A Thick Plate Rolling Control Method for Eliminating the Edge Defects of Casting Slab

A control method and edge technology, used in contour control, metal rolling stands, metal rolling mill stands, etc., can solve the problem of poor plane shape, failure to reduce edge cutting damage, and failure to fully utilize the characteristics of thick plate equipment, etc. problems, to achieve the effect of reducing the amount of trimming, reducing the cutting loss, and improving the yield

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

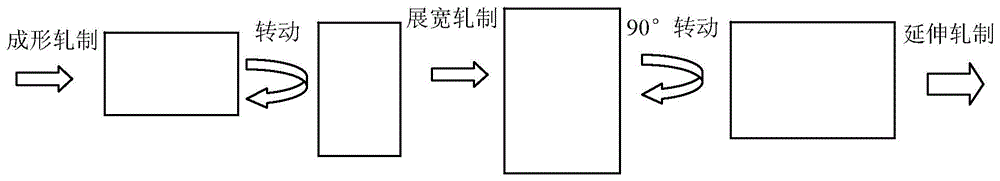

Method used

Image

Examples

Embodiment

[0077] Assume that the continuous casting slab has a length of slab_length of 3 meters and a width of 2 meters, and the steel type is a steel type prone to edge defects.

[0078] see Figure 9 , in the production planning stage before rolling, the continuous casting slab is marked with a new rolling mode label in the computer system.

[0079] Before rolling, the rolling mill control model judges to adopt a new rolling mode.

[0080] When the steel plate comes to the steel turning roller table in front of the rough rolling mill, the control system automatically gives the steel turning instruction and opens the side guide plate.

[0081] Side guide plate opening = 461mm.

[0082] After the steel transfer is completed, in the control system, slab_length=2m, slab_width=3m, and use this as the basic data, switch to the second steel transfer mode, re-calculate the rolling setting, and continue to complete the follow-up according to the calculation results rolling process.

[008...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com