High-light-transmittance optical transparent adhesive for pasting touch screen and synthesis method thereof

A technology of optical transparent glue and high light transmittance, which is applied in the field of electronic information, can solve problems such as corrosion electrodes, and achieve the effects of improving light transmittance, reducing light loss, and being easy to use

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

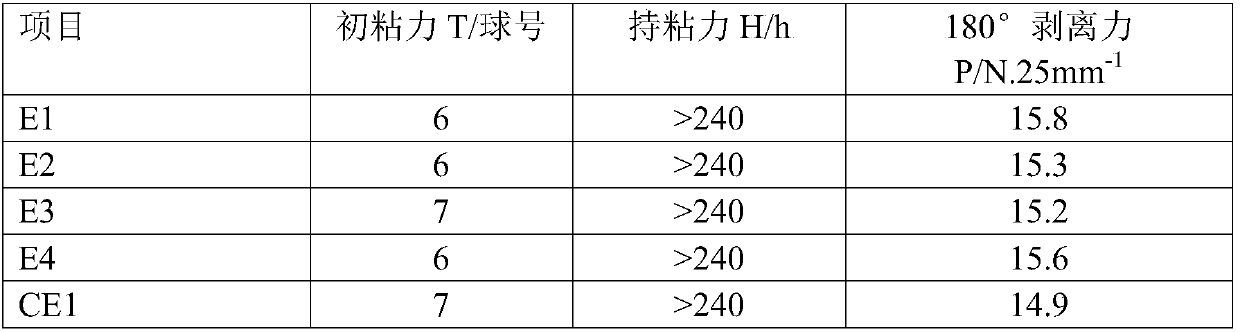

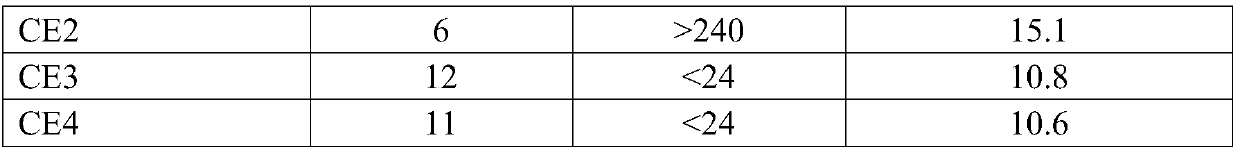

Examples

Embodiment 1

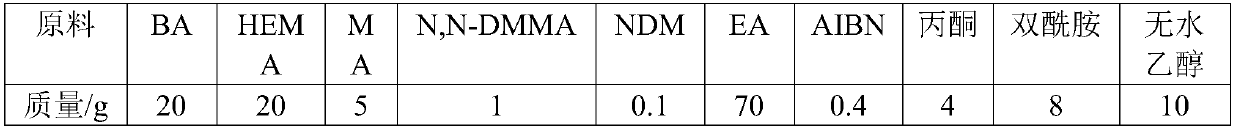

[0046] Embodiment 1 (E1): raw material formula sees Table 1

[0047] Table 1 Embodiment 1 raw material formula table

[0048] raw material

BA

HEA

IBOMA

NVP

NDM

EA

AIBN

Bisamide

Absolute ethanol

Mass / g

20

20

5

1

0.1

70

0.4

4

8

10

[0049] Pretreatment of raw materials: butyl acrylate (BA), hydroxyethyl acrylate (HEA), isobornyl methacrylate (IBOMA), N-vinylpyrrolidone (NVP) and cross-linking agent bisamide were vacuum dehydrated for 1 h before use , the temperature of the oil bath is the same as the respective boiling points, and then the monomers (BA, HEA, IBOMA, NVP), the cross-linking agent bisamide and the solvent ethyl acetate (EA) are subjected to 3A molecular sieve adsorption and dehydration for 12h, dodecyl Mercaptan (NDM) and azobisisobutyronitrile AIBN were placed in a vacuum oven for 12 hours before use.

[0050] Add BA, HEA, IBOMA, NVP and NDM after pretreatment into...

Embodiment 2

[0051] Embodiment 2 (E2): raw material formula sees Table 2

[0052] Table 2 Example 2 formula table

[0053] raw material

BA

HPA

MMA

NMMA

NDM

EA

AIBN

Bisamide

Absolute ethanol

Mass / g

20

20

5

1

0.1

70

0.4

4

8

10

[0054] Pretreatment of raw materials: BA, hydroxypropyl acrylate (HPA), methyl methacrylate (MMA), N-methylmethacrylamide (NMMA) and cross-linking agent bisamide were vacuum dehydrated for 2 hours before use, and oil bath The pot temperature is 5°C higher than their respective boiling points, and then BA, HPA, MMA, NMMA, bisamide, EA, acetone and absolute ethanol are subjected to 4A molecular sieve adsorption and dehydration for 12 hours, dodecyl mercaptan (NDM) and azo Diisobutyronitrile AIBN was placed in a vacuum oven for 12 hours for use.

[0055] Add BA, HPA, MMA, NMMA and NDM after pretreatment into a 500ml four-neck flask according to the formula, and then add ...

Embodiment 3

[0056] Embodiment 3 (E3): raw material formula sees Table 3

[0057] Table 3 Example 3 formula table

[0058]

[0059] Raw material pretreatment: BA, hydroxyethyl methacrylate (HEMA), methyl acrylate (MA), N,N-dimethylmethacrylamide (N,N-DMMA) and cross-linking agent bisamide before use Carry out vacuum dehydration for 3 hours, and the temperature of the oil bath is 5°C higher than their respective boiling points, then BA, HEMA, MA, N,N-DMMA, bisamide, EA, acetone and absolute ethanol are subjected to 5A molecular sieve adsorption dehydration for 36 hours, ten Dialkylmercaptan (NDM) and azobisisobutyronitrile AIBN were placed in a vacuum oven for 24 hours before use.

[0060] Add the pretreated BA, HEMA, MA, N,N-DMMA and NDM into a 500ml four-neck flask according to the formula, and then add 55g of EA. The experimental device is equipped with a mechanical stirrer with digital display function, a condensation device and a thermometer. The temperature is 120r / min, the oil b...

PUM

| Property | Measurement | Unit |

|---|---|---|

| thickness | aaaaa | aaaaa |

| transmittivity | aaaaa | aaaaa |

| transmittivity | aaaaa | aaaaa |

Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com