Heat treatment technology of ZG18MnCrMoRE steel

A process and water quenching technology, applied in the field of material science, can solve the problems of unsatisfactory strength, elongation and impact toughness of ZG18MnCrMoNiRE

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

experiment example

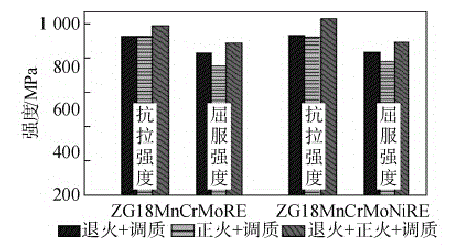

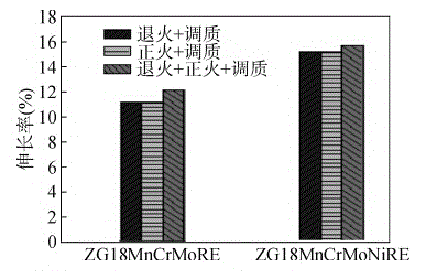

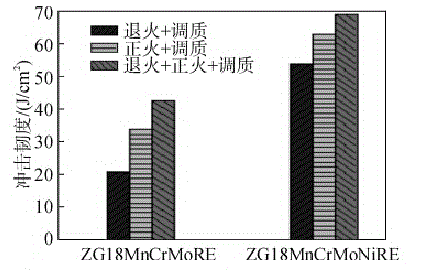

[0015] 1 heat treatment process

[0016] Process 1: annealing + quenching and tempering, that is: heat preservation at 930 °C for 100 min, then air cooling with furnace to 550 °C; water quenching at 900 °C for 100 min, water quenching at 530 °C for 3 h.

[0017] Process 2: normalizing + quenching and tempering, namely: holding at 910 °C for 100 min in air cooling; holding at 900 °C for 100 min with water quenching, and holding at 530 °C for 3 h in water.

[0018] Process 3: annealing + normalizing + quenching and tempering, namely: holding at 930°C for 100 minutes, then cooling with the furnace to 550°C in air; holding at 910°C for 100 minutes in air cooling; holding at 900°C for 100 minutes and water quenching at 530°C for 3 hours.

[0019] 2 Effect of heat treatment process on test steel structure

[0020] The microstructures of ZG18MnCrMoRE steel after three different heat treatments are all tempered sorbite maintaining the martensitic orientation. Among the three hea...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com