Method for reducing cutting loss of wide and thick plates

A technology for wide and thick plates and steel plates, which is applied in the field of reducing the shear loss of wide and thick plates, can solve the problems that the shape of the head, tail and edge of the steel plate is not optimized, and the shape of the head, tail and edge is large, and achieves significant economic benefits. The effect of improving the yield and reducing the cutting loss

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

[0025] Embodiment 1: Q690D high-strength board;

[0026] Billet size: 260×2070×2792mm; order size: 25×2500×21600mm;

[0027] Rolling method: vertical-horizontal-longitudinal;

[0028] Width ratio: 1.23;

[0029] The method flow is as follows Figure 4 As shown, the specific steps are as follows:

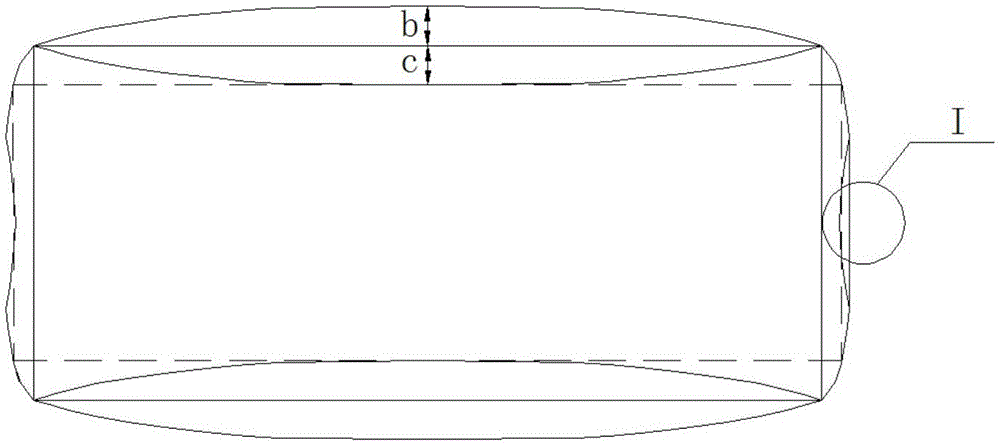

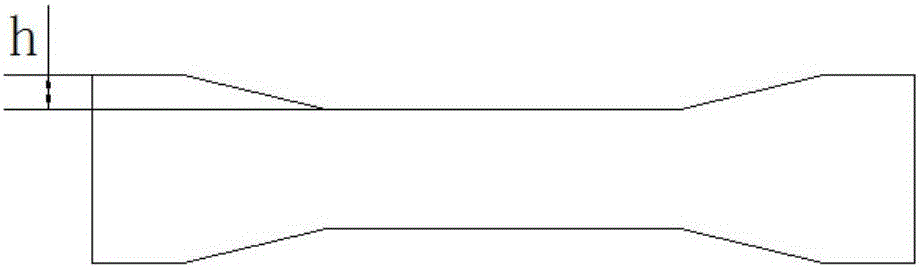

[0030] Initial conditions: the step height h of the rolled piece after the forming pass MAS rolling is 2.6mm, and the step height h of the rolled piece after the widening pass MAS rolling is 3.0mm.

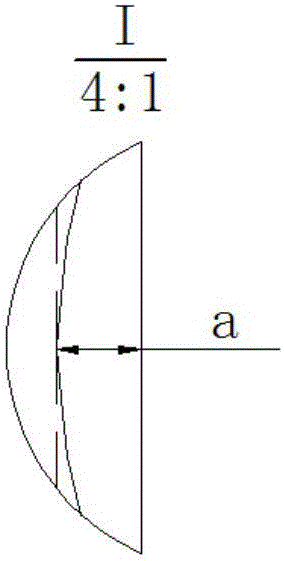

[0031] After rolling, the plane shape detection device on the shearing line detects the plane shape of the steel plate after rolling and obtains the plane shape data of the steel plate. The steel plate data fed back is: the actual size of the steel plate is 25×2533×23195mm, and the fishtail of the steel plate head is concave The value at is -40mm, and the concave value aw of the tail of the steel plate is -20mm, and the concave value a of the fishtail at the head and tail of the stee...

Embodiment 2

[0036] Embodiment 2: S355J low carbon structural steel plate;

[0037] Billet size: 260×2070×2792mm; order size: 35×3500×11000mm;

[0038] Rolling method: vertical-horizontal-longitudinal;

[0039] Width ratio: 1.74;

[0040] The method flow is as follows Figure 4 As shown, the specific steps are as follows:

[0041] 1. Initial conditions: the step height h of the rolled piece after the forming pass MAS rolling is 4.2mm, and the step height h of the rolled piece after the widening pass MAS rolling is 0.2mm.

[0042] 2. The plane shape detection device on the shearing line after rolling detects the plane shape of the steel plate after rolling and obtains the plane shape data of the steel plate. The steel plate data fed back is: the actual size of the steel plate is 35×3650×11760mm, the head of the steel plate is fishtail The concavity value at is 0mm, the concavity value aw of the tail of the steel plate is -10mm, and the concavity value a of the fishtail at the head and t...

PUM

| Property | Measurement | Unit |

|---|---|---|

| length | aaaaa | aaaaa |

| length | aaaaa | aaaaa |

Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com