Energy-saving type airlock discharger

A technology for shutting off fans and unloaders, which is applied in the field of shutting down fans, and can solve problems such as reduced use costs, high use costs, and poor wind-off effects, and achieves the effects of reduced use costs, convenient manufacturing, and reduced air leakage

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

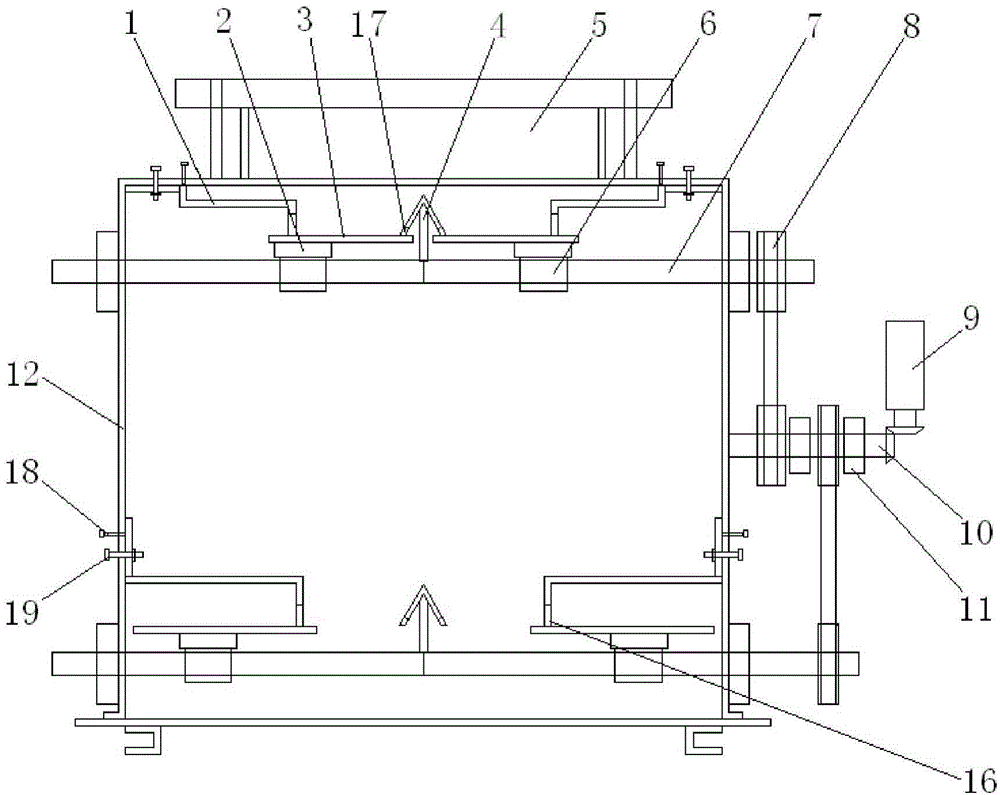

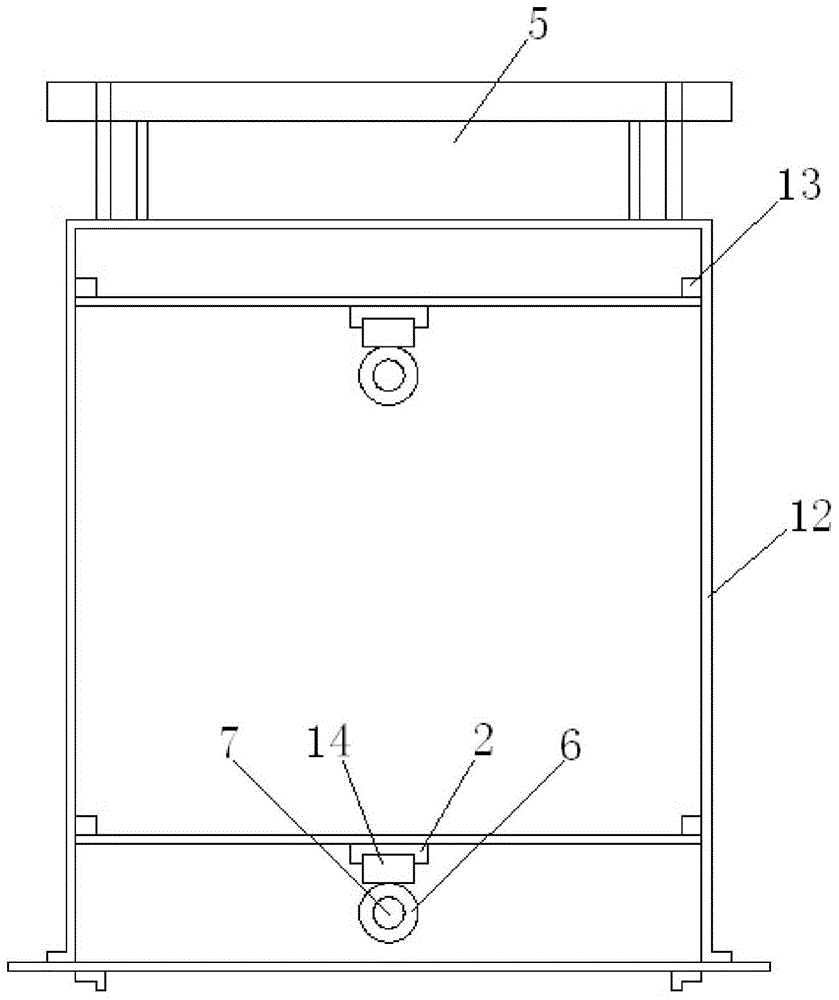

[0032] Such as figure 1 and figure 2 As shown, a kind of energy-saving fan-off unloader of the present embodiment includes a body 12 and a driving mechanism, the upper end of the body 12 is provided with a feed port 5, the lower end is provided with a discharge port, and the inside of the body 12 is provided with a The feeding mechanism of 55 and the blanking mechanism near the discharge port, the feeding mechanism and the blanking mechanism respectively include two movable plates 3, the two movable plates 3 of the feeding mechanism and the two movable plates 3 of the blanking mechanism are both Driven by the driving mechanism to move to both sides to open or move to the middle to close, the two movable plates 3 of the feeding mechanism and the two movable plates 3 of the unloading mechanism open and close alternately to realize the conveying of materials.

[0033] The driving mechanism of the present embodiment is controlled by a control system, and mainly includes a ball s...

Embodiment 2

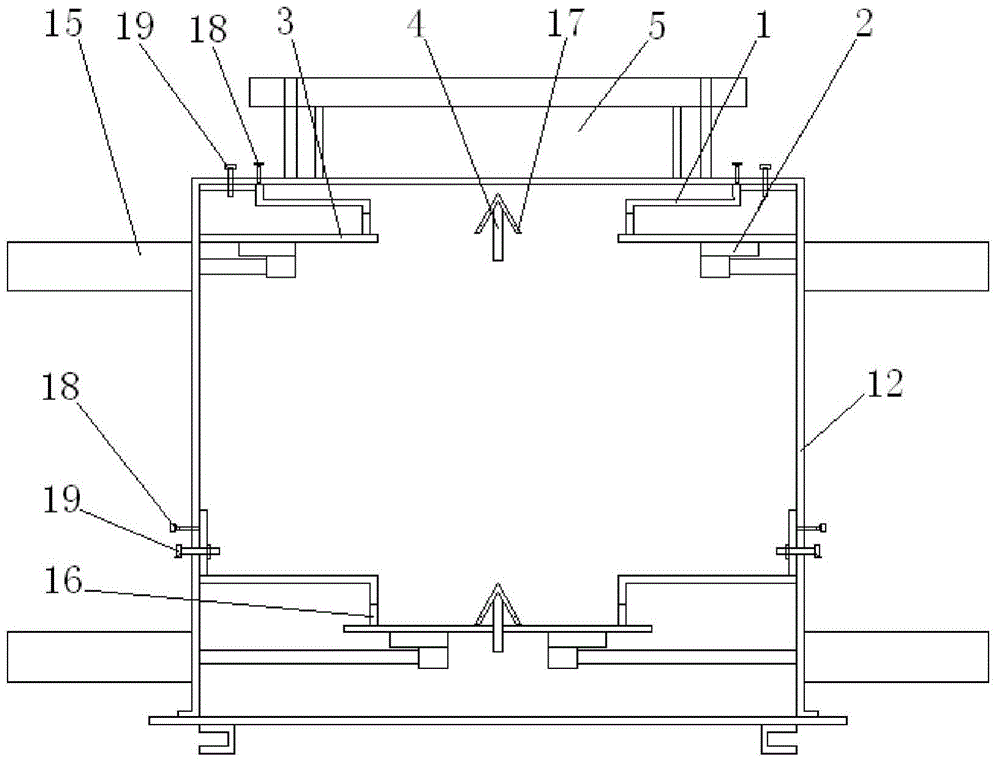

[0038] Such as image 3 and Figure 4 As shown, a kind of energy-saving fan shut-off unloader of this embodiment is basically the same structure as the above-mentioned embodiment 1, the difference is that: the driving mechanism of this embodiment includes a cylinder 15, and the cylinder 15 is installed on the body 12, Corresponding to the movable plate 3, the piston rod of the cylinder 15 extends horizontally to push and pull the movable plate 3 to make a linear movement along the axis of the piston rod, and the movable plate 3 and the piston rod of the cylinder 15 are also passed through the slider. The slide rail mechanism is connected.

[0039] When conveying materials, the control system controls the drive mechanism to drive the two movable plates 3 of the unloading mechanism to move to the middle to close the discharge port, and then drives the two movable plates 3 of the feeding mechanism to move to both sides to open the feed port 5, so that The material passes betwee...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com