Reinforced plastic dual-phase steel for 800MPa-grade hot galvanizing and preparation method of reinforced plastic dual-phase steel

A 800mpa, hot-dip galvanizing technology, applied in heat treatment equipment, hot dip plating process, heat treatment process control, etc., can solve the problems of difficult to achieve stable and controllable product performance, rising alloy cost, fine-tuning, etc., to achieve stable and controllable product performance. , the effect of reducing alloy and process costs and increasing stability

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

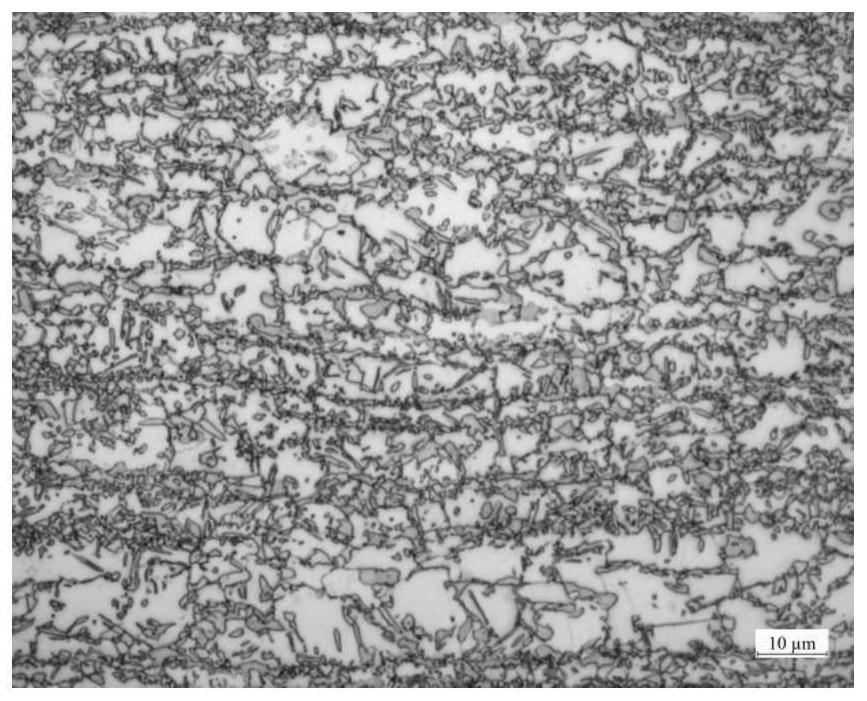

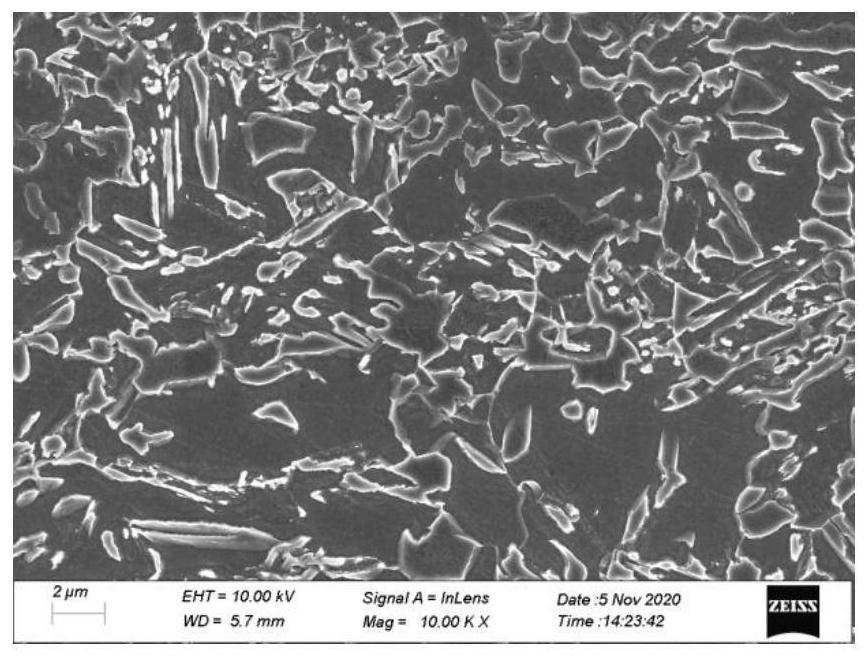

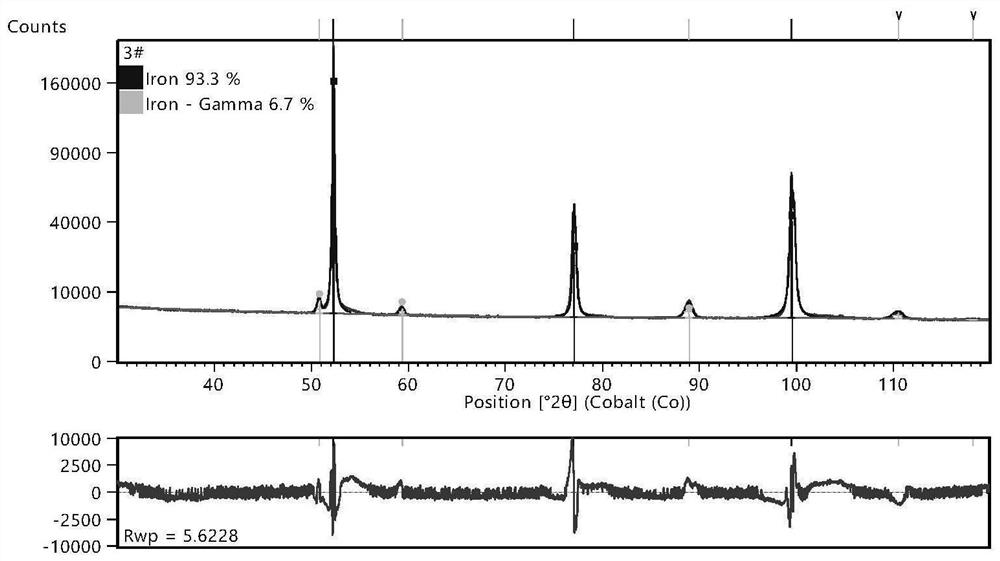

Image

Examples

preparation example Construction

[0036] The present invention also provides a preparation method for the above-mentioned 800MPa grade hot-dip galvanized reinforced plastic dual-phase steel, comprising the following steps:

[0037] a. Smelting process: smelting according to the set chemical composition and casting into slabs;

[0038] b. Hot rolling process: the slab in step a is heated, dephosphorized, rough rolled, finished rolled and laminar cooling to obtain hot rolled coils; the final rolling temperature is 860-930°C; the laminar cooling adopts the front stage cooling The cooling rate of the upper and lower surfaces is 40-50% and 70-80% respectively; the coiling temperature of 100m from the head and tail of the U-shaped coil is 670-730°C, and the coiling temperature in the middle of the strip is 630-680°C , due to the large temperature drop at the head and tail of the strip, the coiling temperature is different from the middle coiling temperature.

[0039] c, acid rolling process: after the hot-rolled co...

Embodiment

[0049] The present invention provides two groups of 800MPa-grade hot-dip galvanized reinforced plastic dual-phase steels, the composition of which is shown in Table 1;

[0050] Table 1800MPa grade hot-dip galvanized reinforced plastic dual-phase steel chemical composition (wt.%)

[0051] Example C the si mn P S N als 1 0.180 0.25 1.90 0.010 0.003 0.0024 0.70 2 0.200 0.30 2.00 0.006 0.002 0.0032 0.75

[0052] The preparation method of the above-mentioned 800MPa level hot-dip galvanized reinforced plastic dual-phase steel, the specific process is as follows:

[0053] A, smelting process: through smelting process, prepare the duplex steel slab of chemical composition as shown in Table 1;

[0054] B, hot-rolling process: the hot-rolled coil is obtained after the slab is heated, dephosphorized, hot-rolled and laminar cooling, and the specific hot-rolling process parameters are as shown in Table 2;

[0055] Table 2 The main process par...

PUM

| Property | Measurement | Unit |

|---|---|---|

| yield strength | aaaaa | aaaaa |

| tensile strength | aaaaa | aaaaa |

| thickness | aaaaa | aaaaa |

Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com