Concrete double-mold structure for top surface of building

A technology for building top surface and concrete, which is applied to building structure, construction, and on-site preparation of building components, etc., can solve the problems of poor surface flatness, complicated construction process, high cost, etc. Permeability and structural strength, the effect of increasing strength

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

[0017] The present invention will be further described in detail below in conjunction with the accompanying drawings and specific embodiments.

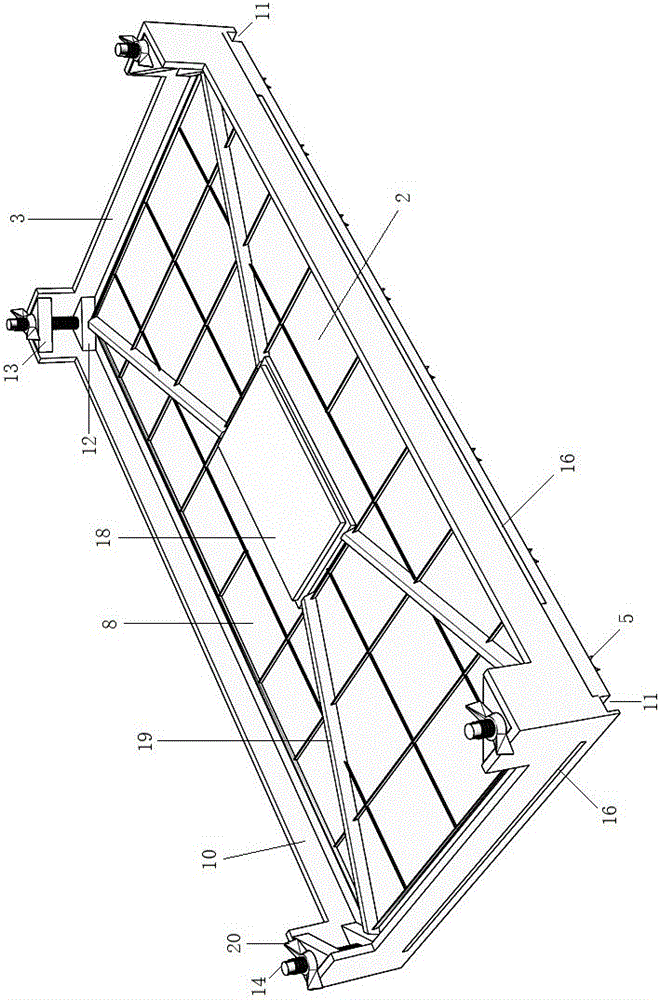

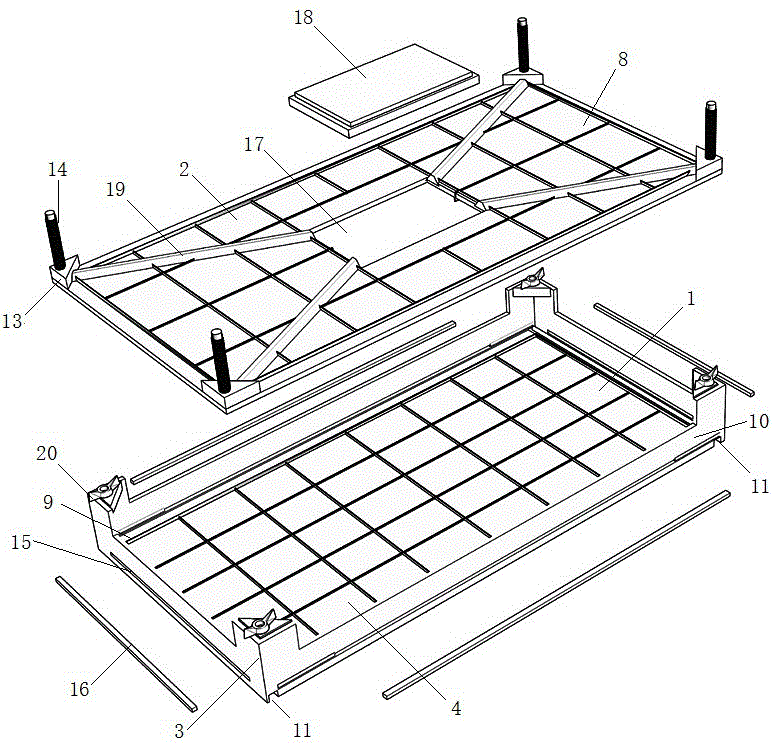

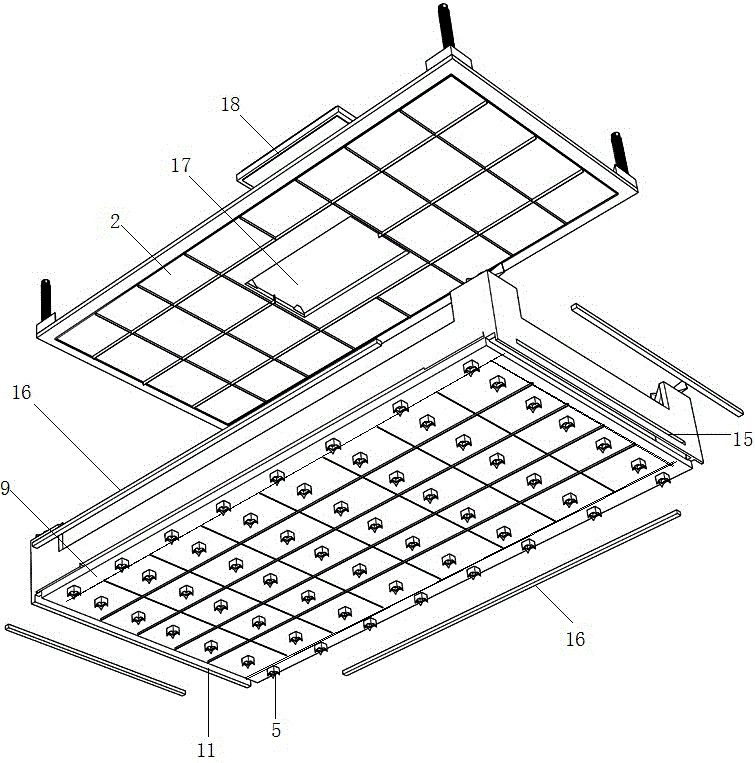

[0018] like Figure 1-4 As shown, the concrete double-mode structure on the top of the building includes a lower assembly plate 1, an upper assembly plate 2, and a ring beam support frame 3; the lower assembly plate 1 is composed of a plurality of lower formwork units 4 assembled in the ring beam support frame 2 ; The bottom of each lower formwork unit 4 is equipped with a pad button 5, the bottom of the pad button 5 is a spherical concave surface 6, and the middle part of the spherical concave surface 6 is provided with a groove 7 with a rectangular cross section inward; the upper assembly The plate 2 is assembled from a plurality of unit surface forms 8; the ring beam support frame 3 is fixed by a rectangular bottom frame 9 and four side templates 10 vertically surrounding the rectangular bottom frame 9; the left end of the rectangu...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com