Patents

Literature

58results about How to "Reduce cutting loss" patented technology

Efficacy Topic

Property

Owner

Technical Advancement

Application Domain

Technology Topic

Technology Field Word

Patent Country/Region

Patent Type

Patent Status

Application Year

Inventor

Process for cutting silicon chip by using steel wire with diameter of 0.11 millimeter

InactiveCN102059748ASignificant comprehensive benefitsReduce cutting lossFine working devicesSilicon chipWire cutting

The invention relates to a process for cutting a silicon chip by using a steel wire with a diameter of 0.11 millimeter. On a multi-wire cutter, the steel wire with the diameter of 0.11 millimeter, cutting fluid and carborundum are used as main auxiliary materials for cutting and processing the silicon chip. The process comprises the steps of mortar preparation, orientation, bar sticking, cutting preheating, cutting, blanking, degumming and cleaning. The steel wire with the diameter of 0.11 millimeter and with proper tension and cutting speed is matched with the cutting fluid and the carborundum to obtain a better cutting surface and effectively reduce the cutting loss; compared with the universally adopted steel wires with diameters of 0.14 millimeter and 0.12 millimeter, the steel wire with the diameter of 0.11 millimeter can save the raw materials by 6.45 percent and 2.15 percent; and the thinner the silicon chip is, the more obvious the benefit is.

Owner:TIANJIN HUANOU SEMICON MATERIAL TECH CO LTD

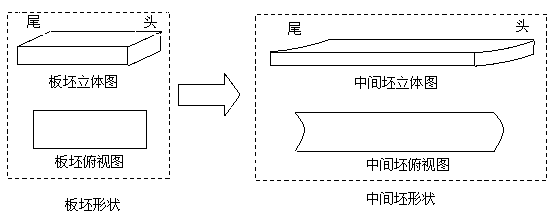

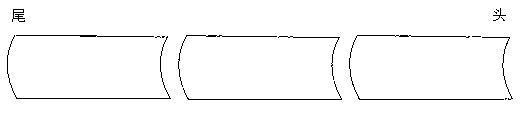

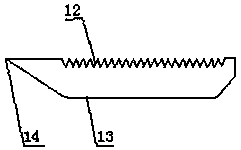

Continuous cast slab head and tail shape pre-controlling method capable of reducing hot-rolled intermediate slab head and tail cutting quantities

InactiveCN103252347AReduce cutting lossHigh yieldMetal rolling arrangementsArch heightMechanical engineering

A pre-control method of head and tail shapes of continuous casting slab for reducing the removed amount from the head and tail of hot-rolled intermediate slab. By a pre-control cutting process for the head and tail shapes of continuous casting slab, the slab is cut into a shape such that its head end surface dents inwards and its tail end surface extrudes towards outside of the slab. In the pre-control cutting process, the head and tail shapes of the slab is cut in accordance with the curve which is linearly symmetrical with respect to the width center of the slab, and the arch height (i.e., the maximum value of the denting portion of the head or the extruding portion of the tail) is controlled in the range of 0 mm to 50 mm. In such a manner, the length of the non-uniform deformation portions of the head and tail of the intermediate slab can be significantly reduced, and thus the reduction of the removed amount from the head and tail of hot-rolled intermediate slab is achieved.

Owner:BAOSHAN IRON & STEEL CO LTD

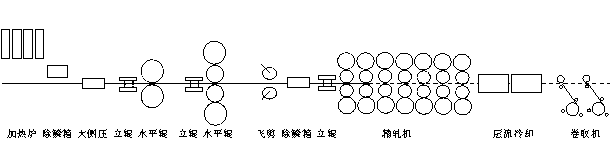

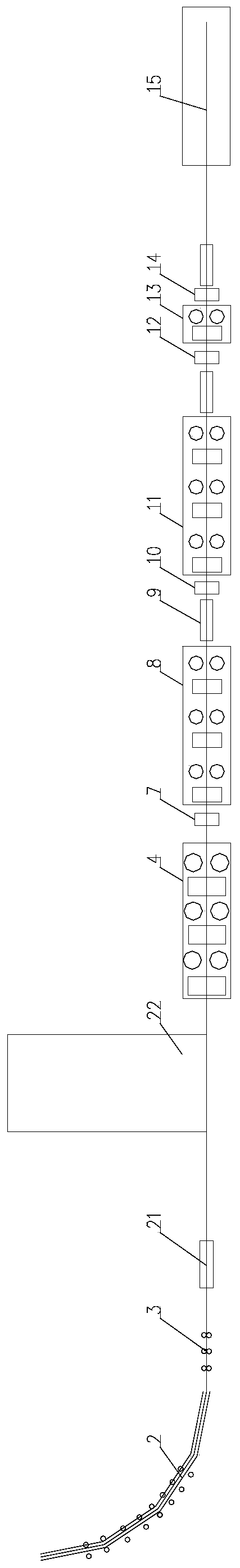

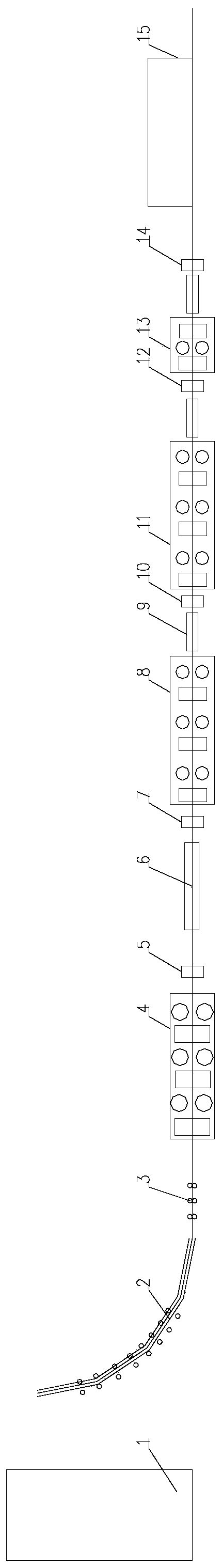

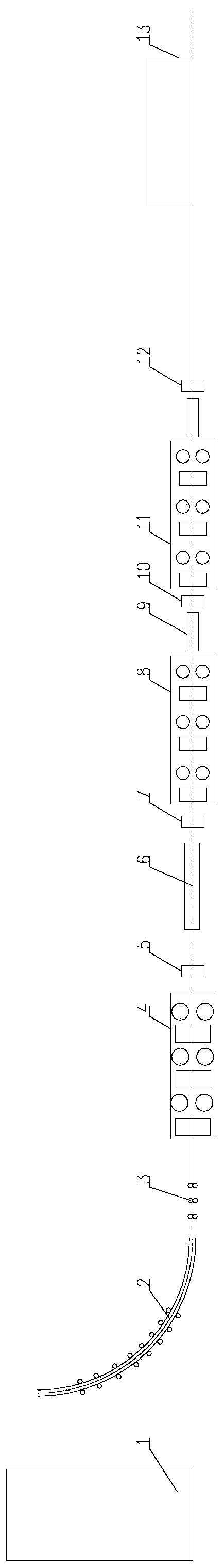

Short-process long material endless rolling production line and short-process long material endless rolling method

PendingCN110052495AGood warming effectLow powerMetal rolling arrangementsProduction lineEconomic benefits

The invention belongs to the technical field of the ferrous metallurgy industry, and relates to a short-process long material endless rolling production line and a short-process long material endlessrolling method. The short-process long material endless rolling production line comprises a steel making furnace, a continuous casting machine, a withdrawal and straightening machine, a rough rollingproduction line, an intermediate rolling production line, a finish rolling production line, a reducing and sizing mill production line and a cooling table. The steel making furnace, the continuous casting machine, the withdrawal and straightening machine, the rough rolling production line, the intermediate rolling production line, the finish rolling production line, the reducing and sizing mill production line and the cooling table are closely connected in sequence. The rough rolling production line comprises a rough rolling unit, an accident shear and cooling table, a heat preservation deviceand a pair of first end cutting flying shears in sequence. The heat preservation device supplements the heat for a casting blank which is subjected to rough rolling operation, and the separation distance between an inlet of the withdrawal and straightening machine and an inlet of the rough rolling unit ranges from 9m to 30m. The intermediate rolling production line comprises an intermediate rolling unit, a water cooling tank and a pair of second end cutting flying shears in sequence. The finish rolling production line comprises a finish rolling unit, a water cooling tank and a pair of third end cutting flying shears in sequence. The reducing and sizing mill production line comprises a reducing and sizing mill unit, a water cooling tank and a pair of fixed-length flying shears in sequence.By the adoption of the short-process long material endless rolling production line, the technological arrangement is simple, the separation distance between the continuous casting machine and the rough rolling unit is small, the rough rolling gripping operation is facilitated, the relative power consumption of the heat preservation or supplement which is conducted after the rough rolling operation is accomplished is low, the cost is low, the industrial production is easily achieved, and the short-process long material endless rolling production line has the obvious economic benefit.

Owner:CISDI ENG CO LTD +1

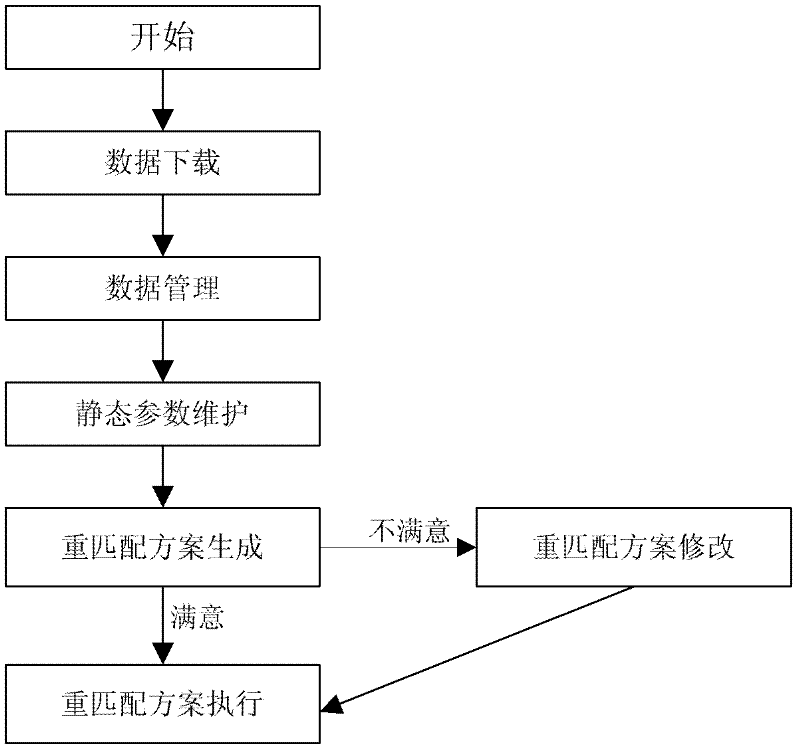

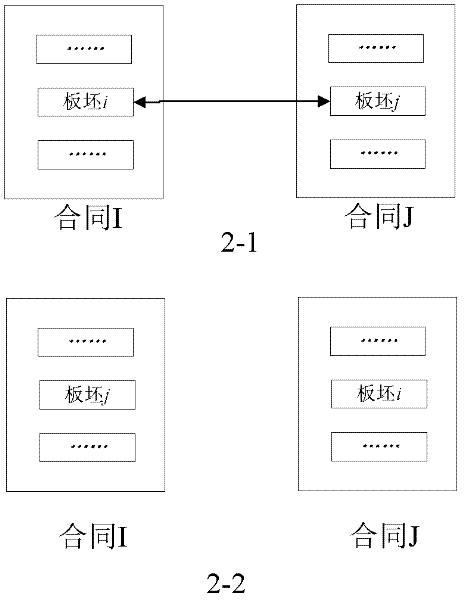

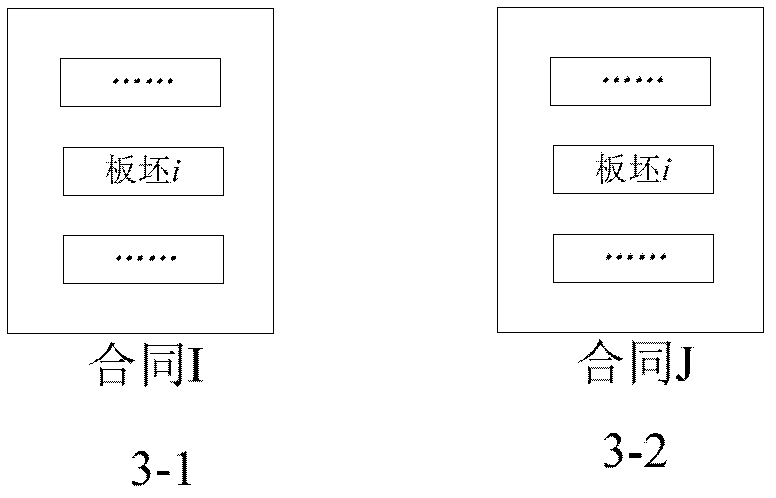

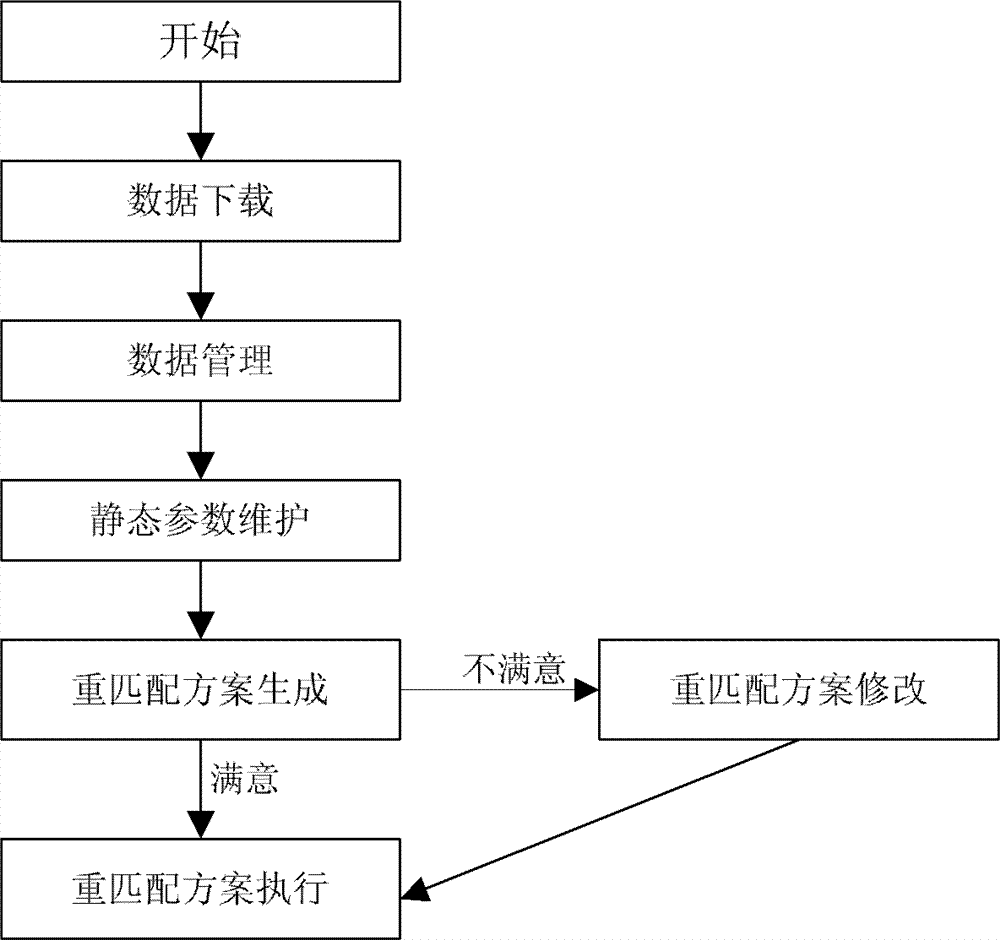

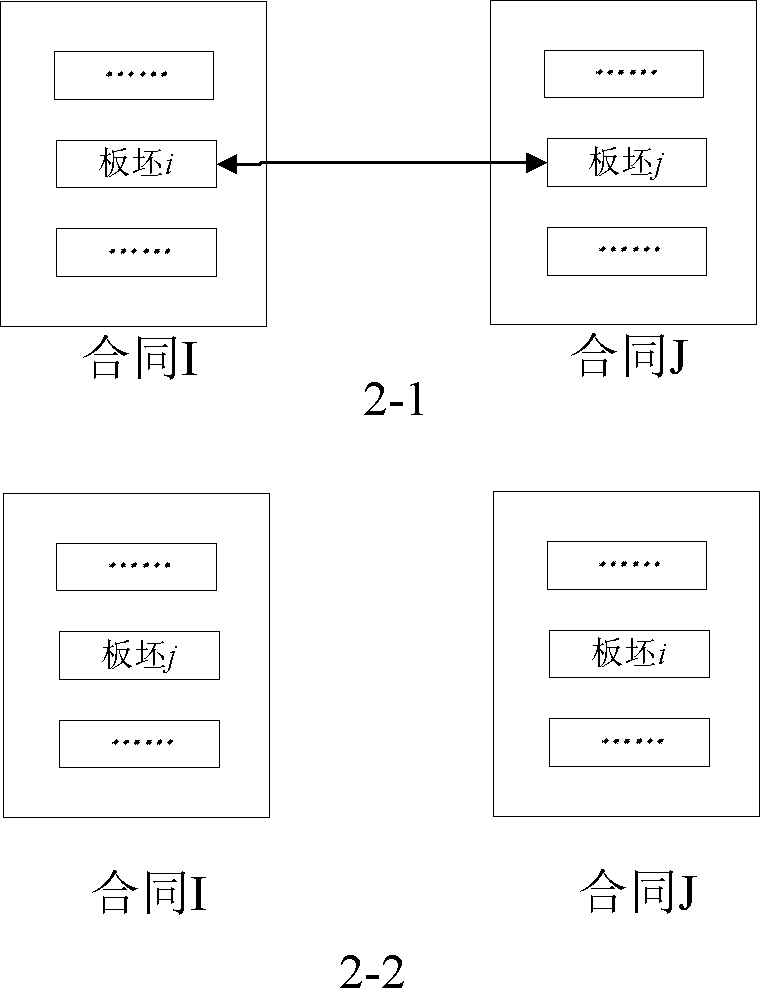

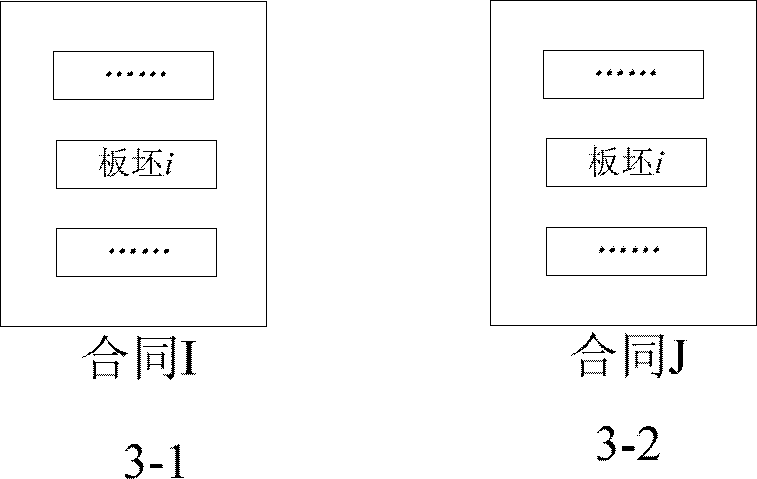

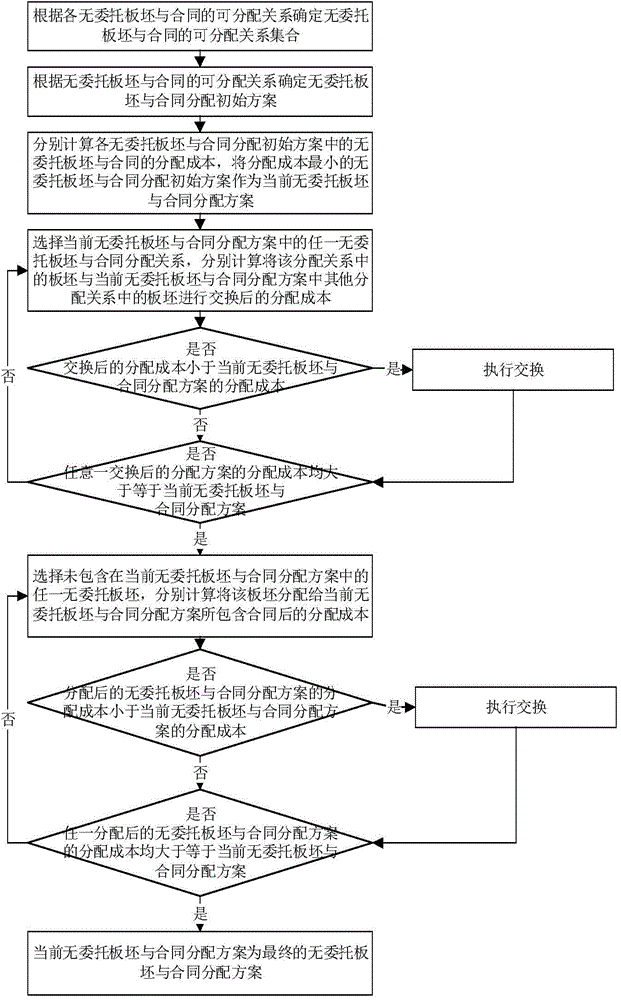

Plate blank and contract transferring and matching method for improving utilization rate of plate blanks of iron and steel enterprise

ActiveCN102651114AImprove match qualityReduce cutting lossLogisticsSpecial data processing applicationsModel parametersTabu search

The invention relates to a matching link of a plate blank of an iron and steel enterprise, belongs to the technical field of automation and particularly relates to a plate blank and contract transferring and matching method for improving the utilization rate of the plate blanks of the iron and steel enterprise, comprising the following steps of: downloading plate blank information and contract information; establishing a mathematic model; carrying out parameter setting on the mathematic model; grouping the plate blanks and contracts; carrying out tabu search algorithm on each group of contract data and each group of plate blank data based on a multi-neighborhood to obtain a matching relation again; and checking a result of the step five; if the result meets the requirements, delivering and executing. Aiming at the condition that a plate blank and contract matching relation is unreasonable, the invention provides the plate blank and contract transferring and matching method, namely the plate blanks in all the contracts are taken off to break through the previous plate blank and contract matching relation; and on the precondition that a unit capacity is balanced, optimization and matching of all the plate blanks capable of being matched and the contracts capable of being matched can be carried out again, so that the matching quality of the plate blanks is effectively improved, the cutting loss amount of the plate blanks is reduced, the residual material amount of the contracts is reduced, the integrity of the contracts is improved and the delivery just-in-time of the emergent contracts is guaranteed.

Owner:NORTHEASTERN UNIV

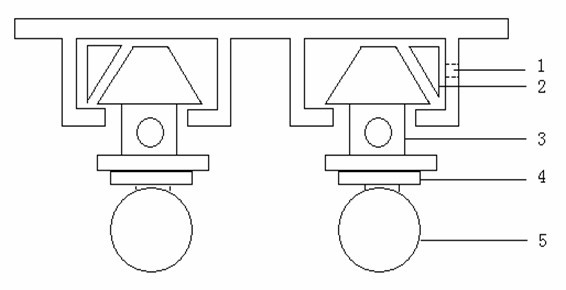

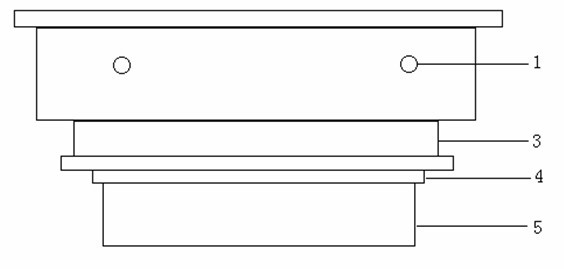

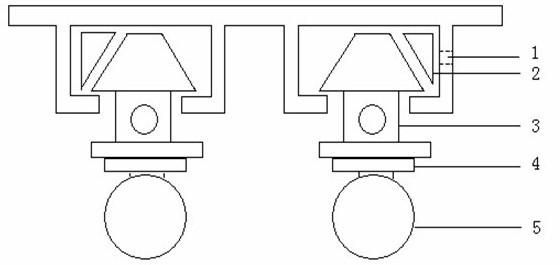

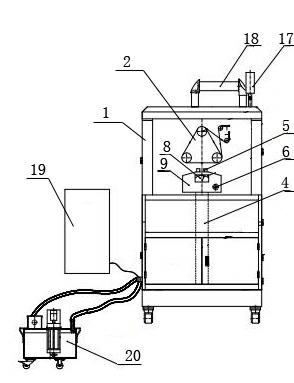

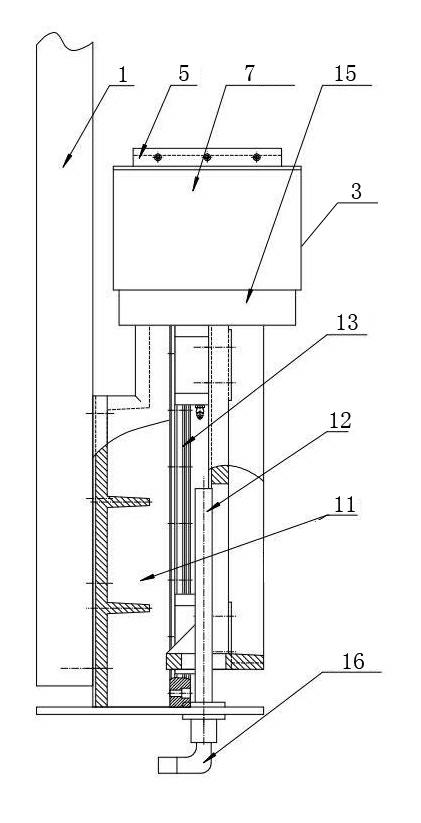

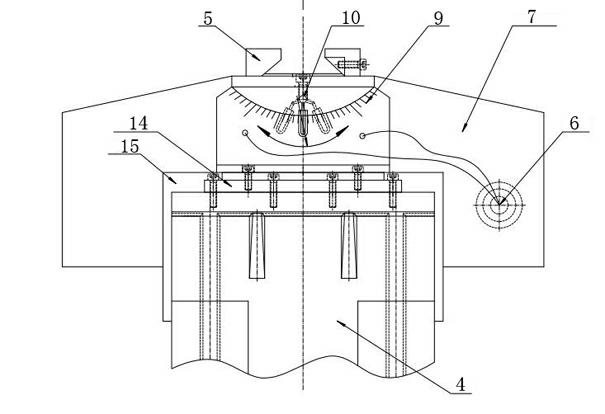

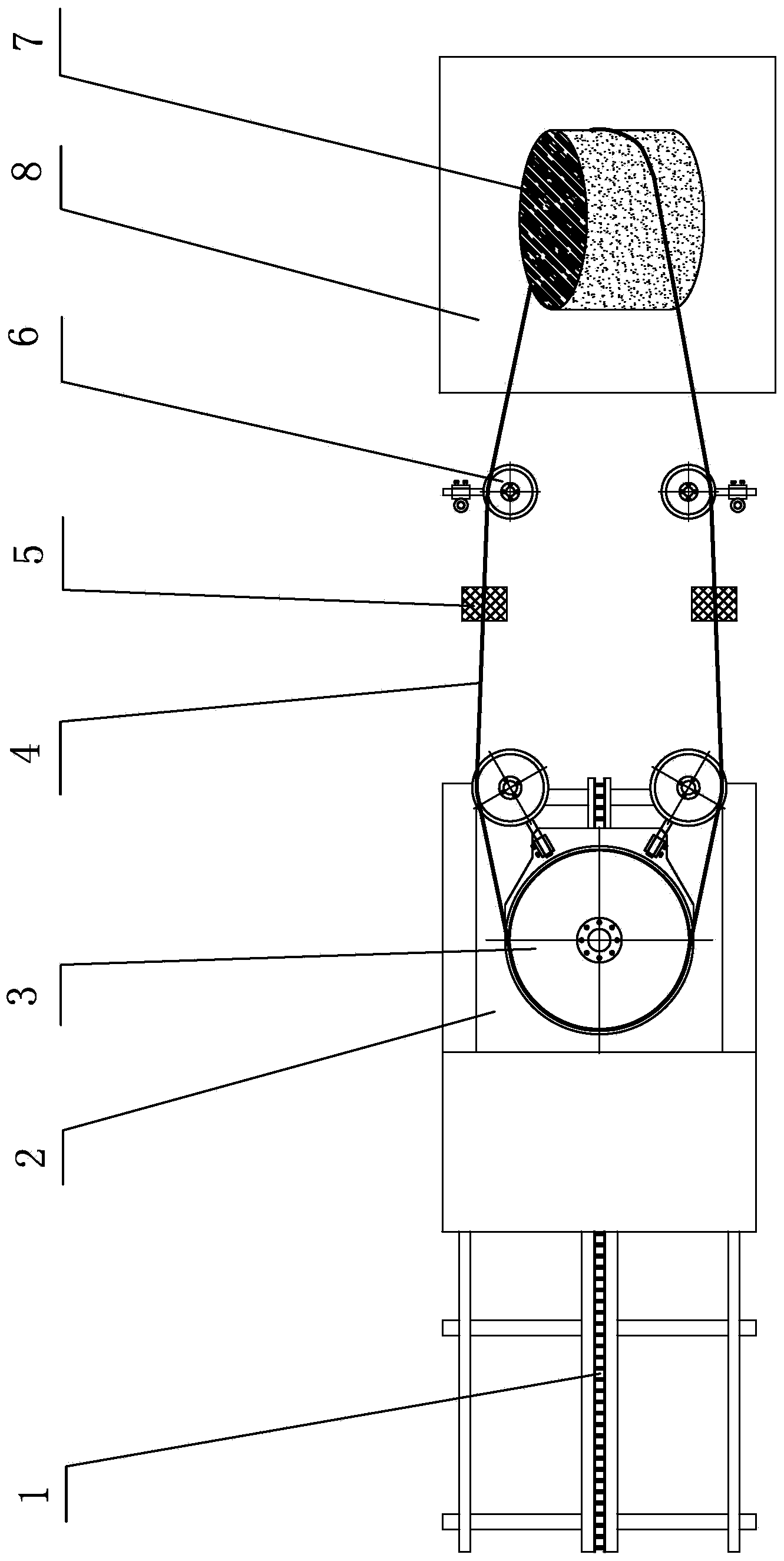

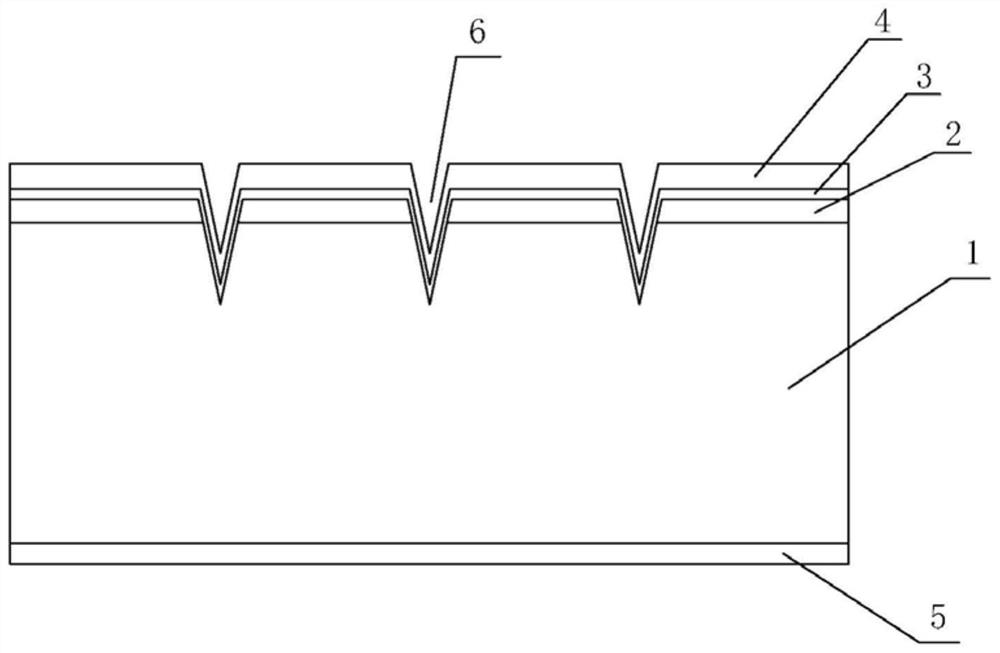

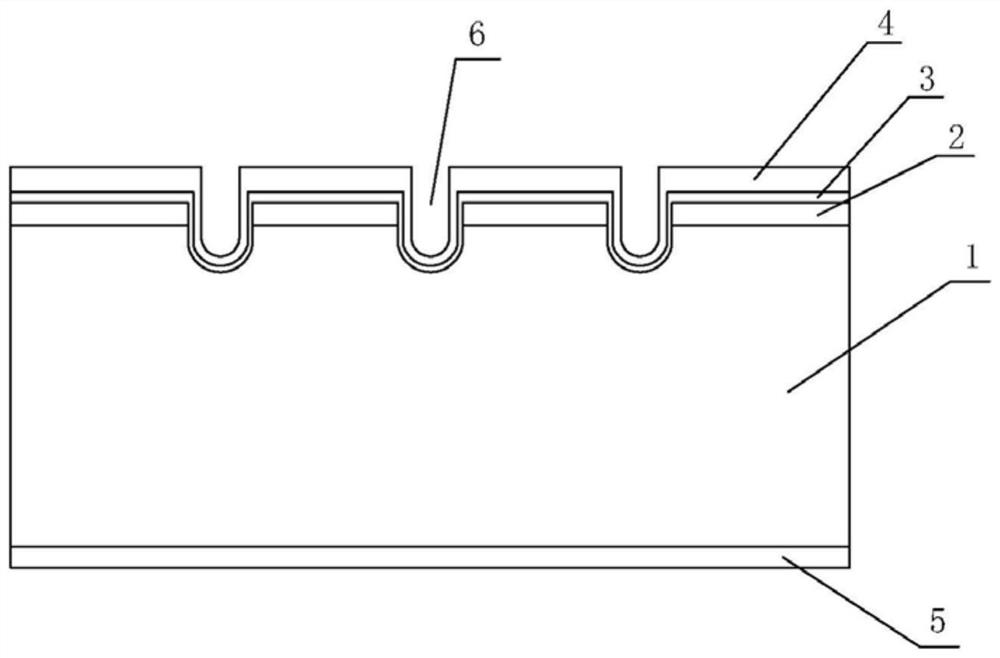

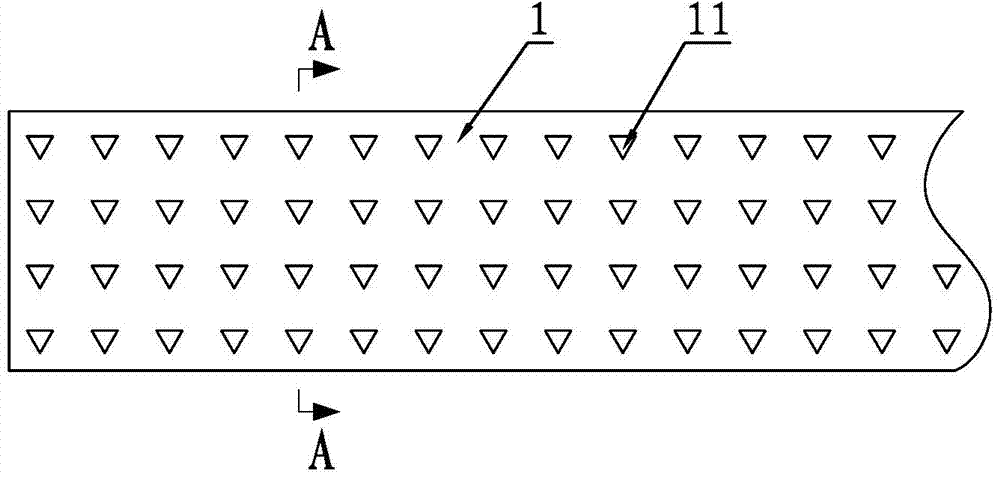

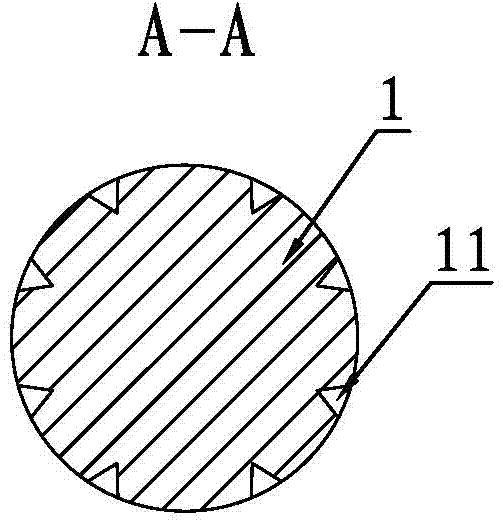

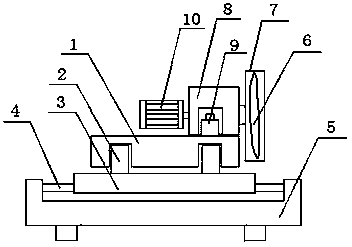

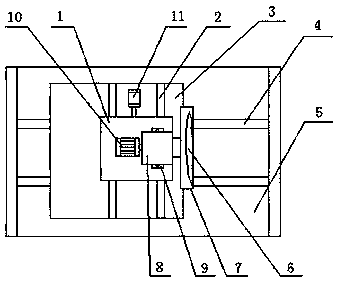

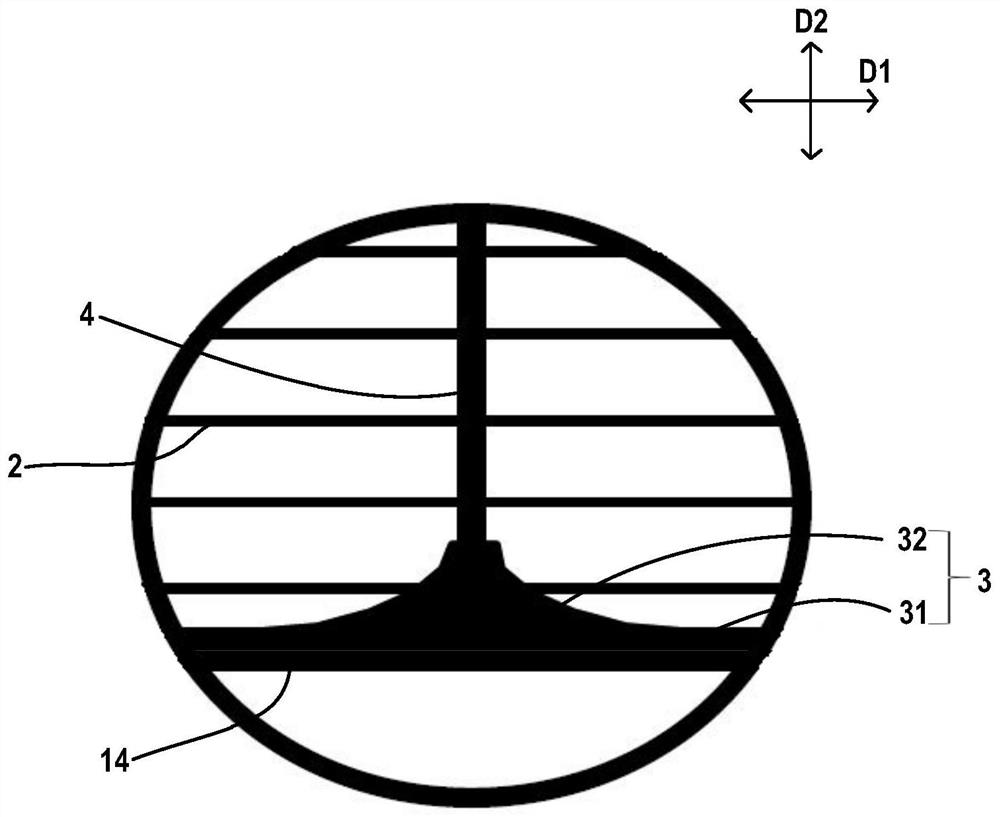

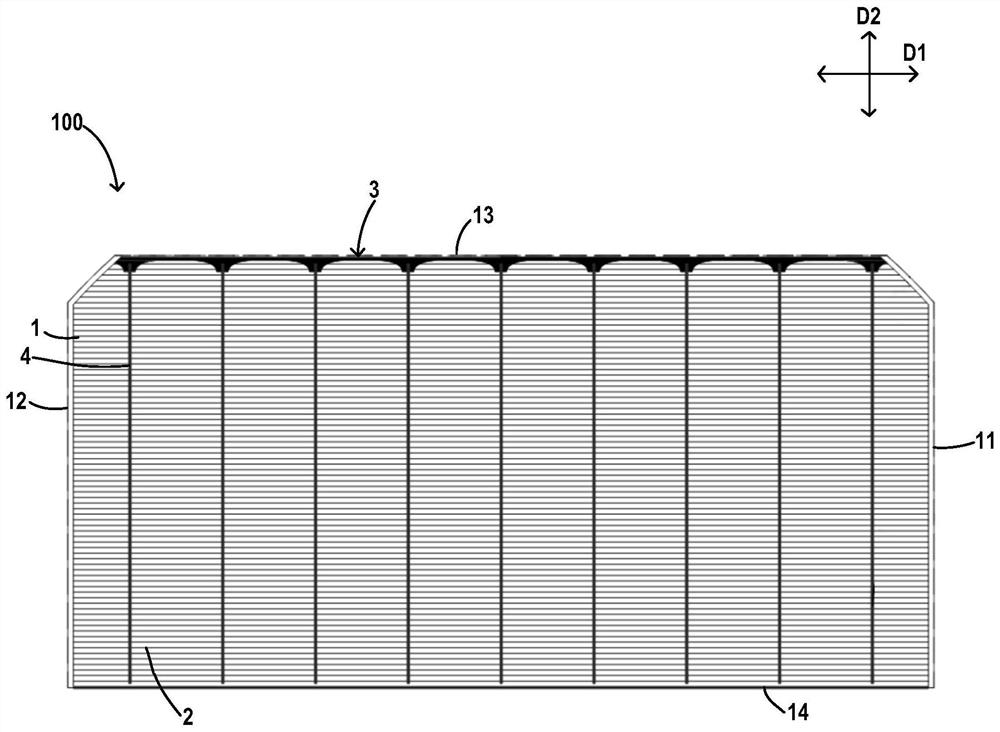

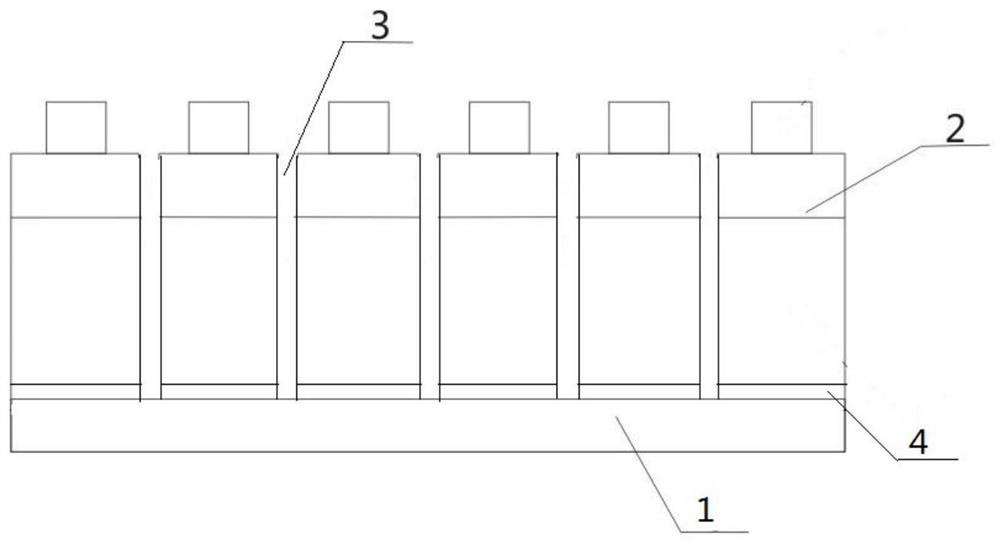

Multi-wire cutter special for sapphire

InactiveCN102189612AFast cutting speedIncrease net speedWorking accessoriesFine working devicesWire cuttingEngineering

The invention relates to a multi-wire cutter special for sapphire, which belongs to the technical field of cutting devices special for sapphire. The technical scheme is as follows: the multi-wire cutter comprises a cutter body (1), a cutting wire mechanism (2), a swing working platform and a lifting body (4), wherein the cutting wire mechanism is arranged on the upper part of the cutter body, the swing working platform is arranged at the lower part of the cutting wire mechanism, the lifting body is connected with the swing working platform and drives the swing working platform to move up and down, and the swing working platform per se swings left and right to ensure that a workpiece on the swing working platform is matched with the cutting wire mechanism so that multi-wire cutting of the sapphire can be completed. The multi-wire cutter is used for adjusting the cutting angle of the sapphire dynamically, and ensures that the angle of a sapphire material can be continuously adjusted with the swing working platform when the sapphire material is cut so that a cutting wire is in less contact with the material and additional friction force is reduced; meanwhile, the feeding speed of the cutting wire can be greatly increased, the problem of low cutting speed caused by high hardness of the sapphire is solved, and the speed is improved to 2-4 times of that of the common multi-wire cutter.

Owner:唐山晶玉科技股份有限公司

Large alloy steel part cutting method through diamond wire saw

InactiveCN104070231ASmooth surfaceReduce cutting lossMetal sawing devicesAlloy steelDiamond wire saw

The invention discloses a large alloy steel part cutting method through a diamond wire saw. Firstly, hanging a large alloy steel part to be cut to a cutting working platform, determining a cutting position of the large alloy steel and making a marker line, then mounting a diamond wire saw, putting the diamond wire saw to the position of the marker line, and adjusting the cutting device to enable the diamond wire saw to be perpendicular to the marker line; secondly, cooling the large alloy steel part with coolant, performing grinding and cutting through closed-loop high-speed rotating of the diamond wire saw; finally, cutting the large alloy steel part to finish cutting. According to the large alloy steel part cutting method through the diamond wire saw, the selected diamond saw is flexible and belongs to high-speed cold machining, not only machining damage and deformation of the large alloy steel part to be cut can be avoided, but also the cutting efficiency and accuracy of the large alloy steel part can be improved, and labor intensity can be effectively reduced.

Owner:GUILIN TEBON SUPERHARD MATERIAL

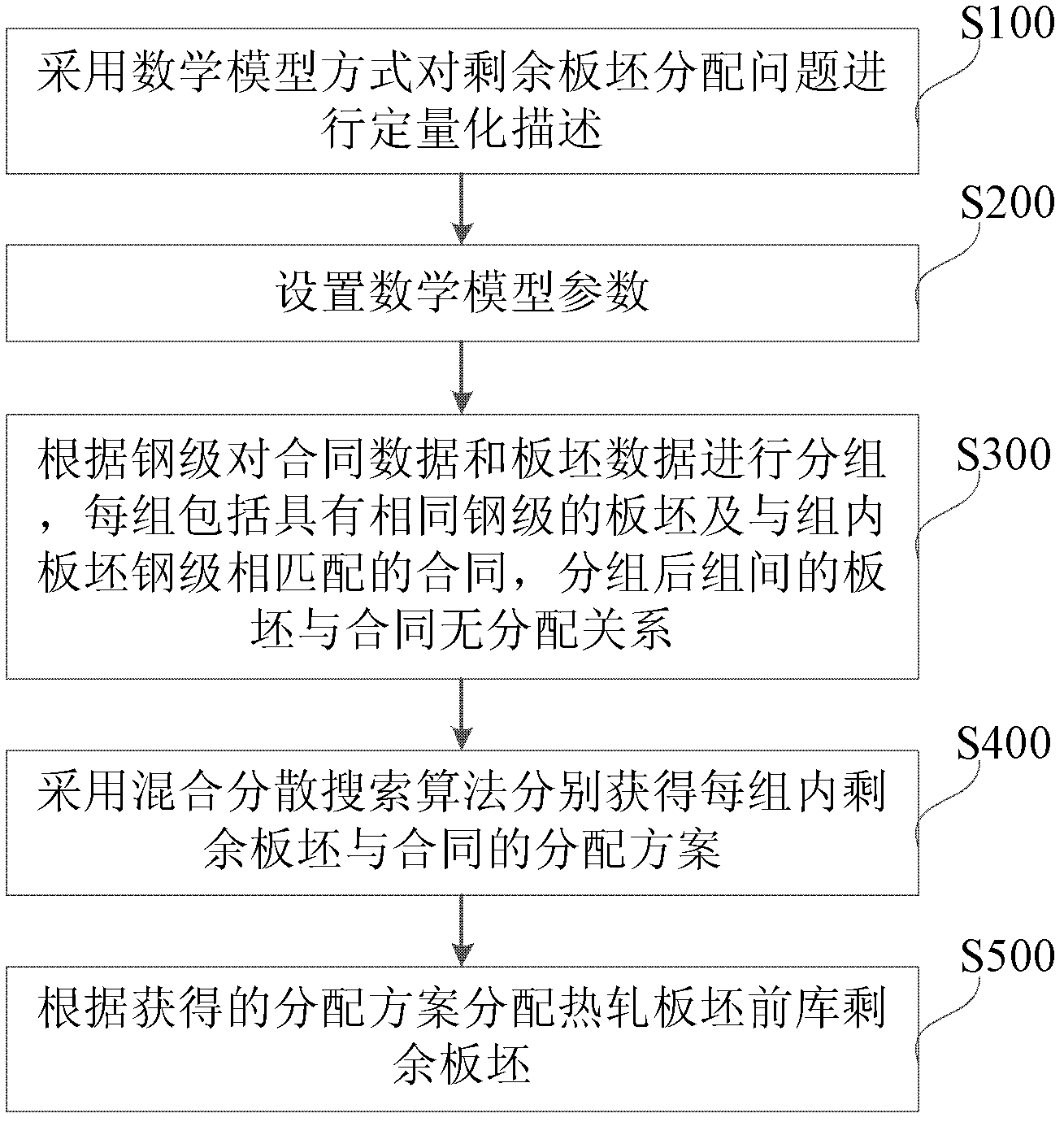

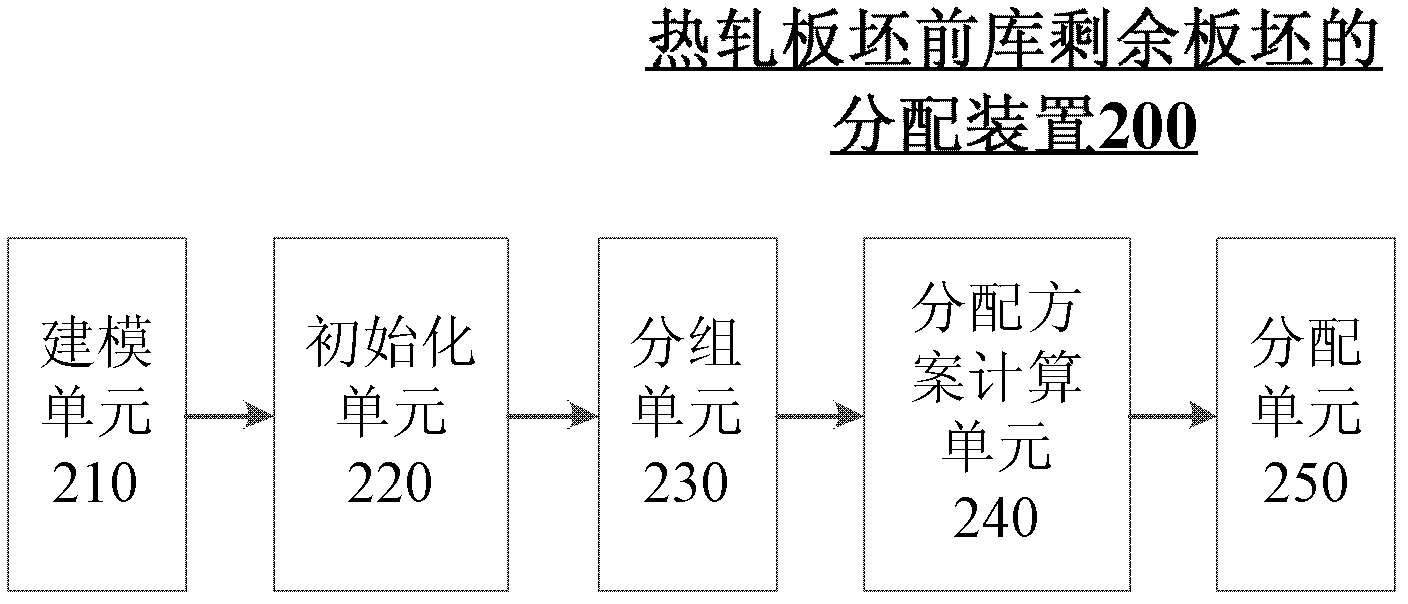

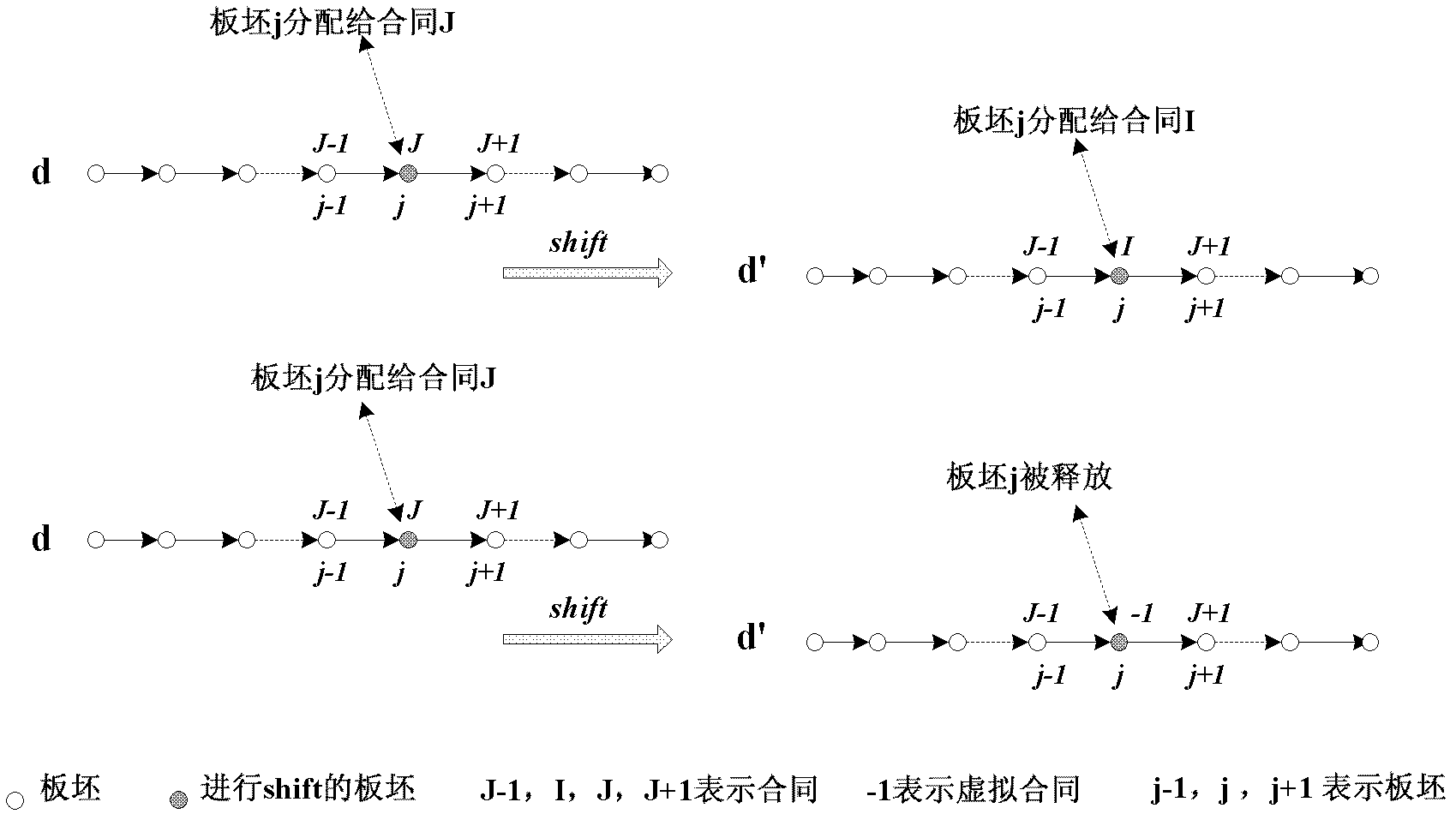

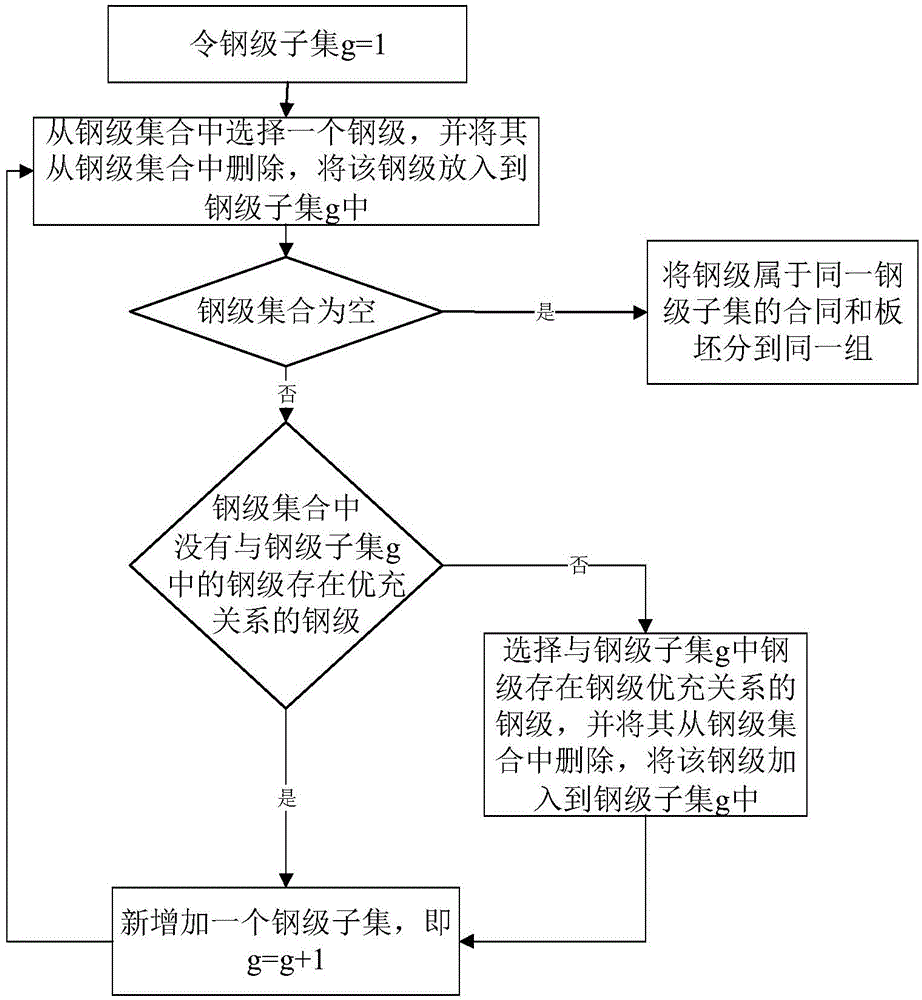

Method and device for distribution of residual plate blanks in hot-rolled plate blank front storeroom

ActiveCN102637272AReduce the amount of remaining slabs in stockReduce cutting lossLogisticsSearch algorithmEngineering

The invention provides a method and a device for distribution of residual plate blanks in a hot-rolled plate blank front storeroom. The method includes the steps: S100, using a mathematical model for quantitative description of a distribution problem of residual plate blanks in the hot-rolled plate blank front storeroom, wherein the quantitative description includes selecting decision variables, setting an optimization target and determining residual plate blank distribution constraints; S200, setting parameters of the mathematical model in the S100; S300, grouping contract data and plate blank data according to steel levels, wherein each group comprises plate blanks of the same steel level and a contract matched with the steel level of the plate blanks in the group, the plate blanks and the contracts have no distribution relation after grouping; S400, using a mixed dispersion searching algorithm to respectively obtain a distribution scheme of the residual plate blanks and the contracts in each group; and S500, distributing the residual plate blanks in the hot-rolled plate blank front storeroom according to the distribution scheme. From a view of global optimization, all aspects of factors are considered comprehensively, and complete and reasonable distribution of residual stock of the hot-rolled plate blank front storeroom is realized.

Owner:NORTHEASTERN UNIV

A water-based wire cutting fluid for silicon wafers

InactiveCN102260582ALow costGood dispersion and suspensionLubricant compositionPolyvinyl alcoholWire cutting

The invention provides a water-based cutting fluid for silicon wafers, which consists of the following raw materials in proportions by mass: polyvinyl alcohol, 2-10 parts, benzotriazole, 0.05 parts, deionized water, 89.95-98 servings. The water-based cutting fluid is characterized by low cost and environmental friendliness. Due to the good viscosity and dispersibility of the polyvinyl alcohol aqueous solution, the dispersibility of the blade in this cutting fluid is good, especially after settling, it is easier to redisperse. Using the water-based cutting fluid of the invention has a high qualified rate of finished products, and the silicon wafers after cutting are easier to clean.

Owner:CHANGZHOU UNIV

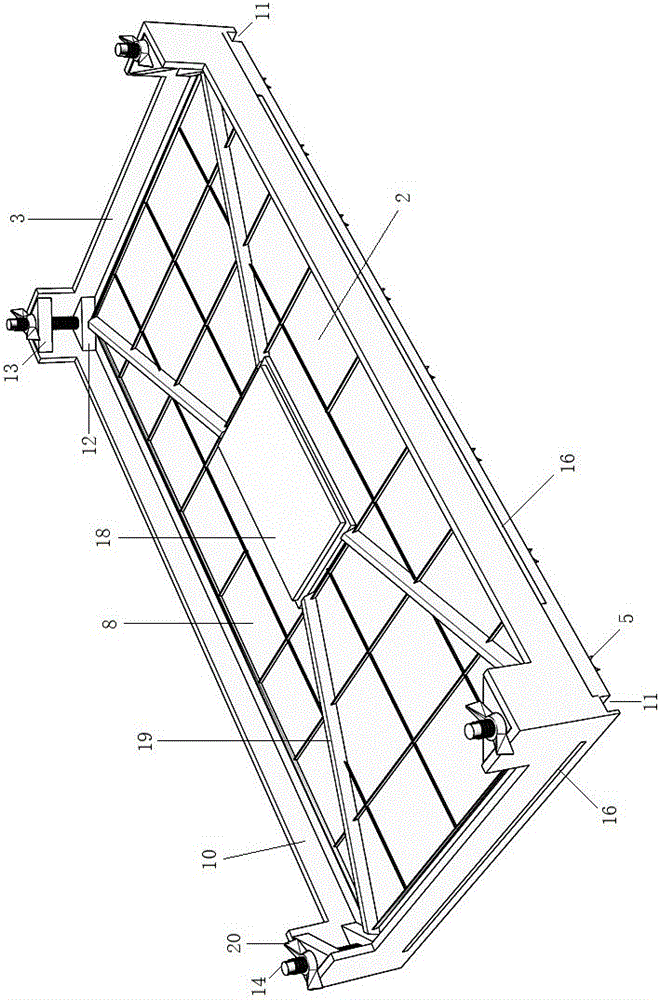

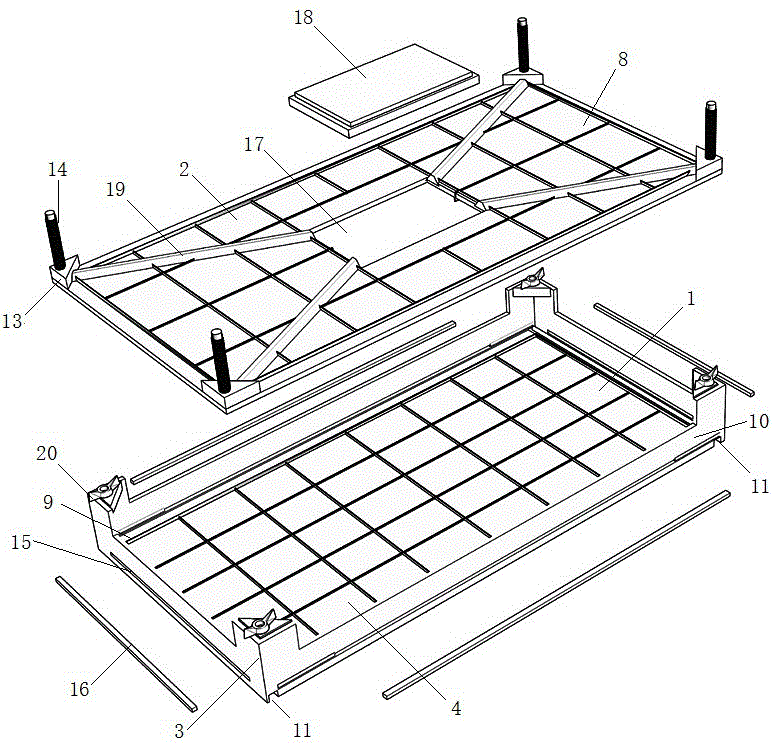

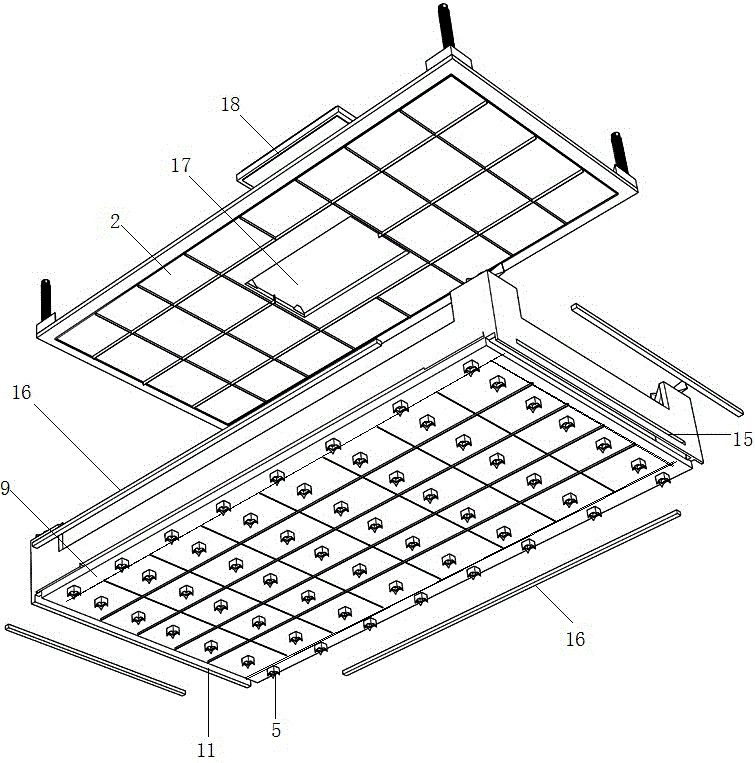

Concrete double-mold structure for top surface of building

ActiveCN106088583AEasy dischargeShorten discharge timeForms/shuttering/falseworksPull forceEngineering

The invention discloses a concrete double-mold structure for the top surface of a building, and relates to the technical field of supporting molds for the top surfaces of buildings. The concrete double-mold structure for the top surface of the building comprises a lower assembly plate, an upper assembly plate and a ring beam supporting frame, wherein the lower assembly plate is formed by multiple lower template units which are assembled in the ring beam supporting frame; the upper assembly plate is formed by assembling multiple unit surface molds; the ring beam supporting frame is formed by fixing a rectangular bottom frame and four side templates perpendicularly surrounding the rectangular bottom frame; the left end part and the right end part of the rectangular bottom frame are both provided with long strip-shaped bonding grooves; the upper ends of the four corners of the ring beam supporting frame are all fixedly provided with fixing blocks; the upper ends of the upper assembly plate are all fixedly provided with regulating blocks; the regulating blocks are all perpendicularly and fixedly provided with tension screw rods; the regulating blocks are all connected with the fixing blocks on the corresponding same sides through the tension screw rods. An integral assembly structure is adopted for the concrete double-mold structure for the top surface of the building; the pouring flatness is high; the thickness is uniform; the construction difficulty can be decreased.

Owner:RIZHAO WEIYE TOOL

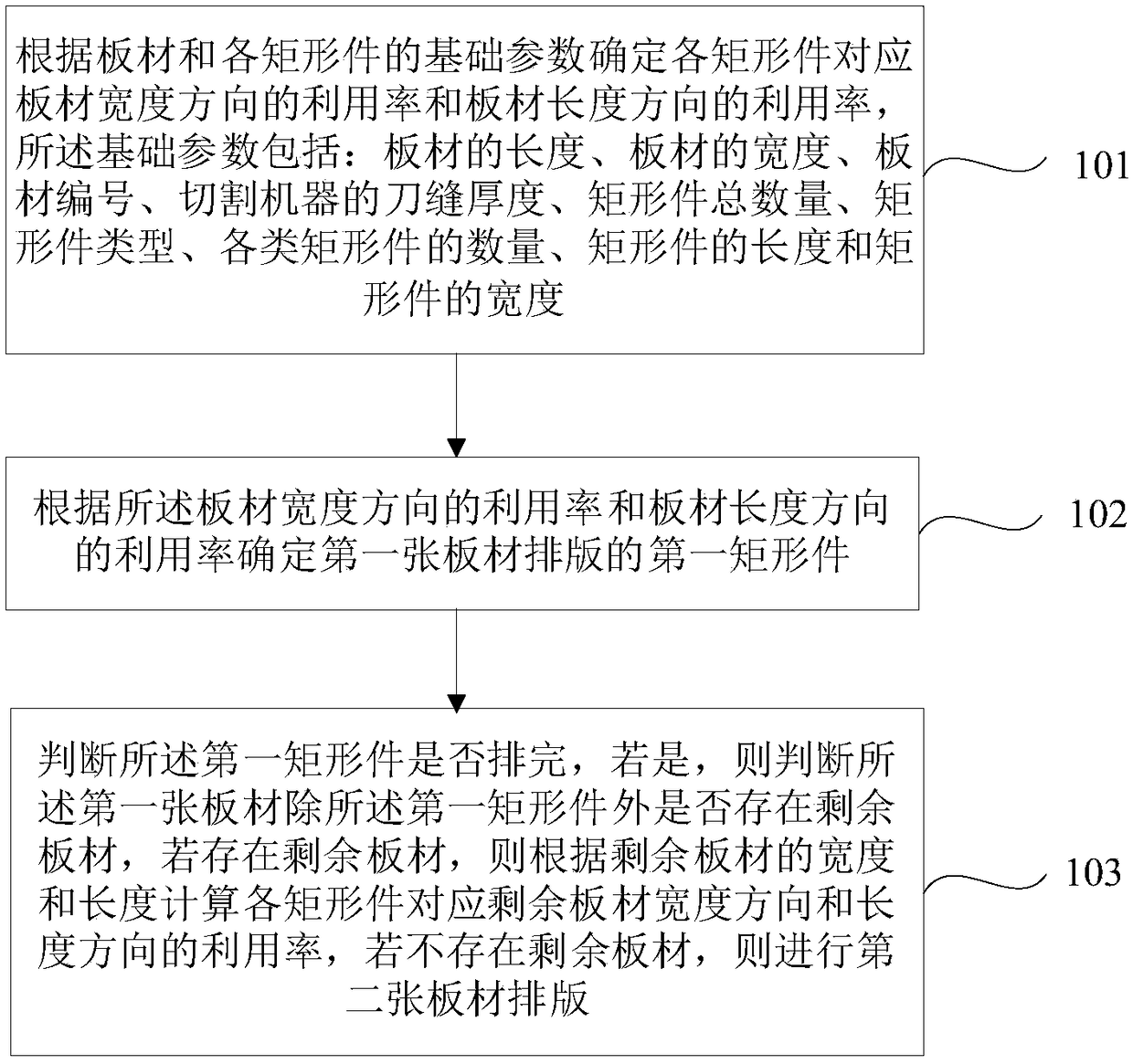

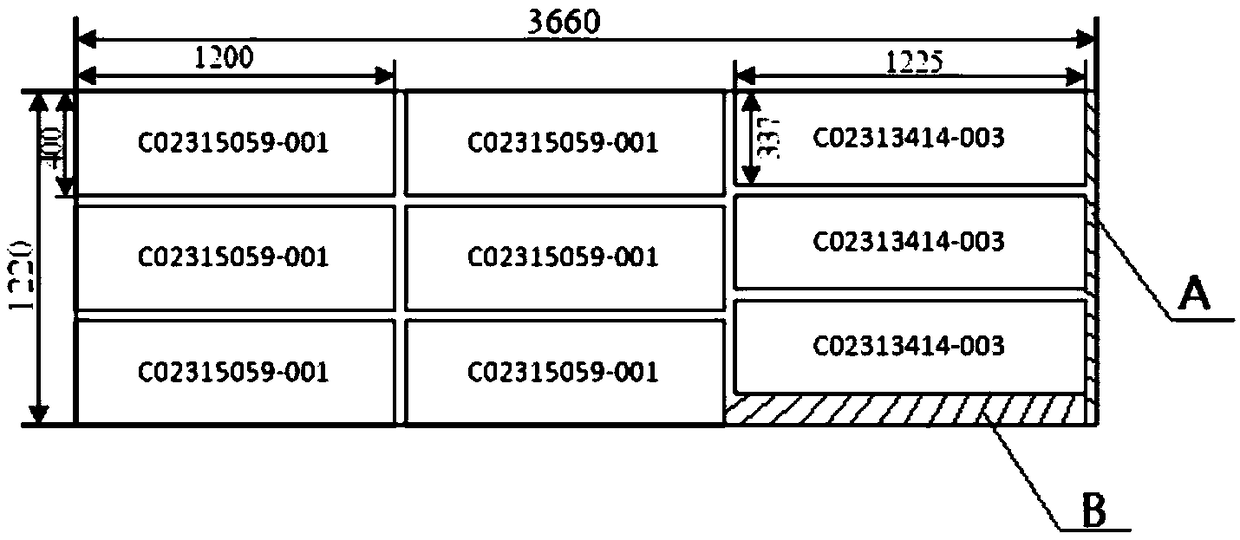

Rectangular piece optimization and stock layout method based on plate utilization rates

ActiveCN108637370AIncrease profitImprove work efficiencyMetal sawing devicesUtilization rateReliability engineering

The invention discloses a rectangular piece optimization and stock layout method based on plate utilization rates. The rectangular piece optimization and stock layout method based on the plate utilization rates includes the steps that according to basic parameters of plates and rectangular pieces, the utilization rates of the plates corresponding to the rectangular pieces in the width direction and in the length direction are determined; according to the utilization rates of the plates in the width direction and in the length direction, first rectangular pieces laid on a first piece of plate are determined; and whether the first rectangular pieces are completely laid or not is judged, if yes, whether the first piece of plate has a remaining plate or not except the first rectangular piecesis judged, if yes, according to the width and the length of the remaining plate, the utilization rates of the remaining plate corresponding to the rectangular pieces in the width direction and in thelength direction are calculated, and if no remaining plate exists, layout of a second piece of plate is performed. Due to the method, the utilization rates of the plates are increased, and raw materials are saved.

Owner:DALIAN MARITIME UNIVERSITY

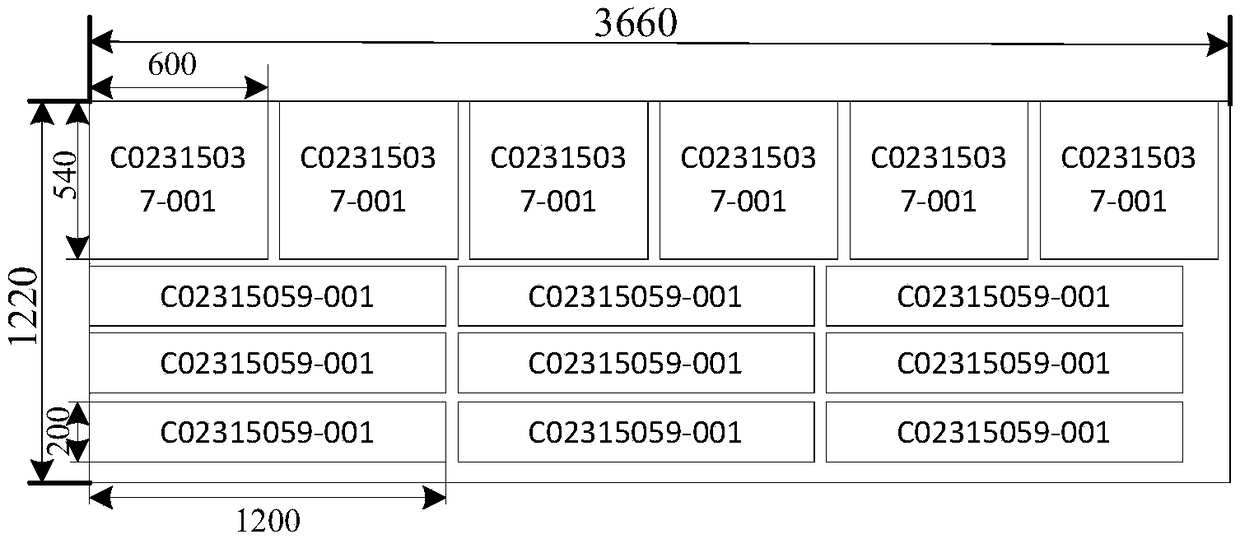

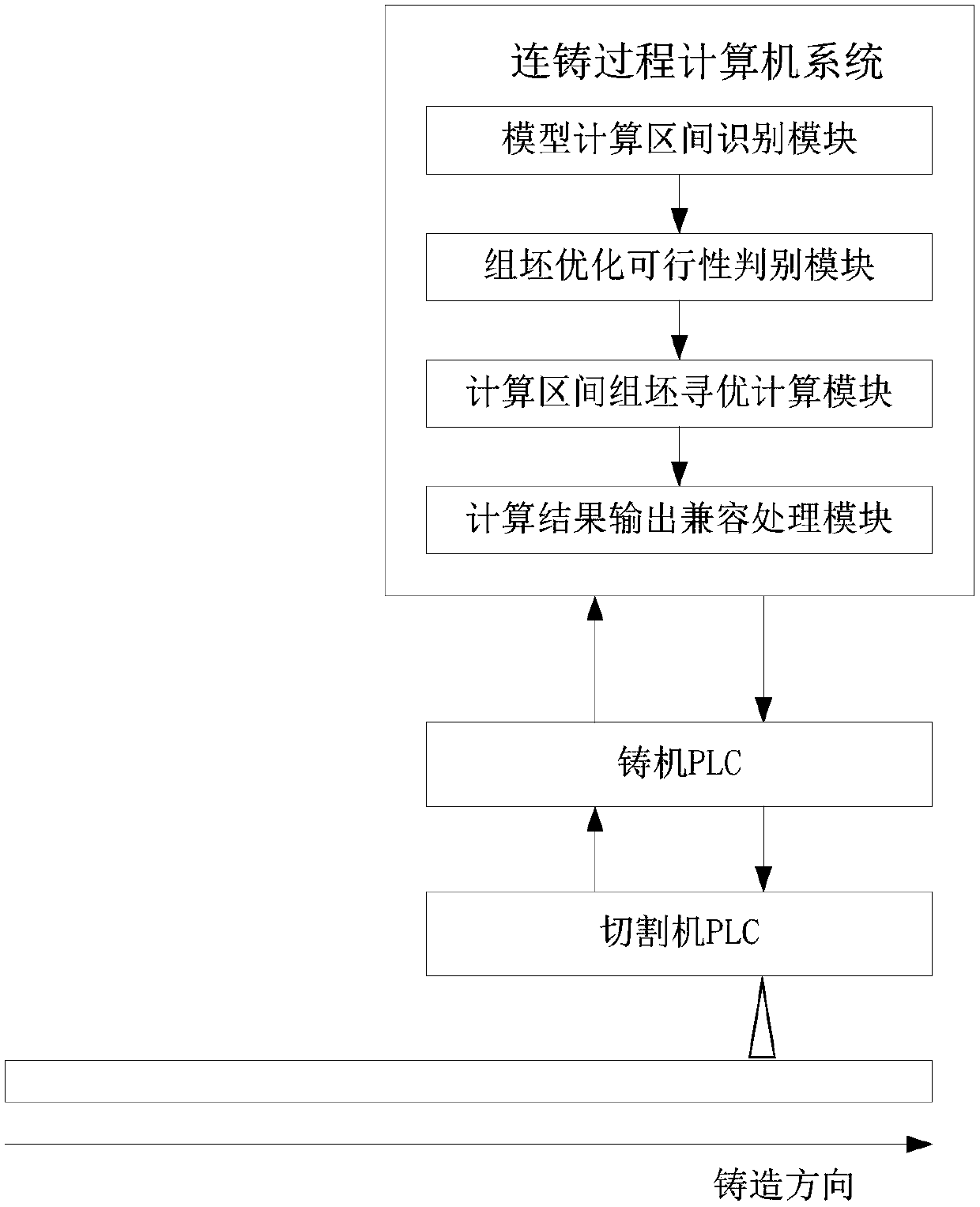

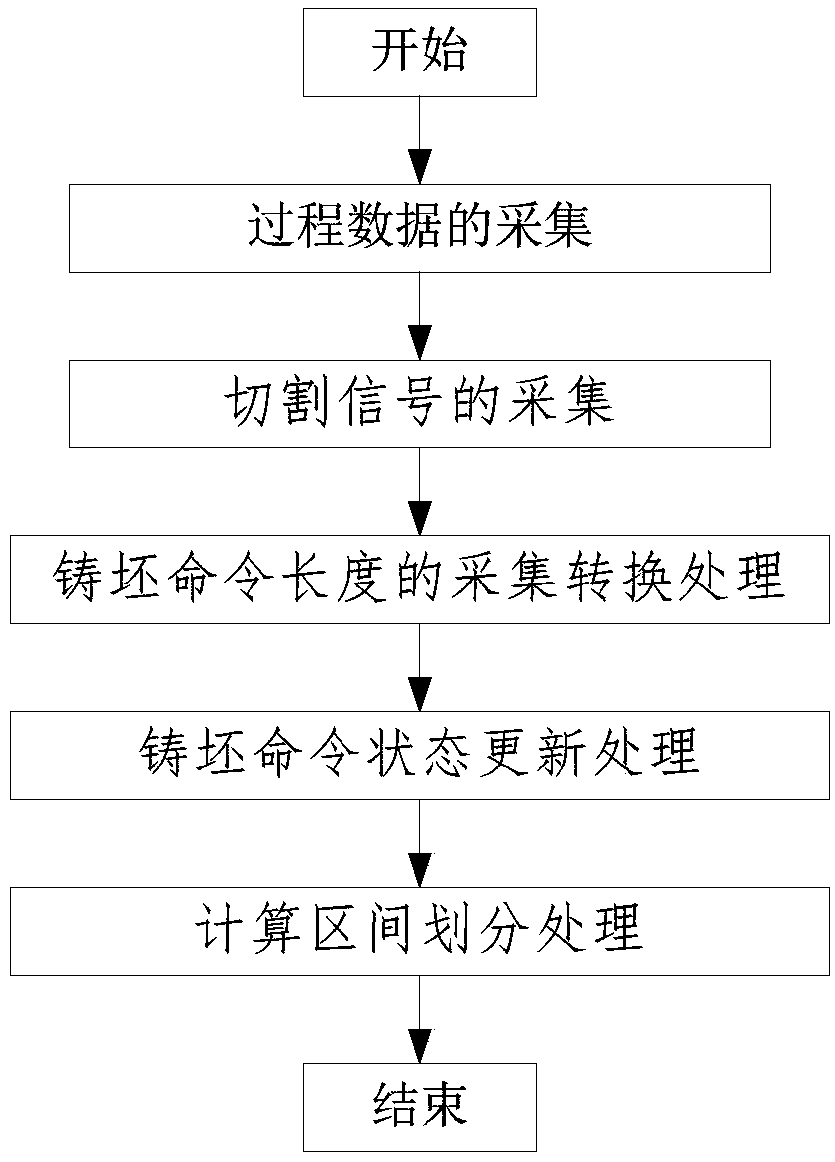

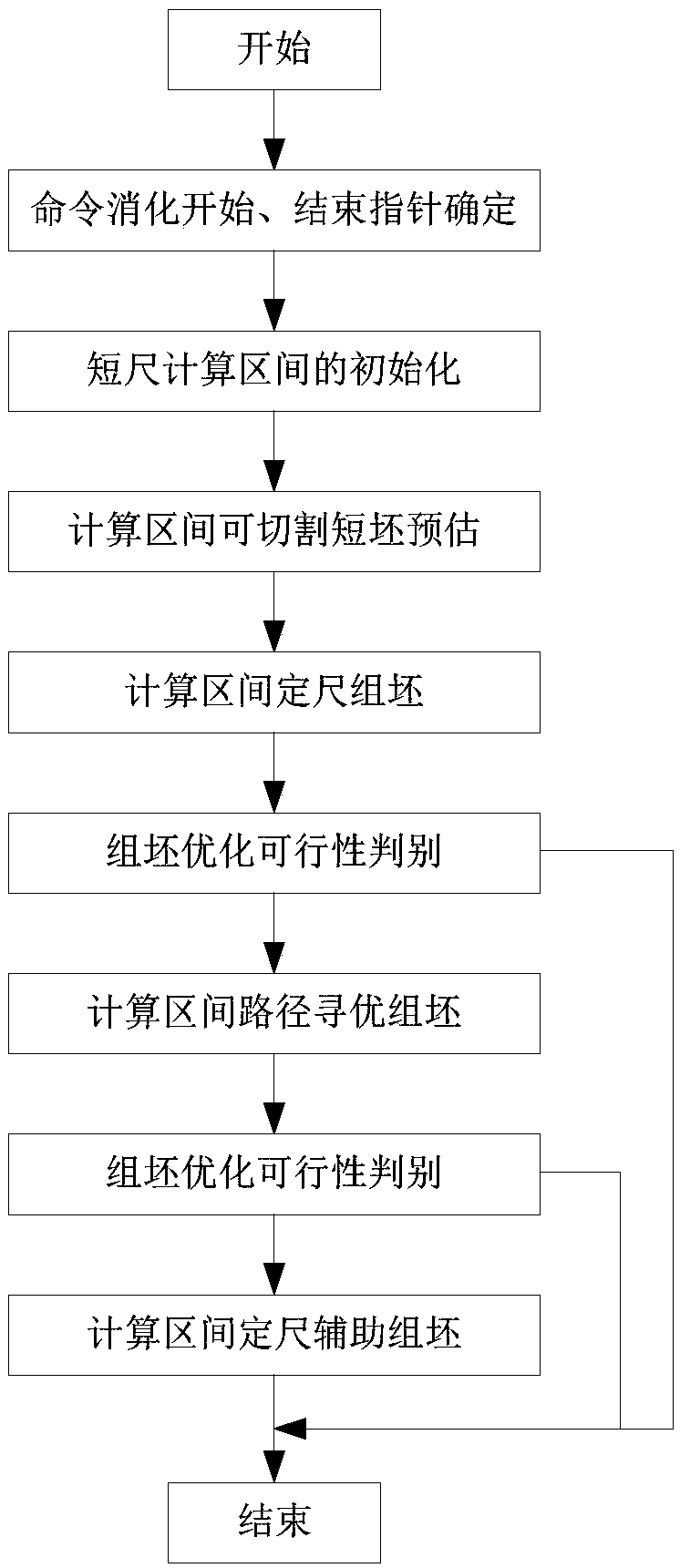

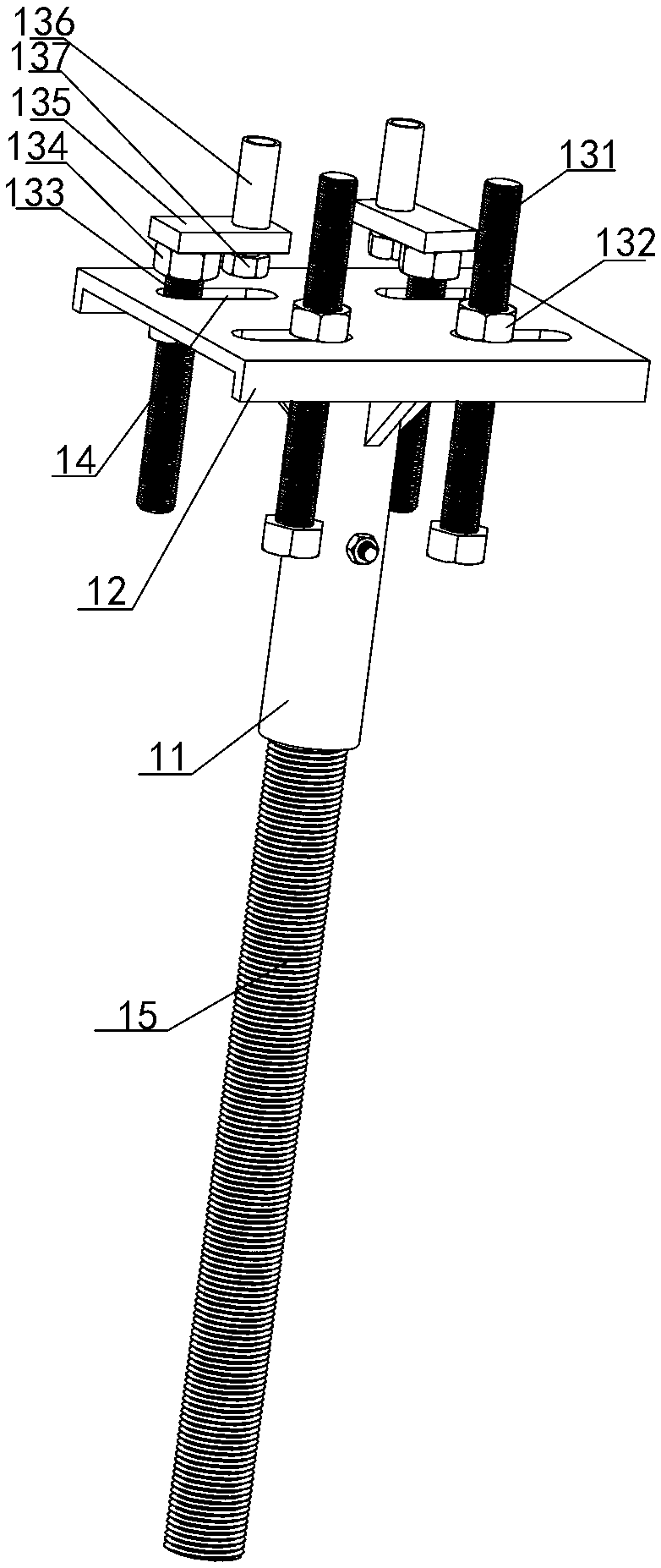

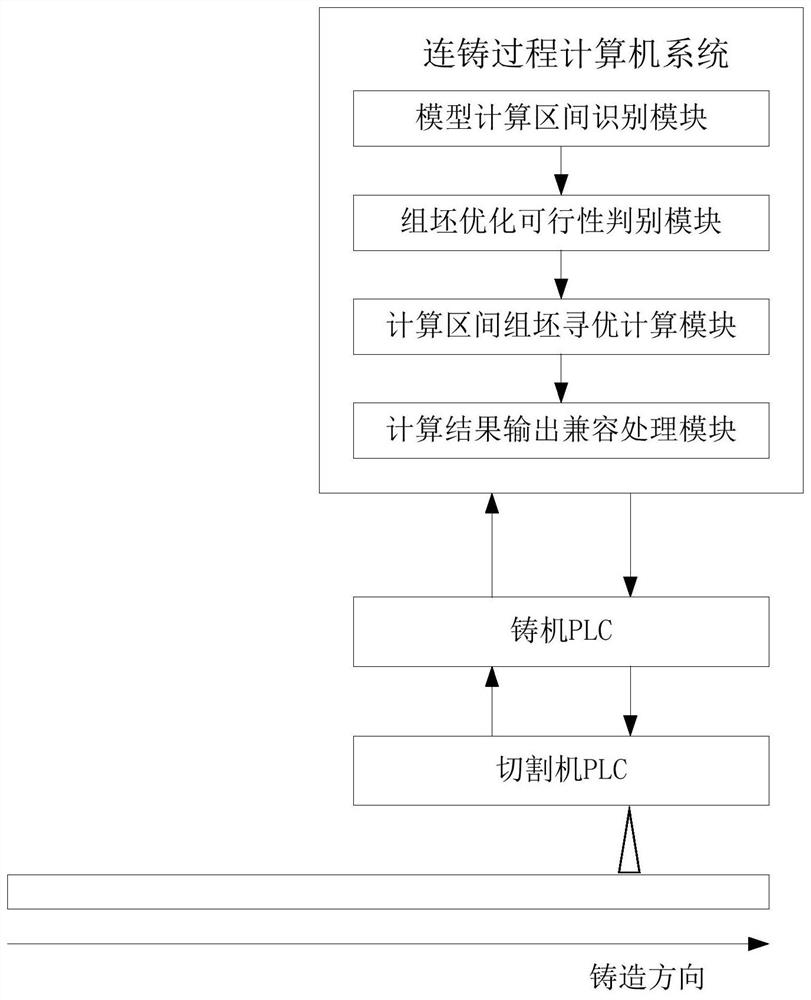

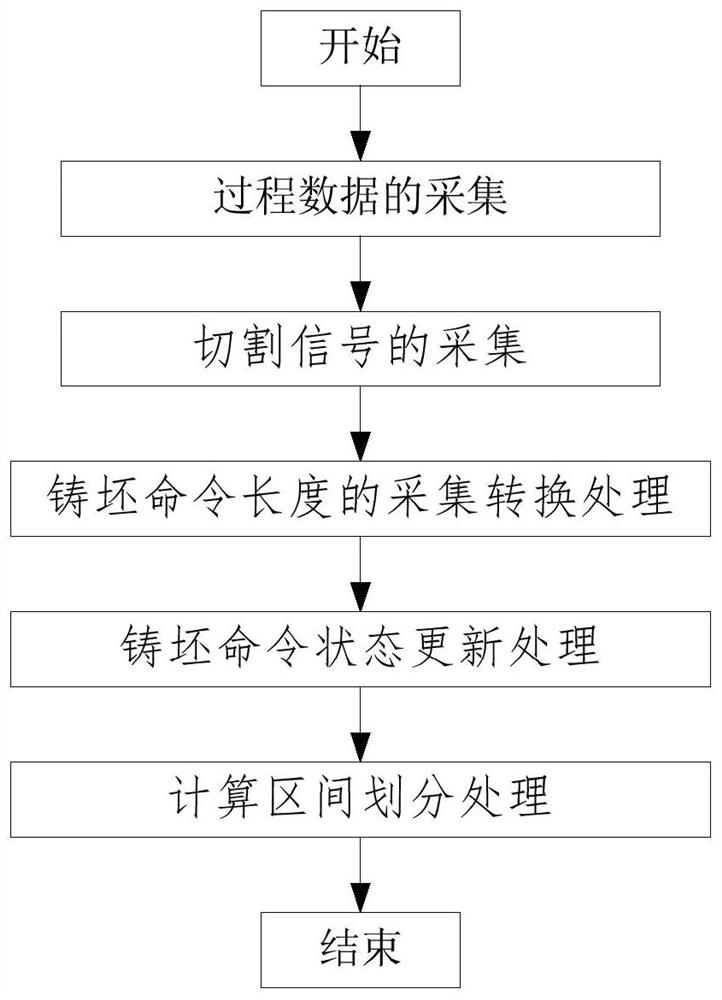

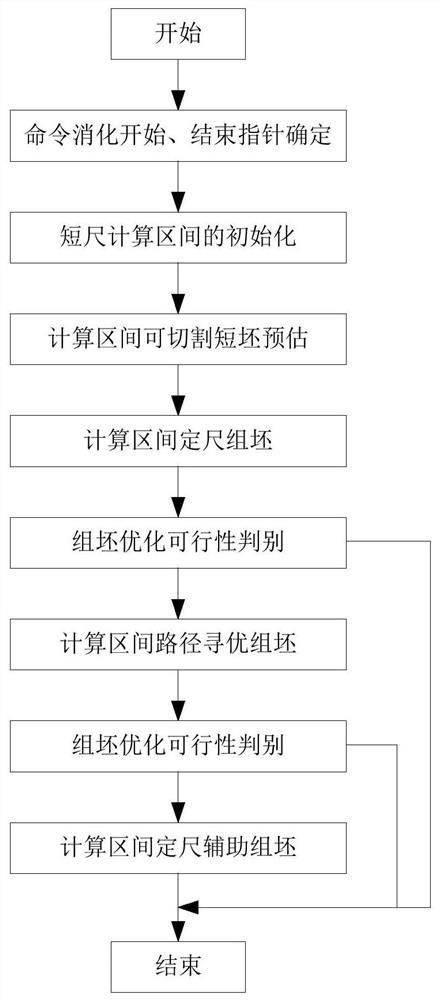

Cutting control system for continuous casting slab of thick plate and assembly optimization calculation method thereof

The invention discloses a cutting control system for a continuous casting slab of a thick plate. A short slab command is sent by using a thick plate rolling mill, data such as a signal are tracked inheat casting process, the assembly optimization of the short slab is performed on the casting slab with the range of a casting machine, and the casting slab is cut according to the length of an optimal long slab; an assembly optimization calculation method of the continuous casting slab of the thick plate can successfully find the optimal assembly strategy, optimal cutting control is performed onthe long slab within the range of the casting machine, and a continuous casting on-line cutter is controlled to perform on-line one-step cutting, so that cutting scraps are decreased, continuous casting, integration and optimization of the efficiency of the thick plate rolling mill are supported, and the assembly cutting efficiency and effect of the continuous casting machine are improved; the user interface is friendly, cut loss can be reduced, scenes of uniflow casting, dual-flow casting and different steel grades casting of the thick plate each heat are supported, and the maximized and optimized efficiency of the casting machine is ensured.

Owner:BAOSHAN IRON & STEEL CO LTD

Plate blank and contract transferring and matching method for improving utilization rate of plate blanks of iron and steel enterprise

ActiveCN102651114BImprove match qualityReduce cutting lossLogisticsComputer aided designMathematical modelStructural engineering

A re-matching method of slab-order for improving slab utilization in iron and steel plants, comprising the steps of Step 1: formulating a mathematical model according to information of slabs and orders, so as to quantitatively describe the optimization problem of slab-order matching; Step 2: dividing the slabs and orders into groups; Step 3: generating a new slab-order matching relationship for each group of slabs and orders by using a multiple neighborhoods based tabu search algorithm on the basis of the formulated mathematical model, tries to re-optimize the matching relationship with consideration of the original slab-order matching relationship and the load balance of all equipment units, so as to improve the slab-order matching relationship, decrease the slab cutting loss, reduce the redundant slab weight of each order, and improve the integrity of an order, thus improving slab utilization, ensuring to deliver an urgent order on time, and improving the customer satisfaction.

Owner:NORTHEASTERN UNIV LIAONING

Solar cell capable of reducing cutting loss and preparation method

PendingCN112490312AReduce cutting lossImprove conversion efficiencyFinal product manufacturePhotovoltaic energy generationElectrical batteryEngineering

The invention discloses a solar cell capable of reducing cutting loss and a preparation method, one side of the solar cell with an emitter is provided with a plurality of strip-shaped pre-cutting windows, and the pre-cutting windows are grooves formed on the surface of the emitter in a laser scribing or corrosive slurry printing manner. According to the battery piece structure disclosed by the invention, the PN junction at the cutting part is removed by presetting the pre-cutting window, so that the cutting loss of a finished battery during cutting is greatly reduced, the conversion efficiencyof the strip-shaped battery unit obtained after cutting is improved, and finally the output power of the module is improved; the proportion of the depth of the pre-cutting window to the thickness ofthe solar cell is small, and the mechanical performance, such as the fragment rate, of the cell piece in the subsequent process is not influenced; and the preparation method can be realized by utilizing the existing laser slicer and screen printer resources, so that the utilization rate of equipment is improved, and the cost is reduced to a certain extent.

Owner:CHANGZHOU SHICHUANG ENERGY CO LTD

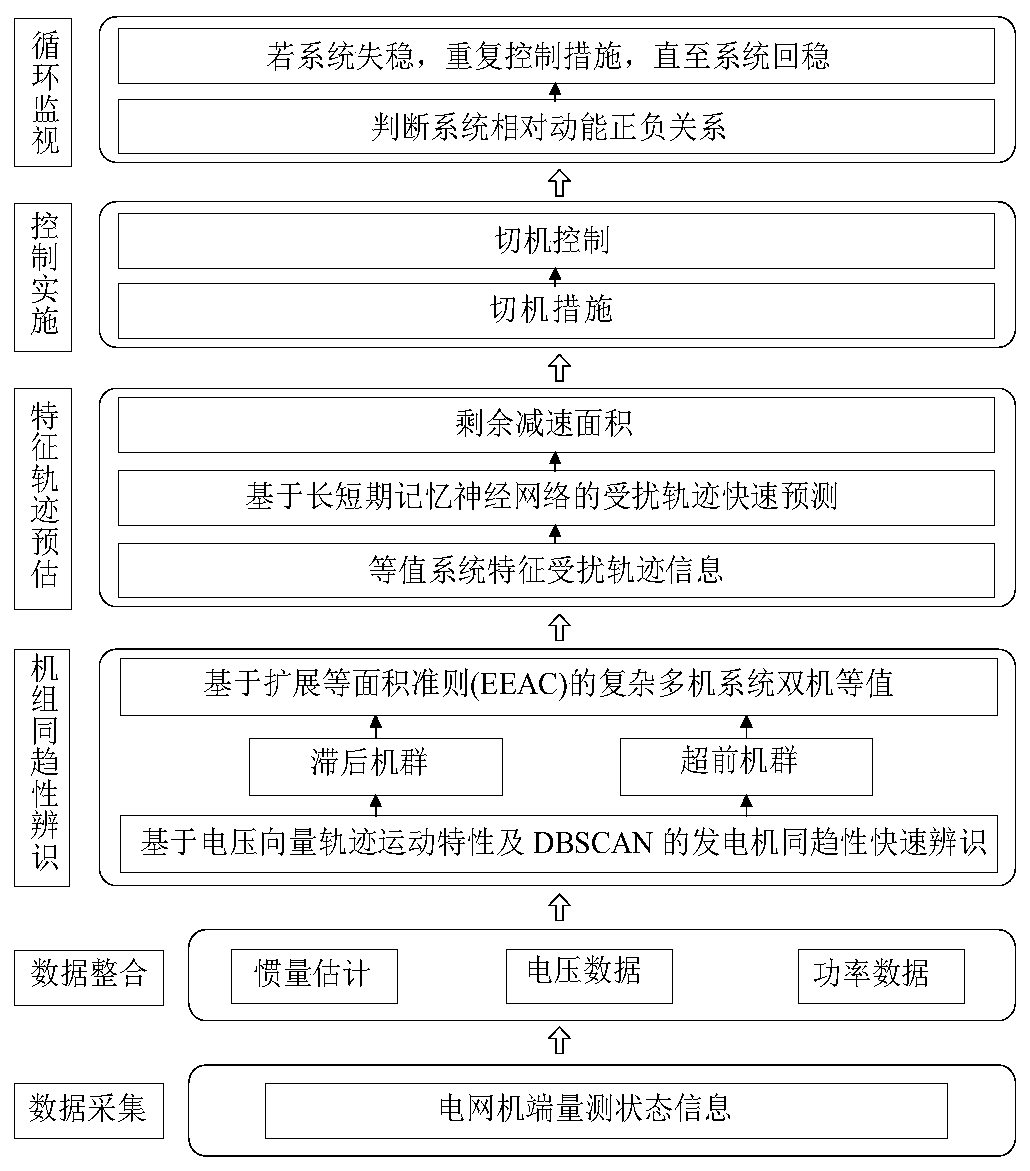

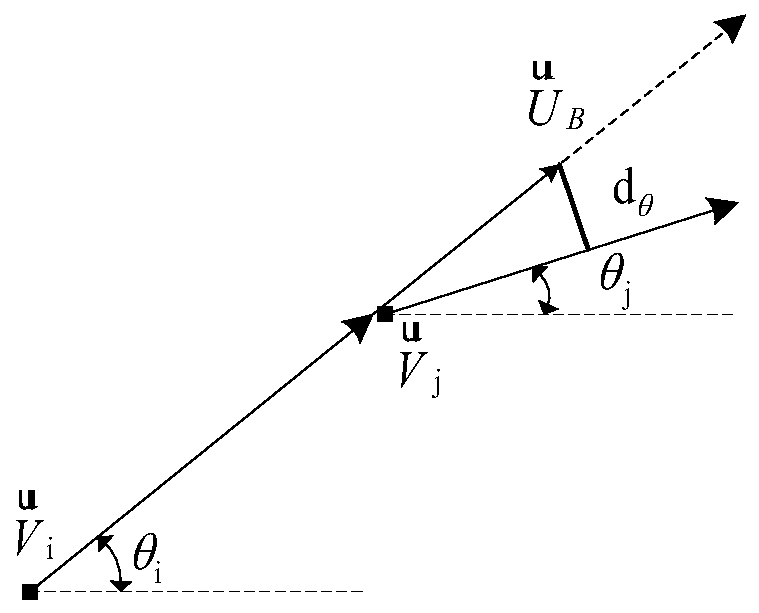

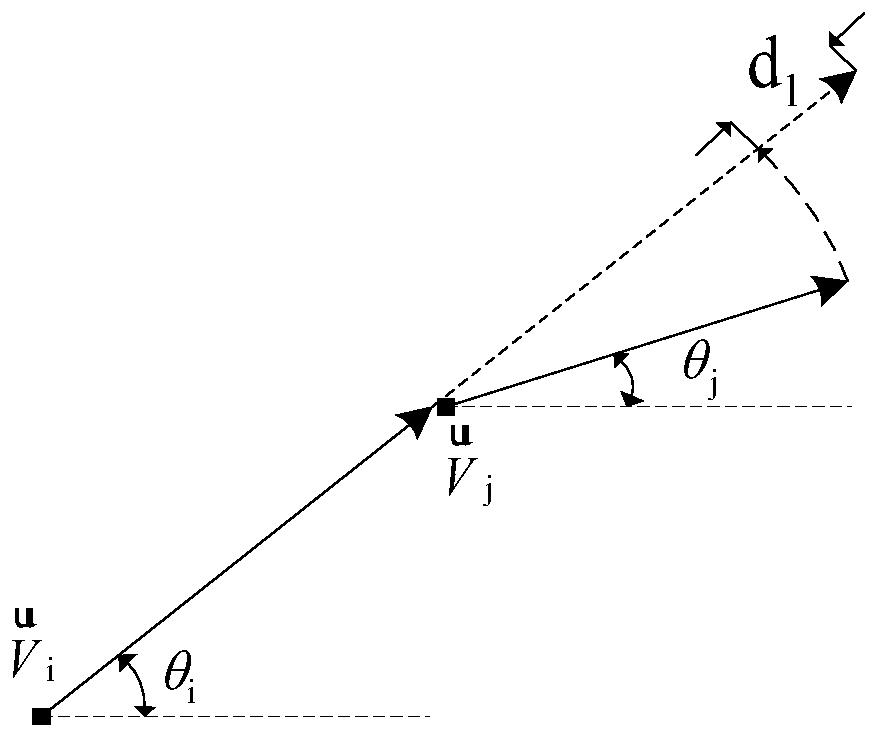

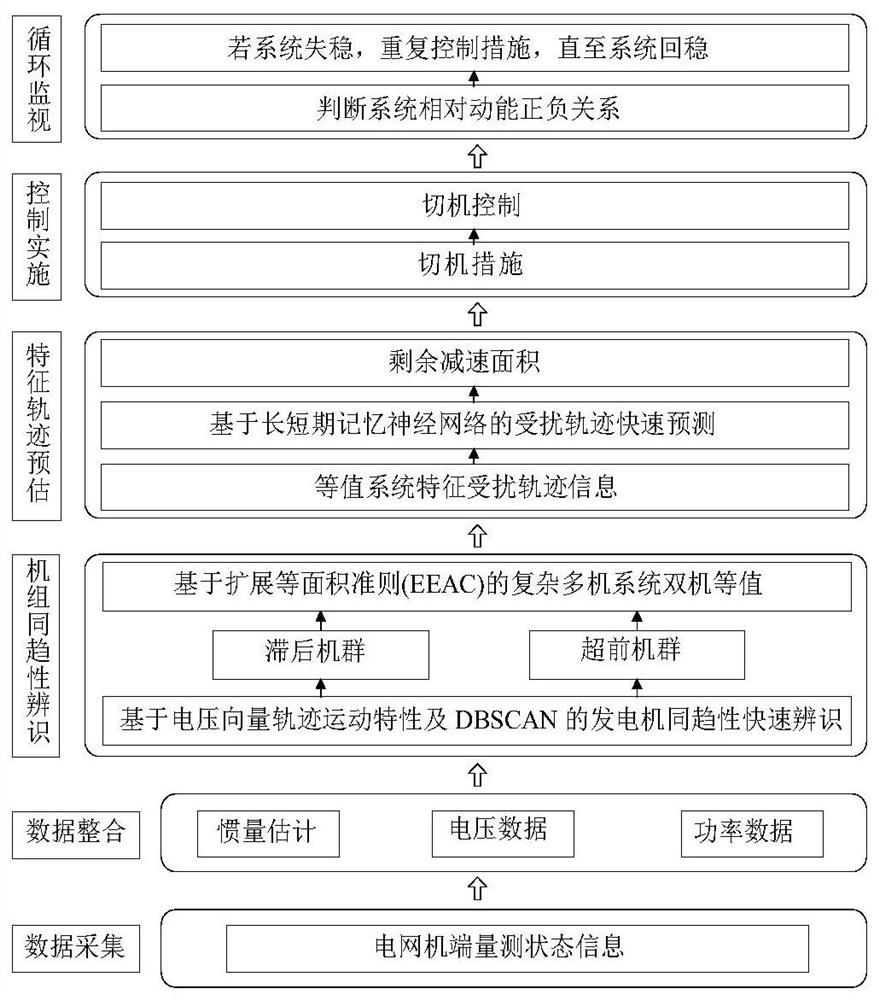

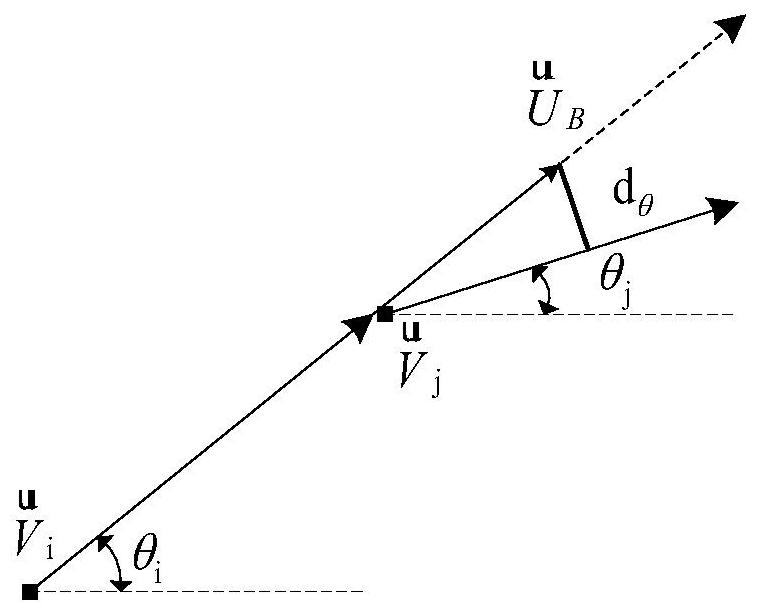

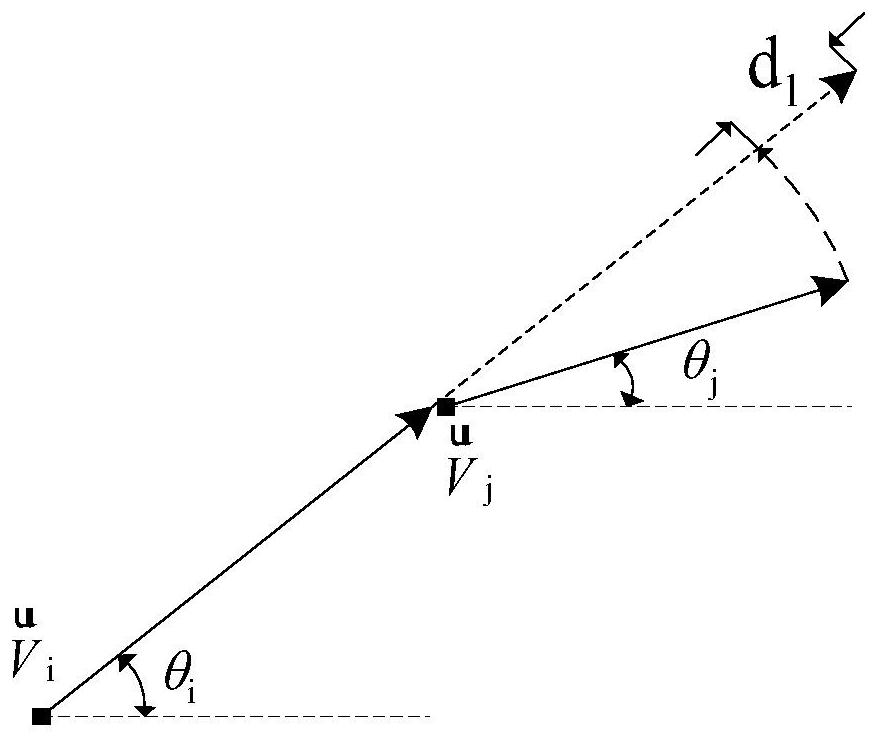

Power grid dynamic track trend prediction method based on long-term and short-term memory network

The invention discloses a power grid dynamic track trend prediction method based on a long-term and short-term memory network. The method is characterized by firstly, aiming at a geometrical characteristic of a voltage time sequence vector track, extracting a time sequence evolution rule of a node state, and quickly identifying a same tropism of a system generator; secondly, rapidly predicting a disturbed track of an equivalent machine system based on the long-term and short-term memory network; and finally, calculating a generator tripping amount according to an extended equal-area criterion,and realizing emergency control of transient power angle stability. The method has advantages of scientific and reasonable performance, high applicability and the like.

Owner:NORTHEAST DIANLI UNIVERSITY

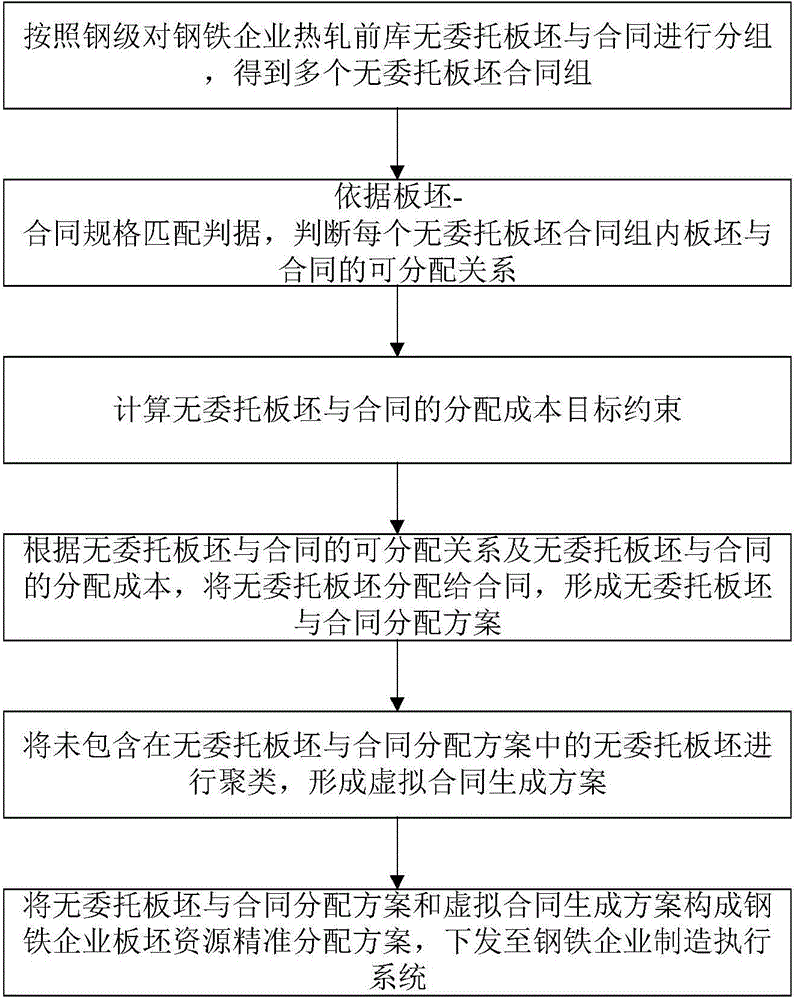

Accurate distribution method for slab resources of iron and steel enterprise

The invention provides an accurate distribution method for slab resources of an iron and steel enterprise. The method comprises the steps that hot rolling front-warehouse non-order slabs of the iron and steel enterprise and contracts are grouped; the distribution relation of the slabs and the contracts in each non-order slab contract set is judged; the distribution cost goal constraint of the non-order labs and the contracts is calculated; the non-order slabs are distributed to the contracts, and a non-order slab and contract distribution scheme is formed; the non-order slabs which are not included in the non-order slab and contract distribution scheme are clustered to form a virtual contract generating scheme, and the virtual contract generating scheme is issued to a manufacturing execution system of the iron and steel enterprise. The problems that due to the fact that the non-order slabs in the iron and steel enterprise are high in inventory and low in utilization rate, inventory cost is high, and the slab shear amount is large are solved, the utilization rate of the non-order slabs is improved, meanwhile, a large amount of energy waste caused by repeated steelmaking is reduced, the shear amount and inventory of the slabs are reduced, and a large amount of production and storage cost is saved for the enterprise.

Owner:NORTHEASTERN UNIV

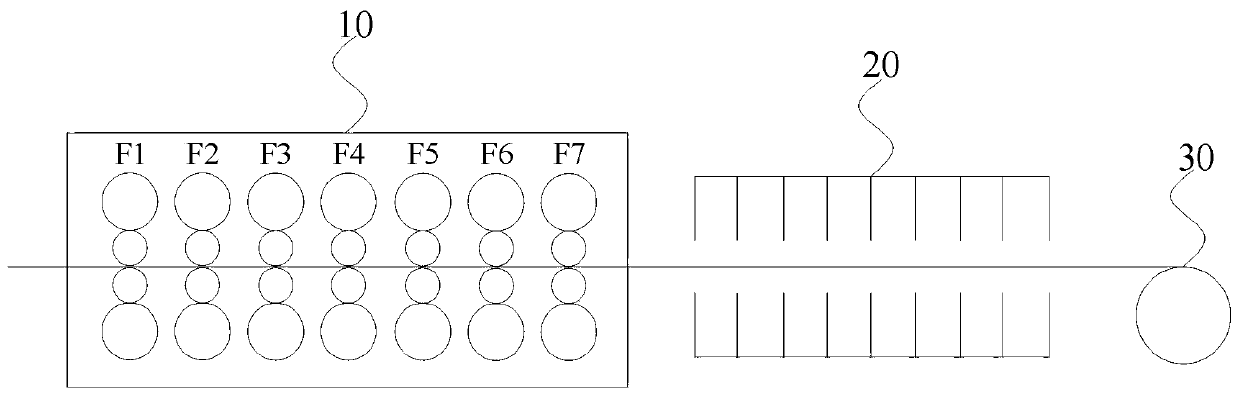

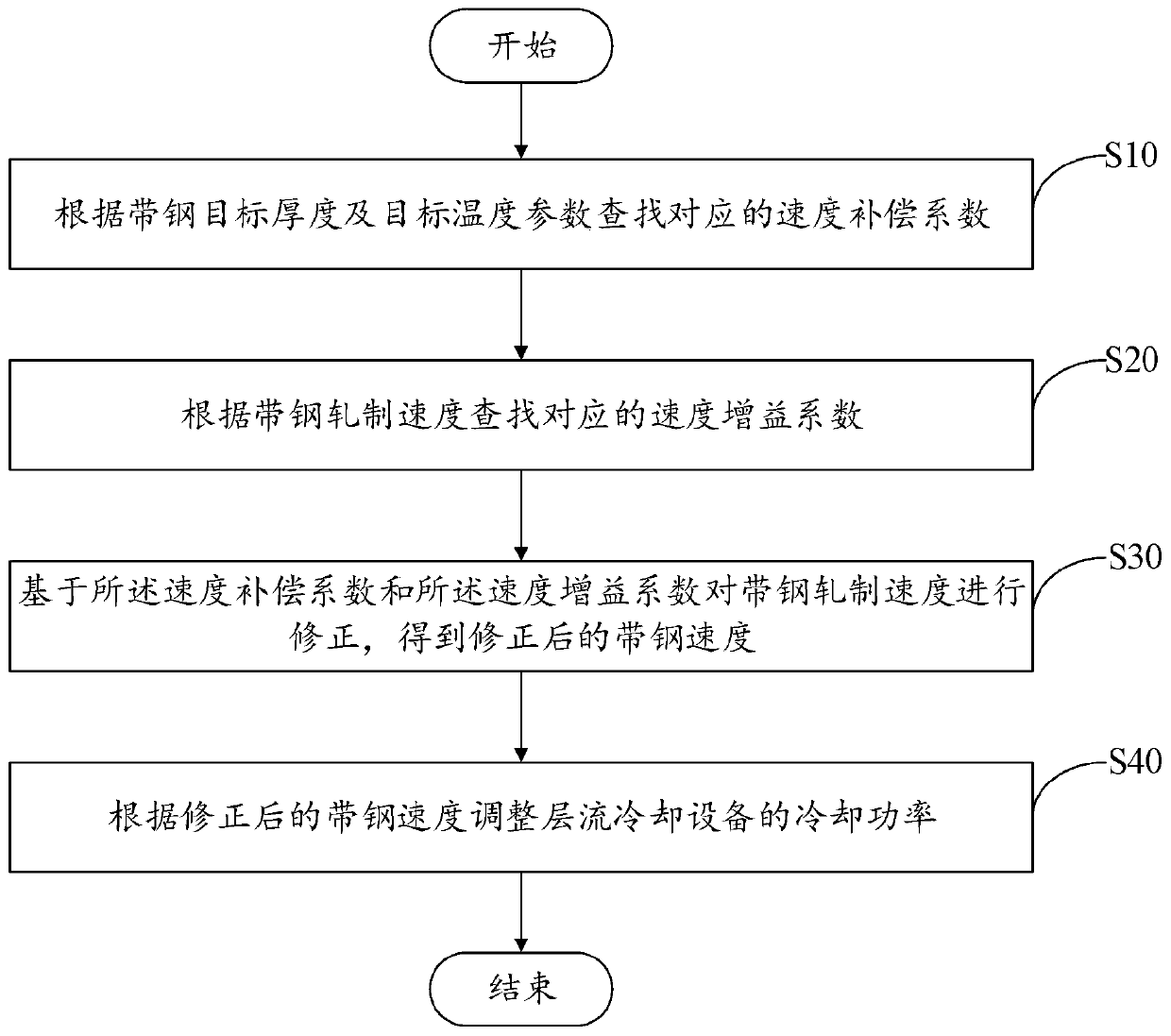

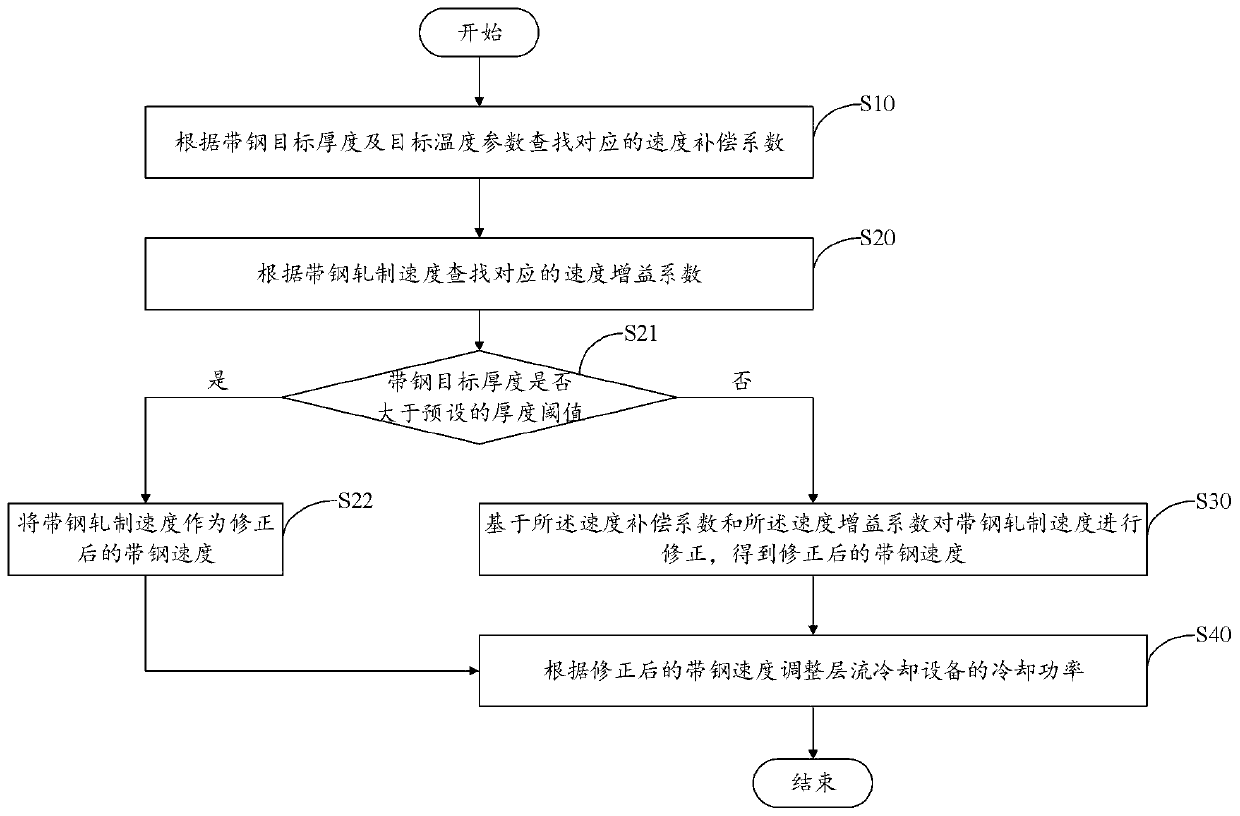

Strip steel winding temperature control method and device and strip steel machining system

ActiveCN110340156AReduce cutting lossTemperature control deviceMeasuring devicesTemperature controlLaminar cooling

The invention discloses a strip steel winding temperature control method and device and a strip steel machining system, and relates to the technical field of strip steel production. The method comprises the steps that a corresponding speed compensation factor is looked up according to the target thickness and target temperature parameters of strip steel; a corresponding speed gain coefficient is found from a second corresponding table according to the strip steel rolling speed; the strip steel rolling speed is corrected based on the speed compensation factor and the speed gain coefficient, andthe corrected strip steel speed is obtained; and according to the corrected strip steel speed, the cooling efficiency of laminar cooling equipment is adjusted. Through the method, dynamic regulationof the cooling efficiency of the laminar cooling equipment can be achieved according to the strip steel rolling speed, accordingly, the situation that the difference between the tail winding temperature and the front section winding temperature of the strip steel is too large due to steel throwing is avoided, and the cutting loss of the strip steel is decreased.

Owner:SHOUGANG JINGTANG IRON & STEEL CO LTD

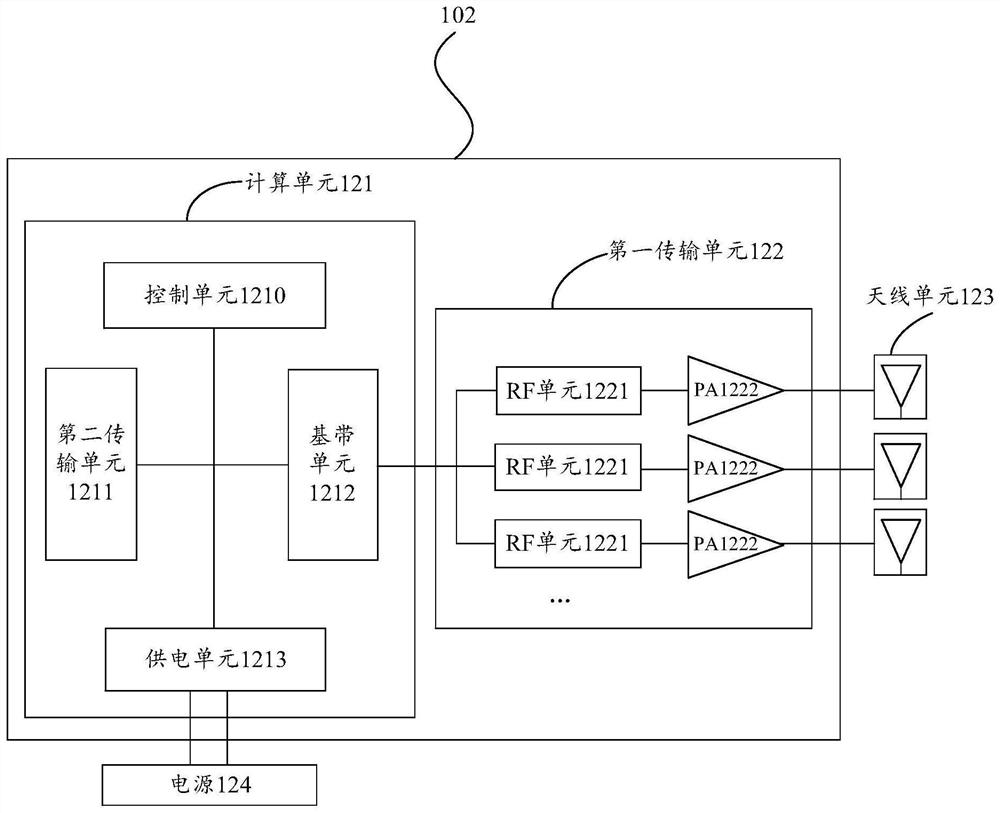

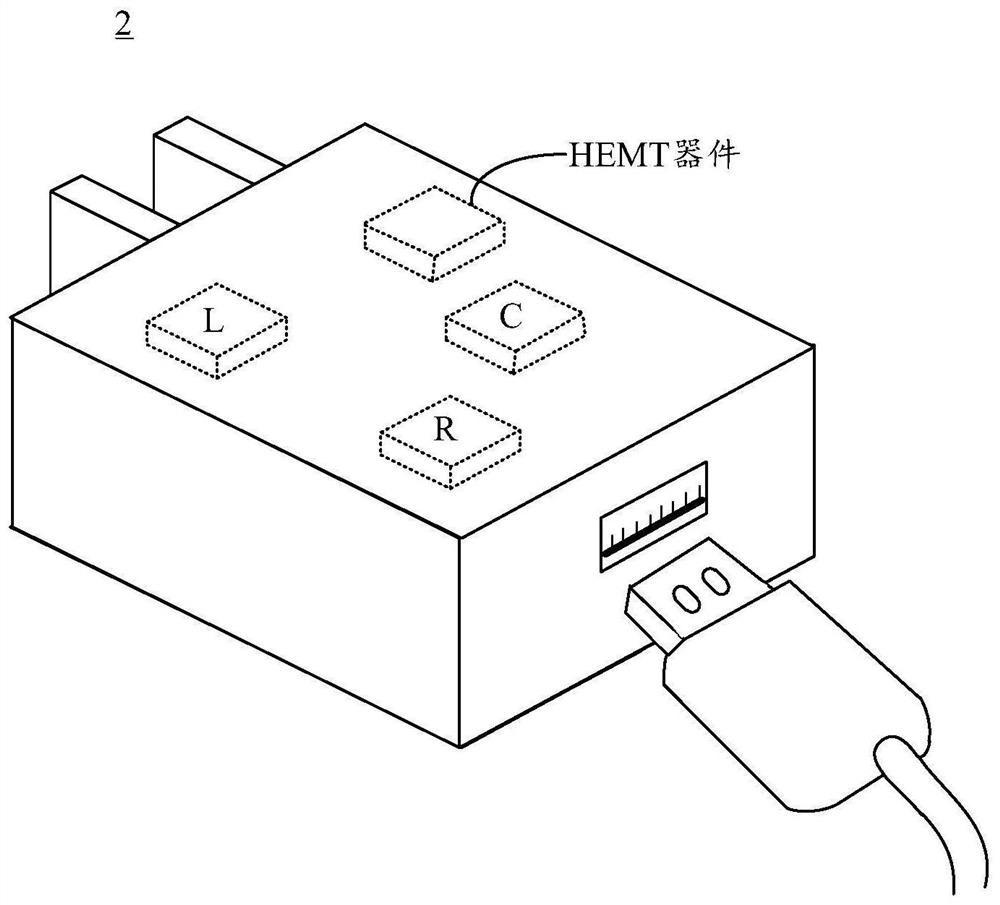

Composite substrate and preparation method thereof, semiconductor device and electronic equipment

PendingCN113658849AIncrease profitReduce cutting lossSemiconductor/solid-state device manufacturingSemiconductor devicesCarbide siliconDevice material

The embodiment of the invention provides a composite substrate and a preparation method thereof, a semiconductor device and electronic equipment, relates to the technical field of semiconductors, and is used for solving the problem of high cost of an AlxGayN-based semiconductor device due to high cost of SiC. The composite substrate comprises a bearing layer, a silicon carbide layer and at least one epitaxial layer, wherein the silicon carbide layer is arranged on the bearing layer and is bonded with the bearing layer; and the material of the silicon carbide layer comprises monocrystalline silicon carbide. At least one epitaxial layer is arranged on one side of the silicon carbide layer away from the bearing layer.

Owner:HUAWEI TECH CO LTD

Method for reducing cutting thickness of solar polycrystalline silicon chip

InactiveCN103692564ASmall cutting resistanceImprove cutting efficiencyFine working devicesEconomic benefitsSilicon chip

The invention discloses a method for reducing the cutting thickness of a solar polycrystalline silicon chip. The structure of a guide wire groove is improved by adopting a small-diameter special cutting steel wire, the cutting steel wire can be cooled, the groove distance of the guide wire groove can be shortened, silicon carbide particles in mortar are polygon bodies of which the particle diameter is 8.2-8.6 mum, and the thickness of the solar silicon chip is reduced by mating three technical schemes. According to the method disclosed by the invention, not only can the thickness of the silicon chip be reduced, but also the processing accuracy of the silicon chip can be increased, the chip obtaining rate can be increased to a large extent, the cutting steel wire cannot rupture even the diameter of the cutting steel wire is small, the cutting efficiency is high, the cutting gap is small, the mortar using amount is less, the cutting loss of a silicon bar can be reduced, the chip obtaining rate can be increased, the production cost can be reduced, and the economic benefit is very significant.

Owner:JIANGSU ZHAOJING PHOTOELECTRIC TECH DEV

Cutting method of silicon carbide crystal

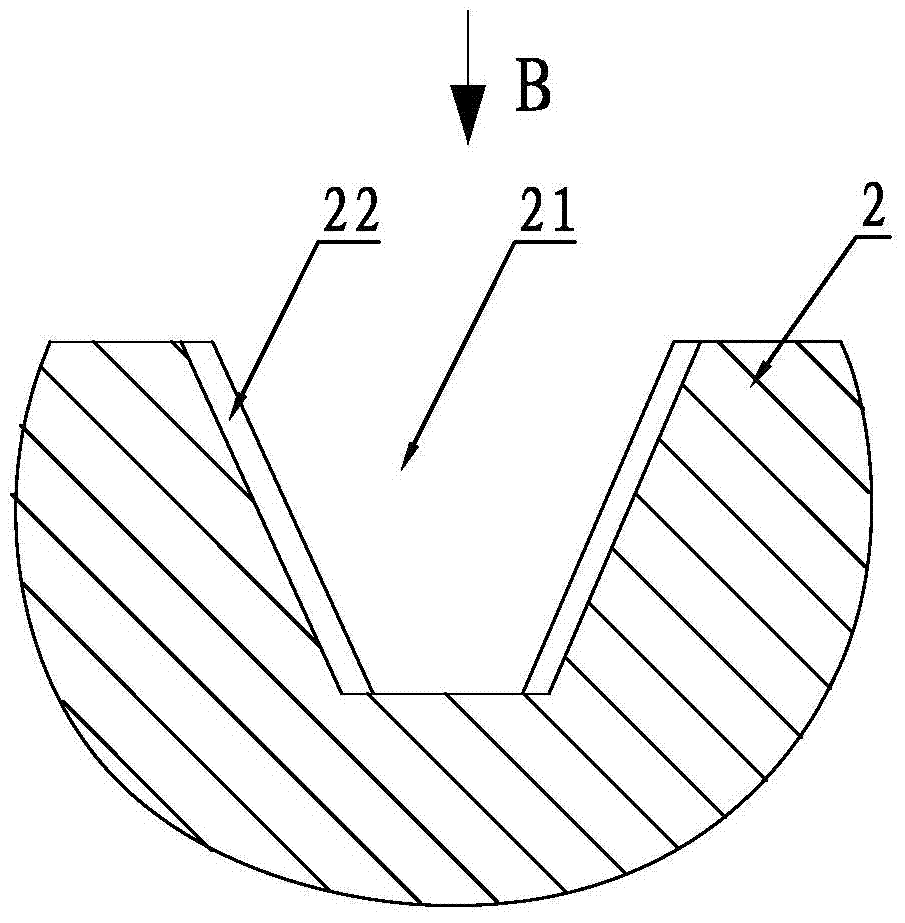

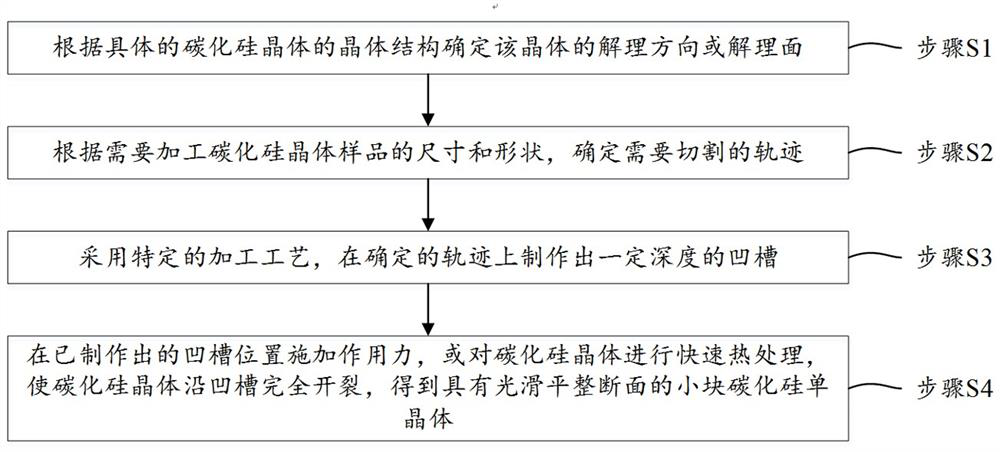

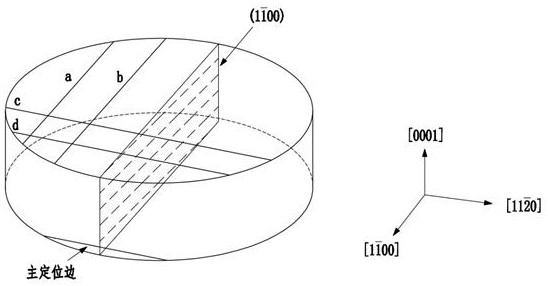

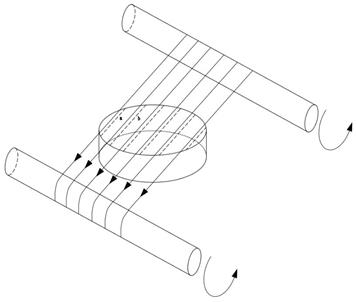

PendingCN113334592AAdvantages of cutting methodIncrease profitPolycrystalline material growthAfter-treatment detailsCarbide siliconCrystal structure

The invention discloses a cutting method of a silicon carbide crystal, and relates to the technical field of silicon carbide crystals. The cutting method is used for solving the technical problems of high cost, low efficiency and rough cutting surfaces of an existing silicon carbide cutting method. The cutting method of the silicon carbide crystal comprises the following steps that a cleavage direction or a cleavage surface of the crystal is determined according to a specific crystal structure of the silicon carbide crystal; according to the size and shape of a silicon carbide crystal sample needing to be processed, a track needing to be cut is determined; a groove with a certain depth is manufactured on the determined track by adopting a specific processing technology; and acting force is applied to the position of the manufactured groove, or rapid heat treatment is carried out on the silicon carbide crystal, so that the silicon carbide crystal is completely cracked along the groove, and a small silicon carbide single crystal with a smooth and level section is obtained.

Owner:HEBEI SYNLIGHT CRYSTAL CO LTD

A profile and pipe cutting machine

ActiveCN106313160BImprove flatnessIncrease production capacityMetal working apparatusEngineeringKnife blades

The invention provides a cutting machine for profiles and pipes. The cutting machine comprises a first base, a second base and a cutting machine body. A sliding rod is arranged on the first base. The second base can slide leftwards and rightwards on the sliding rod. The second base is provided with a sliding groove used for forward and backward sliding of the cutting machine body, and a positioning air cylinder. The positioning air cylinder is connected with the cutting machine body. A sliding block which is in sliding fit with the sliding groove in the second base is arranged at the bottom of the cutting machine body. A machine head is arranged on the cutting machine body. Lifting air cylinders are arranged on the two sides of the machine head. Two blades and a rotating motor used for driving the blades to rotate are arranged on the machine head. A flat cutting edge and a sawtooth type cutting edge are formed on two corresponding sides of each blade correspondingly. A single-blade or double-blade sharp knife is arranged at one end of each blade. The two blades are fixedly arranged on a rotary shaft with the included angle between the two blades being 180 degrees, and the identical cutting edges of the two blades are in the same direction. A U-shaped silencing structure is arranged at the front end of the machine head. The cutting machine for profiles and pipes is simple in structure, capable of reducing cost, high in cutting capacity and low in nose, and little sawdust is generated.

Owner:CHANGSHA KENBEI TECH

Cutting method for reducing cutting loss of LED chip

ActiveCN112151642AEasy to dry etchReduce lossesSemiconductor/solid-state device manufacturingSemiconductor devicesEngineeringPhotoresist

The invention discloses a cutting method for reducing the cutting loss of an LED chip. The method comprises steps of firstly carrying out the half-cutting of a P surface of the chip, carrying out thetesting through a testing machine, and facilitating the output of photoelectric parameters, such as brightness, voltage and wavelength, of the chip; coating photoresist on the P surface of the chip byusing a spin coater to form a shielding film, exposing and developing the P surface of the chip, and corroding and exposing a cutting channel; coating photoresist on the N surface of the chip to protect the metal on the N surface and facilitate subsequent dry etching; washing off the shielding film on the P surface, pasting a blue film, finally washing off the adhesive film on the N surface, pouring the film, and finishing the cutting operation. According to the cutting method for reducing the cutting loss of the LED chip, the N-surface adhesive film design is utilized, and dry etching is matched, so situations of edge breakage, wafer flying and the like during chip cutting are effectively avoided, cutting loss of the chip is reduced, meanwhile, light emitting efficiency of tube core particles is guaranteed, the product yield is increased, and practicability is high.

Owner:SHANDONG INSPUR HUAGUANG OPTOELECTRONICS

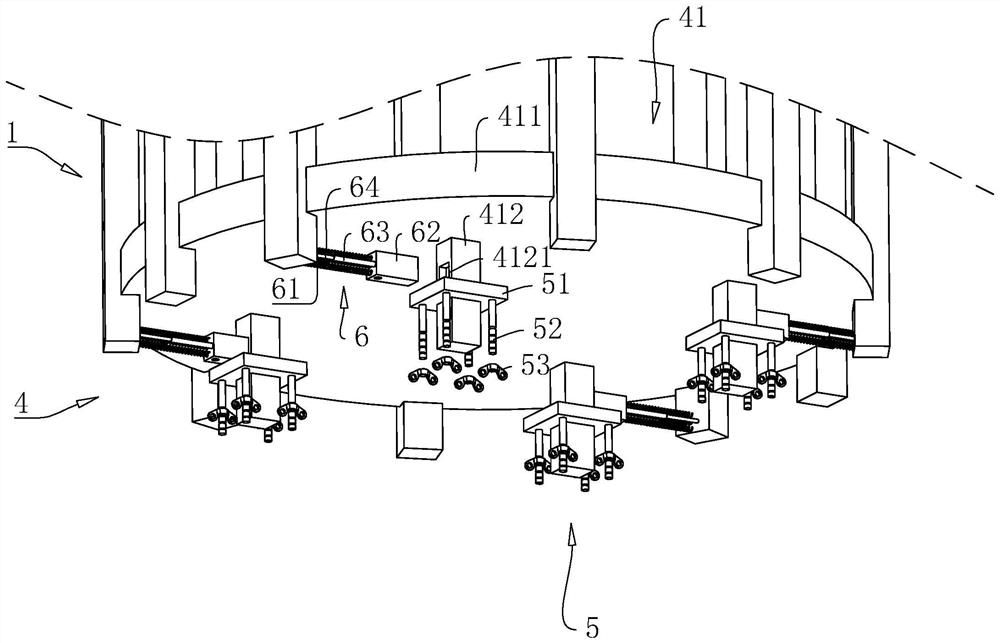

Ultrahigh-pressure water jet device for cutting reinforced concrete slab and using method thereof

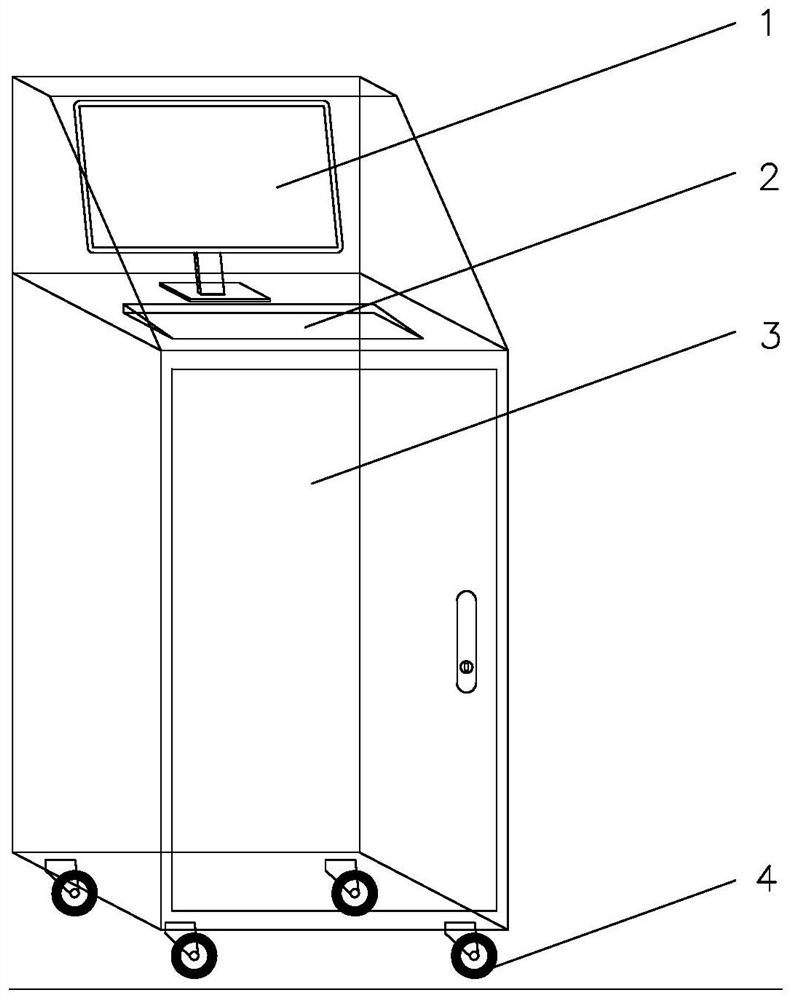

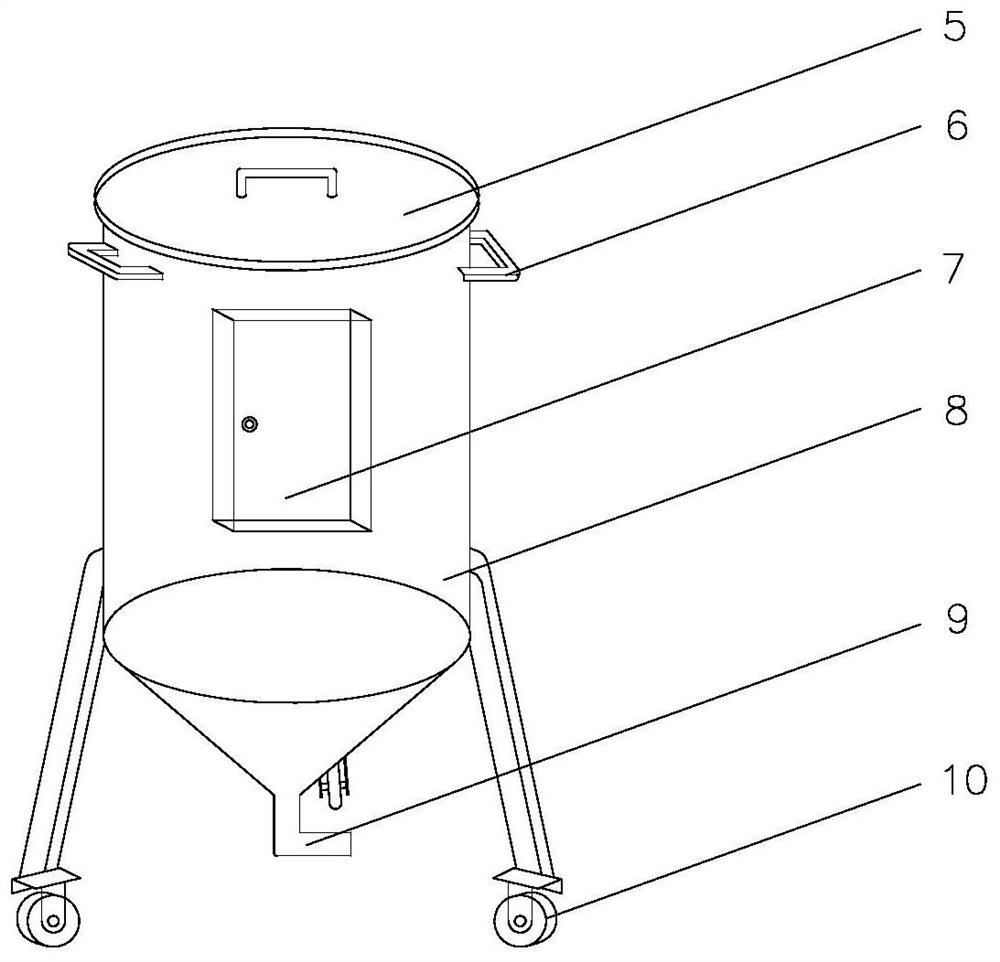

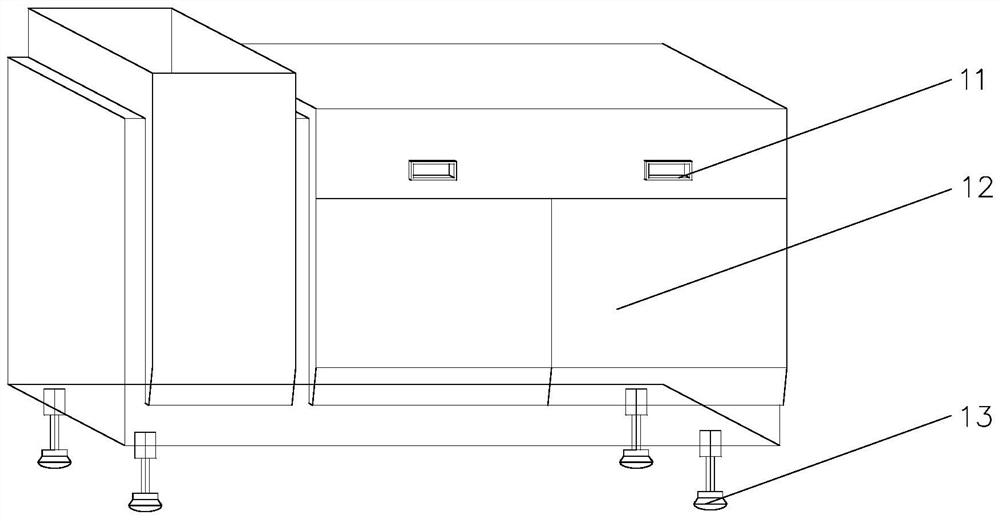

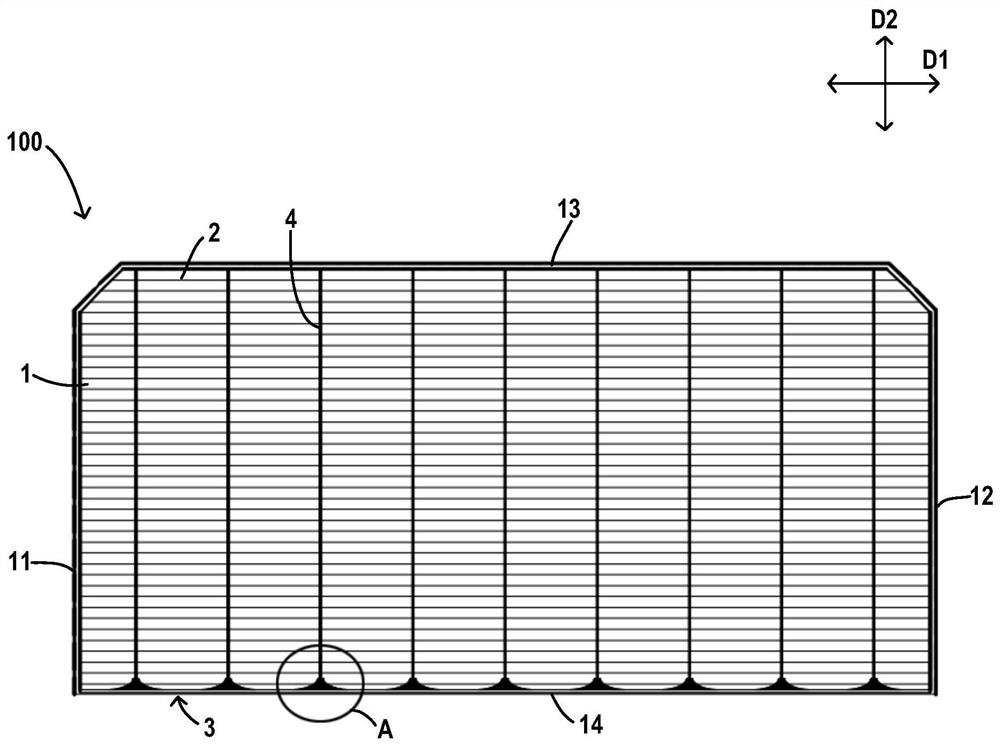

The invention discloses an ultrahigh-pressure water jet device for cutting a reinforced concrete slab. The ultrahigh-pressure water jet device is characterized in that the device comprises a numericalcontrol system, an automatic sand supply system, an ultrahigh-pressure generator and a water cutting main machine; the numerical control system comprises a control computer, a keyboard, an operationplatform and rollers; the automatic sand supply system comprises a cover, a handle, a sand supply controller, a sand cylinder, a sand discharge hole and a roller foot stool; the ultrahigh-pressure generator comprises a monitoring hole, a pressurizing main machine and a foot support, the monitoring hole is located in the side face of the pressurizing main machine, and the foot support is located atthe bottom of the pressurizing main machine; and the water cutting main machine comprises a stable base, an X-direction workbench, an X-direction rail, an X-direction crawler belt disc, an X-direction crawler belt, an emergency brake, an X-direction pedestal, a Y-direction working bridge frame, a Y-direction crawler belt, a Y-direction rail, a water jet cutter arm, a sand tank and a water jet cutter spray head. By means of the ultrahigh-pressure water jet device, the problems of large current concrete cutting raised dust and noise, irregular cutting and the like can be effectively solved.

Owner:ZHEJIANG UNIV

Imbricated assembly and manufacturing method thereof

PendingCN112768546AImprove efficiencyReduce stressFinal product manufacturePhotovoltaic energy generationSolar batteryEngineering physics

The invention relates to an imbricated assembly and a manufacturing method thereof. The top surface and / or the bottom surface of each solar cell in the imbricated assembly are / is provided with: a plurality of auxiliary grid lines, wherein each auxiliary grid line extends along a first direction; imbricated conductive structures, wherein the imbricated conductive structures located on the top surfaces and the imbricated conductive structures located on the bottom surfaces are located at the two end portions of the solar cell pieces in a second direction respectively, and the imbricated conductive structures are configured in the mode that when the multiple solar cell pieces are arranged in the imbricated mode, the adjacent solar cells are conductively connected through an imbricated conductive structure; and a plurality of conductive strips, wherein each conductive strip is in contact with the plurality of auxiliary grid lines and the imbricated conductive structure. According to the solar cells in the imbricate assembly, efficiency loss caused by slicing of the cells can be avoided or reduced, and the problems that the auxiliary grid lines are too long and the transmission capacity is insufficient can also be avoided.

Owner:CHENGDU YEFAN SCI & TECH CO LTD

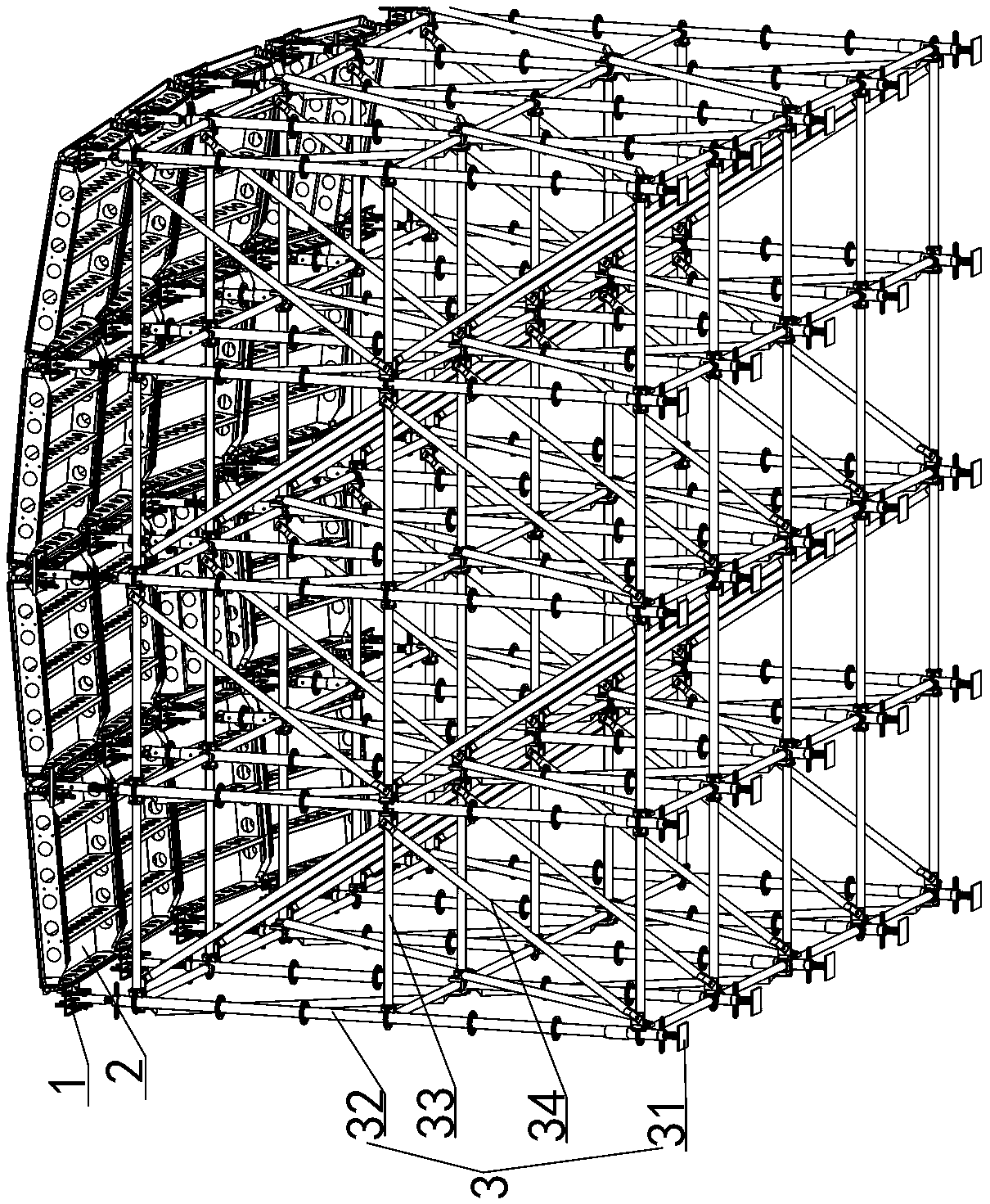

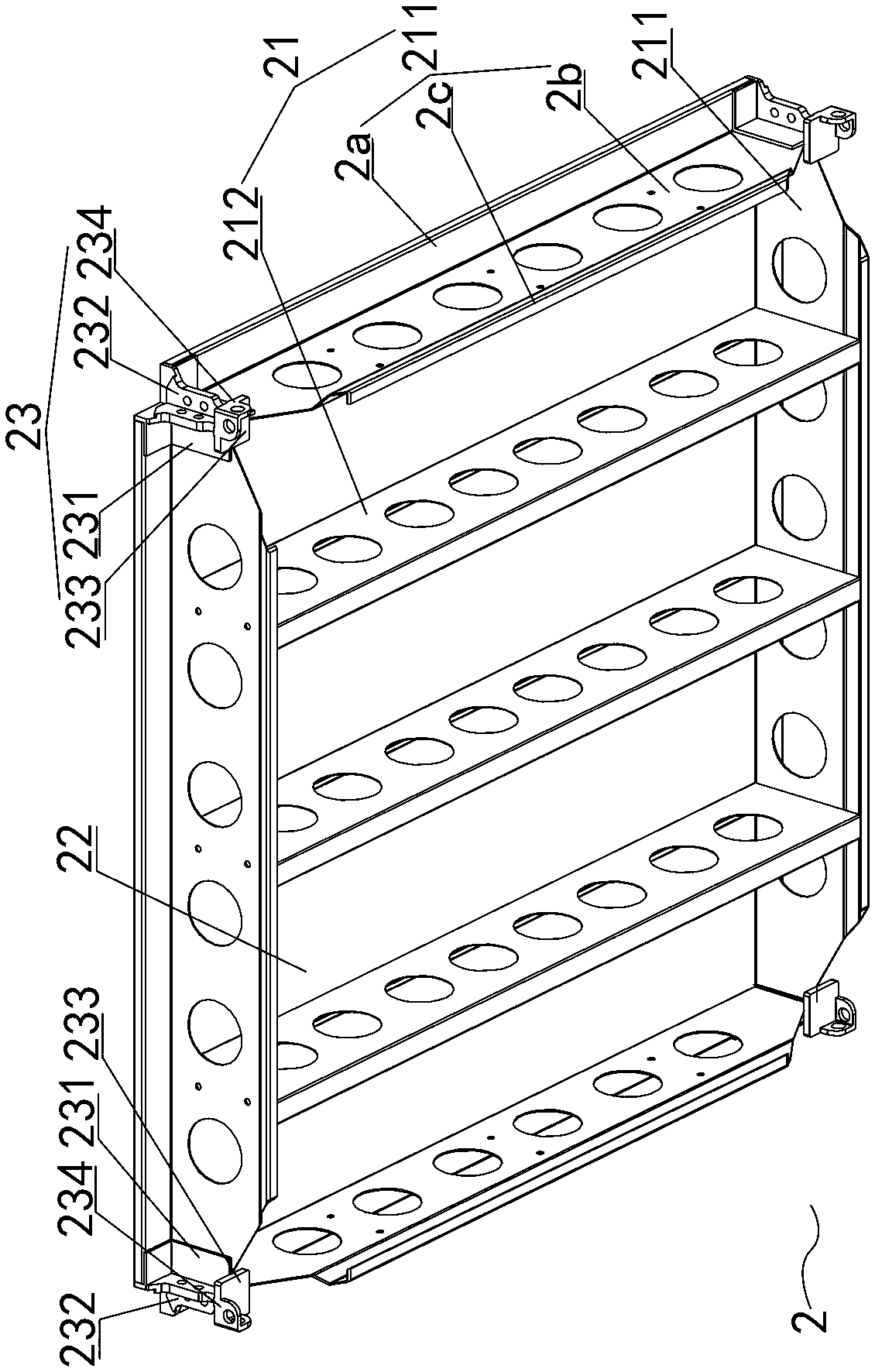

Cast-in-place gentle-gradient spatial curved roof formwork system and construction method thereof

PendingCN109372256AEasy to operateSave operating timeForms/shuttering/falseworksBuilding material handlingFalseworkKeel

The invention discloses a cast-in-place gentle-gradient spatial curved roof formwork system and a construction method thereof. The formwork system comprises a supporting structure and a panel structure; the supporting structure comprises a bottom all-round scaffold and a group of height-adjustable jacking and connecting assemblies, the number of the jacking and connecting assemblies is the same asthat of vertical rods, and the jacking and connecting assemblies are fixedly connected to the top ends of the vertical rods; and the panel structure is divided into a group of rectangular unit modules, each unit module comprises formwork keels, formwork panels and formwork connecting assemblies, the formwork connecting assemblies are fixedly connected to the four corners of each unit module, andthe formwork connecting assemblies of every four adjacent unit modules intersect at the same position and are located on the top of the same jacking and connecting assembly. The cast-in-place gentle-gradient spatial curved roof formwork system is suitable for a large-thickness curved roof of which the curvature change is irregular and the curved unit is approximately regarded as a plane and meetsthe designed curvature requirement. The construction method is high in operability, not only can meet the bearing force requirement, but also can be fitted with the curved surface curvature change, and has the very high market value.

Owner:CHINA CONSTR FIRST BUILDING GRP CORP LTD +1

A Thick Plate Continuous Casting Slab Cutting Control System and Its Optimization Calculation Method

The invention discloses a thick-slab continuous casting billet cutting control system, which utilizes thick-slab rolling mill to send commands to short billets, heat pouring process tracking signals and other data, and optimizes the billet grouping of short billets within the scope of the casting machine , to ensure that the slab is cut according to the optimal length of the long slab; a calculation method for optimizing the slab grouping of thick slab continuous casting slabs can successfully find the optimal slab strategy, and optimize the cutting control of the long slab within the range of the casting machine , to control the continuous casting online cutting machine to perform online one-time cutting, thereby reducing cutting scrap, supporting the integration and optimization of continuous casting and thick plate rolling mill efficiency, and improving the efficiency and effect of continuous casting machine billet cutting; the invention has a friendly user interface, It can reduce cutting loss, support scenarios such as single-strand casting, double-strand casting, and casting of different steel types from thick plates to furnaces, ensuring the maximum and optimization of casting machine performance.

Owner:BAOSHAN IRON & STEEL CO LTD

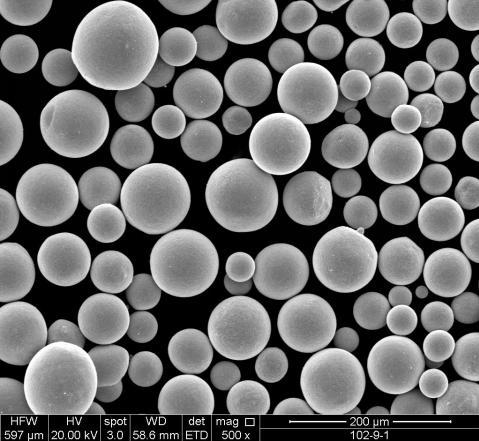

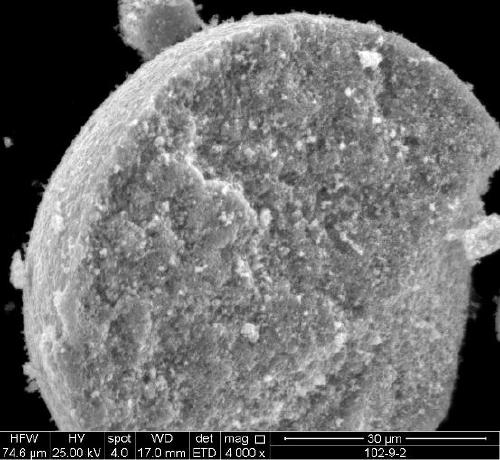

A method for preparing high-performance ito granulated powder

The invention provides a high-performance ITO granulation powder preparation method, which comprises: weighing indium oxide nanometer powder with a purity of more than 99.99% and tin oxide nanometer powder with a purity of more than 99.99% according to a mass ratio of 9:1, adding deionized water and a dispersing agent to prepare a slurry with a certain solid content, and carrying out ball milling with a sand mill to achieve a certain fineness; adding a binder and an antifoaming agent, and carrying out spray drying to obtain powder; adding cyclone powder, a certain amount of a dispersing agent and water to the powder to prepare a slurry with a certain solid content; and carrying out high speed dispersing, and carrying out spray drying to obtain the final granulation powder. According to the present invention, the prepare granulation powder has the solid sphere shape and the large bulk density, and the prepared indium tin oxide has the single-phase micro-particle dispersed state, has the characteristics superior to the agglomerated powder, has good fluidity and good gradation, and is beneficial for meeting the molding requirement of the high-end ITO target.

Owner:725TH RES INST OF CHINA SHIPBUILDING INDAL CORP

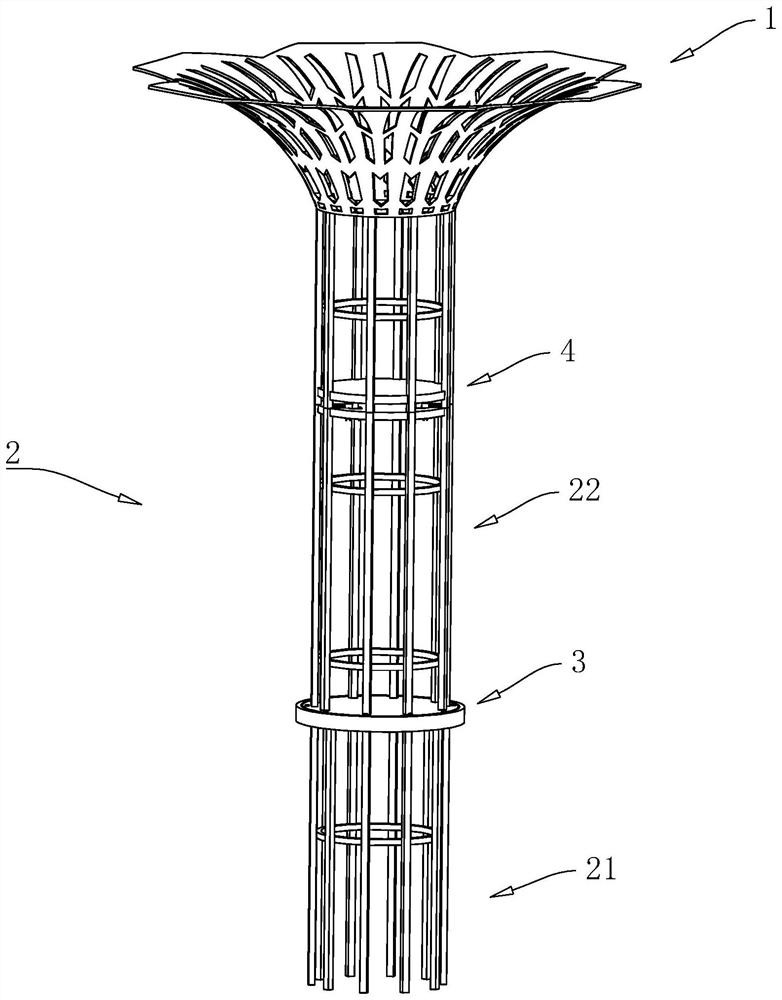

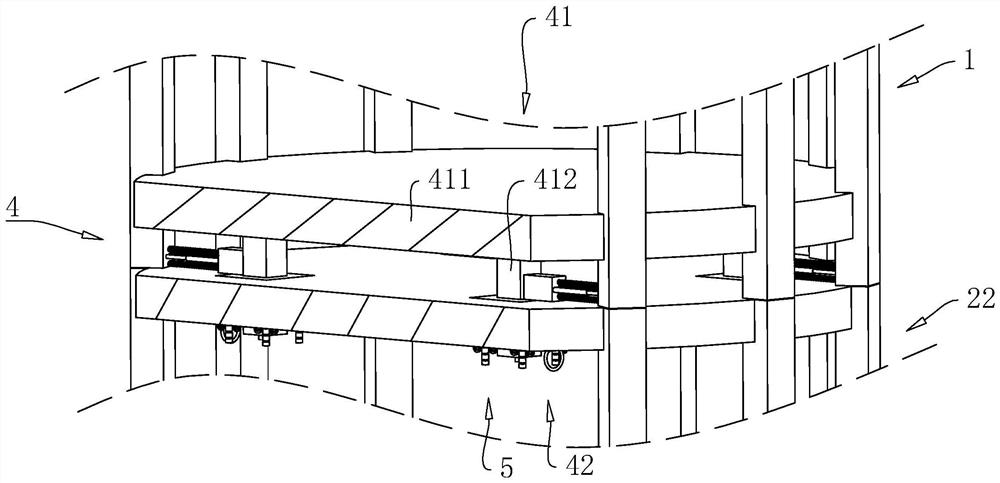

Steel structure landscape mushroom tree and installation method thereof

ActiveCN114876269AReduce installation inconvenienceImprove work efficiencyTowersBuilding material handlingTree trunkButt joint

The invention relates to a steel structure landscape mushroom tree and an installation method thereof, and relates to the technical field of landscape steel frames. The trunk part comprises a trunk I, a trunk II and a connecting assembly, and the trunk I is connected with the trunk II through the connecting assembly; a butt joint mechanism is arranged between the second trunk and the tree head part, and the butt joint mechanism comprises an inserting part and a bearing part; the inserting part comprises a top connecting plate, an inserting square column and a connecting piece, the top connecting plate is arranged on the tree head part, and the inserting square column is arranged on the top connecting plate; the bearing part comprises a bearing plate, the bearing plate is provided with a guide channel for the insertion square column to penetrate through, and the connecting piece is used for connecting the insertion square column and the bearing plate; the installation method comprises the following installation steps of splicing, positioning and butt joint. The mushroom tree mounting device has the effects of improving the mushroom tree mounting efficiency of constructors and being energy-saving and environment-friendly.

Owner:广州市林华园林建设工程有限公司

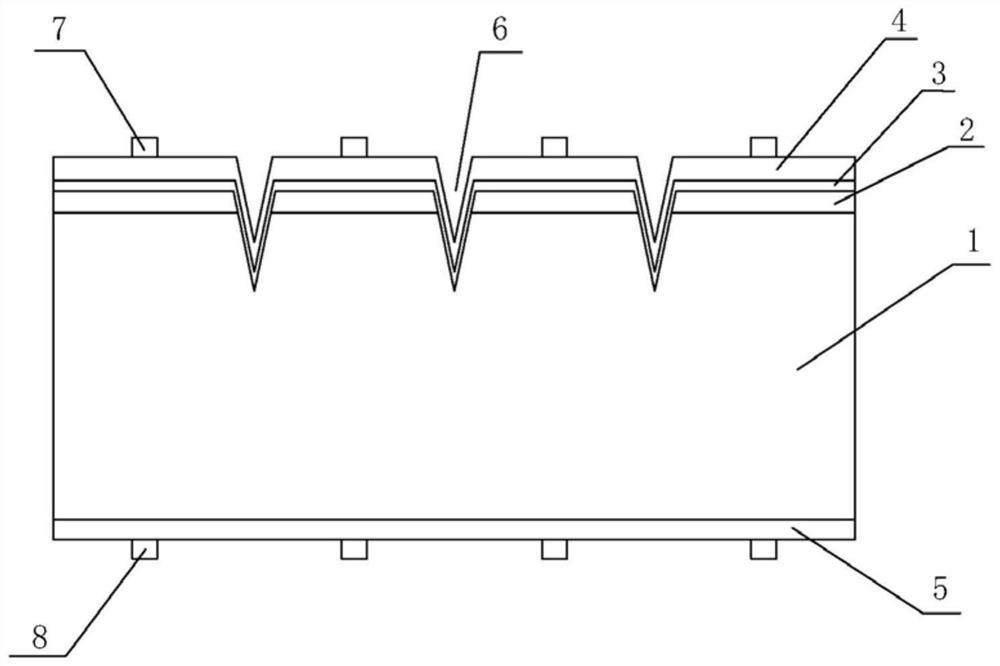

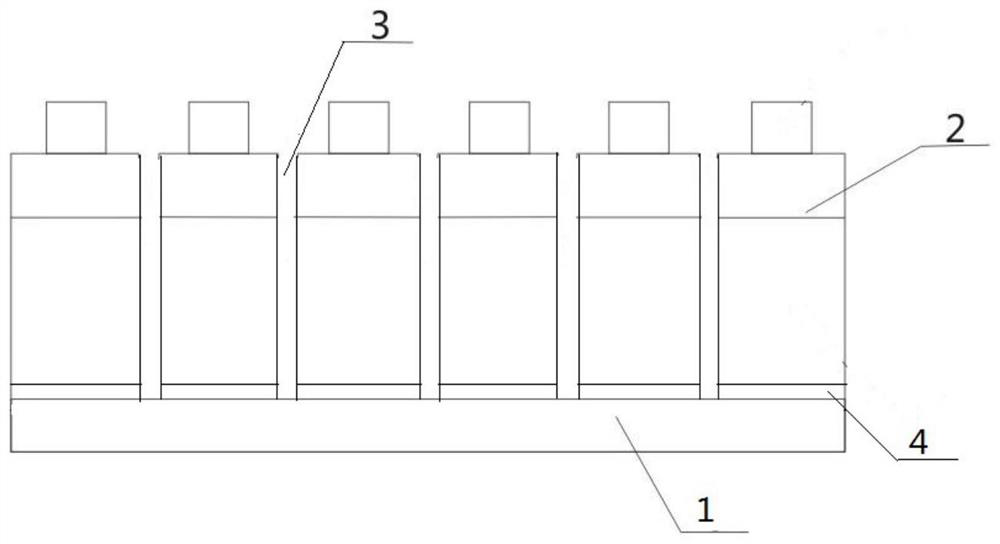

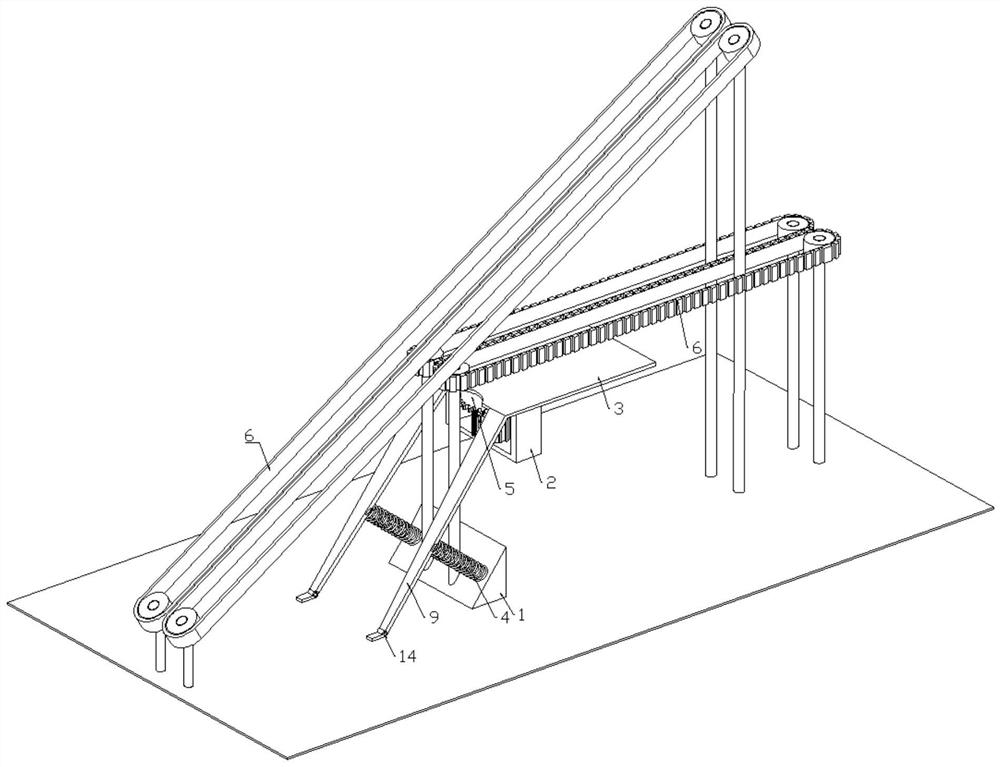

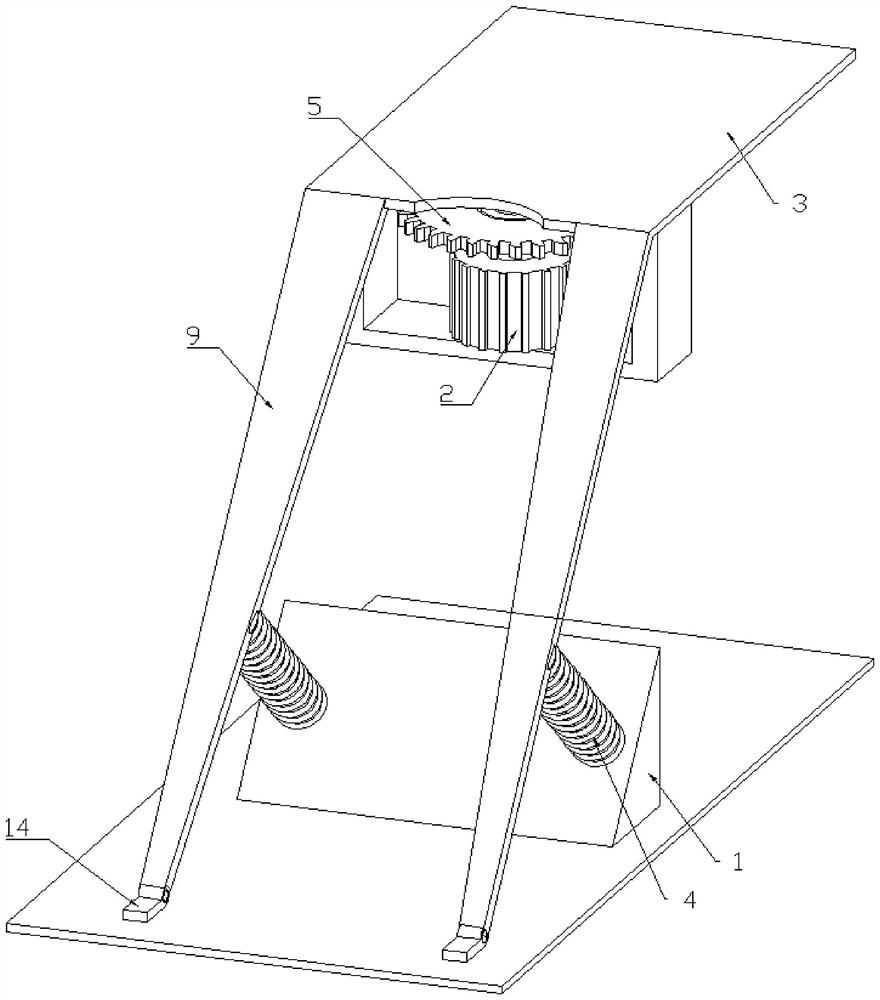

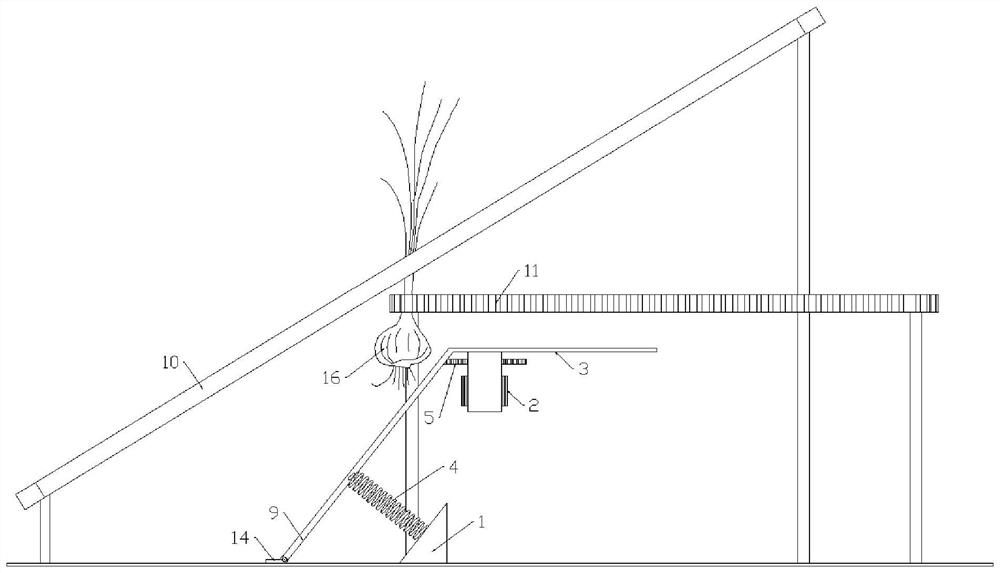

Elastic cutting system for modified root-tuber crops

PendingCN113854603AReduce cutting lossImprove economic efficiencyFood treatmentAgricultural engineeringTuber crops

The invention provides an elastic cutting system for modified root-tuber crops, and relates to the technical field of agricultural machinery. The elastic cutting system comprises a base and a driving device, wherein a floating plate is arranged above the base, an elastic supporting mechanism is arranged between the base and the floating plate, a first cutting knife is arranged at the bottom end of the floating plate, and the driving end of the driving device is connected with the first cutting knife; and the edge of the first cutting knife extends out of the edge of the floating plate, a clamping conveying belt is arranged above the floating plate, and the clamping conveying belt clamps the modified root-tuber crops to move towards the first cutting knife. According to the system, modified root crops can be automatically and mechanically cut, by arranging the combination of the floating plate and the elastic supporting mechanism, the floating plate can be forced to float up and down according to different sizes of modified rhizomes, so that the first cutting knife does not cut the modified roots while having a mechanical cutting function, the cutting loss is reduced, the cutting efficiency is improved, in addition, the economic benefits are increased, the structure is exquisite, and the practicability is extremely high.

Owner:王学堂

A method for predicting dynamic trajectory trend of power grid based on long short-term memory network

ActiveCN110635474BEfficient identificationSafe and stable operationAc network circuit arrangementsTransient statePredictive methods

The invention is a power grid dynamic trajectory trend prediction method based on a long-term and short-term memory network. Secondly, the disturbed trajectory of the equivalent machine system is quickly predicted based on the long short-term memory network; finally, the amount of machine cutting is calculated according to the extended equal area criterion to realize the emergency control of transient power angle stability. It has the advantages of scientific and reasonable method and strong applicability.

Owner:NORTHEAST DIANLI UNIVERSITY

A Cutting Method for Reducing Cutting Loss of LED Chips

ActiveCN112151642BEasy to dry etchReduce lossesSemiconductor/solid-state device manufacturingSemiconductor devicesPhotoresistDry etching

The invention discloses a cutting method for reducing the cutting loss of LED chips. The invention first cuts the P surface of the chip in half, and uses a testing machine to test, so as to facilitate the output of photoelectric parameters such as brightness, voltage, and wavelength of the chip; Coating photoresist on the P side of the chip to form a protective film, and then exposing and developing the P side of the chip to corrode and expose the cutting line; then coating the photoresist on the N side of the chip to protect the N side metal and facilitate Subsequent dry etching; wash off the protective film on the P side and paste the blue film, and finally wash off the adhesive film on the N side, pour the film, and end the cutting operation. The invention designs a cutting method for reducing the cutting loss of LED chips, which is designed by using the N-face adhesive film and combined with dry etching, which effectively avoids edge chipping and flying pieces during chip cutting, and reduces the chip cutting loss , At the same time, it also ensures the light extraction efficiency of the die core, improves the product yield, and has high practicability.

Owner:SHANDONG INSPUR HUAGUANG OPTOELECTRONICS

Features

- R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

Why Patsnap Eureka

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Social media

Patsnap Eureka Blog

Learn More Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com