Method for preparing curcumin-loaded polyacrylonitrile fiber by dope dyeing method

A technology for coloring polyacrylonitrile fibers loaded with curcumin and dope solution is applied in the preparation of spinning solutions, chemical characteristics of fibers, wet spinning methods, etc., and can solve problems such as high cost, high pollution, and high energy consumption.

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

[0022] A kind of stock solution coloring method prepares the method that loads curcumin polyacrylonitrile fiber:

[0023] The first step is to prepare spinning dope. First prepare the polyacrylonitrile spinning stock solution according to the existing technology, wherein the dry solid content A of polyacrylonitrile is 99 parts by weight, then add curcumin and drug transdermal absorption accelerator into the spinning stock solution and stir evenly, The dry solid amount B that adds curcumin is 0.5 weight part, and the drug transdermal absorption accelerator that adds is oleic acid, and dry solid amount C is 0.5 weight part, and analytical pure N, N-dimethylacetamide (DMAc) aqueous solution is used as Solvent, D is 400 parts by weight, (A+B+C): (A+B+C+D)=20%.

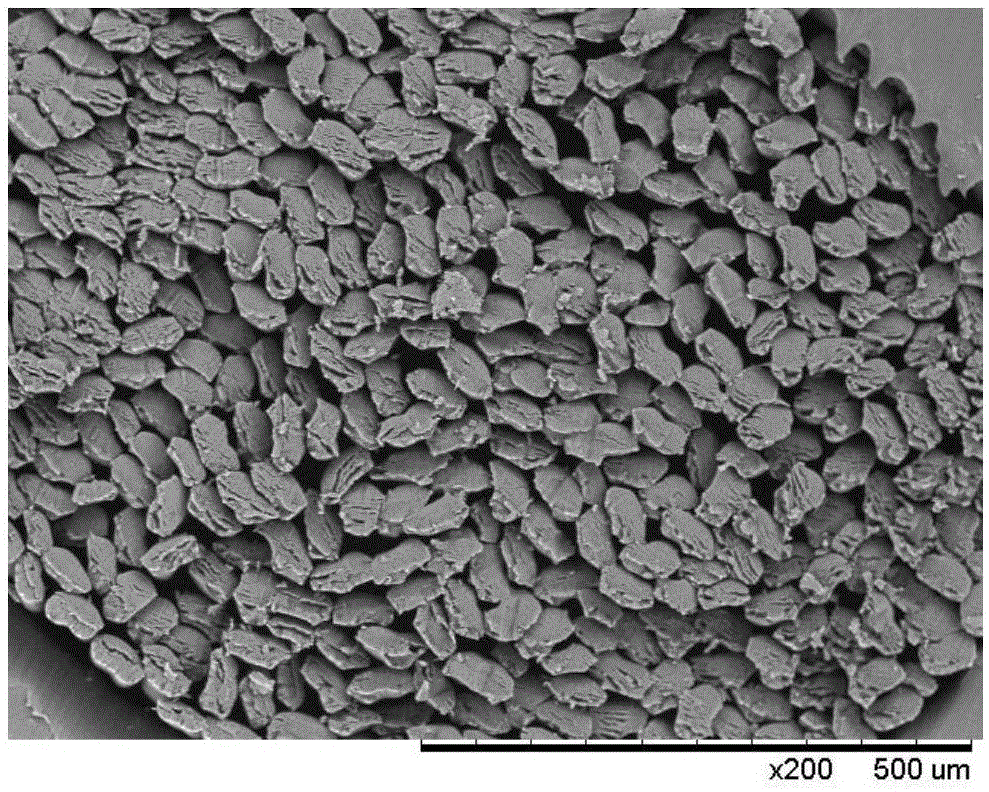

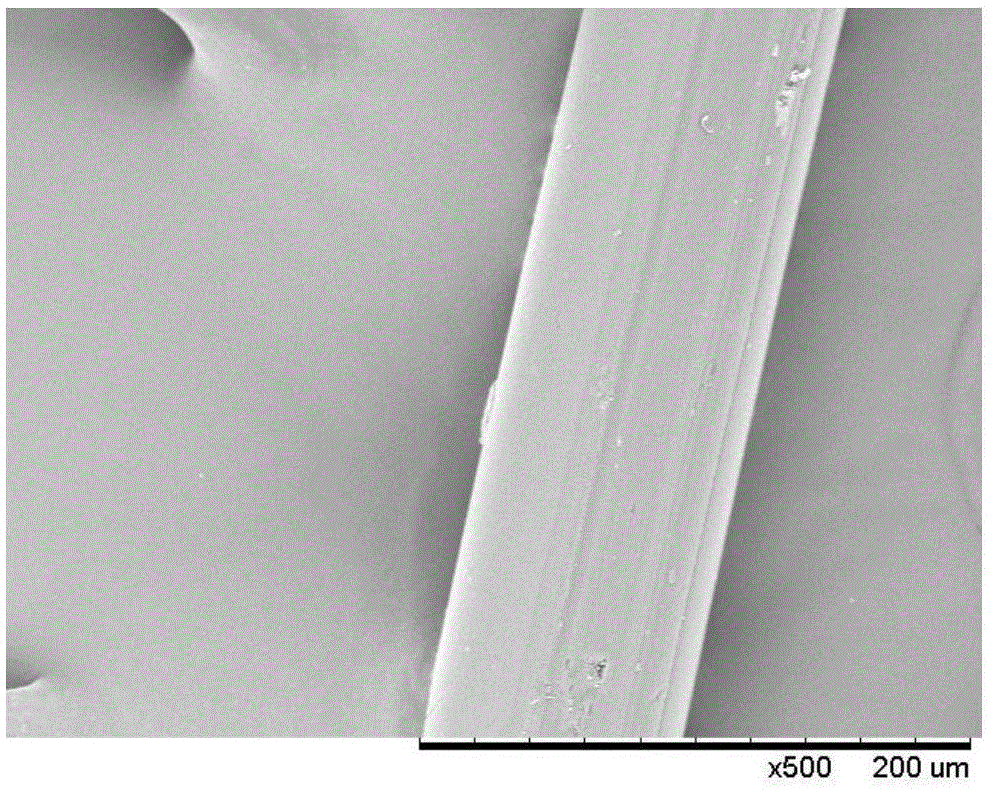

[0024] The second step is to make polyacrylonitrile fiber from the spinning stock solution containing curcumin and drug transdermal absorption accelerator, adopt wet spinning process, and use 50% N,N-dimethylacetamide aqu...

Embodiment 2

[0026] In the present embodiment, the dry solid content A of polyacrylonitrile is 85 parts by weight, then curcumin and drug transdermal absorption accelerator are added in this spinning dope and stirred evenly, the dry solid content B of adding curcumin is 10 parts by weight part, the drug transdermal absorption accelerator added is oleic acid, and the dry solid content C is 5 parts by weight, and analytically pure N,N-dimethylacetamide (DMAc) aqueous solution is used as solvent, and D is 355 parts by weight, (A+ B+C): (A+B+C+D) = 22%. The dry-jet wet-spinning process is adopted, the 50% N,N-dimethylacetamide aqueous solution at 5°C is used as the coagulation bath, the three-stage drafting is carried out, and the bright yellow drug-loaded fiber is finally made into a winding roller. Other methods are the same as in Example 1.

Embodiment 3

[0028] In the present embodiment, the dry solid content A of polyacrylonitrile is 80 parts by weight, then curcumin and drug transdermal absorption accelerator are added in this spinning dope and stirred evenly, the dry solid content B of adding curcumin is 15 parts by weight part, the drug transdermal absorption accelerator added is azone, and the dry solid amount C is 5 parts by weight, and the analytically pure N,N-dimethylacetamide (DMAc) aqueous solution is used as a solvent, and D is 456 parts by weight, (A+ B+C): (A+B+C+D) = 18%. The dry-jet wet-spinning process is adopted, the 50% N,N-dimethylacetamide aqueous solution at 5°C is used as the coagulation bath, the three-stage drafting is carried out, and the bright yellow drug-loaded fiber is finally made into a winding roller. Other methods are the same as in Example 1.

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com