Electroplastic Incremental Forming Method of Magnesium Alloy Sheet

A magnesium alloy plate, incremental forming technology, applied in the field of metal processing, can solve the problems of poor forming accuracy and forming quality, low sheet forming limit, poor sheet forming performance, etc., achieve good forming accuracy and forming quality, and avoid oxidation. As well as the growth of microscopic grains and the effect of high forming limit

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

[0024] In order to make the technical problems, technical solutions and advantages to be solved by the present invention clearer, the following will describe in detail with reference to the drawings and specific embodiments.

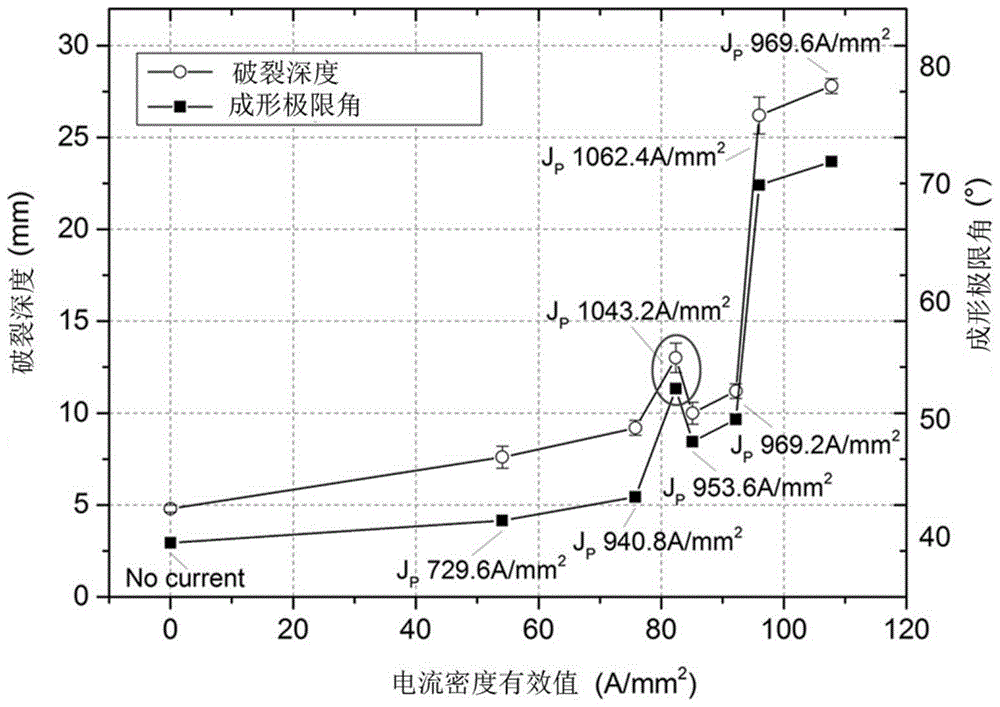

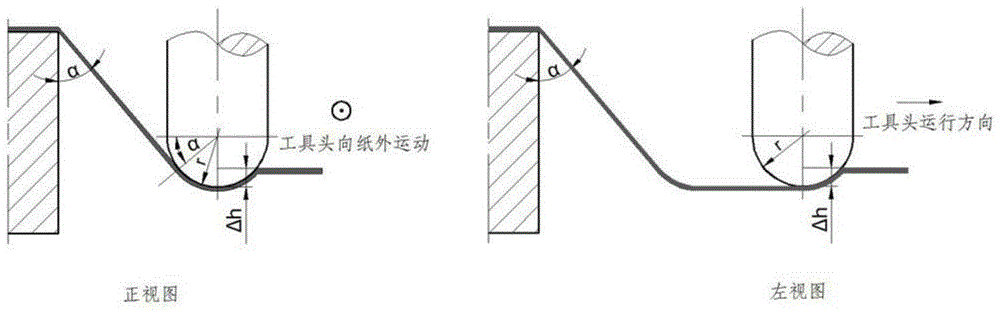

[0025] The invention provides a progressive electroplastic forming method for a magnesium alloy sheet material. The magnesium alloy sheet material is progressively formed by a machine tool. The upper and lower surfaces of the magnesium alloy sheet material are connected with a pulse power supply, and the output voltage of the pulse power supply is a narrow-point shock triangular wave. pulse, such as Figure 5 As shown, the pulse width of narrow sharp shock triangular wave (t i ) is 60-80μs (preferably 70μs), the output voltage of the pulse power supply is greater than or equal to 70V, the output frequency of the pulse power supply is greater than or equal to 200Hz, and the effective value of the current density flowing through the magnesium alloy sheet i...

PUM

| Property | Measurement | Unit |

|---|---|---|

| current density | aaaaa | aaaaa |

| thickness | aaaaa | aaaaa |

| thickness | aaaaa | aaaaa |

Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com