High-manganese non-magnetic steel containing niobium and preparation method thereof

A technology of non-magnetic steel and high manganese is applied in the field of non-magnetic steel production to achieve the effects of energy saving, grain refinement and simple preparation method

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

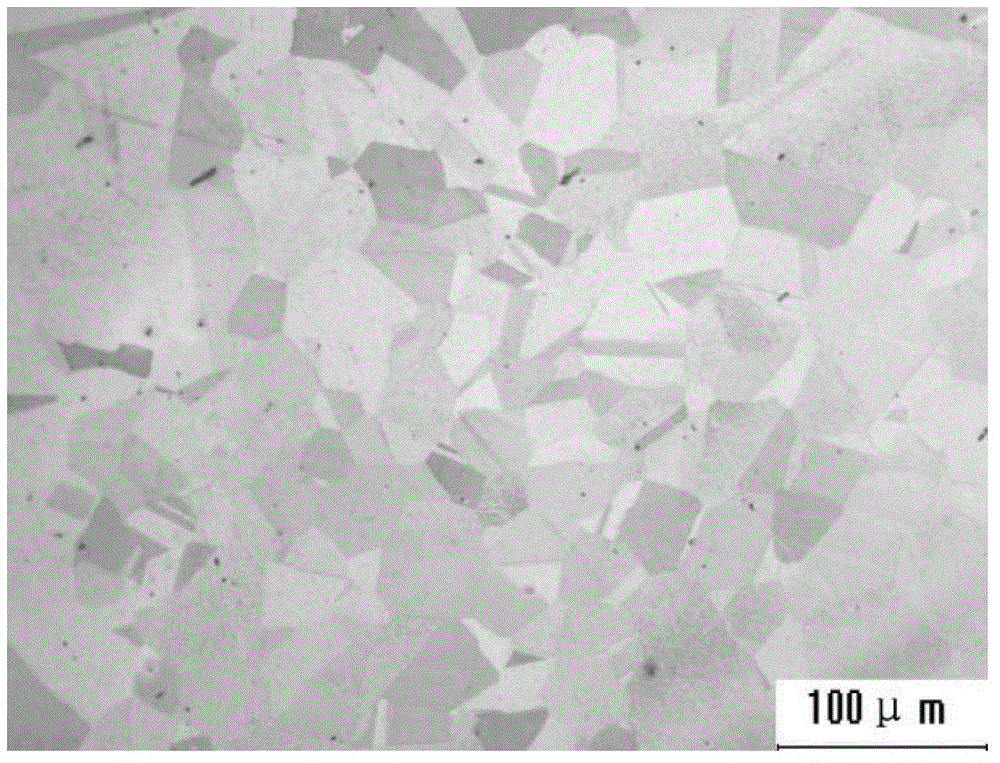

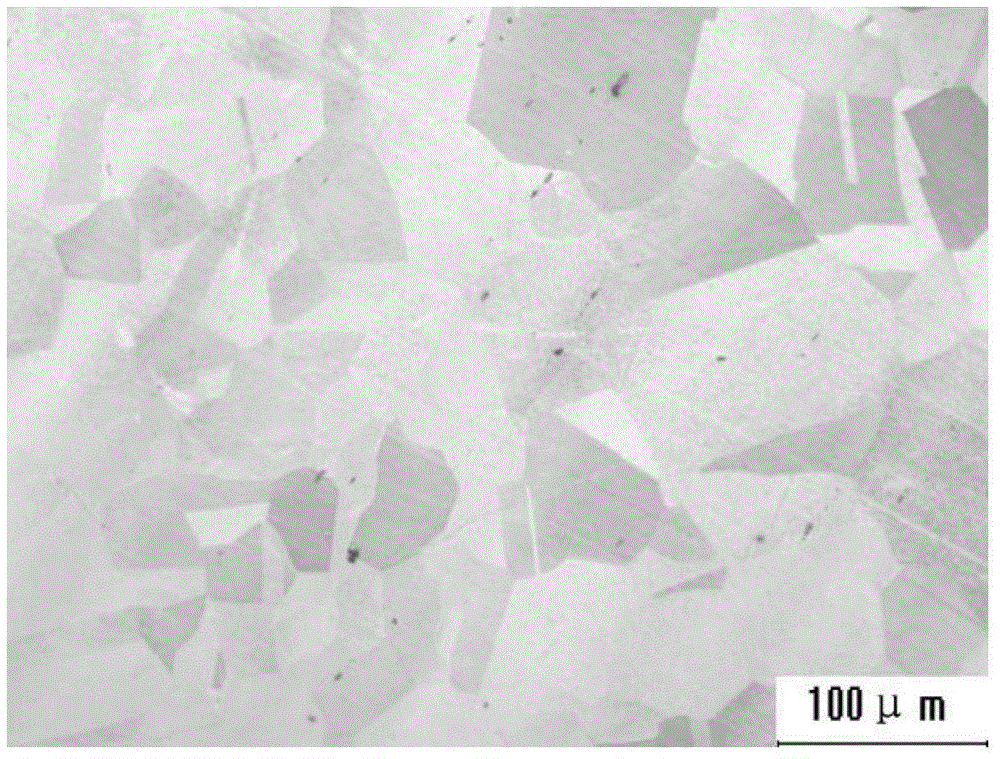

Embodiment 1

[0030] Composition: C: 0.95%, Mn: 14.9%, Si: 0.38%; Nb: 0.012%; P≤0.007%; S≤0.0047; the rest is iron or unavoidable impurities.

[0031] Smelting: Vacuum smelting in an electromagnetic induction furnace, protected by argon gas, to obtain ingots that meet the composition requirements.

[0032] Forging: The forging temperature is slowly heated during the forging process, heating temperature: 1150-1200°C, holding time: 30min, starting forging temperature: 1200°C, final forging temperature: ≥900°C.

[0033] Rolling process: hot rolling heating temperature 1200°C, heat preservation for 1 hour, hot rolling on a 350 two-roll hot rolling mill to obtain a hot-rolled sheet with a thickness of about 6-7mm, and a total deformation of 80-90%. The rolling and final rolling temperatures are 1050°C and 900°C respectively, followed by water toughening treatment.

[0034] Water toughening treatment process: heat a 7mm thick hot-rolled steel plate to 1000°C, keep it warm for 15 minutes, and the...

PUM

| Property | Measurement | Unit |

|---|---|---|

| tensile strength | aaaaa | aaaaa |

| thickness | aaaaa | aaaaa |

| tensile strength | aaaaa | aaaaa |

Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com