A method and device for monitoring the internal temperature field during the forming process of a three-dimensional woven composite material

A molding process and composite material technology, applied in measuring devices, thermometers, thermometers with physical/chemical changes, etc., can solve problems such as difficult to realize three-dimensional weaving temperature field monitoring, reduce test monitoring costs, improve survival rate, The effect of increasing strength

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

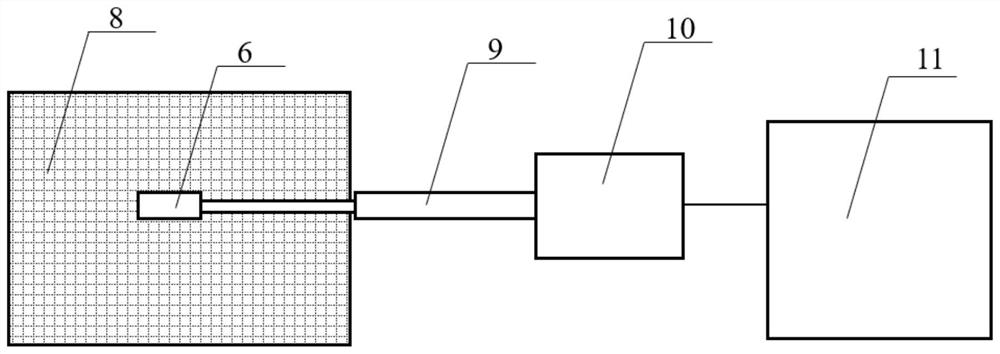

[0040] Such as Figure 1-3 As shown, the working process of monitoring the internal temperature field during the forming process of three-dimensional woven composite materials includes:

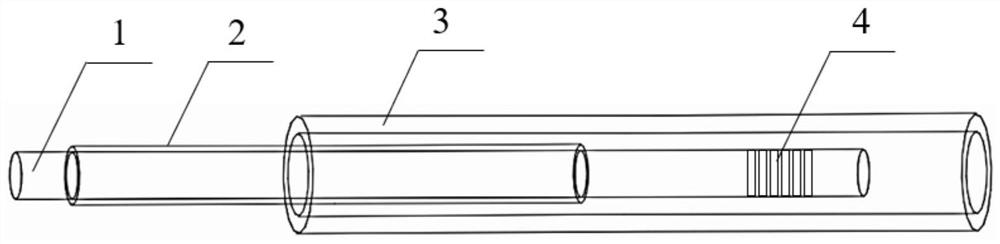

[0041] (1) Select a number of standard optical fibers 1 with diameter (125 μm), coated with polyimide coating 2 on the outside, grating segment 4 length 4mm, and FBG sensor 6 with a central wavelength of 1500nm-1600nm, and cut the optical fiber on one side of the grating segment , use polyimide wire strippers to strip off the coating of the grating segment (or ablate the grating segment with fire, wipe it off with alcohol after the coating turns black), use 0.9mm diameter steel pipe 3 to set into the grating segment, and The edges are sealed with silicone rubber.

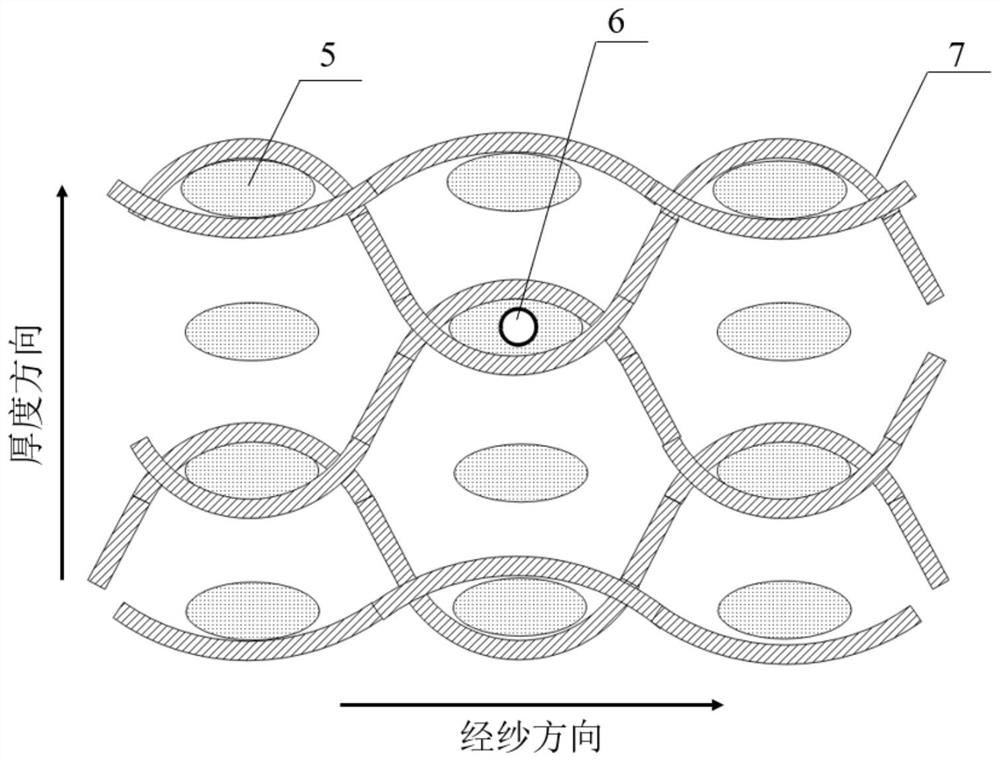

[0042] (2) Before the fiber bundle is spun, first determine the weft yarn 5 corresponding to the position to be measured, and extract part of the fiber bundle in the weft yarn, so that the total thickness of the remaining fiber bu...

PUM

| Property | Measurement | Unit |

|---|---|---|

| length | aaaaa | aaaaa |

| wavelength | aaaaa | aaaaa |

| diameter | aaaaa | aaaaa |

Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com