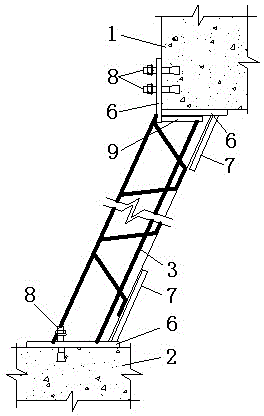

Ultra-thin steel truss inclined wall construction method and formwork structure

A construction method and technology of steel truss, applied in the direction of formwork/template/work frame, connection parts of formwork/formwork/work frame, building structure, etc. Difficulty and other problems, to achieve the effect of good construction quality, saving construction period and high installation efficiency

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment

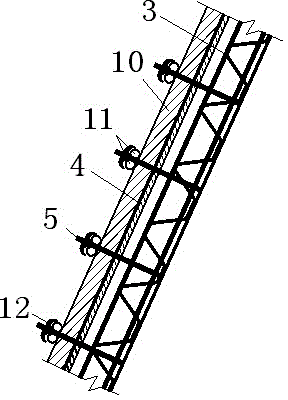

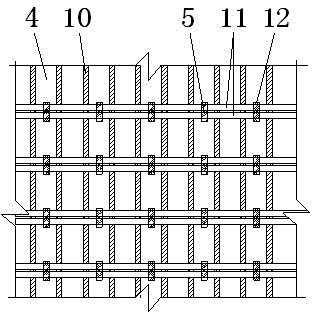

[0024] The specifications of the components in this example are as follows:

[0025] The model of steel truss formwork 3 is TD7-120 steel truss formwork; the fixed plate 6 is made of 150X50X10mm steel plate with a spacing of 500mm; the reinforcement plate 9 is made of 150X50X10mm steel plate with a space of 500mm; The specification of the bolt 8 is Φ19X400; the horizontal back flute 11 adopts double steel pipes, and the steel pipe specification is Φ48X3.6mm; the vertical back flute 10 adopts 40X90 wooden squares, and the horizontal spacing is 200mm; the common formwork 4 adopts 18mm thick nine plywood; The length of the screw rod is greater than the thickness of the wall plus the thickness of the formwork on both sides, and the horizontal distance is 500mm; the butterfly buckle 11 adopts the butterfly buckle matched with the Φ48 steel pipe.

[0026] In specific implementation, it can be as Figure 1-Figure 3 As shown, follow the steps below to implement:

[0027] 1. Reservin...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com