Method for controlling side turning of hot rolling stainless steel band

A control method and technology for stainless steel strips, applied in the direction of metal rolling stands, metal rolling mill stands, etc., can solve the problems of loss, large metal, affecting the yield of cold plates, etc.

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

[0012] Through the collection of various rolling data in the stainless steel hot rolling process, combined with the measured value of the rollover width of the strip surface, after comparative analysis and research, on the basis of ensuring the width and rolling stability, Taiyuan Iron and Steel Co., Ltd. developed the 1549 hot rolling strip Edge rollover control method. The main technical solutions are as follows:

[0013] 1. Optimize the width matching between the continuous casting slab and the finished hot-rolled coil to realize small-width rolling.

[0014] In order to ensure the finished width of the hot-rolled coil, and at the same time require that the side pressure of the rough rolling vertical roll should not be too large, it is necessary to reasonably match the continuous casting billet and the hot-rolled coil. The target value is controlled by 5mm narrower than the width of the finished hot roll.

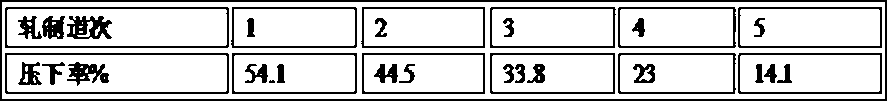

[0015] 2. Determine the side pressure control value of each pass ...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com