Traverse feeding device of external groove plungecut grinder

A technology of lateral feeding and equipment, which is applied in the direction of grinding/polishing equipment, metal processing equipment, grinding machine tool parts, etc., which can solve the problem of difficult to ensure the processing accuracy of ring products, the difficulty of ensuring the accuracy of bearing rings, static pressure, etc. Guide rails are difficult to repair and other problems, achieving the effect of not easy maintenance, stable machine tool feed, and easy maintenance

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

[0020] The present invention will be further described below in conjunction with accompanying drawing and specific embodiment:

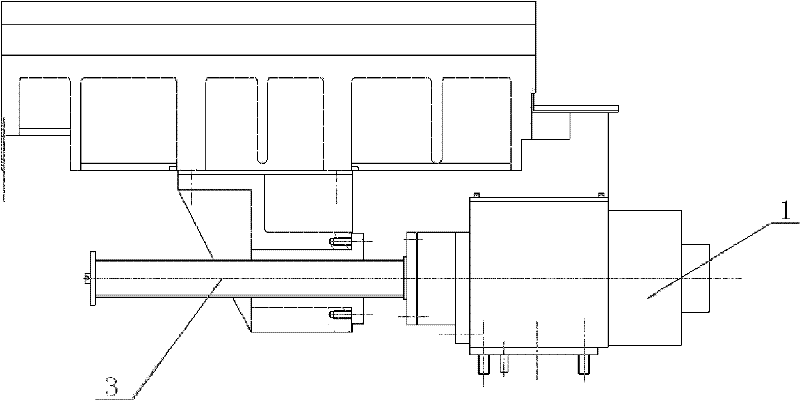

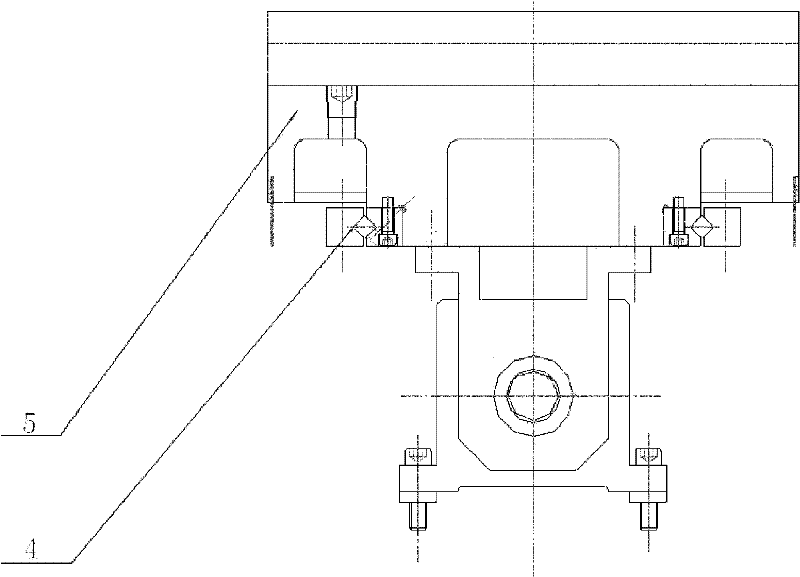

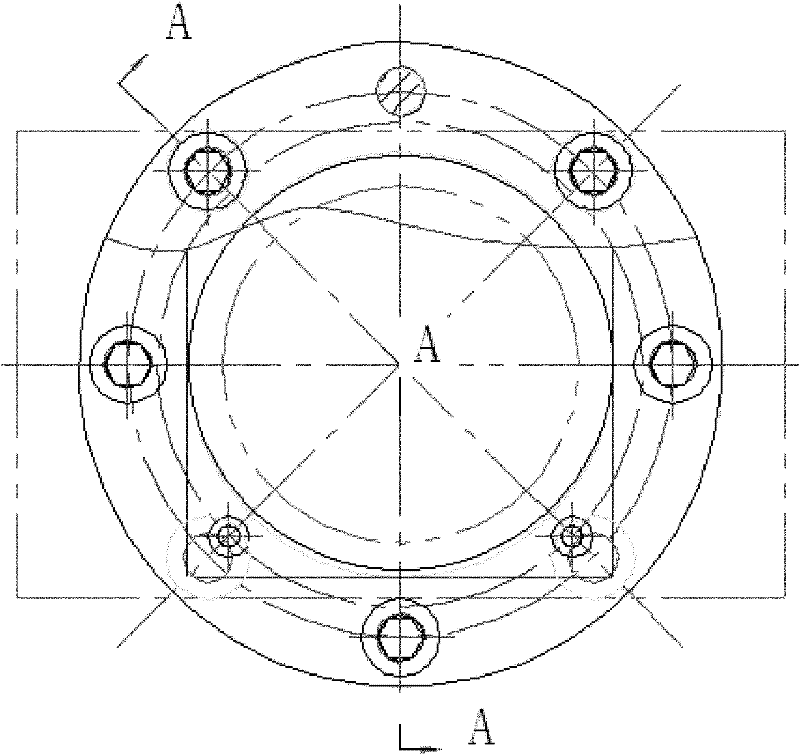

[0021] combine Figure 1-Figure 6 , this embodiment includes a roller cross guide pair 4, an infeed table 5 and a transmission part, the roller cross guide pair 4 includes a guide rail, a roller cage 7, and a cylindrical roller 8, and the cylindrical roller 8 passes through the roller cage 7 is set on the guide rail, the guide rail includes two guide rails 6 with V-shaped raceways, and the cylindrical rollers 8 are arranged crosswise on the guide rails 6 of the V-shaped raceways; the transmission part includes stepping motor 1, harmonic reducer 2 and The ball screw 3, the stepping motor 1 drives the harmonic reducer 2 to connect the ball screw 3, the output shaft of the harmonic reducer 2 is fixedly connected to the shaft end of the screw of the ball screw 3, and the nut of the ball screw 3 is connected to the transverse The feeding table 5 is conne...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com