A Thick Plate Continuous Casting Slab Cutting Control System and Its Optimization Calculation Method

A control system and billet assembly technology, applied in the field of automatic control of continuous casting and cutting

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

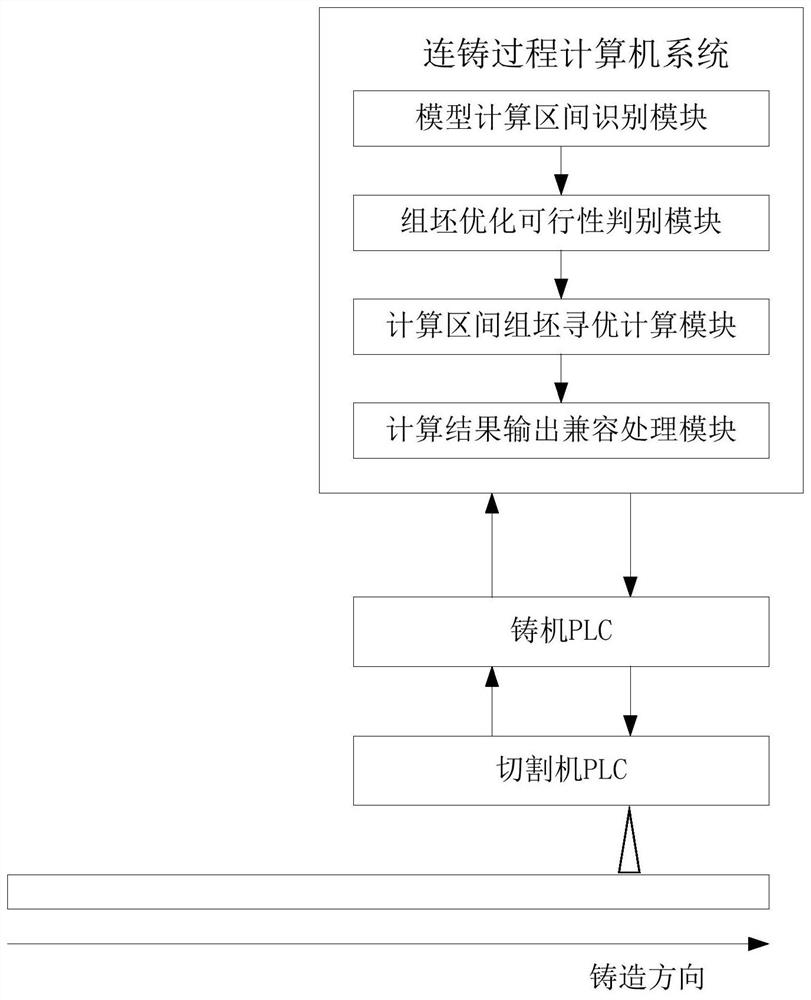

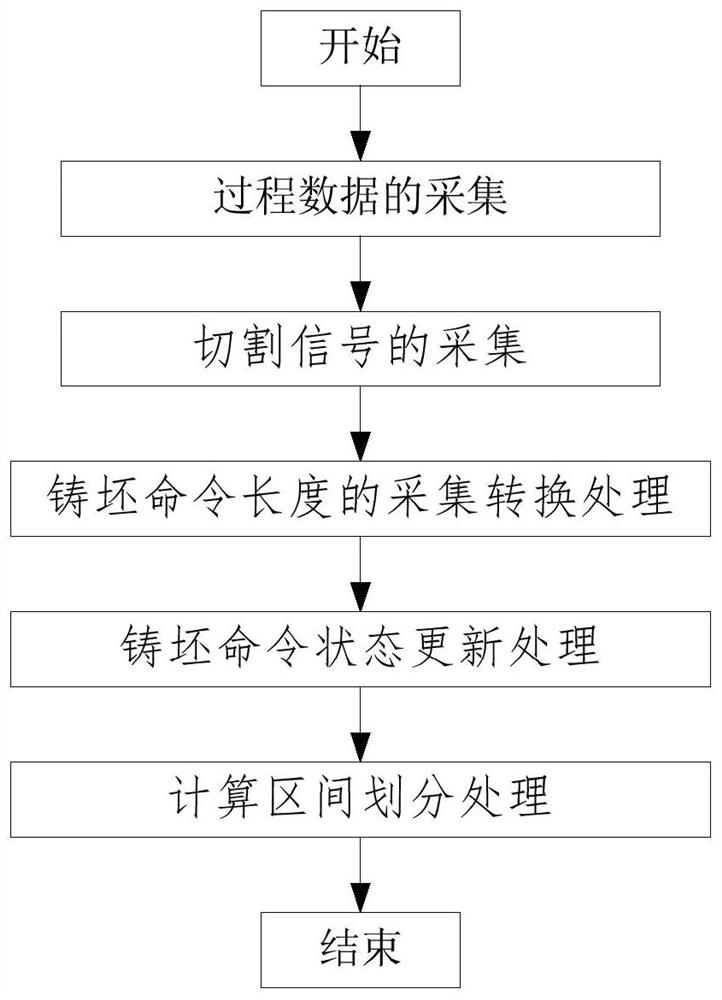

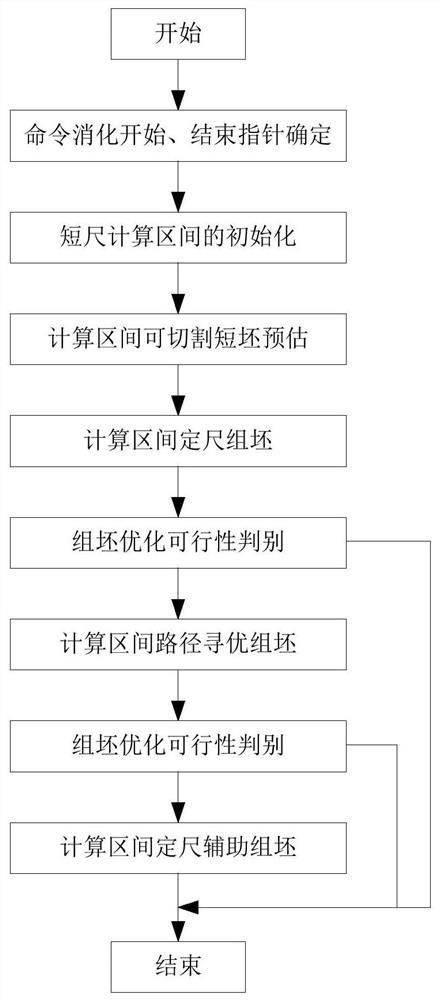

Method used

Image

Examples

Embodiment 1

[0193] Embodiment 1: the embodiment of fixed-length blank assembly

[0194] (1) The calculation interval [50552mm, 77147mm] is 26595mm long in total.

[0195] (2) Furnace order information

[0196]

[0197] (3) Estimation results of cuttable short billets in the calculation interval

[0198] Within the calculation interval, there are 9 short billets that can be digested.

[0199]

[0200] (4) The results of billet assembly to length

[0201] The billet grouping method with fixed length was adopted, and the billet grouping optimization feasibility judgment method was adopted to meet the billet grouping conditions, and 3 long billets were successfully assembled at the fixed length. The long blank length results are as follows:

[0202]

Embodiment 2

[0203] Embodiment 2: the embodiment of path optimization billet formation

[0204] (1) The calculation interval [33742mm, 71897mm] is 38155mm long in total.

[0205] (2) Furnace order information

[0206]

[0207]

[0208] (3) Estimation results of cuttable short billets in the calculation interval

[0209] Within the calculation interval, only 11 short billets can be digested.

[0210]

[0211] (4) The results of billet assembly to length

[0212] Using the fixed-length billet assembly method, after forming 4 long billets, there is still a surplus length of 4287mm, which is less than the equipment lower limit of 5800mm. Through the billet assembly optimization feasibility judgment method, the billet assembly conditions are not met, and the results are as follows:

[0213]

[0214] (5) path optimization billet assembly

[0215] A total of 12 billet assembly paths were generated by using the path optimization method, and the results are as follows:

[0216] ...

Embodiment 3

[0222] Embodiment 3: the embodiment of sizing auxiliary blank assembly

[0223] (1) The calculation interval [45552mm, 77147mm] is 31595mm long in total.

[0224] (2) Furnace order information

[0225]

[0226]

[0227] (3) Estimation results of cuttable short billets in the calculation interval

[0228] Within the calculation interval, there are 7 short billets that can be digested.

[0229]

[0230] (4) The results of billet assembly to length

[0231] Using the fixed-length billet assembly method, after forming 3 long billets, there is still a surplus length of 4595mm, which is less than the equipment lower limit of 5800mm. Through the billet assembly optimization feasibility judgment method, the billet assembly conditions are not met, and the results are as follows:

[0232]

[0233]

[0234] (5) path optimization billet assembly

[0235] Using the method of path optimization for billet assembly, a total of one billet path is generated, which is still th...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com