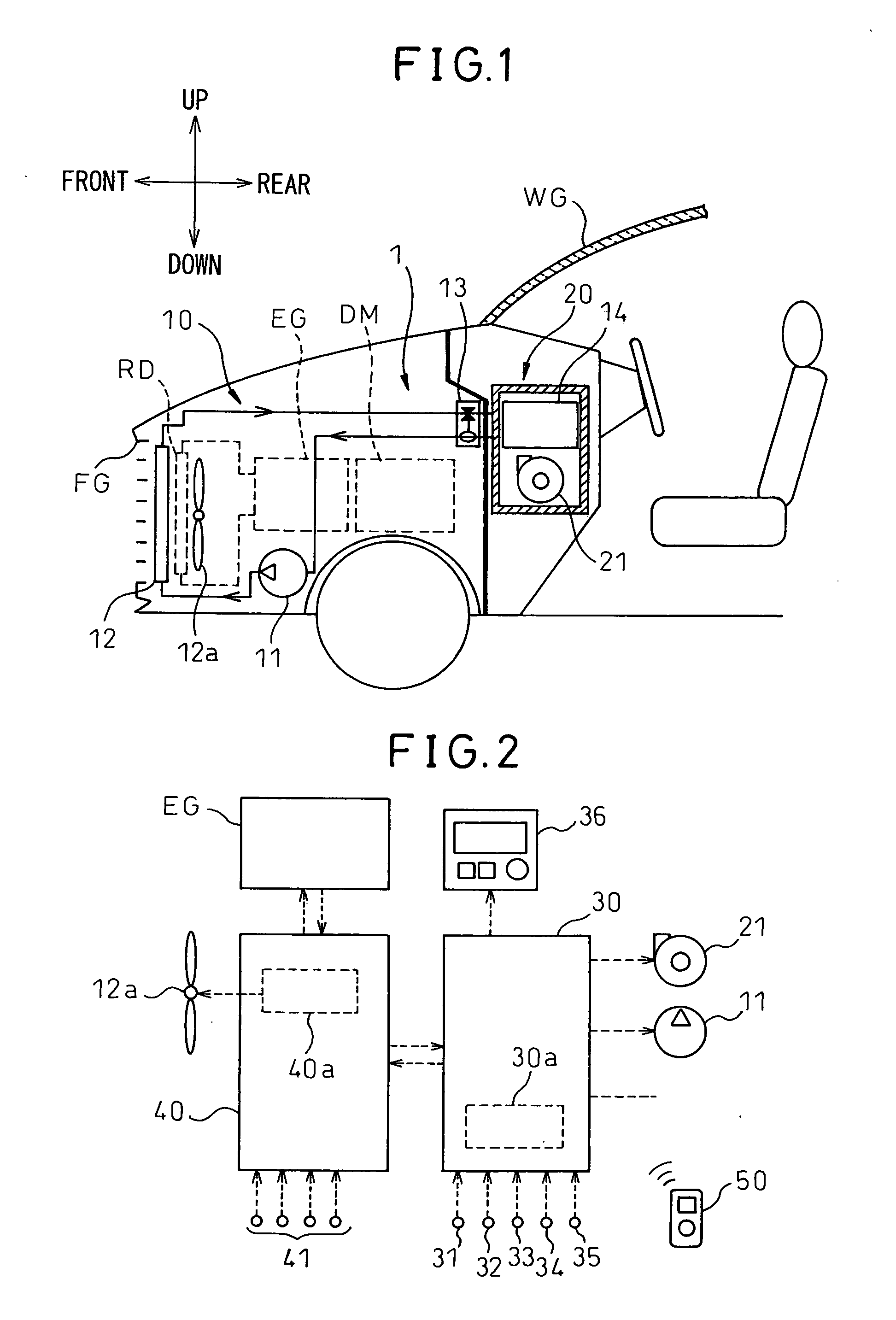

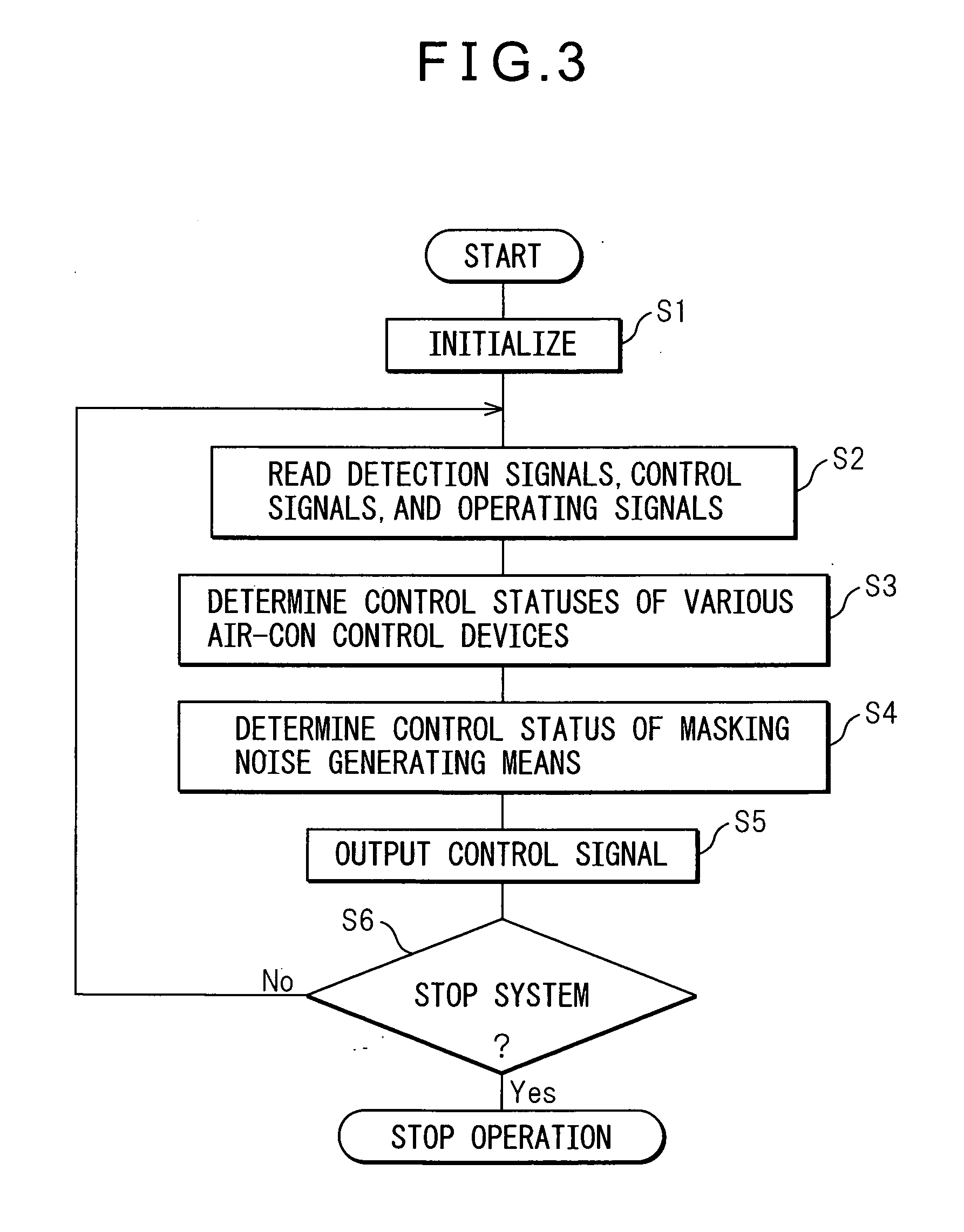

[0036]Using FIGS. 1 to 6, a first embodiment of the present invention will be explained. FIG. 1 is a view of the overall configuration of a vehicular air-conditioning system 1 using a vehicular refrigeration cycle apparatus 10 of the present embodiment. This vehicular air-conditioning system 1 is applied to a so-called hybrid car obtaining drive power for vehicle operation from an internal combustion engine (engine) EG and a drive-use electric motor DM. Note that, the arrows in the top, bottom, front, and back directions in FIG. 1 show the top, bottom, front, and back directions in the state mounting the vehicular air-conditioning system 1 in a vehicle.

[0037]The hybrid car of the present embodiment can operate or start the engine EG in accordance with the drive load etc. of the vehicle and switch between a driving state where it operates by obtaining drive power from both the engine EG and drive-use electric motor DM and a driving state where it operates by making the engine EG stop...

second embodiment

[0094]In the above-mentioned first embodiment, the example of the engine EG being stopped at the control step S42 was explained, but in the present embodiment, as shown in the flowchart of FIG. 7, step S42 is changed to S42′. Specifically, at step S42′ of the present embodiment, it is determined if the vehicle speed Vv which is detected by the vehicle speed sensor has become a predetermined reference vehicle speed KVv or less.

[0095]That is, at step S42′, it is determined if the vehicle is at a stop or is being driven at a reference vehicle speed KVv or less. When it is determined at step S42′ that the vehicle speed Vv is the reference vehicle speed KVv or less, the routine proceeds to step S43, while when it is determined that the vehicle speed Vv is not the reference vehicle speed KVv or less, the routine proceeds to step S47. Note that, the reference vehicle speed KVv is determined as an extremely low speed such as parking where almost no road noise is generated.

[0096]The rest of ...

third embodiment

[0098]In the above-explained embodiments, the example where the masking noise generating means was configured by the condenser-use blower 12a was explained, but in the present embodiment, the example where the masking noise generating means is configured by the evaporator-use blower 21 will be explained.

[0099]In this case, at step S44 shown in FIG. 4 of the first embodiment, it is sufficient to make the control voltage which is output to the evaporator-use blower 21 the highest value Hi and, at step S45, to make the control voltage which is output to the evaporator-use blower 21 an intermediate voltage Lo of an extent whereby the operating noise of the evaporator-use blower 21 becomes noise of a sufficient volume as the afore-mentioned masking noise. The rest of the overall configuration and control modes are the same as in the first embodiment.

[0100]Here, the operating noise of the evaporator-use blower 21 which blows air into the cabin is noise which persons inside the cabin are u...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com