Cooking appliance with automatic exhaust function

A cooking utensil and automatic exhaust technology, applied in the direction of pressure cooker, etc., can solve the problems of large resistance, affecting sealing, eccentricity of weight, etc., and achieve the effect of simple structure, avoiding potential safety hazards, and convenient operation

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment approach 1

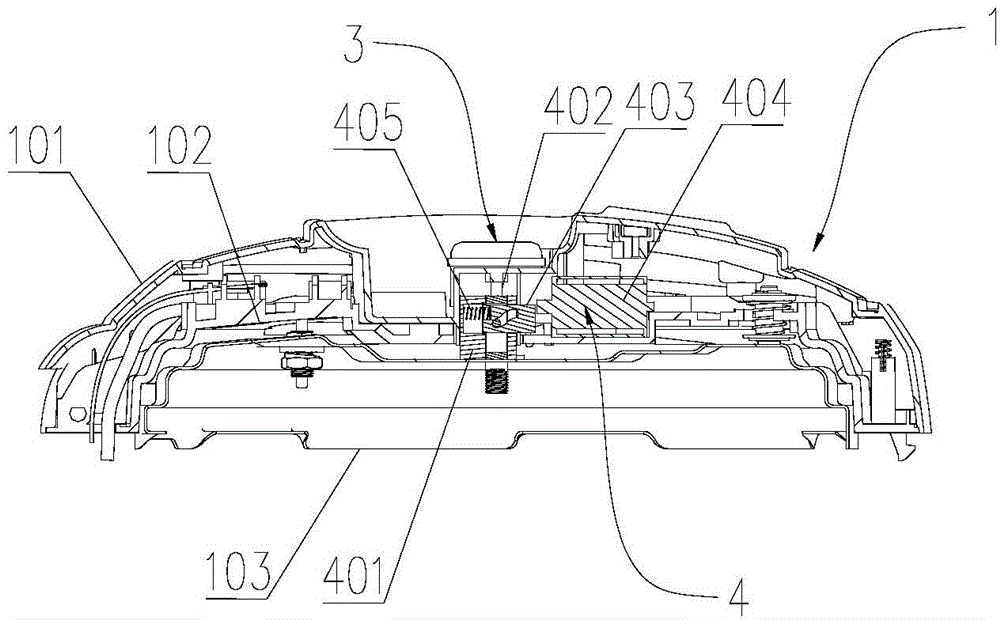

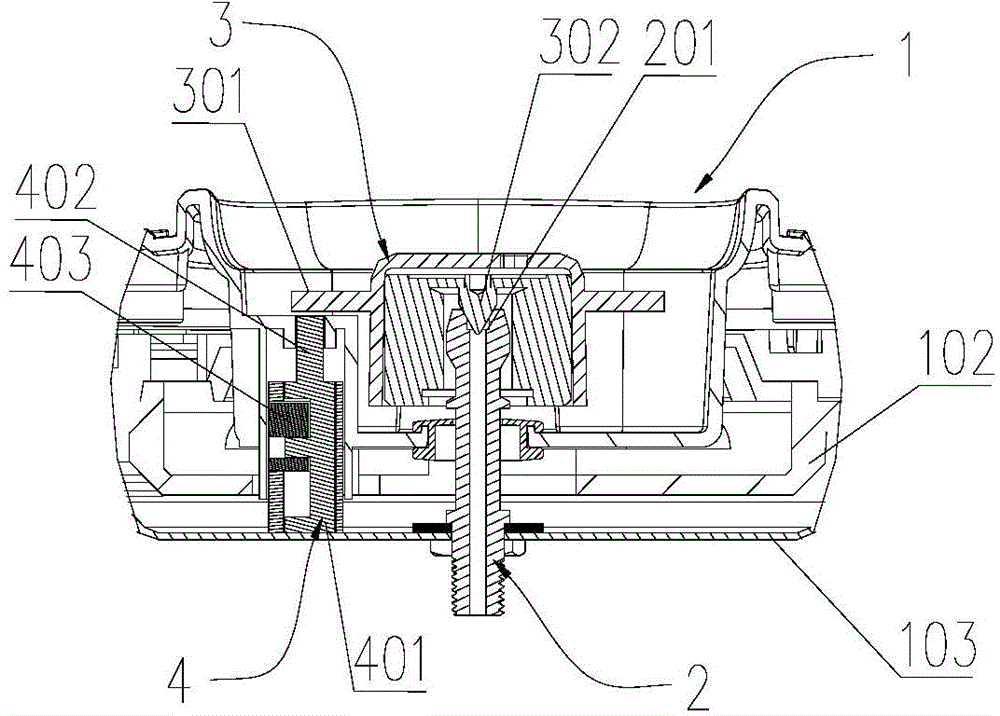

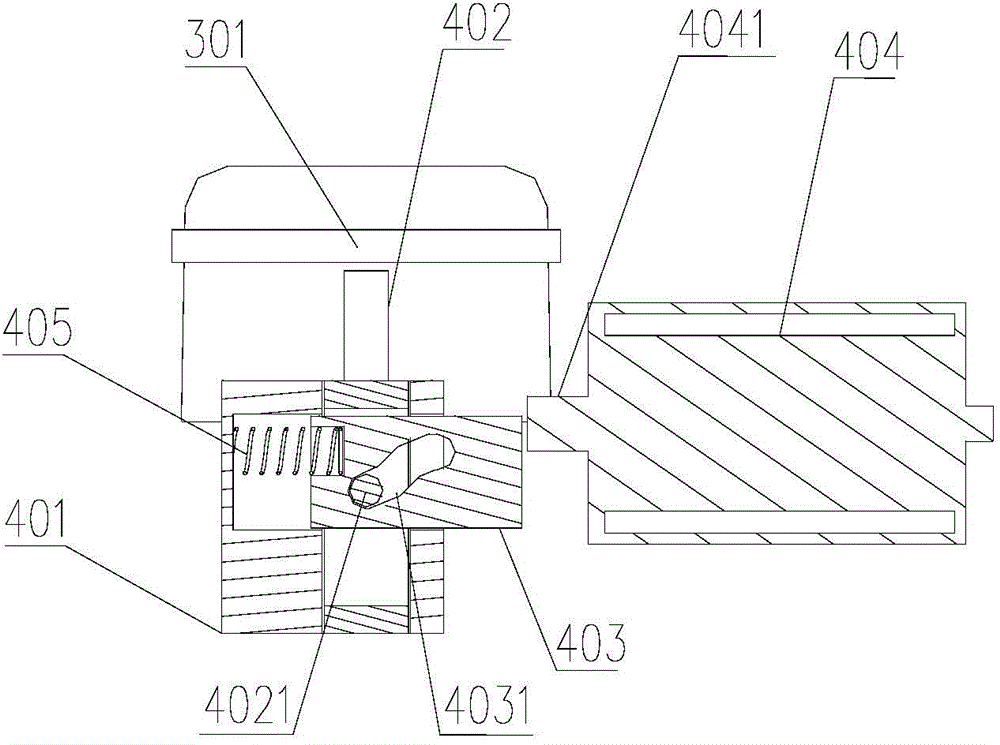

[0038] like Figure 1 to Figure 5 As shown, in this embodiment, the application provides a cooking utensil with an automatic exhaust function, including a cover body 1, an exhaust pipe 2 arranged on the cover body 1, and an exhaust pipe sleeved on the exhaust pipe 2 The exhaust port 201 is used to seal the exhaust port 201 or unseal the pressure limiting valve 3, which also includes a pressure limiting valve driving device 4 and a control device (not shown), and the pressure limiting valve driving device 4 can be used in Under the control of the control device, the pressure limiting valve 3 is driven to move upwards and release the seal on the exhaust port 201 .

[0039] In this application, through the cooperation of the control device and the pressure limiting valve driving device 4, the sealing of the pressure limiting valve 3 to the exhaust port 201 can be released, and the exhaust of the electric pressure cooker can be realized. It avoids the potential safety hazard caus...

Embodiment approach 2

[0052] like Image 6 As shown, in this embodiment, the present application provides another structural form of the pressure limiting valve driving device. In this embodiment, the pressure limiting valve driving device includes a rack 406, a gear 407 that cooperates with the rack 406, and a motor 408 that drives the gear 407 to rotate. The rack 406 moves linearly under the drive of the gear 407 and moves toward the pressure limiting valve arm. 301 apply force.

[0053] Specifically, the rack 406 is slidably arranged on the cover 1, and the gear 407 drives the rack 406 engaged with it to move up and down along the cover 1 under the drive of the forward and reverse rotation of the rotor of the motor 408, and during the upward movement An upward force can be applied to the pressure limiting valve arm 301 , and then the pressure limiting valve 3 releases the seal on the exhaust port 201 to perform exhaust.

[0054] In this embodiment, except that the driving device of the pressur...

Embodiment approach 3

[0056] like Figure 7 As shown, in this embodiment, the present application provides another structural form of the pressure limiting valve driving device. The pressure limiting valve driving device includes a driving motor 409 , and a cam 410 driven by the driving motor 409 to rotate and apply force to the pressure limiting valve arm 301 .

[0057] Specifically, the driving motor 409 is arranged on the cover body 1, and the cam 410 is arranged under the pressure limiting valve arm 301. When the cam 410 rotates under the drive of the driving motor 409, the flange of the cam 410 and the pressure limiting valve arm When 301 is in contact, an upward force can be applied to the pressure limiting valve arm 301, thereby causing the pressure limiting valve 3 to release the seal on the exhaust port 201 for exhausting. When the valve arm 301 is not in contact, the pressure limiting valve arm 301 is no longer subject to the upward force exerted by the flange, and under the action of gr...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com