A VOC extractant used for modified polypropylene, and a preparing method and applications thereof

A polypropylene and extractant technology, applied in the field of VOC extractant for modified polypropylene and its preparation, can solve the problems of affecting other properties of plastics, health damage, poor compatibility of polypropylene plastics, etc. The effect of reducing VOC content and suitable for mass production

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

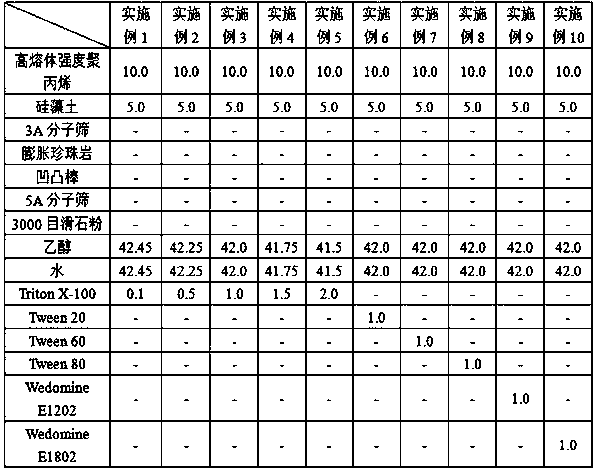

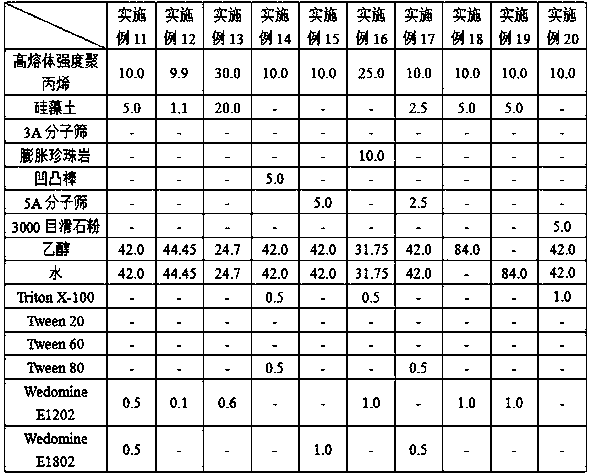

Embodiment 1-20 and comparative example 1-2

[0058] Preparation of polypropylene carrier:

[0059] According to the ratios in Table 1 and Table 2, the polypropylene and the porous adsorbent are fully mixed in a high-speed mixer, melt blended, extruded and granulated in an extruder to obtain a foamed polypropylene precursor; using a physical foaming agent The foamed polypropylene precursor was foamed to obtain a polypropylene carrier; the performance test results of the polypropylene carrier are shown in Table 4.

[0060] Preparation of VOC extractant for modified polypropylene:

[0061] According to the proportions in Table 1 and Table 2, the prepared polypropylene carrier and non-fluorine non-ionic surfactant solution are passed through a high-speed mixer according to the proportion, and stirred at a speed of 1000 rpm for 3-5 minutes to obtain a modified polypropylene VOC extractant for propylene.

Embodiment 21-40 and comparative example 3-4

[0063] Preparation of environmentally friendly modified polypropylene composite materials:

[0064] The VOC extraction agent for modified polypropylene prepared in the order of Table 1 and Table 2 is used to further prepare environment-friendly modified polypropylene composite materials (Example 1-20 corresponds to Example 21-40 in sequence, and Comparative Example 1-2 corresponds to Example 21-40 in sequence) Coping ratio 3-4): Put 20 parts by weight of talcum powder into the extruder from the side feeding port, 78 parts by weight of polypropylene and 2 parts by weight of VOC extraction agent are mixed evenly in the high-speed mixer, and then put into the double feeder from the main feeding port Melt blending in a screw extruder. The degree of vacuum is controlled, extruded and granulated to obtain an environmentally friendly modified polypropylene composite material. The odor performance test results of the environmentally friendly modified polypropylene composite material ...

PUM

| Property | Measurement | Unit |

|---|---|---|

| melt strength | aaaaa | aaaaa |

| strength | aaaaa | aaaaa |

Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com