Dyeing technique for polylactic acid fabric/cotton blended shuttle weaving

A polylactic acid fiber and cotton blending technology is applied in the processing of textile materials, dyeing methods, liquid/gas/steam textile material processing, etc. Appropriate, suitable depth, bright color effect

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

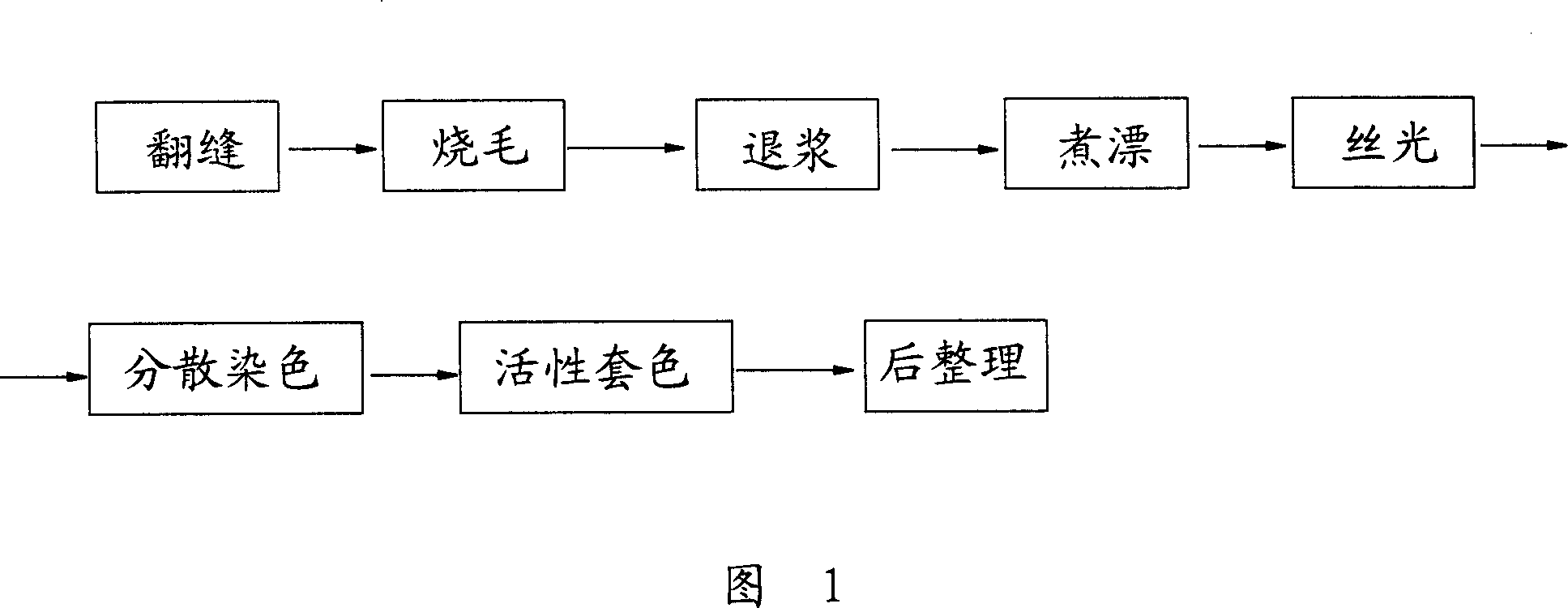

Image

Examples

Embodiment 1

[0032] 1) Desizing process

[0033] Configure the desizing lotion according to the following parameters: the concentration of amylase is 4g / L, and the concentration of penetrant AP-810 is 1g / L;

[0034] Add polylactic acid fiber / cotton blended woven fabric at room temperature, raise the temperature to 60°C, let stand for 30min, wash with water, and dry;

[0035] 2) Cooking and bleaching process

[0036] Configure the rinse solution according to the following parameters: the concentration of hydrogen peroxide is 10g / L, the concentration of sodium bicarbonate is 30g / L, the concentration of refining agent JFS is 5g / L, the concentration of penetrant AP-810 is 1g / L, stabilizer The concentration of 8601 is 8g / L.

[0037] 3) The mercerizing process adopts a semi-mercerizing process, and its sodium carbonate concentration is 190g / L.

[0038] 4) The dyeing process is divided into three steps: 1% to 2% of the weight of the polylactic acid fiber / cotton blended woven fabric, and an aux...

Embodiment 2

[0046] 1) Desizing process

[0047] Configure the desizing lotion according to the following parameters: the concentration of amylase is 4g / L, and the concentration of penetrant AP-810 is 1g / L;

[0048] Add polylactic acid fiber / cotton blended woven fabric at room temperature, raise the temperature to 60°C, let stand for 30min, wash with water, and dry;

[0049] 2) Cooking and bleaching process

[0050] Configure the rinse solution according to the following parameters: the concentration of hydrogen peroxide is 18g / L, the concentration of sodium bicarbonate is 40g / L, the concentration of refining agent JFS is 5g / L, the concentration of penetrant AP-810 is 1g / L, stabilizer The concentration of 8601 is 10g / L;

[0051] c. Mercerizing process

[0052] Sodium carbonate concentration is 200g / L;

[0053] The dyeing process is divided into three steps:

[0054] The first step, disperse dyeing step: C.I. disperse blue 79 is 2% of polylactic acid fiber / cotton blended woven fabric wei...

Embodiment 3

[0061] Reactive dyestuff adopts RealanWN dyestuff, and all the other are with embodiment 1.

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com