Patents

Literature

56results about How to "Lower recrystallization temperature" patented technology

Efficacy Topic

Property

Owner

Technical Advancement

Application Domain

Technology Topic

Technology Field Word

Patent Country/Region

Patent Type

Patent Status

Application Year

Inventor

High plastic-strain ratio galvanized steel sheet and production method

InactiveCN101255529ALower recrystallization temperaturePromotes secondary phase formationHot-dipping/immersion processesMetal rolling arrangementsChemical compositionSheet steel

The invention relates to a hot galvanizing sedan plate and the production method thereof, which solves the following problems: P and S in steel are difficult to control because of being lowly required; as to a horizontal Sendzimir hot galvanizing machine, the recrystallization temperature of a steel plate is slightly high, and the plastic strain ratio and extension are low. The high-plastic-strain-ratio galvanizing plate is composed of no more than 0.004% by weight of C, no more than 0.020% by weight of Si, 0.05% to 0.20% by weight of Mn, no more than 0.016% by weight of 0.016, no more than 0.015% by weight of S, 0.04% to 0.07% by weight of Ti, 0.02% to 0.06% by weight of Als, no more than 0.003% by weight of N, and the balance Fe and unavoidable impurity. The production steps are as follows: smelting by hot metal desulphurization and secondary refining process; hot rolling; cold rolling with a total reduction of 80%; and galvanizing. The invention has the characteristics that the method is pure Ti processing; the control scopes of S and P are wide; the plastic strain ratio is r90 DEG C >=2.5, the extension A80mm is 45% to 50%; and the current process route and equipment is unchanged.

Owner:武钢集团有限公司

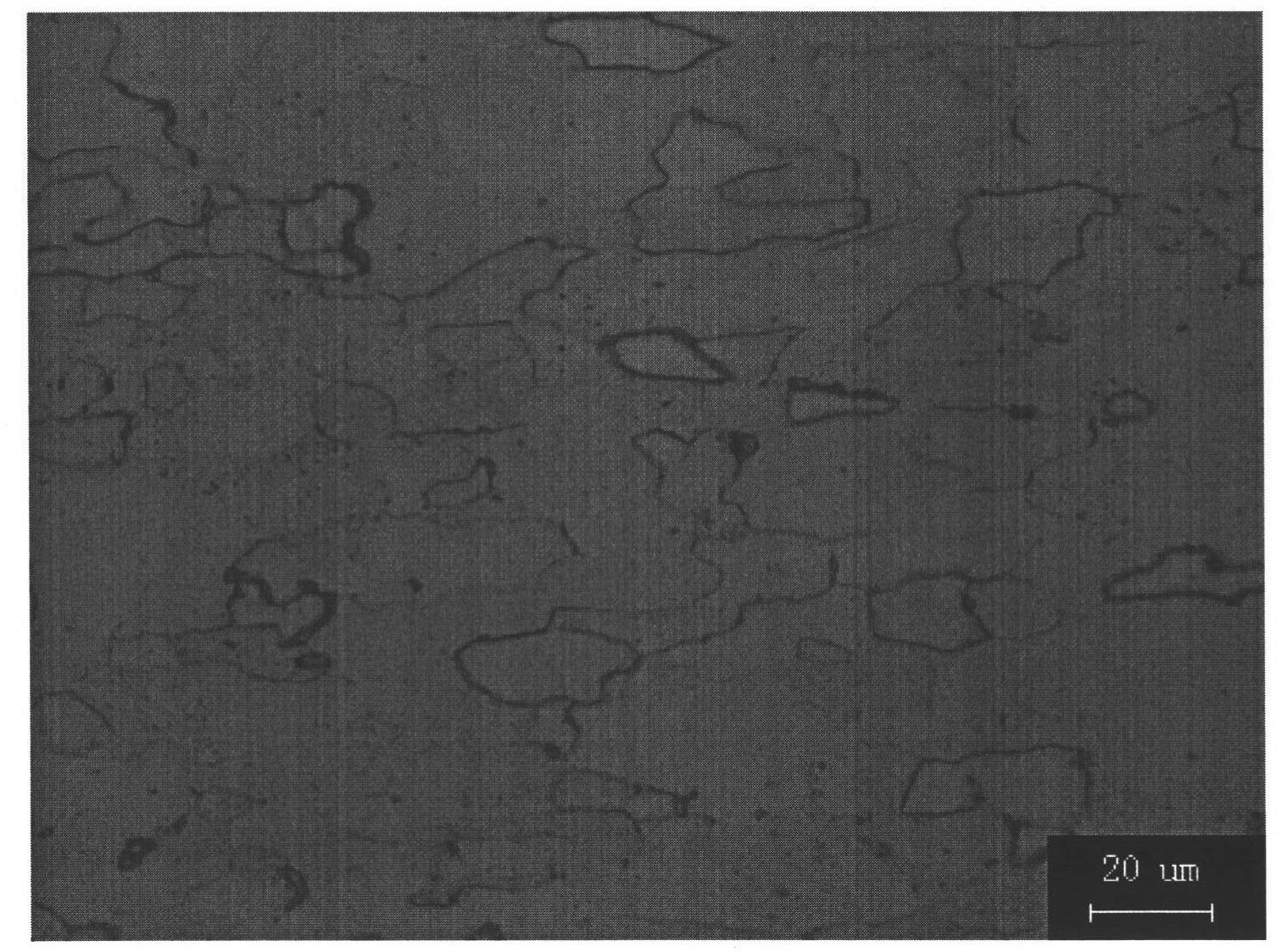

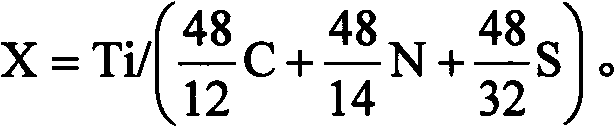

Low-temperature continuous-annealing interstitial-free atom cold-rolled steel plate and production method thereof

ActiveCN102653839ALower recrystallization temperatureRealize the structureChemical compositionReduction ratio

The invention relates to a low-temperature continuous-annealing interstitial-free atom cold-rolled steel plate and a production method thereof and belongs to the technical field of iron-based alloys. The production method of the cold-rolled steel plate comprises the following steps of: controlling the components of the cold-rolled steel plate in percentage by mass: 0.0005-0.0025% of C, less than or equal to 0.03% of Si, 0.05-0.15% of Mn, less than or equal to 0.015% of P, less than or equal to 0.01% of S, less than or equal to 0.0025% of O, less than or equal to 0.0025% of N, 0.015-0.050% of Al, 0.03-0.07% of Ti, and the balance of Fe and inevitable mixed elements; and meanwhile, controlling the continuous-annealing temperature of the cold-rolled steel plate to be 710-740 DEG C, and controlling the cold-rolling reduction ratio to be not less than 80%. According to the cold-rolled steel plate and the production method thereof, the reasonable chemical components and the suitable control of cold-rolling reduction are adopted, the recrystallization temperature is lowered, full-old-rolled microstructures are formed, and a lower continuous-annealing temperature can be adapted, so that the equipment cost and energy consumption are reduced, the control difficulty of a production process is reduced, the product defects and production accidents are avoided.

Owner:SHANGHAI MEISHAN IRON & STEEL CO LTD

Production method of ultra-low-carbon steel for sedan car cortical plate

InactiveCN101096034AReduce manufacturing costLower recrystallization temperatureTemperature control deviceWork treatment devicesHigh energyHeating furnace

The invention provides a producing method for ultra low steel carbon used in car outer plate, characterized in that liquid steel is cast into plate slab in the pulling speed of 1.5-4m / min; the thickness of plate slab is 100-170mm; casting machine adopts dynamic light pressure and crystallizer electromagnetic braking technology and tundish superheat is 20-45deg.C; the plate slab is installed in heat directly and the charging temperature is more than 800deg.C; the plate slab is heated to 1150-1250deg.C in heating furnace; after the temperature is maintained for 30-90min rough rolling cogging is carried out. By adopting continuous rolling and casting short-flow process of medium-thin plate slab and collocating casting machine and heating furnace compactly quick charging is realized; charging material temperature is improved; problems of large investment and high energy consumption in conventional process are solved; inner limitation generated in continuous casting process of thin plate is eliminated; it is guaranteed that product is provided with good surface quality and stable mechanical property.

Owner:ANGANG STEEL CO LTD

Laser sinter powder with metal soaps, process for its production, and moldings produced from this laser sinter powder

InactiveUS20080300353A1Increase resistanceLarge tensile strainAdditive manufacturing apparatusFibre treatmentTensile strainSurface finish

A sinter powder containing a polyamide and metal soaps, in particular particles of a salt of an alkanemonocarboxylic acid. A process for laser sintering, and to moldings produced from the sinter powder. The moldings formed using the powder have advantages in appearance and in surface finish when recyclability in the selective laser sintering (SLS) process is taken into account. Moldings produced from recycled sinter powder have improved mechanical properties, in particular in the modulus of elasticity and tensile strain at break.

Owner:DEGUSSA AG

Soft tin-plate of hardness HR30T 51+/-3 and its making process

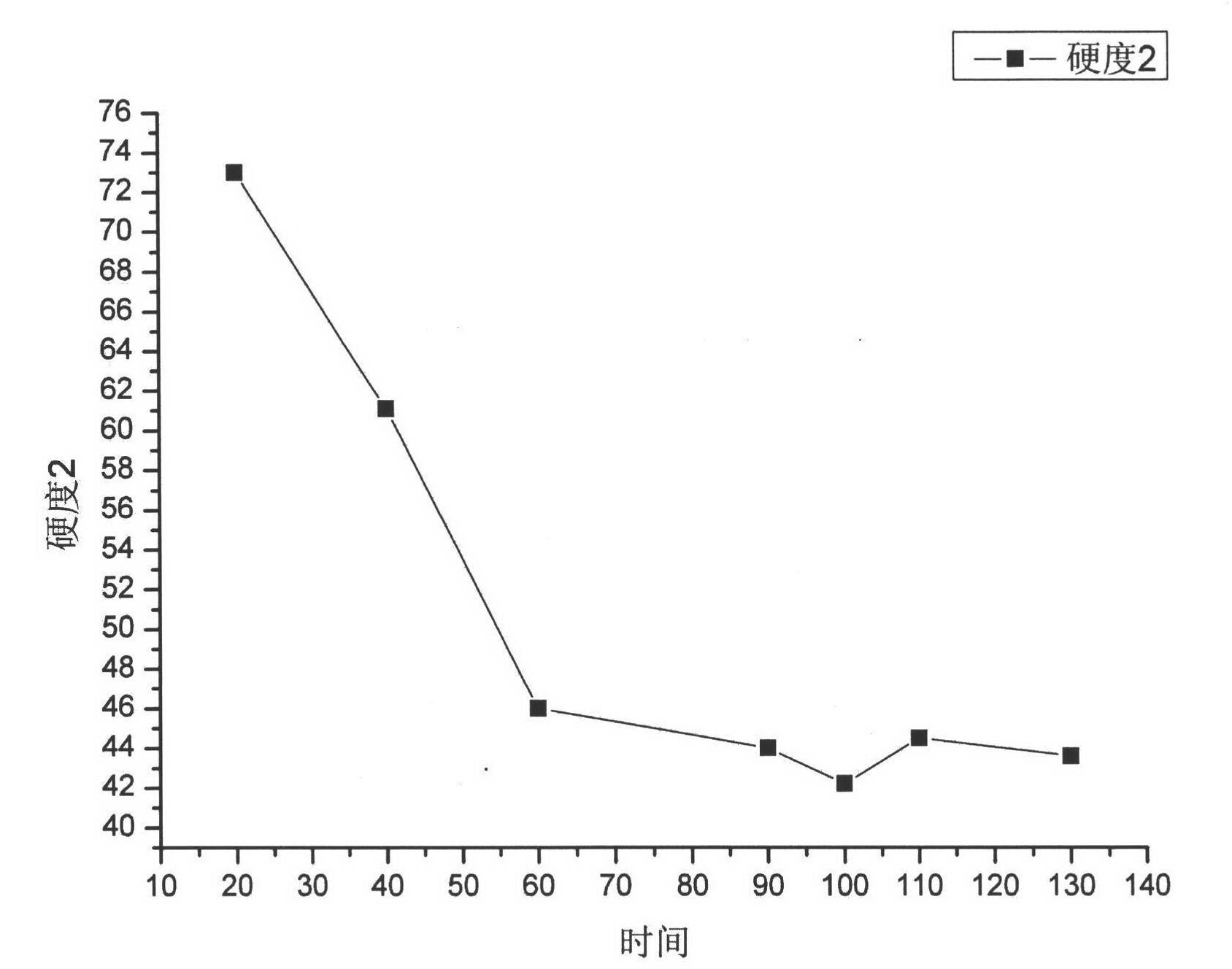

ActiveCN1888113ALower yield strengthReduce hardnessRoll mill control devicesFurnace typesHardnessTin plating

The soft tin-plate of hardness HR30T 51+ / -3 consists of C not more than 0.005 wt%, Mn 0.20-0.30 wt%, Al 0.03-0.06 wt%, Si not more than 0.03 wt%, Ti 0.03-0.06 wt%, P not more than 0.012 wt%, S not more than 0.015 wt%, N not more than 0.003 wt%, O not more than 0.004 wt%, and Fe and inevitable impurities for the rest. Its production process includes the following steps: smelting steel, continuous casting and rolling, hot rolling, acid pickling and rolling, continuous annealing, flattening and tin plating.

Owner:BAOSHAN IRON & STEEL CO LTD

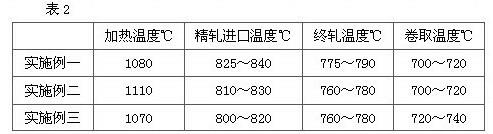

Processing method for producing low-cost high-formability IF (interstitial-free) steel

InactiveCN102581008AHigh drawabilityIncrease productivityTemperature control deviceMetal rolling arrangementsSlow coolingWater cooling

The invention relates to a processing method for producing low-cost high-formability IF (interstitial-free) steel, which is based on thin-slab continuous casting and rolling and adopts a ferrite rolling process to produce the IF steel, belonging to the technical field of IF steel production. The processing method comprises the following working procedures of steelmaking, continuous casting, heating, rolling, cooling and coiling. A thin-slab continuous casting machine is adopted, the thickness of a continuous casting slab is at most 100mm, and the charging temperature is at least 880 DEG C. During hot rolling, a roughing mil and a finishing mill keep a continuous rolling relationship and keep micro-tension control, and water cooling equipment is used between the roughing mil and the finishing mill and is used for uniformly reducing the temperature of an intermediate slab with a thickness of 12-25mm from the temperature at least 950 DEG C of the outlet of the roughing mil into the range of 750-850 DEG C. Finish rolling is carried out in a ferrite area, and a lubrication rolling technology is adopted. The coiling temperature is higher and is 680-760 DEG C, slow cooling is carried out after coiling, and thereby an annealing process is finished. The invention provides a method for obtaining high-formability hot rolled sheets without cold rolling and cover annealing. The method has the advantages of being simple in process, low in cost, high in production efficiency, short in flow and the like, and the formability of products is higher.

Owner:HEBEI IRON AND STEEL

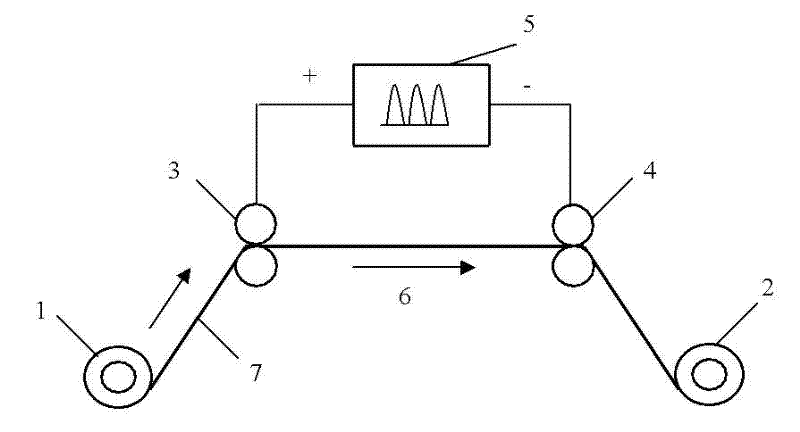

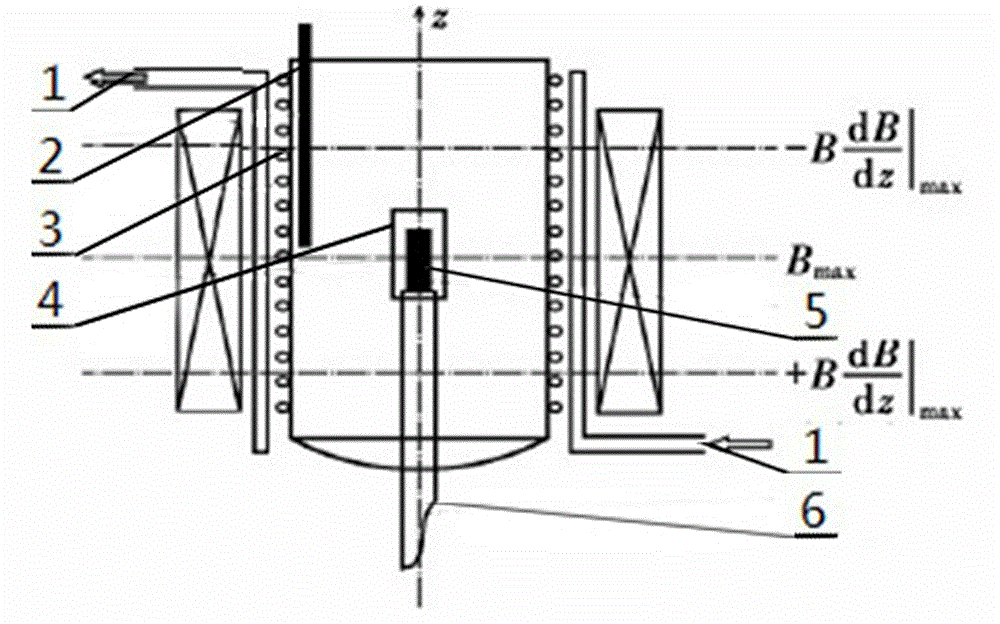

Method for promoting growth of GOSS textures of silicon steel strips by using pulse current

InactiveCN102212671AReduce the degree of oxidationShort initial recrystallization timeFurnace typesHeat treatment furnacesAir atmosphereElectricity

The invention discloses a method for promoting growth of GOSS textures of silicon steel strips by using pulse current. The method comprises the following steps of: conveying the silicon steel strips at the speed of 2 to 10 meters per minute under the drive of a conveying device; and guiding the pulse current of a pulse power supply to a moving silicon steel strip electrifying zone through a pair of electric contact devices, and performing electric stimulation treatment on the silicon steel strip electrifying zone in air atmosphere to promote the generation of a large amount of GOSS textures in the primary re-crystallization process, wherein the silicon steel strips are in a high magnetic induction cold-rolled state, the thickness of the silicon steel strips is 0.1 to 0.5 millimeter, the width of the silicon steel strips is 10 to 150 millimeters and the silicon content of the silicon steel strips is 0.5 to 6.5 percent. Compared with the traditional thermal treatment furnace annealing treatment process, the method has the advantages of low energy consumption, high production efficiency and low production cost, and the GOSS textures in the primary re-crystallization process have manycomponents. By electron back-scattered diffraction (EBSD) detection, the GOSS texture content of the silicon steel strips treated by adopting electric stimulation of the pulse current reaches 15 to 25 percent.

Owner:SHENZHEN GRADUATE SCHOOL TSINGHUA UNIV

High-performance wrought magnesium alloy material

The invention relates to a high-purity high-performance magnesium alloy material, which consists of the following components in percentage by mass: 6.2 to 6.4 percent of Zn, 0.5 to 0.6 percent of Zr, 0.007 to 0.011 percent of inevitable Fe, Si, Cu, Ni and other impurities, and the balance magnesium. The material is prepared by the following steps: selecting raw magnesium with higher purity as a raw material; melting the raw magnesium by using the semicontinuous casting technology; properly increasing the melt standing time to ensure that compound particles containing Fe, Si and other impurity elements can be sufficiently deposited and a high-purity alloy cast blank can be prepared; and preparing the Mg-Zn-Zr wrought magnesium alloy by adopting the conventional extruding technology. The wrought magnesium alloy can maintain the high strength of traditional commercial ZK60 magnesium alloy to ensure that the plasticity and forming performance of the alloy can be greatly improved and the application potential of the material is sufficiently developed. Furthermore, the technical equipment used in the invention is conventional universal equipment, and the preparation process is simple.

Owner:CHONGQING UNIV

Laser sintered powder with metallic soaps method of its manufacture and shaped element made of such laser sintered powder

InactiveCN1504511ALess quantityLow update rateAdditive manufacturing apparatusAdditive manufacturing with solidsSurface finishTensile strain

A sinter powder containing a polyamide and metal soaps, in particular particles of a salt of an alkanemonocarboxylic acid. A process for laser sintering, and to moldings produced from the sinter powder. The moldings formed using the powder have advantages in appearance and in surface finish when recyclability in the selective laser sintering (SLS) process is taken into account. Moldings produced from recycled sinter powder have improved mechanical properties, in particular in the modulus of elasticity and tensile strain at break.

Owner:EVONIK OPERATIONS GMBH

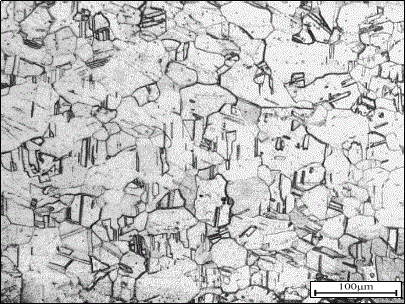

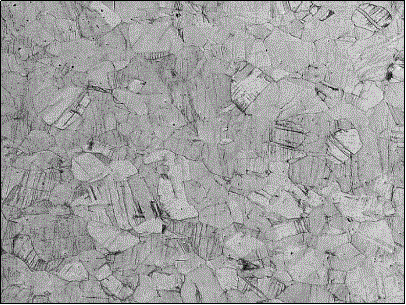

Low-anisotropic-index high-intensity Cu-Ni-Si alloy and preparing process thereof

The invention discloses a low-anisotropic-index high-intensity Cu-Ni-Si alloy and a preparing process thereof. The low-anisotropic-index high-intensity Cu-Ni-Si alloy and the preparing process are suitable for cold rolling copper-based thin panels for lead frames. The alloy comprises, by chemical mass percent, 2%-3% of Ni, 0.5%-1.0% of Si, 0.1%-0.5% of Sn, 0.05%-0.1% of Fe, 0.1%-0.3% of Mg, 0.05%-0.08% of Zn, 0.2%-0.5% of RE and the balance Cu. Yttrium-based heavy rare earth is added for purifying a copper solution, and Ni2Si precipitation is improved; meanwhile, harmful texture is effectively restrained through the process that low temperature annealing is combined with grading solid dissolving before solid dissolving; and by controlling the cold rolling reduction rate, a transverse shearing belt is obtained for a product, and anisotropism is greatly improved. The alloy has the beneficial effects that the strength of extension ranges from 650 MPa to 750 MPa, the elongation ranges from 13% to 18%, the in-plane anisotropy (IPA) of the intensity is smaller than 6%, the in-plane anisotropy (IPA) of the elongation is smaller than 8%, and defects of warping, deformation and cracking of the Cu-Ni-Si alloy in the blanking process can be effectively reduced.

Owner:LONGNAN LONGYI HEAVY RARE EARTH TECH CO LTD

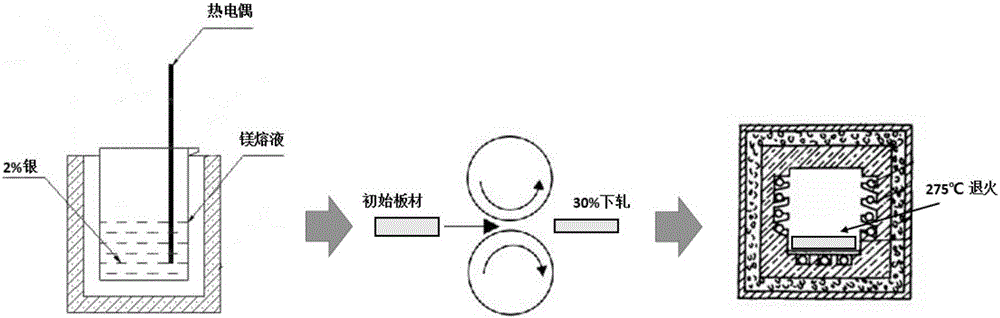

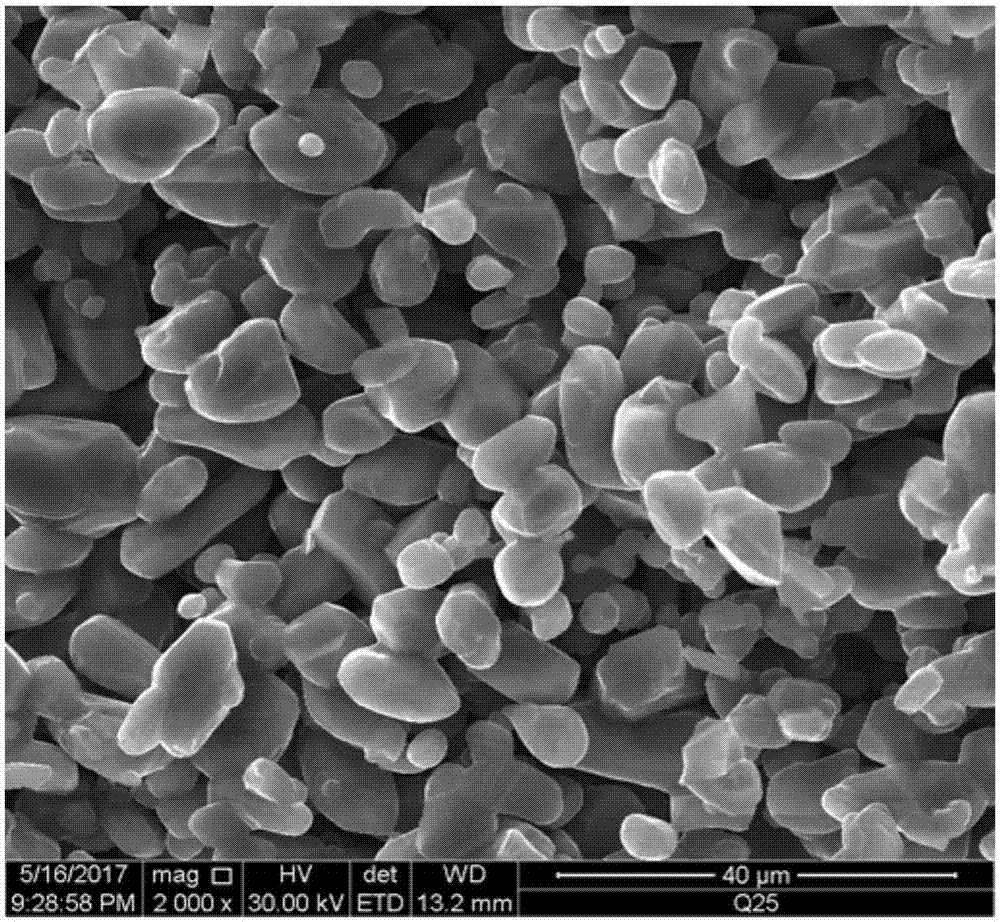

Method for preparing large nanocrystalline magnesium alloy through small deformation

InactiveCN106048269AThere will be no fracture and instabilityInhibit growthSmelting processRoom temperature

The invention provides a method for preparing a large nanocrystalline magnesium alloy through small deformation. The method includes three processes of magnesium alloy smelting, cold plasticity deformation and low-temperature short-time thermal treatment. The method is characterized in that a small amount of Ag is added in the alloy smelting process; after casting and ingot forming, the small-deformation cold plastic deformation is applied at the room temperature; and a sample is subjected to thermal treatment for a short time at the lower temperature after deformation, and after 1 pass to 8 passes of repeated cold plastic deformation and thermal treatment, the nanocrystal magnesium alloy material with the even grain size is obtained finally, wherein the grain size ranges from 40 nm to 100 nm.

Owner:BEIJING UNIV OF TECH

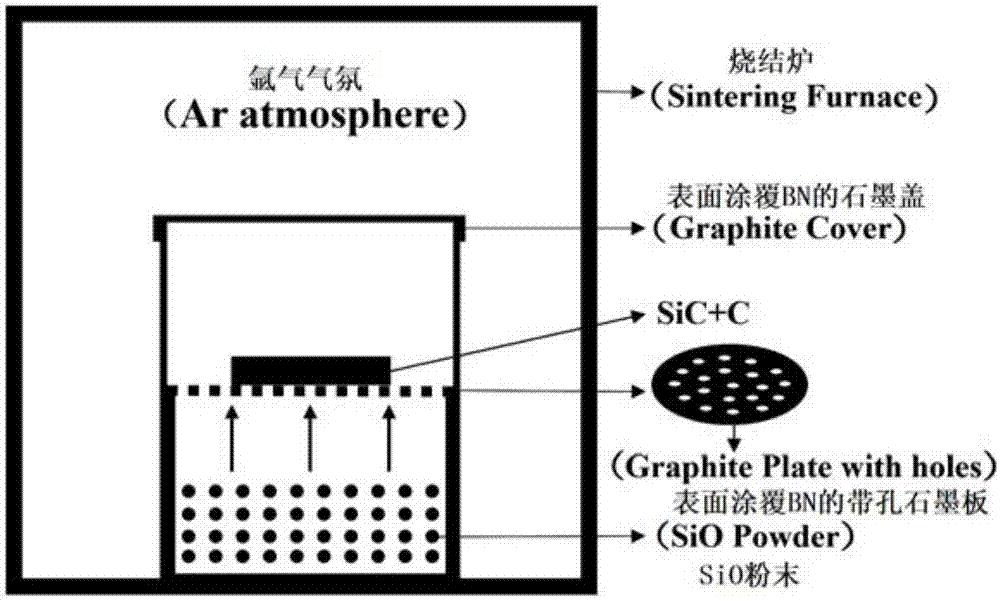

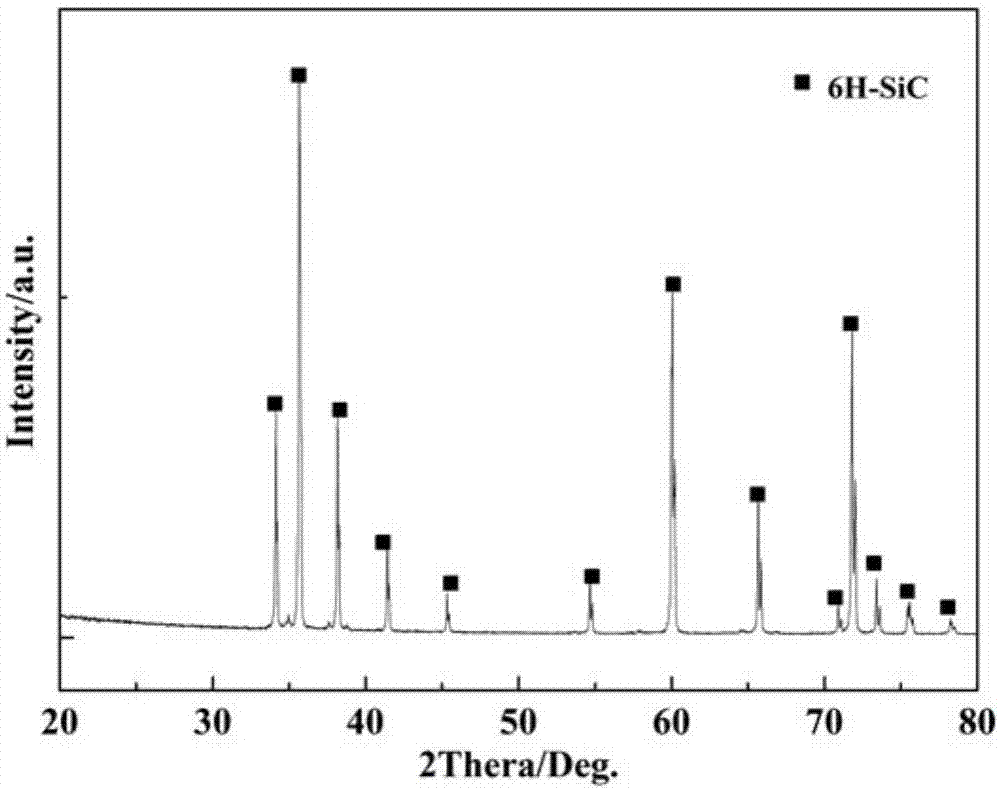

Method for preparing recrystallized silica carbide porous ceramic with gas-solid reaction method

InactiveCN107337453AIncreased sintered neck areaHigh strengthCeramicwareParticulatesArgon atmosphere

The invention discloses a method for preparing recrystallized silica carbide porous ceramic with the gas-solid reaction method. The method includes the following steps that 1) SiO powder is put into the bottom of a crucible, mixed powder of 70 wt%-95 wt% of silicon carbide and 5 wt%-30 wt% of nano-carbon black is subjected to compression molding forming to form a green ware body according to the mass percent, the green ware body is put into the middle of the crucible, the crucible is put into a multifunctional sintering furnace, argon is introduced, the temperature is kept for 1 hour to 3 hours at the temperature of 1,650 DEG C to 1,800 DEG C, a gas-solid reaction is carried out, and a pre-sintering body is obtained; 2) the pre-sintering body is put into an induction sintering furnace, the temperature is increased to 1,900 DEG C to 2,100 DEG C in the argon atmosphere, the product is recrystallized for 1 hour to 3 hours, and the porous SiO ceramic can be obtained. The silicon carbide porous ceramic prepared with the method can be widely applied to the fields of a diesel-vehicle tail-gas particulate matter filter or a catalyst carrier or the like.

Owner:XI AN JIAOTONG UNIV

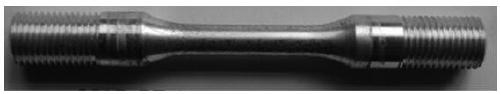

High-strength corrosion-resistant aluminum alloy for variable-diameter drill pipe body and manufacturing method of aluminium alloy

The invention discloses a high-strength corrosion-resistant aluminum alloy for a variable-diameter drill pipe body and a manufacturing method of the aluminium alloy. The aluminium alloy comprises, inpercentage by weight, Zn: 5.5-6.3%, Mg: 2.5-3.1 %, Cu: 0.5 to 0.9%, Fe: <=0.2%, Zr: <= 0.15%, Ti: <=0.1%, Mn: 0.1 to 0.3%, Cr: 0.1 to 0.25%, and the balance being Al and unavoidable impurities. An aluminum alloy variable-diameter drill pipe body prepared by manufacturing method of the invention has high strength, good corrosion resistance and fatigue resistance, and the technical indexes such as dimensional precision and concentricity are high in control level, and the prepared drill pipe body is stable in quality, good in overall performance, low in cost and conducive to industrial batch production and field application.

Owner:山东兖矿轻合金有限公司

Preparation method for 5754 alloy aluminum plate used for automobile

The invention discloses a preparation method for a 5754 alloy aluminum plate used for an automobile. The preparation method comprises the following steps of: preparing an aluminum melting body; carrying out continuous casting and tandem rolling: firstly, adopting a soft alloy aluminum melting body as a melting body head for carrying out casting, and meanwhile, adopting gas protection during the casting; carrying out homogenizing annealing; carrying out cold casting; and carrying out finished product annealing. The invention provides a method for producing the 5754 alloy aluminum plate used forthe automobile by a continuous casting and tandem rolling way, working efficiency is improved, and a working procedure is shortened.

Owner:广西润泰铝业有限公司

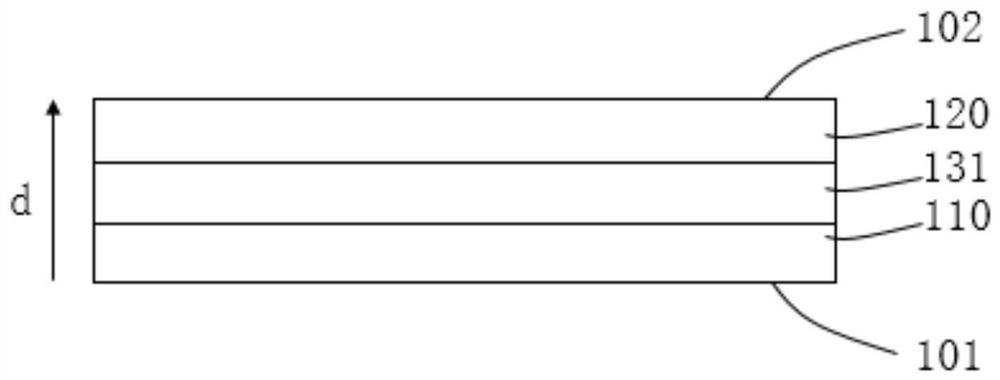

Semiconductor device connection high purity copper fine wire

ActiveCN103283009AGuaranteed StrengthLower recrystallization temperatureSolid-state devicesSemiconductor/solid-state device manufacturingCrystalliteCopper wire

To provide high purity copper wire, particularly of sub-millimeter diameter, with which, by making a dual layer structure in a cross-section configuration of the high purity copper fine wire, mechanical strength is increased, and which is optimal for high-temperature power semiconductors in which on-off cycles are repeated over multiple iterations in a short time. The present invention relates to high purity copper fine wire which is contiguously extended for connecting a semiconductor device and which is formed from copper of a purity of 99.997mass%-99.99994mass% having an oxide film, in which the area of the top 10 grains in a cross-section configuration of the high purity copper fine wire is 5-25% of the total cross-section configuration, and 80% or more of the grain area is within a surface skin layer which is defined as 1 / 20 or less of the diameter. The high purity copper fine wire is prepared by continuously pulling and is used for connecting the semiconductor device.

Owner:TANAKA DENSHI KOGYO KK

Preparation method of high conductive aluminum alloy plate belt

The invention belongs to the technical field of aluminum alloy manufacturing and relates to a preparation method of a high conductive aluminum alloy plate belt. An aluminum alloy ingot is prepared from the following compositions in percentage by mass: less than or equal to 0.15% of Si, less than or equal to 0.20% of Fe, 0.3-0.5% of Cu, less than or equal to 0.01% Mn, less than or equal to 0.02% ofMg, less than or equal to 0.01% of Cr, less than or equal to 0.03% of Zn, 0.03-0.05% of Er, 0.008-0.015% of Ti, less than or equal to 0.01% of B, less than or equal to 0.05% of remaining individual impurities and the balance of Al; and the total content of the impurities is less than or equal to 0.15%. In the process of aging heat treatment, a cold-rolled aluminum alloy plate is subjected to dual-stage aging heat treatment, wherein first stage aging heat treatment is conducted at a temperature of 280-310 DEG C and the thermal insulation duration is 30-140 min, and second stage aging heat treatment is conducted at a temperature of 180-220 DEG C and the thermal insulation duration is 10-20 h. The preparation method solves the problems that, according to the prior art, semi-continuous casting and rolling preparation technology of high conductive aluminum alloy plates is insufficient, rigidity and conductivity are difficult to balance, and high alloying casting is highly difficult and hashigh production cost.

Owner:TIANJIN ZHONGWANG ALUMINUM IND CO LTD

Cold-rolled low-temperature acid dew point corrosion resistant steel and manufacturing method thereof

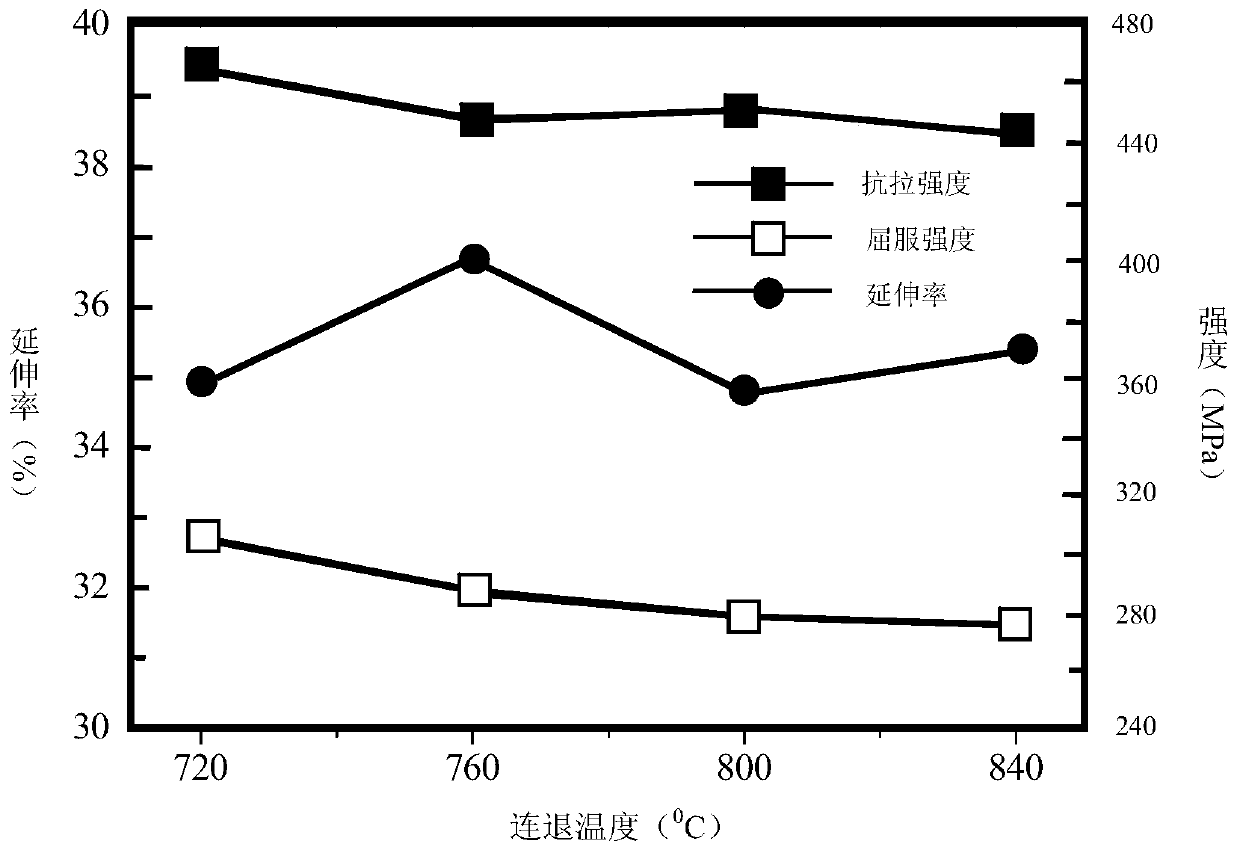

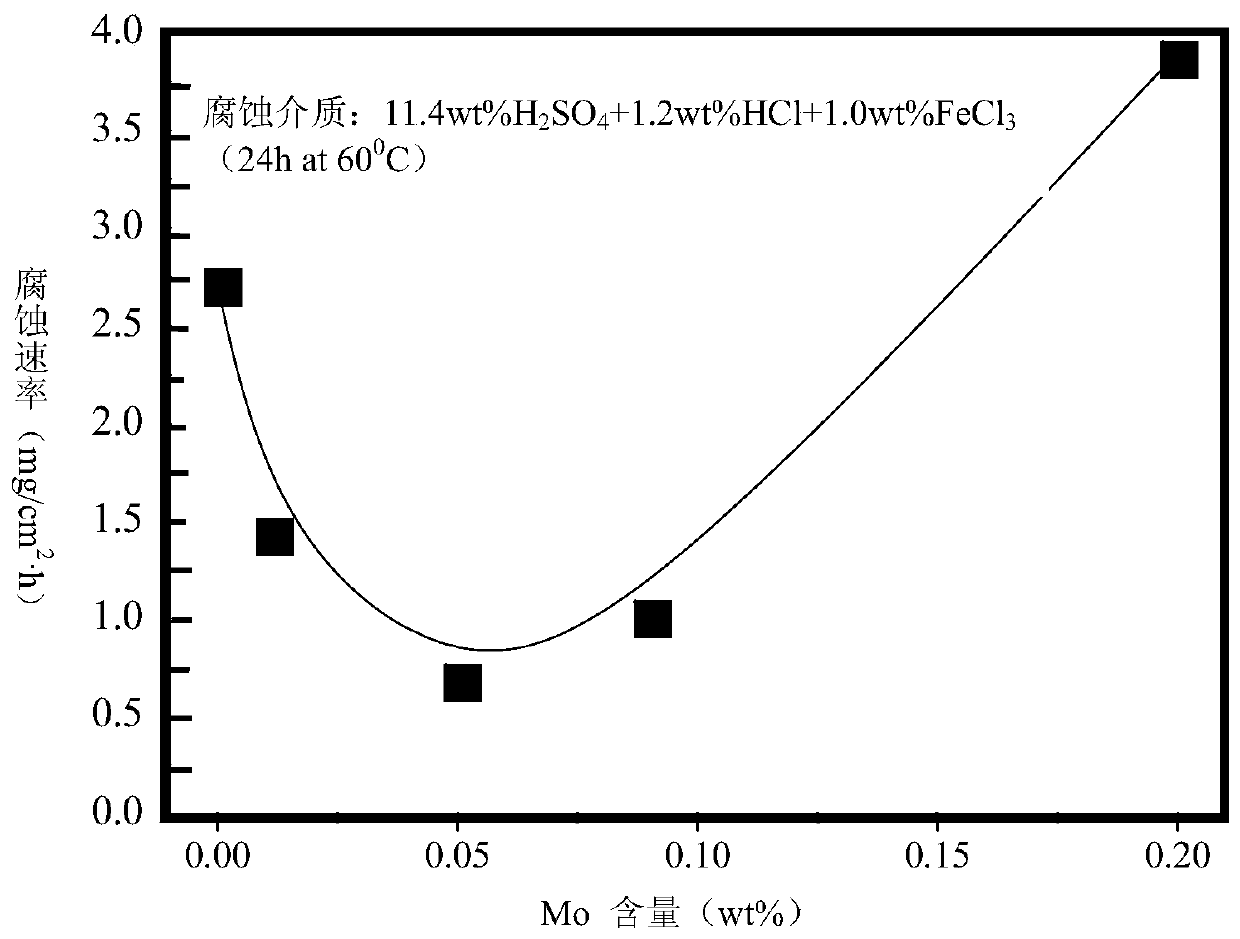

The invention discloses a cold-rolled low-temperature acid dew point corrosion resistant steel and a manufacturing method thereof. The cold-rolled low-temperature acid dew point corrosion resistant steel comprises the following chemical components of, in percentage by mass, 0.04% to 0.12% of C, 0.25% to 0.35% of Si, 0.35% to 0.65% of Mn, less than or equal to 0.035% of P, 0.005% to 0.020% of S, 0.25% to 0.40% of Cu, 0.7% to 1.2% of Cr, 0.03% to 0.10% of Mo, 0.06% to 0.12% of Sb and the balance Fe and inevitable impurity elements. Meanwhile, the element content is controlled to meet the conditions that CR is larger than or equal to 0.25 and smaller than or equal to 0.5, CR = 0.5 w (Cu) + w (Sb) + 2w (Mo), and 10w (C)-CR is smaller than or equal to 0.8. A cold-rolled steel strip with excellent low-temperature sulfuric acid and hydrochloric acid mixed acid dew point corrosion resistance is prepared through continuous casting, hot rolling, cold rolling, continuous annealing and leveling, the yield strength is larger than or equal to 260 MPa, the tensile strength is larger than or equal to 400 MPa, the elongation is larger than or equal to 30%, and the cold-rolled steel strip is suitable for low-temperature flue gas treatment, waste heat recovery and other systems for thermal power, petrifaction, metallurgy, waste incineration and the like.

Owner:BAOSHAN IRON & STEEL CO LTD

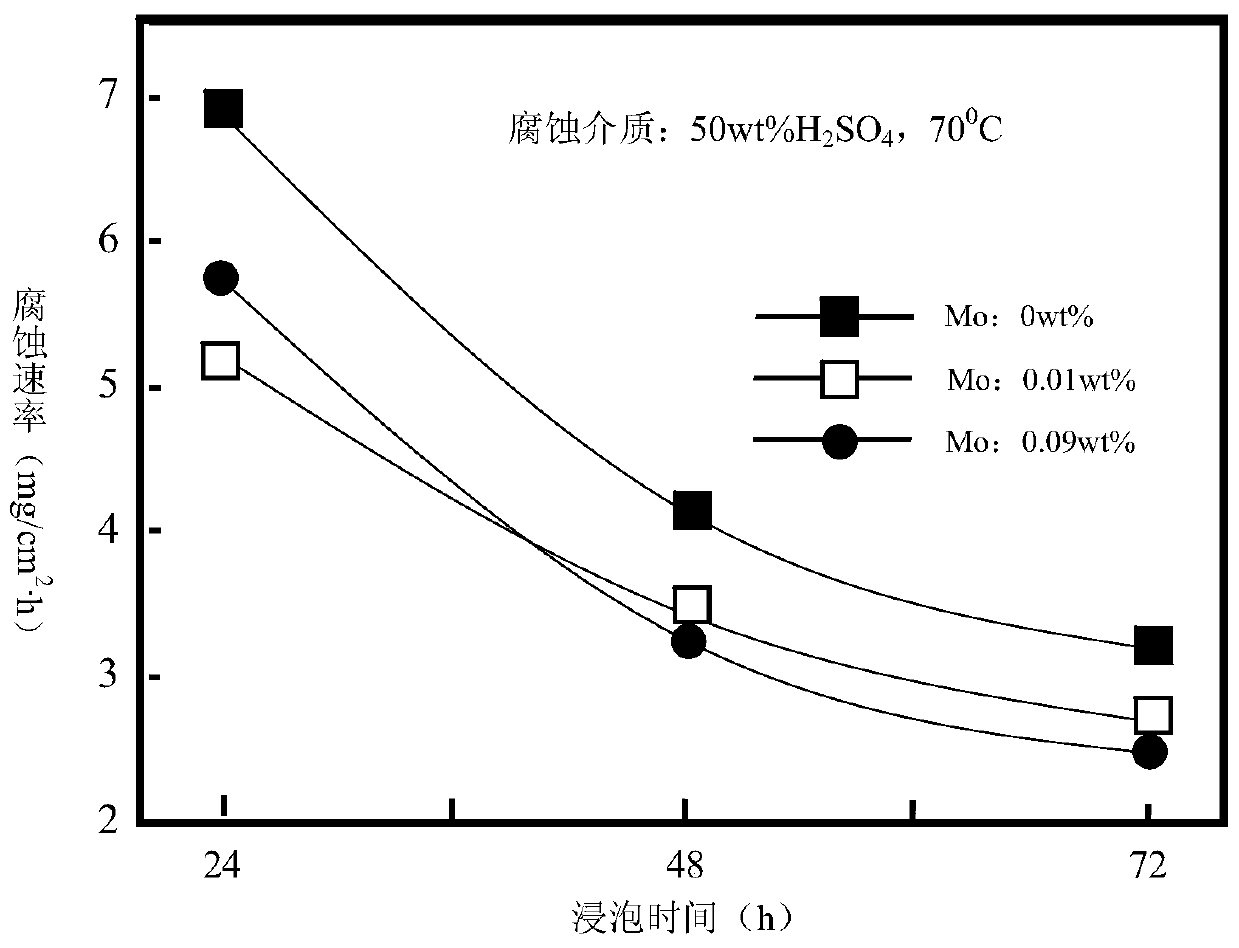

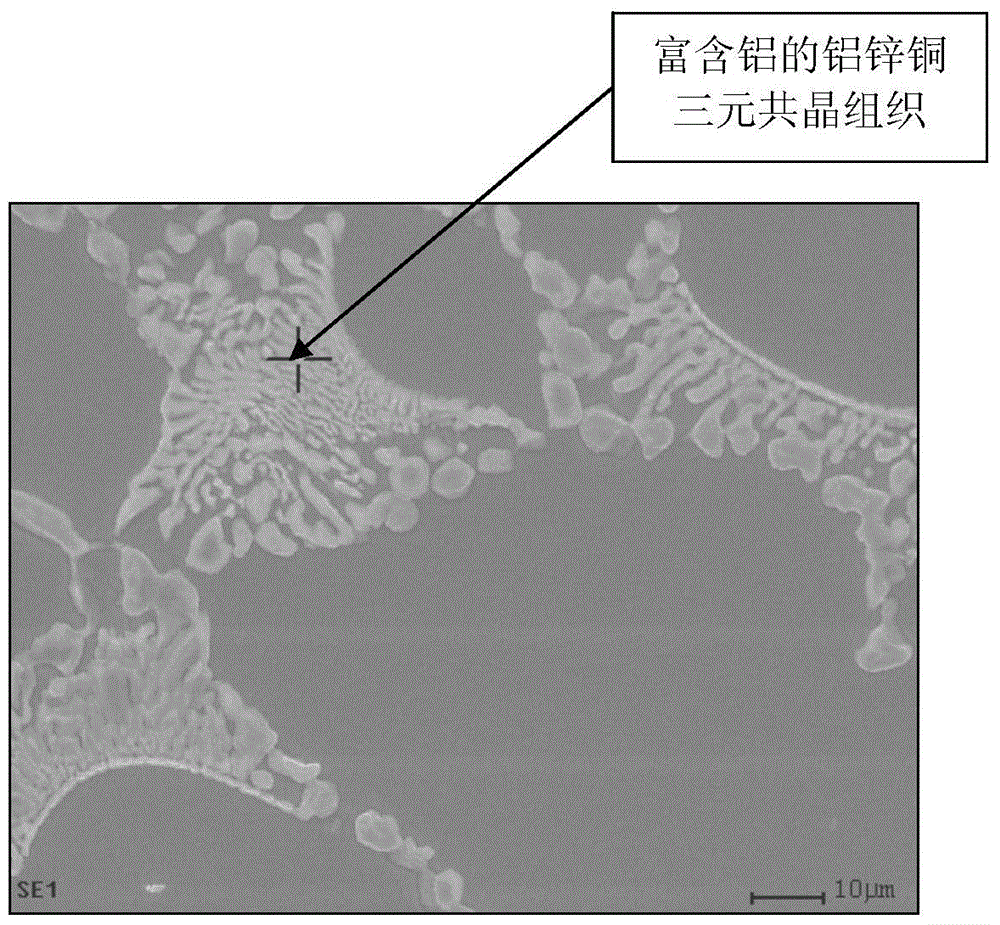

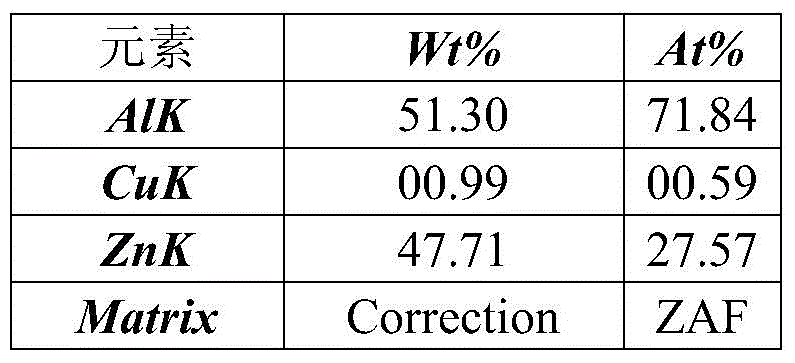

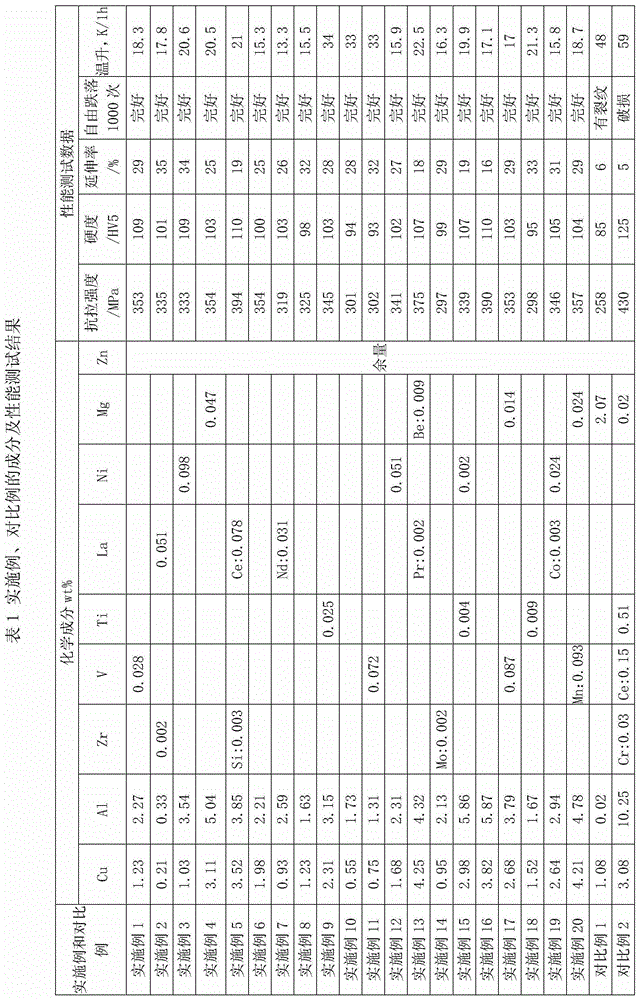

A rivetable deformable low-copper alloy material and its application

ActiveCN104073686BAppropriate intensityAppropriate hardnessCoupling contact membersImpurityLow copper

Disclosed is a low-copper alloy material consisting of Al, Cu, M, Zn and unavoidable impurities, M being at least one element of Ni, V, Ti, Zr, La, Ce, Pr, Nd, Mo, Si, Be, Cr, Mn, Co and Mg, and the impurities comprising at least one element of Fe, Pb, Sn, Sb and Cd. The weight percentage composition of the low-copper alloy material is: the Al content x = 0.1 - 6.0 wt%, the Cu content y = 0.1 - 4.0 wt%, the M content z = 0.001 - 1.0 wt%, the total amount of the impurities is less than or equal to 0.1 wt%, and the remainder is Zn. The sum of the Al and Cu contents satisfies 0.5 wt% ≤ x+y ≤ 9.0 wt%, and the ratio of the Al and Cu contents satisfies 1 ≤ x / y ≤ 4. The alloy may be applied to components such as power supply plugs of household appliances, said components requiring riveting and stamping processing.

Owner:NINGBO POWERWAY ALLOY MATERIAL

Soft tin-plate of hardness HR30T 51+/-3 and making process thereof

ActiveCN100473740CLower yield strengthReduce hardnessRoll mill control devicesFurnace typesTin platingHardness

The soft tin-plate of hardness HR30T 51+ / -3 consists of C not more than 0.005 wt%, Mn 0.20-0.30 wt%, Al 0.03-0.06 wt%, Si not more than 0.03 wt%, Ti 0.03-0.06 wt%, P not more than 0.012 wt%, S not more than 0.015 wt%, N not more than 0.003 wt%, O not more than 0.004 wt%, and Fe and inevitable impurities for the rest. Its production process includes the following steps: smelting steel, continuous casting and rolling, hot rolling, acid pickling and rolling, continuous annealing, flattening and tin plating.

Owner:BAOSHAN IRON & STEEL CO LTD

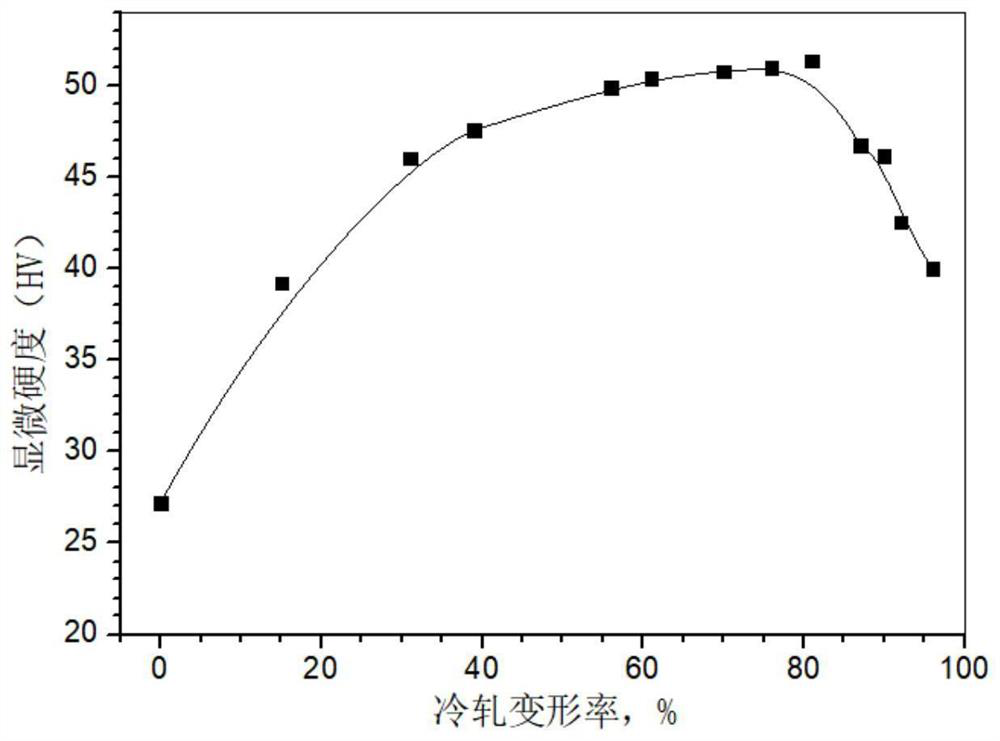

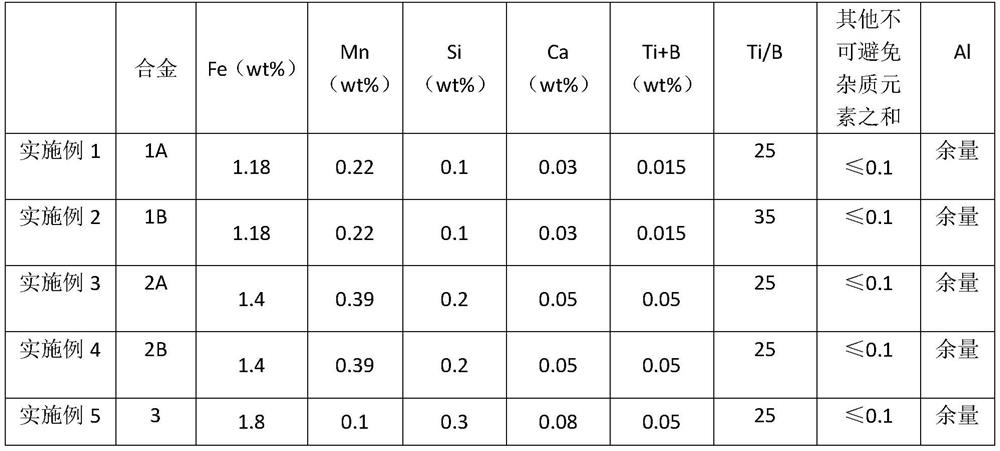

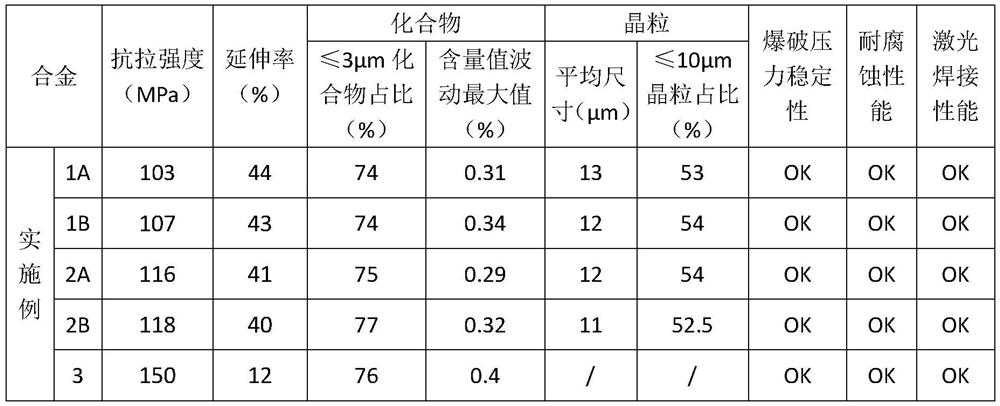

Aluminum alloy plate strip for lithium battery cover plate and preparation method of aluminum alloy plate strip

InactiveCN113088764AGuaranteed process softeningHigh strengthCell component detailsMaterials scienceLaser soldering

The invention discloses an aluminum alloy plate strip for a lithium battery cover plate and a preparation method of the aluminum alloy plate strip. The aluminum alloy plate strip comprises the following components of, in percentage by mass, 1.18 wt%-1.8 wt% of Fe, Mn less than or equal to 0.395 wt% 0.03 wt%-0.08 wt% of Ca, 0.1 wt%-0.3 wt% of Si and the balance Al and inevitable impurities, wherein Fe + Mn is less than 2 wt%, Fe / Mn is more than or equal to 2.5, Mn + Si is less than 0.6 wt%, and (Fe + Mn + Ca) / Si is more than or equal to 2.5. According to the aluminum alloy plate strip for the lithium battery cover plate and the preparation method of the aluminum alloy plate strip, the alloy has good mechanical performance, forming performance and laser welding performance at the same time, especially the performance stability of a material can be improved, and a prepared explosion-proof valve has stable explosion pressure.

Owner:CHINALCO MATERIALS APPL RES INST CO LTD +1

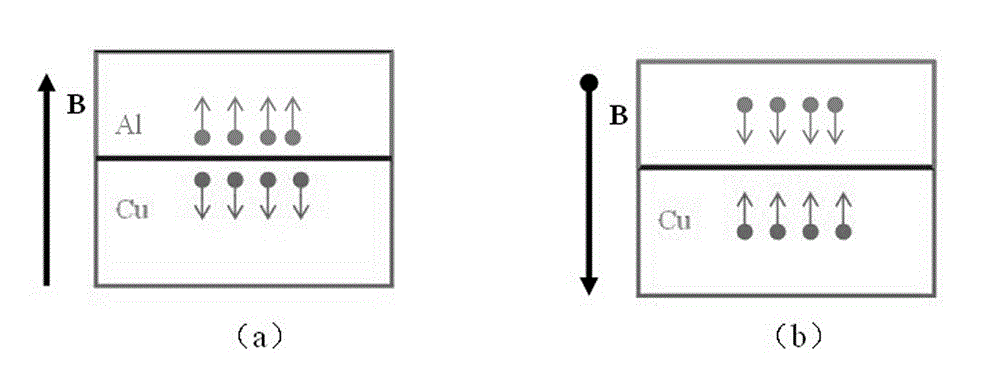

Method for improving interfacial bond strength of copper/aluminum cold rolling composite ultrathin strip

InactiveCN102978348AIncrease the speed of diffusionPromote recrystallizationFurnace typesHeat treatment furnacesInterface layerRoom temperature

The invention belongs to the technical field of processing of metal materials, and particularly relates to a method for improving interfacial bond strength of a copper / aluminum cold rolling composite ultrathin strip. The method comprises the following steps in sequence: thermally processing 0.1 to 0.15mm of ultrathin copper / aluminum cold rolling composite ultrathin strip; applying the a positive magnetic field, and increasing the strength of the positive magnetic field from 0 to 0.01-6T; heating a sample until reaching 350 to 450 DEG C at temperature increase rate of 5 to 10 DEG C per second; maintaining the temperature for 5 to 30 minutes; cooling to reach room temperature; reducing the strength of the magnetic field to reach 0T; and then taking out the sample. According to the method, the electromagnetic field is applied during thermally processing the copper / aluminum cold rolling ultrathin composite strip, the average dimension of a sample interface layer is reduced, the shear strength is improved, the yield ratio is reduced, the plasticity index-elongation is greatly improved, and the interfacial bond strength of the copper / aluminum cold rolling composite ultrathin strip is improved.

Owner:NORTHEASTERN UNIV

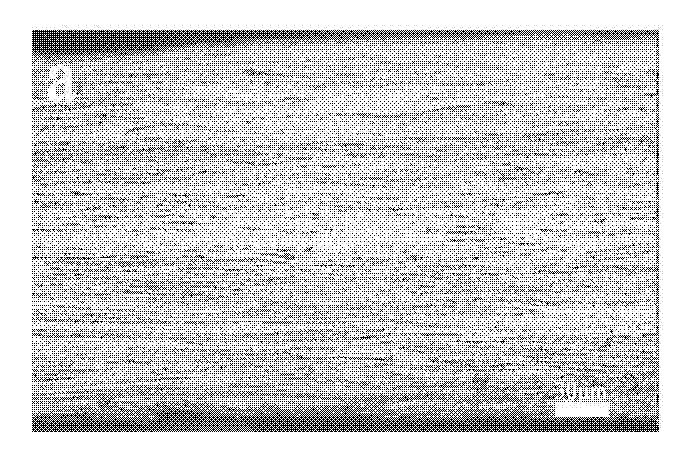

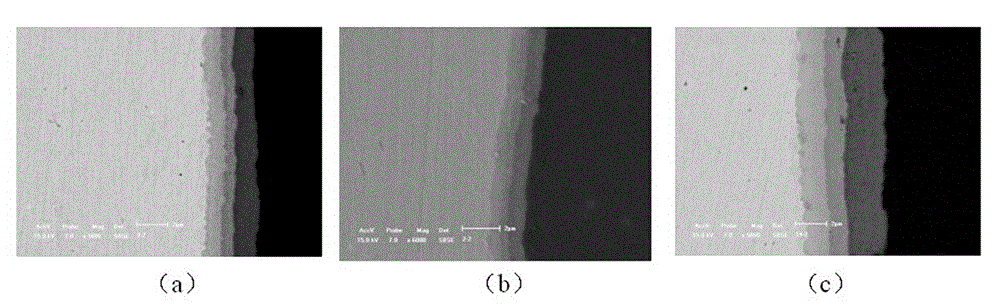

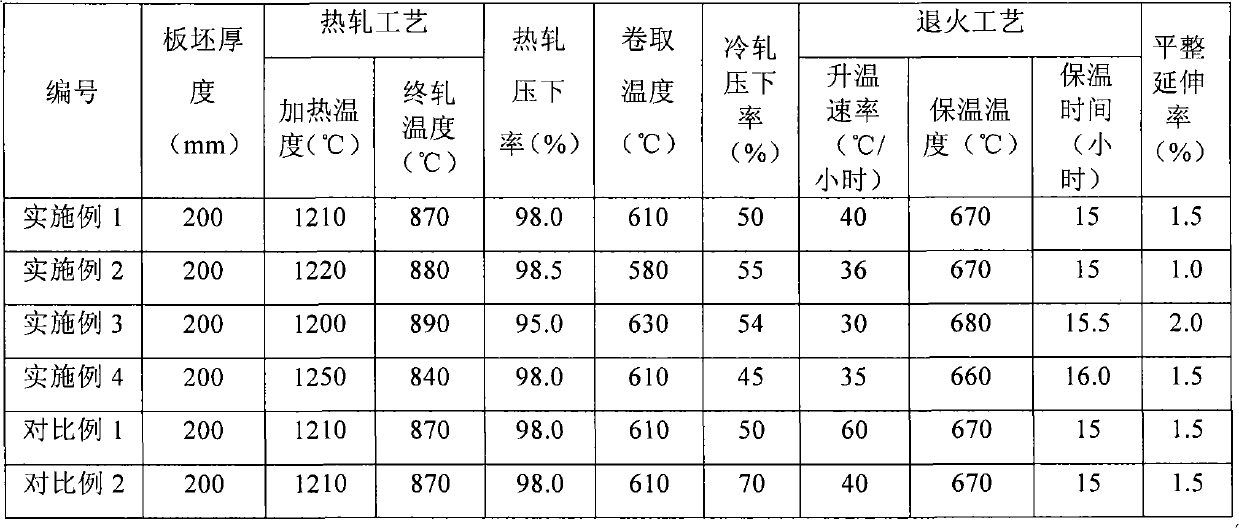

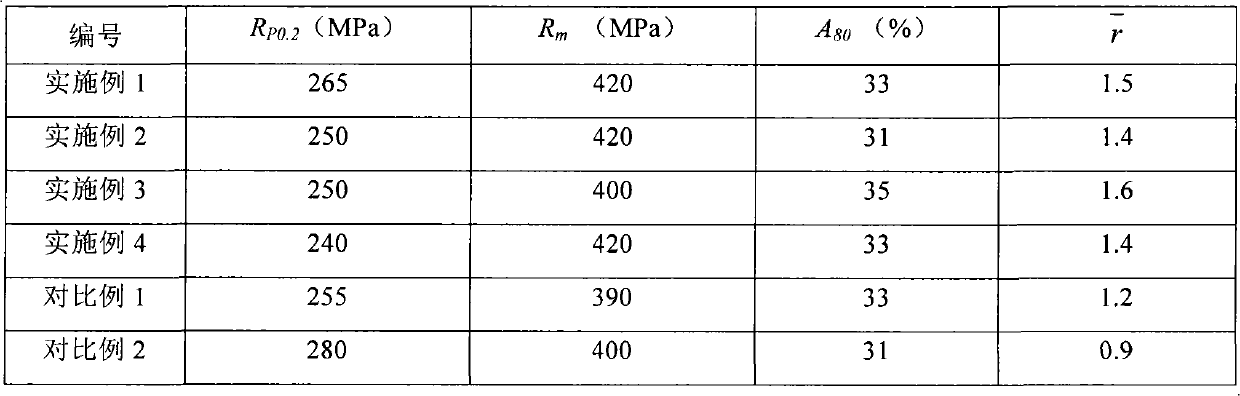

Carbon structural steel plate and preparation method thereof

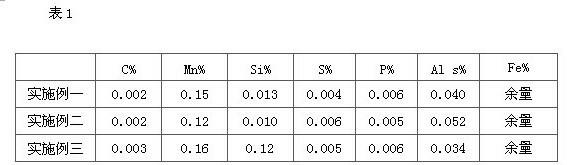

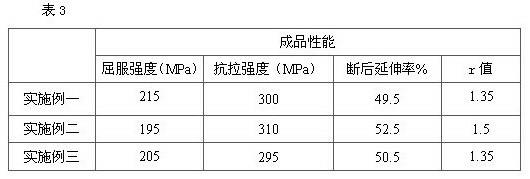

InactiveCN102337454AImprove deep drawing performanceExcellent conventional mechanical propertiesReduction rateSheet steel

The invention provides a carbon structural steel plate and a preparation method thereof. On the basis of the total weight of the carbon structural steel plate, the carbon structural steel plate comprises 0.12-0.17 wt% of C, 0.70-1 wt% of Mn, 0.015-0.07 wt% of Als, and 98.77-99.16 wt% of Fe, wherein, Als represents acid-soluble aluminum. According to a testing method prescribed by GB / T5027-2007, the carbon structural steel plate has a weighted average value of plastic strain ratio in the range from 1.3 to 1.8. By controlling a cold rolling reduction rate at 45-55%, an annealing temperature at 660-680DEG C, an annealing temperature rising rate at 30-40DEG C / h within a temperature range from 450DEG C to the annealing temperature, the method of the invention can process ordinary carbon structural steel into a carbon structural steel plate with a weighted average value of plastic strain ratio up to 1.3-1.8, thus substantially improving the deep-drawing shaping performance of the carbon structural steel plate.

Owner:PANGANG GROUP VANADIUM TITANIUM & RESOURCES +3

Super-large-section aluminum alloy profile, manufacturing method thereof and application

The invention relates to the technical field of hot extrusion manufacturing, in particular to a super-large-section aluminum alloy profile, a manufacturing method thereof and application of the super-large-section aluminum alloy profile serving as a vehicle body structural material. The aluminum alloy profile is composed of 0.45%-0.75% of Si, smaller than or equal to 0.25% of Fe, smaller than or equal to 0.20% of Cu, smaller than or equal to 0.50% of Mn, 0.50%-0.75% of Mg, smaller than or equal to 0.30% of Cr, smaller than or equal to 0.10% of Zn, smaller than or equal to 0.10% of Ti, smallerthan 0.01% of Pb, and the balance Al and inevitable impurities, wherein the amount of Mn and Cr is smaller than or equal to 0.50%. The manufacturing method comprises the steps of casting, two-stage homogenization treatment, turning, extrusion treatment, online solution treatment, tension stretching and artificial aging. The ultra-large-section aluminum alloy profile has high strength, good weldability and fatigue resistance, a high dimensional precision technical index control level, stable quality, good comprehensive performance and low cost.

Owner:山东兖矿轻合金有限公司

Production method of ultra-low-carbon steel for sedan car cortical plate

InactiveCN101096034BReduce manufacturing costLower recrystallization temperatureMetal rolling arrangementsChemical compositionHigh energy

The invention provides a producing method for ultra low steel carbon used in car outer plate, characterized in that liquid steel is cast into plate slab in the pulling speed of 1.5-4m / min; the thickness of plate slab is 100-170mm; casting machine adopts dynamic light pressure and crystallizer electromagnetic braking technology and tundish superheat is 20-45deg.C; the plate slab is installed in heat directly and the charging temperature is more than 800deg.C; the plate slab is heated to 1150-1250deg.C in heating furnace; after the temperature is maintained for 30-90min rough rolling cogging iscarried out. By adopting continuous rolling and casting short-flow process of medium-thin plate slab and collocating casting machine and heating furnace compactly quick charging is realized; chargingmaterial temperature is improved; problems of large investment and high energy consumption in conventional process are solved; inner limitation generated in continuous casting process of thin plate iseliminated; it is guaranteed that product is provided with good surface quality and stable mechanical property.

Owner:ANGANG STEEL CO LTD

Manufacturing method of aluminum material for automobile heat insulation sheet

ActiveCN110964950AImprove elongation and plastic deformation capacityUniform particle sizeAluminiumMaterials processing

The invention belongs to the field of aluminum material processing and relates to a manufacturing method of an aluminum material for an automobile heat insulation sheet. The method comprises the following steps that: raw materials are added into a smelting furnace; after the raw materials in the smelting furnace are completely liquefied, component blending is conducted, and an obtained material isintroduced into a holding furnace after being heated; molten aluminum in the holding furnace is subjected to cast rolling, so that a cast and rolled coil can be produced; and cold rolling and annealing are performed after the cast rolling is performed. According to the manufacturing process of the aluminum material for the automobile high-extensibility heat insulation sheet, waste self-produced aluminum, waste commercial aluminum and aluminum ingots for re-melting are used as raw materials; and through control over a processing rate and annealing, the elongation and plastic deformation ability of the aluminum material are improved.

Owner:JIANGSU DINGSHENG NEW MATERIAL JOINT STOCK CO LTD

Flat emitter and X-ray tube

The invention relates to a flat plate emitter of an X-ray tube. The flat plate emitter of the X-ray tube comprises a first surface and a second surface which are opposite to each other, the material of the flat plate emitter comprises a tungsten-rhenium alloy material, the content of rhenium metal in the tungsten-rhenium alloy material is increased in the first direction, and the direction from the first surface to the second surface is the first direction. And the flat emitter is made of a tungsten-rhenium alloy material. The tungsten-rhenium alloy material has the characteristics of high melting point, high hardness, high plasticity and high recrystallization temperature (2500 DEG C or above), and the ductile-brittle transition temperature of tungsten is reduced to room temperature or below by the tungsten-rhenium alloy material. The recrystallization temperature of the tungsten-rhenium alloy material is very high, thermal deformation or cracks are not likely to happen when the tungsten-rhenium alloy material is subjected to thermal shock, and then the service life of the flat emitter is prolonged.

Owner:WUHAN UNITED IMAGING HEALTHCARE CO LTD

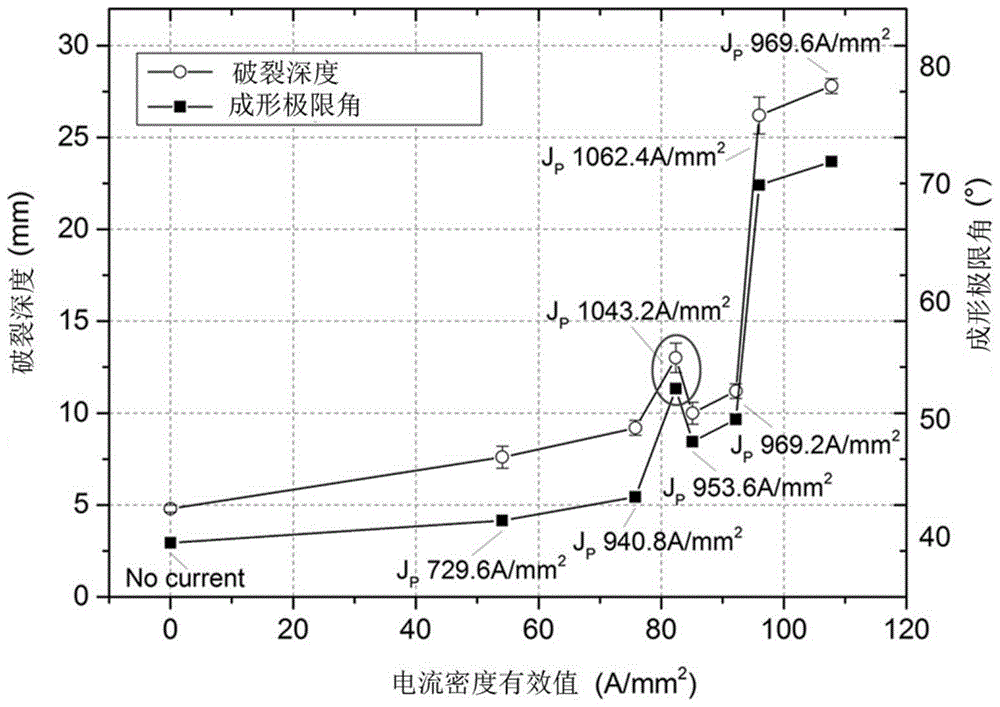

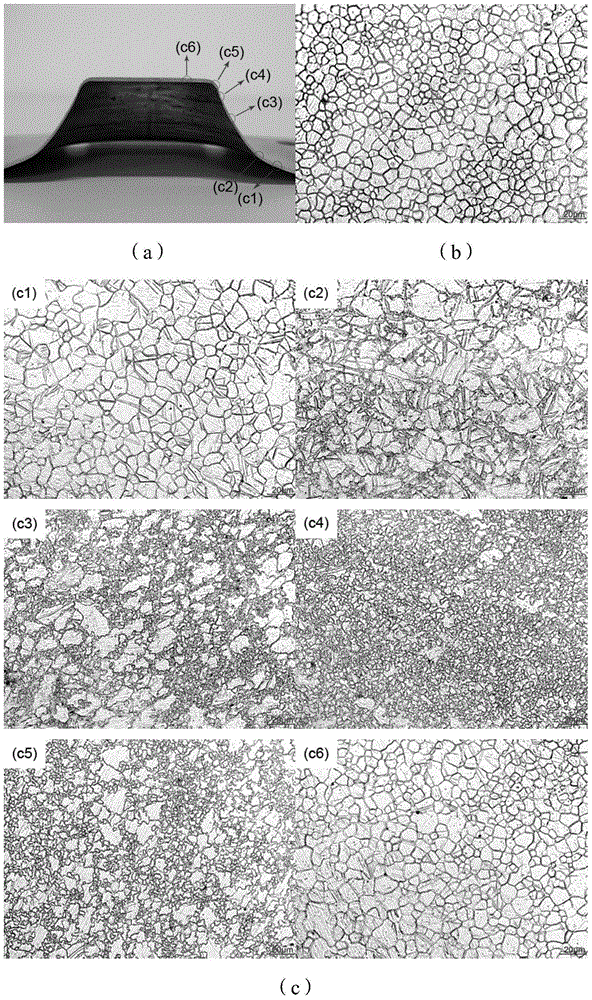

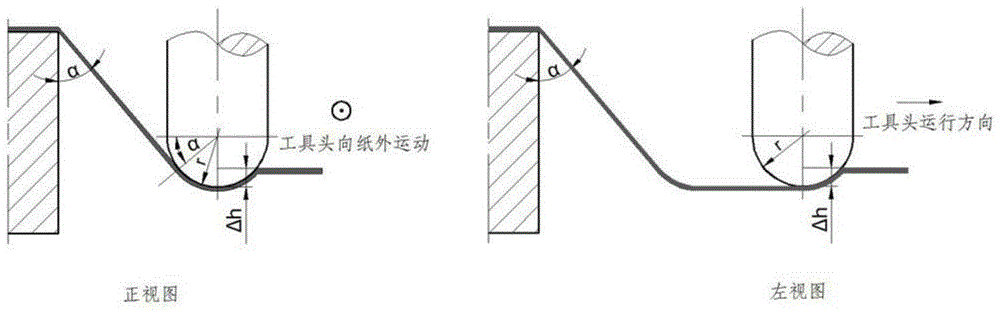

Electroplastic Incremental Forming Method of Magnesium Alloy Sheet

The invention discloses an electroplastic progressive forming method for a magnesium alloy sheet, which belongs to the field of metal processing. The magnesium alloy sheet is progressively formed by a machine tool. The upper and lower surfaces of the magnesium alloy sheet are connected with a pulse power supply, and the output voltage of the pulse power supply is It is a narrow-tip shock triangular wave pulse, the narrow-tip shock triangular wave pulse width is 60-80μs, the output voltage of the pulse power supply is greater than or equal to 70V, the output frequency of the pulse power supply is greater than or equal to 200Hz, and the effective value of the current density flowing through the magnesium alloy sheet is greater than or equal to 95A / mm2. When the effective value of the current density is greater than or equal to 95A / mm2, the magnesium alloy sheet material has good formability, high shape limit, good forming accuracy and good forming quality; the present invention reduces the recrystallization temperature of the magnesium alloy sheet material; Pulse power supplies generate less Joule heat. Compared with the prior art, the invention has high forming limit, good forming precision and good forming quality of the magnesium alloy sheet material, and can obtain better quality parts at lower temperature.

Owner:SHANDONG UNIV

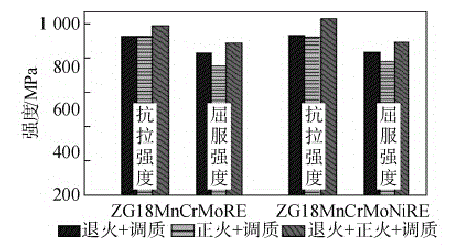

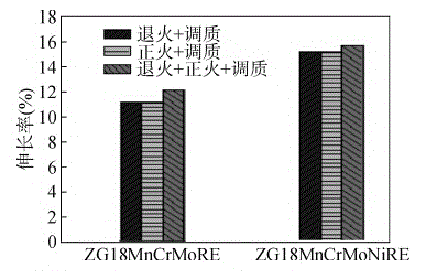

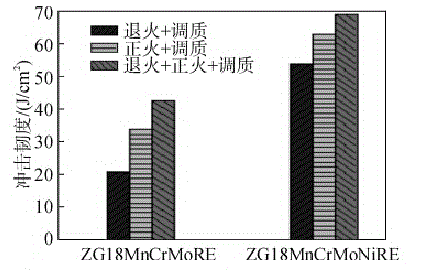

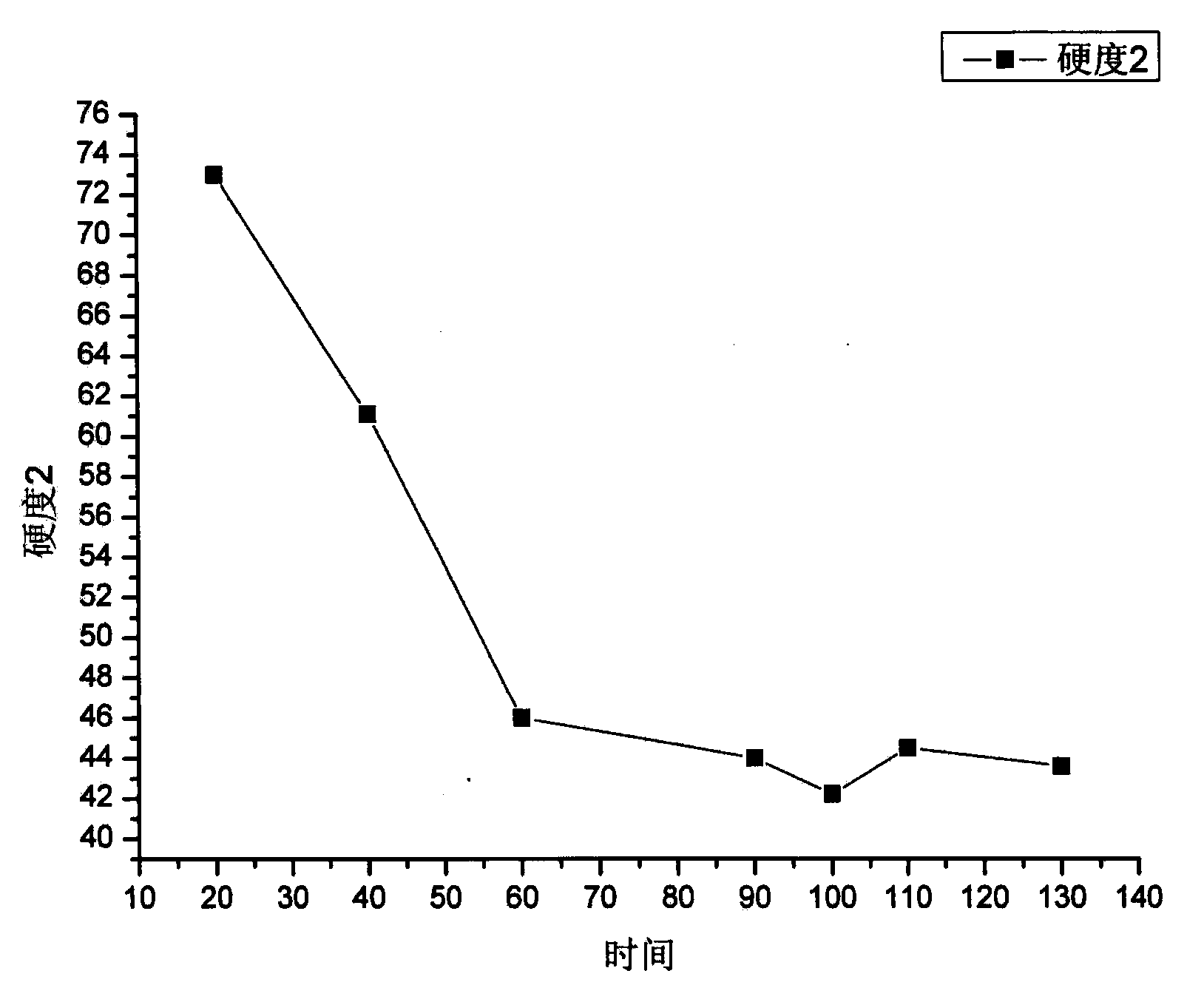

Heat treatment technology of ZG18MnCrMoRE steel

The invention provides a heat treatment technology of ZG18MnCrMoRE steel. The technology comprises the following steps: 1 annealing and tempering: carrying out heat preservation at 930 DEG C for 100 minutes, cooling with a furnace to 550 DEG C, carrying out air cooling, carrying out heat preservation at 900 DEG C for 100 minutes and water quenching, and carrying out heat preservation at 530 DEG C for 3 hours and water quenching; 2 normalizing and tempering: carrying out heat preservation at 910 DEG C for 100 minutes and air cooling, carrying out heat preservation at 900 DEG C for 100 minutes and water quenching, and carrying out heat preservation at 530 DEG C for 3 hours and water quenching; and 3 annealing, normalizing and tempering: carrying out heat preservation at 930 DEG C for 100 minutes, cooling with a furnace to 550 DEG C, carrying out air cooling, carrying out heat preservation at 910 DEG C for 100 minutes and air cooling, carrying out heat preservation at 900 DEG C for 100 minutes and water quenching, and carrying out heat preservation at 530 DEG C for 3 hours and water quenching. According to the heat treatment technology, the problems that the strength, the elongation and the impact toughness of the ZG18MnCrMoRE are not ideal are solved. The heat treatment technology belongs to the field of material science.

Owner:李达

Low-temperature continuous annealing interstitial-free cold-rolled steel sheet and production method thereof

ActiveCN102653839BLower recrystallization temperatureRealize the structureChemical compositionSheet steel

The invention relates to a low-temperature continuous-annealing interstitial-free atom cold-rolled steel plate and a production method thereof and belongs to the technical field of iron-based alloys. The production method of the cold-rolled steel plate comprises the following steps of: controlling the components of the cold-rolled steel plate in percentage by mass: 0.0005-0.0025% of C, less than or equal to 0.03% of Si, 0.05-0.15% of Mn, less than or equal to 0.015% of P, less than or equal to 0.01% of S, less than or equal to 0.0025% of O, less than or equal to 0.0025% of N, 0.015-0.050% of Al, 0.03-0.07% of Ti, and the balance of Fe and inevitable mixed elements; and meanwhile, controlling the continuous-annealing temperature of the cold-rolled steel plate to be 710-740 DEG C, and controlling the cold-rolling reduction ratio to be not less than 80%. According to the cold-rolled steel plate and the production method thereof, the reasonable chemical components and the suitable control of cold-rolling reduction are adopted, the recrystallization temperature is lowered, full-old-rolled microstructures are formed, and a lower continuous-annealing temperature can be adapted, so that the equipment cost and energy consumption are reduced, the control difficulty of a production process is reduced, the product defects and production accidents are avoided.

Owner:SHANGHAI MEISHAN IRON & STEEL CO LTD

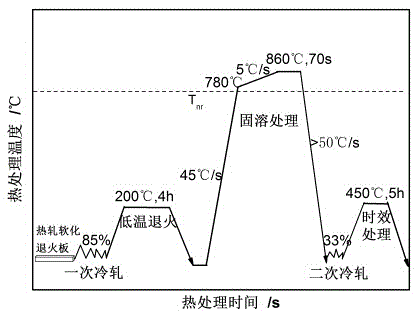

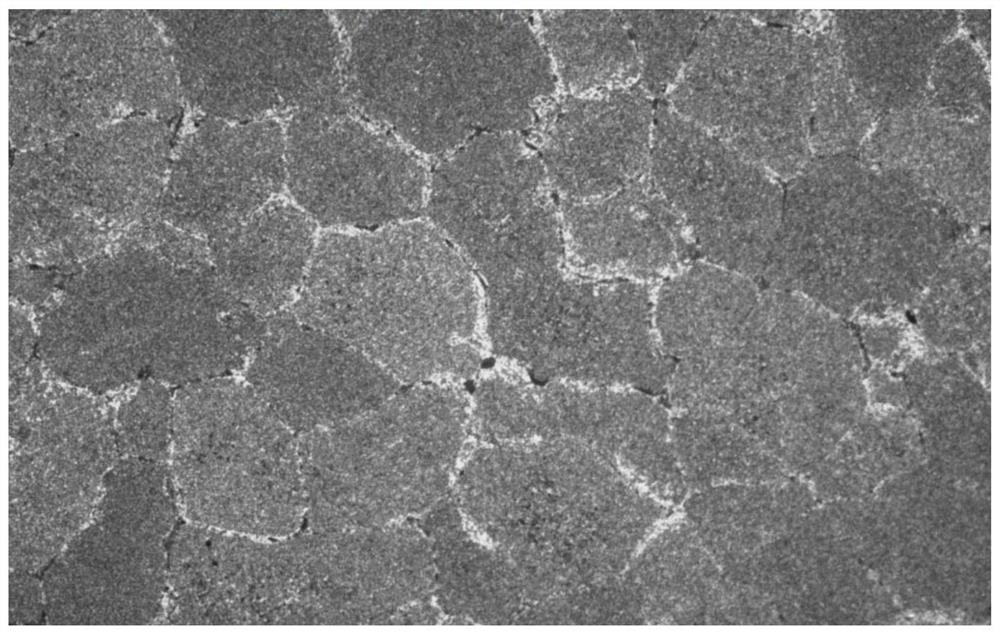

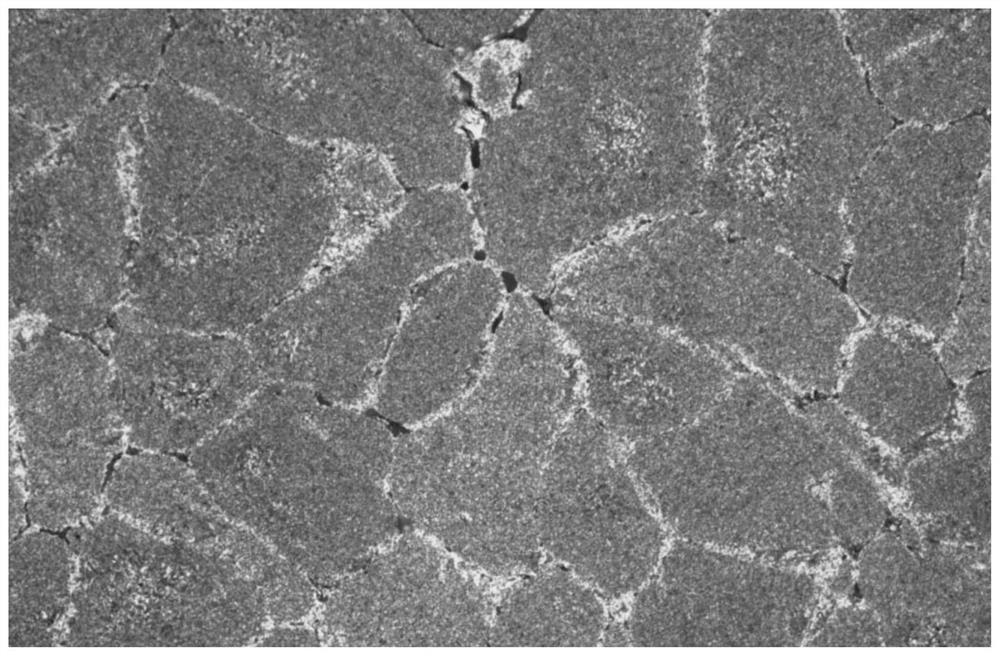

Reinforced plastic dual-phase steel for 800MPa-grade hot galvanizing and preparation method of reinforced plastic dual-phase steel

PendingCN114045437AImprove stabilityLow costHot-dipping/immersion processesHeat treatment process controlUltimate tensile strengthDual-phase steel

The invention belongs to the technical field of cold-rolled strip production, and particularly relates to reinforced plastic dual-phase steel for 800MPa-grade hot galvanizing and a preparation method of the reinforced plastic dual-phase steel. The technical problem to be solved by the invention is to provide the reinforced plastic dual-phase steel for 800MPa-grade hot galvanizing and the preparation method of the reinforced plastic dual-phase steel. Through reasonable design of chemical components of the dual-phase steel and adjustment of preparation process parameters, the yield strength of the obtained 800MPa-grade reinforced plastic dual-phase steel for hot galvanizing ranges from 455 MPa to 525 MPa, the tensile strength ranges from 810 MPa to 880 MPa, and the elongation A80 ranges from 23.0% to 29.0%; the microstructure of the steel plate is composed of 40%-50% of ferrite, about 25%-30% of martensite, 5%-25% of bainite and 5%-10% of retained austenite.

Owner:PANZHIHUA IRON & STEEL RES INST OF PANGANG GROUP

Features

- R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

Why Patsnap Eureka

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Social media

Patsnap Eureka Blog

Learn More Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com