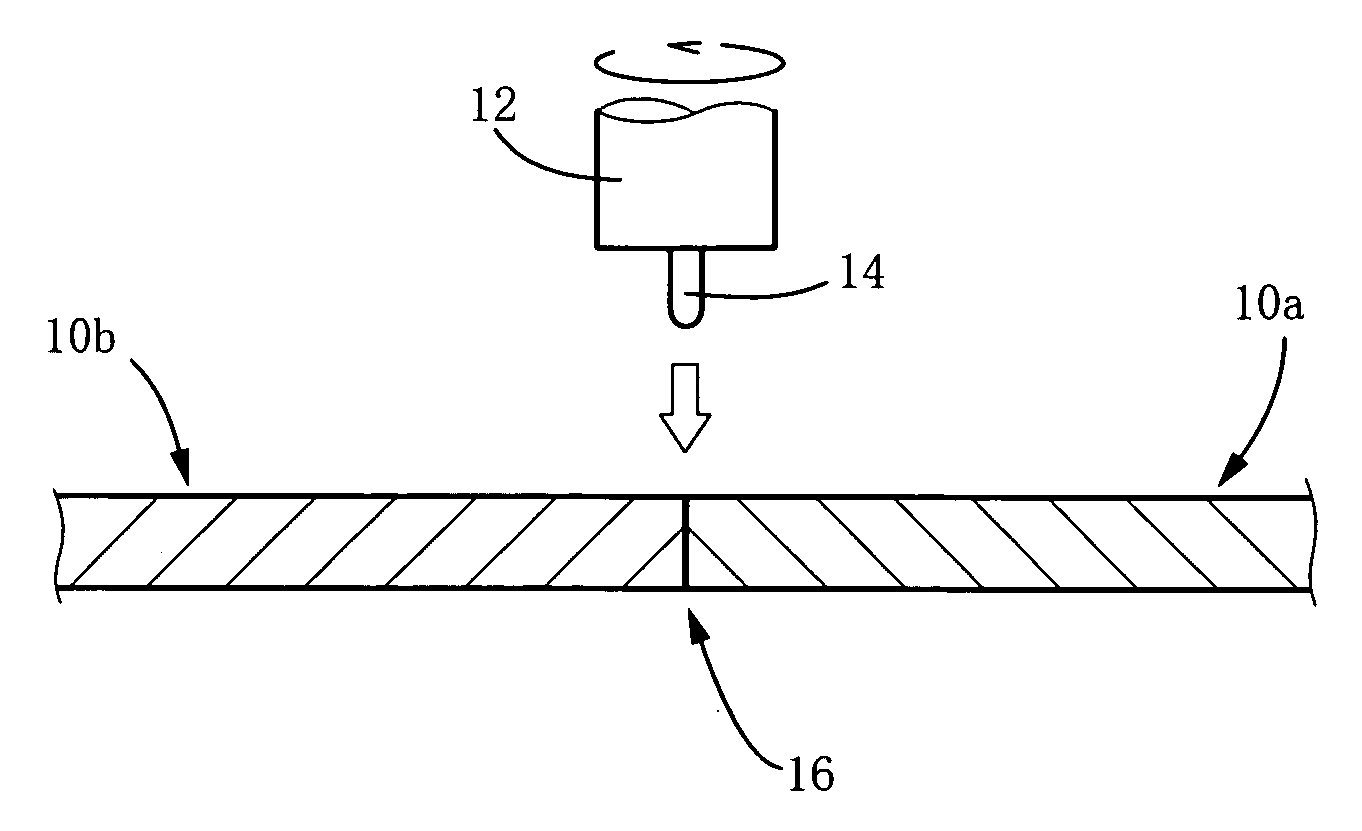

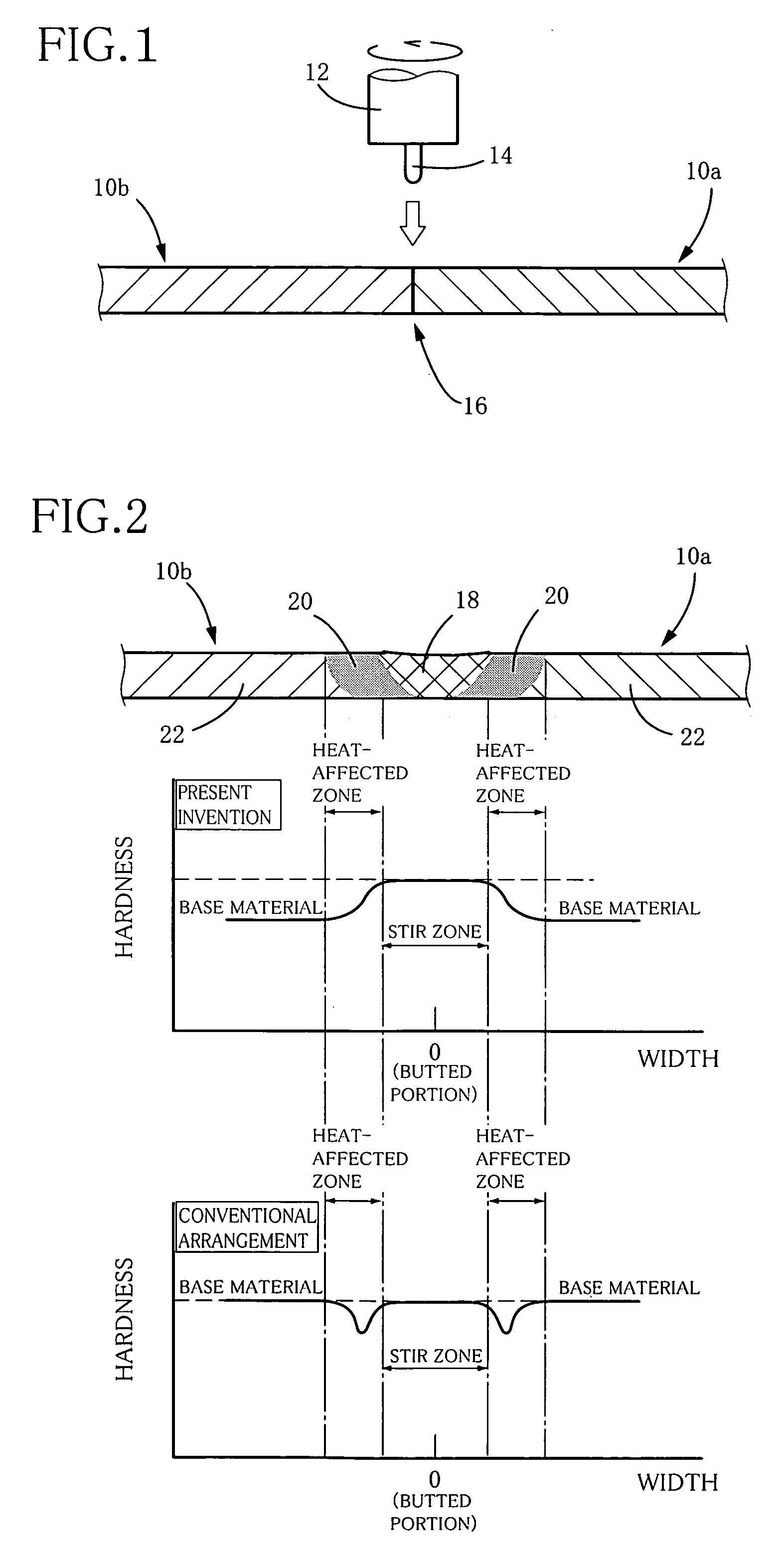

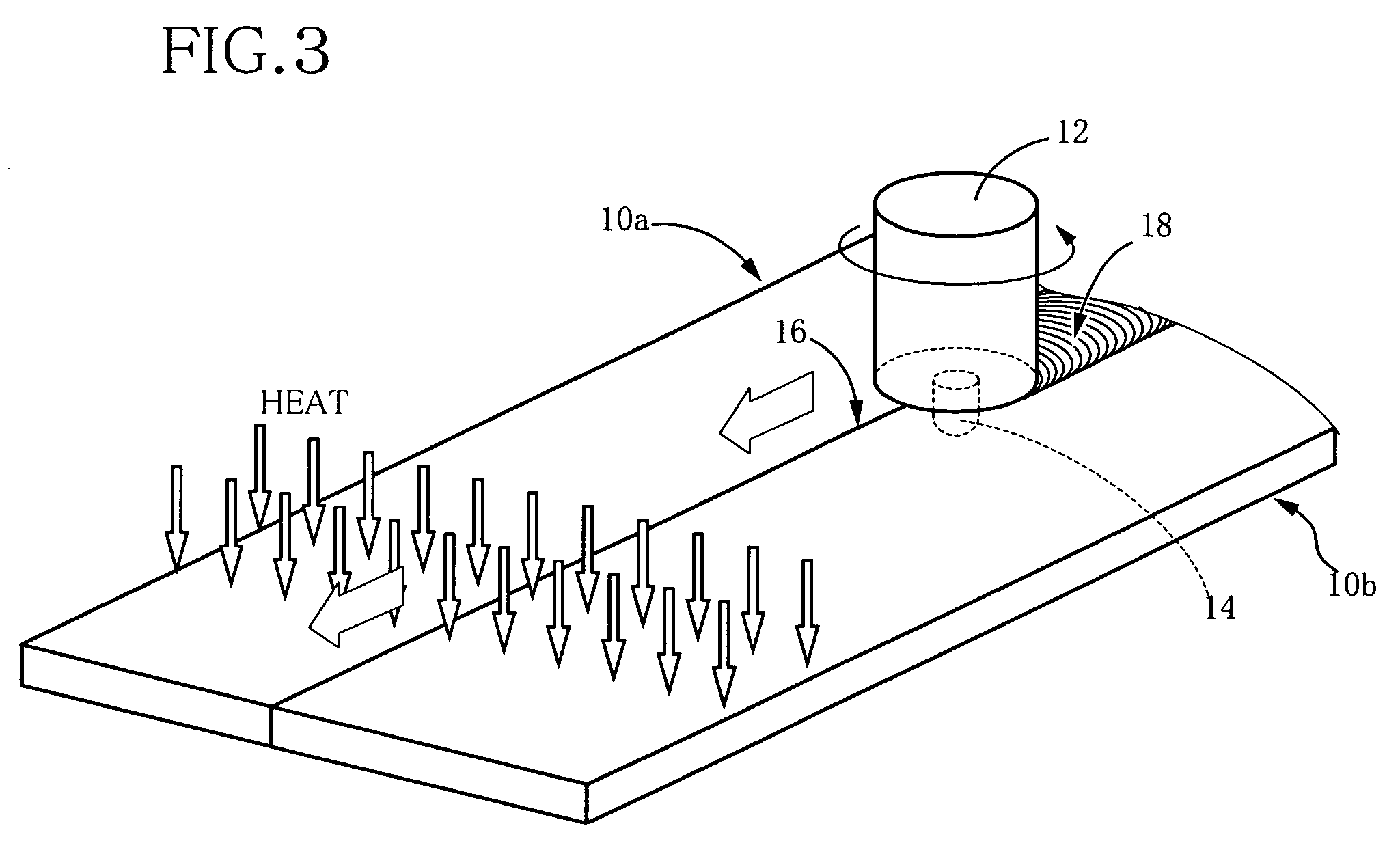

Method of joining heat-treatable aluminum alloy members by friction stir welding and joined product obtained by the method and used for press forming

a technology of friction stir welding and heat-treatable aluminum alloy, which is applied in the direction of non-electric welding apparatus, welding apparatus, manufacturing tools, etc., can solve the problems of heat-affected zones deforming faster than the other portions of the blank, affecting the degree of elongation or ductility of the blank, and inevitably affecting the softening of the material

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Benefits of technology

Problems solved by technology

Method used

Image

Examples

example 1

[0092] Ten aluminum alloys A-J having respective chemical compositions shown in the following TABLE 1 were cast into ingots according to a DC casting method in an ordinary manner. The obtained cast ingots were then subjected to homogenization, hot rolling and cold rolling, thereby providing aluminum alloy plate members each having thickness of 1.0 mm. Subsequently, the aluminum alloy plate members were subjected to a solution heat treatment and quenching into water, and then naturally aged at room temperature for ten days. Thus, there were obtained T4 temper members.

TABLE 1Composition (mass %)AlloySiFeCuMnMgCrZnTiAlSeries of alloyA0.60.324.50.80.420.020.090.04balance2000B0.50.284.30.60.60.020.070.03balance2000C0.120.184.50.61.50.010.020.02balance2000D0.420.150.030.060.50.020.030.03balance6000E0.70.130.320.121.10.180.020.02balance6000F1.00.160.010.070.50.010.010.02balance6000G1.00.120.010.090.50.020.230.02balance6000H1.00.150.70.090.40.030.010.03balance6000I0.110.170.160.251.30.094...

example 2

[0105] Ten aluminum alloys K-T having respective chemical compositions shown in the following TABLE 6 were cast into ingots according to a DC casting method in an ordinary manner. The obtained cast ingots were then subjected to homogenization, hot rolling and cold rolling, thereby providing aluminum alloy plate members each having thickness of 1.0 mm. Subsequently, the aluminum alloy plate members were subjected to a solution heat treatment and quenching into water, and then naturally aged at room temperature for seven days. Thus, there were obtained T4 temper members.

TABLE 6Composition (mass %)AlloySiFeCuMnMgCrZnTiAlSeries of alloyK0.60.284.40.80.440.030.070.03balance2000L0.50.294.30.60.60.040.080.02balance2000M0.140.204.50.71.50.020.030.02balance2000N0.440.180.040.060.50.030.040.02balance6000O0.70.150.340.151.10.220.020.03balance6000P1.00.140.010.090.50.020.010.02balance6000Q1.00.150.020.070.50.010.210.02balance6000R1.00.180.70.070.40.020.010.02balance6000S0.140.190.140.241.30.0...

PUM

| Property | Measurement | Unit |

|---|---|---|

| Temperature | aaaaa | aaaaa |

| Temperature | aaaaa | aaaaa |

| Temperature | aaaaa | aaaaa |

Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com