Patents

Literature

222results about How to "Improve stamping formability" patented technology

Efficacy Topic

Property

Owner

Technical Advancement

Application Domain

Technology Topic

Technology Field Word

Patent Country/Region

Patent Type

Patent Status

Application Year

Inventor

Aluminum alloy for automobile body of automobile and plate manufacturing method thereof

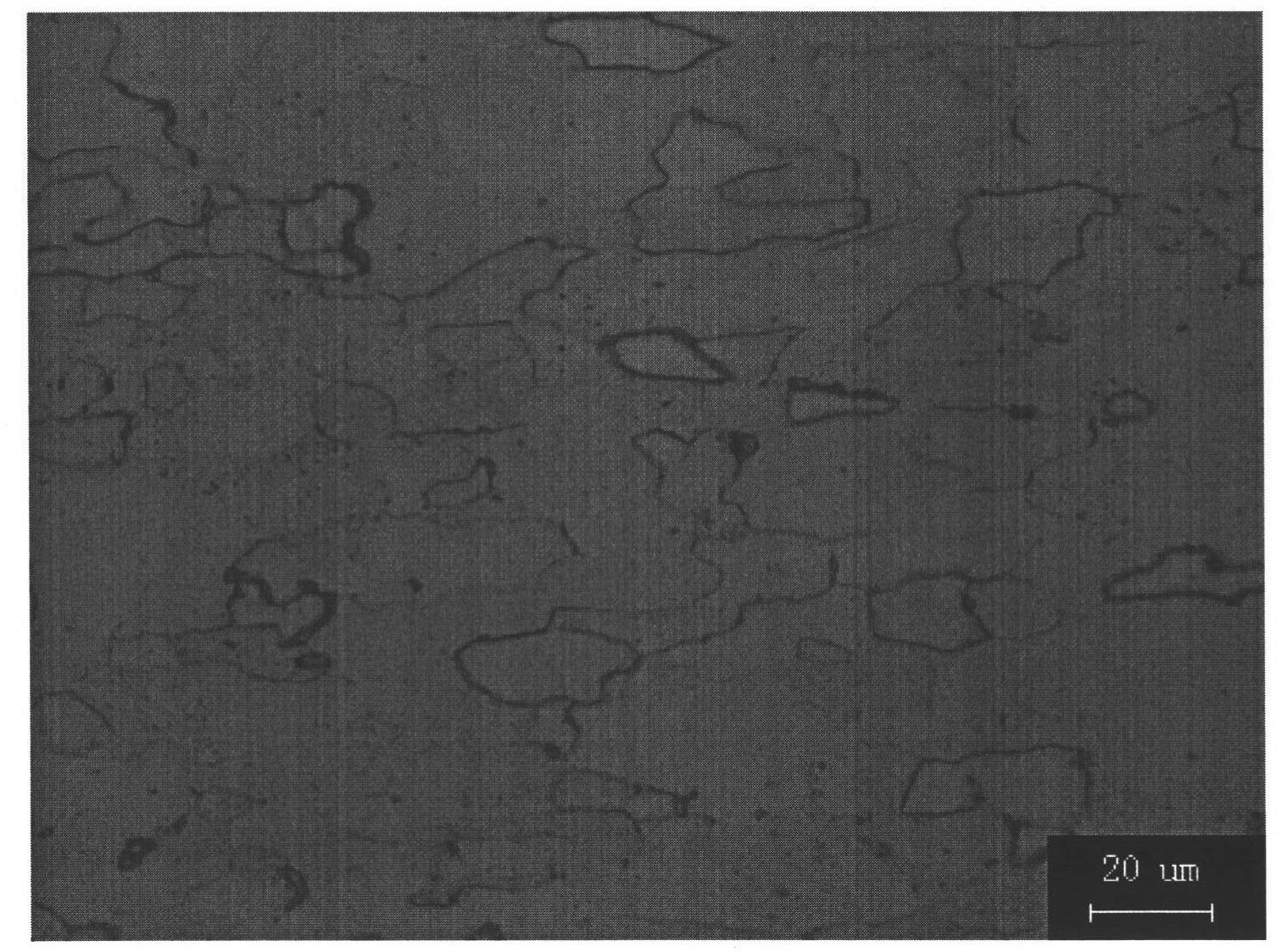

The invention relates to an aluminum alloy for an automobile body of an automobile and a plate manufacturing method thereof and belongs to the technical field of aluminum alloy. The alloy comprises the following components in percentage by weight: 0.6 to 1.33 percent of Mg, 0.6 to 1.33 percent of Si, 0.3 to 0.7 percent of Cu, less than or equal to 0.3 percent of Zn, less than or equal to 0.15 percent of Fe, 0.2 to 0.8 percent of Mn, 0.01 to 0.3 percent of Cr, 0.01 to 0.3 percent of Ti and the balance of Al, wherein the mass fraction ratio of Mg to Si is 1; the total content of the mass fractions of Mn, Cr and Ti alloy elements is more than or equal to 0.3 percent; and Cu content is more than or equal to 0.3 percent. The method for manufacturing the aluminum alloy for the automobile body of the automobile comprises the following steps of: (1) smelting the alloy; (2) shaping the alloy by casting; (3) performing pre-nucleation treatment; (4) performing homogenization treatment; (5) performing hot rolling; (6) performing intermediate annealing; (7) performing cold rolling; (8) performing solid solution water quenching treatment; (9) standing a product at room temperature; and (10) performing pre-ageing and standing the product at the room temperature for more than two weeks. The aluminum alloy and the method are characterized in that: an alloy casting process and a plate production process of the invention are simple and convenient to control; an alloy plate of the invention has high intensity and excellent stamping forming property; and the stamping yield of a covering part for the aluminum alloy automobile body can be effectively enhanced and stamping cost is lowered.

Owner:NORTHEASTERN UNIV

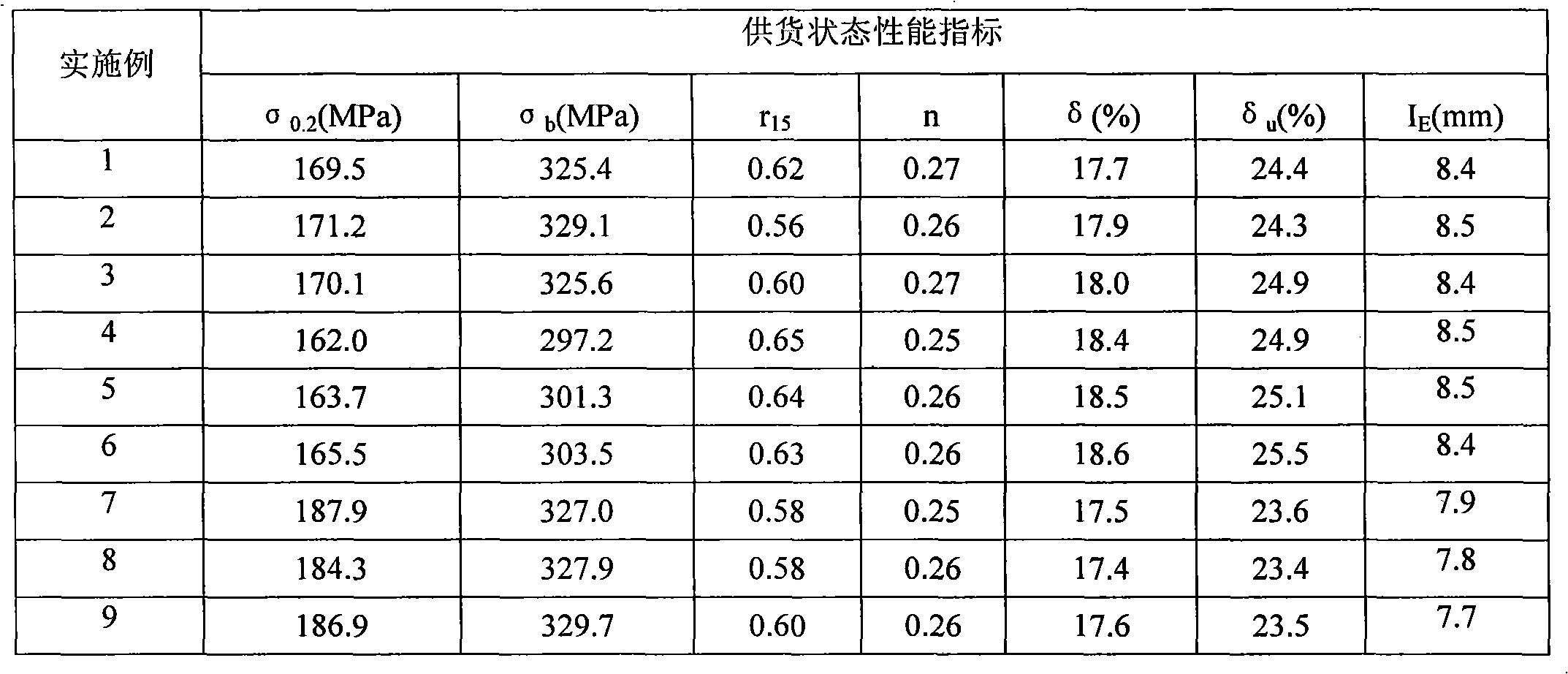

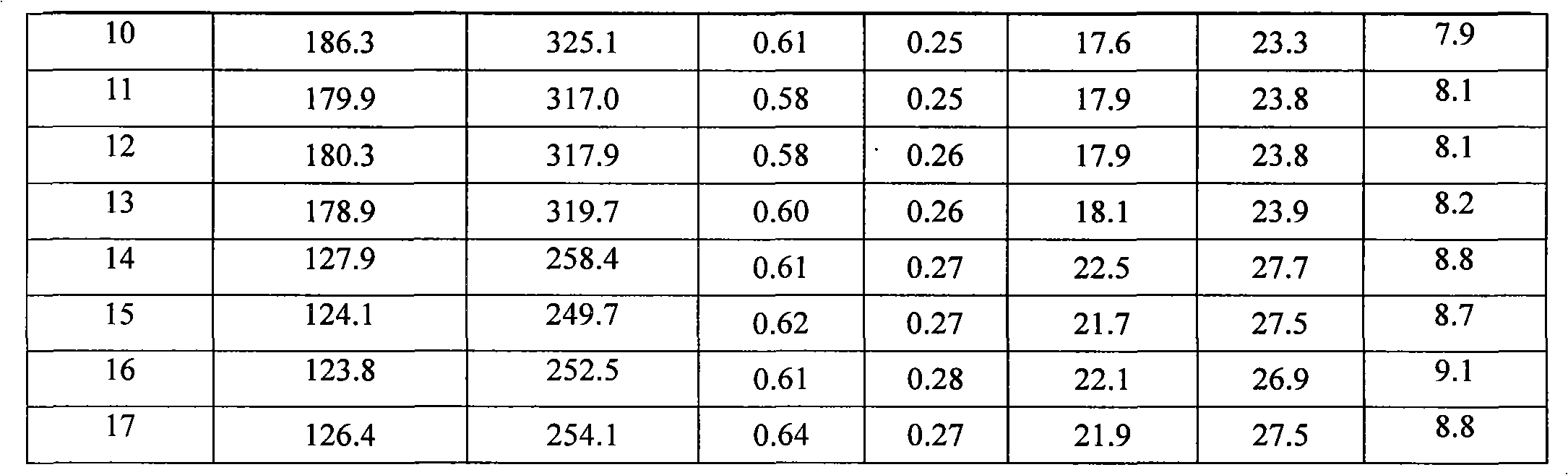

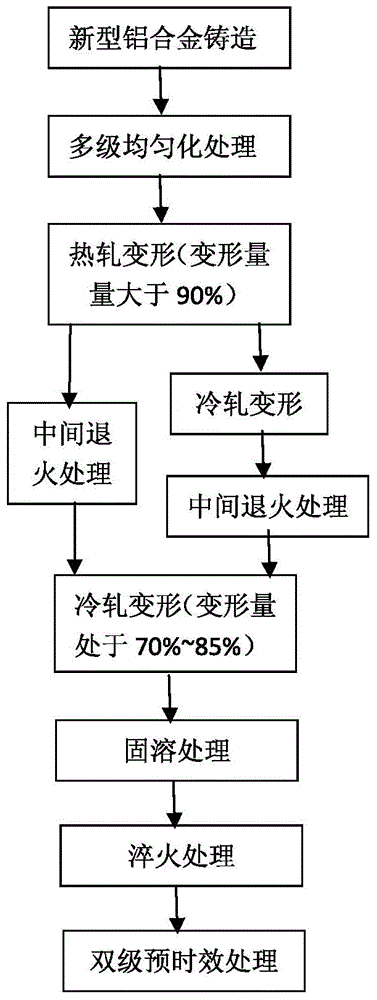

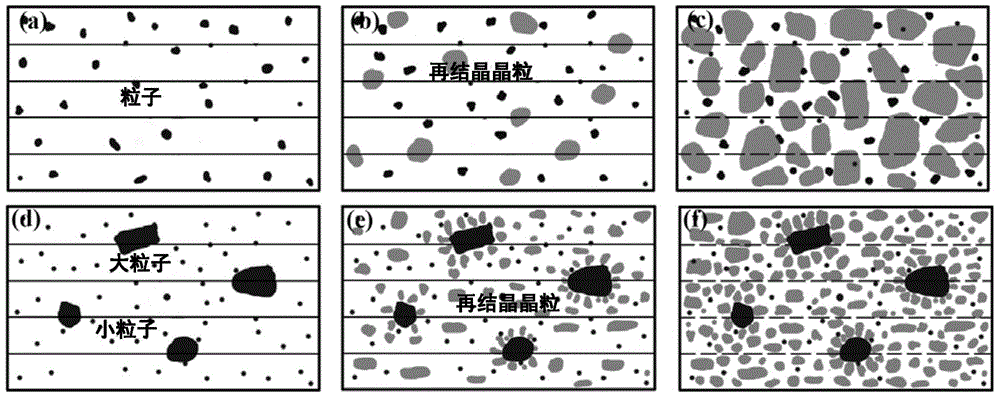

Automotive high-formability aluminum alloy material and preparation method thereof

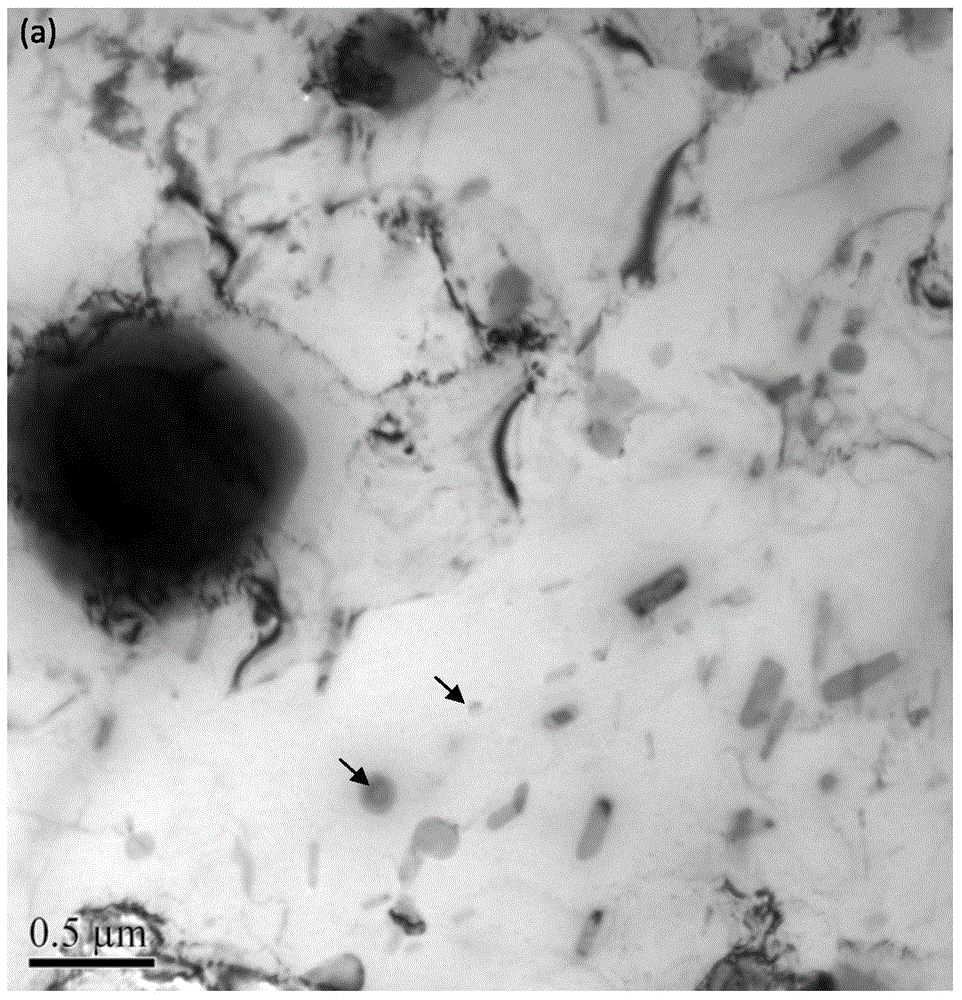

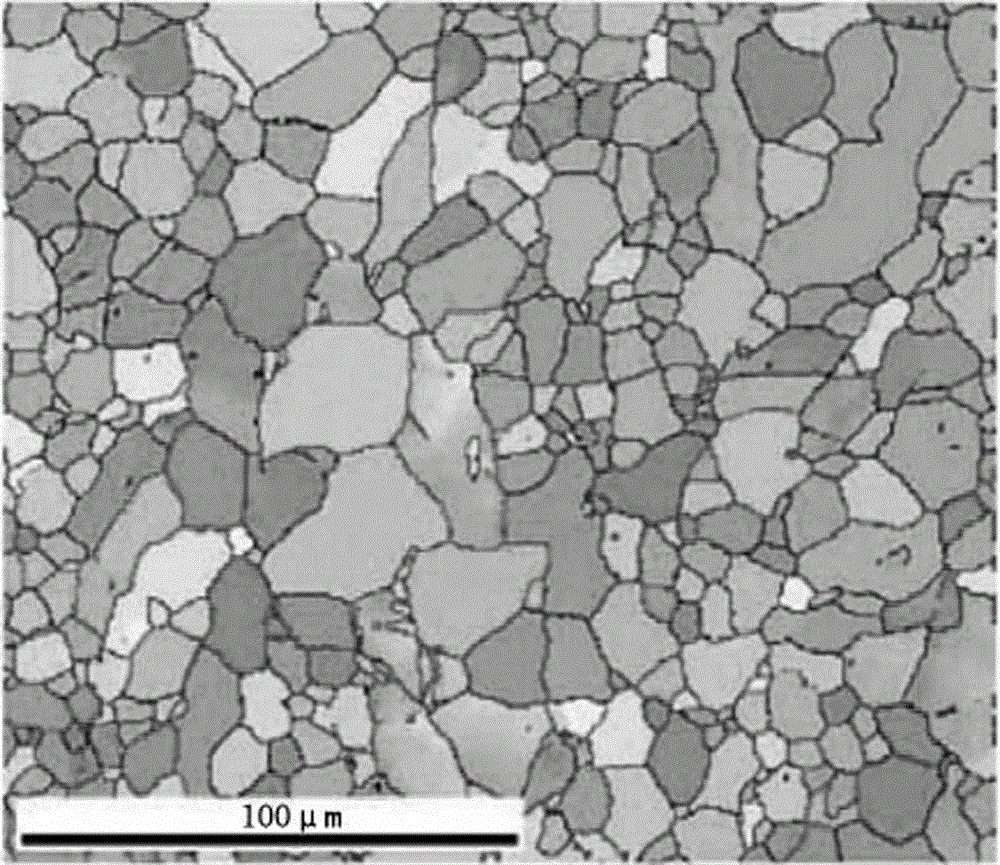

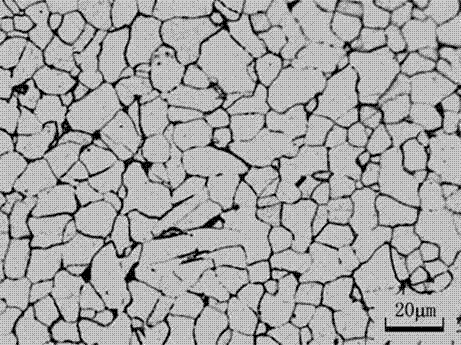

The invention provides an automotive high-formability aluminum alloy material and a preparation method thereof. The preparation method comprises the steps of selection of novel aluminum alloy components, alloy preparation and melting-casting, homogenization, hot rolling deformation, intermediate annealing or cold rolling deformation and intermediate annealing, intermediate annealing, solution treatment, quenching and multistage pre-ageing treatment. By using the double effects that a certain quantity of multi-scale particles can be formed among different solute elements in the alloy material and then oversize particles are stimulated, re-crystallized and nucleated while fine particles block the growth of the re-crystallized grains in the high-temperature heat treatment process, so that the structure of an alloy plate is formed by the fine and uniformly distributed re-crystallized grains, the anisotropy of the alloy plate is well controlled, and the stamping forming performance is relatively excellent. Meanwhile, the novel aluminum alloy with high formability and high baking varnish hardening increment is very suitable for manufacturing of automotive body outer plates, particularly manufacturing of parts having relatively high requirements for stamping formability and baking varnish hardening increment and having complex shapes.

Owner:UNIV OF SCI & TECH BEIJING

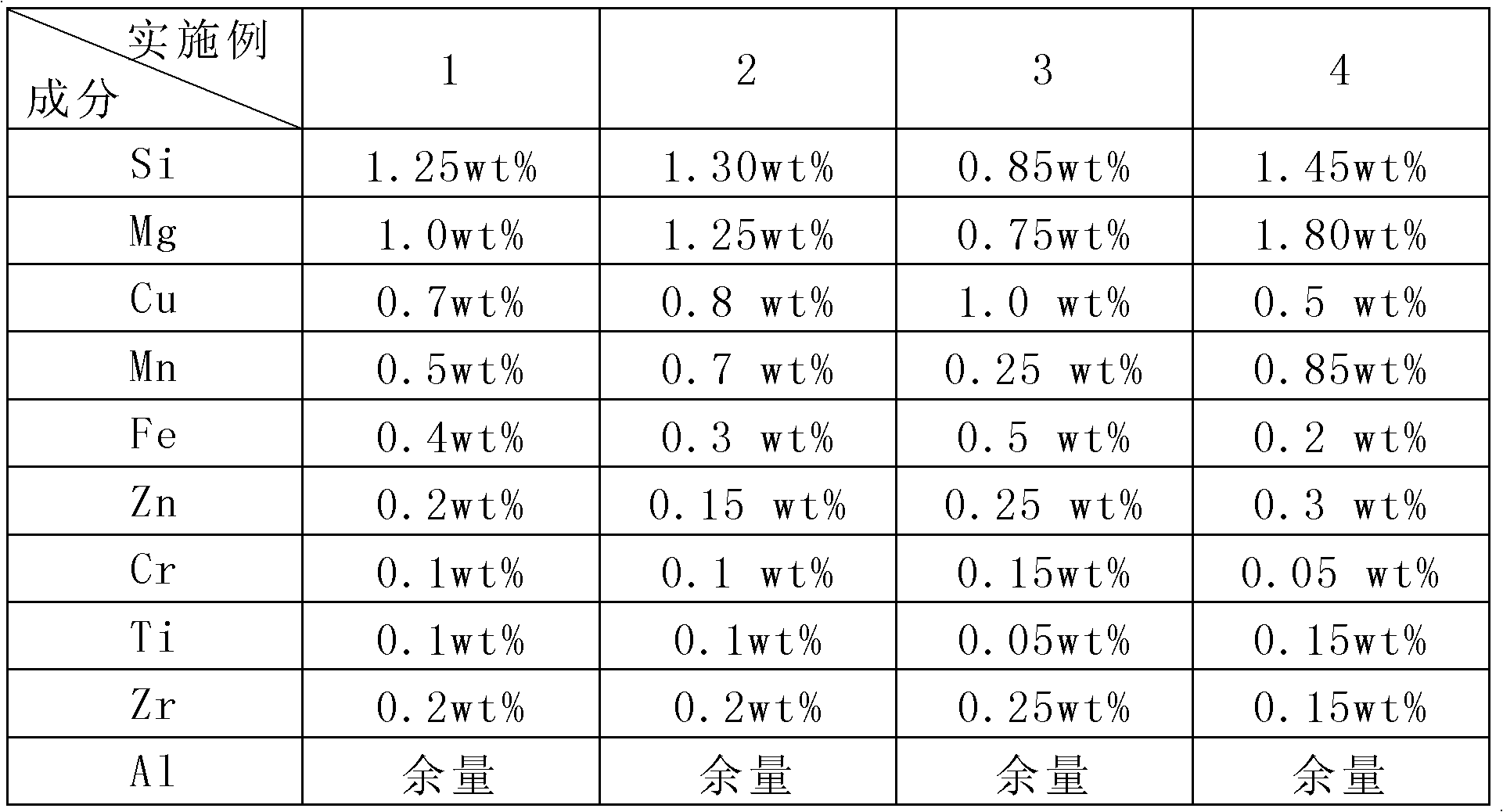

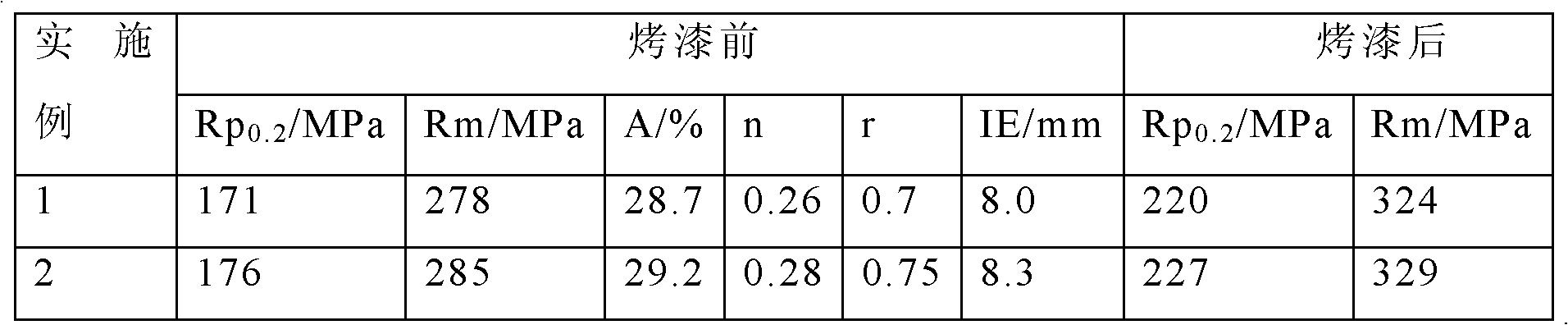

Al-Mg-Si alloys for automobile body sheets and manufacturing method thereof

ActiveCN101880805AStrong impact resistanceLower yield strengthCooking & bakingUltimate tensile strength

The invention provides Al-Mg-Si alloys for automobile body sheets and a manufacturing method thereof, belonging to the technical field of alloy materials. The invention solves the following problems: the existing 6000 series alloys have poor stamping forming performance and the strength of the alloys is possibly reduced through paint baking after stamping. The alloys comprise the following components in percentage by weight: 0.75-1.5% of Si, 0.2-0.5% of Fe, 0.2-1.0% of Cu, 0.25-1.0% of Mn, 0.75-1.85% of Mg; 0.15-0.3% of Zn, 0.05-0.15% of Cr, 0.05-0.15% of Ti, 0.05-0.35% of Zr and the balance Al. The alloys have the advantages of low yield strength, convenient stamping, high plasticity and good impact resistance and baking hardenability.

Owner:ZHEJIANG GKO IND CO LTD

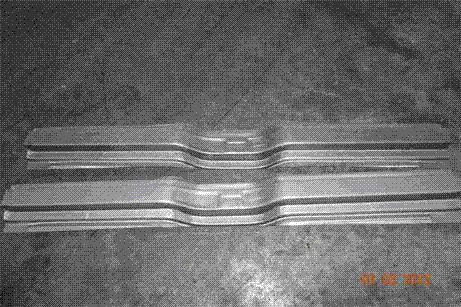

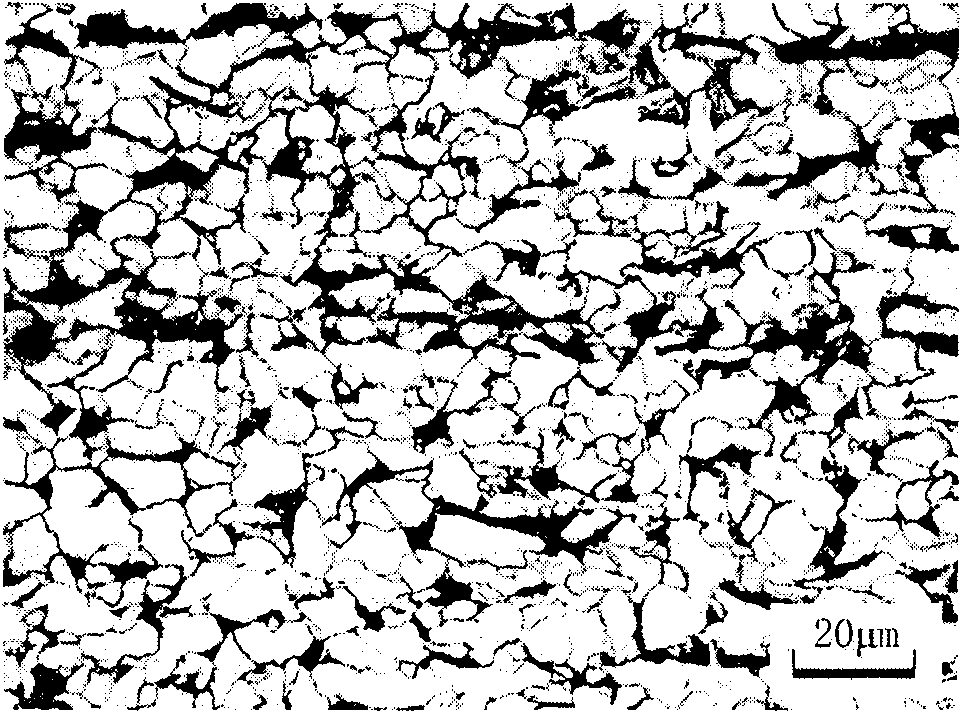

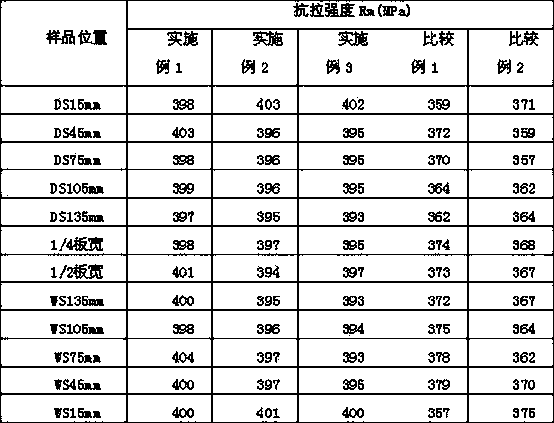

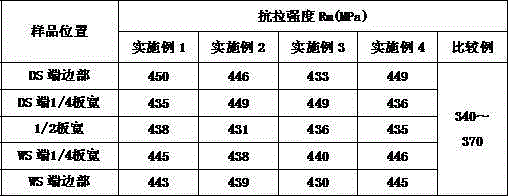

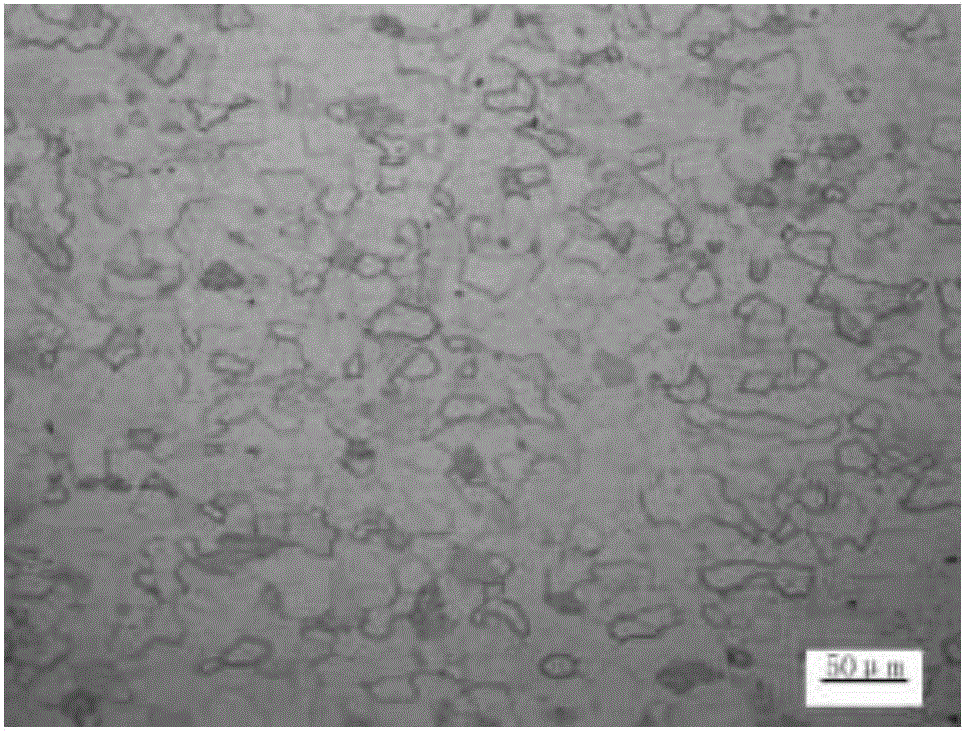

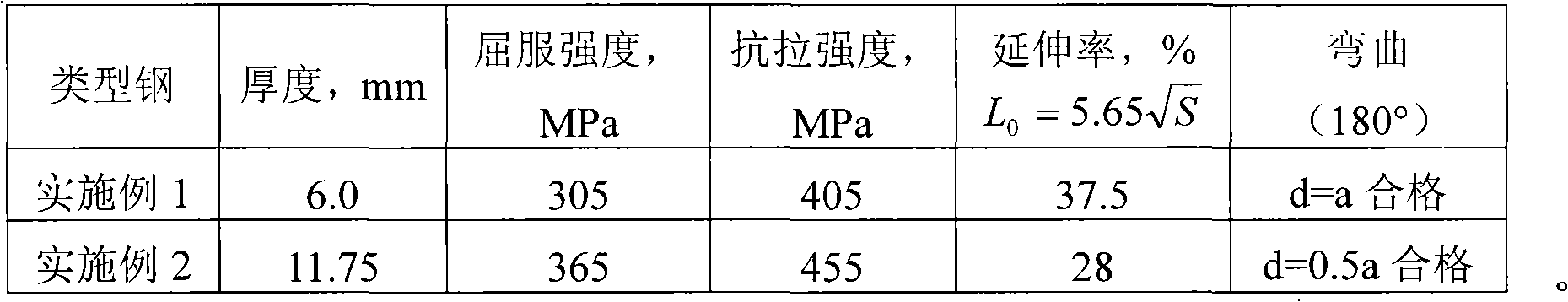

Diphasic steel plate by continuous casting and rolling middle bar strip and manufacturing method thereof

ActiveCN101130847ASimple chemical compositionHigh tensile strengthMetal rolling arrangementsChemical compositionSheet steel

The present invention provides a dual phase steel sheet made up by using medium-thin sheet billet through a certain continuous-casting and continuous-rolling process. The component composition of said steel sheet includes (by wt%) 0.04%-0.11% of C, 0.02%-1.5% of Si, 0.6%-2.50% of Mn, 0.02%-2.0% of Cr, also can contain Mo or Ti, the rest is Fe and unavoidable impurity. The microscopic structure of said steel sheet includes: matrix phase is ferrite and second phase mainly is martensite. Besides, said invention also provides the concrete operation steps of its production method.

Owner:ANGANG STEEL CO LTD

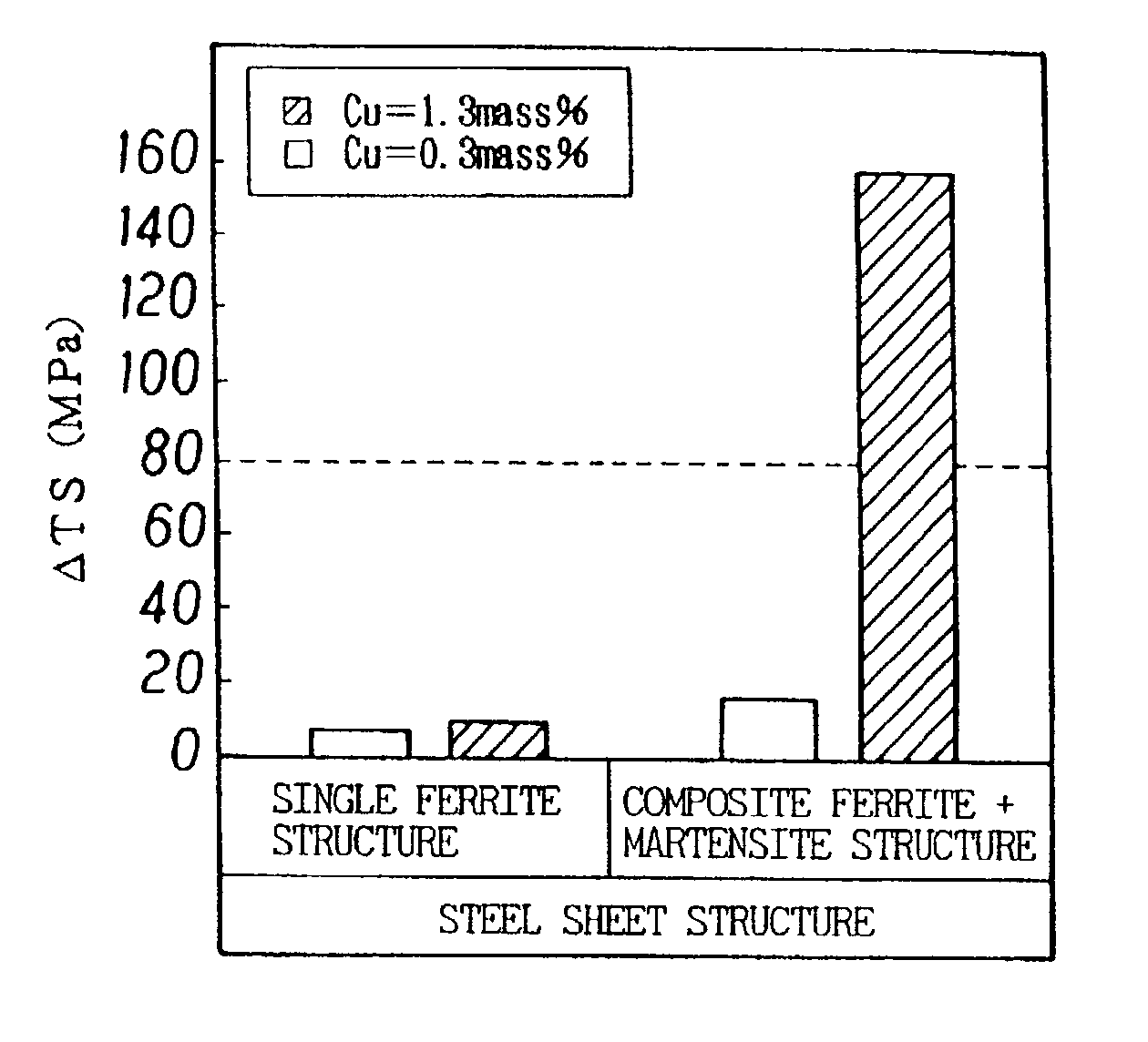

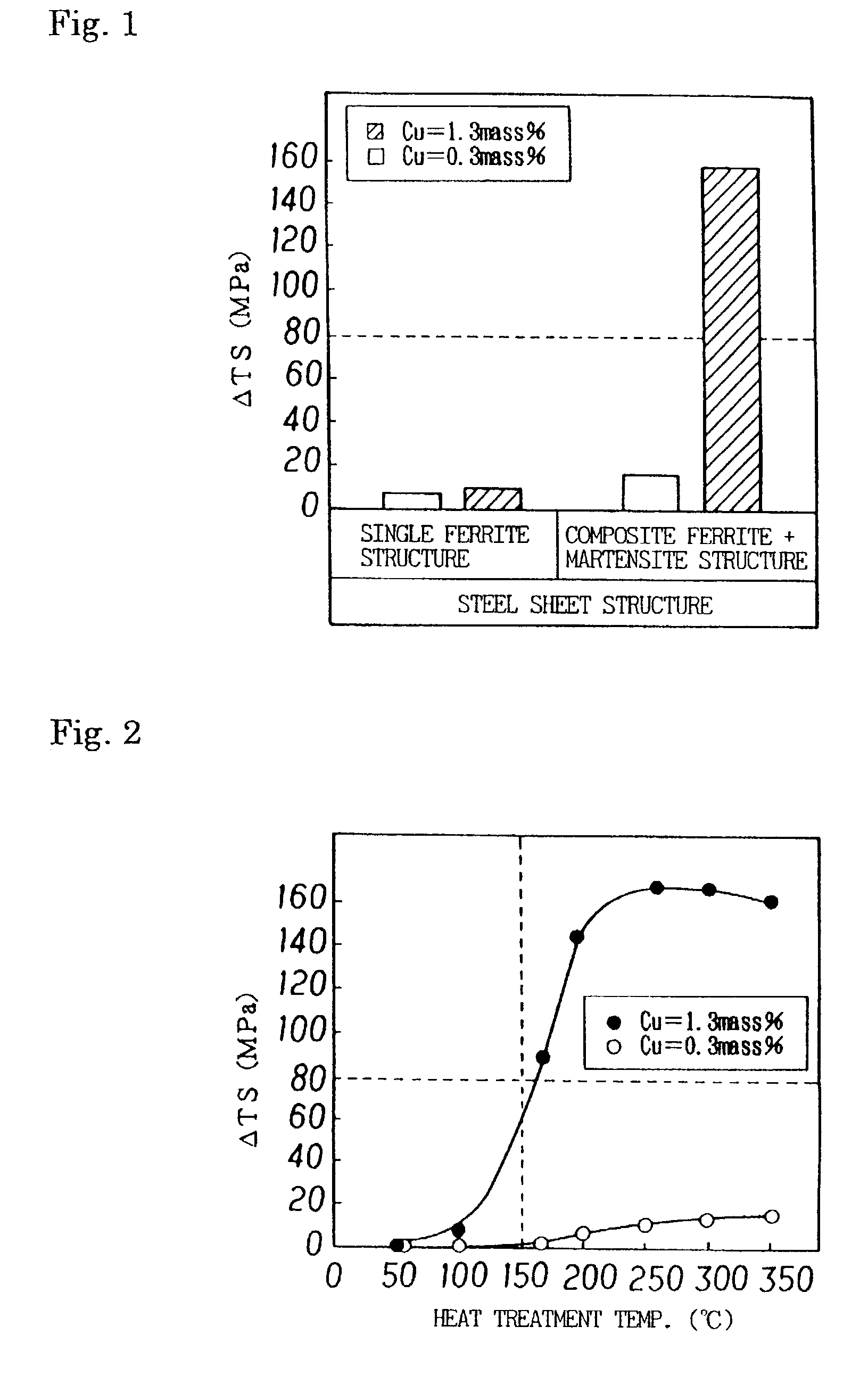

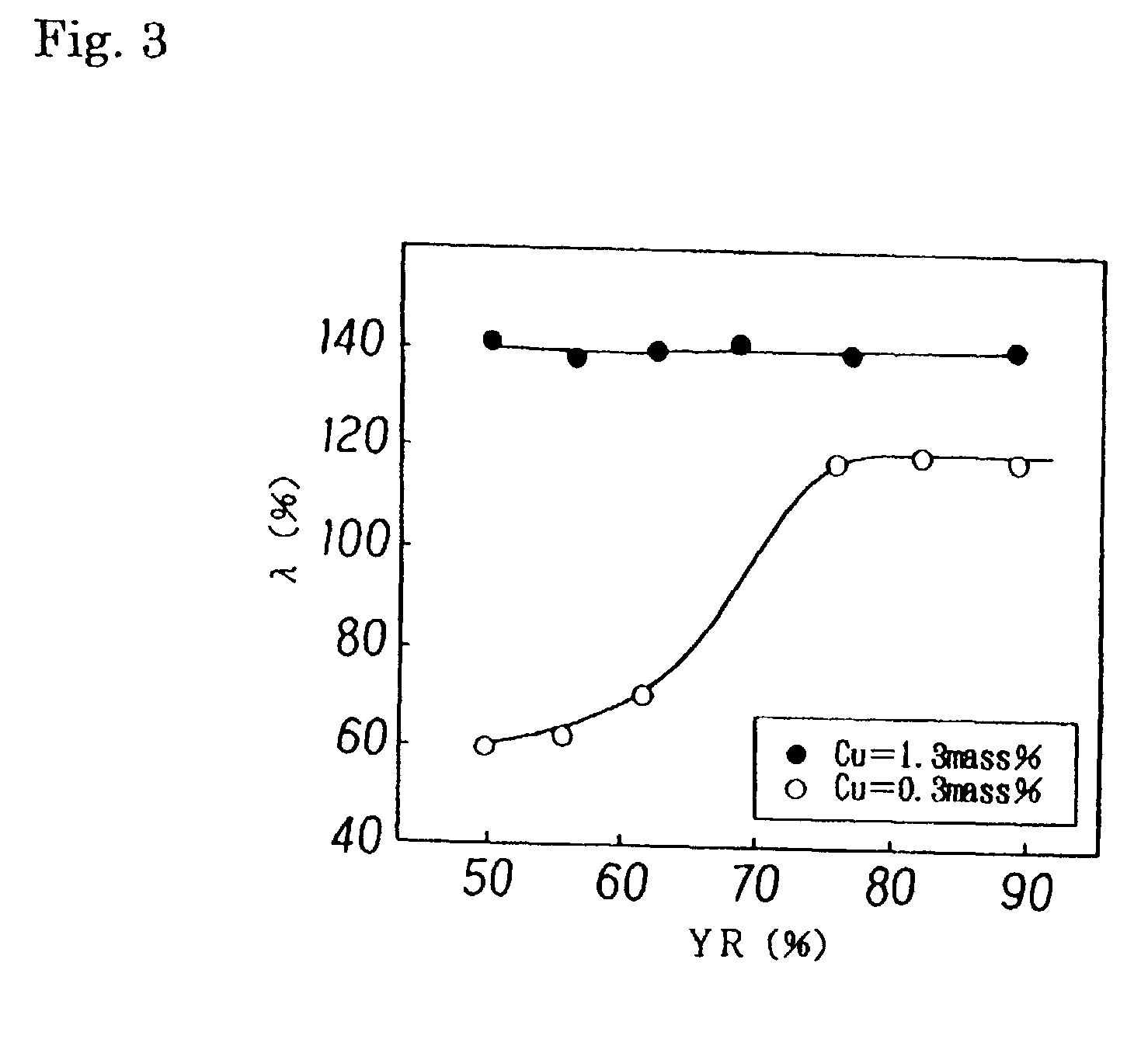

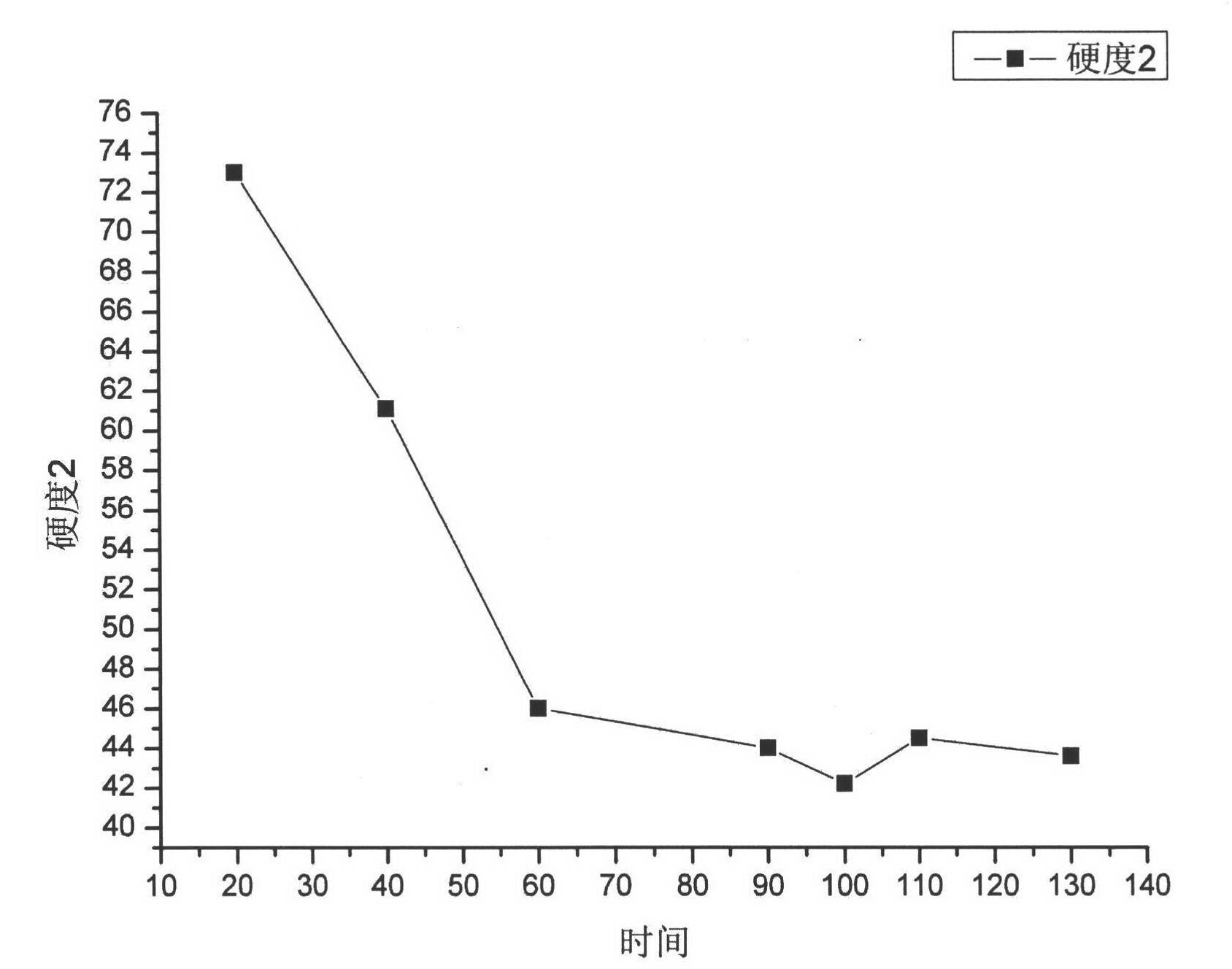

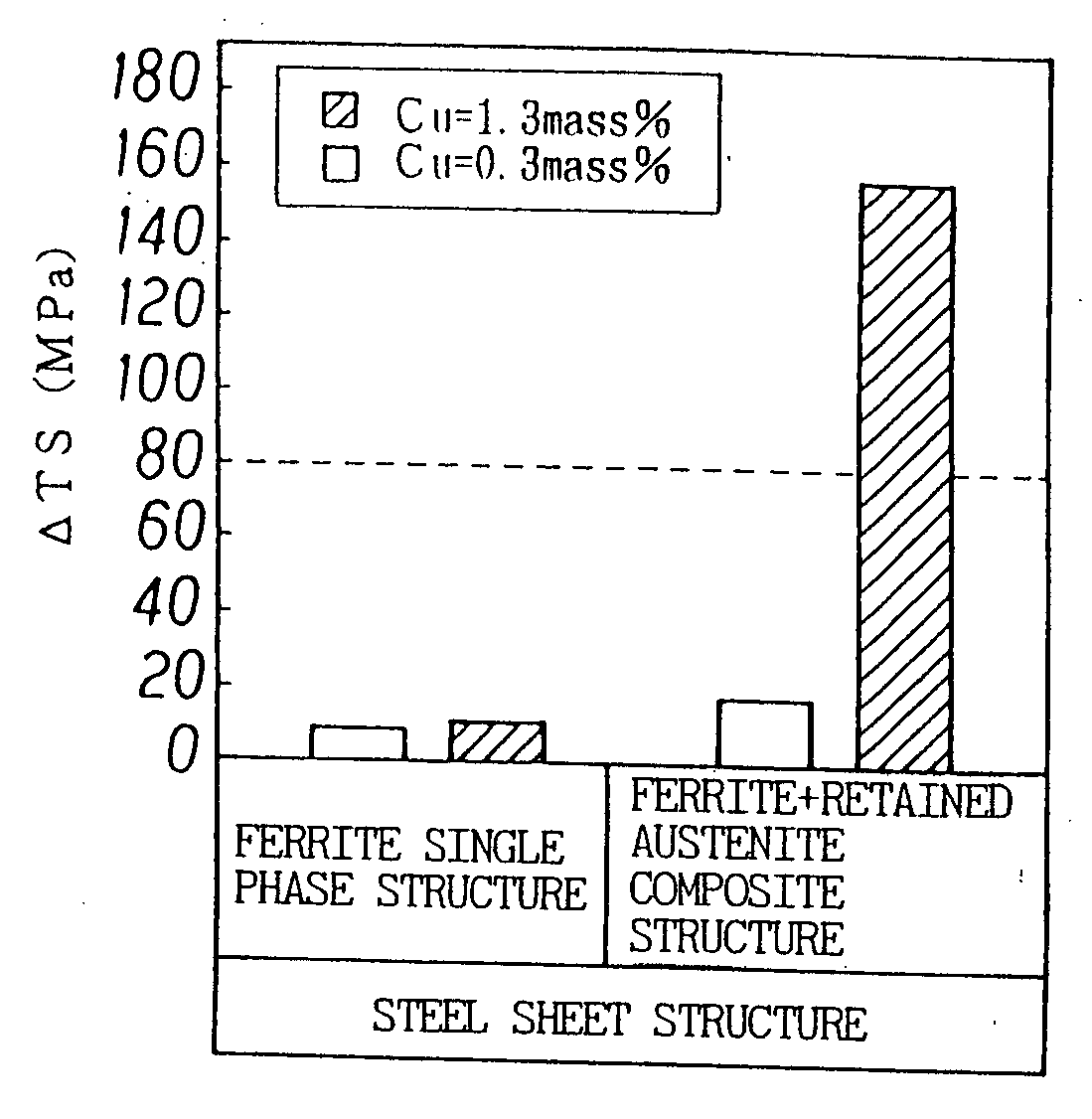

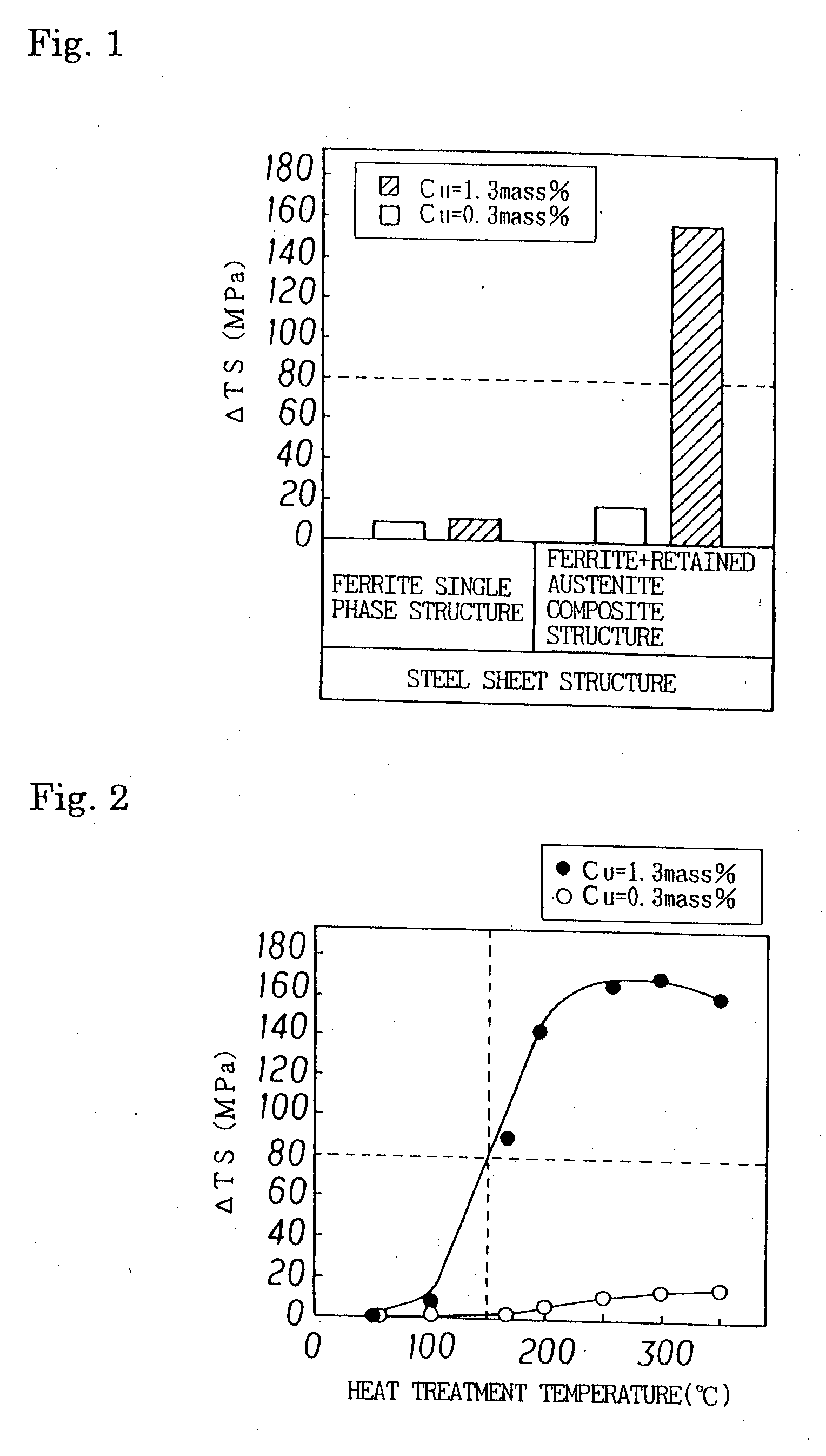

Hot rolled steel plate, cold rolled steel plate and hot dip galvanized steel plate being excellent in strain aging hardening characteristics, and method for their production

InactiveUS20030111144A1Improve stamping formabilityGood strainHot-dipping/immersion processesFurnace typesSheet steelChemical composition

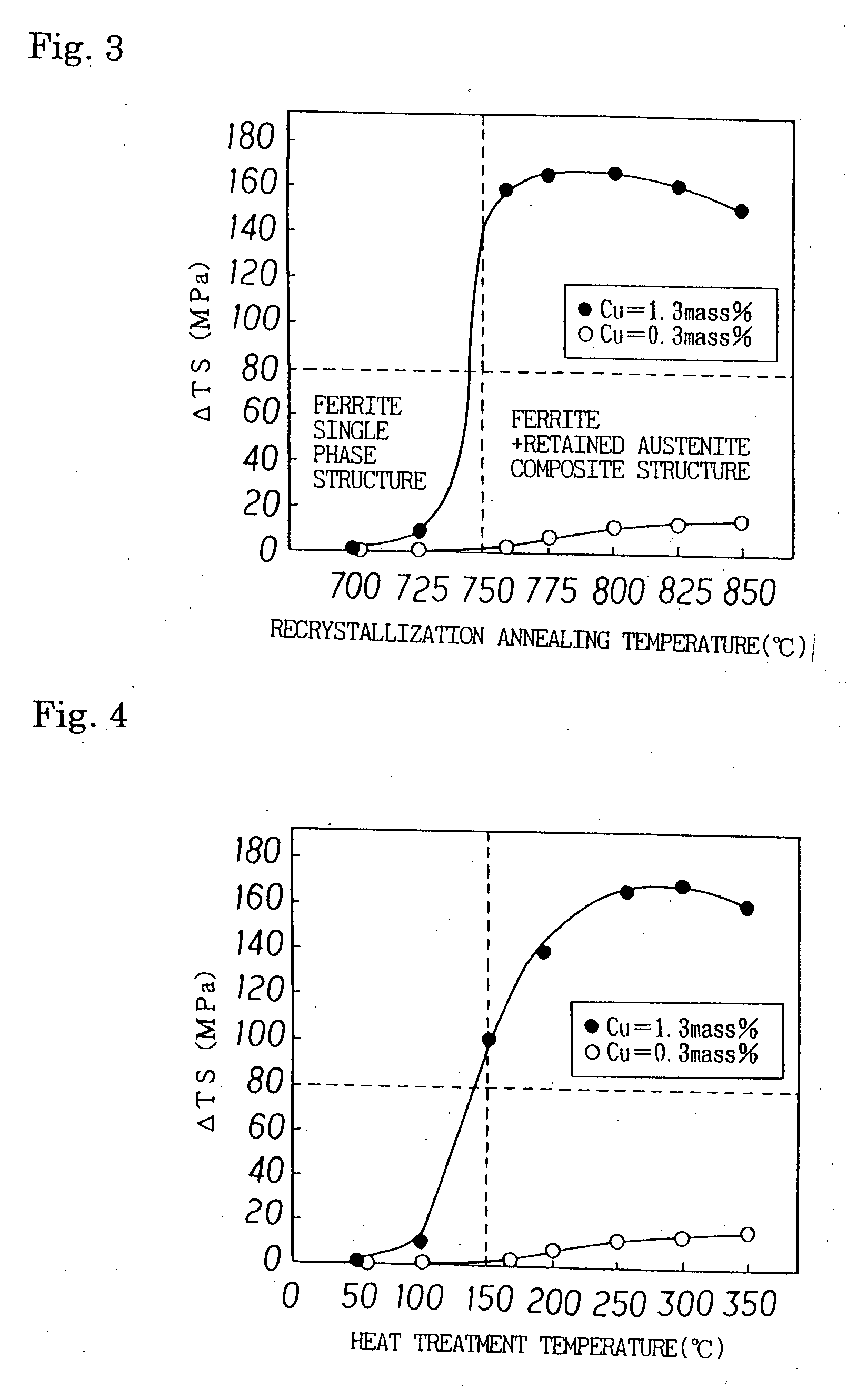

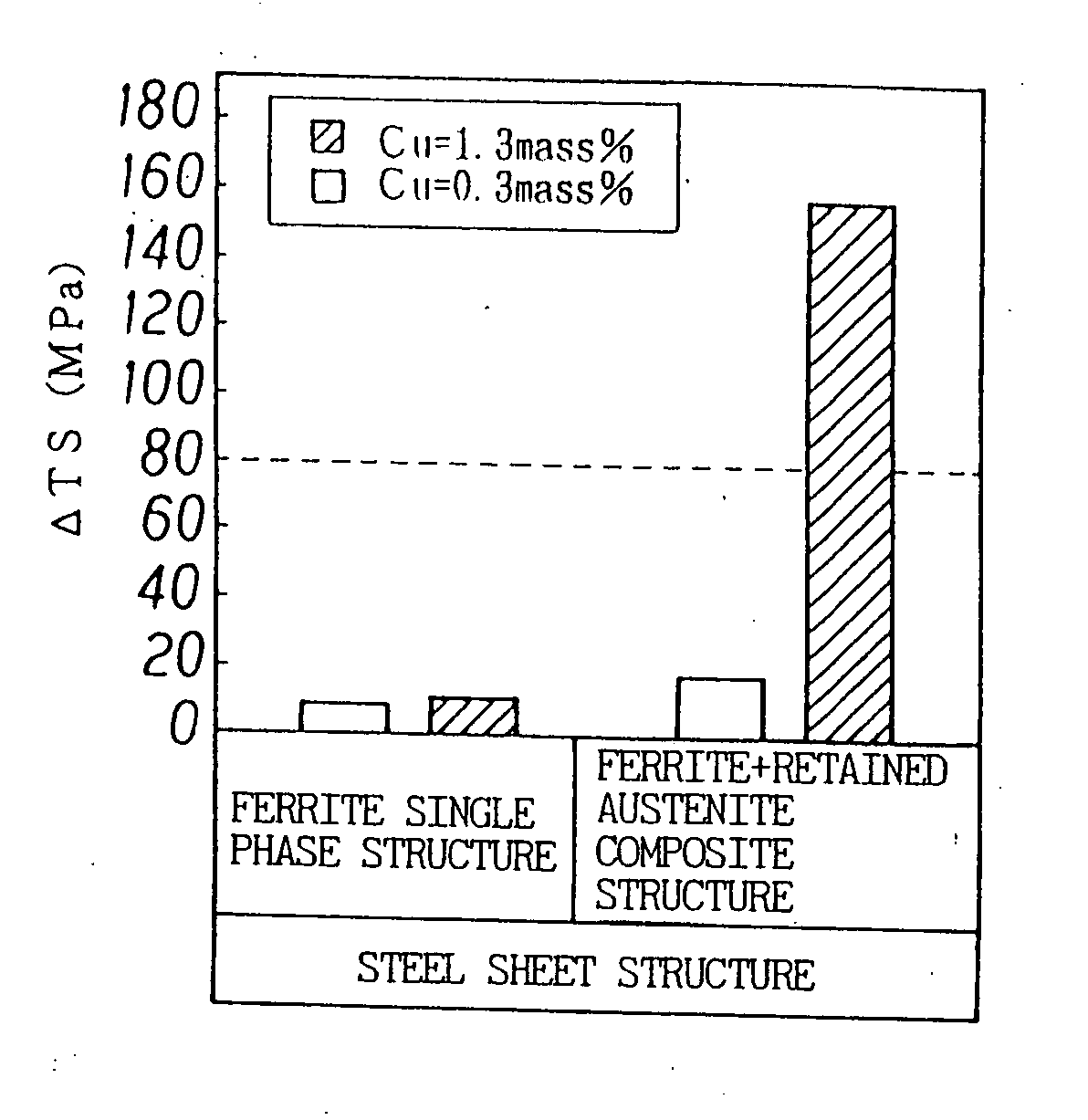

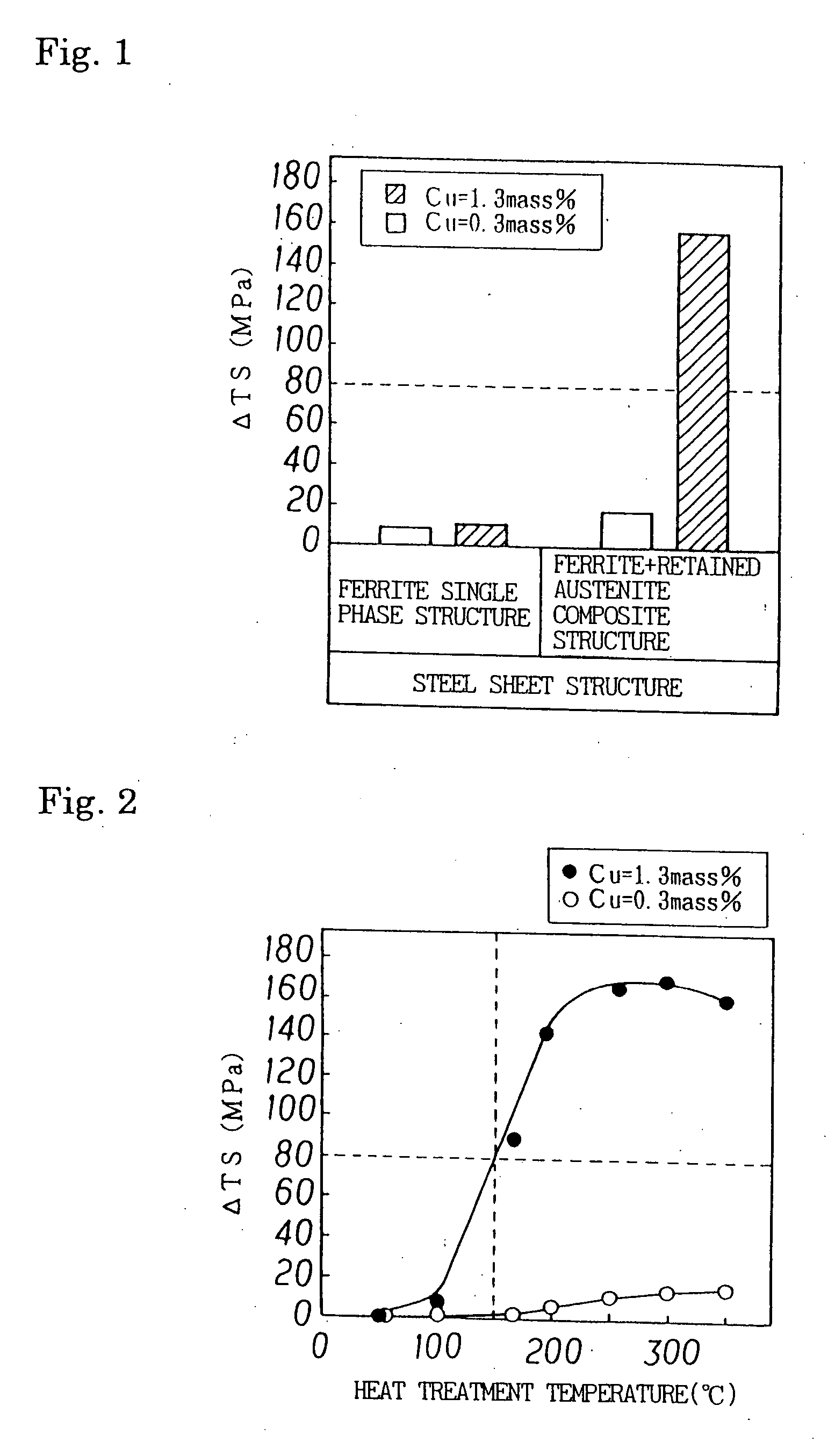

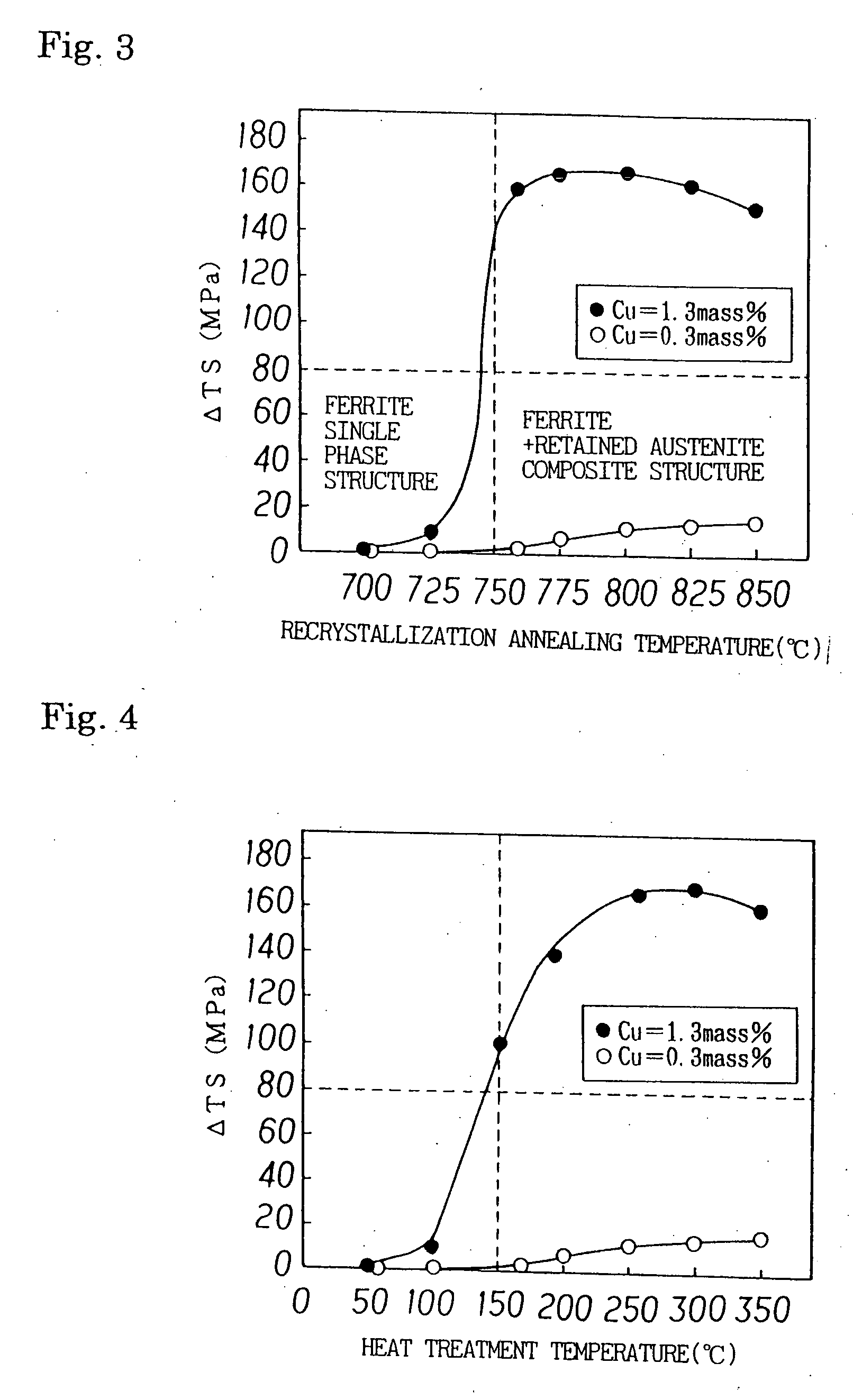

The present invention provides a steel sheet having a chemical composition comprising 0.15% or less C, 2.0% or less Si, 3.0% or less Mn, P, S, Al and N in adjusted amounts, from 0.5 to 3.0% Cu, or one or more of Cr, Mo and W in a total amount of 2.0% or less, and having a composite structure comprising ferrite and martensite having an area ratio of 2% or more. The steel sheet is in the form of a high-strength hot-rolled steel sheet, a high-strength cold-rolled steel sheet, or a hot-dip galvanized steel sheet. There is thus available a steel sheet excellent in press-formability and in strain age hardening property as represented by a DELTATS of 80 MPa or more.

Owner:JFE STEEL CORP

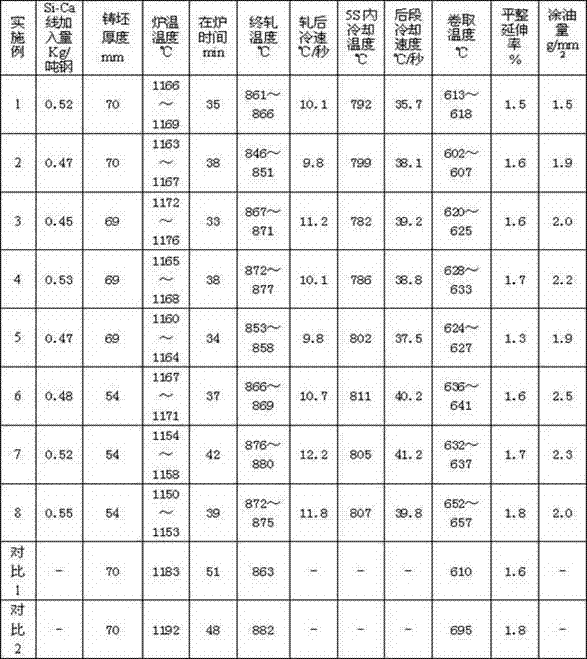

Low-temperature continuous-annealing interstitial-free atom cold-rolled steel plate and production method thereof

ActiveCN102653839ALower recrystallization temperatureRealize the structureChemical compositionReduction ratio

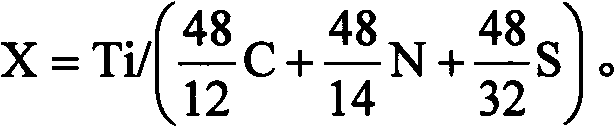

The invention relates to a low-temperature continuous-annealing interstitial-free atom cold-rolled steel plate and a production method thereof and belongs to the technical field of iron-based alloys. The production method of the cold-rolled steel plate comprises the following steps of: controlling the components of the cold-rolled steel plate in percentage by mass: 0.0005-0.0025% of C, less than or equal to 0.03% of Si, 0.05-0.15% of Mn, less than or equal to 0.015% of P, less than or equal to 0.01% of S, less than or equal to 0.0025% of O, less than or equal to 0.0025% of N, 0.015-0.050% of Al, 0.03-0.07% of Ti, and the balance of Fe and inevitable mixed elements; and meanwhile, controlling the continuous-annealing temperature of the cold-rolled steel plate to be 710-740 DEG C, and controlling the cold-rolling reduction ratio to be not less than 80%. According to the cold-rolled steel plate and the production method thereof, the reasonable chemical components and the suitable control of cold-rolling reduction are adopted, the recrystallization temperature is lowered, full-old-rolled microstructures are formed, and a lower continuous-annealing temperature can be adapted, so that the equipment cost and energy consumption are reduced, the control difficulty of a production process is reduced, the product defects and production accidents are avoided.

Owner:SHANGHAI MEISHAN IRON & STEEL CO LTD

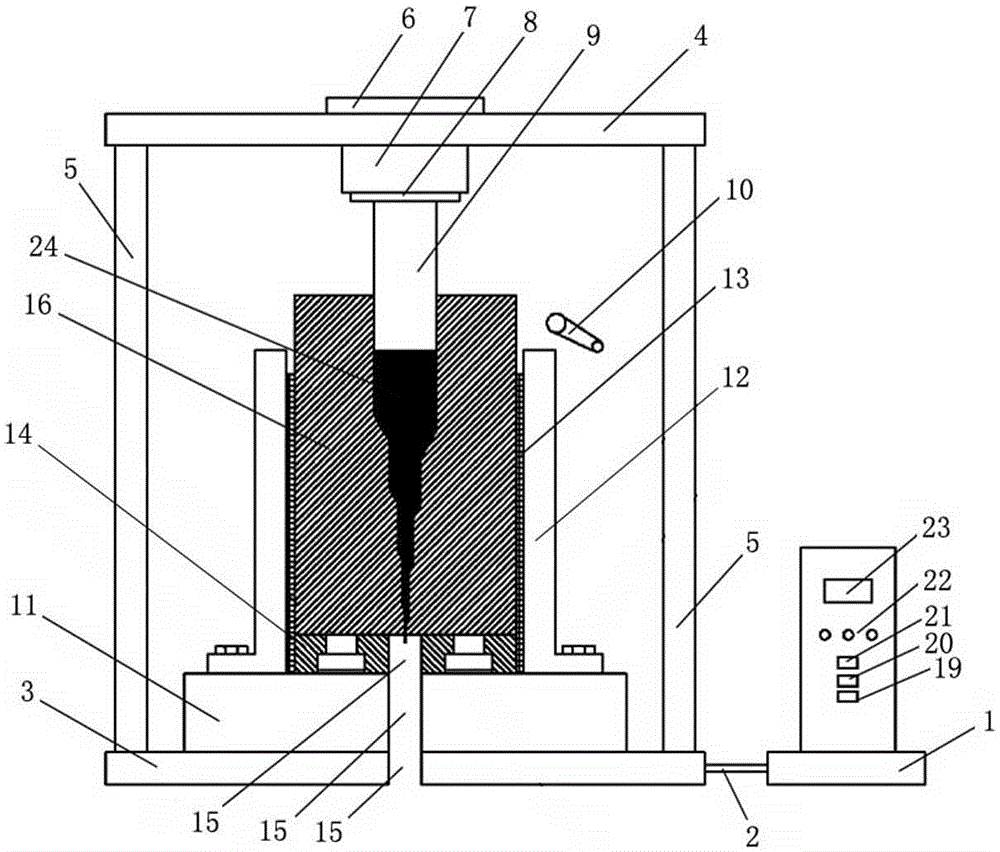

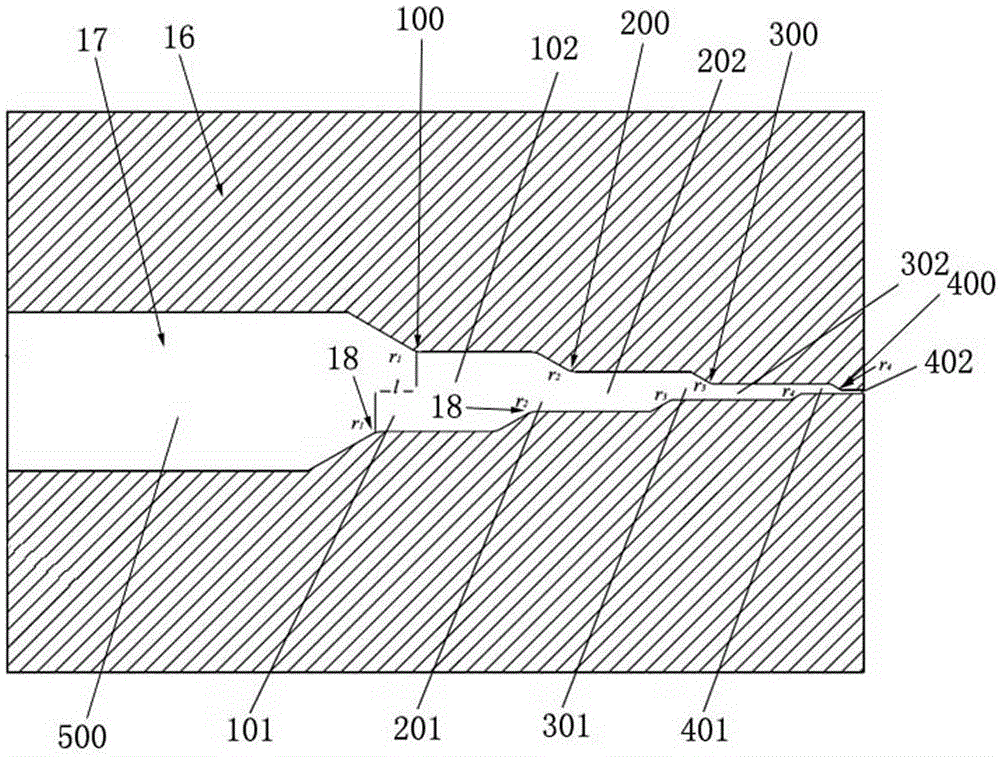

Continuous extrusion machining device used for magnesium alloy sheet strip with weak basal texture and extrusion machining method

ActiveCN105032964AAverage grain size reductionHigh strengthExtrusion diesAsymmetric distributionMachining process

The invention relates to a continuous extrusion machining device used for a magnesium alloy sheet strip with a weak basal texture and an extrusion machining method. The device comprises an extrusion system mainly composed of a pressure motor, an extrusion telescopic head, a male die and a female die, and multiple inclined steps gradually getting close to the axis of a die cavity are arranged at the two sides below the upper middle portion in the die cavity of the female die and are distributed asymmetrically. In the extrusion machining process, a magnesium alloy blank is placed in the die cavity of the female die and extruded by the descending male die, and as the male die descends continuously, the magnesium alloy blank is gradually thinned to form a magnesium alloy sheet with the weak basal texture. Due to step-by-step grain refinement and basal texture weakening, extrusion force in the extrusion process is greatly reduced, the average grain size of the magnesium alloy is greatly reduced compared with that of a magnesium alloy extruded normally, and the (0002) basal texture is reduced to 8.2 from 27.6 compared with that of a sheet obtained through normal extrusion.

Owner:TAIYUAN UNIV OF TECH

Thin hot-rolled pickled steel with good formability and production method thereof

ActiveCN102787270AReduce the difficulty of productionImprove surface qualityMetal rolling arrangementsChemical compositionHigh pressure water

The invention relates to a thin hot-rolled pickled steel with good formability, which comprises the following chemical components by weight percent (wt%): 0.04-0.07% of C, 0.10-0.30% of Si, 0.41-0.60% of Mn, 0.025% of P or less, 0.012% of S and 0.010-0.030% of Als. The preparation method of the thin hot-rolled pickled steel with good formability comprises the following steps: desulphurizing molten iron, smelting by a converter, alloying, treating by a ladle furnace, casting and rolling continuously, dephosphorizing high-pressure water, controlling rolling, cooling by laminar flow, curling, pickling by acid levelling and finishing adopting static oil removal. The produced hot-rolled pickled steel which has the tensile strength of 370MPa or higher and the thickness of 1.8 mm or lower, is low production difficulty and good in surface quality and is convenient to weld, oil and paint. In addition, the thin hot-rolled pickled steel has the advantages of good punch formability, high forming size accuracy, short production cycle, high yield and low cost.

Owner:武汉钢铁有限公司

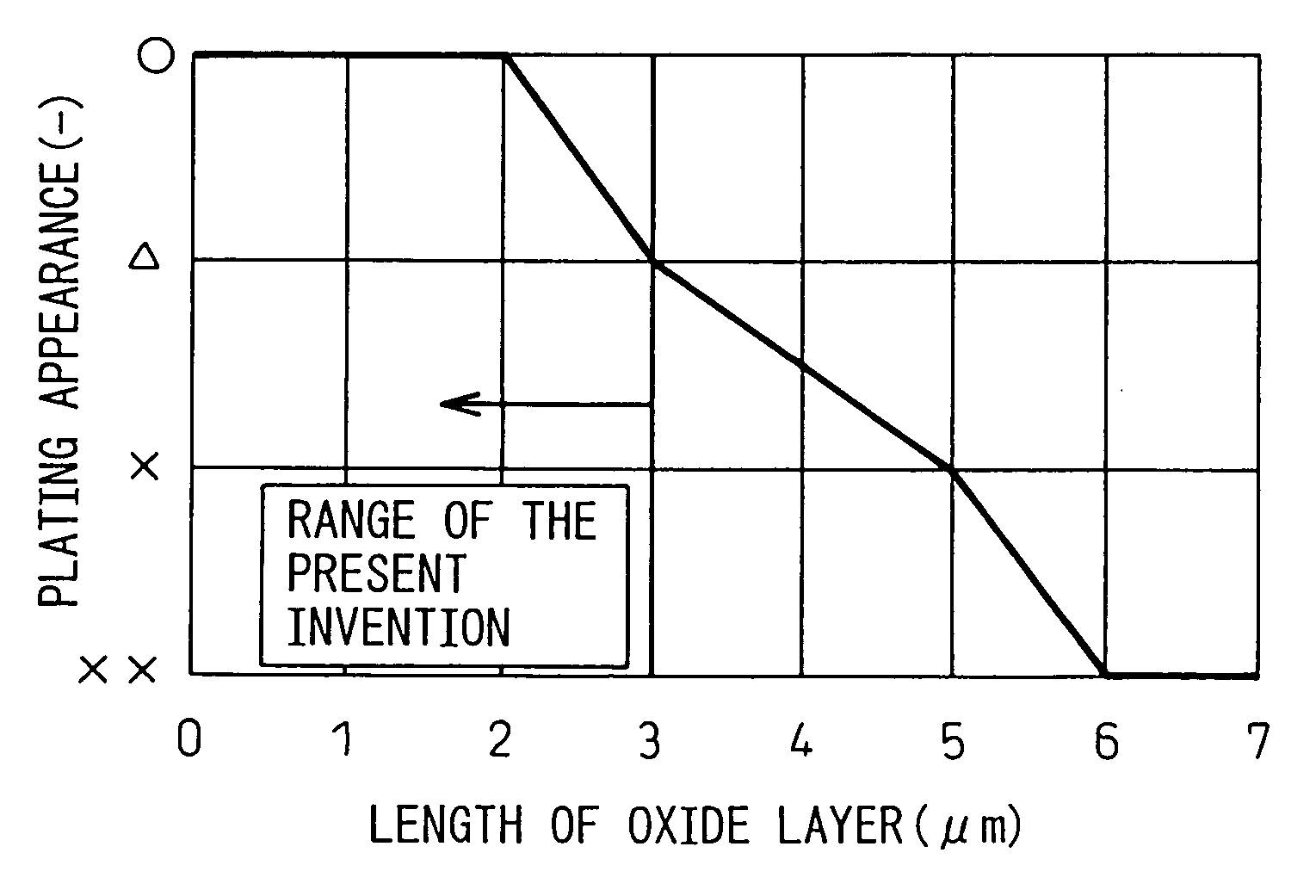

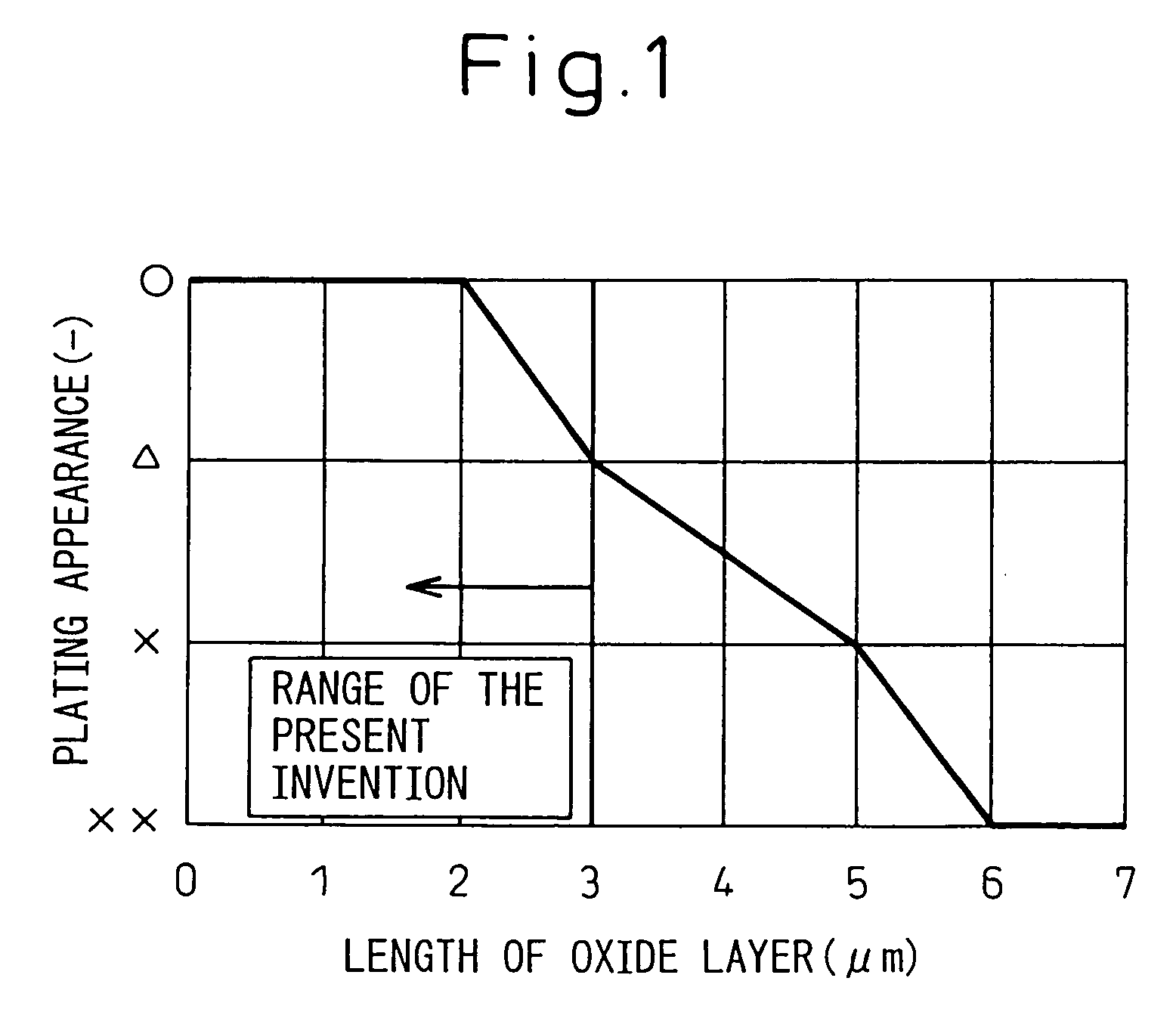

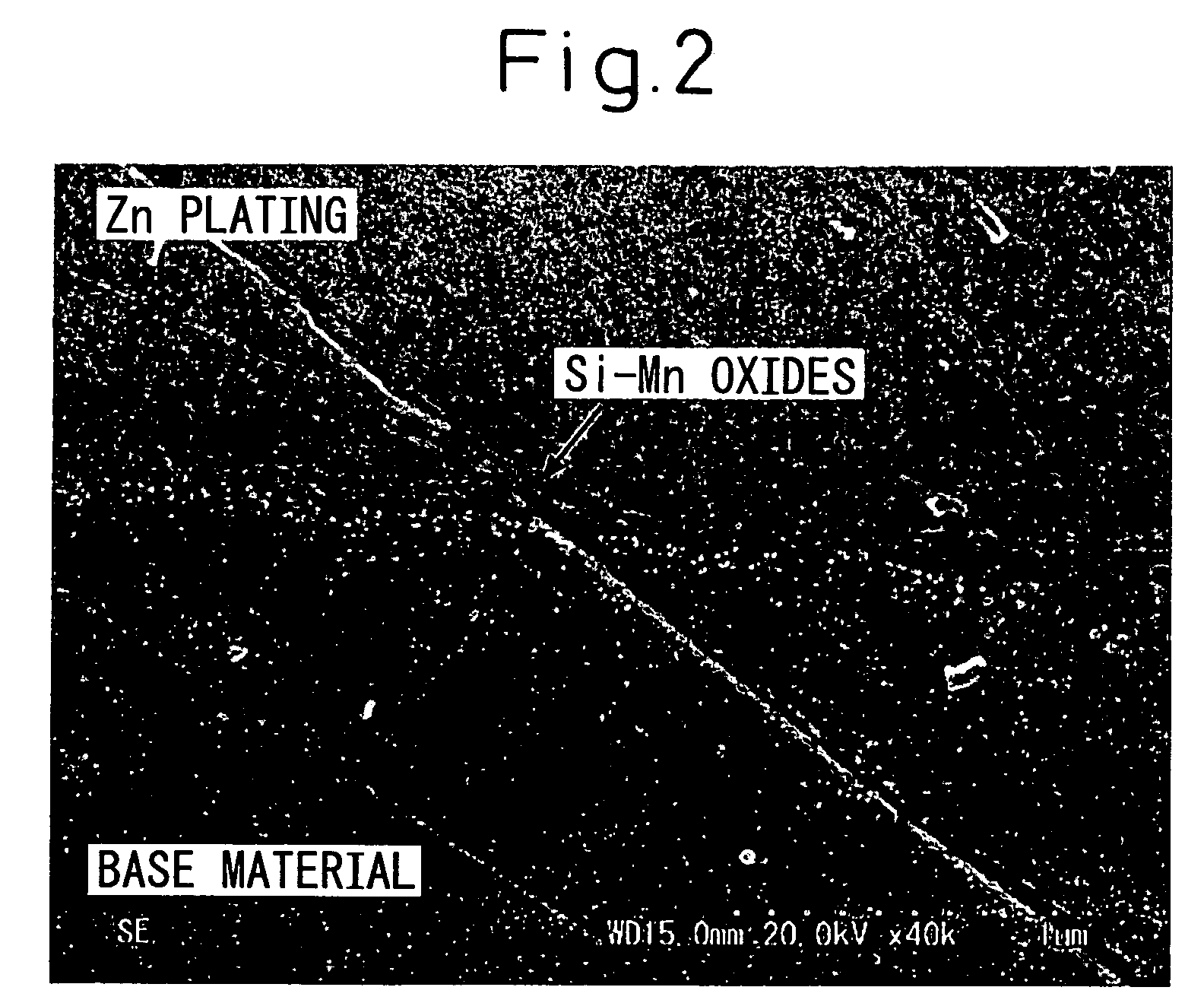

High strength hot-dip galvanized or galvannealed steel sheet having improved plating adhesion and press formability and process for producing the same

InactiveUS6911268B2Improve stamping formabilityImprovement in surface corrosionHot-dipping/immersion processesFurnace typesCeriumAustenite

Disclosed are a high strength hot-dip galvanized or galvannealed steel sheet, which has improved press formability and plating adhesion and is useful as a member for automobile, building, electric or other members, and a process for producing the same.This high strength hot-dip galvanized or galvannealed steel sheet comprises: (a) a steel sheet substrate comprising, by weight, carbon (C): 0.05 to 0.2%, silicon (Si): 0.2 to 2.0%, manganese (Mn): 0.2 to 2.5%, and aluminum (Al): 0.01 to 1.5%, the silicon and the aluminum having a mutual relationship represented by formula 0.4(%)≦Si+0.8 Al (%)≦2.0(%), the steel sheet substrate further comprising at least one member selected from the group consisting of (i) 0.003 to 1.0% of tin (Sn), (ii) 0.005 to 1.0% in total of at least one member selected from antimony (Sb), bismuth (Bi), and selenium (Se), (iii) 0.005 to 1.0% in total of at least one member selected from beryllium (Be), magnesium (Mg), calcium (Ca), and zirconium (Zr), and (iv) 0.005 to 1.0% in total of at least one member selected from scandium (Sc), yttrium (Y), lanthanum (La), and cerium (Ce), with the balance consisting of iron (Fe) and unavoidable impurities, the volume fraction of retained austenite in the steel structure being 2 to 20%; and (b) a zinc (Zn) coating layer provided on said steel sheet substrate.

Owner:NIPPON STEEL CORP

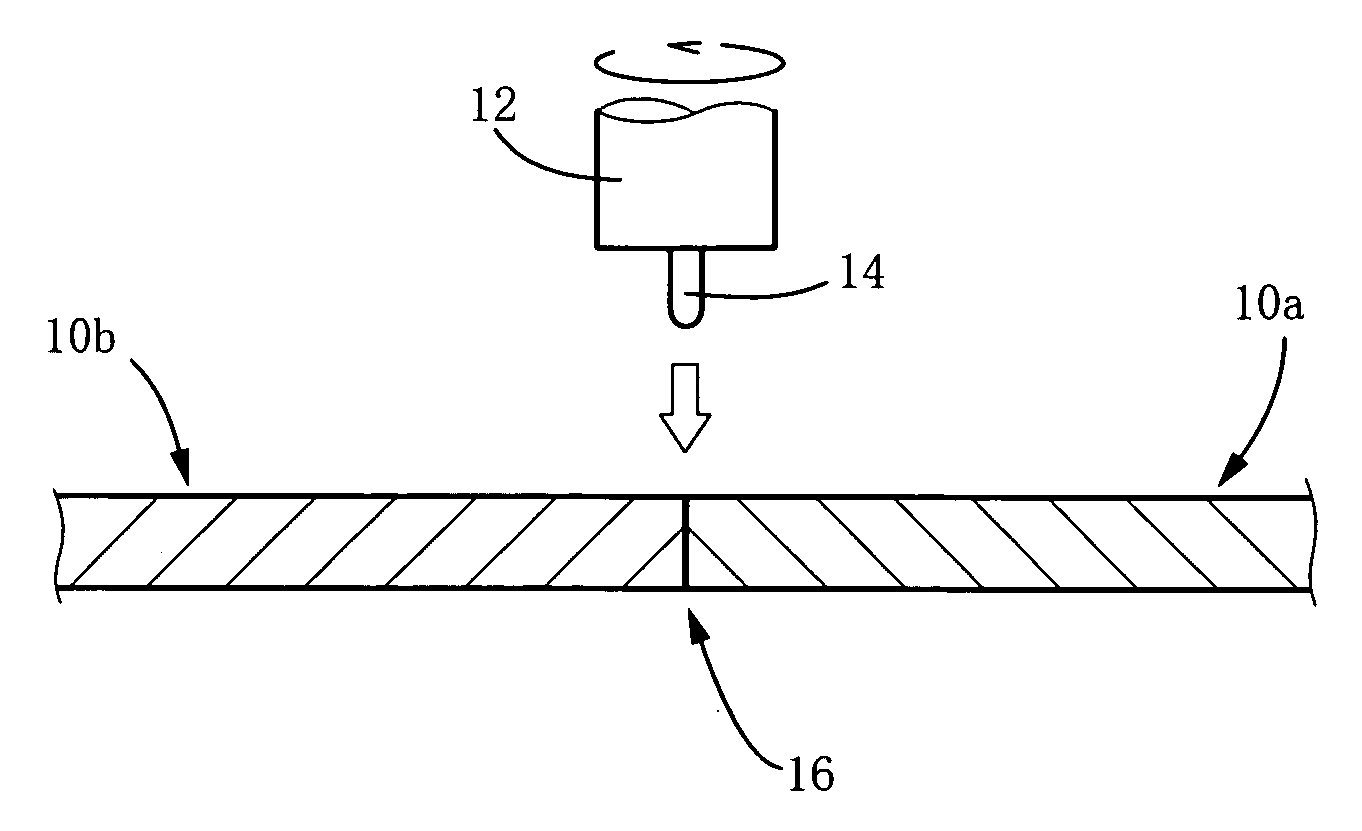

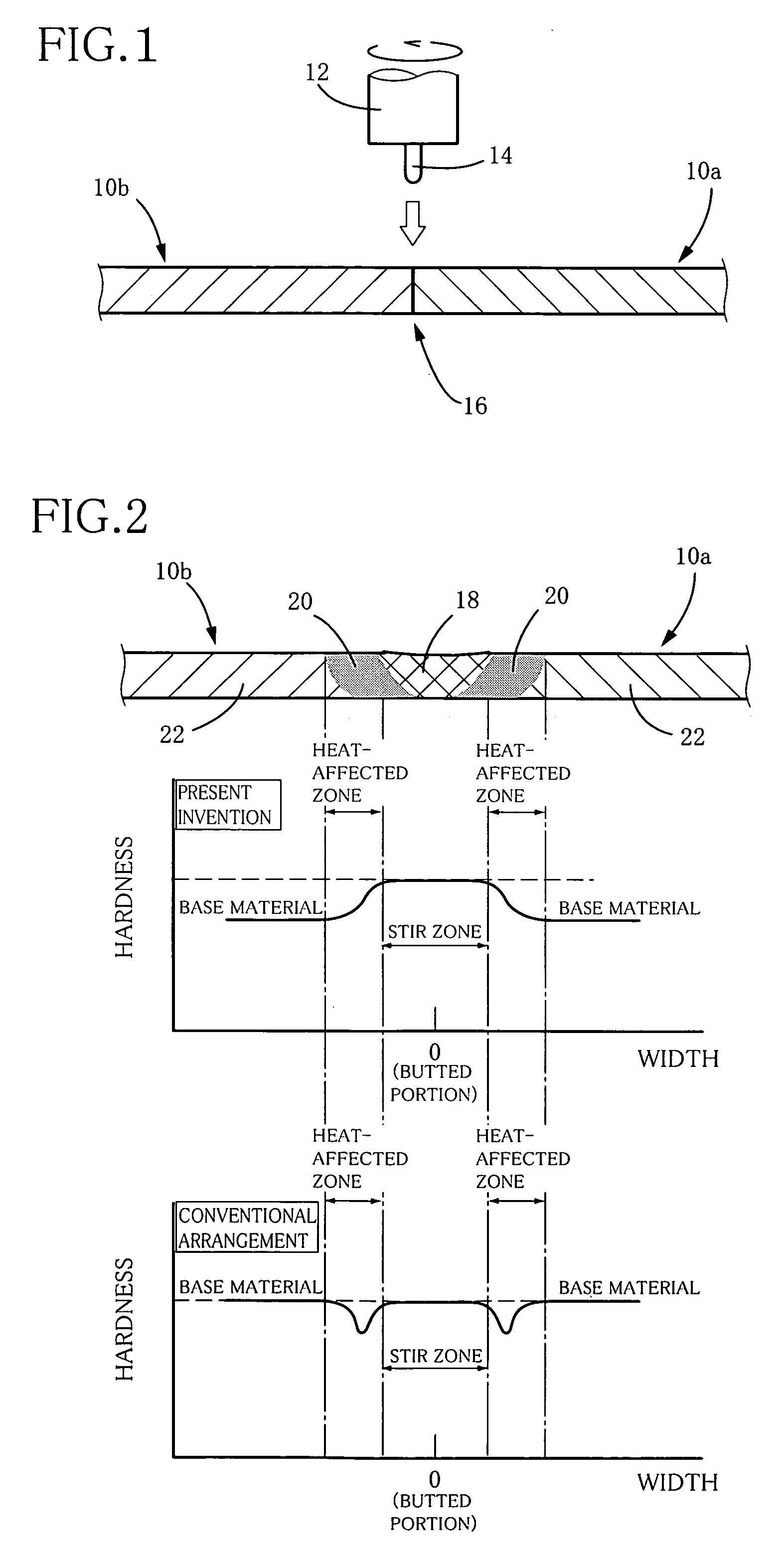

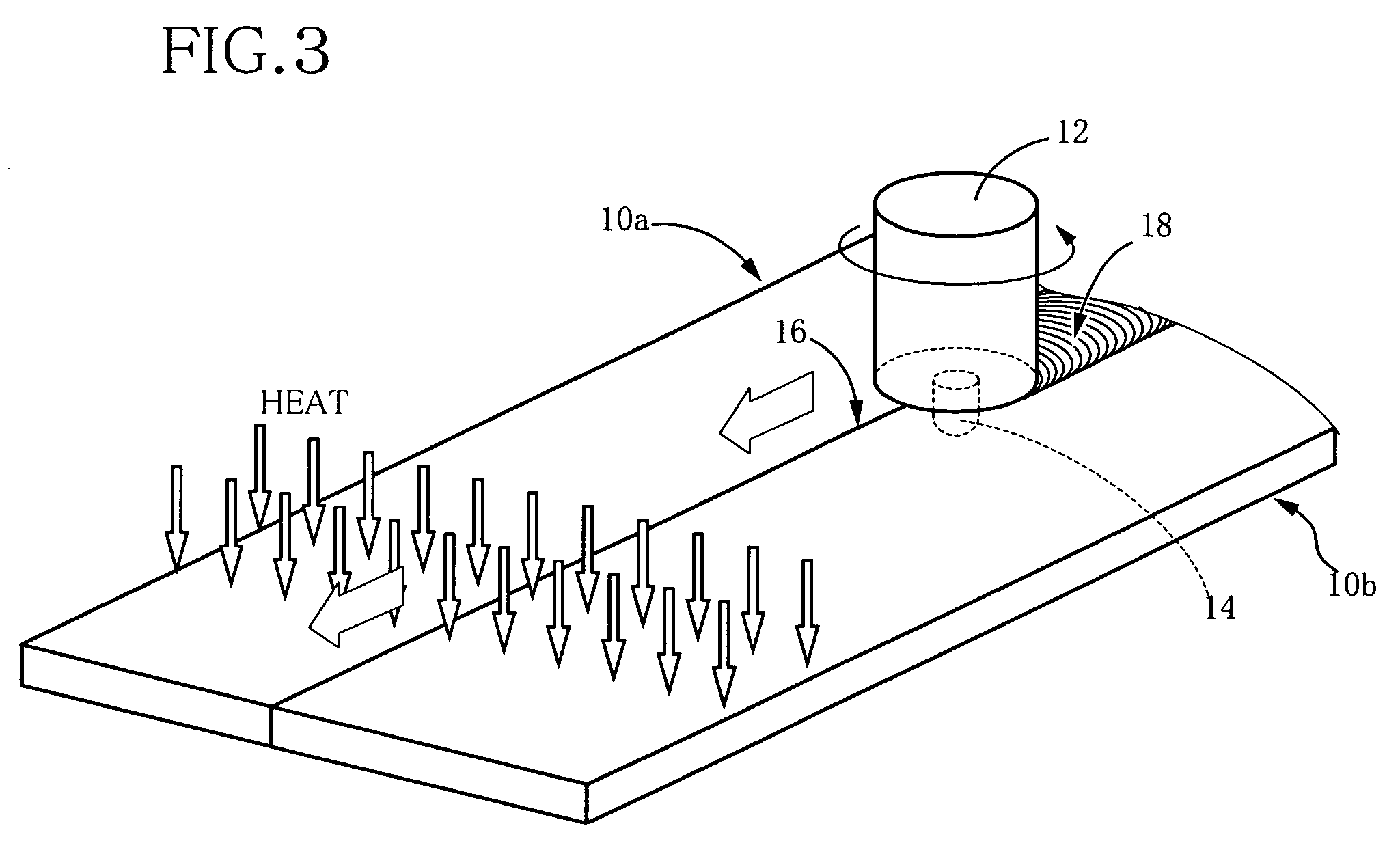

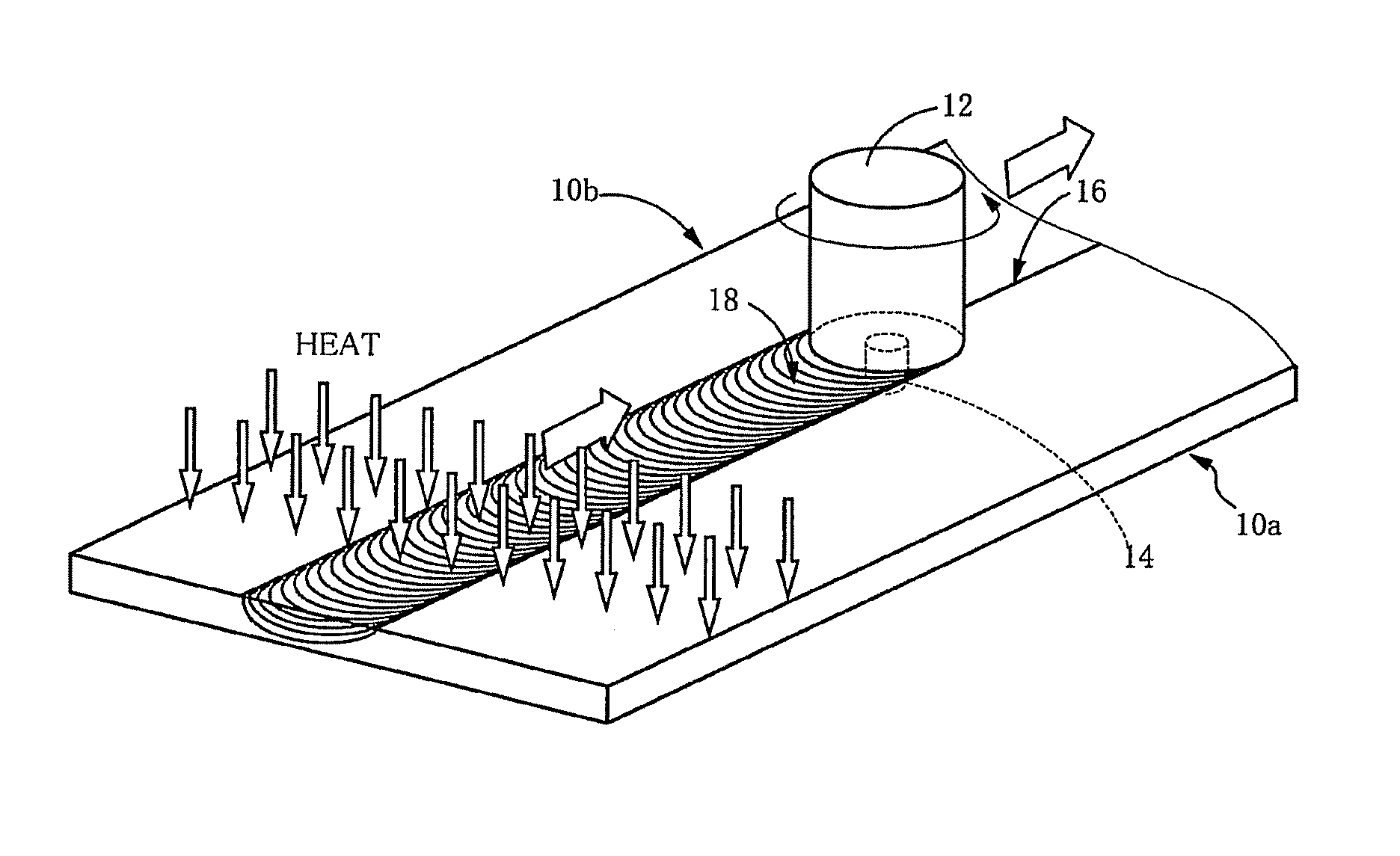

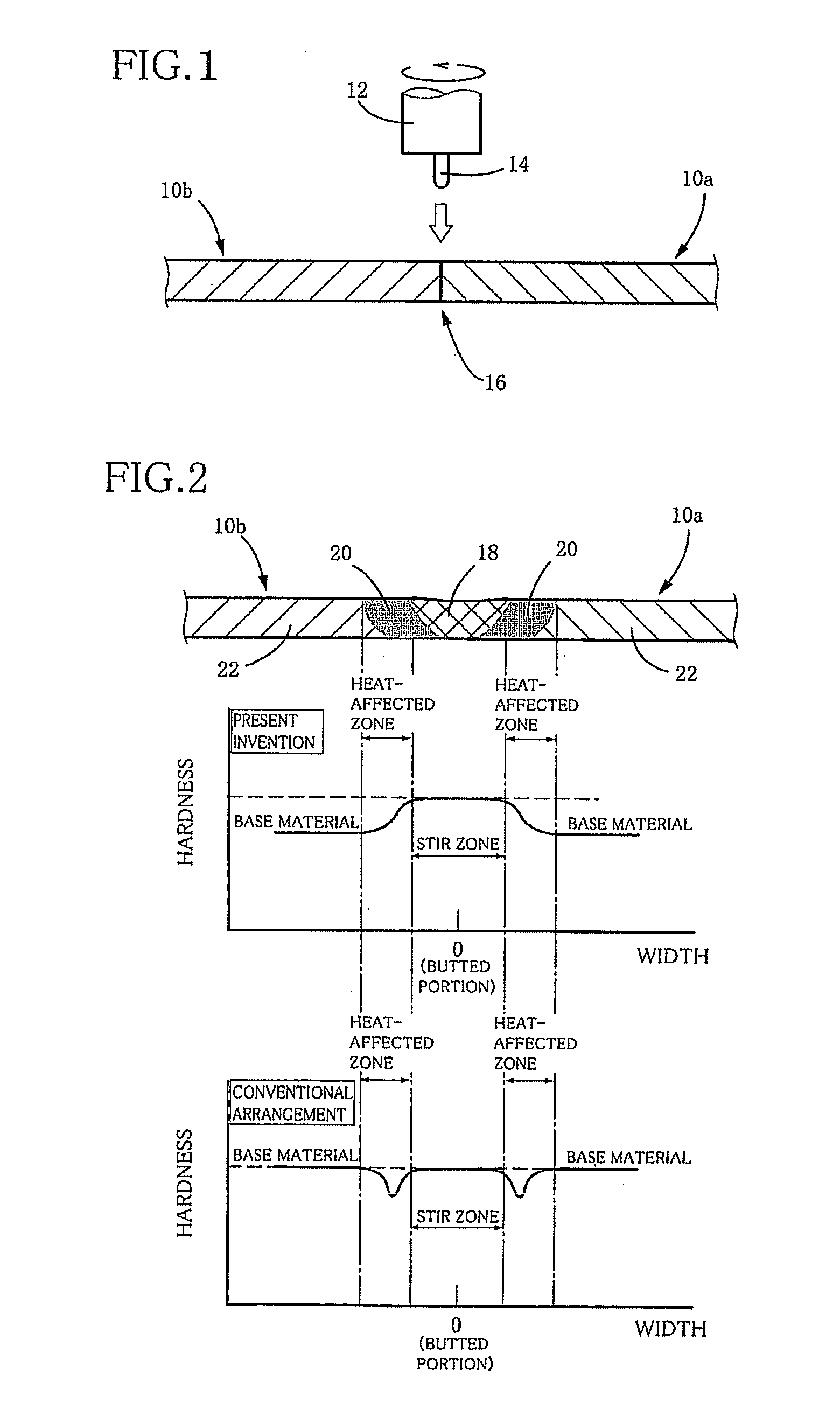

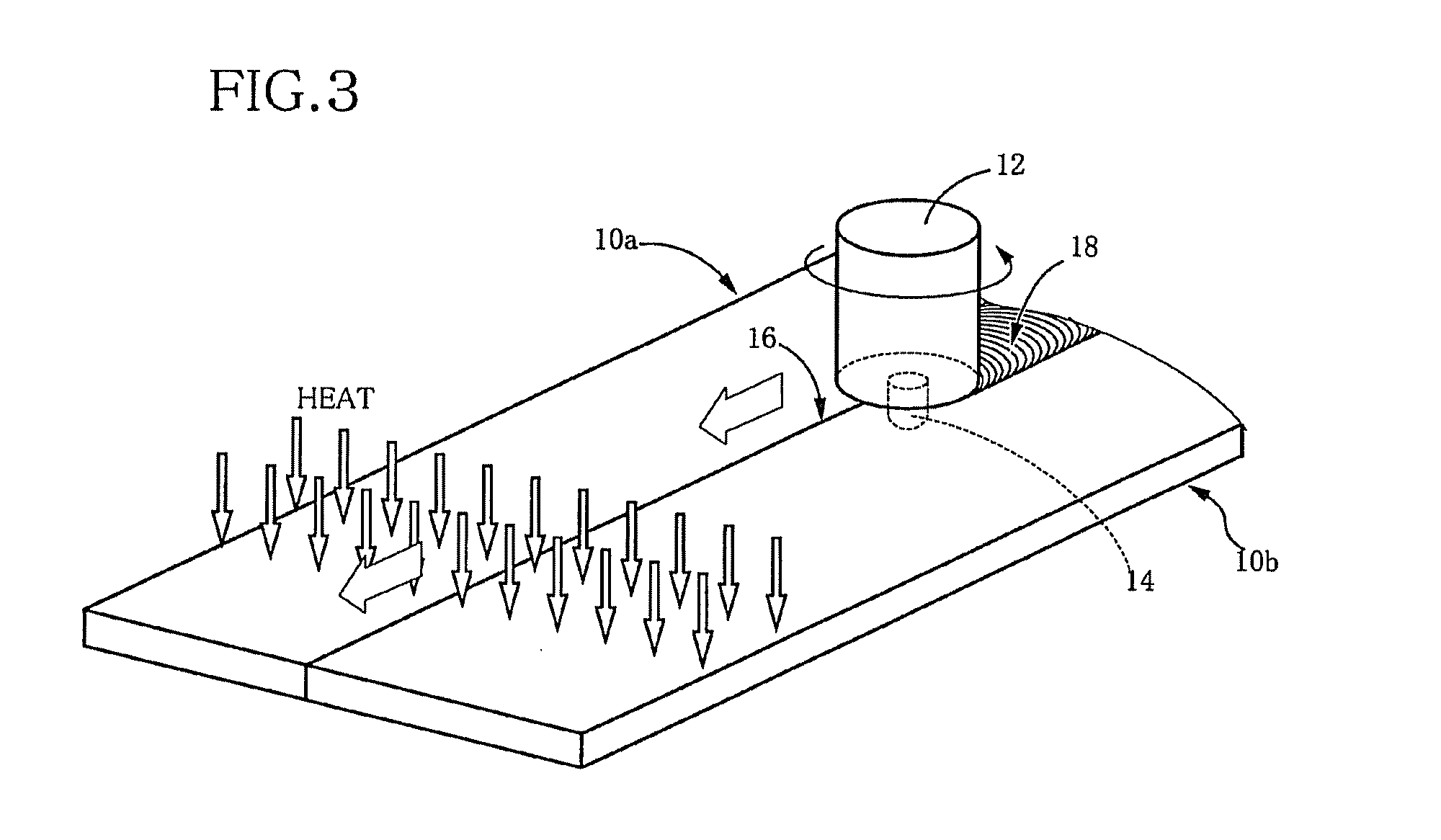

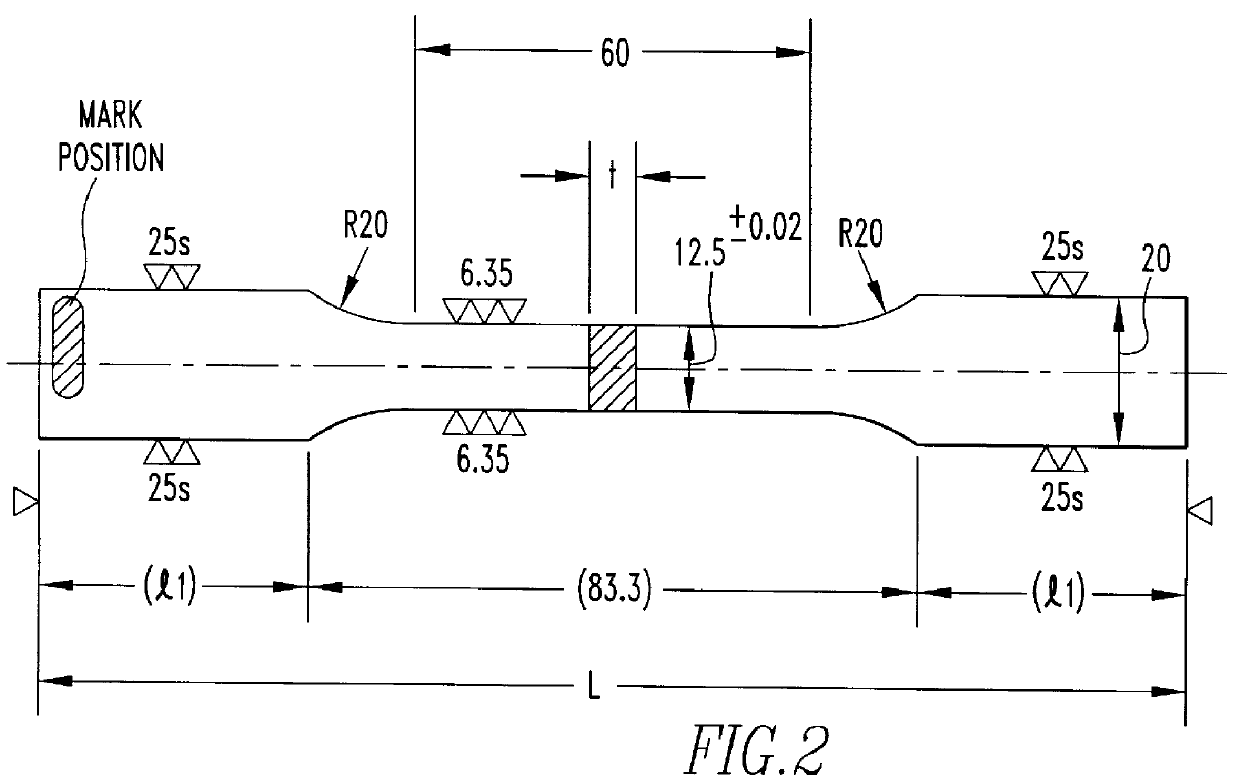

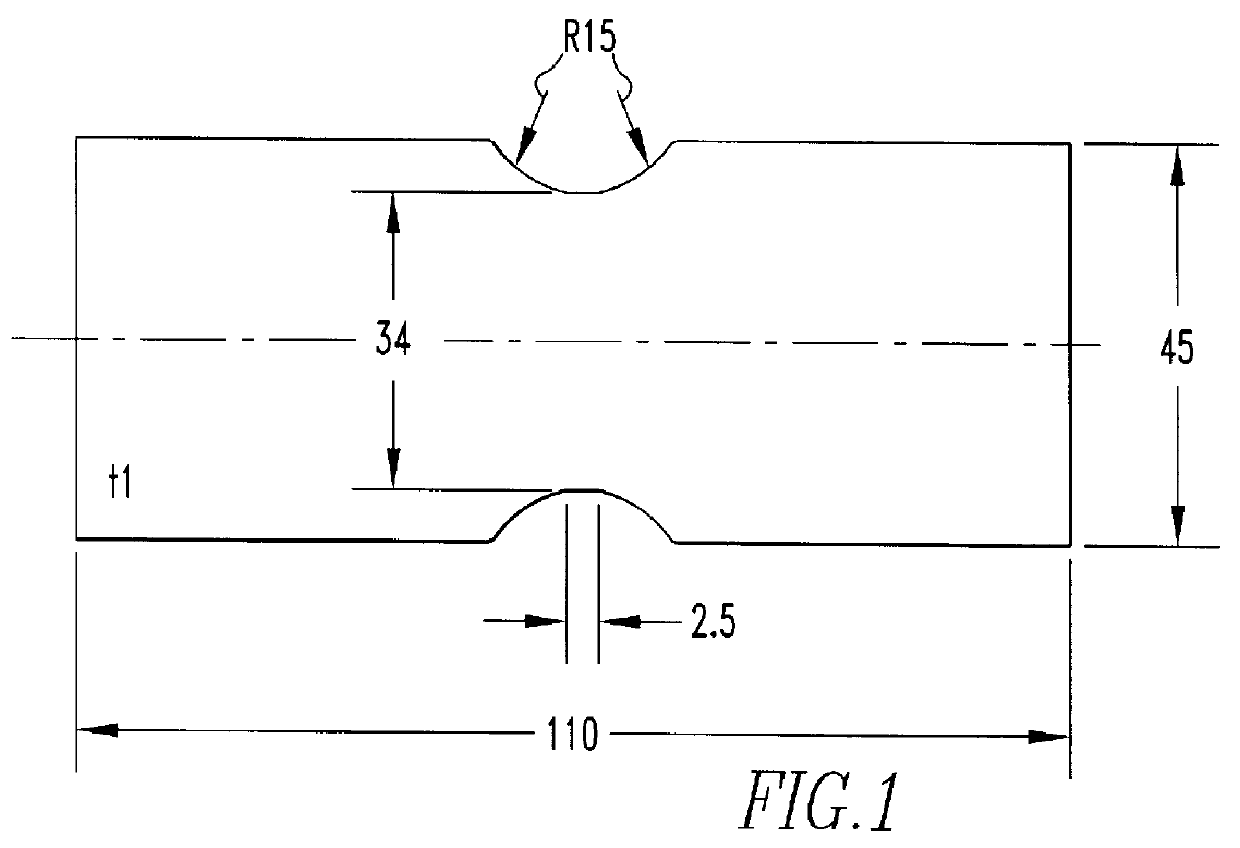

Method of joining heat-treatable aluminum alloy members by friction stir welding and joined product obtained by the method and used for press forming

InactiveUS20070138239A1Avoid stress concentrationReduce hardnessWelding/cutting media/materialsWelding/soldering/cutting articlesFriction stir weldingHeat treating

A method of joining heat-treatable aluminum alloy members by friction stir welding, including the steps of: a T4-treatment-performing step of performing a T4 treatment on heat-treatable aluminum alloy members so as to impart T4 temper to the heat-treatable aluminum alloy members; a joining step of joining the heat-treatable aluminum alloy members with T4 temper by friction stir welding to provide a joined product; and a reversion-treatment-performing step of performing a reversion treatment, the reversion-treatment-performing step being carried out prior to or after the joining step.

Owner:SUMITOMO LIGHT METAL INDS LTD

Hot rolled steel plate surface oxidation iron sheet control method for vanadium-containing automobile beam

InactiveCN101147920AImprove toughnessImprove stamping formabilityTemperature control deviceSurface oxidationImpurity

The present invention discloses a surface scale control method of hot-rolled steel plate for vanadium-bearing automobile frame. It is characterized by that the mass percentage of molten steel chemical components of raw material steel of said method is as follows: C is 0.06%-0.12%, Si is less than or equal to 0.30%, Mn is 1.05%-1.25%, V is 0.04%-0.10%, P is less than or equal to 0.025%, S is less than or equal to 0.015% and the rest is Fe and other impurity. Its slab drop-out temperature is controlled at 1200deg.C-1230deg.C, initial temperature of rough rolling is controlled at 940deg.C-1020deg.C and its final rolling temperature range, is 840deg.C-880deg.C.

Owner:PANZHIHUA IRON & STEEL RES INST OF PANGANG GROUP

High-ductility steel sheet excellent in press formability and strain age hardenability, and method for manufacturing the same

InactiveUS20050016644A1Stable productionImprove stamping formabilityHot-dipping/immersion processesThin material handlingMartensiteUltimate tensile strength

A steel sheet composition contains appropriate amounts of C, Si, Mn, P, S, Al and N and 0.5 to 3.0% Cu. A composite structure of the steel sheet has a ferrite phase or a ferrite phase and a tempered martensite phase as a primary phase, and a secondary phase containing retained austenite in a volume ratio of not less than 1%. In place of the Cu, at least one of Mo, Cr, and W may be contained in a total amount of not more than 2.0%. This composition is useful in production of a high-ductility hot-rolled steel sheet, a high-ductility cold-rolled steel sheet and a high-ductility hot-dip galvanized steel sheet having excellent press formability and excellent stain age hardenability as represented by a ΔTS of not less than 80 MPa, in which the tensile strength increases remarkably through a heat treatment at a relatively low temperature after press forming.

Owner:JFE STEEL CORP

High-ductility steel sheet excellent in press formability and strain age hardenability, and method for manufacturing the same

InactiveUS20050019601A1Stable productionImprove stamping formabilityHot-dipping/immersion processesThin material handlingMartensiteUltimate tensile strength

A steel sheet composition contains appropriate amounts of C, Si, Mn, P, S, Al and N and 0.5 to 3.0% Cu. A composite structure of the steel sheet has a ferrite phase or a ferrite phase and a tempered martensite phase as a primary phase, and a secondary phase containing retained austenite in a volume ratio of not less than 1%. In place of the Cu, at least one of Mo, Cr, and W may be contained in a total amount of not more than 2.0%. This composition is useful in production of a high-ductility hot-rolled steel sheet, a high-ductility cold-rolled steel sheet and a high-ductility hot-dip galvanized steel sheet having excellent press formability and excellent stain age hardenability as represented by a ΔTS of not less than 80 MPa, in which the tensile strength increases remarkably through a heat treatment at a relatively low temperature after press forming.

Owner:JFE STEEL CORP

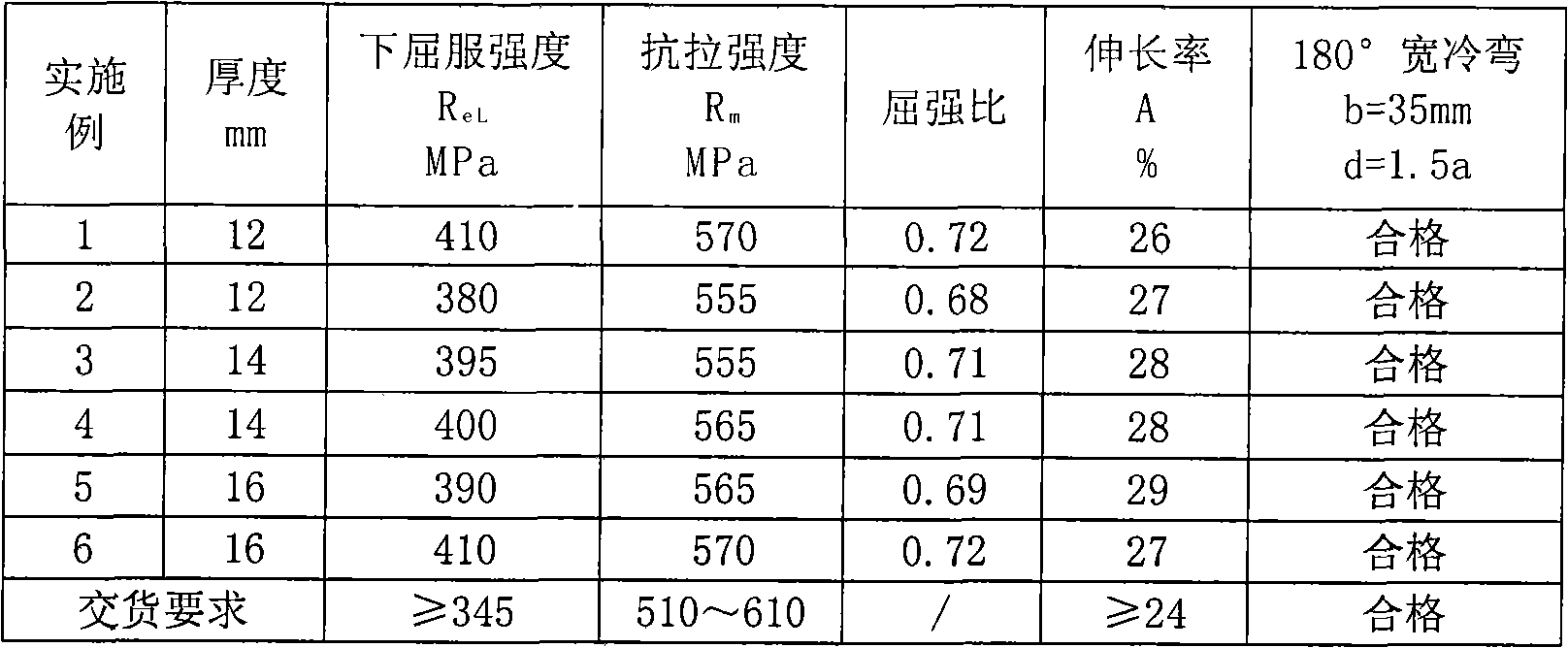

Hot-rolling stamping axle housing steel for automobile with 510Mpa-grade tensile strength and preparation method thereof

InactiveCN101660093AImprove stamping formabilityImprove welding effectTemperature control deviceAxle unitsChemical compositionHigh intensity

The invention relates to hot-rolling stamping axle housing steel for an automobile with 510Mpa-grade tensile strength and a preparation method thereof. The axle housing steel comprises the following chemical components in percentage by weight: 0.12-0.20 percent of C, 0.20-0.60 percent of Si, 1.20-1.60 percent of Mn, less than or equal to 0.030 percent of P, less than or equal to 0.008 percent of S, 0.01-0.06 percent of Als, 0.005-0.030 percent of Ti and the balance of Fe and inevitable impurities. The axle housing steel has high strength, excellent stamping and forming properties and good welding performance, is suitable for hot-rolling forming process and a cold-stamping forming process, and has small rebound during stamping to form and excellent shape keeping performance.

Owner:武钢集团有限公司

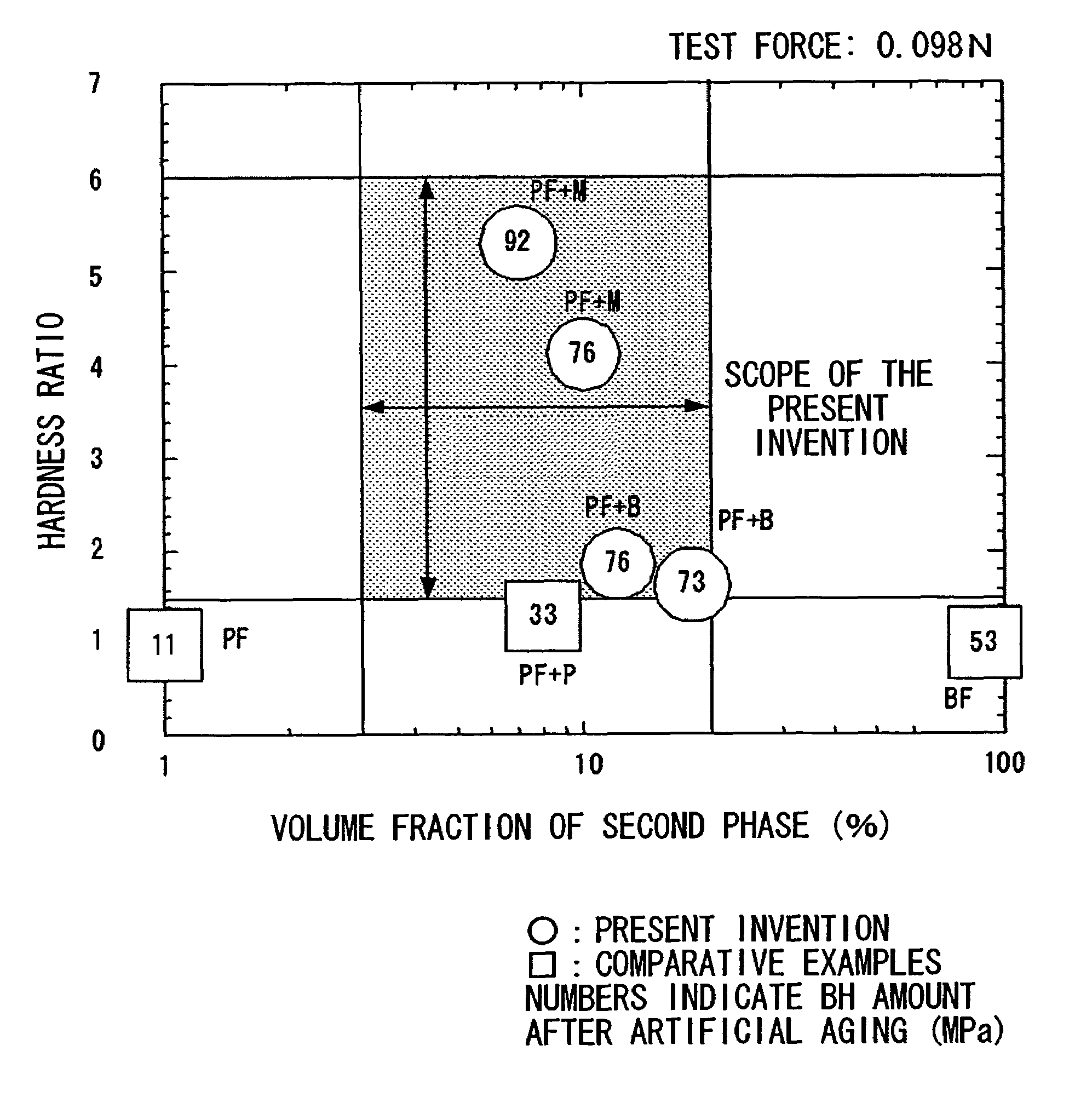

Hot rolled steel sheet for processing and method for manufacturing the same

ActiveUS7381478B2Excellent bake hardenabilityLittle decrease in BH amountHot-dipping/immersion processesFurnace typesHardness ratioSheet steel

An exemplary hot rolled steel sheet for processing can include, in terms of percent by mass, C of 0.01 to 0.2%; Si of 0.01 to 0.3%; Mn of 0.1 to 1.5%; P of ≦0.1%; S of ≦0.03%; Al of 0.001 to 0.1%; N of ≦0.006%; and as a remainder, Fe and unavoidable impurities. The microstructure may include a main phase in the form of polygonal ferrite and a hard second phase, a volume fraction of the hard second phase is 3 to 20%, a hardness ratio (hardness of the hard second phase / hardness of the polygonal ferrite) is 1.5 to 6, and a grain size ratio (e.g., grain size of the polygonal ferrite / grain size of the hard second phase) is 1.5 or more.

Owner:NIPPON STEEL CORP

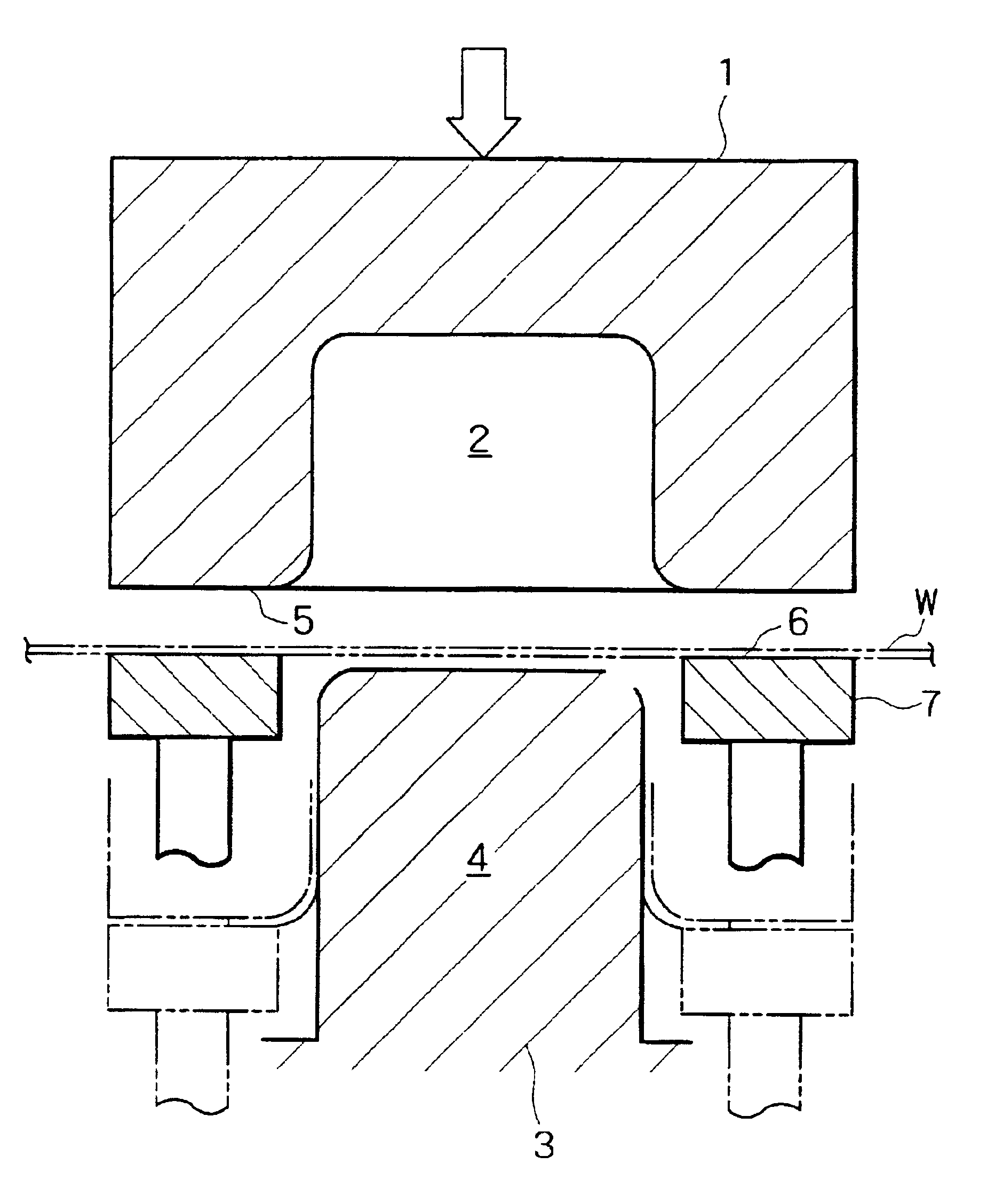

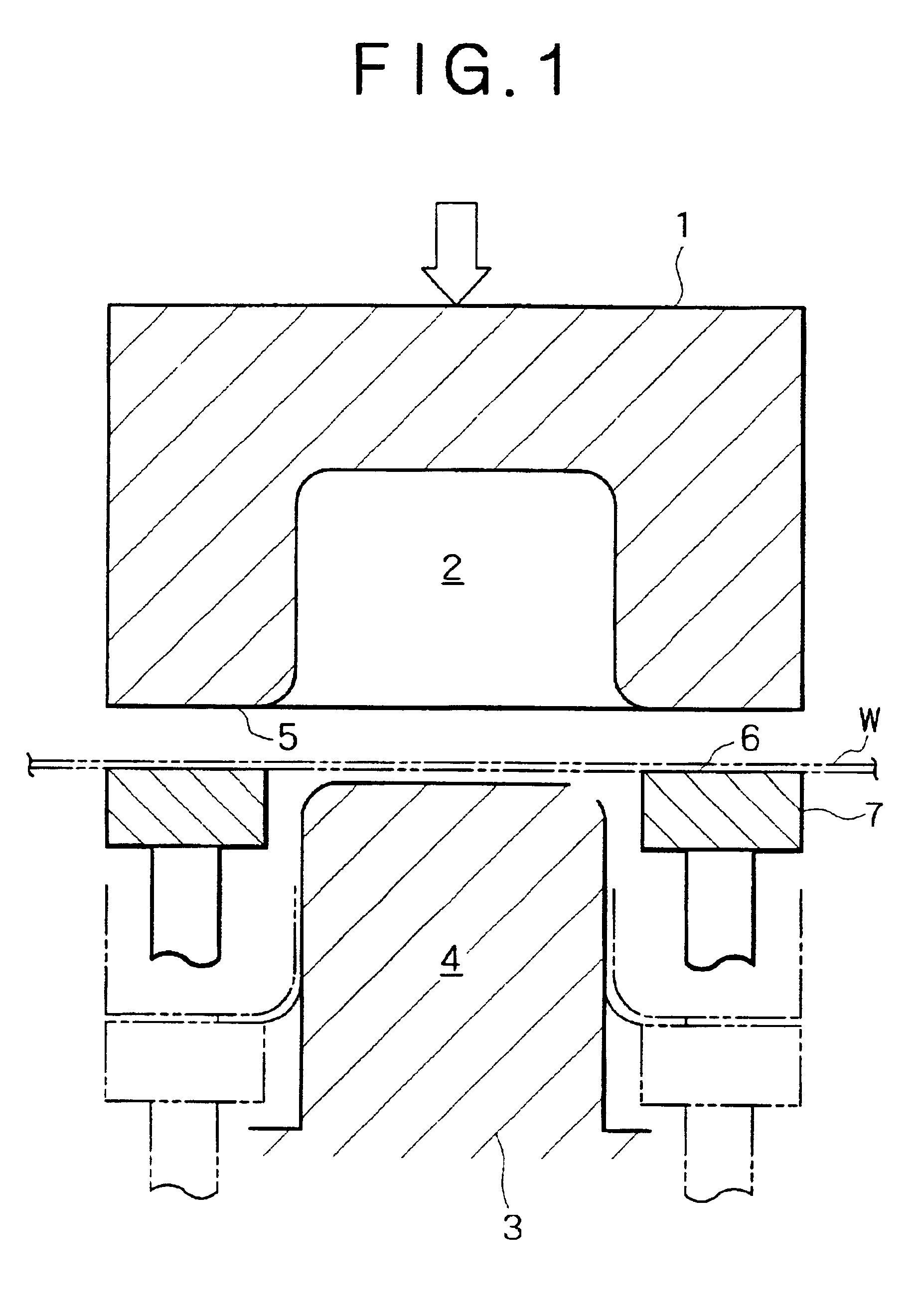

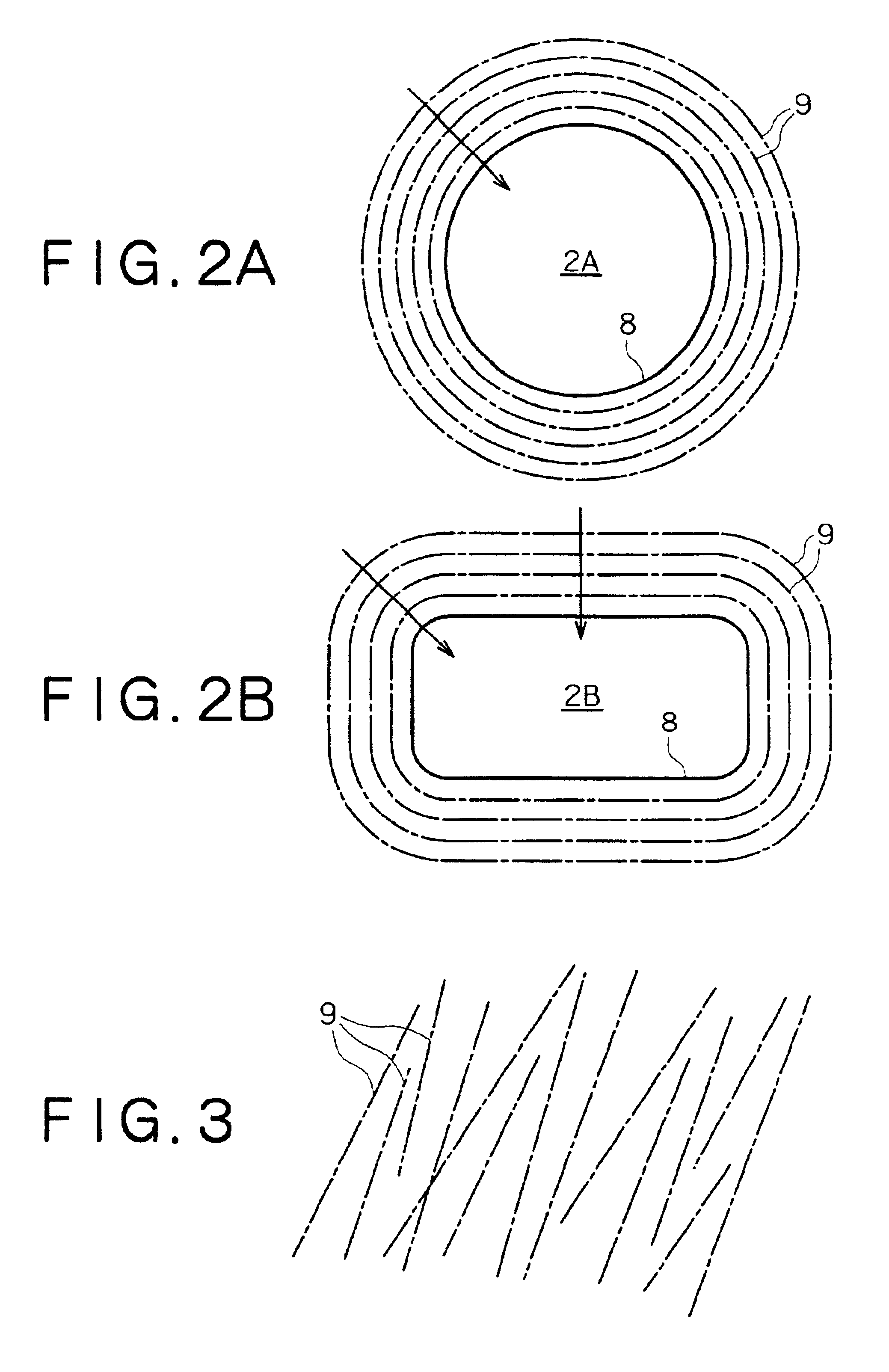

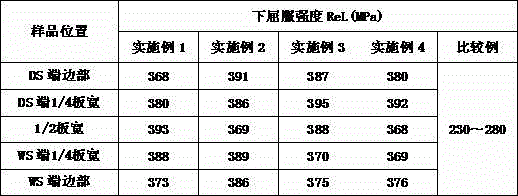

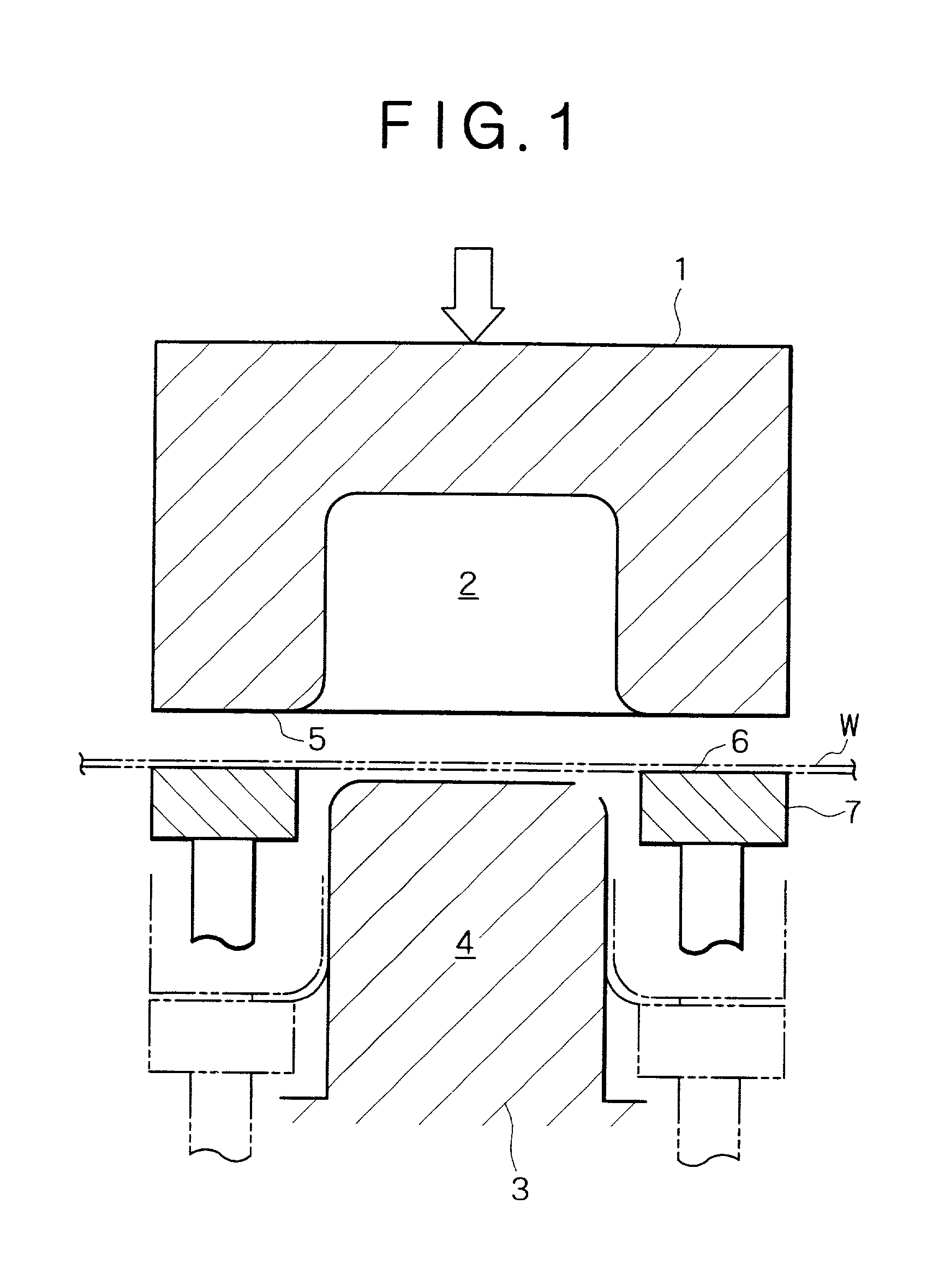

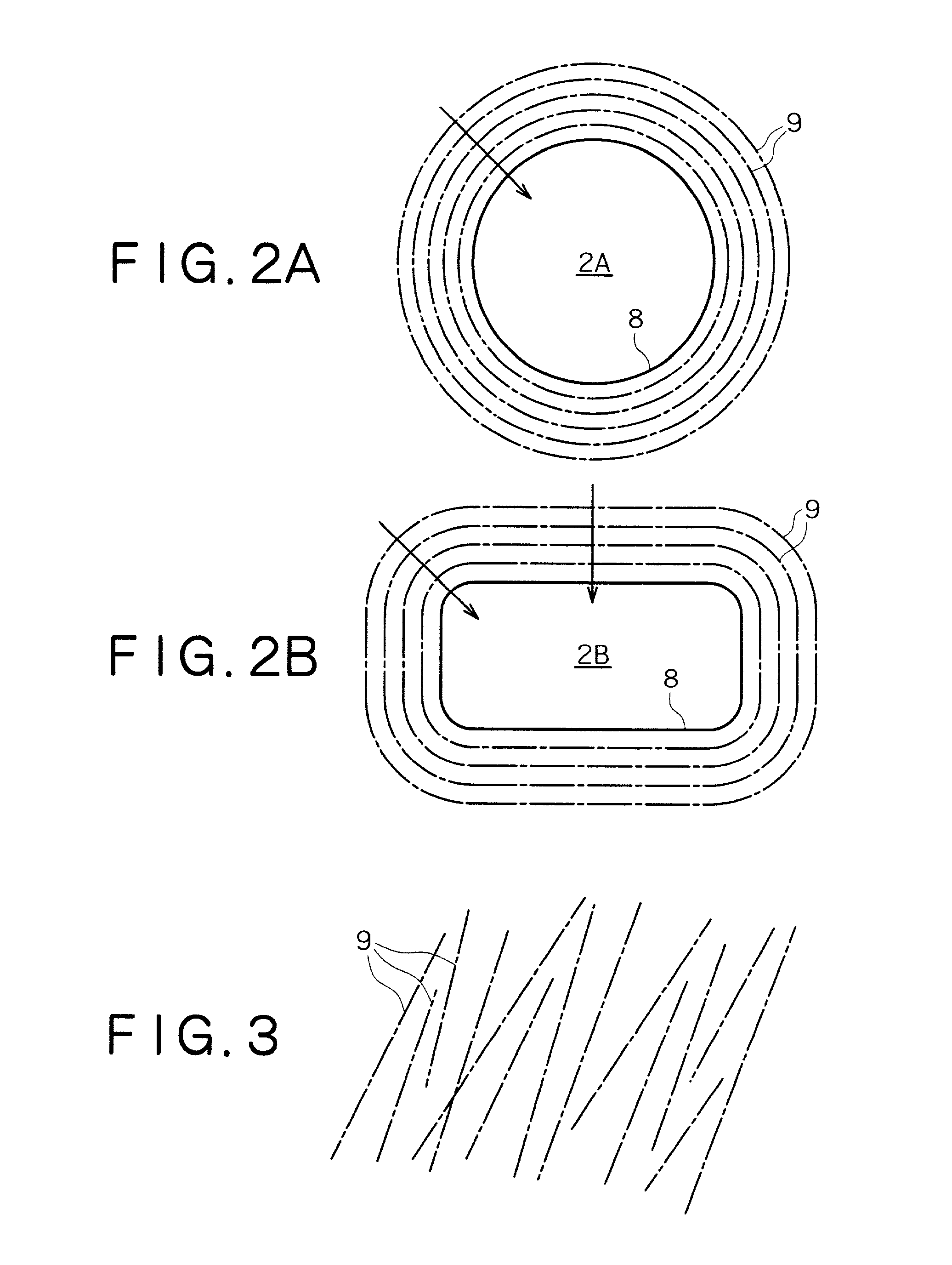

Press die

InactiveUS6807838B2Easy to slidePrevents the blank from becoming thinCeramic shaping apparatusDough shapingEngineeringMechanical engineering

A press die composed of an upper die having a concave part (with the peripheral surface of the opening of said concave part functioning as a first blank pressing face), a lower die having a convex part (to form the blank into a desired form in cooperation with said concave part), and a blank holder (which has a second blank pressing face), said press die working in such a way that said first blank pressing face and said second blank pressing face hold a blank between them while permitting it to flow into said concave part during pressing, characterized in that at least either of said first blank pressing face and said second blank pressing face has a roughened surface with a plurality of striated projections which are formed in the direction inclined in a range of -25° to +25° (preferably approximately parallel) toward the circumferential direction of the edge of the opening of said concave part.The press die permits the blank to slide easily and hence prevents the blank from decreasing in thickness during press forming.

Owner:KOBE STEEL LTD

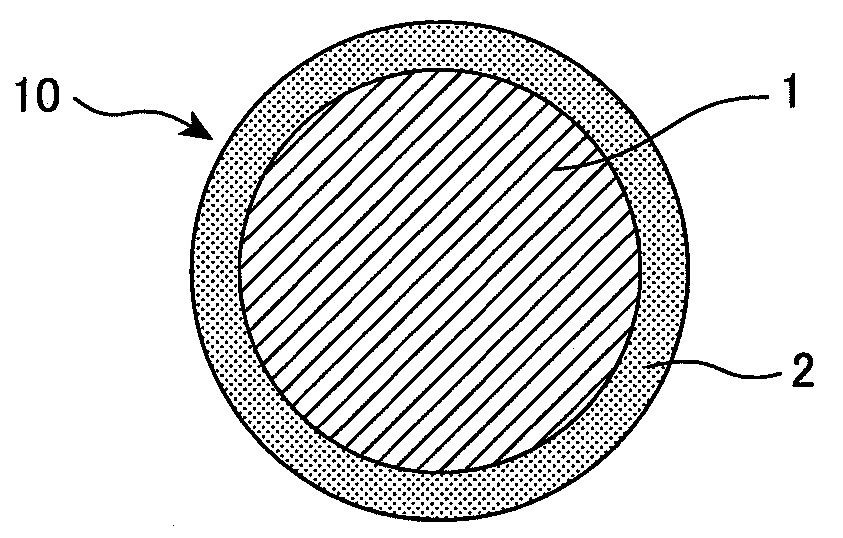

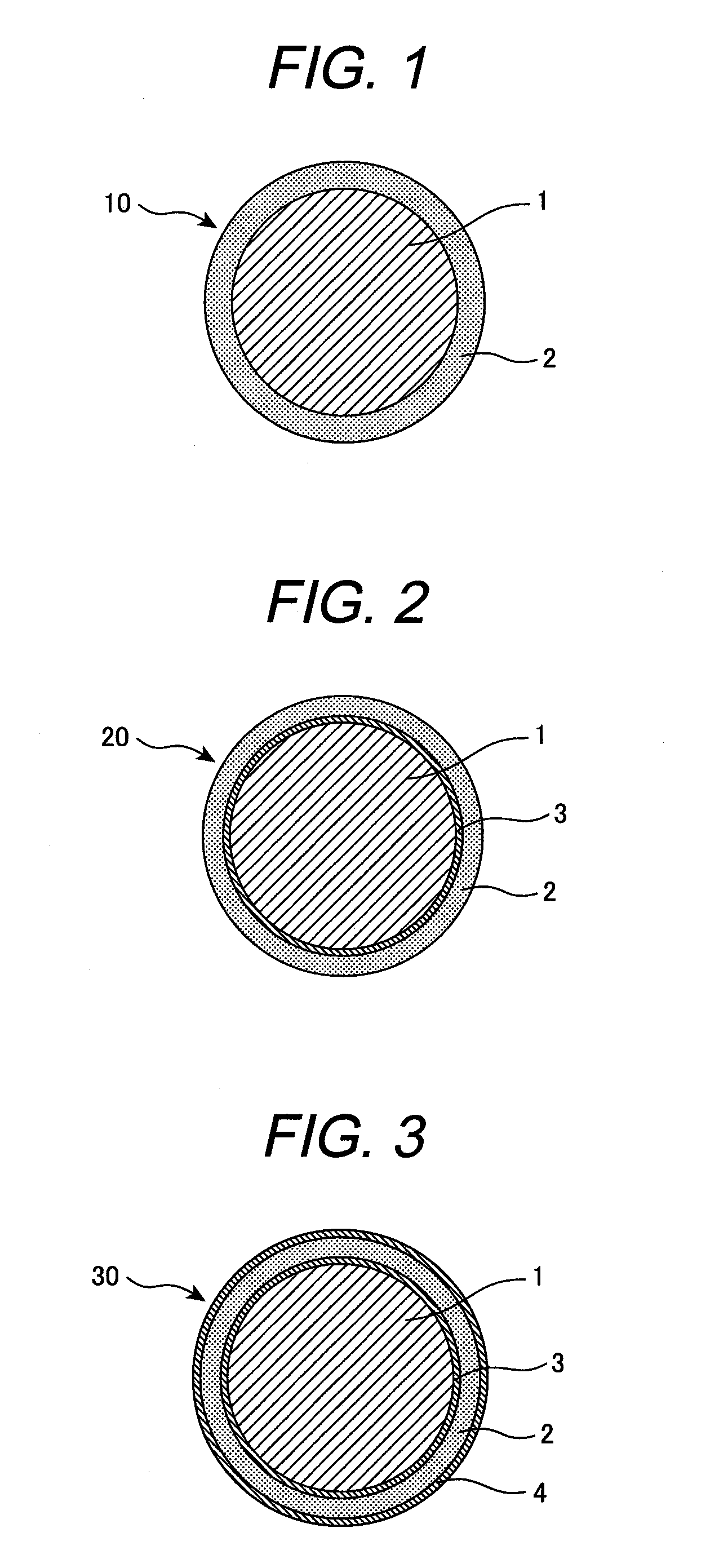

Polyamide-imide resin based insulating varnish and insulated wire covered with same

ActiveUS20110048766A1Improve stamping formabilityIncrease flexibilityPlastic/resin/waxes insulatorsCoatingsElectrical conductorPolyamide-imide

There is provided an insulated wire including: a conductor wire; and a polyamide-imide insulation coating formed around the conductor wire, the polyamide-imide insulation coating being made from a polyamide-imide resin based insulating varnish, the varnish being synthesized by reaction of an isocyanate constituent and an acid constituent in a solvent, the isocyanate constituent including 5 to 50 mol % of 2,4′-diphenylmethane-diisocyanate having a flexible molecular structure.

Owner:HITACHI METALS LTD

Method of joining heat-treatable aluminum alloy members by friction stir welding

InactiveUS20090250144A1Avoid stress concentrationReduce hardnessWelding/soldering/cutting articlesMetal working apparatusHeat treatedFriction stir welding

A method of joining heat-treatable aluminum alloy members by friction stir welding, including the steps of: a T4-treatment-performing step of performing a T4 treatment on heat-treatable aluminum alloy members so as to impart T4 temper to the heat-treatable aluminum alloy members; a joining step of joining the heat-treatable aluminum alloy members with T4 temper by friction stir welding to provide a joined product; and a reversion-treatment-performing step of performing a reversion treatment, the reversion-treatment-performing step being carried out prior to or after the joining step.

Owner:SUMITOMO LIGHT METAL INDS LTD

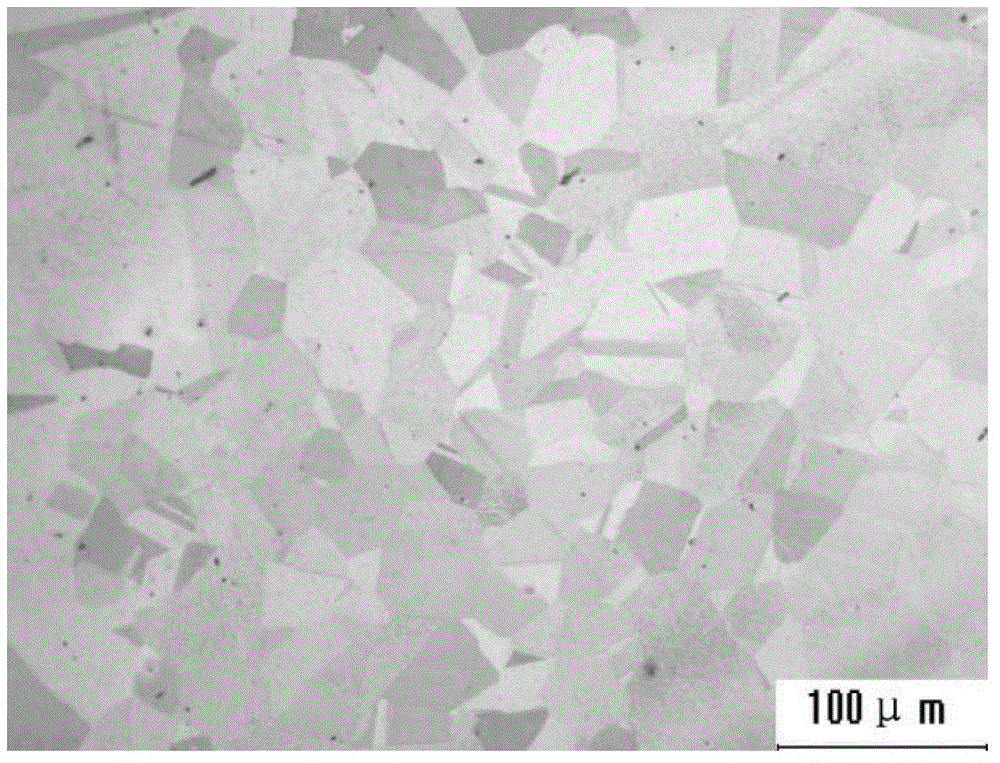

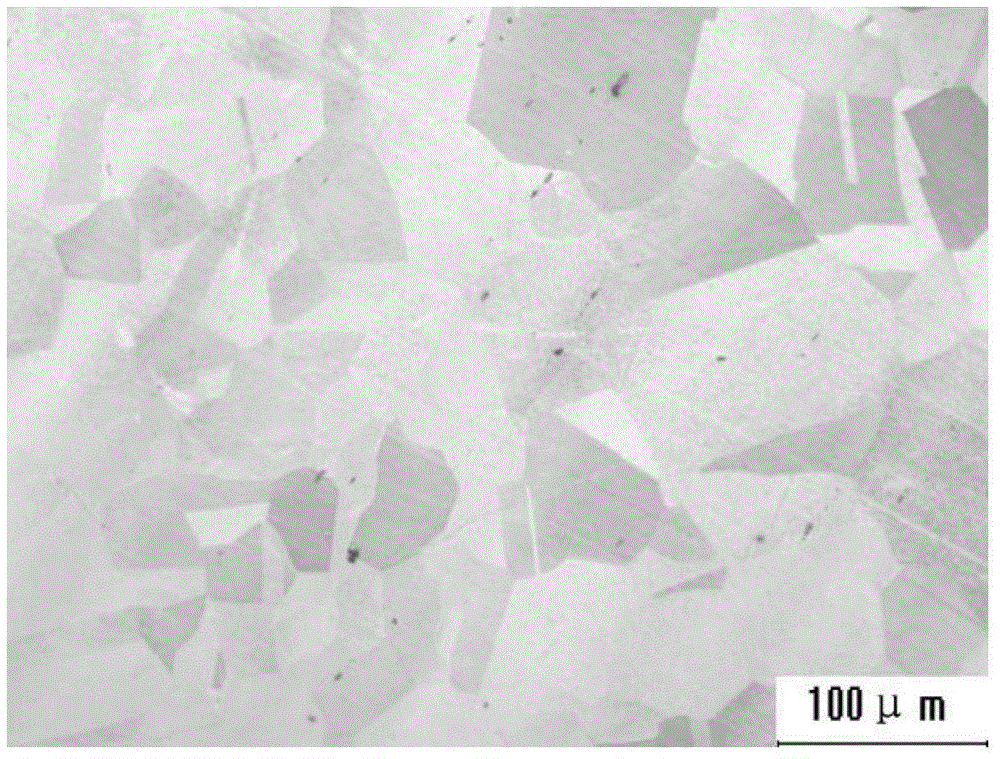

Al-Mg based alloy sheets with good press formability

By careful control of composition and processing, Al-Mg based alloy sheets with preferred grain sizes and crystallographic textures that result in good press formability are disclosed. The Al-Mg alloy preferably contains 2-6 wt % Mg, and at least 0.03 wt % of at least one element selected from Fe, Mn, Cr, Zr, and Cu. The crystallographic texture is comprised of grains with a volume fraction in a range of about 5% to 20% in the CUBE orientation {100} <001>, a volume fraction in a range of about 1% to 5% in the GOSS orientation {110} <001>, a volume fraction in a range of about 1% to 10% in each of the BRASS orientation {110} <1+E,ovs 1+EE 2>, S orientation {123} <63+E,ovs 4+EE >, and COPPER orientation {112} <11+E,ovs 1+EE >, wherein the grain size is in a range of about 20 to 70 mu m.

Owner:KOBE STEEL LTD +1

Method of manufacturing steel sheet having excellent workability and shape accuracy

InactiveUS6982012B2Low yield pointSufficient workabilityHot-dipping/immersion processesLiquid surface applicatorsHigh intensityMachinability

A method of manufacturing a high strength steel sheet containing, in mass %, C: 0.02 to 0.04%, Si: at most 0.4%, Mn: 0.5-3.0%, P: at most 0.15%, S: at most 0.03%, Al: at most 0.50%, N: at most 0.01%, and Mo: 0.01-1.0%. The method includes performing hot rough rolling either directly or after heating to a temperature of at most 1300° C., commencing hot finish rolling either directly or after reheating or holding, completing finish rolling at a temperature of at least 780° C., performing coiling after cooling to a temperature of 750° C. or below at an average cooling rate of at least 3° C. / second, heating to an annealing temperature of at least 700° C. and then cooling to a temperature of 600° C. or below at an average cooling rate of at least 3° C. / second, then holding in a temperature range of 450-600° C. for at least 10 seconds, and performing hot dip galvanizing after cooling.

Owner:NIPPON STEEL CORP

High-manganese non-magnetic steel containing niobium and preparation method thereof

A high-manganese non-magnetic steel containing niobium and a preparation method thereof belong to the technical field of non-magnetic steel production. Components of the high-manganese non-magnetic steel containing niobium comprises, by mass percent, 10 to 15 % of Mn, 0.8 to 1.2 % of C, 0.3 to 0.5 % of Si, less than 0.008 % of P, less than 0.005 % of S, 0.01 to 0.02 % of Nb, and the balance being Fe. The preparation method comprises steps of smelting, forging, hot rolling, water toughening, and water quenching after the hot-rolled plate is kept in a heating furnace for 15 minutes at 1000 DEG C. The method is advantageous in that the high manganese steel is pre-deformed by using a rolling method, thereby being capable of refining grain size and improving organization and performance, and a finished product has tensile strength of 900 to 1100 MPa, elongation percentage of 50 to 60%, Rockwell hardness of 15 to 22 HRC and magnetic permeability of less than 1.0002. According to the invention, the non-magnetic steel is superior in magnetic, mechanical and processing properties, and the method is simple in production, low in economic cost, and is applicable in the fields of mechanical production and transportation, such as nonmagnetic structural members and nonmagnetic molds used for magnetic shielding in large and medium-sized transformer oil tanks, train tracks, etc.

Owner:UNIV OF SCI & TECH BEIJING

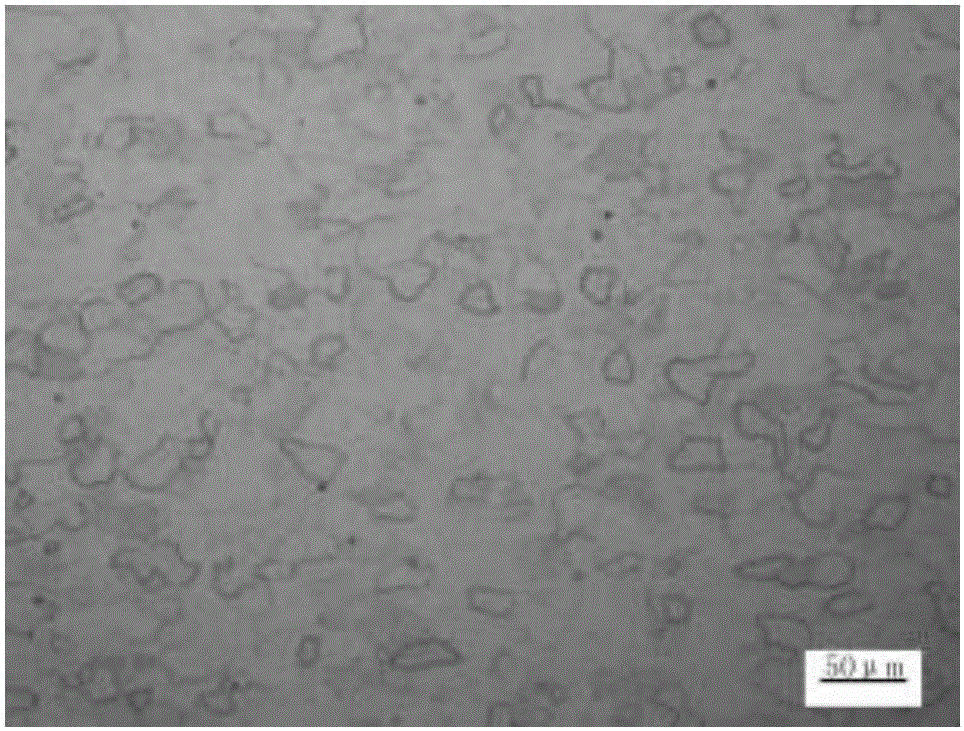

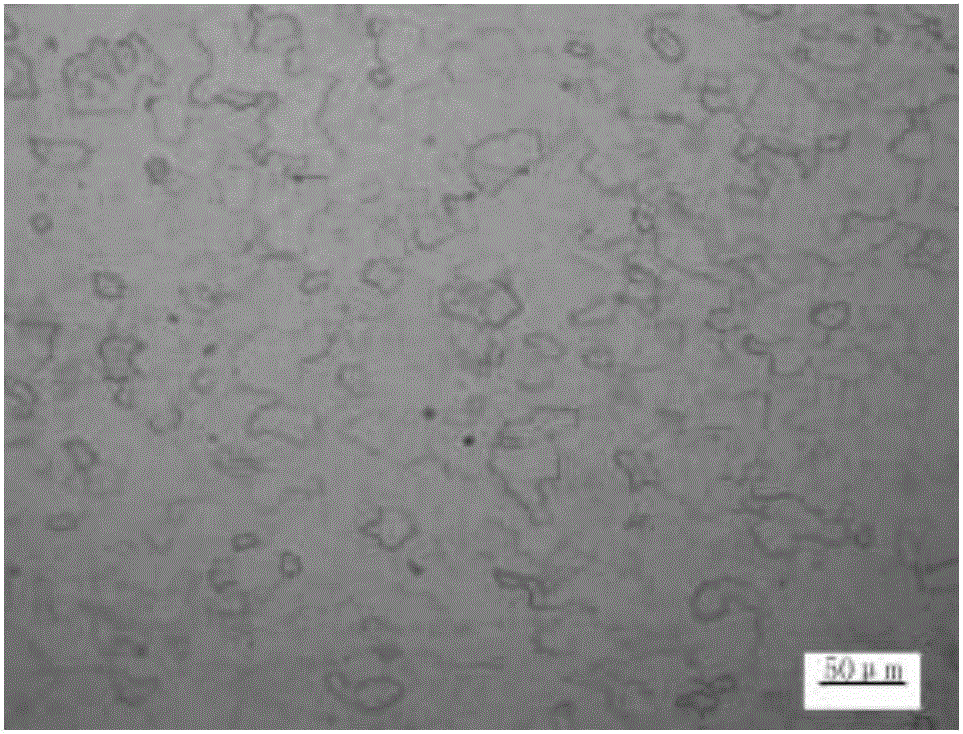

Preparation method of aluminum alloy panel for vehicle with both high strength and high forming property

The invention relates to a preparation method of an aluminum alloy panel for a vehicle with both high strength and a high forming property and belongs to the technical field of aluminum alloys. By regulating and controlling nucleation, grow-up and distribution of casted progenetic phases by means of microalloying and being supplemented by regulation in a follow-up thermal processing course, the progenetic phases in an alloy matrix can be in approximately spherical uniformly dispersive distribution states, and positive influence is also generated on evolution of alloy tissues and textures in the follow-up thermal processing course by means of the progenetic phases with special distribution characteristics. The developed alloy panel is refined in structure, and the texture is remarkably weakened, so that an excellent stamping punching property is shown. The plastic strain ratio r which represents the stamping punching property can reach over 0.73 while deltar value is only -0.06. The developed aluminum alloy material with the high forming property and a preparation method thereof are quite suitable for manufacturing outer panels of an automotive body, in particular parts with complicated shapes with relatively high demands on stamping punching property, flanging property, paint bake hardenability increment and the like.

Owner:UNIV OF SCI & TECH BEIJING

Hot-dip aluminum-zinc plate/strip used for highly deep drawing and preparation method thereof

ActiveCN105970105AImprove mechanical propertiesExcellent ultra-deep drawing performanceHot-dipping/immersion processesTemperature resistanceZinc

The invention relates to a hot-dip aluminum-zinc plate / strip and a preparation method thereof, in particular to a hot-dip aluminum-zinc plate / strip with highly deep drawing performance and a preparation method thereof. The hot-dip aluminum-zinc plate / strip used for highly deep drawing comprises an IF steel base plate and a coating, wherein the IF steel base plate is composed of, by weight, 0-0.005% of C, 0-0.02% of Si, 0-0.15% of Mn, 0-0.010% of P, 0-0.010% of S, 0.020%-0.060% of Als, 0.050%-0.085% of Ti, 0.005%-0.030% of Nb and the balance Fe and inevitable impurities; and the coating is composed of, by weight, 53%-56% of Al, 42%-44% of Zn and 1.4 %-1.8% of Si. According to the hot-dip aluminum-zinc plate / strip used for highly deep drawing, the mechanical performance and the highly deep drawing performance are excellent; the yield strength is 130-190 Mpa; the tensile strength is 280-350 Mpa; the elongation is larger than or equal to 38%; n is larger than or equal to 0.19; r is larger than or equal to 2.2; the surface quality is good; the using requirements of automobiles, household appliances and other highly deep drawing users can be met; and in addition, the coating of the hot-dip aluminum-zinc plate / strip is compact and uniform, so that the good stamping formability, high temperature resistance and corrosion resistance are achieved.

Owner:PANZHIHUA IRON & STEEL RES INST OF PANGANG GROUP

Cold-rolling hot-dipping steel plate used for liquid-crystal module backboard and production method of the steel plate

The invention relates to a cold-rolling hot-dipping steel plate used for a liquid-crystal module backboard and a production method of the steel plate, and solves technical problems of cracking and deformation of hot-dipping steel plates produced from low carbon aluminum killed steel when the hot-dipping steel plates are used in stamping forming processes of liquid-crystal module backboards. The production method includes sequential steps of smelting according to components, desulfurizing molten iron, performing combined top-bottom blowing in a converter, blowing bottom argon to a steel ladle or refining in an LF furnace, casting low-carbon steel casting powder while blowing Ar for protection, heating slabs by a heating furnace, descaling, performing rough rolling, performing precision rolling, coiling to obtain hot rolled steel coils, uncoiling again, washing with an acid, performing cold rolling, annealing by a horizontal continuous annealing furnace, performing hot dipping, flattening, withdrawing and straightening and coiling to obtain a finished product. The finish rolling temperature of the precision rolling is 860-900 DEG C. The coiling temperature is 580-650 DEG C. The cold-rolling reduction ratio is 78-85%. The temperature of cold-rolled strip steel in hard state in the soaking section of the horizontal continuous annealing furnace ranges from 730 DEG C to 770 DEG C. The heating time of the strip steel in the horizontal continuous annealing furnace is 80-100 s. The flatness rate after the hot dipping step is 0.6%-1.2% and the withdrawing and straightening rate is 0.3-0.8%. The steel plate is mainly used for the liquid-crystal module backboard of liquid-crystal and flat-panel displays.

Owner:SHANGHAI MEISHAN IRON & STEEL CO LTD

High-strength hop-dip galvanized steel sheet and method for producing the same

ActiveUS20060124907A1High tensile strengthNo non-plated portionHot-dipping/immersion processesConductive materialHydrogen concentrationTRIP steel

The present invention stably provides a high-strength hot-dip galvanized steel sheet having a high tensile strength and no non-plated portions and being excellent in workability and surface properties even when the employed equipment has only a reduction annealing furnace and a steel sheet containing relatively large amounts of Si, Mn and Al that are regarded as likely to cause non-plated portions is used as the substrate. The present invention: secures good plating performance even when the steel sheet contains Si, Mn and Al by adding Ni to a steel sheet, thus forming oxides at some portions in the steel sheet surface layer, and resultantly suppressing the surface incrassation of Si, Mn and Al at the portions where oxides are not formed; enhances the effect of Ni and accelerates the formation of oxides by further adding Mo, Cu and Sn; and moreover, in the case of a TRIP steel sheet, secures austenite by determining the ranges of Si and Al strictly, avoiding the deterioration of plating performance caused by the addition of Ni, and further adding Mo in a balanced manner. In addition, the present invention, in a TRIP steel sheet, improves press formability by regulating a retained austenite ratio and accelerates the formation of oxides by regulating a hydrogen concentration and a dew point in annealing before plating.

Owner:NIPPON STEEL CORP

Cold-rolled tin plate for beverage can bottom cover and production method of cold-rolled tin plate

ActiveCN104946968AMeeting stamping and forming manufacturing needsGuaranteed Yield StrengthTinningSteelmaking

The invention relates to a cold-rolled tin plate for a beverage can bottom cover and a production method of the cold-rolled tin plate to mainly solve the technical problems that the existing cold-rolled tin plate for the beverage can bottom cover generates cracks and is poor in performance stability in the stamping forming process of manufacturing the beverage can bottom cover. The production method comprises the following steps: smelting according to components; preparing a hot-rolled steel coil by sequentially adopting molten iron desulfurization, converter top and bottom combined blowing, ladle bottom blowing of argon or LF furnace refining, whole process of Ar blowing for protecting casting, plate blank heating furnace heating, rough rolling, finish rolling and coiling; and then uncoiling newly, and performing acid cleaning, cold rolling, annealing by using a vertical continuous annealing furnace, electro-tinning and coiling to obtain a finished product with the thickness of 0.17-0.20mm, wherein the finish rolling temperature is 851-879 DEG C, the hot rolling coiling temperature is 640-660 DEG C, the cold rolling reduction ratio is 70-79%, the temperature range of the strip steel in a rolling hard state after cold rolling in a soaking zone of the vertical continuous annealing furnace is 560-580 DEG C, and the soaking time of the strip steel in the vertical continuous annealing furnace is 95-105s. The cold-rolled tin plate provided by the invention is mainly used for preparing the beverage can bottom cover.

Owner:SHANGHAI MEISHAN IRON & STEEL CO LTD

Press die

InactiveUS20020068108A1Easy to slideImprove stamping formabilityCeramic shaping apparatusDough shapingEngineeringMechanical engineering

A press die composed of an upper die having a concave part (with the peripheral surface of the opening of said concave part functioning as a first blank pressing face), a lower die having a convex part (to form the blank into a desired form in cooperation with said concave part), and a blank holder (which has a second blank pressing face), said press die working in such a way that said first blank pressing face and said second blank pressing face hold a blank between them while permitting it to flow into said concave part during pressing, characterized in that at least either of said first blank pressing face and said second blank pressing face has a roughened surface with a plurality of striated projections which are formed in the direction inclined in a range of -25° to +25° (preferably approximately parallel) toward the circumferential direction of the edge of the opening of said concave part. The press die permits the blank to slide easily and hence prevents the blank from decreasing in thickness during press forming.

Owner:KOBE STEEL LTD

Deep-drawn-grade Ti-IF cold-rolled steel plate and preparation method thereof

The invention discloses a deep-drawn-grade Ti-IF cold-rolled steel plate. The cold-rolled steel plate comprises the following chemical components in percentage by mass: 0.001-0.003% of C, 0.004-0.006% of Si, 0.14-0.16% of Mn, P not more than 0.010%, S not more than 0.006%, and 0.055-0.075% of Ti. The invention further discloses a preparation method of the deep-drawn-grade Ti-IF cold-rolled steel plate. A steel strip prepared by the deep-drawn-grade Ti-IF cold-rolled steel plate has such performances as low yield ratio, excellent plasticity, high plastic strain ratio and excellent punching formation, and is suitable for the demands of such complex forming modes as the punching process.

Owner:INNER MONGOLIA BAOTOU STEEL UNION

Steel belt for spoke of vehicle wheel and manufacturing method thereof

InactiveCN101280389AGood welding performanceStable controlTemperature control deviceManufacturing convertersChemical compositionSteel belt

The invention relates to a steel strip for the wheel spoke of the vehicle and the manufacturing method thereof. The chemical composition of the steel strip has the following weight percentage: C is larger than 0 and lower than or equal to 0.26 percent, Si is lower than or equal to 0.50 percent, Mn is larger than 0 and lower than or equal to 2.0 percent, P is lower than or equal to 0.035 percent, S is lower than or equal to 0.035 percent, Al is larger than 0 and lower than or equal to 0.10 percent, Nb is larger than 0 and lower than or equal to 0.060 percent, and the residue is Fe and micro impurities. The steel strip of the invention adopts molten iron desulphurization, converter smelting, LF ladle refining, slab continuous casting, rolling by hot continuous rolling mill, which has superior welding performance and molding performance, the mechanical property is uniform, the processing of the spinning spoke of vehicle wheels in varied specifications can be performed, and the finished product rate is high. The steel strip for the wheel spoke of the vehicle of the invention has the advantages that the cost is low, the producing operation is easy, and the industrialization is easy.

Owner:SHANDONG IRON & STEEL CO LTD

Aluminum alloy plate and process for producing the same

InactiveCN101107373AImprove the balance of strength and ductilityImprove stamping formabilityDuctilitySurface plate

The present invention provides an Al-Mg series alloy sheet of high-Mg with improved press formability and homogeneity which can be applied to automobile outer panels and inner panels. This is an Al-Mg series aluminum alloy sheet having 0.5 to 3 mm in thickness cast by twin-roll continuous casting and cold rolled, comprising over 8% but not more than 14% Mg, 1.0% or less Fe, and 0.5% or less Si with the remainder being Al and unavoidable impurities, wherein the mean conductivity of the aluminum alloy sheet is in the range of at least 20 IACS% but less than 26 IACS%, the strength-ductility balance (tensile strength x total elongation) as a material property of the aluminum alloy sheet is 11000 (MPa%) or more, and the homogeneity and press formability of the sheet have been improved.

Owner:KOBE STEEL LTD

Features

- R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

Why Patsnap Eureka

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Social media

Patsnap Eureka Blog

Learn More Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com