High-strength high-toughness X80 hot rolling coiled sheet for spiral buried arc welding and production method thereof

A high-strength toughness, submerged arc welding technology, applied in the field of steel rolling, can solve the problems of product thickness and performance requirements not meeting the application conditions, not using high Nb content, high production cost pressure, etc., to enlarge the rolling process window and reduce Risk, effect of reducing rolling load

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

[0046] 18.4mm X80 hot rolled coil

[0047] Chemical composition (wt%)

[0048]

[0049] Routing

[0050] Raw material preparation → molten iron pretreatment → converter smelting → refining outside the furnace → slab continuous casting → slab reheating → controlled rolling → controlled cooling → laminar cooling → coiling → inspection and storage

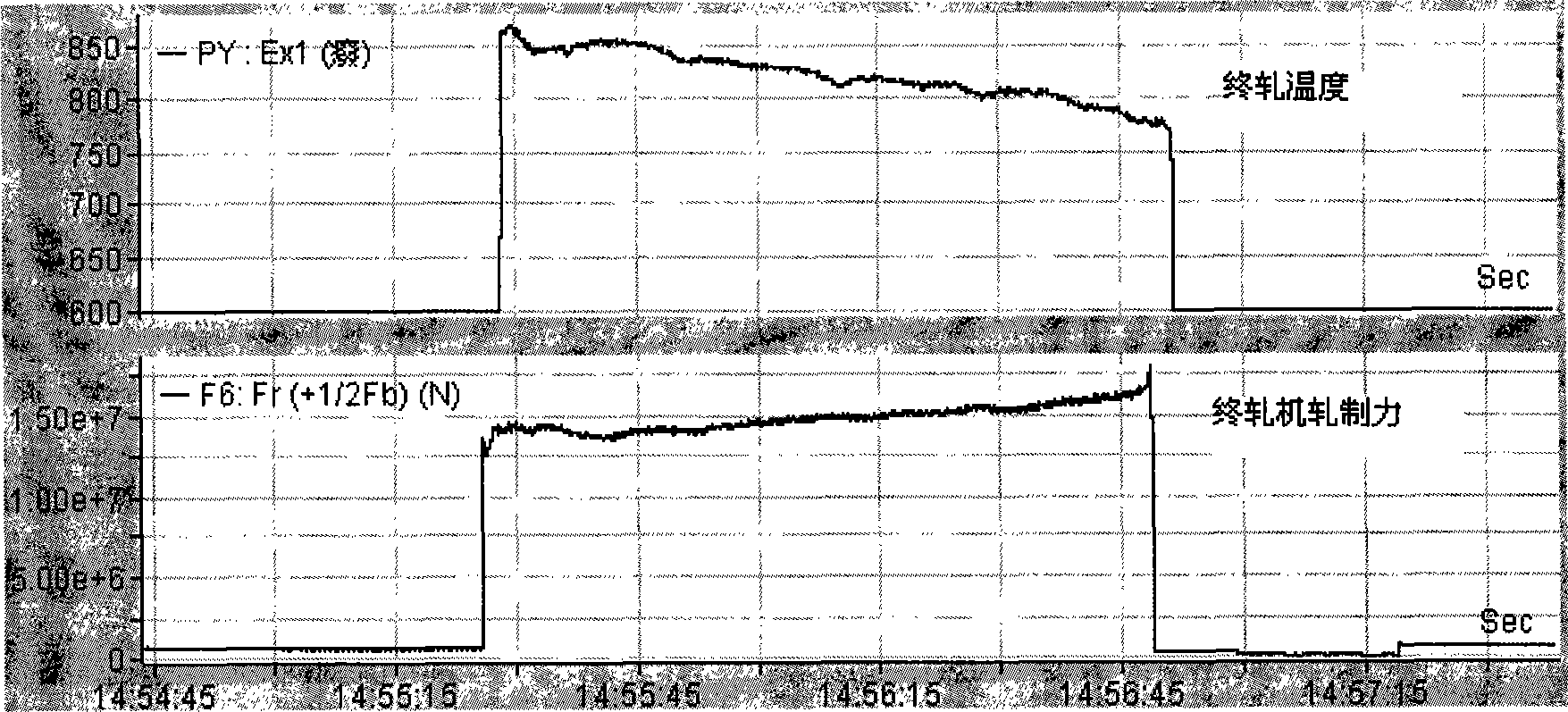

[0051] Key points of steel rolling process

[0052]

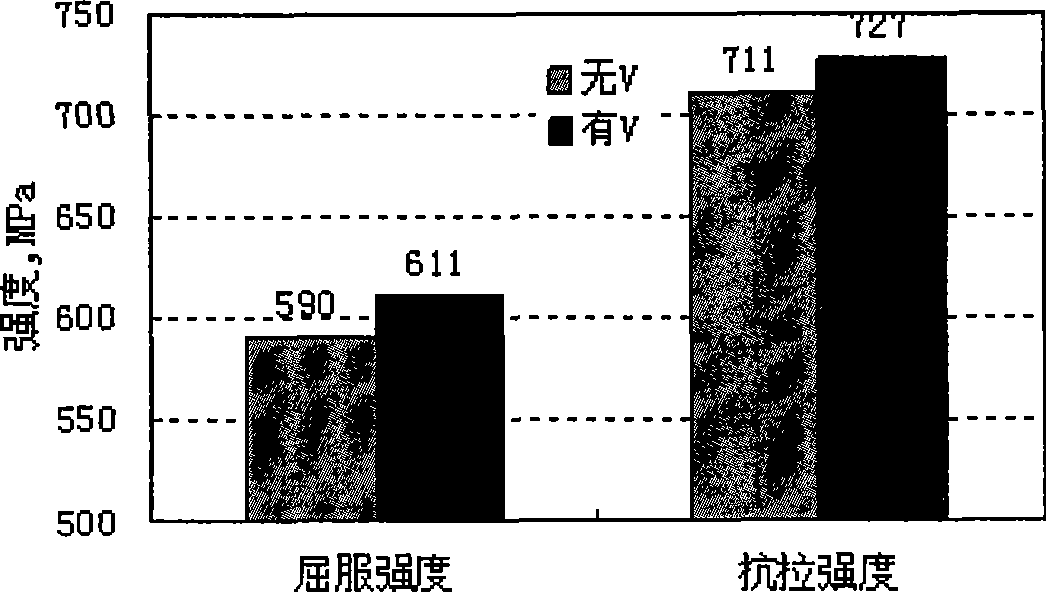

[0053] performance results

[0054] 1) Tensile, cold bending and hardness properties of X80 hot-rolled coil

[0055]

[0056]

[0057] Note: The tensile sample is a round bar sample type

[0058] 2) Fracture toughness of X80 hot-rolled coil

[0059]

[0060] 3) Metallographic structure

[0061] The metallographic structure is acicular ferrite structure, which is dominated by granular bainite structure and contains dispersed M / A components. see attached Figure 4 ~ attached Figure 6 .

[0062] Economic significance and social significance of the pre...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com