Pretreatment method used before processing fast growing wood surface concave-convex textures

A technology of surface unevenness and pretreatment, which is used in wood processing appliances, wood impregnation, and impregnation of wood, etc., can solve the problems of great influence on strength and stiffness, combustion and explosion, and high corrosion rate, so as to achieve no secondary pollution and low cost. , the effect of easy processing

Inactive Publication Date: 2012-11-21

NANJING FORESTRY UNIV

View PDF3 Cites 5 Cited by

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

[0005] ③Hydrogen peroxide (commonly known as hydrogen peroxide, molecular formula, H 2 o 2 ) has strong oxidizing properties. Although it is not flammable itself, the oxygen generated during decomposition can strongly support combustion. It will cause an explosion when it comes into contact with combustibles and organic substances. There is a danger of combustion and explosion when it is hit, rubbed and shaken.

[0007] The chemical reagents strong acids and alkalis used in traditional wood pretreatment methods have a very high corrosion rate on the cell walls of fast-growing wood, and wood cell walls are the basic units and foundations that constitute the strength and stiffness of wood. Traditional wood pretreatment chemical reagents strong acid , Strong alkali pretreatment of fast-growing wood has a great influence on its strength and stiffness

Method used

the structure of the environmentally friendly knitted fabric provided by the present invention; figure 2 Flow chart of the yarn wrapping machine for environmentally friendly knitted fabrics and storage devices; image 3 Is the parameter map of the yarn covering machine

View moreImage

Smart Image Click on the blue labels to locate them in the text.

Smart ImageViewing Examples

Examples

Experimental program

Comparison scheme

Effect test

Embodiment Construction

[0032] 1. Metasequoia uses 3% NH 3 .H 2 O solution, treated at 10°C for 2h;

[0033] 2. Paulownia uses 2% NH 3 .H 2 O solution, treated at 30°C for 2h;

[0034] 3. Masson pine uses 2% NH 3 .H 2 O solution, treated at 30°C for 2h.

the structure of the environmentally friendly knitted fabric provided by the present invention; figure 2 Flow chart of the yarn wrapping machine for environmentally friendly knitted fabrics and storage devices; image 3 Is the parameter map of the yarn covering machine

Login to View More PUM

Login to View More

Login to View More Abstract

The invention relates to a pretreatment method used before processing fast growing wood surface concave-convex textures, wherein a purpose of the present invention is to overcome serious influence on strength and stiffness of fast growing wood due to traditional wood pretreatment chemical reagents such as strong acids and strong bases. The present invention provides a scheme for carrying out a softening pretreatment on Chinese redwood, paulownia, and pinus massoniana lamb by using a NH3.H2O solution separately providing an effect, wherein the Chinese redwood is treated for 2 hours at a temperature of 10 DEG C by using a 3% NH3.H2O solution, the paulownia is treated for 2 hours at a temperature of 30 DEG C by using a 2% NH3.H2O solution, and the pinus massoniana lamb is treated for 2 hours at a temperature of 30 DEG C by using a 2% NH3.H2O solution. The pretreatment method of the present invention has the following advantages that: strength of fast growing wood pretreated by the pretreatment process of the present invention is not significantly reduced; with processing, decorative solid wood boards with a large breadth and natural texture concave-convex effects are obtained; the product can be widely used in interior decorations and furniture manufacturing decorations; a new approach is developed for application of fast growing wood in engineering and industrial wood fields; no secondary pollution is generated, cost is low, and the processing method is easy to popularize.

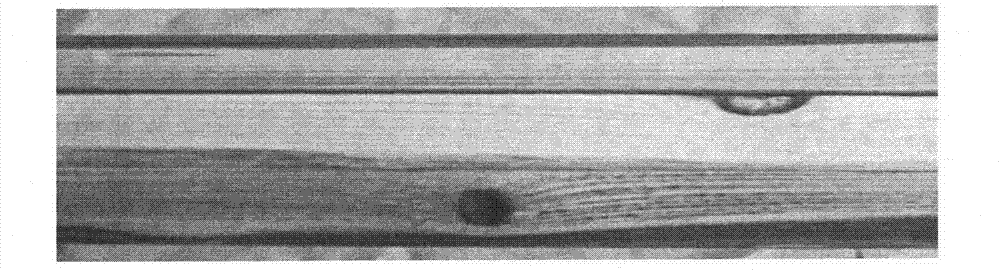

Description

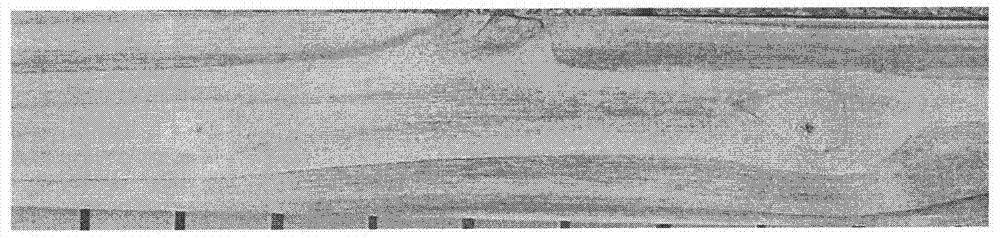

1. Technical field [0001] The invention relates to a method for softening the surface of wood before processing the concave-convex texture on the surface of wood, especially the surface softening pretreatment for fast-growing materials such as metasequoia, paulownia and masson pine, which are easy to process concave-convex texture. The wood is processed into a decorative wood with a concave-convex texture on the surface. 2. Background technology [0002] At present, in Wenzhou, Shanxi, Beijing and other places in China, there are old furniture that have been used for a long time, and there are some defects that the surface of the early wood is partially peeled off. These panels with certain "defects" are pretreated with strong alkali solution or strong acid solution, and then It is processed into panels with concave and convex textures, and then assembled into antique furniture after painting and polishing, so that the old furniture can show historical charm and modern style...

Claims

the structure of the environmentally friendly knitted fabric provided by the present invention; figure 2 Flow chart of the yarn wrapping machine for environmentally friendly knitted fabrics and storage devices; image 3 Is the parameter map of the yarn covering machine

Login to View More Application Information

Patent Timeline

Login to View More

Login to View More Patent Type & Authority Applications(China)

IPC IPC(8): B27K3/02B27K3/16

Inventor 朱典想王宏斌朱捷茆光华李迎超

Owner NANJING FORESTRY UNIV

Features

- R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

Why Patsnap Eureka

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Social media

Patsnap Eureka Blog

Learn More Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com