Strain monitoring method and device for forming process of three-dimensional woven composite material

A molding process and composite material technology, applied in measuring devices, using electrical devices, using optical devices, etc., can solve problems such as the inability to detect three-dimensional woven composite materials, and achieve the effect of improving molding quality

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

[0039] like Figure 1-3 As shown, the working process of monitoring the strain during the forming process of 3D woven composites includes:

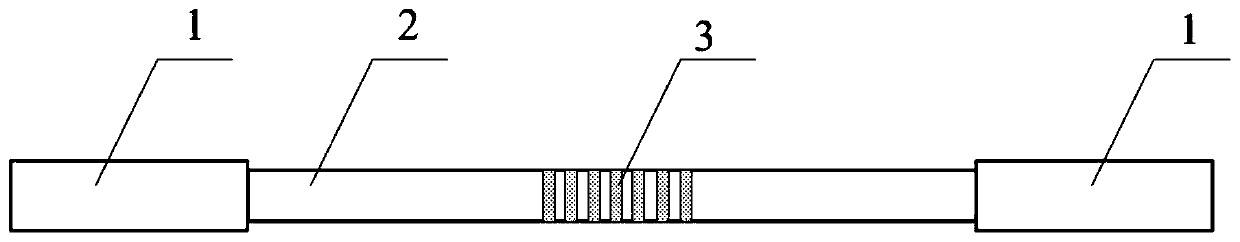

[0040](1) Select a number of standard optical fibers 2 with a diameter (125 μm), a grating segment 3 with a length of 4 mm, a FBG sensor 4 with a central wavelength of 1500 nm-1600 nm, and a fiber protection tube 1 with an outer diameter of 0.9 mm;

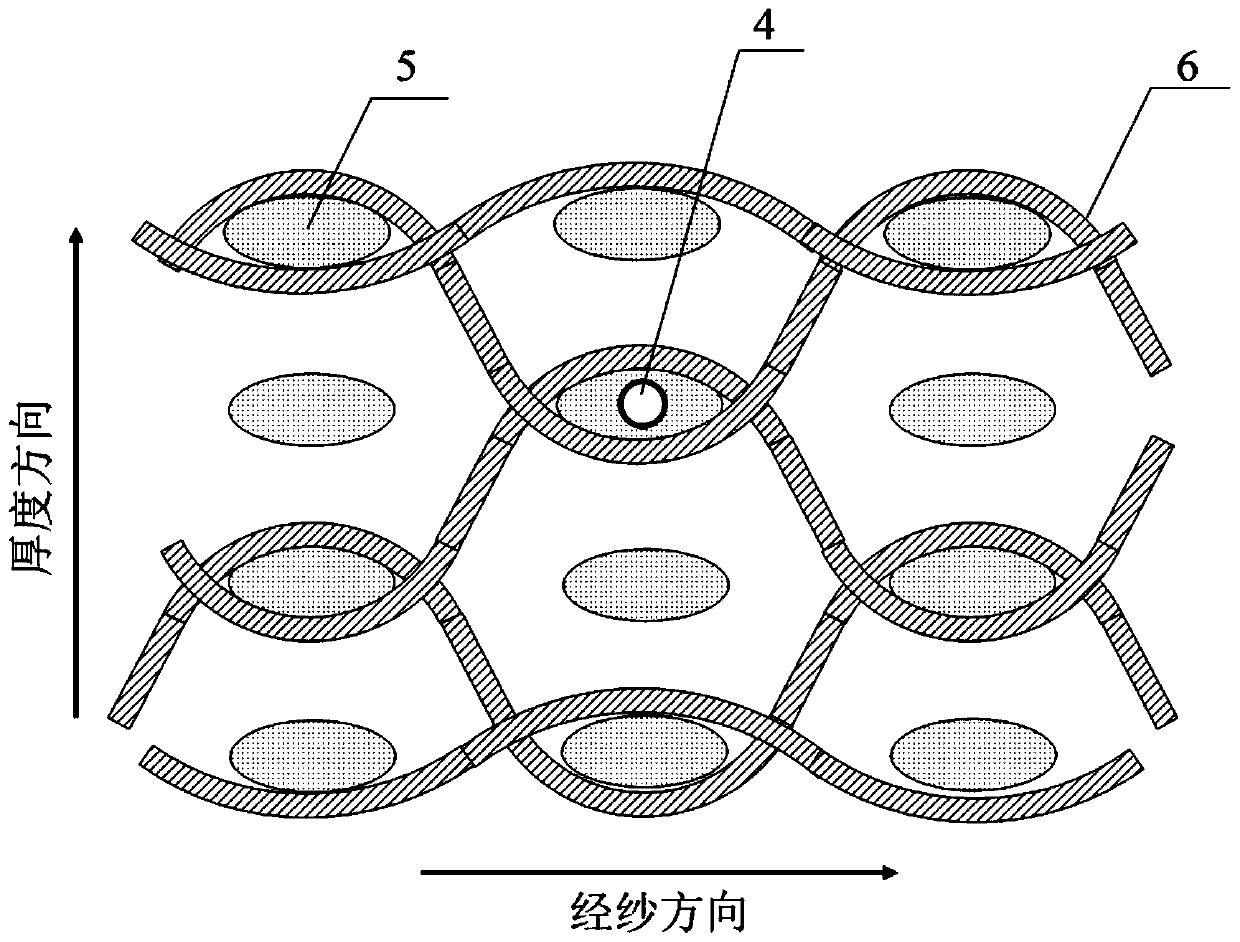

[0041] (2) Before the fiber bundle is spun, first determine the weft yarn 5 corresponding to the position to be measured, embed the FBG sensor 4 into the weft yarn so that it is wrapped by the fiber, and pull the FBG sensor so that the grating section corresponds to the position to be measured position, when the textile feeds the yarn, the FBG sensor is wrapped by the warp yarn 6 along with the weft yarn;

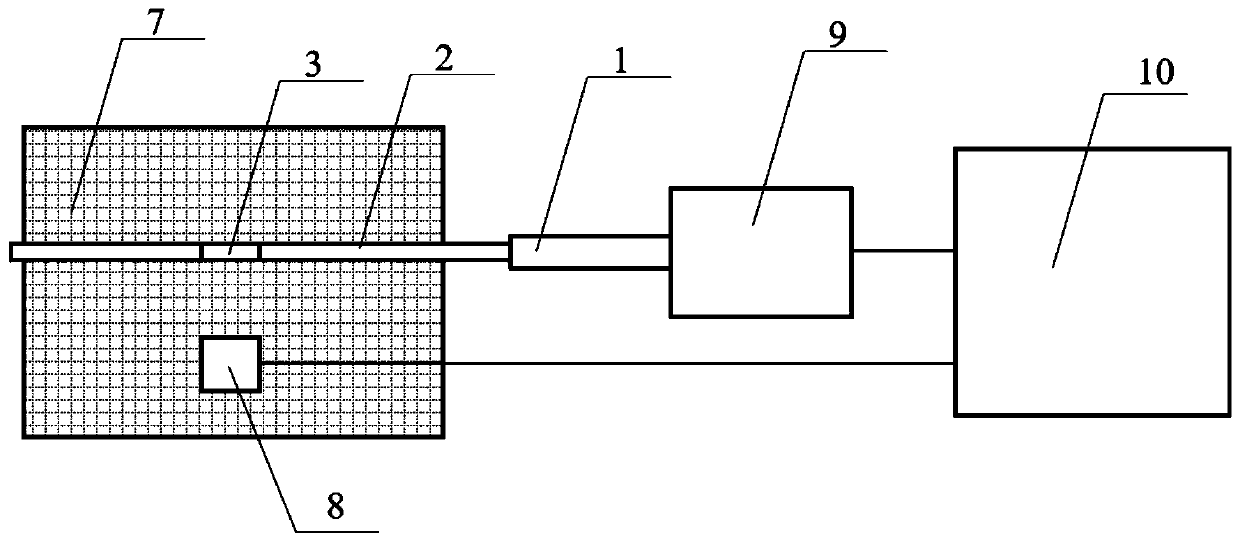

[0042] (3) Put the three-dimensional woven prefabricated body 7 into the mould, and paste the thermocouple sensor 8 on the prefabricated body, lead its wire out from the mould, along with...

PUM

| Property | Measurement | Unit |

|---|---|---|

| length | aaaaa | aaaaa |

| wavelength | aaaaa | aaaaa |

Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com