Patents

Literature

53results about How to "Reduce rolling load" patented technology

Efficacy Topic

Property

Owner

Technical Advancement

Application Domain

Technology Topic

Technology Field Word

Patent Country/Region

Patent Type

Patent Status

Application Year

Inventor

Processing method for producing low-cost high-formability IF (interstitial-free) steel

InactiveCN102581008AHigh drawabilityIncrease productivityTemperature control deviceMetal rolling arrangementsSlow coolingWater cooling

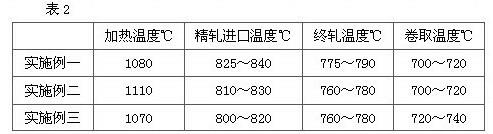

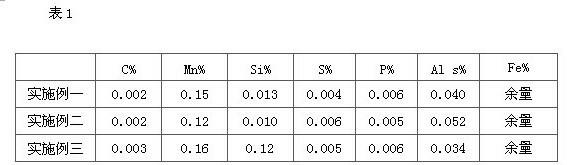

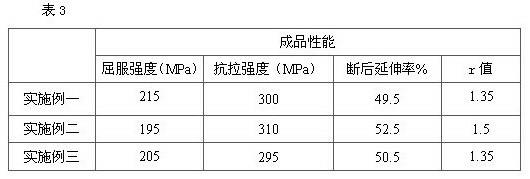

The invention relates to a processing method for producing low-cost high-formability IF (interstitial-free) steel, which is based on thin-slab continuous casting and rolling and adopts a ferrite rolling process to produce the IF steel, belonging to the technical field of IF steel production. The processing method comprises the following working procedures of steelmaking, continuous casting, heating, rolling, cooling and coiling. A thin-slab continuous casting machine is adopted, the thickness of a continuous casting slab is at most 100mm, and the charging temperature is at least 880 DEG C. During hot rolling, a roughing mil and a finishing mill keep a continuous rolling relationship and keep micro-tension control, and water cooling equipment is used between the roughing mil and the finishing mill and is used for uniformly reducing the temperature of an intermediate slab with a thickness of 12-25mm from the temperature at least 950 DEG C of the outlet of the roughing mil into the range of 750-850 DEG C. Finish rolling is carried out in a ferrite area, and a lubrication rolling technology is adopted. The coiling temperature is higher and is 680-760 DEG C, slow cooling is carried out after coiling, and thereby an annealing process is finished. The invention provides a method for obtaining high-formability hot rolled sheets without cold rolling and cover annealing. The method has the advantages of being simple in process, low in cost, high in production efficiency, short in flow and the like, and the formability of products is higher.

Owner:HEBEI IRON AND STEEL

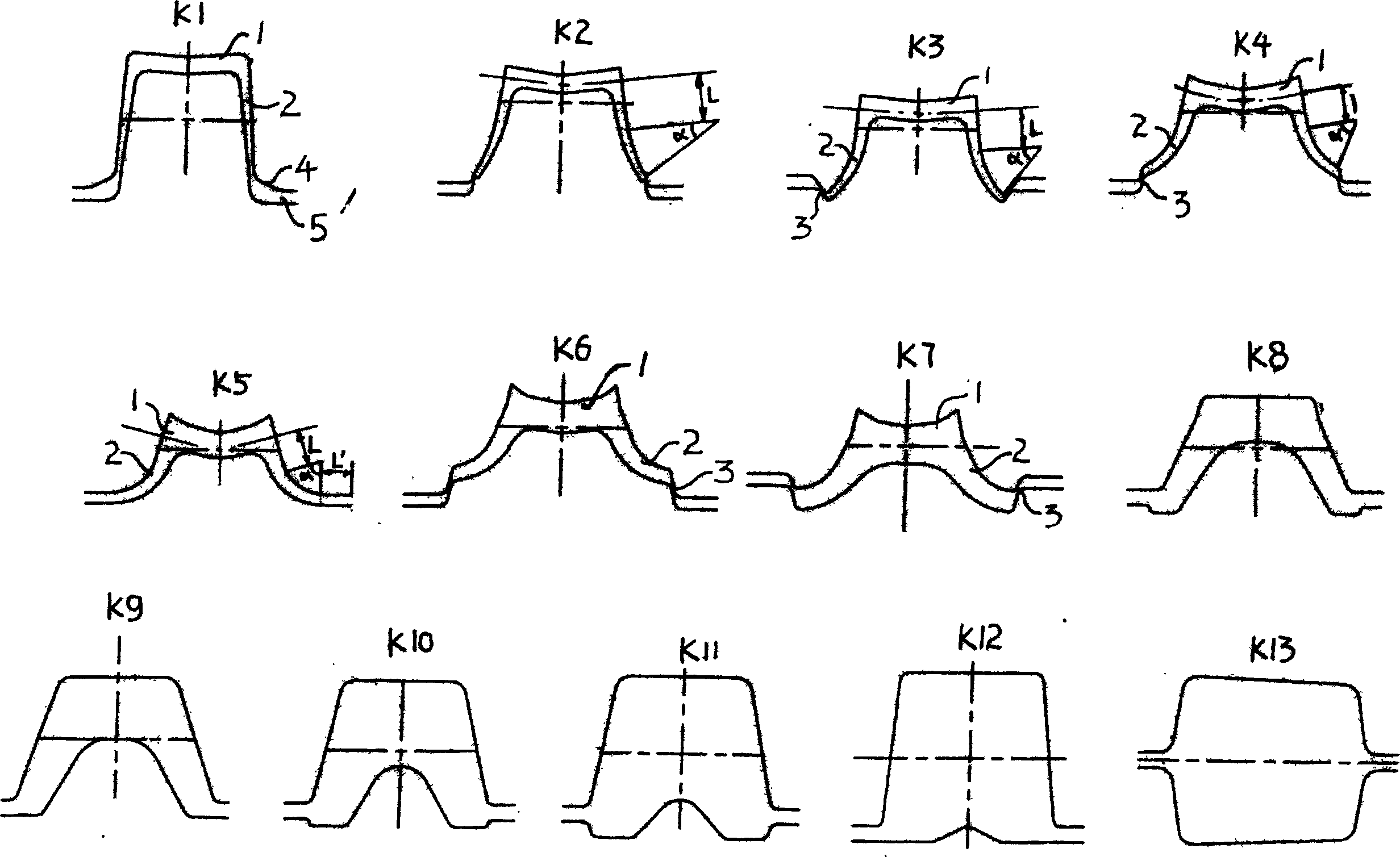

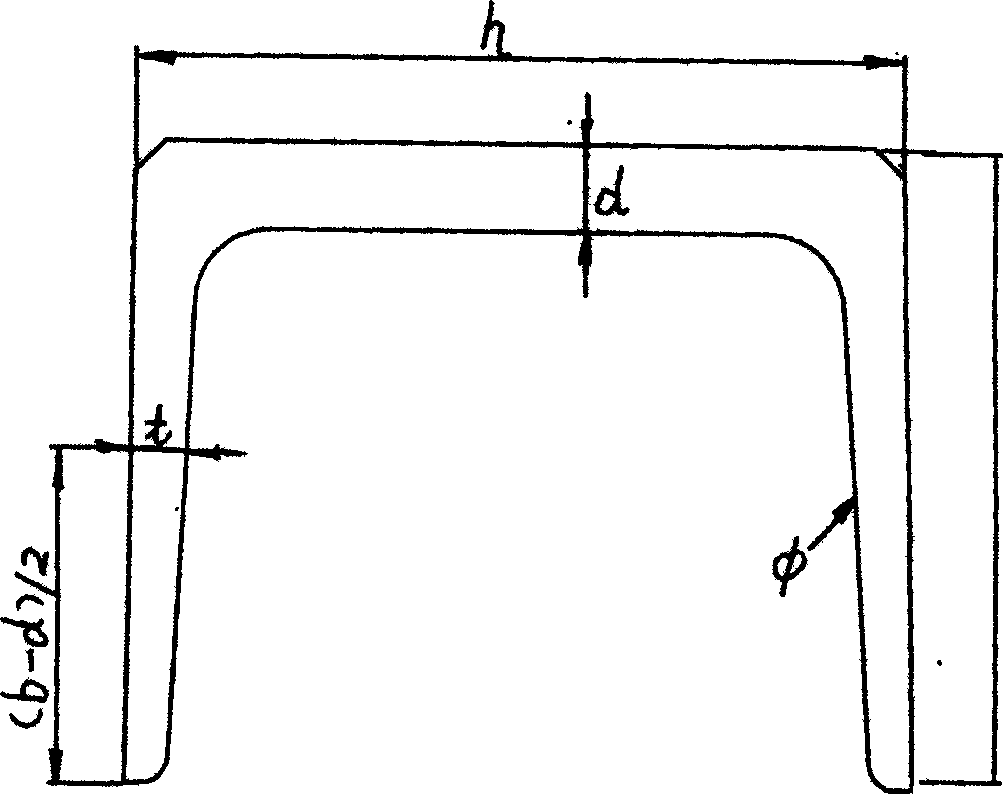

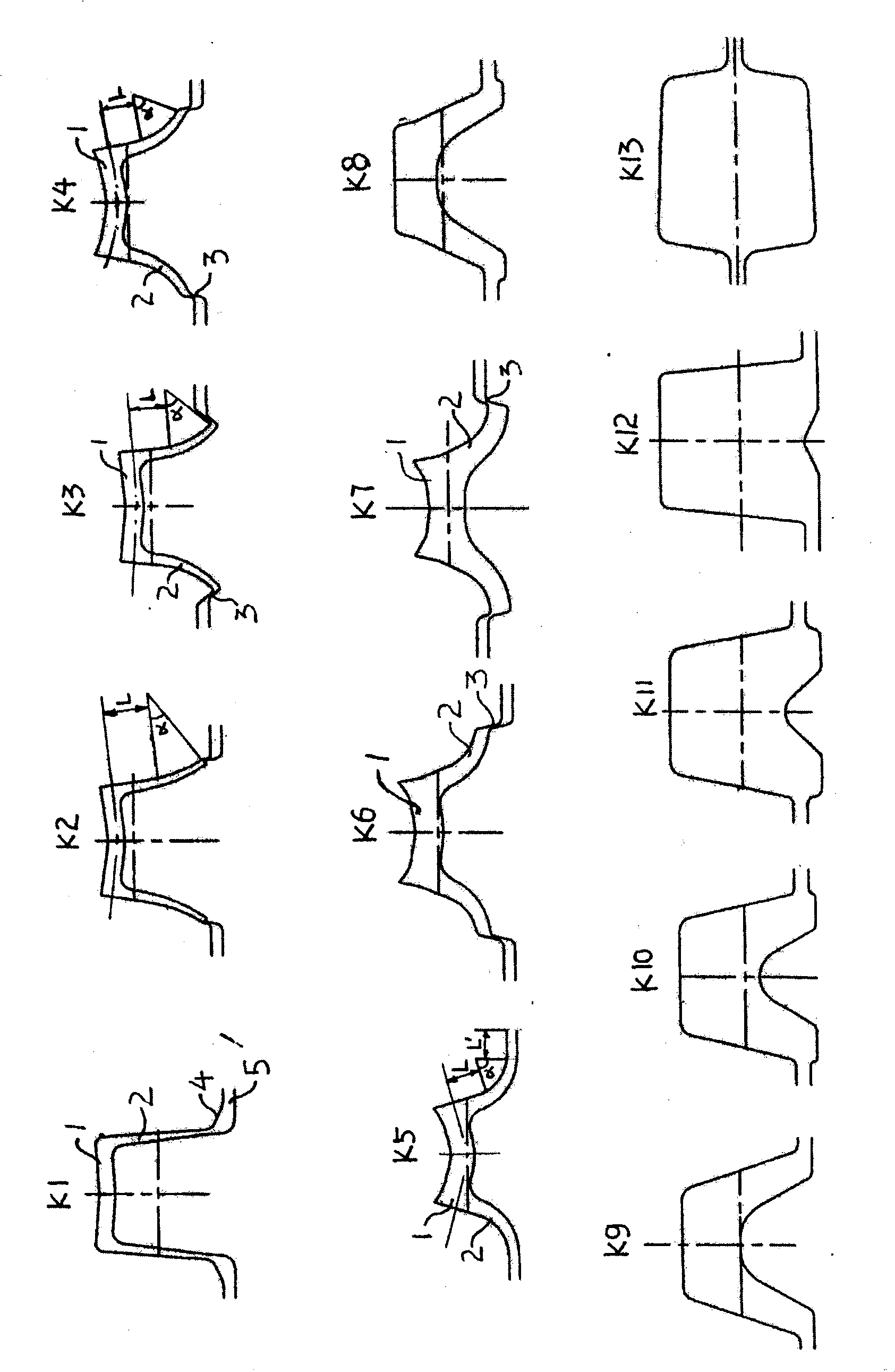

Rolling pass system for deformed channel steel

ActiveCN1608759AImprove deformation conditionsFavorable growthMetal rolling arrangementsLeg lengthChannel width

The present invention discloses one kind of rolling pass system for deformed channel steel with leg length / channel width ratio of 0.8-1.1 in small scale rolling mill. The rolling pass system consists of directly deepening coarse rolling pass, butterfly type middle rolling pass arranged in narrow-wide-narrow rule and straight leg finish gage pass with optimized nip condition. The present invention has improved deforming condition to realize rolling large steel material in small rolling mill, and has the positive effects of raising rolling capacity of rolling mill, reducing pass height, reducing depth of roller slot, decreasing rolling load, etc.

Owner:MAANSHAN IRON & STEEL CO LTD

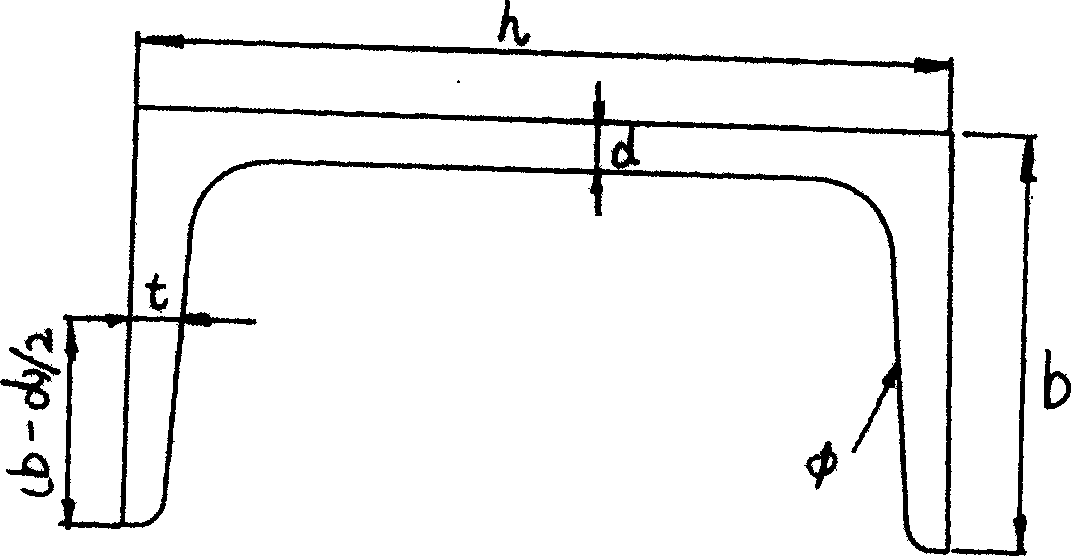

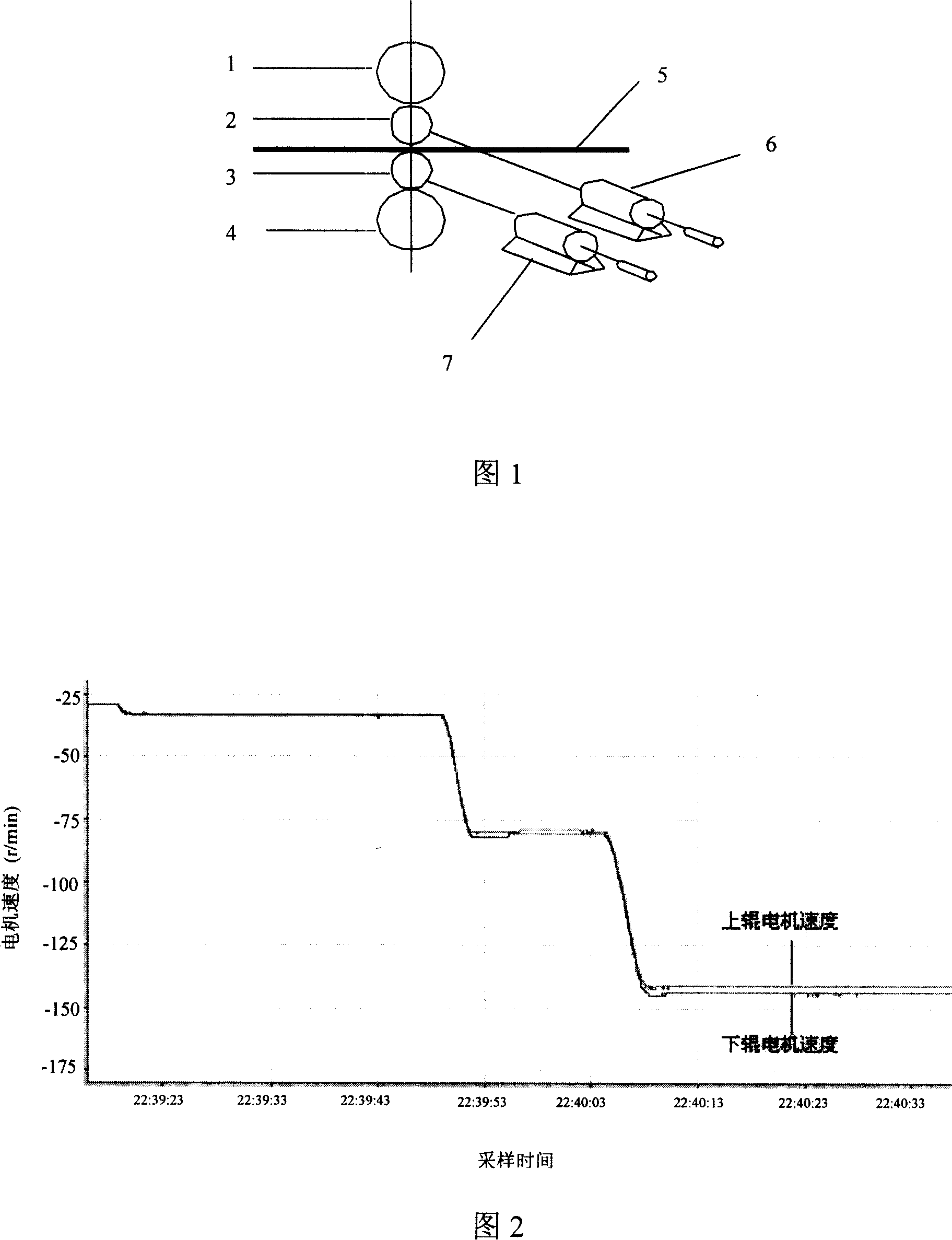

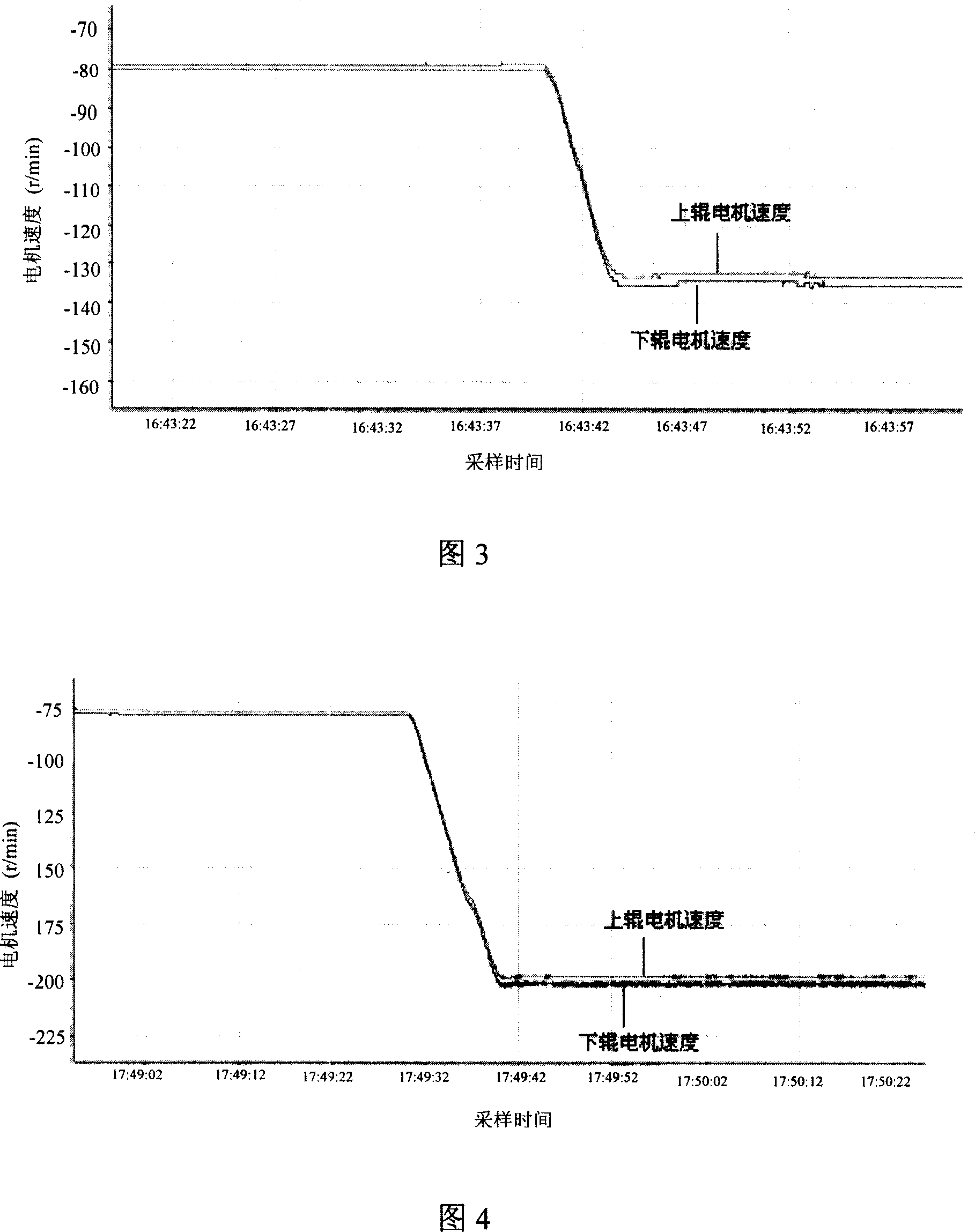

Method for controlling load balance of rolling mill for cold rolled steel strip driven by dual electrical motors

InactiveCN101091965AReduce rolling loadReduce the speed difference between the upper and lower work rollsTension/compression control deviceMetal rolling arrangementsMotor speedMotor drive

The invention discloses a control method for load balance of cold-strip steel rolling mill of double motor drive. The feature is that it is realized by control the technical parameter of roller, technical parameter of emulsion, dynamically adjusting rolling unit tension, percent of reduction and acceleration of raising speed of driving motor. The invention could compensate the work roller friction by the control parameters of percent of reduction, unit tension and acceleration of driving motor according to the actual parameter of rolling strip steel. The method could improve the stability during rolling process and control the motor speed difference caused by load difference by 3%.

Owner:ANGANG STEEL CO LTD

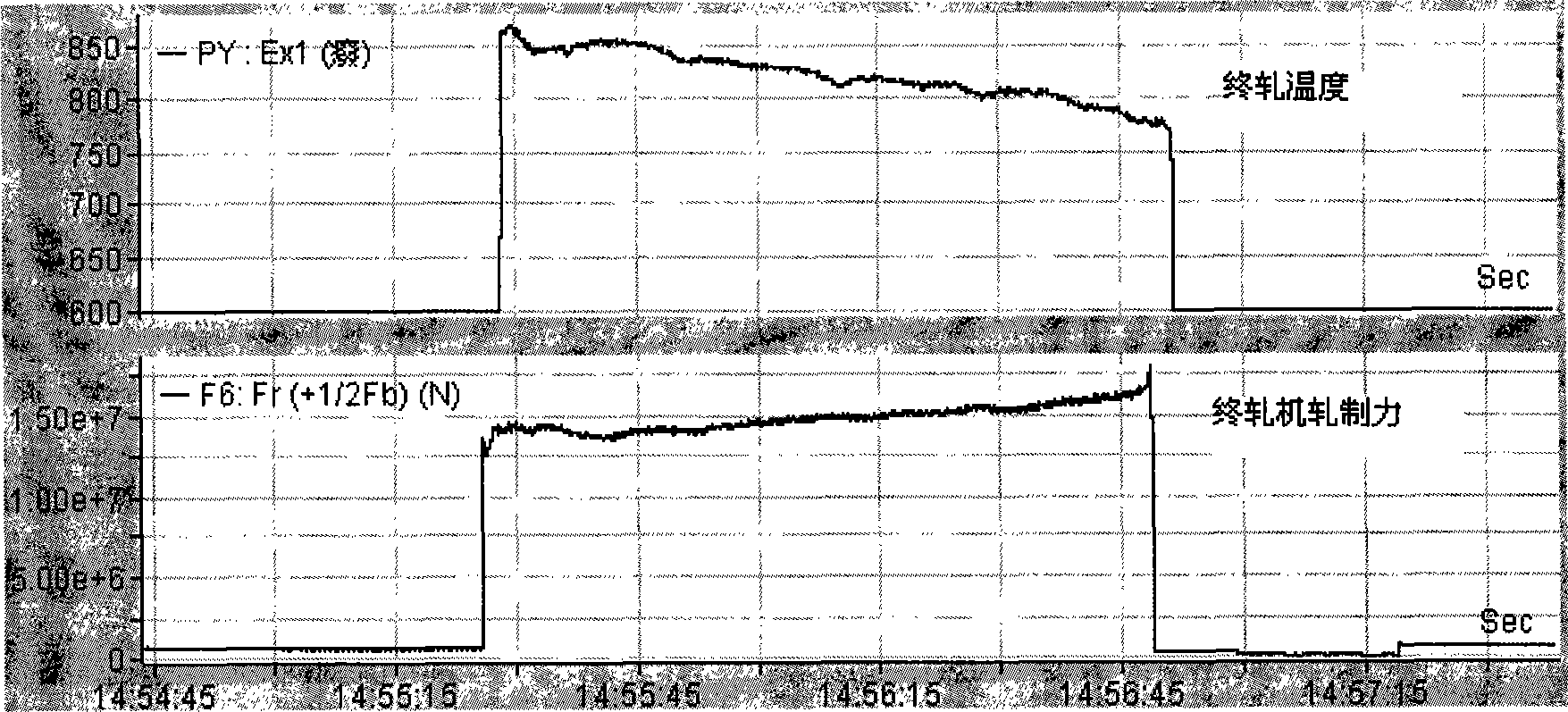

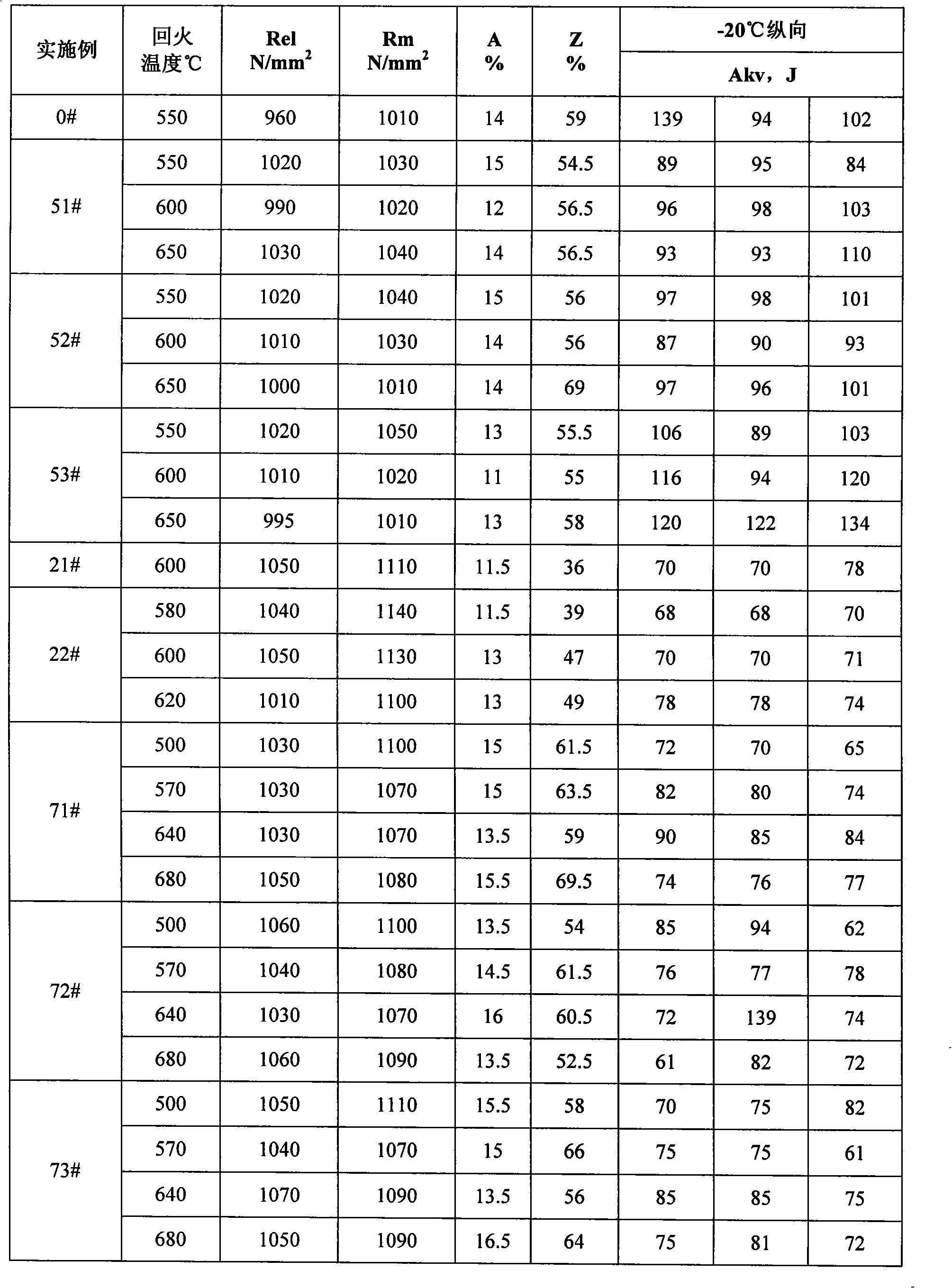

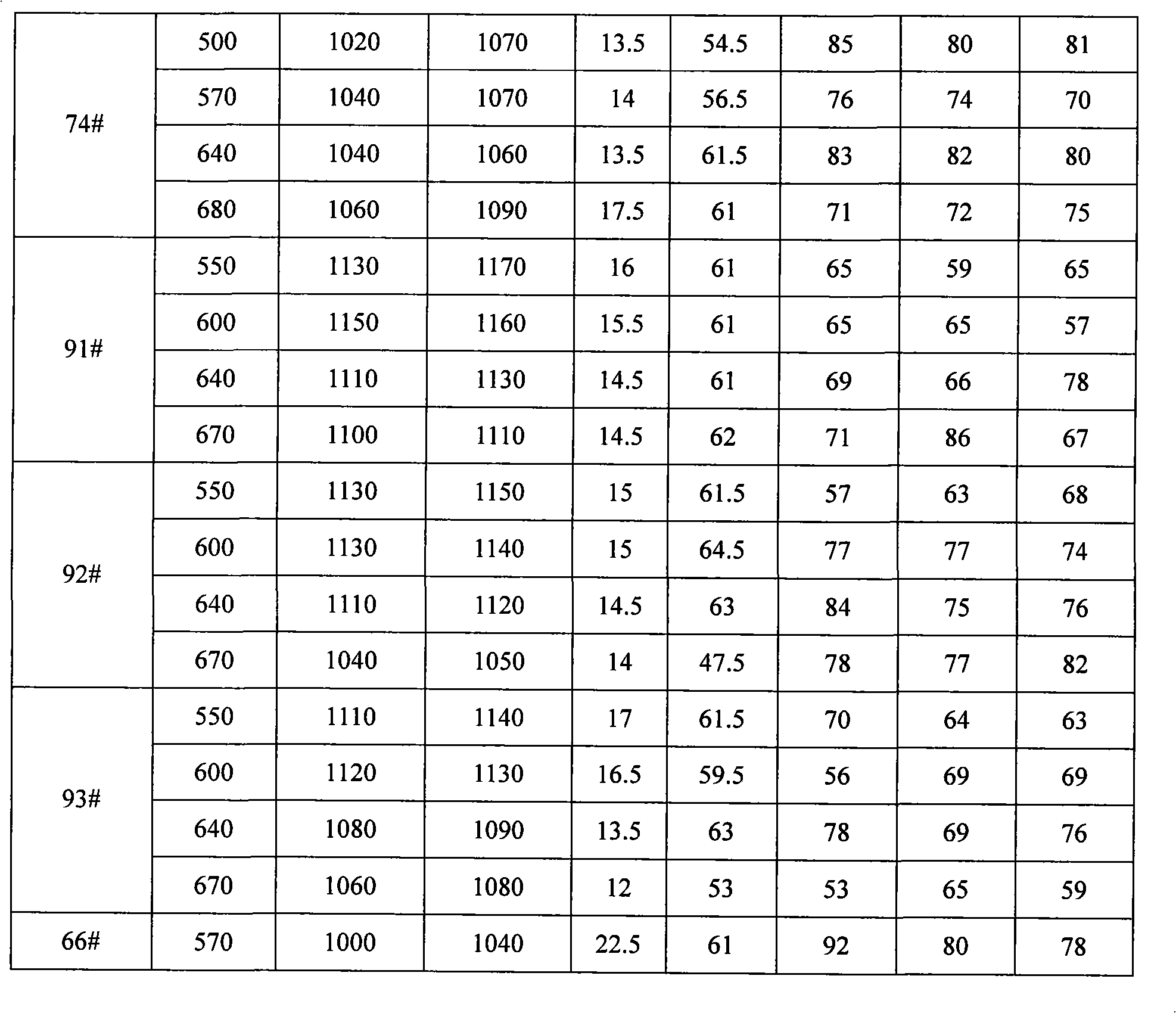

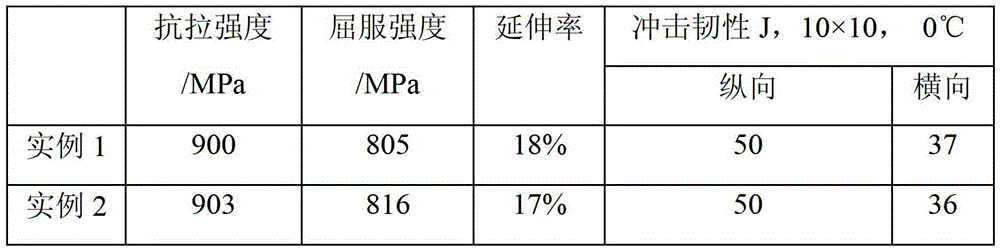

High-strength high-toughness X80 hot rolling coiled sheet for spiral buried arc welding and production method thereof

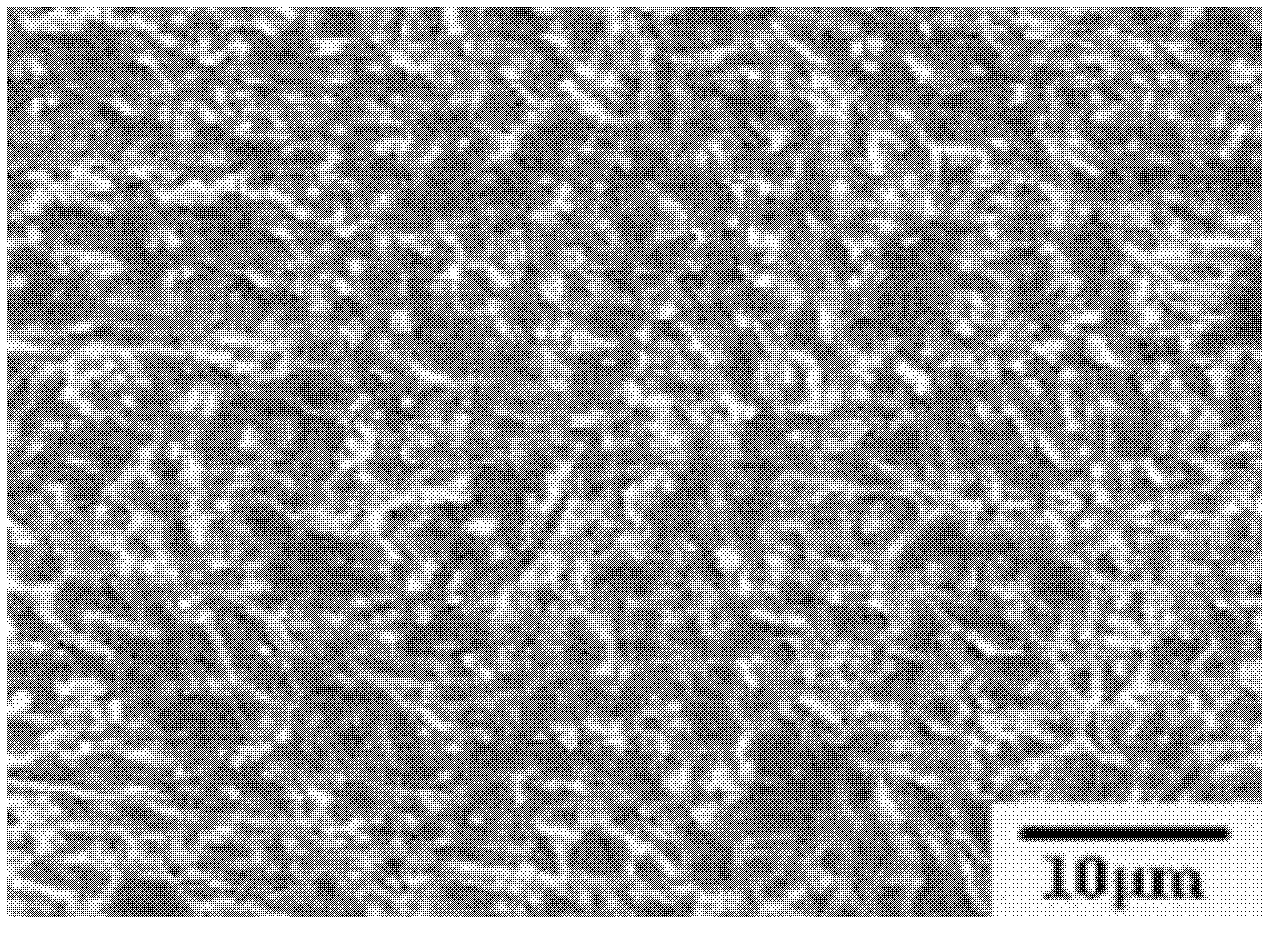

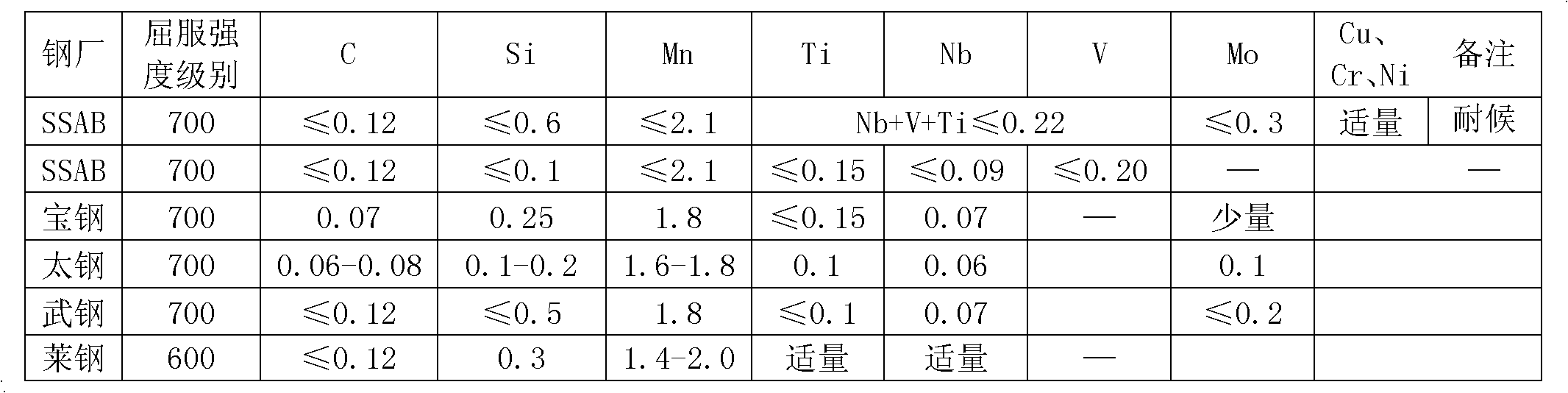

The invention provides an X80 hot rolling steel plate used for a high-obdurability spiral hidden arc welded tube and a production method thereof, which belong to the technical field of steel rolling. The X80 hot rolling steel plate comprises the following compositions in weight percentage: 0.03 to 0.08 weight percent of carbon, 0.10 to 0.25 weight percent of silicon, 1.60 to 1.95 weight percent of manganese, 0.09 to 0.11 weight percent of niobium, 0.020 to 0.030 weight percent of vanadium, 0.010 to 0.020 weight percent of titanium, 0.10 to 0.30 weight percent of molybdenum, 0.10 to 0.30 weight percent of copper, 0.10 to 0.30 weight percent of nickel, 0 to 0.30 weight percent of Cr, less than or equal to 0.018 weight percent of phosphor, less than or equal to 0.003 weight percent of sulfur, less than or equal to 0.006 weight percent of nitrogen, 0 to 0.0005 weight percent of boron, less than or equal to 0.0003 weight percent of hydrogen, and the balance being ferrum and unavoidable trace impurities. The production method comprises the following steps: heating the compositions at a temperature of between 1,150 and 1220 DEG C; stopping rough rolling at a temperature of between 1,020 and 1,080 DEG C; stopping fine rolling at a temperature of between 800 and 840 DEG C; coiling the rolled steel sheet at a temperature of between 400 and 480 DEG C; and performing fine rolling according to the compression ratio, that is the thickness of an intermediate billet to that of finishing outlet is more than or equal to 3. The X80 hot rolling steel plate is particularly suitable to be used in a gas pipeline with high pressure, long distance and large aperture.

Owner:SHOUGANG CORPORATION

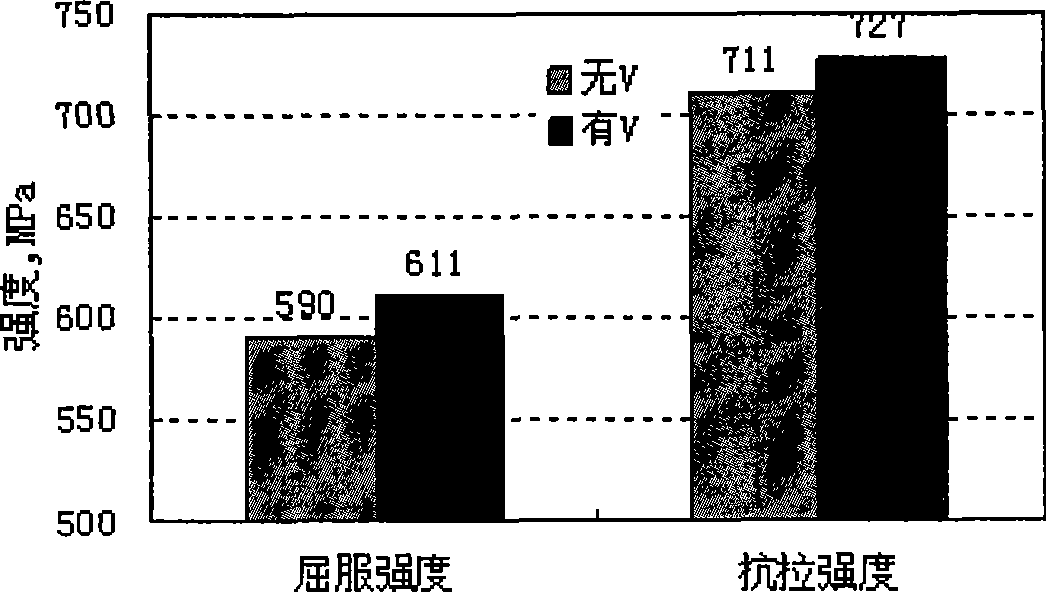

Production method of high-strength saw bit steel coil

ActiveCN103173685AGuaranteed stabilityImproved shape controlTemperature control deviceHeat treatment process controlHardnessSlow cooling

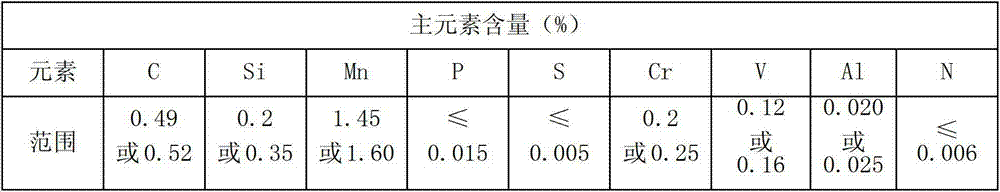

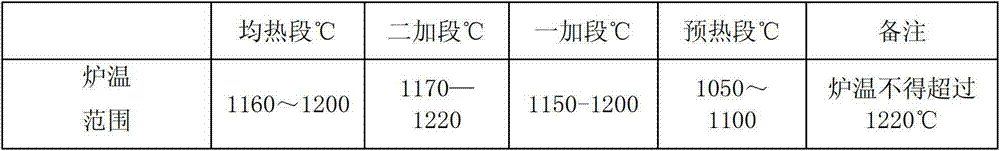

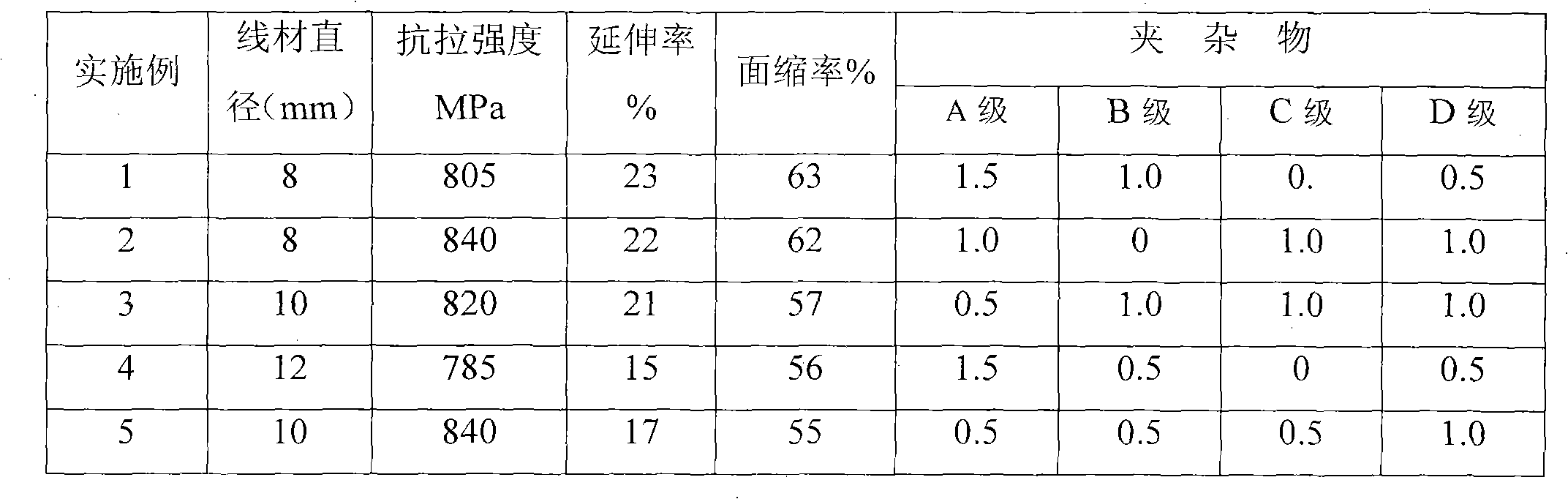

The invention provides a production method of a high-strength saw bit steel coil. The production method is suitable for a rolled steel coil of saw bit or saw blade steel with the thickness of 3.0-14.0mm. The component design comprises 0.49-0.52 of C, 0.2-0.35 of Si, 1.45-1.60 of Mn, less than or equal to 0.015 of P, less than or equal to 0.005 of S, 0.2-0.25 of Cr, 0.12-0.16 of V, 0.020-0.025 of Al and less than or equal to 0.006 of N by weight percent. The production process adopts a converter smelting-LF (ladle furnace) refining-hot continuous rolling process and comprises slab continuous casting and segregation control in saw bit steel production, control of the slab continuous offline slow cooling temperature of the saw bit steel and the control of the roll rolling start temperature, the rolling finished temperature and the coiling temperature. The horizontal yield of the saw bit steel coil is MPa600-750, the horizontal tensile strength is MPa930-1040, the elongation is 19.5-26%, and the hardness of HRC is 20-28.

Owner:XINJIANG BAYI IRON & STEEL

Drahtstahl for high strength fastening piece and production method thereof

InactiveCN101787491AWith energy savingReduce manufacturing costMetal rolling arrangementsWire rodHigh intensity

The invention relates to a drahtstahl for a fastening piece and a production method thereof, and the drahtstahl comprises the following components by weight percent: 0.39-0.48 % of C, 0.15-0.35% of Si, 0.30-0.90% of Mn, 0.60-1.20% of Cr, 0.010-0.07% of Als, less than or equal to 0.035% of P, less than or equal to 0.035% of S and the balance Fe and unavoidable impurity; and the production method comprises the following steps: smelting with a clean steel process and casting into a blank, and adding Si-Ca line in the refining; heating the continuous casting to 980-1,080 DEG C; rough rolling: controlling the deflection to be 70-80%; intermediate rolling: controlling the deflection to be 80-90%; pre-precision rolling: controlling the deflection to be 65-75%; water-cooling until the temperature is cooled to be 1,000-1,020 DEG C; precision rolling: controlling the deflection to be 60-90%; water-cooling for the second time until the temperature is cooled to be 800-900 DEG C; spinning; cooling to phase change initial temperature, namely the range from Ar3 to 50 DEG C higher than Ar3 by adopting an aerial fog mixed method; and continually cooling until the temperature is cooled to be 400-500 DEG C and naturally cooling to environment temperature. The invention can be drawn directly, has good cold deformation and is not easy to crack.

Owner:武钢集团有限公司

Control method for surface oxidation pocking defects of hot-rolled pickled plate

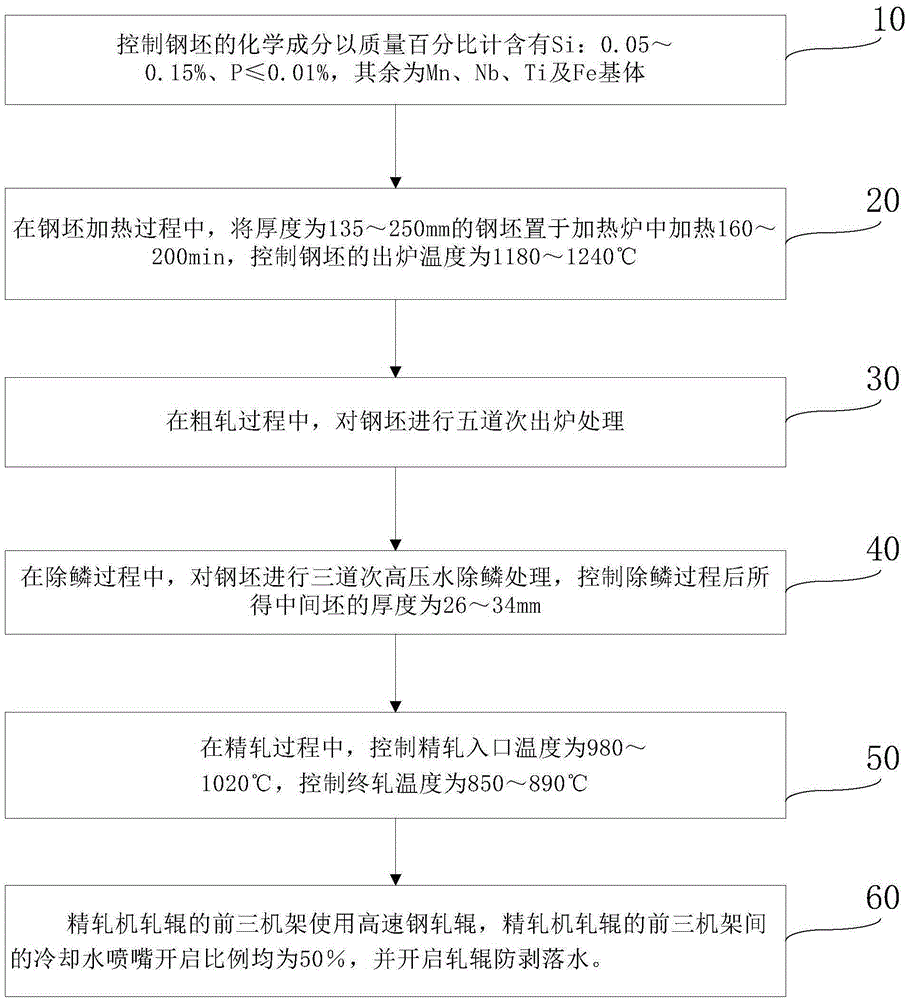

ActiveCN105251779AReduce the chance of occurrenceReduced rolling load on rollsProfile control deviceSurface oxidationInlet temperature

The invention relates to the technical field of hot rolling, in particular to a control method for surface oxidation pocking defects of a hot-rolled pickled plate. The control method includes the steps that the chemical components of a steel billet are controlled to include, by mass, 0.05-0.15% of Si, at most 0.01% of P and the balance Mn, Nb, Ti and a Fe substrate. In the heating process of the steel billet, the steel billet with the thickness being 135-250 mm is put into a heating furnace and heated for 160-200 min, and the tapping temperature of the steel billet is controlled to be 1180-1240 DEG C. The thickness of an intermediate billet is controlled to be 26-34 mm after a descaling process. In the precision rolling process, the precision rolling inlet temperature is controlled to be 980-1020 DEG C, and the finish rolling temperature is controlled to be 850-890 DEG C. The control method for surface oxidation pocking defects of the hot-rolled pickled plate can effectively restrain the occurrence of surface oxidation pocking defects of the hot-rolled pickled plate with the thickness being at most 2 mm and the tensile strength being at least 500 MPa.

Owner:SHOUGANG CORPORATION +1

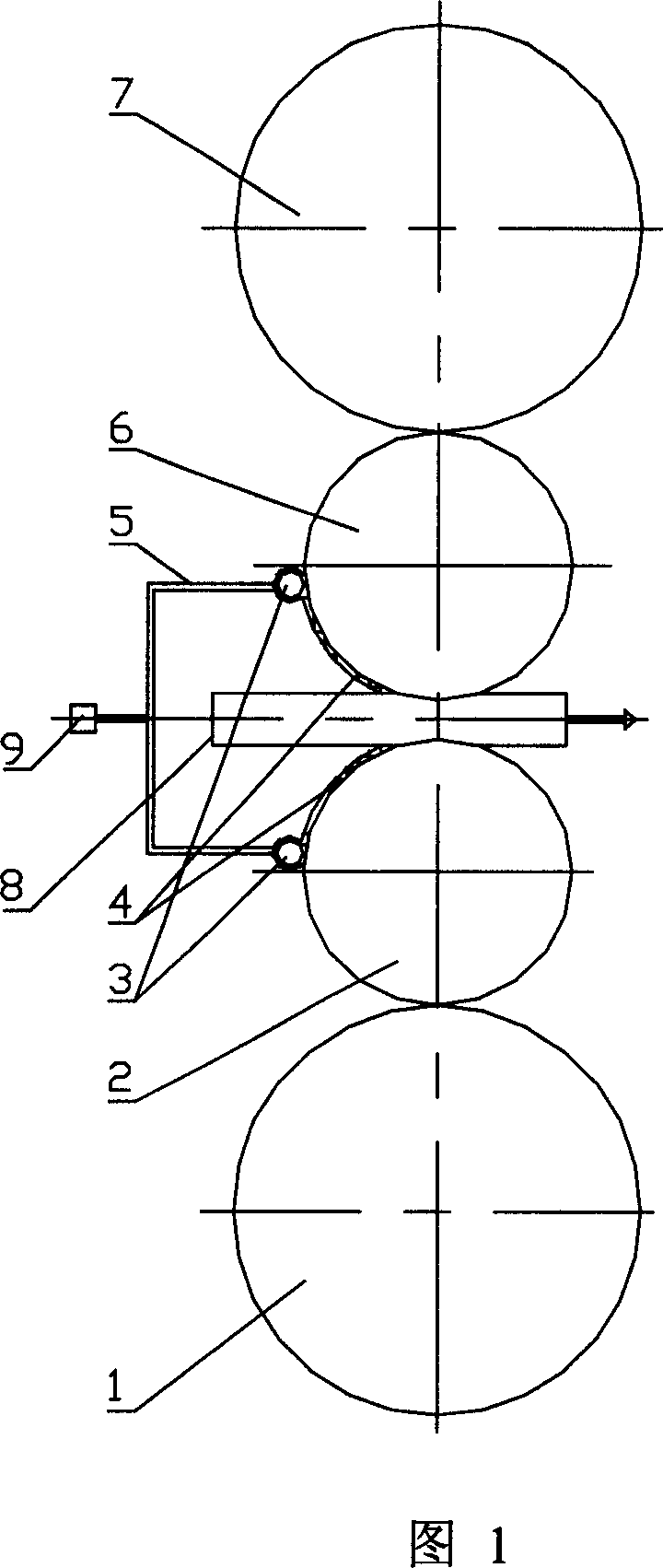

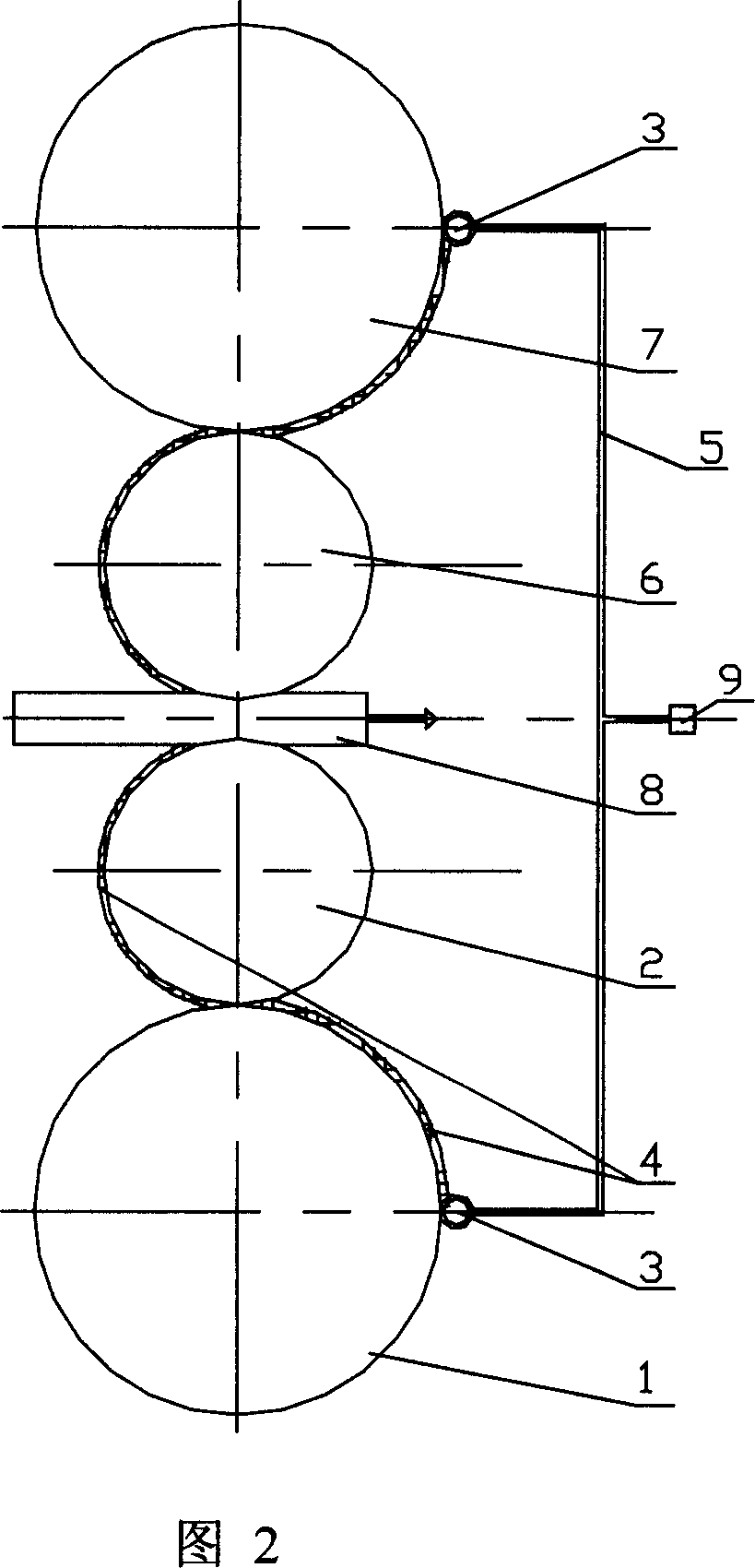

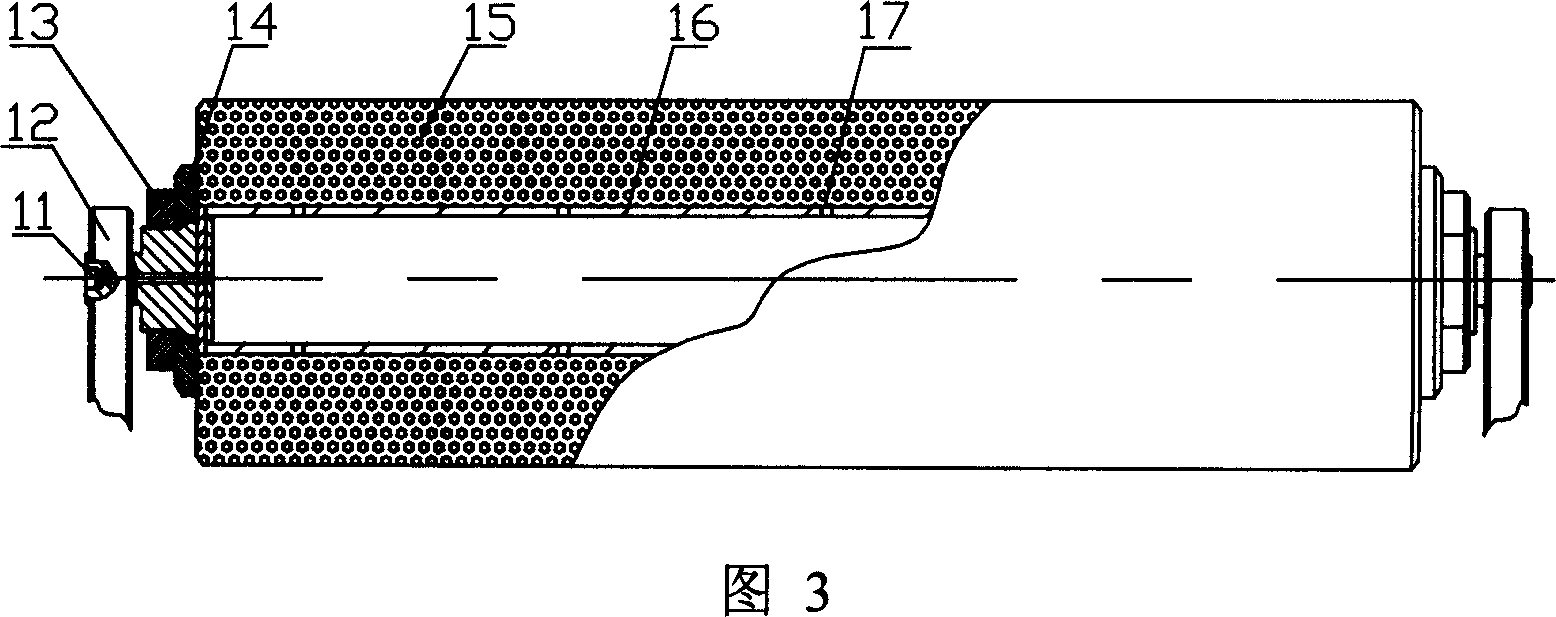

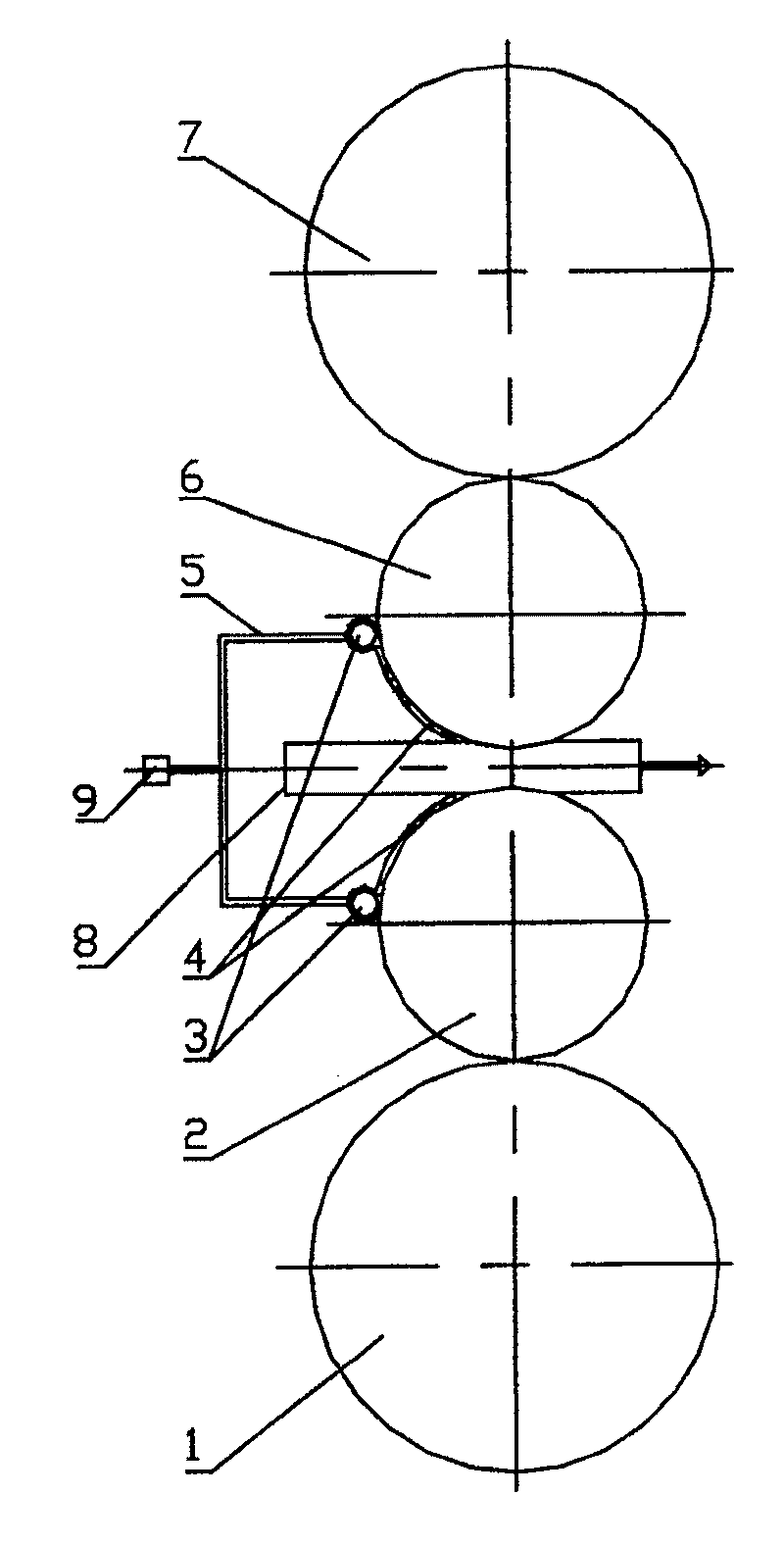

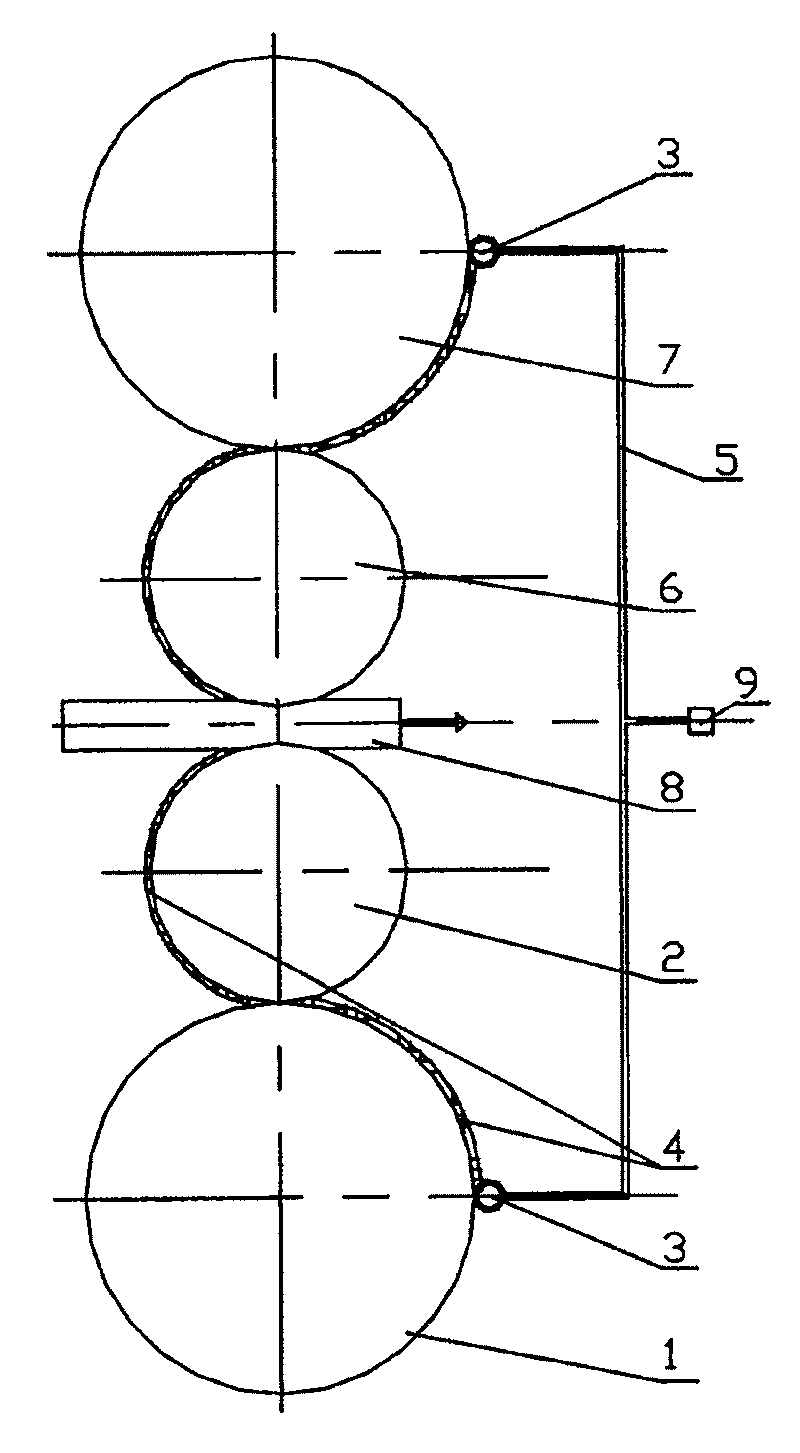

Rolled lubricating process of rolling band-steel

ActiveCN101028632AGood adhesionImprove sintering resistanceRollsMetal rolling arrangementsStrip steelPetroleum engineering

A roller-type lubricating method for rolling steel band features that the lubricating oil is transferred via oil tube onto the oil applying roller pressed on the working roller, and the oil applying roller is driven to rotate by said working roller to coat the surface of working roller to form an oil film layer.

Owner:BAOSHAN IRON & STEEL CO LTD

High-strength container steel plate and preparation method thereof

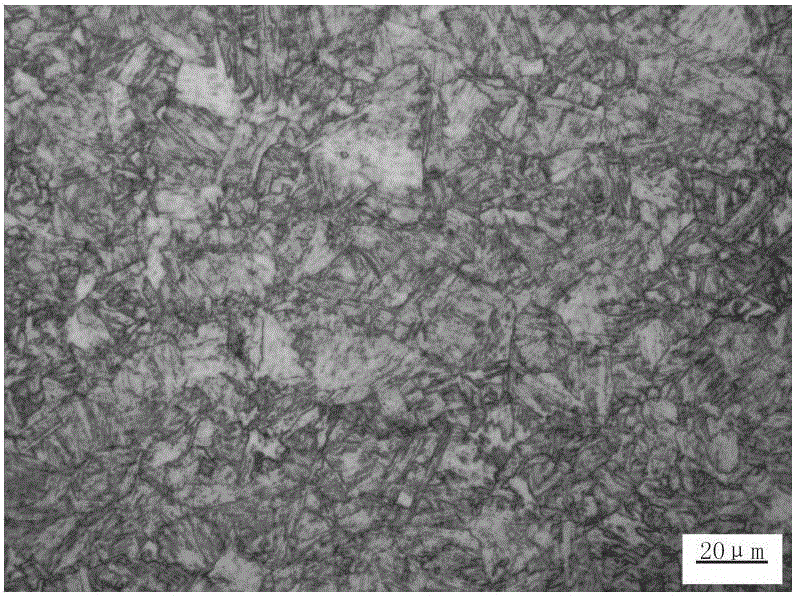

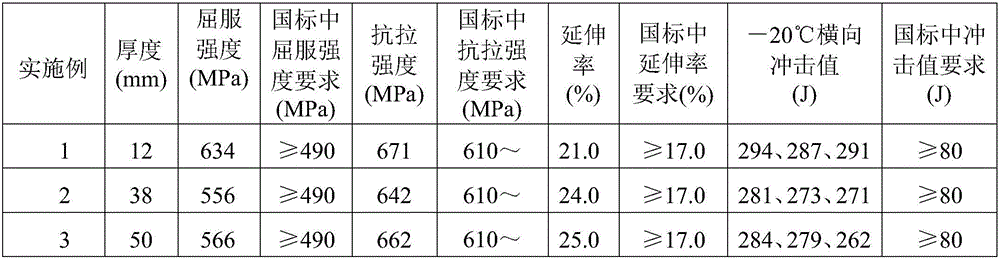

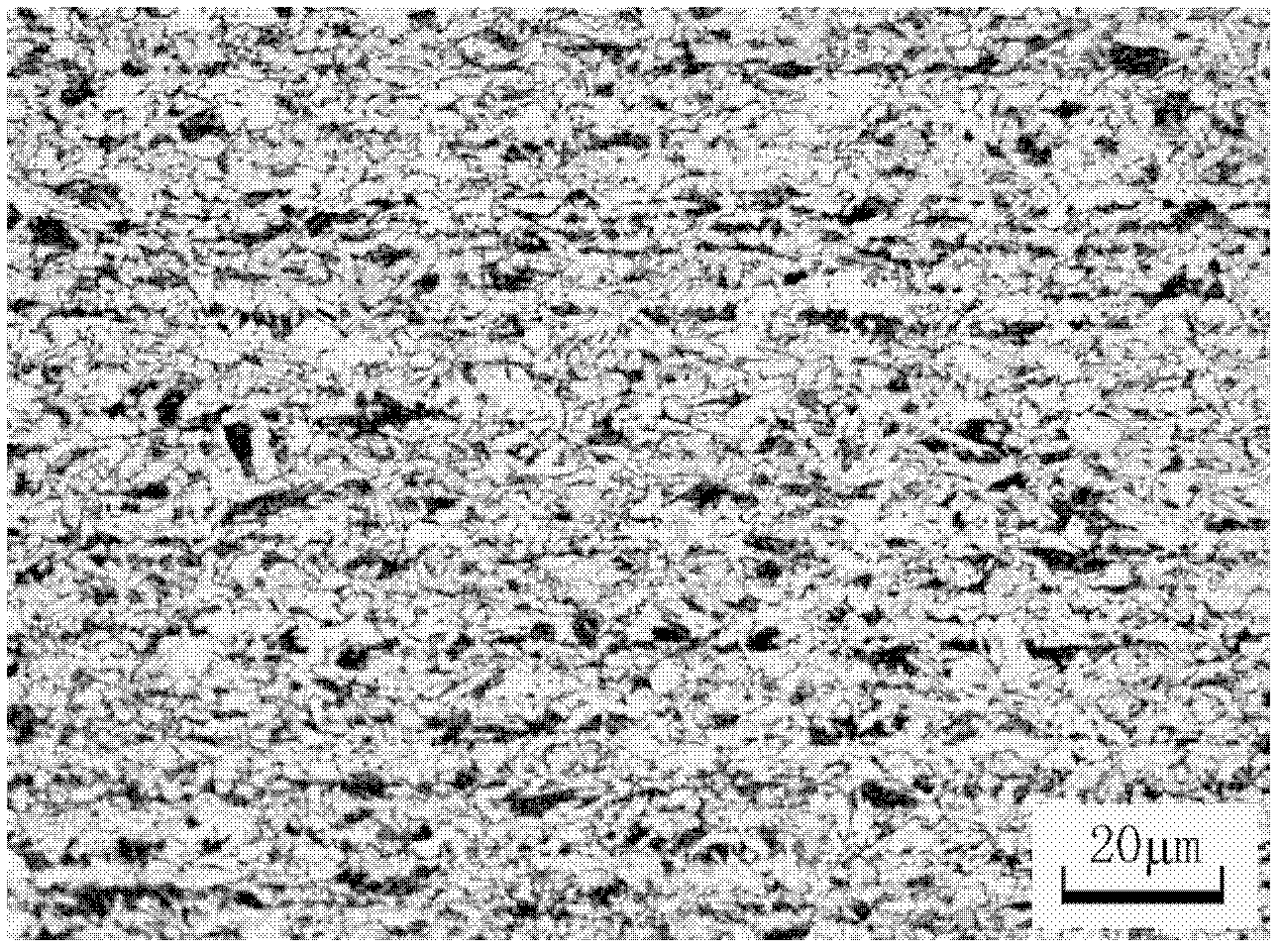

InactiveCN106591713AImprove plasticityImprove low temperature impact toughnessImpurityImpact toughness

The invention provides a high-strength container steel plate and a preparation method thereof. The high-strength container steel plate comprises the following chemical components in percentage by weight: 0.06-0.08% of C, 0.20-0.30% of Si, 1.3-1.5% of Mn, less than or equal to 0.010% of P, less than or equal to 0.005% of S, 0.035-0.045% of Nb, 0.20-0.30% of Ni, 0.15-0.25% of Cr, 0.15-0.25% of Mo, 0.035-0.045% of V, 0.01-0.02% of Ti and the balance Fe and inevitable impurities. The high-strength container steel plate provided by the invention has tensile strength greater than 610 MPa, and is a low-welding-crack-sensitivity steel plate with good plasticity and excellent low-temperature impact toughness. A final metallographic structure of the steel plate is tempered sorbite and tempered bainite.

Owner:INNER MONGOLIA BAOTOU STEEL UNION

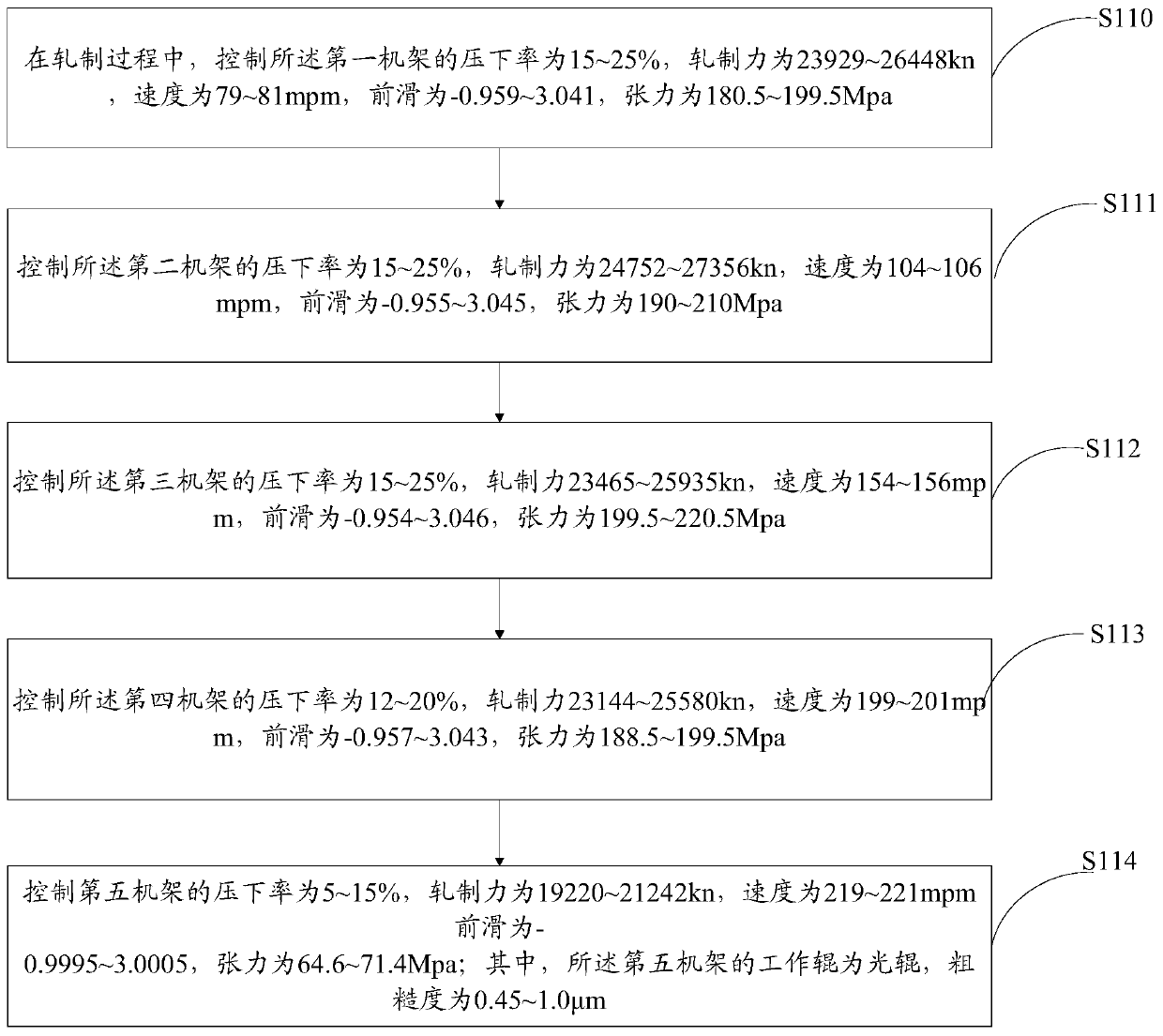

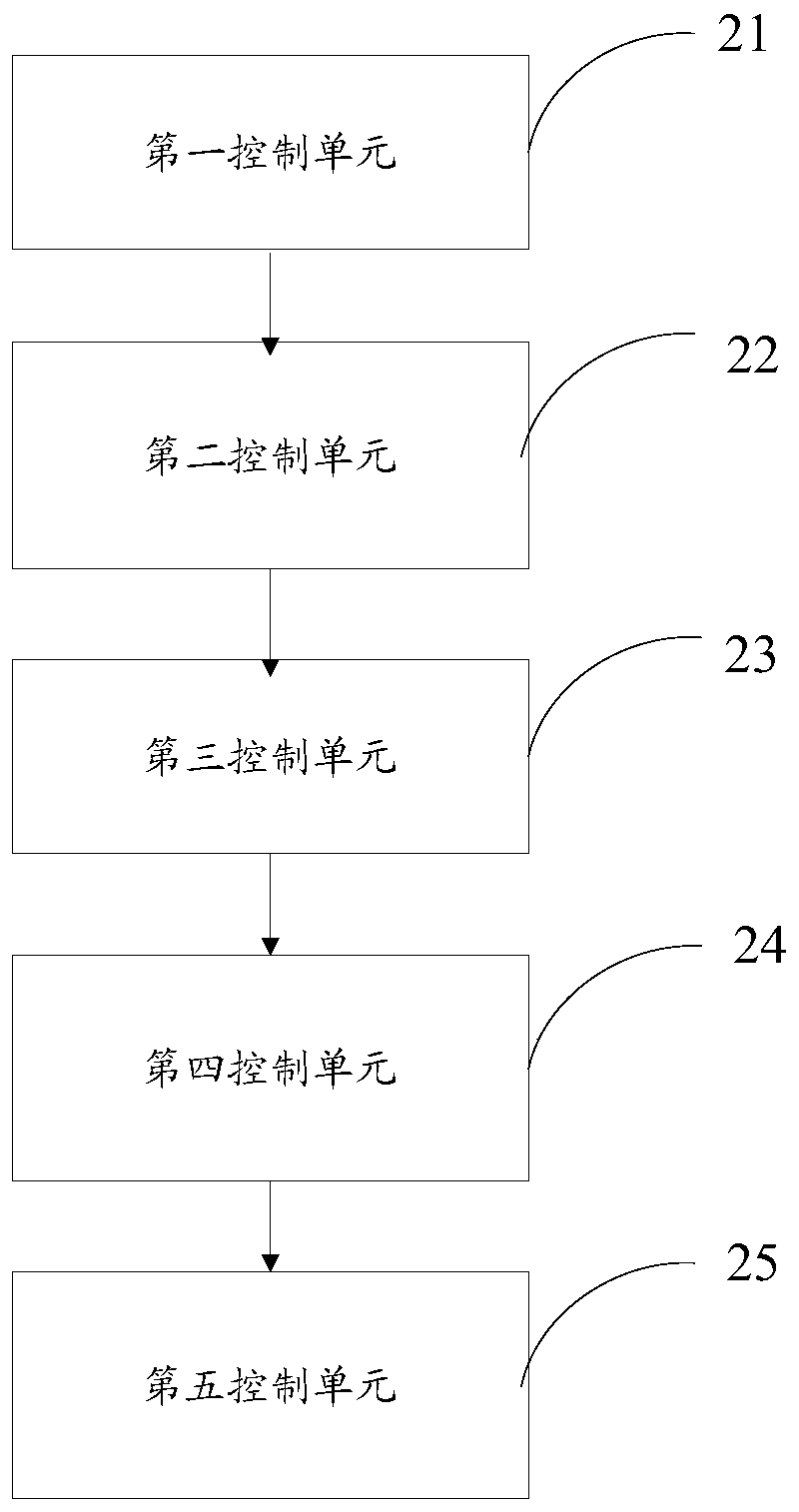

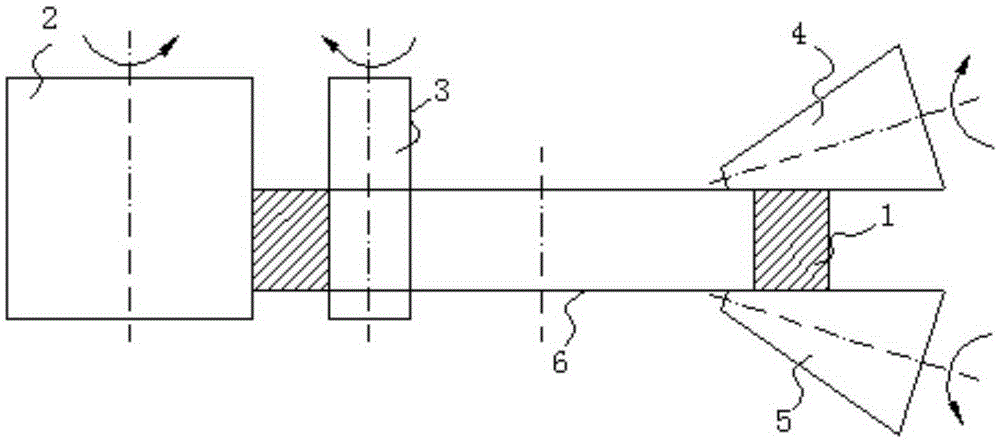

High-strength steel rolling method and device

ActiveCN110722000AReduce rolling loadStable rolling processRoll force/gap control deviceTension/compression control deviceStructural engineeringMechanical engineering

An embodiment of the invention provides a high-strength steel rolling method and device. The method comprises the steps of controlling the reduction ratio of a first rack to be 15% to 25%, the rollingforce to be 23929 kn to 26448 kn and the speed to be 79 mpm to 81 mpm; controlling the reduction ratio of a second rack to be 15% to 25%, the rolling force to be 24752 kn to 27356 kn, the speed to be104 mpm to 106 mpm and the forward slip to be -0.955 to 3.045; controlling the reduction ratio of a third rack to be 15% to 25%, the rolling force to be 23465 kn to 25935 kn, the speed to be 154 mpmto 156 mpm and the forward slip to be -0.954 to 3.046; controlling the reduction ratio of a fourth rack to be 12%-20%, the rolling force to be 23144 kn to 25580 kn, the speed to be 199 mpm to 201 mpmand the forward slip to be -0.957 to 3.043; and controlling the reduction ratio of a fifth rack to be 5% to 15%.

Owner:SHOUGANG JINGTANG IRON & STEEL CO LTD

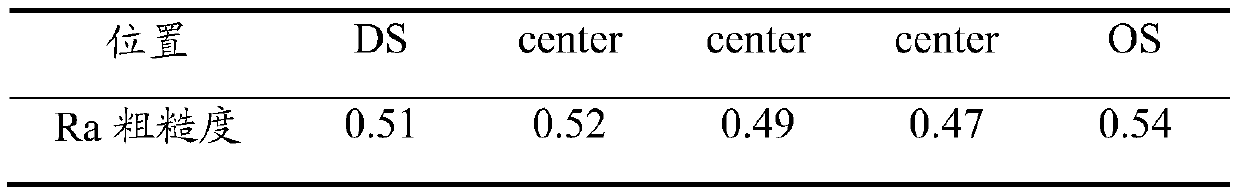

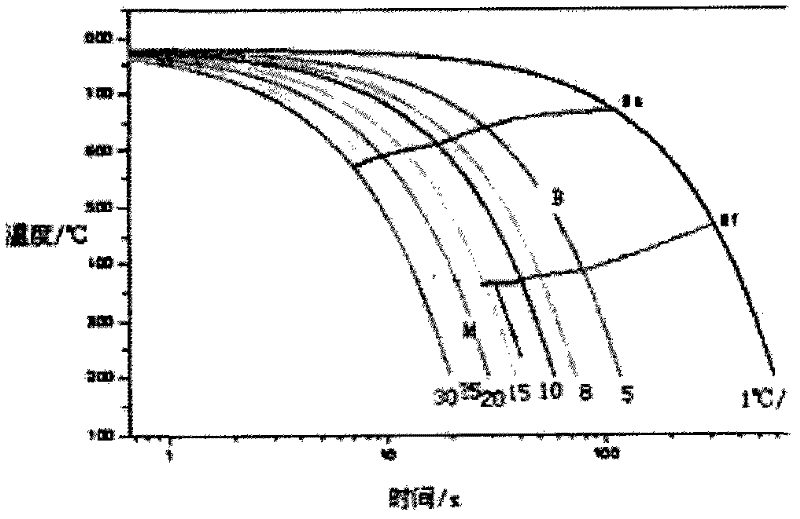

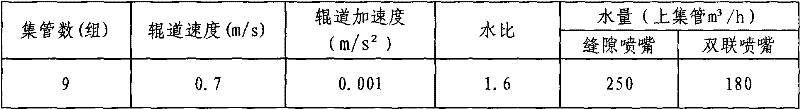

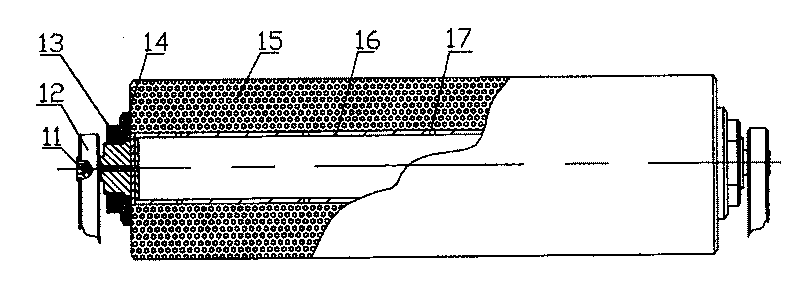

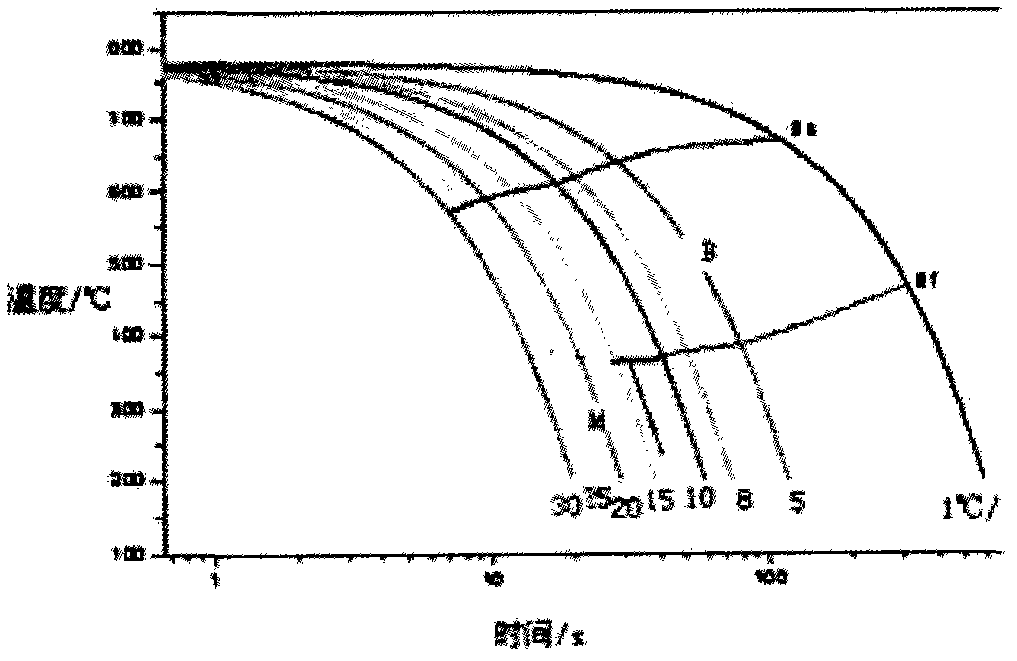

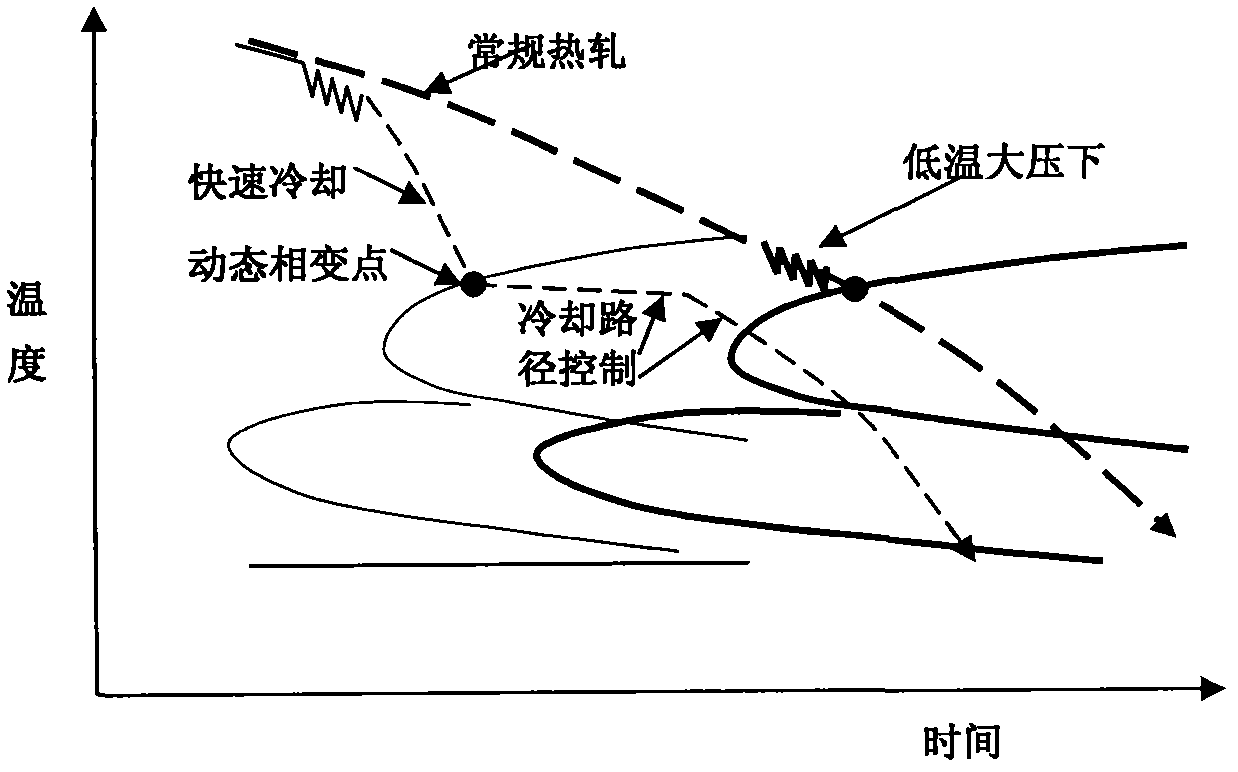

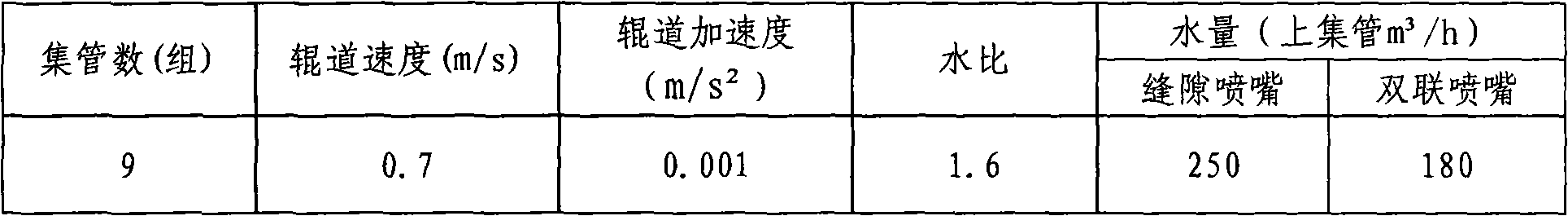

Production method for rapidly cooling medium plate after rolling

ActiveCN102343372ALow carbon equivalentLow weld crack susceptibilityWork treatment devicesMetal rolling arrangementsSheet steelPhase change

The invention discloses production method for rapidly cooling a medium plate after rolling, belonging to the technical field of production of medium plates. The method comprises the following process steps of: adjusting an ultrafast cooling (UFC) frame to 300mm+h till the cross point between extension lines of upper and lower nozzles of equipment is positioned on the central line of a steel plate; during ultrafast cooling, setting cooling rules and parameters according to the steel kind, specification as well as required final cooling temperature and cooling speed of the steel plate; startingmiddle spraying, side spraying and air blowing to remove residual water from the surface of steel plate to increase the cooling uniformity, starting UFC equipment, and spraying water onto the steel plate with a gap nozzle and a ganged nozzle for cooling; and controlling the cooling speed and cooling termination point according to the CCT (Continuous Cooling Transformation) curve of steel, whereinthe cooling speeds of steel plates of different thicknesses are 5-80 DEG C / s, and the final cooling temperature is controlled at 450-800 DEG C. The method has the advantages: by controlling the cooling process of the steel plate after rolling, control over phase change and organization is realized, and the aim of enhancing the roughness of the steel plate is fulfilled.

Owner:SHOUGANG CORPORATION

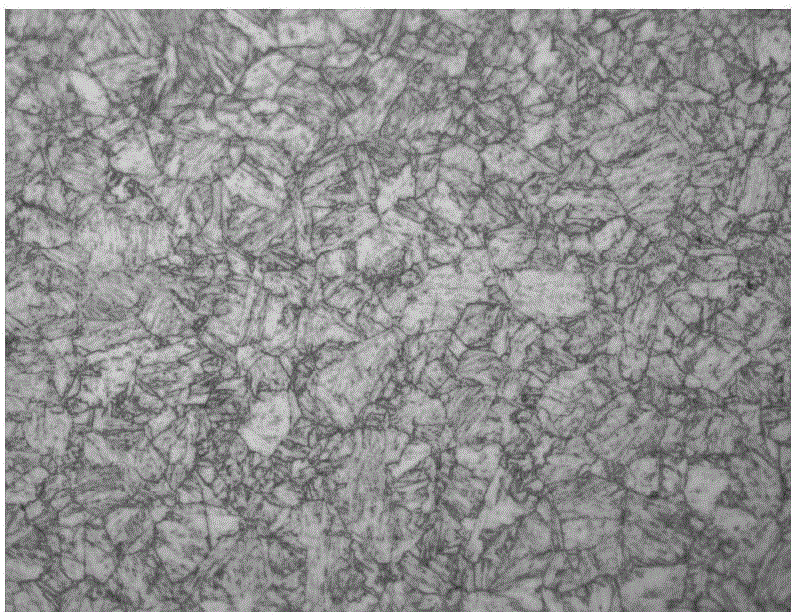

Ti-containing medium-carbon steel, as well as method for continuous casting and continuous rolling by adopting sheet billets

The invention relates to Ti-containing medium-carbon steel for a car floor or a cold roll forming structural piece, as well as a method for continuous casting and continuous rolling by adopting sheet billets. The Ti-containing medium-carbon steel comprises the following constituents by weight percent: 0.17 to 0.20 percent of C, 0.1 to 0.4 percent of Si, 0.6 to 1.8 percent of Mn, 0.04 to 0.15 percent of Ti, 0.02 to 0.06 percent of Als, 0 to 0.025 percent of P, 0 to 0.005 percent of S, 0 to 0.65 percent of Ni, 0 to 0.2 percent of Cu, and 0 to 0.008 percent of N. The Ti-containing medium-carbon steel is produced according to the following steps: smelting; outside furnace refining and continuous casting to produce casting blanks; uniformly heating the casting blanks; rolling; reeling after laminar flow; and standing by. As the Ti-containing medium-carbon steel and the method are adopted, the invention has the advantages that the constituents are simple; a steel plate has no internal stress; the shape of the steel plate is beautiful; and the yield strength is at least 550 MPa.

Owner:武汉钢铁有限公司

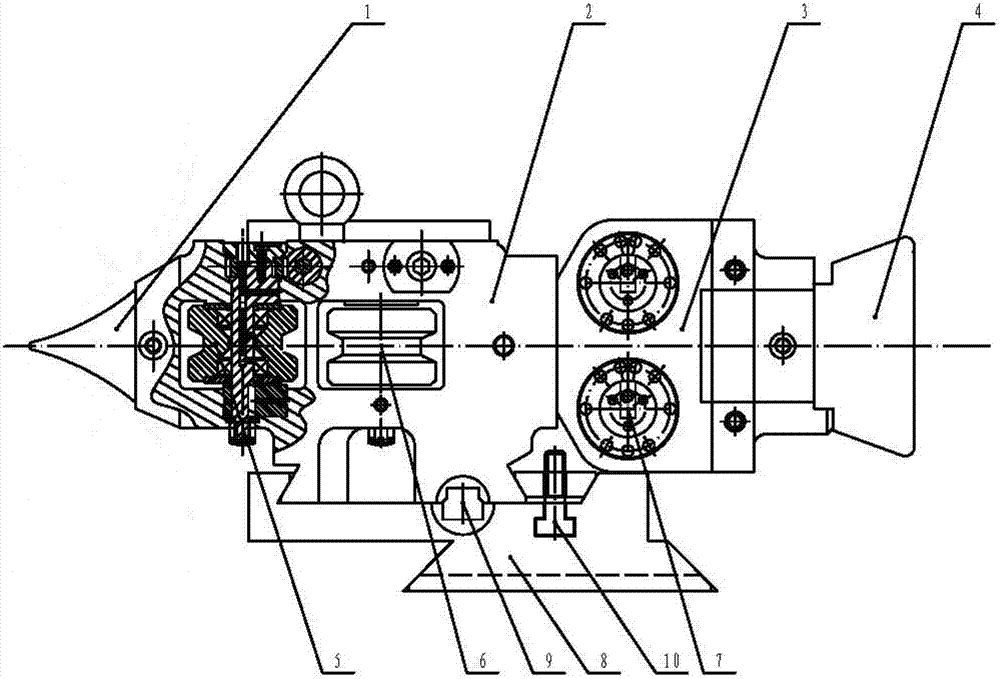

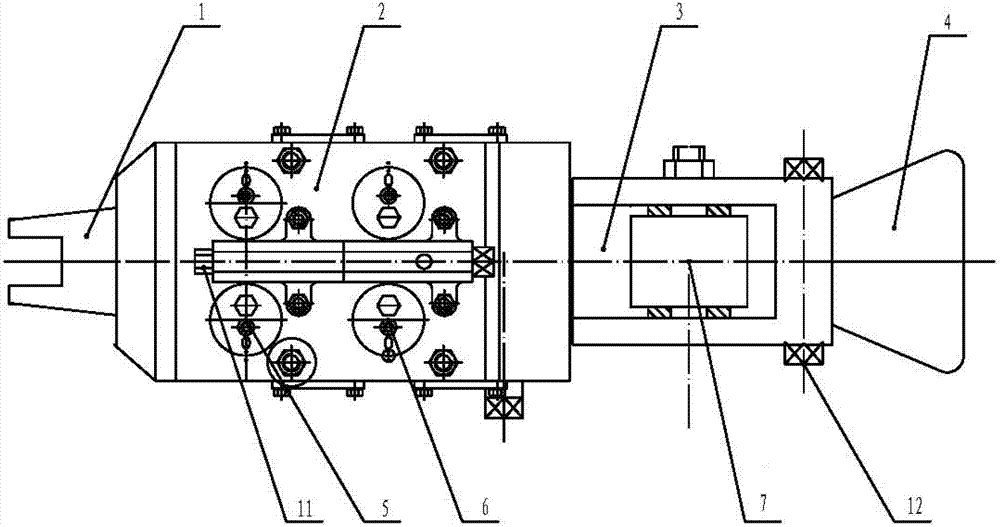

Large-space hole-free rolling device and rolling method of bar production line

ActiveCN102896147AEasy to replaceAvoid shiftingGuiding/positioning/aligning arrangementsCooling bedsProduction lineMetal machining

The invention discloses a large-space hole-free rolling device and a rolling method of a bar production line. The rolling device comprises a box body, wherein the box body is installed on a base; a horizontal roller bracket is arranged at one end of the box body; a guide point is arranged at the other end of the box body; a vertical guide roller is arranged on the box body; a horizontal guide roller is arranged on the horizontal roller bracket; and a horn mouth is connected with the horizontal roller bracket. The rolling method comprises the following steps of: heating, reserving a distance of 38m-45m between a rolling machine group and a fine rolling machine group, cooling and finishing. The rolling production line cn be used for implementing production successfully, adopts a high-technical production technique, breaks through the bottleneck of hole-free rolling, lays basic theories for industrial large-scale production, and improves theories of metal machining deformation in China. The rolling device is high in rolling capacity and low in production cost. Rolling rollers can be repeatedly used, so that the rolling roller consumption is reduced; the production operation efficiency and the production capacity are improved; the power consumption of a motor is reduced; and the market competitiveness of enterprises is improved.

Owner:西安盛日机电科技有限公司

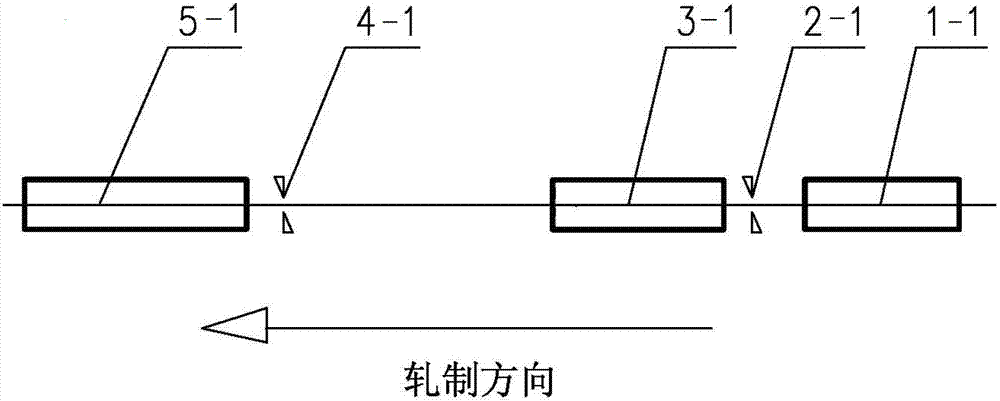

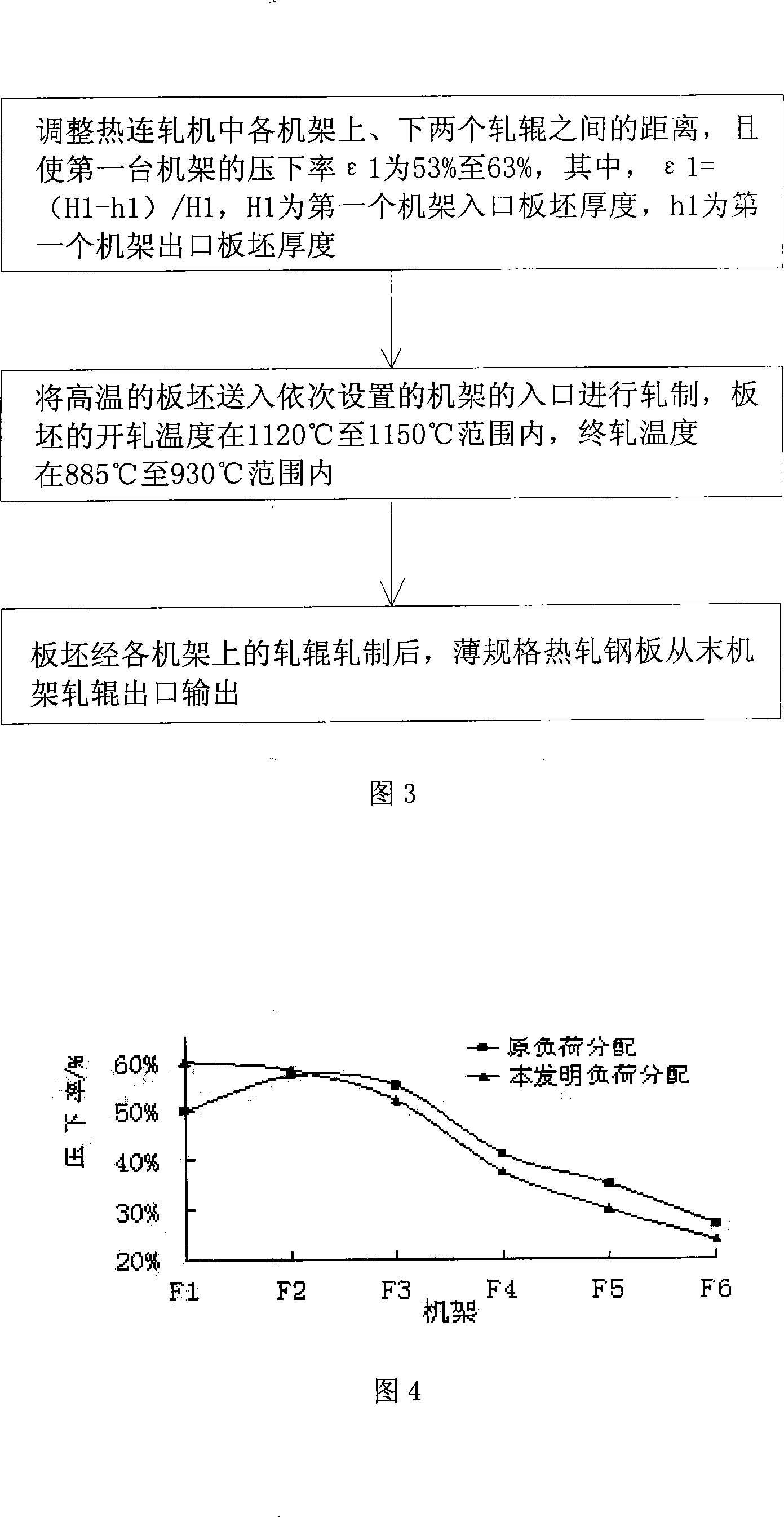

Method for producing thin format hot rolled steel plate

InactiveCN101219439ALarge amount of deformationReduce rolling loadRoll force/gap control deviceTemperature control deviceSheet steelHot rolled

The invention discloses a production method for a light-gauge hot rolled steel plate, which comprises the steps that: a. the distance between an upper roller and a lower roller of each frame of a hot strip mill is adjusted and the percent of reduction epsilon 1 of a first frame is adjusted to be 53 percent to 63 percent, wherein, the epsilon 1 is equal to (H1-h1) / H1, therein, H1 is the thickness of a slab at an inlet of the frame, h1 is the thickness of a slab at an outlet of the fame; b. high temperature slabs are sent to a rolling inlet of the frames that are arranged in sequence for rolling; c. the light-gauge hot rolled steel plate is output from a rolling outlet of a last frame after the slabs are rolled by the varied frames. The invention promotes the percent of reduction of the first frame as high as possible when ensuring security to reduce the load of rollers of rear frames, thereby improving rolling efficiency and product quality.

Owner:GUANGZHOU PEARL RIVER STEEL & IRON

Steel plate for low-carbon high-niobium extra-high strength welding structure and method for manufacturing same

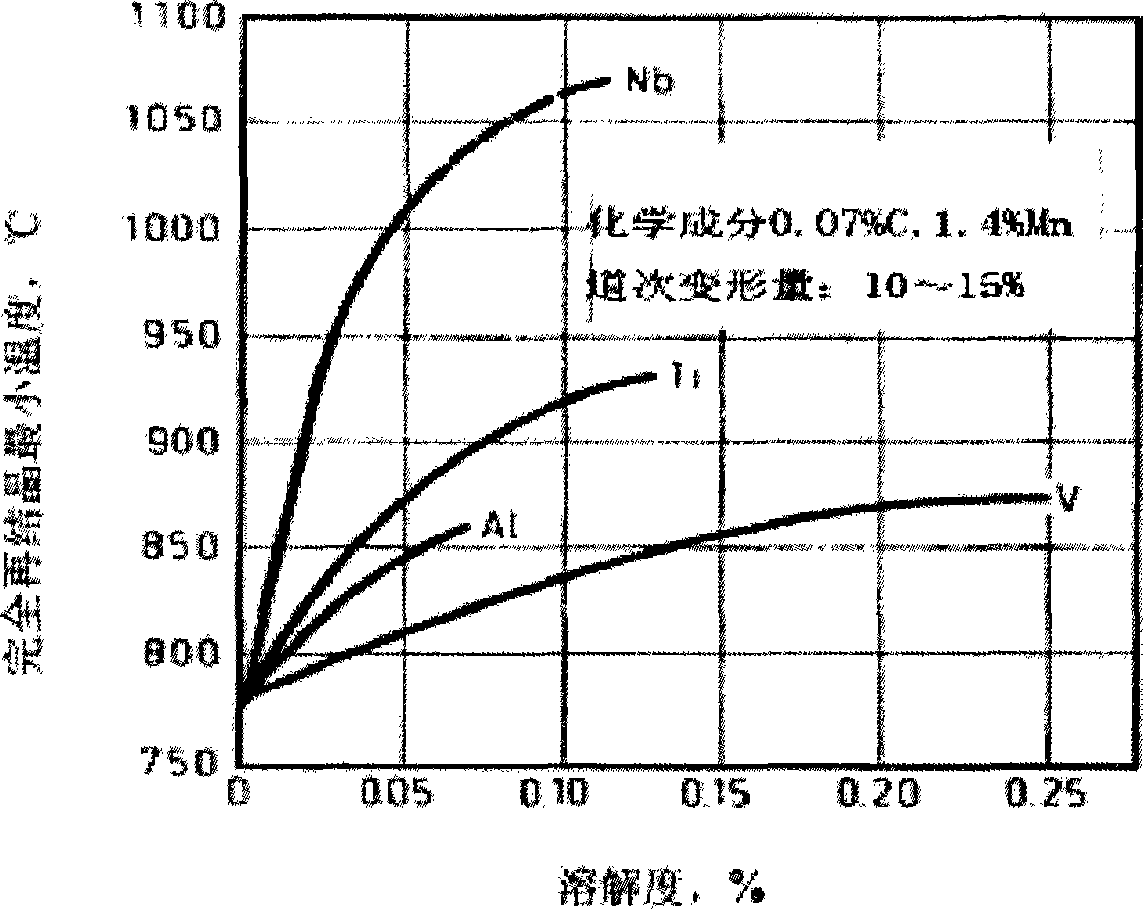

InactiveCN101619422ARaise the rolling temperatureIncrease productivityTemperature control deviceNiobiumRotary furnace

The invention provides a steel plate for a low-carbon high-niobium high strength welding structure. The steel plate comprises the following chemical components in percentage by weight: 0.015 to 0.075 percent of C, 0.20 to 0.50 percent of Si, 1.63 to 2.0 percent of Mn, 0.081 to 0.12 percent of Nb, 0.005 to 0.030 percent of Ti, 0.0005 to 0.0030 percent of B, 0.50 to 0.95 percent of Cr, 0.70 to 1.25 percent of Cu, 0.50 to 1.50 percent of Ni, 0.30 to 0.60 percent of Mo, 0.010 to 0.050 percent of Als, and the balance of Fe and inevitable impurities. The method for manufacturing the steel plate comprises the steps of molten iron pretreatment, rotary furnace smelting, refining, continuous casting and rolling, wherein the rolling process adopts the HTP plus RPC process, the heating temperature before rolling is between 1,140 and 1,220 DEG C, and two-stage controlled rolling is adopted. The steel plate is low in carbon content and high in Nb content, so that the initial rolling temperature of the non-recrystallization controlled rolling is increased, the temperature holding time is short, and the manufacturing efficiency is high; because the carbon content and the carbon equivalent are low, the welding performance is good; and with the HTP plus RPC plus annealing process, the steel plate for the welding structure with good toughness and plasticity and the yield strength more than or equal to 960N / mm<2> can be manufactured.

Owner:ANGANG STEEL CO LTD +1

Production method of hot dipped steel coil

ActiveCN103103538AOvercome the defect of low width precisionImprove width precisionHot-dipping/immersion processesNiobiumManganese

The invention provides a production method of a hot dipped steel coil. The method comprises steps of hot rolling, cold rolling, annealing, galvanizing and straightening on a billet. The batching temperature of the hot rolling is 500-550 DEG C; and the billet contains, calculated by a total weight of the billet, 0.04-0.1 wt% of carbon, 0.2-0.5 wt% of manganese, 0.06-0.09 wt% of phosphorus and 0.015-0.03 wt% of niobium. The method provided by the invention can obtain structural hot dipped steel coil with high width precision, and yield strength level of grade 350M Pa.

Owner:PANGANG GROUP RESEARCH INSTITUTE CO LTD +2

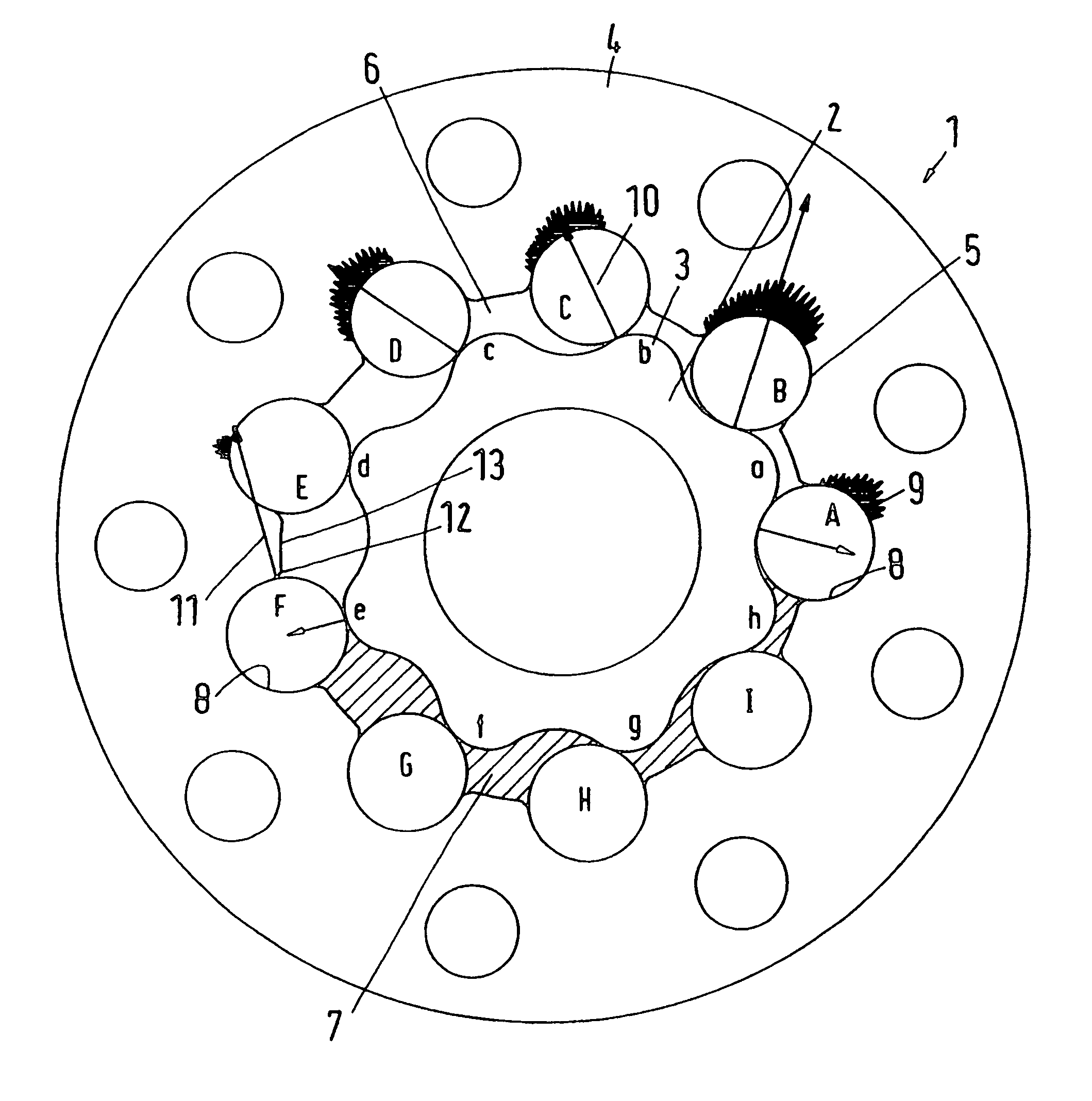

Hydraulic machine

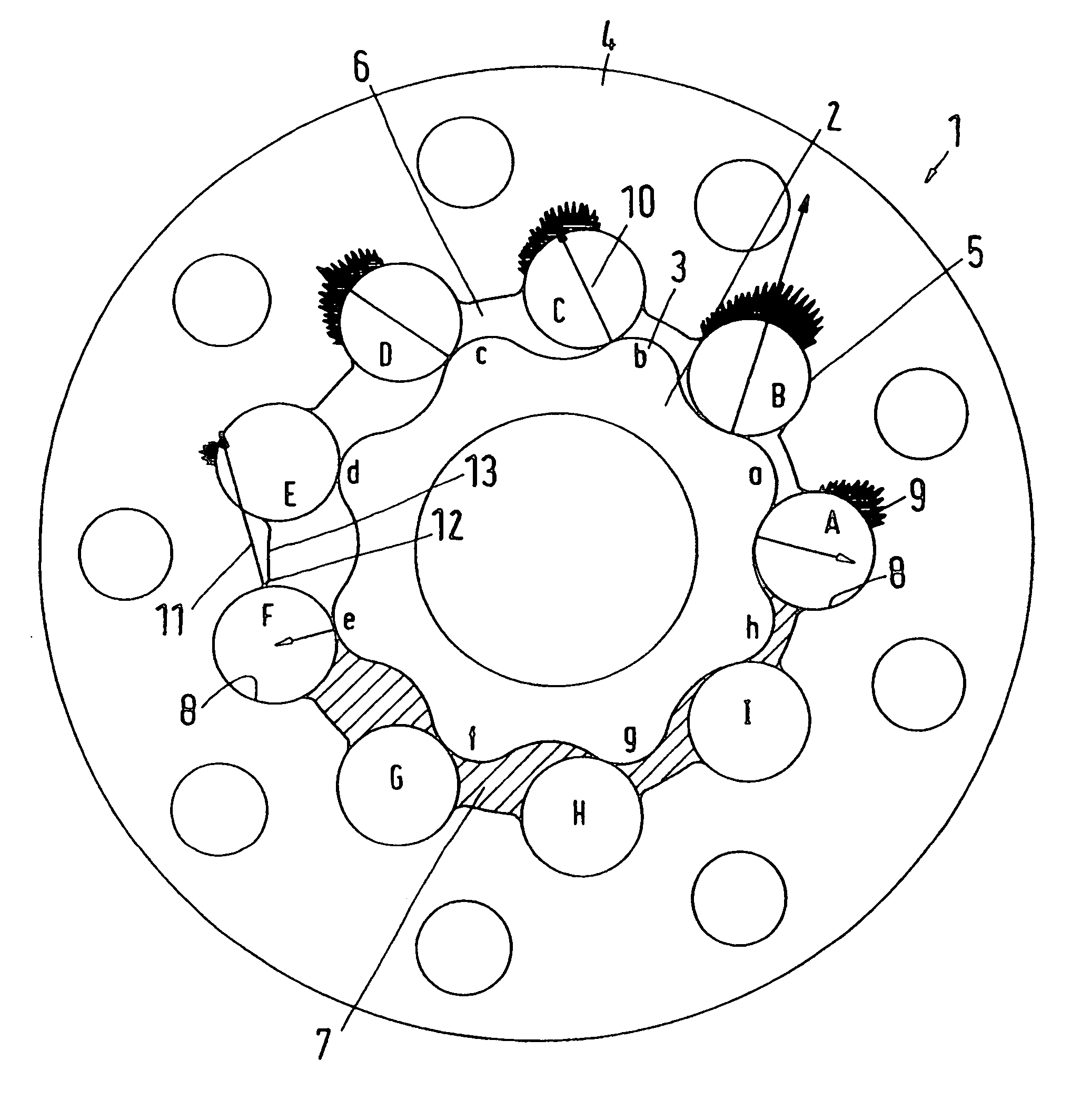

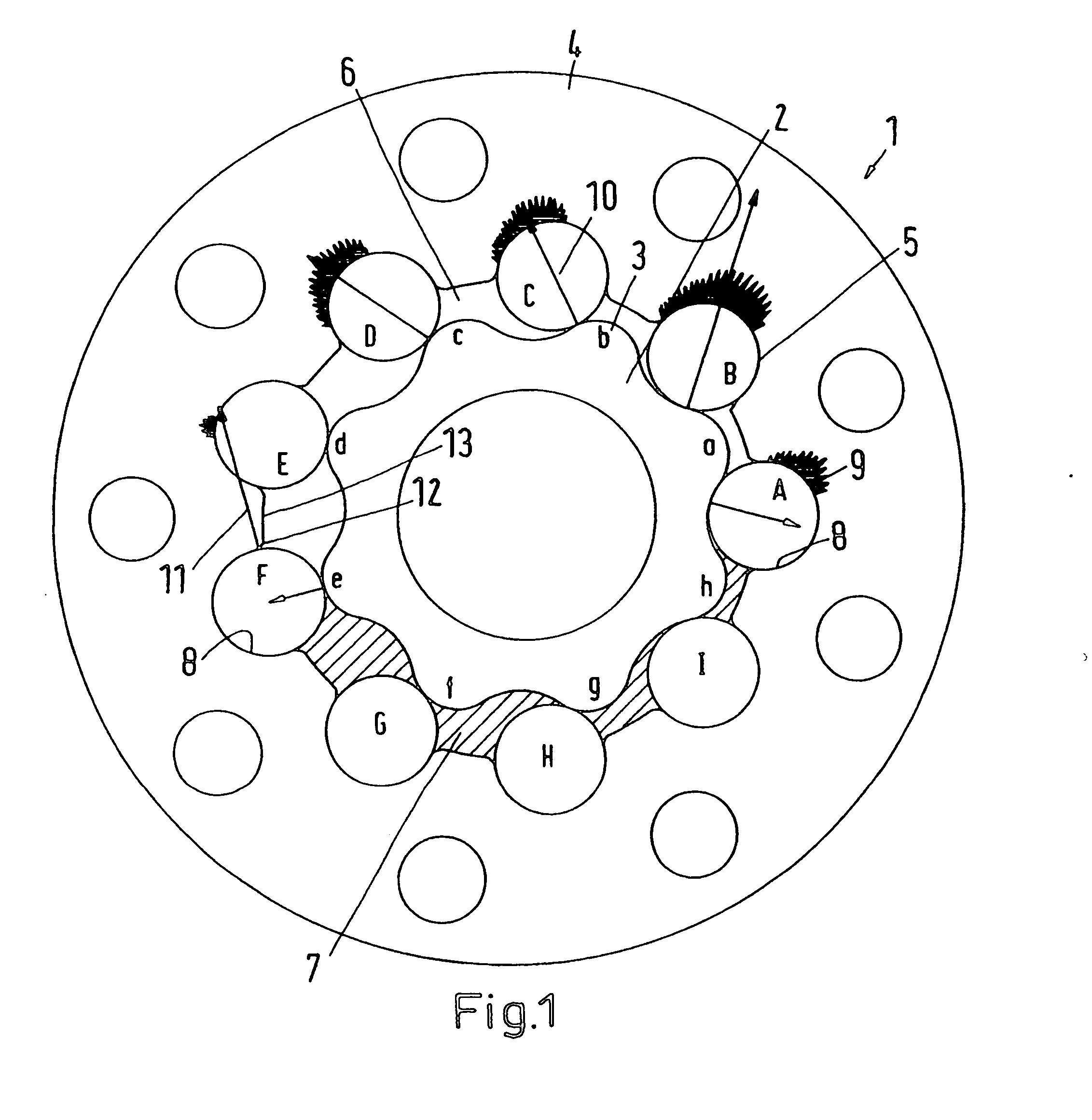

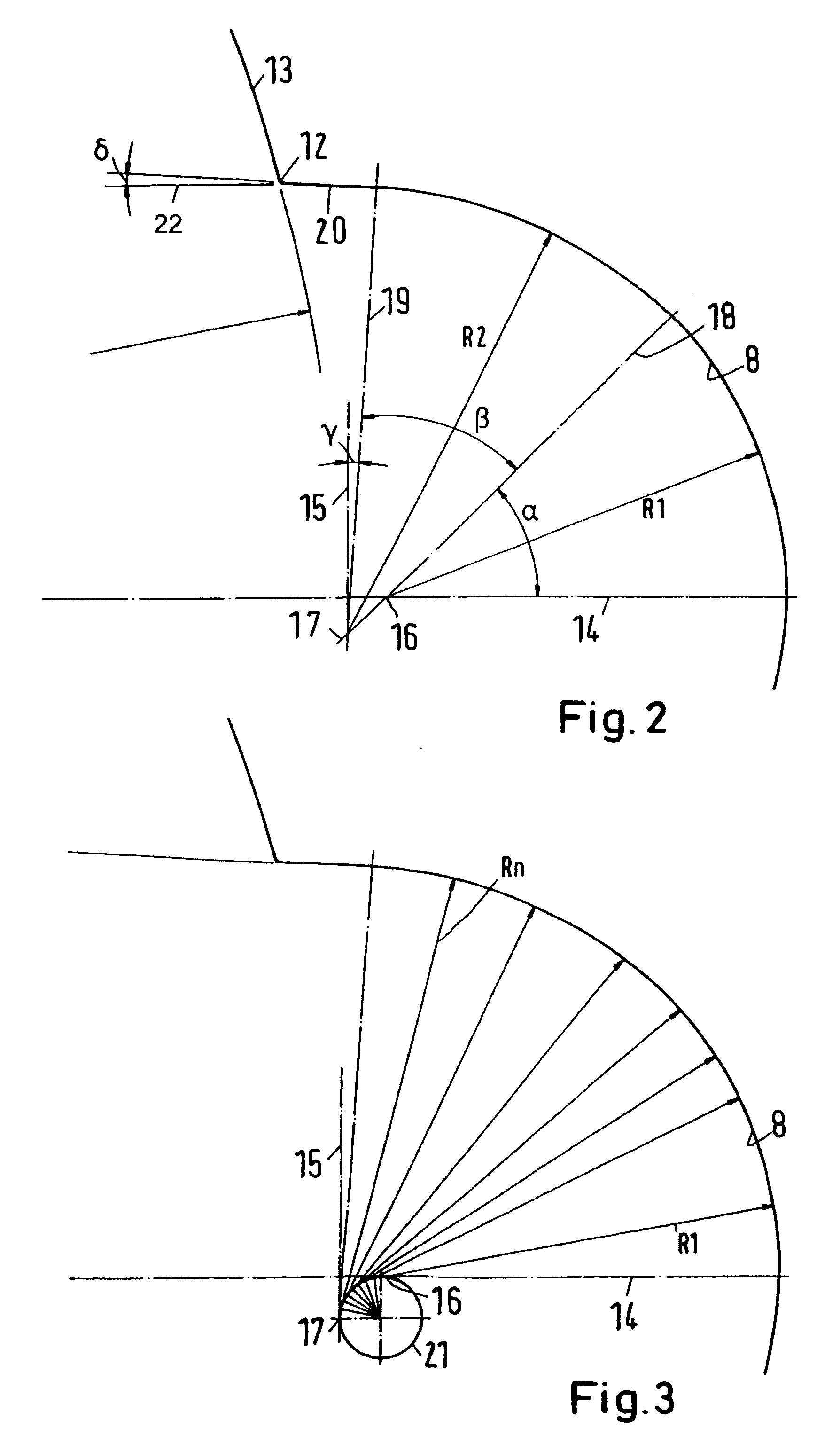

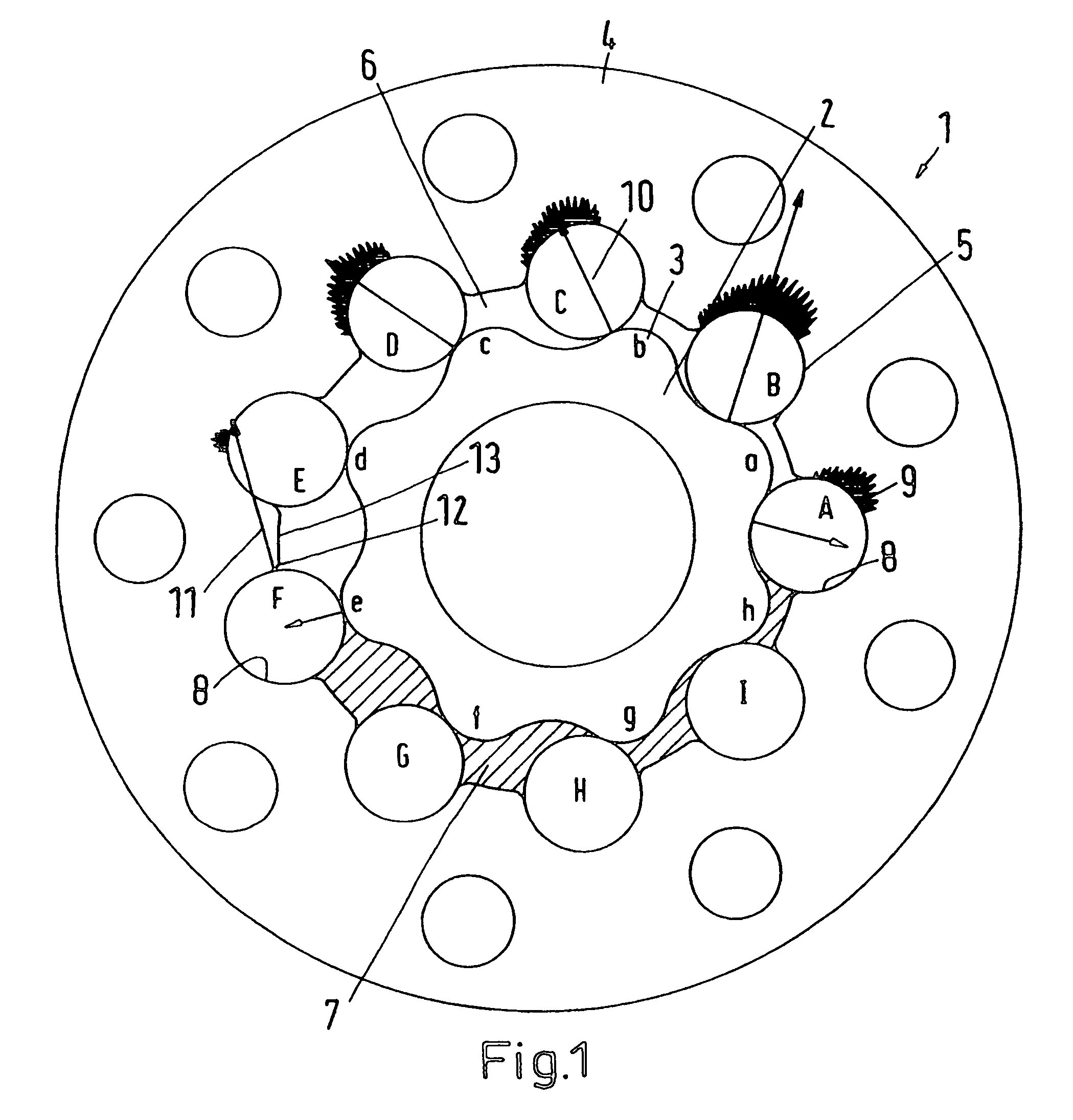

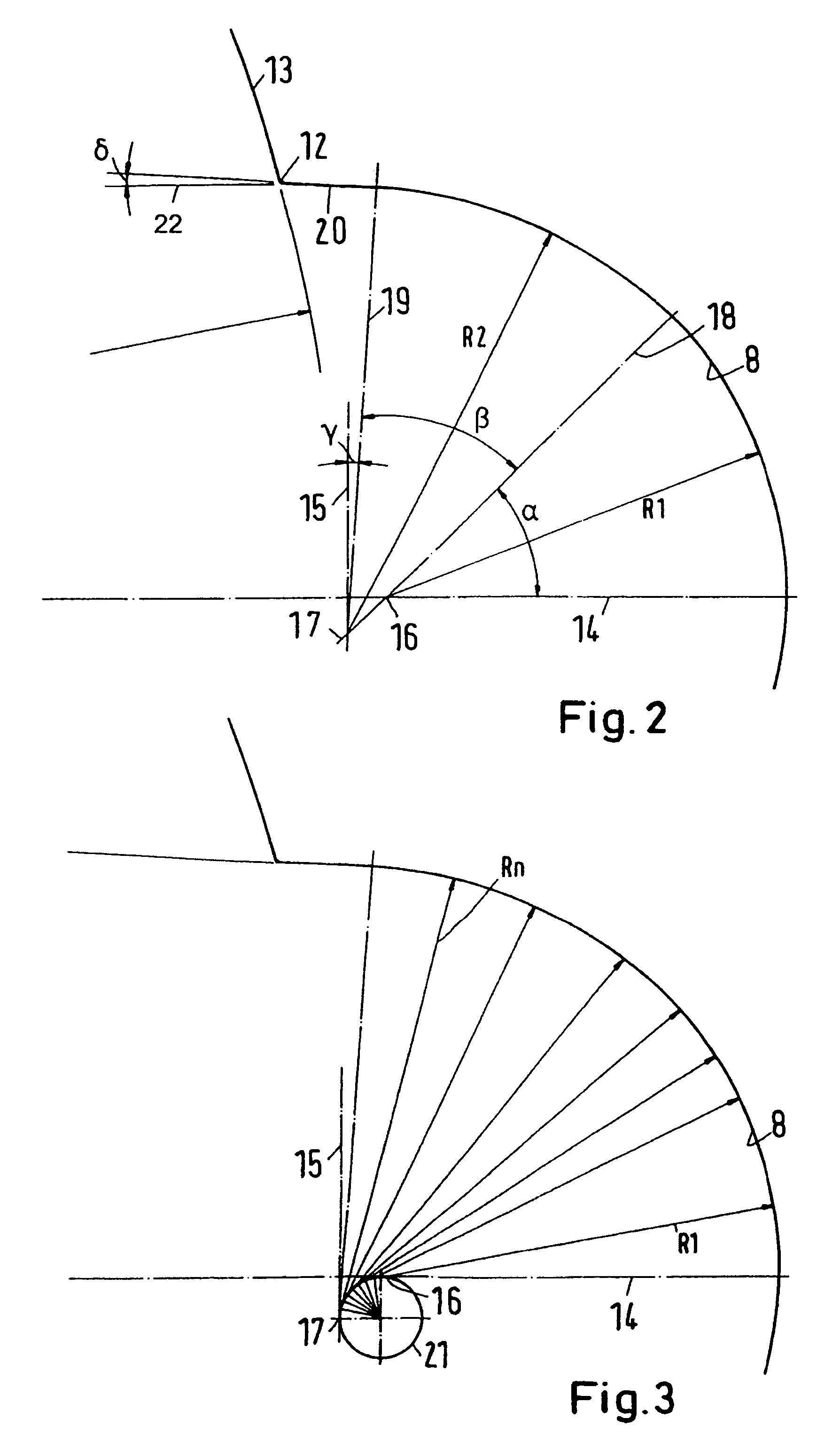

ActiveUS20070134119A1Improve sealingReduce riskEngine of arcuate-engagement typeOscillating piston enginesGear wheelEngineering

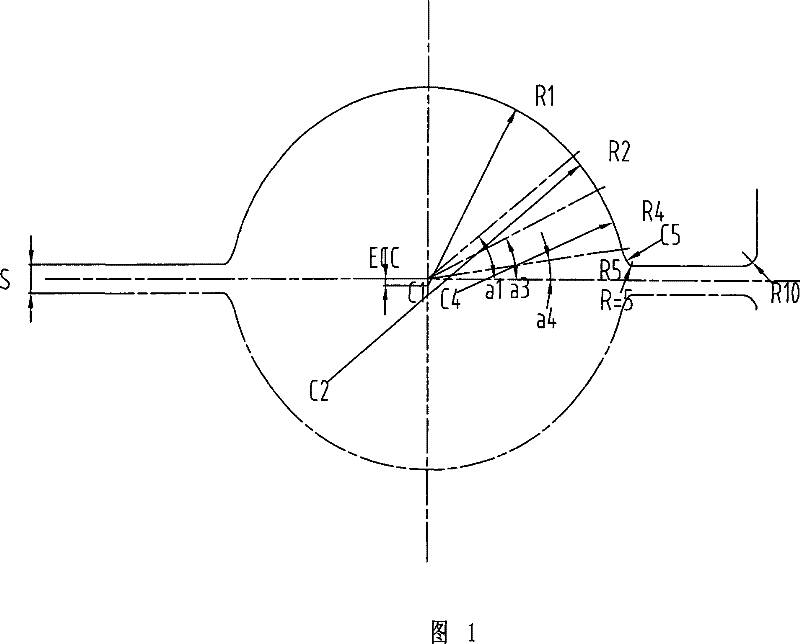

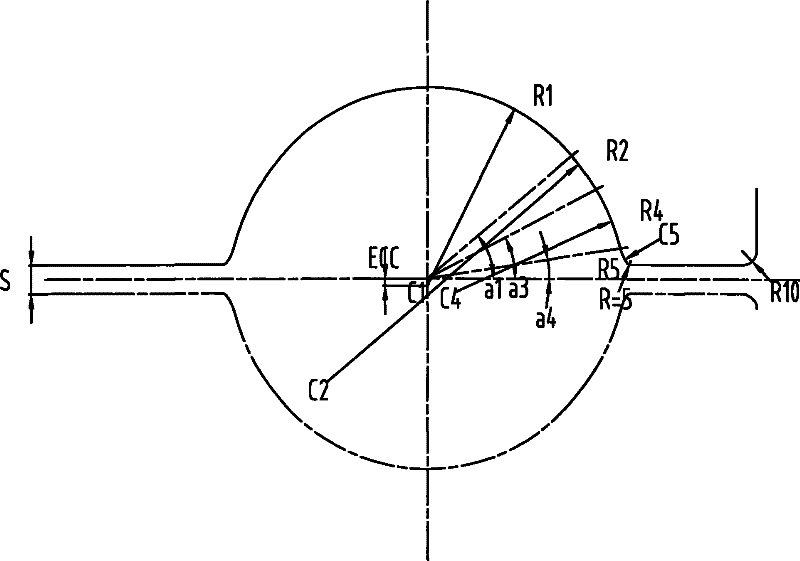

A hydraulic machine has a gear wheel (2) with outwardly extending teeth and a gear ring (4) with inwardly extending teeth formed by rollers each of which is supported in a pocket (8) in the gear ring, and pressurized spaces are formed between the gear wheel and the inwardly extending teeth. To keep the wear of the machine small each pocket (8) has at least two different radii (R1, R2, Rn) whereby a radius (R2, Rn) at a smaller displacement from the edge (12) of the pocket is larger than a radius (R1) at a larger displacement from the same edge (12) of the pocket (8).

Owner:DANFOSS PAUER SOLYUSHENS APS

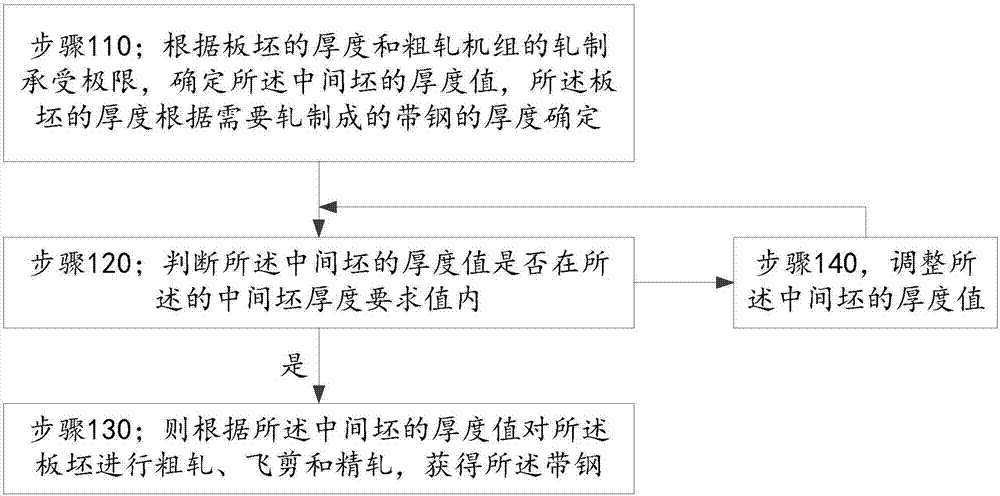

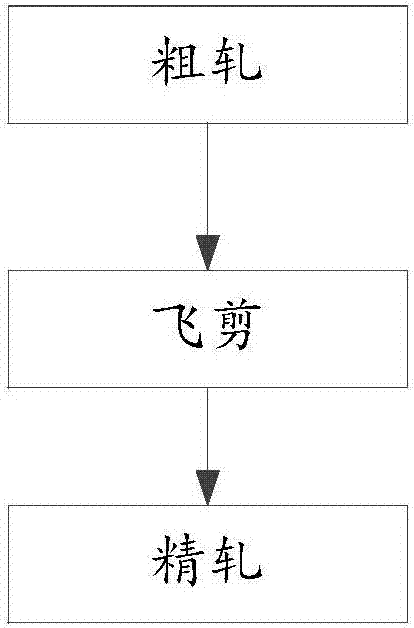

Rolling method for strip steel

InactiveCN107088585AReduce thicknessIncreasing the thicknessRoll mill control devicesMetal rolling arrangementsFront and back endsStrip steel

The invention discloses a rolling method for strip steel. The rolling method comprises the following steps of: determining a thickness value of intermediate billet according to thickness of slab and rolling bearing limit of a rough milling unit, wherein the thickness of the slab is determined according to the thickness of to-be-rolled strip steel; judging whether the thickness value of the intermediate billet is within a required thickness value of the intermediate billet or not; and if the thickness value of the intermediate billet is within the required thickness value of the intermediate billet, performing rough rolling, fly-shearing and finish rolling on the slab to obtain the strip steel. According to the rolling method disclosed by the invention, the thickness value of the intermediate billet is determined according to the thickness of the slab and the rolling bearing limit of the rough milling unit, so that the thickness of the intermediate billet is reduced as much as possible, weight of cropping of front and back ends of the intermediate billet is reduced, the yield is increased, production cost is reduced, and the technical problems that the thickness of the intermediate billet rolled by the rolling method in the prior art is relatively great, weight of cropping of front and back ends is increased, the yield of strip steel finished products is greatly reduced, and production cost is increased are improved.

Owner:SHOUGANG JINGTANG IRON & STEEL CO LTD

A rolling pass system for special-shaped channel steel

ActiveCN1608759BImprove deformation conditionsImprove abilitiesMetal rolling arrangementsEngineeringWaist

The invention discloses a special-shaped channel-steel pass system capable of smoothly rolling out a special cross-section between leg length / waist width=0.8-1.1 by using a rolling mill with a smaller specification. The present invention is composed of directly cut deep rough rolling holes, butterfly middle rolling holes arranged according to the rule of narrow-width-narrow, and straight-leg finished holes with optimized rolling mill biting conditions. It can be fully utilized, and the rolled piece can be forced to extend to the horizontal section. At the same time, the straight-leg control port is canceled, so that the rolled piece can be rolled through several butterfly holes with control ports alternately facing in turn, and then directly enter a straight-leg finished hole for rolling. This can fully improve the deformation conditions of the rolling mill, realize the rolling of large materials in small rolling mills, improve the capacity of the rolling mill and the technical and economic indicators, and bring about a lower pass height, shallower grooves on the rolls, and reduced rolling loads, etc. positive effect. Compared with the channel steel of the existing standard section, the invention can produce the special-shaped channel steel with thinner and longer legs, smaller inclination of the inner side of the legs and thicker waist.

Owner:MAANSHAN IRON & STEEL CO LTD

Hydraulic machine

ActiveUS7726958B2Large capacityReduce rolling loadEngine of arcuate-engagement typeOscillating piston enginesGear wheel

A hydraulic machine has a gear wheel (2) with outwardly extending teeth and a gear ring (4) with inwardly extending teeth formed by rollers each of which is supported in a pocket (8) in the gear ring, and pressurized spaces are formed between the gear wheel and the inwardly extending teeth.To keep the wear of the machine small each pocket (8) has at least two different radii (R1, R2, Rn) whereby a radius (R2, Rn) at a smaller displacement from the edge (12) of the pocket is larger than a radius (R1) at a larger displacement from the same edge (12) of the pocket (8).

Owner:DANFOSS PAUER SOLYUSHENS APS

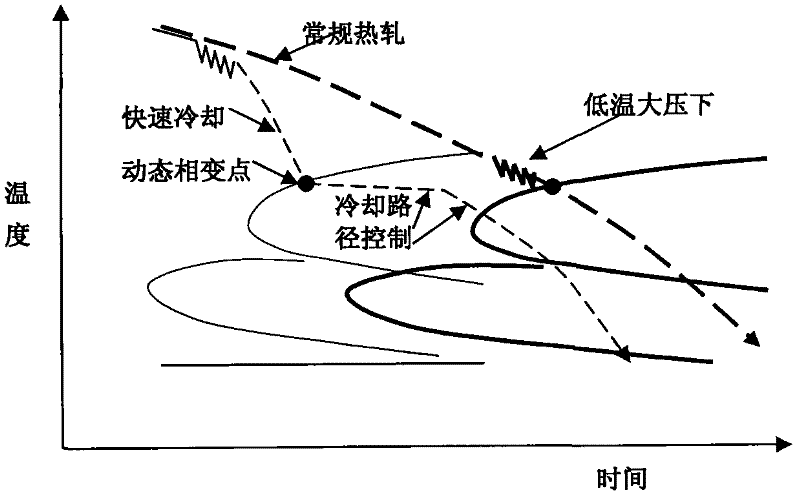

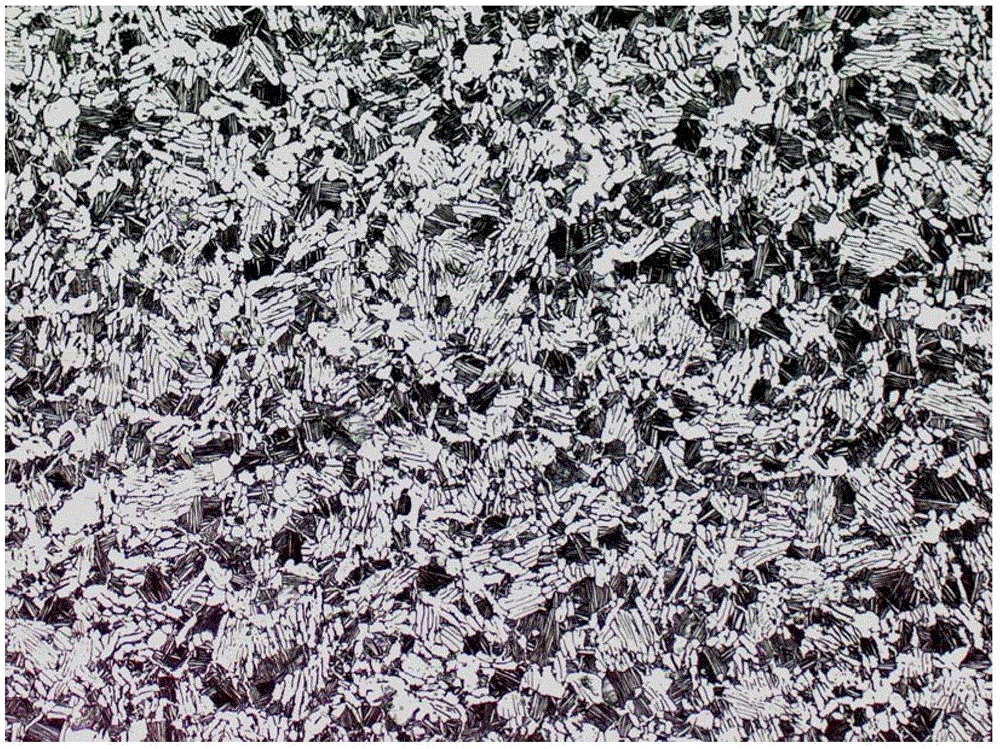

Non-quenched and non-tempered 980 MPa grade high-strength strapping steel and production method thereof

The invention discloses non-quenched and non-tempered 980 MPa grade high-strength strapping steel and a production method thereof. The production method comprises work procedures of hot rolling, cooling, cold rolling and bluing. The non-quenched and non-tempered 980 MPa grade high-strength strapping steel is characterized in that chemical components of the non-quenched and non-tempered 980 MPa grade high-strength strapping steel comprise, by weight percentage, 0.17%-0.23% of C, 1.15%-1.35% of Mn, smaller than or equal to 0.35% of Si, smaller than or equal to 0.015% of S, smaller than or equal to 0.025% of P, larger than or equal to 0.015% of Als, smaller than or equal to 0.0060% of N and the balance iron and inevitable impurities. According to the method, medium low C is adopted, compared with conventional Mn component design, by means of control over a cooling path of the cooling work procedure, the partition of C in the phase change process of the steel is adjusted, medium temperature reeling is controlled, the pearlite transformation organization conversion is avoided, a ferrite bainite organization with the performance better than that of ferrite pearlite can be obtained, and ferrite bainite steel has high tensile strength, good uniform elongation performance and high n value. By means of the method, the high-strength strapping steel with the tensile strength larger than or equal to 980 Mpa and the elongation rate A30 larger than or equal to 10% can be obtained.

Owner:TANGSHAN STAINLESS STEEL +1

Aluminum alloy ring piece radial-axial rolling lubricant and lubrication process thereof

InactiveCN106554842AImprove adsorption capacityGood chemical stabilityWork treatment devicesRollsMass ratioGraphite

The invention belongs to an aluminum alloy plasticity processing lubrication technology method, which concretely discloses an aluminum alloy ring piece radial-axial rolling lubricant and a lubrication process thereof. The lubricant comprises the following components by mass ratio: 65-80% of lard, 15-30% of graphite, 3.5-4.5% of molybdenum disulfide and 0.5-1.5% of barium petroleum sulfonate. The lubrication process aims at specific phases for lubrication, and has good adaptability for radial-axial rolling shaping on the aluminum alloy ring piece, the defect of roll banding, surface peeling, polygon and ellipse during an aluminum alloy ring piece rolling process can be effectively solved, rolling process stability, primary rolling qualified rate and product size precision are increased, production period is shortened, production cost is reduced, and product quality is guaranteed.

Owner:CAPITAL AEROSPACE MACHINERY +1

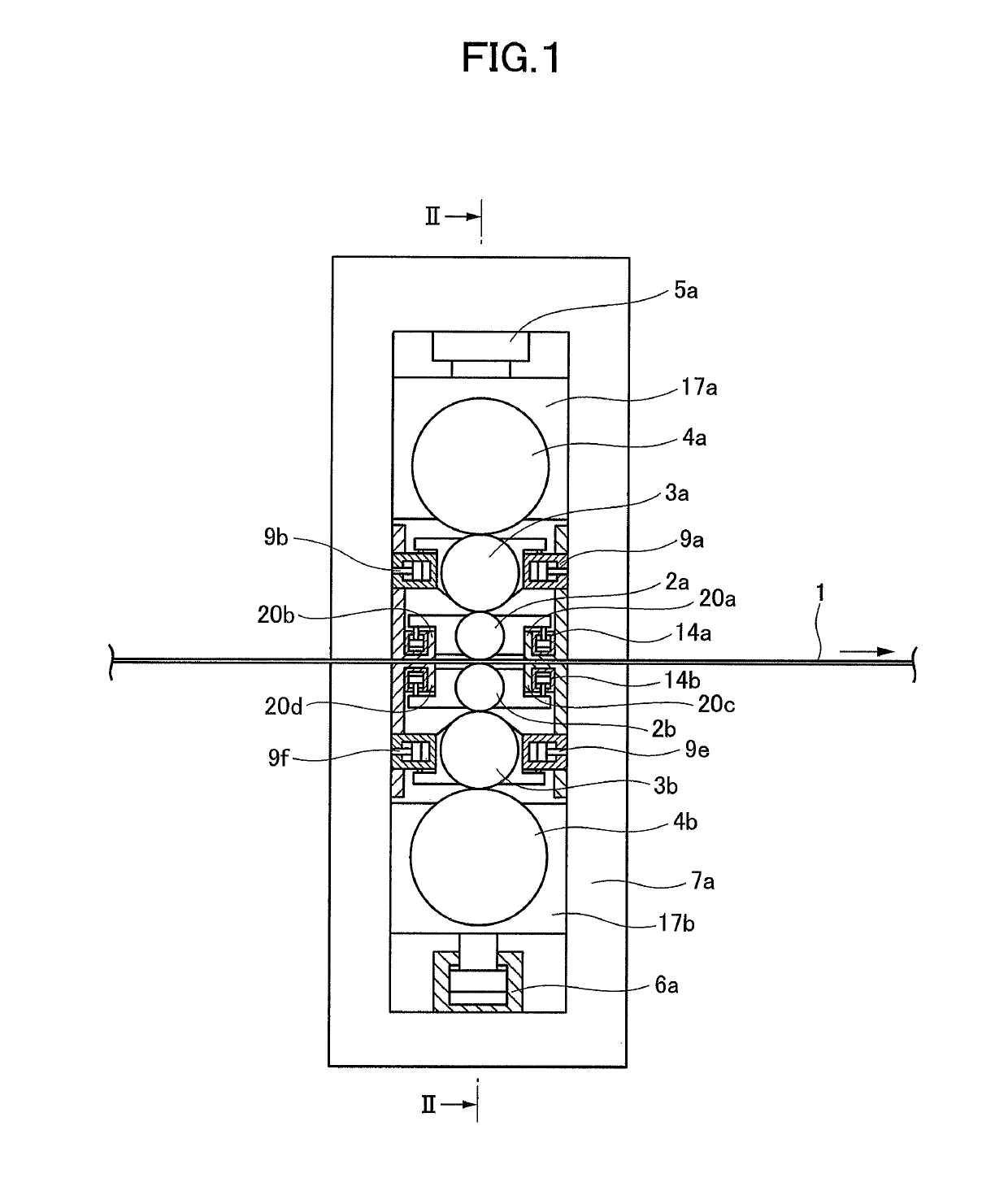

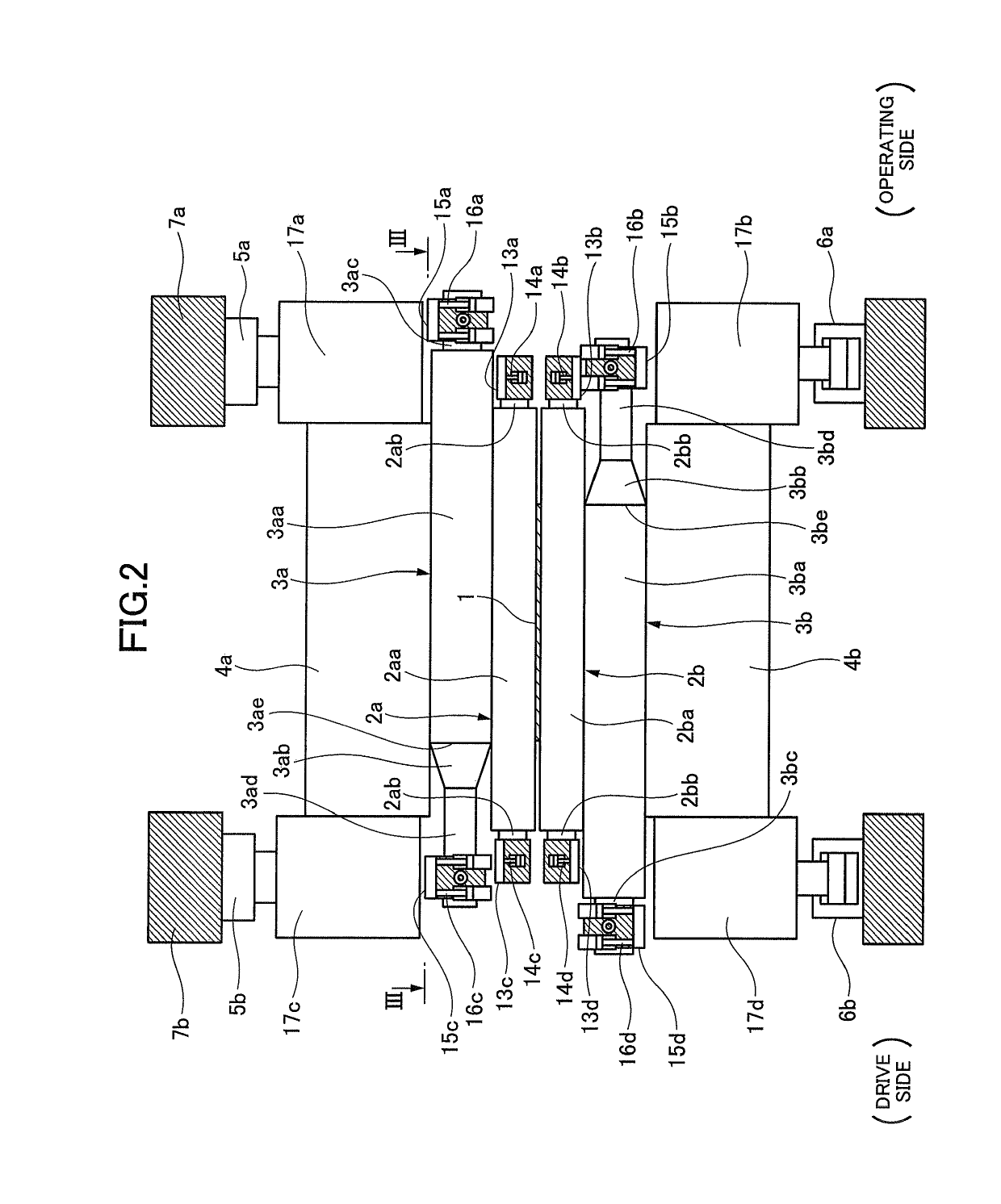

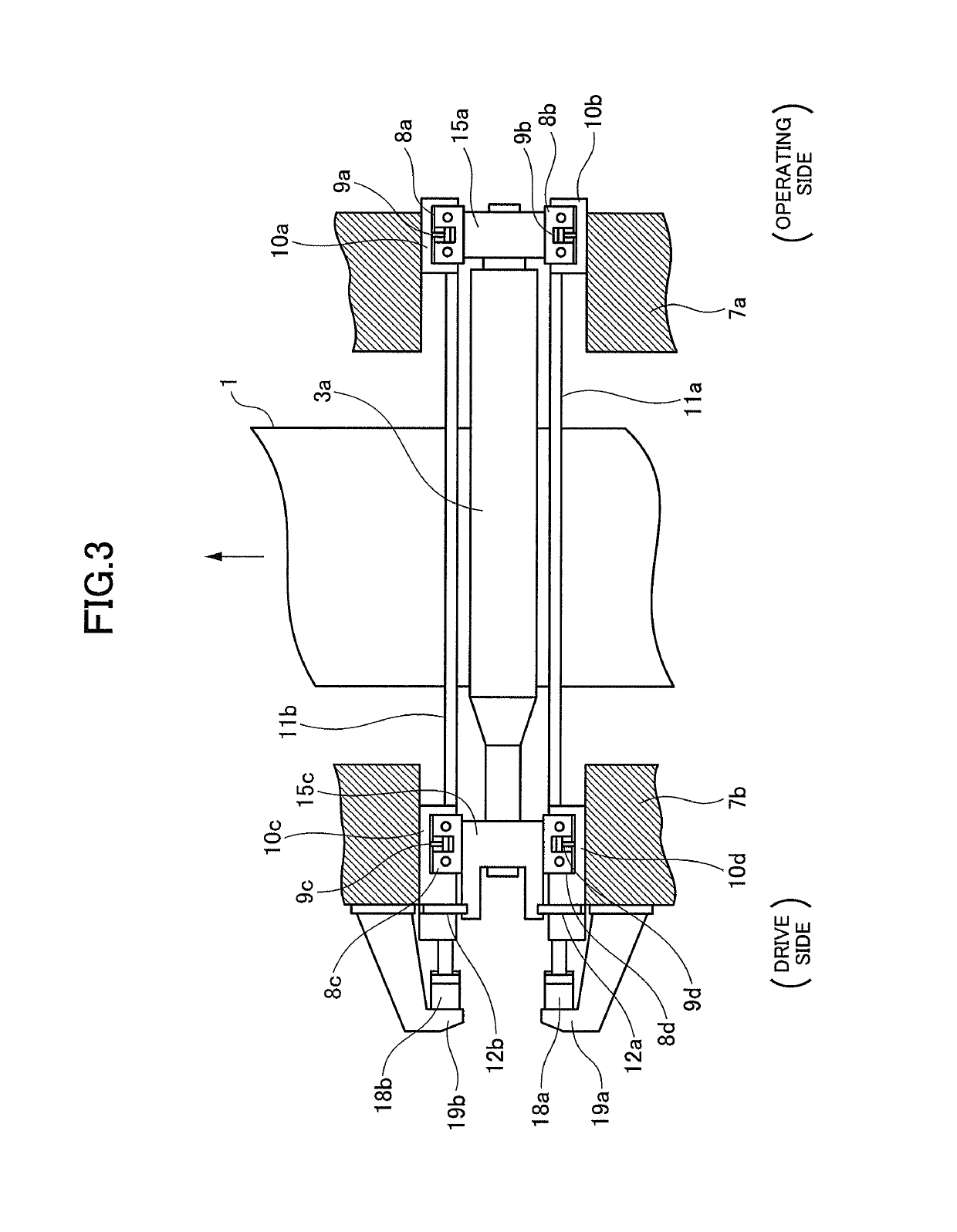

Rolling mill and rolling method

ActiveUS10421106B2Good strip shapeReduce rolling loadRoll force/gap control deviceMetal rolling stand detailsHorizontal forceWork roll

Owner:PRIMETALS TECHNOLOGIES JAPAN LTD

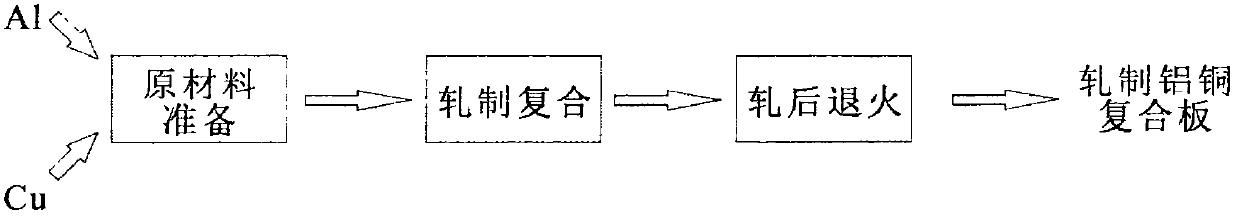

Rolled aluminum-copper composite board with high peeling strength and preparation method of composite board

InactiveCN110757935ASimplify production stepsIncrease productivityLamination ancillary operationsLaminationMaterials preparationManufactured material

The invention discloses a rolled aluminum-copper composite board with high peeling strength and a preparation method of the composite board. The method comprises the three steps of raw material preparation, rolling-bonding and after-rolling annealing, wherein according to raw material preparation, firstly, an aluminum board and a copper board are subjected to annealing treatment under the temperature of 350 DEG C and 300 DEG C respectively for 45min and 30min respectively, then the two boards are taken out, and to-be-bonded surfaces of the two boards are subjected to polishing treatment; according to rolling-bonding, the aluminum board subjected to surface treatment is maintained under the temperature of 280-300 DEG C for 30min and then is taken out to be rolled-bonded with the copper board to form an aluminum-copper composite board; and according to after-rolling annealing, the aluminum-copper composite board obtained after rolling-bonding is placed in an annealing furnace for annealing under the annealing temperature of 200-210 DEG C for 20min, so that a layer of aluminum-copper intermetallic compounds with the thickness of 3 microns is formed at an interface between an aluminumlayer and a copper. The aluminum-copper composite board prepared through the preparation method has high peeling strength and bending strength; and in the rolling process, it is needless to control afurnace atmosphere, so that the production steps are reduced, and production efficiency is improved.

Owner:JIANGSU RUNBANG NEW MATERIAL GRP CO LTD

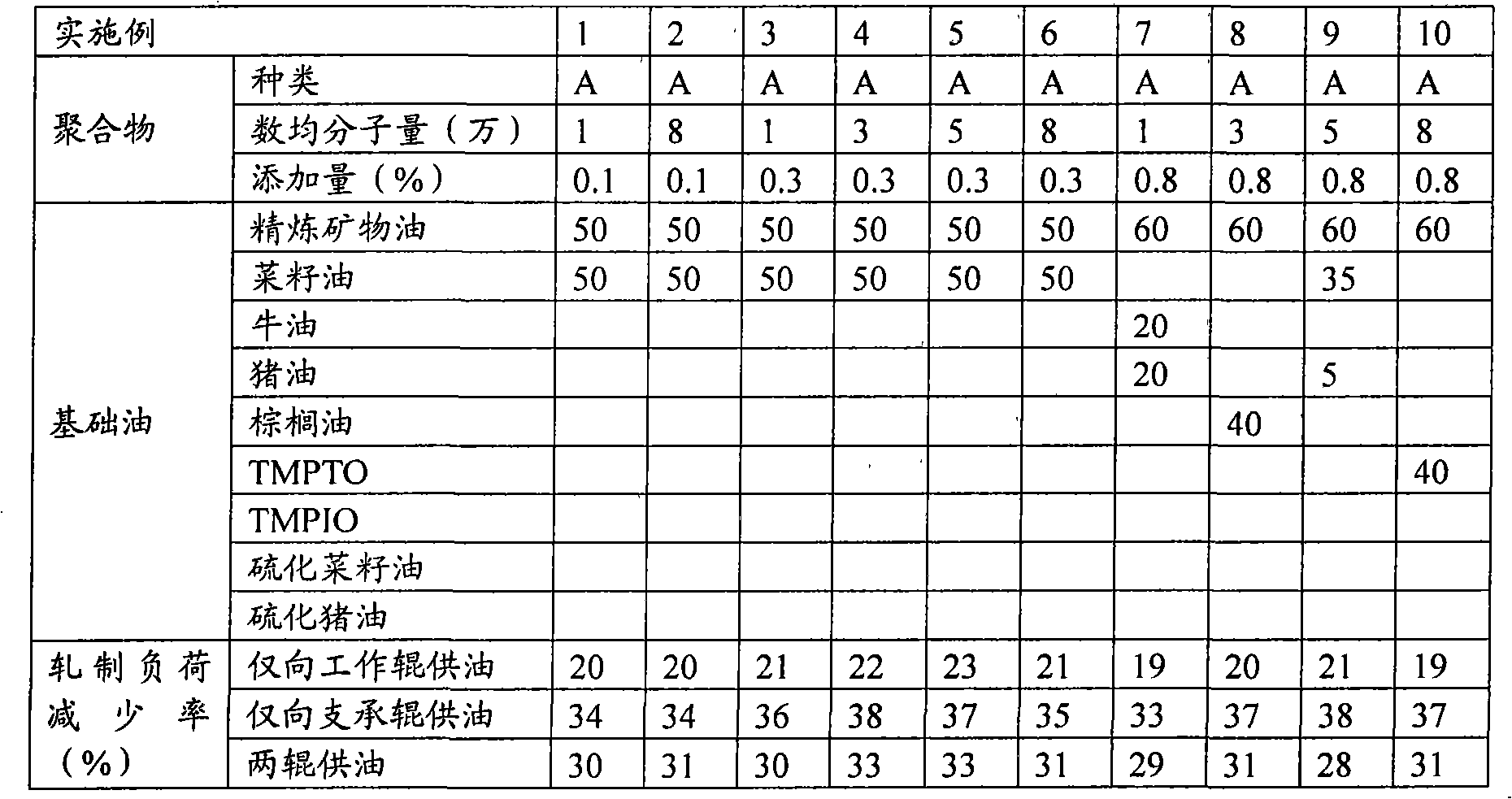

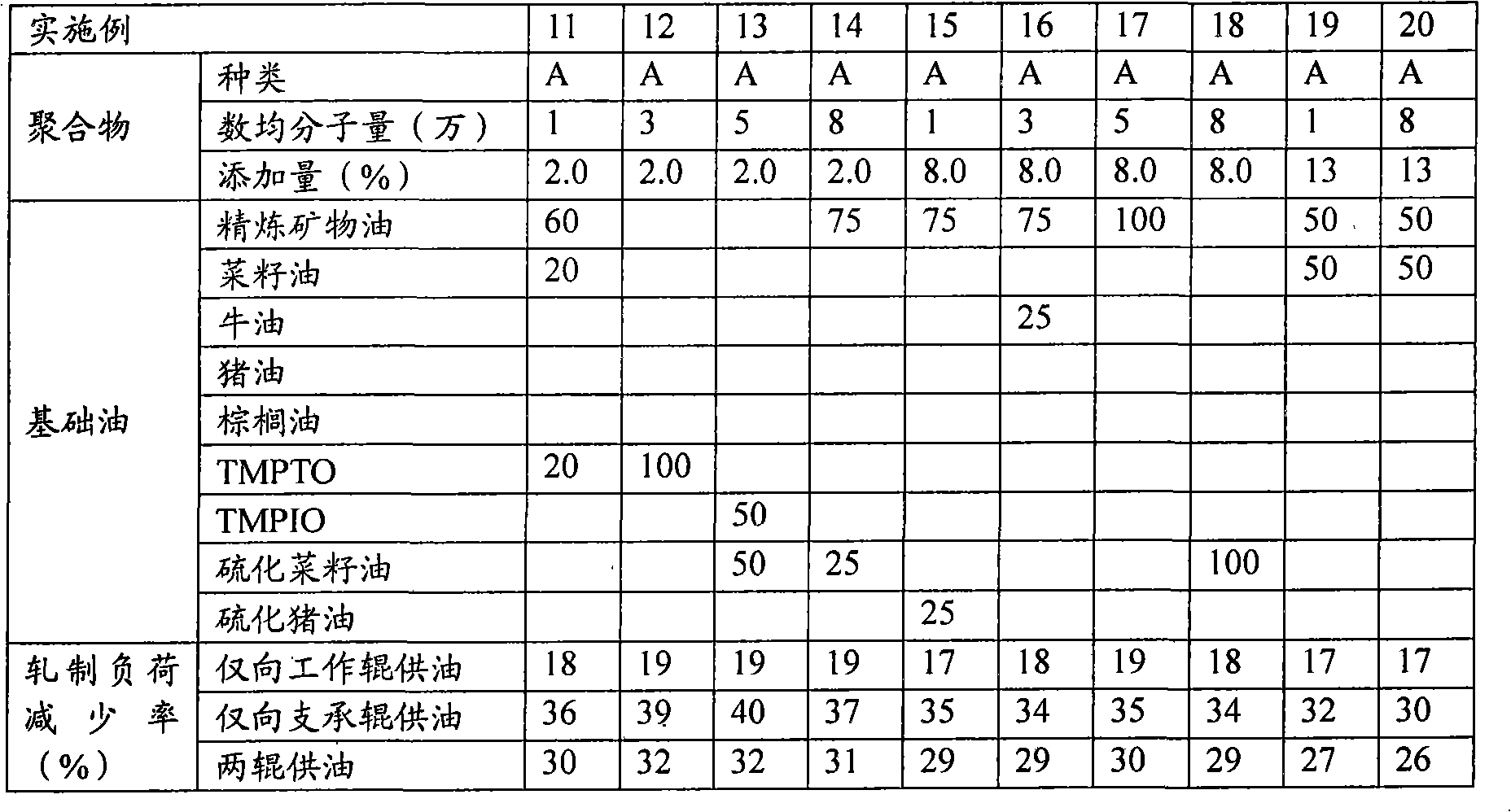

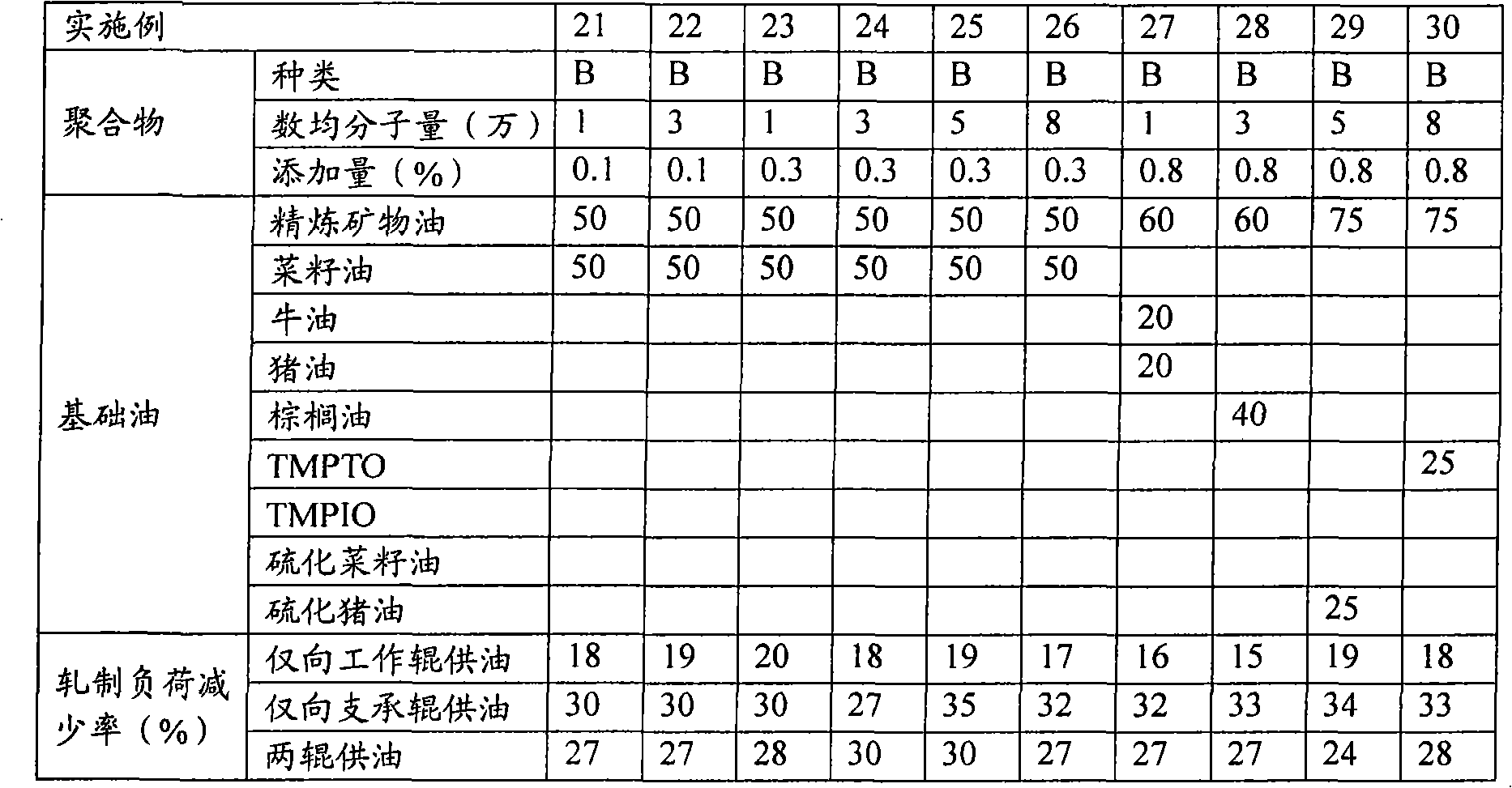

Hot rolling oil for steel member and method for hot rolling steel member

InactiveCN101605878AReduce rolling loadReduce rolling costsCounter-pressure devicesRollsMetallurgyEthylene Homopolymers

Disclosed is a hot rolling oil which enables to reduce a rolling cost by effectively decreasing a rolling load when a steel member is heated and rolled within a temperature range of 200-1200 DEG C. Also disclosed is a method for hot rolling a steel member by using such a hot rolling oil. Specifically disclosed is a hot rolling oil containing a base oil and at least one polymer selected from the group consisting of isobutylene homopolymers and isobutylene copolymers having a number average molecular weight of 8,000-100,000. Also specifically disclosed is a method for hot rolling a steel member, which is characterized in that the hot rolling oil is fed by a water injection system.

Owner:KYODO YUSHI CO LTD

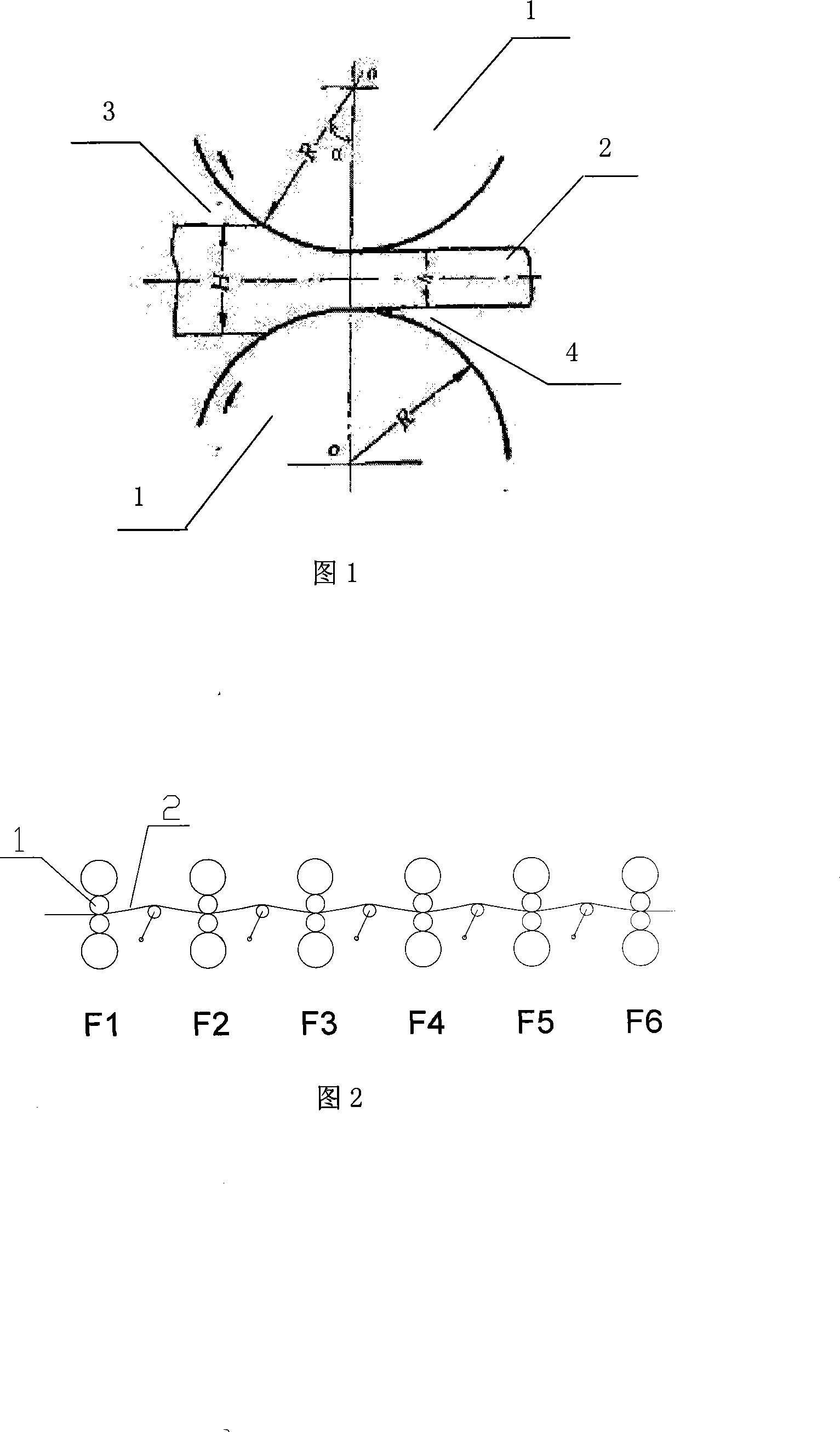

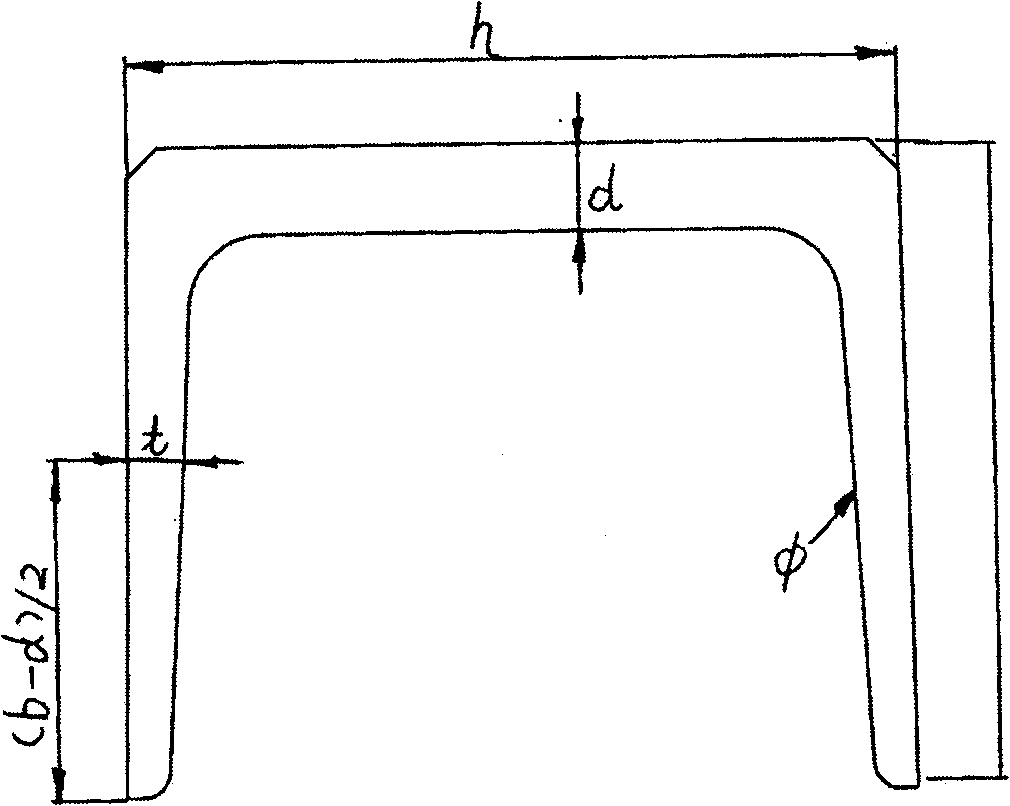

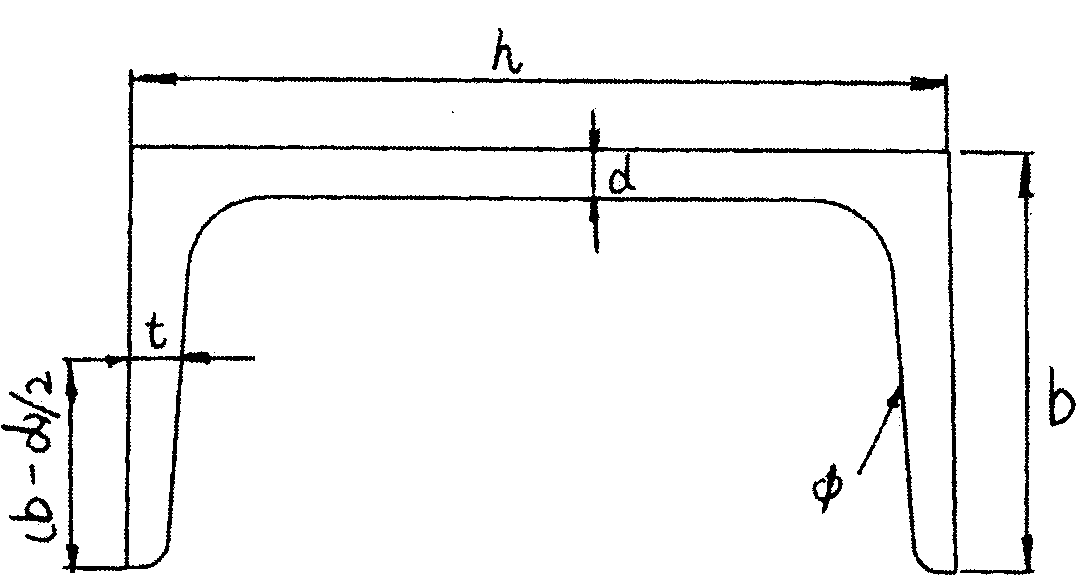

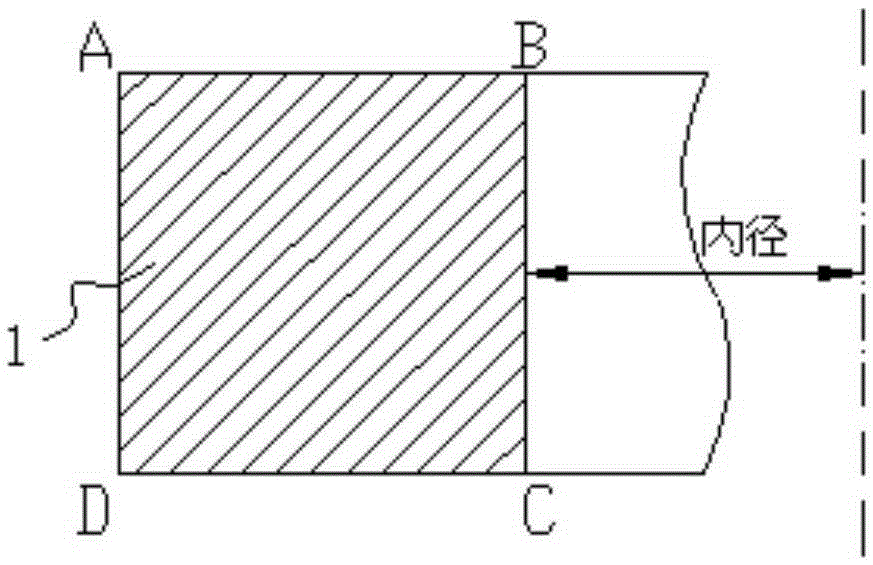

A Five-Stand Confined Mandrel Continuous Rolling Mill Conducive to Reducing Roll and Mandrel Consumption

InactiveCN101468359BIncrease lateral flowReduce rolling loadMetal rolling arrangementsEllipseEngineering

Owner:WUXI SEAMLESS OIL PIPE

Hot-rolled thin enamelled steel with yield strength of 330mpa grade and manufacturing method

InactiveCN103540845BMeet the needs of steelExcellent anti-scale explosion performanceChemical compositionSheet steel

The invention discloses hot-rolled thin plate enamelled steel with the yield strength of 330 MPa and a manufacturing method thereof; the thickness of the enamelled steel is 1.0-2.5 mm; the enamelled steel disclosed by the invention comprises the following chemical components in percentage by weight: 0.02-0.07% of C, less than or equal to 0.05% of Si, 0.10-0.50% of Mn, less than or equal to 0.020% of P, less than or equal to 0.010% of S, 0.04-0.10% of Ti, 0.02-0.08% of Als, less than or equal to 0.008% of N, and the balance of Fe and unavoidable inclusions; Ti / C=1.0-1.5; the manufacturing method is a CSP (Compact Strip Production) process and sequentially comprises the following fully continuous production steps: desulfurating molten iron; blowing the top and bottom of a converter in a compound manner; carrying out vacuum treatment; continuously casting into slabs; soaking through a soaking furnace; hotly and continuously rolling, and rolling and cooling in a controlled manner; rolling into steel coils. The hot-rolled thin plate enamelled steel disclosed by the invention has the advantages of being low in rolling load, good in plate shape control, low in production cost and high in efficiency, and therefore, the steel plate manufactured by the enameled steel has good scale blast resistance, high intensity and better seep drawing process performance.

Owner:武汉钢铁有限公司

Rolled lubricating process of rolling band-steel

ActiveCN101028632BGood adhesionImprove sintering resistanceRollsMetal rolling arrangementsStrip steelPetroleum engineering

A roller-type lubricating method for rolling steel band features that the lubricating oil is transferred via oil tube onto the oil applying roller pressed on the working roller, and the oil applying roller is driven to rotate by said working roller to coat the surface of working roller to form an oil film layer.

Owner:BAOSHAN IRON & STEEL CO LTD

A kind of manufacture method of titanium alloy tie hoop material

The invention provides a manufacturing method of titanium alloy coupling stock. The method comprises the steps of smelting, wherein titanium sponge is smelted for three times in a vacuum arc remelting electric-arc furnace to obtain a round billet with a diameter of 150mm; heating, wherein the round billet is placed into an annular furnace to be heated; punching, wherein the round billet is rolled to be a tubular billet with a punching machine; reducing, wherein the tubular billet is placed into a reheating furnace to be heated again to 970 DEG C, then kept at the temperature for 1h and finally reduced to obtain a finished tube; heat treatment, wherein the punched tubular product is kept at a temperature of 950-960 DEG C for 50-60min and then air-cooled. The manufacturing method of the titanium alloy coupling stock has the advantages that due to the fact that the hot-punched tubular billet is directly reduced to obtain the titanium alloy coupling stock, spiral lines on the punched tubular billet can be completely eliminated through sizing, and good appearance quality of a steel tube is guaranteed; rolling is eliminated, the process is simple, and cost is low; due to the fact that the heating temperature is below the phase transformation point of titanium alloy, the appearance of thick Beta tissue is avoided; due to the fact that the tubular billet is placed into the reheating furnace to be heated again before the reducing, rolling load of a reducing mill is reduced.

Owner:TIANJIN PIPE GROUP CORP

Production method for rapidly cooling medium plate after rolling

ActiveCN102343372BLow carbon equivalentLow weld crack susceptibilityWork treatment devicesMetal rolling arrangementsSpray nozzlePhase change

The invention discloses production method for rapidly cooling a medium plate after rolling, belonging to the technical field of production of medium plates. The method comprises the following process steps of: adjusting an ultrafast cooling (UFC) frame to 300mm+h till the cross point between extension lines of upper and lower nozzles of equipment is positioned on the central line of a steel plate; during ultrafast cooling, setting cooling rules and parameters according to the steel kind, specification as well as required final cooling temperature and cooling speed of the steel plate; starting middle spraying, side spraying and air blowing to remove residual water from the surface of steel plate to increase the cooling uniformity, starting UFC equipment, and spraying water onto the steel plate with a gap nozzle and a ganged nozzle for cooling; and controlling the cooling speed and cooling termination point according to the CCT (Continuous Cooling Transformation) curve of steel, wherein the cooling speeds of steel plates of different thicknesses are 5-80 DEG C / s, and the final cooling temperature is controlled at 450-800 DEG C. The method has the advantages: by controlling the cooling process of the steel plate after rolling, control over phase change and organization is realized, and the aim of enhancing the roughness of the steel plate is fulfilled.

Owner:SHOUGANG CORPORATION

Features

- R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

Why Patsnap Eureka

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Social media

Patsnap Eureka Blog

Learn More Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com