Patents

Literature

64results about How to "No reduction in strength" patented technology

Efficacy Topic

Property

Owner

Technical Advancement

Application Domain

Technology Topic

Technology Field Word

Patent Country/Region

Patent Type

Patent Status

Application Year

Inventor

Al-Mg-Si alloys for automobile body sheets and manufacturing method thereof

ActiveCN101880805AStrong impact resistanceLower yield strengthCooking & bakingUltimate tensile strength

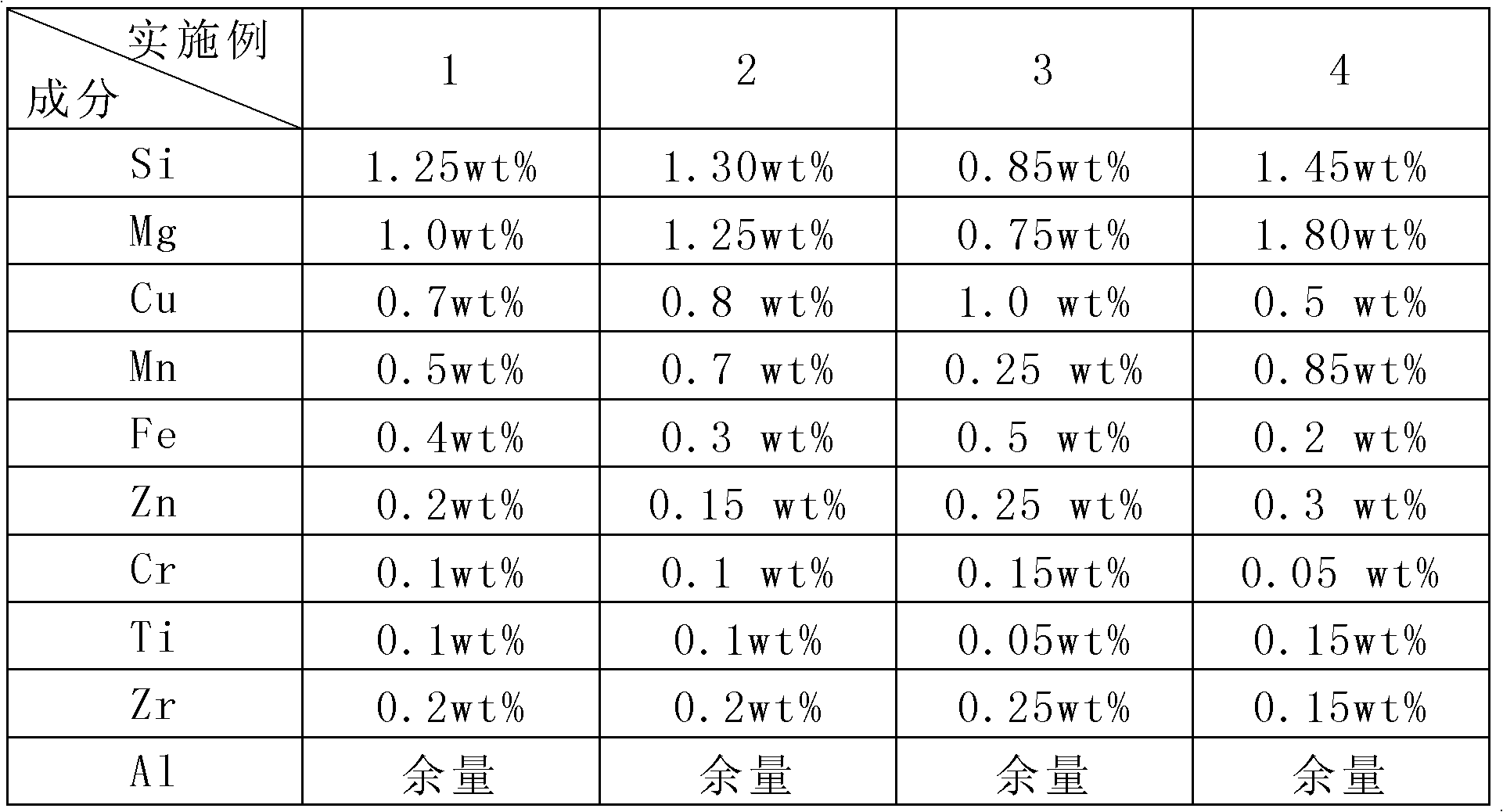

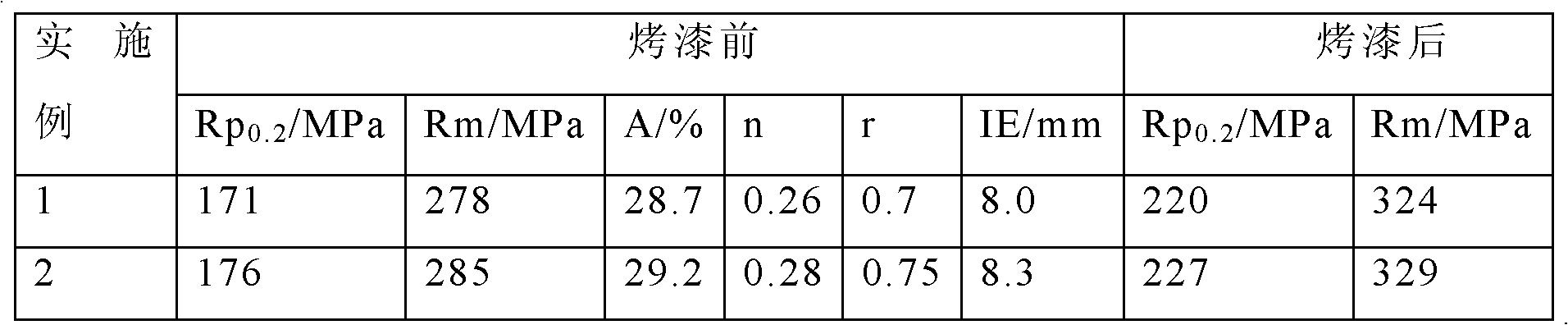

The invention provides Al-Mg-Si alloys for automobile body sheets and a manufacturing method thereof, belonging to the technical field of alloy materials. The invention solves the following problems: the existing 6000 series alloys have poor stamping forming performance and the strength of the alloys is possibly reduced through paint baking after stamping. The alloys comprise the following components in percentage by weight: 0.75-1.5% of Si, 0.2-0.5% of Fe, 0.2-1.0% of Cu, 0.25-1.0% of Mn, 0.75-1.85% of Mg; 0.15-0.3% of Zn, 0.05-0.15% of Cr, 0.05-0.15% of Ti, 0.05-0.35% of Zr and the balance Al. The alloys have the advantages of low yield strength, convenient stamping, high plasticity and good impact resistance and baking hardenability.

Owner:ZHEJIANG GKO IND CO LTD

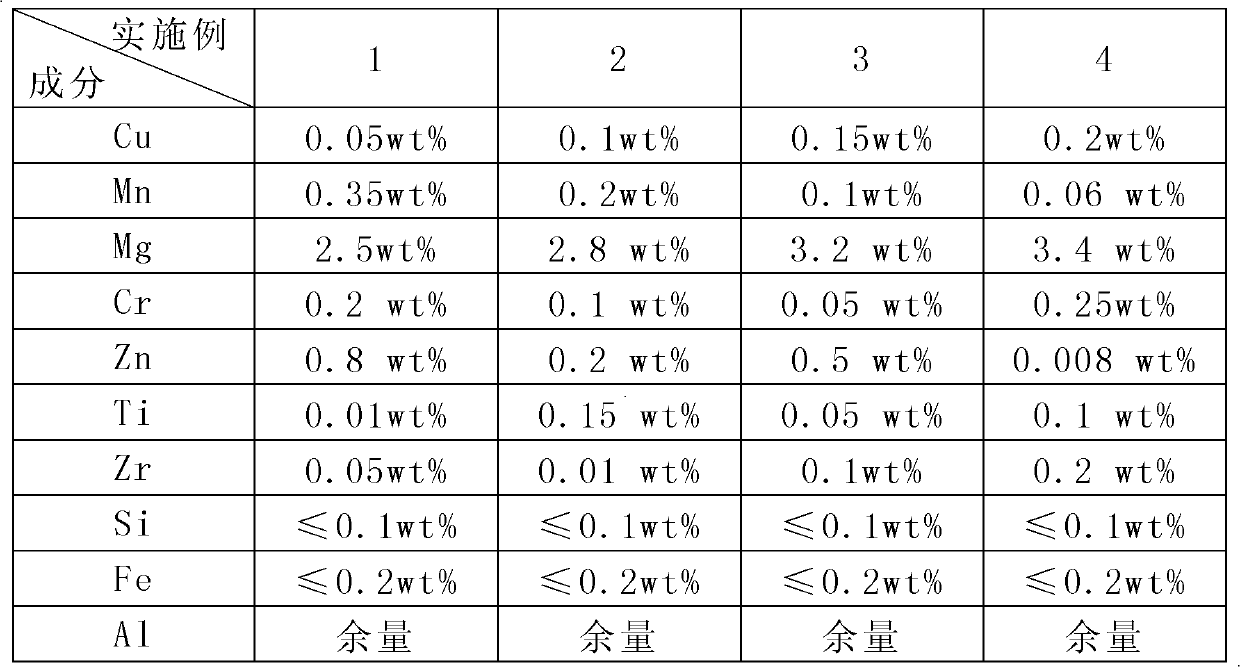

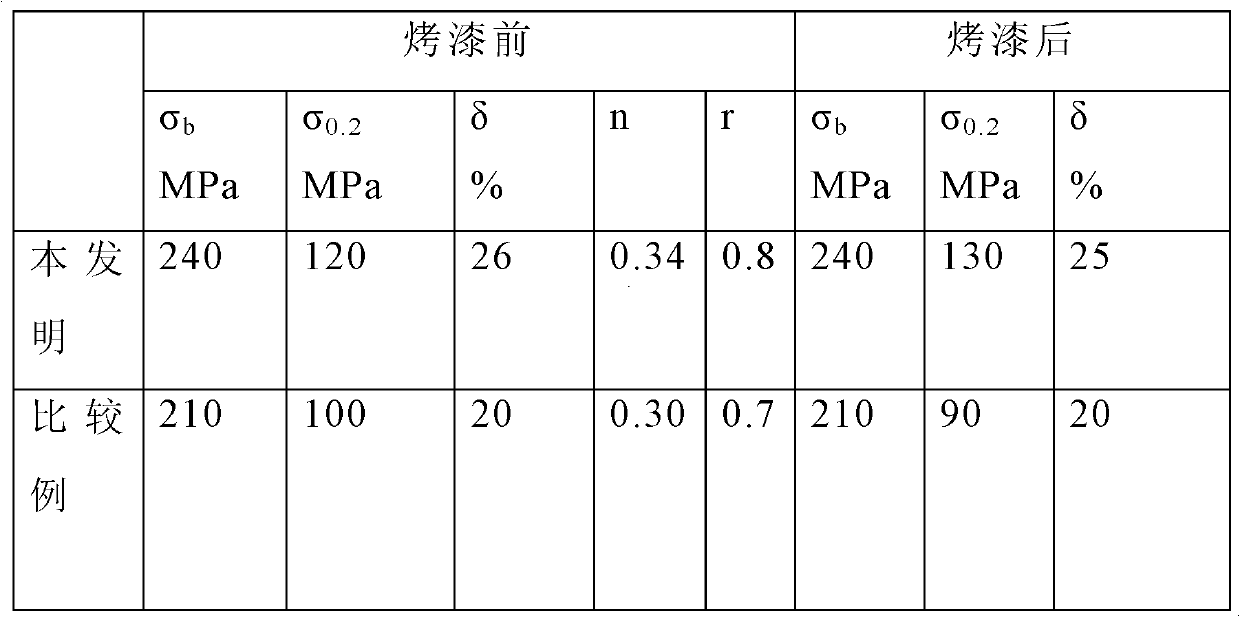

Al-Mg alloys for automobile body sheets and manufacturing method thereof

ActiveCN101880803AImprove corrosion resistance and plasticityGood impact resistanceMg alloysAluminium alloy

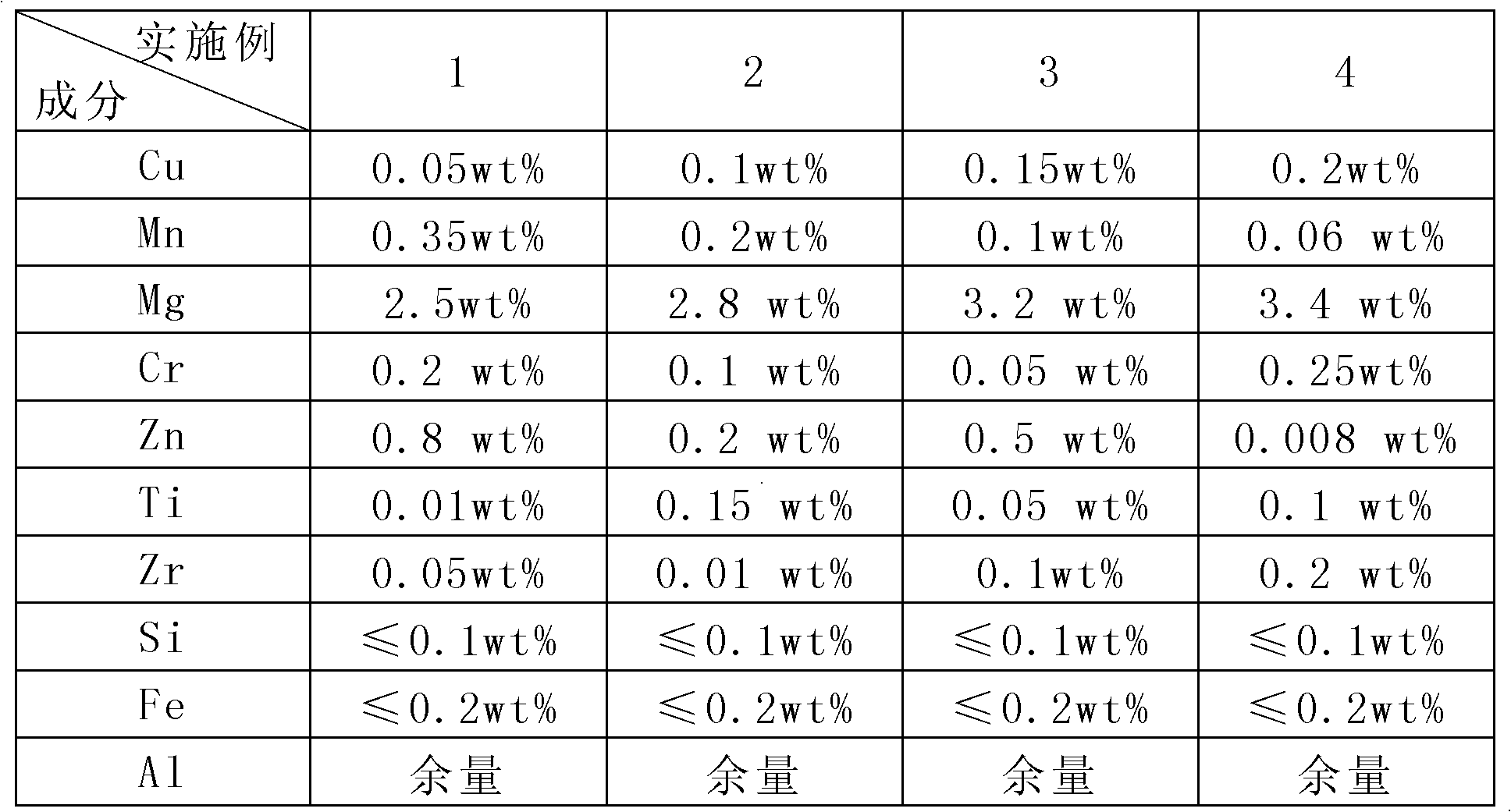

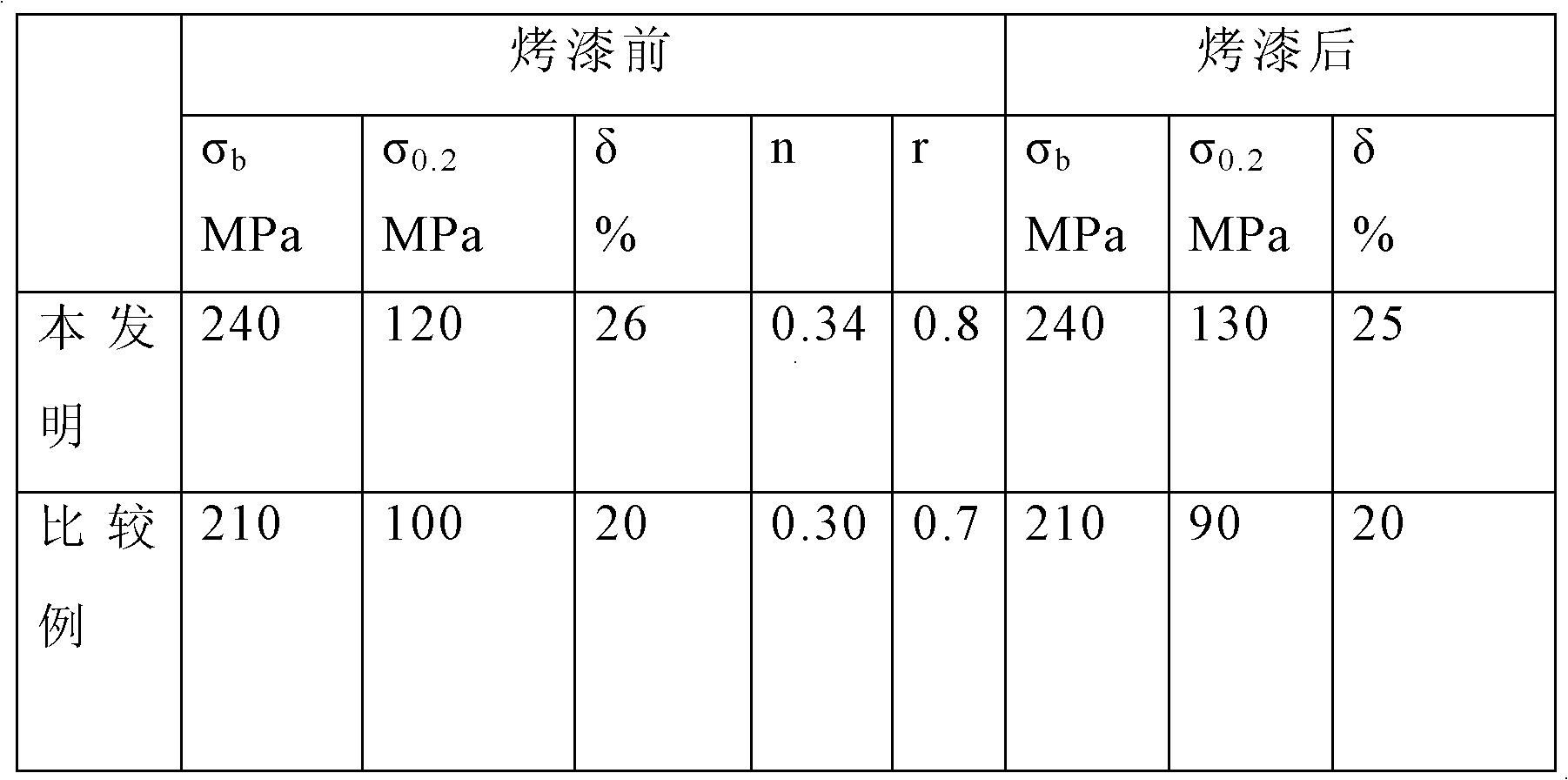

The invention provides Al-Mg alloys for automobile body sheets and a manufacturing method thereof, belonging to the technical field of alloy materials. The invention solves the problem that the existing 5754 series alloys have poor strength and impact resistance. The alloys comprise the following components in percentage by weight: 0.001-0.25wt% of Cu, 0.05-0.35wt% of Mn, 2.5-3.5wt% of Mg; 0.005-0.25wt% of Cr, 0.008-0.8wt% of Zn, 0.01-0.15wt% of Ti, 0.001-0.2wt% of Zr, not more than 0.2wt% of Si, not more than 0.3wt% of Fe and the balance Al. The alloys have the advantages of good impact resistance and plasticity and strong feasibility, and the manufacturing method has the advantage of realizing the aims of energy conservation and emission reduction in the process of machining.

Owner:ZHEJIANG GKO IND CO LTD

Reformable soft gasket

The reformable soft gasket consists of chloroprene rubber 2-10 wt%, teflon emulsion 50-84 wt%, silk floss or polymer fiber 3-20 wt%, reinforcing stuffing 0.5-5 wt%, lubricating oil 10-20 wt%, plasticizer 0.5-3 wt% and graphite 0-24 w. The gasket of the present invention has the features of excellent sealing performance, high durability, low friction coefficient, no need of water cooling, good self-lubricating performance, no wear of shaft and muff, power saving, corrosion resistance, capacity of being reused, etc.

Owner:关晓辉

High-strength and high-conductivity heat-resistant aluminum alloy wire and preparation method thereof

ActiveCN108559874AImprove mechanical propertiesReduce layer spacingConductive materialMetal/alloy conductorsHeat resistanceCerium

The invention provides a high-strength and high-conductivity heat-resistant aluminum alloy wire. The high-strength and high-conductivity heat-resistant aluminum alloy wire comprises the following compositions of, by weight, 0.2-2% of zirconium Zr, 5-12% of cerium Ce, 0.05-0.2% of iron Fe, 0.05-0.1% of silicon Si, less than 0.10% of other impurities and the balance aluminum. The invention furtherprovides a preparation method of the high-strength and high-conductivity heat-resistant aluminum alloy wire. The high-strength and high-conductivity heat-resistant aluminum alloy wire simultaneously has high strength, high conductivity and high heat resistance and low running line loss, the tensile strength of the heat-resistant aluminum alloy wire is greater than 280 MPa and can reach 322 MPa, the conductivity reaches 62% IACS, and the long-term running temperature can reach 210 DEG C. After heating at 280 DEG C for 1 hour for short-term heat resistance test, the strength increases instead ofdecreasing.

Owner:SHANGHAI JIAO TONG UNIV +1

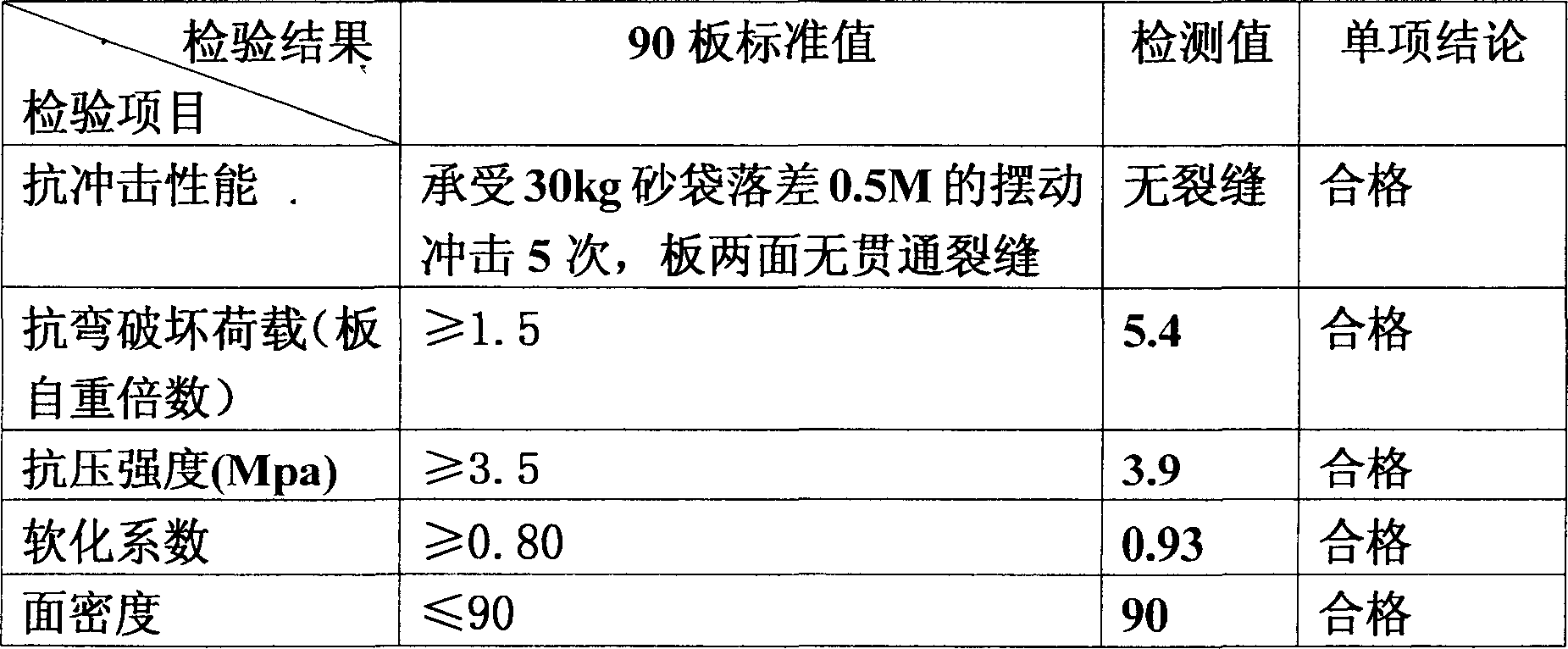

Light heat insulating sound proofing wall partition board and its production method

InactiveCN1785887ALight in massHigh strengthCeramic shaping apparatusSurface strengthMaterials science

The present invention relates to a light heat-insulating sound-proof partition wall board and its production method. It is made up by using cement, light asbestos wool, light stone granules and polypropylene fibre through a certain production process. Besides, said invention also provides the concrete steps of said production process.

Owner:杨立峰

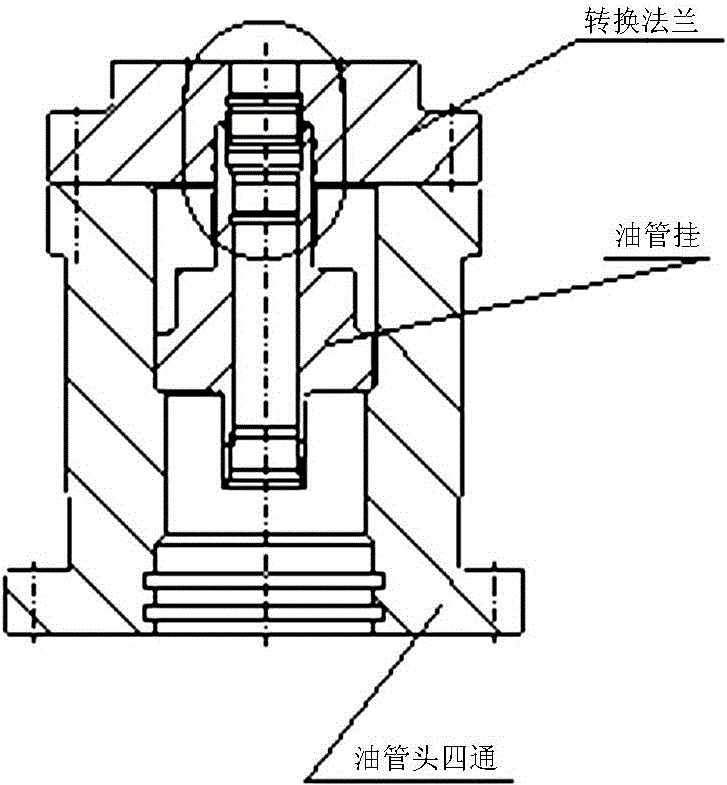

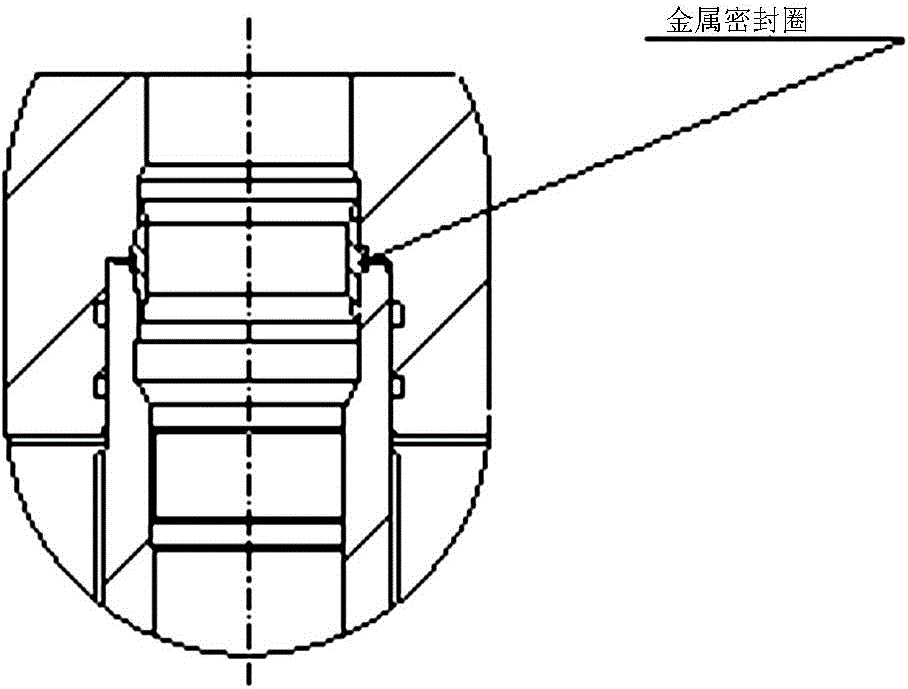

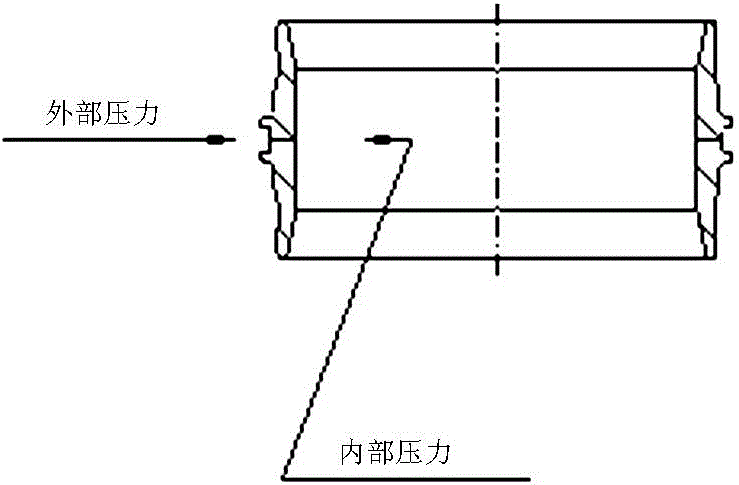

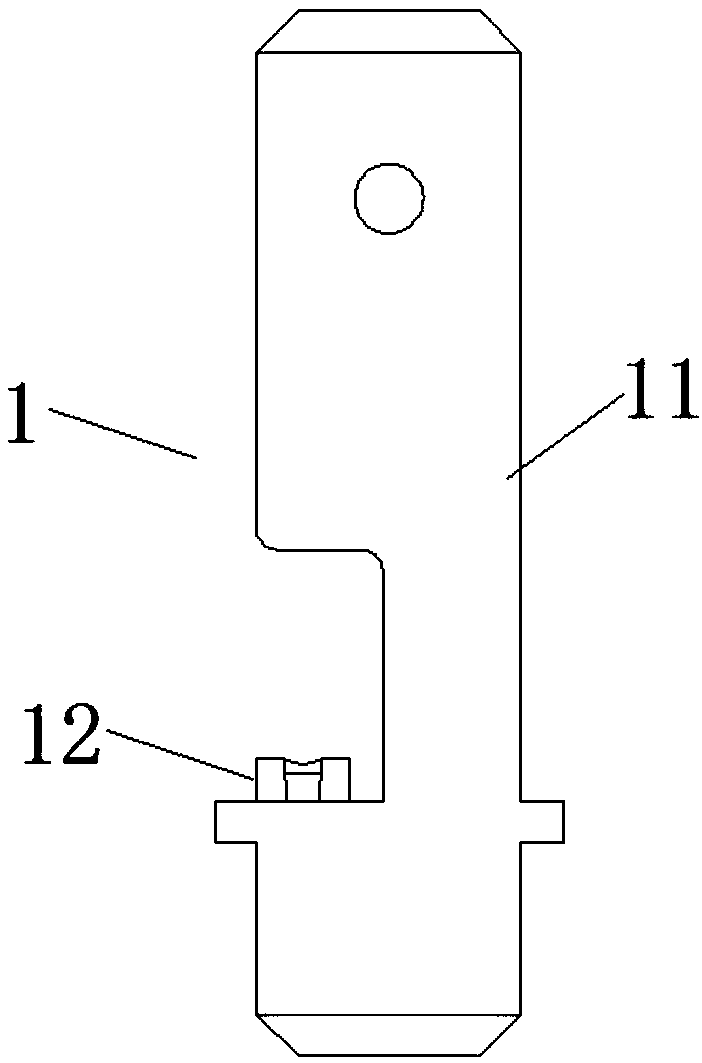

Metal sealing ring for end part of oil pipe hanger, and sealing device

InactiveCN106065947ASimple structureReduce volumeEngine sealsSealing/packingTubing hangerEngineering

The invention discloses a metal sealing ring for an end part of an oil pipe hanger, and a sealing device. The metal sealing ring comprises a metal sealing ring body, wherein the longitudinal section of the metal sealing ring body is rhombic, and a plurality of annular stress relief grooves and deformation grooves which are horizontally arranged are formed in both of the inner wall and the outer wall of the metal sealing ring body at intervals from top to bottom. The sealing device comprises an upper support ring, a lower support ring and the metal sealing ring, wherein the upper support ring and the lower support ring are arranged on the top surface and the bottom surface of the metal sealing ring respectively; the bottom surface of the upper support ring is an inclined surface, and the inclined surface contacts with the vertex angle of the metal sealing ring body and has an angle difference; and the top surface of the lower support ring is an inclined surface, and the inclined surface contacts with the base angle of the metal sealing ring body and has an angle difference. The metal sealing ring and the sealing device, which are disclosed by the invention, have the advantages of being simple in structure, small in size, liable to deform, capable of forming metal sealing with a carrier, good in sealing reliability, and capable of being used for a corrosion environment; and meanwhile, stress deformation is elastic deformation, and the metal sealing ring and the sealing device can be repeatedly used without damage to the carrier, so that the cost can be reduced.

Owner:SHANDONG KERUI WELL CONTROL SYST MFG

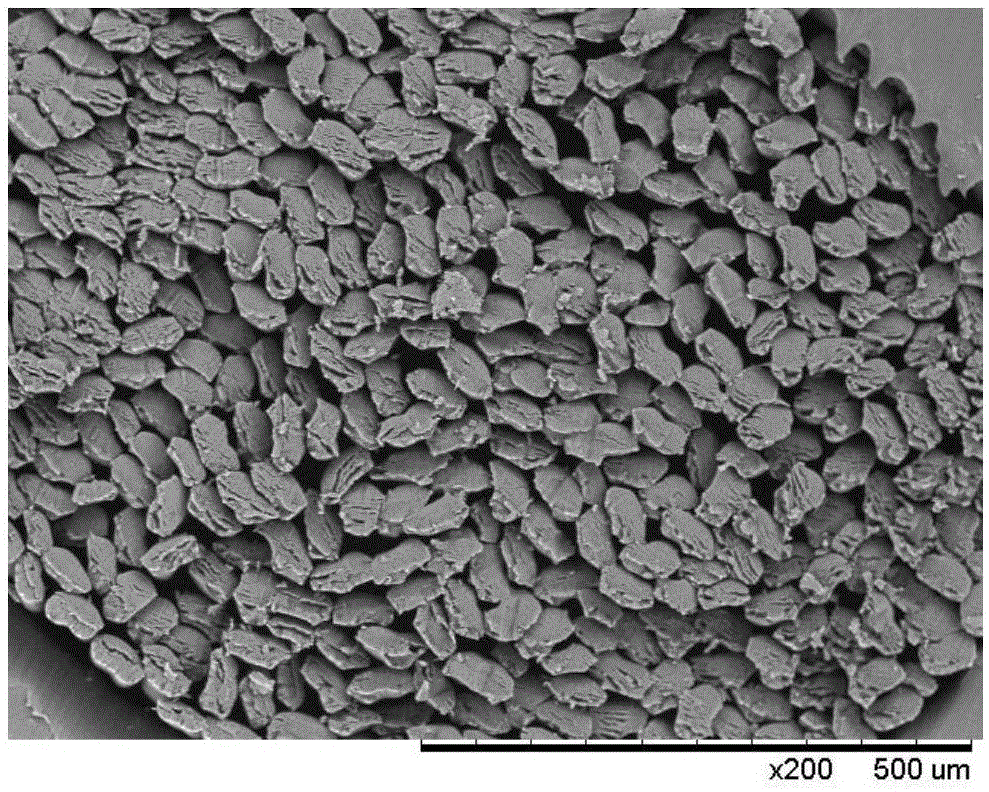

Preparation method of low-temperature quick-soluble agar

InactiveCN106977752ALower melting temperatureImprove solubilityHigh pressureUltimate tensile strength

The invention discloses a preparation method of low-temperature quick-soluble agar. The method comprises the following steps: 1, mixing agar powder with water to obtain a mixture, and heating at high temperature until the mixture is completely dissolved to form an agar solution; 2, carrying out ultrasonic treatment of the agar solution; 3, adding cosolvent into the solution obtained in the step 2, fully dissolving and evenly stirring; 4, carrying out high pressure homogenization treatment of the solution obtained in the step 3; 5, carrying out granulation treatment of the solution obtained in the step 4; and 6, sieving to prepare the low-temperature quick-soluble agar. Under the premise of reducing a melting point of the low-temperature quick-soluble agar, the low-temperature quick-soluble agar has relatively strong gel strength.

Owner:青岛德慧海洋生物科技有限公司

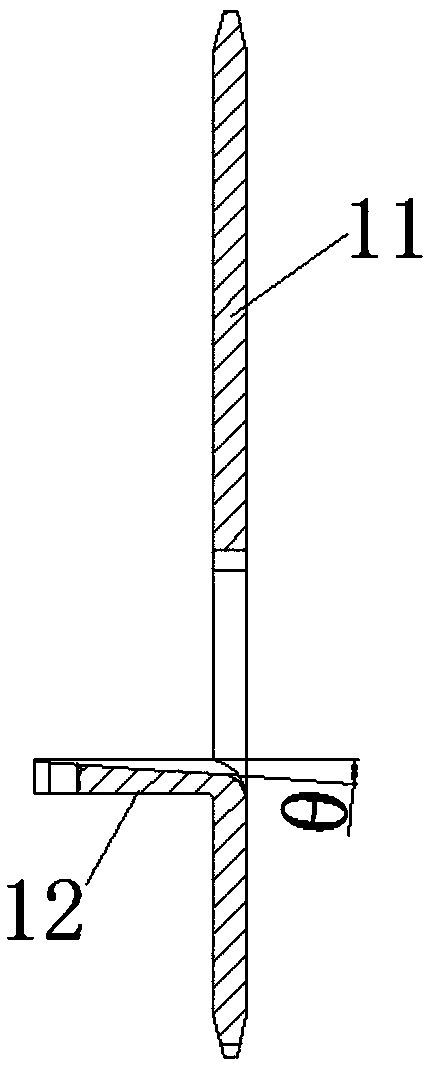

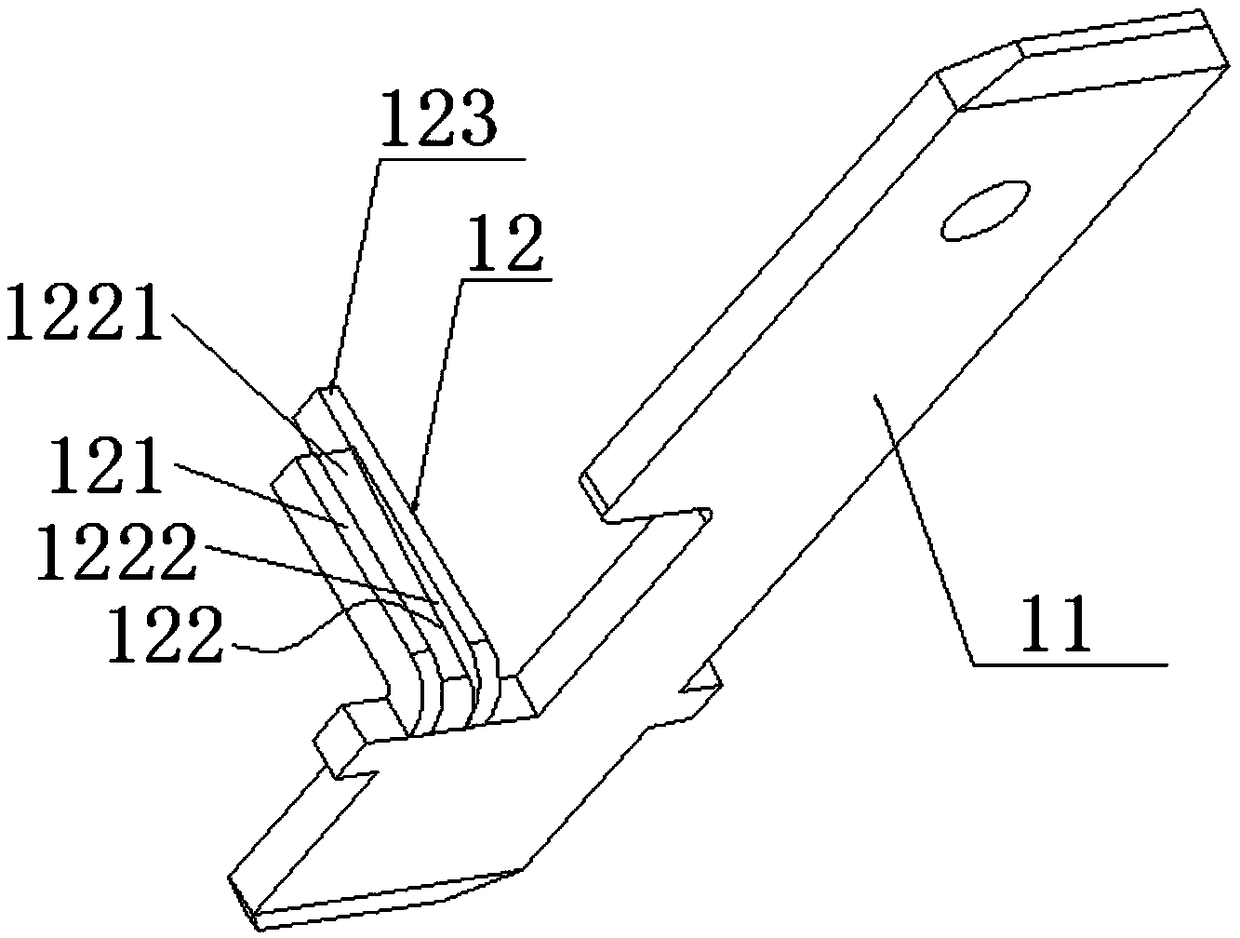

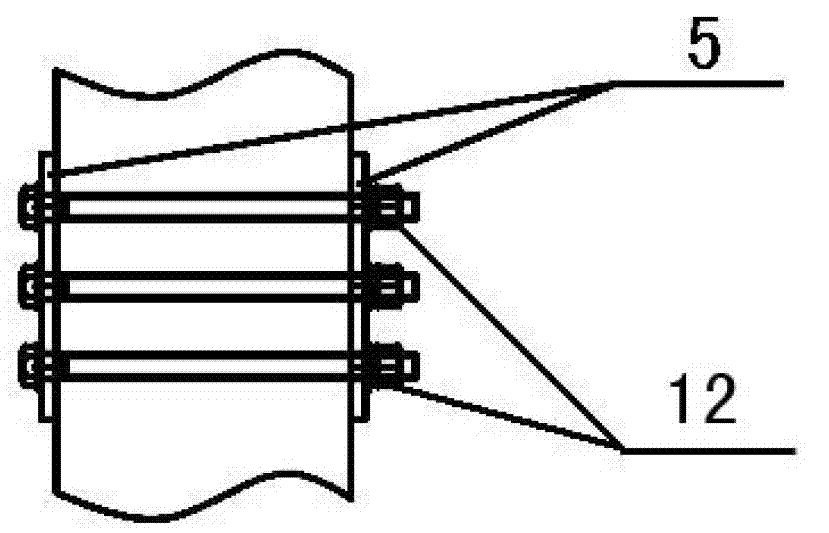

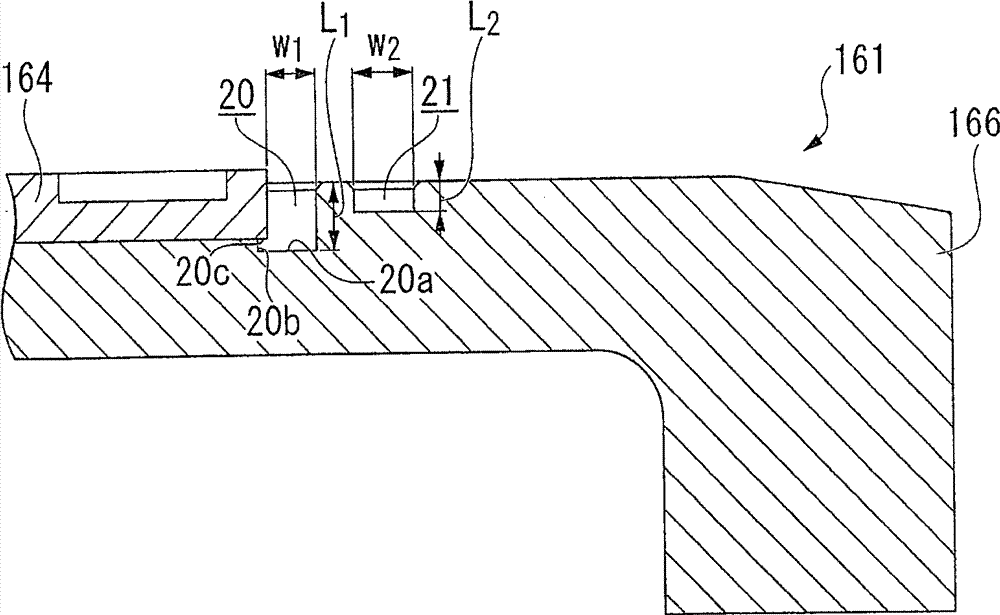

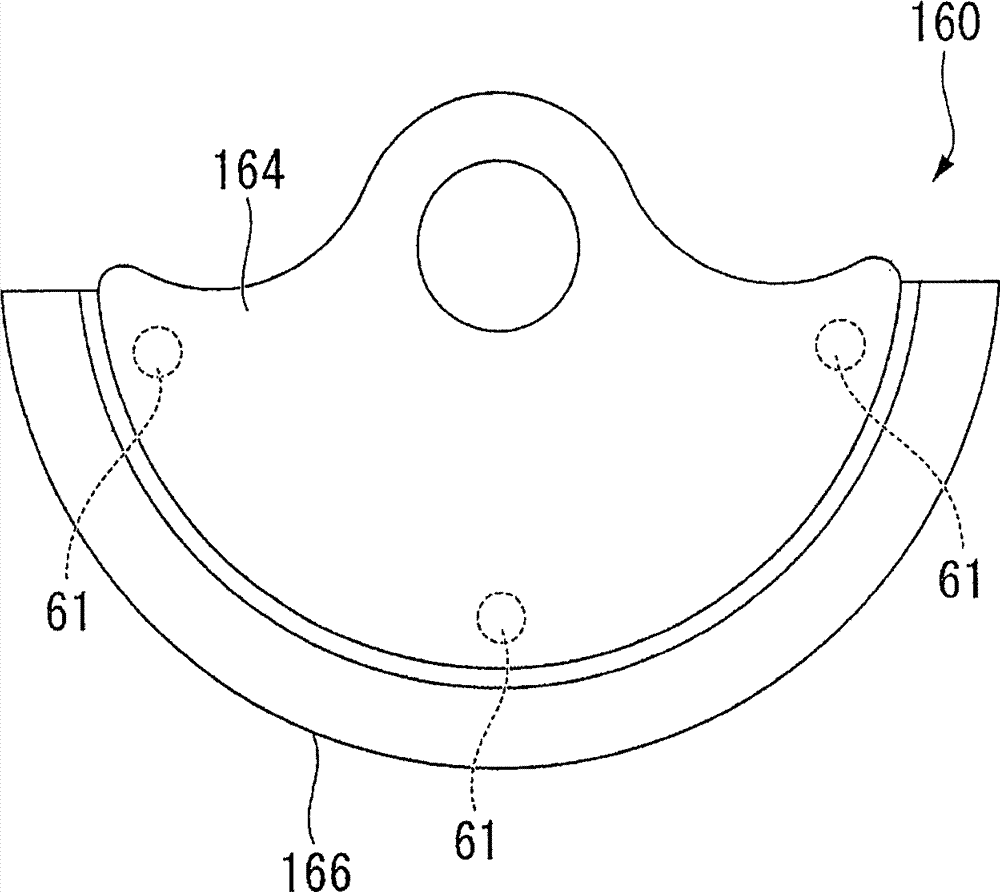

Connection structure of wiring terminal and enameled wire, method, coil assembly and motor

PendingCN109301567ARealize butt welding connectionReduce the possibility of corrosionLine/current collector detailsCoupling device detailsBinding postEngineering

The invention provides a connection structure of a wiring terminal and an enameled wire, a connection method, a coil assembly and a motor. The wiring terminal of the present invention comprises a wiring terminal body, and a wiring post which is connected with the wiring end of the enamel wire; the wiring post is fixed to the wiring terminal body and includes a first surface, and a first groove which is formed in the first surface and faces downwardly; the connection structure of the wiring terminal and the enameled wire includes the enameled wire and the wiring terminal; the wiring end of theenameled wire is arranged in the first groove; a fixing terminal is crimped and is fixed to the wiring end of the enameled wire and the wiring post; and the wiring end of the enameled wire is butt-welded to the fixing terminal and the wiring post. With the connection structure, and the connection method of the invention adopted, the enameled wire can be arranged and fixed on the wiring post more conveniently and firmly, the enameled wire can be favorably protected, and the enameled wire is unlikely to be damaged due to external forces; the butt-welded connection of the enameled wire and the wiring post is realized, and therefore, the length of the removed sheath of the enameled wire can be controlled, and the service life of the coil assembly or motor can be prolonged.

Owner:HANYU GRP CO LTD

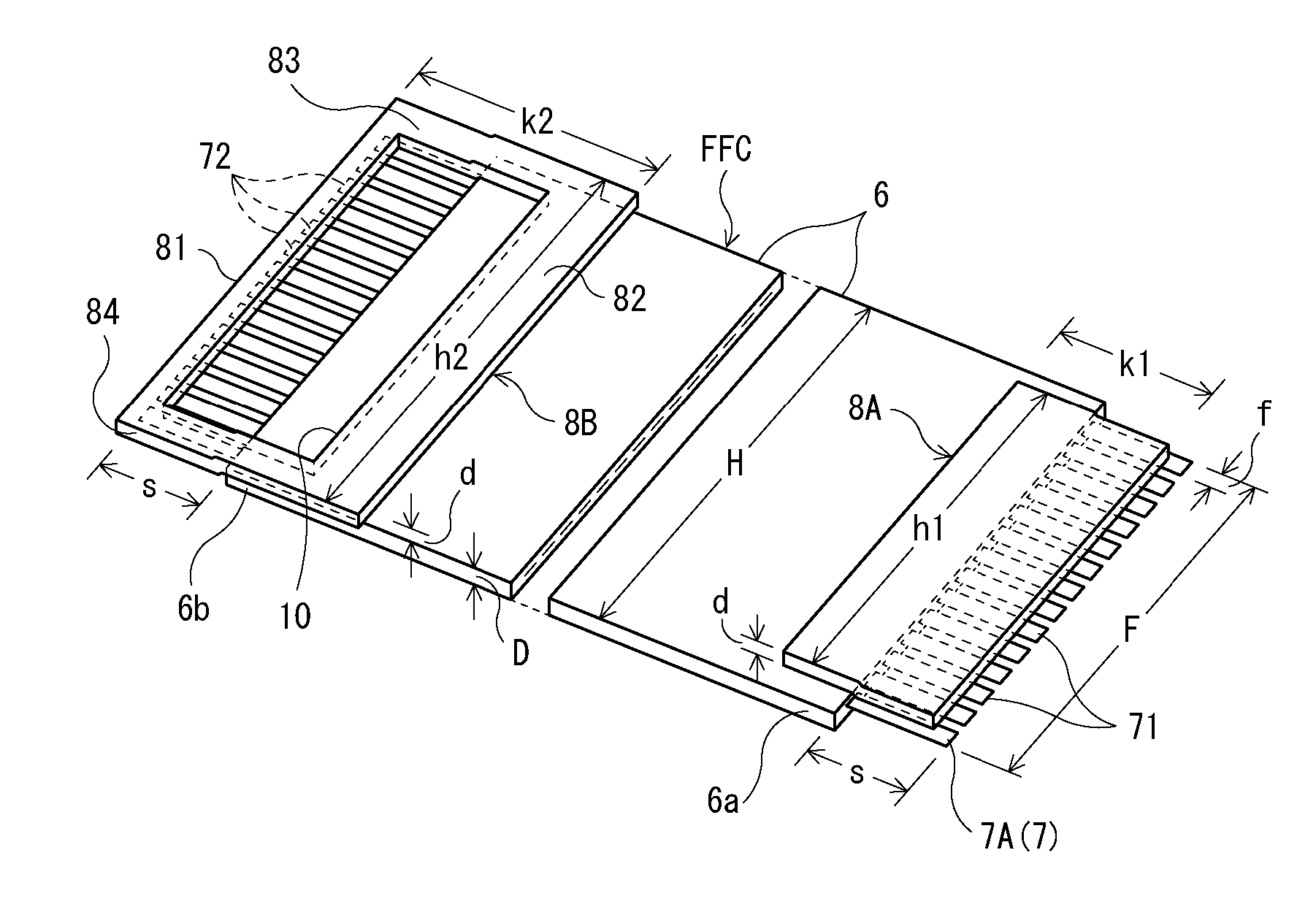

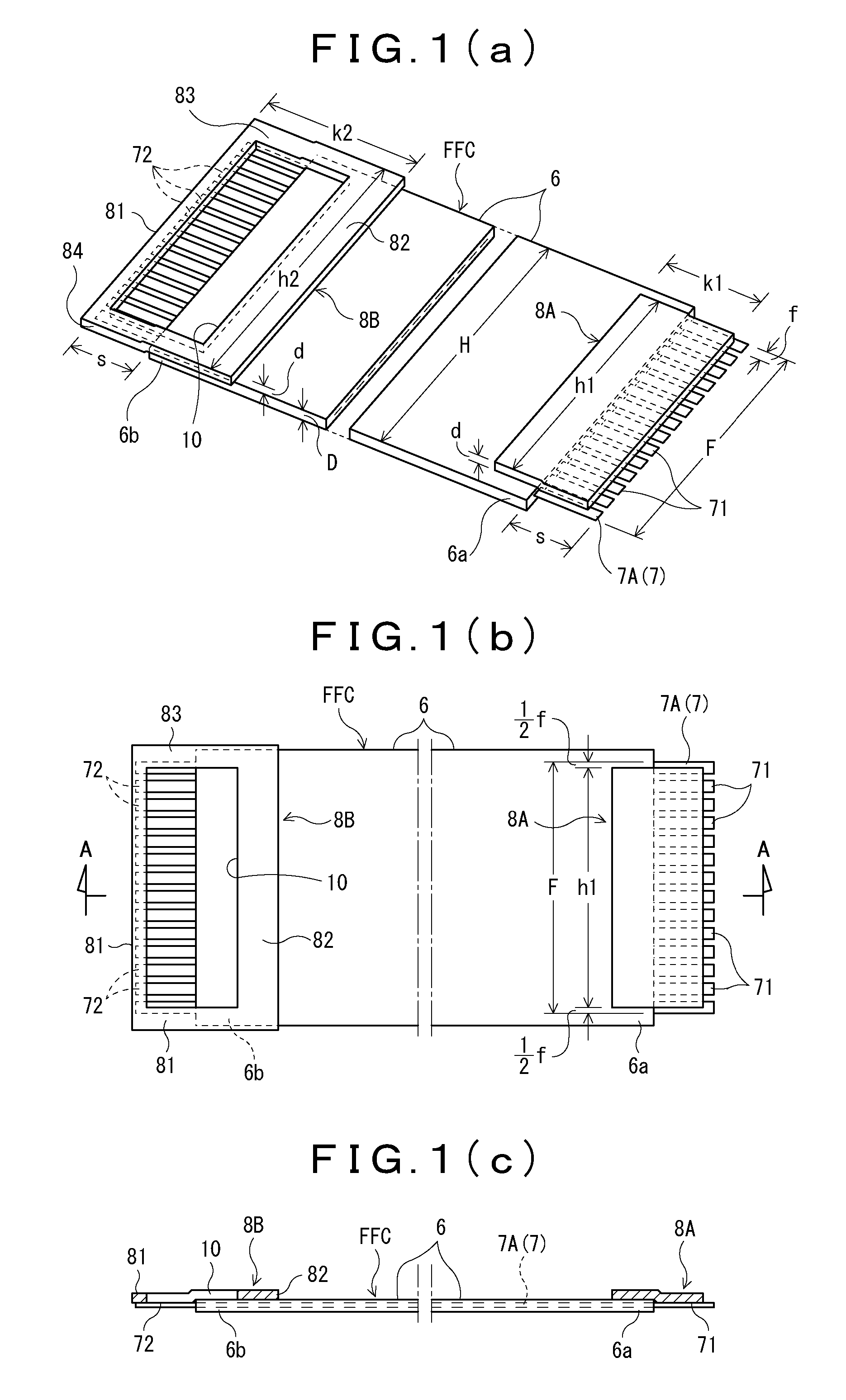

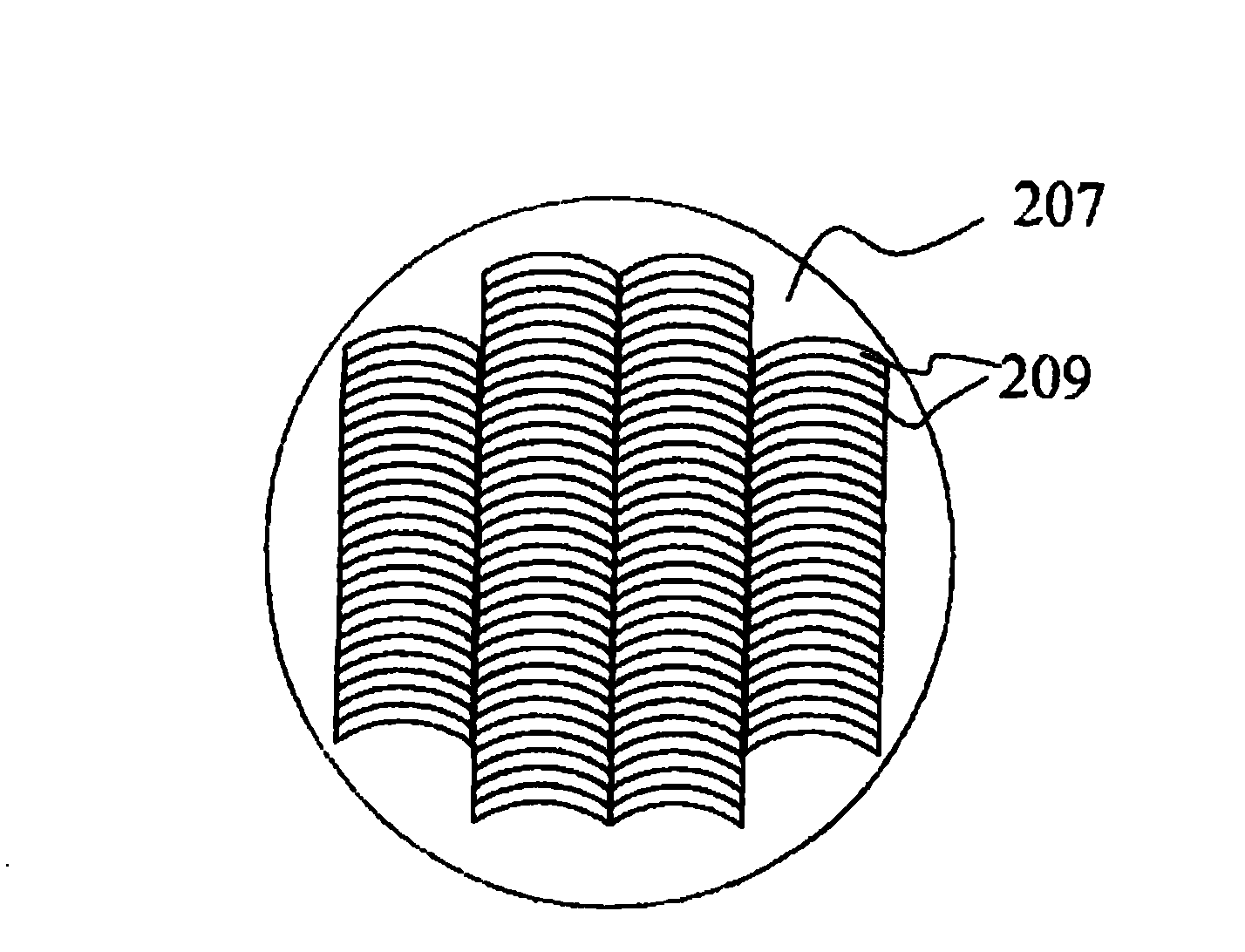

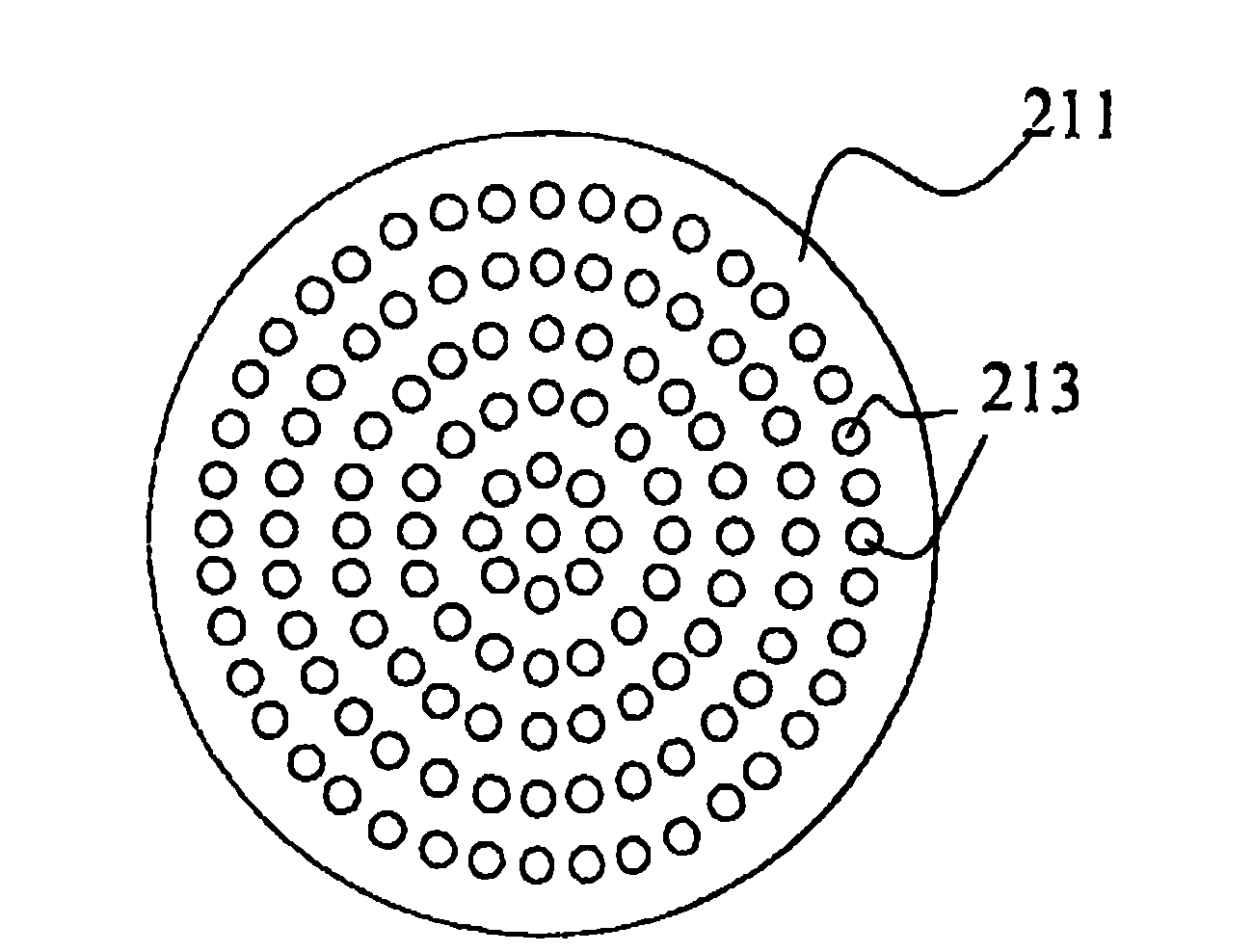

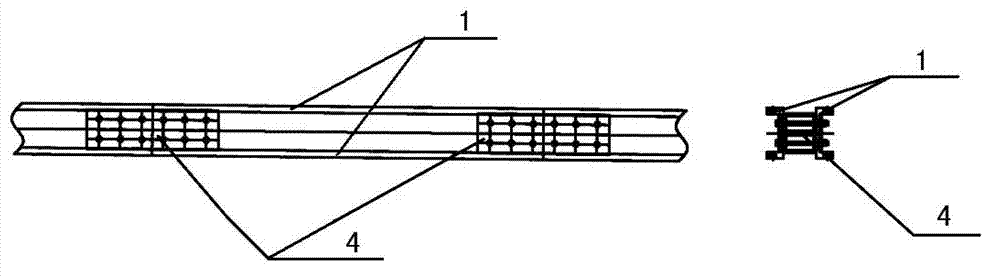

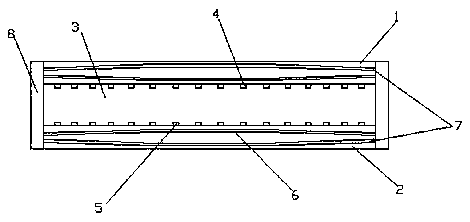

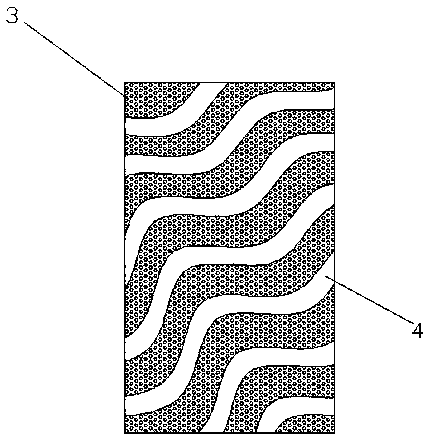

Flexible flat cable, method and apparatus for assembling the same

InactiveUS20070068698A1Reduce material costsWithout riskElastomeric connecting elements apparatusFlat/ribbon cablesEngineeringSynthetic resin

A flexible flat cable and an apparatus for assembling the flexible flat cable are provided. The flexible flat cable has a conductive wire group including conductive wires disposed parallel to each other and arranged in a synthetic resin cover, in which both end portions and of the conductive wire group protrude outward from the end edges of the cover, and a pair of synthetic resin reinforcing plates are fixed to areas extending from one surface at the respective end portions of the cover through one surface at the respective end portions of the conductive wire group. One of the reinforcing plates includes a hollow square reinforcing plate formed by providing a through hole at the center of a reinforcing plate, and the other reinforcing plate includes a central reinforcing plate extracted from the hollow square reinforcing plate.

Owner:FUNAI ELECTRIC CO LTD

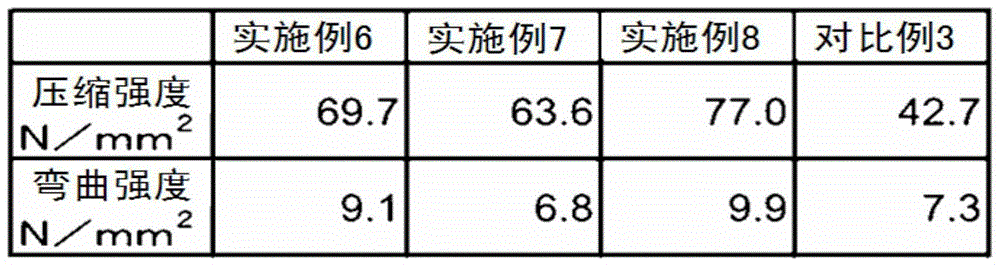

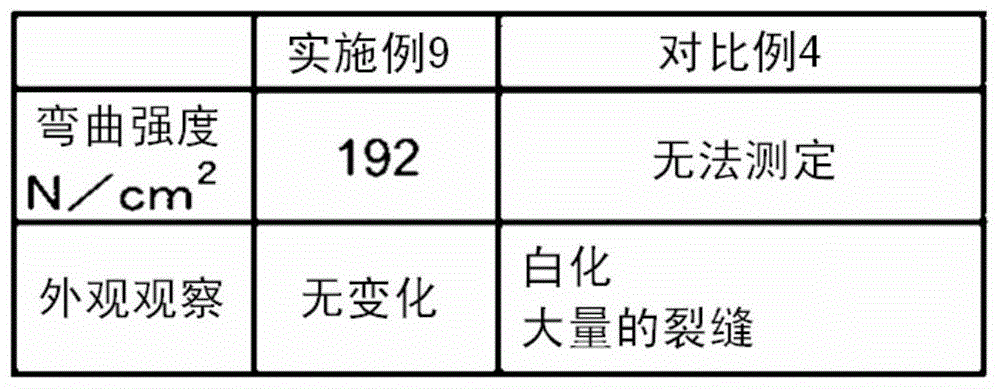

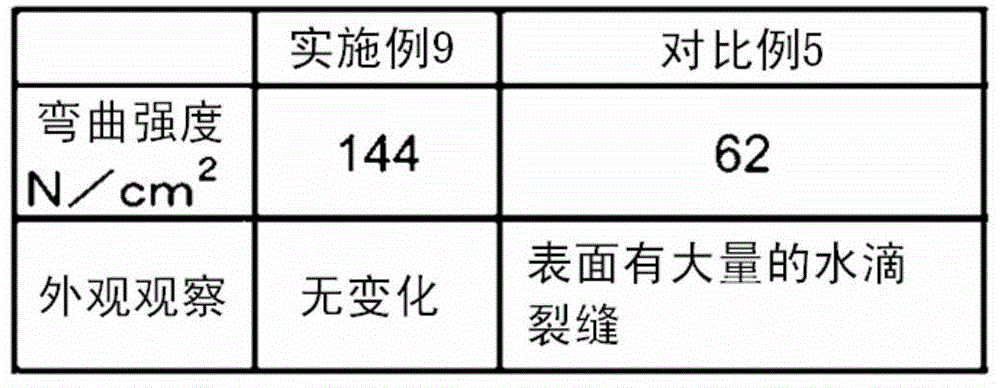

Magnesia cement

InactiveCN106007426AConducive to preservationNo reduction in strengthOxideMagnesium sulphate heptahydrate

The invention provides magnesia cement that has an excellent storage property and is cured to become magnesia concrete having excellent stability. The magnesia cement at least comprises (a) magnesium oxide, (b) at least one of mono- to hexa-hydrates of magnesium chloride, and (c) at least one of mono- to hepta-hydrates of magnesium sulfate. When (b) magnesium chloride includes mono-hydrate or hepta-hydrate, (c) magnesium sulfate is not hepta-hydrate.

Owner:AKO KASEI CO LTD

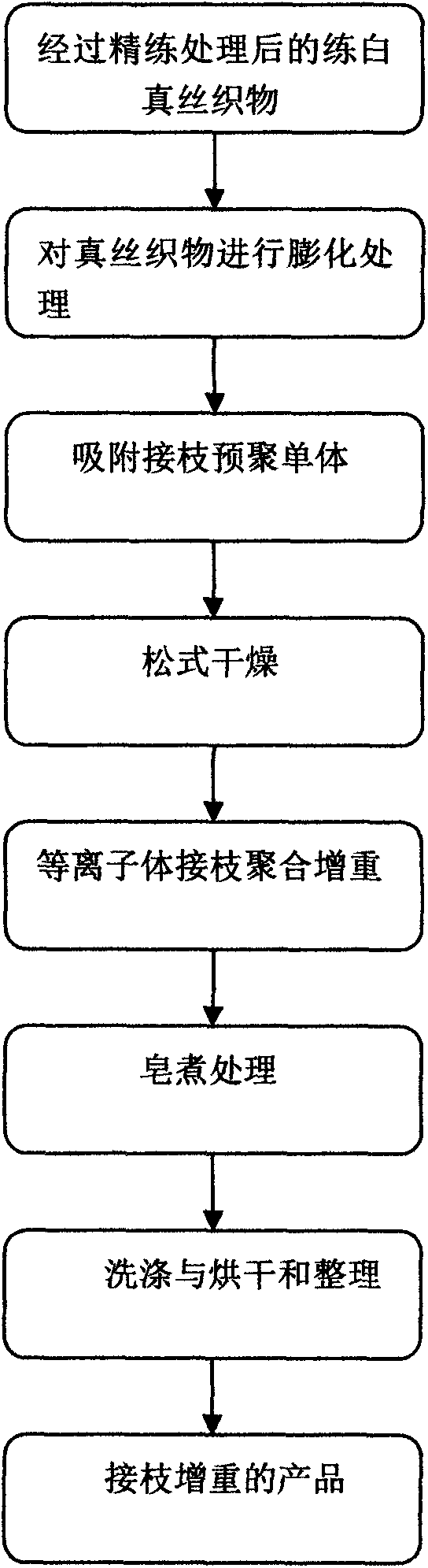

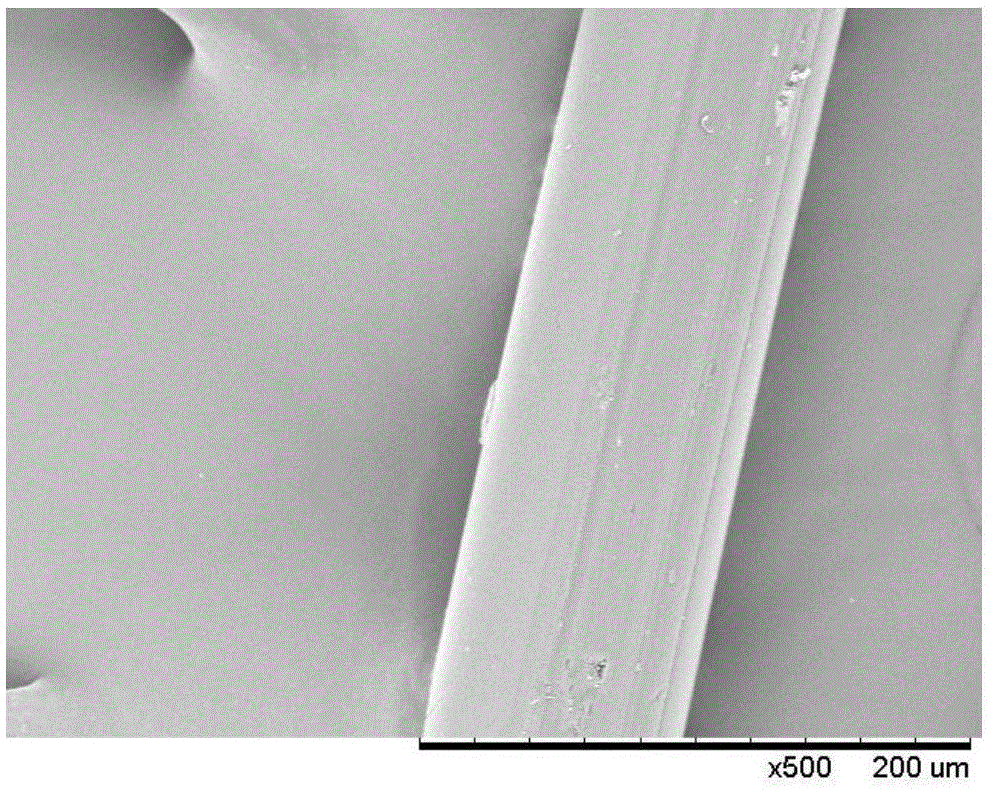

Method for plasma graft weight gaining of real silk fabric

ActiveCN103437171AImprove uniformityHigh degree of bindingDry-cleaning apparatus for textilesAnimal fibresWeight gainingMonomer

The invention discloses a method for plasma graft weight gaining of real silk fabric, and belongs to the technical field of functional arranging of fabric. The method comprises the steps of real silk fabric preparing, refining processing, expansion processing, graft liquid adsorbing, loose drying, plasma graft polymerization weight gaining, soap boiling processing, washing, stoving and arranging. Prepolymerized graft monomers with certain molecular weight are utilized to be adsorbed on to-be-grafted fabric firstly, and then led into the inner surface and the outer surface of the real silk fabric; then the real silk fabric is led into plasma graft equipment to be carried out graft weight gaining polymerization reaction; industrialized production can be carried out; the graft liquid can be repeatedly used; the method has the advantages that the effect is good, the technology is simple, the energy is conserved, the efficiency is high, and the cleaning production and the environmental protection are facilitated; the graft degree is just right on the basis that the original style of the real silk fabric is not influenced; thick and elastic effects of lighter real silk fabric are realized; the purpose of improving wearability of the real silk fabric is achieved.

Owner:DALI SILK ZHEJIANG

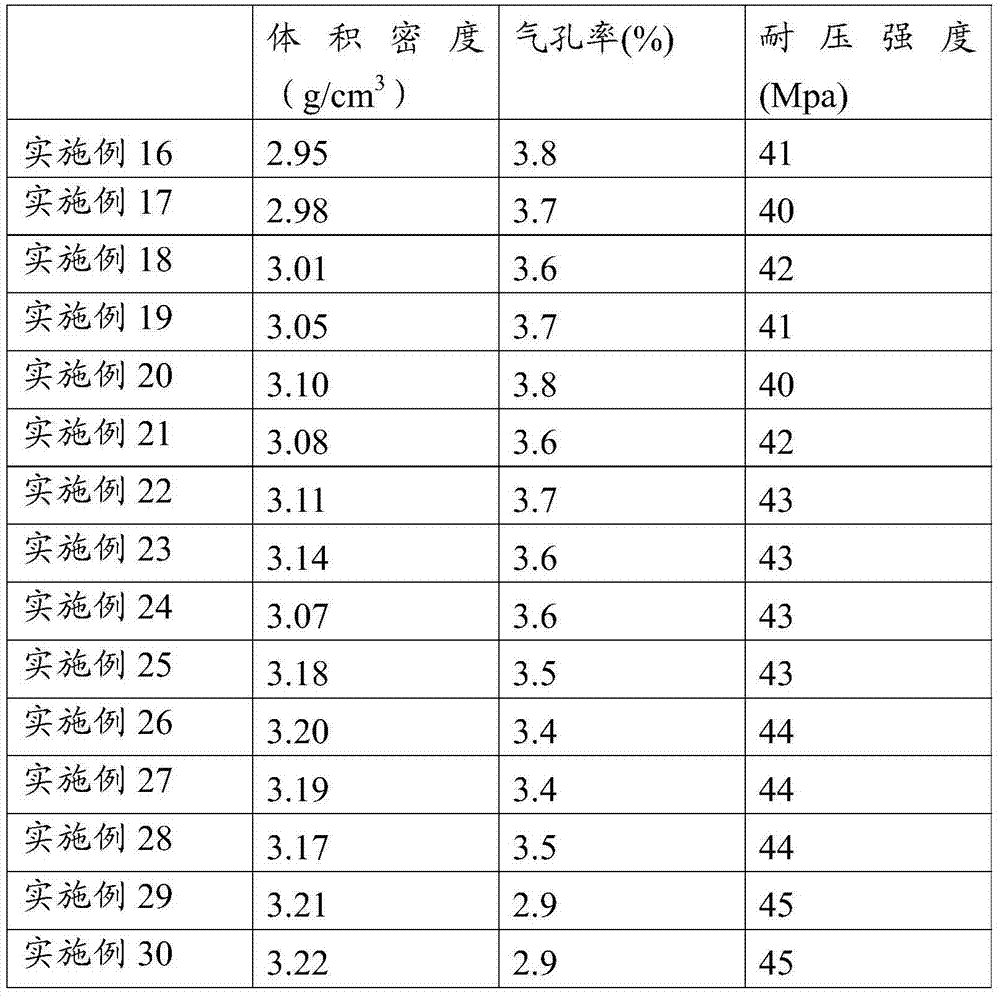

Refractory material

The invention provides a refractory material which is prepared from a refractory-material main material and an auxiliary materials. The auxiliary material comprises a lignin-saccharide composition and phenol formaldehyde resin; the lignin-saccharide composition comprises lignosulfonate and saccharides; the saccharides are selected from one or more of monosaccharide, disaccharide, oligosaccharide and sugar alcohol; the mass ratio of the lignosulfonate to the saccharides is (5 to 90):(90 to 5). The refractory material provided by the invention is prepared from the refractory-material main material and the auxiliary materials, wherein the auxiliary material comprises the lignin-saccharide composition. The lignin-saccharide composition provided by the invention can partially replace the phenol formaldehyde resin to be used as an adhesive of the refractory material, has a good adhering effect when being applied to the field of the refractory material. Moreover, the lignin-saccharide composition provided by the invention is low in preparation cost, has no residual harmful substances such as free phenol, free aldehyde and the like, and is environmental-friendly.

Owner:JINAN SHENGQUAN GROUP SHARE HLDG

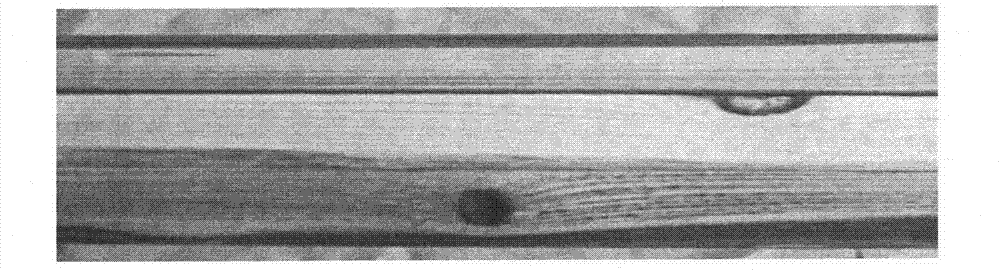

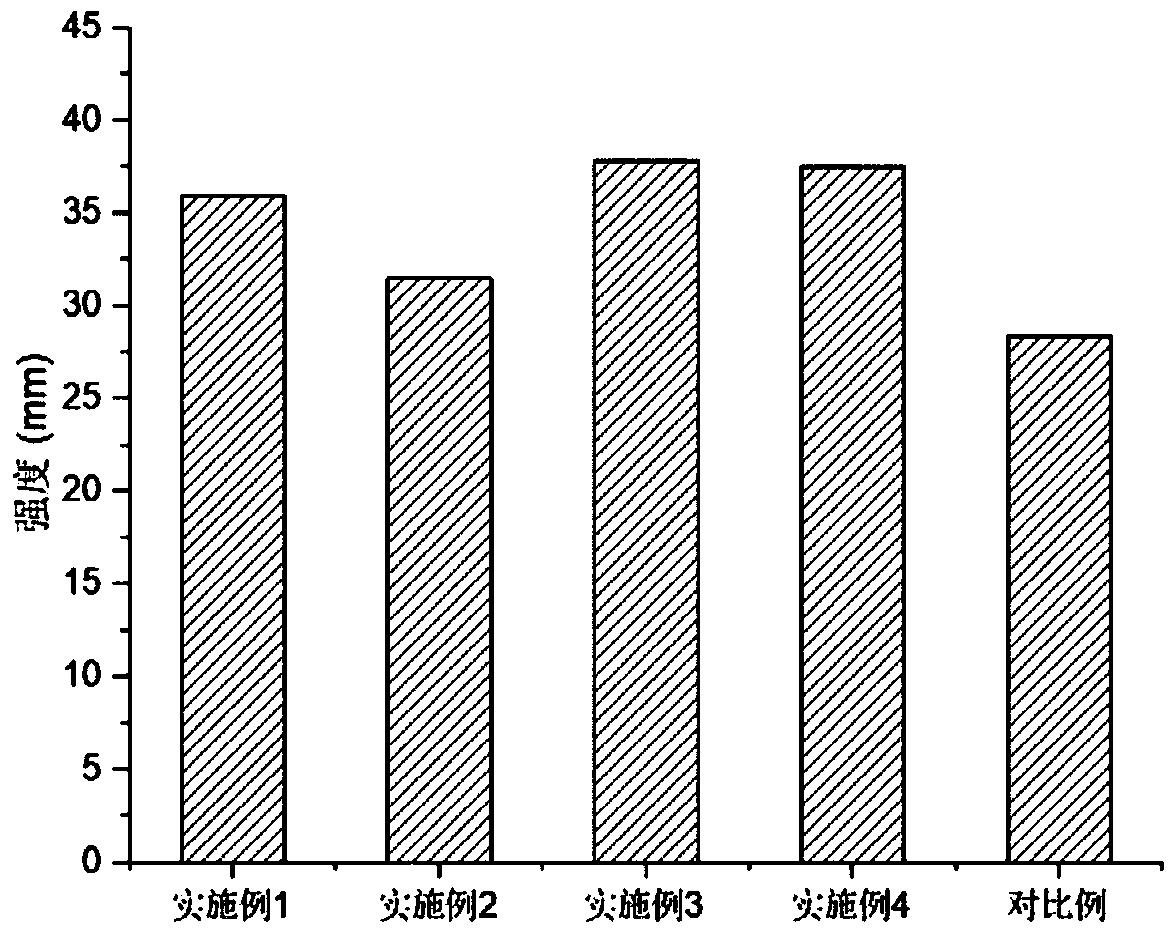

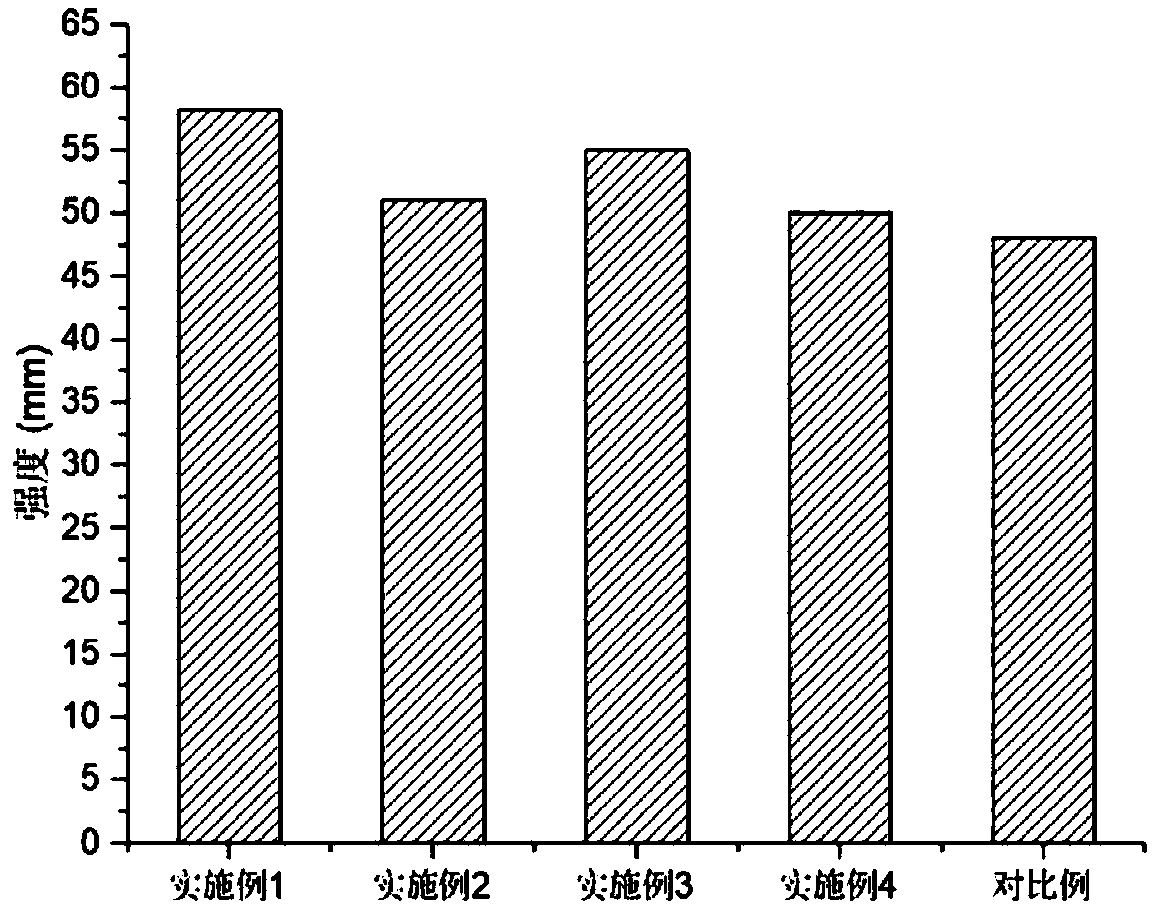

Pretreatment method used before processing fast growing wood surface concave-convex textures

InactiveCN102785274ANo reduction in strengthLittle change in intensityWood impregnation detailsSolid woodPaulownia

The invention relates to a pretreatment method used before processing fast growing wood surface concave-convex textures, wherein a purpose of the present invention is to overcome serious influence on strength and stiffness of fast growing wood due to traditional wood pretreatment chemical reagents such as strong acids and strong bases. The present invention provides a scheme for carrying out a softening pretreatment on Chinese redwood, paulownia, and pinus massoniana lamb by using a NH3.H2O solution separately providing an effect, wherein the Chinese redwood is treated for 2 hours at a temperature of 10 DEG C by using a 3% NH3.H2O solution, the paulownia is treated for 2 hours at a temperature of 30 DEG C by using a 2% NH3.H2O solution, and the pinus massoniana lamb is treated for 2 hours at a temperature of 30 DEG C by using a 2% NH3.H2O solution. The pretreatment method of the present invention has the following advantages that: strength of fast growing wood pretreated by the pretreatment process of the present invention is not significantly reduced; with processing, decorative solid wood boards with a large breadth and natural texture concave-convex effects are obtained; the product can be widely used in interior decorations and furniture manufacturing decorations; a new approach is developed for application of fast growing wood in engineering and industrial wood fields; no secondary pollution is generated, cost is low, and the processing method is easy to popularize.

Owner:NANJING FORESTRY UNIV

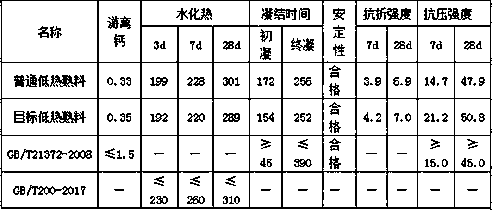

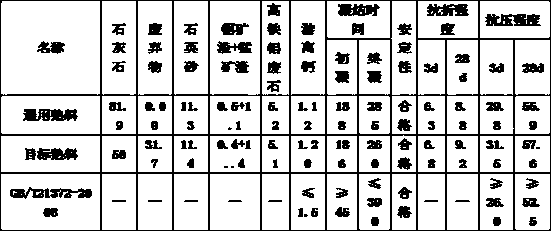

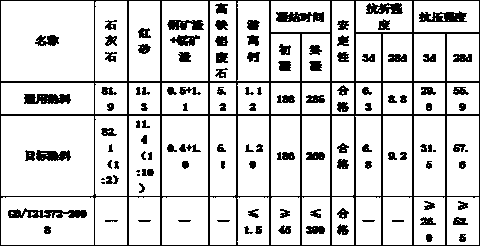

Silicate cement clinker and preparation method thereof

The invention discloses silicate cement clinker and a preparation method thereof, and relates to the technical field of preparation of cement. The silicate cement clinker prepared by the invention isprepared from the following raw materials in percentage by weight: 42-72% of limestone as a calcium material, 1-20% of a silicon material, 10-40% of a supplement calcium material, 0-5% of an iron material, and 3-15% of an iron-aluminium material. The supplement calcium material is limestone moulding sand waste. According to the invention, the limestone moulding sand waste is applied to the cementclinker, so that cost of the enterprises can be reduced; waste can be changed into things of value; and great social benefits and economic benefits are achieved for society and the enterprises.

Owner:JIAHUA SPECIAL CEMENT

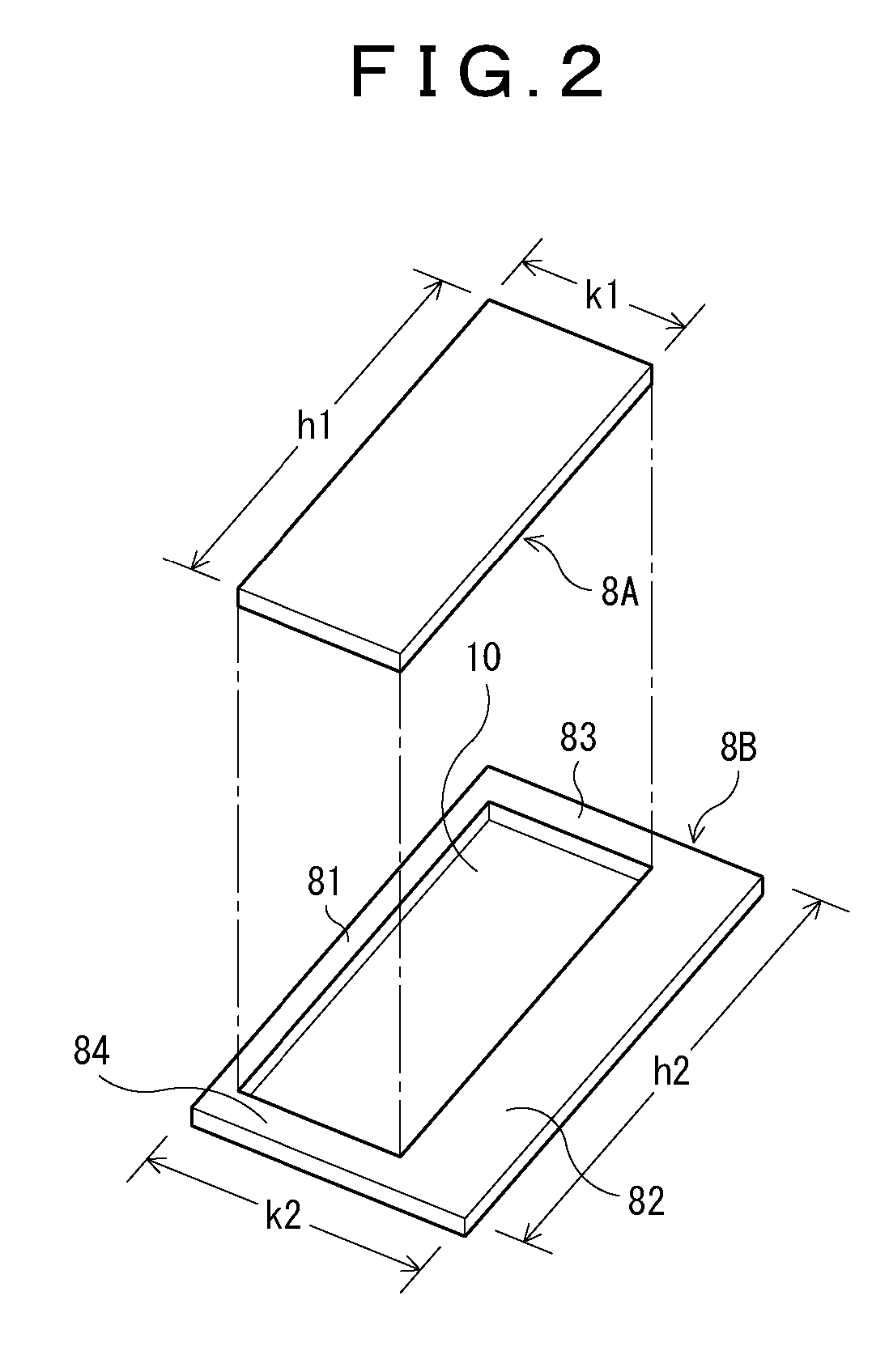

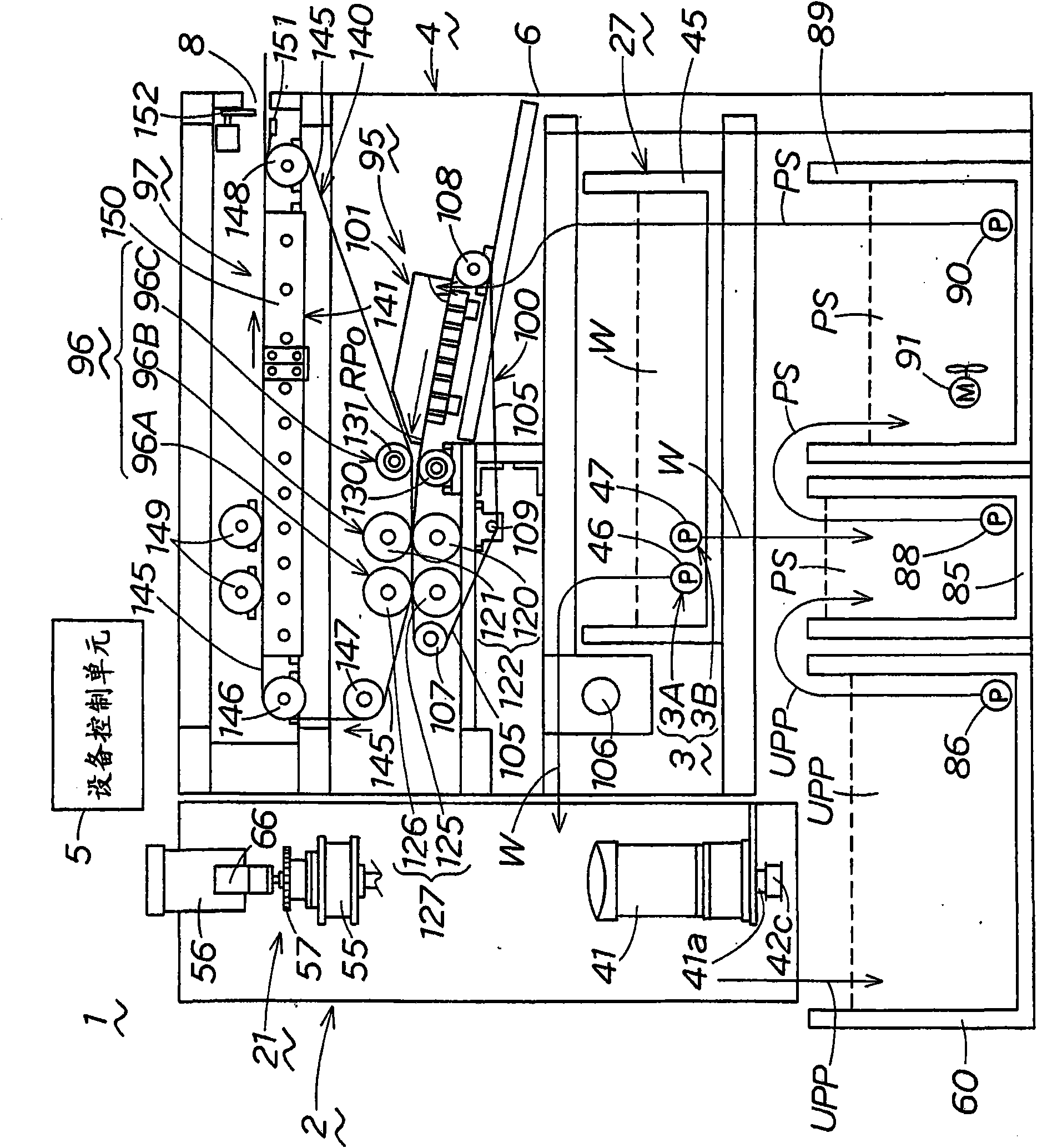

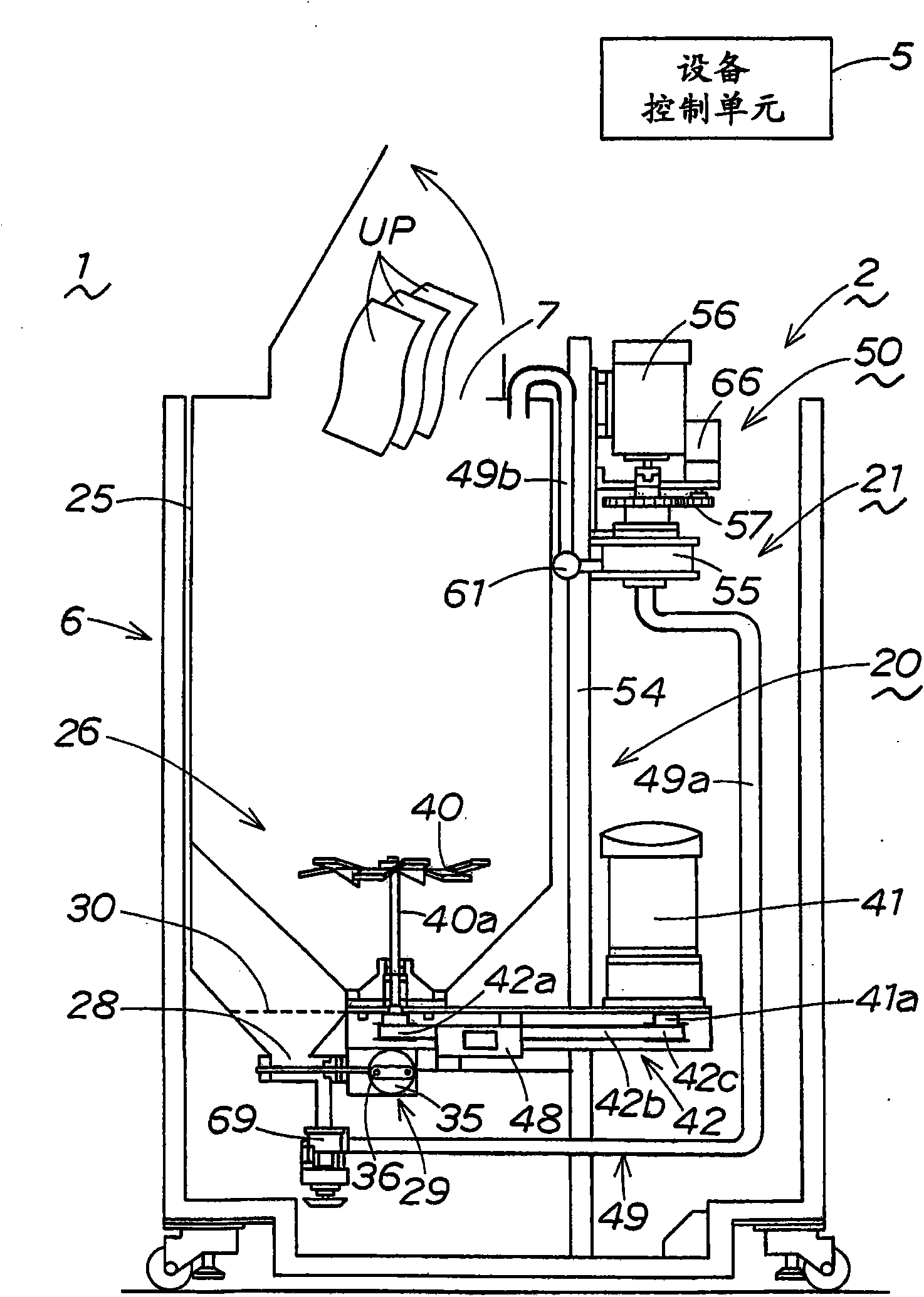

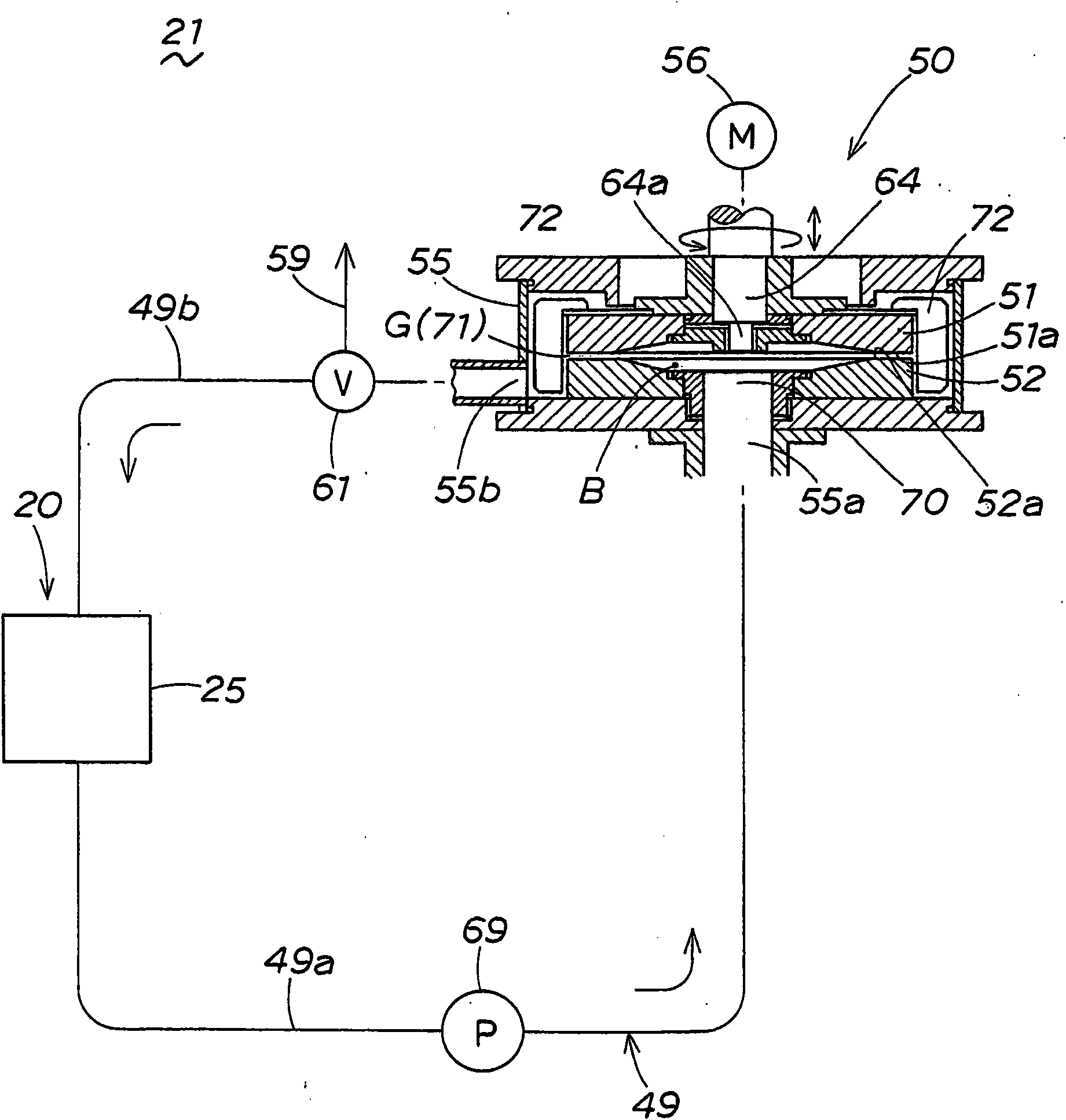

Dewatering device of used paper recycling apparatus and used paper recycling apparatus

InactiveCN101876151AUniform paper quality without differencesPrevent leakagePaper recyclingWaste paper working-upPaper recyclingGeneral family

The invention relates to a paper making apparatus of a used paper recycling apparatus of furniture size and a used paper recycling apparatus. In the used paper recycling apparatus of furniture size that can be installed not only in a big office, but also in a small shop or general household room, this is a paper making device for making and producing recycled paper that is hardly lowered in strength if re-used repeatedly. The running condition of the mesh belt which runs while filtering and dewatering the pulp suspension is set in a range of maintaining the pulp fibers in the pulp suspension supplied on the mesh belt in a non-directional and disorderly array state, and therefore the manufactured recycled paper is free from so-called 'texture of paper' and the paper quality is uniform in anisotropy not different in longitudinal and lateral directions, and is sufficiently high in strength.

Owner:SEED RUBBER CO LTD

Method for preparing curcumin-loaded polyacrylonitrile fiber by dope dyeing method

ActiveCN105040137AHigh color fastnessHigh affinitySenses disorderMuscular disorderPolymer scienceSolvent

The invention discloses a method for preparing a curcumin-loaded polyacrylonitrile fiber by a dope dyeing method. A wet spinning technology, a dry spinning technology or a dry-jet wet spinning technology can be adopted by a spinning solution which is prepared from polyacrylonitrile, curcumin, a skin penetration enhancer and a solvent; the prepared fiber is beautiful yellow, and can be continuously used directly as a colored fiber without dyeing processing; the color fastness is greater than or equal to 4-5 grades; the method is applied to a drug-loaded functional fiber, has a drug sustained-release effect, and is convenient to medicate and small in side effect; and the curcumin-loaded polyacrylonitrile fiber has weaving mechanical property and can be woven into a fabric.

Owner:LANGSHA KNITTING

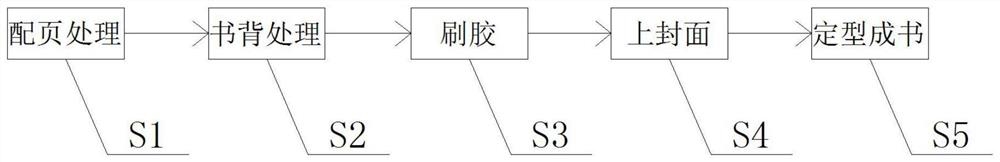

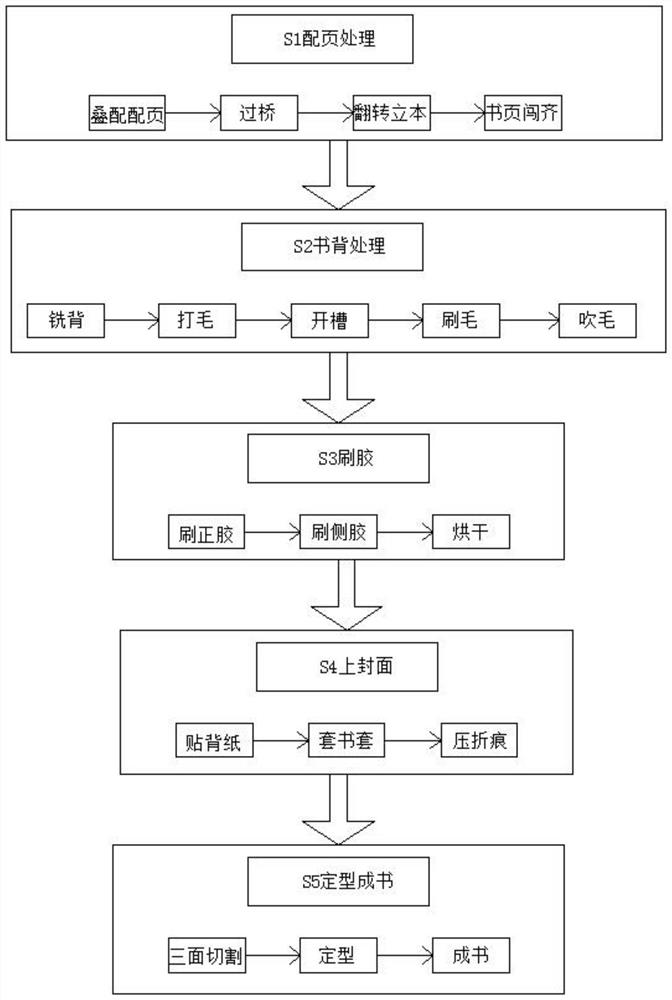

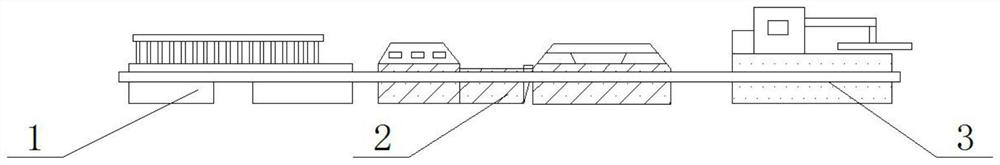

Book gluing and binding method

InactiveCN112572012AInhibit productionSave production raw materialsBook making processesBookbinding adhesivePaper dustAdhesive glue

The invention discloses a book gluing and binding method. The method comprises the steps of book feeding treatment, book back treatment, gluing, covering and book shaping. A page detection device is arranged, so that unqualified pages are prevented from flowing into subsequent procedures, the qualification rate of books is effectively improved, and the waste of raw materials is avoided; a book back treatment mechanism is redesigned, so that paper scraps are prevented from affecting adhesion of glue, strength of the books is improved, meanwhile, the paper scraps on the pages can be prevented from falling into a glue pool, and purity of the glue is guaranteed. A first glue roller, a second glue roller and a distance sensor are arranged, so that gluing of the pages is neither too thick nor too thin, gluing is more uniform, waste of the raw materials can be avoided, and strength and reading experience of the books are not influenced. PUR hot melt adhesive is adopted for book adhesive binding, so that the reading comfort of a reader is improved, and use at high temperature or low temperature can be facilitated. Finally, the cooling time of PUR adhesive coating is shorter, so that the book processing speed is increased.

Owner:储茂东

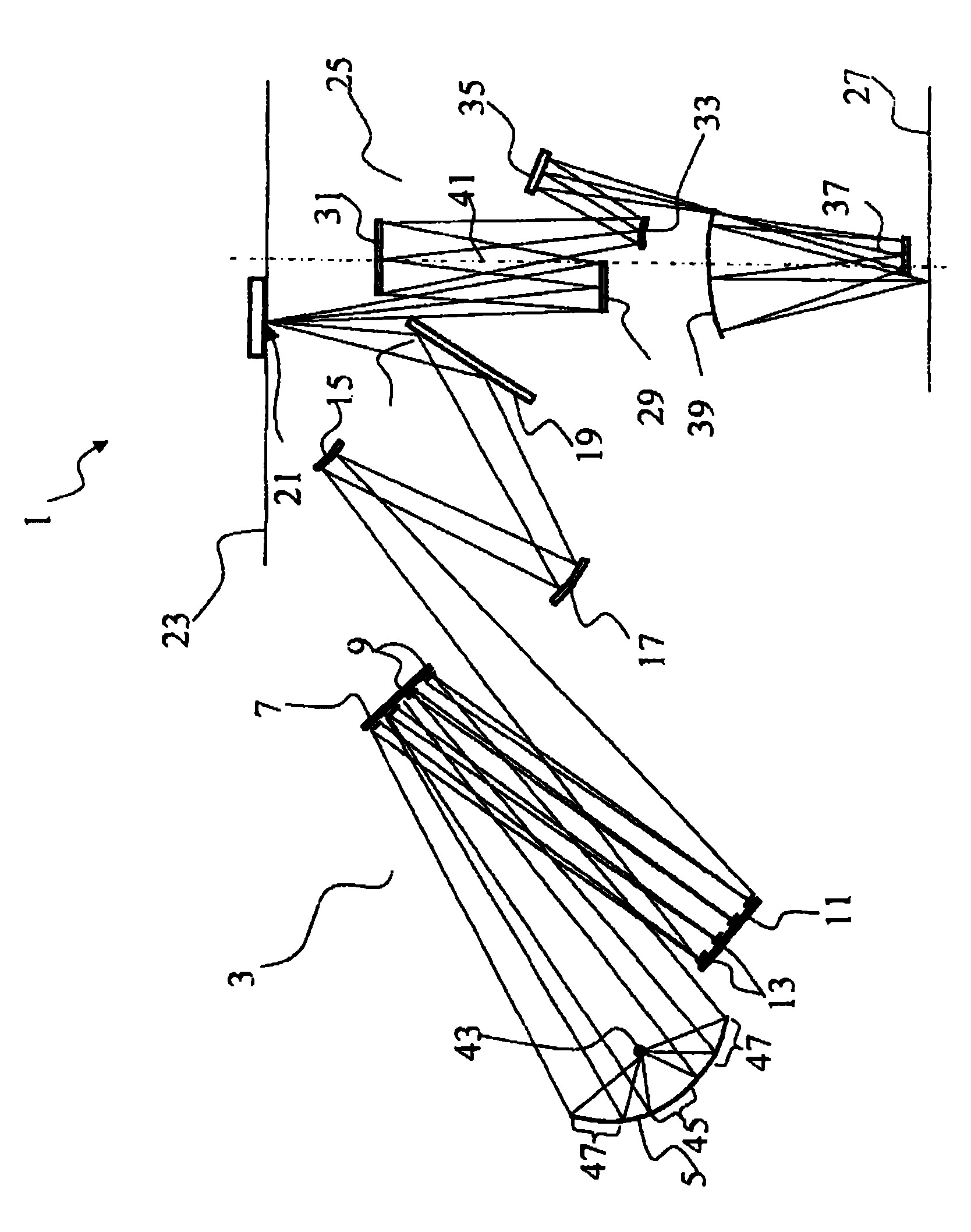

Illumination optical unit for microlithography

InactiveCN102549461ACost efficientEasy to manufactureHandling using polarising devicesHandling using diffraction/refraction/reflectionOptical polarizationObject field

Illumination optical unit comprising a collector mirror, which produces a polarization distribution that is applied to the first faceted optical element during the operation of the illumination optical unit, wherein there are at least two first facet elements to which radiation having a differing polarization is applied, and furthermore the first faceted optical element has at least one first state in which the normal vectors of the reflective surfaces of the first facet elements are selected in such a way that a first predetermined polarization distribution results at the location of the object field during the operation of the illumination optical unit.

Owner:CARL ZEISS SMT GMBH

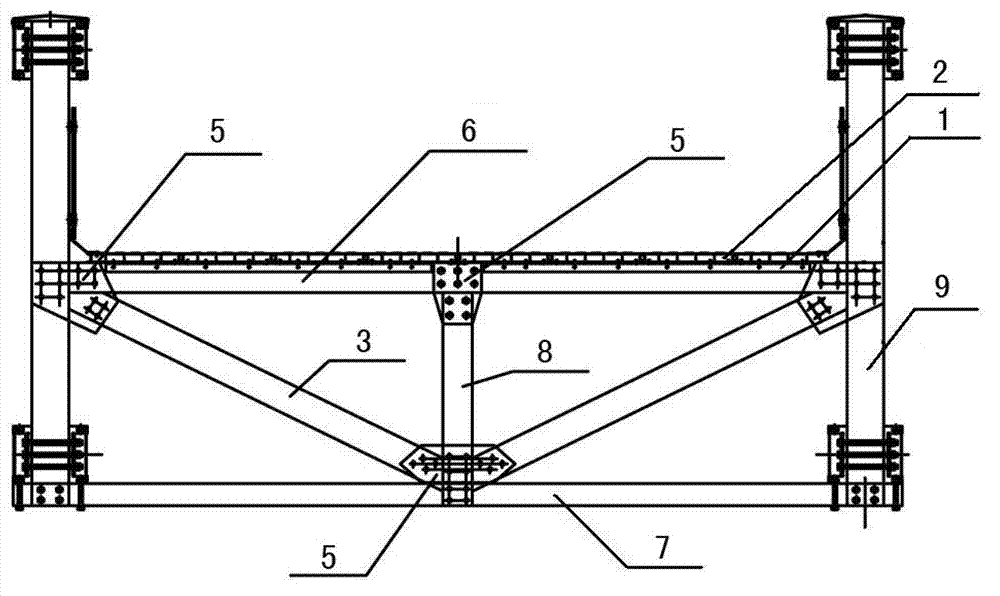

Structural member of aluminum alloy passenger foot-bridge

ActiveCN102966032AHigh strengthImprove on-site installation efficiencyBridge structural detailsBridge materialsBridge materialEngineering

The invention relates to a structural member of an aluminum alloy passenger foot-bridge. The structural member comprises a supporting frame, chord members and channel plates, wherein the chord members are laid side by side on the supporting frame and are fixedly connected with the supporting frame; the channel plates are laid side by side on the chord members and are fixedly connected with the supporting frame; the chord members are mutually connected by connection rectangular tubes; the supporting frame, the chord members and the channel plates are mutually connected through plywoods; and the channel plates are mutually connected in an inserted manner. With the adoption of the structural member of the aluminum alloy passenger foot-bridge, the intensity performances of base metals and an integral structure are improved, the defect caused by welding is avoided, the field installation efficiency is improved and the integral bridge material cost and the processing cost are lowered.

Owner:SHANDONG NOLLVETEC LIGHTWEIGHT EQUIP CO LTD

Gypsum-based composite hydraulic curing agent and gypsum-based composite hydraulic curing block

The invention discloses a gypsum-based composite hydraulic curing agent and a gypsum-based composite hydraulic curing block, which relate to the field of gypsum-based composite hydraulic gel materials. The gypsum-based composite hydraulic curing agent comprises the components of cement, gypsum and active chemical substances A and B (metal salt, alkali metal salt and alkaline-earth metal salt). The gypsum-based composite hydraulic curing agent is used for preparing the gypsum-based composite hydraulic curing block.

Owner:昆明晶活生物科技有限公司

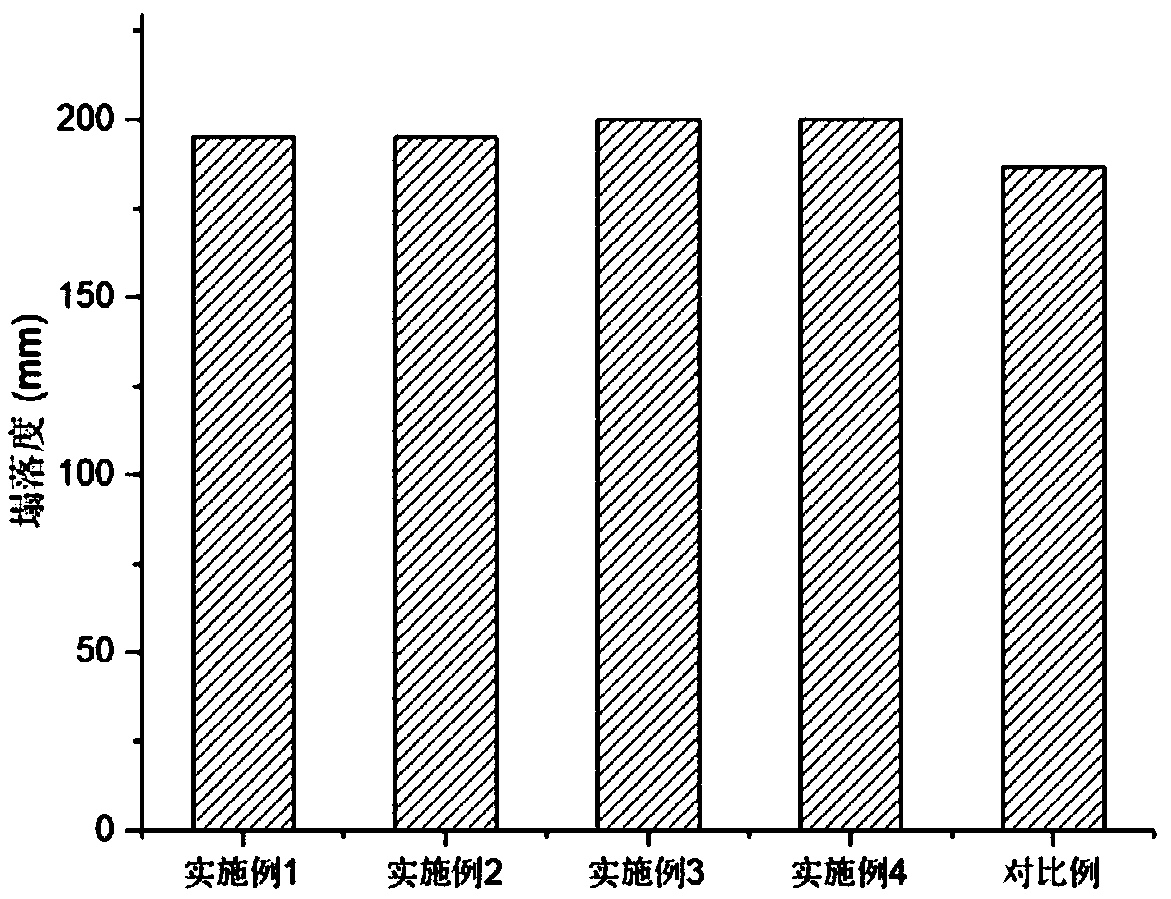

Method for preparing recycled concrete by using unqualified ready-mixed concrete and recycled powder

The invention relates to a method for preparing recycled concrete by using unqualified ready-mixed concrete and recycled powder. The method includes the following steps: mixing a retarder with the mass accounting for 0.06-0.13% of the unqualified ready-mixed concrete into the unqualified ready-mixed concrete for preservation; preparing new concrete according to the standard and mixing the unqualified ready-mixed concrete into new concrete by 10-50% mass ratio; then mixing a water reducer accounting for 0.16-0.31% of the total mass of a mixture and regenerated powder accounting for 10-40% of the total mass of the mixture, mixing mechanically and uniformly to obtain the recycled concrete. The concrete can better solve the problem of unqualified ready-mixed concrete treatment in concrete production, does not pollute the environment, and reduces the amount of materials used in concrete production. The recycled concrete can meet the performance requirements of the concrete replaced. Therefore, the method has significant economic benefits, environmental benefits and social benefits.

Owner:TONGJI UNIV

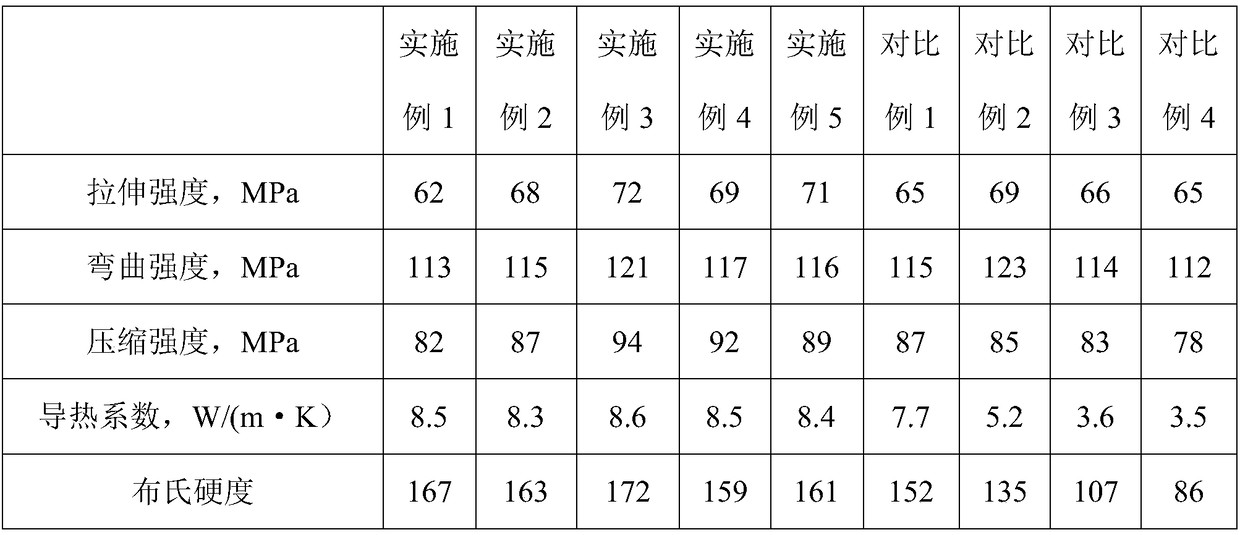

Plastic with good thermal conductivity and preparation method thereof

InactiveCN108976753AImprove thermal conductivityImprove performanceHeat-exchange elementsElastomerPolyolefin

The invention discloses a plastic with good thermal conductivity. The plastic is prepared from the following raw materials in parts by weight: 80 to 120 parts of polycarbonate, 30 to 50 parts of polyhexamethylene succinate, 10 to 20 parts of polyolefin elastomer, 5 to 10 parts of calcium carbonate, 8 to 16 parts of silicon carbide, 6 to 12 parts of aluminum oxide, 5 to 10 parts of graphene, 4 to 8parts of diamond micropowder, 3 to 6 parts of glass fiber, 5 to 10 parts of silane coupling agent, 30 to 50 parts of polyethylene glycol, 4 to 7 parts of 2-hydroxyl-4-methoxydiphenylketone, 2 to 5 parts of calcium stearate, and 3 to 5 parts of 2,4-dichlorobenzoyl peroxide. The invention also discloses a preparation method of the plastic with good thermal conductivity. The prepared plastic has good thermal conductivity under the cooperation function of the raw materials.

Owner:陈强挥

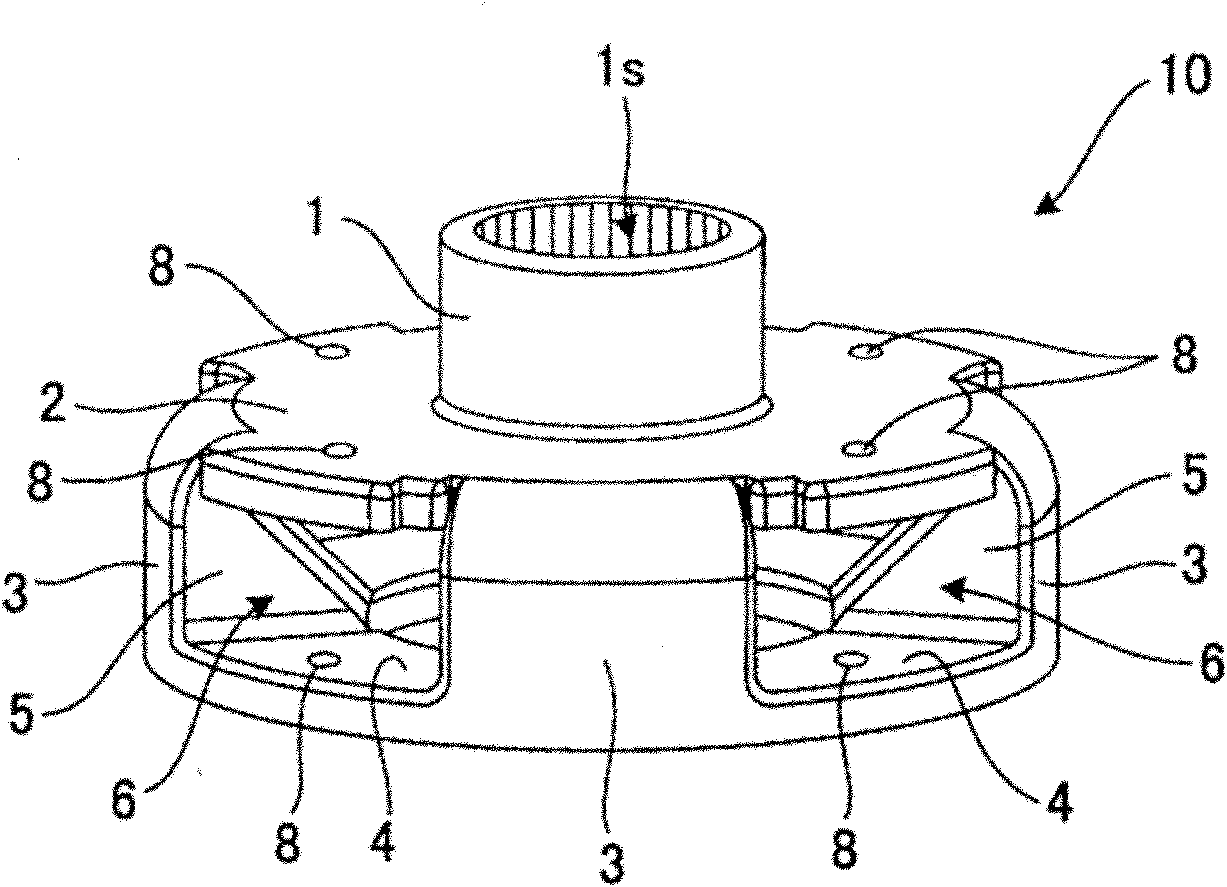

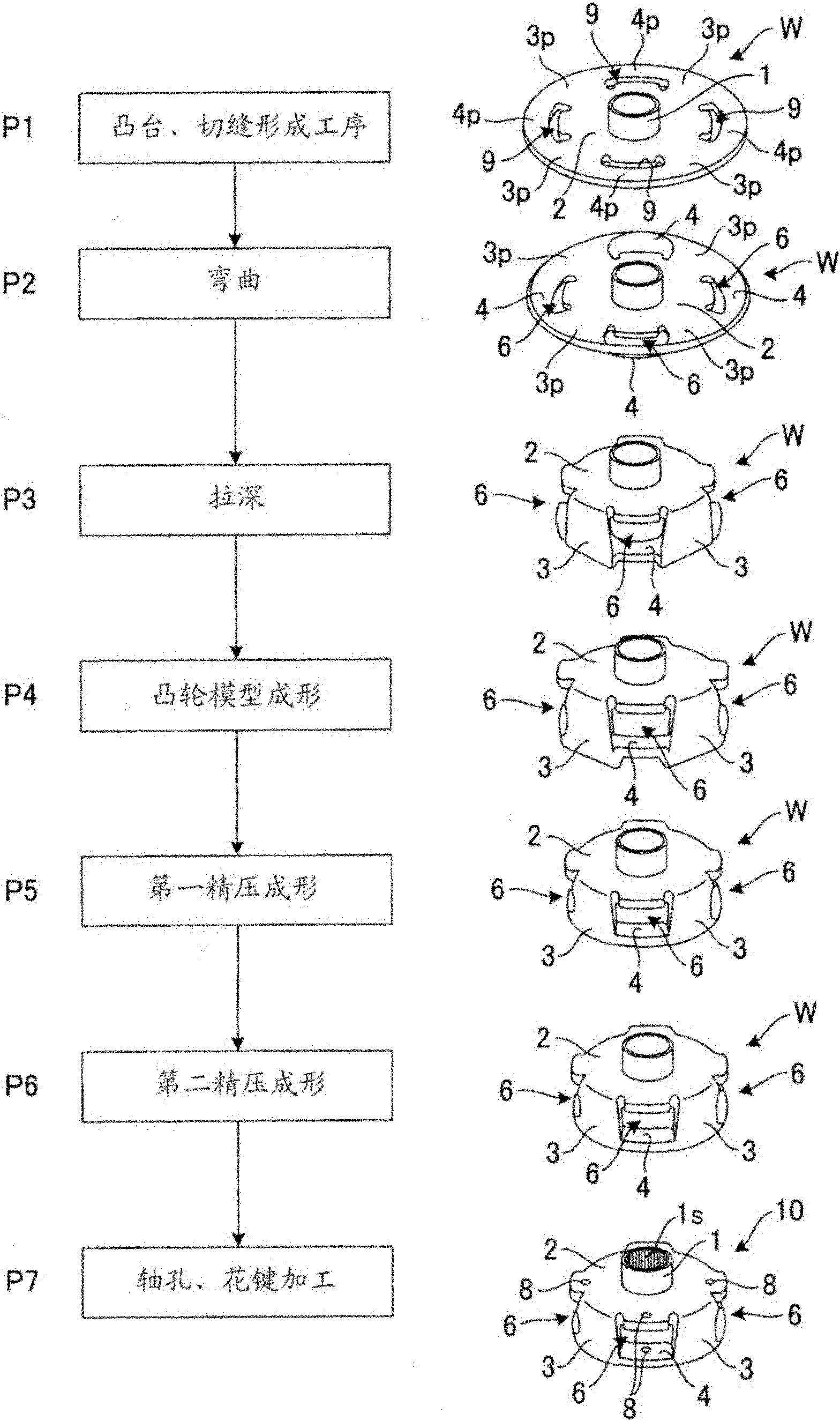

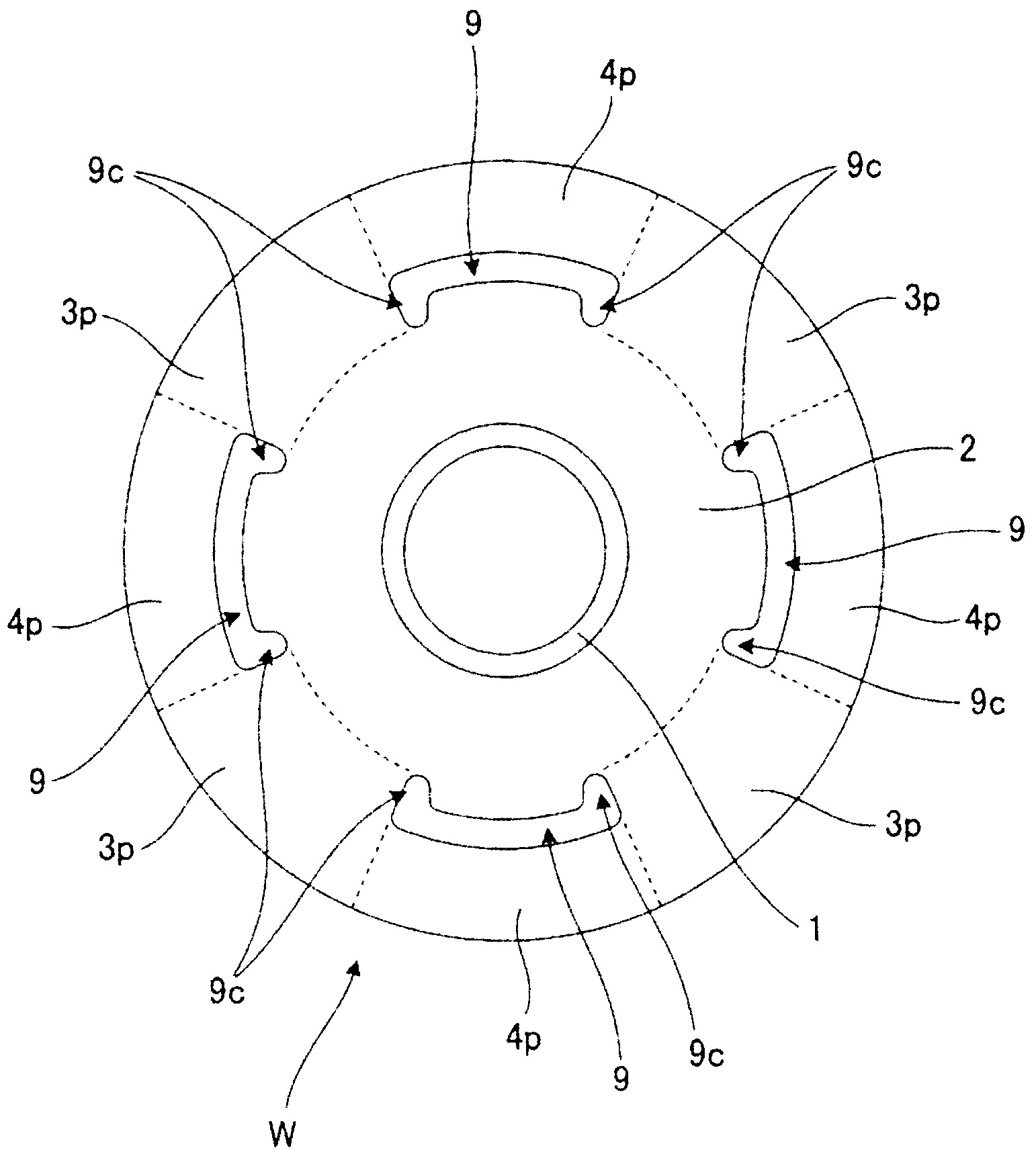

Planetary gear rack and manufacture method thereof

InactiveCN102233394AReduce in quantityReduce the number of processing stepsMetal-working apparatusGearing detailsEngineeringMechanical engineering

The invention provides a planetary gear rack and a manufacture method thereof, which are capable of reducing component number and processing steps during manufacture of a planetary gear rack, and improving yield of materials. Raw materials (W) of a side wall preset part (3p) and a seat surface preset position (4p) are alternatively configured at the surrounding of a protruding edge (2), via expansion of the seat surface preset position (4p), a seat surface (4) of a small gear is formed, and an opening (6) used for making the small gear be exposed is formed. Via stretching of the side wall preset part (3p), the side wall preset part (3p) is formed to be a side wall (3) connected with the protruding edge (2), and also the seat surface (4) is made to move toward the lower part of the protruding edge (2).

Owner:JATCO LTD

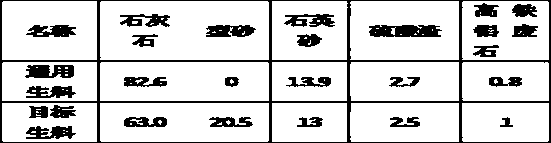

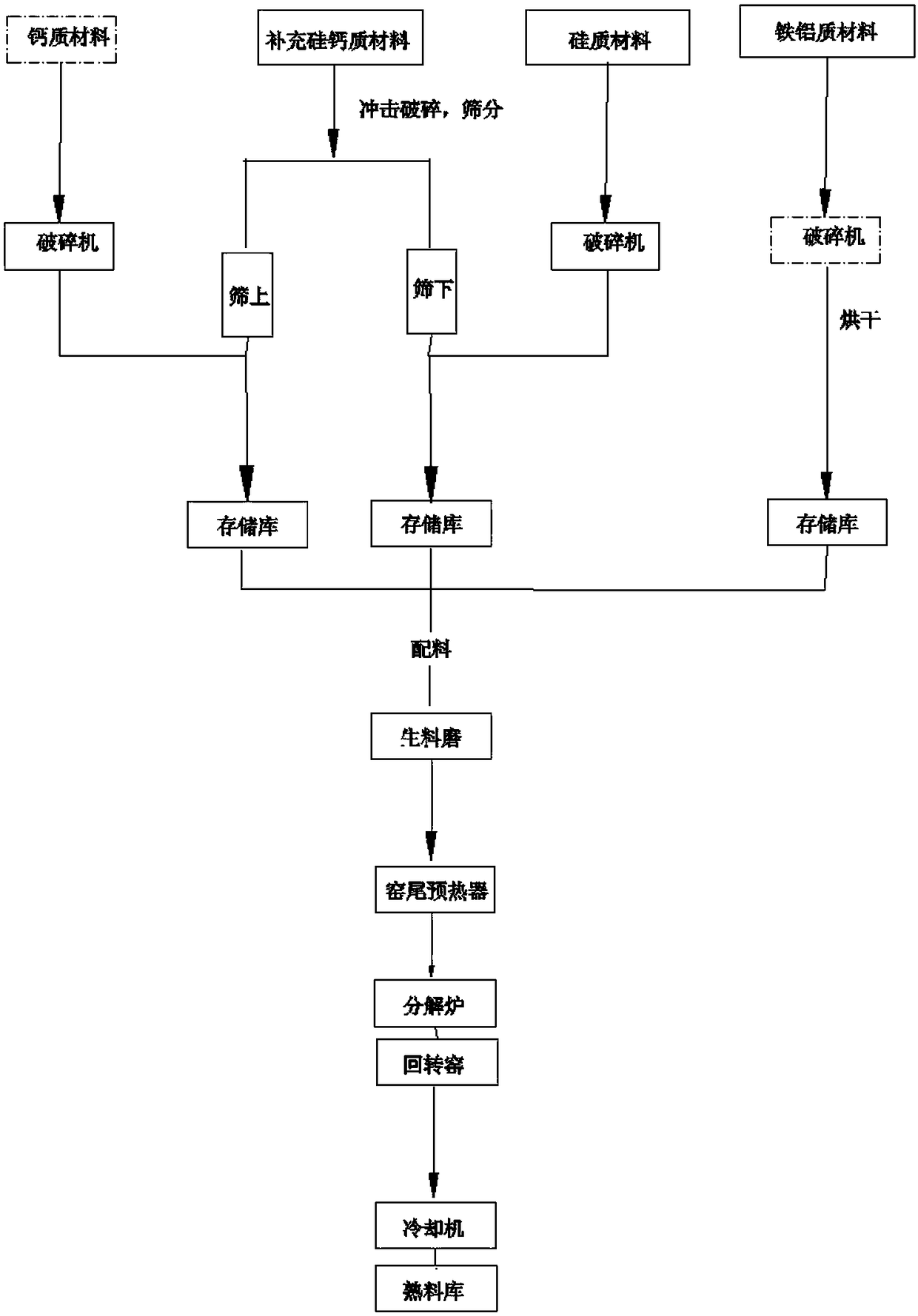

Preparation process for silicate cement clinker

ActiveCN109437617AReduce burning energy consumptionLow costCement productionSilicate CementCement manufacturing

The invention discloses a preparation process for silicate cement clinker, and relates to the technical field of cement manufacturing. According to the invention, limestone moulding sand waste is applied to calcination of clinker to the greatest extent by adopting a limestone moulding sand waste harmful component stripping method, and limestone moulding sand waste partly or completely replace limestone. According to the invention, the limestone moulding sand waste is applied to the calcination of the cement clinker, so that cost of enterprises can be reduced, and waste is changed into things of value, and therefore, great social benefits and economic benefits are achieved for society and the enterprises.

Owner:EMEISHAN QIANGHUA SPECIAL CEMENT

Precoatable anaerobic adhesive microcapsule capable of raising penetration resistance of wall materials and preparation method thereof

InactiveCN104941545AImprove penetration resistanceReduce precipitationMicroballoon preparationMicrocapsule preparationActive agentAntifoam agent

The invention relates to a precoatable anaerobic adhesive microcapsule capable of raising penetration resistance of wall materials and a preparation method thereof. The microcapsule is composed of the following ingredients, by weight, 4-10 parts of urea, 10-30 parts of a formaldehyde solution, 5-15 parts of montmorillonite, 1-10 parts of a core material, 30-80 parts of water, 1-8 parts of a promoter, 1-10 parts of a surfactant and 0.01-3 parts of other auxiliary agents. The preparation method comprises the following steps: firstly adding urea, formaldehyde and montmorillonite into a reaction bottle, adjusting pH to 7-8 and reacting at 72 DEG C for 1.5h; then adding an emulsified solution of the core material, water, an antifoaming agent and the surfactant, adjusting pH to 2-4 and reacting for 4h; and finally filtering and washing to obtain the microcapsule. According to the invention, penetration resistance of the prepared microcapsule is greatly raised, and within a certain period of time, precipitation quantity of the microcapsule in acetone is obviously reduced. In addition, high-temperature storage stability of the microcapsule is enhanced, but strength is not reduced.

Owner:TONSAN ADHESIVES INC

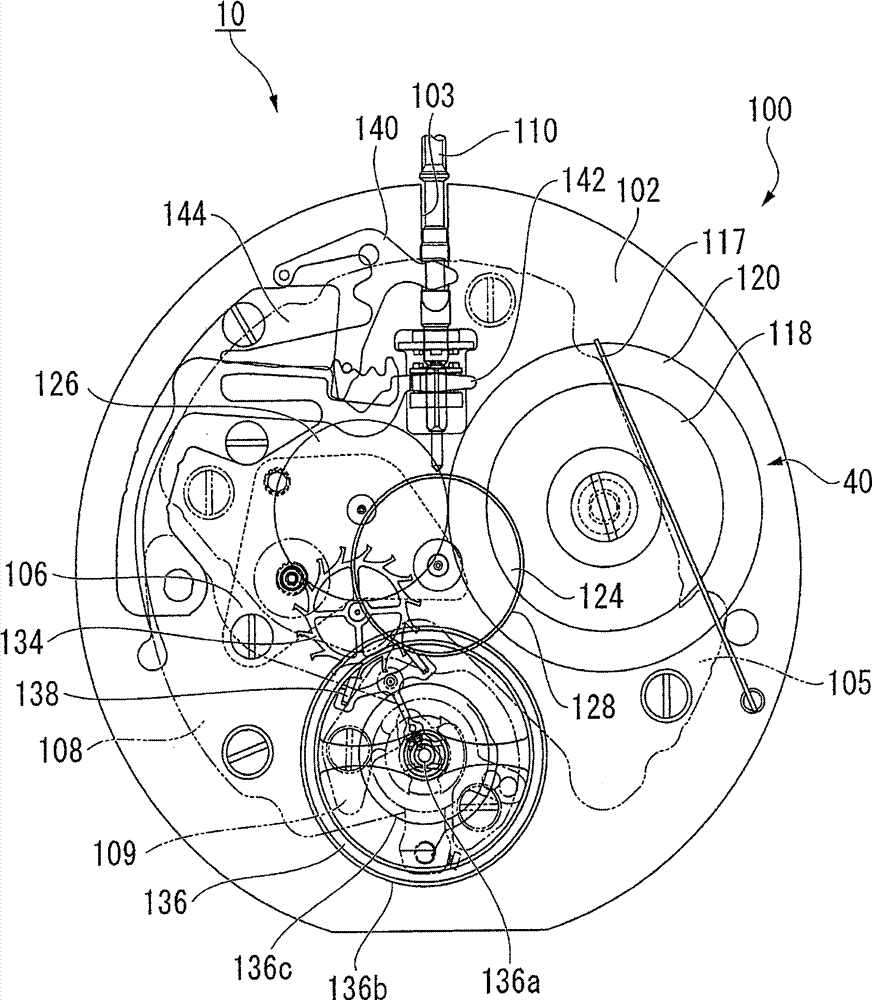

Decoration component, clock component, and manufacturing methods thereof

InactiveCN103320789AUniform colorDissolution inhibitionSurface reaction electrolytic coatingVacuum evaporation coatingElectrolysisGas phase

The present invention relates to a decoration component, a clock component, and manufacturing methods thereof. In the case of coloring by performing electrolytic treatment on a titanium coated film obtained by a vapour deposition method in the decoration component with a complicated shape, dissolution of a base material occurs on a titanium coated film unforming part at an internal surface of a recess or a hole, so that defect exists in the coloring aspect. An electroplating coated film is formed at the surface of the component, then the titanium coated film is formed through a vapor phase method, and oxidation treatment is performed on the surface to form an oxidation coated film. In addition, used as a metal material for forming the electroplating coated film, the material with standard oxidation reduction potential which is higher than the standard oxidation reduction potential of the material of the decoration component is used. Therefore, dissolution of the component does not occur on the titanium coated film unforming part in the process of electrolytic treatment due to the formed electroplating coated film, and the decoration component which is colored uniformly can be provided.

Owner:SEIKO INSTR INC

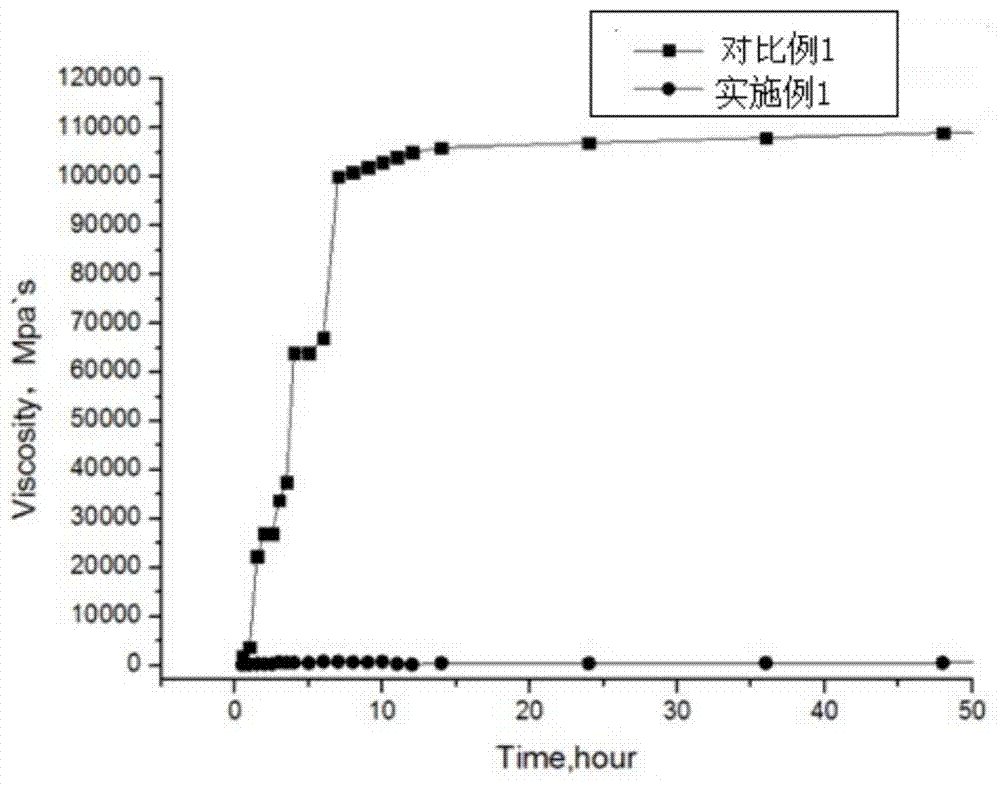

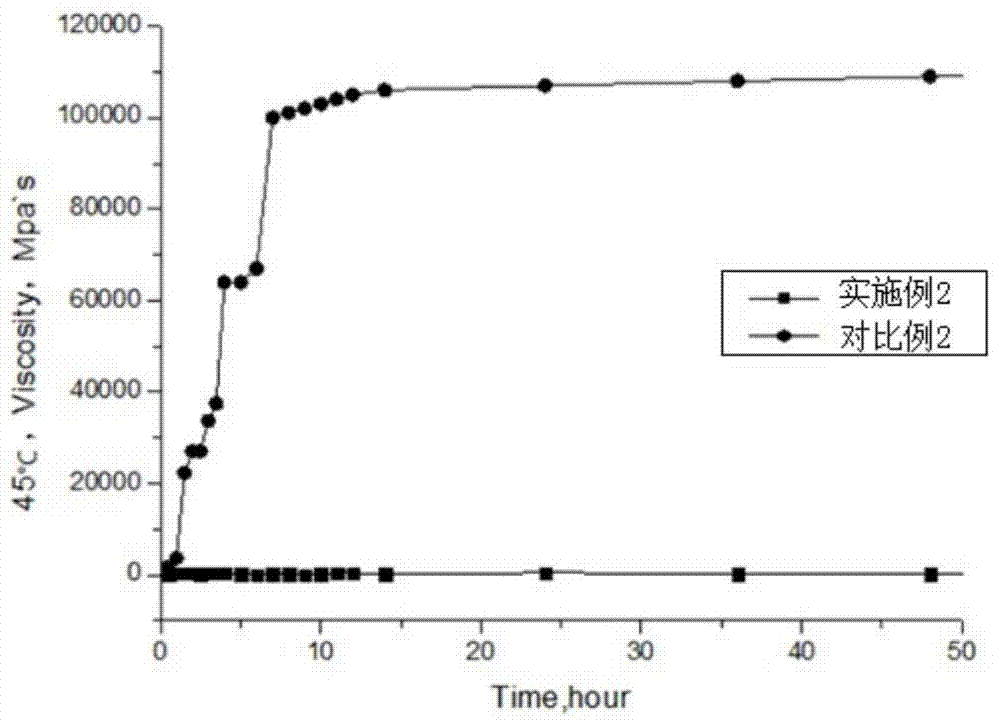

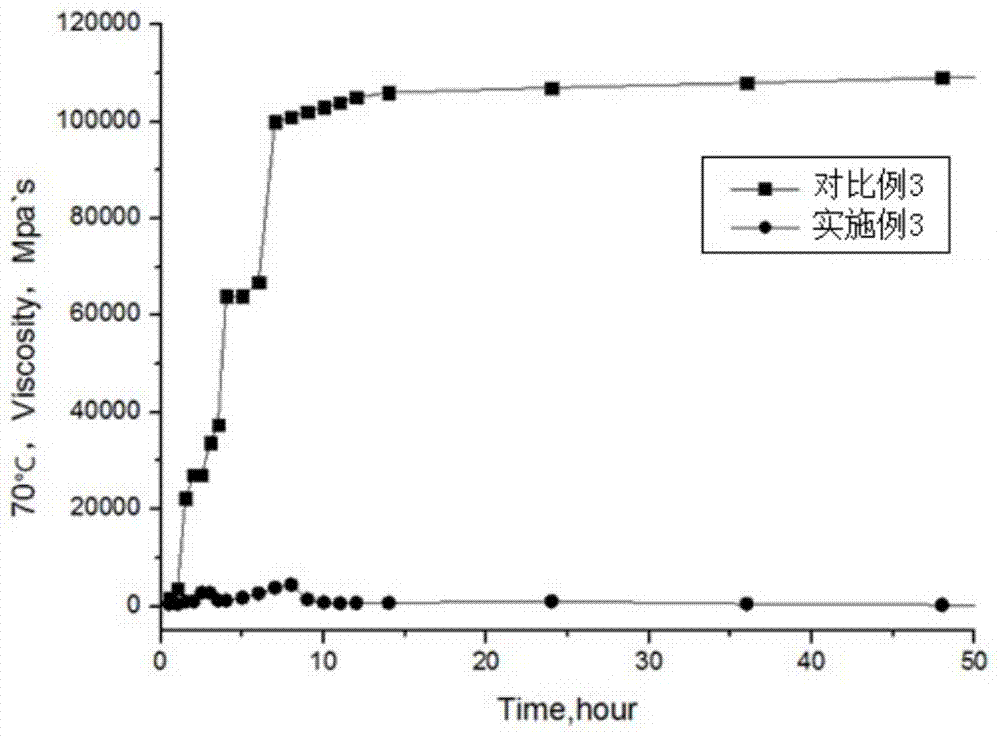

A medium and high temperature resistant biological profile control and water shutoff agent for oilfield development

ActiveCN104498008BNo reduction in strengthReduce use costDrilling compositionSealing/packingPolyolBiological profile

The invention discloses a medium-high temperature-resistant biological profile control and water shutoff agent for oil field development, which consists of a microbial polysaccharide basic profile control agent and a delayed gelling agent; the microbial polysaccharide basic profile control water shutoff agent is microbial polysaccharide available Colloid compounded hydrogen bond bonding strength accelerator or microbial polysaccharide curdlan gum and coagulant; the delayed gelling agent is one or any of polyol, high molecular polymer hydrolyzed polyacrylamide, gluconate Several kinds. The invention also discloses a preparation method of the biological profile control water blocking agent. The profile control and water shutoff agent of the present invention can maintain the fluidity of the system at medium and high temperature (65°C-90°C), and the viscosity increases slowly, so that it can meet the requirement of smooth transportation to a specific depth underground.

Owner:ANJIEYU BEIJING OILFIELD TECHNICAL SERVICES CO LTD

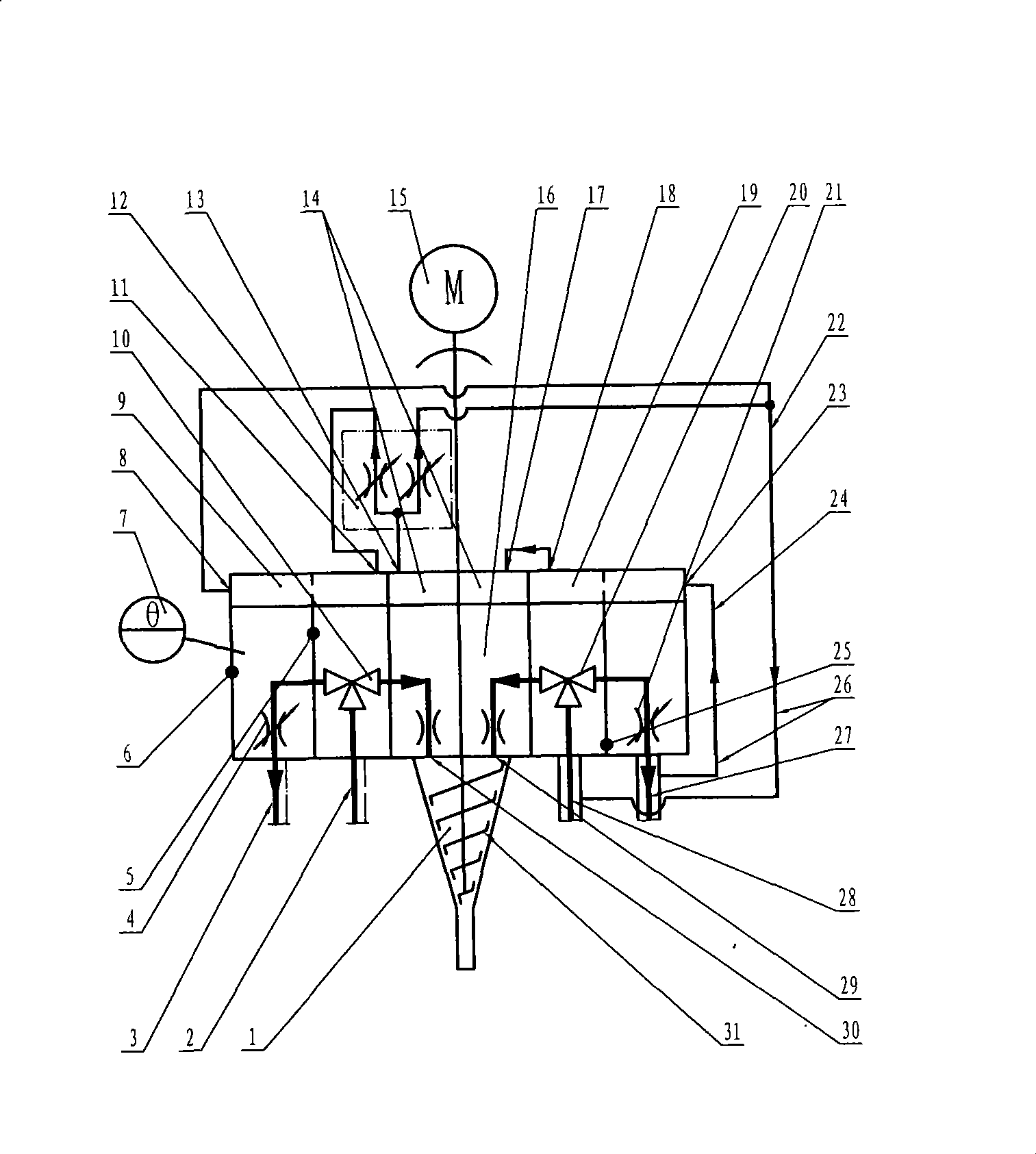

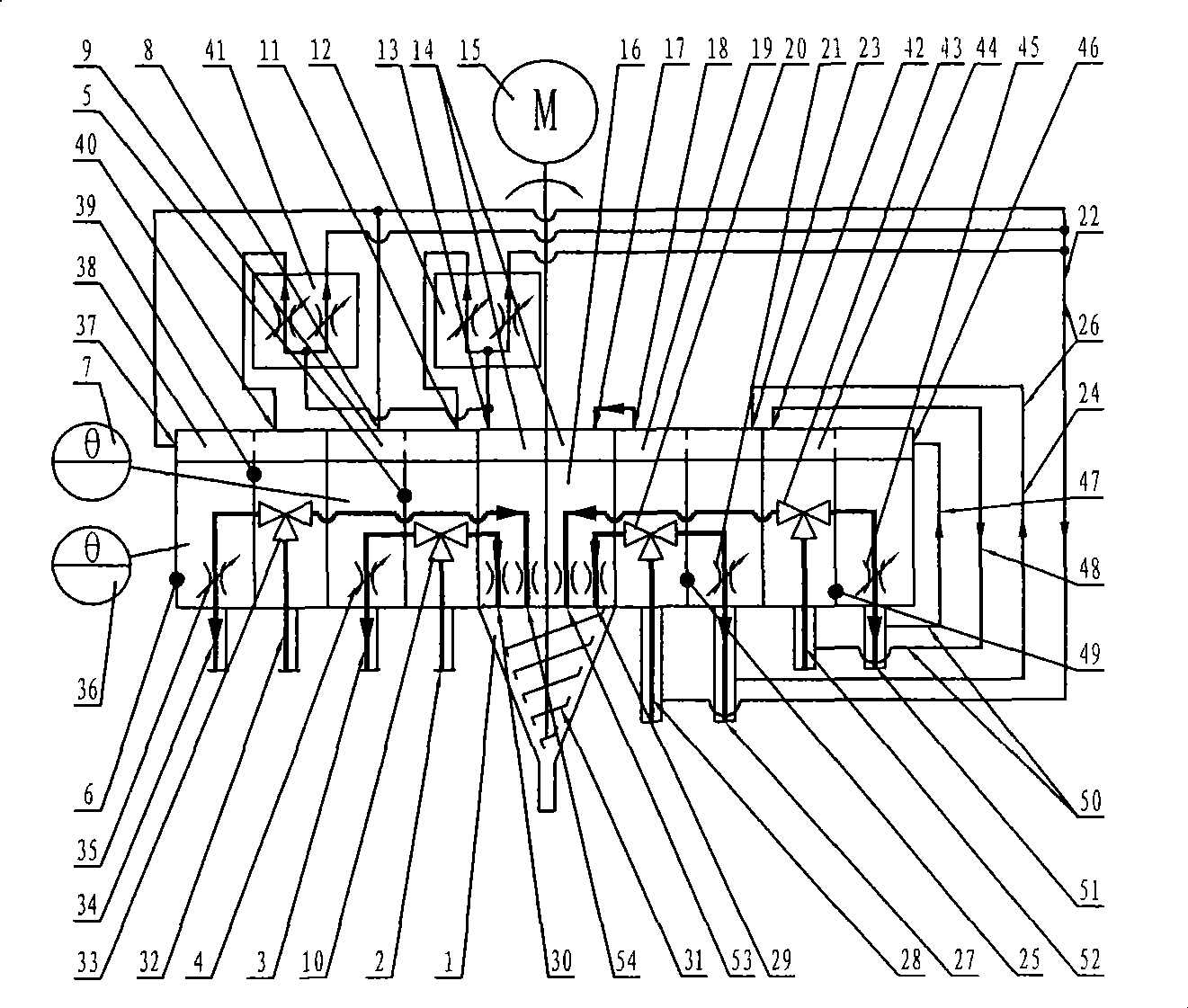

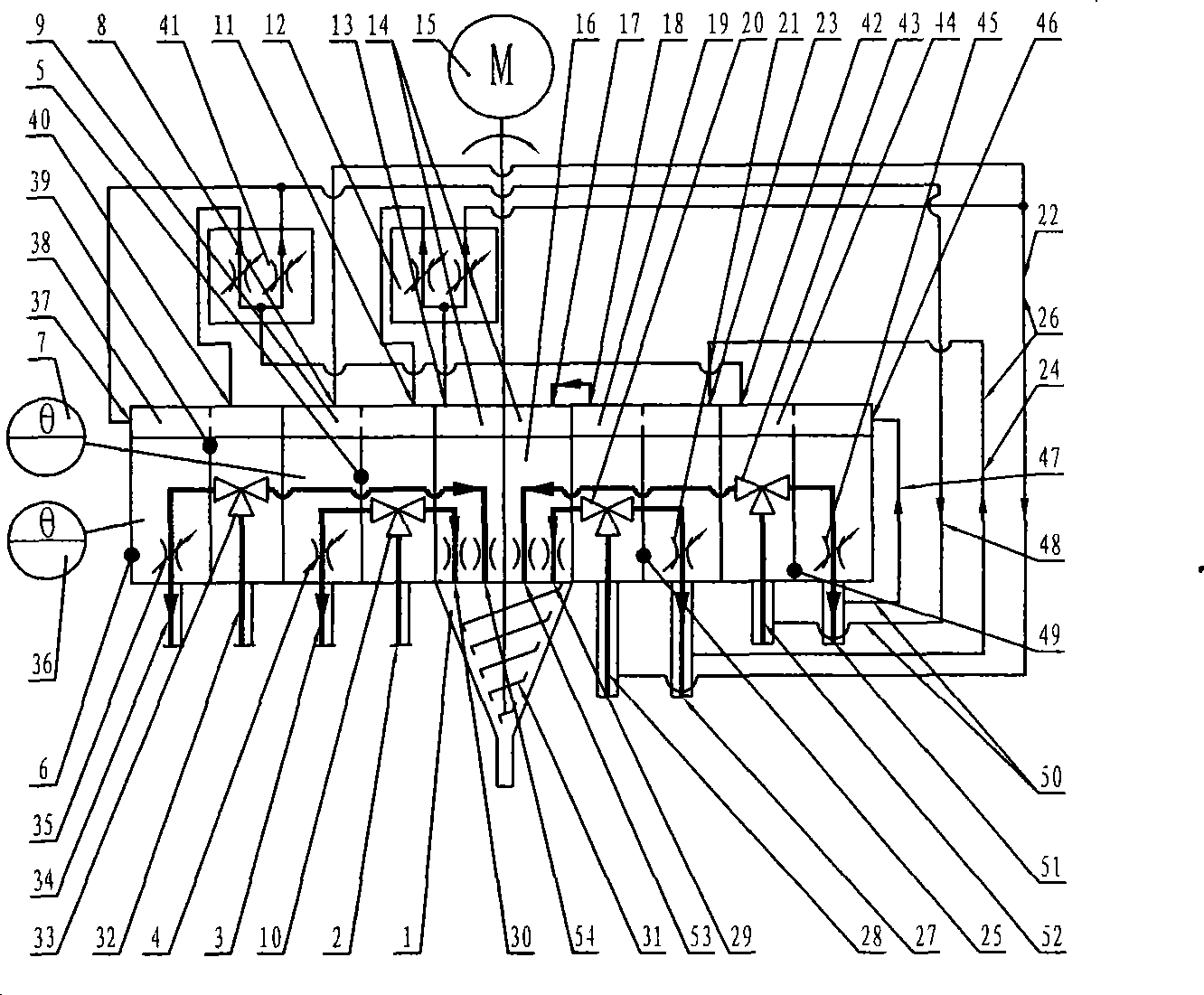

Casting machine head capable of adjusting pipe accessory temperature with different material constituents

InactiveCN101362367ALow local temperature control accuracyLow heating uniformity requirementsTemperature controlHeat conducting

The invention discloses a machine head of a casting machine being capable of adjusting the temperature of pipeline fittings of different raw material components, which comprises a machine body, a raw material mixing chamber and a heat-conducting medium circulating loop. The machine head is characterized in that a high-temperature raw material chamber and a low-temperature raw material chamber which are mutually isolated and internally provided with a heat exchange pipeline, a heat-conducting medium inlet opening and a heat-conducting medium outlet opening respectively, and an intermediate feeding chamber are respectively arranged in the machine body, and more than one high-temperature and low-temperature raw material chambers are arranged at the side of the intermediate feeding chamber; the respective heat-conducting media of the high-temperature raw material chambers performs heating and heat preserving to the high-temperature raw material chambers, the heat-conducting media of the high-temperature raw material chambers with operating temperature higher than that of the low-temperature raw material chambers and with higher demand to the local temperature controlling accuracy performs heating and heat preserving to all the low-temperature raw material chambers, the temperature thereof is controlled by adjusting the flow of the heat-conducting media divided by a flow dividing valve per unit time, and the heat-conducting media of one high-temperature raw material chamber performs heating and heat preserving to the intermediate feeding chamber. The invention has the advantages of accurate temperature control, simplified structure, convenient maintenance and prolonging service life of the equipment.

Owner:江浩

Bamboo-wood combined chopping board

The invention discloses a bamboo-wood combined chopping board. The bamboo-wood combined chopping board includes a chopping board body. The chopping board body includes an upper bamboo board layer anda lower bamboo board layer. A pressed wood board layer is arranged between the upper bamboo board layer and the lower bamboo board layer. The structural points of the bamboo-wood combined chopping board are that the upper surface and the lower surface of the pressed wood board layer are respectively provided with upper stripe grooves and lower stripe grooves, the upper stripe grooves and the lowerstripe grooves are arranged to be wavy and inclined, inclination directions of the upper stripe grooves and the lower stripe grooves are opposite, the lower surface of the upper bamboo board layer and the upper surface of the lower bamboo board layer are provided with frosted layers, and the pressed wood board layer is bonded and compacted with the upper bamboo board layer and the lower bamboo board layer by high-strength waterproof glue. Compared with the prior art, the beneficial effects of the bamboo-wood combined chopping board are that the bamboo-wood combined chopping board is reasonable in design and simple in structure, reduces the production cost without reducing the strength of force, reduces the weight to facilitate transportation, and can make use of discarded wood chips.

Owner:江苏金茂木业有限公司

Al-Mg alloys for automobile body sheets and manufacturing method thereof

ActiveCN101880803BLower yield strengthEasy to stamp and formUltimate tensile strengthEnergy conservation

The invention provides Al-Mg alloys for automobile body sheets and a manufacturing method thereof, belonging to the technical field of alloy materials. The invention solves the problem that the existing 5754 series alloys have poor strength and impact resistance. The alloys comprise the following components in percentage by weight: 0.001-0.25wt% of Cu, 0.05-0.35wt% of Mn, 2.5-3.5wt% of Mg; 0.005-0.25wt% of Cr, 0.008-0.8wt% of Zn, 0.01-0.15wt% of Ti, 0.001-0.2wt% of Zr, not more than 0.2wt% of Si, not more than 0.3wt% of Fe and the balance Al. The alloys have the advantages of good impact resistance and plasticity and strong feasibility, and the manufacturing method has the advantage of realizing the aims of energy conservation and emission reduction in the process of machining.

Owner:ZHEJIANG GKO IND CO LTD

Features

- R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

Why Patsnap Eureka

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Social media

Patsnap Eureka Blog

Learn More Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com