High-strength Al-Mg-Si-Cu alloy and preparation method thereof

A high-strength, alloy technology, which is applied in the field of high-strength Al-Mg-Si-Cu alloy forging materials and its preparation, can solve the problems of reducing material plasticity and toughness, reducing mechanical properties, and failing to obtain strength values, etc., to improve mechanical properties. performance effect

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

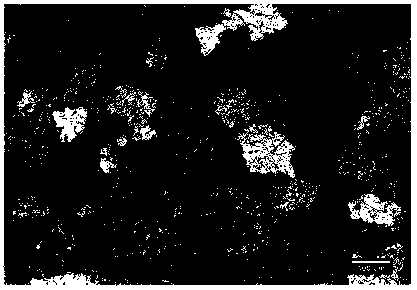

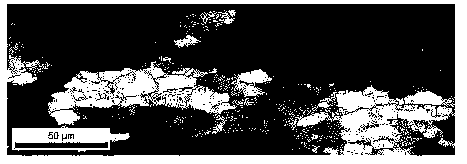

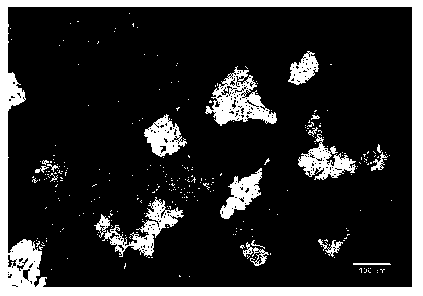

[0018] High-strength Al-Mg-Si-Cu alloy, the mass percentage of the composition is: Mg 0.8~1.4wt.%, Si 0.8~1.6wt.%, Cu 0.2~0.8wt.%, Mn 0.2~1.0wt.% , Cr 0.1~0.4wt.%, Ti 0.01~0.1wt.%, Fe≤0.25wt.%, the sum of unavoidable impurities ≤0.15wt.%, and the balance is Al. The as-cast grain size of the alloy is less than 130 μm, the secondary dendrite arm spacing is not more than 40 μm, the grain size of the T6 state is less than 15 μm, the yield strength of the material is above 370 MPa, and the elongation is greater than 12%.

[0019] Mg and Si are the main alloying elements in the 6××× series aluminum alloys, forming the main strengthening phase Mg of the alloy 2 Si. This series of alloys improves the material strength by controlling the Mg / Si ratio and excess Si content. When the Mg and Si content is too low, the Mg 2 The amount of Si strengthening phase is small, and the strength of the material is low; when the content of Mg and Si is too high, on the one hand, the formability of ...

PUM

| Property | Measurement | Unit |

|---|---|---|

| yield strength | aaaaa | aaaaa |

| yield strength | aaaaa | aaaaa |

| yield strength | aaaaa | aaaaa |

Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com