Patents

Literature

42results about How to "Reduce cut loss" patented technology

Efficacy Topic

Property

Owner

Technical Advancement

Application Domain

Technology Topic

Technology Field Word

Patent Country/Region

Patent Type

Patent Status

Application Year

Inventor

Non-groove rolling method for high speed wire bar intermediate rolling train

InactiveCN101152654AImprove work rateImprove productivityRoll force/gap control deviceTemperature control deviceReduction rateWire rod

The invention discloses a non-groove rolling method for high speed wire rod roughing mill group and mainly solves rolling technical problem of the high speed wire rod roughing mill group. The non-groove rolling method comprises two pass non-groove rolling, four pass non-groove rolling or six pass non-groove rolling; the ratio of height and width of the rolling component is 0.90 to 1.58, reduction rate of pass is 15 percent to 45 percent, rolling temperature is 1000 celsius degree to 1100 celsius degree, the adaptation range of blank is 120*120mm to 180*180mm, and the absolute spread coefficient range is 0.25 to 0.45. The invention adopts a pass-free flat roller to replace a rough rolling pass roller of the prior art and realizes non-groove rolling of the high speed wire rod roughing mill group. The invention aims to provide the non-groove rolling method for the high speed wire rod roughing mill group adopting the flat roller to replace the rough pass roller, meanwhile, decreasing production cost, improving product quality and productivity of the mill and expanding the adaptation range of blank.

Owner:BAOSHAN IRON & STEEL CO LTD +1

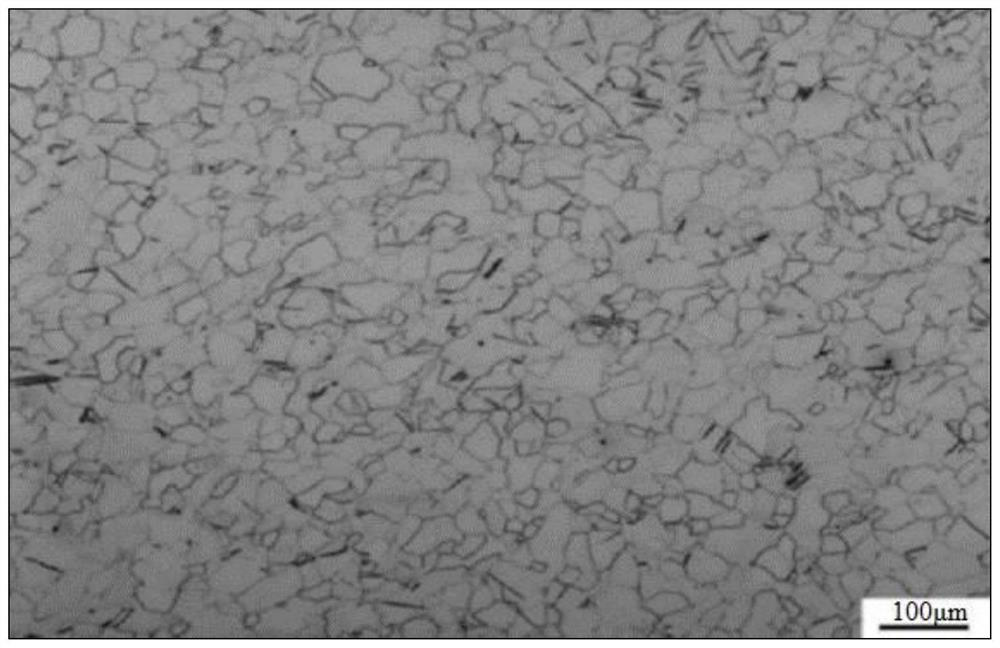

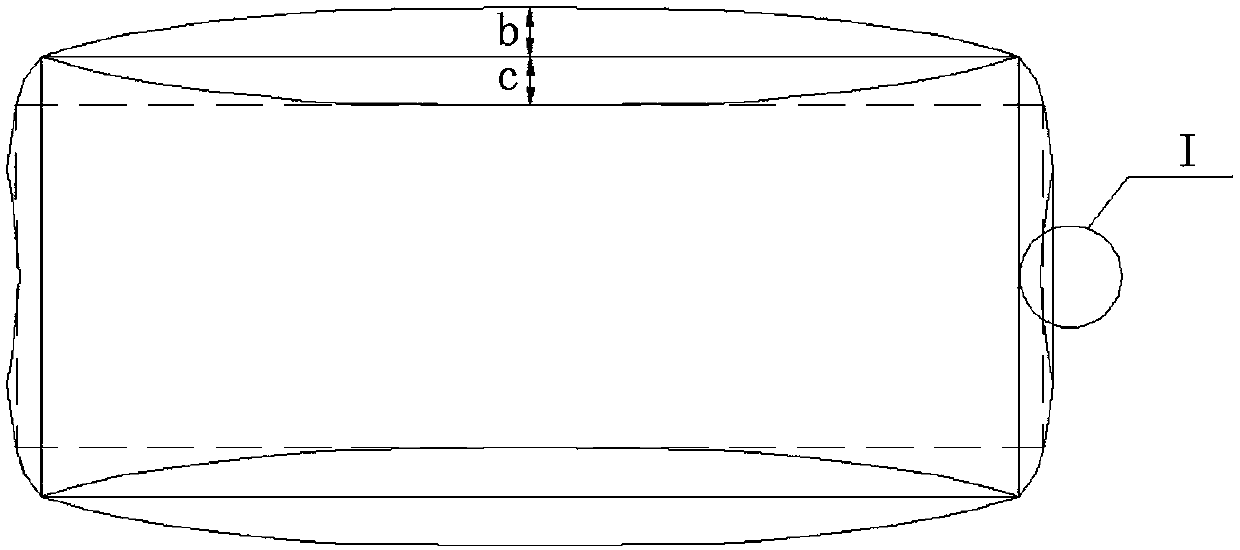

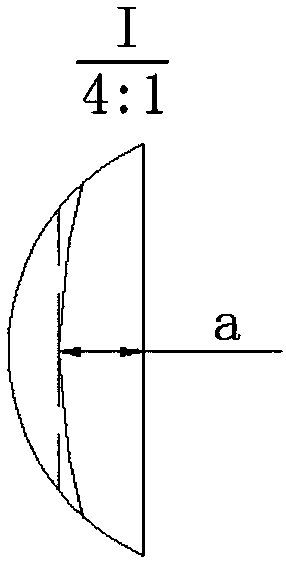

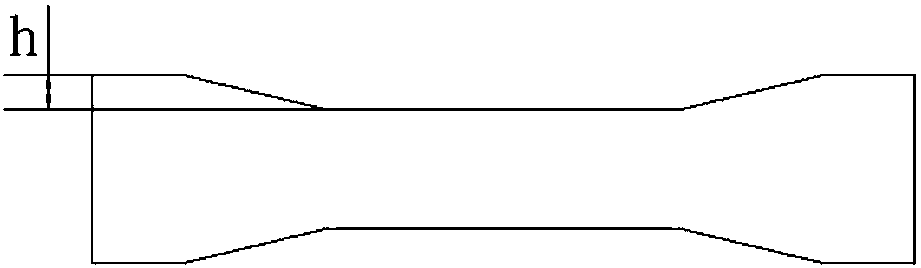

Preparation method of thick slab of chamfer titanium alloy

The invention discloses a preparation method of a thick slab of a chamfer titanium alloy. The preparation method comprises the following steps: 1, cogging-forging a titanium alloy ingot to obtain a titanium alloy forging stock; 2, carrying out intermediate forging on the titanium alloy forging stock 2-3 heating times; 3, upsetting and stretch-forging the intermediate forged titanium alloy forging stock, shaping, chamfering edges on the upper surface and the lower surface of the shaped titanium alloy forging stock, and shaping to obtain a slab; and 4, machining the slab to obtain the chamfer titanium alloy with the thickness of 180-400mm. According to the invention, the large size chamfer titanium alloy slab with the thickness of 180-400mm can be prepared by adopting multi-heating and a manner combining repeatedly upsetting and stretching. By adopting the titanium alloy slab prepared with the method of the invention to roll, the edge folding of a sheet material can be reduced, so the cutting loss of the sheet material head, the sheet material tail and sheet material side surfaces is reduced, the sheet material rolling yield is improved by 5-8%, and the production cost is substantially reduced.

Owner:WESTERN TITANIUM TECH

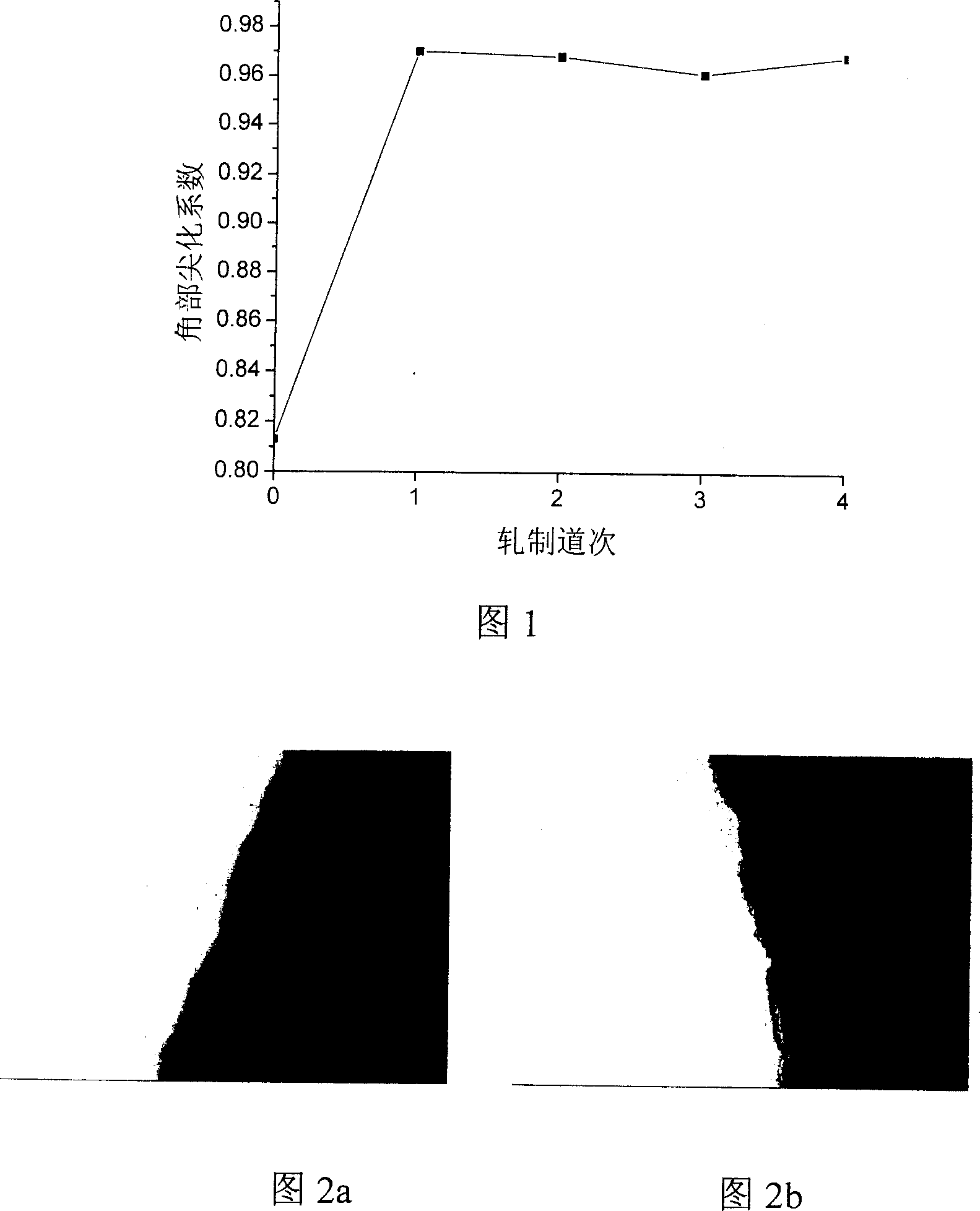

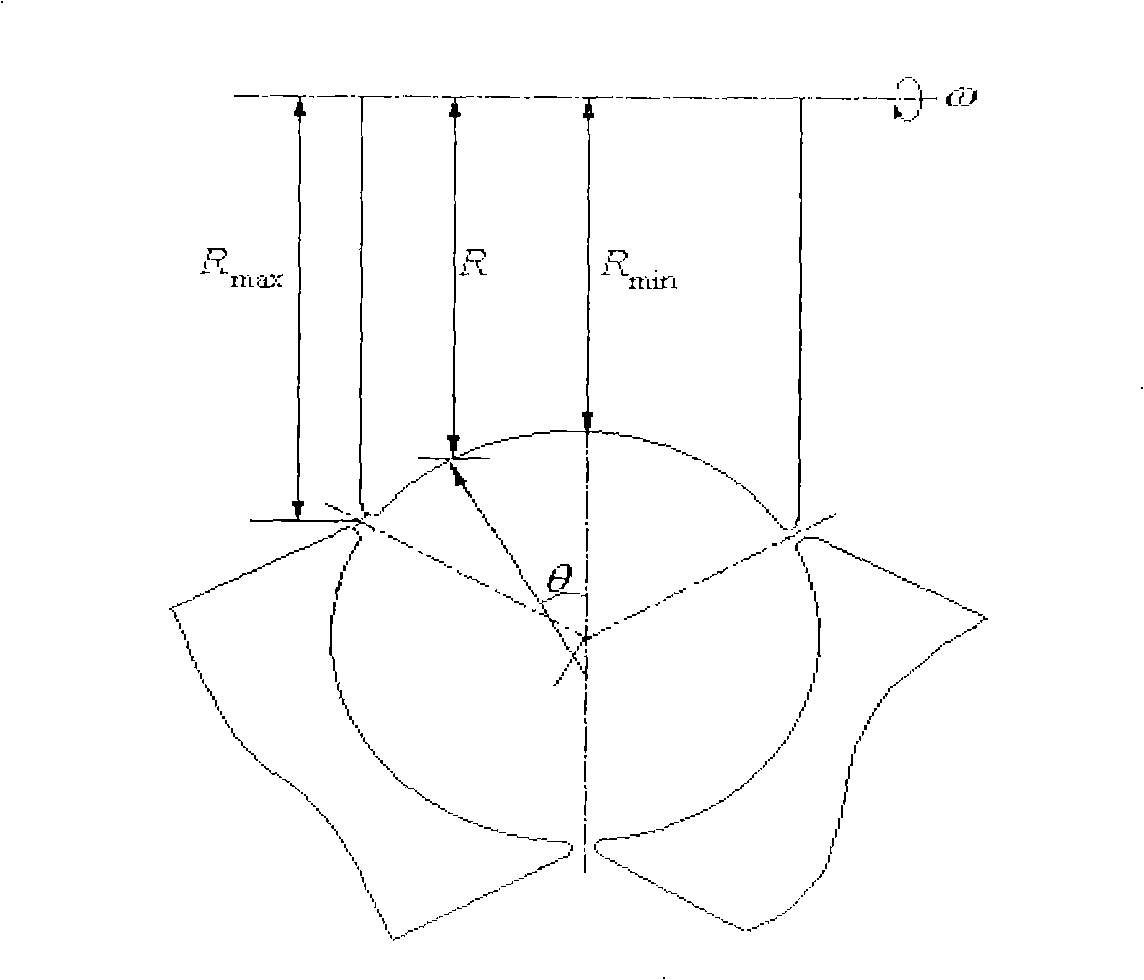

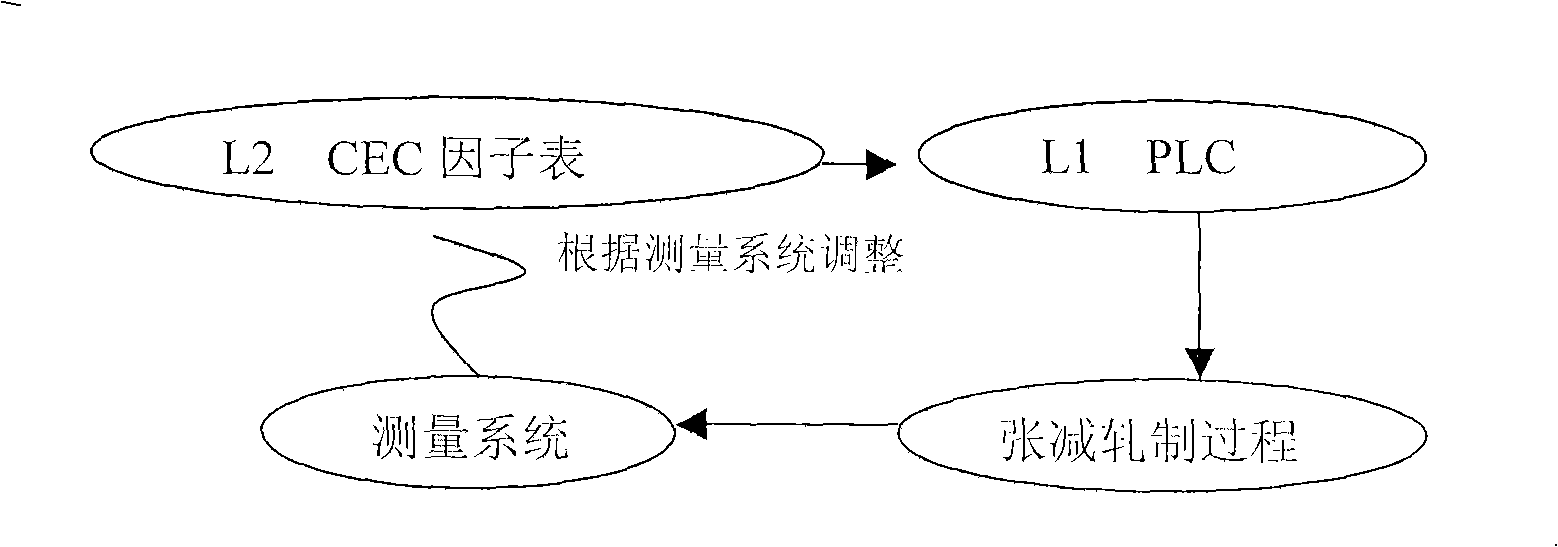

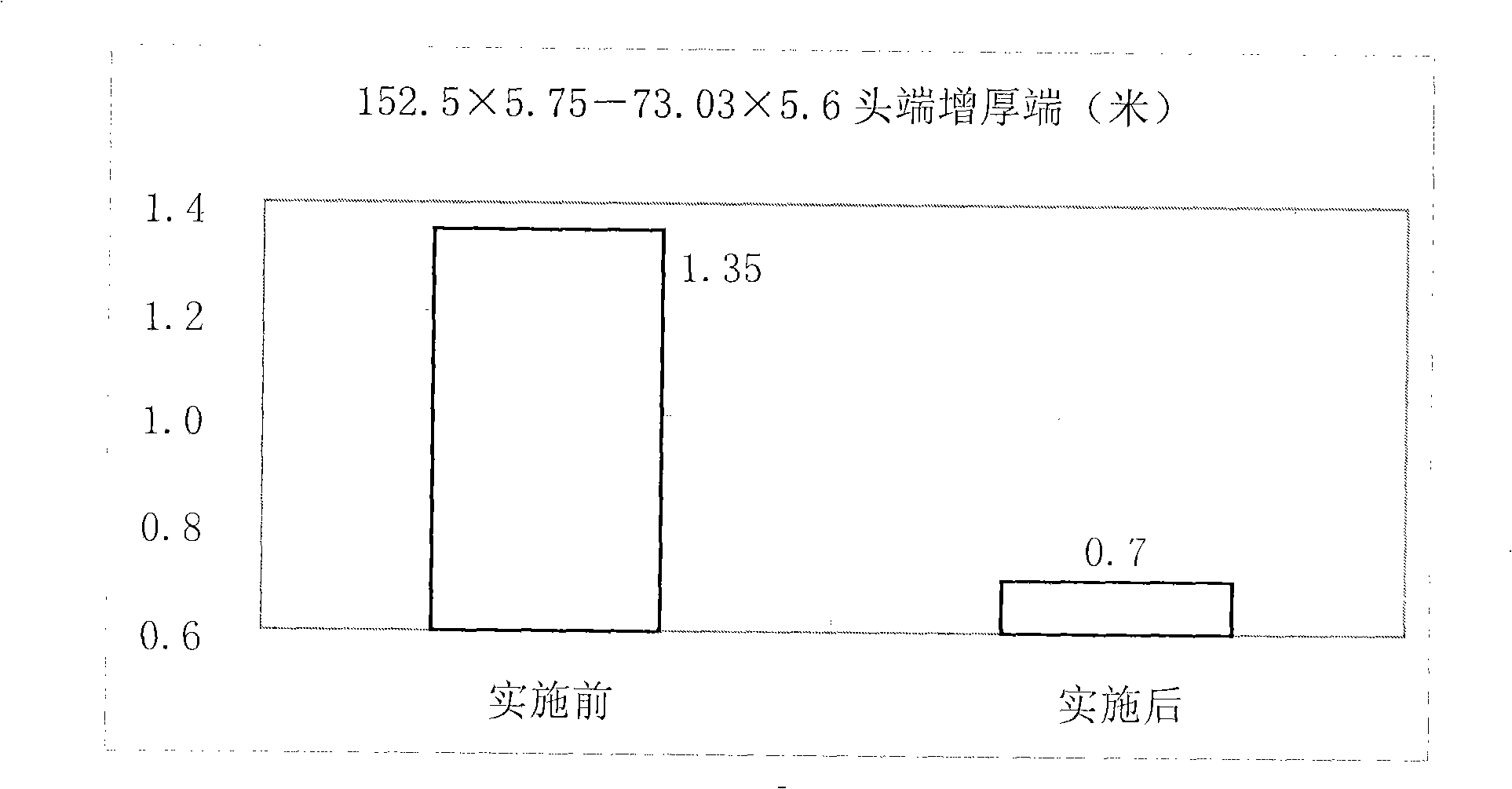

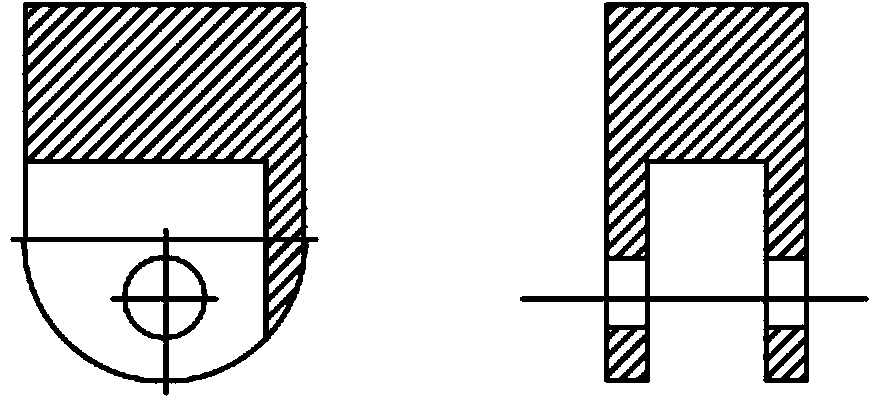

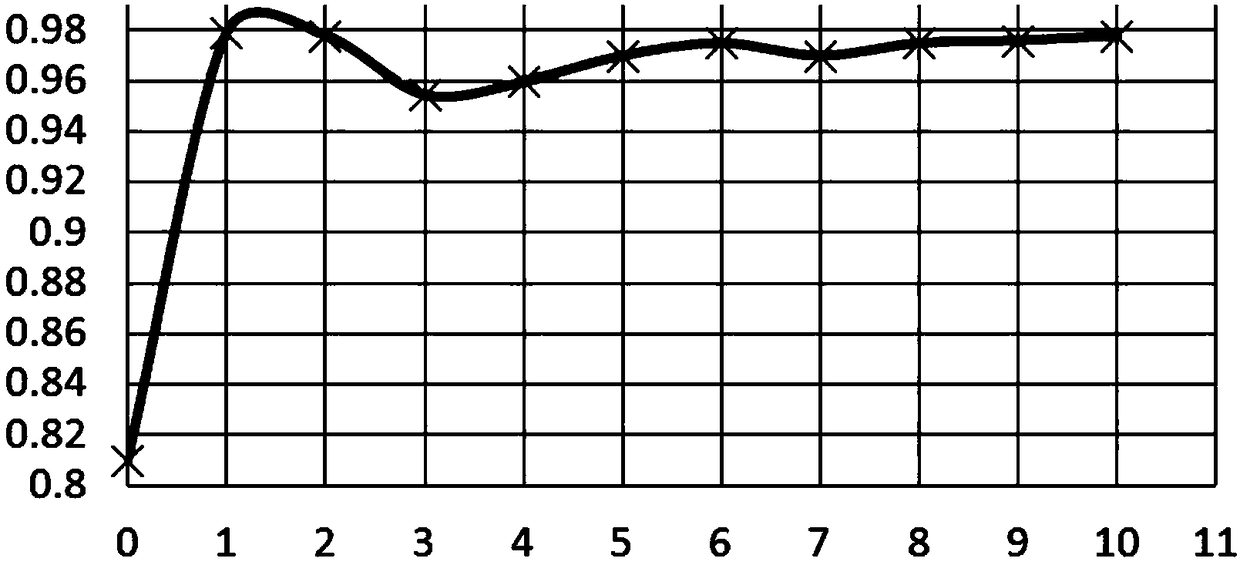

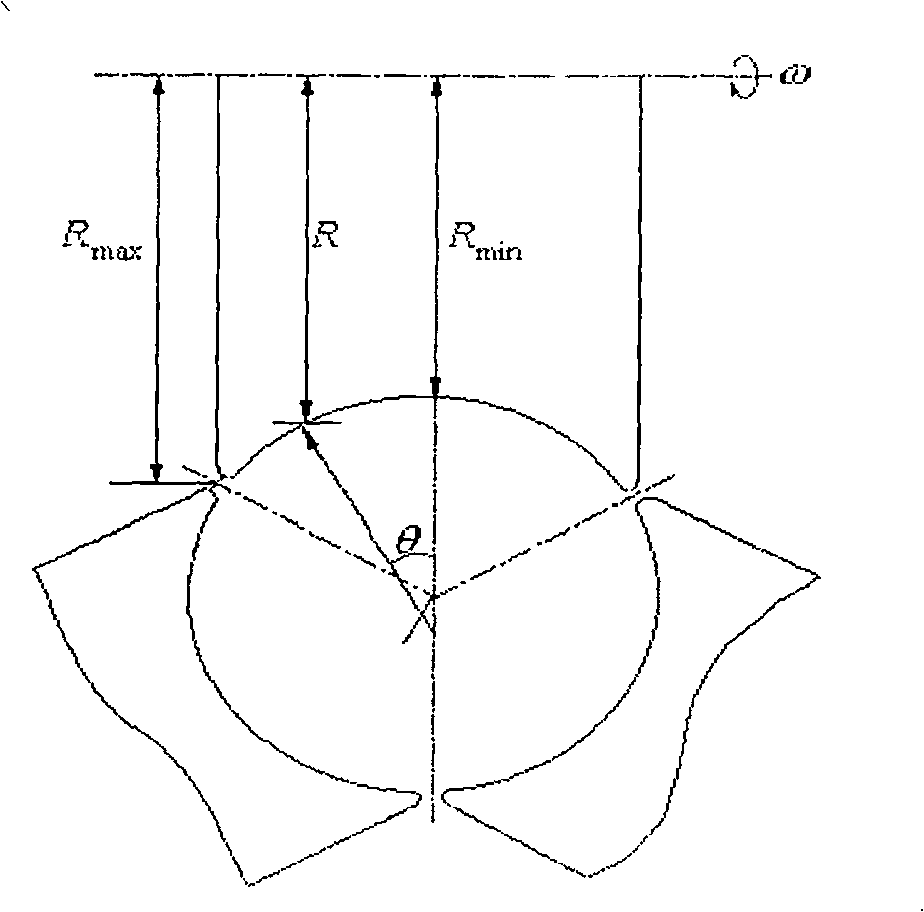

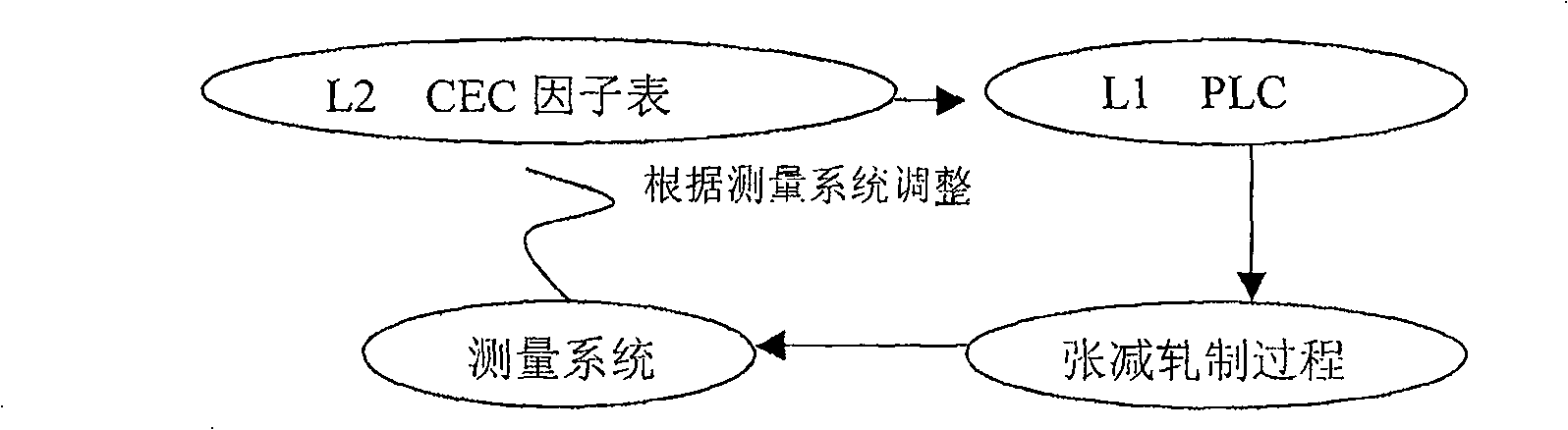

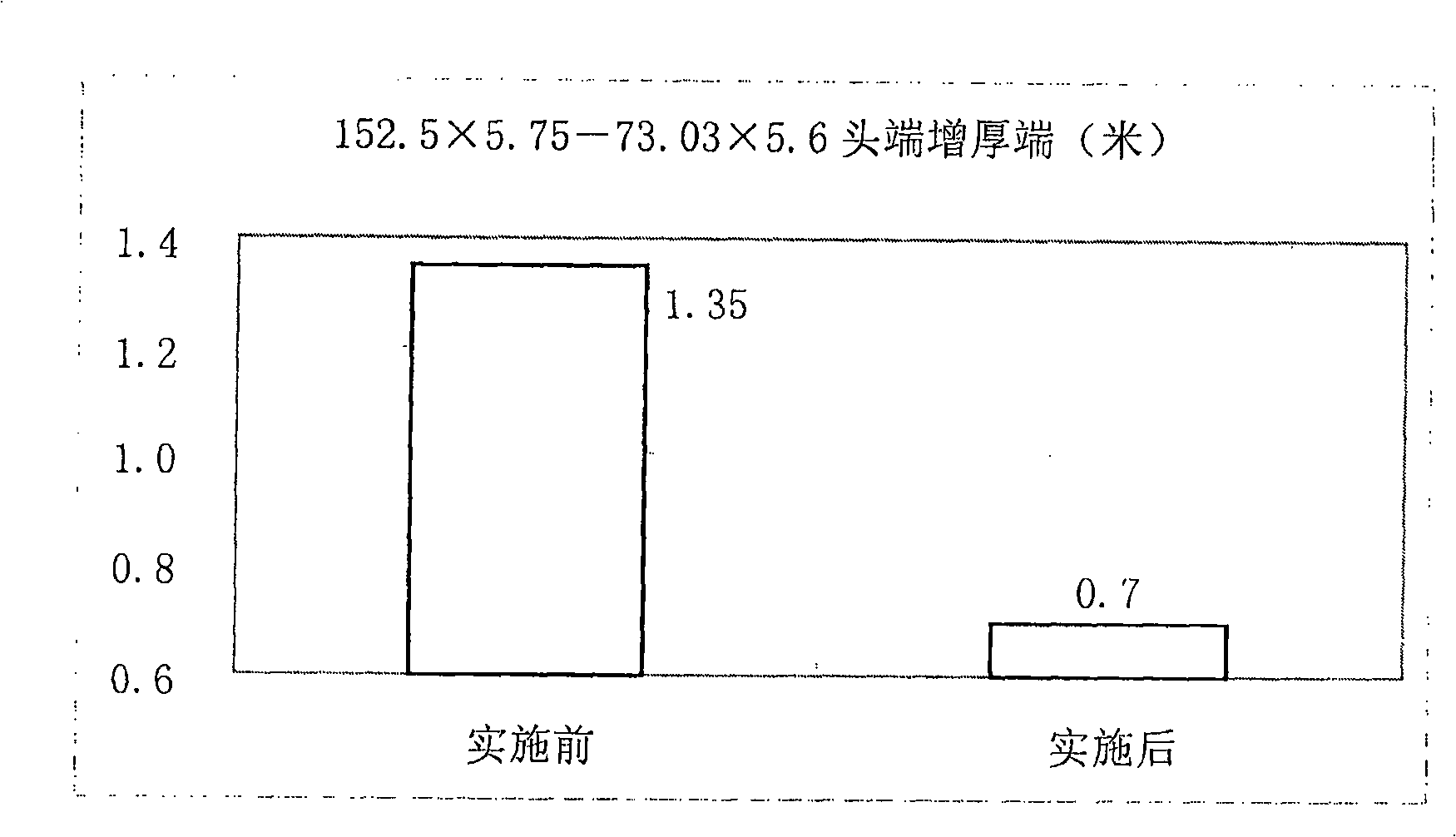

Control method of stretch-reducing mill steel tube thickening terminal

ActiveCN101274335AShorten the lengthHigh yieldRoll mill control devicesMaterial dimension controlSteel tubeDistribution rule

The invention relates to a chipping control technique of head and rear thickened ends of a steel tube which is used in a stretch reducing process of a seamless steel tube. A control method of the thickened ends of the steel tube of a stretch reducing machine computes a control factor table of the thickened ends of the steel tube according to the thickness distribution rule of tube end walls of the stretch reducing machine, and by utilizing the factor table, the control method can adaptively increase and decrease the number of machine frames that participate in the CEC action according to the length change of the thickened ends in the rolling process, and realize the shortening of the head and rear thickened ends by coordinating with the adjustment of additive tension that acts on the head and rear thickened ends of the steel tube; the computation of the CEC factor table of the stretch reducing machine comprises the following steps: a basic speed governing level and a largest speed governing level are determined according to average tension; original CEC speed governing factors are computed according to the working diameter change of a roller; an original CEC speed governing factor table is constructed; the number of the machine frames that simultaneously participate in the CEC action in each machine frame position is determined according to the extensibility of the steel tube; the original CEC factor table is revised by combining with the number of the machine frames that simultaneously participate in the CEC action in each machine frame position. The chipping control technique of the head and rear thickened ends of the steel tube can effectively shorten the length of the thickened ends of the steel tube and improve the steel tube yield.

Owner:BAOSHAN IRON & STEEL CO LTD

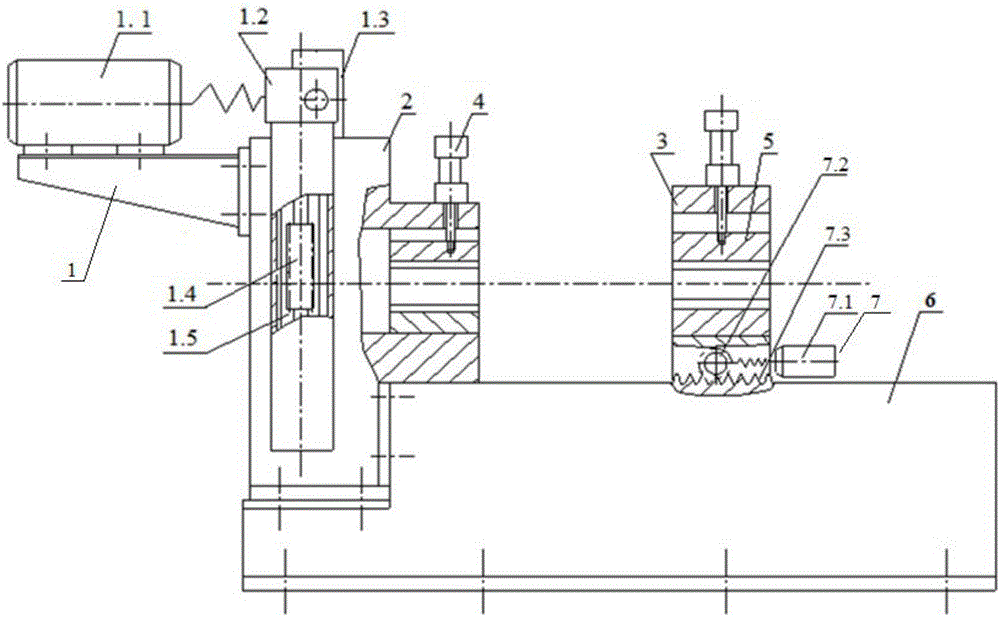

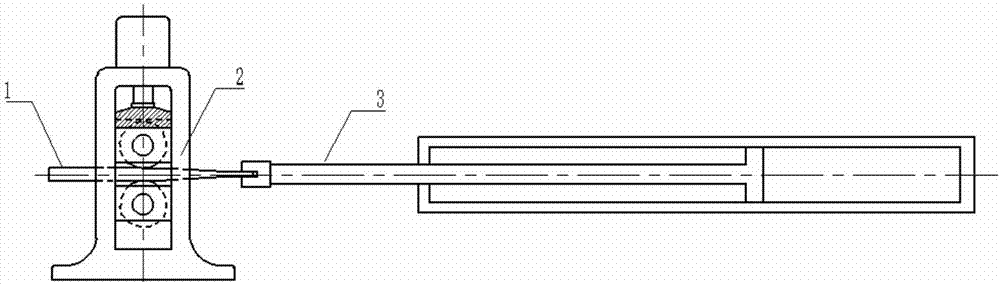

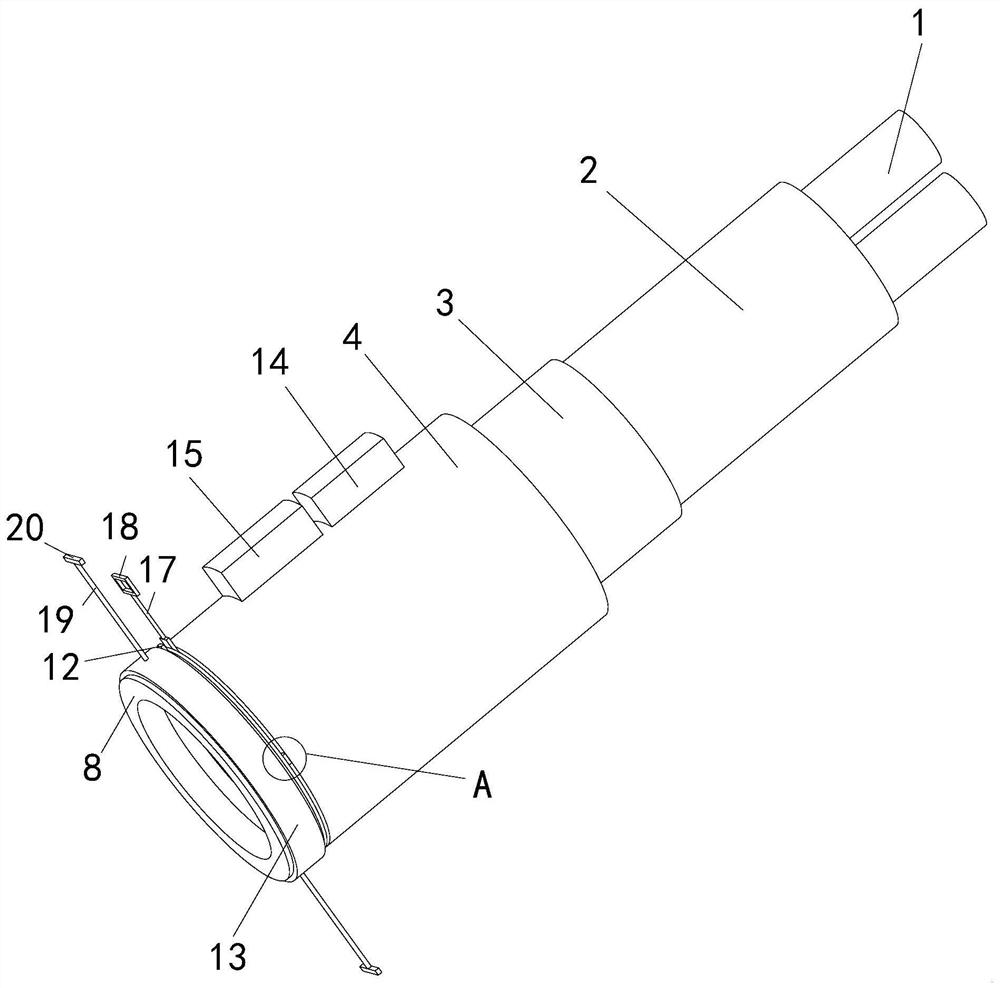

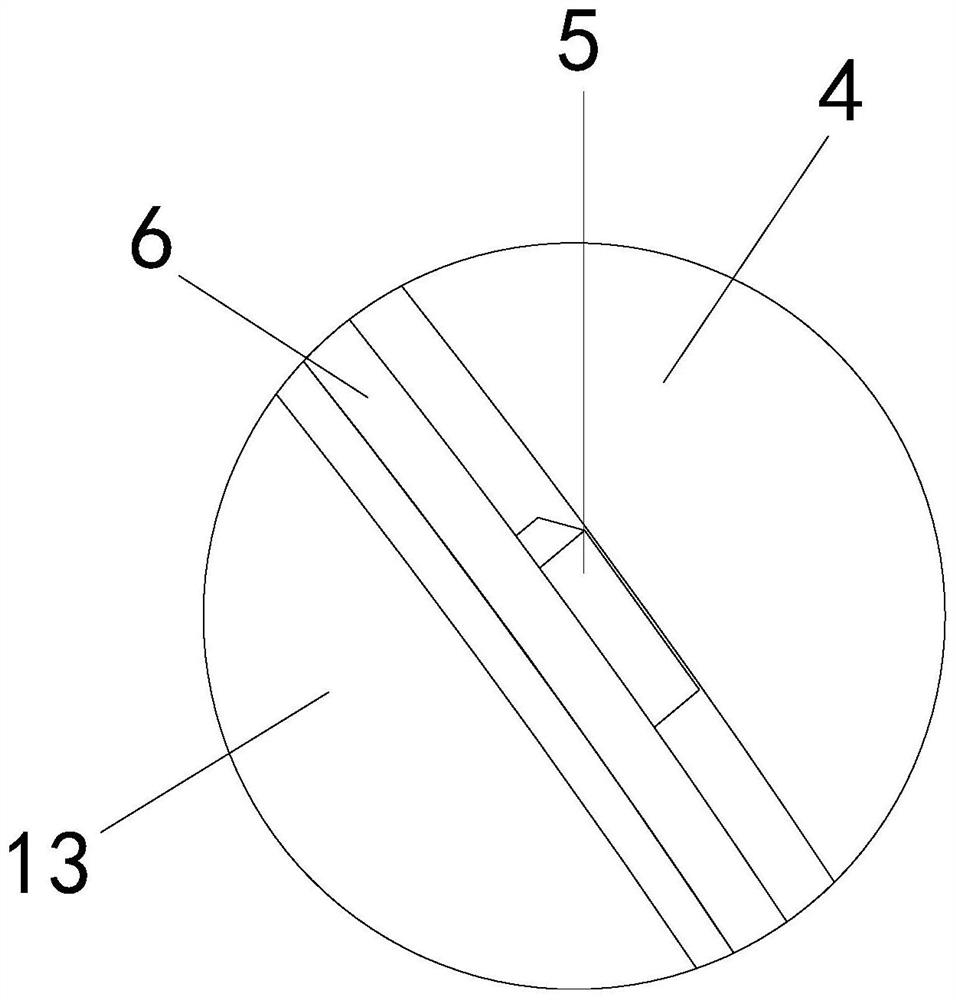

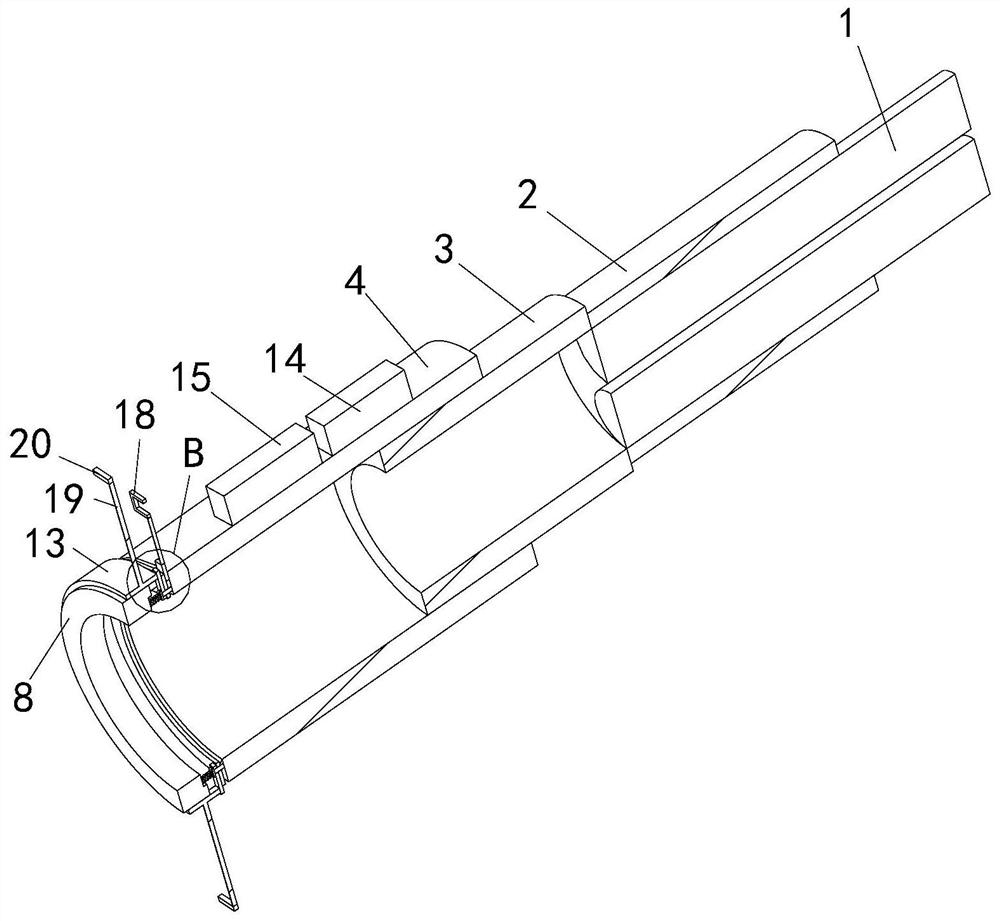

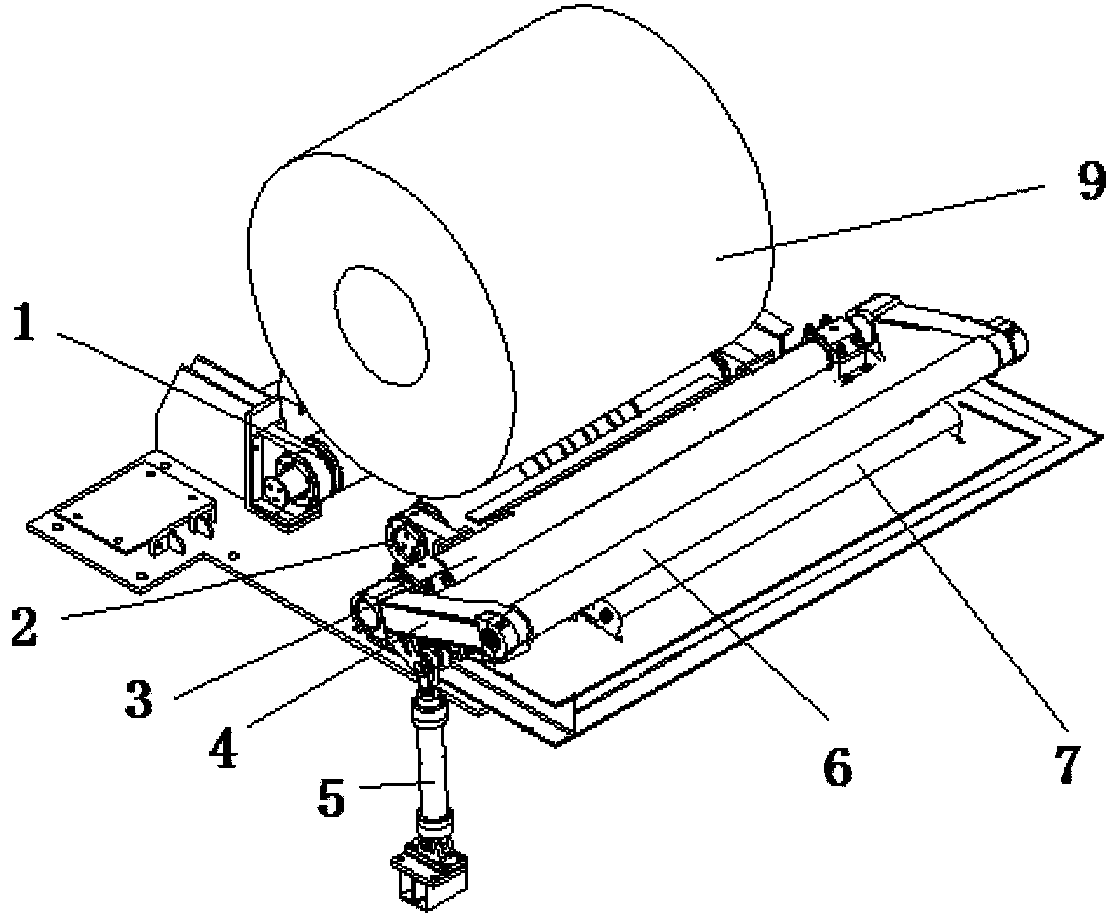

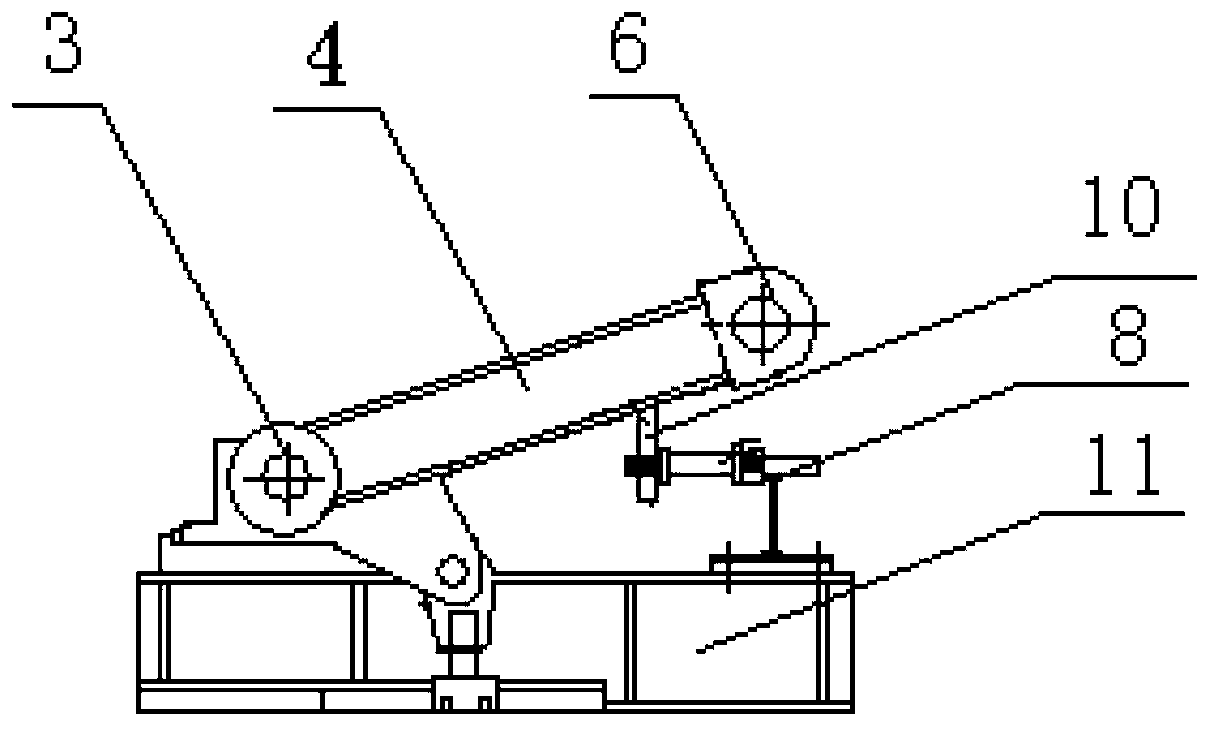

Aluminum alloy profile torque correction device

InactiveCN106238515AAvoid damageAdaptableMetal-working feeding devicesMetal working apparatusMechanical engineeringAluminium alloy

The invention discloses an aluminum alloy profile torque correction device which at least comprises a torsion transmission mechanism. The side edge of the torsion transmission mechanism is connected with a front end profile clamping device, a base of the torsion transmission mechanism is connected with a fixed torsion machine base through a bolt, the fixed torsion machine base is connected with a lathe bed through a bolt, the lathe bed is provided with a movable clamping machine base capable of sliding along a track on the lathe bed, the bottom of the movable clamping machine base is connected with a driving device, and the side edge of the upper portion of the movable clamping machine base is connected with a rear end profile clamping device. A low-energy-consumption and mechanical braking mode is utilized to be matched with a torsion angle precision measurement system, the torsion angle of the profile cross section of an incoming material is determined accurately, precise reversal angle values are given, and thus the cross section torsion form of a profile is corrected. By controlling the position of a profile clamping device through a displacement sensor, the damage to the clamped part of the profile can avoided, and the cut damage caused by torsion correction is reduced.

Owner:CHINA NAT HEAVY MACHINERY RES INSTCO

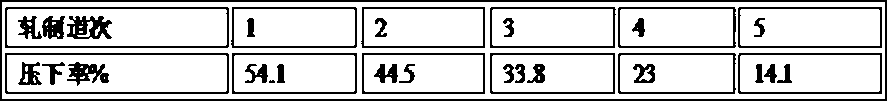

Method for controlling side turning of hot rolling stainless steel band

ActiveCN103252354ARoll Width ControlCold-rolled slitting and trimming reductionMetal rolling stand detailsReduction rateMetal

A method for controlling side turning of a hot rolling stainless steel band belongs to the metallurgy field. The method is characterized in that regarding a rough rolling vertical roll, the side pressure of a first pass is smaller than and equal to 200KN, the side pressure of a third pass is from 300KN to 800KN, and the side pressure of a fifth pass is from 100KN to 300KN. Regarding a rough rolling flat roll, the reduction rate of a first pass is 54.1%, the reduction rate of a second pass is 44.5%, the reduction rate of a third pass is 33.8%, the reduction rate of a fourth pass is 23%, and the reduction rate of a fifth pass is 14.1%. By means of reasonable control of flow deformation of metal in the process of stainless steel hot rolling, the method for controlling side turning of the hot rolling stainless steel band controls rough rolling and broadsiding in an appropriate range, effectively controls the side turning width of the stainless steel band, reduces trimming amount of cold rolling finished products, and improves yield of the cold rolling finished products.

Owner:SHANXI TAIGANG STAINLESS STEEL CO LTD

Length detection method of uncooled section of head of hot rolled strip steel

InactiveCN102671961AImprove efficiencyImprove the yield of thick gaugeMeasuring devicesMetal rolling arrangementsProduction lineImaging processing

The invention discloses a length detection method of an uncooled section of a head of a hot rolled strip steel. The detection method is characterized by comprising the following steps of: (1) arranging image acquisition equipment between a laminar flow cooler and a coiler of a hot rolling production line; (2) connecting the image acquisition equipment with an image processing and recognition system through a network; (3) connecting the image processing and recognition system with a production line process control system; (4) photographing and acquiring an image of the head of the strip steel by the image acquisition equipment when the head of the strip steel enters a working region of the image acquisition equipment; (5) transmitting the acquired image of the head of the strip steel to the image processing and recognition system; and (6) processing and analyzing, by the image processing and recognition system, the image of the head to obtain a length value of the uncooled section of the head of the strip steel. According to the detection method, the problem of length detection of the uncooled section of the head of the strip steel in a hot rolled strip steel production process is solved, and the yield of thick specification production of hot rolling plants is improved.

Owner:SHANXI TAIGANG STAINLESS STEEL CO LTD

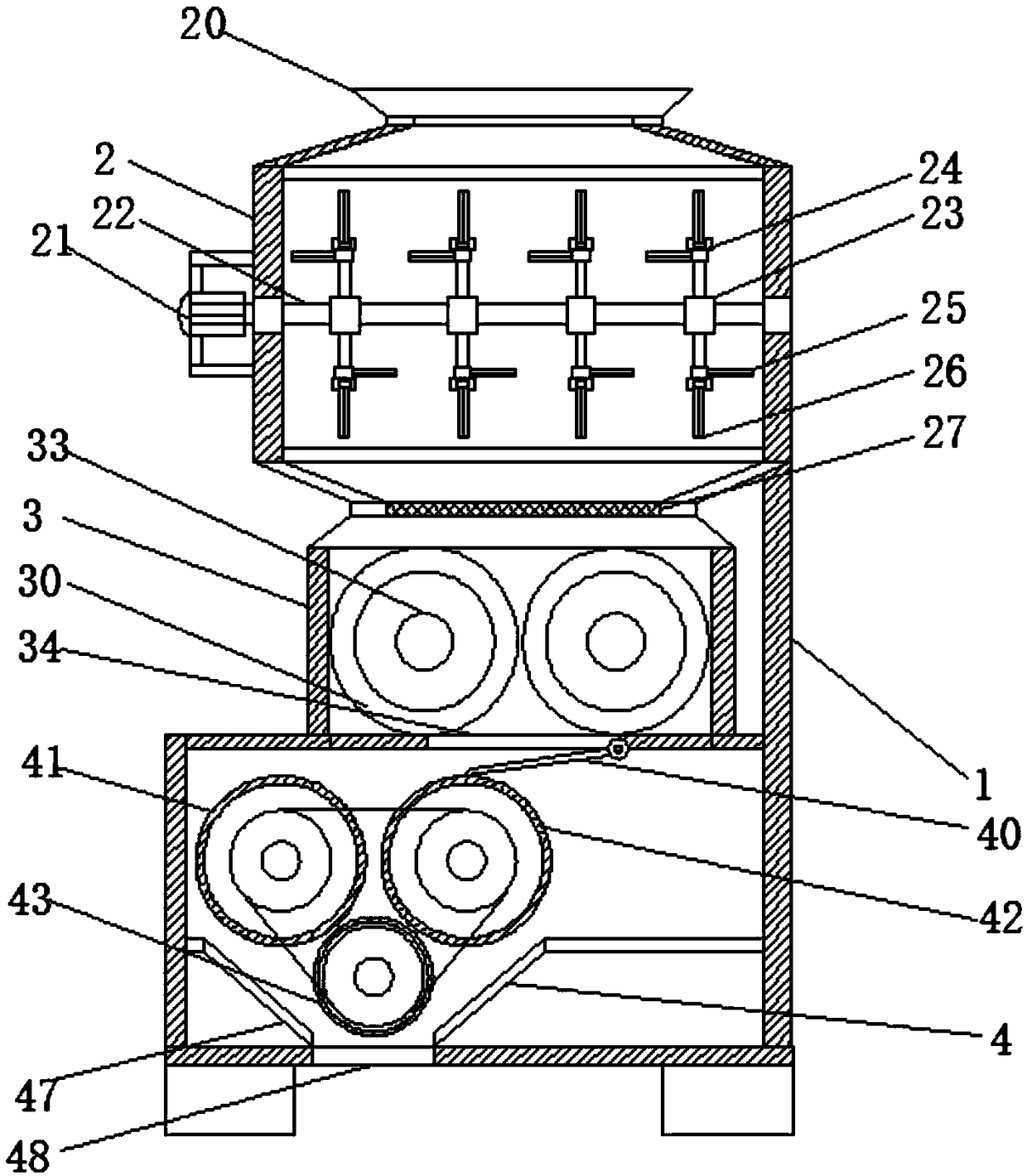

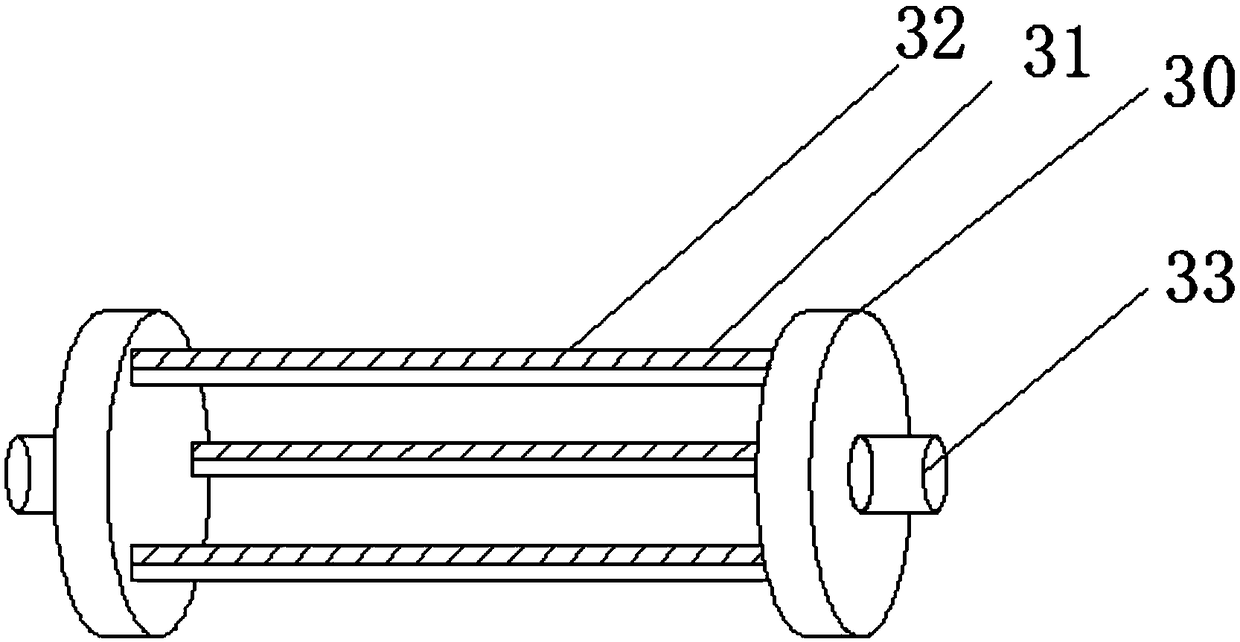

Multistage forage cutting and crushing device

InactiveCN108714472AGuaranteed qualityIncrease cutting surfaceFeeding-stuffGrain treatmentsAnimal ForagingEngineering

The invention discloses a multistage forage cutting and crushing device. The multistage forage cutting and crushing device comprises a processing box, a primary cutting box, a secondary cutting box and a crushing box are arranged in an inner cavity of the processing box, a feeding hopper is arranged at the top end of the primary cutting box, a cutting rotating shaft is transversely arranged in theprimary cutting box, a cutting motor is arranged on the side wall of the primary cutting box, the cutting rotating shaft is connected with a motor shaft of the cutting motor through a coupler, a plurality of cutting knife rests are arranged on the cutting rotating shaft at equal intervals, locking bolts are arranged on the cutting knife rests, and vertical cutters and horizontal cutters are installed on the locking bolts correspondingly. According to the device, the vertical cutters and the horizontal cutters operate in a cooperating mode, so that forage is cut and crushed in a multi-dimensional cutting direction, and the quality of material processing is ensured.

Owner:侯添有

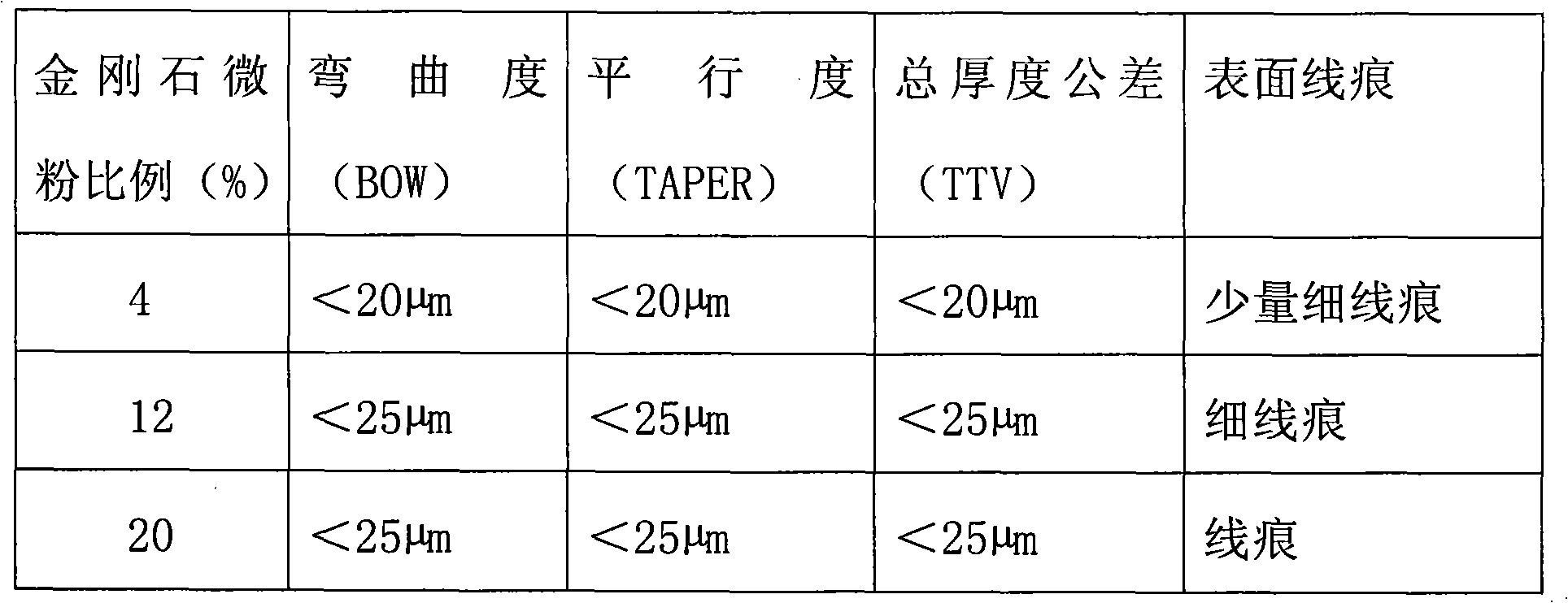

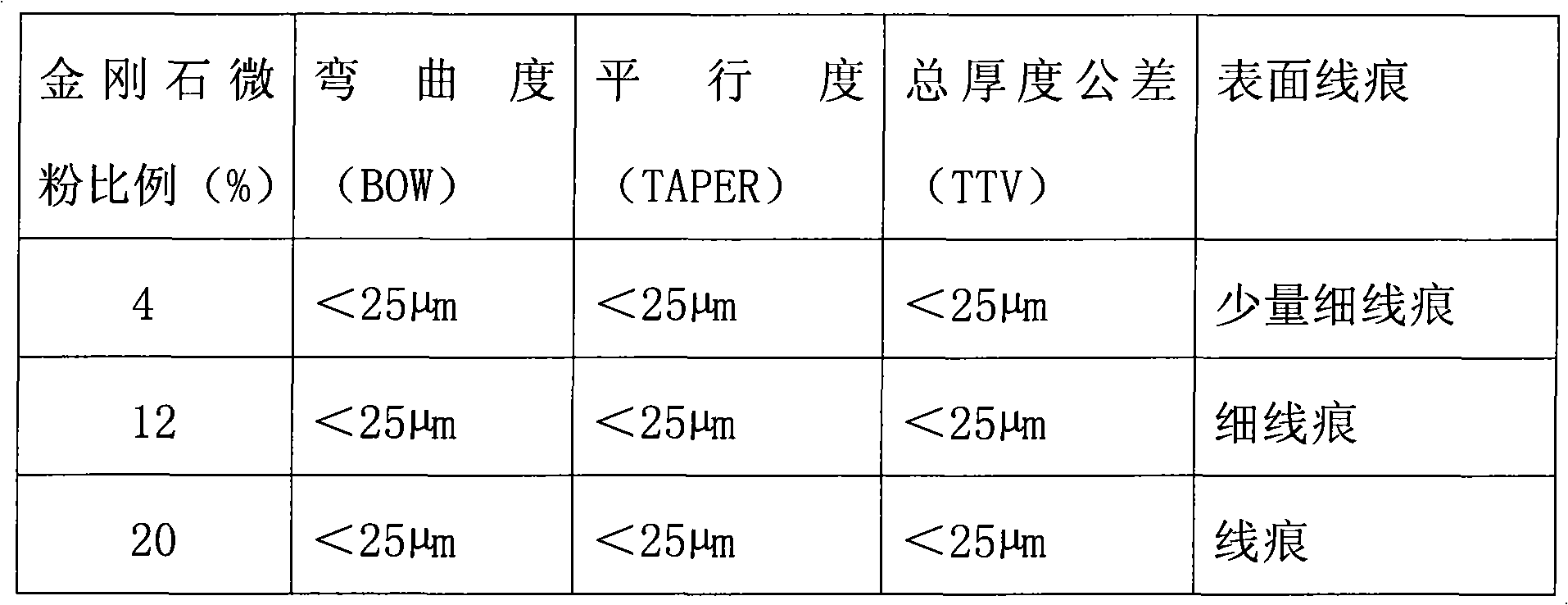

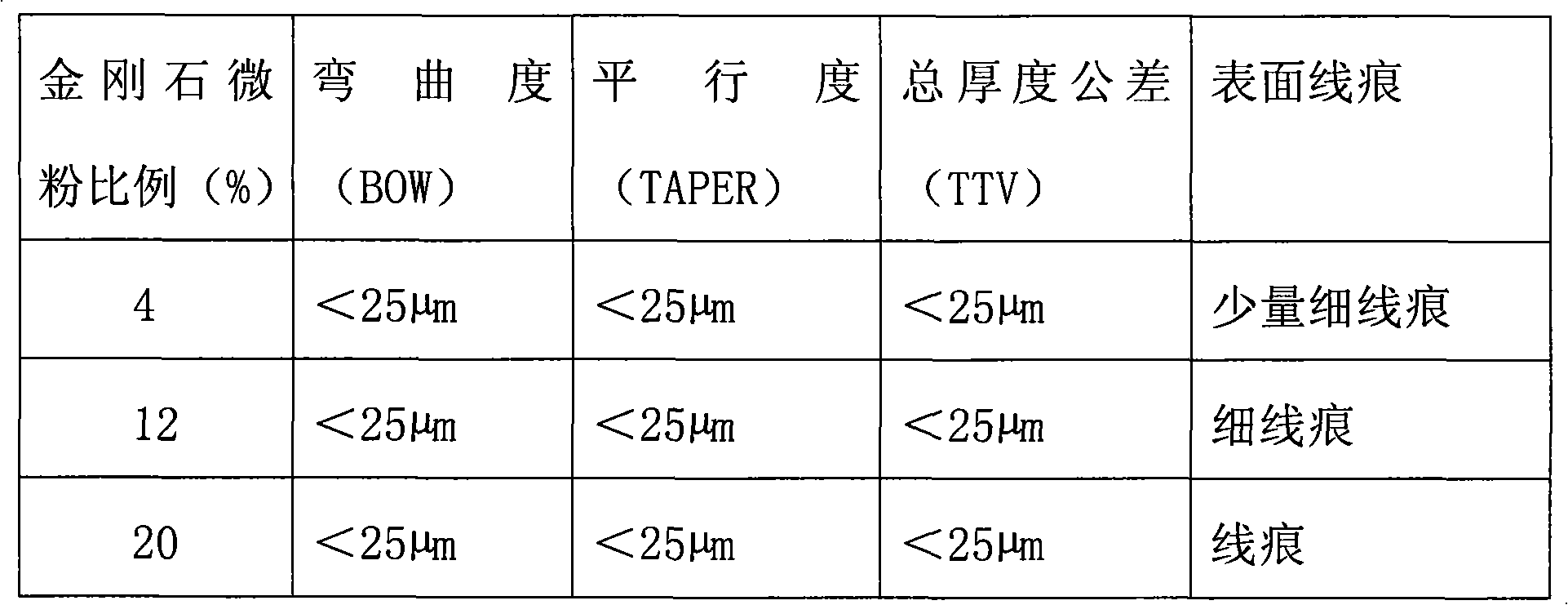

Mortar cutting fluid for cutting sapphire wafers

InactiveCN101870850AImprove liquidityModerate viscosityEdge grinding machinesPolishing compositions with abrasivesMicrometerSapphire wafer

The invention discloses a mortar cutting fluid for cutting sapphire wafers, which is formed by mixing a grinding material and cutting oil, wherein the grinding material is diamond micro powder of which the particle size is 4 to 12 micrometers; and the normal-temperature viscosity of the cutting oil is 20 to 50mpa.s. The diamond micro powder accounts for 4 to 20 percent of the weight of the mortar cutting fluid. The mortar cutting fluid prepared by the invention can be used on multi-line cutting machines of crystals for processing the sapphire wafers. The cutting of the sapphire wafers by using the mortar cutting fluid has the advantages of high cutting efficiency, high cutting precision, small equipment investment, small cutting loss and low cutting cost.

Owner:铜陵市琨鹏光电科技有限公司

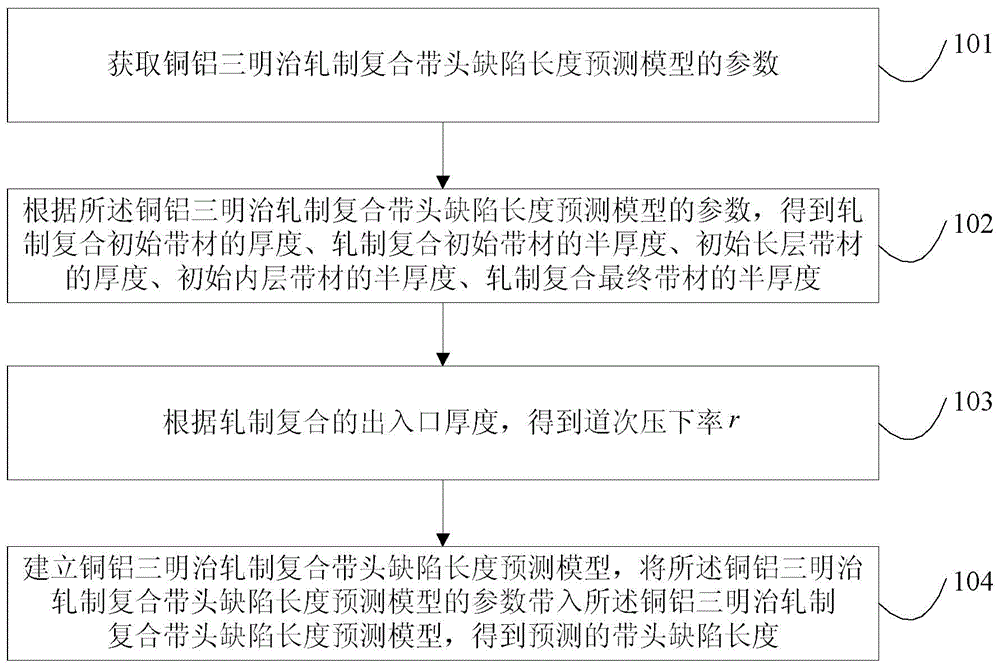

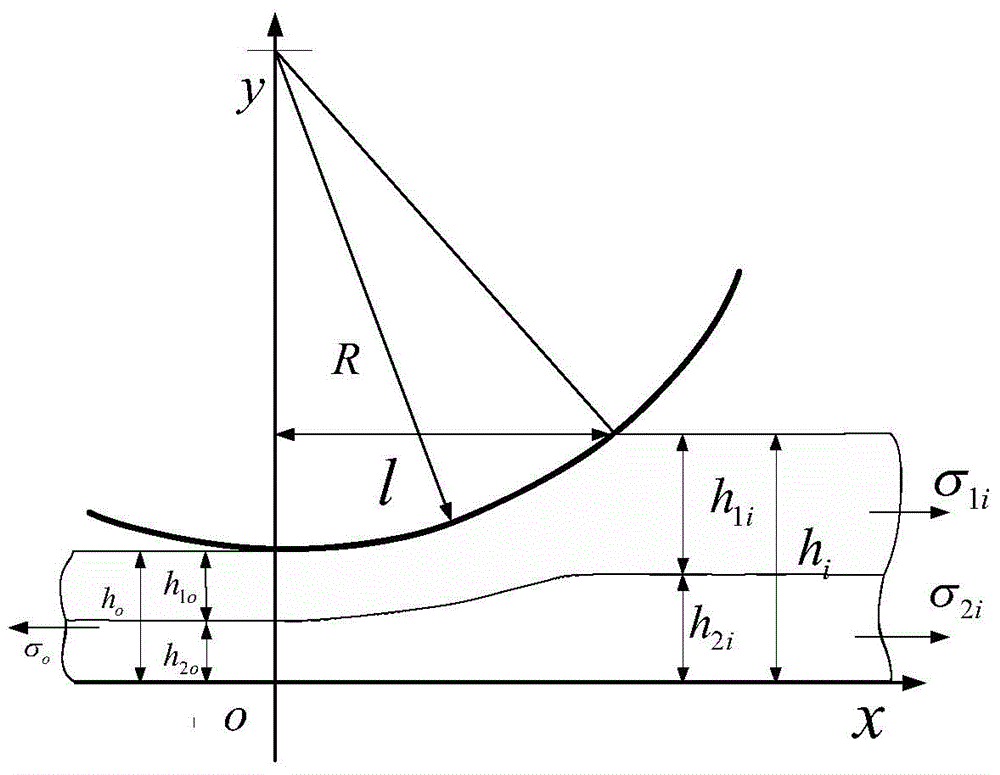

Prediction method for flaw length of Cu-Al sandwich rolling-bonded band head

ActiveCN104985007AIncrease productionReduce cut lossMeasuring devicesMetal rolling arrangementsReduction rateComputer science

The invention provides a prediction method for the flaw length of a Cu-Al sandwich rolling-bonded band head. The prediction method comprises the following steps: obtaining the parameters of a prediction model for the flaw length of the Cu-Al sandwich rolling-bonded band head, and according to the parameters of the prediction model for the flaw length of the Cu-Al sandwich rolling-bonded band head, obtaining the thickness of a rolling-bonded initial band material, the half-thickness of the rolling-bonded initial band material, the thickness of an initial upper-layer band material, the half-thickness of an initial inner-layer band material and the half-thickness of a rolling-bonded final band material; obtaining a pass reduction rate according to the thicknesses of a rolling bonding outlet and a rolling bonding inlet; and obtaining the predicted flaw length of the band head through establishing the prediction model for the flaw length of the Cu-Al sandwich rolling-bonded band head and substituting the parameters of the prediction model for the flaw length of the Cu-Al sandwich rolling-bonded band head into the prediction model for the flaw length of the Cu-Al sandwich rolling-bonded band head. Therefore, the flaw length of the bonded band head can be predicted; as a result, the yield can be greatly increased, and unnecessary cutting losses are reduced.

Owner:NORTHEASTERN UNIV

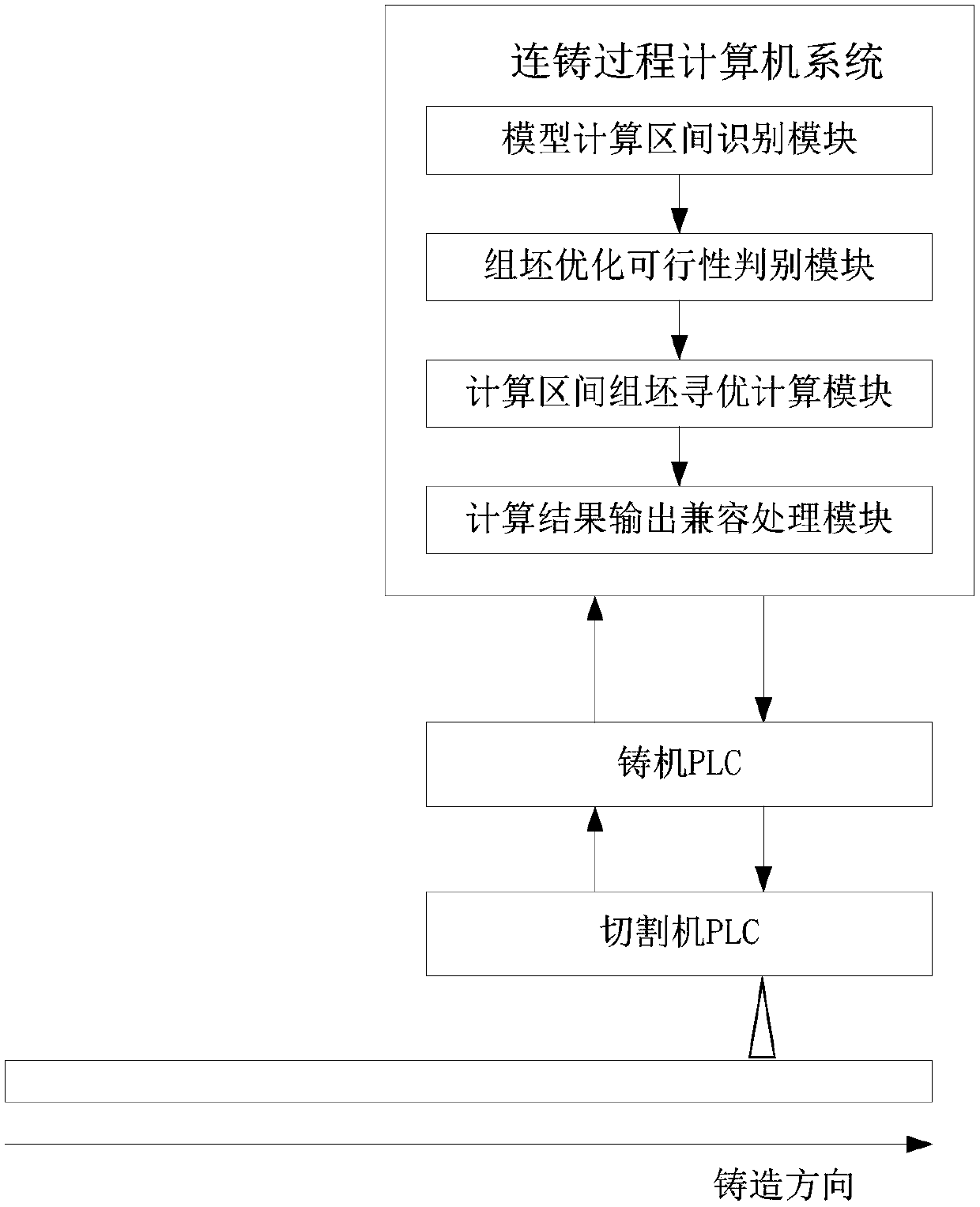

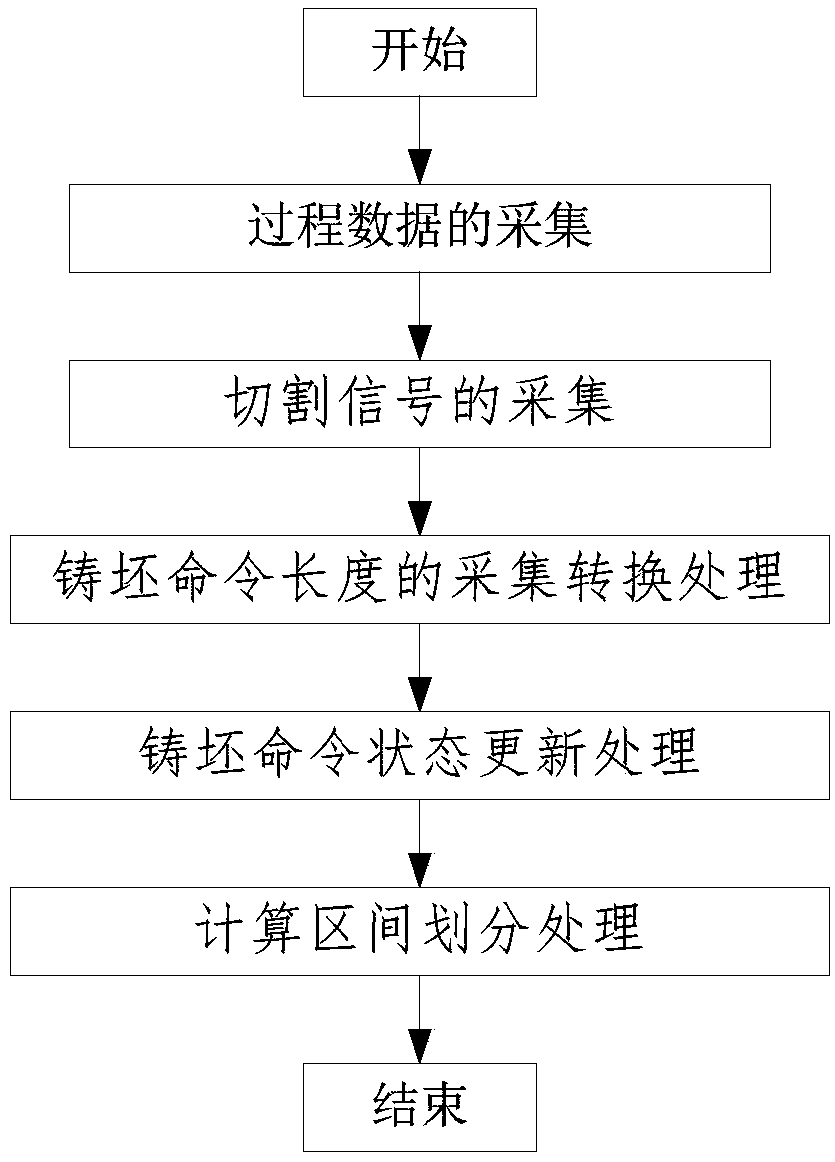

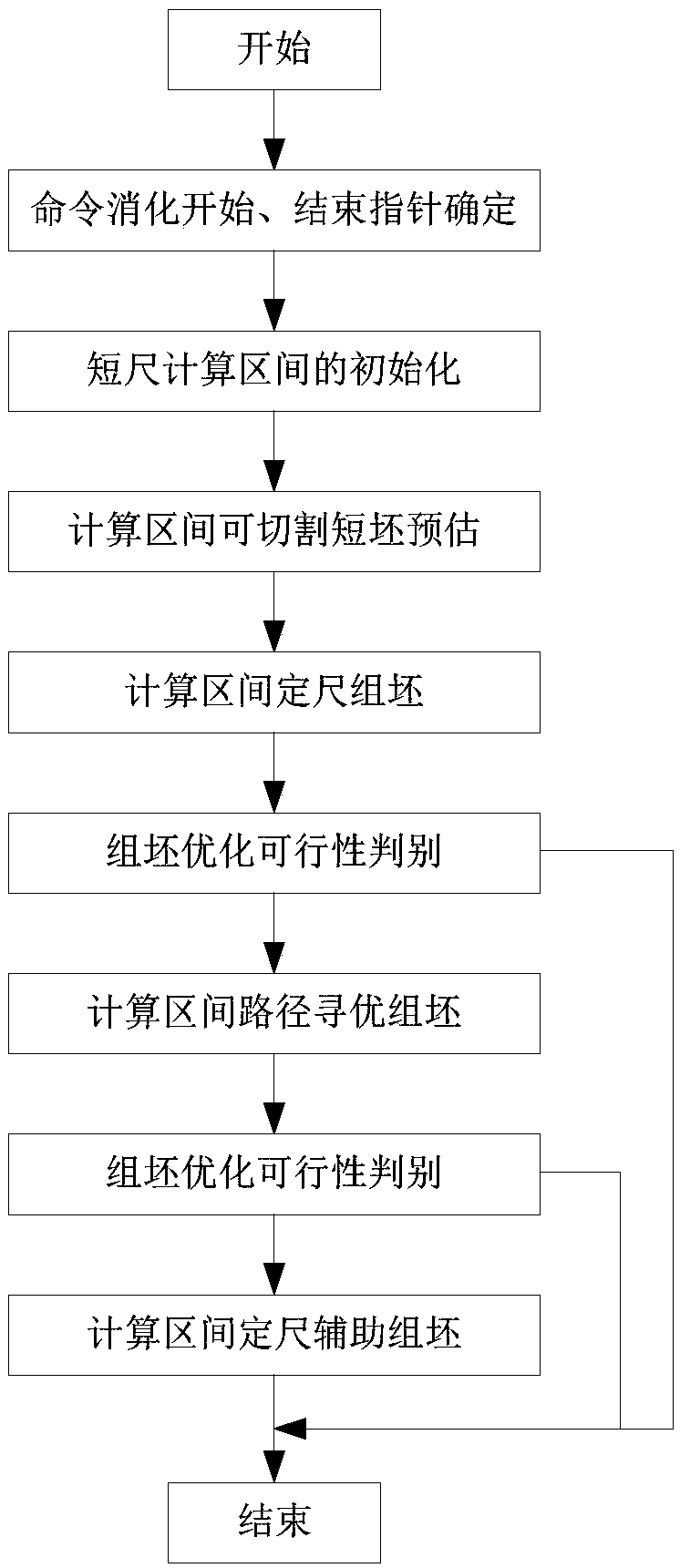

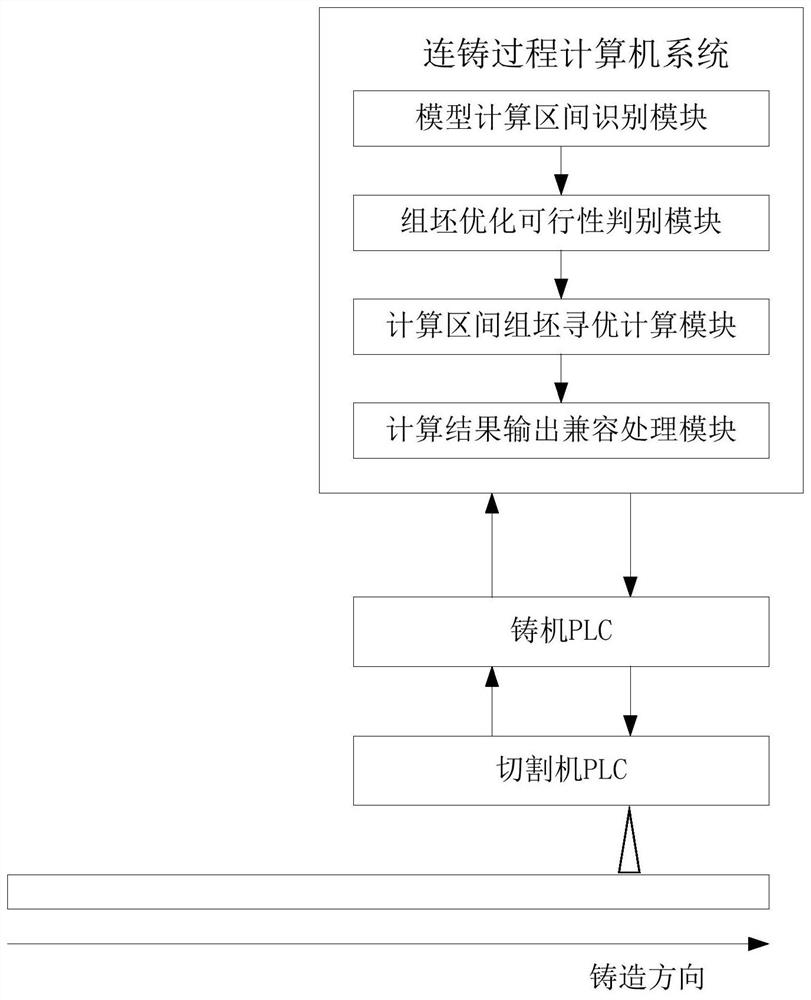

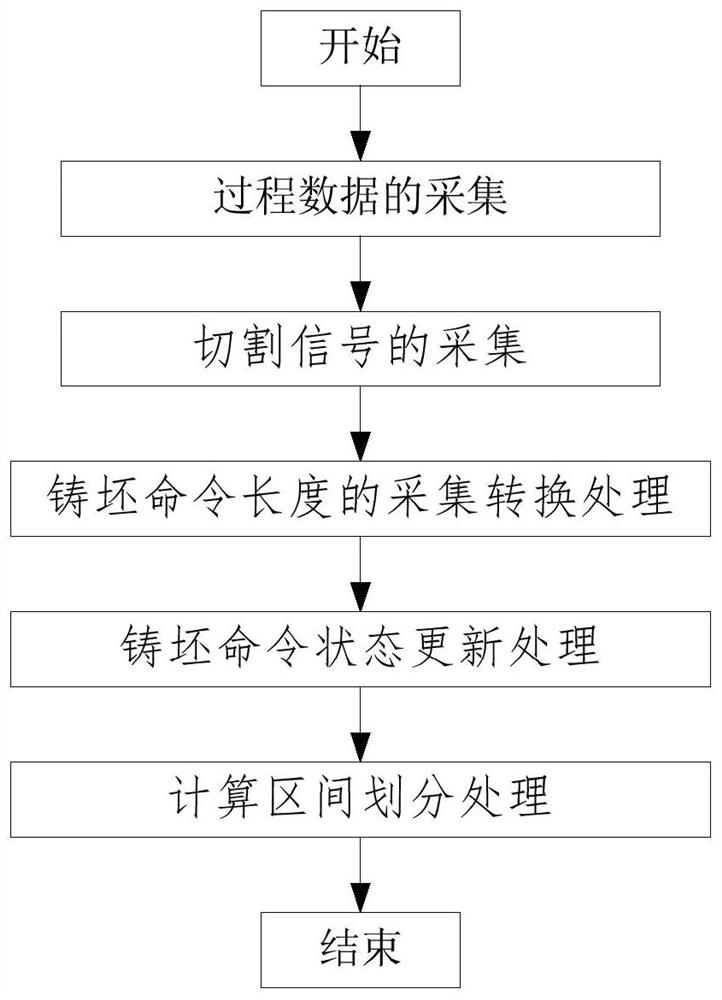

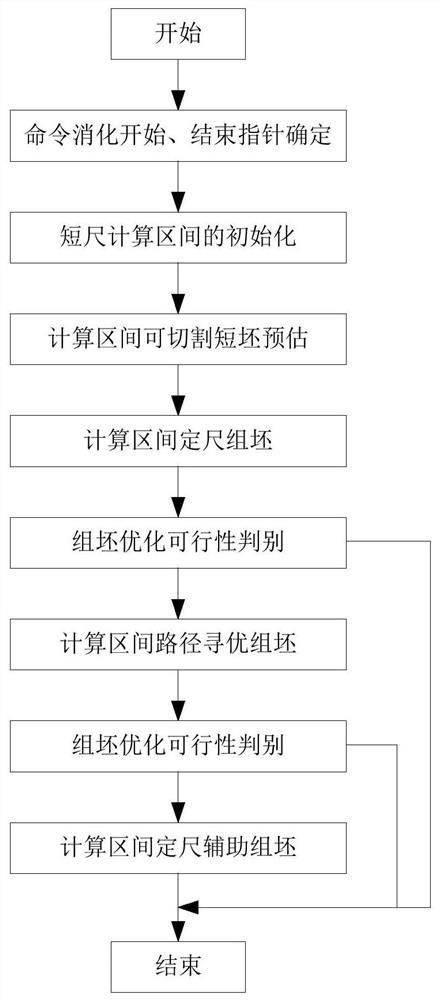

Cutting control system for continuous casting slab of thick plate and assembly optimization calculation method thereof

The invention discloses a cutting control system for a continuous casting slab of a thick plate. A short slab command is sent by using a thick plate rolling mill, data such as a signal are tracked inheat casting process, the assembly optimization of the short slab is performed on the casting slab with the range of a casting machine, and the casting slab is cut according to the length of an optimal long slab; an assembly optimization calculation method of the continuous casting slab of the thick plate can successfully find the optimal assembly strategy, optimal cutting control is performed onthe long slab within the range of the casting machine, and a continuous casting on-line cutter is controlled to perform on-line one-step cutting, so that cutting scraps are decreased, continuous casting, integration and optimization of the efficiency of the thick plate rolling mill are supported, and the assembly cutting efficiency and effect of the continuous casting machine are improved; the user interface is friendly, cut loss can be reduced, scenes of uniflow casting, dual-flow casting and different steel grades casting of the thick plate each heat are supported, and the maximized and optimized efficiency of the casting machine is ensured.

Owner:BAOSHAN IRON & STEEL CO LTD

Preparation method of thick slab of chamfer titanium alloy

The invention discloses a preparation method of a thick slab of a chamfer titanium alloy. The preparation method comprises the following steps: 1, cogging-forging a titanium alloy ingot to obtain a titanium alloy forging stock; 2, carrying out intermediate forging on the titanium alloy forging stock 2-3 heating times; 3, upsetting and stretch-forging the intermediate forged titanium alloy forging stock, shaping, chamfering edges on the upper surface and the lower surface of the shaped titanium alloy forging stock, and shaping to obtain a slab; and 4, machining the slab to obtain the chamfer titanium alloy with the thickness of 180-400mm. According to the invention, the large size chamfer titanium alloy slab with the thickness of 180-400mm can be prepared by adopting multi-heating and a manner combining repeatedly upsetting and stretching. By adopting the titanium alloy slab prepared with the method of the invention to roll, the edge folding of a sheet material can be reduced, so the cutting loss of the sheet material head, the sheet material tail and sheet material side surfaces is reduced, the sheet material rolling yield is improved by 5-8%, and the production cost is substantially reduced.

Owner:WESTERN TITANIUM TECH

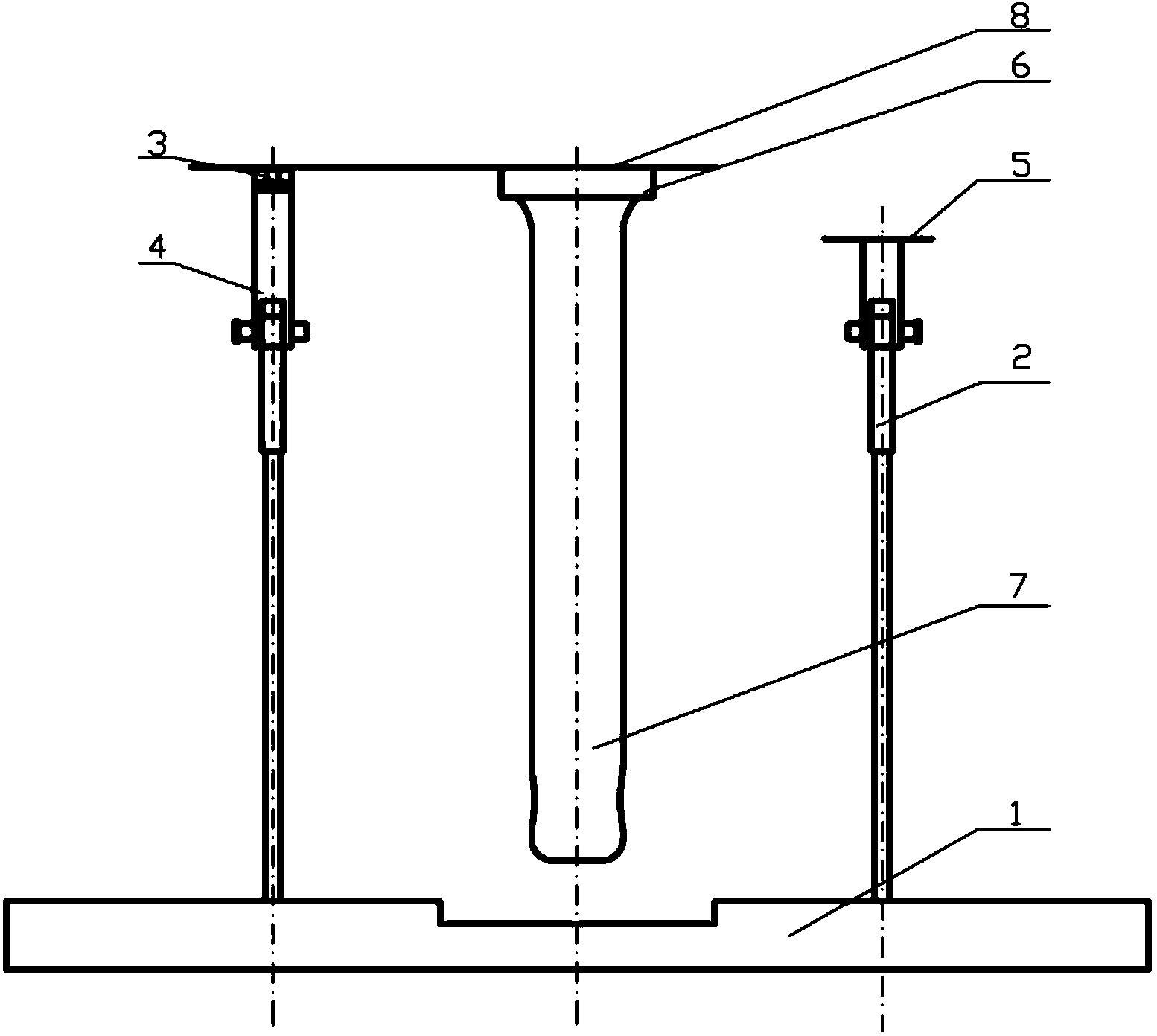

Device and method for different steel grade continuous casting automatic iron plate insertion

ActiveCN103862009AFully automatedIncrease the number of continuous pouring furnacesMelt-holding vesselsRefractoryAutomation

The invention discloses a device for different steel grade continuous casting automatic iron plate insertion, and belongs to the technical field of metallurgy continuous casting. The device comprises a T-shaped base of a tundish, a nozzle quick-changing oil cylinder swing part, a movable swing part and an iron plate insertion body part. The invention also discloses a method for different steel grade continuous casting automatic iron plate insertion, which comprises the steps of during different steel grade continuous casting, inserting the movable swing part on the T-shaped base of the tundish so as to enable the movable swing part to be located at the middle of the bottom of the tundish, meanwhile putting down a swing rod of the nozzle quick-changing oil cylinder swing part, respectively connecting two long rods of the iron plate insertion body part into hollow swing rods at the lower parts of the nozzle quick-changing oil cylinder swing part and the movable swing part from the inner arc side of a crystallizer, and connecting firmly by using iron wires. By adopting the device and the method, the different steel grade same-tundish continuous casting iron plate insertion automation is realized, the continuous casting furnace number of a casting machine is increased, the cost of tundish refractories is reduced, the operability of the casting machine is indirectly improved, the production preparation time is saved, and the molten steel yield is also improved.

Owner:BEIJING SHOUGANG CO LTD

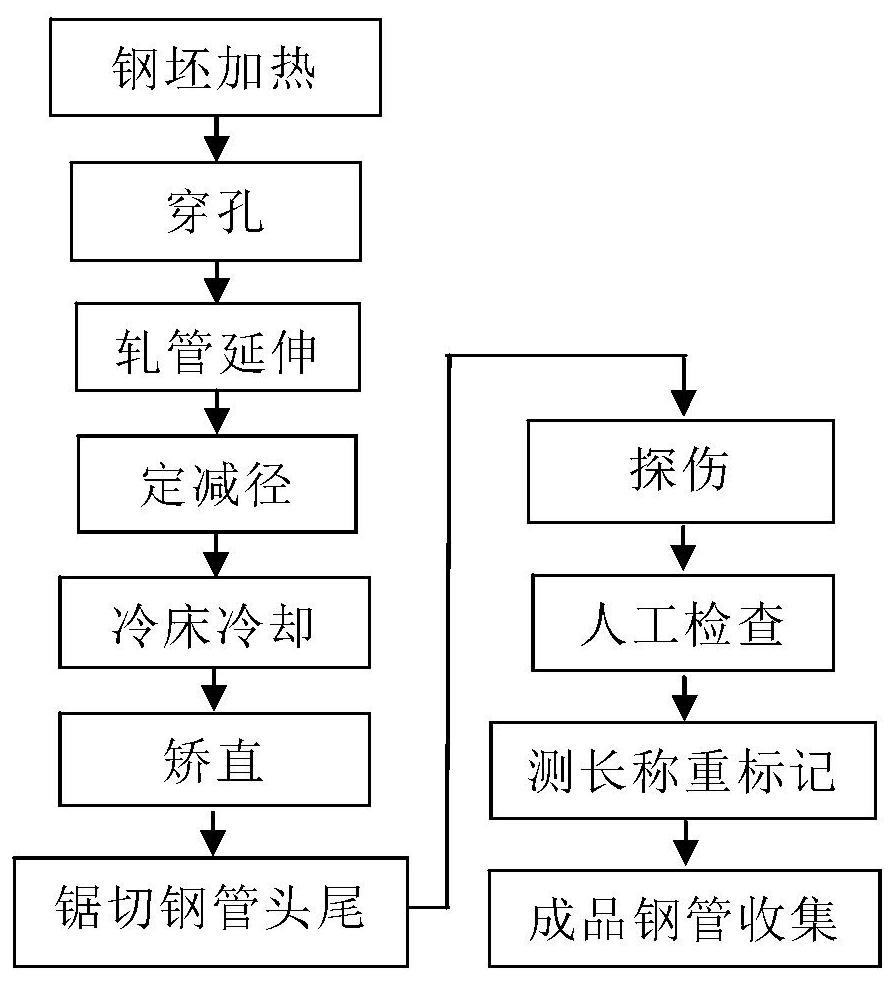

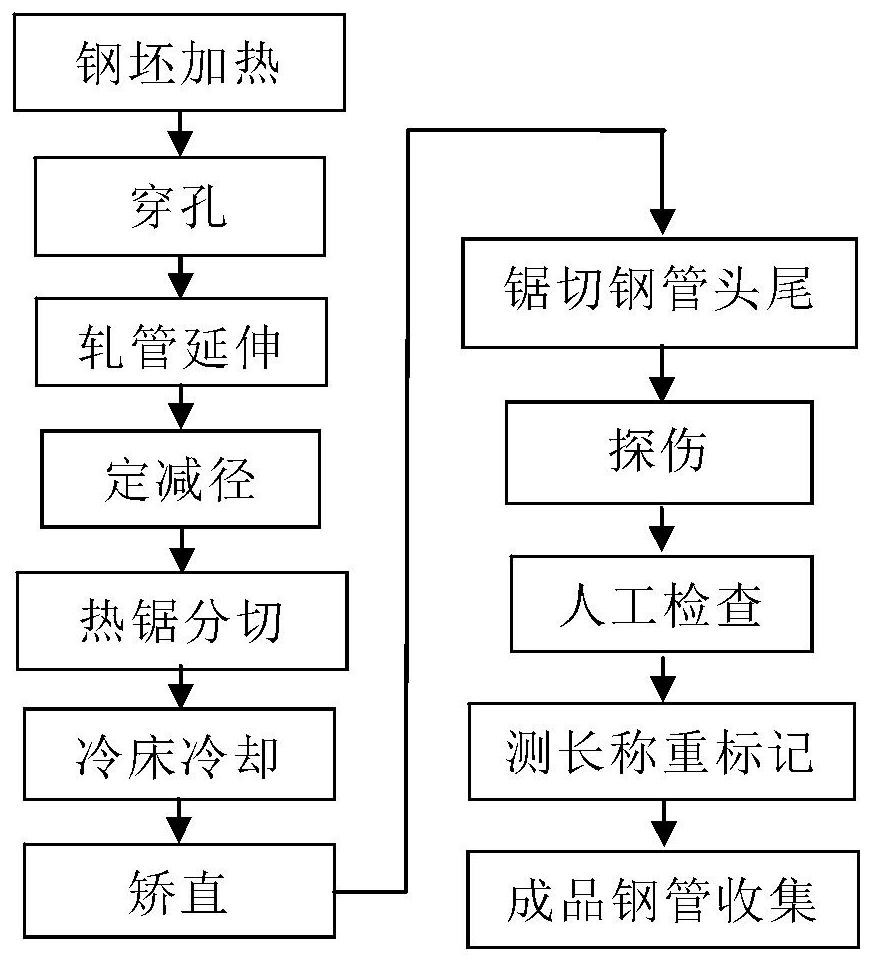

Production method of hot-rolled seamless steel pipes

InactiveCN112775186AIncrease production capacityReduce yieldMetal rolling arrangementsProcess engineeringHeating furnace

The invention discloses a production method of hot-rolled seamless steel pipes. The production method comprises the following steps: heating a steel billet in a heating furnace; perforating the steel billet into a hollow billet by using a perforating machine; rolling pipes and extending; sizing and reducing; thermally sawing and cutting; cooling by using a cooling bed; straightening by using a straightening machine; sawing the heads and the tails of the steel pipes to saw the steel pipes into required lengths; checking and accepting, and completing production of finished products of seamless steel pipes. According to the production method of the hot-rolled seamless steel pipes, the shortcomings and the defects that the hot-rolled seamless steel pipe manufacturing process in the prior art can only achieve single-length production, the production efficiency is low, the yield is low, and the productivity improvement of a production line is restricted are overcome; upgrading and transformation from single-length production to double-length or multi-length production are achieved; and the production method of the hot-rolled seamless steel pipes has the advantages of small cutting loss, high yield, low unit product manufacturing cost and high production line productivity.

Owner:TAIYUAN HEAVY IND TECH IND CO LTD

High-speed bar yield improvement method

InactiveCN110180890AIncrease water pressureUniform heating temperatureTemperature control deviceMetal rolling arrangementsTemperature controlHeating furnace

The invention relates to the technical field of high-speed bar yield improvement, and discloses a high-speed bar yield improvement method. The method comprises the following steps that (1) the yield is improved by controlling a heating zone with the heating temperature controlled at 1,000-1,400 DEG C to be preserved for 4-7 hours, the start heating temperature in a heating furnace is 1,100 DEG C,and the temperature in the heating furnace is controlled higher than or equal to 850 DEG C after the heating is finished; a heating system is strictly executed, and the heating efficiency is improved,so that the billet heating temperature is promoted to be uniform, black marks do not appear, the oxidation burning loss is reduced, the furnace condition is kept normal, the maintenance difficulty ofthe bottom of the heating furnace is reduced, and the production is guaranteed to be smooth. According to the method, less finished scale is generated due to good guide groove air nozzles of water tanks, good water nozzle gaps, correct maintenance and water pressure increase of the water tanks, the yield of high-speed bars is integrally improved from multiple aspects, therefore, it is convenientfor an enterprise to implement the method effectively and efficiently, the implementation efficiency and the yield of the high-speed bars are improved, and the method is convenient to apply.

Owner:成渝钒钛科技有限公司

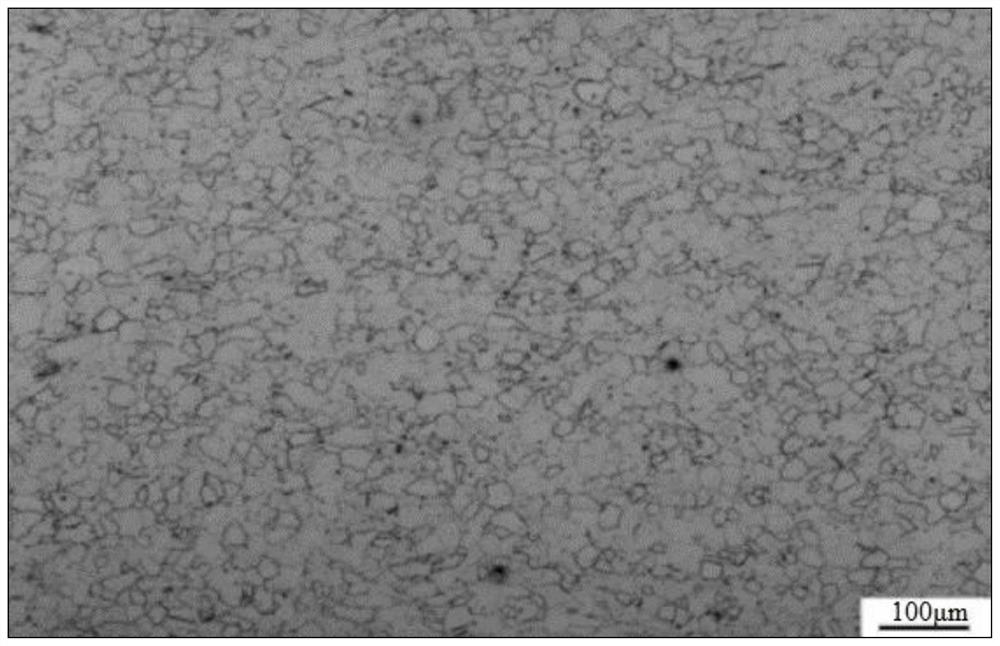

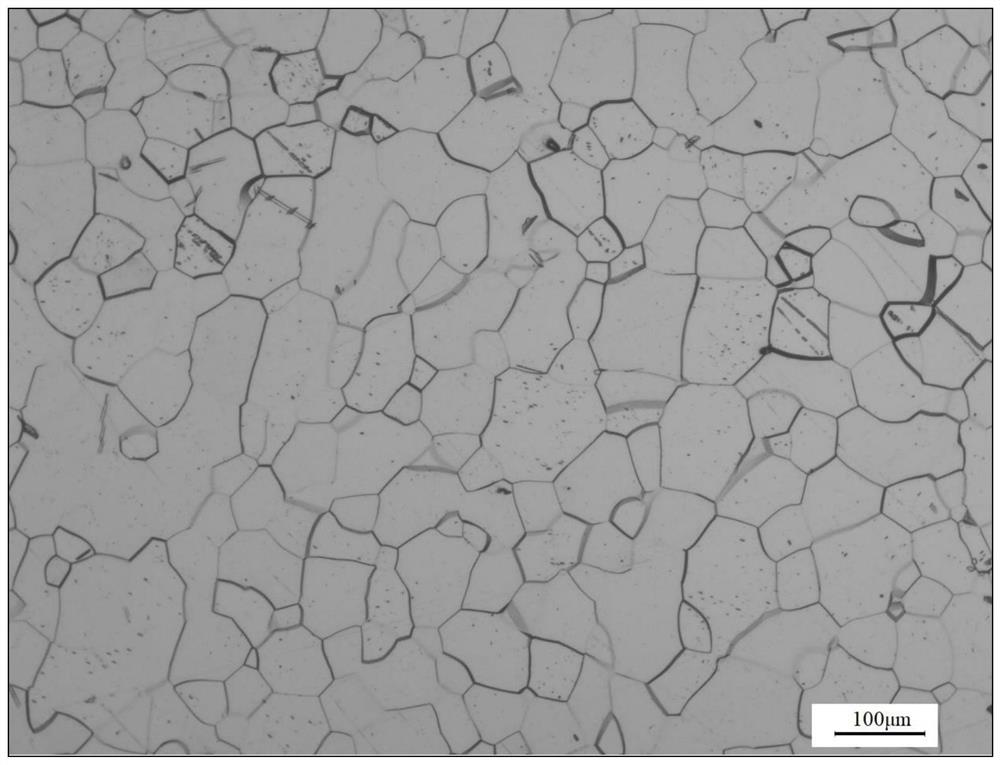

High-efficiency and low-cost preparation method of ultra-long fine-grain industrial pure titanium rod billet for cross piercing

PendingCN114871277AAvoid growing up problemsEfficient crushingForging/pressing devicesTemperature control deviceIngotTitanium

The invention discloses a high-efficiency and low-cost preparation method of an ultra-long fine-grain industrial pure titanium rod billet for cross piercing. The method comprises the following steps: 1, carrying out one-heating-number blooming forging on an industrial pure titanium cast ingot at 1000-1050 DEG C to obtain a rolled forging stock; 2, grinding the rolled forging stock to obtain a ground blank; thirdly, the coping blank is subjected to one-heating-number rolling at the temperature ranging from (Tbeta-15 DEG C) to (Tbeta-45 DEG C), and a finished rolled bar blank is obtained; and 4, peeling and sawing to obtain the industrial pure titanium rod billet for cross piercing. According to the method, the process of beta-phase region single-heating-number cogging and large-tonnage rolling mill one-heating-number large-deformation rolling forming is adopted, the problem of grain growth during multi-heating-number forging heating is avoided, efficient crushing of grains is achieved through combination of single-direction large deformation and alternation of multiple deformation modes, generation of fine grain structures in products is guaranteed, and the yield of the products is improved. And meanwhile, the forging heating number and the grinding number are reduced, the technological process is remarkably shortened, the length of a product bar blank is increased, and the preparation cost is reduced.

Owner:WESTERN TITANIUM TECH

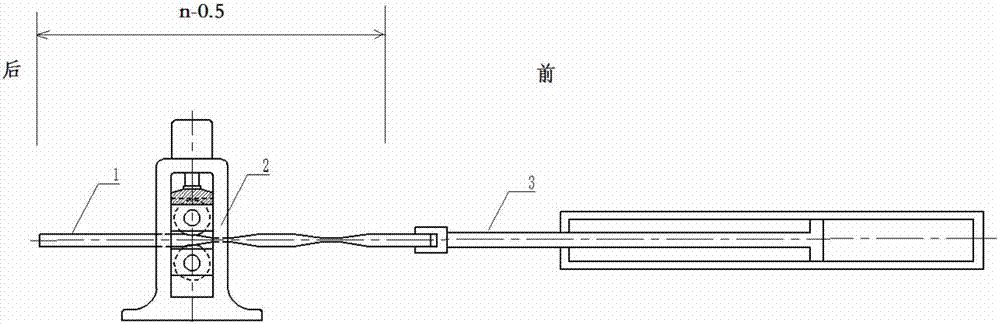

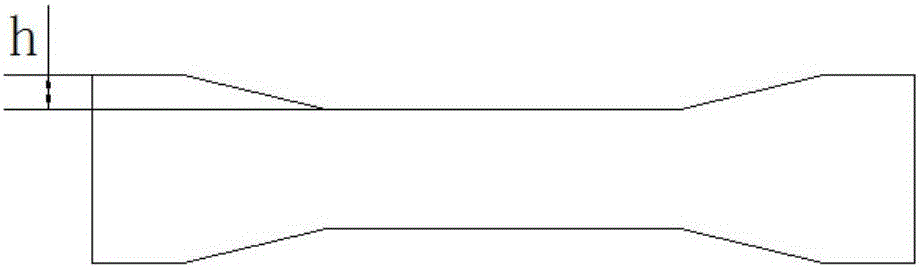

Drawing and rolling combined type multi-plate continuous forming method for variable-section plate springs

The invention relates to a drawing and rolling combined type multi-plate continuous forming method for variable-section plate springs. According to the drawing and rolling combined type multi-plate continuous forming method, the manner that one raw material is continuously rolled into multiple variable-section plate springs is adopted, a flat steel product raw material of n times of length is heated and fed into a variable-section rolling machine, a drawing machine clamps the flat steel product raw material and applies tension to the flat steel product raw material at the front end, under the combined action of the tension and the rolling force, variable-section rolling of the n-0.5 plate springs at the back end is completed firstly, and then the remaining 0.5 plate spring is rolled. By the adoption of the drawing and rolling combined type multi-plate continuous forming method for the variable-section plate springs, the production efficiency can be significantly improved, the end cut loss can be reduced, and the yield can be improved; and in this way, the production cost is reduced, and economic benefits are increased.

Owner:NORTHEASTERN UNIV

Low-voltage fireproof cable

ActiveCN112768133AReduce cut lossReduce separationInsulated cablesInsulated conductorsEngineeringStructural engineering

The invention relates to the technical field of cables, and particularly relates to a low-voltage fireproof cable which comprises a cable core, an insulating layer, a protective layer, a protective tube, two connecting blocks and a limiting tube. The limiting tube is fixedly connected with the opposite ends of the connecting blocks, a cutting knife is arranged between the limiting tube and the protective tube and is in a circular ring shape, and positioning holes are formed in the upper portion and the lower portion of the cutting knife. The free end of the limiting tube is fixedly connected with a guide pipe, a receding groove is formed in the end, close to the limiting pipe, of the guide pipe, two springs are arranged in the receding groove, one end of each spring is fixedly connected with the inner wall of the receding groove, two circular plates are arranged in the receding groove, and each circular plate is fixedly connected with the opposite end of the corresponding spring. The other end of each circular plate is fixedly connected with a positioning shaft, and one end of each positioning shaft penetrates through the corresponding limiting tube and is inserted into the corresponding positioning hole. A user can conveniently cut off a cable in time, and the situation that the cable is cut by a cutter is reduced.

Owner:金太阳电缆有限公司

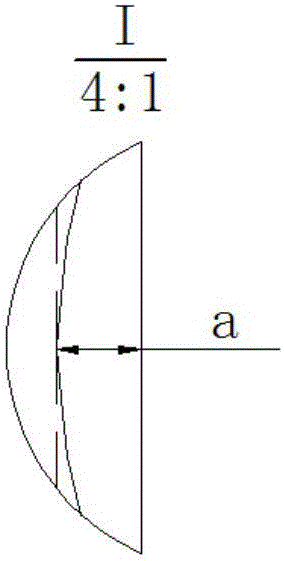

Ten-gate holeless rod continuous rolling process

InactiveCN108296283AImprove the annual operating rateImprove productivityTemperature control deviceRollsReduction rateStrip mill

The invention discloses a ten-gate holeless rod continuous rolling process, and belongs to a metal rolling process. The ten-gate holeless rod continuous rolling process is characterized in that hole rollers in previous ten gates of rod continuous rolling are replaced by flat rollers; hole rolling of rods in the previous ten gates is replaced by holeless rolling; holeless rolling in the previous ten gates is adopted to roll the rods; the rolling parameters are as follows: the rolling height-width ratio is 0.90-1.8; the reduction rate in each gate is 20%-60%; the rolling temperature is 950 DEG C-1100 DEG C; the height*width range of blanks is 150 mm*150 mm-165 mm*165 mm; the absolute broadsiding coefficient range is 0.18-0.45; holeless rolling of the rods in the previous ten gates is realized; the production cost is reduced; the product quality and the utilization rate of a rolling mill are improved; and the application range of the blanks is widened.

Owner:HUATIAN NANJING ENG & TECH CORP MCC

Control method of stretch-reducing mill steel tube thickening terminal

ActiveCN100534656CShorten the lengthHigh yieldRoll mill control devicesMetal rolling arrangementsSheet steelWork roll

The invention relates to the cutting loss control technology of the thickened end of the steel pipe head and tail during the tension reduction process of the seamless steel pipe. A method for controlling the thickening end of a tensioning and reducing machine steel pipe is to calculate the control factor table of the thickening end of the steel pipe according to the distribution law of the wall thickness of the pipe end of the tensioning and reducing machine. Adaptive increase or decrease in the number of racks participating in the CEC action, and the adjustment of the additional tension acting on the thickening end of the steel pipe head and tail to shorten the thickening end of the head and tail; the steps to calculate the CEC factor table of the tensioning and reducing machine are: determine the basic adjustment according to the average tension Speed grade and maximum speed regulation grade; calculate the original CEC speed regulation factor according to the change of roll working diameter; construct the original CEC speed regulation factor table; The number of racks participating in the CEC function at the same time, and the original CEC factor table is corrected. The invention can effectively shorten the length of the thickening end of the steel pipe and improve the yield of the steel pipe.

Owner:BAOSHAN IRON & STEEL CO LTD

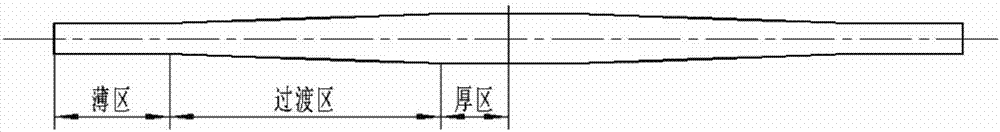

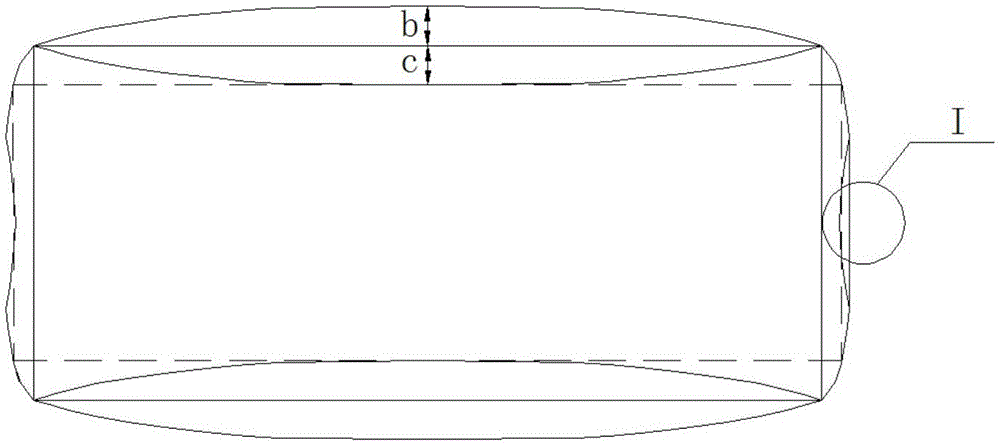

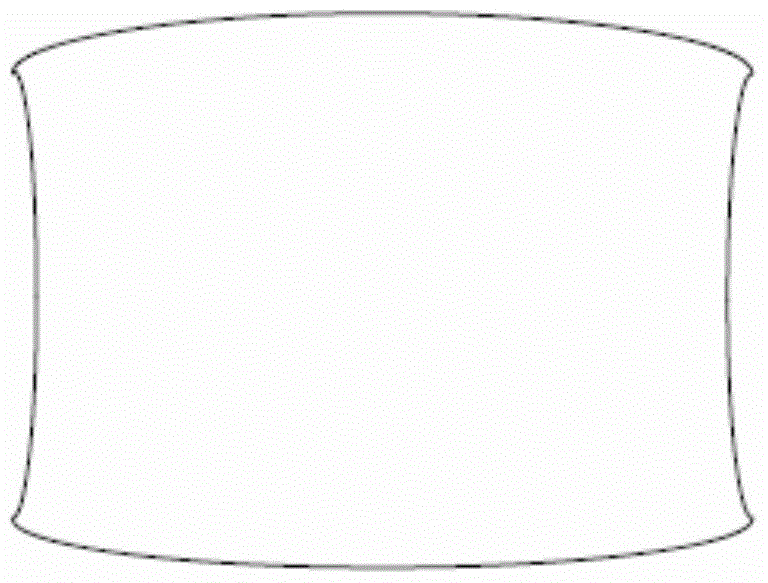

A Method of Reducing Cutting Loss of Wide and Heavy Plates

ActiveCN106311757BReduce cut lossHigh yieldRare end control deviceMetal rolling arrangementsSheet steelThick plate

The invention relates to a method for reducing cutting loss of wide and thick plates. The edge cutting amount of steel plates can be reduced effectively by reasonably controlling values of head tails and fish tails of the steel plates and the recessed values of edges, so that the yield of the wide and thick plates is improved. Compared with the prior art, the method for reducing the cutting loss of the wide and thick plates has the advantages that the cutting loss of the steel plates is reduced obviously after the method is used, and the yield of each steel plate can be increased by about 0.2%-0.7%.

Owner:NANJING IRON & STEEL CO LTD +1

Method for reducing cutting loss of wide and thick plates

ActiveCN106311757AReduce cut lossHigh yieldRare end control deviceMetal rolling arrangementsThick plateEngineering

The invention relates to a method for reducing cutting loss of wide and thick plates. The edge cutting amount of steel plates can be reduced effectively by reasonably controlling values of head tails and fish tails of the steel plates and the recessed values of edges, so that the yield of the wide and thick plates is improved. Compared with the prior art, the method for reducing the cutting loss of the wide and thick plates has the advantages that the cutting loss of the steel plates is reduced obviously after the method is used, and the yield of each steel plate can be increased by about 0.2%-0.7%.

Owner:NANJING IRON & STEEL CO LTD +1

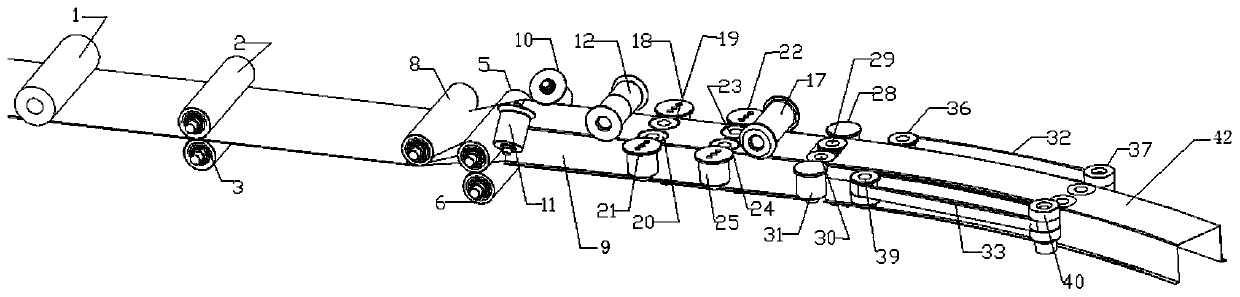

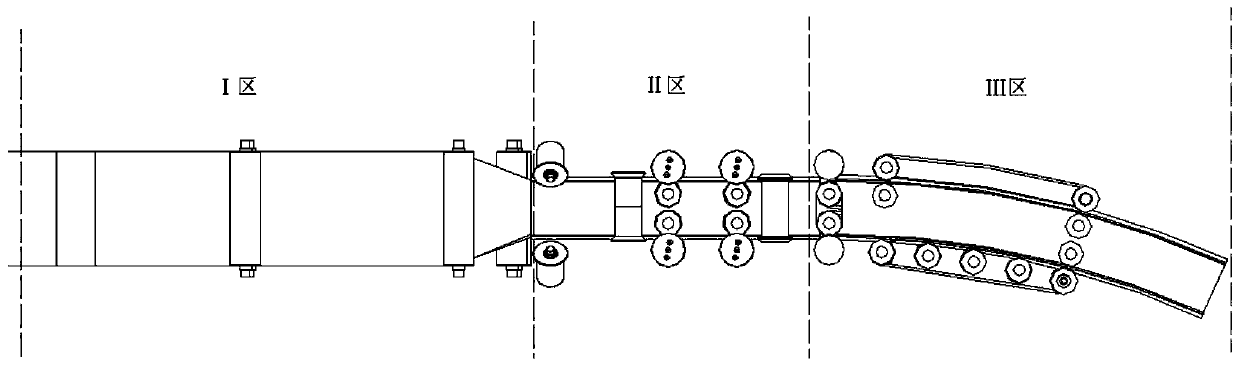

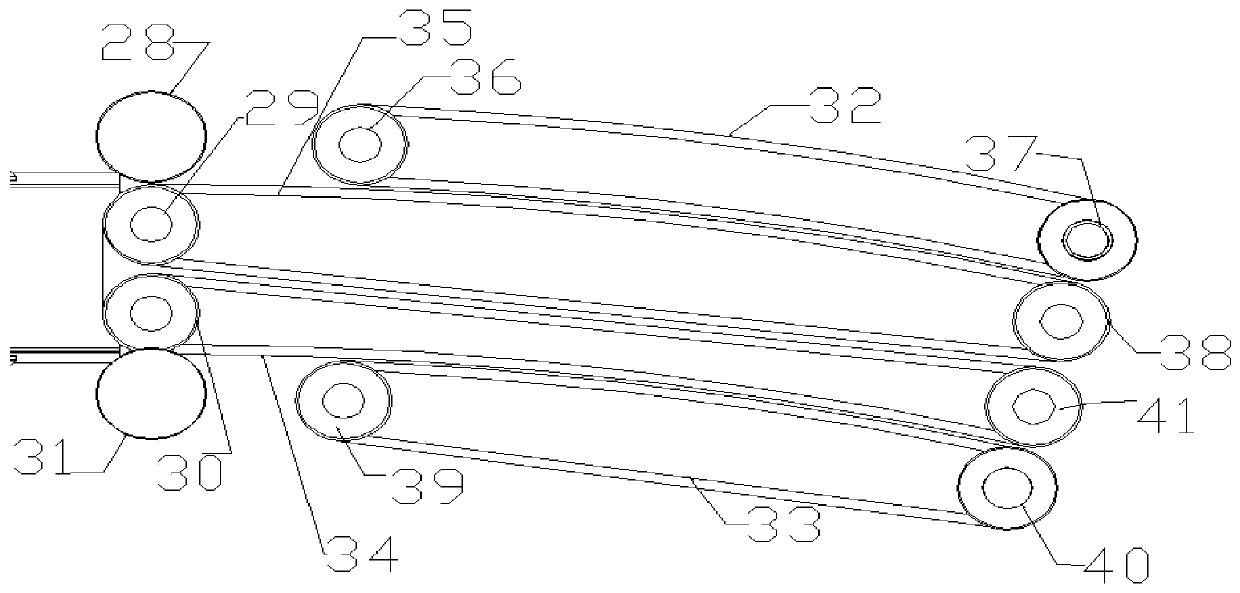

Preparation equipment and method for prefabricated body with bent section

ActiveCN111203996AEnabling high-performance manufacturingImprove reliabilityEngineeringResin-Based Composite

The invention belongs to the technical field of resin-based composite material forming, and relates to preparation equipment and method for a prefabricated body with a bent section. For the laying process of an undevelopable complex curved surface, the external force applied by a hand is uncontrollable and high in randomness, the actual orientation of fibers is difficult to predict, so that the mechanical property dispersity of the composite material is high, and the performance value deviates from an expected design value; and the preparation equipment of the prefabricated body with the bentsection is used for forming a planar strip into the prefabricated body with the n-shaped section, and comprises a feeding and flat strip double-roller guide area I, a geometric section rolling formingarea II and a bent rolling forming and guide output area III which are sequentially connected. Fibrosis is controllable, and reliability and repeatability are good; the operation is continuous, the process is continuously repeated to obtain the preform with unlimited length, and the production efficiency is high; and the cutting loss in the forming process is small, the material cost can be reduced, and forming of preforms with different sections is met.

Owner:AVIC BASIC TECH RES INST

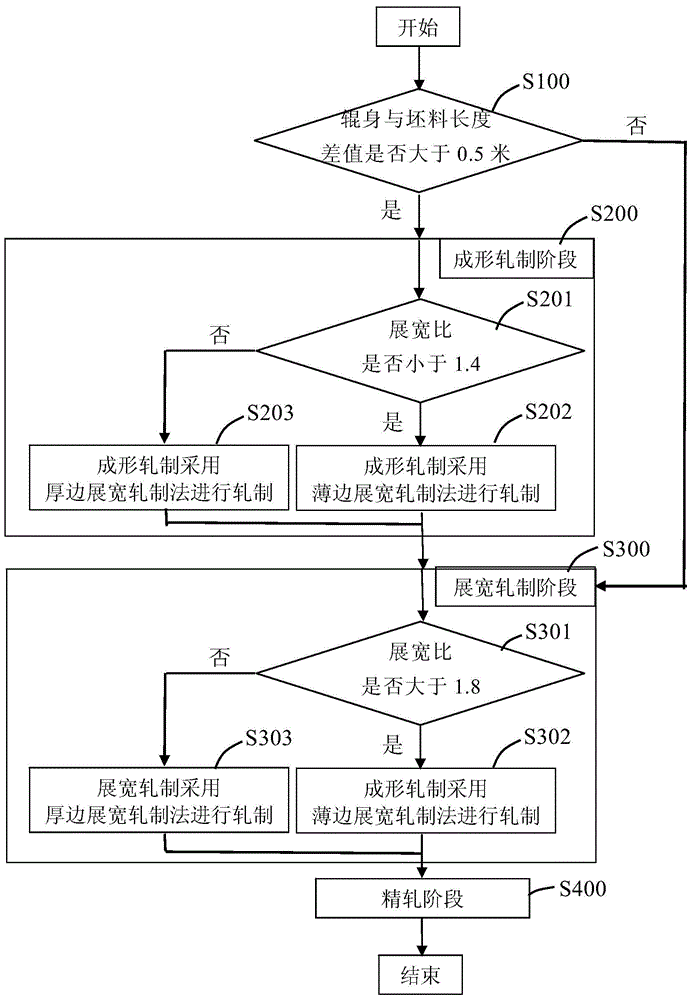

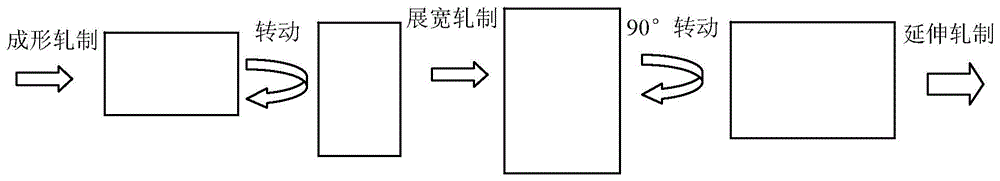

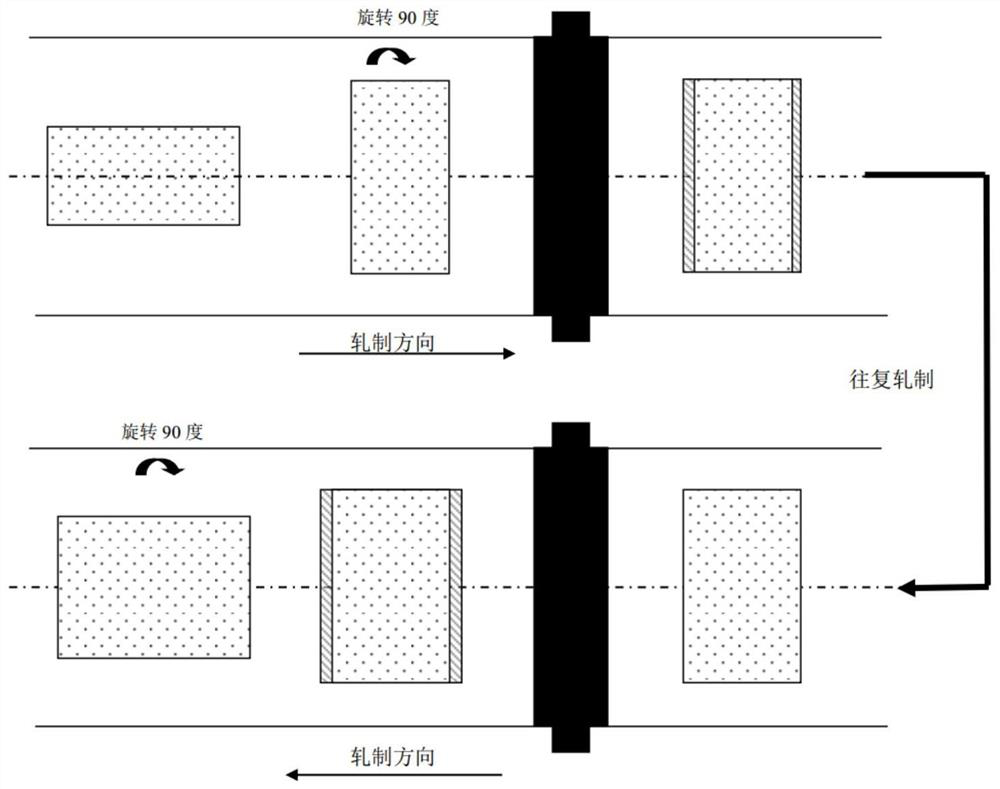

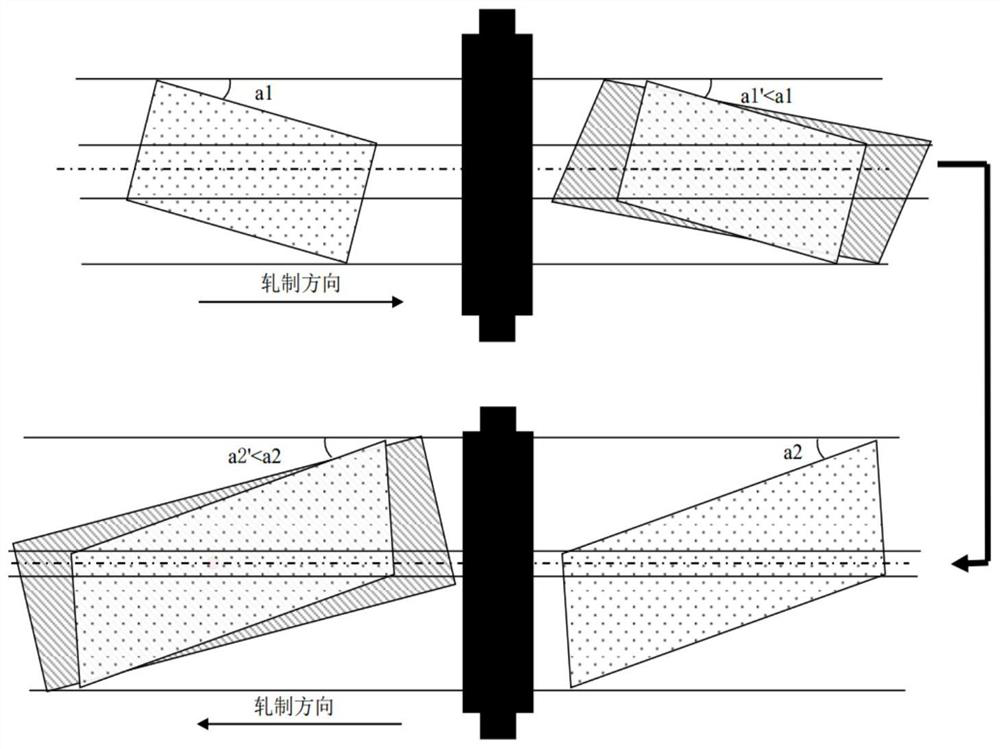

Slab rolling method

ActiveCN106269859AImprove uniformityReduce cut lossProfile control deviceMetal rolling arrangementsControl systemSizing

The invention discloses a slab rolling method comprising the following phases: sizing rolling, broadside rolling and finishing rolling; before sizing rolling, whether the difference between a rolling mill barrel length and a blank length is bigger than 0.5m or not is determined; if the difference is <=0.5m, the broadside rolling is directly carried out; if the difference is bigger than 0.5m, the sizing rolling is carried out; when the sizing rolling is carried out, whether the blank broadside rolling ratio is smaller than 1.4 or not is determined; if the blank broadside rolling ratio is smaller than 1.4, a thin-side broadside rolling mode is carried out; if the blank broadside rolling ratio is not smaller than 1.4, a Mizushima Automatic Plan View Pattern Control System (MAS) mode is carried out; the slab rolling method can reduce cutting loss, thus improving rolling yield.

Owner:BAOSHAN IRON & STEEL CO LTD

A Thick Plate Rolling Control Method for Eliminating the Edge Defects of Casting Slab

ActiveCN103752622BThere will be no "bucket waist" phenomenonReduce trimmingMetal rolling stand detailsProfile control deviceThick plateMaterials science

Owner:BAOSHAN IRON & STEEL CO LTD

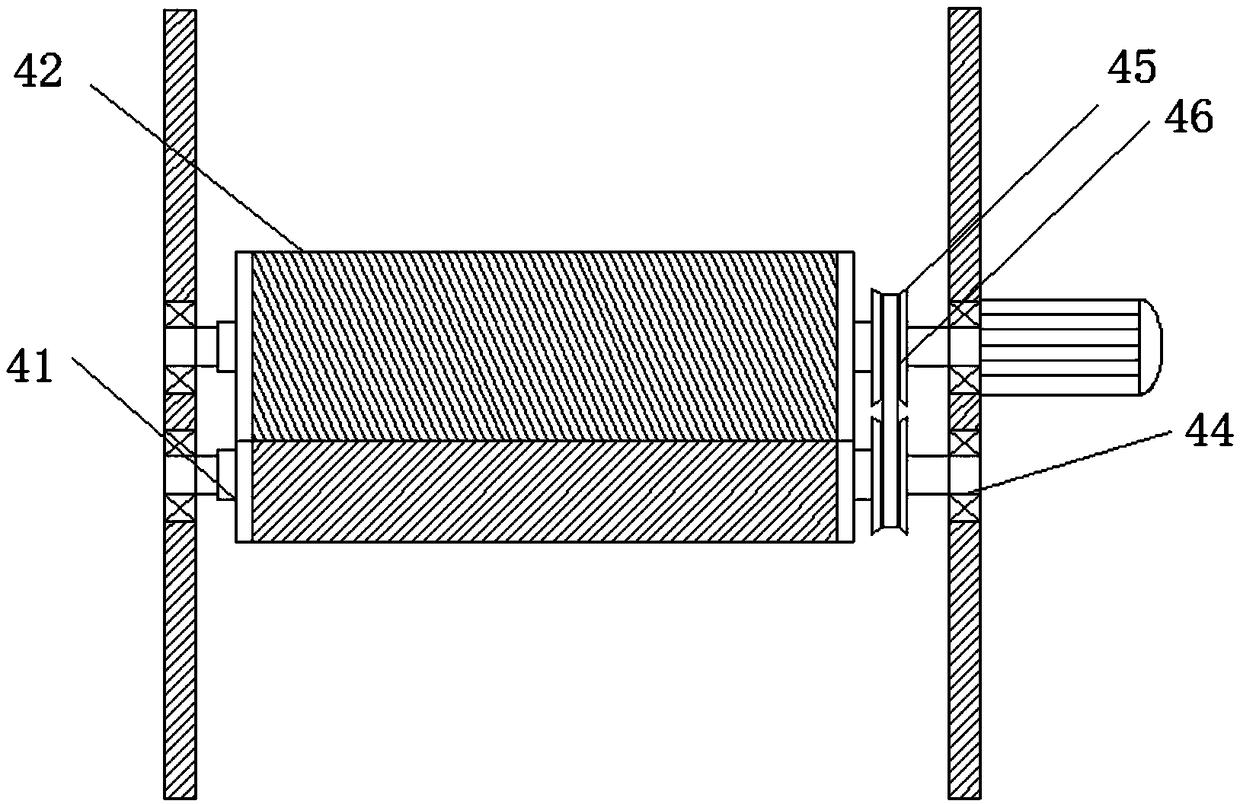

Steel-coil-sampling fixing device

ActiveCN103398866AReduce cut lossAvoid personal injuryWithdrawing sample devicesDrive shaftHydraulic cylinder

The invention provides a steel-coil-sampling fixing device, and belongs to the technical field of steel coil sampling. The device comprises a land-roll driving roll, a land-roll driven roll, a universal driving shaft arranged at the outer side of the land-roll driven roll, swing arms connected to two end of the universal driving shaft, an upper pinch roll arranged between terminal parts of the swing arms, a lower pinch roll located below the upper pinch roll, and a swing hydraulic cylinder which is connected with the swing arms, and can control lifting and falling of the upper pinch roll by driving the swing arms. The steel-coil-sampling fixing device can ensure that steel coils are cut according to required lengths, reduce the cutting loss caused by overlength lengths of unfolded steel coils, and the security in the process of steel sample cutting can be improved.

Owner:BEIJING SHOUGANG CO LTD

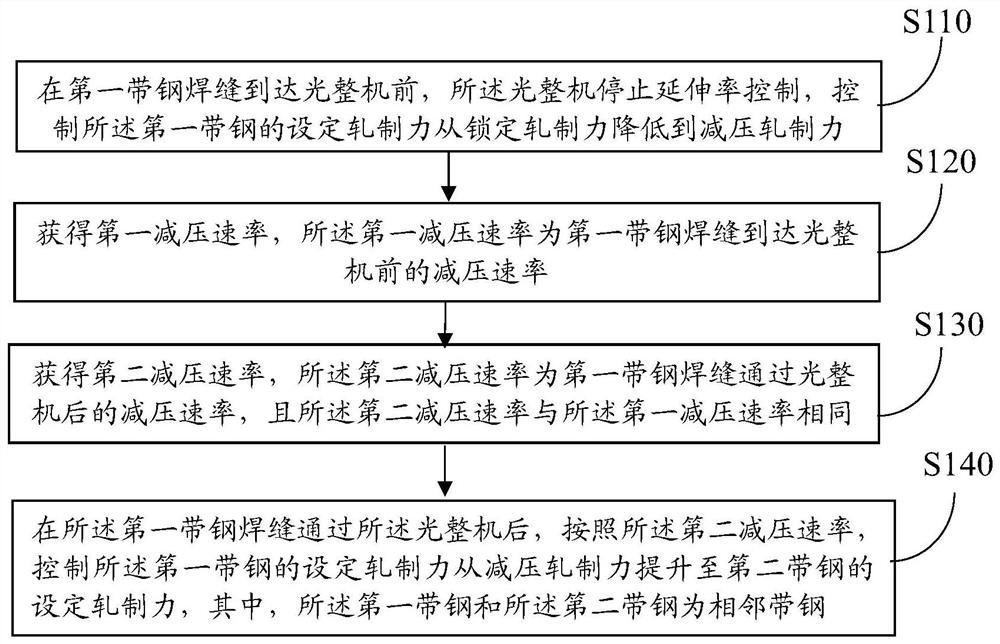

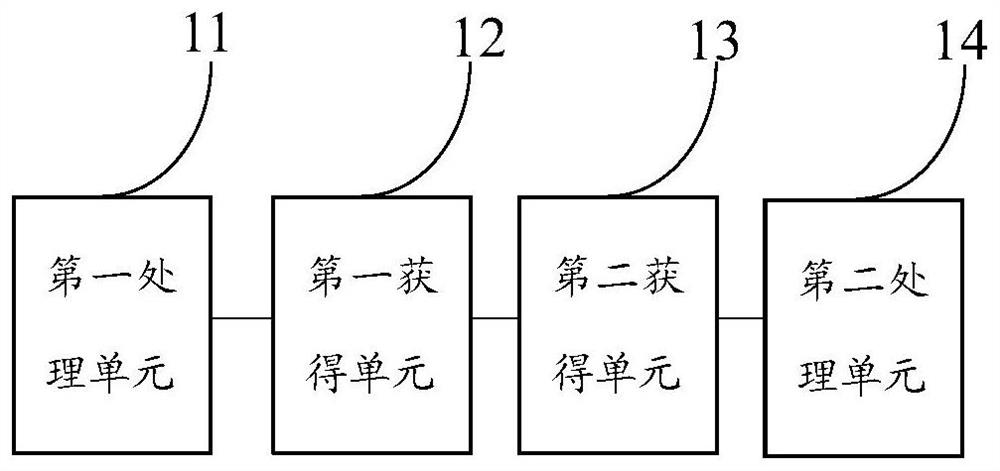

A method and device for controlling tension fluctuation of a galvanized wire weld seam finishing machine

ActiveCN110142314BImprove mechanical propertiesSolve the technical problem of twill defectRoll force/gap control deviceTension/compression control deviceStructural engineeringWeld seam

The invention provides a method for controlling the tension fluctuation of a galvanized wire weld passing through a skin pass machine, comprising: before the first strip weld reaches the skin pass machine, the skin pass machine stops elongation control and controls its setting The rolling force is reduced to the decompression rolling force; the first decompression rate is obtained, and the first decompression rate is the decompression rate before the first strip weld seam reaches the skin pass mill; the second decompression rate is obtained, so The second decompression rate is the same as the first decompression rate; after the first strip weld passes through the skin pass mill, the set rolling force is controlled to increase to the second decompression rate according to the second decompression rate. The set rolling force for the strip. It solves the technical problem in the prior art that the tension of the skin-pass machine fluctuates greatly due to the drastic change of the reduction amount during the decompression, and the twill defect of the weld seam of the strip steel is caused. Through the control algorithm and program, the tension fluctuation when the galvanized wire weld passes through the skin pass machine is reduced, and then the mechanical properties of the strip are improved, the cutting loss is reduced, and the technical effect of the yield is guaranteed.

Owner:BEIJING SHOUGANG COLD ROLLED SHEET

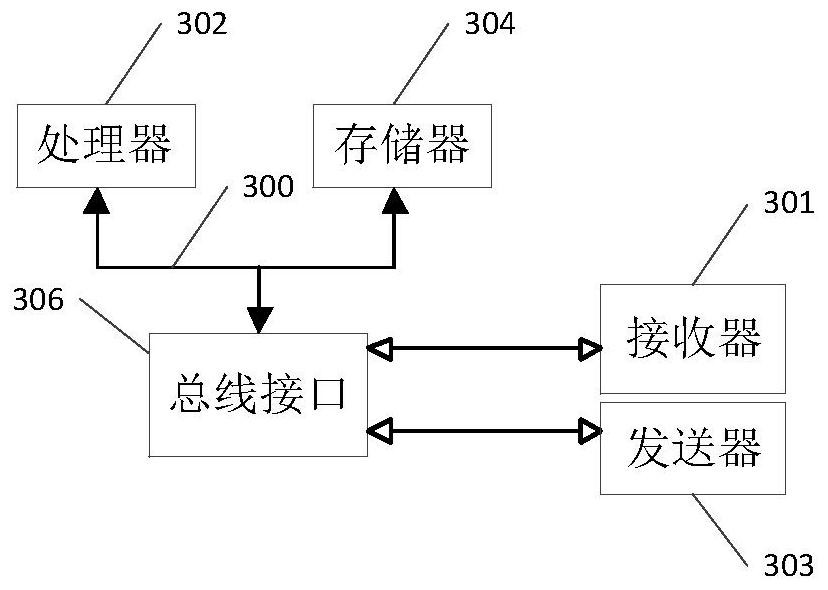

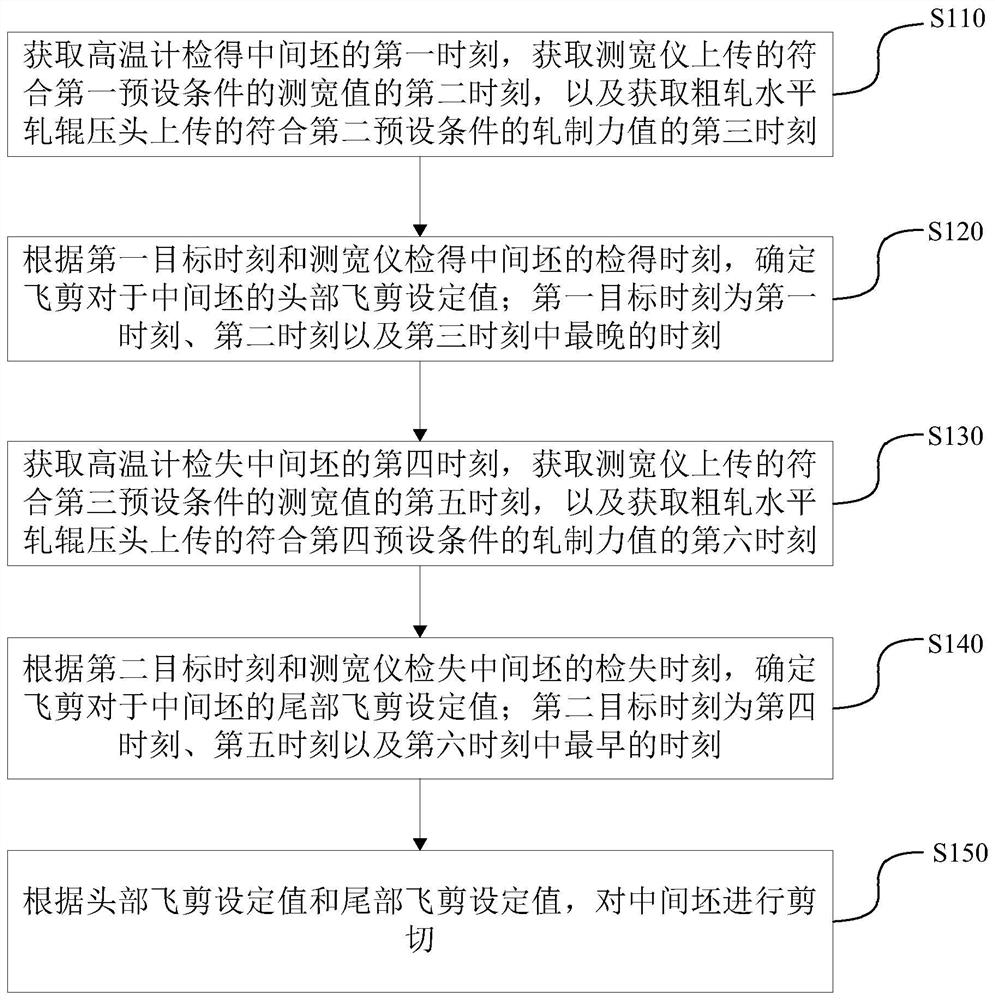

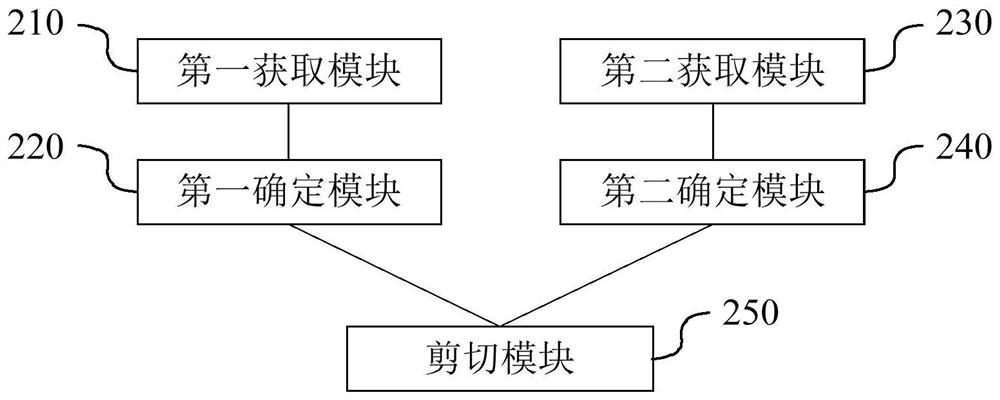

Flying shear shearing method and device and flying shear device

InactiveCN112387786AImprove reliabilityShear length minimizationRoll mill control devicesMetal rolling arrangementsClassical mechanicsMechanics

The invention is applicable to the technical field of metal smelting, and provides a flying shear shearing method and device and a flying shear device. The method comprises the steps that a first moment when a pyrometer detects an intermediate billet is obtained, a second moment of a width measurement value which is uploaded by a width gauge and meets a first preset condition is obtained, and a third moment of a rolling force value which is uploaded by a rough rolling horizontal rolling head and meets a second preset condition is obtained; according to a first target moment and the detection moment when the width gauge detects the intermediate billet, a head flying shear set value of a flying shear relative to the intermediate billet is determined, wherein the first target moment is the latest moment in the first moment, the second moment and the third moment; and according to the head flying shear set value and a tail flying shear set value, the intermediate billet is sheared. By means of the flying shear shearing method and device and the flying shear device, the reliability of the flying shear set values of the flying shear can be improved.

Owner:HEBEI IRON AND STEEL

A Thick Plate Continuous Casting Slab Cutting Control System and Its Optimization Calculation Method

The invention discloses a thick-slab continuous casting billet cutting control system, which utilizes thick-slab rolling mill to send commands to short billets, heat pouring process tracking signals and other data, and optimizes the billet grouping of short billets within the scope of the casting machine , to ensure that the slab is cut according to the optimal length of the long slab; a calculation method for optimizing the slab grouping of thick slab continuous casting slabs can successfully find the optimal slab strategy, and optimize the cutting control of the long slab within the range of the casting machine , to control the continuous casting online cutting machine to perform online one-time cutting, thereby reducing cutting scrap, supporting the integration and optimization of continuous casting and thick plate rolling mill efficiency, and improving the efficiency and effect of continuous casting machine billet cutting; the invention has a friendly user interface, It can reduce cutting loss, support scenarios such as single-strand casting, double-strand casting, and casting of different steel types from thick plates to furnaces, ensuring the maximum and optimization of casting machine performance.

Owner:BAOSHAN IRON & STEEL CO LTD

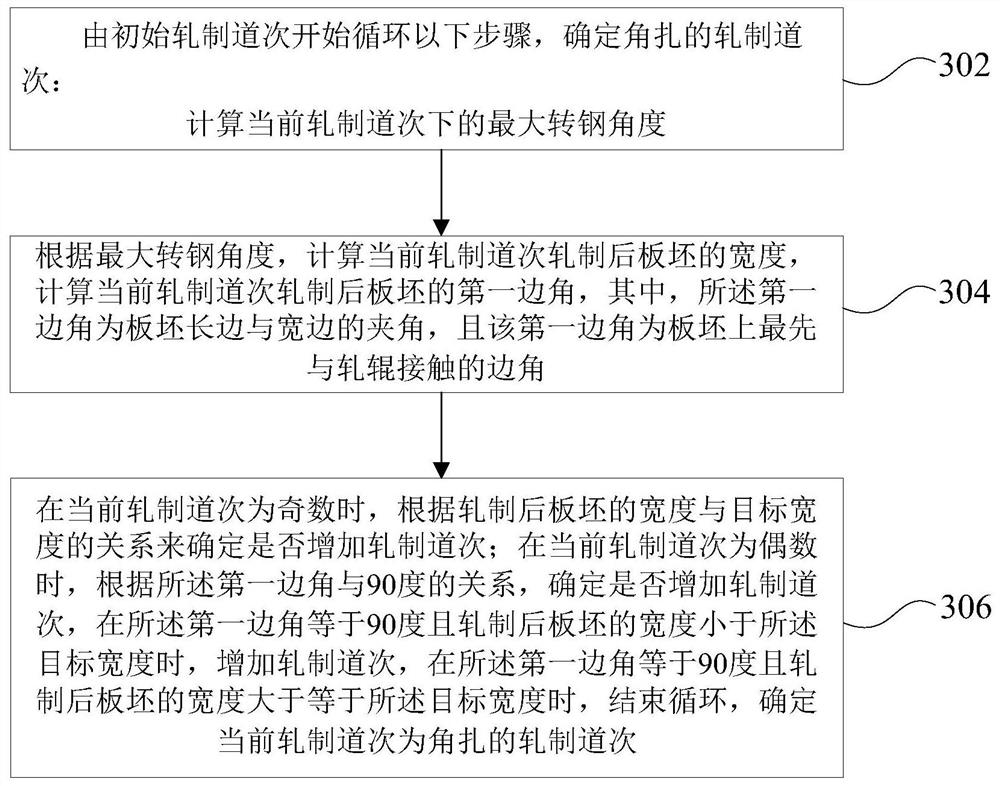

Angle rolling process parameter determination method, device and equipment and readable storage medium

PendingCN114329303AEasy to shapeReduce the impactMetal rolling arrangementsComplex mathematical operationsEngineeringMechanical engineering

Owner:MCC CAPITAL ENGINEERING & RESEARCH

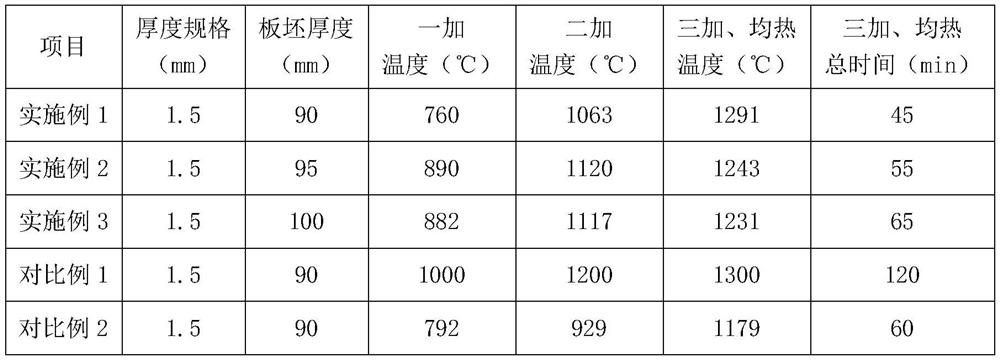

Production process for rolling extreme thin gauge checkered plate through thin slab

ActiveCN113996665AReduce deformation resistanceReduce rolling loadTemperature control deviceWork heating devicesFurnace temperatureLaminar cooling

The invention discloses a production process for rolling an extreme thin gauge checkered plate through a thin slab, which belongs to the field of steel production. The production process comprises the steps of slab heating, rough rolling, finish rolling, laminar cooling and coiling, in the slab heating process, the thickness of the slab is selected to be 90-105 mm, the slab is placed in the middle of a furnace, and the cantilever amount of the two ends of the slab is controlled to be smaller than or equal to 700 mm; the overall time in the furnace is controlled to be 70-140 minutes; the furnace temperature of the first heating furnace is controlled to be 750-900 DEG C; the furnace temperature of the second heating is controlled to be 1050-1130 DEG C, and the total in-furnace time of the first heating and the second heating is controlled to be 35-70 min; and the temperature of the third heating furnace section and the soaking furnace section is controlled in combination with the in-furnace time. Compared with the prior art, the method can be used for continuously and stably producing the extreme thin checkered plates in batches by using the thin slabs.

Owner:RIZHAO STEEL HLDG GROUP

Features

- R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

Why Patsnap Eureka

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Social media

Patsnap Eureka Blog

Learn More Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com