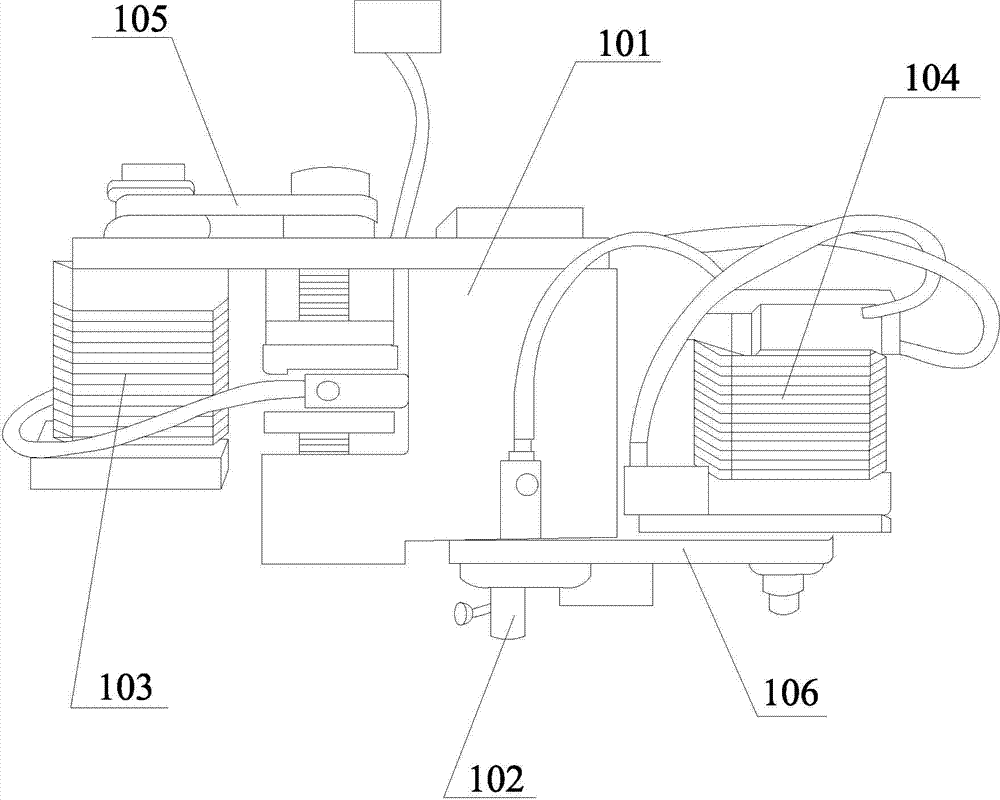

Pneumatic rotatable glass cutting machine

A cutting machine and glass technology, applied in glass cutting devices, glass manufacturing equipment, manufacturing tools, etc., can solve the problems of expanding the processing range of special-shaped glass cutting machines, difficult to increase the cutting speed, and the knife is not fast enough to raise labor productivity. , The equipment control system is simple and cost-saving

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

[0020] The present invention will be further described below in conjunction with accompanying drawing and by specific embodiment:

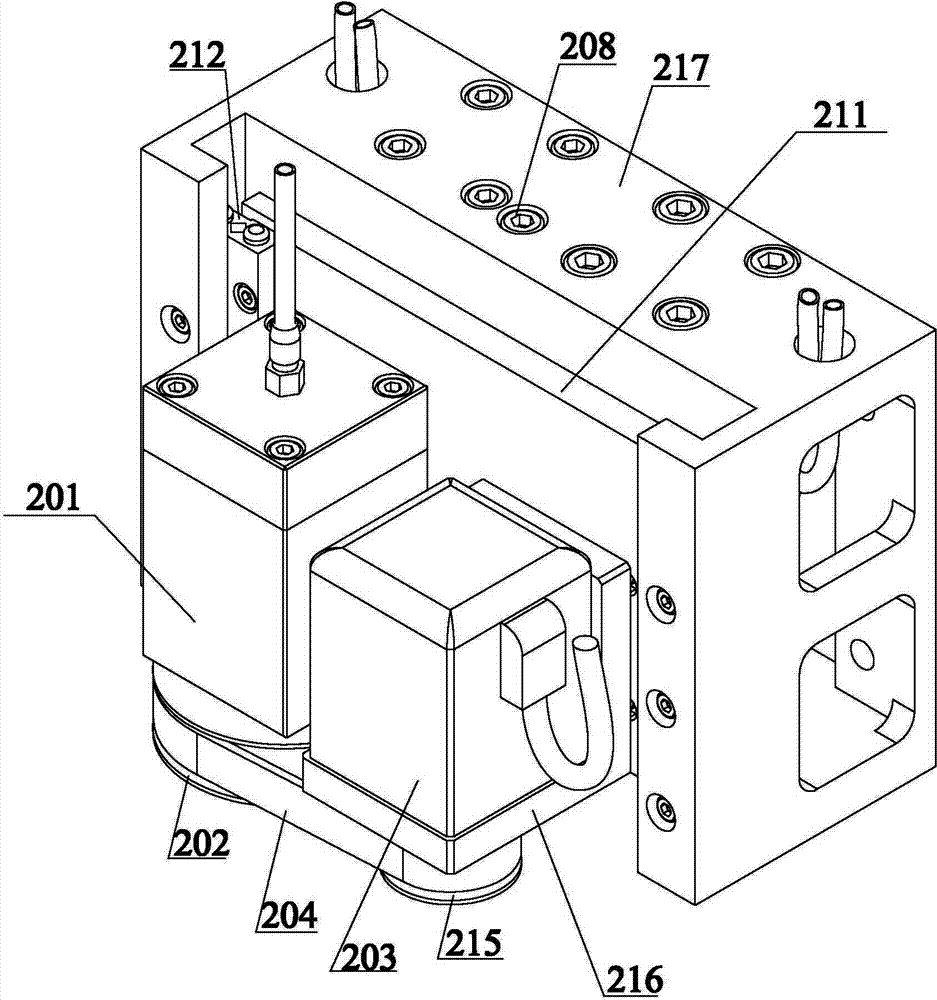

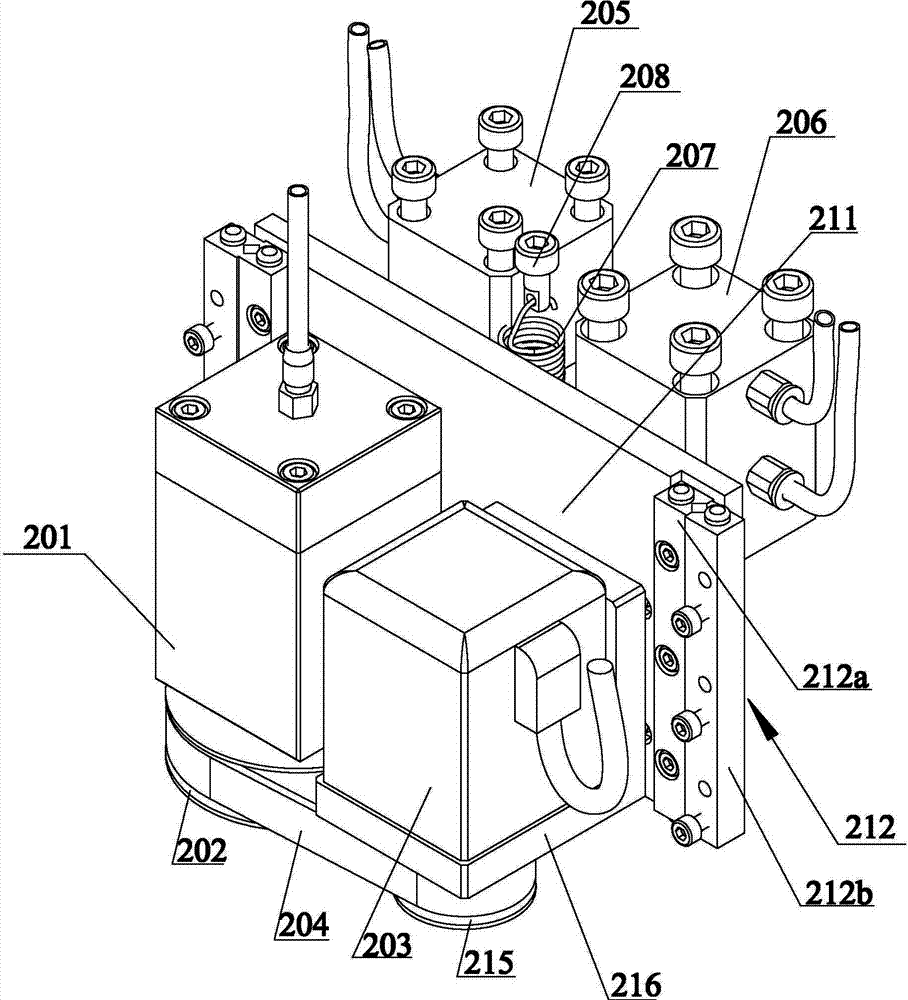

[0021] see Figure 2 to Figure 7 :

[0022] The pneumatic rotatable glass cutting machine includes a knife box lifting mechanism and a knife wheel rotating mechanism: the knife box lifting mechanism includes a knife box 201, a standard cylinder 205 for controlling the lifting of the knife box 201, and a low-friction cylinder 206. The lower end of the knife box 201 has a The cutter shaft 213 of the stepping rotary cutter wheel 214 is installed, the synchronous belt driven wheel 202 is fixed on the cutter shaft 213, the cutter box 201 is fixed on the front of the mounting plate 211, and the left and right sides of the mounting plate 211 respectively have a cross roller guide rail 212, cross The slide block 212a of the roller guide rail 212 is fixed on the mounting plate 211, the linear guide rail 212b of the cross roller guide rail 212 is fixed on ...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com