Low-temperature continuous annealing interstitial-free cold-rolled steel sheet and production method thereof

A technology of interstitial-free, cold-rolled steel plates, applied in the field of iron-based alloys, can solve the problems of ribbing, increased construction of annealing furnaces, maintenance costs and energy consumption, and high recrystallization temperature

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

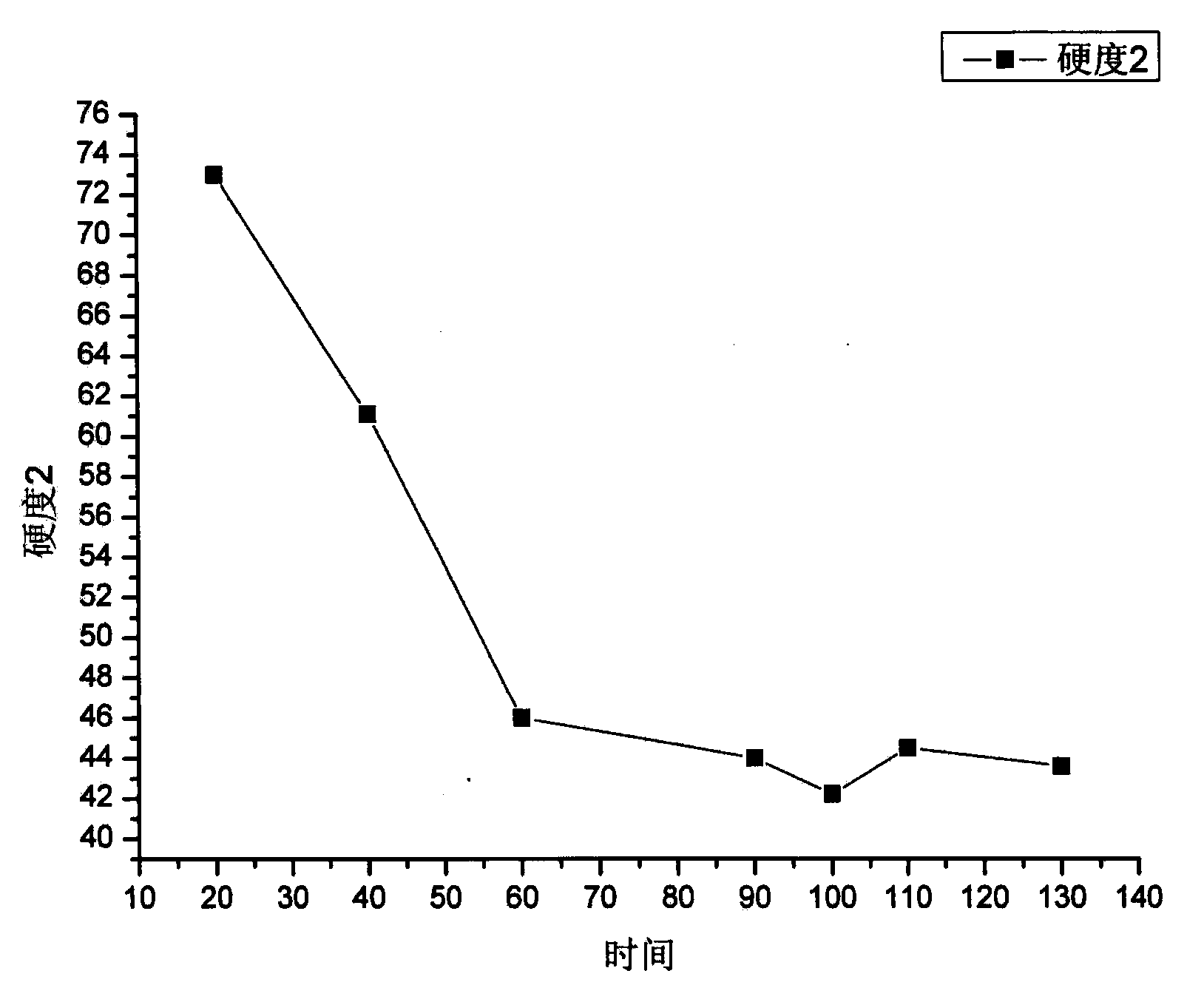

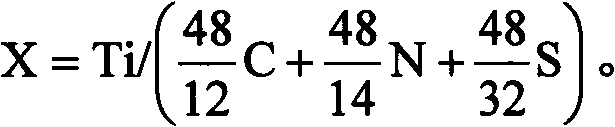

[0048] The low-temperature continuous annealing non-interstitial atom cold-rolled steel sheet of this specific embodiment is divided into four embodiments according to its composition and content. The cold-rolled steel sheets of the four embodiments contain components and mass percentage content as shown in Table 1:

[0049] Table 1 Composition and mass percentage content of cold-rolled steel plate during steelmaking

[0050]

[0051] The method for producing cold-rolled steel sheets in the four examples of this specific embodiment includes a steelmaking process, a hot rolling process, a cold rolling process, and a continuous annealing process.

[0052] The steelmaking process includes: using molten iron pre-desulfurization, converter top-bottom composite blowing, LF furnace heating up and ensuring that the bottom blowing Ar stirring time is greater than 5 minutes, RH furnace is subjected to vacuum cycle degassing treatment to ensure that RH pure degassing time is greater than 15 minu...

PUM

| Property | Measurement | Unit |

|---|---|---|

| thickness | aaaaa | aaaaa |

| thickness | aaaaa | aaaaa |

Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com