Patents

Literature

118results about How to "Improve on-site installation efficiency" patented technology

Efficacy Topic

Property

Owner

Technical Advancement

Application Domain

Technology Topic

Technology Field Word

Patent Country/Region

Patent Type

Patent Status

Application Year

Inventor

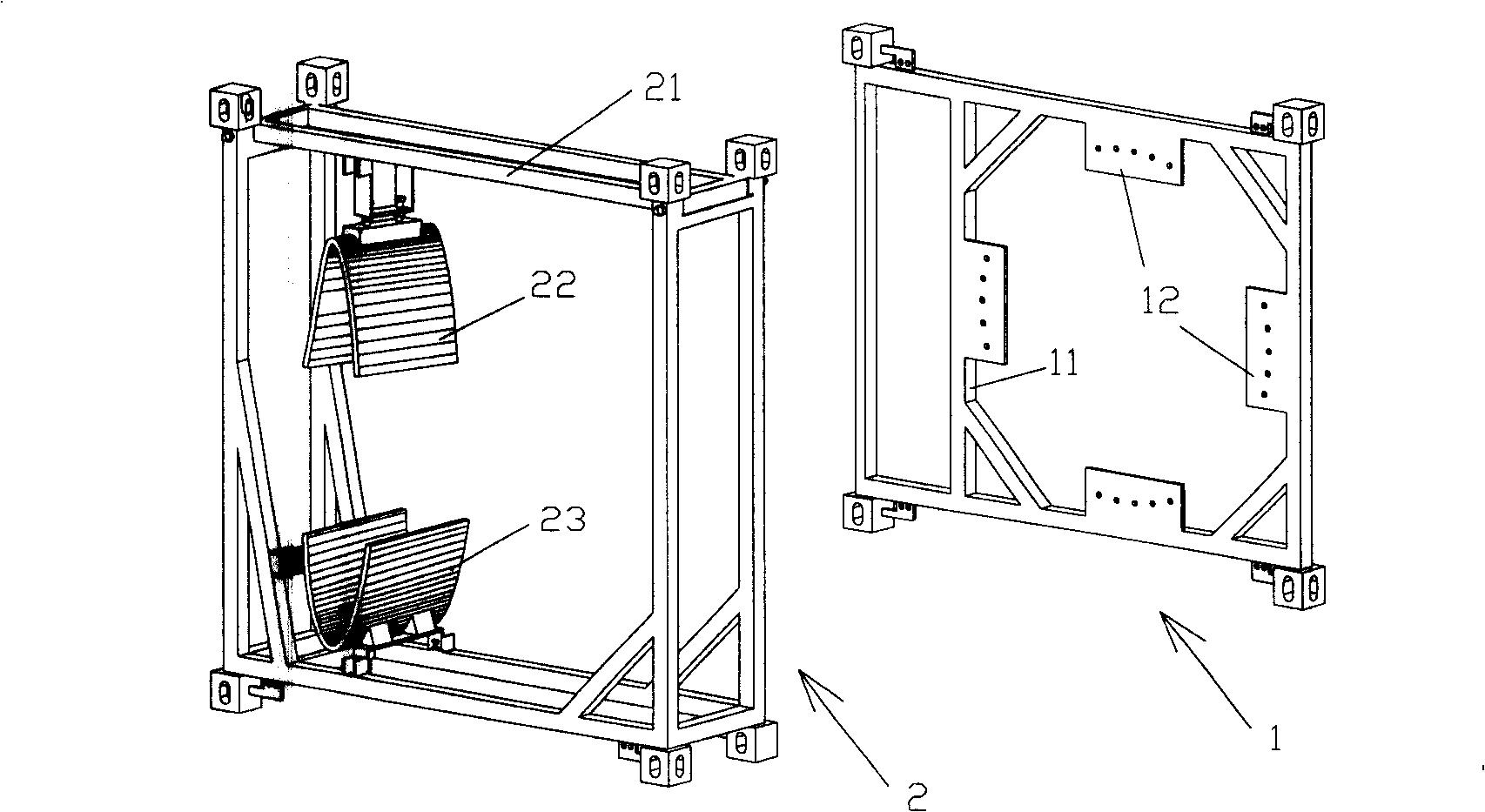

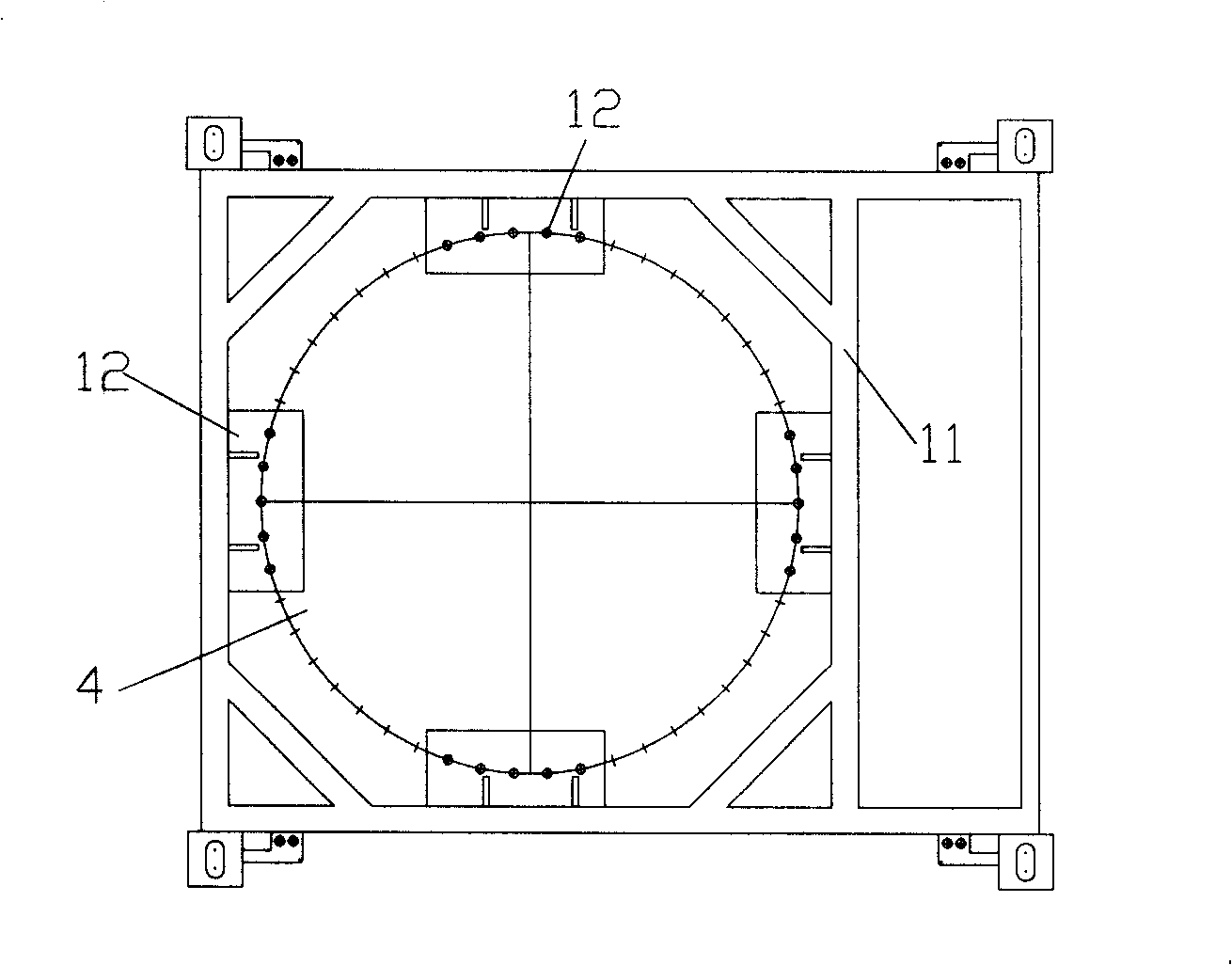

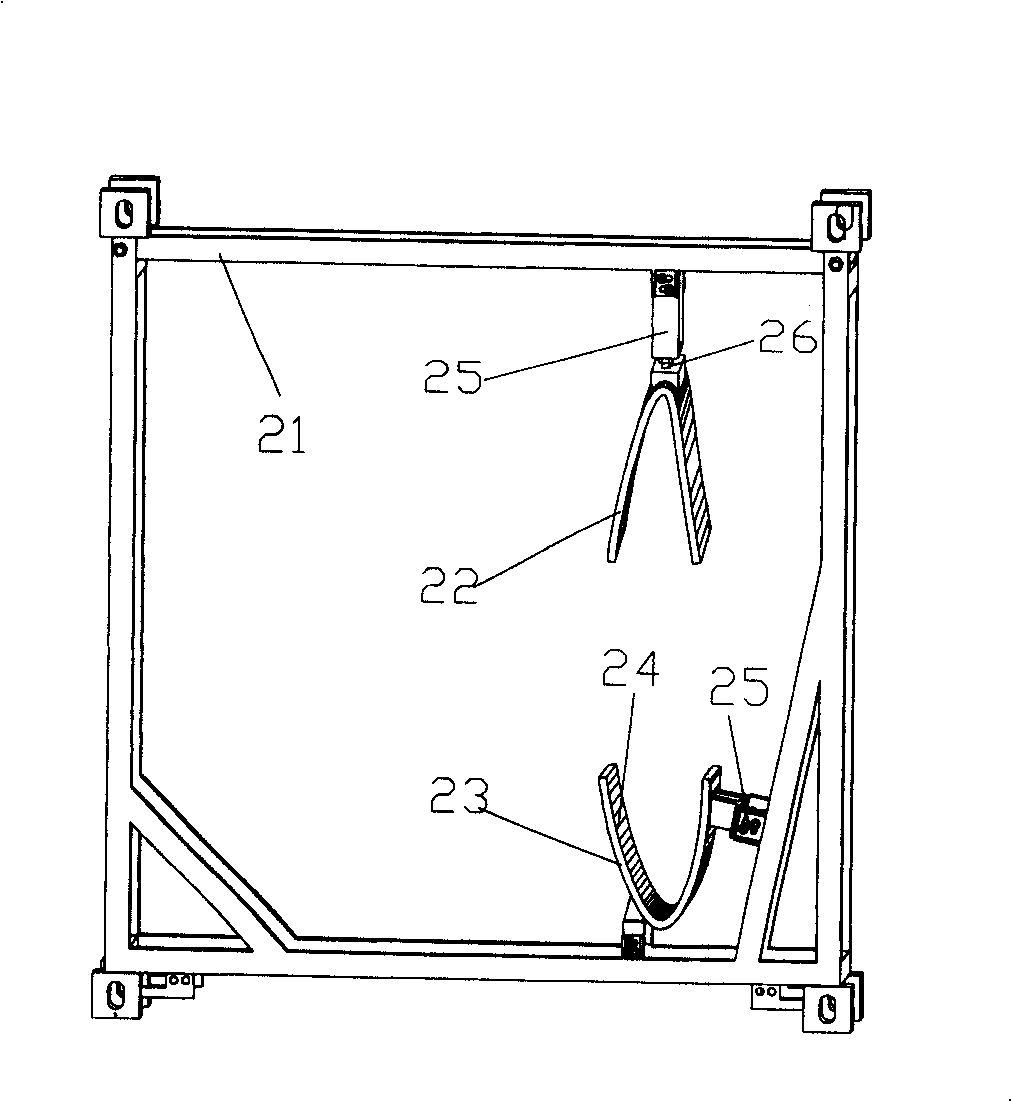

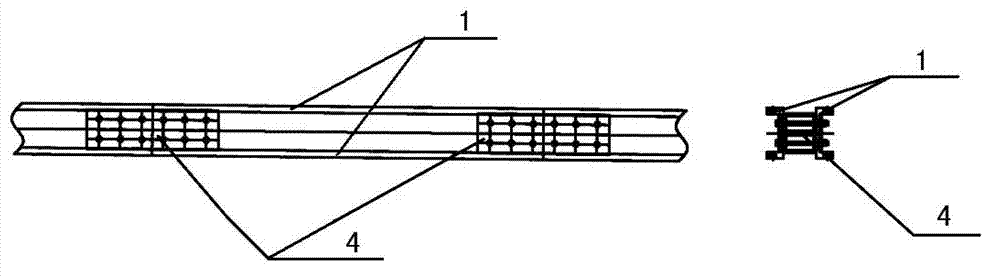

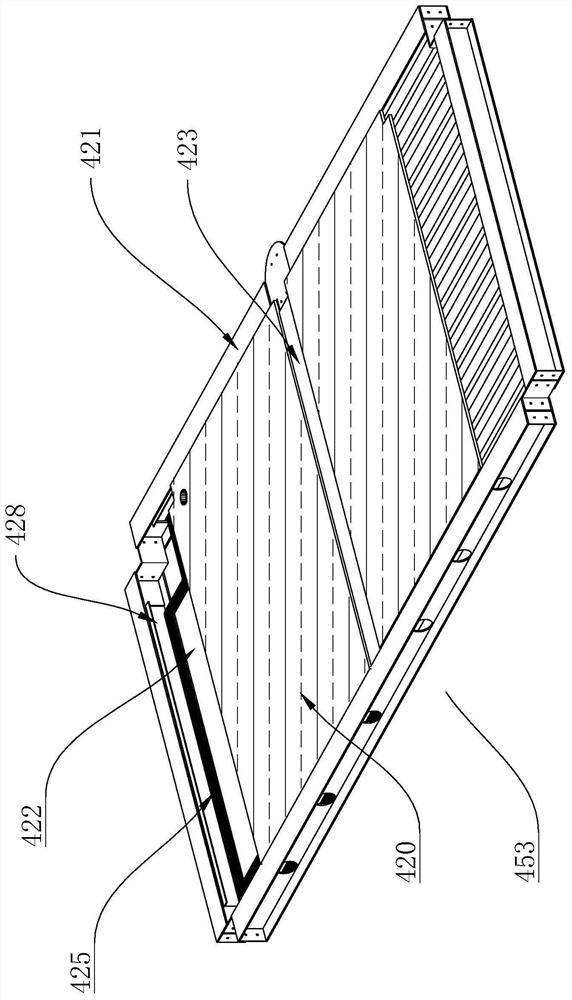

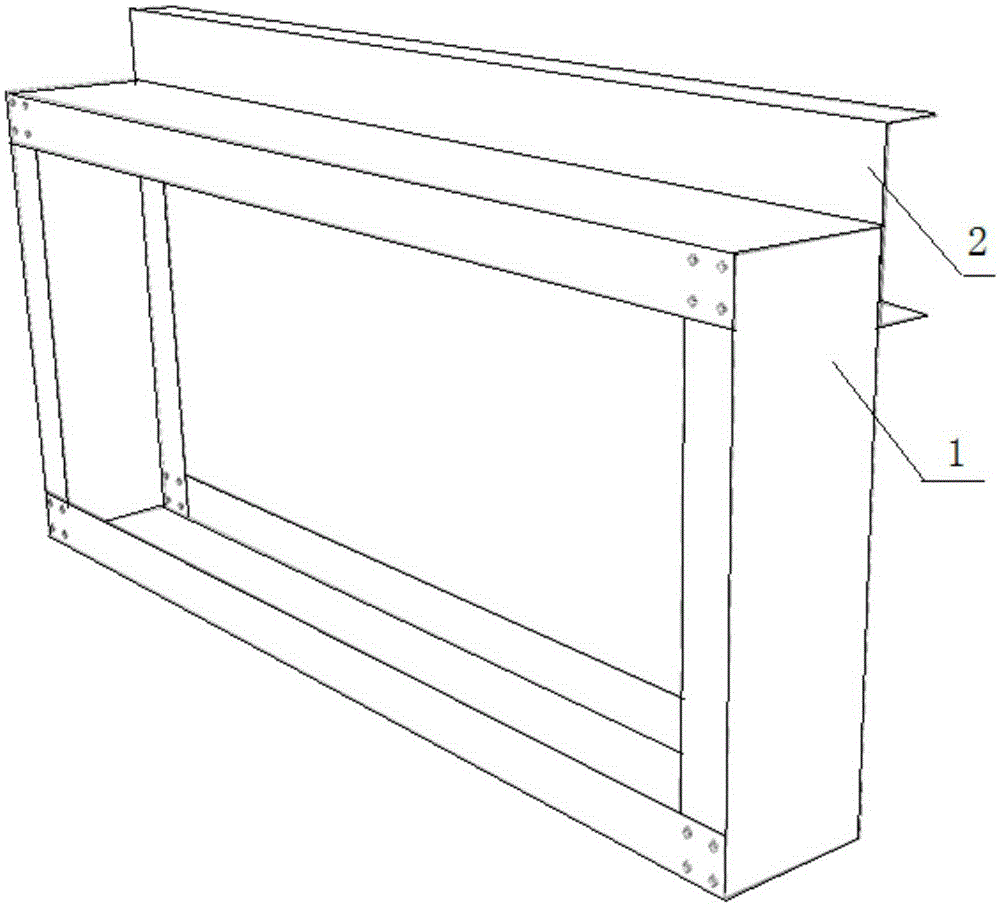

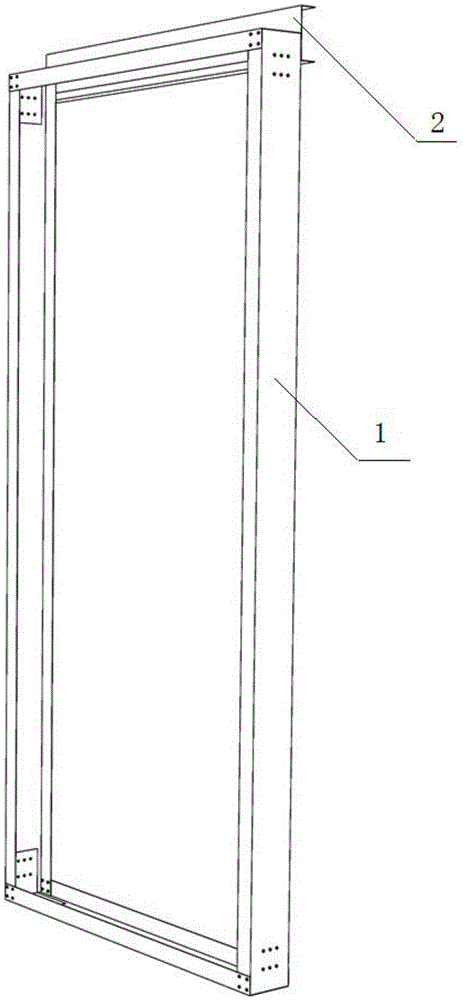

Assembly for transporting windmill generator vane

InactiveCN101259897AReduce manufacturing costReduce shipping costsPackaging vehiclesContainers for machinesFixed frameEngineering

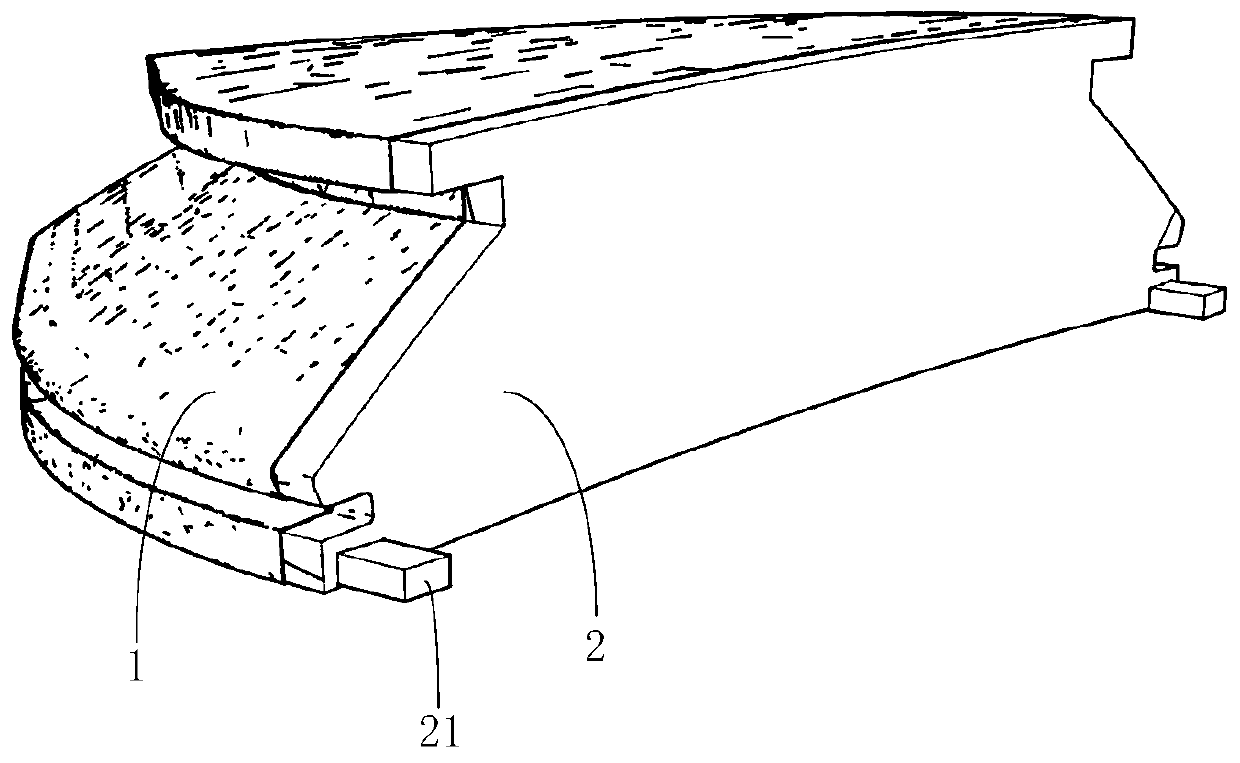

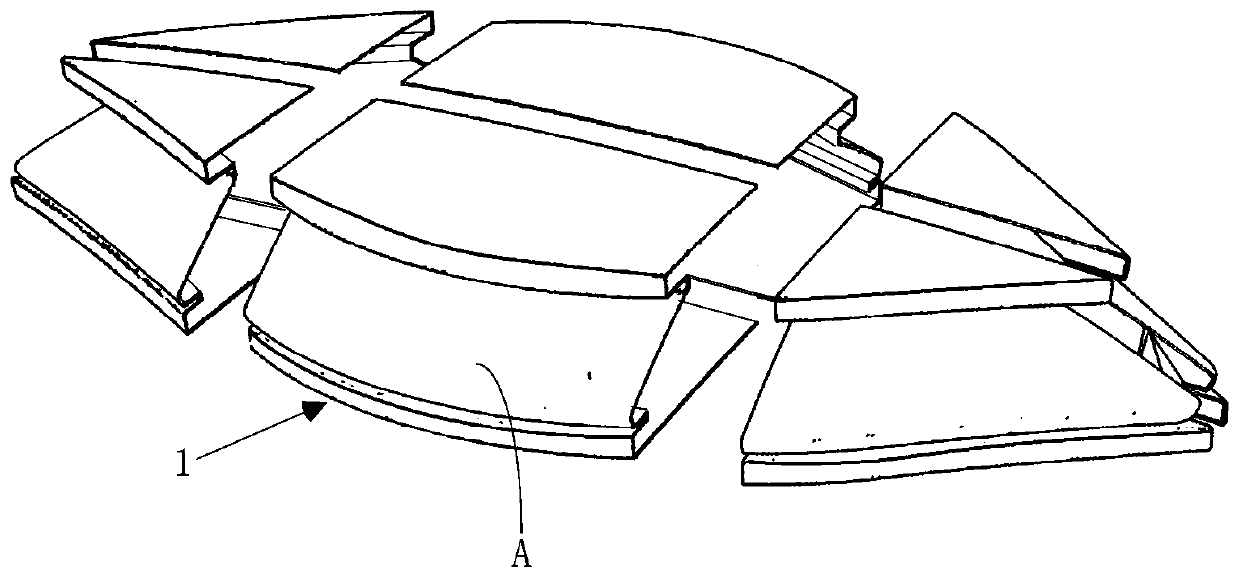

The invention relates to a processing device used for delivering the vanes of a wing-power generator and a usage method thereof. The processing device comprises a front group and a rear group of a vane root fixed frame (1) and a vane supporting frame (2); the vane root fixed frame is a rectangle structure which is provided with a vertical cutting connecting rod (11) which divides the vane root fixed frame into a large rectangle area and a small rectangle area where the vane and the vane root are respectively arranged; the four edges of the vane root area are respectively provided with a vane root connecting block (12); the vane supporting frame is provided with a rectangle frame structure which is provided with an openable upper pressing plate (11); furthermore, the horizontal upper pressing plate (22) and the horizontal lower pressing plate (23) of the rectangle frame structure are provided with a pair of vane pressing plates with openings that are corresponding to each other. The processing device leads one transport vehicle to deliver two vanes at the same time, and greatly reduces the transport cost.

Owner:SHANGHAI ELECTRIC WIND POWER GRP CO LTD

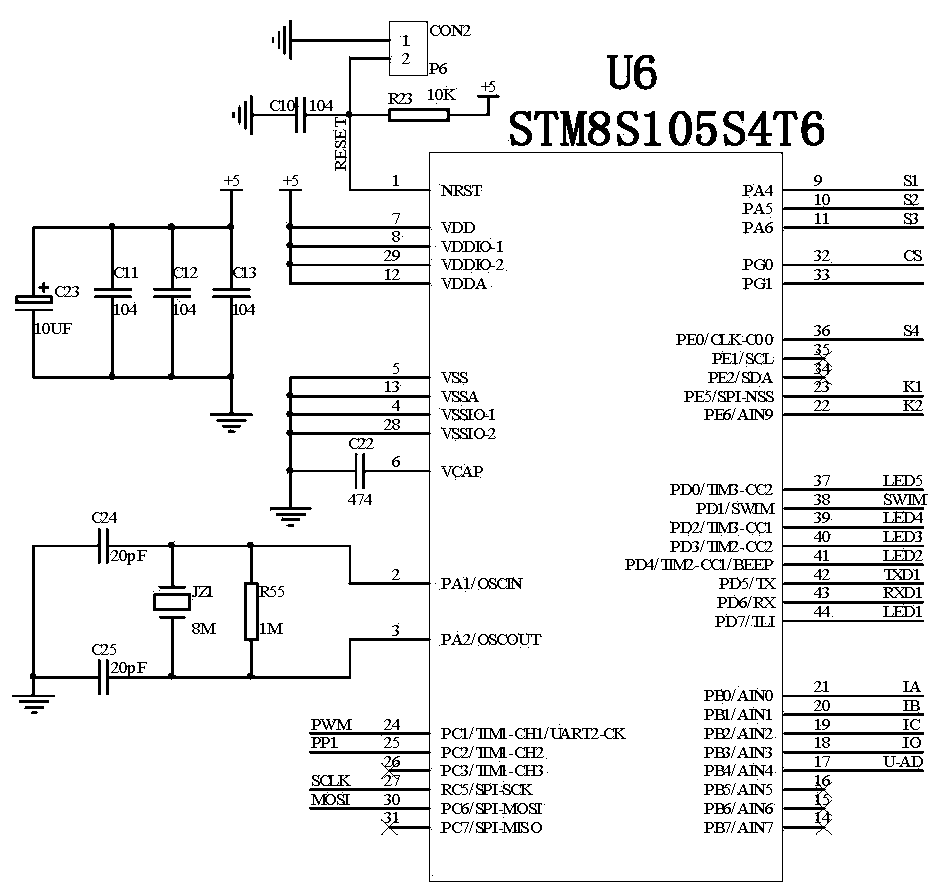

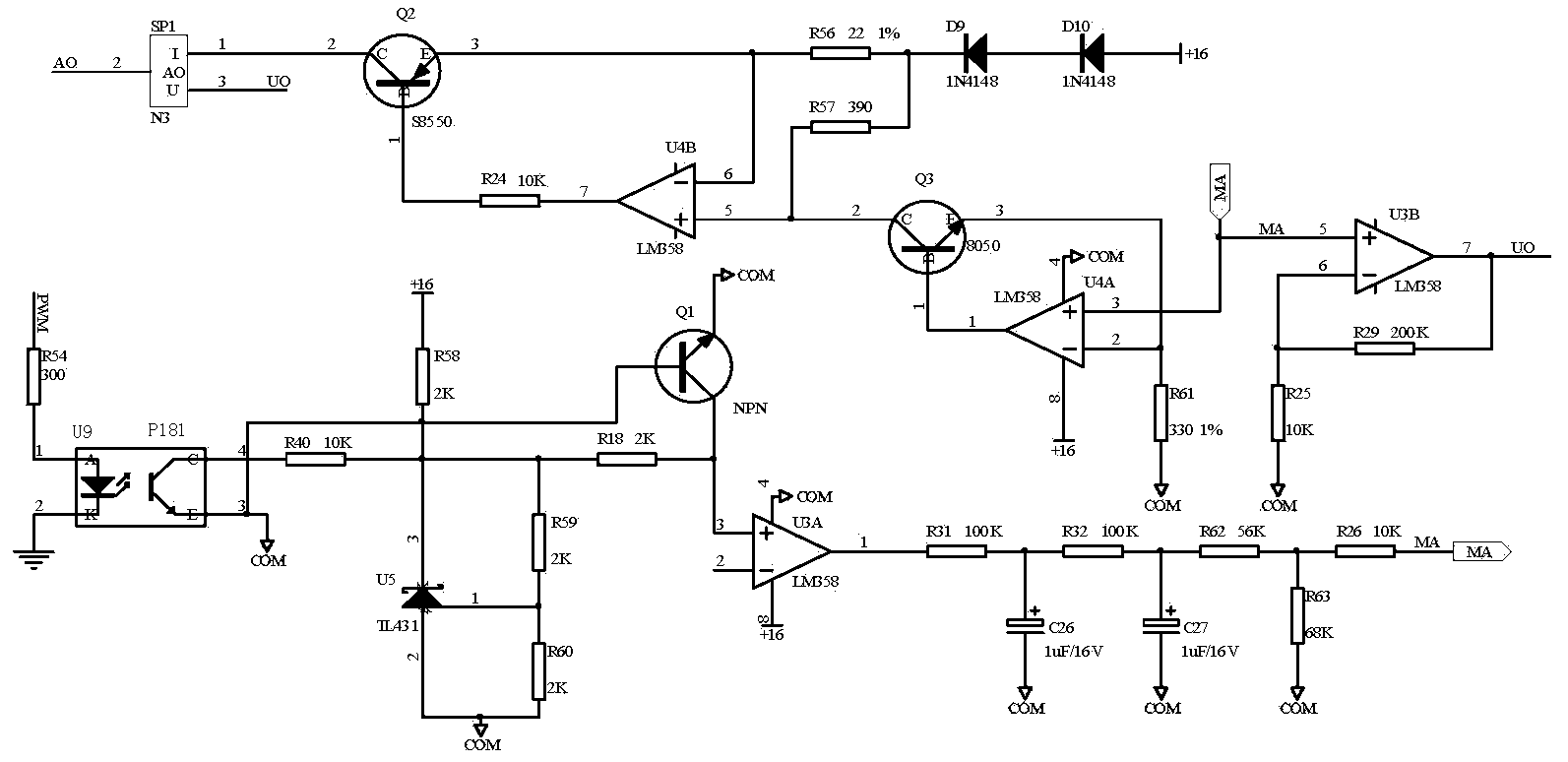

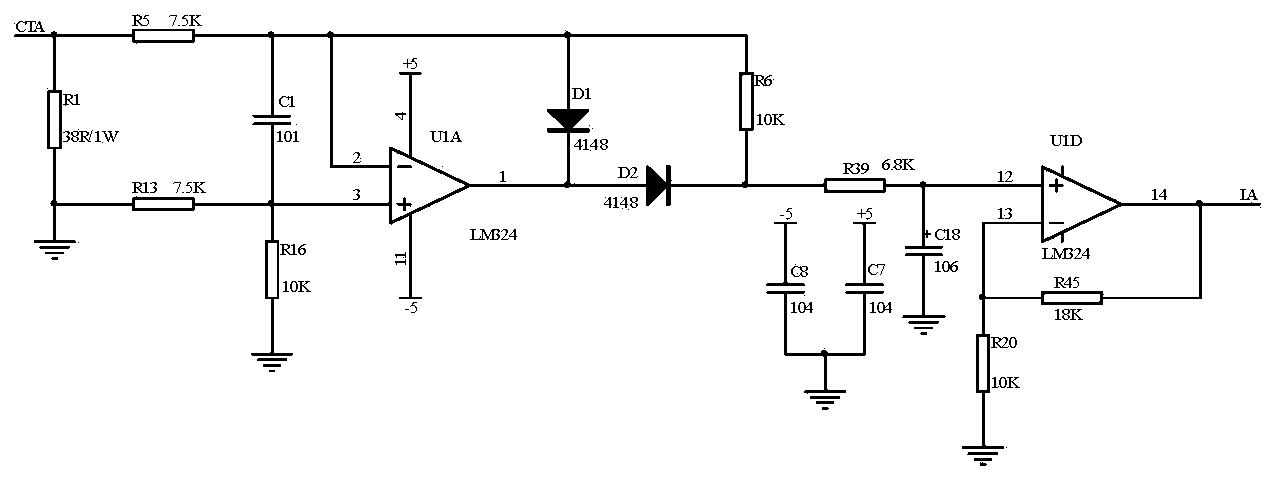

Intelligent motor protector

ActiveCN103401217AGood technical effectImprove compatibilityEmergency protective circuit arrangementsOvervoltageSignal processing circuits

The invention relates to automation control and motor protectors and discloses an intelligent motor protector, comprising a current sampling circuit, a power supply circuit, a voltage sampling circuit, a signal processing circuit, a central processing unit and a control module. The intelligent motor protector has the advantages of being compact in structure, high in current rectifying and sampling precision, capable of displaying the current value in real time in the operation process of a motor, and has multiple functions of undervoltage property, overvoltage, short circuit, three-phase unbalance protection and remote communication, and has higher practical value.

Owner:巨元智能电气(浙江)有限公司

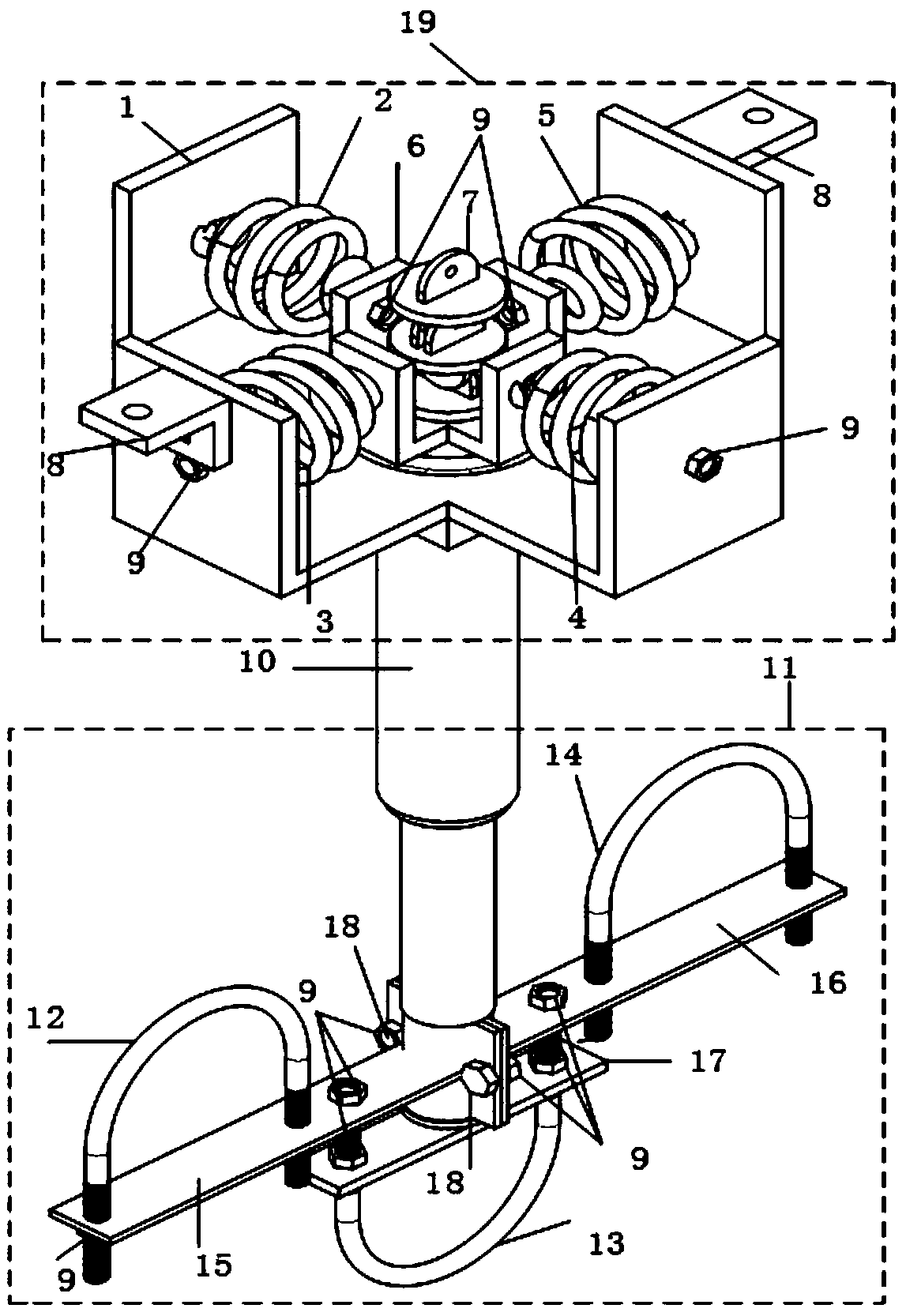

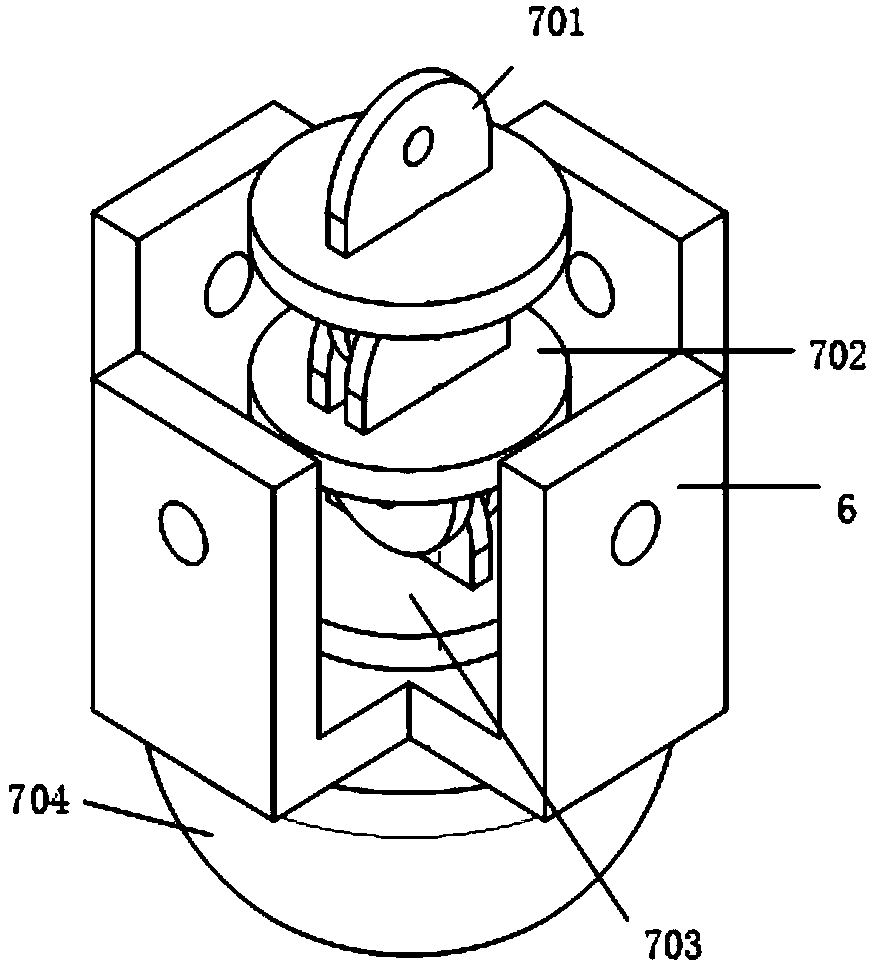

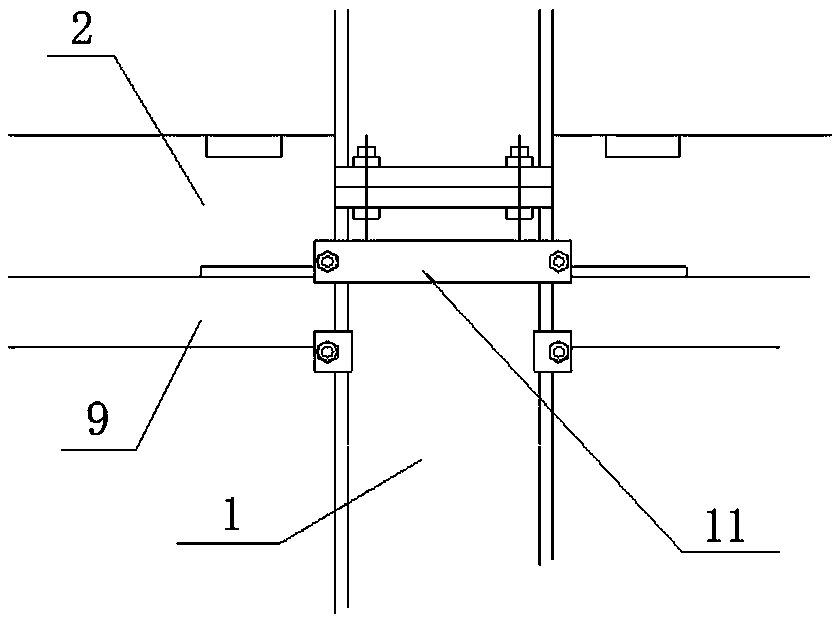

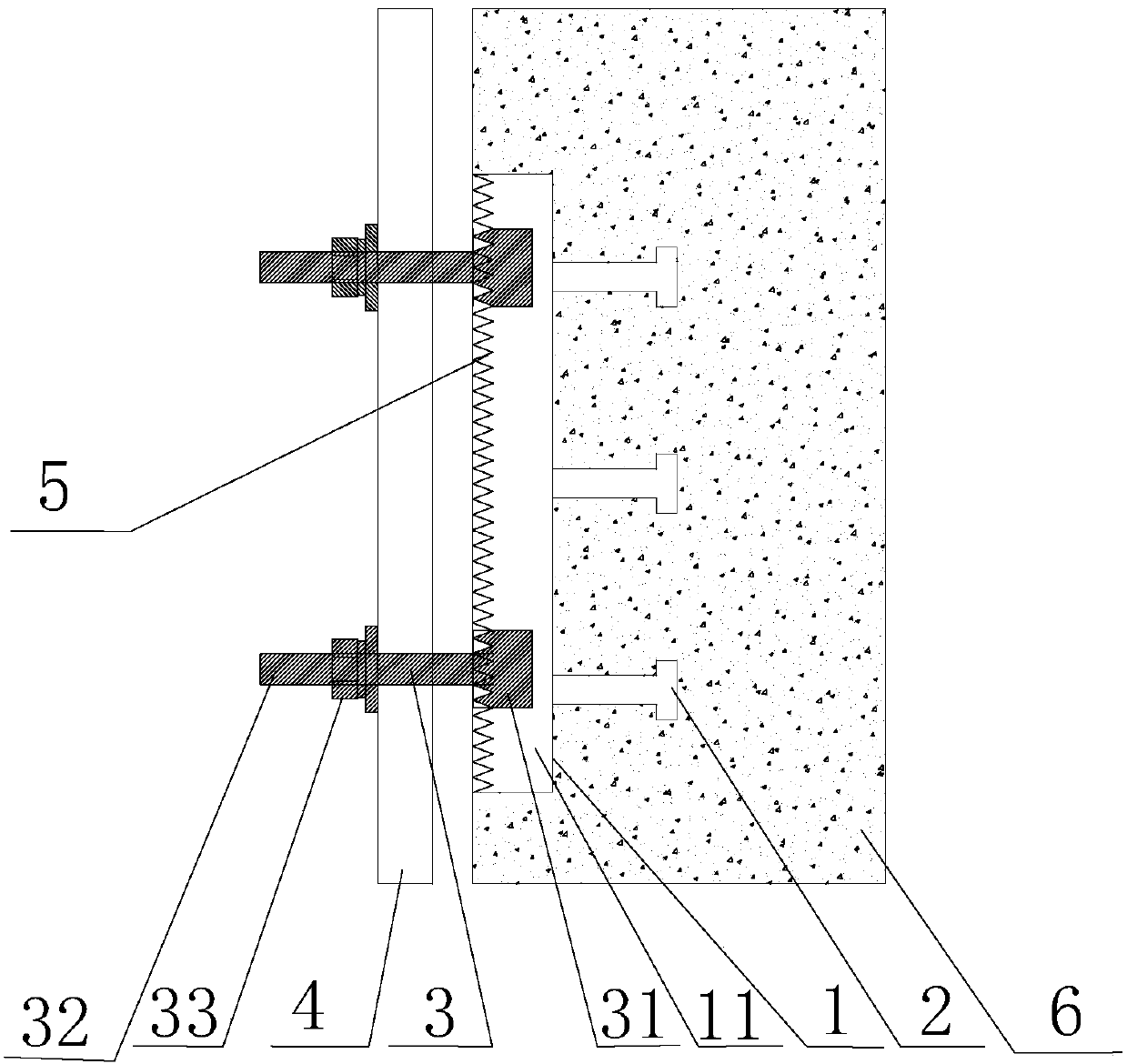

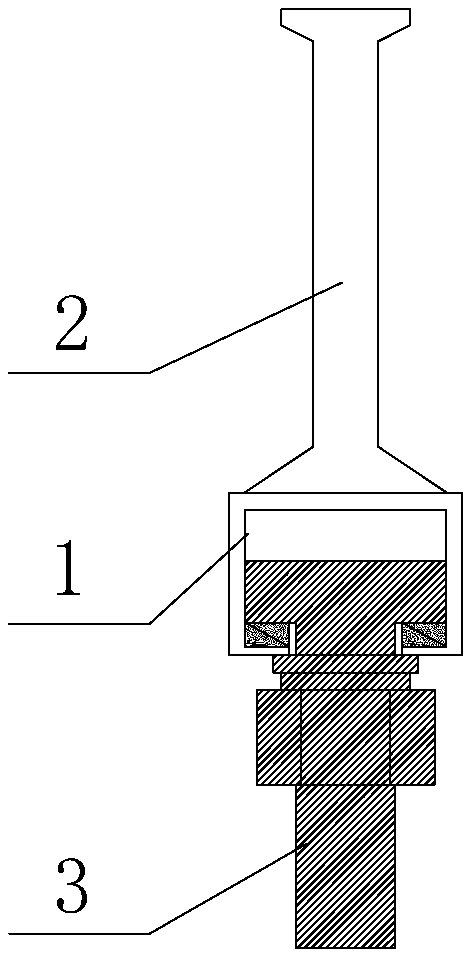

Novel single-rod universal anti-knock support hanger

ActiveCN108548012AReduce up and down vibrationRealize the buffering effectPipe supportsNon-rotating vibration suppressionEngineeringSmall hole

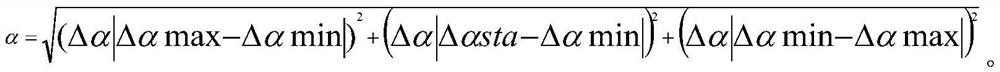

The invention provides a novel single-rod universal anti-knock support hanger. The novel single-rod universal anti-knock support hanger comprises an upper connecting device, a vertical anti-knock hanging rod and a pipe clamp device which are sequentially arranged from top to bottom; through damping small holes and hydraulic oil in the vertical anti-knock hanging rod, earthquake energy is consumed,the vertical anti-knock hanging rod can effectively buffer whole up and down vibration in a pipeline, and through the design, the great impact in the vertical direction can be borne; in the upper connecting device, through stretching and compressing of two opposite springs and the joint effect of springs in the four directions, earthquake energy can be effectively converted into elastic potentialenergy of the springs, the buffer effect on the side face vibration in any direction of the pipeline can be achieved, and the side anti-knock property of the support hanger can be greatly improved; the field mounting efficiency is improved, multi-direction anti-knock supporting force can be provided, and the occasion with the higher equipment safety can be met.

Owner:JIANGSU DANENG ELECTRIC TECH CO LTD

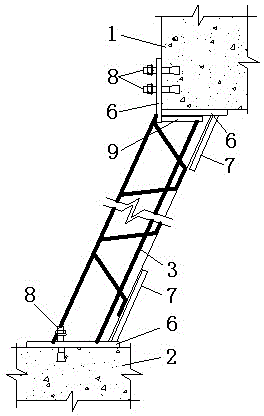

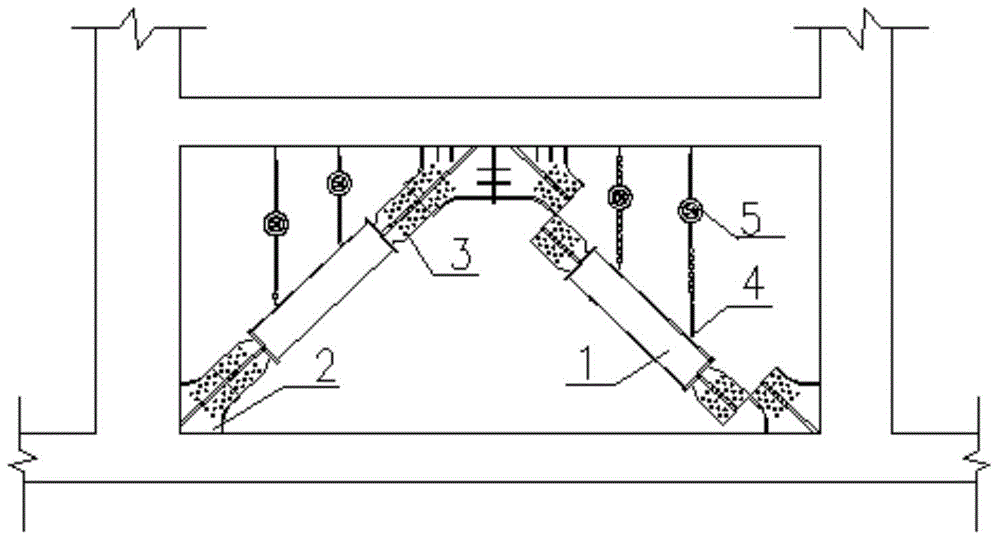

Ultra-thin steel truss inclined wall construction method and formwork structure

ActiveCN103603494ASolving the Difficulties in Supporting Inclined WallsEnsure safety and qualityForms/shuttering/falseworksAuxillary members of forms/shuttering/falseworksMaterials processingRebar

The invention discloses an ultra-thin steel truss inclined wall construction method and structure. The ultra-thin steel truss inclined wall construction method is characterized in that a connecting member is fixed between a superstructure and a substructure; the outside of an inclined wall body utilizes a steel bar truss formwork as a supporting member, and two ends of the steel bar truss formwork are connected with the connecting member of the superstructure and the substructure to serve as the outer supporting formwork of the inclined wall body; the inside of the wall body utilizes an ordinary formwork; the ordinary formwork and the steel bar truss formwork are connected through a split bolt; the pouring of concrete utilizes self-compacting concrete. According to the ultra-thin steel truss inclined wall construction method and structure, the steel bar truss formwork serves as the support of the outside of the inclined wall body, and the inside of the inclined wall body still utilizes the ordinary formwork, so that the difficulty in the supporting of the inclined wall is overcome; the technology is simple, the field installation efficiency is high, the quality is reliable, the construction period is short, the labor intensity is low, and labor force can be arranged for performing construction simultaneously; materials can be processed in a material processing factory, field assembly can be performed directly, and the construction period is shortened; the construction quality meets design requirements.

Owner:CHINA CONSTR 4TH ENG BUREAU 6TH

Prefabricated-slab connecting structure

PendingCN108265822AHigh degree of prefabricationImprove prefabrication rateFloorsSteel barComposite slab

The invention relates to a prefabricated-slab connecting structure, and belongs to the field of prefabricated components in constructional engineering. According to the connecting structure between composite slabs, the composite slabs are composed of slab prefabricated parts and slab cast-in-place parts; the slab cast-in-place parts are located at connecting areas between the composite slabs; theslab prefabricated parts are each in a step shape with the middle being protruding and the periphery being sunken; upper layer steel bars of the slab prefabricated parts extend out of the middle protruding areas of the slab prefabricated parts, and lower layer steel bars of the slab prefabricated parts do not extend out of the periphery sunken areas of the slab prefabricated parts; additional lower layer steel bars are arranged on the lower layers of the slab cast-in-place parts, and the additional lower layer steel bars and the lower layer steel bars are indirectly connected in an overlappedmode; and steel bar meshes are laid on the upper layers of the slab cast-in-place parts, and the steel bar meshes and the upper layer steel bars are connected in an overlapped mode. Similarly, the prefabricated-slab connecting structure can also be used for connecting between the composite slabs and composite beams as well as between the composite slabs and a wall. According to the prefabricated-slab connecting structure, the prefabrication rate is increased, the manufacturing cost is low, the stiffness is large, and the formwork removing and hoisting requirements can be met.

Owner:EAST CHINA ARCHITECTURAL DESIGN & RES INST

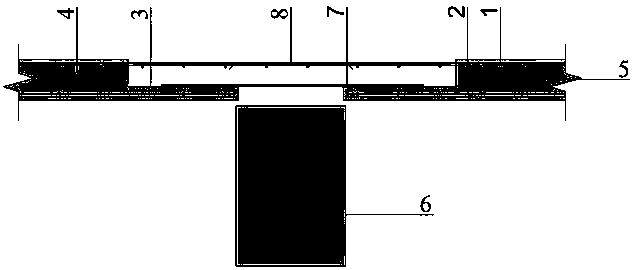

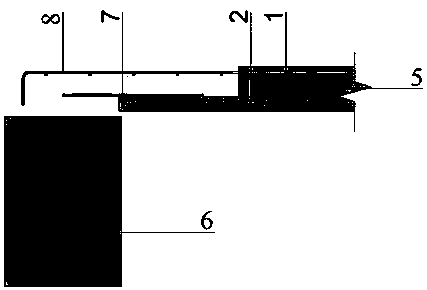

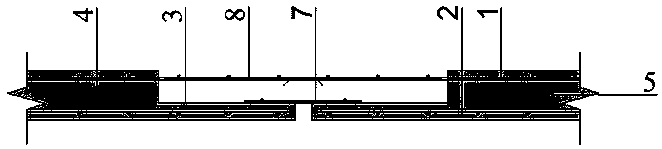

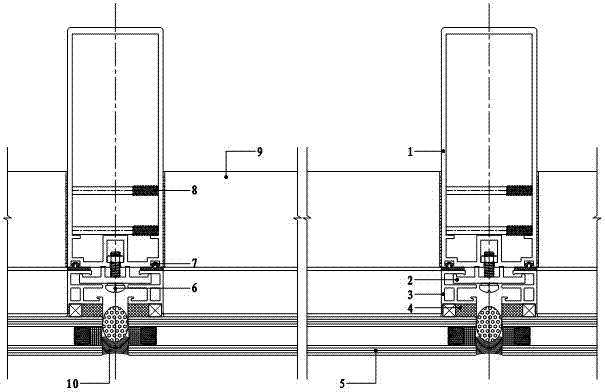

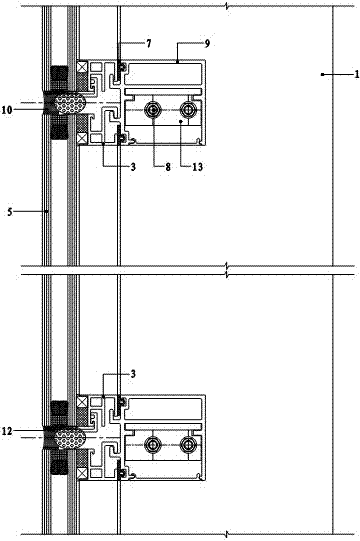

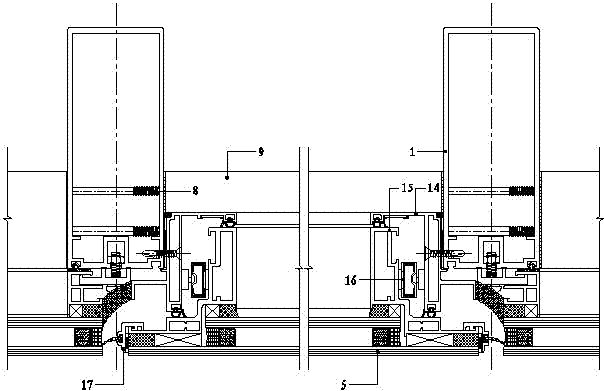

Hitching hidden-frame glass curtain wall

InactiveCN103397724ARapid positioningImprove on-site installation efficiencyWallsAdhesiveEngineering

The invention provides a hitching hidden-frame glass curtain wall comprising a main frame, an auxiliary frame, a cross beam, an opening frame, an opening sash and glass. Left and right vertical sides in the main and auxiliary frames are connected through pressure plates, and top and bottom horizontal sides in the main and auxiliary frames are connected through hooks. The cross beam is fixed on the main frame. The auxiliary frame is hitched to the cross beam, and a carrier strip is disposed at the lower end of the auxiliary frame. The glass is adhered to the auxiliary frame through silicone structural adhesive. The upper end of the opening frame is hitched to the cross beam. The opening frame is connected with the opening sash in a hitched structure. A channeled carrier strip is disposed at the upper end of the opening sash. The hitching hidden-frame glass curtain wall has the advantages that small-unit glass plates are positioned fast, field installation efficiency is improved, and the problems such as shedding of corners of the opening sash and frame-sash scratching are prevented effectively.

Owner:秦皇岛市中贤幕墙装饰工程有限公司

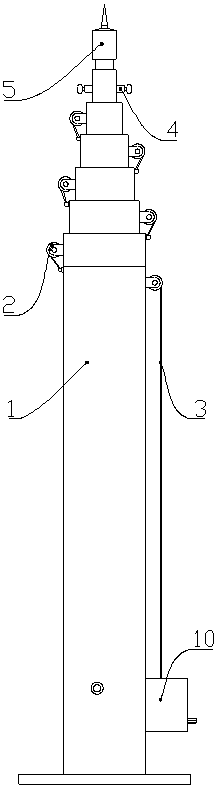

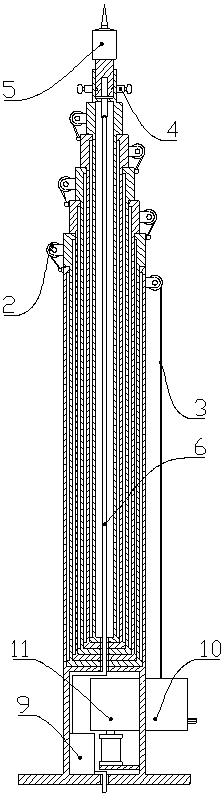

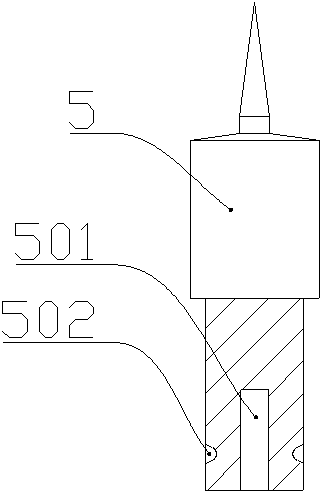

Intelligent full-automatic lifting type lightning-protection equipment

ActiveCN107732669AQuick Response DriverQuick conversionWind energy generationCorona dischargeLower limitMicrocontroller

The invention discloses intelligent full-automatic lifting type lightning-protection equipment. The equipment comprises a rod boy formed by multi-stage retractable sleeving rods, differential pulley sets fixed at the upper ends of the retractable sleeving rods of all stages and traction ropes winding the differential pulley sets; the top of the rod body is connected with a lightning-protection rodthrough a quick connecting device, the outer side surface of the lower end of the rod body is fixedly provided with a rope winding device driven in a manual mode and an electric driving modes, an insulating down lead penetrates through the interior of the inner-layer retractable sleeving rod of the rod body, the upper end of the inner-layer retractable sleeving rod is provided with a traction plate connected with the down lead, the lower end of the rod body is provided with an inner cavity, the inner cavity is internally provided with a spring type automatic wire winding device and a controldevice, the control device is a microcontroller, the microcontroller is connected with a micro-control switch and a wireless transceiver module, and the outer-layer retractable sleeving rod of the rodbody is provided with an upper limit sensor and a lower limit sensor. The intelligent full-automatic lifting type lightning-protection equipment has the advantages of being intelligent, high in response speed, convenient to install, high in lifting efficiency, capable of saving manpower and effectively preventing rotation.

Owner:HENAN YANGBO LIGHTNING PROTECTION TECH

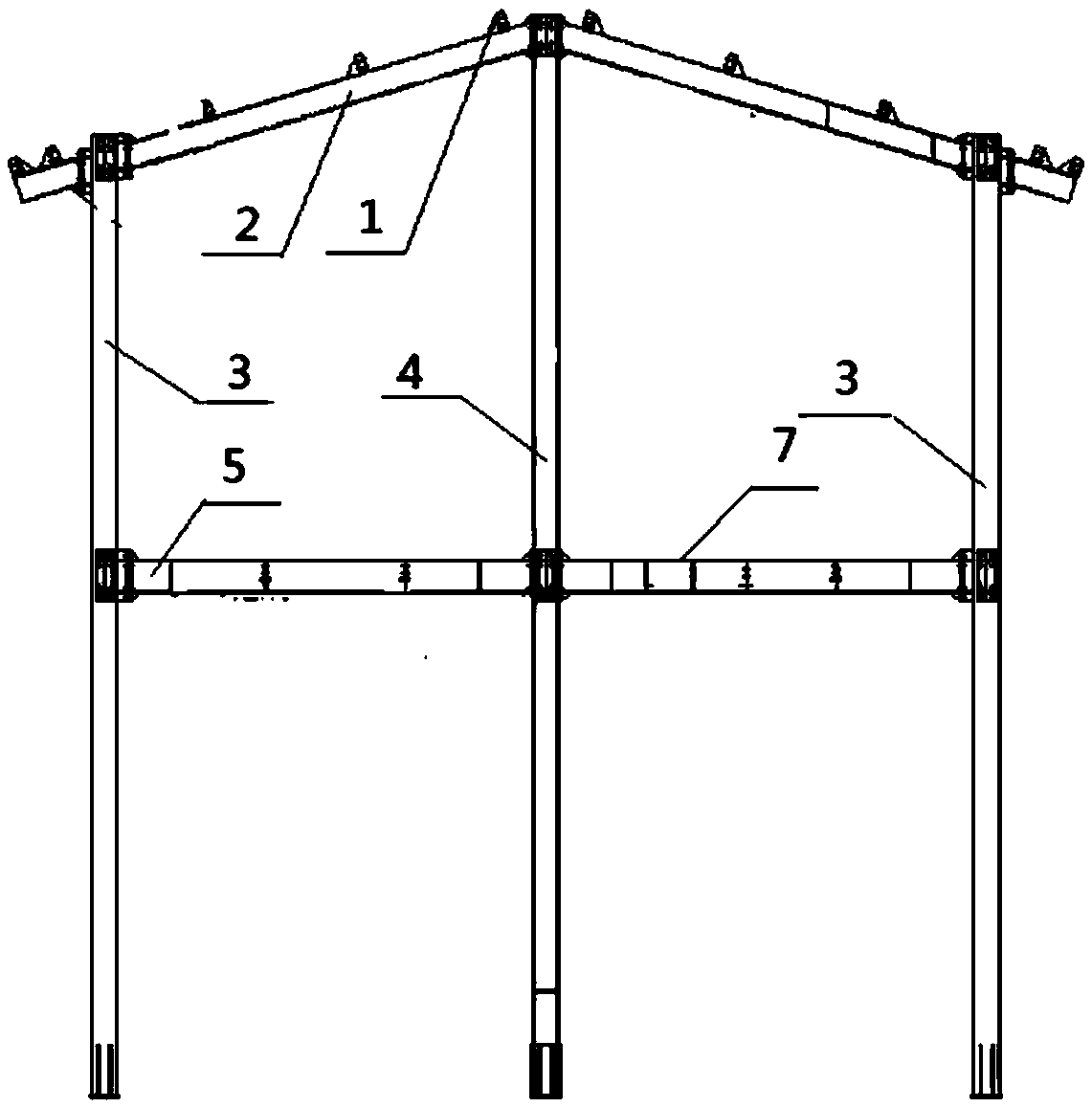

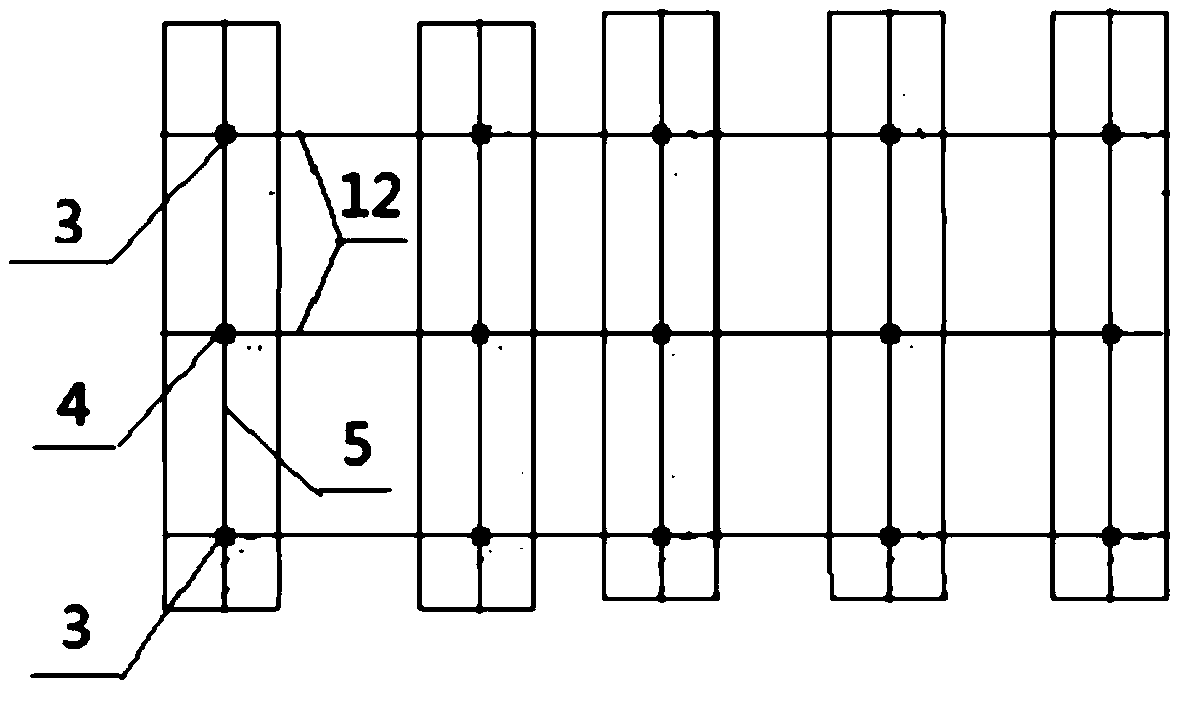

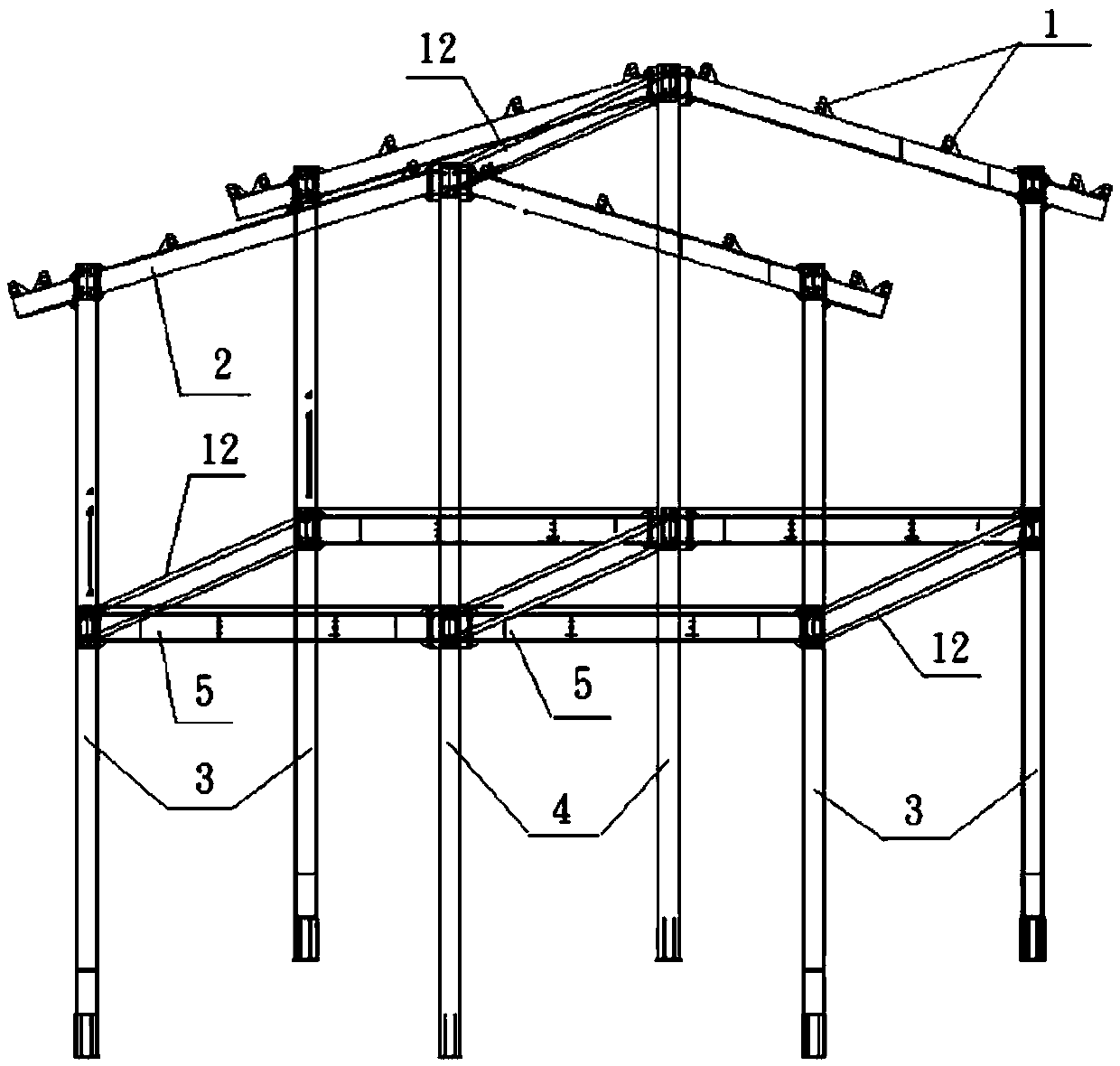

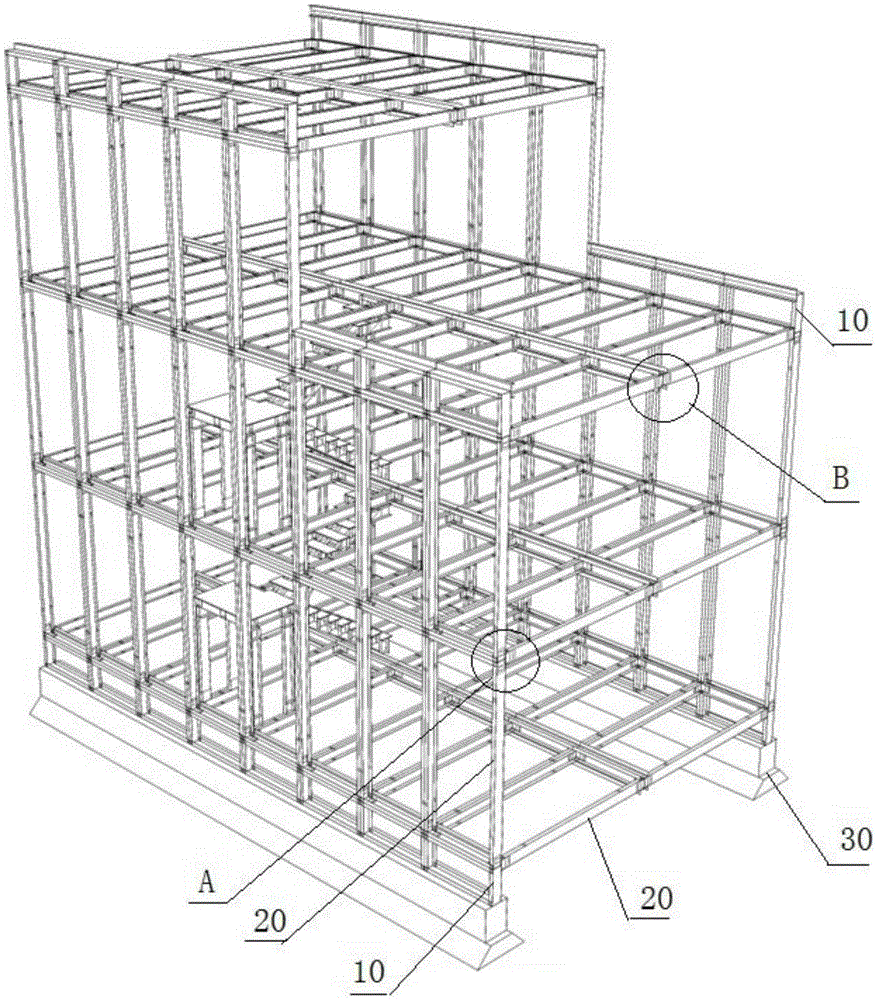

Earthquake-proof folk house steel framework and installation method thereof

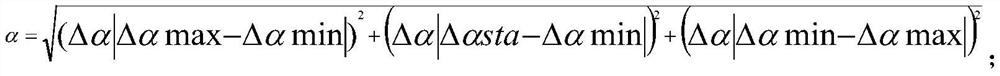

The invention discloses an earthquake-proof folk house steel framework and an installation method thereof. The earthquake-proof folk house steel framework comprises a plurality of beam and column integration units, and a plurality of horizontal floor support plate integration units; each beam and column integration unit comprises two roof beams in lap joint to form a herringbone shape, a middle column in lap joint between the two roof beams and downwards extending, edge columns respectively in lap joint with the edge parts or the end parts of the two roof beams and downwards extending, and horizontal cross beams in lap joint between the middle column and the edge columns and perpendicular to the middle column and the edge columns; the beam and column integration units are arranged side by side at intervals according to the length of a built house; the beam and column integration units are connected through a plurality of horizontal longitudinal beams; the horizontal floor support plate integration units are arranged on a rectangular frame formed by the horizontal cross beams and the horizontal longitudinal beams; and the horizontal floor support plate integration units comprise baseplates, skeletons arranged on the baseplates at intervals, and concrete filled between the upper sides of the baseplates and the skeletons. The earthquake-proof folk house steel framework is convenient and fast in field installation, high in efficiency, high in installation precision, short in construction period, safe and reliable, effectively saves both manpower and material resources, and has a better operability.

Owner:云南昆钢钢结构股份有限公司

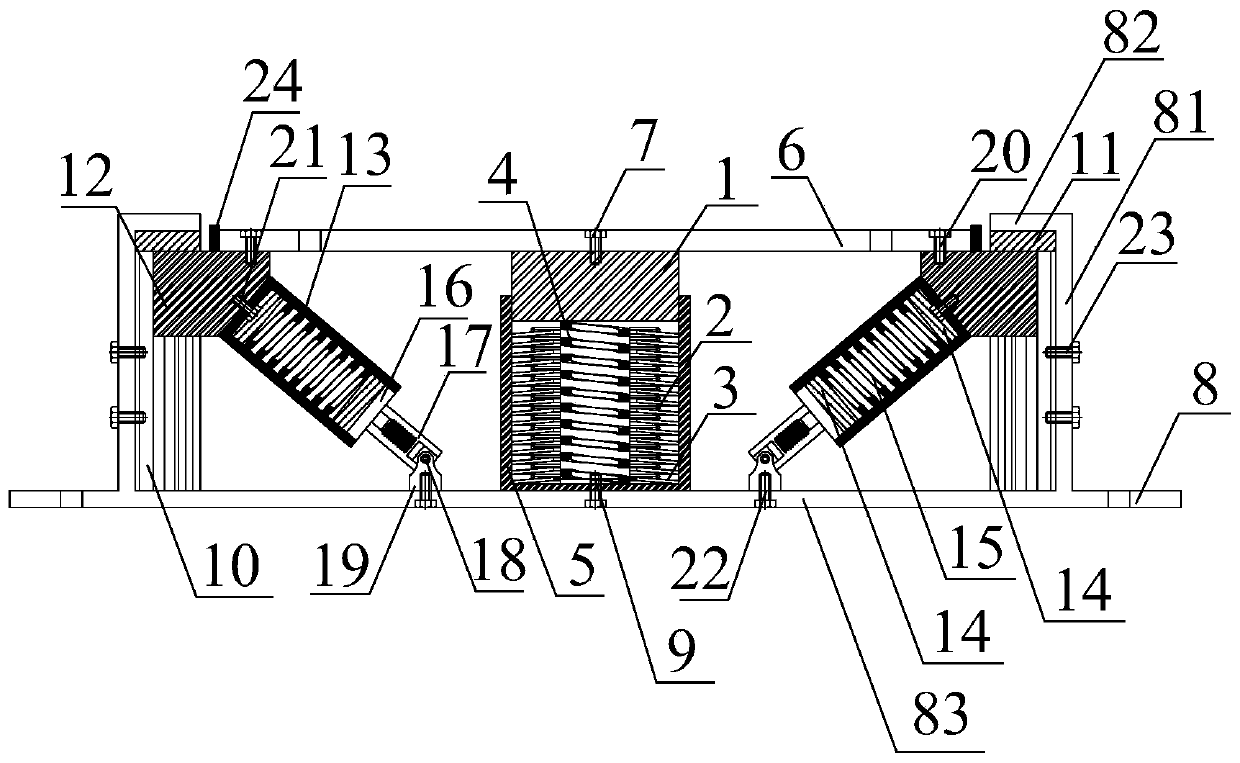

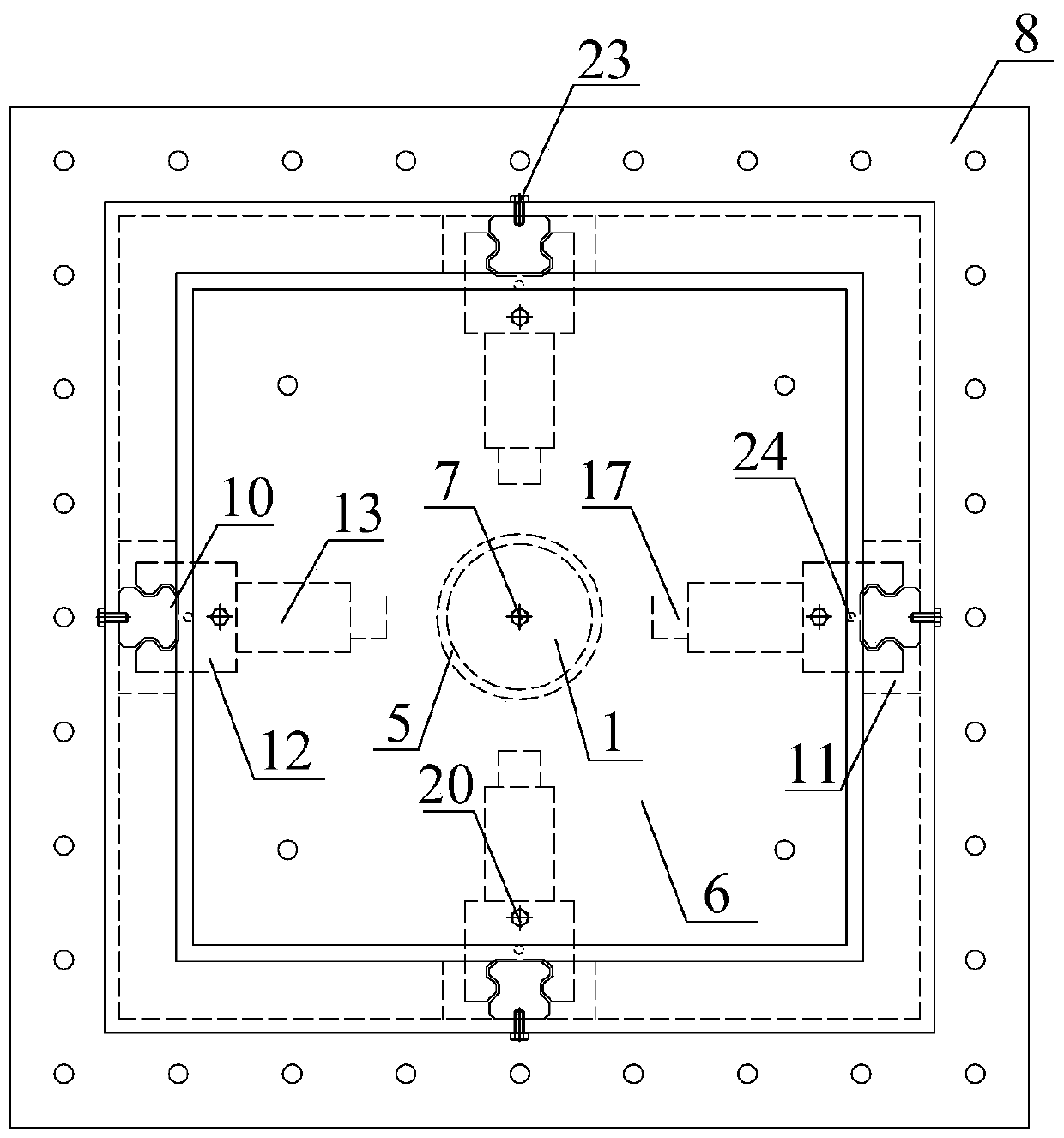

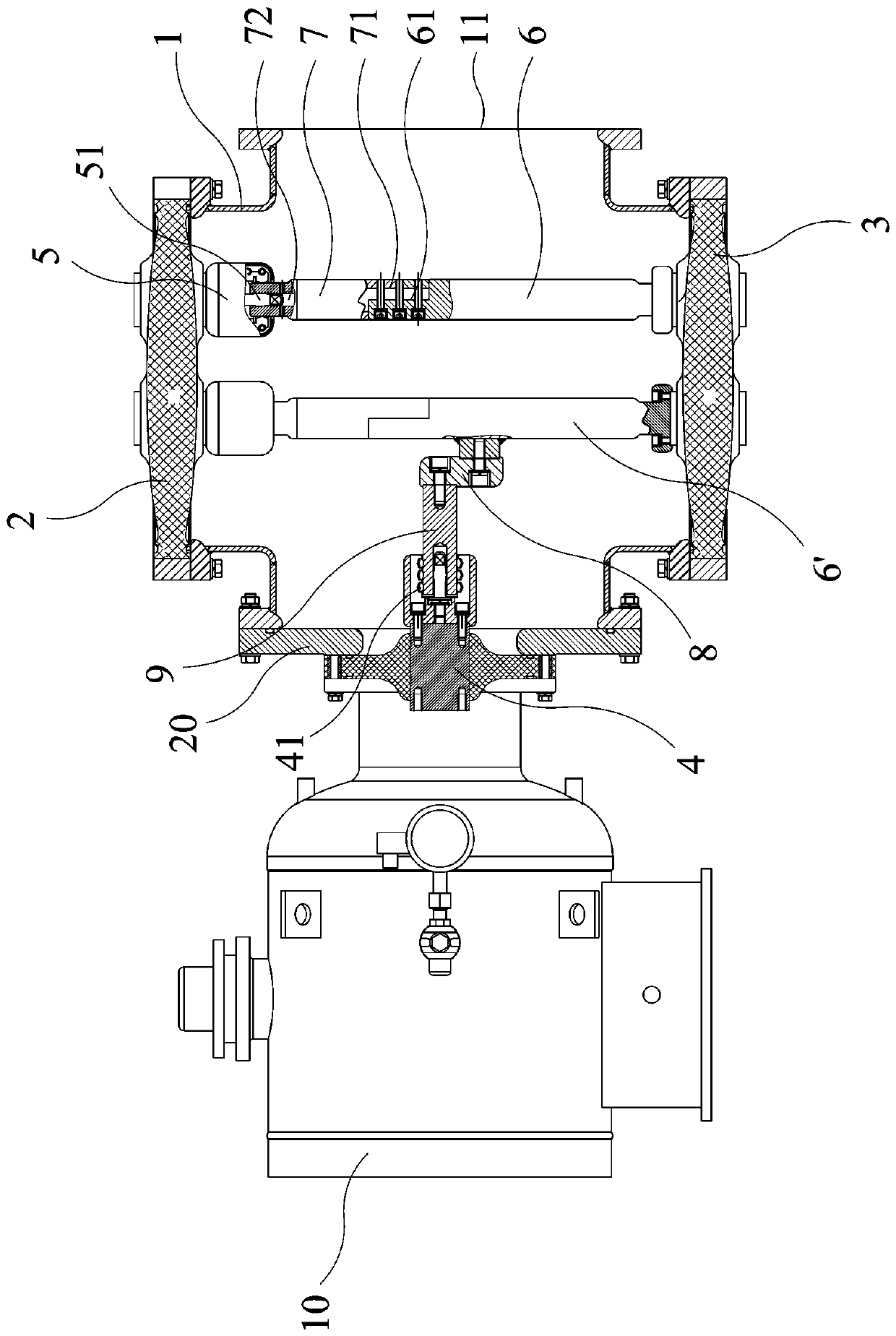

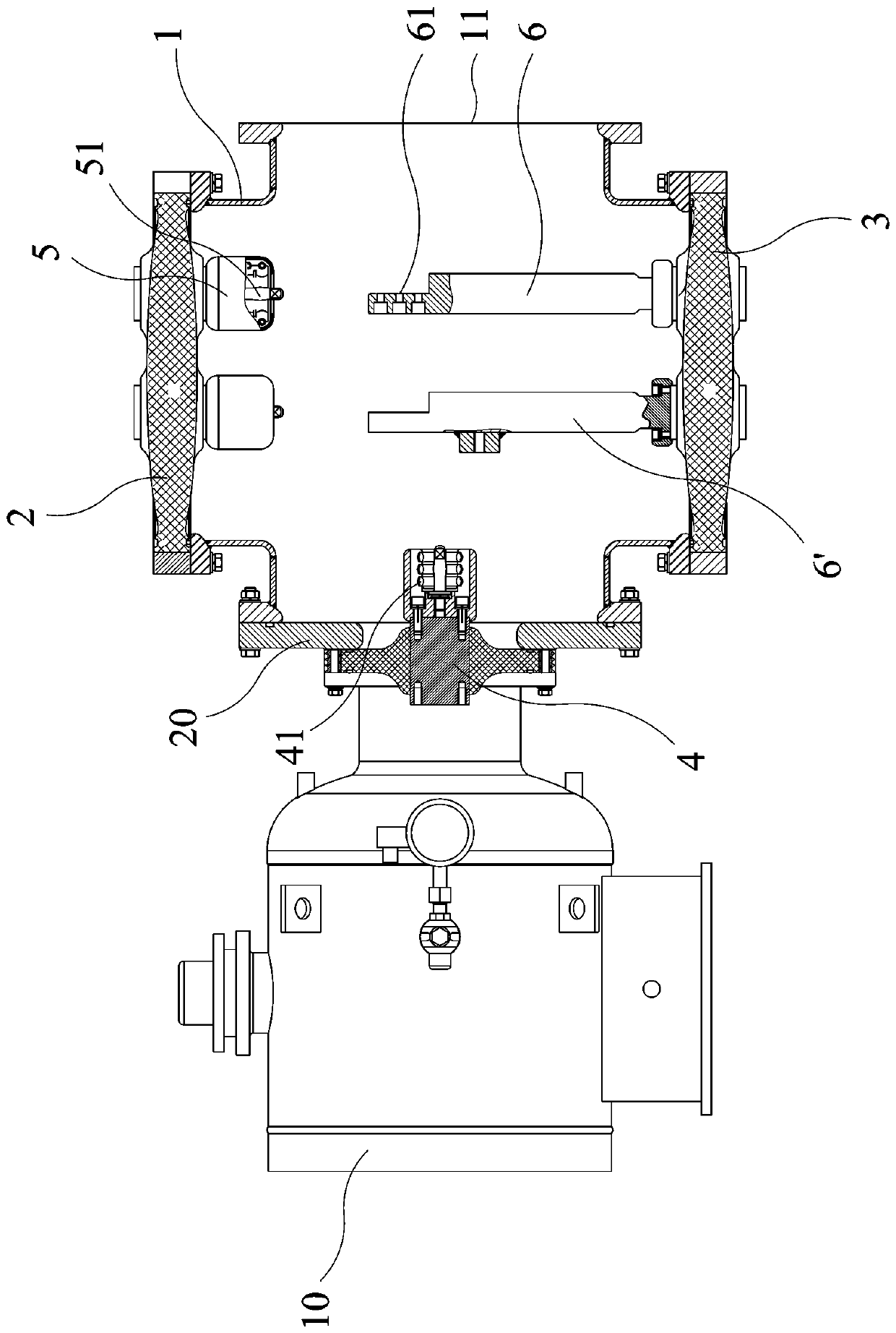

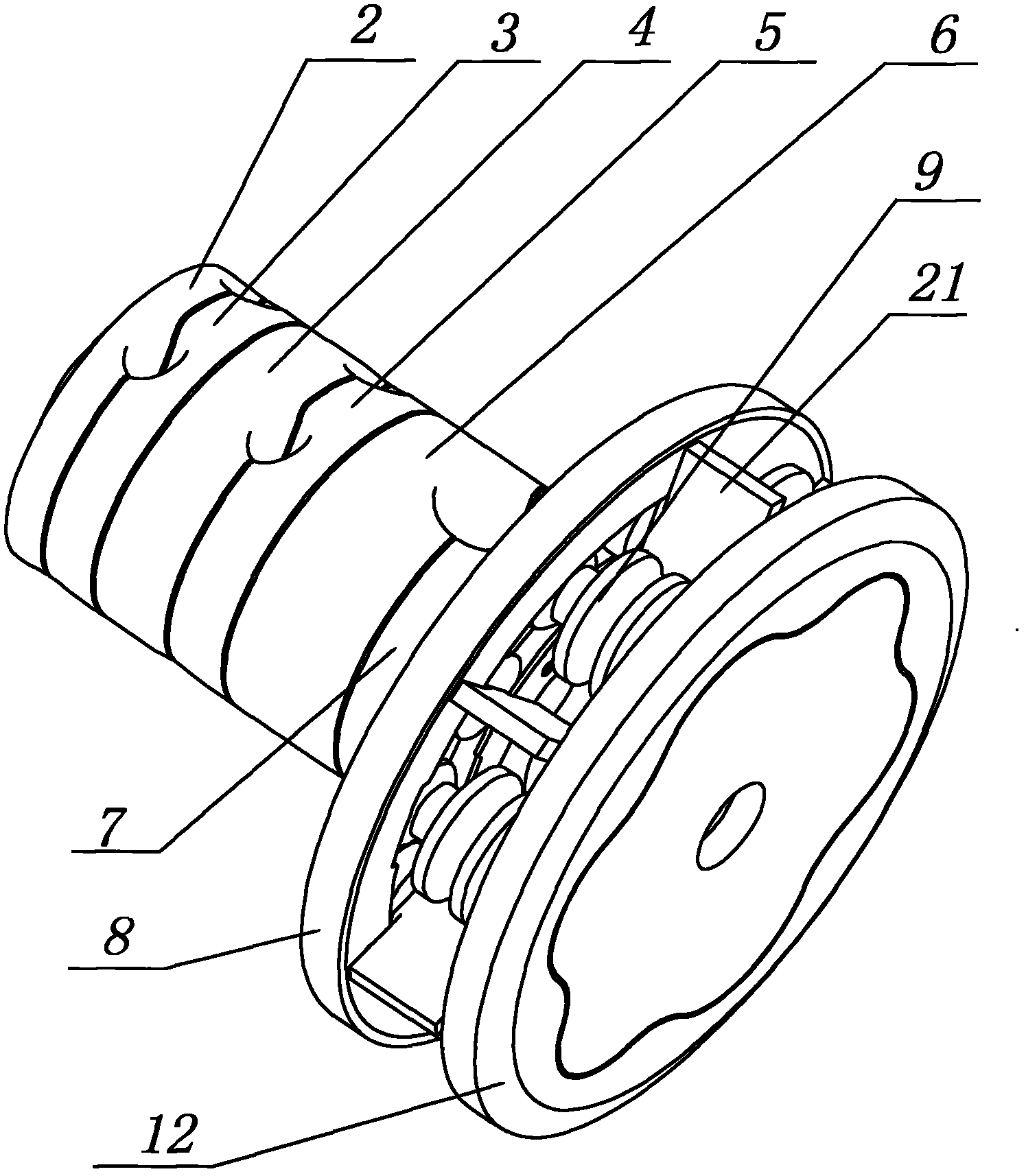

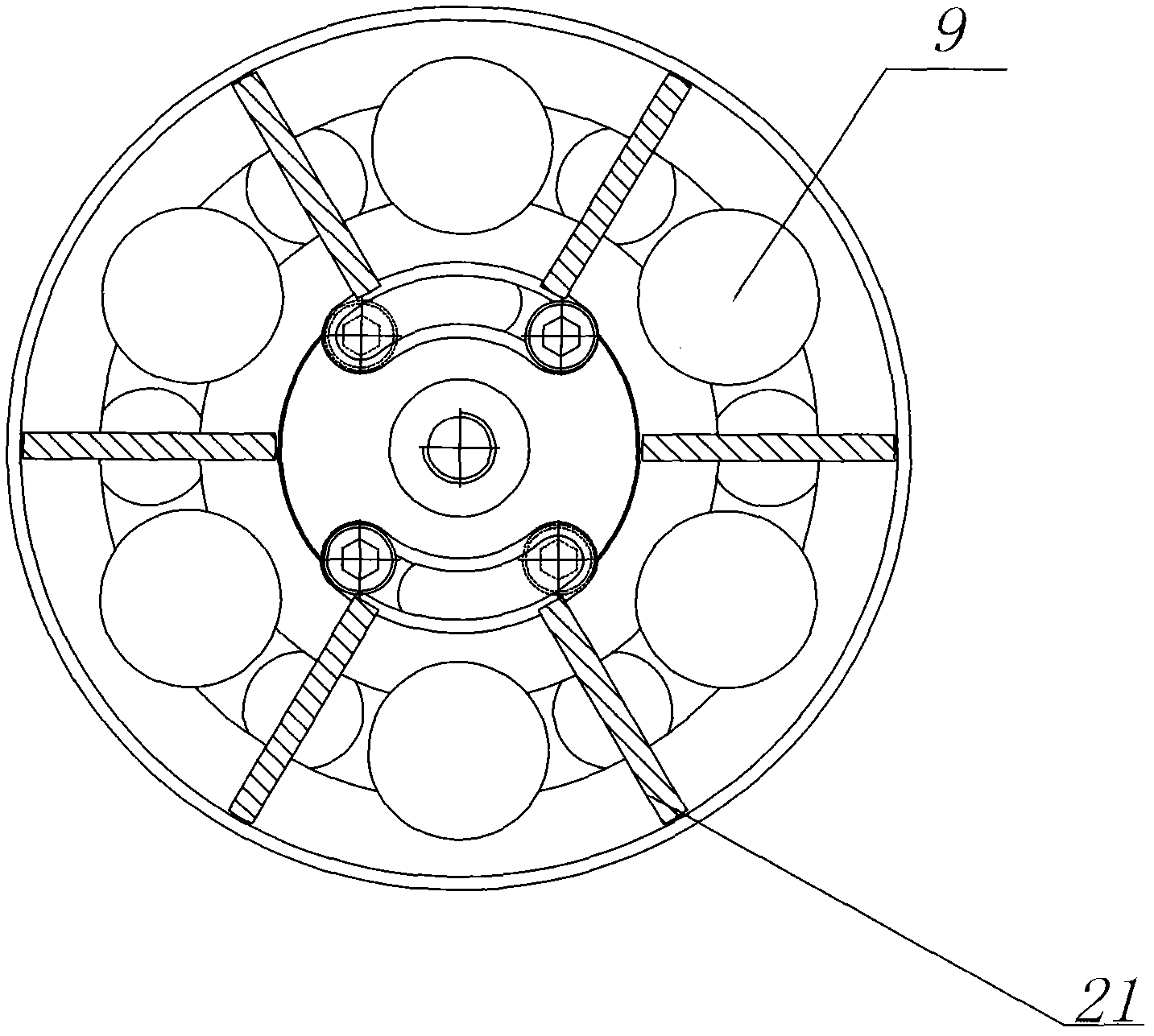

Vertical vibration isolation device

InactiveCN111336204AEasy to assembleEfficient energy consumptionHigh internal friction springsProtective buildings/sheltersVertical vibrationUniversal joint

The invention discloses a vertical vibration isolation device. The vertical vibration isolation device mainly comprises an upper connecting plate, an adaptive stiffness unit, slidable oblique rectangular compression spring units and a lower connecting plate. The adaptive stiffness unit is mainly composed of a positioning loading ring, a belleville spring and a pre-compressed rectangular spring, wherein the positioning loading ring and the belleville spring work in parallel to provide vertical negative stiffness, the pre-compressed rectangular spring provides vertical positive stiffness, and the positioning loading ring, the belleville spring and the pre-compressed rectangular spring work together to generate adaptive stiffness; and the slidable oblique rectangular compression spring unitsare each composed of a directional linear guide rail, an oblique rectangular compression spring and a universal joint, vertical sliding blocks move down along the directional linear guide rails to cause axial compression deformation of the oblique rectangular springs, and energy is dissipated through the mutual conversion of elastic potential energy and kinetic energy. The adaptive stiffness unitand the slidable oblique rectangular compression spring units work in parallel, collaboratively deform and jointly achieve vertical vibration isolation. The vertical vibration isolation device can bewidely applied to buildings or large and medium-sized mechanical equipment with high requirements for vibration reduction and near rail transit.

Owner:TONGJI UNIV

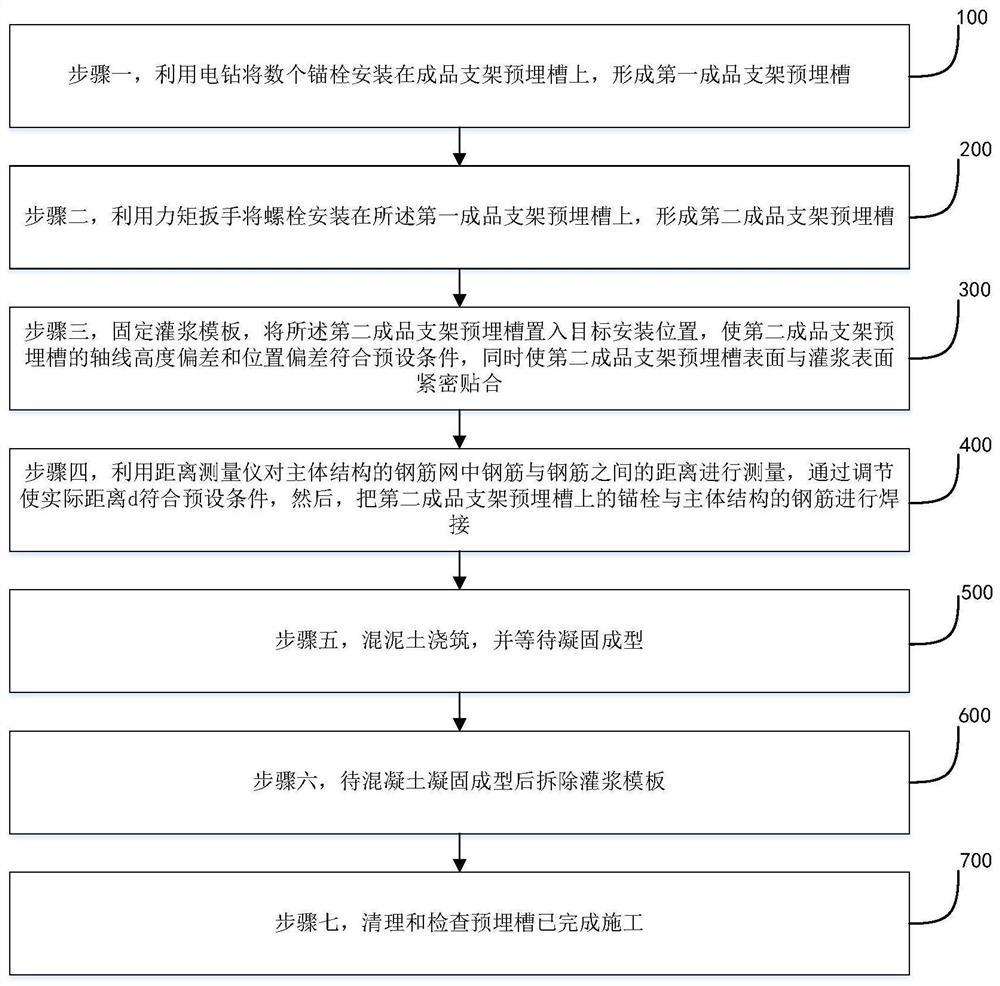

Anti-displacement construction method for finished support pre-buried groove

ActiveCN112411765AFit tightlyPrecise control of verticalityBuilding constructionsClassical mechanicsMesh reinforcement

The invention relates to an anti-displacement construction method for a finished support pre-buried groove. The anti-displacement construction method comprises the steps that 1, a plurality of anchorbolts are installed on the finished support pre-buried groove through an electric drill, and a first finished support pre-buried groove is formed; 2, bolts are installed on the first finished supportpre-buried groove through a torque wrench, and a second finished support pre-buried groove is formed; 3, a grouting formwork is fixed, the second finished support pre-buried groove is placed in a target installation position, the axis height deviation and the position deviation of the second finished support pre-buried groove meet preset conditions, and meanwhile the surface of the second finishedsupport pre-buried groove is tightly attached to the grouting surface; and 4, the distance between steel bars in a steel bar net of a main body structure is measured through a distance measuring instrument, the actual distance d meets the preset conditions, and welding is conducted. Accordingly, the perpendicularity of the second finished support pre-buried groove can be precisely controlled, then the finished support pre-buried groove can be prevented from deviating, and the field installation efficiency is improved.

Owner:XINJIANG VITAL DEV & CONSTR GRP

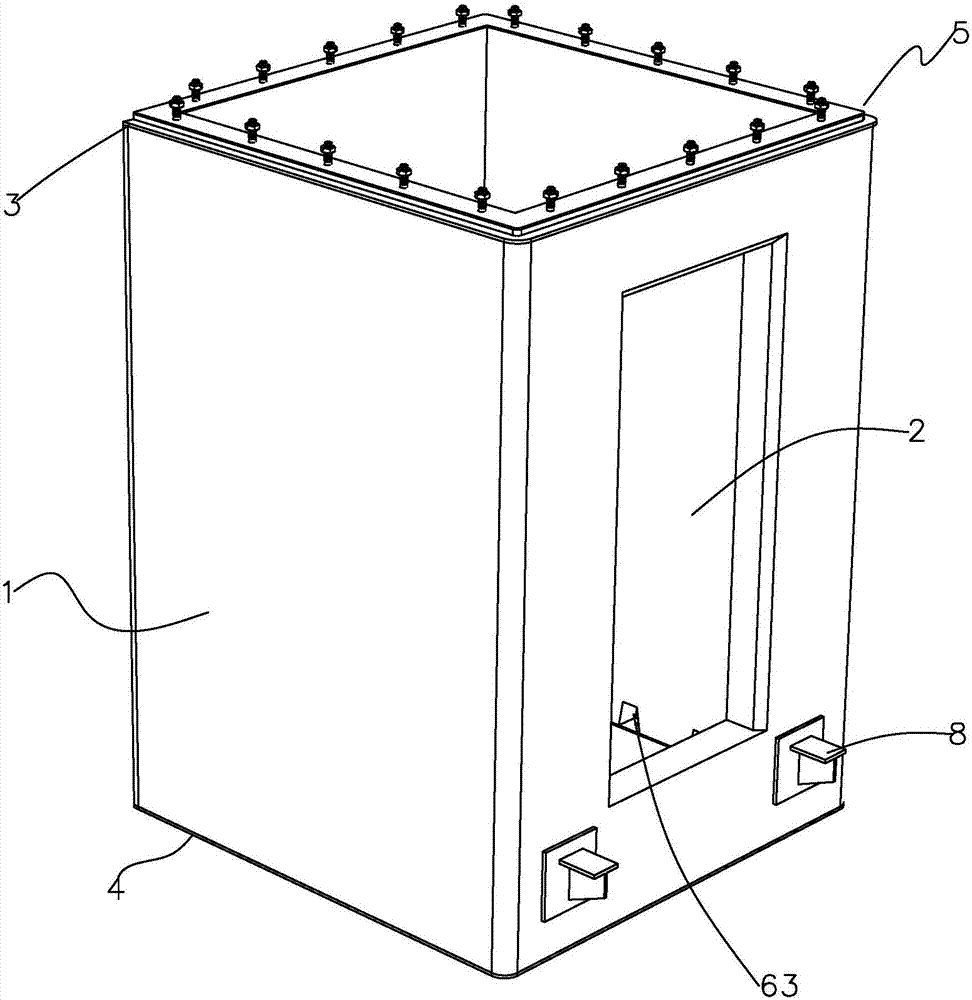

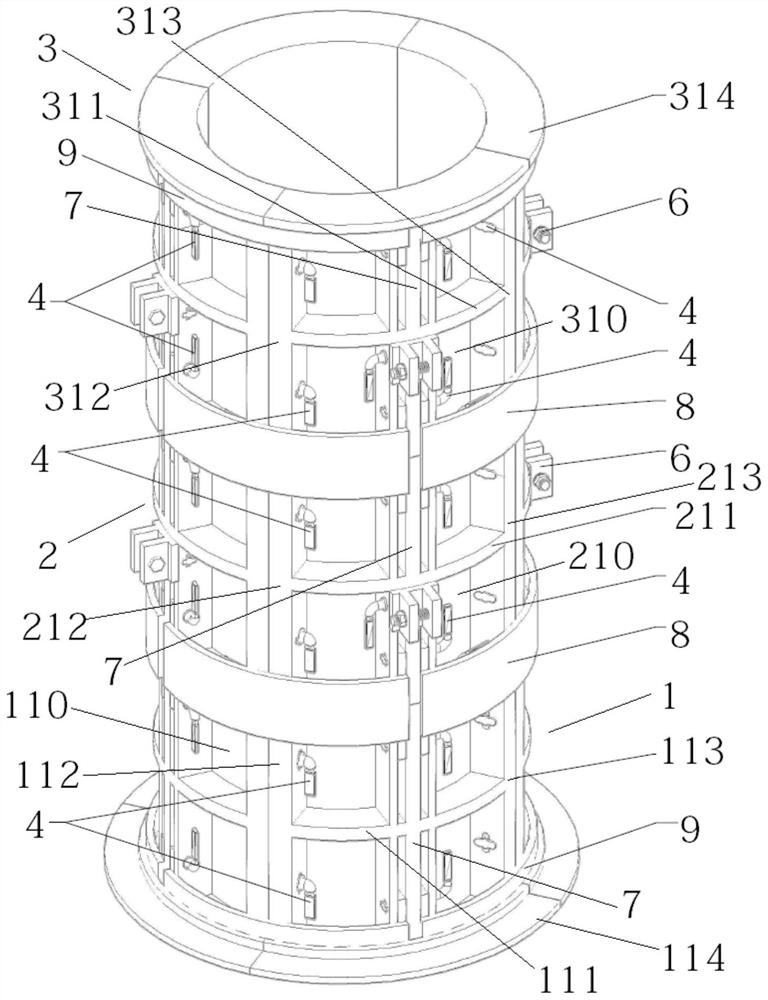

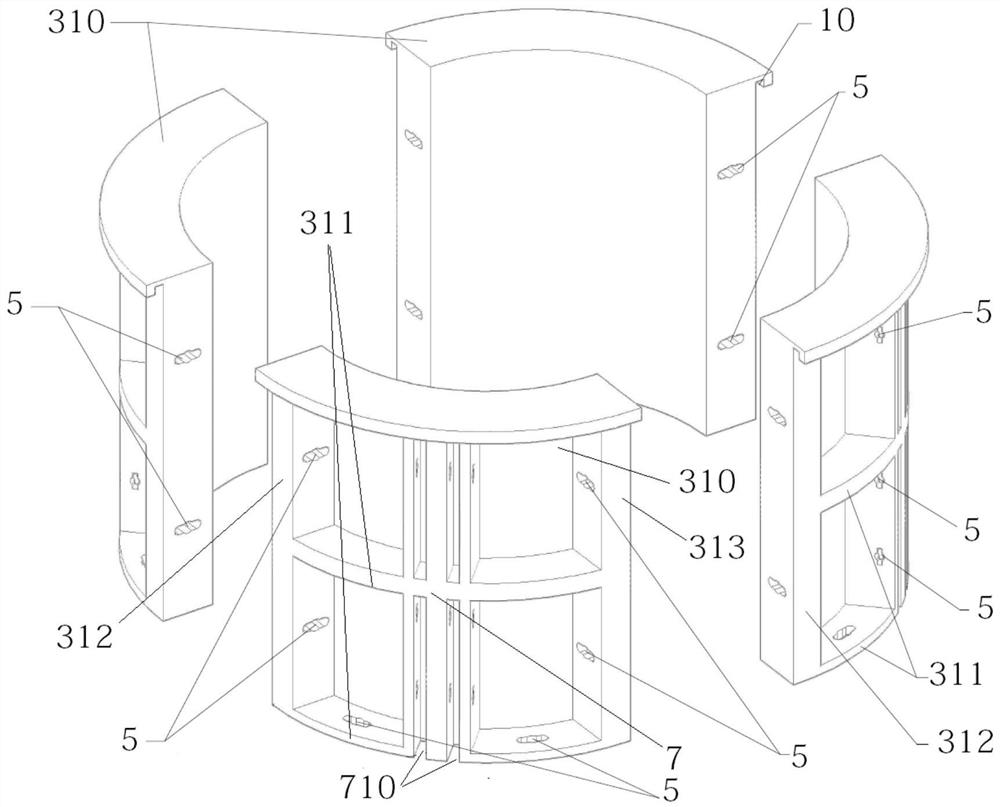

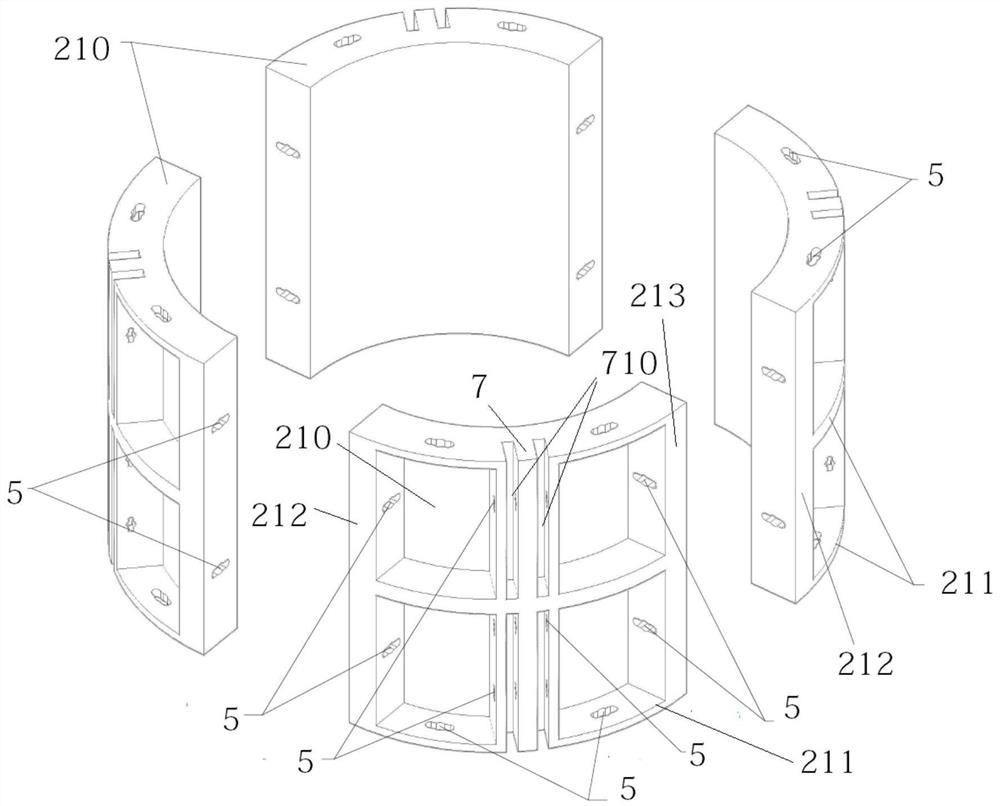

Movable assembly type heating furnace capable of carrying out electric heating in furnace to eliminate stress and construction method thereof

The invention relates to a movable assembly type heating furnace capable of carrying out electric heating in the furnace to eliminate stress and a construction method thereof. The heating furnace comprises ground beams, stand columns, a furnace cover, furnace body plates, a temperature measuring device, an electric heating device and a component support. A plurality of ground beams are spliced toform a plane furnace bottom. Base anchors are welded to the bottoms of the stand columns. The stand columns and the ground beams are vertically connected by the adoption of bolts. A plurality of furnace body plates are laid between the stand columns and on the inner side of the furnace cover. The temperature measuring device comprises a plurality of thermocouples and temperature recorders. The electric heating device comprises temperature control cabinets and a plurality of electric heating plates. The temperature control cabinets and the thermocouples are connected by the adoption of compensating lead wires. According to the heating furnace, in the process of centralized overall heat treatment of an installing and welding framework of a steel structure framework, centralized heat treatment of all the processes of heat treatment can be completed at a time; compared with a traditional electric heating fin tying method adopting local heat treatment, the heating furnace has the characteristics that construction is convenient, the stress eliminating effect is good, the recycling rate of a heat preserving material is high, consumed labor time is short, the cost is low, and efficiency ishigh; the heat treatment quality is ensured, the first-pass yield of heat treatment is increased greatly, the site installing efficiency is improved greatly, all joints can be assembled and disassembled rapidly, and recycling is convenient.

Owner:CHINA CHEM ENG SECOND CONSTR

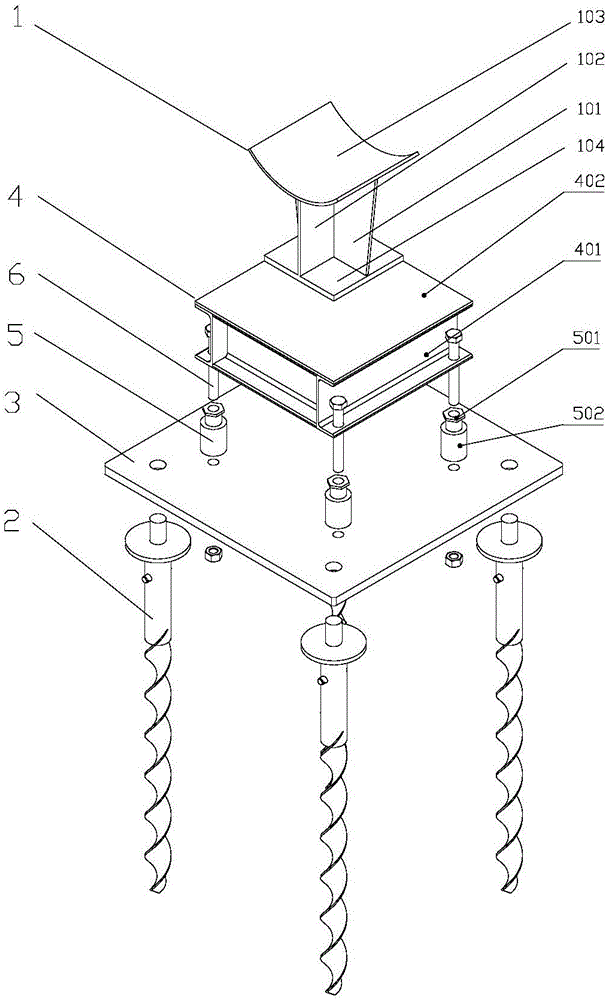

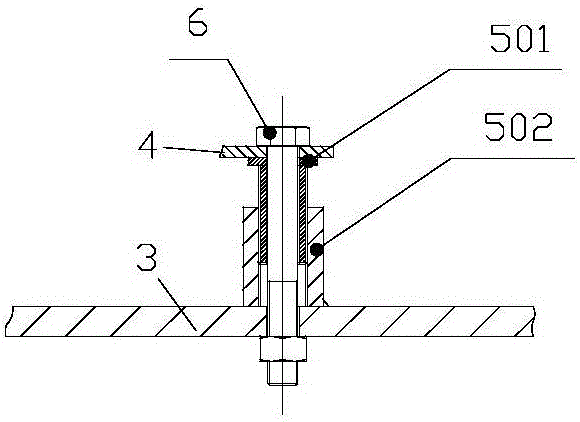

Assembled support post embedded component and embedding assembly construction method thereof

PendingCN107893431ASimple structureEasy to installArtificial islandsUnderwater structuresEngineeringPoor quality

The invention discloses an assembled support post embedded component and a construction method thereof. The embedded component comprises an embedded steel channel and an embedded fixed part, wherein an anchor bolt is arranged on the back of the embedded steel channel; a T-shaped screw is arranged at the notch of the embedded steel channel; the cap of the T-shaped screw is arranged in the notch ofthe embedded steel channel, and the threaded end of the T-shaped screw is arranged outward; a mounting hole matched with the outer diameter of the T-shaped screw is formed in the embedded fixed part;and the threaded end of the T-shaped screw penetrates through the mounting hole and then is fixed by a nut. The assembled support post embedded component has the advantages of simple structure and convenience in assembly, and can effectively overcome the problems of low standard degree, poor quality control, poor perpendicularity, low success rate, poor compactness and the like.

Owner:CHINA CONSTR IND & ENERGY ENG GRP CO LTD

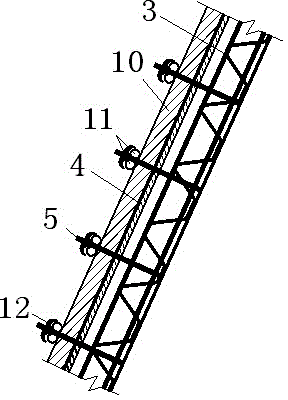

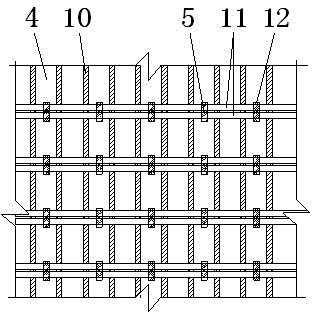

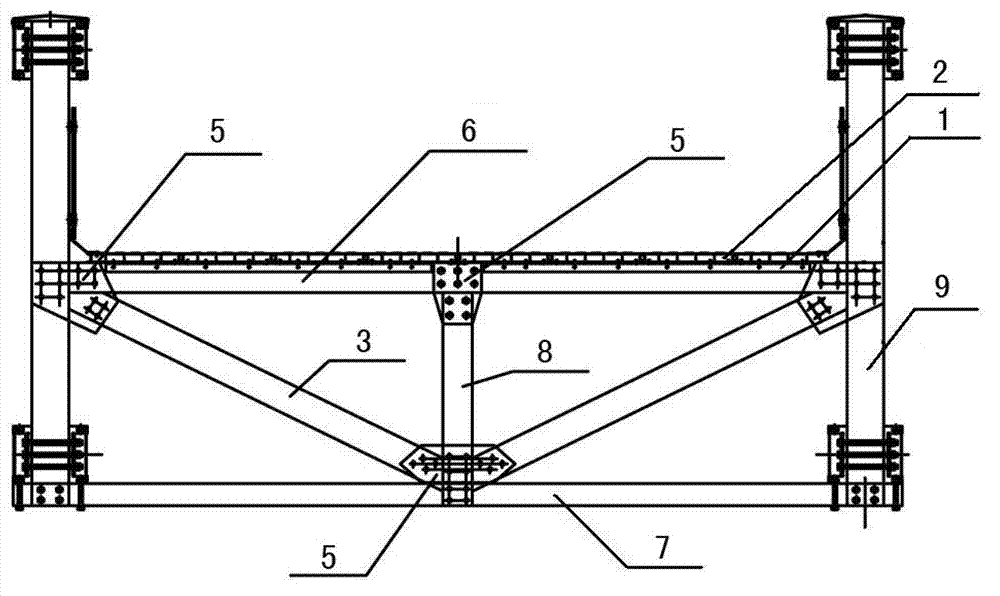

Structural member of aluminum alloy passenger foot-bridge

ActiveCN102966032AHigh strengthImprove on-site installation efficiencyBridge structural detailsBridge materialsBridge materialEngineering

The invention relates to a structural member of an aluminum alloy passenger foot-bridge. The structural member comprises a supporting frame, chord members and channel plates, wherein the chord members are laid side by side on the supporting frame and are fixedly connected with the supporting frame; the channel plates are laid side by side on the chord members and are fixedly connected with the supporting frame; the chord members are mutually connected by connection rectangular tubes; the supporting frame, the chord members and the channel plates are mutually connected through plywoods; and the channel plates are mutually connected in an inserted manner. With the adoption of the structural member of the aluminum alloy passenger foot-bridge, the intensity performances of base metals and an integral structure are improved, the defect caused by welding is avoided, the field installation efficiency is improved and the integral bridge material cost and the processing cost are lowered.

Owner:SHANDONG NOLLVETEC LIGHTWEIGHT EQUIP CO LTD

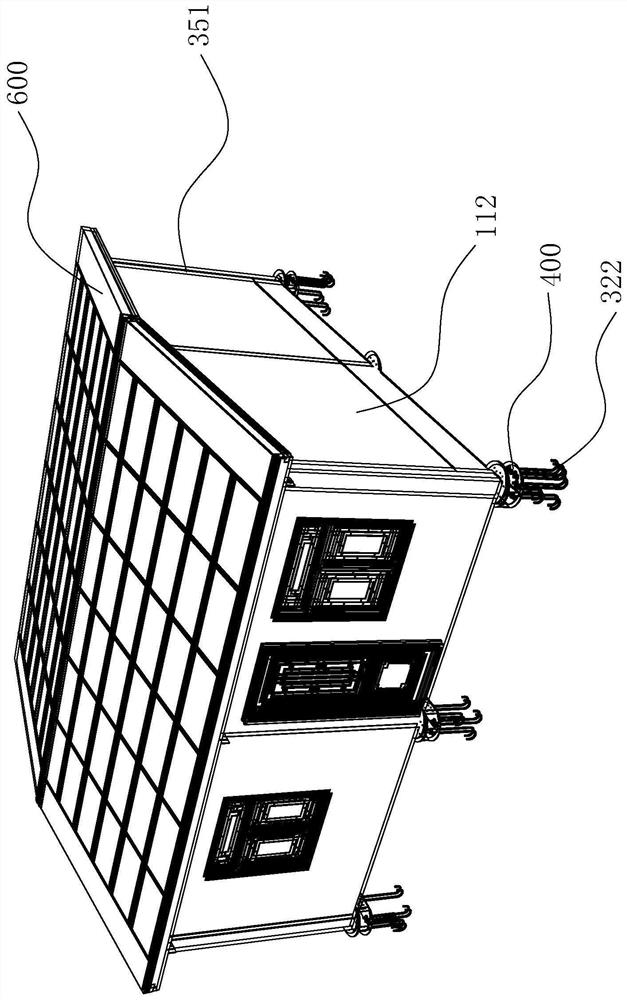

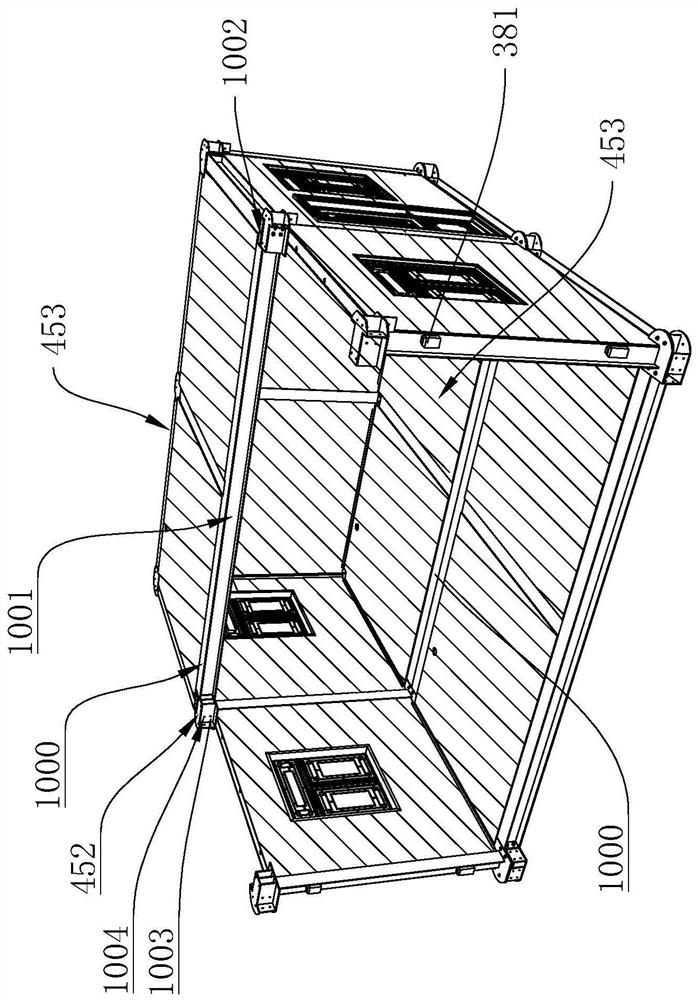

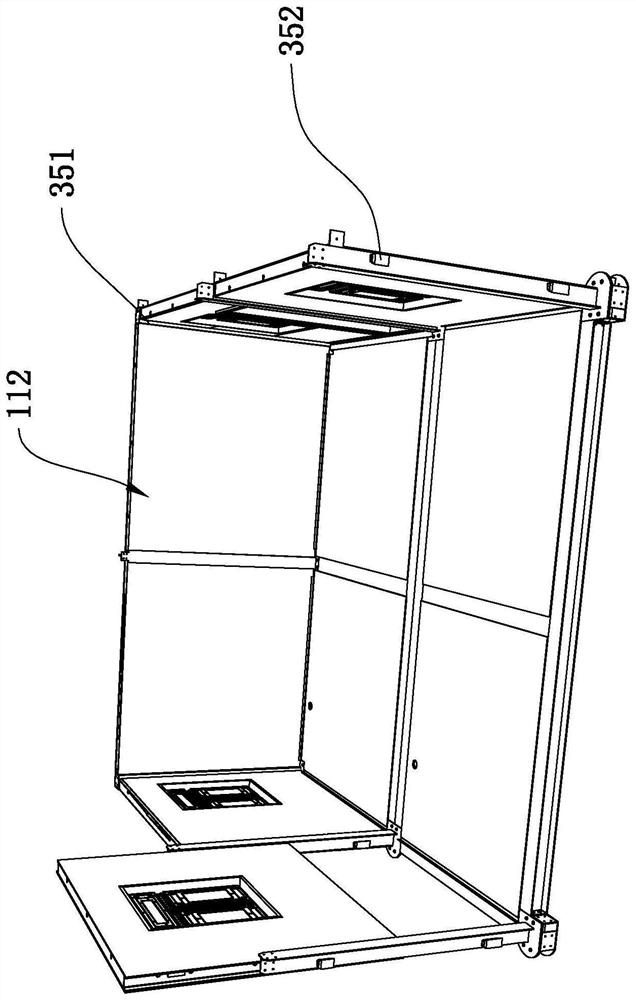

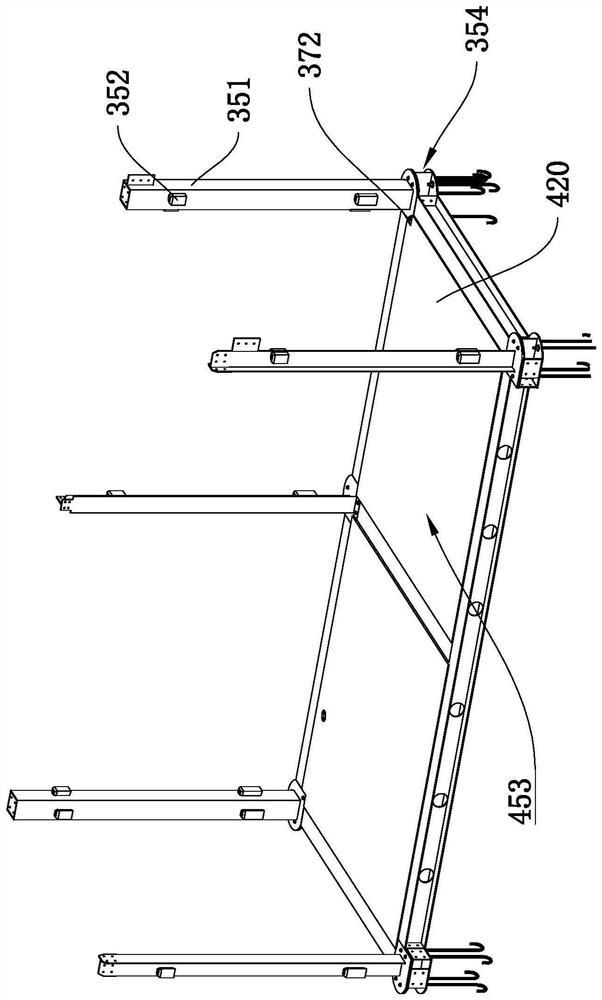

Modularized room convenient to assemble

PendingCN113914479AEasy to assemble and disassembleEasy to assembleBuilding constructionsStructural engineeringMechanical engineering

The invention belongs to the technical field of building installation, and particularly relates to a modular room convenient to assemble. The modular floor comprises a horizontal cross beam, two supporting seats are connected to the horizontal cross beam and connected with the ends of the horizontal cross beam, floor mounting grooves are formed in the two sides of the horizontal cross beam, and the modular floor further comprises a modular floor assembly. The modular floor assemblies on the same layer can be rapidly connected through the multiple supporting bases and the multiple horizontal cross beams, disassembly and assembly are convenient, after the modular floor assemblies are connected and laid on the same layer, the modular wall bodies and the modular floor assemblies are connected through the corner columns, connection forming of the floor and the wall face is completed, and the modular floor assembly is convenient to assemble and disassemble. And then the roof part, the tops of the corner columns and the tops of the modular wall bodies are clamped, installed and fixed, assembling and forming of the modular room are completed, a detachable structure is adopted for rapid disassembling, assembling and fixing, assembling is convenient, stability is good after installation, practicability is high, the field installation efficiency is greatly improved, and the transportation cost is reduced.

Owner:CHANGDA STEEL STRUCTURE CO LTD

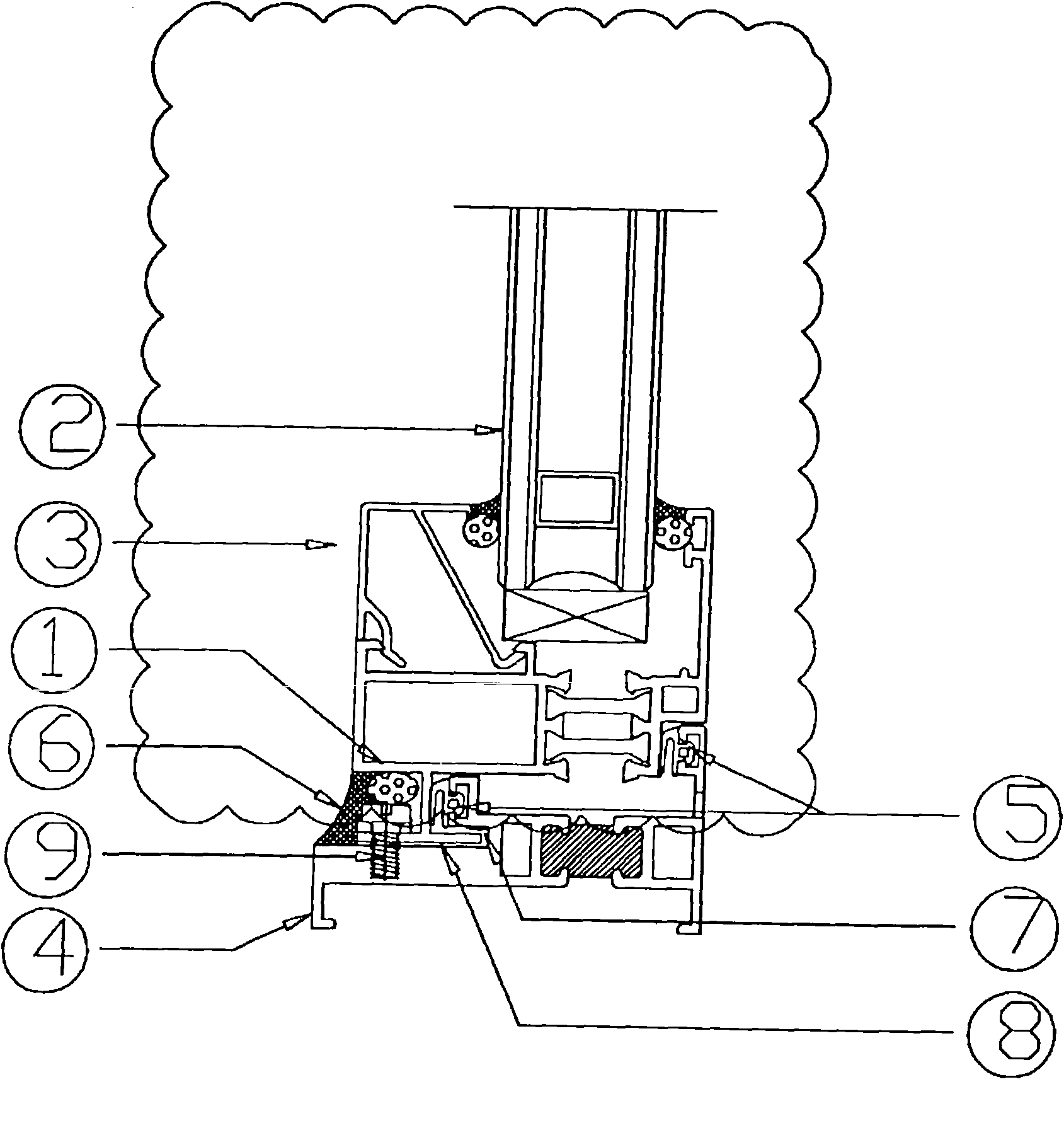

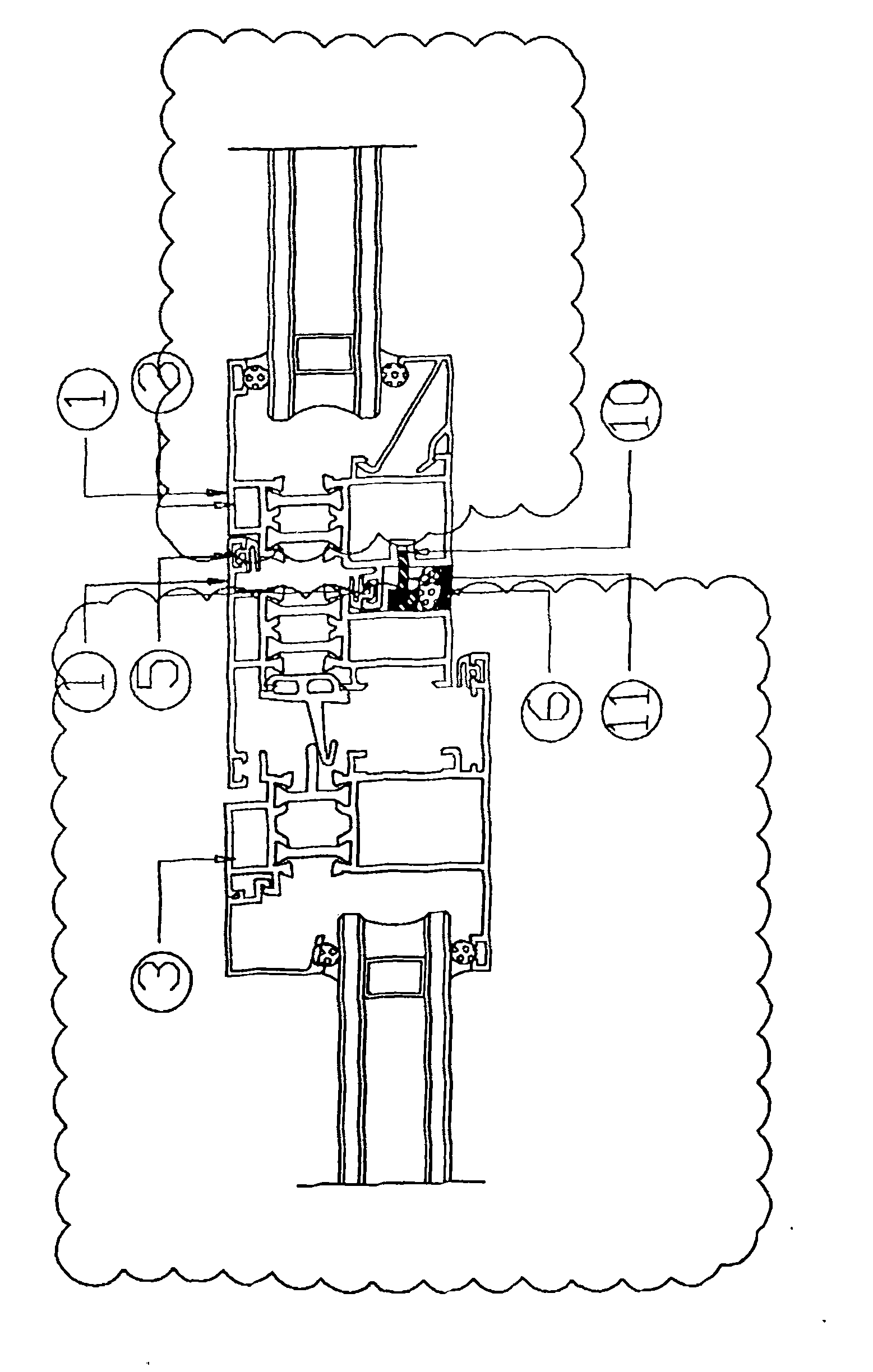

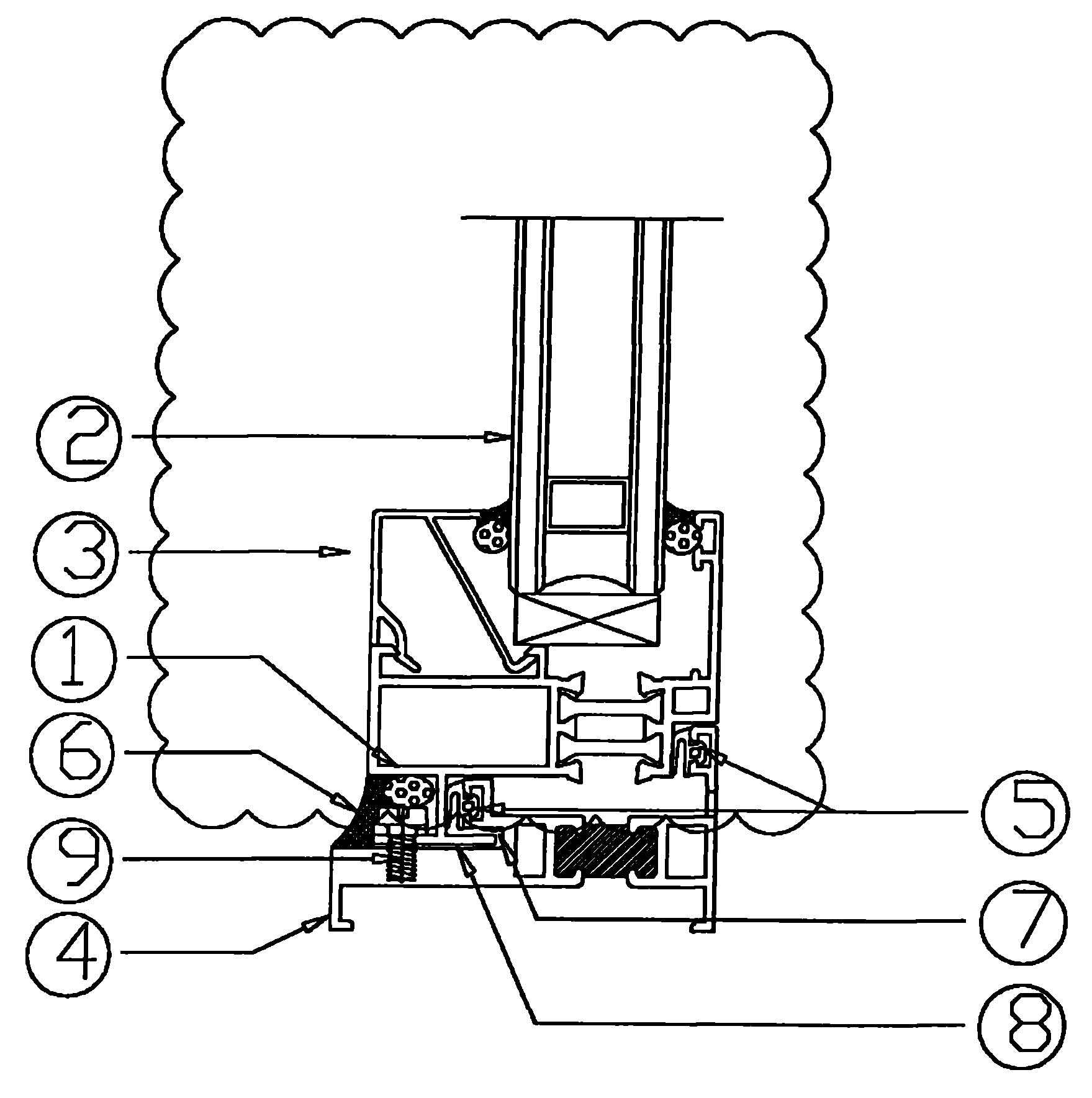

Unit type door window

InactiveCN101929286AImprove efficiencyQuality is easy to guaranteeBase framesSealing arrangementsEmbedded systemSash window

The invention relates to a unit type door window. A window frame and window sashes form a unit assembly together. The door window also comprises an embedded window frame embedded in a window hole in advance, the unit assembly is located in the embedded window frame, and the window frame of the unit assembly is fixedly connected with the embedded window frame. A sealing rubber strip is arranged between the connecting end faces of the window frame and the embedded window frame, and a sealant is arranged at binding parts of the window frame and the embedded window frame at the in-door side. The traditional door window with complete structure is completely produced and assembled in manufacturing shops and directly installed in the field. The field installation only means the simple fixation and connection of the window frame and the embedded window frame, so that the invention has high efficiency and low management cost, and the requirement for high efficiency of a construction party is satisfied. Because the door window is assembled before field installation, the quality can be ensured more easily, the uniformity is better, and the technical difficult of field installation is reduced.

Owner:四川瑞博斯环保科技有限公司

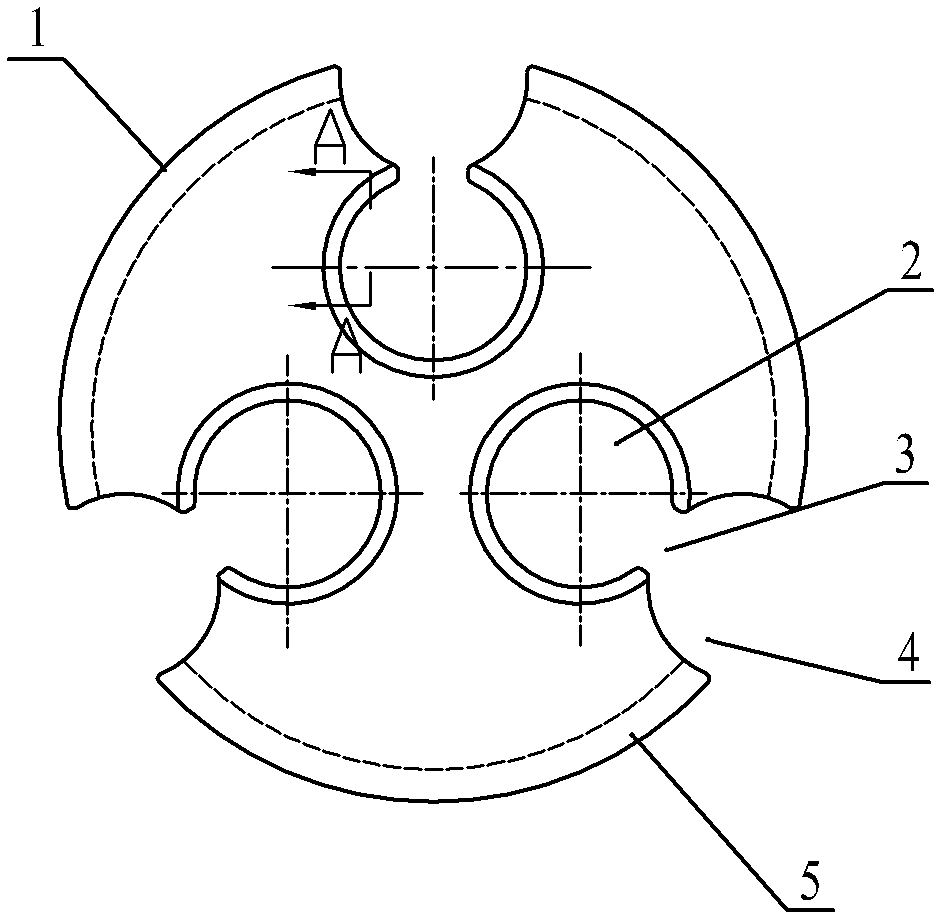

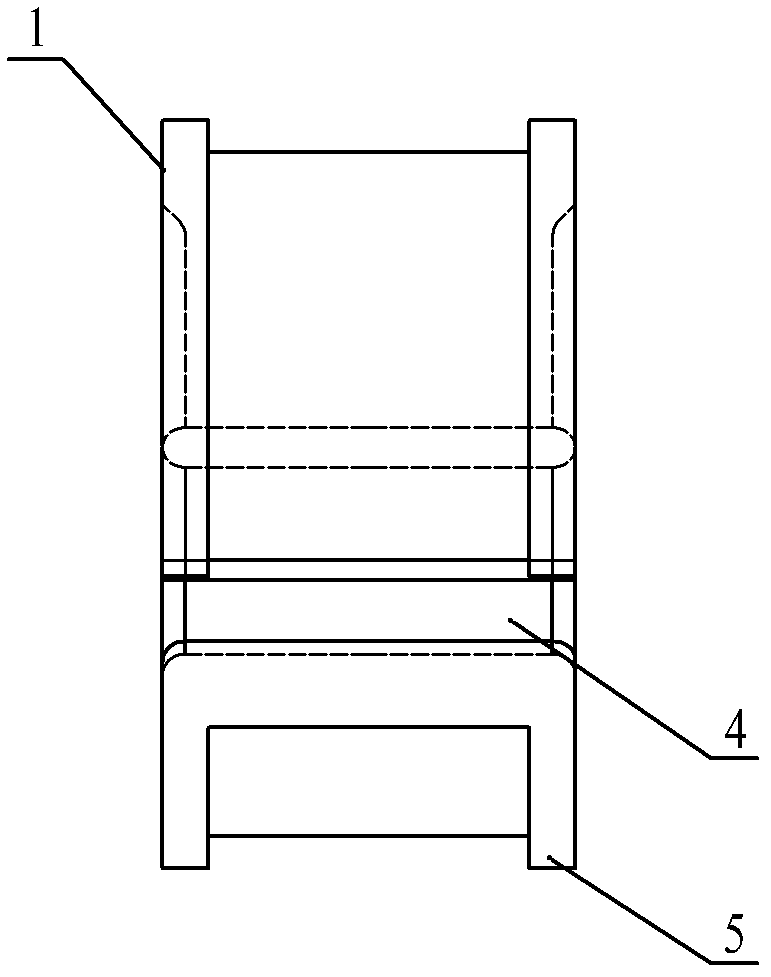

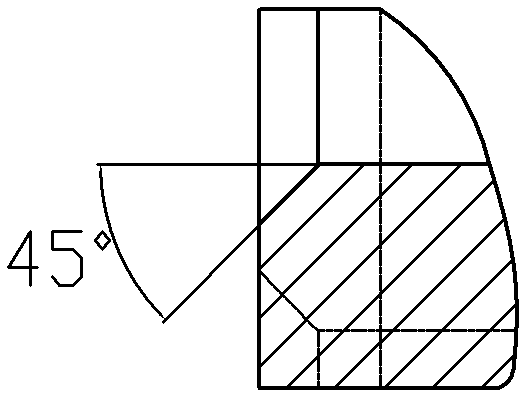

Cable clamp

ActiveCN102324714AEasy to organize and fixImprove on-site installation efficiencyElectrical apparatusRubber materialInlet channel

The invention relates to a cable clamp for sorting out and fixing cables. According to the technical scheme provided by the invention, the cable clamp comprises a clamp body, and is characterized in that: the clamp body is a cylinder made from a rubber material; three axial wire holes are reserved on the clamp body and uniformly distributed along a circumferential direction; and three inlet channels for feeding the cables into the wire holes are formed on the clamp body. The cable clamp has a simple and ingenious structure, can conveniently sort out and fix the cables, greatly improve the field assembly efficiency of the cables and reduce construction cost, is favorable for post maintenance, and can be adapted to specific application environments of locomotives. The cable clamp is made from the rubber material with high ageing resistance, high abrasion resistance, high vibration resistance, high oil resistance and high bending resistance, simultaneously has high insulating properties and high flame retardant properties, and can greatly improve the running security of the locomotives.

Owner:SHENGFENG DAMPENER WUXI CITY

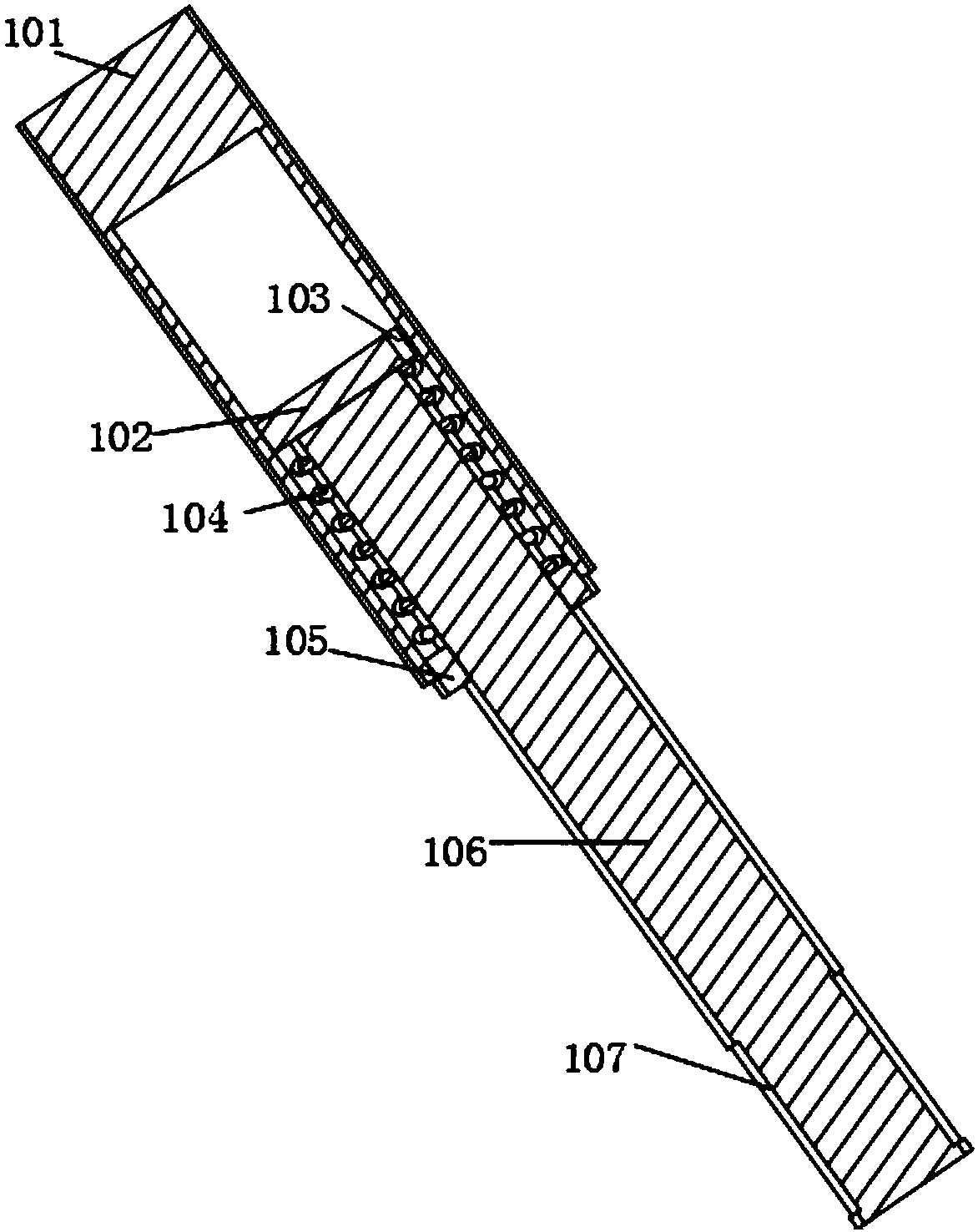

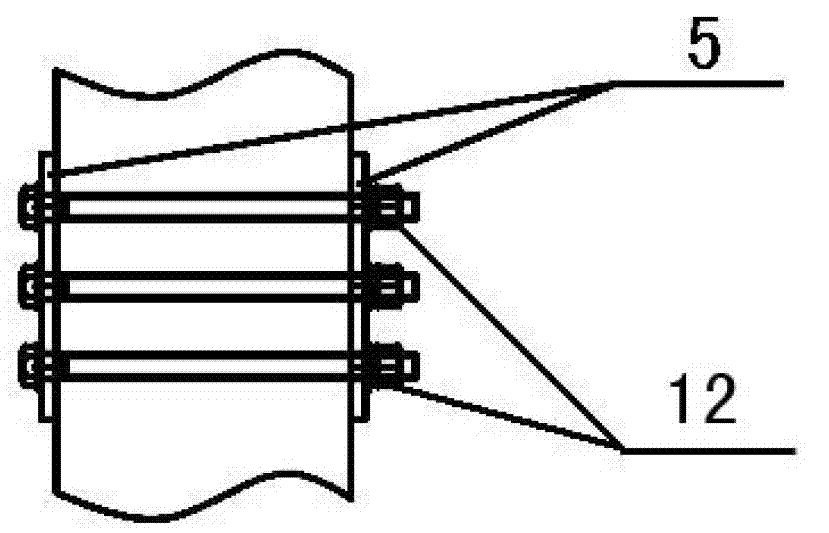

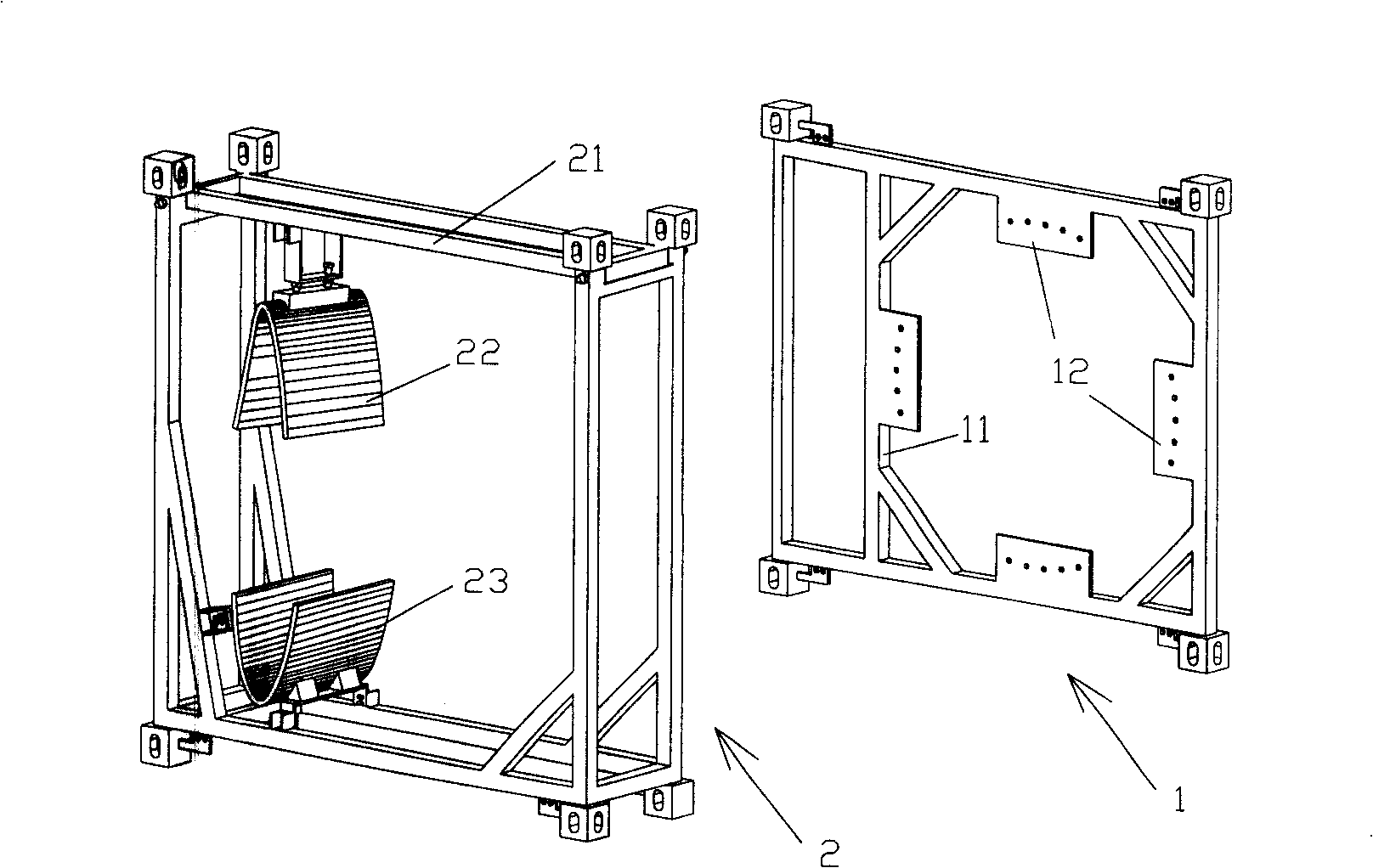

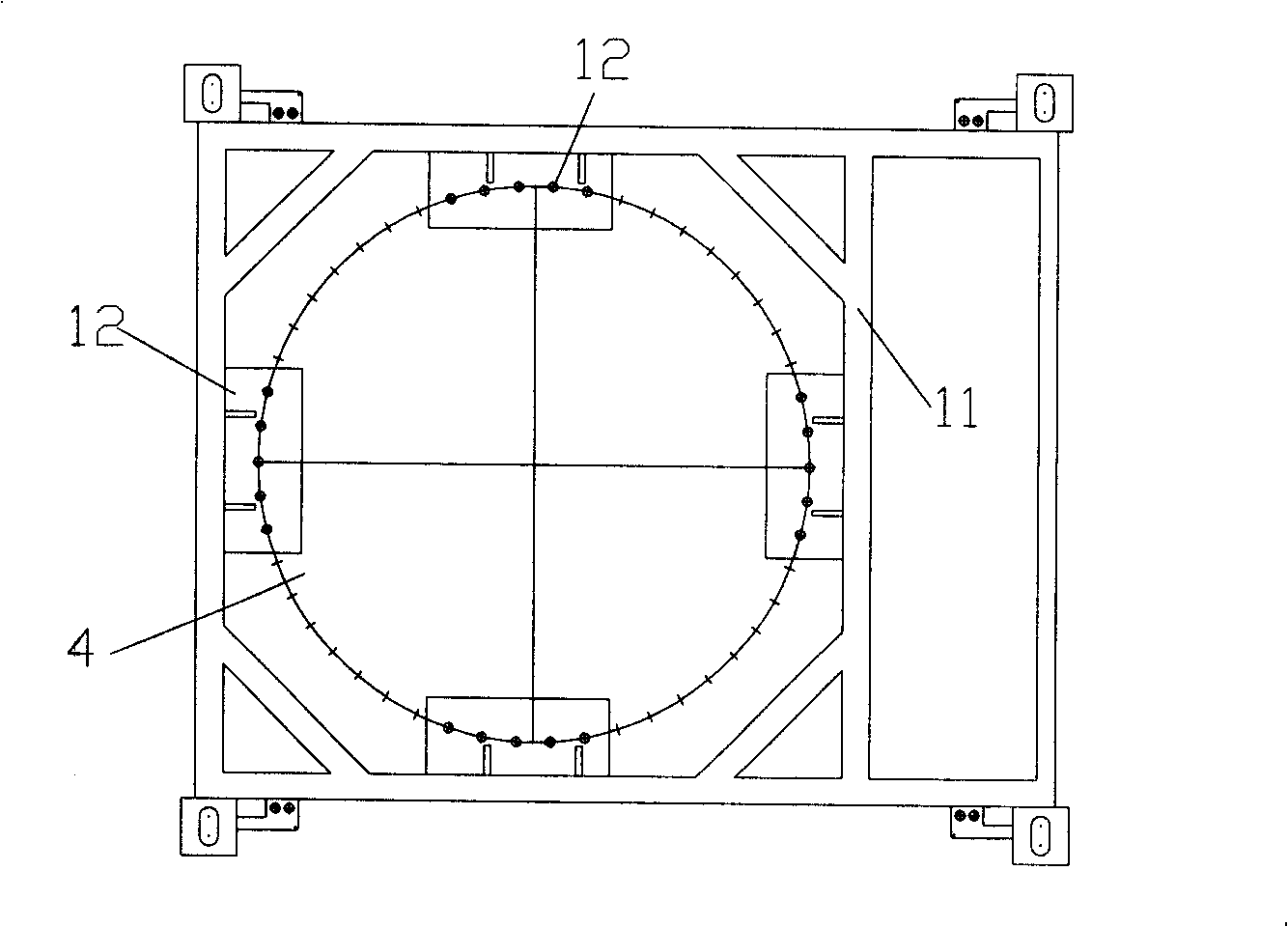

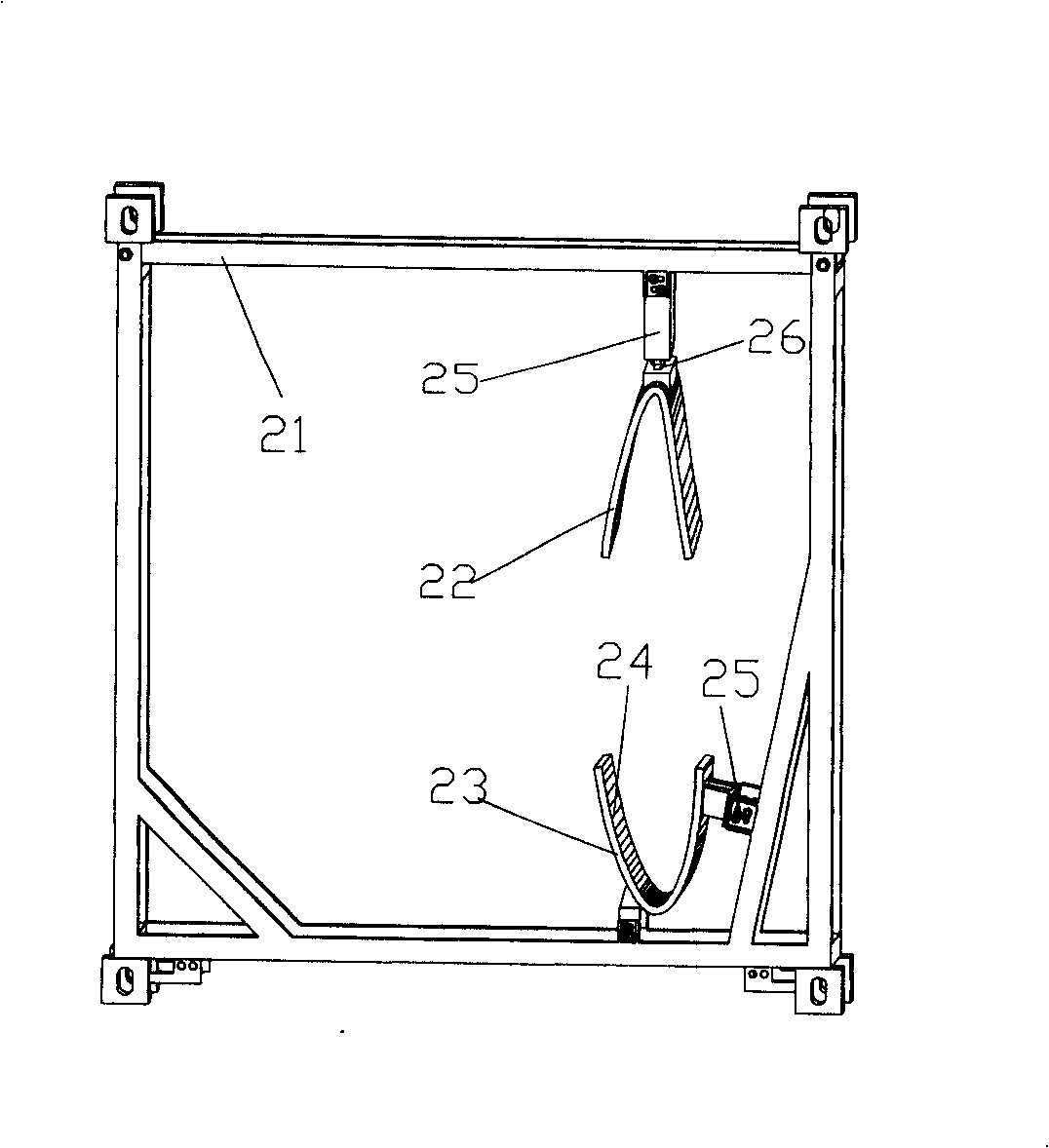

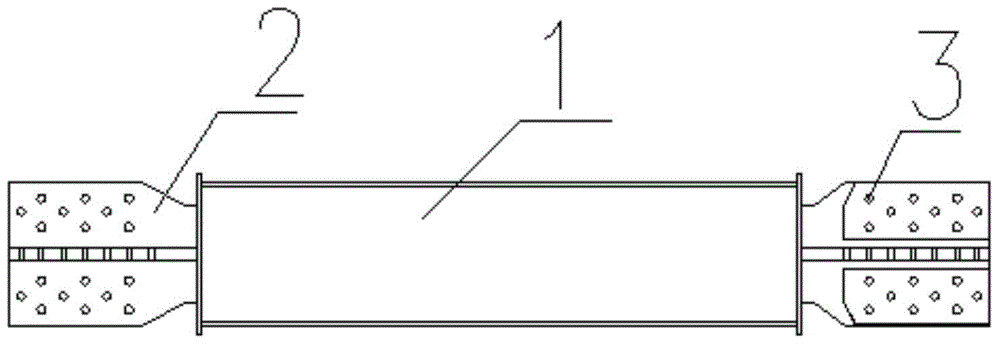

Assembly for transporting windmill generator vane and using method thereof

InactiveCN101259896AReduce manufacturing costReduce shipping costsPackaging vehiclesContainers for machinesFixed frameWindmill

The invention relates to a processing device used for delivering the vanes of a wind-power generator and a usage method thereof. The processing device comprises a front group and a rear group of a vane root fixed frame (1) and a vane supporting frame (2); the vane root fixed frame is a rectangle structure and is provided with a vertical cutting connecting rod (11) which divides the vane root fixed frame into a large rectangle area and a small rectangle area where the vane and the vane root are respectively arranged; four edges of the vane root area are respectively provided with a vane root connecting block (12); the vane supporting frame is provided with a rectangle frame structure and an openable upper pressing plate (21); furthermore, a horizontal upper pressing plate (22) and a horizontal lower pressing plate (23) are provided with a pair of vane pressing plates with openings that are corresponding to each other. The usage method is that the vane is assembled with the vane root, two groups of processing devices are arranged in line, the vane root end is fixed on the vane root connecting block, meanwhile, the front wing part of the vane is arranged in the lower pressing plate of the other group of processing device, the other vane is reversely arranged, the upper pressing plate of the forward and backward vane supporting frame is closed, the vane is fixed, and the processing device and the vane are hoisted and fixed onto a transport vehicle for delivery.

Owner:SHANGHAI ELECTRIC WIND POWER GRP CO LTD

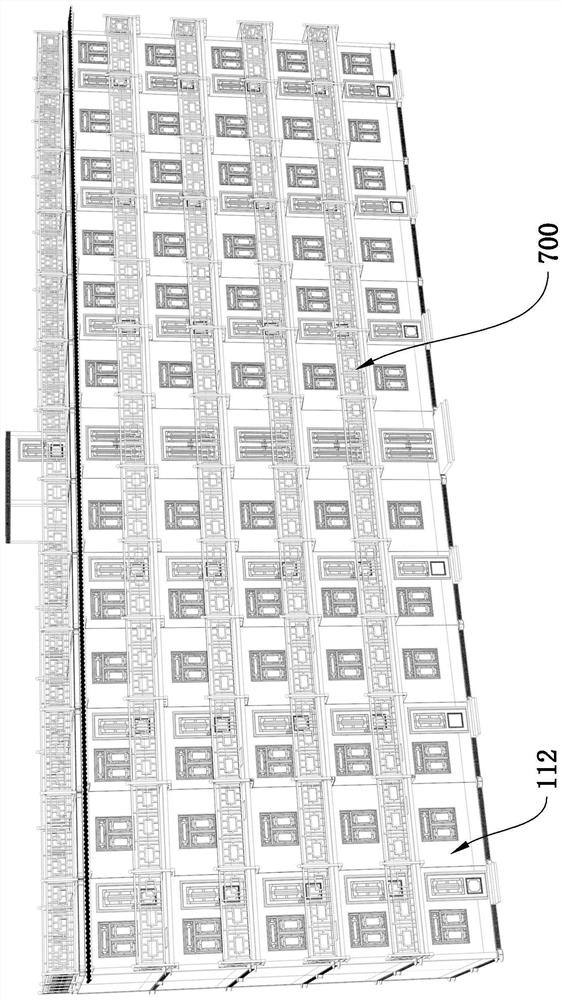

Standard modular components for buildings and prefabricated building comprising same

ActiveCN105297894ALower research costsImprove on-site installation efficiencyBuilding constructionsManufacturing engineering

Owner:郭育正 +1

Modularized fabricated building

ActiveCN113914478AQuick connectionReduce wasteShutters/ movable grillesWallsArchitectural engineeringEconomic benefits

The invention belongs to the technical field of building installation, and particularly relates to a modular fabricated building. The modular wall comprises a plurality of modular wall bodies and corner columns for connecting every two adjacent modular wall bodies, and first limiting assemblies are arranged on the two adjacent side faces of each corner column correspondingly. The modular floor components on the same layer can be quickly connected, disassembly and assembly are convenient, after the modular floor components are connected and laid on the same layer, the modular wall bodies and the modular floor components are connected through the corner columns, the floors and the wall surfaces are connected and formed, and then horizontal extension or vertical extension is conducted; a stable building is formed, a detachable structure is adopted for rapid dismounting and fixing, the stability is good after installation, the practicability is high, the field installation efficiency is greatly improved, the transportation cost is reduced, the modular design of the same specification is adopted, material waste is greatly reduced, and good economic benefits are achieved.

Owner:CHANGDA STEEL STRUCTURE CO LTD

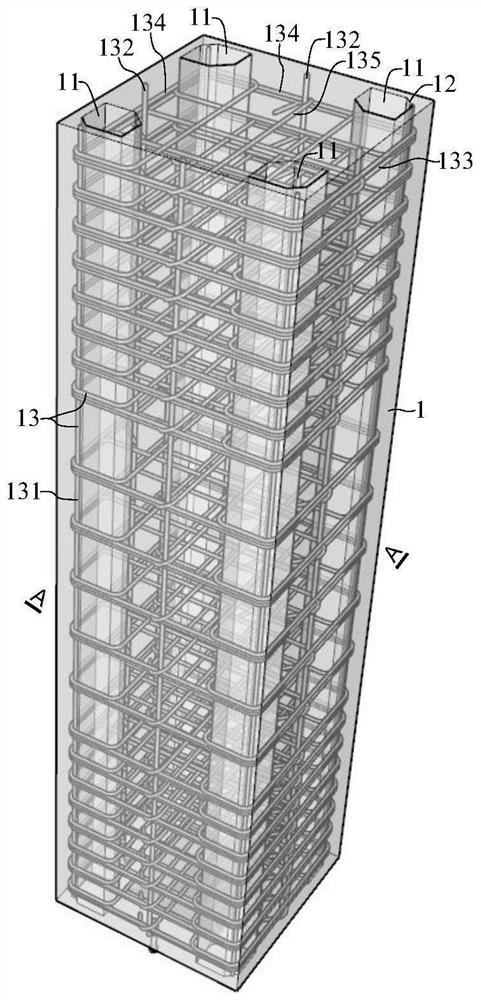

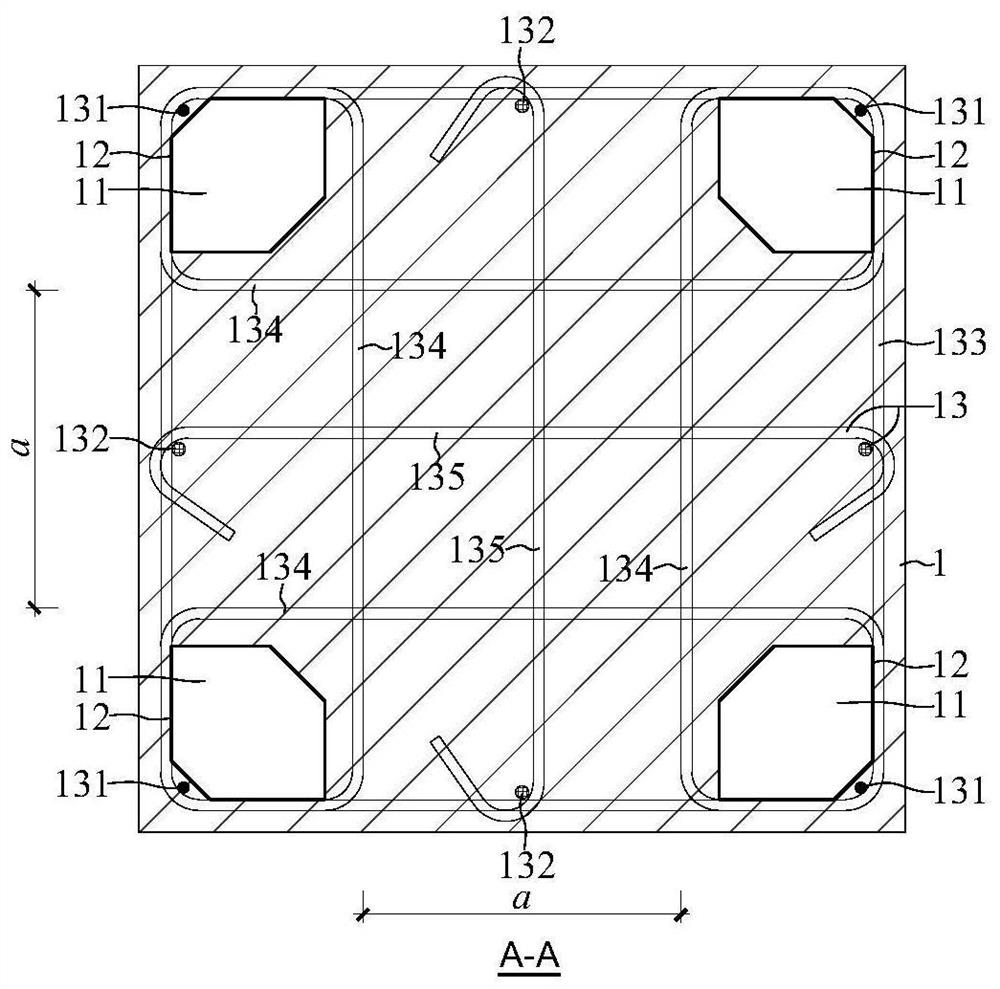

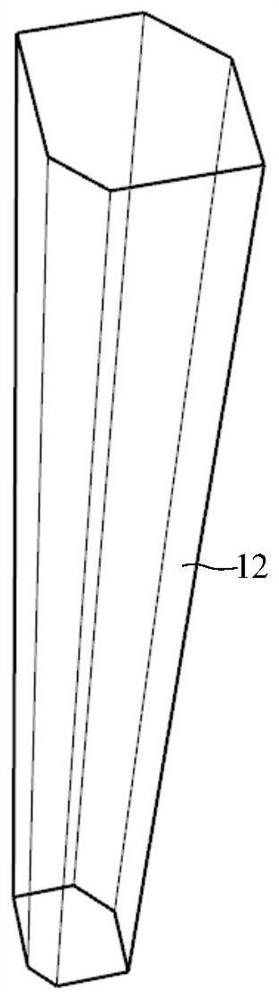

Corner vertical hole centralized arrangement and direct stress longitudinal bar connection overlapping column and construction technology

PendingCN111691601ALow costLongitudinal tendon load-bearing efficiency is highStrutsProtective buildings/sheltersArchitectural engineeringRebar

The invention discloses a corner vertical hole centralized arrangement and direct stress longitudinal bar connection overlapping column and a construction technology. Sizing pipeline embedding is conducted, penetration vertical holes are formed in four corner parts of a prefabricated column, only construction longitudinal bars, auxiliary longitudinal bars, stirrups and tie bars are arranged in theprefabricated column, and no steel bars stretch out of the prefabricated column. In the construction site, column stress longitudinal bars are arranged in the corner vertical holes of the prefabricated column in a centralized manner, and upper-layer and lower-layer column stress longitudinal bars are directly connected at the root of the prefabricated column through a mechanical connection connector. After post pouring of concrete in pouring vertical holes, the overlapping column is formed by the prefabricated column and the post-pouring part to participate in structure stress. Sizing pipelines are manufactured through rolling and folding of a thin-wall steel plate. When the column section is large, a penetration pouring hole is formed in the middle portion of the section of the prefabricated column, stress longitudinal bars are not arranged in the prefabricated column, and the standard degree of a die and a steel bar cage is high; and the stress longitudinal bars are directly connected, connection is reliable, and cost is low; and conventional grouting construction does not exist on the site, the construction speed is high, and the quality is easy to guarantee.

Owner:CHINA INST OF BUILDING STANDARD DESIGN & RES

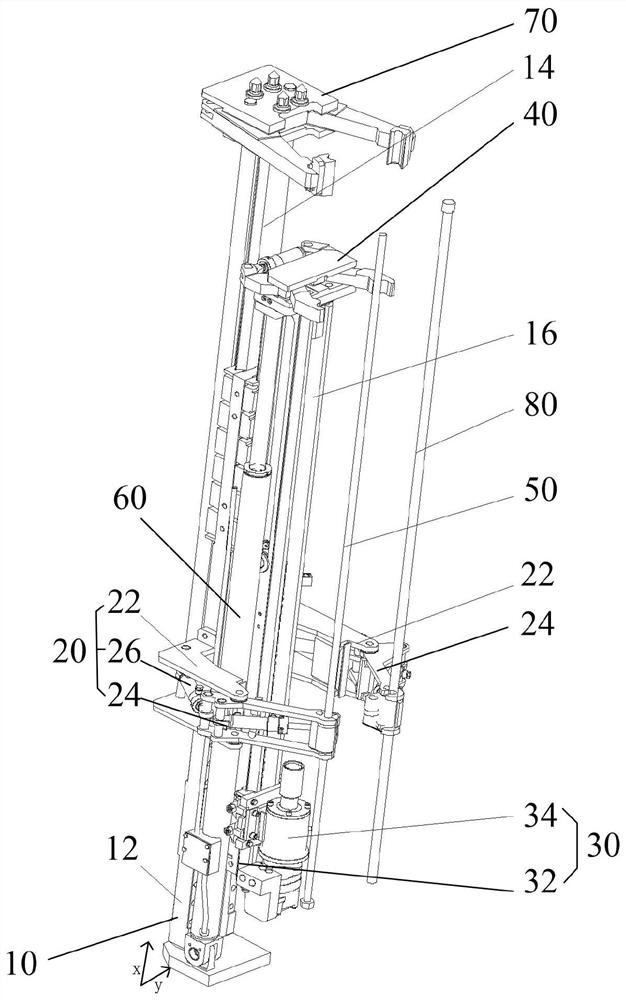

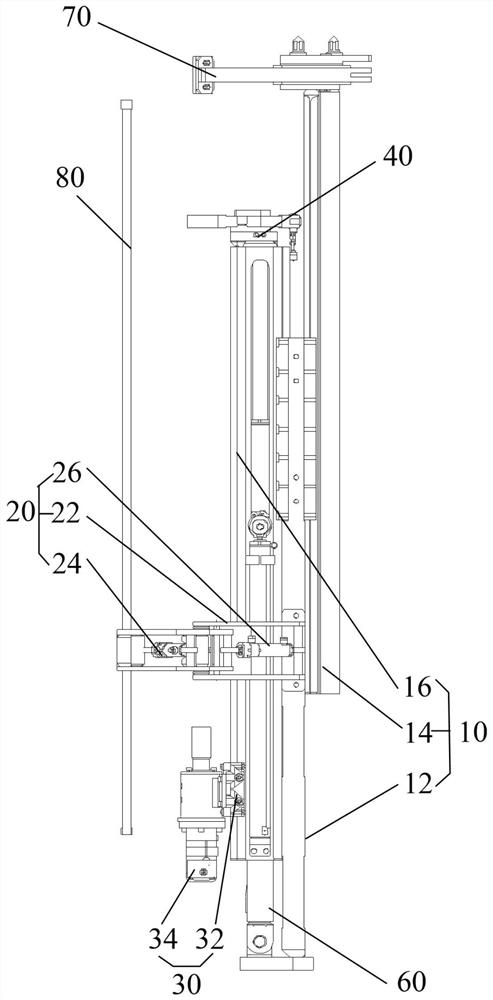

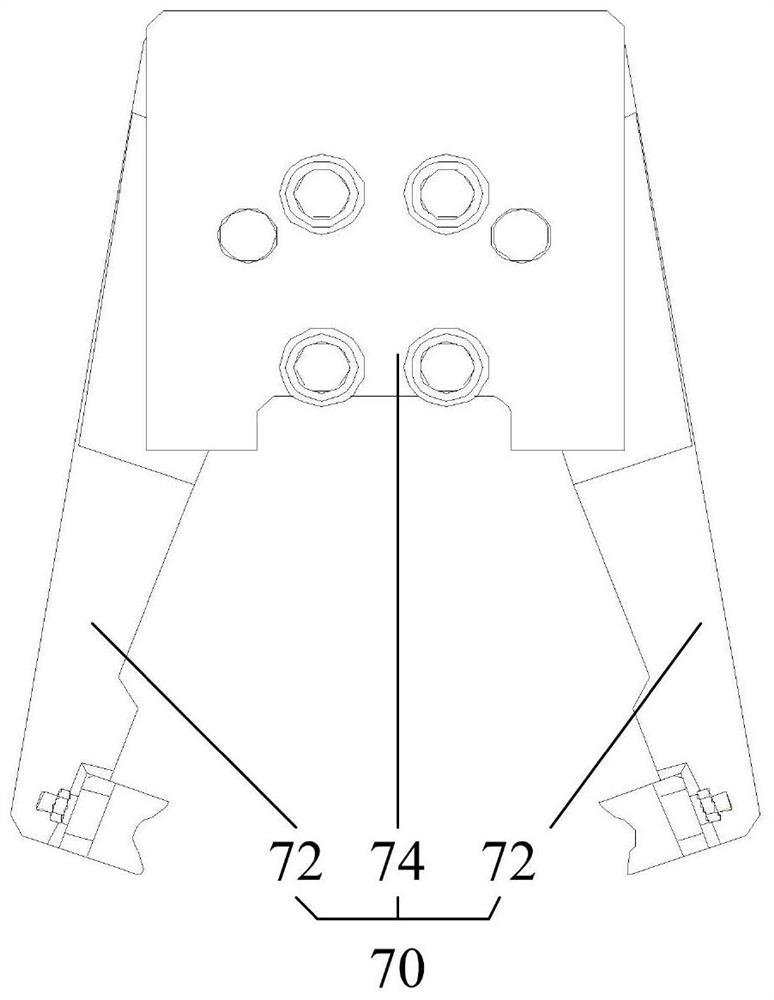

Installation device and installation system

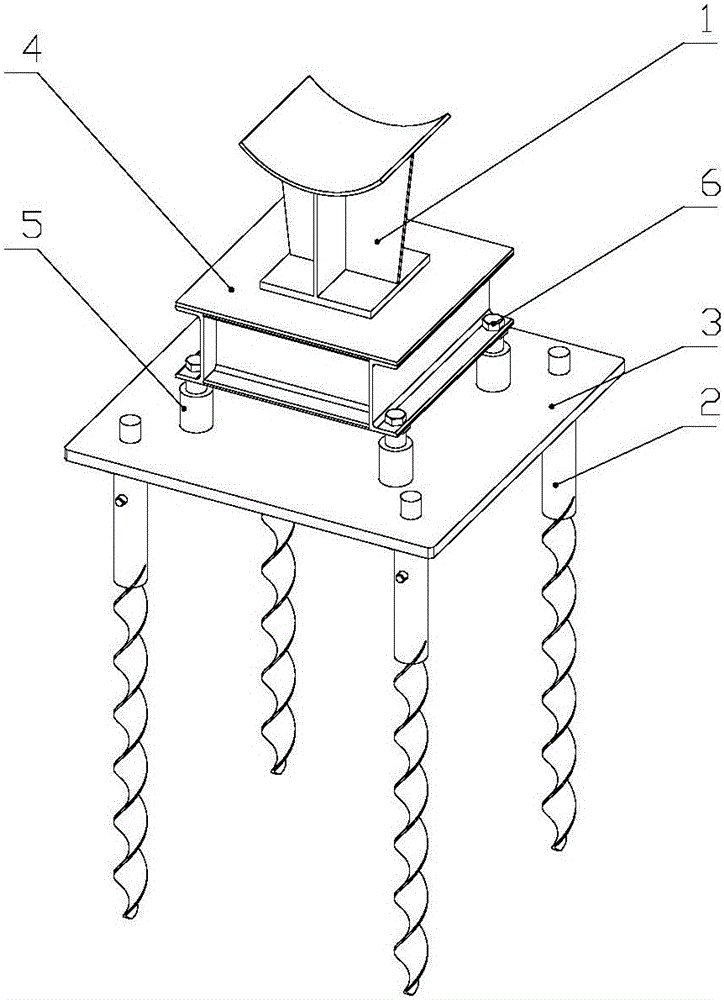

PendingCN111794788ARealize fully automated installation functionImprove on-site installation efficiencyDrilling rodsDrilling casingsStructural engineeringMechanical engineering

The invention provides an installation device and an installation system. The installation device comprises a rack assembly, a clamping claw assembly, a propeller assembly and a drilling rod, whereinthe propeller assembly can slide on the rack assembly in the first direction, one end of the drilling rod can be connected with the propeller assembly, the propeller assembly can drive the drilling rod to move in the first direction relative to the rack assembly, meanwhile, the propeller assembly can further drive the drilling rod to rotate around the axis of the drilling rod, the clamping claw assembly can install the drilling rod or an anchor rod on the propeller assembly, or the clamping claw assembly can take out the drilling rod from the propeller assembly. According to the technical solution, the clamping claw assembly can be used for installing the drilling rod and installing the anchor rod into the propeller assembly, so that the automatic installing function of the installation device on the drilling rod and the installing function of the installation device on the anchor rod are achieved, then the on-site installing efficiency of the anchor rod is improved, meanwhile, the labor intensity of on-site personnel is further reduced, and therefore, the labor cost for installing the anchor rod on site is saved.

Owner:SANY HEAVY EQUIP

Lifting and installation method of buckling restrained braces

InactiveCN103982046AFreely adjust the installation angleImprove on-site installation efficiencyBuilding material handlingWork periodFloor slab

The invention discloses a lifting and installation method of buckling restrained braces. The method provided by the invention is characterized in that the buckling restrained braces are lifted at first; when being lifted on a to-be-installed storey, the buckling restrained braces are pulled into a floor by using a rope tied on the braces in advance; next, the buckling restrained braces are moved to a to-be-installed location by using a hand-push hydraulic forklift; at the moment, the buckling restrained braces are lifted up by using electric hoists on a beam for butt joint with pre-buried components in the beam and columns; finally, cover plates are added and are connected by bolts to complete the installation of the buckling restrained braces. According to the lifting and installation method, the lifting and installation process is convenient and rapid; therefore the project progress is accelerated; the work period is shortened; the labor intensity is lowered; the on-site installation efficiency of the buckling restrained braces is improved greatly.

Owner:CHINA CONSTR 4TH ENG BUREAU 6TH

Three-way module

InactiveCN110994432AImprove installation efficiencyEliminate insulation risksSwitchgear arrangementsElectrically conductiveDisconnector

The invention discloses a three-way module. The three-way module comprises a shell, a first insulator connected with a lightning arrester, a second insulator connected with a GIS equipment bus or an isolating switch, a plurality of first communication assemblies, a conductive seat connected with a voltage transformer and a second communication assembly. The shell is provided with an operation opening; the second insulator and the first insulator are respectively arranged on two opposite surfaces of the shell; the first communication assemblies are arranged in the shell and connected between the first insulator and the second insulator, and comprise plum blossom contacts arranged on the first insulator, first conducting rods arranged on the second insulator, and detachable conductors of which the two ends are detachably connected with the plum blossom contacts and the first conducting rods respectively; the conductive seat is arranged on the shell; and the second communication assemblyis arranged in the shell, is connected between one first conducting rod and the conductive seat, and comprises a bus coupler conductor arranged on the first conducting rod and a second conducting rodof which the two ends are respectively connected with the bus coupler conductor and the conductive seat. According to the invention, the on-site installation efficiency can be improved, and the insulation risk of the lightning arrester and the voltage transformer is eliminated.

Owner:XUJI XIAMEN INTELLIGENT SWITCHGEAR MFG

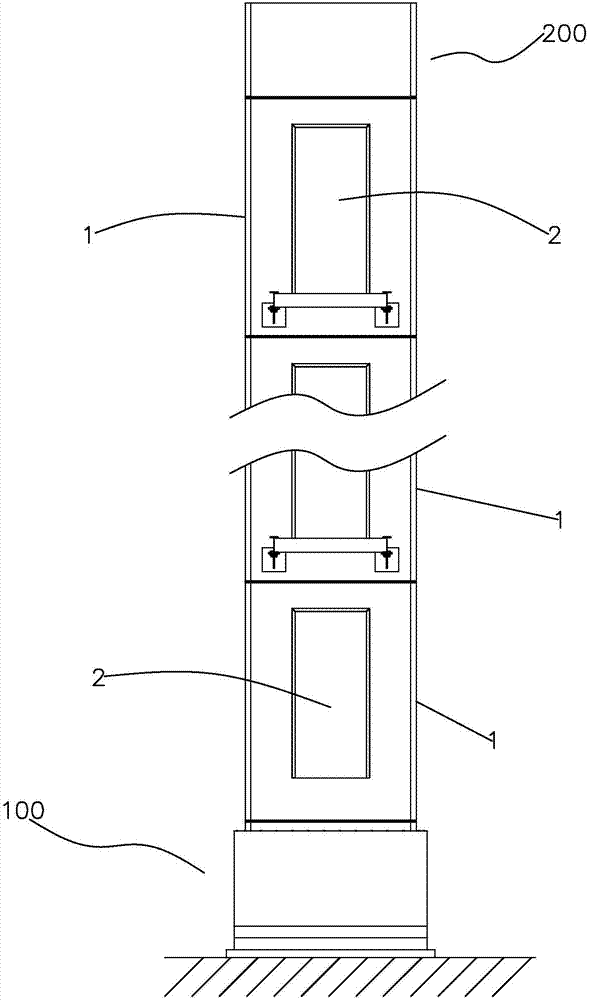

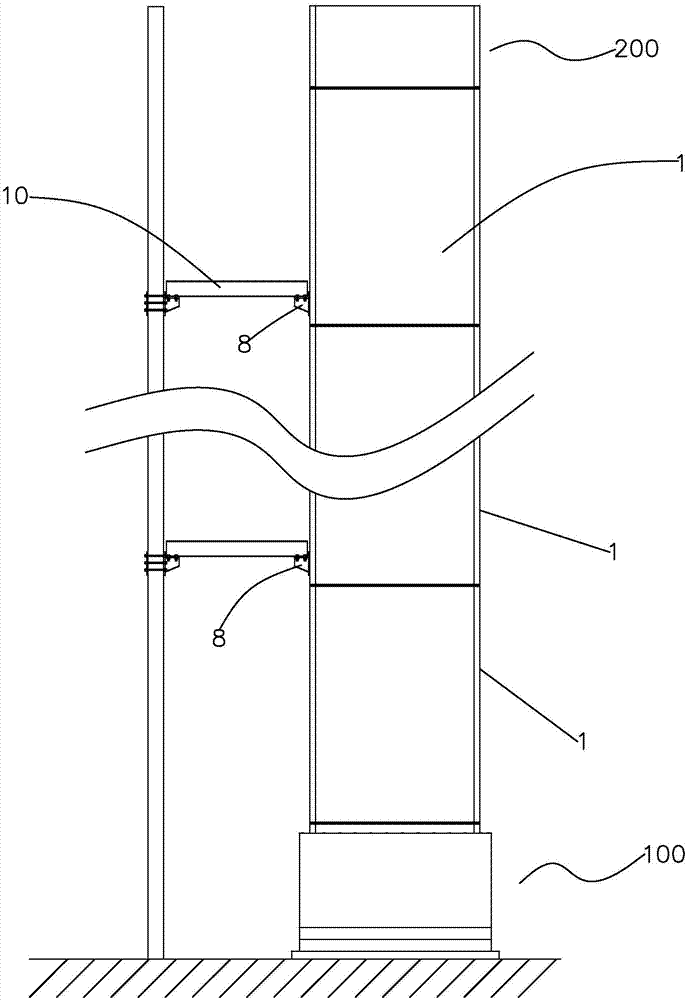

Hoistway for additional mounting of elevator in existing building

PendingCN106939683AImprove on-site installation efficiencyReduce construction costsVertical ductsRebarReinforced concrete

The invention discloses a hoistway for additional mounting of an elevator in an existing building. The elevator hoistway comprises a foundation and prefabricated piece bodies connected sequentially on the foundation in an overlaid mode in the vertical direction. The prefabricated piece bodies adopt steel bar concrete structures, are hollow and opened up and down. Prefabricating is conducted in advance outside a site. The two prefabricated piece bodies can be aligned through an upper butt joint structure and a lower butt joint structure to be mounted rapidly. The hoistway has the characteristics of being simple in structure, safe, reliable and high in mounting efficiency in site.

Owner:GUANGDONG YIJIATI TECH CO LTD

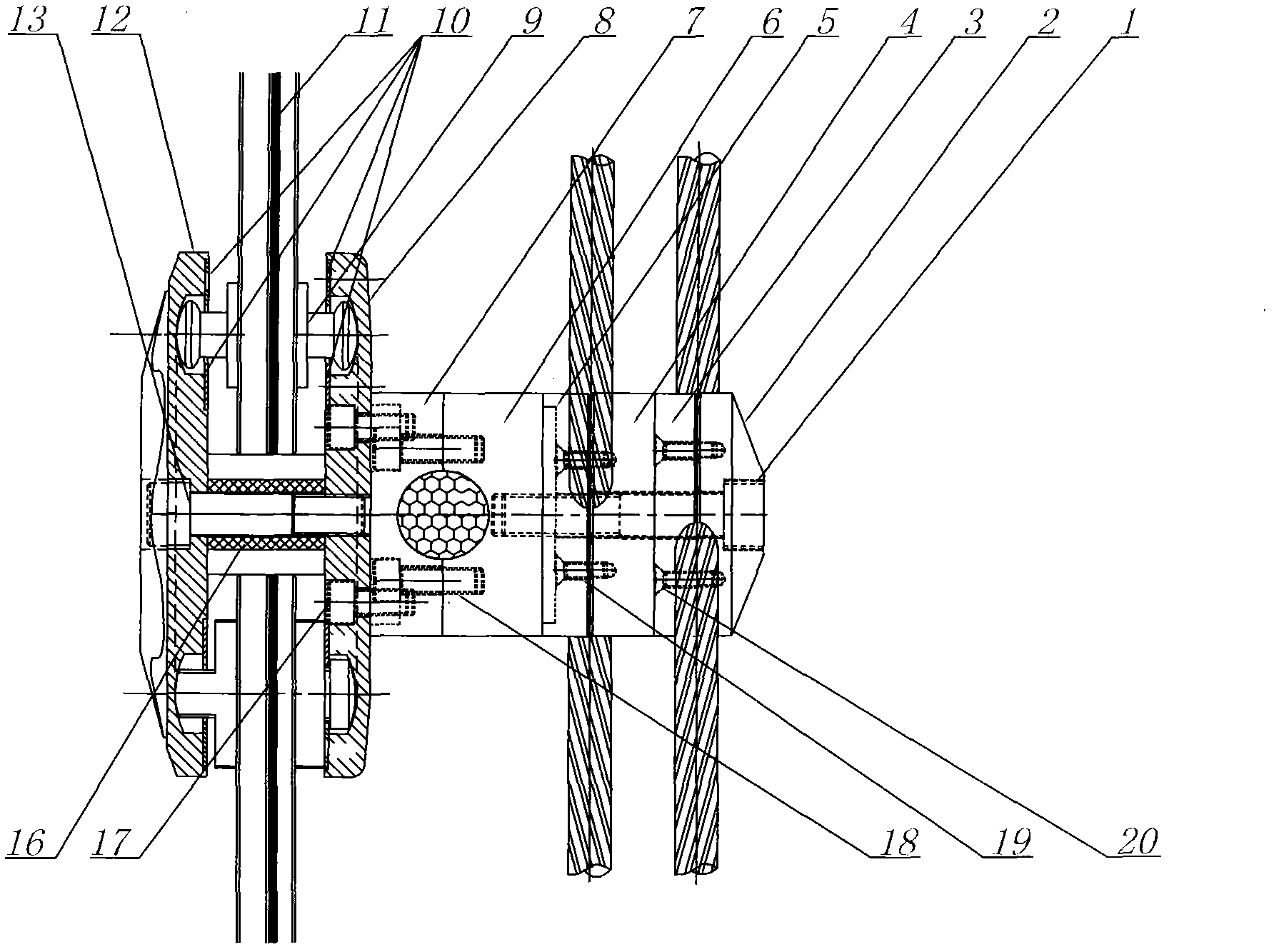

Round glass fixture for stay rope curtain wall

ActiveCN102644345AExtended service lifeImprove on-site installation efficiencyWallsMechanical engineeringBuilding construction

The invention discloses a round glass fixture for a stay rope curtain wall. The glass fixture comprises a pressure block for fixing a steel cable, a connecting cover, a gland, a locking ring and a moving ball; the connecting cover and the gland are arranged in a matched mode to form the fixture for clamping glass; the pressure block is fixedly arranged on the connecting cover; the moving ball is arranged on the connecting cover and the gland by the locking ring; and the moving ball is arranged between the connecting cover and the gland. According to the invention, the service life of the glass curtain wall can be improved, the construction cost is saved and the engineering period is shortened.

Owner:河源迪奇亚工业技术有限公司

Circular concrete formwork capable of being assembled and reinforcement method

ActiveCN111852003ALight weightSolve the inconvenience of transportationForms/shuttering/falseworksAuxillary members of forms/shuttering/falseworksArchitectural engineeringStructural engineering

The invention relates to a circular concrete formwork capable of being assembled. The circular concrete formwork comprises a base, a standard segment, an end and handles, wherein the end, the standardsegment and the base are sequentially arranged from top to bottom; the outer walls of the end, the standard segment and the base are provided with transverse ribs a, transverse ribs b and transverseribs c respectively, and the transverse ribs a, the transverse ribs b and the transverse ribs c are each provided with a plurality of notches; one ends of part of the handles extend into the notches in the transverse ribs b through the notches in the transverse ribs a and rotate by a preset angle to make the end detachably connected with the standard segment; and one ends of part of the handles extend into the notches in the transverse ribs c through the notches in the transverse ribs b and rotate by a preset angle to make the standard segment detachably connected with the base. The circular concrete formwork is environmentally friendly, durable, high in strength, resistant to corrosion, low in weight, capable of being recycled many times, not liable to deformation, good in concrete forming effect, convenient and fast to disassemble and assemble, convenient to transport, economical and practical, and effectively solves the problems that a traditional circular steel formwork is thick and heavy, troublesome to assemble and low in construction efficiency and a circular timber formwork cannot be firmly reinforced and is liable to deviation.

Owner:CHINA FIRST METALLURGICAL GROUP

Support frame for water conservancy and hydropower construction

The invention discloses a support frame for water conservancy and hydropower construction. The support frame comprises a bracket base, mounting rails, fixing fixtures, a pipeline to be laid, a pipe bracket, fastening screws and sliding grooves. The pipe bracket is mounted at the top of the bracket base, the two symmetrical sliding grooves are formed in the top of the bracket base, and the two sliding grooves are separately formed in two sides of the pipe bracket. The mounting rails are arranged on one sides of the sliding grooves, the mounting rails are fixed to the top of the bracket base, and the two fastening screws are installed in the mounting rails. By designing the mounting rails, when the support frame is erected, just the bottom ends of support plates are clamped inside the rails,and the fastening screws are tightened on mounting holes to complete fixing. The support frame is laid fast and the installation is quite convenient and quick, therefore the on-site installation efficiency is significantly improved, the construction speed is ensured, the fixing fixtures can be disassembled and recycled after the completion of laying, and waste of resources is reduced.

Owner:ANHUI CAREMIC CONSULTING CO LTD

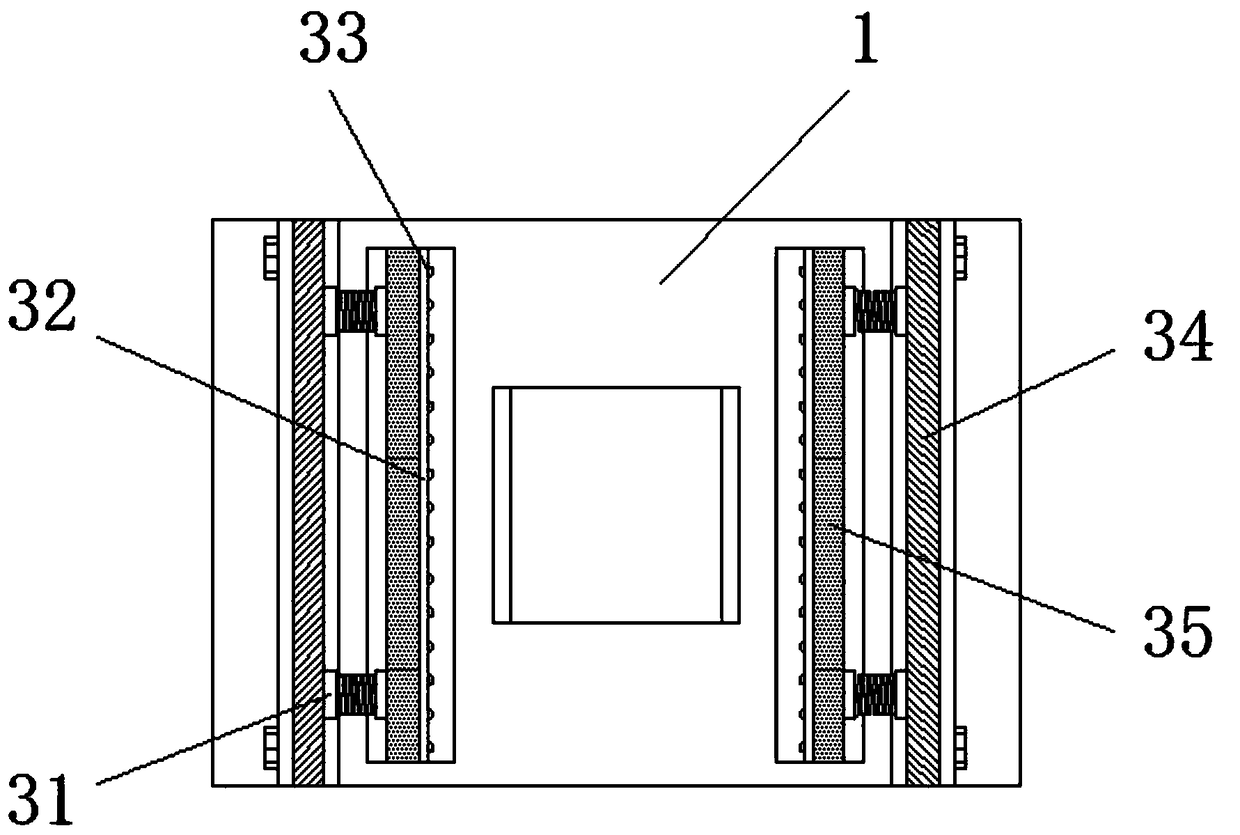

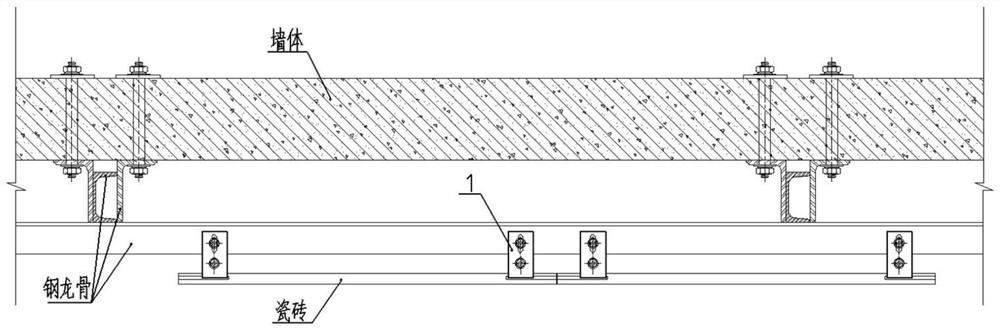

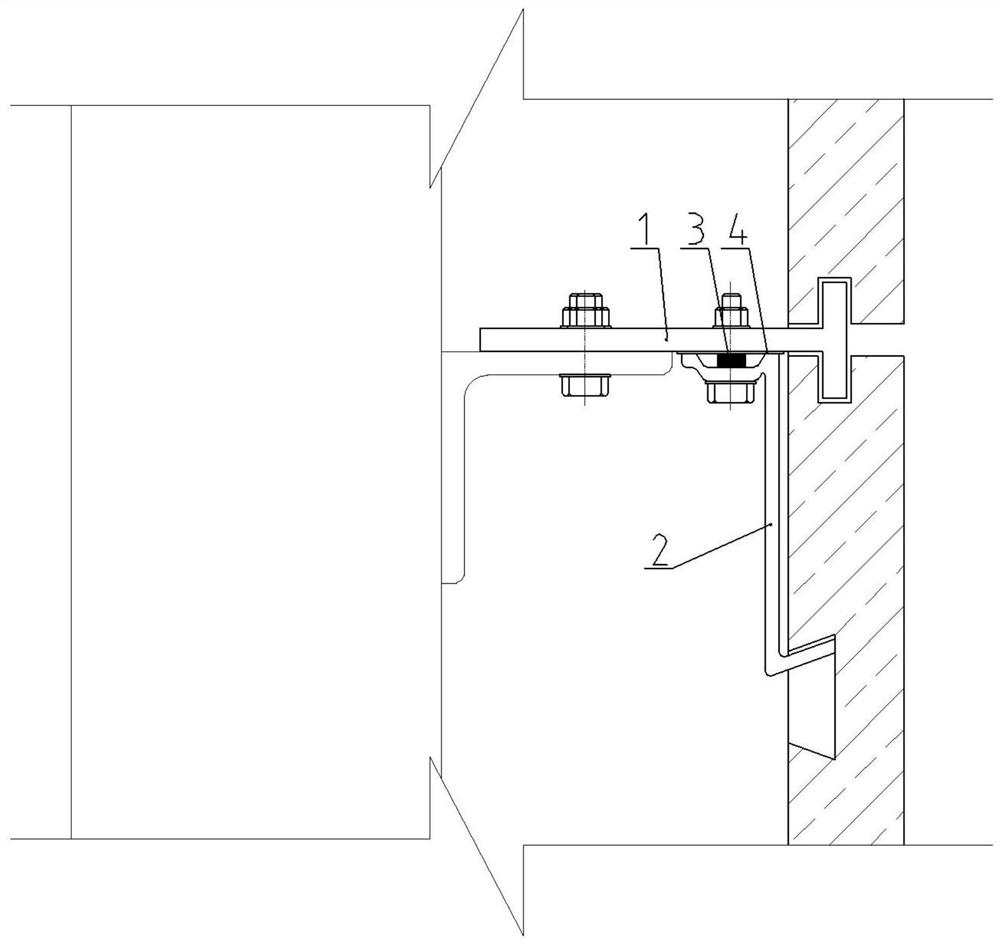

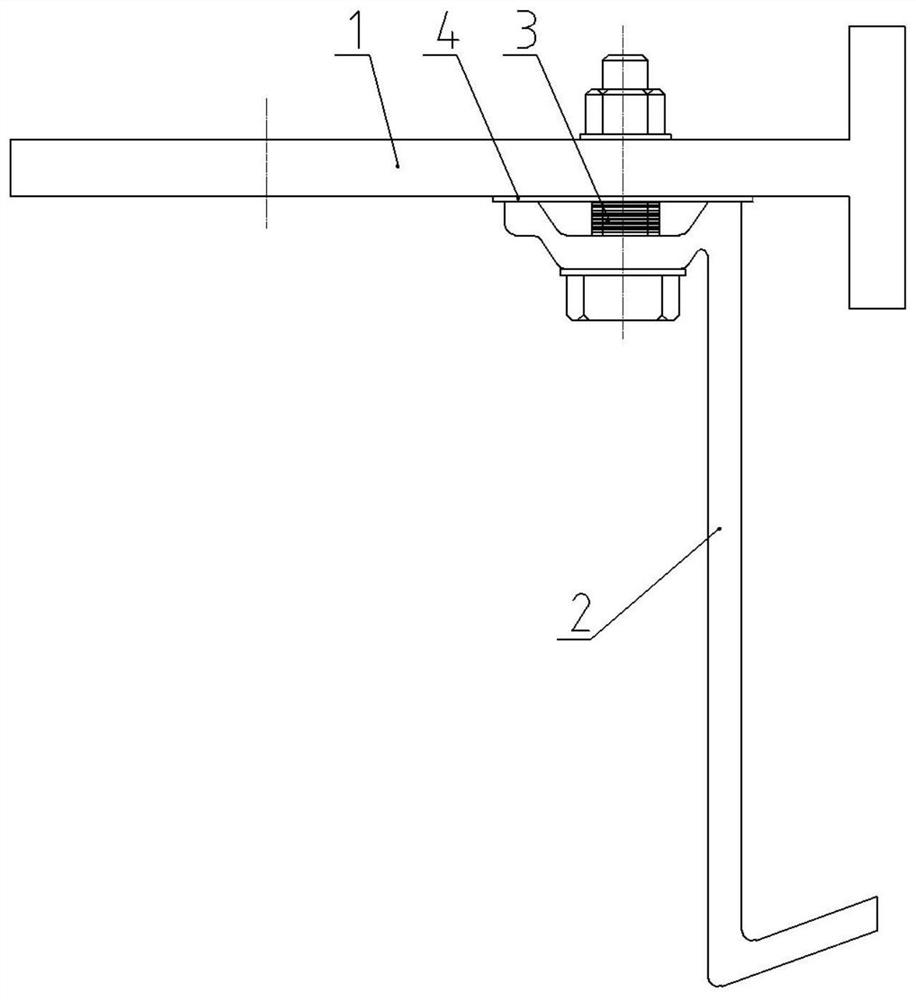

Indoor wall tile dry hanging assembly and application method thereof

The invention discloses an indoor wall tile dry hanging assembly and an application method thereof. The dry hanging assembly comprises a horizontal connecting piece and a vertical hanging piece, wherein the horizontal connecting piece is a horizontally-inverted T-shaped plate, the vertical hanging piece comprises a vertical plate, a hook at the lower end of the vertical plate and a connector at the upper end of the vertical plate, the hook is obliquely arranged on one side of the vertical plate upwards, the connector is located on the other side of the vertical plate, the hook hooks notches formed in the back face of a ceramic tile, the connector is detachably connected to a horizontal plate of the T-shaped plate through a fastener, and the horizontal plate is detachably connected to a steel keel on the outer side of a wall through a fastener. According to the indoor wall tile dry hanging assembly and the application method thereof, by combining the designed novel dry hanging assemblywith the multidirectional notches in the ceramic tile, the ceramic tile can be safely and efficiently fixed to the wall surface in a high-quality mode, fixation is structurally enhanced, potential safety hazards of hollowing and falling-off quality of the ceramic tile are prevented, operation is convenient, the work efficiency is improved, the effect is guaranteed, the cost is reduced, and the problems existing in three ceramic tile dry hanging processes in the prior art are solved.

Owner:中建五局装饰幕墙有限公司

Multi-curved-surface modeling lining mold for concrete structure and a manufacturing method thereof

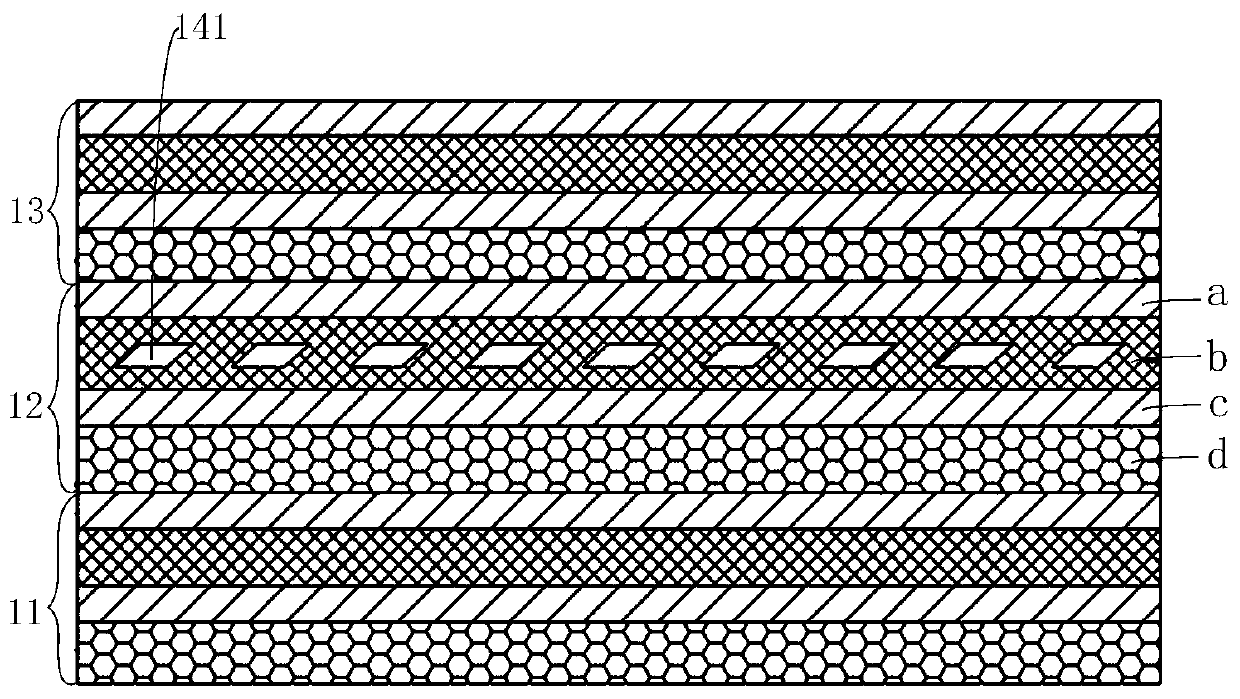

ActiveCN110774423AEasy to processFast processingMouldsSynthetic resin layered productsGlass fiberStructural engineering

The invention provides a multi-curved-surface modeling lining mold for a concrete structure and a manufacturing method thereof. The multi-curved-surface modeling lining mold comprises a glass fiber reinforced plastic outer mold housing and a supporting mold core, wherein a filling cavity is formed in the glass fiber reinforced plastic outer mold housing; the side wall of the glass fiber reinforcedplastic outer mold housing comprises an outer surface layer; an inner base layer and a middle core layer arranged between the outer surface layer and the inner base layer; a framework is embedded inthe middle core layer; the filling cavity is filled with the supporting mold core; and the supporting mold core is connected to the inner wall of the filling cavity. According to the multi-curved-surface modeling lining mold for the concrete structure and the manufacturing method of the multi-curved-surface modeling lining mold, the problems that a traditional lining mold is prone to deformation,heavy, not easy to transport and low in field mounting efficiency are solved.

Owner:CHINA CONSTR EIGHT ENG DIV CORP LTD

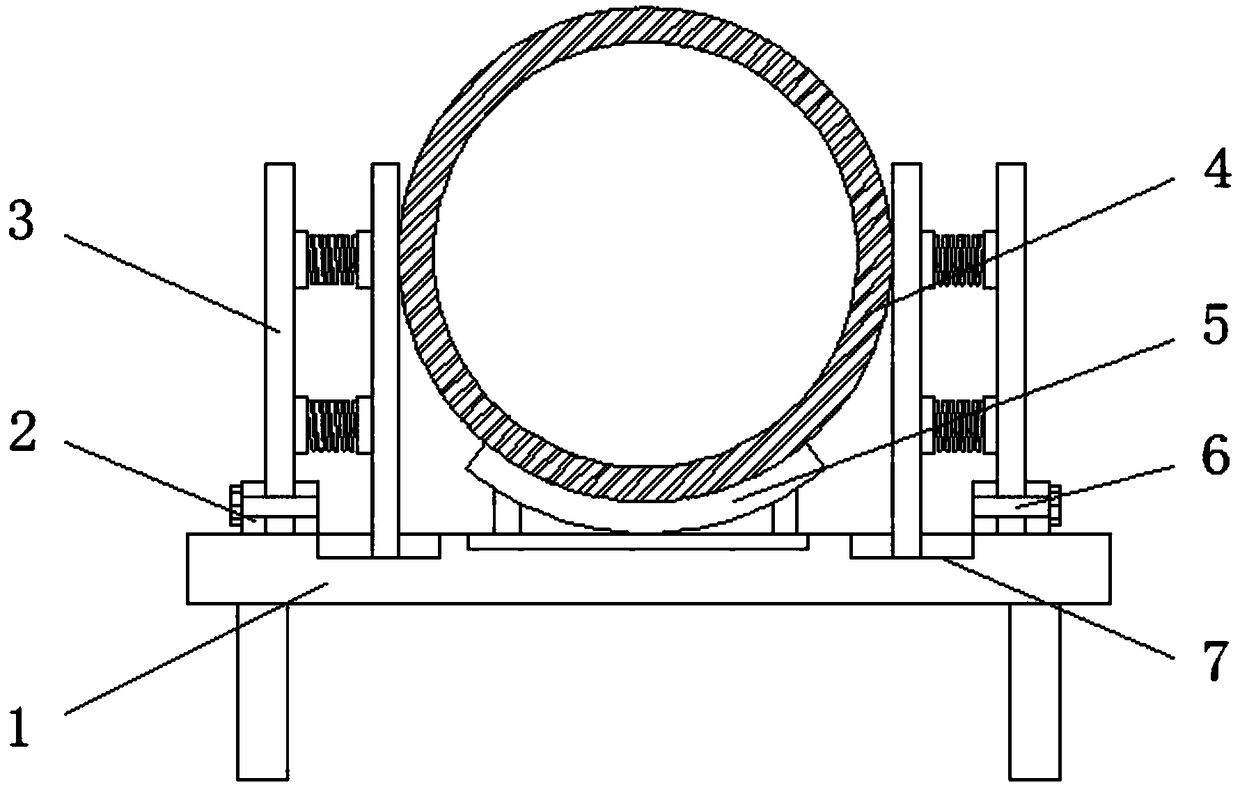

Combined fast-assembly pipeline support and mounting method thereof

ActiveCN106051307AOvercome the disadvantage of not being able to adjust the heightGuarantee the construction qualityPipe supportsBulkheads/pilesEngineeringPipe support

The invention relates to a combined fast-assembly pipeline support, meanwhile provides a mounting method of the combined fast-assembly pipeline support and belongs to the technical field of pipeline supporting. The combined fast-assembly pipeline support comprises a pipe holder supported on an upper panel of a base. The base is mounted on a basic plate through at least three elevation adjustment devices. The basic plate is at least supported on three adjustable piles. The pipe holder is formed by fixedly connecting a bottom brace on the lower portion and a circular arc holder at the top. The base is formed by fixedly connecting box iron braces by which a rectangular frame is defined with the panel. Each elevation adjustment device is composed of a pair of vertical spiral pair components mounted on the basic plate and supported under the base. In the mounting process of the pipeline support, the elevation of the support can be adjusted by adjusting the elevation adjustment devices, the levelness of the basic plate can be adjusted through the adjustable piles, the defect that the height of a traditional heat supply network pipeline support cannot be adjusted is overcome, and it is guaranteed that supporting is stable and reliable as well; and mounting is quite convenient and fast, so that the field installation efficiency is improved remarkably, and construction quality is guaranteed.

Owner:AEROSUN CORP

Features

- R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

Why Patsnap Eureka

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Social media

Patsnap Eureka Blog

Learn More Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com