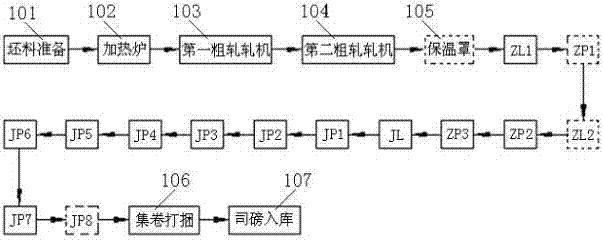

Ultra-thin hot-rolled narrow strip steel production line and its supporting technology

A narrow strip steel and production line technology, applied in metal rolling, temperature control and other directions, can solve the problems of difficult production, unstable rolling, high production cost, avoid rolling temperature drop, increase rolling speed, and reduce temperature. drop effect

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

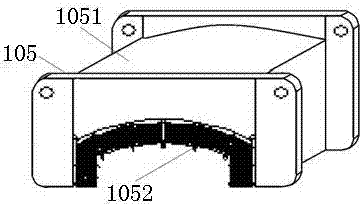

Method used

Image

Examples

Embodiment 1

[0049] Embodiment 1: In this implementation example, the rolling steel grade is Q235, and the specification is 132×1.3mm hot-rolled narrow strip steel.

[0050] During the rolling process, the rolling temperature of the steel strip is strictly controlled. The heating temperature (soaking section), starting rolling temperature and finishing rolling temperature of the steel strip are controlled at 1200-1310°C, 1140-1260°C, and ≥855°C, respectively. In this embodiment: the heating temperature is 1290°C, the best control is 1250-1300°C; the rolling start temperature is 1250°C, the best control is 1240-1260°C; the final rolling temperature is 865°C, the best control is ≥870°C.

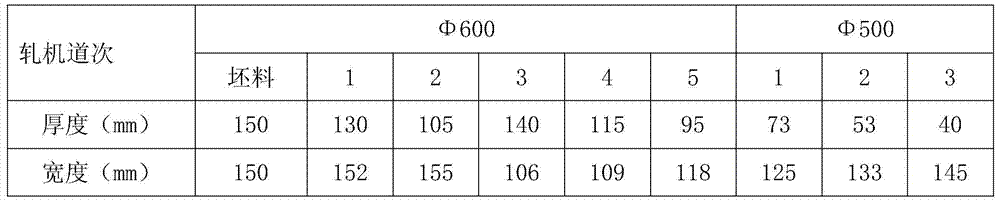

[0051] During the rolling process, the rolling system of the steel strip is strict. details as follows:

[0052] 1. Rough rolling: single-stand rolling, including 5 passes with Φ600 rolling mill unit at a rolling speed of 2.7mm / s, and 3 passes with a Φ500 rolling mill unit at a rolling speed of 2.6mm / s. T...

Embodiment 2

[0057] In this implementation example, the rolling steel grade is Q195, and the specification is 163×1.2mm hot-rolled narrow strip steel.

[0058] In this embodiment: the heating temperature is 1280°C, the best control is 1240-1290°C; the rolling start temperature is 1240°C, the best control is 1230-1260°C; the final rolling temperature is 878°C, the best control is ≥860°C.

[0059] 1. Rough rolling: single-stand rolling, in which the Φ600 rolling mill unit rolled 3 passes at a rolling speed of 2.7mm / s, and the Φ500 rolling mill unit rolled 3 passes at a rolling speed of 2.6mm / s. The rolling schedule of each pass is the change of the cross-sectional area of the rolled billet, which is expressed by length × width, and the length of the billet will continue to stretch and become longer according to the degree of deformation. The specific changes for each pass are shown in the table below:

[0060]

[0061] 2. Intermediate and finishing rolling: There are 14 passes in total...

PUM

| Property | Measurement | Unit |

|---|---|---|

| thickness | aaaaa | aaaaa |

Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com