High-ductility steel sheet excellent in press formability and strain age hardenability, and method for manufacturing the same

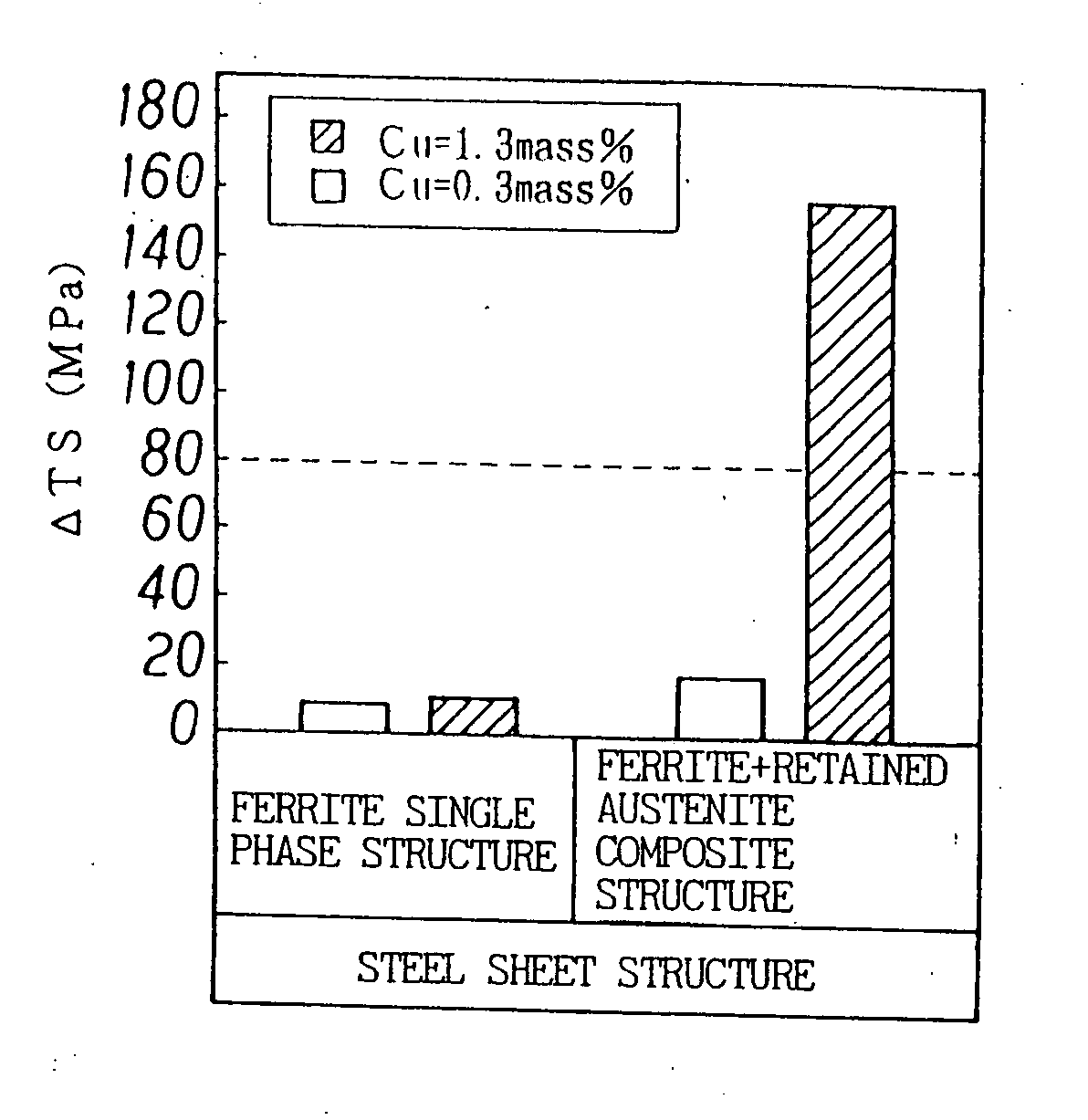

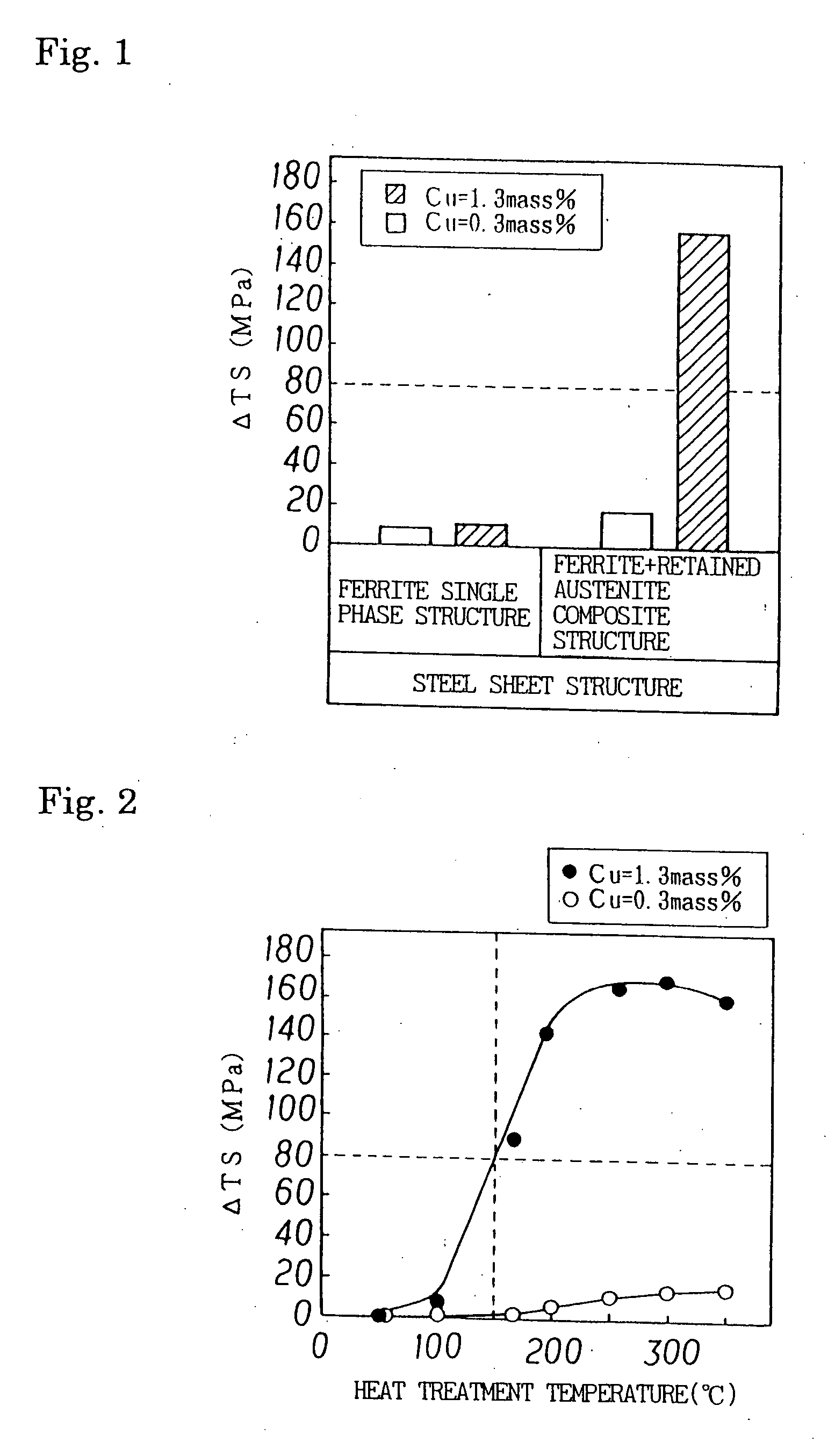

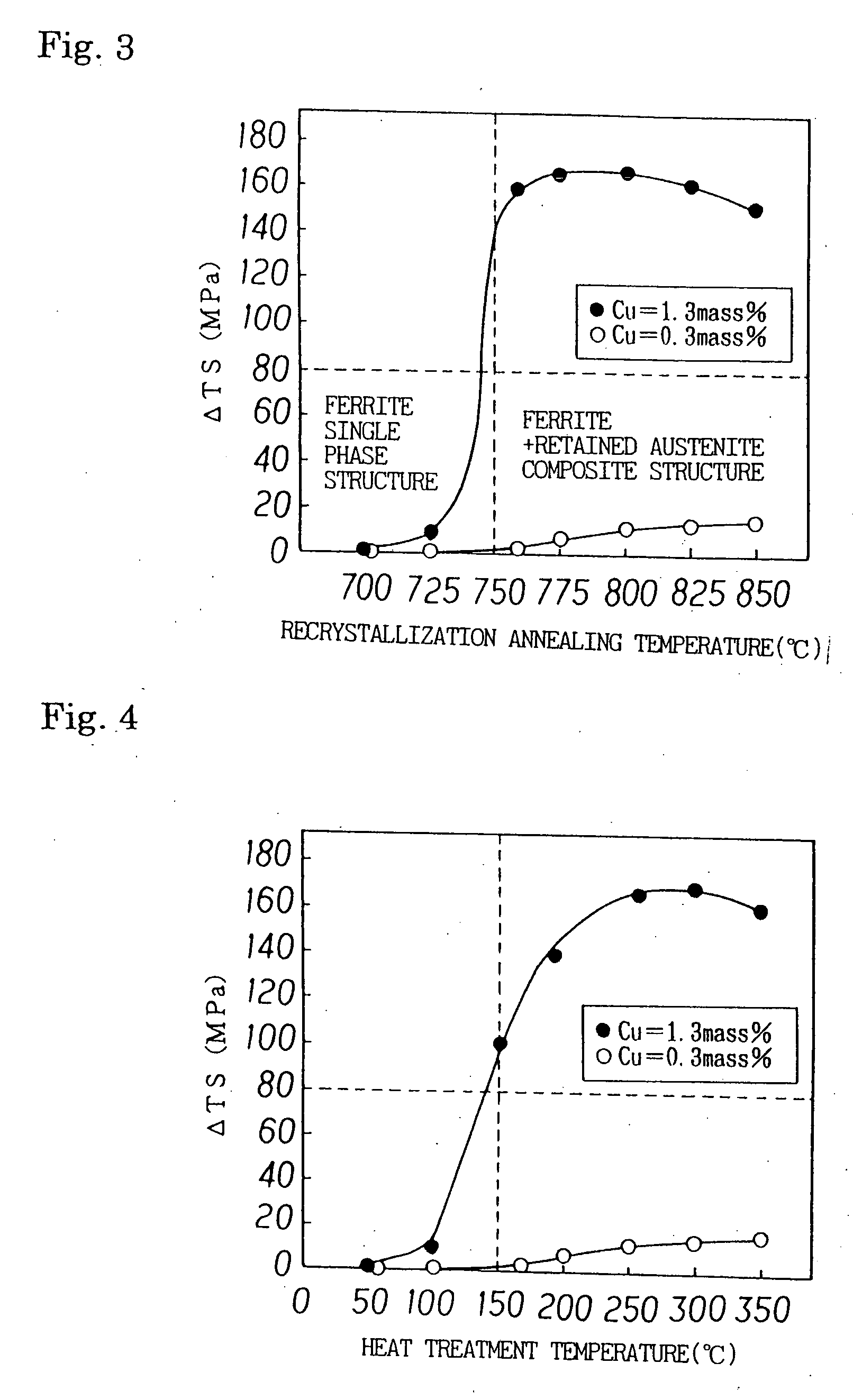

a high-ductility steel and press formability technology, applied in the field of automobile steel sheets, can solve the problems of poor press formability, ductility and a lower hole-expanding ratio, and weight reduction in automobile bodies has become a very important factor, and achieve excellent press formability, excellent strain age hardenability, and improved tensile strength.

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Benefits of technology

Problems solved by technology

Method used

Image

Examples

example 1

Molten steels having the compositions shown in Table 1 were made in a converter and cast into steel slabs by a continuous casting process. Each of these steel slabs was reheated, and hot-rolled under conditions shown in Table 2 into a hot-rolled steel strip (hot-rolled sheet) having a thickness of 2.0 mm. The hot-rolled sheet was temper-rolled at a reduction of 1.0%.

TABLE 1STEELCOMPOSITION (wt. %)NO.CSiMnPSAlNCuNiCr, Mo,Nb, Ti, VA0.091.451.050.010.0030.0340.0021.52———B0.121.501.200.010.0020.0300.0021.430.65Mo: 0.32—C0.101.481.350.010.0020.0280.0021.250.52Cr: 0.53—D0.151.531.450.010.0030.0330.0021.330.44—Nb: 0.01,Ti: 0.01,V: 0.01E0.121.481.550.010.0050.0320.0020.15———F0.111.501.080.010.0040.0320.0020.68———G0.131.521.220.010.0040.0320.0020.98———H0.121.421.220.010.0030.0330.0021.550.62——I0.111.521.520.010.0030.0310.0021.49—Cr: 0.15,—Mo: 0.12J0.131.431.480.010.0030.0280.0021.43—Mo: 0.21—K0.151.581.050.010.0030.0300.0021.52——Nb: 0.01L0.141.601.210.010.0030.0280.0021.48—Cr: 0.11Ti: 0.0...

example 2

Molten steels having the compositions shown in Table 4 were made in a converter and cast into steel slabs by a continuous casting process. Each of these steel slabs were reheated, and hot-rolled under conditions shown in Table 5 into a hot-rolled steel strip (hot-rolled sheet) having a thickness of 2.0 mm. The hot-rolled steel strip was temper-rolled at a reduction of 1.0%.

TABLE 1STEELCOMPOSITION (wt. %)NO.CSiMnPSAlNCuNiCr, Mo,Nb, Ti, VA0.091.451.050.010.0030.0340.0021.52———B0.121.501.200.010.0020.0300.0021.430.65Mo: 0.32—C0.101.481.350.010.0020.0280.0021.250.52Cr: 0.53—D0.151.531.450.010.0030.0330.0021.330.44—Nb: 0.01,Ti: 0.01,V: 0.01E0.121.481.550.010.0050.0320.0020.15———F0.111.501.080.010.0040.0320.0020.68———G0.131.521.220.010.0040.0300.0020.98———H0.121.421.220.010.0030.0330.0021.550.62——I0.111.521.520.010.0030.0310.0021.49—Cr: 0.15,—Mo: 0.12J0.131.431.480.010.0030.0280.0021.43—Mo: 0.21—K0.151.581.050.010.0030.0300.0021.52——Nb: 0.01L0.141.601.210.010.0030.0280.0021.48—Cr: 0.11...

example 3

Molten steels having the composition shown in Table 7 were made in a converter and cast into steel slabs by a continuous casting process. Then, each of these steel slabs was reheated to 1,250° C., and hot-rolled in a hot rolling step of hot rolling at a finish rolling end temperature of 900° C. and a coiling temperature of 600° C. into a hot-rolled steel strip (hot-rolled sheet) having a thickness of 4.0 mm. Then, the hot-rolled steel strip (hot-rolled sheet) was subjected to a cold rolling step of pickling and cold-rolling into cold rolled steel strip (cold-rolled sheet) having a thickness of 1.2 mm. Thereafter, the cold-rolled steel strip (cold-rolled sheet) was subjected to recrystallization annealing step comprising heating and soaking treatment and a subsequent retaining treatment under the conditions shown in Table 8 on the continuous annealing line to obtain cold-rolled annealed sheet. The resultant steel strip (cold-rolled annealed sheet) was further temper-rolled at an red...

PUM

| Property | Measurement | Unit |

|---|---|---|

| temperature | aaaaa | aaaaa |

| temperature | aaaaa | aaaaa |

| temperature | aaaaa | aaaaa |

Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com